Patents

Literature

40results about How to "Reduced risk of flaking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

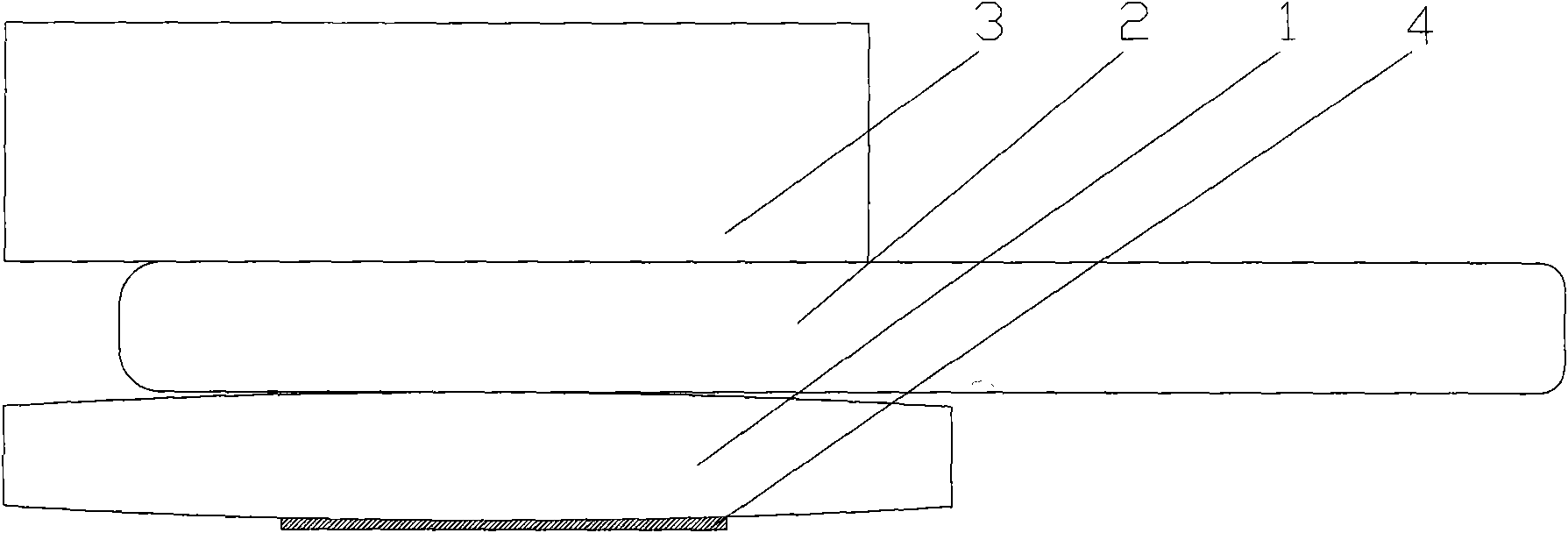

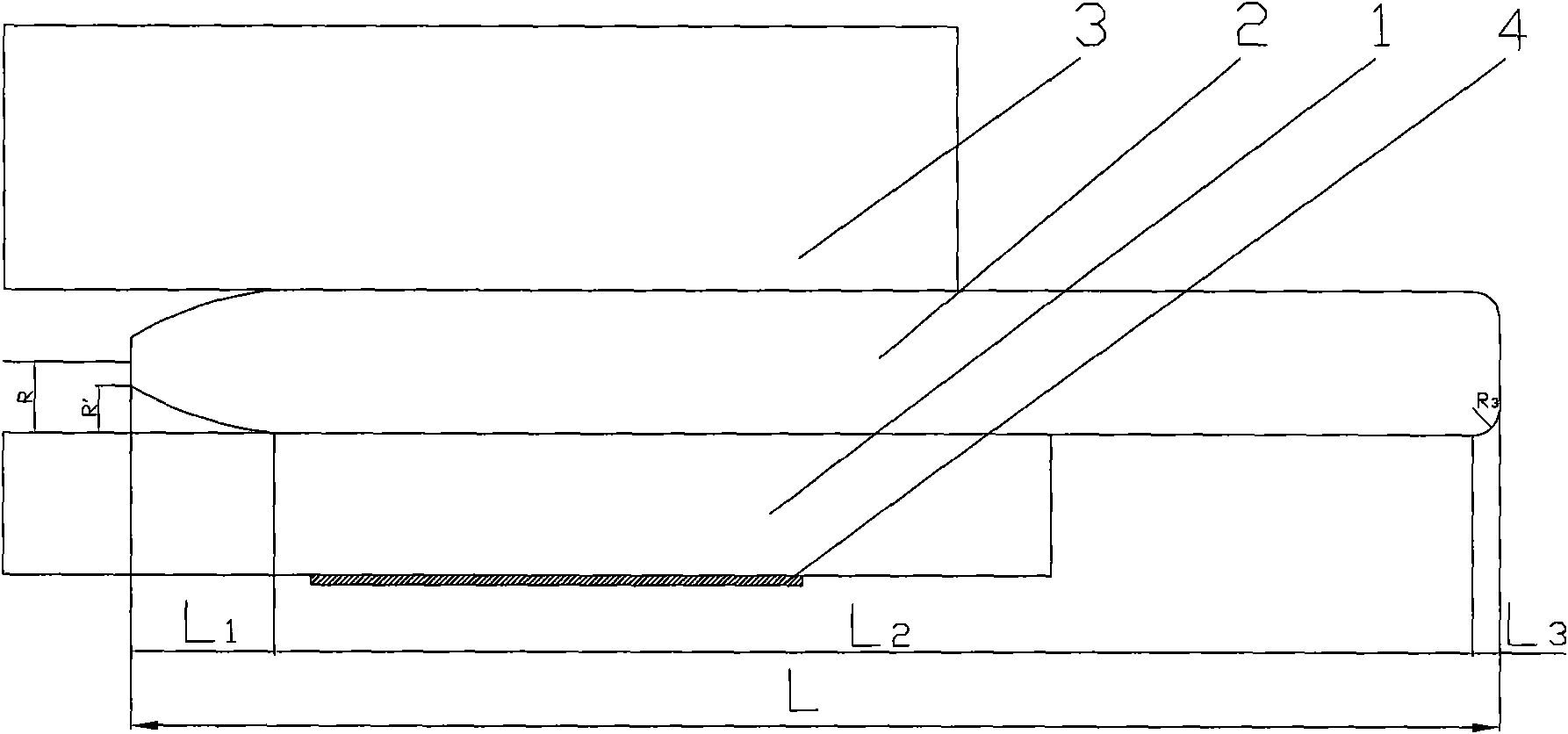

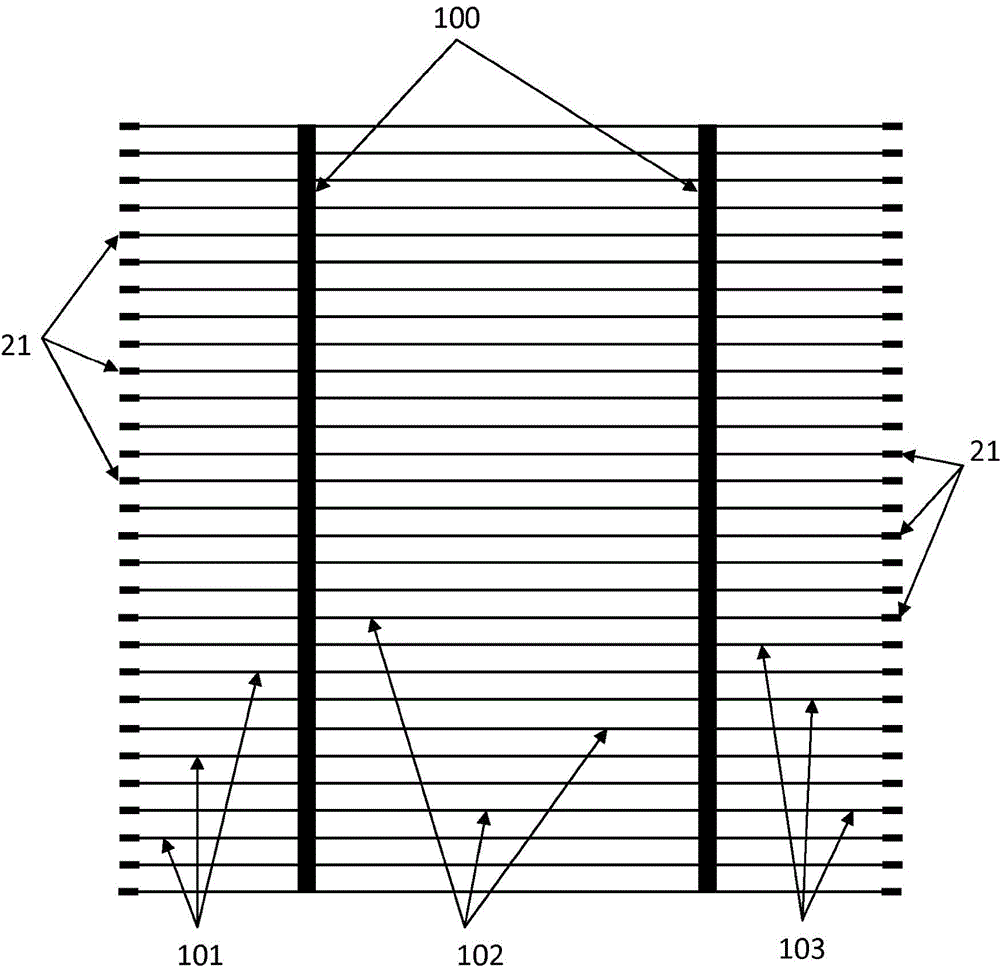

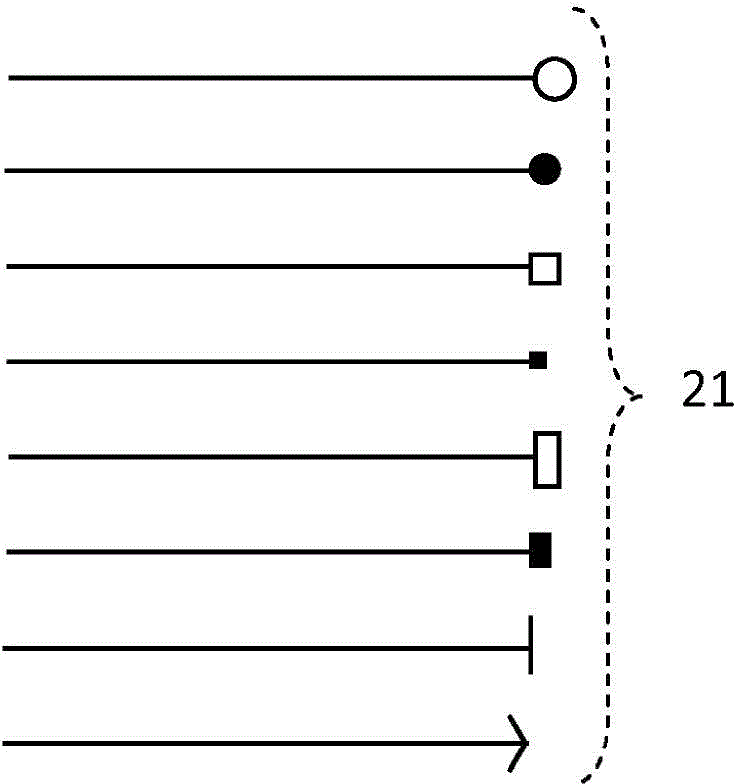

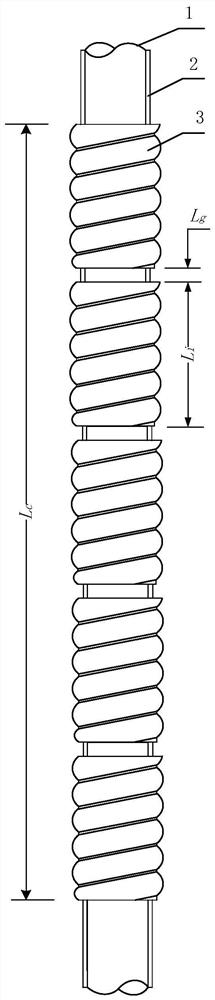

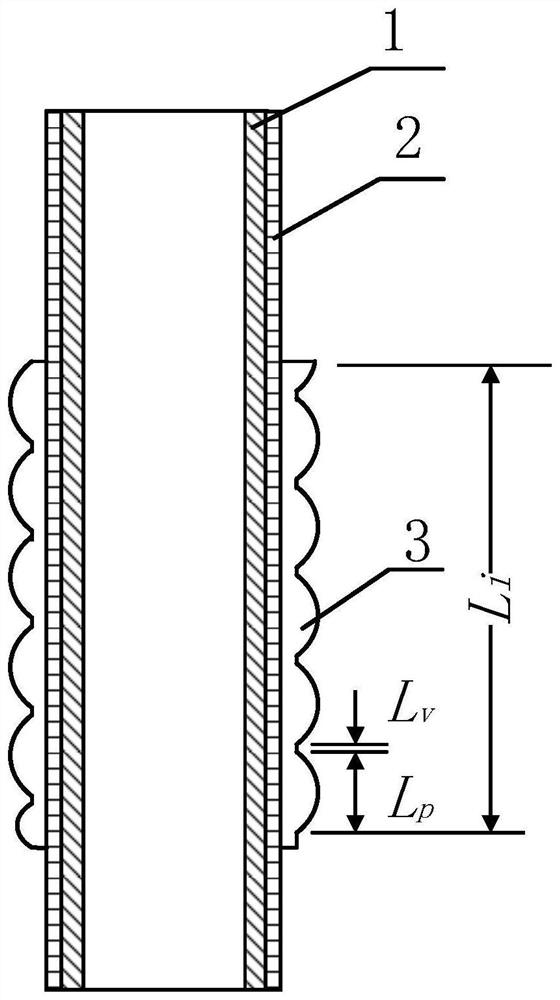

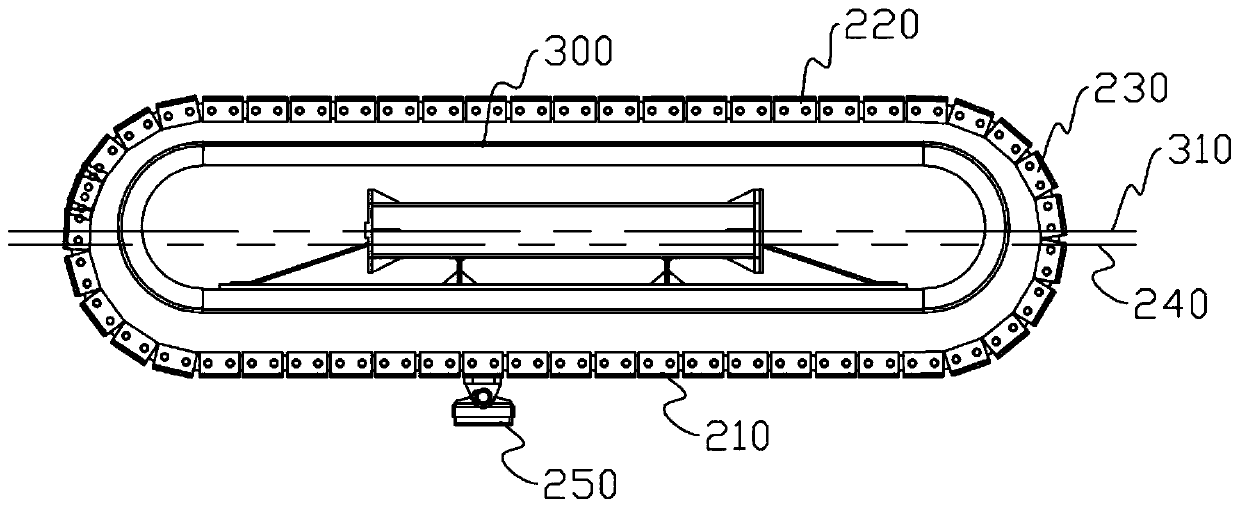

Intermediate roller contour of intermediate roller movable type convexity high-accuracy control temper mill

InactiveCN102107214AReduced contact pressure distributionUniform contact pressure distributionRollsMetal rolling arrangementsContact pressureMovable type

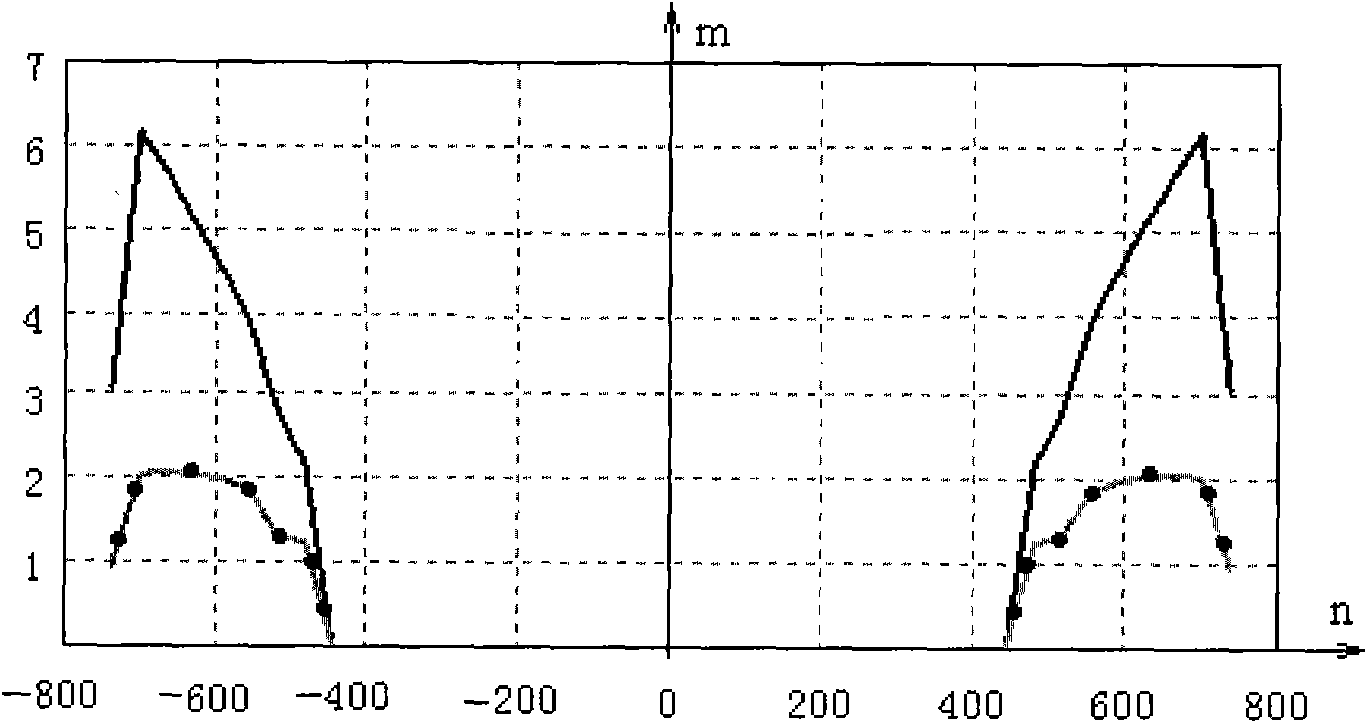

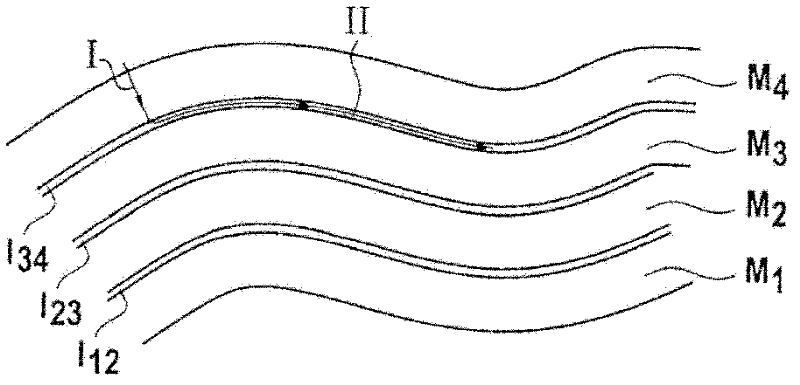

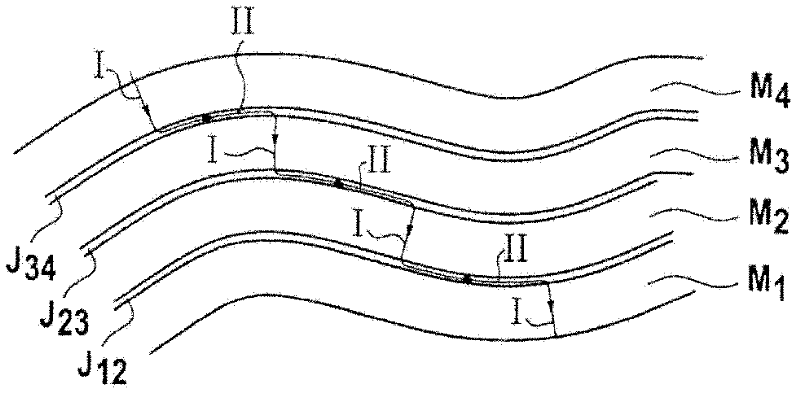

The invention relates to an intermediate roller contour, in particular to an intermediate roller contour of an intermediate roller movable type convexity high-accuracy control temper mill. The intermediate roller contour of the intermediate roller movable type convexity high-accuracy control temper mill consists of three continuous line segments, wherein a polynomial curve equation of a head roller contour is y=A2x<2>+A4x<4>+A6x<6>+A8x<8> by taking a crossing point of a head part and an intermediate segment as an origin of coordinates, axial direction of the intermediate roller as an X axis and radial direction of the intermediate roller as a Y axis; and in the equation, the origin of coordinates is the crossing point of the head roller contour and the intermediate segment, the axial direction of the intermediate roller is the X axis, the radial direction of the intermediate roller is the Y axis, R' is radius difference between roller bodies of two roller-shaped ends of the head, and L1 is more than 0 and less than or equal to L / 3 and the R' is more than 0 and less than R. Through the roller contour, a forced-contact condition is greatly relieved, contact pressure between rollers is uniformly distributed, a peak value of the contact pressure is greatly reduced, the improvement on the service periods of the rollers is facilitated, a set value of rolling force is reduced, the service life of the rollers is prolonged, and the risk of roller spalling is reduced.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Method of cutting workpiece of film filter

InactiveCN1455271AIncrease the effective thicknessReduce residual stressOptical filtersWavelength-division multiplex systemsEngineeringTransition layer

The method includes two implementing modes. In the first mode, before cutting the work piece, the transition layer connects the assistant substrate to the glass substrate. In the second mode, an other work piece comprises one glass substrate with the thickness being thicker than the final expected thickness. Then, the unwanted part of the glass substrate is removed. The method of the two implementing modes increases the effective thickness of the work piece so as to reduce residual stress of the film filter plate finished product. Moreover, the risk of the film stack peeled off from the glass substrate is reduced when the work piece is cut.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

