Patents

Literature

103results about How to "Processing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cleaning and drying device conveniently removing impurities for down feather production and processing

ActiveCN108168222AFacilitate subsequent processingProcessing effectDrying solid materials without heatWool fibre washing/scouringEngineeringWater pipe

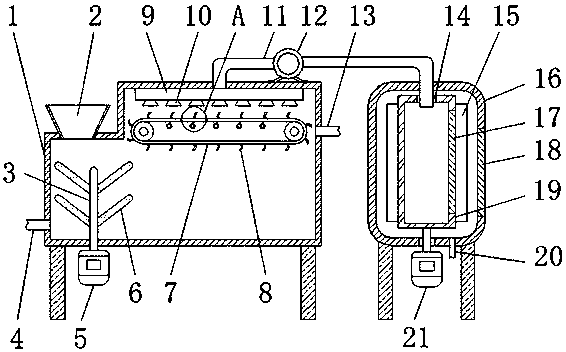

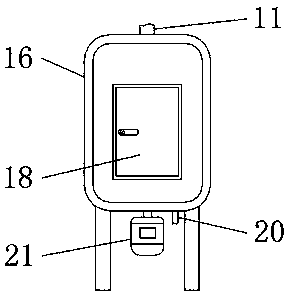

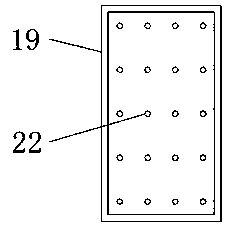

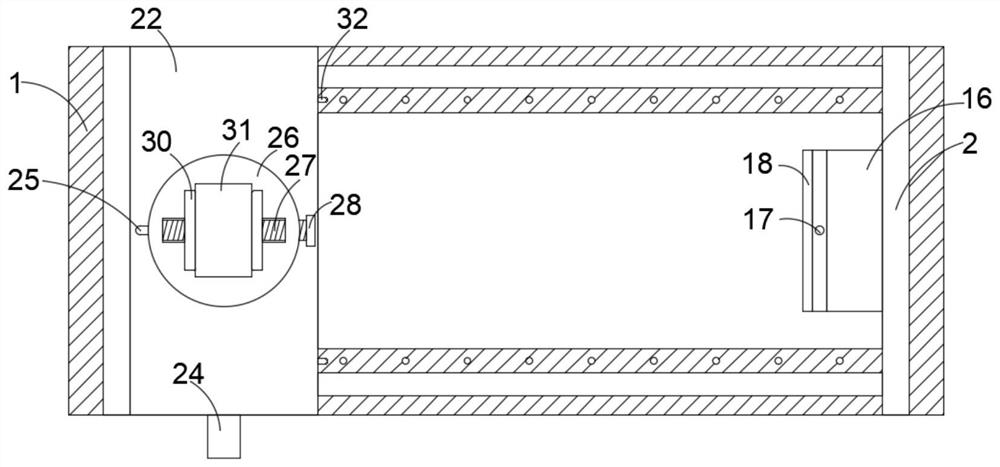

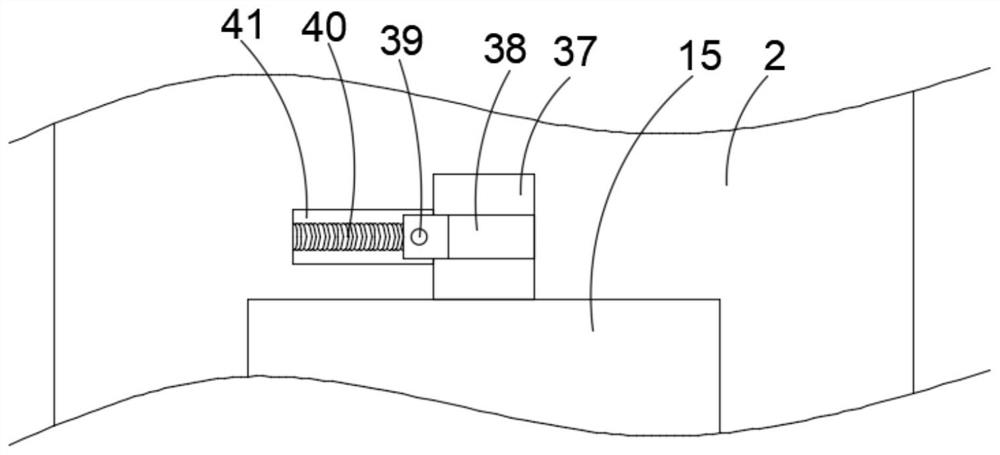

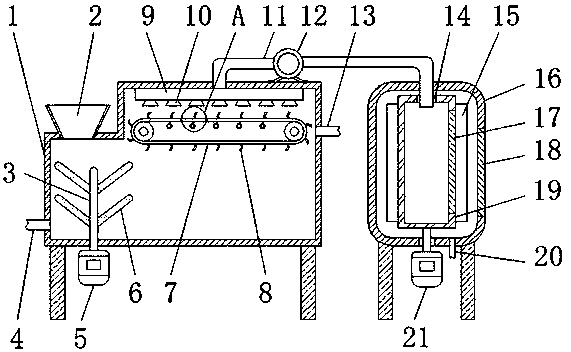

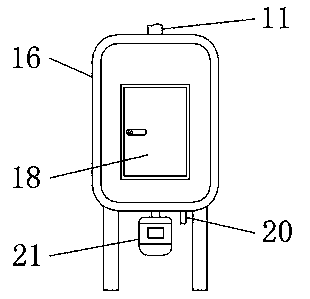

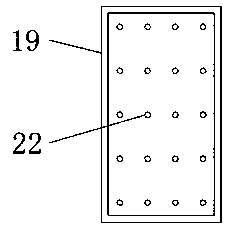

The invention discloses a cleaning and drying device conveniently removing impurities for down feather production and processing. The cleaning and drying device includes a cleaning device, a water inlet pipe, a stirring rod, a transmission belt, a suction opening, a fan, a first water outlet, a protective cover, a protective door, an air-tight door, a spin-dry revolving drum, a second air hose anda blowpipe; the upper of the cleaning device is provided with a feed inlet, the lower of the feed inlet is provided with a rotating rod, the water inlet pipe is located below the left side of the cleaning device, and the cleaning device is internally connected with a first motor through the rotating rod; and the stirring rod is located at the outer side of the rotating rod, the second air hose isarranged in the transmission belt which is provided with through holes, and the through holes are connected with scraping plates. According to the cleaning and drying device conveniently removing theimpurities for the down feather production and processing, the cleaning device is arranged to clean down feather, subsequent processing can be prevented from affection due to impurities in the down feather, and the cleaning of the down feather is facilitated.

