Compressed air drying system and drying method thereof

A drying system and compressed air technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of affecting the adsorption effect of compressed air and the decline of adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

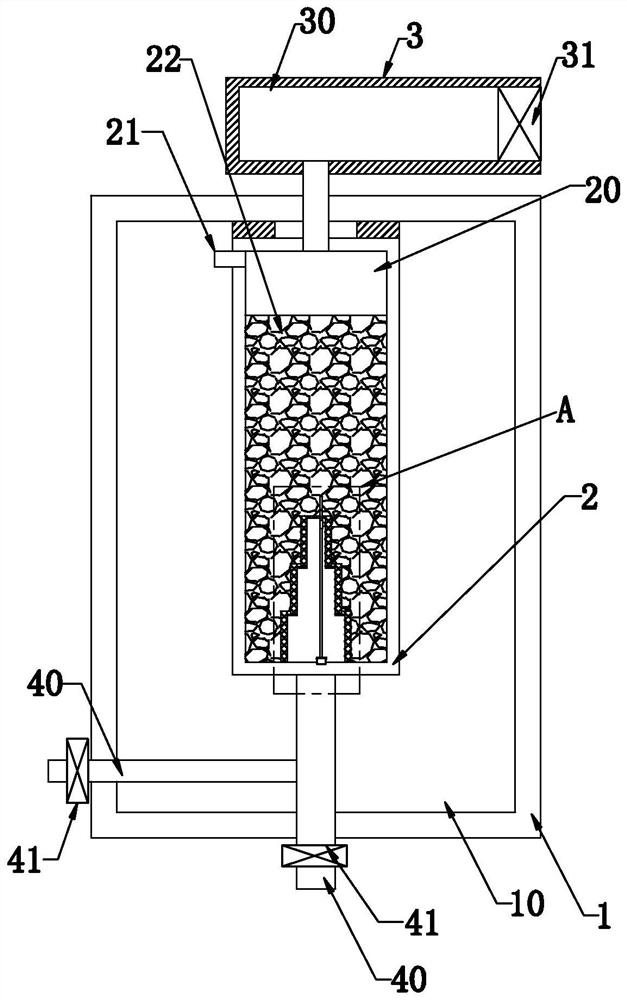

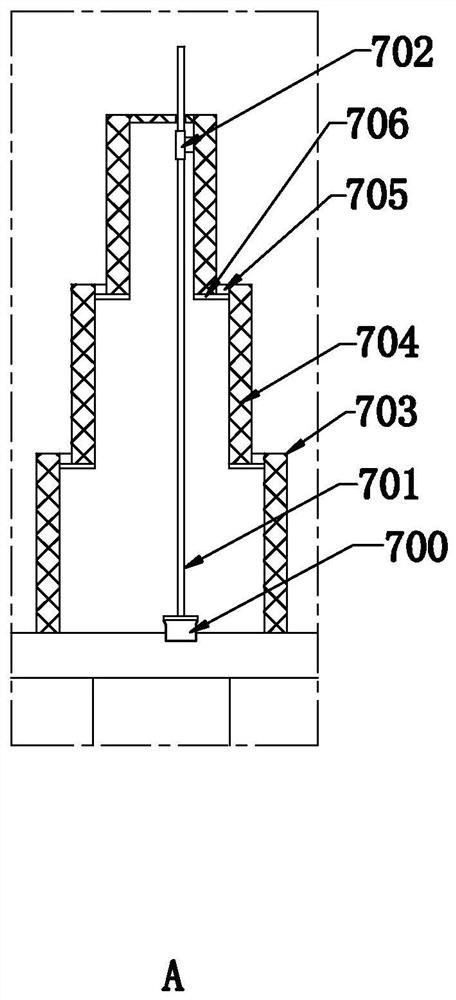

Image

Examples

Embodiment 2

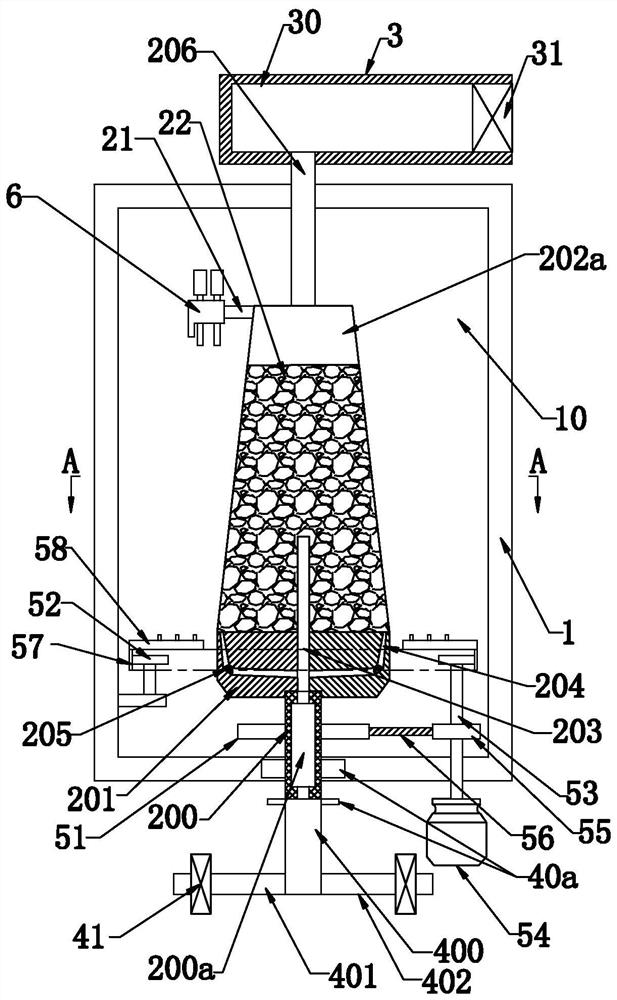

[0039] Embodiment 2, the difference with embodiment 1 is:

[0040] Such as Figure 3-Figure 5 As shown, in a specific embodiment of the present invention, the inner body 2 includes a base 201 rotatably connected to the bottom of the first cavity 10 through a rotating shaft 200 and controlled by a driving part, and a container body mounted on the base 201 202; wherein, the base 201 is formed with a main chamber 203 coaxially arranged with the base 201 and several auxiliary chambers 204 distributed circumferentially around the main chamber 203, one end of the auxiliary chamber 204 is connected to The main cavity 203 communicates, the other end of the secondary cavity 204 extends to the top end surface of the base 201, and a check valve 205 is installed in the secondary cavity 204; the container body 202 has an adsorption cavity 202a, and The cross-sectional area of the adsorption chamber 202a gradually expands from top to bottom, and on the inner wall of the adsorption chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com