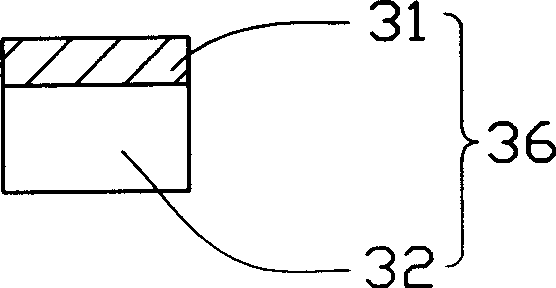

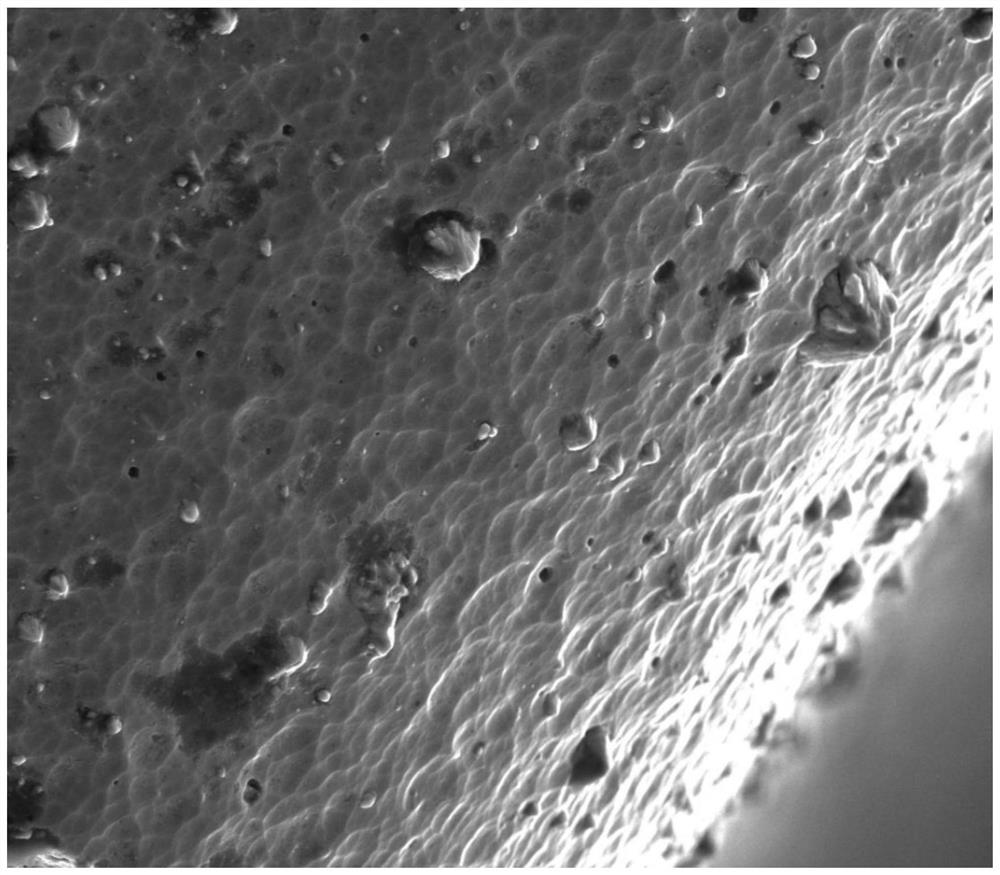

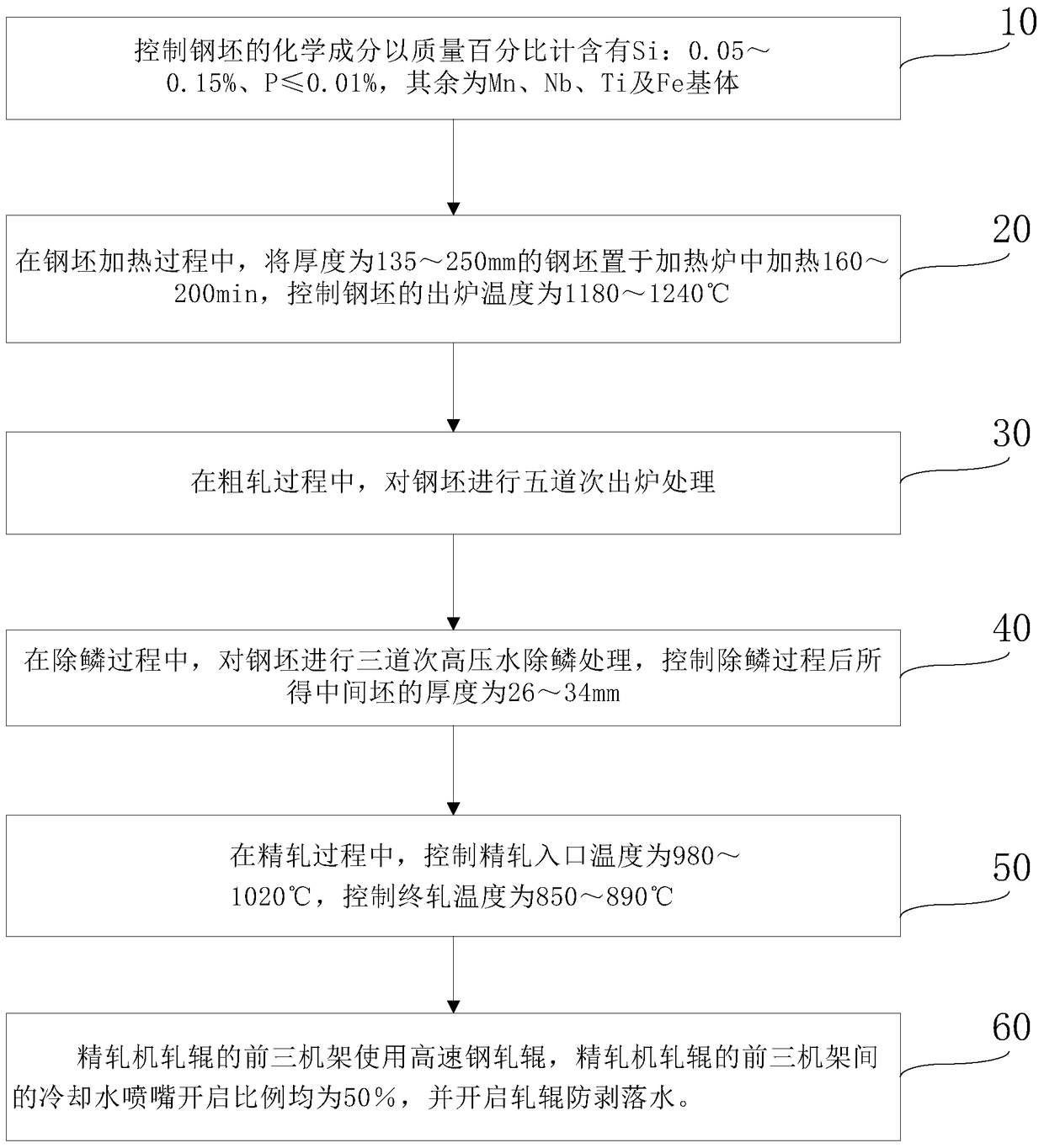

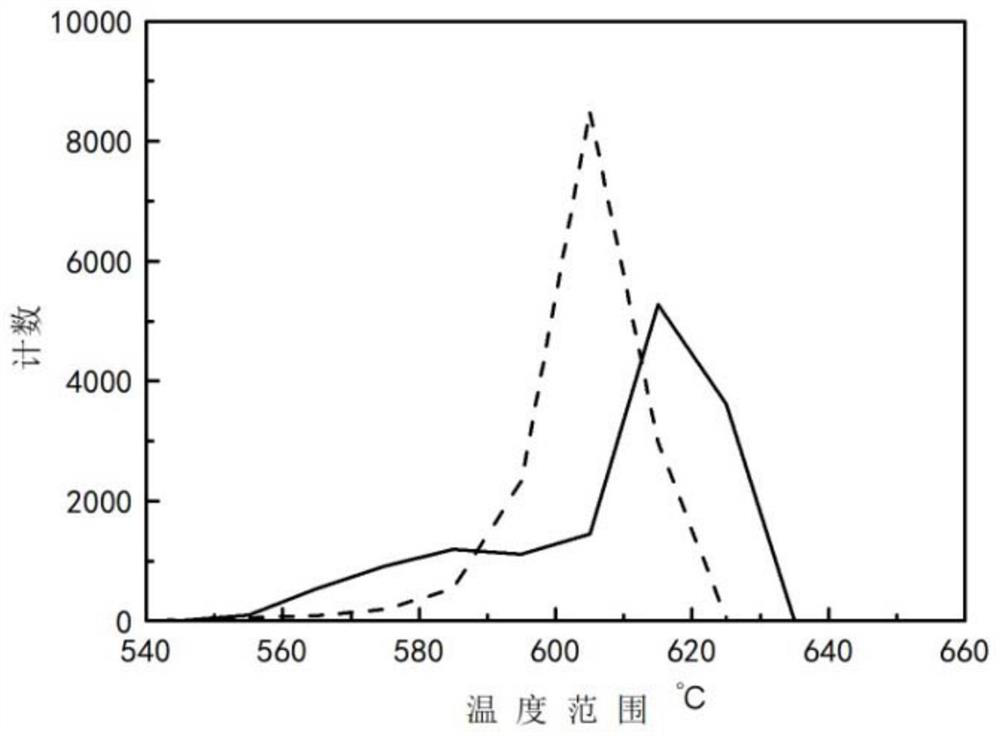

Control method for surface oxidation pocking defects of hot-rolled pickled plate

ActiveCN105251779AReduce the chance of occurrenceReduced rolling load on rollsProfile control deviceSurface oxidationInlet temperature

The invention relates to the technical field of hot rolling, in particular to a control method for surface oxidation pocking defects of a hot-rolled pickled plate. The control method includes the steps that the chemical components of a steel billet are controlled to include, by mass, 0.05-0.15% of Si, at most 0.01% of P and the balance Mn, Nb, Ti and a Fe substrate. In the heating process of the steel billet, the steel billet with the thickness being 135-250 mm is put into a heating furnace and heated for 160-200 min, and the tapping temperature of the steel billet is controlled to be 1180-1240 DEG C. The thickness of an intermediate billet is controlled to be 26-34 mm after a descaling process. In the precision rolling process, the precision rolling inlet temperature is controlled to be 980-1020 DEG C, and the finish rolling temperature is controlled to be 850-890 DEG C. The control method for surface oxidation pocking defects of the hot-rolled pickled plate can effectively restrain the occurrence of surface oxidation pocking defects of the hot-rolled pickled plate with the thickness being at most 2 mm and the tensile strength being at least 500 MPa.

Owner:SHOUGANG CORPORATION +1

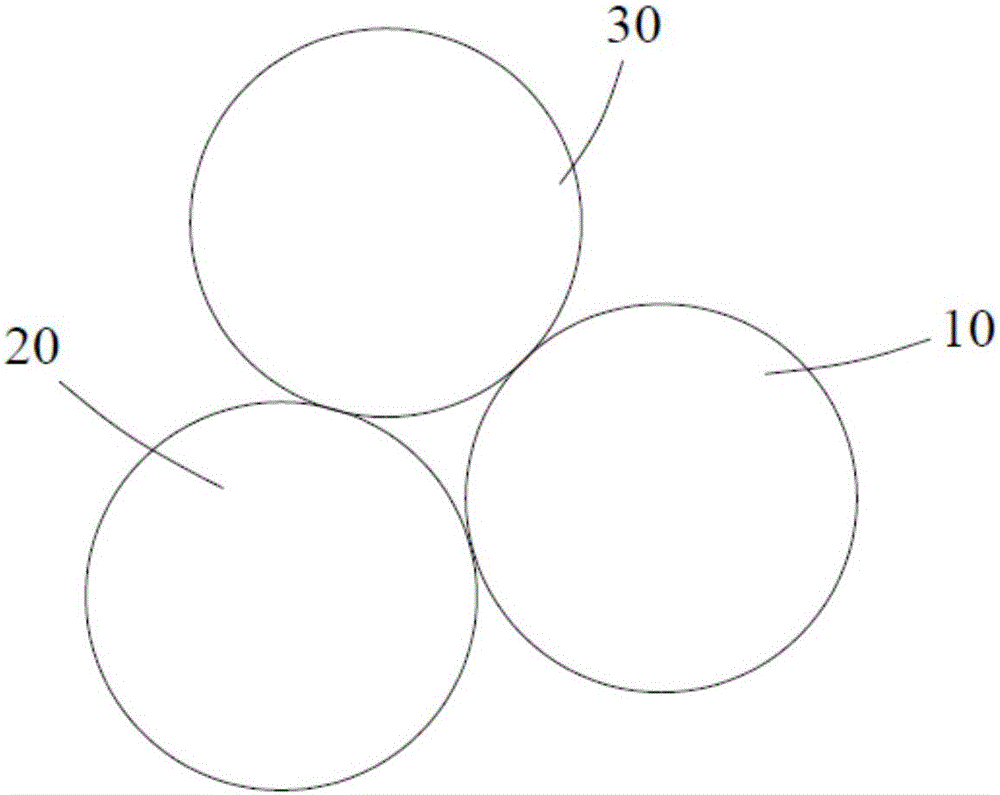

Aramid-spandex sheath-core composite fiber and preparation method thereof

ActiveCN106757508AIncrease elasticityImprove high temperature resistanceConjugated synthetic polymer artificial filamentsDry spinning methodsPolymer scienceSolid structure

The invention relates to an aramid-spandex sheath-core composite fiber and a preparation method thereof. The method is characterized in that a sheath layer spinning solution and a core layer spinning solution are simultaneously extruded in a sheath-core structure and subjected to dry spinning through a spinneret plate assembly of which a spinneret orifice is in a concentric circle form. A sheath layer of the aramid-spandex sheath core composite fiber is made of an aramid 1313 and a core layer is made of spandex; the section of the fiber is of a concentric circle solid structure; the sheath layer accounts for 5-20% of total weight of the fiber; the prepared aramid-spandex sheath core composite fiber has high resilience and also has high temperature resistance, chemical resistance and wear resistance; and meanwhile, the problems that the sheath layer aramid 1313 fiber is not easy to dye, the sheath-core composite fiber is difficult to spin and mold and the contact interface of the sheath layer and the core is easy to peel off are solved.

