Abrasion resisting workpiece and surface treatment method thereof

A surface treatment and workpiece technology, applied in metal material coating process, vacuum evaporation plating, coating, etc., can solve the problem of large difference in hardness between tungsten buffer layer and DLC layer, DLC layer peeling, DLC layer and tungsten buffer layer can be Decreased associativity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiment of wear-resistant workpiece and surface treatment method thereof:

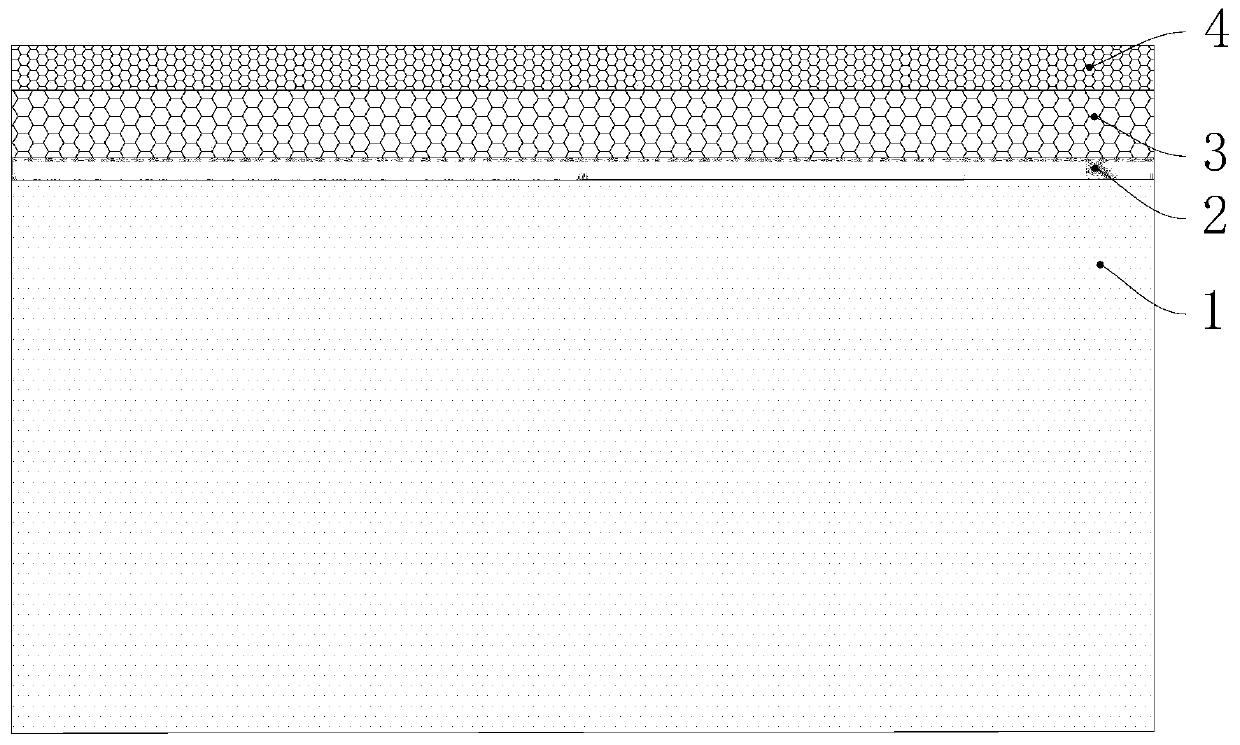

[0023] Carbon has a variety of forms, such as graphite in layered structure and diamond in network structure. Among them, there are SP2 bonds between carbon atoms in graphite, and SP3 bonds between carbon atoms in diamond. Diamond-like carbon coating (Diamond-likecarbon , DLC) is a substance composed of carbon elements, which is similar in nature to diamond, and has the structure of graphite atoms.

[0024] DLC has both SP2 and SP3 bonds. The higher the content of SP3 bonds in DLC, the higher the hardness of DLC, and the closer the properties of DLC are to diamond; on the contrary, the lower the content of SP3 bonds in DLC, the lower the hardness of DLC. The properties are closer to graphite.