Owner:ZHANJIANG ZIJIN DOWN PROD

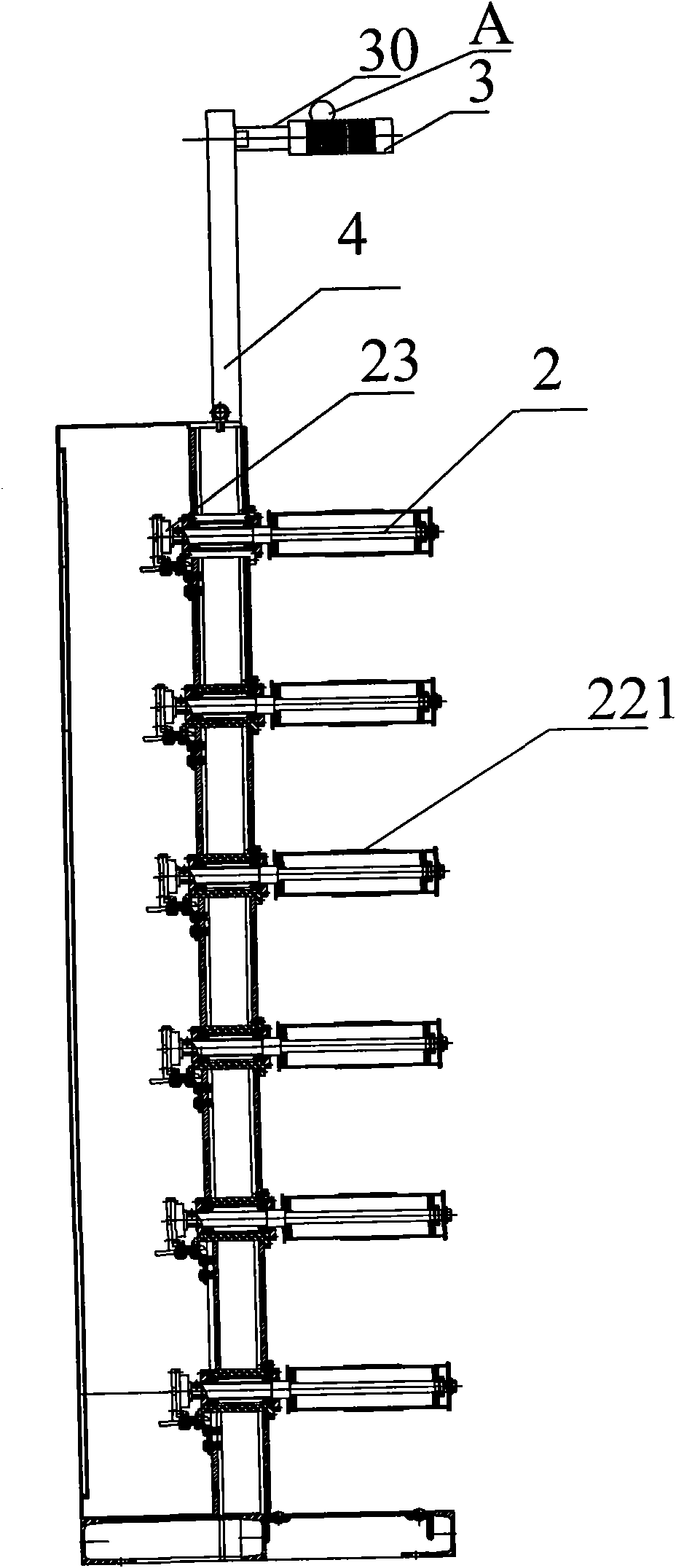

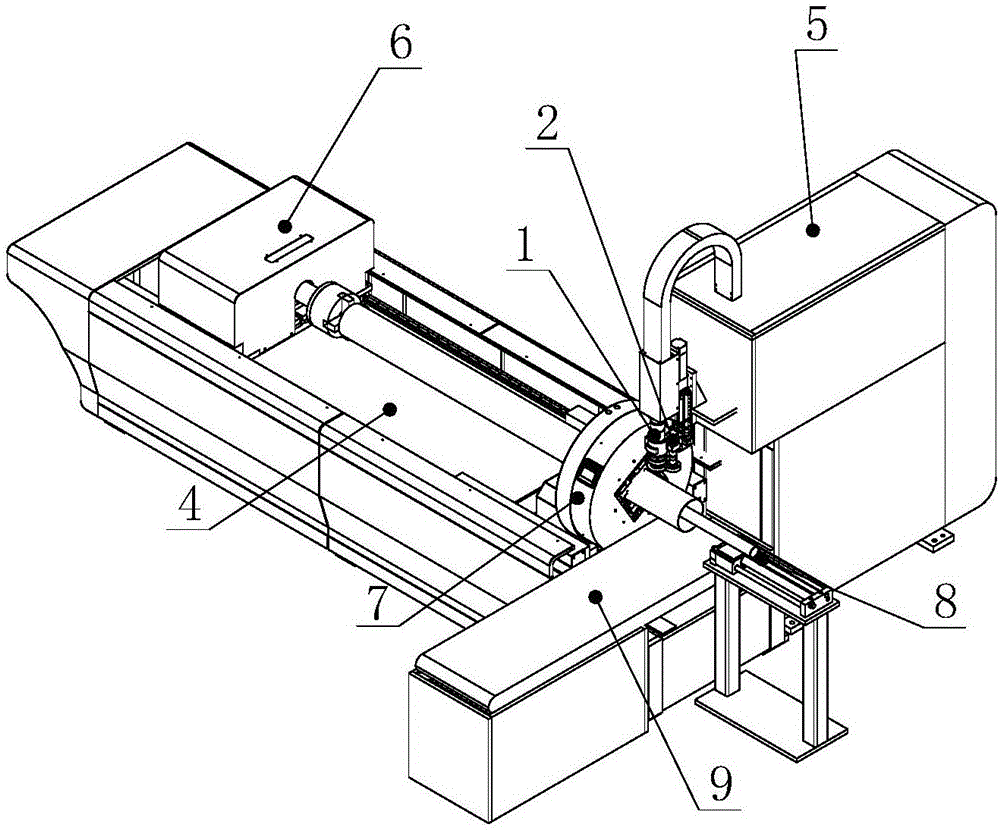

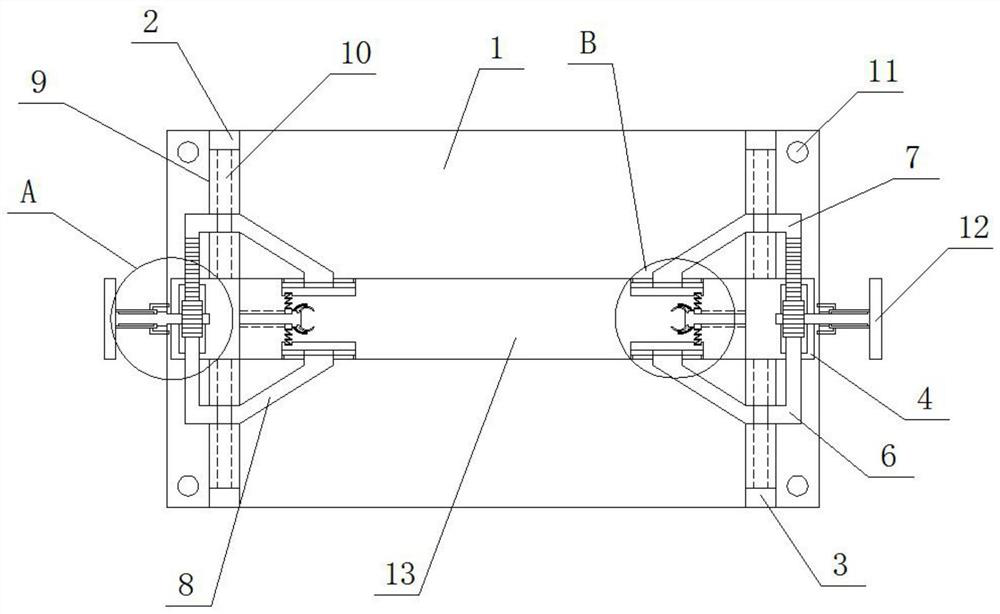

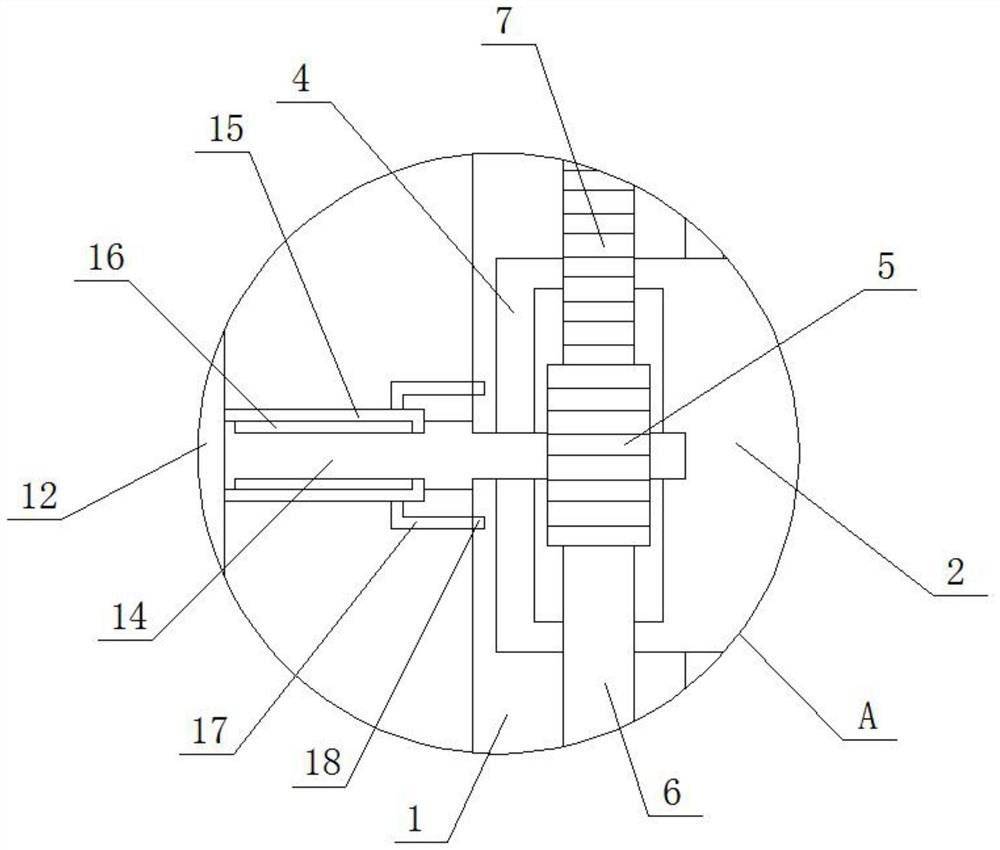

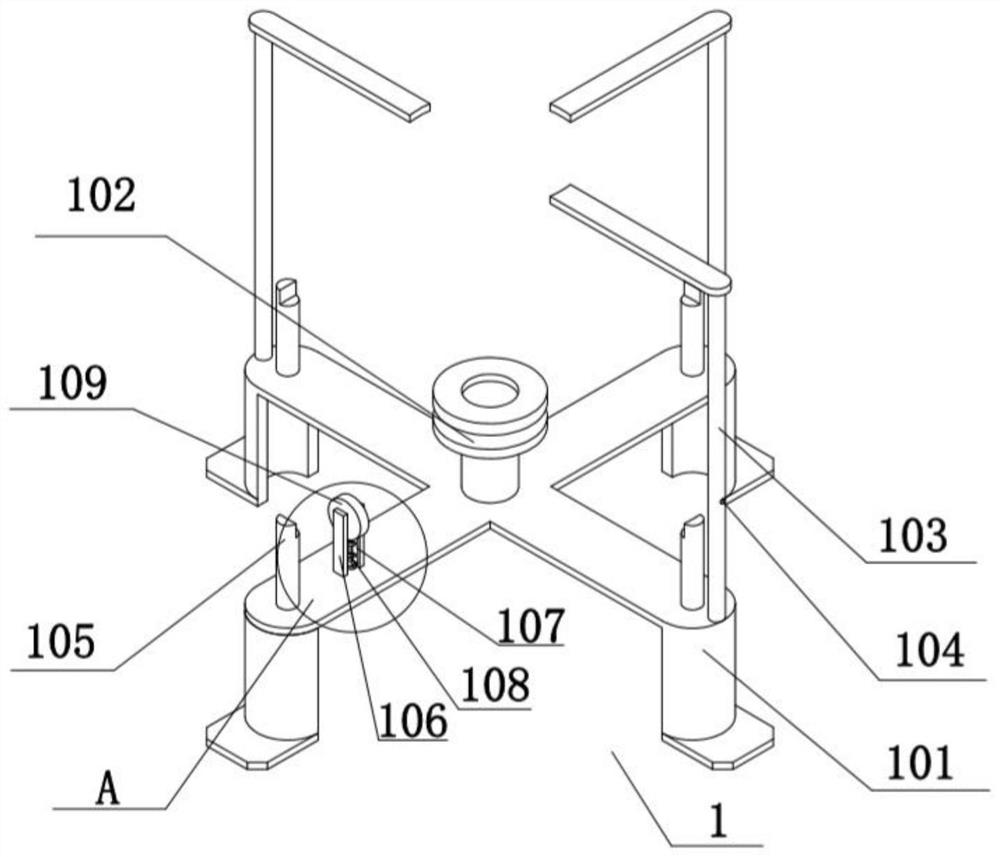

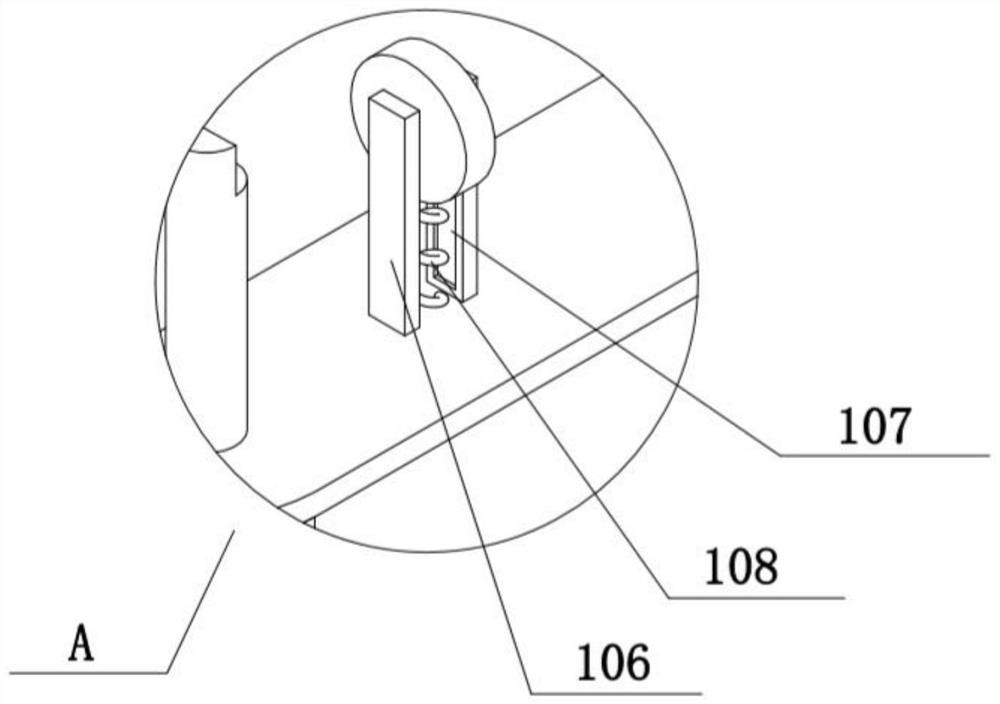

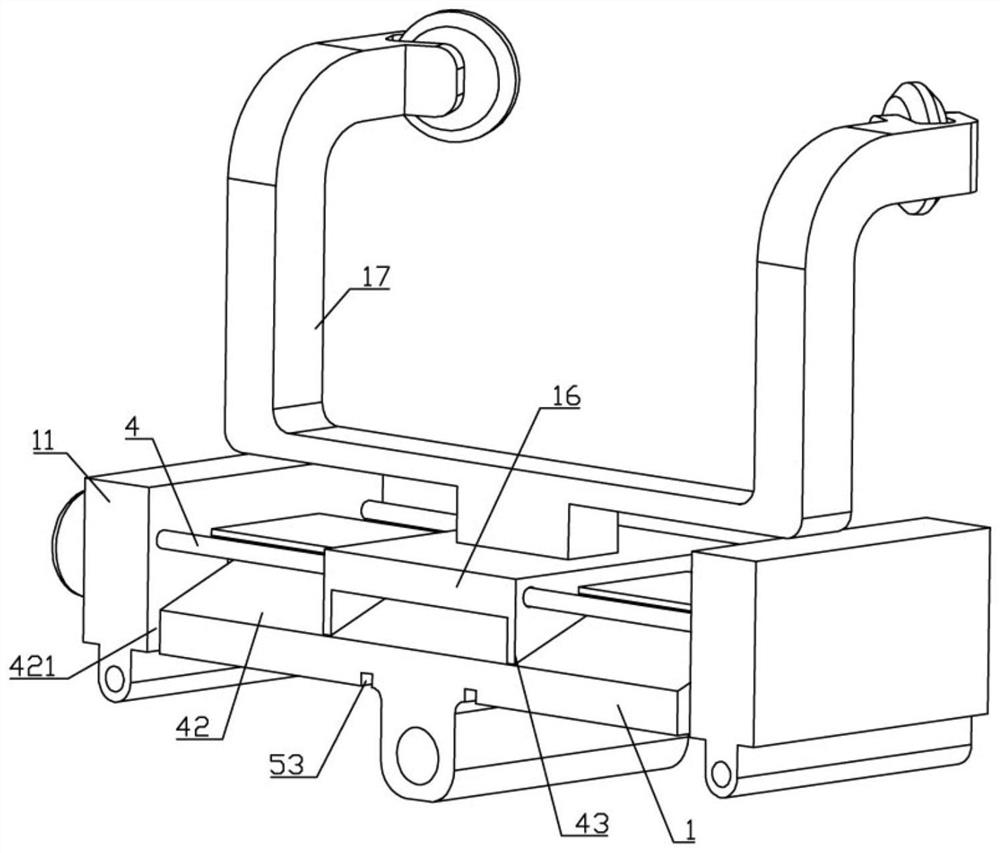

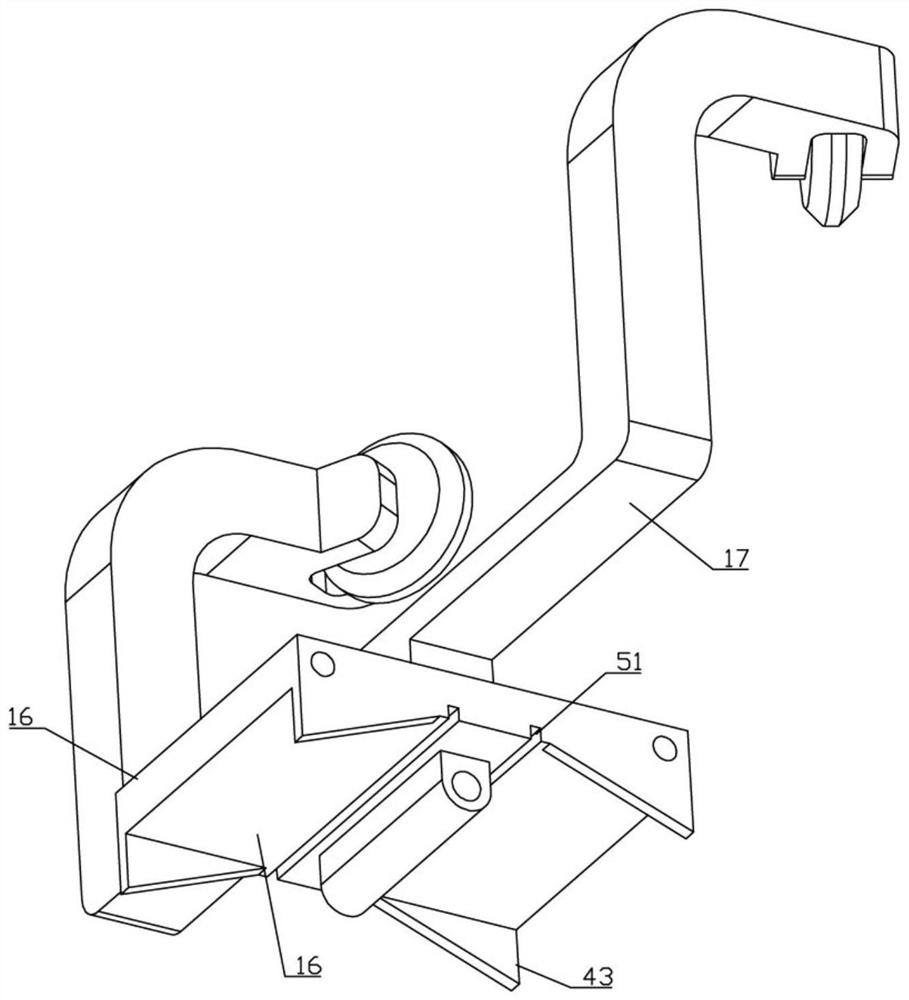