Owner:ZHEJIANG HUAFENG SPANDEX

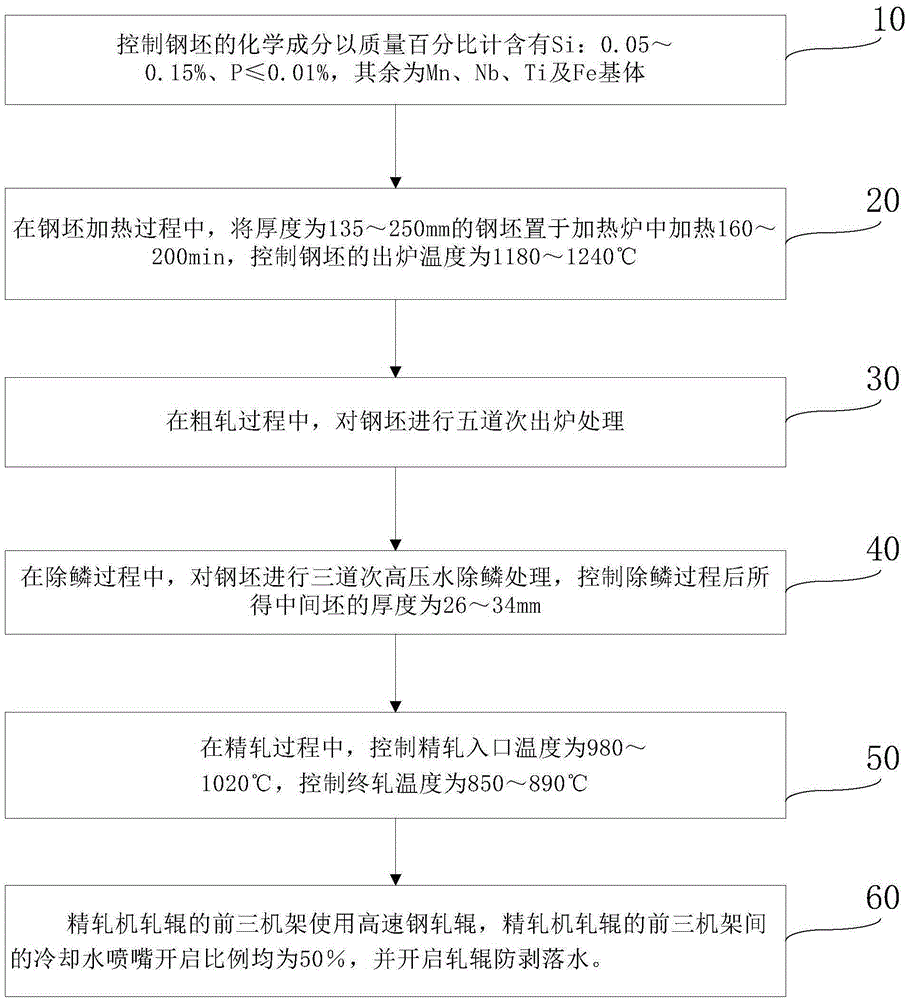

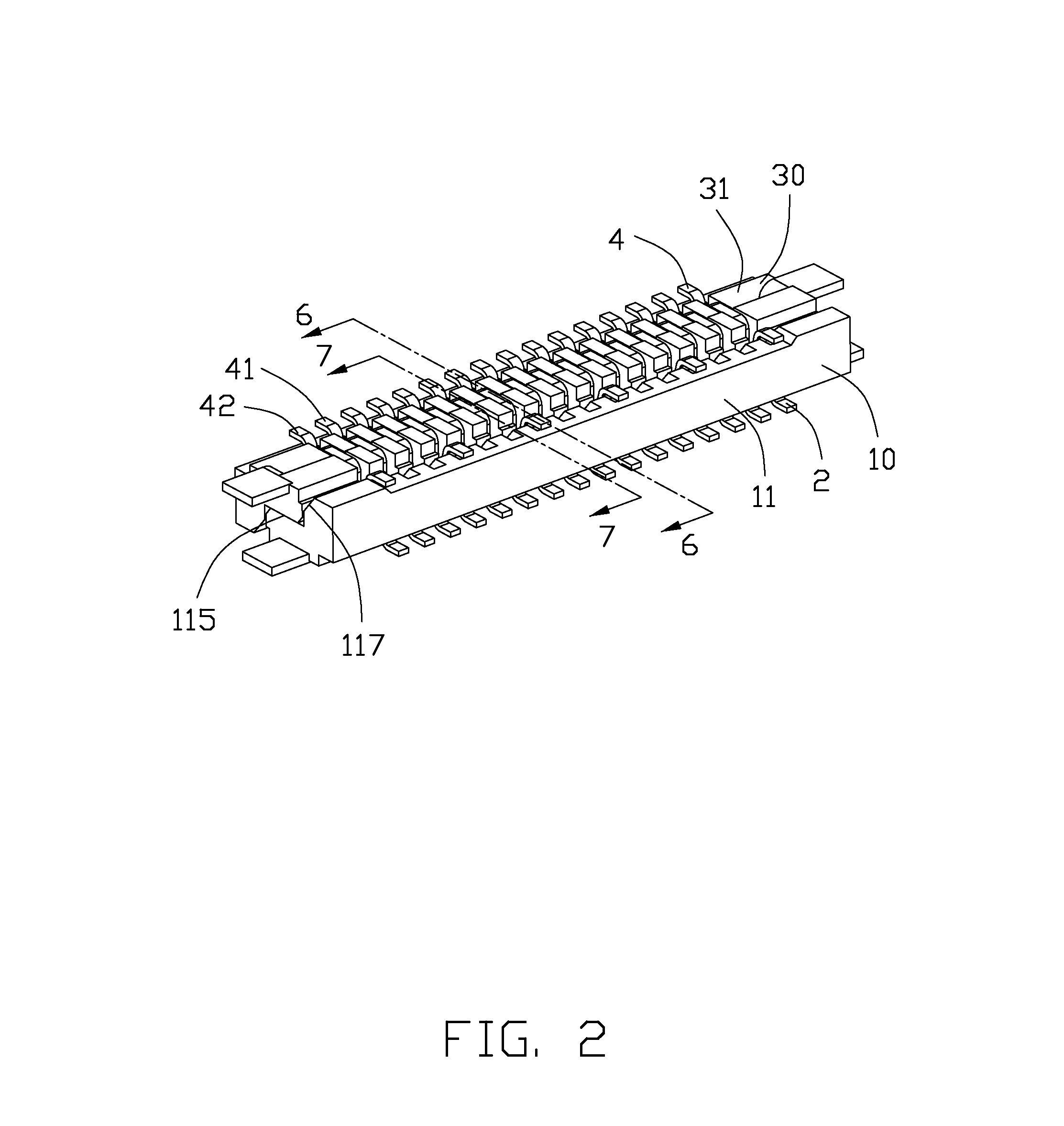

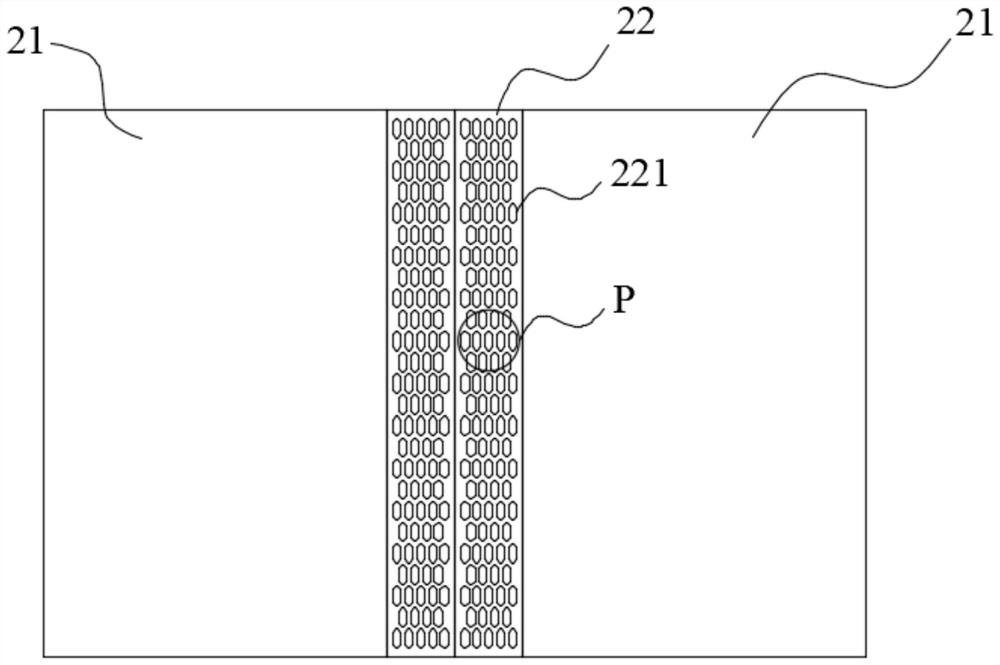

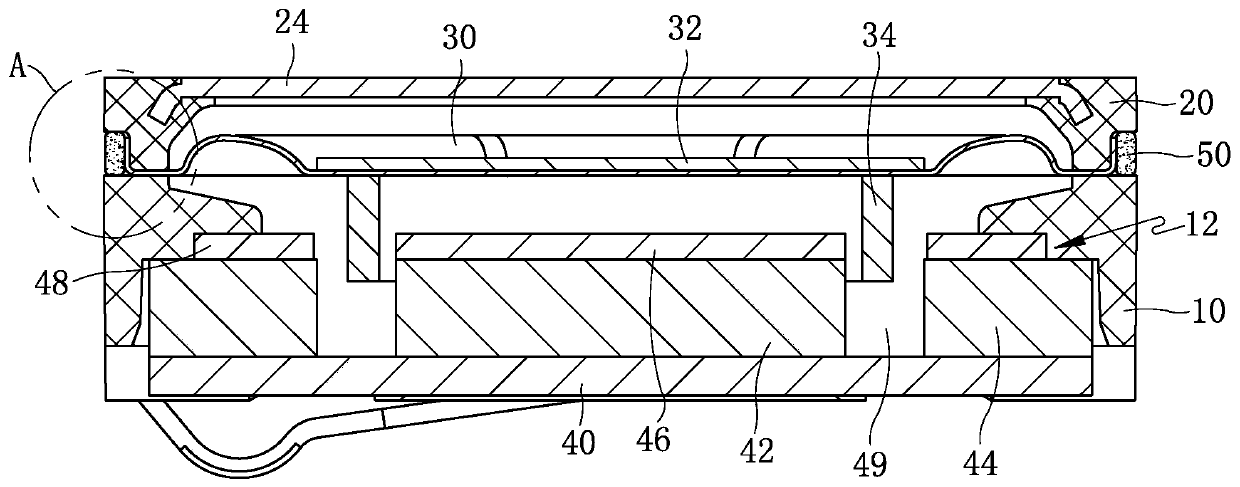

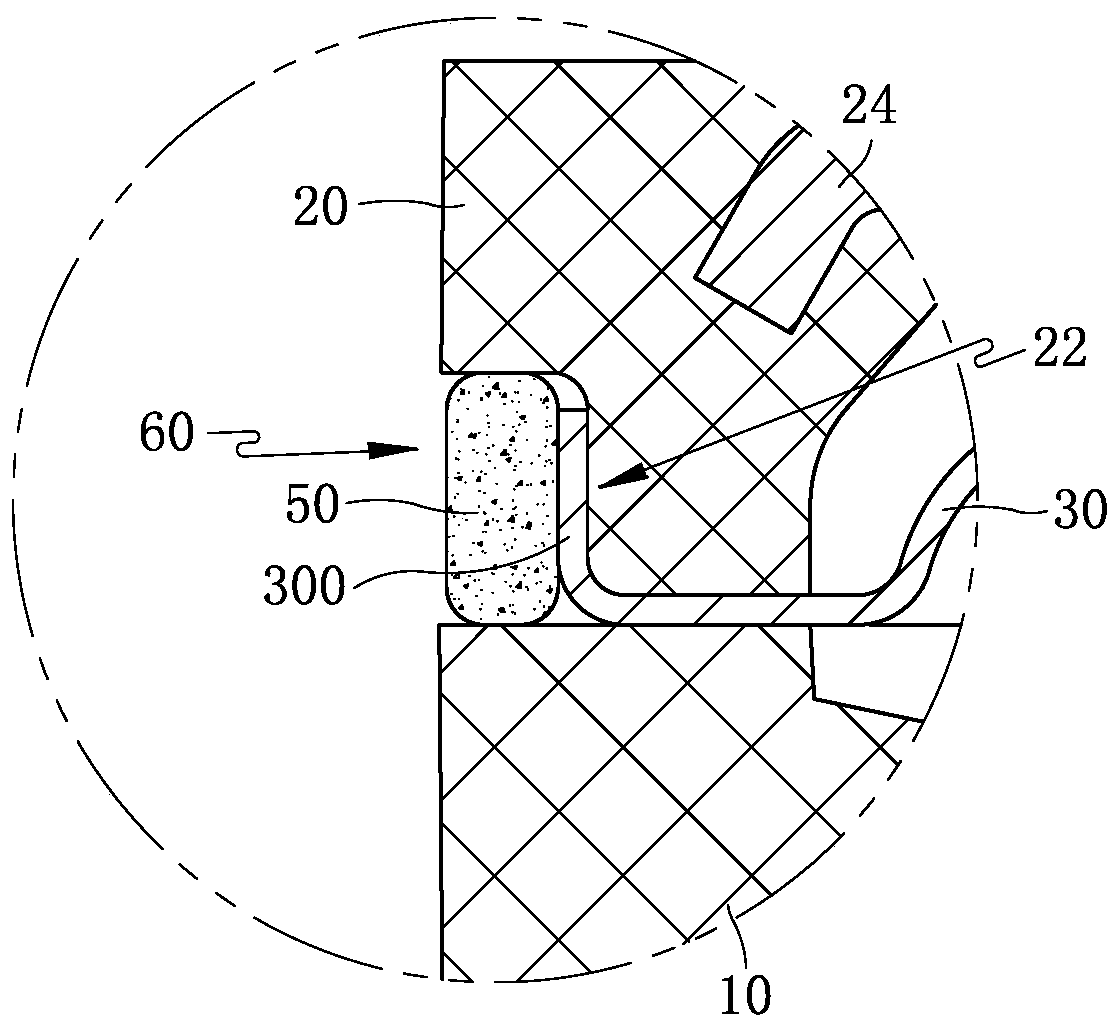

Board to board connector assembly having improved terminal arrangement

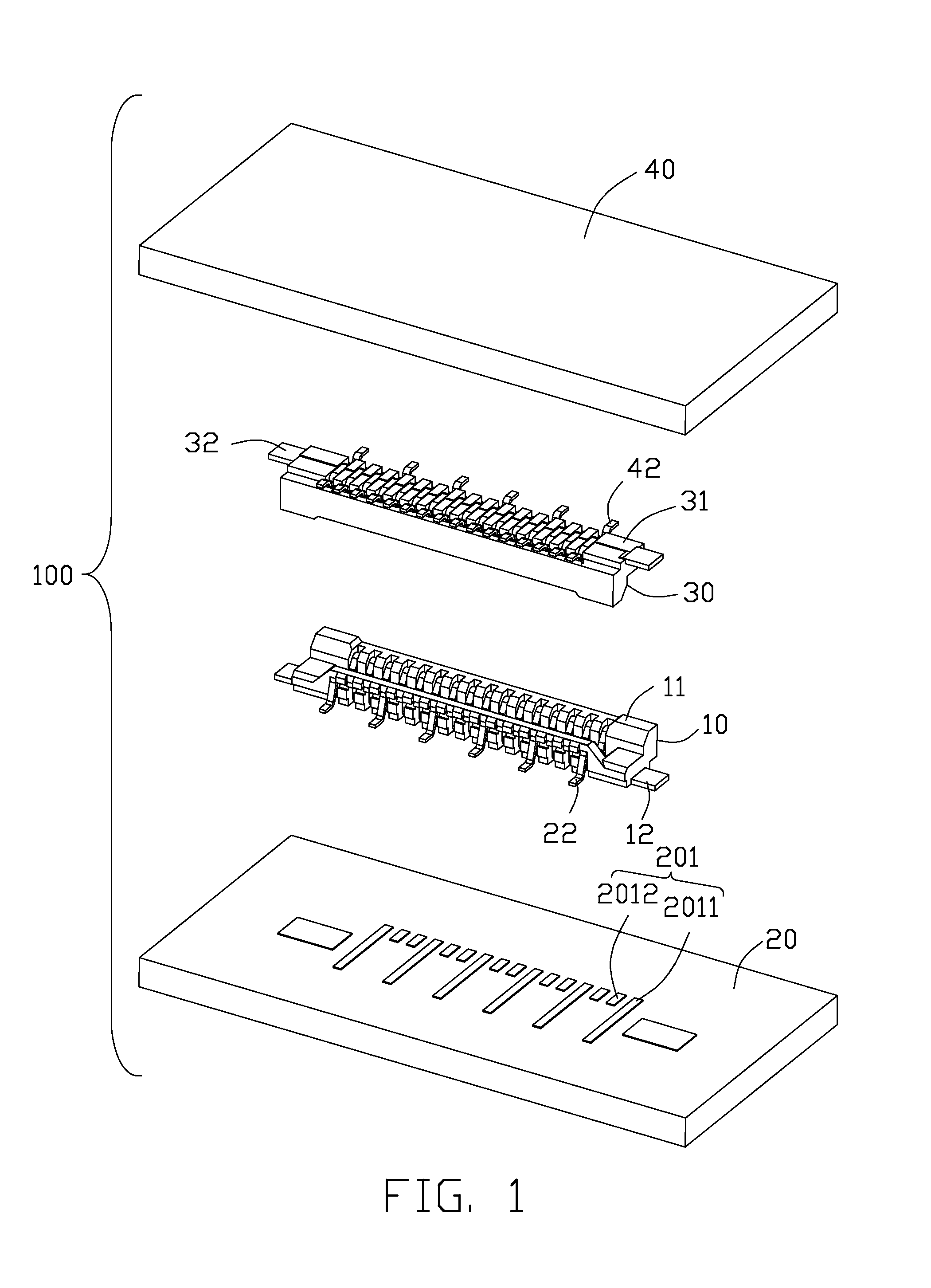

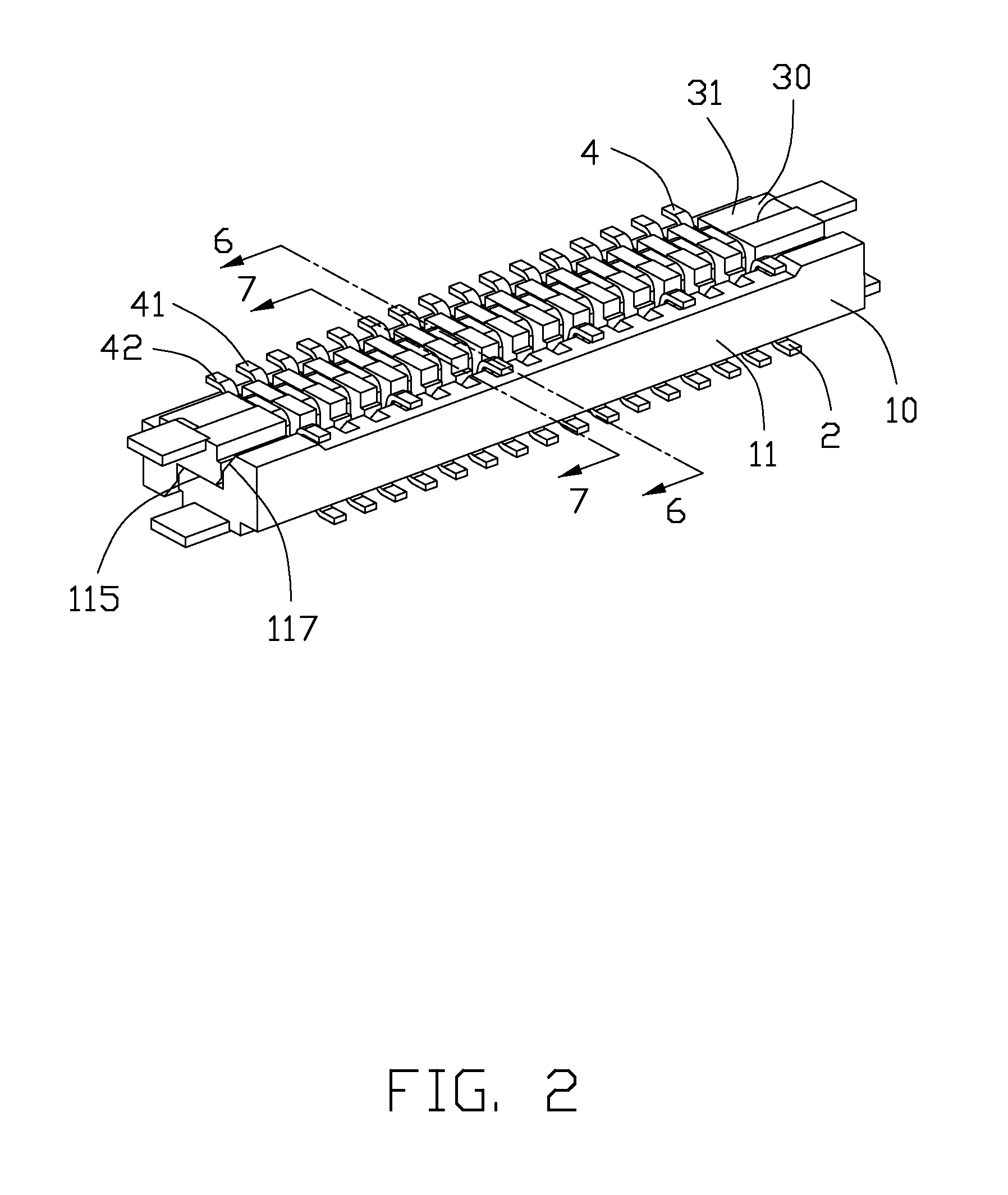

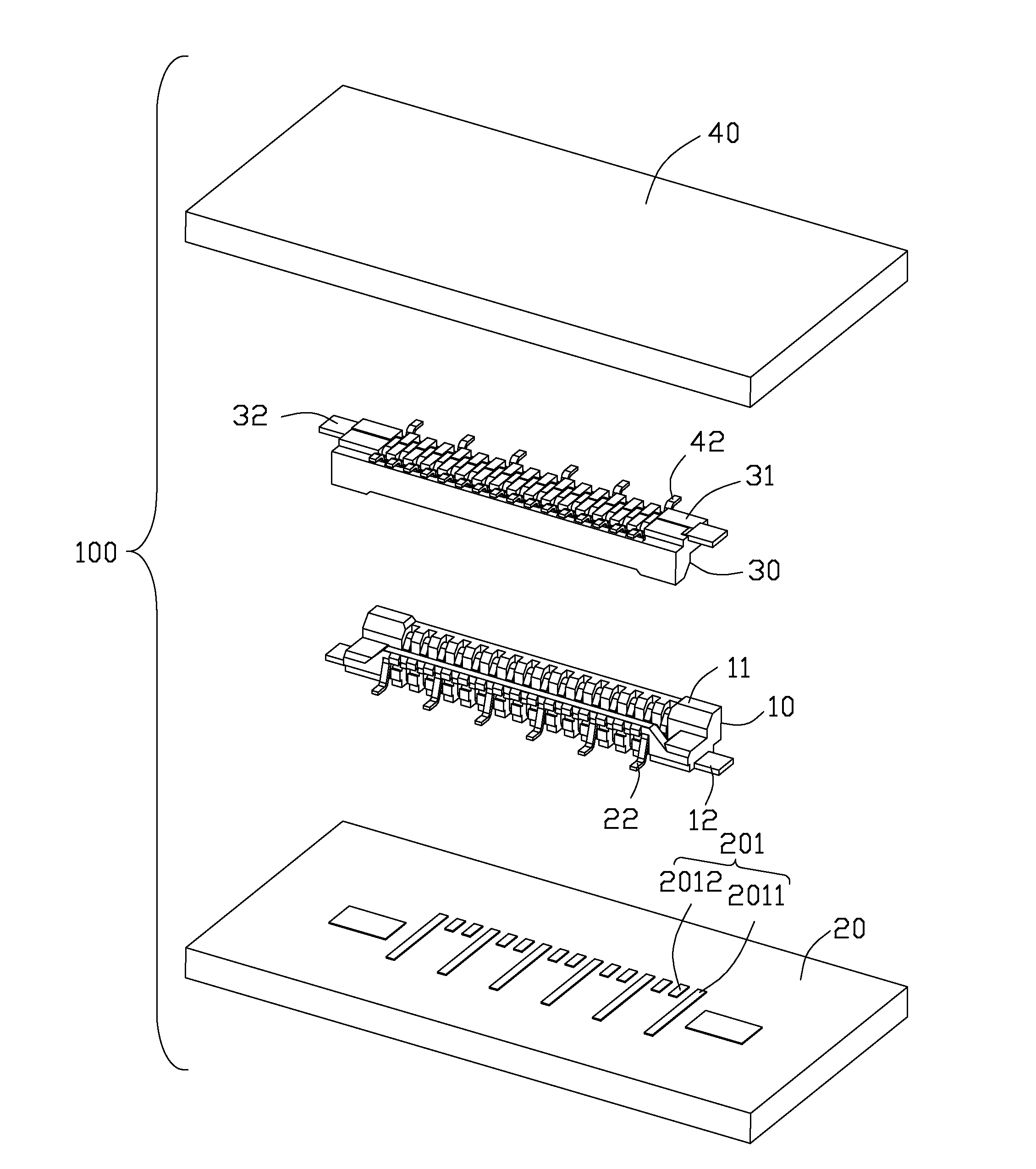

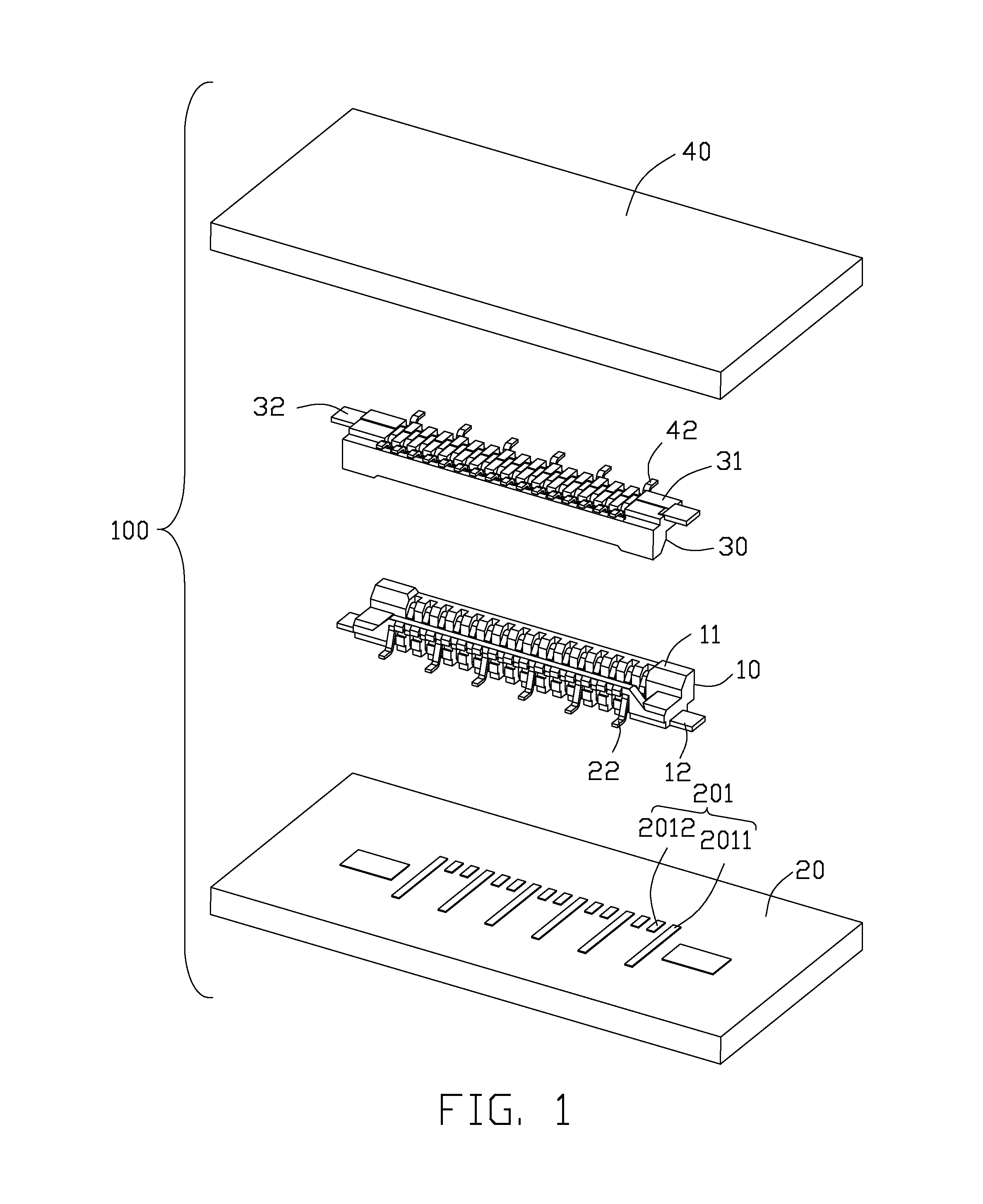

InactiveUS9190752B1Reduced risk of flakingReduce peeling riskCoupling device detailsTwo-part coupling devicesBoard-to-board connectorEngineering

Owner:FOXCONN INTERCONNECT TECH LTD

Board to board connector assembly having improved terminal arrangement

InactiveUS20150311610A1Reduced risk of flakingReduce peeling riskElectric discharge tubesCoupling contact membersBoard-to-board connectorEngineering

A primary connector (10, 20) includes a primary housing (11, 31) and a number of terminal groups. The primary housing includes a periphery wall (111, 311) and a side wall (112, 312) disposed at opposite sides of the primary housing and extending along a longitudinal direction, a slot (113, 313) defined between the periphery wall and the side wall, and a number of passageways (114, 314) extending along a transverse direction for receiving the number of terminal groups. Each terminal group includes a predetermined terminal (22, 42) having a contact section (221, 421) exposed to the slot and a pair of soldering portions (222, 422) respectively extending from opposite sides of the contact section and inserted outwardly from the periphery wall and the side wall.

Owner:FOXCONN INTERCONNECT TECH LTD

Moderate-temperature antioxidation coating and preparation method thereof, and carbon/carbon composite product

The invention provides a moderate-temperature antioxidation coating which is prepared by sintering a coating intermediate. The coating intermediate comprises a first coating compounded on a matrix surface, a second coating compounded on the first coating, and an ethyl orthosilicate layer compounded on the second coating. The first coating is prepared from a H3BO3-H3PO4 mixed acid solution. The second coating is prepared from B2O3, SiO2, Mn(H2PO4)2, ZrO2, CaF2, Al2O3, B4C, CeO2 and silica sol. The manganese can promote the flowability of the anti-glass phase in the sintering process; and by using the ethyl orthosilicate as a hole sealing agent, the silicon dioxide generated in the sintering process can fill pores in the antioxidation coating and reduce the risk of peeling of the antioxidation coating. The invention also provides a preparation method of the moderate-temperature antioxidation coating and a carbon / carbon composite product.

