Organosilicon fluidized bed reactor

A silicon fluidized bed and reactor technology, applied in chemical instruments and methods, chemical/physical processes, etc., can solve problems such as uneven temperature between heat exchange tubes and dead angles in surrounding areas, achieve uniform gas distribution and reduce carryover The effect of increasing the volume and intake speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

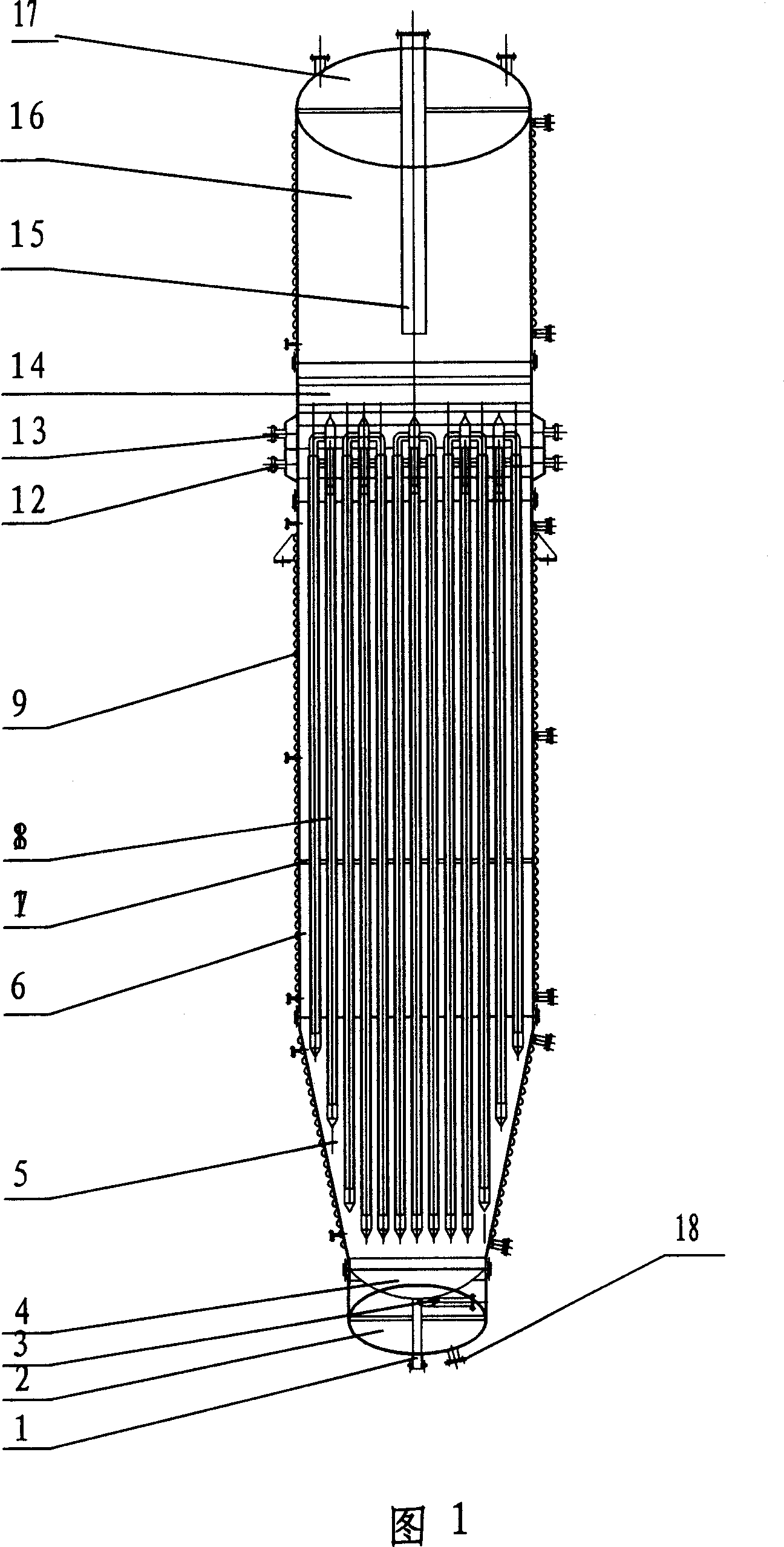

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings.