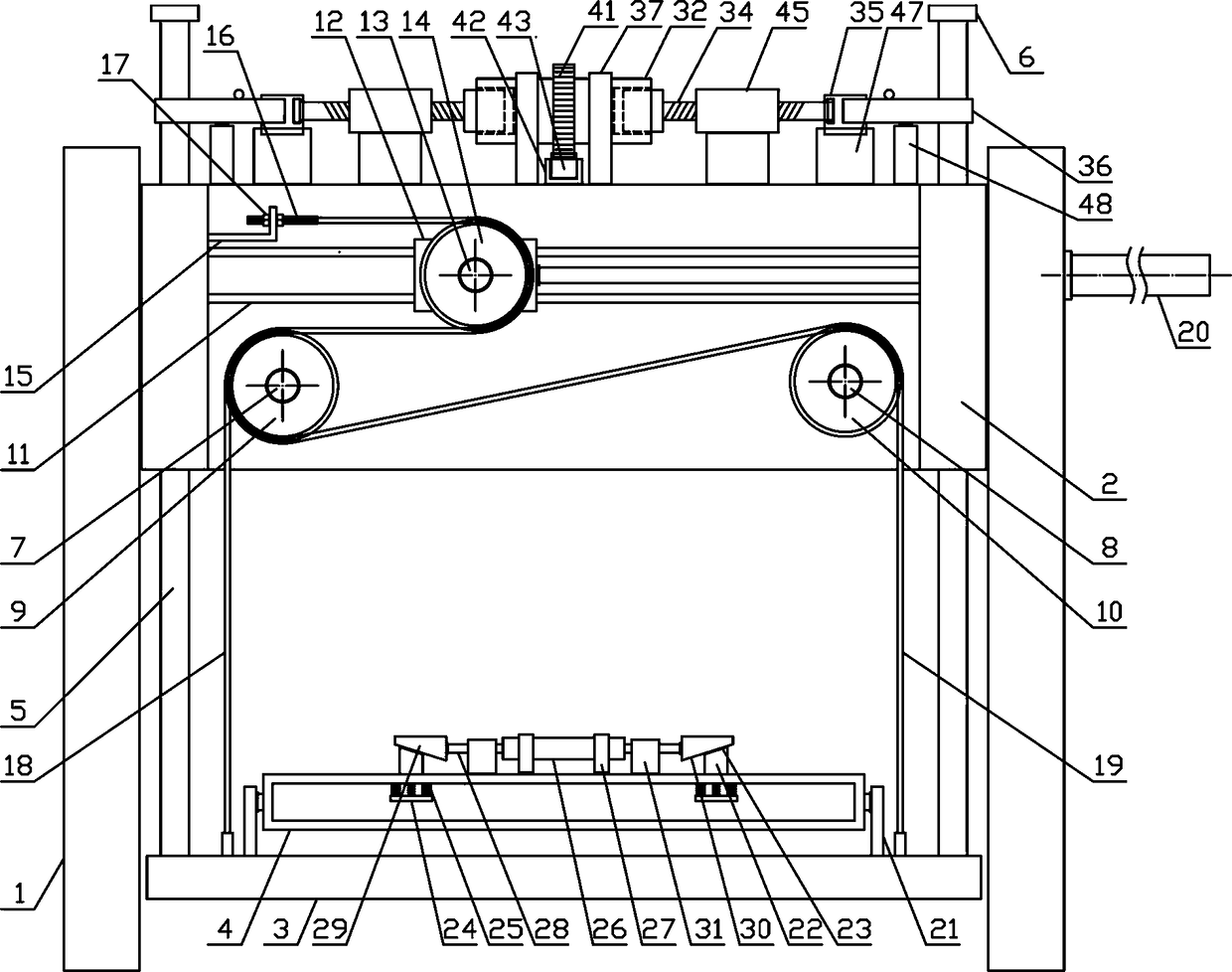

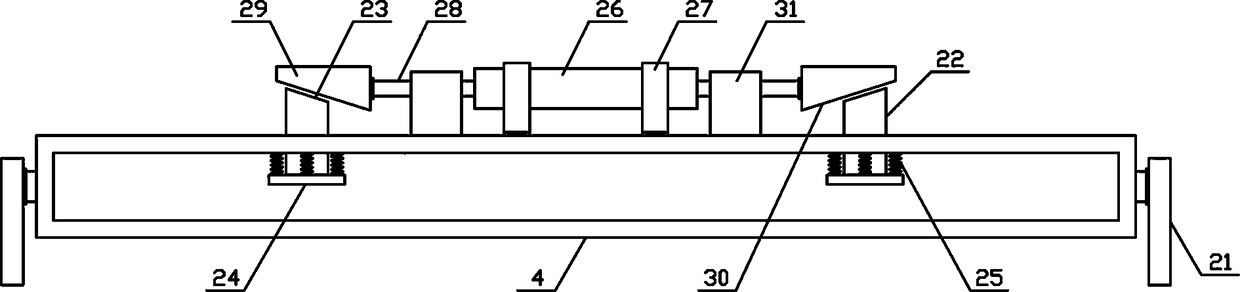

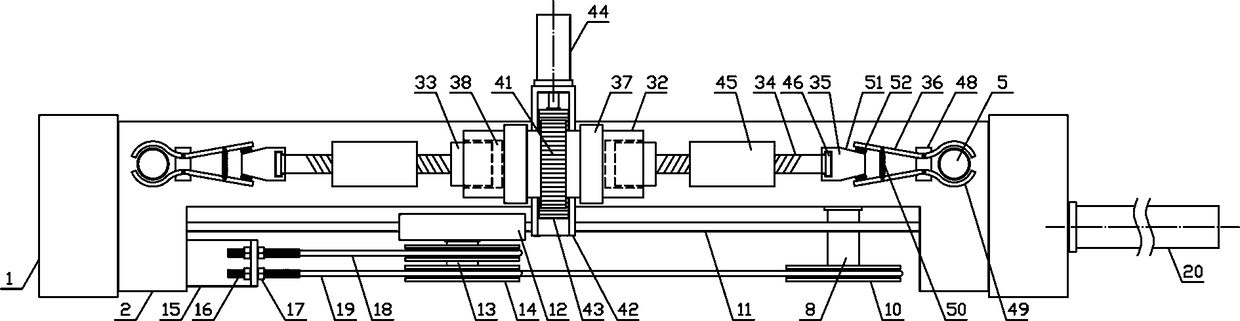

Carbon fiber silk supplying machine

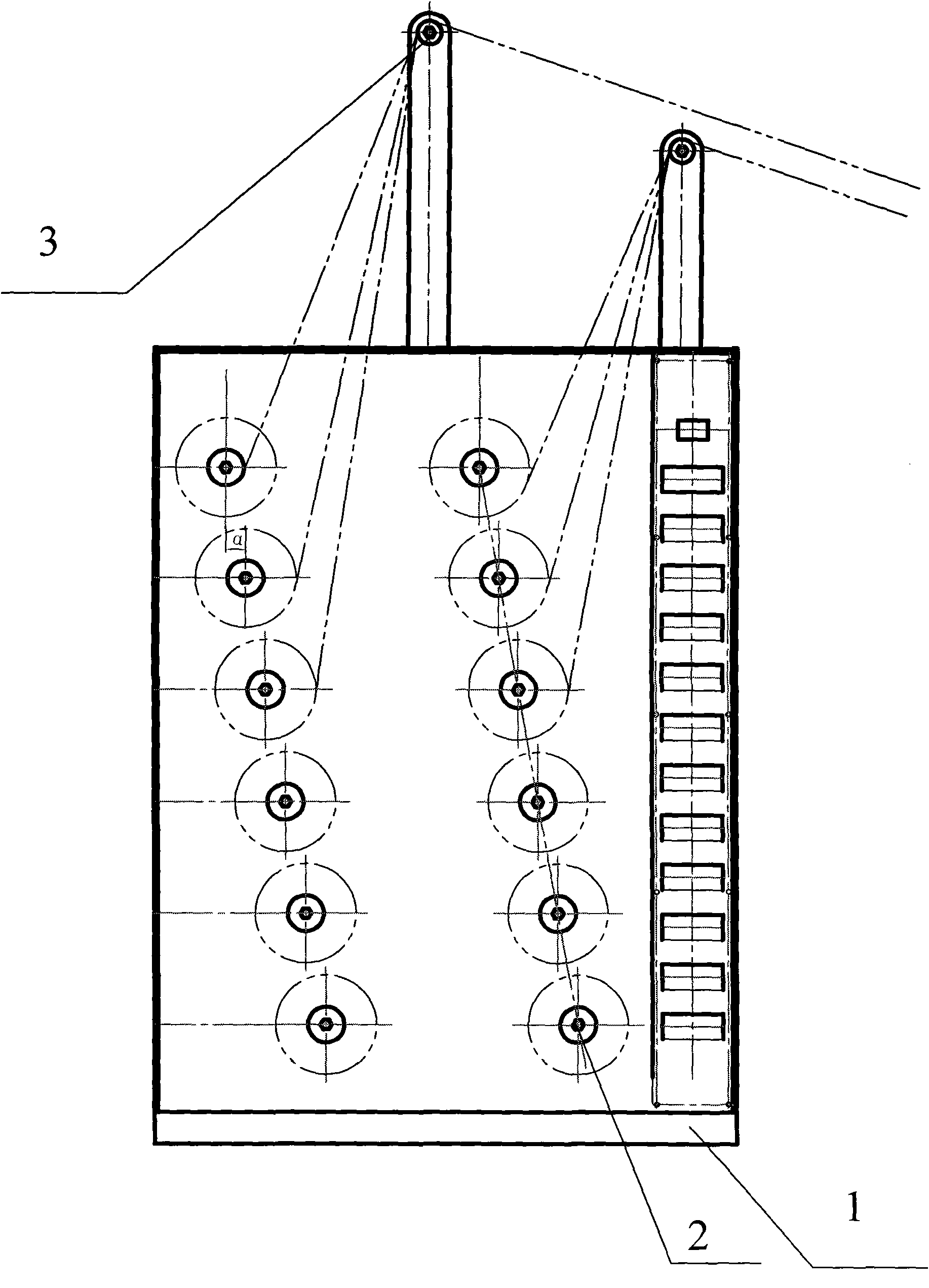

The invention provides a carbon fiber silk supplying machine which comprises a machine base and a plurality of silk placing rollers, wherein the silk placing rollers are divided into a plurality of rows and uniformly arranged at one side of the machine base, silk guide rollers matched with each row of silk placing rollers are arranged at the top end of the machine base, and the silk guide rollersare arranged at the top end of the machine base; the axial lines of the silk guide rollers are parallel to the axial lines of the silk placing rollers; the silk placing rollers are arranged at one side of the machine base through a rotating shaft, the rotating shaft penetrates through one side of the machine base, one end of the rotating shaft is positioned at the inner side of the machine base, and the other end extends to the outer side of the machine base; and the silk placing rollers are fixedly arranged at one end of the rotating shaft extending to the outer side of the machine base, anda damper is fixedly arranged at one end of the rotating shaft positioned at the inner side of the machine base. The invention ensures stable silk supplying tension of carbon fibers in the silk supplying process, avoids nonuniform silk supply and improves the quality of the carbon fibers.

