Livestock intestine cleaning method

A technology for intestines and poultry, which is applied in poultry cleaning/disinfection, cleaning intestines, poultry processing, etc. It can solve the problems of low cleaning efficiency, difficulty in ensuring hygienic quality, and difficult cleaning of adherents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

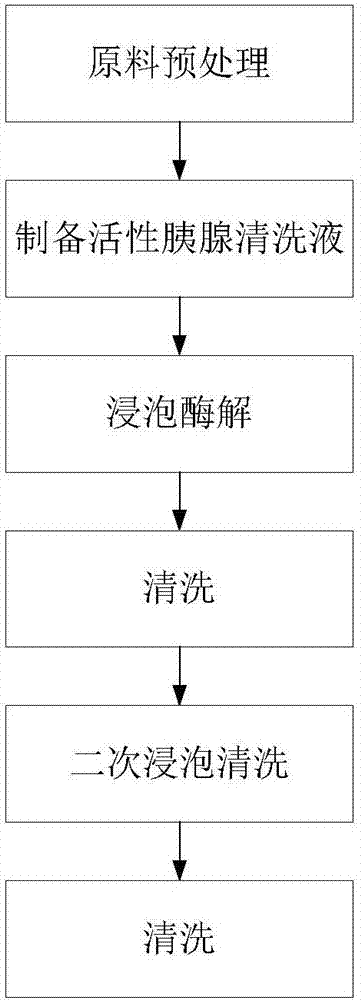

Method used

Image

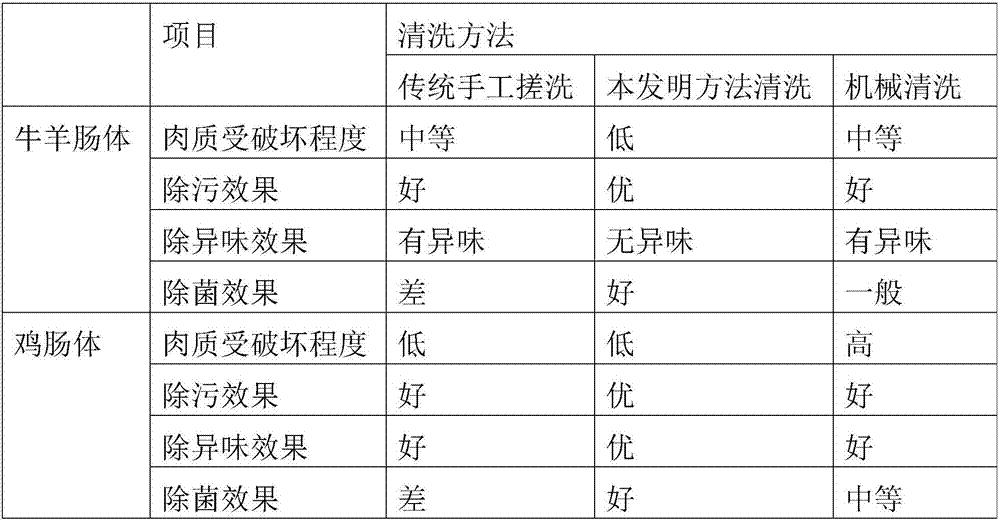

Examples

Embodiment 1

[0074] (1) Raw material pretreatment

[0075] After slaughtering beef cattle that meet hygienic standards, take 10 pairs of large intestines, weighing about 10kg, trim the surface fat and fascia to ensure that the intestines are not damaged, rinse them with clean water for 3 times, and remove feces inside the intestines;

[0076] (2) Preparation of Active Pancreatic Plasma Washing Solution

[0077] a) Pancreas selection finishing

[0078] Choose 3kg of bovine pancreas that has passed the hygienic inspection, repair and remove surface impurities, wash and twist into 1cm 3 left and right Xiaoding;

[0079] b) Preparation of active pancreatic juice

[0080] Put the twisted pancreas into a tissue masher at a speed of 5000r / min for 7min, and mash it to make pancreas pulp; add 15g of CaCl 2 , 80g starch, 1kg water, mixed evenly and stored at 4°C for 10h to activate trypsin to obtain active pancreatic juice;

[0081] c) Preparation of Active Pancreatic Plasma Washing Solution

...

Embodiment 2

[0101] (1) Raw material pretreatment

[0102] After slaughtering the chickens that meet the hygienic standard requirements, take 1000g of intestines, repair the superficial fascia, rinse the inside and outside of the intestines with clean water 3 times, remove feces, and cut them longitudinally;

[0103] (2) Preparation of Active Pancreatic Plasma Washing Solution

[0104] a) Pancreas selection finishing

[0105] Choose 0.5kg of porcine pancreas that has passed the hygienic inspection, trim off the surface impurities, wash and twist into 1.2cm 3 left and right Xiaoding;

[0106] b) Preparation of active pancreatic juice

[0107]Put the twisted pancreas into a tissue masher at a speed of 7000r / min for 3min, and mash it to make pancreas pulp; add 2g of CaCl 2 , 10g of starch, and 0.3kg of water, mixed evenly and stored at 6°C for 5 hours to activate trypsin to obtain active pancreatic juice;

[0108] c) Preparation of Active Pancreatic Plasma Washing Solution

[0109] Weig...

Embodiment 3

[0124] (1) Raw material pretreatment

[0125] After slaughtering beef cattle that meet hygienic standards, take 10 pairs of large intestines, weighing about 10kg, trim the surface fat and fascia to ensure that the intestines are not damaged, rinse them with clean water for 3 times, and remove feces inside the intestines;

[0126] (2) Preparation of Active Pancreatic Plasma Washing Solution

[0127] a) Pancreas selection finishing

[0128] Choose 3kg of bovine pancreas that has passed the hygienic inspection, repair and remove surface impurities, wash and twist into 1cm 3 left and right Xiaoding;

[0129] b) Preparation of active pancreatic juice

[0130] Put the twisted pancreas into a tissue masher at a speed of 5000r / min for 7 minutes, and mash it to make pancreas pulp; add 3g of CaCl 2 , 80g starch, 1kg water, mixed evenly and stored at 4°C for 4 hours to activate trypsin to obtain active pancreatic juice;

[0131] c) Preparation of Active Pancreatic Plasma Washing Sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com