Owner:HUNAN BOYUN NEW MATERIALS

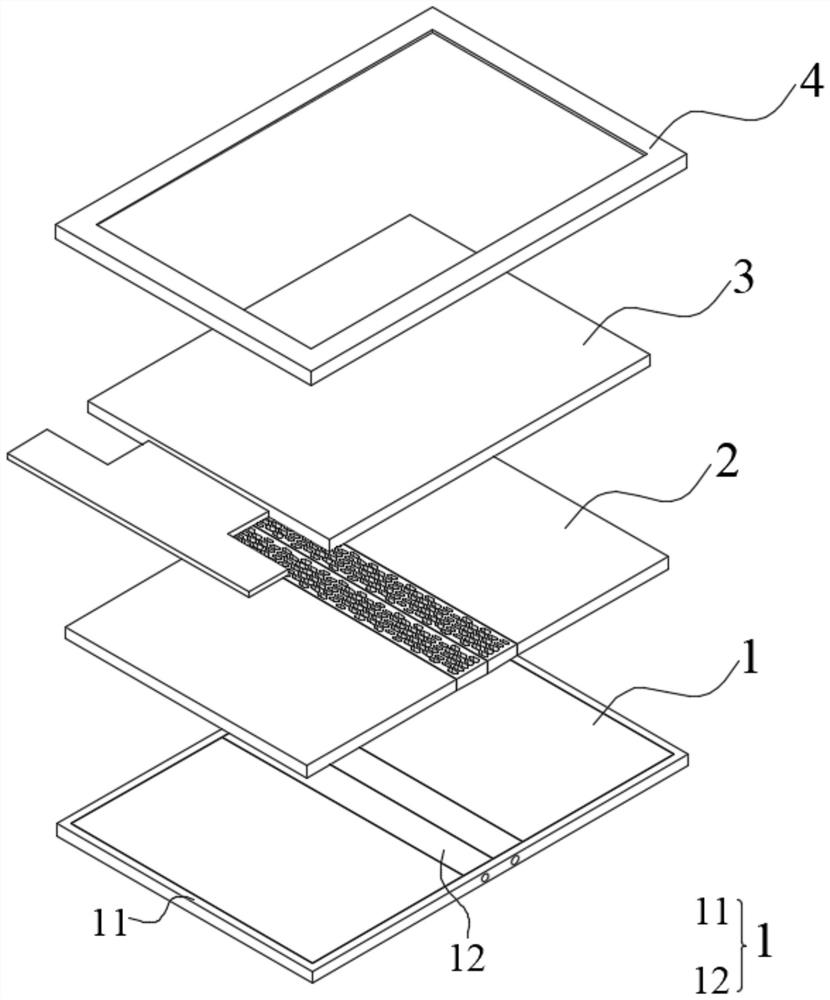

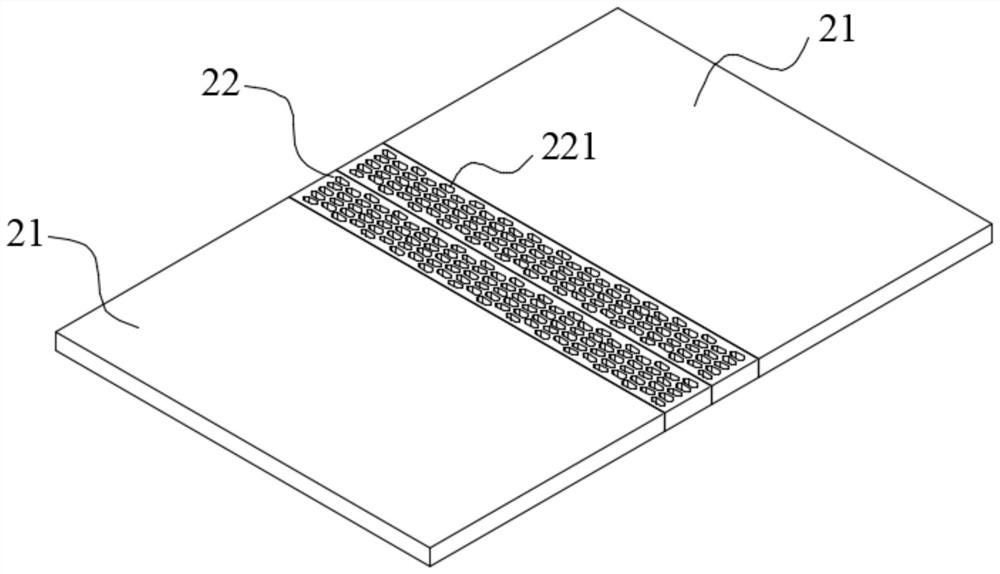

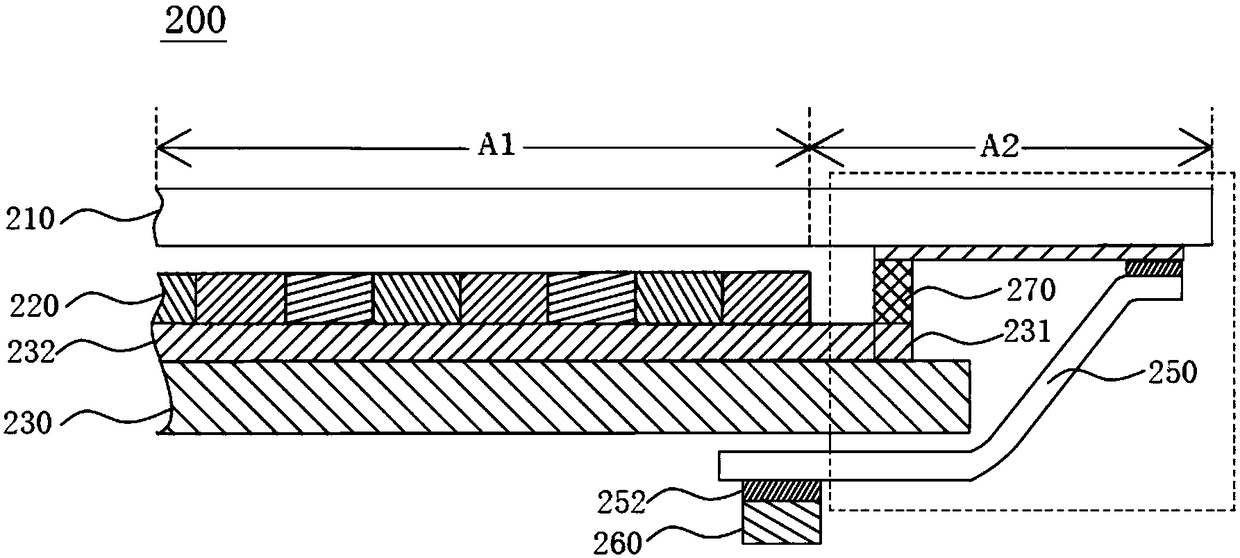

Foldable display panel and foldable display device

The invention discloses a foldable display panel and a foldable display device. The foldable display panel comprises a front cover plate, a flexible screen module, a supporting plate and a bending assembly which are stacked in sequence. The supporting plate comprises at least two non-bending areas and a bending area connected with each non-bending area, the bending area comprises a plurality of rows of open holes formed at intervals, and every two adjacent rows of open holes are formed in a staggered mode. The metal plate and the supporting plate are integrated, patterned trepanning is conducted on the bent area of the supporting plate, the segment difference is eliminated, the relative dislocation amount is reduced, the peeling risk is reduced, meanwhile, due to the fact that the bendingresistance, the recovery performance and the material strength are good, the unevenness is reduced, the good supporting and protecting effects are achieved, assembly and matching with the whole machine are facilitated, the production cost is reduced, and the production yield and the product quality are improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

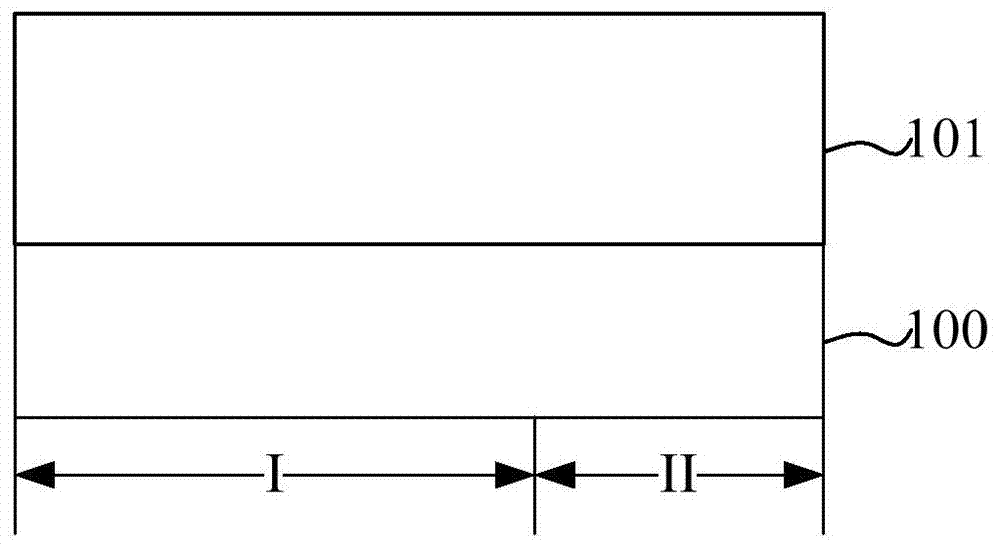

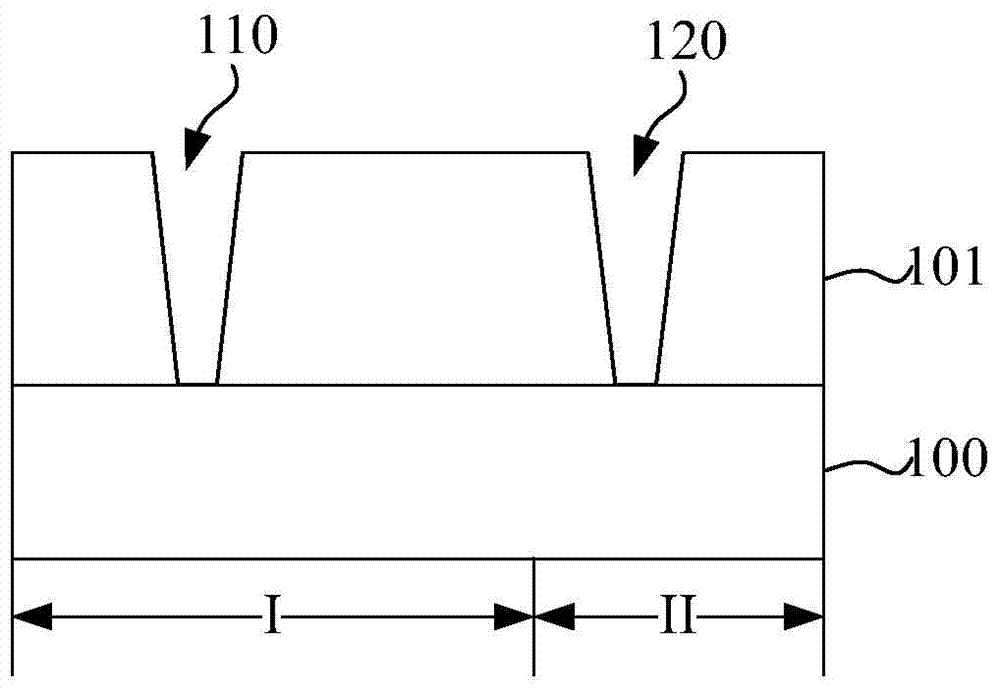

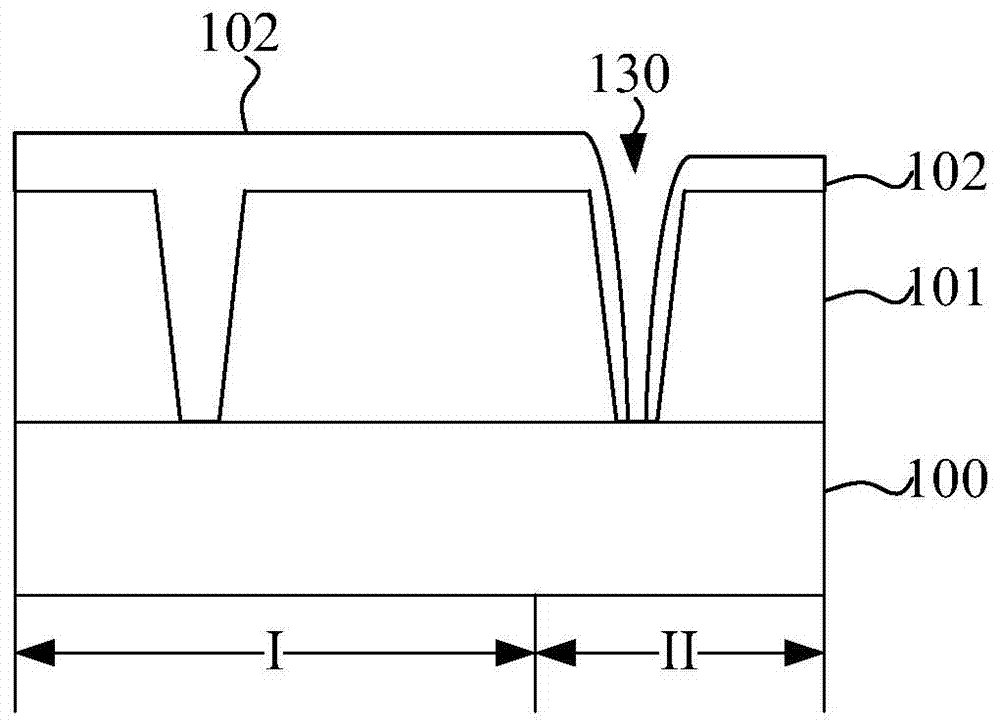

Semiconductor device and forming method thereof

ActiveCN104752320AWon't hurtImprove adhesionSemiconductor/solid-state device detailsSolid-state devicesDielectric layerSemiconductor

A semiconductor device and a forming method thereof are provided. The forming method of the semiconductor device comprises the following steps: providing a wafer which is divided into a device region and a wafer edge; forming a first dielectric layer on the wafer; forming a first contact hole corresponding to the device region and a second contact hole corresponding to the wafer edge in the first dielectric layer; forming a conductive layer which covers the first dielectric layer, fills the first contact hole completely and fills the second contact hole, wherein the conductive layer in the second contact hole is provided with a hole communicating the opening with the bottom of the second contact hole; forming a filling layer which covers the conductive layer and fills the hole completely; and removing the conductive layer and the filling layer on the first dielectric layer, wherein the remaining conductive layer in the first contact hole is used as a first plug layer, and the remaining filling layer and the reaming conductive layer in the second contact hole are used as a first pseudo plug layer. The first pseudo plug layer can bear large stress, and multiple dummy plug layers and pseudo metal layers do not peel off. Thus, the first dielectric layer has better insulation isolation performance.

Owner:SEMICON MFG INT (SHANGHAI) CORP

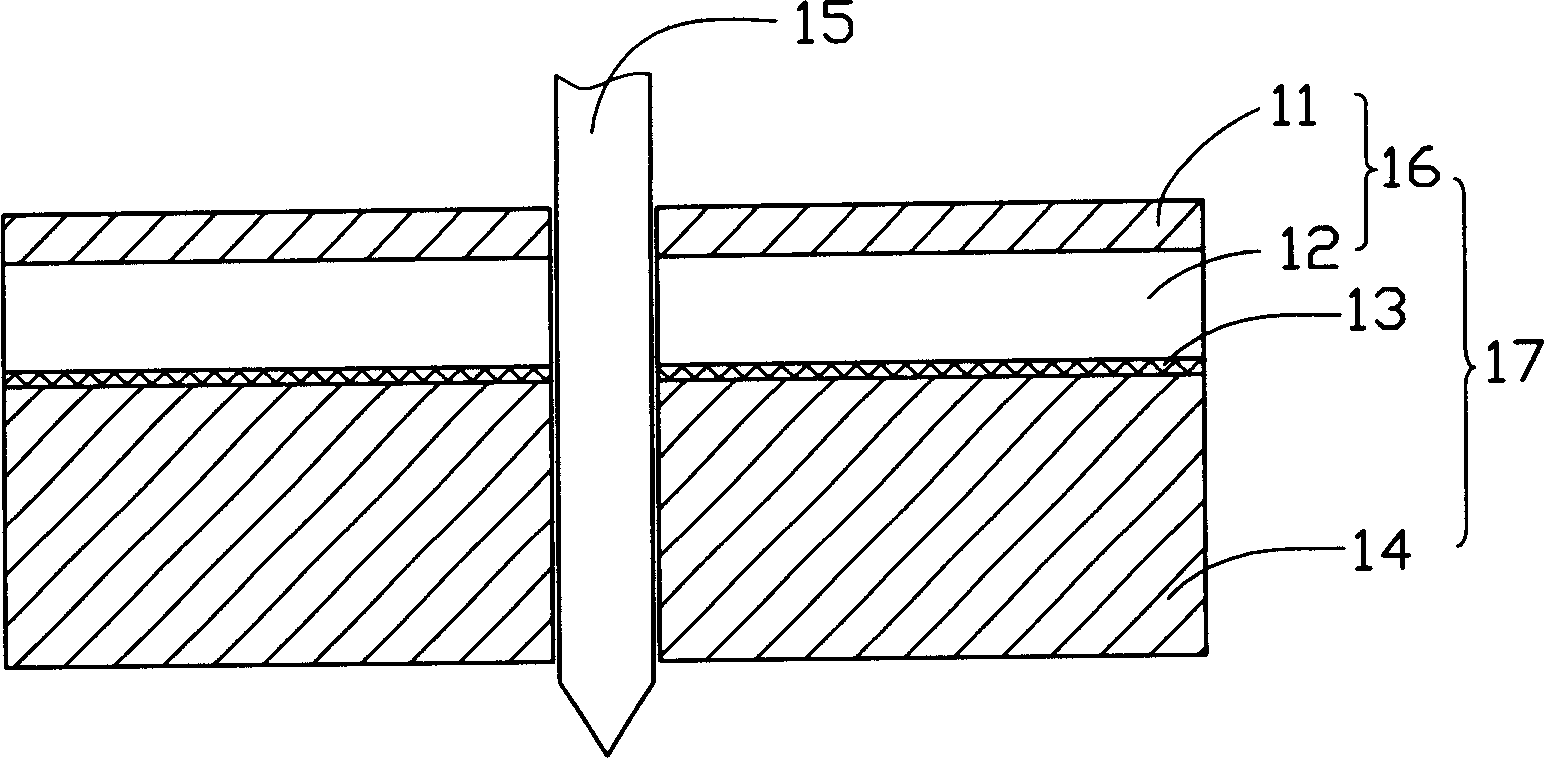

Composite material part having a ceramic matrix, and method for manufacturing same

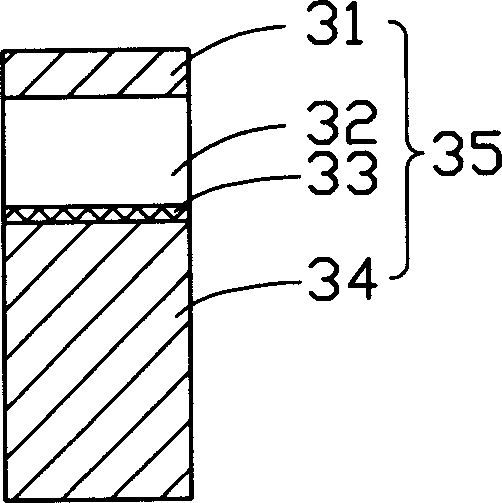

InactiveCN102470630AIncrease resistanceReduced risk of flakingLayered productsThin material handlingContact padMaterials science

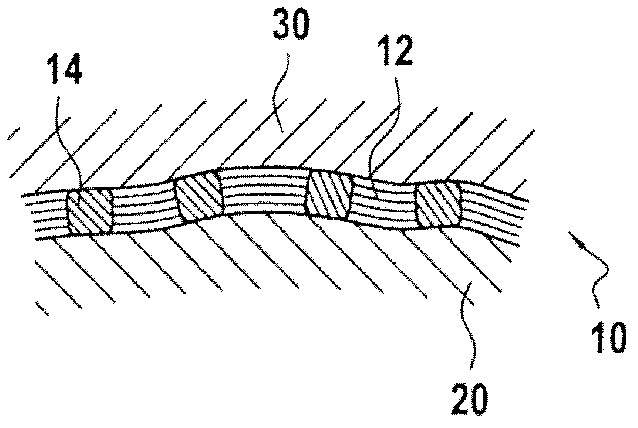

In a composite material part having a ceramic matrix and including a fibrous reinforcement which is densified by a matrix consisting of a plurality of ceramic layers having a crack-diverting matrix interphase positioned between two adjacent ceramic matrix layers, the interphase (10) includes: a first phase (12) made of a material conducive to the diversion of a crack reaching the interphase according to a first propagation mode in the transverse direction through one of the two ceramic matrix layers adjacent to the interphase, such that the propagation of the crack continues according to a second propagation mode along the interphase; and a second phase consisting of discrete contact pads (14) that are distributed within the interphase and conducive to the diversion of the crack that propagates along the interphase according to the second propagation mode, such that the propagation of the crack is diverted and continues according to the first propagation mode through the other ceramic matrix layer that is adjacent to the interphase.

Owner:GERAKL

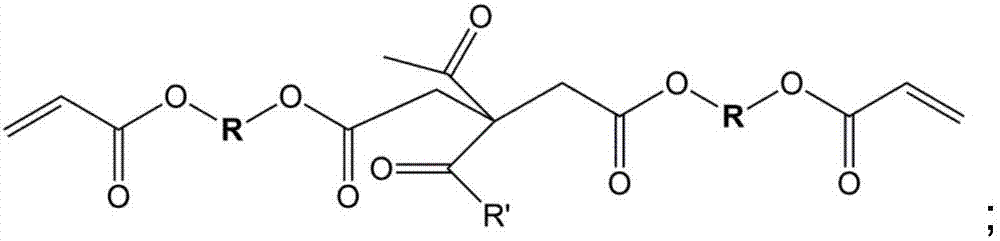

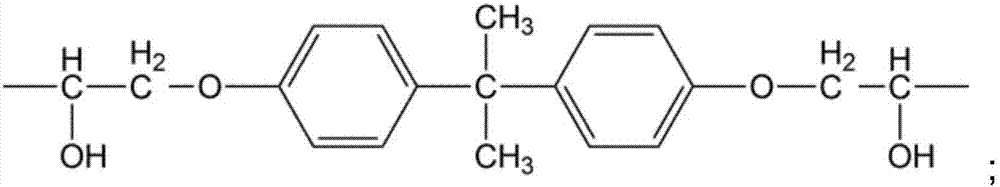

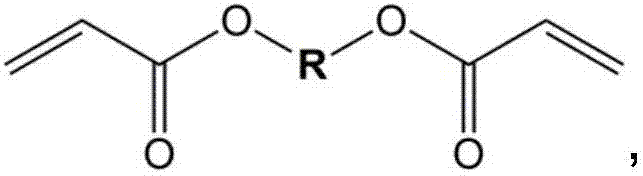

Photoresist composition and photoresist

The invention provides a photoresist composition and photoresist. The photoresist composition is prepared from, by mass, 4-10% of a resin matrix, 5-8% of pigment / dye, 0-5% of reactive diluent monomer and 70-80% of solvent, the resin matrix contains acrylic resin and self-initiated resin, and the self-initiated resin is 0-2% by mass. According to the photoresist composition and the photoresist, in a curing system, the mobility is small, and the deep curability is good; the surface layer and the bottom layer of the photoresist composition can both perform sufficient curing reactions, and the risk of peeling off of the cured photoresist composition is reduced.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

Multi-component parallel type functional fibre and preparation method thereof

InactiveCN105734756AReduced risk of flakingGood antibacterial effectFilament/thread formingYarnFlax fiberCotton fibre

The application discloses a multi-component side-by-side functional fiber, which includes three bundles of fiber bodies mixed with each other, and the three bundles of fiber bodies are antibacterial fibers, cotton fibers and flax fibers respectively. For the fiber skin layer covering the outer side of the fiber core layer, the inner wall of the fiber skin layer protrudes inwardly with reinforcing ribs embedded in the fiber core layer, and the outer wall of the fiber skin layer is wound with silver fibers. The invention also discloses a preparation method of multi-component side-by-side functional fibers. The present invention integrates the superior characteristics of more than three kinds of raw materials, allowing them to be reflected on the same fiber, so that the prepared fabric not only has the softness, close-fitting and air permeability of cotton and linen, but also has been treated with antibacterial agents, which is more healthy and antibacterial, and obtains a Clothing fabric with various functions.

