Impurity collecting and discharging device

A discharge device and impurity technology, applied to the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of poor impurity discharge, low cost, and inconvenient installation of the separation device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

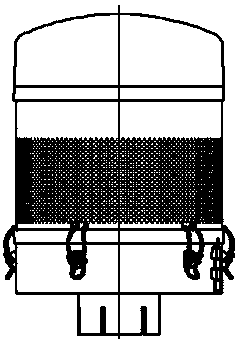

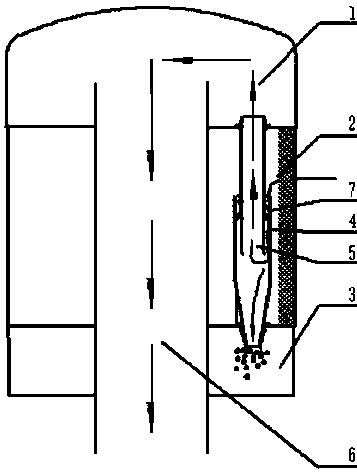

[0066] Embodiment 1: A kind of fluid impurity separation device, see figure 1 and figure 2 , including: including the first cavity 1, the second cavity 2, the third cavity 3, the fourth cavity 4, the fifth cavity 5, the sixth cavity 6 and the swirl tube 10, wherein the first cavity 1. The second cavity 2 and the third cavity 3 are arranged sequentially from top to bottom. The second cavity 2 communicates with the outside. The external fluid first enters the second cavity 2 and then flows into the fourth cavity 4. The fourth cavity The upper part of the body 4 communicates with the second cavity 2, the lower part of the fourth cavity 4 communicates with the third cavity 3, the fifth cavity 5 is located inside the fourth cavity 4 and communicates with the inside of the fourth cavity 4, and the fifth cavity The upper part of the body 5 communicates with the first cavity 1, the sixth cavity 6 is located at the central axis of the separation device, the upper part of the sixth ca...

Embodiment 2

[0090] Embodiment 2: see attached Figure 1-5 , The modular air primary filter dust collector includes a cap-shaped top cover, a modular dust collector housing, a swirl tube air filter device, an air intake grille, an air outlet pipe, a dust collection chamber and an automatic ash discharge device, a cap-shaped top cover, The modular dust collector shell and the dust collection chamber are composed of three parts sealed and connected. In order to facilitate the disassembly of internal components, the hat-shaped top cover, the modular dust collector housing and the dust collection chamber can be detachably connected together through threaded structures, snap-fit structures, etc.

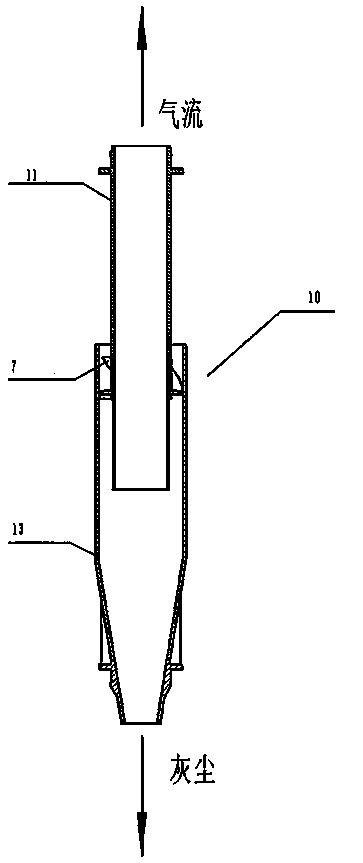

[0091] The shell of the dust collector is cylindrical, with a height of 409.5cm and a diameter of the cylindrical part of 307cm. The swirl tube 10 is arranged in the shell and is located below the air intake grille. The swirl tube 10 is arranged in the vertical direction. Two circles of swirl tubes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com