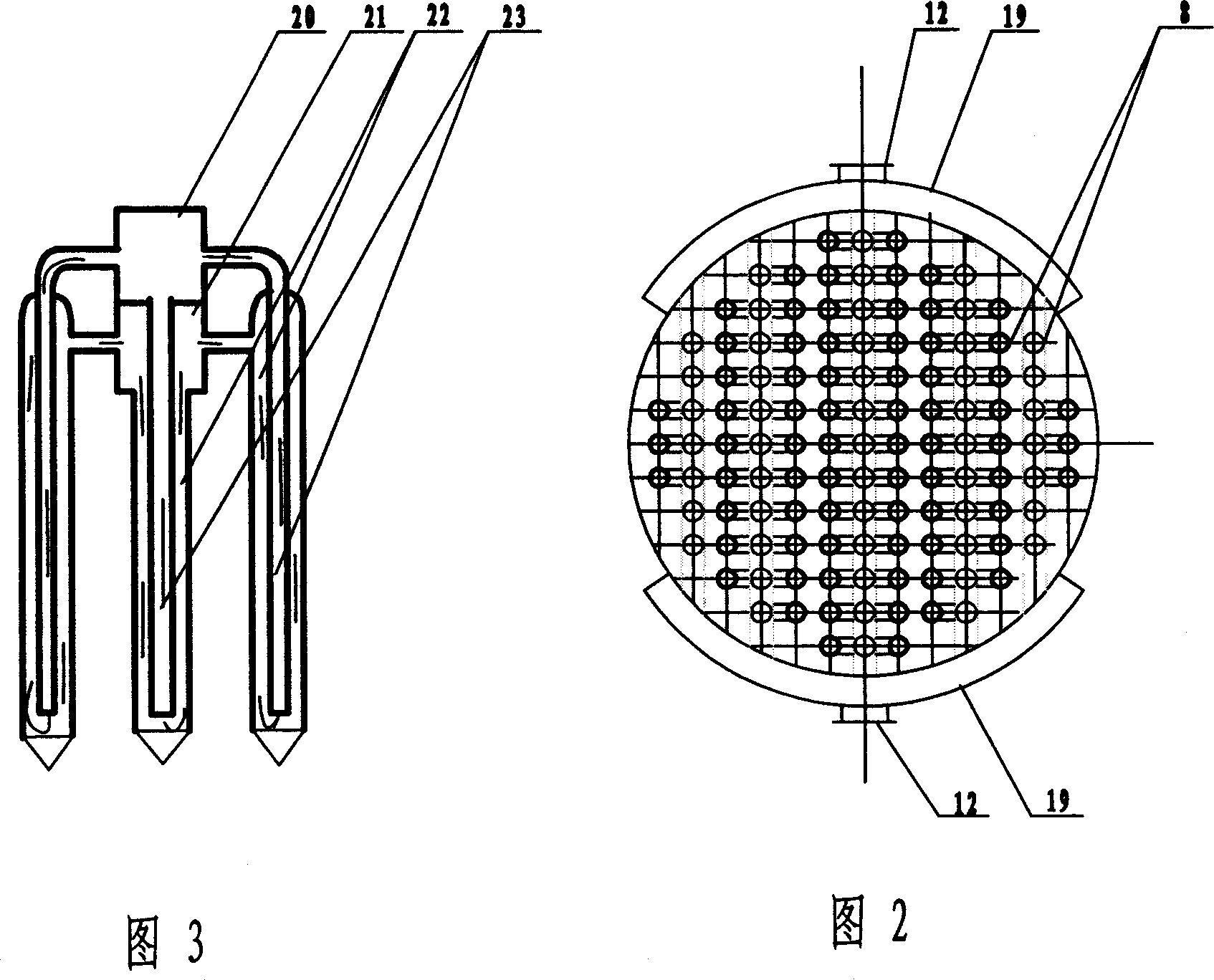

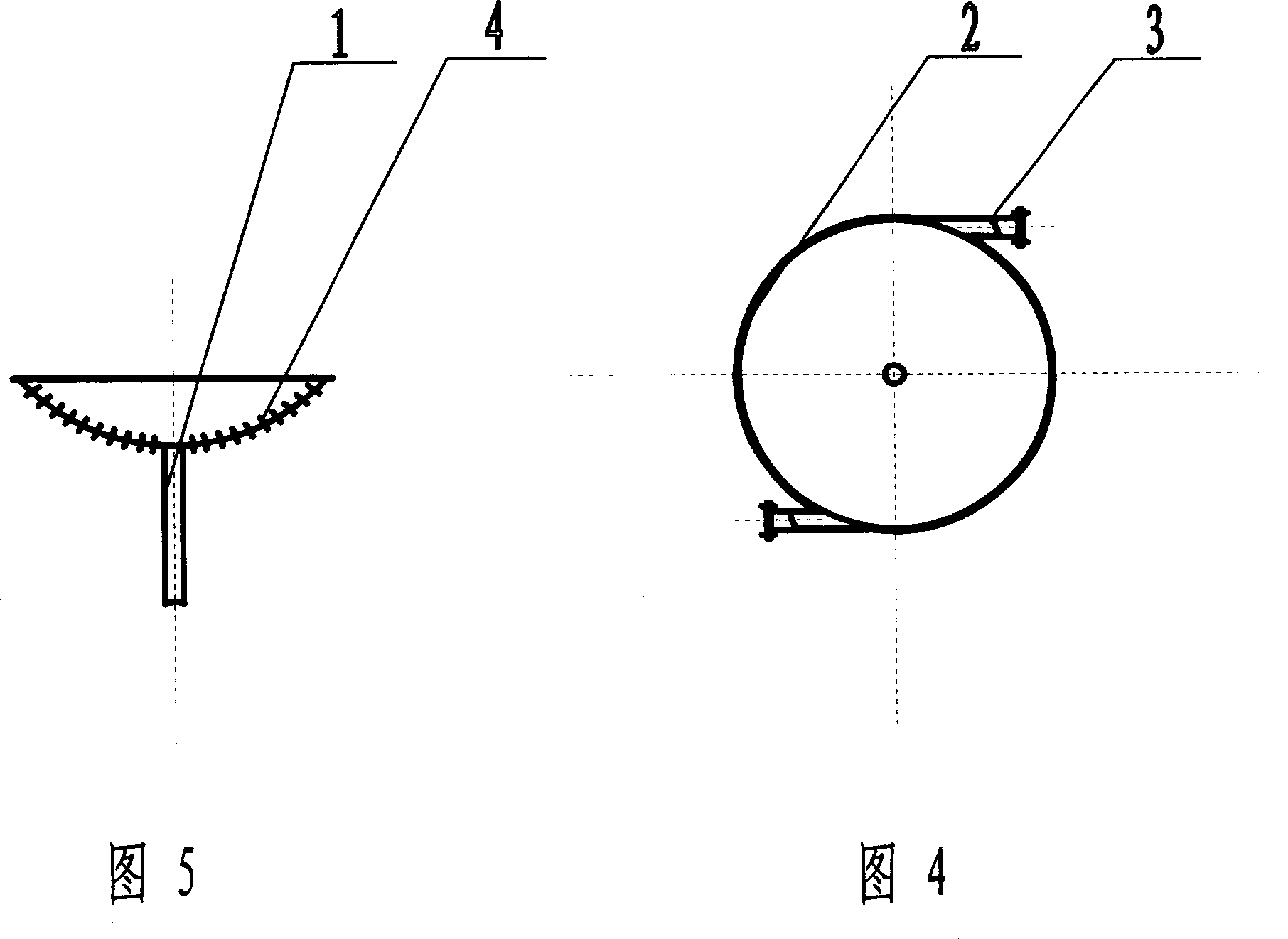

[0018] Referring to Fig. 1, the organosilicon fluidized bed reactor of the present invention consists of a cylindrical cylinder 6 and a conical cylinder 5 below it to form a bed, and the cylinder 6 has a helical half-pipe jacket 9 outside. There is a lower head 2 at the bottom of the bed body, and an upper head 17 at the top. Wherein the cross-section of the lower sealing head 2 is circular, the central feeding port 1 is located at the center of the lower sealing head 2, and the discharge end of the central feeding port 1 is located at the center of the gas distributor 4, and the cross section of the gas distributor of the present invention is Arc-shaped (as shown in FIG. 5 ), the gas phase feed port 3 is located at the bottom of the gas distributor 4 at the tangent position of the circular inner wall of the lower head 2 (as shown in FIG. 4 ). A silicon powder settl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com