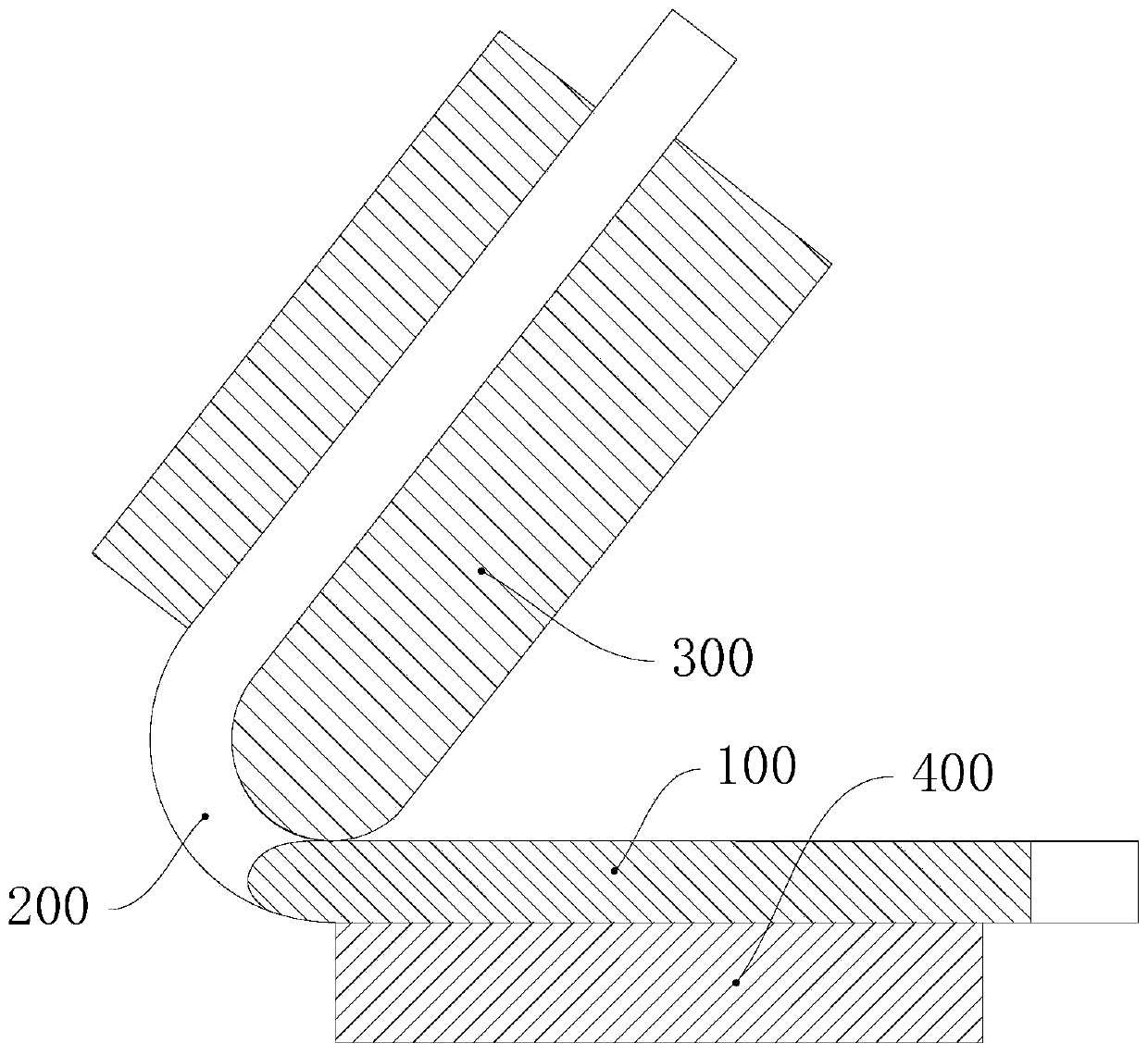

[0025] There are many types of anti-friction workpieces, and the anti-friction workpiece of the present invention can be any parts subject to friction. The friction workpiece of this embodiment is an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com