Owner:JIANGSU BIG WELL MICRO FIBER MFG

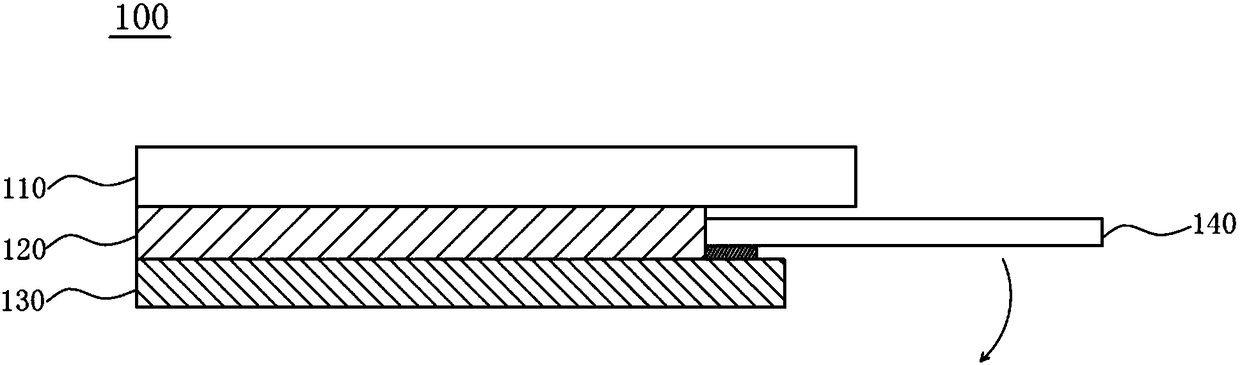

OLED display device

InactiveCN108364996AReduced risk of flakingImprove fit stabilityCasings/cabinets/drawers detailsSolid-state devicesDisplay deviceEngineering

The invention discloses an OLED display device. The OLED display device comprises a bottom plate and a cover plate which are opposite, and the bottom plate is provided with a first surface and a second surface which are opposite. The OLED display device further comprises a display area, a non-display area, an OLED light-emitting assembly, first electrodes, second electrodes, conductive protrusionsand a flexible printed circuit board, wherein the OLED light-emitting assembly is arranged on the first surface of the bottom plate; the first electrodes are arranged on the first surface of the bottom plate and located in the non-display area; the second electrodes are arranged on the cover plate and located in the non-display area; the conductive protrusions are arranged between the bottom plate and the cover plate and are electrically connected with the first electrodes and the second electrodes respectively; the flexible printed circuit board is provided with a first end and a second endwhich are opposite, the first end is electrically connected with the second electrodes, and the second end extends to the side, wherein the second surface is located, of the bottom plate. According tothe OLED display device, the risk that the flexible printed circuit board is peeled off is reduced, and the fitting stability of the flexible printed circuit board is improved.

Owner:AU OPTRONICS CORP

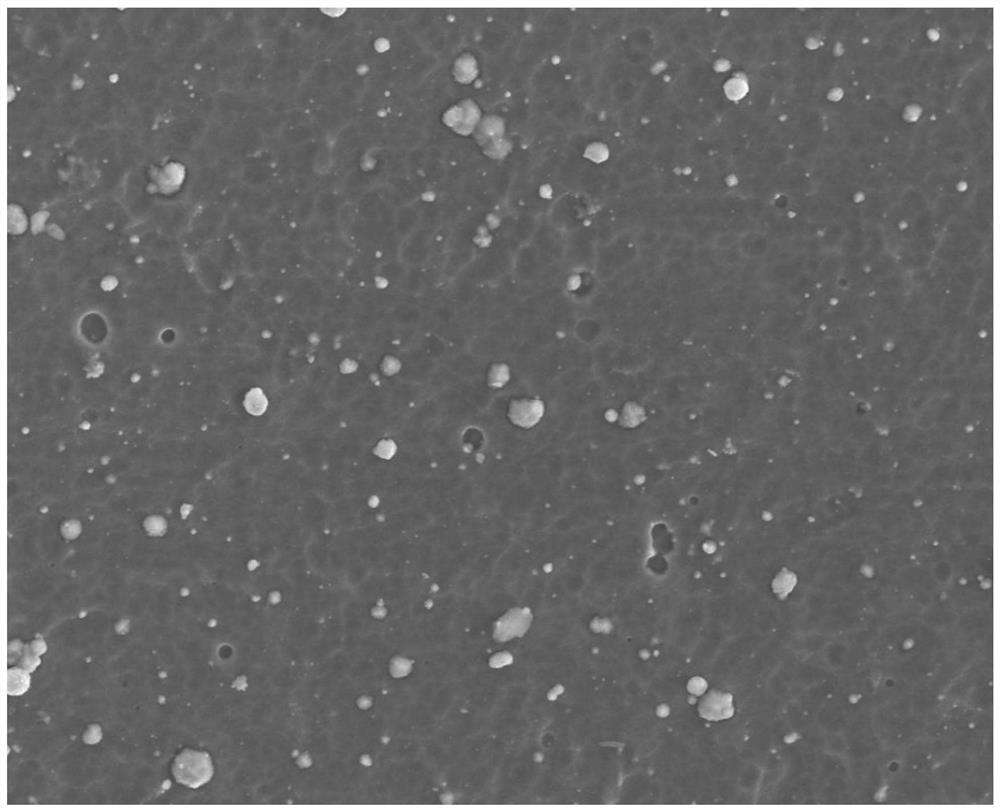

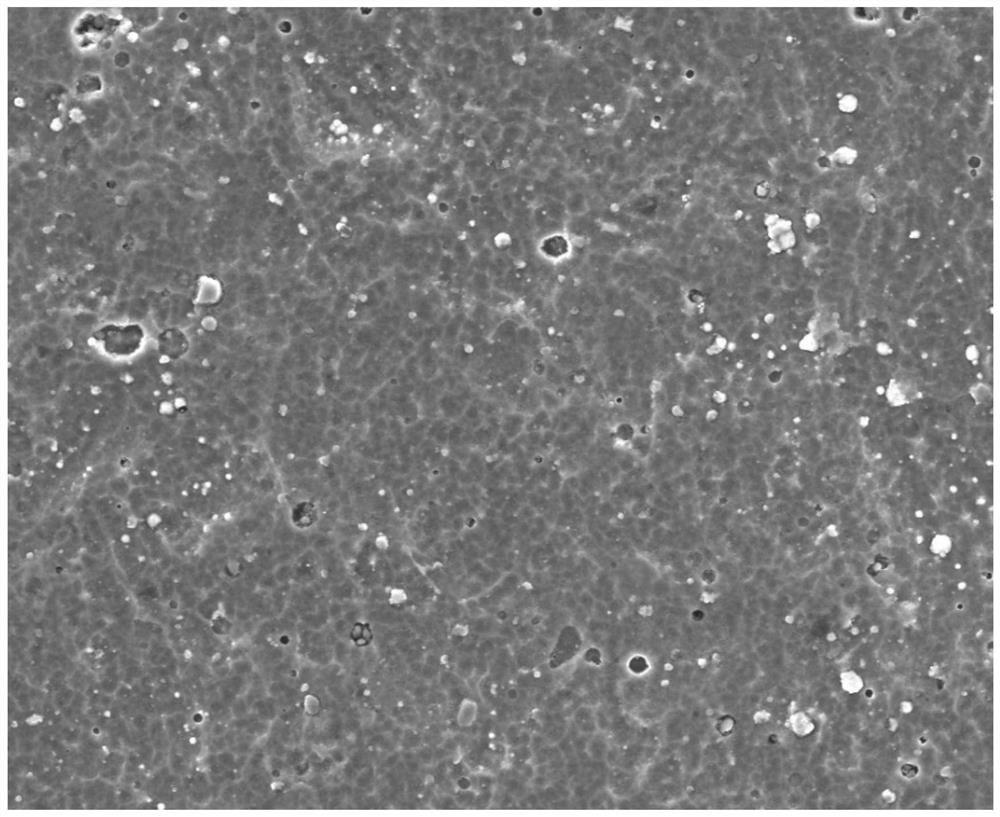

Method for improving the adhesion of plated metal layers to silicon

InactiveCN104603956AReduced risk of flakingImprove adhesionPhotovoltaic energy generationSemiconductor devicesElectrical and Electronics engineeringMetal

A method is disclosed for fabricating photovoltaic cells, the method comprising providing plated metal contacts with a contact pattern comprising a plurality of fingers and at least one first pinning element at the free ends of each of the plurality of fingers; and associated photovoltaic cells.

Owner:INTERUNIVERSITAIR MICRO ELECTRONICS CENT (IMEC VZW) +1

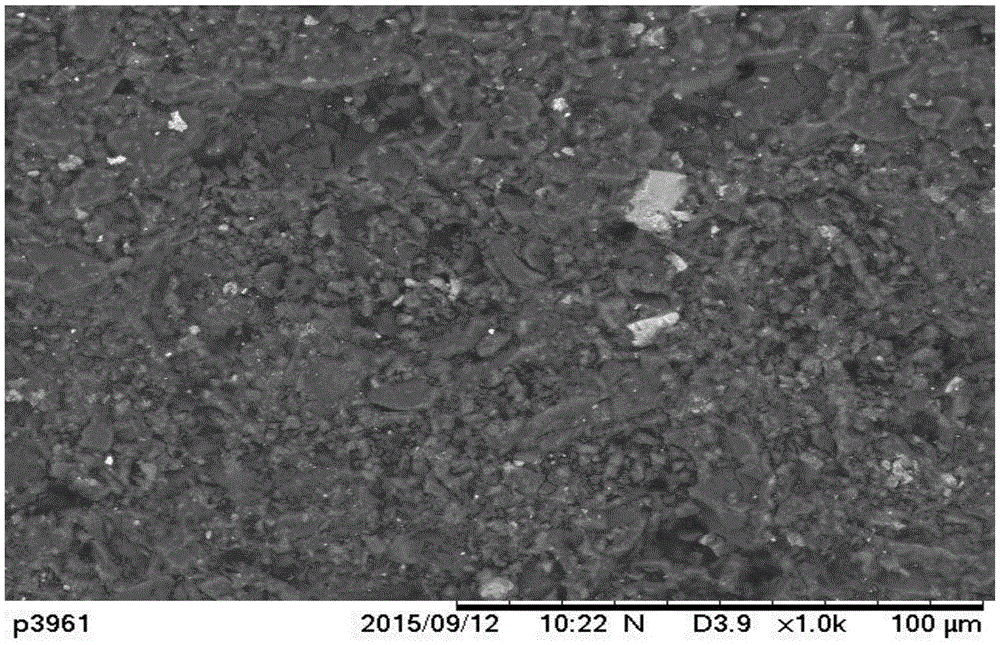

Cleaning method used before coating of hard alloy numerical control blade

ActiveCN113373453AExtended service lifeReduced risk of flakingCleaning using liquidsNumerical controlMegasonic cleaning

The invention relates to the technical field of production of hard alloy numerical control coating blades, and particularly discloses a cleaning method used before coating of a hard alloy numerical control blade. The cleaning method comprises the steps that first cleaning liquid, second cleaning liquid, third cleaning liquid, fourth cleaning liquid and fifth cleaning liquid suitable for a WC-Co type hard alloy numerical control blade base body are prepared, and the surface of a coating base body is cleaned through an improved ultrasonic cleaning process; the first cleaning liquid is powerful alkaline metal cleaning liquid; the third cleaning liquid is weak alkaline metal cleaning liquid; the fifth cleaning liquid is cleaning liquid containing an antioxidant; and the second cleaning liquid and the fourth cleaning liquid are pure water. The first cleaning liquid, the second cleaning liquid, the third cleaning liquid, the fourth cleaning liquid and the fifth cleaning liquid and the improved ultrasonic cleaning process are adopted, the cleanliness of the surface of the coating base body can be guaranteed, the production efficiency can be improved, meanwhile, it can be guaranteed that the surface of the hard alloy numerical control blade base body is not oxidized by moisture in multiple working days after cleaning, and therefore the bonding strength of the coating and the hard alloy numerical control blade base body is improved, and the service life of the hard alloy numerical control coating blade is prolonged.

Owner:江西江钨硬质合金有限公司

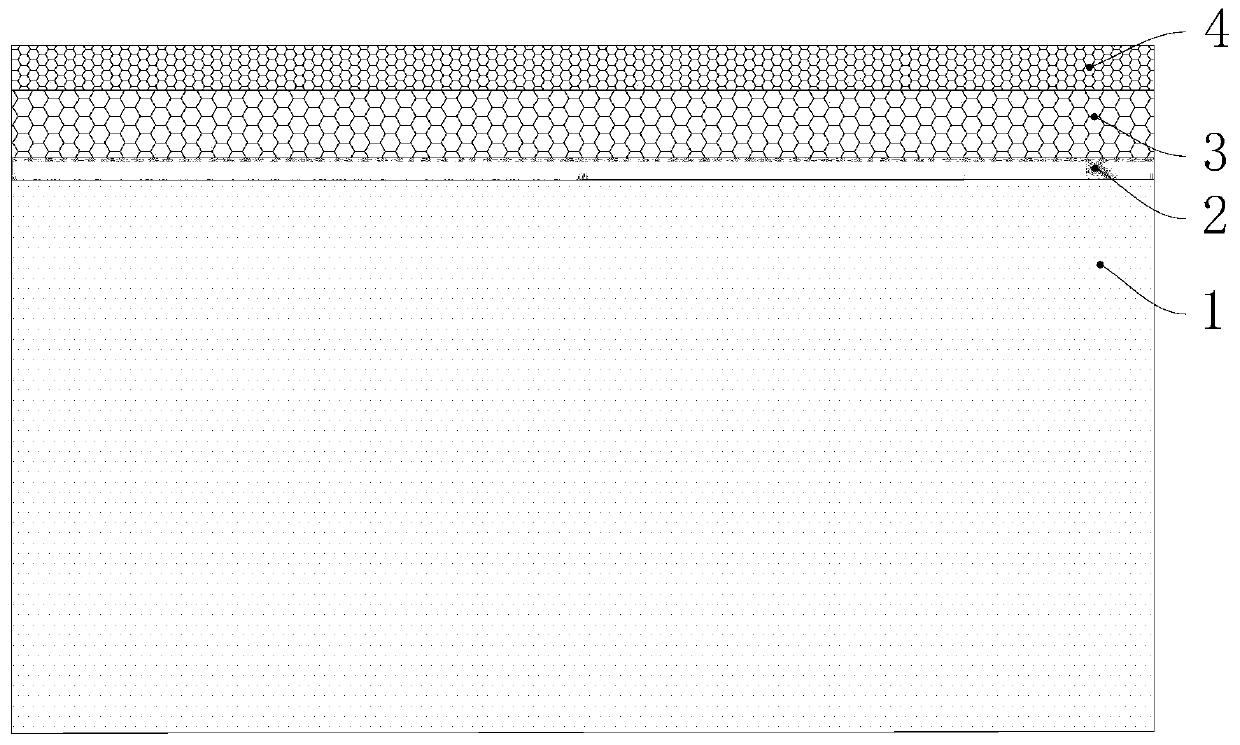

Radial tire bead wire containing surface coating and preparation method of radial tire bead wire

InactiveCN113005494AReduce the number of plating layersReduced risk of plating spallingTyre beadsComposite materialRadial tire

The invention discloses a radial tire bead wire containing a surface coating.The radial tire bead wire is characterized in that the surface of the radial tire bead wire is plated with the coating, the coating comprises an inner layer and an outer layer, the outer layer is a copper-nickel-aluminum-zinc coating with the thickness being 0.04-0.06 micron, and the inner layer is a copper-nickel-zinc coating with the thickness being 0.05-0.08 micron; the content of copper in the copper-nickel-aluminum-zinc coating is 30-38 wt%, the content of nickel in the copper-nickel-aluminum-zinc coating is 21-28 wt%, the content of aluminum in the copper-nickel-aluminum-zinc coating is 5-12 wt%, the balance is zinc, the content of copper in the copper-nickel-zinc coating is 32-48 wt%, the content of nickel in the copper-nickel-zinc coating is 22-26 wt%, and the balance is zinc. The invention further discloses a preparation method of the radial tire bead wire containing the surface coating. According to the radial tire bead wire containing the surface coating, the number of coatings is reduced, the copper-nickel-aluminum-zinc coating is adopted as the outer layer, the bonding force is improved while the coating stripping risk is reduced, and the radial tire bead wire can be suitable for various kinds of rubber.

Owner:无锡益联机械有限公司

A kind of aramid-spandex sheath-core composite fiber and preparation method thereof

ActiveCN106757508BIncrease elasticityImprove high temperature resistanceConjugated synthetic polymer artificial filamentsDry spinning methodsPolymer scienceSolid structure

The invention relates to an aramid-spandex sheath-core composite fiber and a preparation method thereof. The method is characterized in that a sheath layer spinning solution and a core layer spinning solution are simultaneously extruded in a sheath-core structure and subjected to dry spinning through a spinneret plate assembly of which a spinneret orifice is in a concentric circle form. A sheath layer of the aramid-spandex sheath core composite fiber is made of an aramid 1313 and a core layer is made of spandex; the section of the fiber is of a concentric circle solid structure; the sheath layer accounts for 5-20% of total weight of the fiber; the prepared aramid-spandex sheath core composite fiber has high resilience and also has high temperature resistance, chemical resistance and wear resistance; and meanwhile, the problems that the sheath layer aramid 1313 fiber is not easy to dye, the sheath-core composite fiber is difficult to spin and mold and the contact interface of the sheath layer and the core is easy to peel off are solved.