Owner:镇江奥立特机械制造有限公司

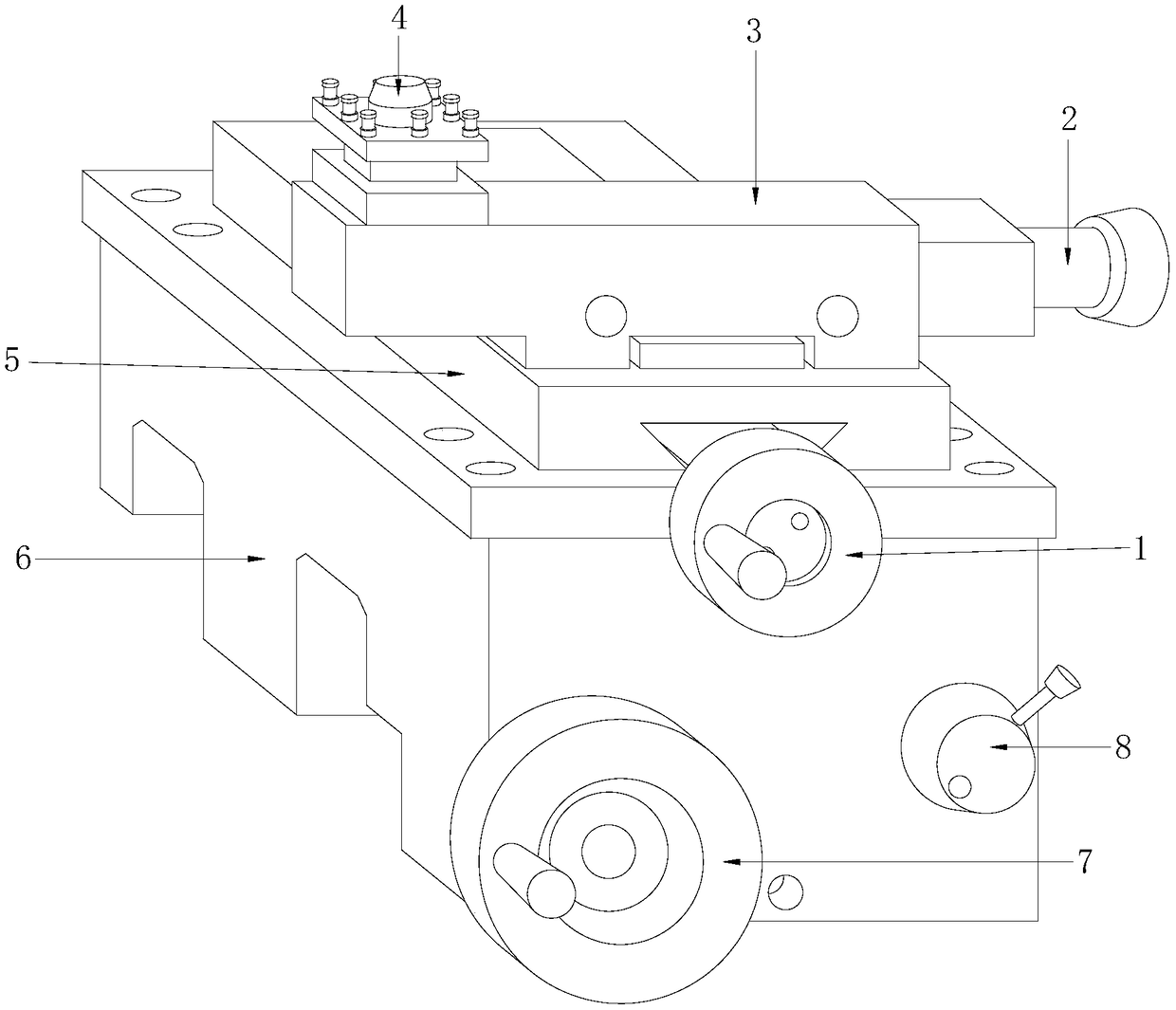

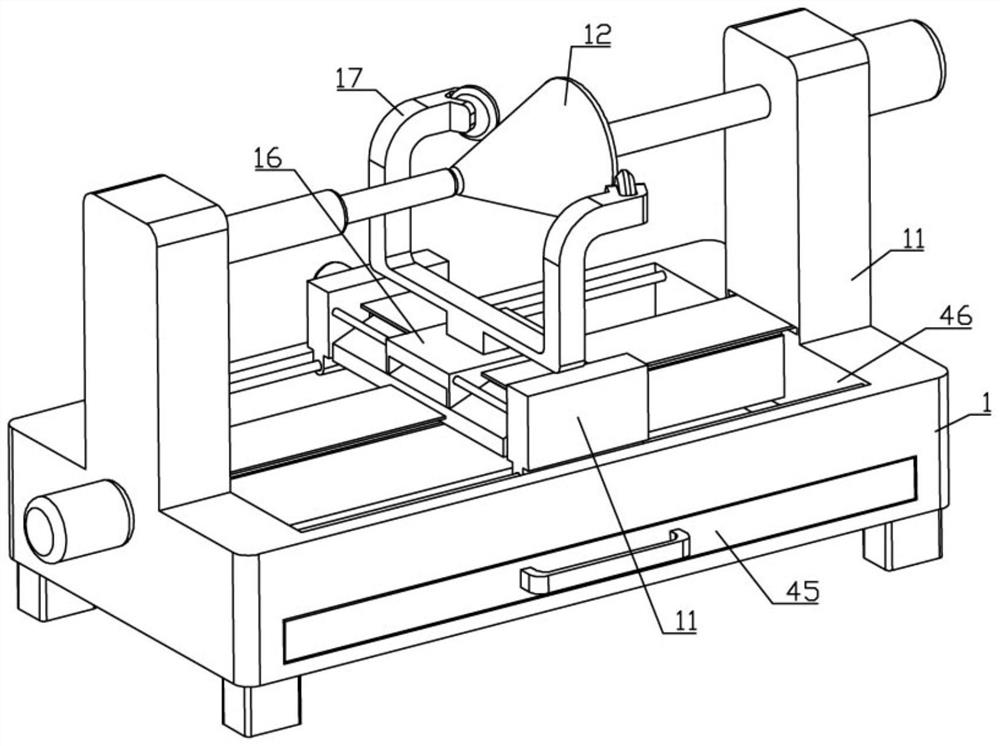

Feeding mechanism for lathe

InactiveCN108856742ATimely processingLarge deviationAutomatic control devicesAuxillary equipmentEngineeringMachining

The invention discloses a feeding mechanism for a lathe. The feeding mechanism structurally comprises a manually-adjusted feeding rotary disc, a tapping tube, a turning and feeding cutter replacementdevice of an automatic-stop anti-collision cutter, a turning cutter rack, a feeding guide rail plate, a cutting depth movement device, a cutting depth adjusting rotary disc and a position locking valve, wherein the manually-adjusted feeding rotary disc is mounted at the direct front end of the cutting depth movement device and is connected with the cutting depth movement device in an embedding manner; the tapping tube is positioned on the right side of the turning and feeding cutter replacement device of the automatic-stop anti-collision cutter and is connected with the turning and feeding cutter replacement device of the automatic-stop anti-collision cutter in an electric welding manner; the turning cutter rack is mounted on the upper surface of the turning and feeding cutter replacementdevice of the automatic-stop anti-collision cutter. According to the feeding mechanism disclosed by the invention, while machining and feeding of the cutter and adapting and replacement of the cutterare controlled, cutter collision caused by over-large feeding quantity can be stopped in time so as to be protected, and therefore, abrasion of cutter edges of the cutter is avoided while chipping andbreaking of the cutter can be prevented at the same time so as to avoid influence of machining of workpieces; meanwhile, an alarm is started to prompt working personnel to maintain the cutter, so that the phenomenon that deviation of molded workpieces is large when the cutter edge is broken and is then machined is avoided.

