A laminar flow-type stair-shaped porous material adsorption unit and an adsorption method thereof

A technology of porous materials and adsorption devices, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve the problem of poor pollutant removal efficiency, poor adaptability of flue gas pollutant concentrations, and low space utilization of convection absorption towers. , large adsorption and saturation of porous materials, etc., to achieve the effect of reducing construction costs, low moving speed, and low bed resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

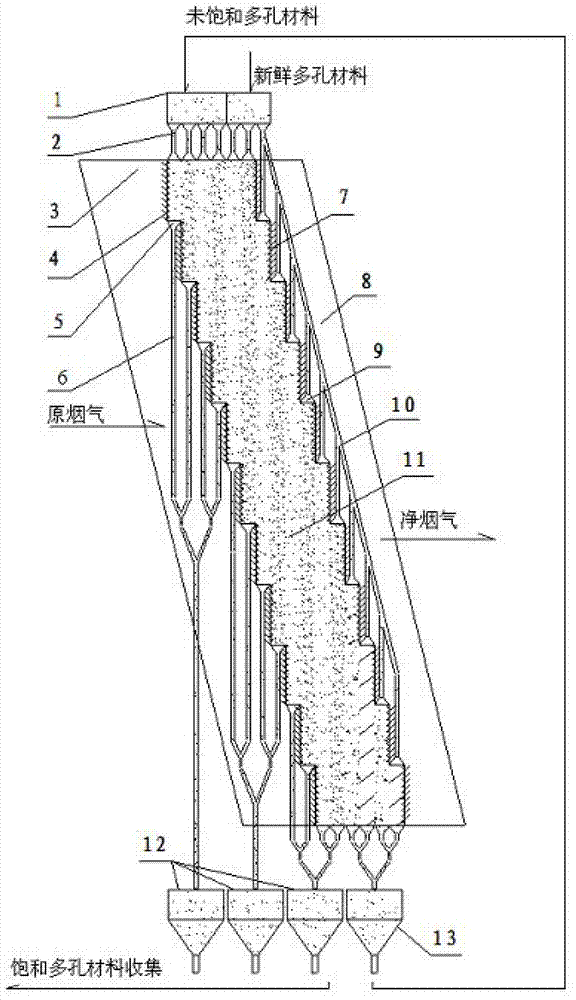

[0030] Such as figure 1 As shown, the feed hopper 1 is connected to the adsorption tower through a feed pipe 2 with a certain height that can seal the gas in the laminar flow ladder tower. During adsorption, the material level gauge for feeding the hopper maintains a certain material level to prevent the gas inside and outside the tower from crossing.

[0031] The flue gas to be purified enters the laminar flow ladder adsorption tower evenly from the smoke inlet side 3 through the inlet grill plate 4, passes through the porous material bed 11, and is discharged from the smoke outlet side through the outlet grill 7. The multi-layer porous material bed 11 in the adsorption tower is arranged in steps.

[0032] Porous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com