Owner:ZHEJIANG HUAFENG SPANDEX

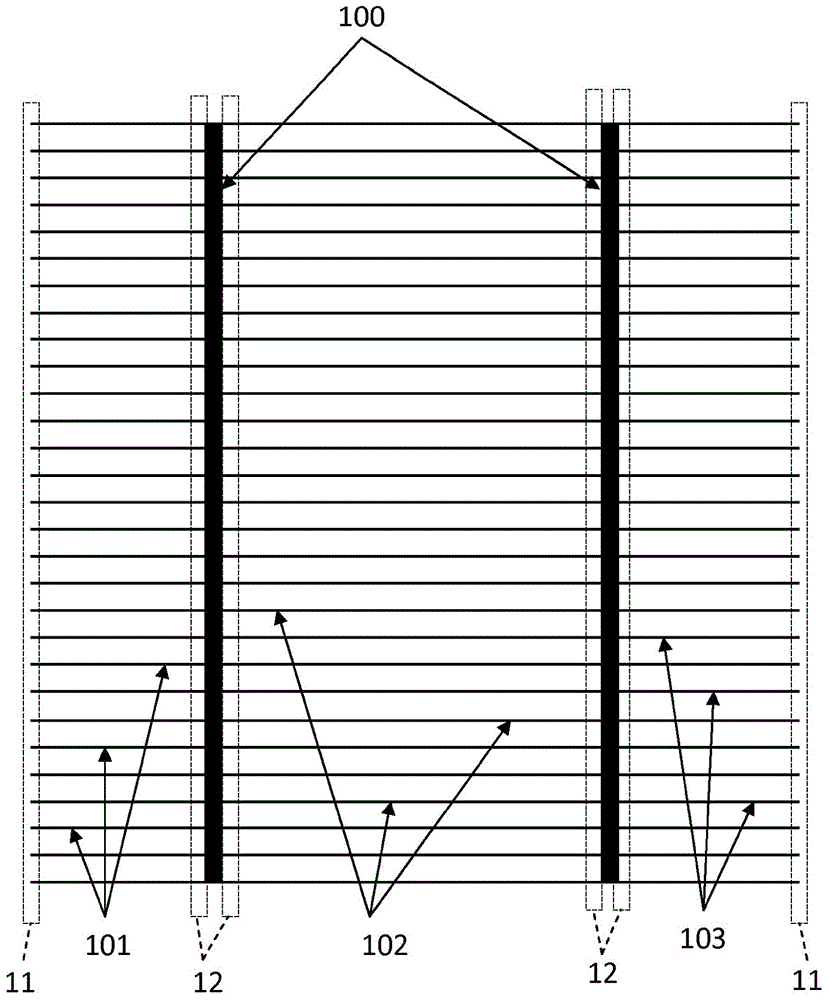

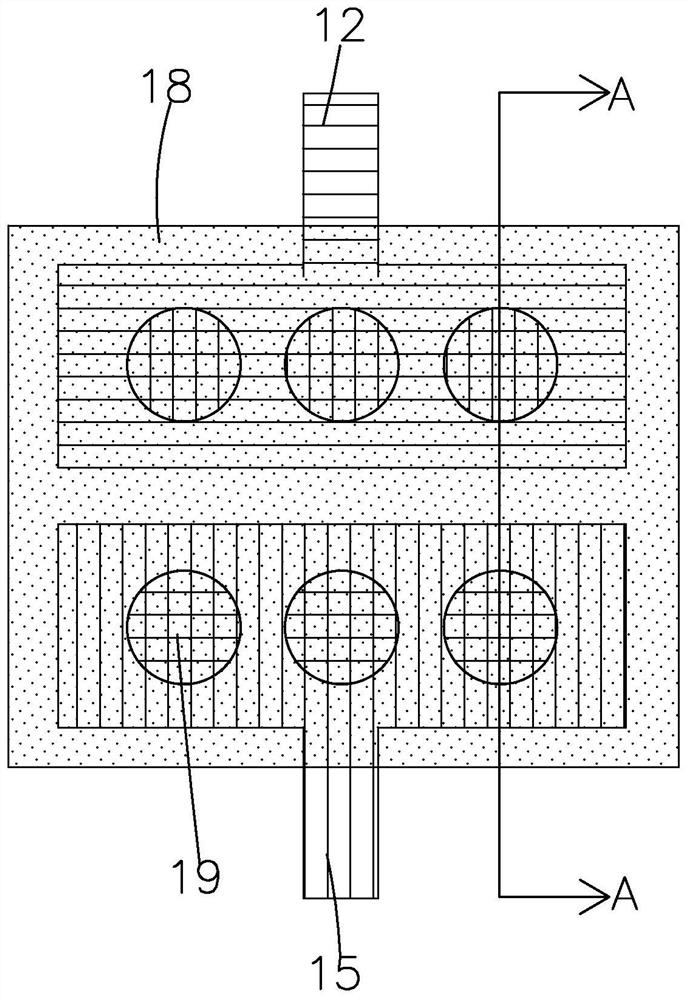

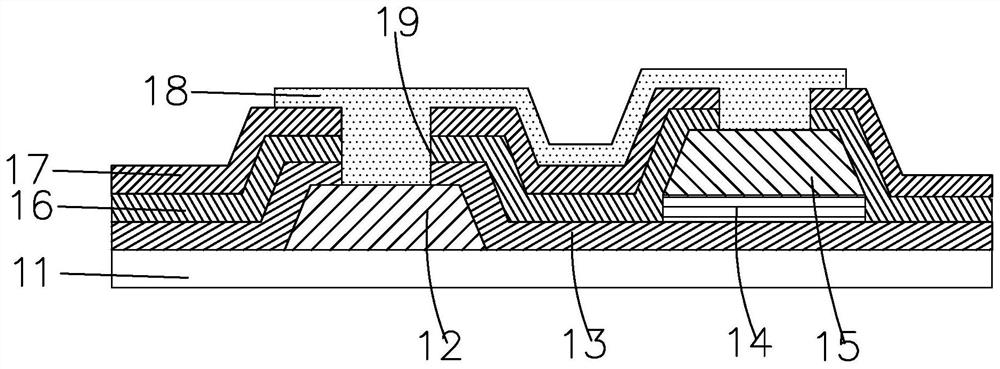

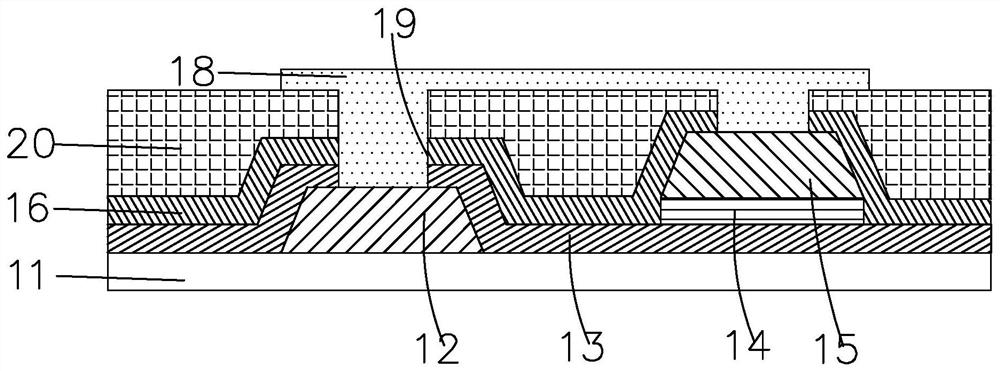

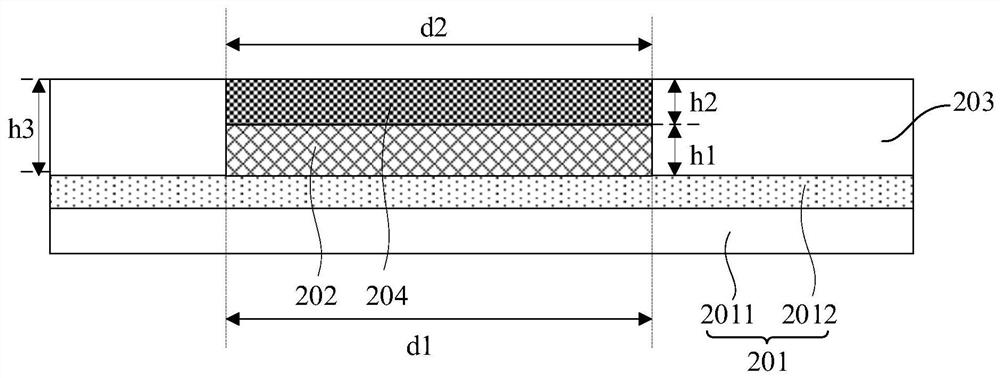

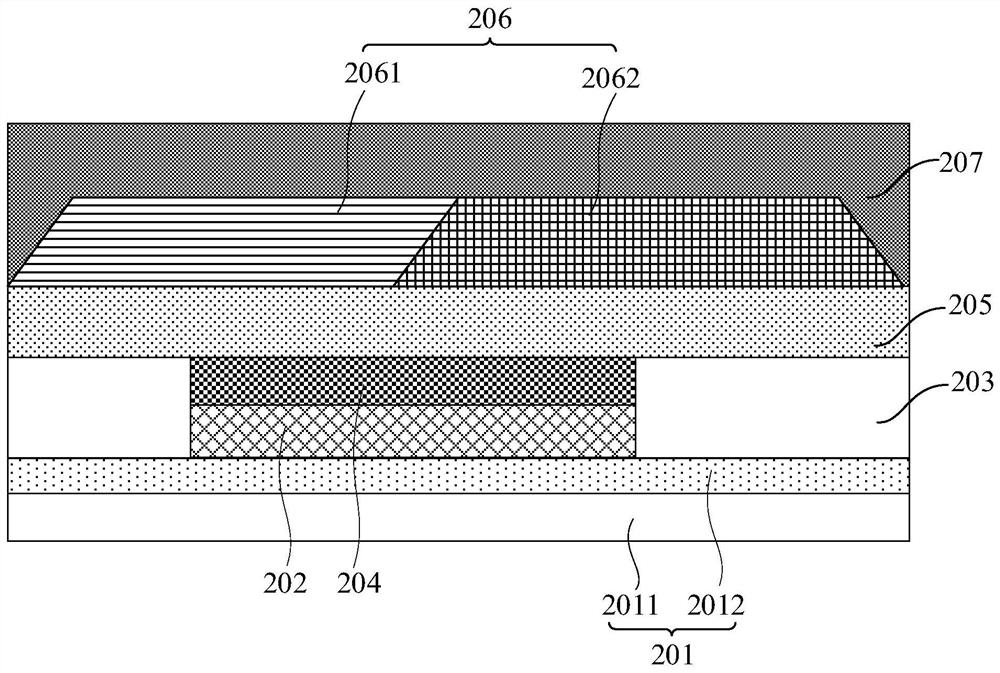

array substrate

ActiveCN108388057BImprove adhesionReduced risk of flakingSolid-state devicesNon-linear opticsHemt circuitsPeripheral

The present invention provides an array substrate, the peripheral circuit area of which includes a peripheral region substrate, a peripheral region TFT layer, a peripheral region passivation layer, a color resist layer, a peripheral region PFA layer, and a connecting line layer arranged in sequence from bottom to top. The resistance layer is provided with a first via hole, and the PFA layer in the peripheral area is correspondingly provided with a second via hole in the first via hole, and the hole wall of the second via hole belongs to the PFA layer in the peripheral area, and the peripheral area The passivation layer is correspondingly provided with a third via hole connected to the second via hole under the second via hole, and the corresponding second via hole and the third via hole together form a transfer via hole, and the connecting line The layer is in contact with the TFT layer in the peripheral area through the transfer via hole, and the color resistance layer is set between the passivation layer in the peripheral area and the PFA layer in the peripheral area, and the via hole for transfer in the PFA layer in the peripheral area is set in the color In the barrier layer, the adhesion of the PFA layer in the peripheral area can be improved, and the risk of peeling off of the PFA layer in the peripheral area can be reduced, thereby improving the yield of PFA products.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

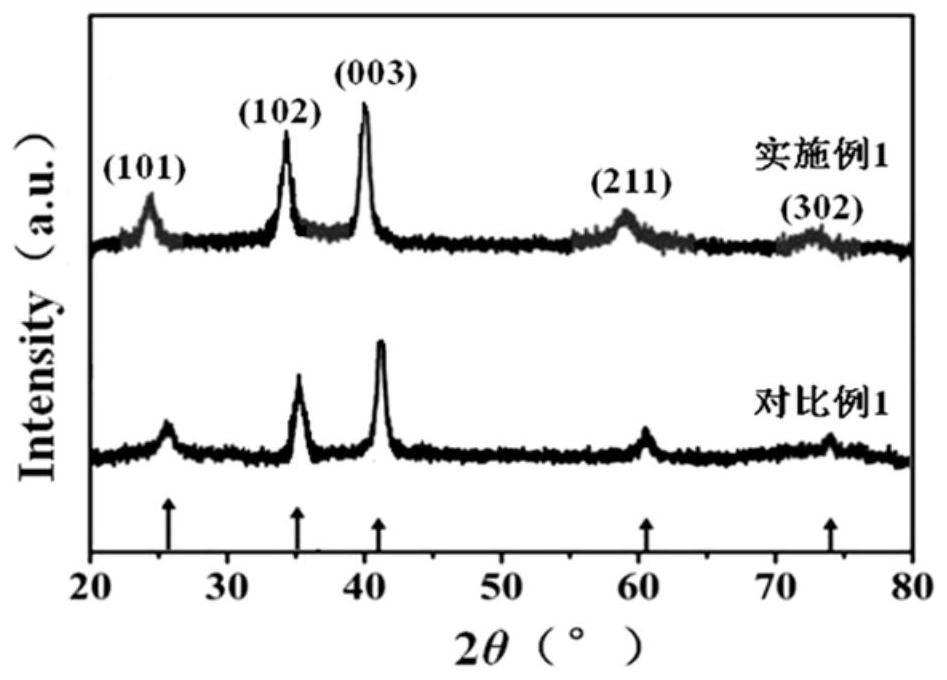

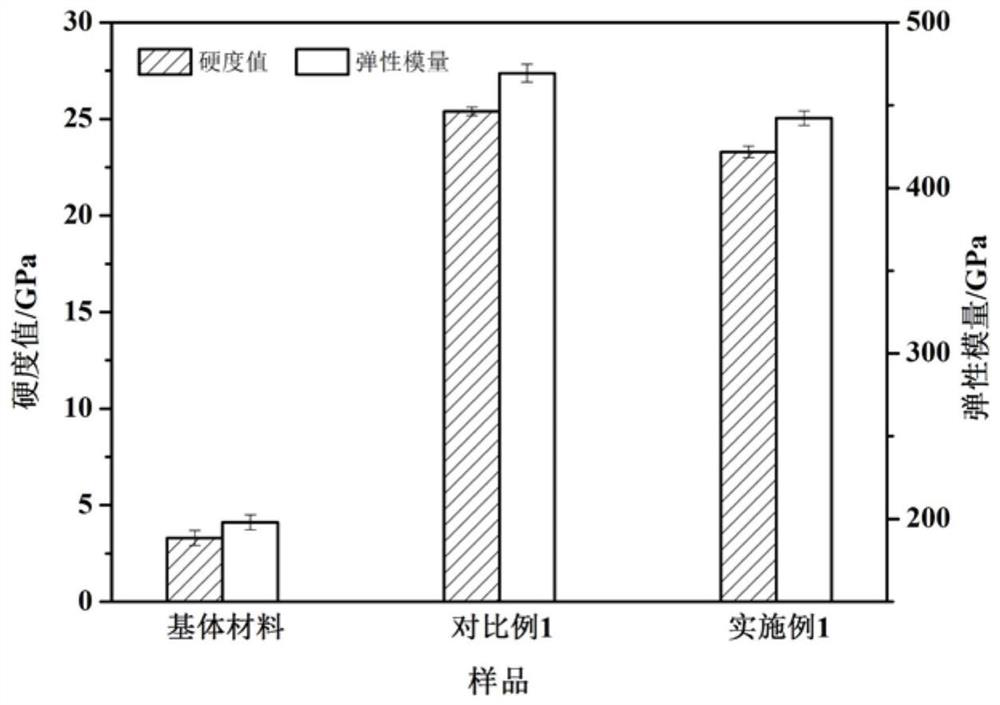

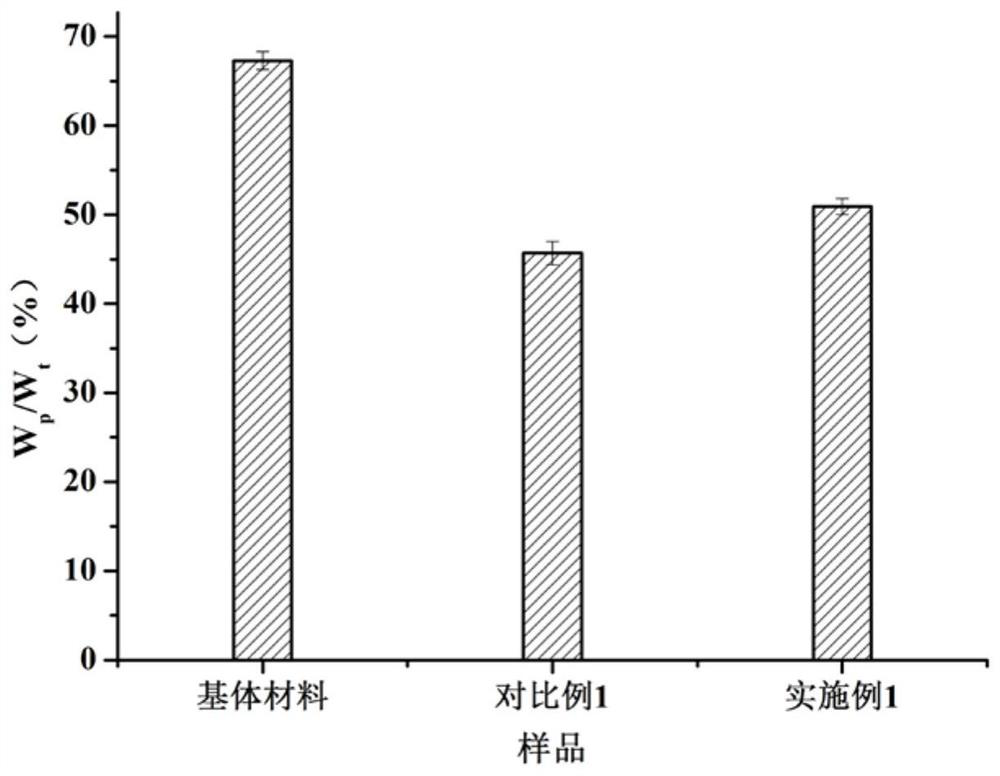

Claw type vacuum pump rotor surface treatment process

ActiveCN112301317AImprove plastic deformation abilityAccelerated corrosionVacuum evaporation coatingSputtering coatingPre treatmentPumping vacuum

The invention discloses a claw type vacuum pump rotor surface treatment process, and relates to the technical field of vacuum pump rotor surface treatment. The surface treatment process specifically comprises the steps of conducting pretreatment, wherein a base body is subjected to hardening and tempering treatment, and then abrasive paper is used for conducting rough grinding to fine grinding treatment; conducting ultrasonic impact nanocrystallization treatment, wherein nanocrystallization treatment is conducted on the surface of the base body through the milligram energy ultrasonic treatmenttechnology; preparing a coating through double-cathode plasma sputtering deposition, cleaning a furnace chamber, installing a workpiece, and fixing a target material and the base body;; and vacuumizing the interior of the furnace chamber, cleaning the workpiece, and depositing the coating. The base material treated through the surface treatment process provided by the invention has excellent corrosion resistance and abrasion resistance, good fatigue performance and long service life.

Owner:连云港恒顺工业科技有限公司

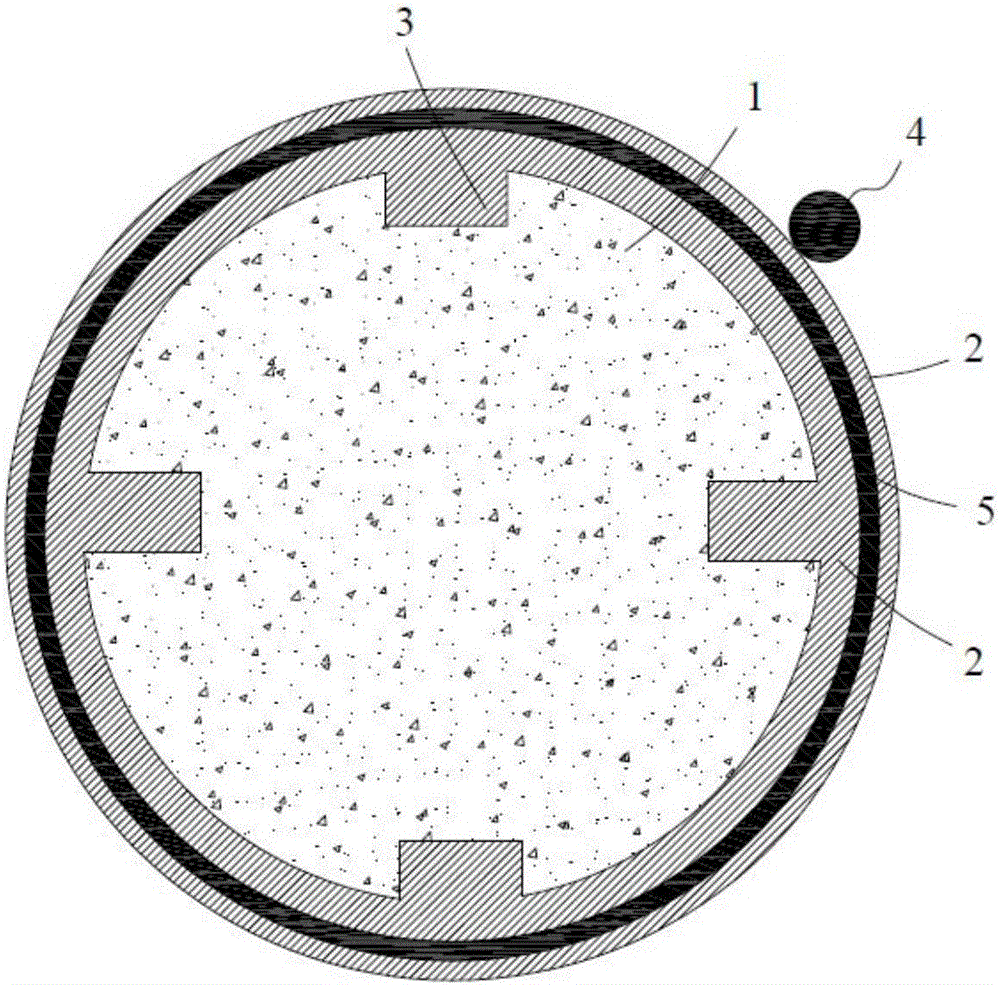

micro sounder

ActiveCN106954149BPlay a blocking roleIncrease bonding areaDiaphragm mounting/tensioningEngineeringFront cover

Owner:GOERTEK INC

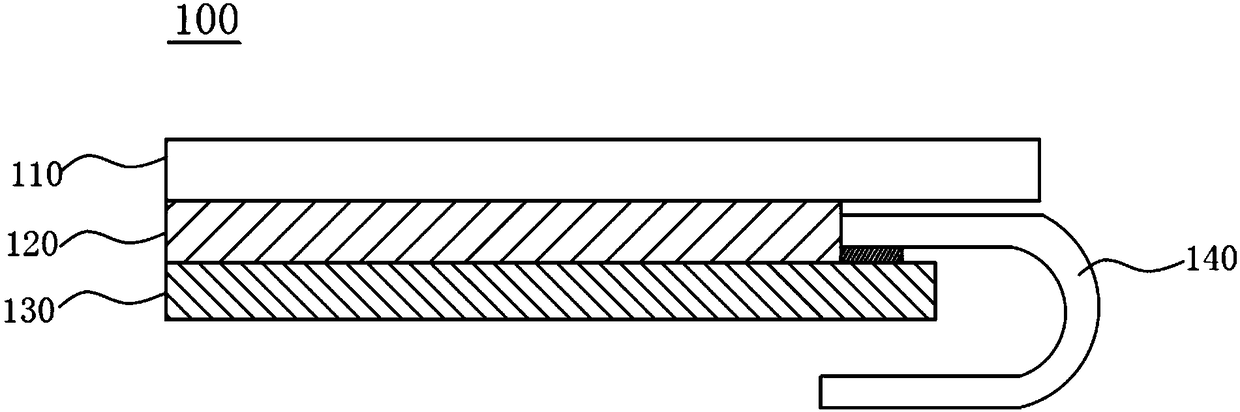

Flexible display device

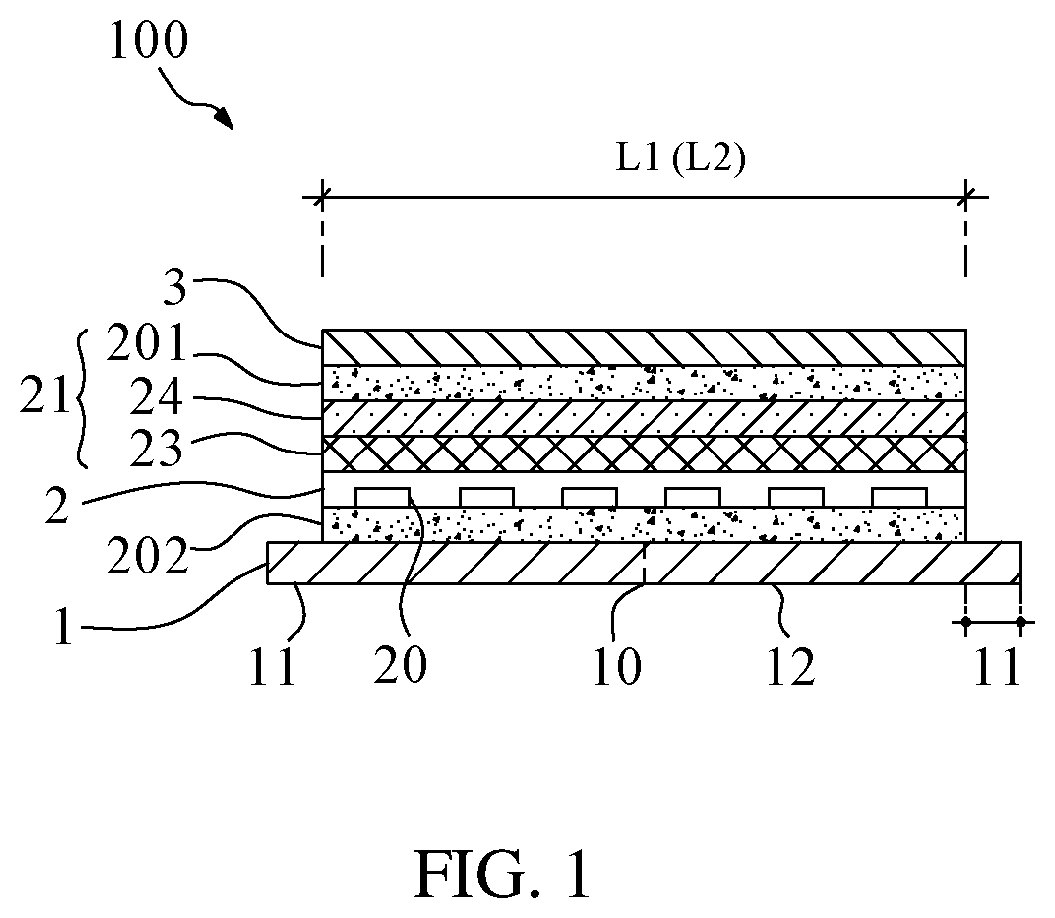

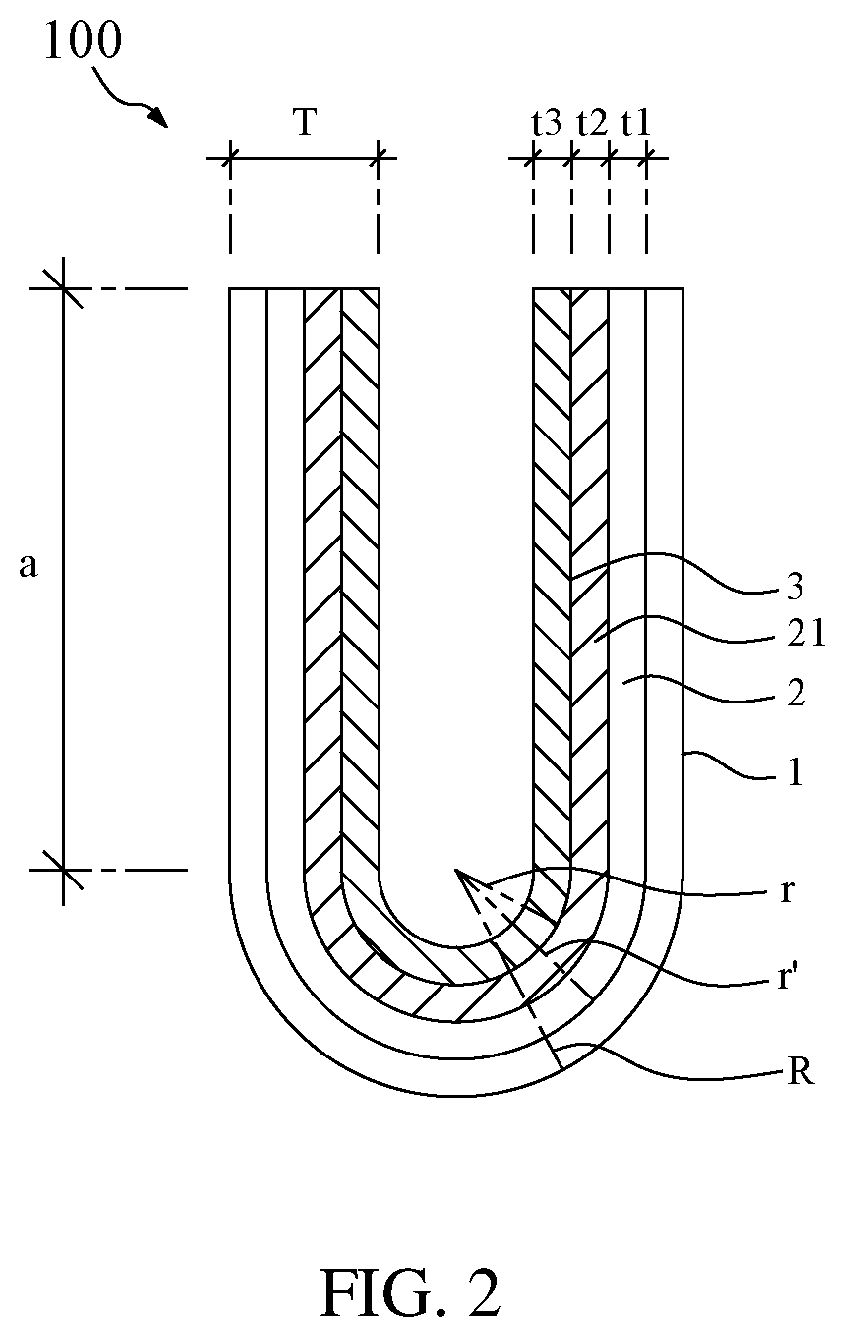

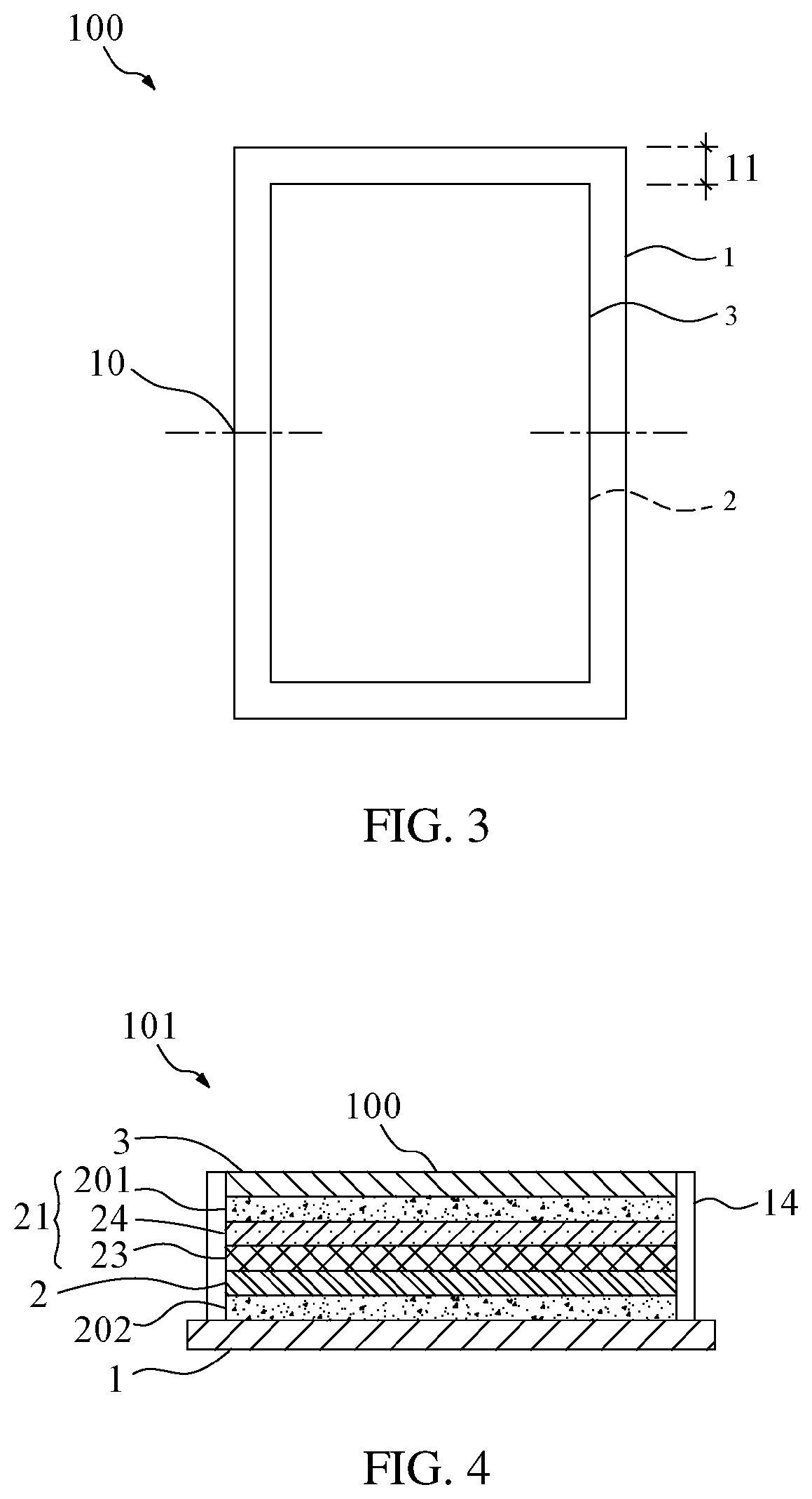

ActiveUS20220140278A1Reduced risk of flakingImprove assembly accuracySolid-state devicesSemiconductor/solid-state device manufacturingFlexible displayMechanical engineering

A flexible display device includes a flexible display panel bendable along a bending axis. A support backplate is disposed on a side of the flexible display panel and located on an outer side of the flexible display panel when bending. The support backplate includes a support area and a plurality of extension areas defined on opposite sides of the bending axis and adjoining two sides of the support area. When the flexible display device is in an expanded state, a difference value between a length of the support backplate and a length of the flexible display panel in a direction perpendicular to the bending axis is greater than or equal to a first threshold. The flexible display device can reduce the risk of peeling of components in a bent state and can ensure a product lifespan.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

A cleaning method for carbide CNC inserts before coating

ActiveCN113373453BExtended service lifeReduced risk of flakingCleaning using liquidsNumerical controlMegasonic cleaning

The invention relates to the technical field of production of hard alloy numerical control coating inserts, and specifically discloses a cleaning method for hard alloy numerical control inserts before coating. The cleaning method is as follows: preparing No. 1-5 cleaning liquids suitable for WC-Co type hard alloy CNC insert substrates, and cleaning the surface of the coated substrate through an improved ultrasonic cleaning process; the No. 1 cleaning liquid is a powerful Alkaline metal cleaning solution; the No. 3 cleaning solution is a weak alkaline metal cleaning solution; the No. 5 cleaning solution is a cleaning solution containing antioxidants; the No. 2 and No. 4 cleaning solutions are pure water. The invention adopts No. 1-5 cleaning liquids and an improved ultrasonic cleaning process, which can ensure the cleanliness of the surface of the coating substrate, improve the production efficiency, and at the same time, it can also ensure that the surface of the substrate of the hard alloy numerical control blade is not damaged within several working days after cleaning. It is oxidized by moisture, thereby improving the bonding strength of the coating and the base of the carbide CNC insert, and prolonging the service life of the carbide CNC coating insert.

Owner:江西江钨硬质合金有限公司

A medium temperature anti-oxidation coating, its preparation method and carbon/carbon composite material product

The invention provides a moderate-temperature antioxidation coating which is prepared by sintering a coating intermediate. The coating intermediate comprises a first coating compounded on a matrix surface, a second coating compounded on the first coating, and an ethyl orthosilicate layer compounded on the second coating. The first coating is prepared from a H3BO3-H3PO4 mixed acid solution. The second coating is prepared from B2O3, SiO2, Mn(H2PO4)2, ZrO2, CaF2, Al2O3, B4C, CeO2 and silica sol. The manganese can promote the flowability of the anti-glass phase in the sintering process; and by using the ethyl orthosilicate as a hole sealing agent, the silicon dioxide generated in the sintering process can fill pores in the antioxidation coating and reduce the risk of peeling of the antioxidation coating. The invention also provides a preparation method of the moderate-temperature antioxidation coating and a carbon / carbon composite product.

Owner:HUNAN BOYUN NEW MATERIALS

A control method for surface oxidation pitting defect of hot-rolled pickling plate

ActiveCN105251779BQuality improvementImprove bindingProfile control deviceSurface oxidationHeating furnace

The invention relates to the technical field of hot rolling, in particular to a control method for surface oxidation pocking defects of a hot-rolled pickled plate. The control method includes the steps that the chemical components of a steel billet are controlled to include, by mass, 0.05-0.15% of Si, at most 0.01% of P and the balance Mn, Nb, Ti and a Fe substrate. In the heating process of the steel billet, the steel billet with the thickness being 135-250 mm is put into a heating furnace and heated for 160-200 min, and the tapping temperature of the steel billet is controlled to be 1180-1240 DEG C. The thickness of an intermediate billet is controlled to be 26-34 mm after a descaling process. In the precision rolling process, the precision rolling inlet temperature is controlled to be 980-1020 DEG C, and the finish rolling temperature is controlled to be 850-890 DEG C. The control method for surface oxidation pocking defects of the hot-rolled pickled plate can effectively restrain the occurrence of surface oxidation pocking defects of the hot-rolled pickled plate with the thickness being at most 2 mm and the tensile strength being at least 500 MPa.

Owner:SHOUGANG CORPORATION +1

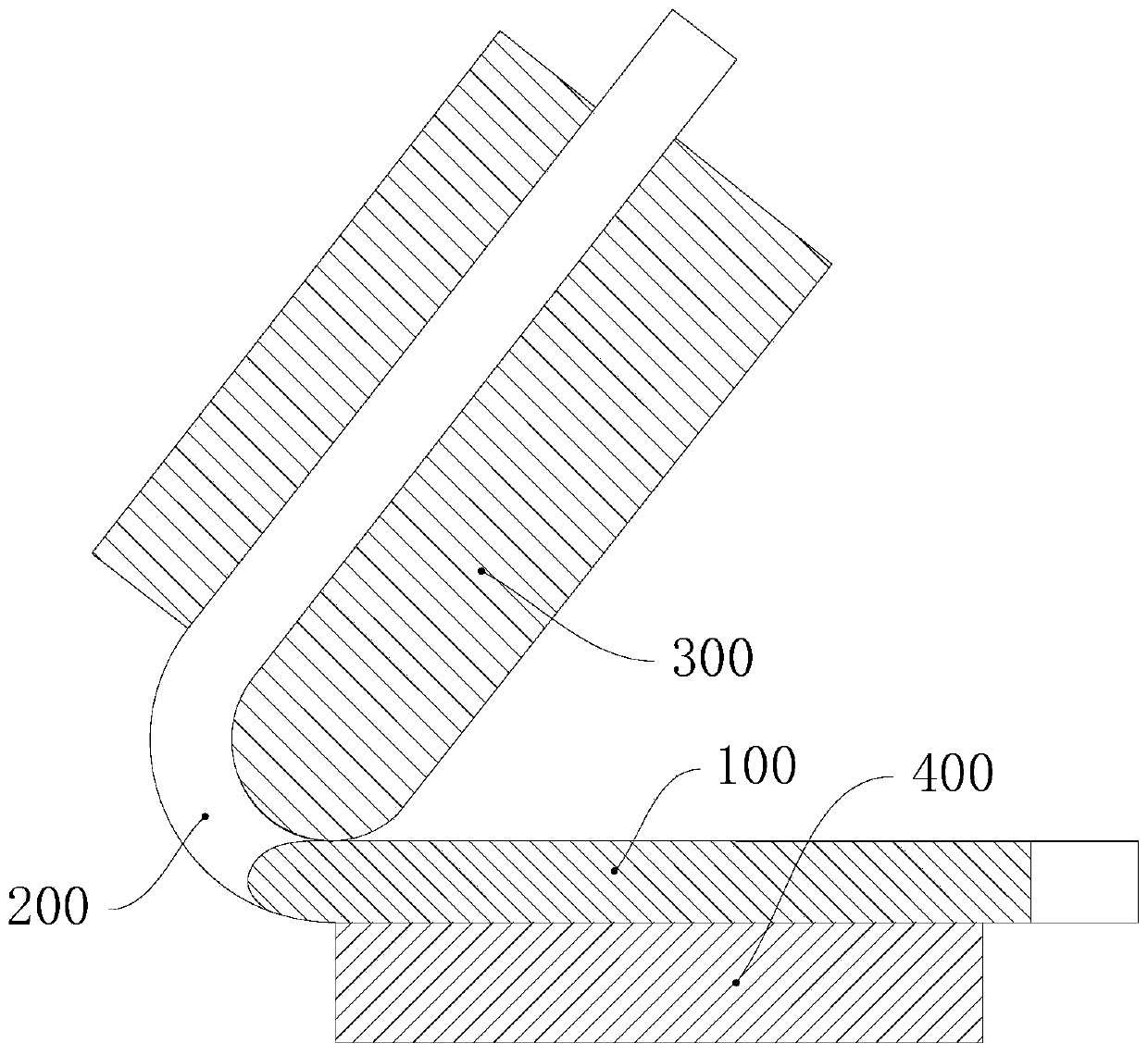

Environmental barrier coating for boiler overtemperature control and preparation method thereof

ActiveCN114774826AImprovement cannot be used reliably for a long timeReduce risk of sheddingMolten spray coatingPressure inorganic powder coatingProcess engineeringWave crest

The invention provides an environmental barrier coating for boiler overtemperature prevention and a preparation method thereof, relates to the technical field of powder additive manufacturing, and is designed for solving the problem that an existing heat insulation coating cannot be reliably used for a long time. The environmental barrier coating for boiler overtemperature prevention and control comprises a transition layer arranged on the surface of a boiler tube and a heat insulation layer arranged on the surface of the transition layer, and the transition layer is continuous and uniform in thickness; the heat insulation layer is arranged in a segmented mode in the axial direction of the furnace tube, and wave crest characteristics and wave trough characteristics which basically alternate in the axial direction are formed in each section of heat insulation layer. The furnace tube can break through the strain tolerance of a traditional uniform heat insulation coating, so that the stress of coating stripping caused by axial deformation of the furnace tube is effectively reduced, and the environmental barrier coating can be reliably used for a long time.

Owner:XIAN THERMAL POWER RES INST CO LTD

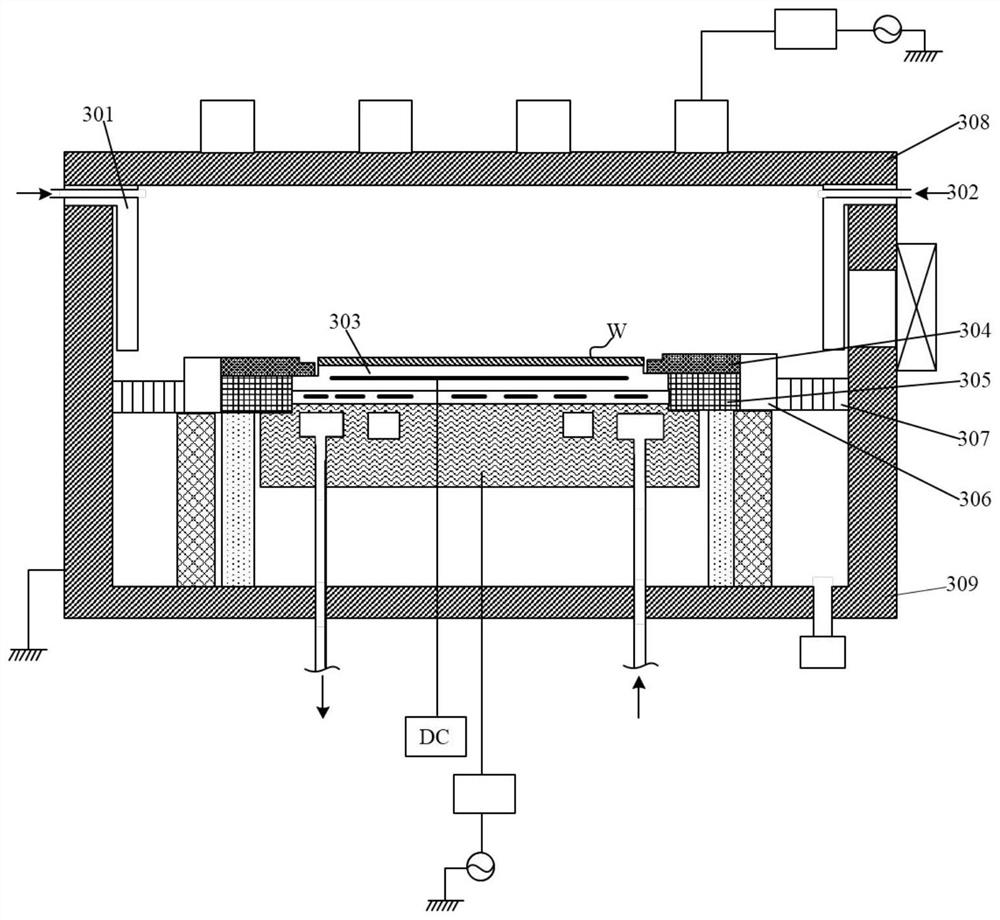

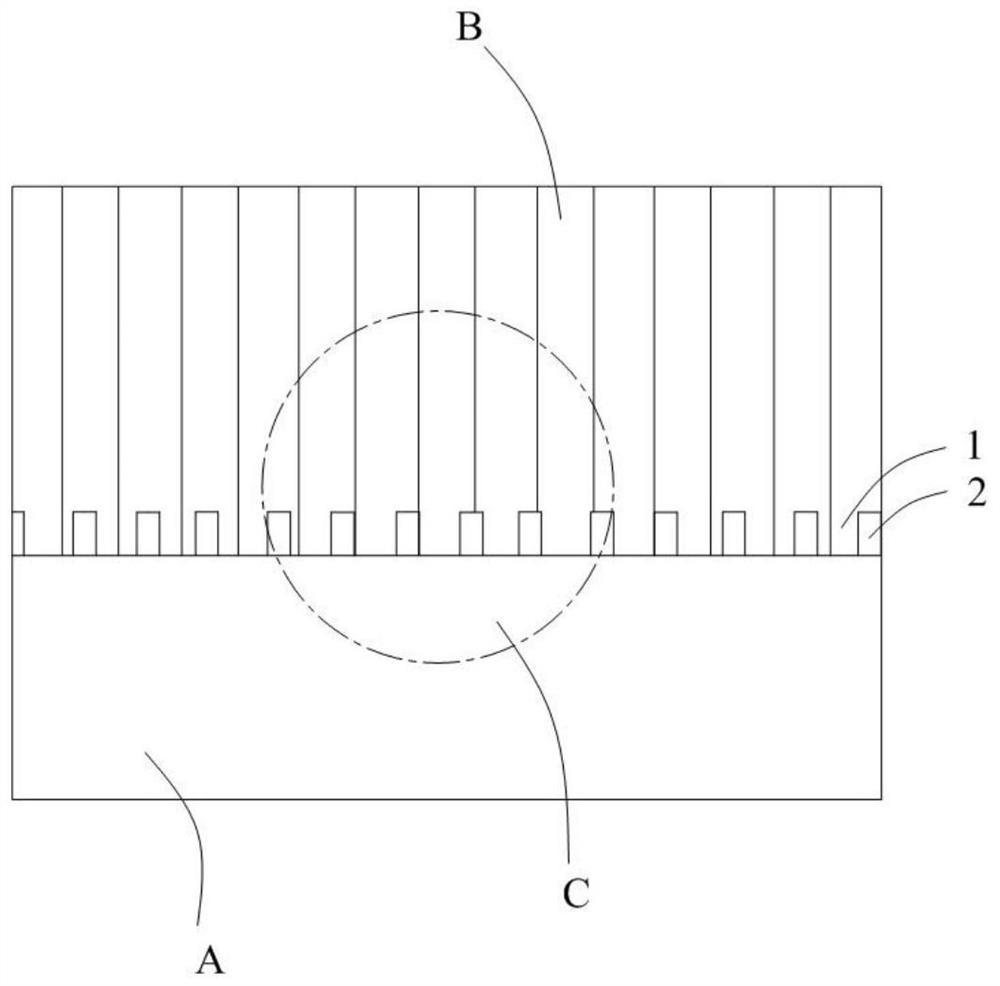

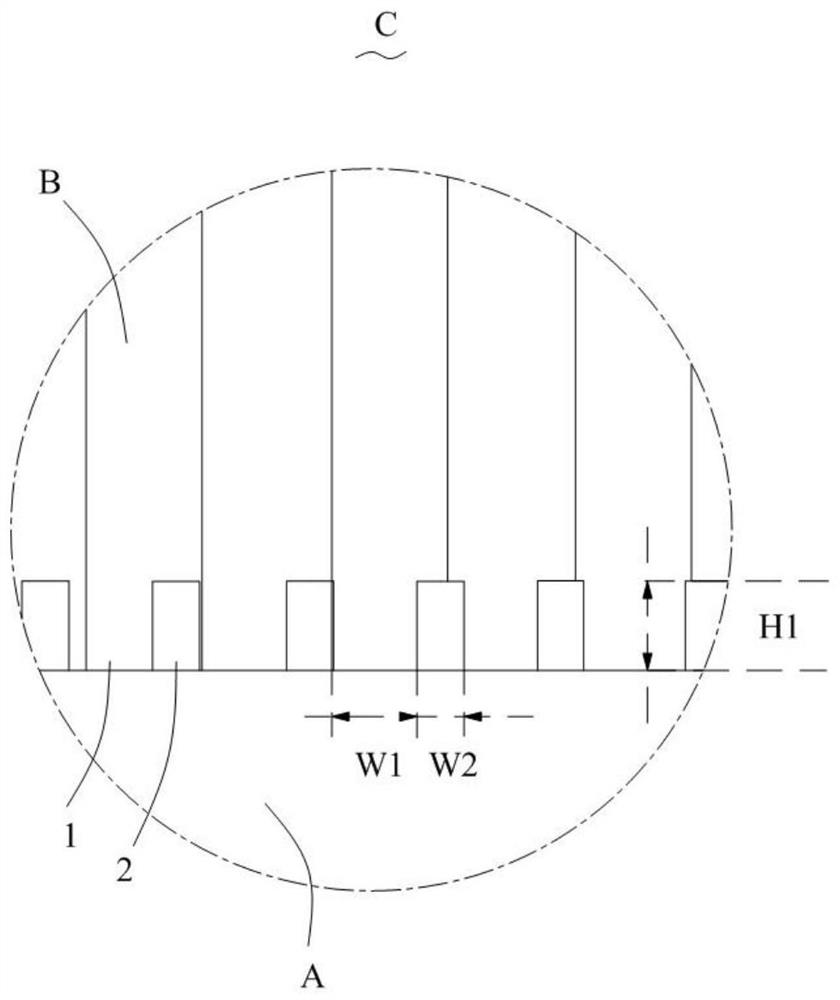

Part, plasma reaction device and part machining method

PendingCN113594014AIncrease contact areaNot easy to fall offElectric discharge tubesPlasma reactionSemiconductor technology

The invention relates to the technical field of semiconductors, in particular to a part, a plasma reaction device and a part processing method. The plasma reaction device comprises a reaction cavity, wherein the interior of the reaction cavity is a plasma environment, and the part is exposed in the plasma environment; the part comprises a substrate and a plasma-resistant coating coated on the surface of the substrate, a plurality of grooves with the width W1<=30 nm and the depth H1<=100 nm are formed in the surface of the substrate, and bulges are formed between adjacent grooves; and the plasma-resistant coating covers the side wall surfaces and the bottom surfaces of the grooves and the top surfaces of the bulges. According to the part provided by the invention, the surface of the substrate is coated with the plasma-resistant coating to carry out plasma-resistant protection on the substrate, and the plasma-resistant coating is not prone to cracking, crack propagation and stripping.

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

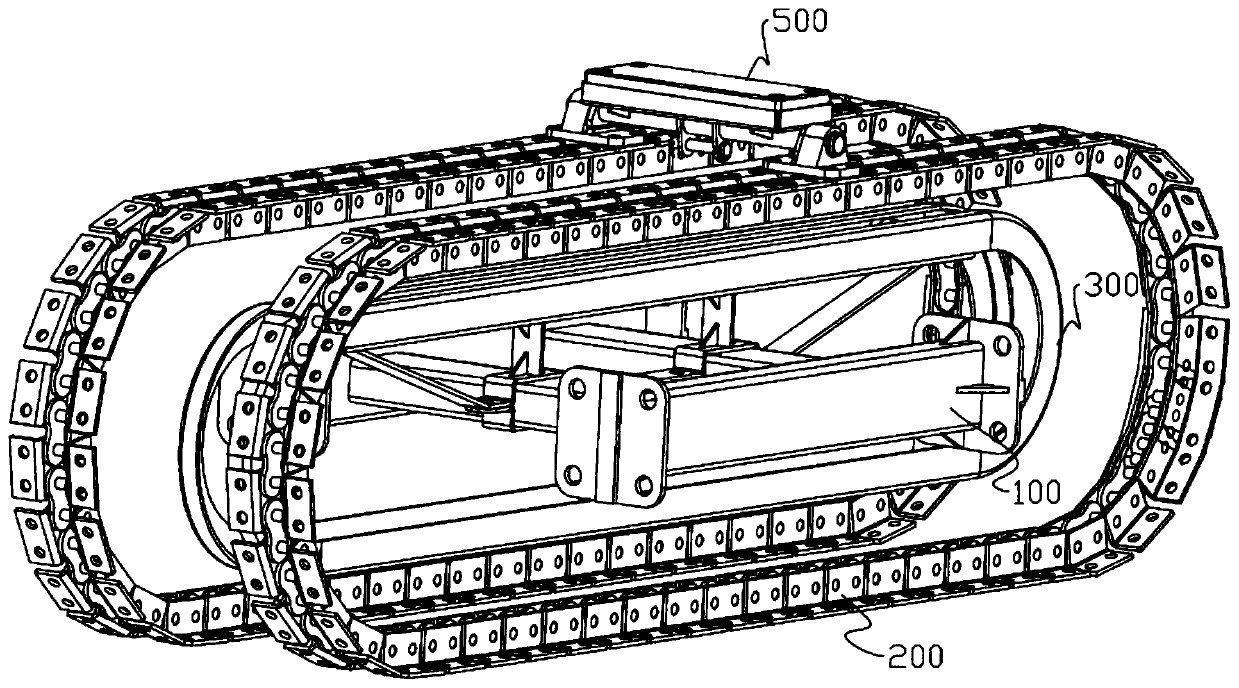

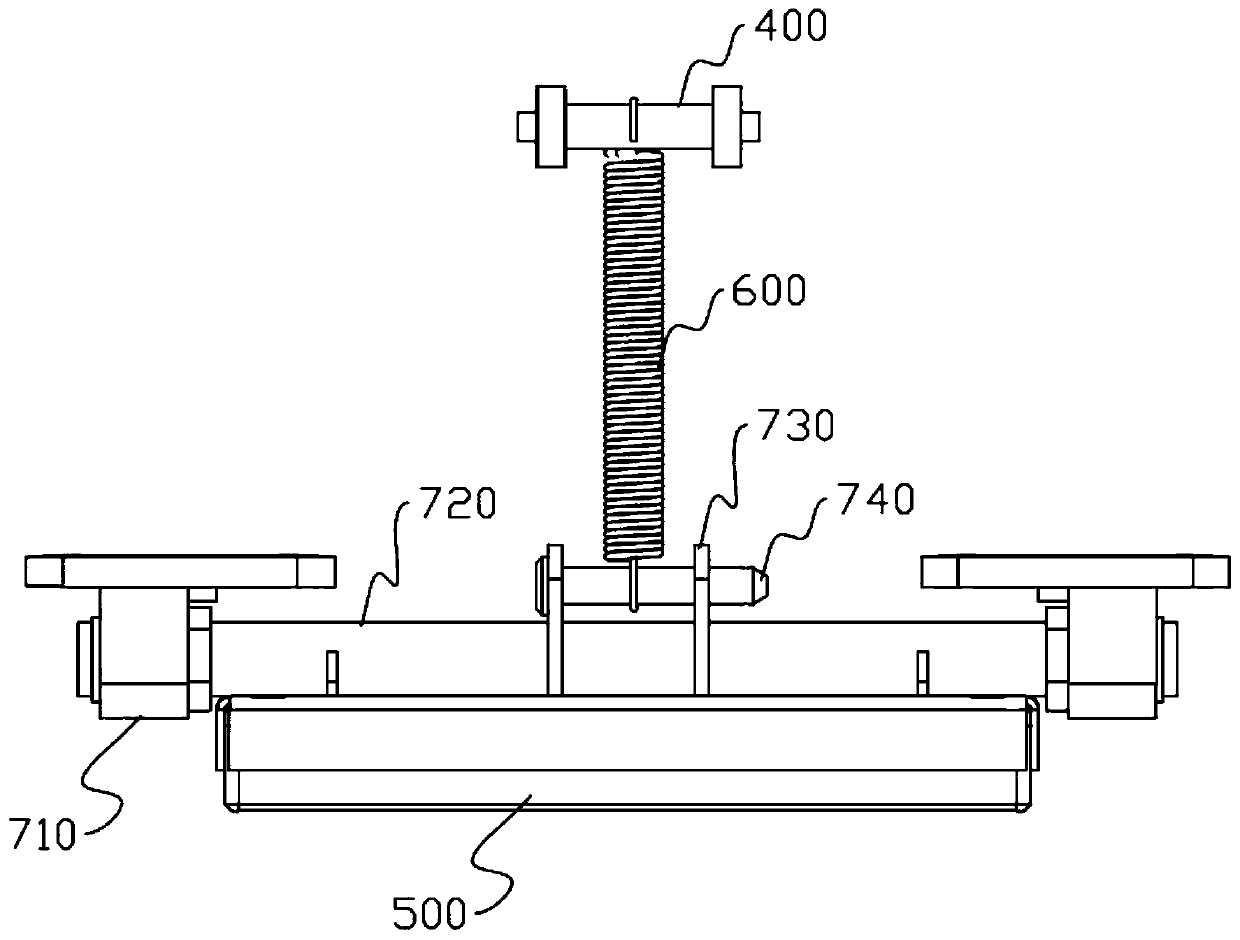

Wall-climbing robot

ActiveCN110861722AReduced risk of flakingImprove stabilityEndless track vehiclesWorkspaceEngineering

The invention provides a wall-climbing robot. The wall-climbing robot comprises a supporting frame. A pair of crawler belts is arranged on the supporting frame, wherein the section of each crawler belt is in a runway shape. A rail is arranged between the pair of crawler belts. Each crawler belt comprises a work area and an idle area, and the rail is arranged on the area on the inner sides of the work areas and the idle areas. Symmetric axes parallel to the advancing direction of the crawler belts serve as first symmetric axes. Symmetric axes, parallel to the advancing direction of the crawlerbelts, of the rail serve as the second symmetric axes. The first symmetric axes are parallel to the second symmetric axes, and the vertical distance between the second symmetric axes and the work areas is larger than the vertical distance between the second symmetric axes and the idle areas. Guide wheels capable of sliding are in clamped connection in the rail. Multiple magnetic adsorption units are arranged between the pair of crawler belts. Elastic connectors are connected between the guide wheels and the magnetic adsorption units. The wall-climbing robot has the advantages that due to the fact that the distance between the work areas and the rail and the distance between the idle areas and the rail are different, the elastic connectors are stretched when the guide wheels move to the corresponding work areas, and therefore robot loads are applied to the work areas.

Owner:天津河工大先进装备研究院有限公司

Abrasion resisting workpiece and surface treatment method thereof

InactiveCN110230027AHigh surface hardnessExcellent surface hardnessVacuum evaporation coatingSputtering coatingHardnessSurface modification

The invention relates to the field of workpiece surface modification. An abrasion resisting workpiece comprises a base body. A tungsten buffering layer, a first DLC layer and a second DLC layer are sequentially deposited on the surface of the base body, and the SP3 key content of the first DLC layer is smaller than that of the second DLC layer. On one hand, by adoption of the first DLC layer, therisk of peeling of the second DLC layer can be better reduced; and on the other hand, the first DLC layer and the second DLC layer are made of carbon simple substance materials, so that the first DLClayer and the second DLC layer have better bondability, good attachment of the second DLC layer is better facilitated, and the risk of peeling of the second DLC layer is better reduced. In addition, the first DLC layer has high hardness and good friction resisting performance, even the second DLC layer peels, the first DLC layer is exposed, and excessive influences on pipe processing are avoided;and the friction resisting performance of the abrasion resisting workpiece cannot be obviously changed, reliability of the abrasion resisting workpiece is further better improved, and good surface performance of the abrasion resisting workpiece is further better guaranteed.

Owner:GREE ELECTRIC APPLIANCES INC

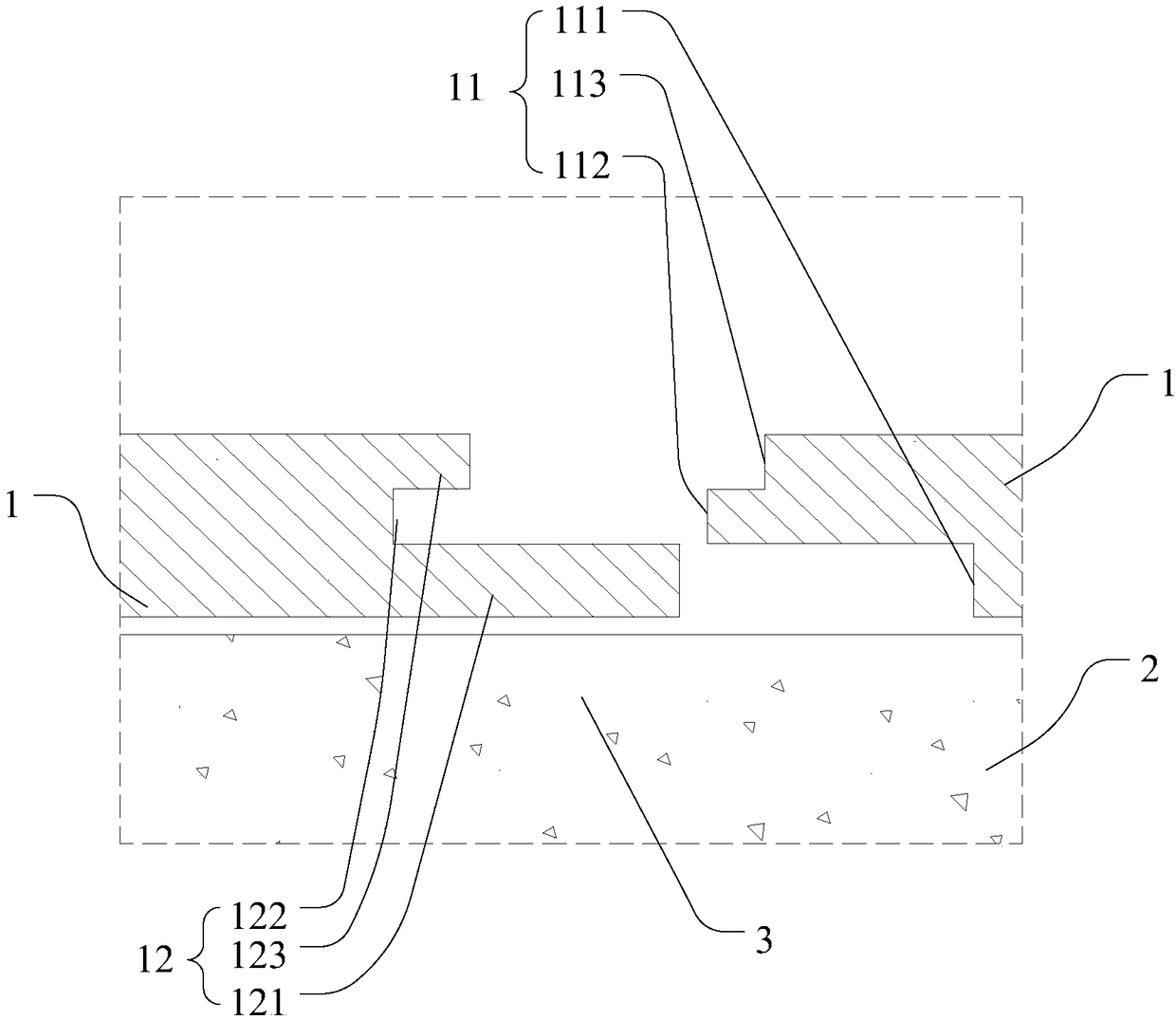

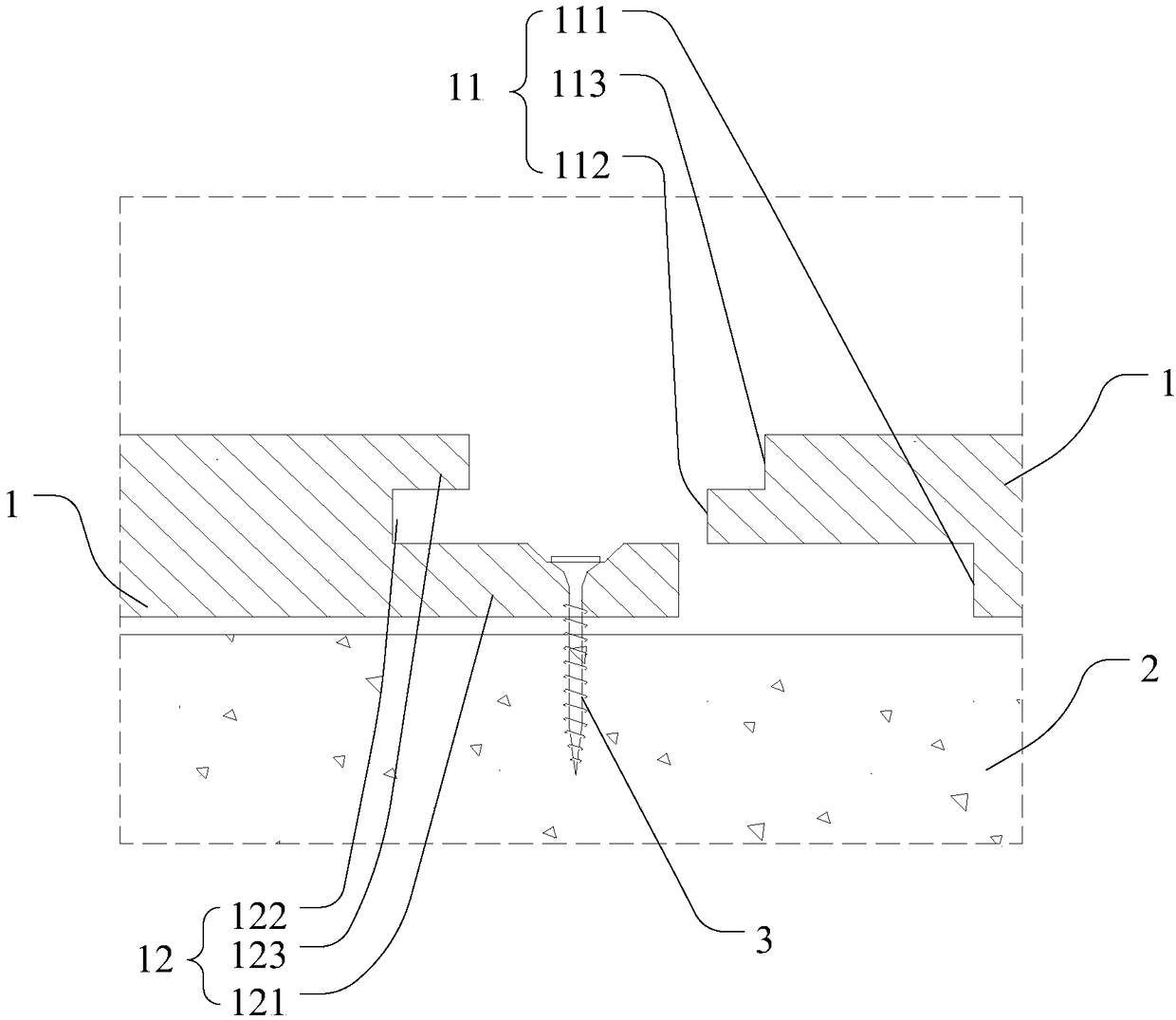

Decorative plate and decorative wall

The invention discloses a decorative plate. The decorative plate is mounted on the outer surface of a wall and used for decorating the wall. A male groove and a female groove are formed in the two opposite side edges of the decorative plate correspondingly. The female groove comprises a first protruding groove, a first concave groove and a second protruding groove which are sequentially formed inthe direction perpendicular to the wall. The first protruding groove is connected with the wall through a connecting piece. The male groove comprises a second concave groove, a third protruding grooveand a third concave groove. According to the decorative plate, the male groove and the female groove which can be connected in mutually-matched and clamped modes are formed in the edge of a mountingplate, and thus splicing between two decorative plates is quite stable; and meanwhile, the decorative plate is fixed to the wall through the connecting piece, the decorative plate and the wall are connected quite stably under the fixing action of the connecting piece and double stabilizing of mutually matched clamped-connecting of the male groove and the female groove, the risk that the decorativeplate falls off from the wall is lowered, and the safety factor is increased.

Owner:深圳新美装饰建设集团有限公司

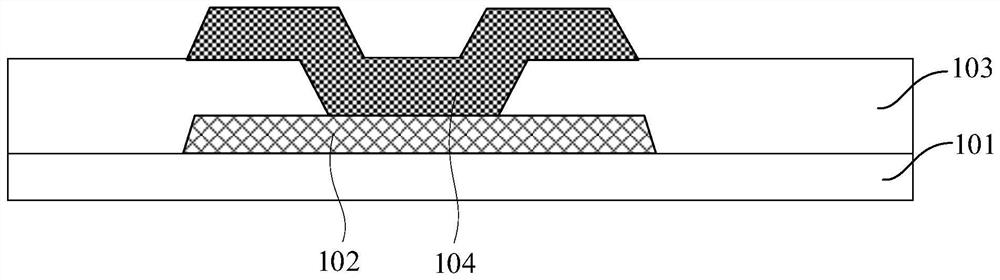

Display panel, manufacturing method thereof and display device

PendingCN112186025AReduce the differenceReduced risk of flakingSolid-state devicesSemiconductor devicesDisplay deviceEngineering

The invention provides a display panel, a manufacturing method thereof and a display device, and relates to the technical field of display. According to the display panel, the resistance reduction wires are arranged on the substrate in the pixel interval area, the interlayer dielectric layer is arranged on the substrate, the interlayer dielectric layer is provided with the openings exposing the resistance reduction wires, the signal wires are arranged in the openings and connected with the resistance reduction wires, and the width of the openings is larger than or equal to that of the signal wires in the row direction of the display panel. The signal lines are formed in the openings of the interlayer dielectric layer, and the widths of the openings are greater than or equal to those of thesignal lines, that is, the signal lines are only located in the openings and do not exceed the surface of the interlayer dielectric layer, and therefore the segment difference of the display panel located in the pixel interval area is reduced; the thickness of the flat layer at each subsequently formed region is relatively uniform, and the planarization effect is relatively good, so that the riskthat the flat layer is peeled off due to the segment difference of the pixel interval regions is reduced, and the reliability of a product is improved.

Owner:HEFEI XINSHENG OPTOELECTRONICS TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com