Owner:黄红兵

Convenient feeding device based on sheet-metal working

ActiveCN111112483AScientific and reasonable structureEasy to useMetal-working feeding devicesCleaning using toolsRatchetSlide plate

The invention discloses a convenient feeding device based on sheet-metal working. The convenient feeding device comprises a conveyor belt, and the two ends of the middle part of one side of a baffle are each provided with a cylinder; one end of each cylinder is provided with a push plate, and a sliding plate is hinged to one end of a connecting plate; the two ends of the top surface of the slidingplate are each provided with a vertical slot, and each vertical slot is internally provided with a first roller; one end of each first roller is provided with a mounting slot, and an arc plate is hinged to the interior of each mounting slot; and a ratchet wheel is installed at the position, corresponding to the arc plate, of one of the vertical slot by screws. Compared with the prior art, the convenient feeding device has the beneficial effects that the conveyor belt is turned on, and metal plates are placed on the conveyor belt; at the moment, the cylinders are turned on, and the metal plates are pushed through the cylinders, so that the metal plates are aligned; when the metal plates transported onto the connecting plate, the metal plates fall down along the sliding plate, and roll in the vertical slots through the first rollers; the arc plates are blocked through the ratchet wheel, and the first rollers are prevented from being rotated reversely; the situation that the metal platesare slide on the sliding plate obliquely, and consequently the subsequent machining of the metal plates is affected is avoided.

Owner:晋江荣达机械有限公司

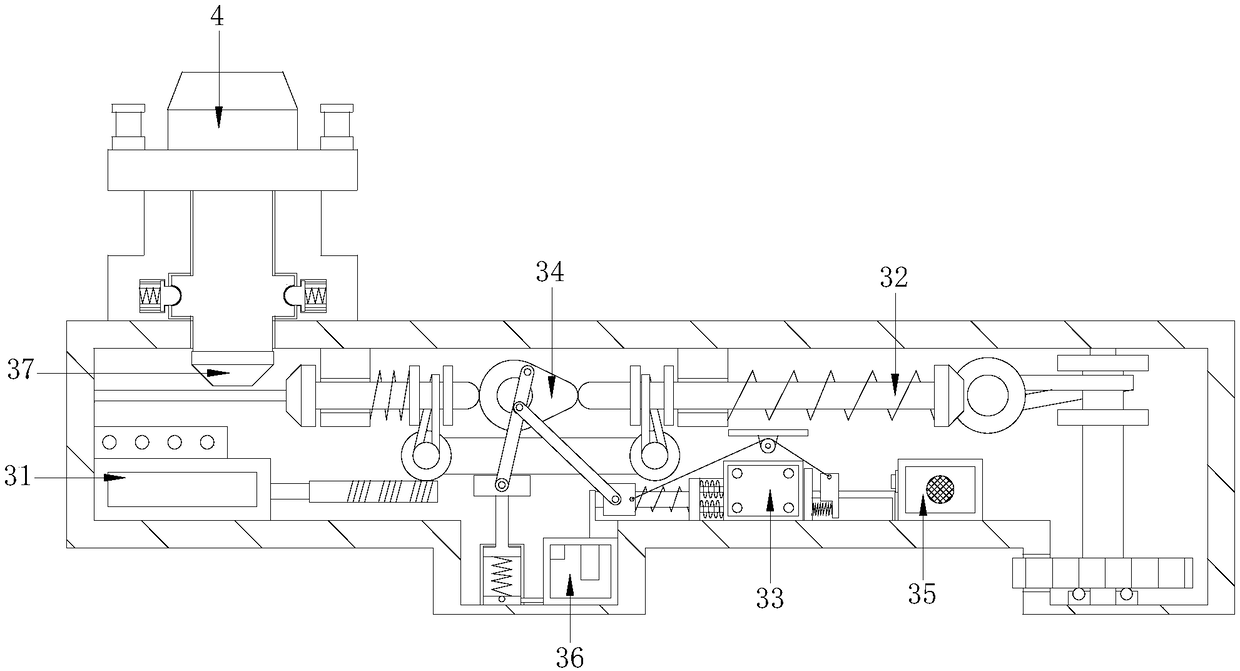

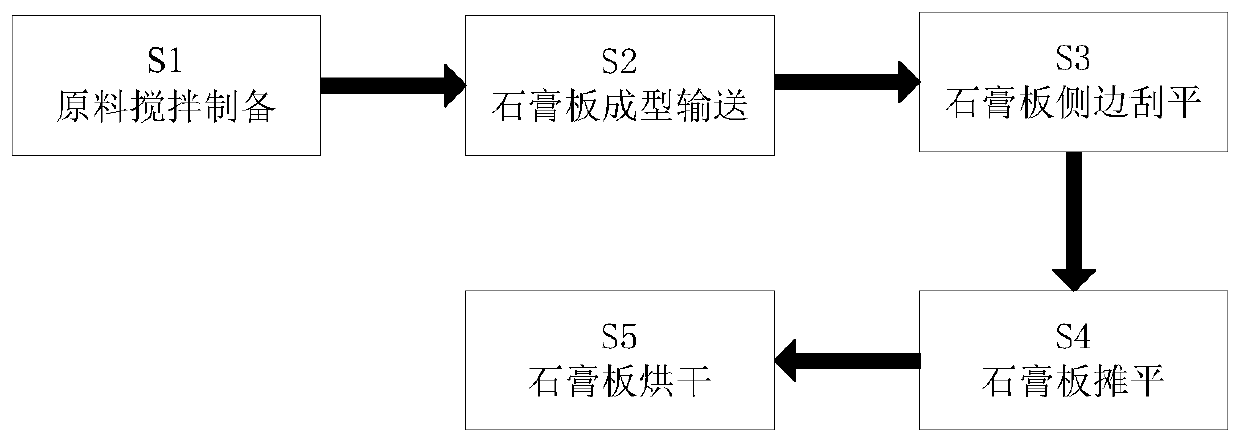

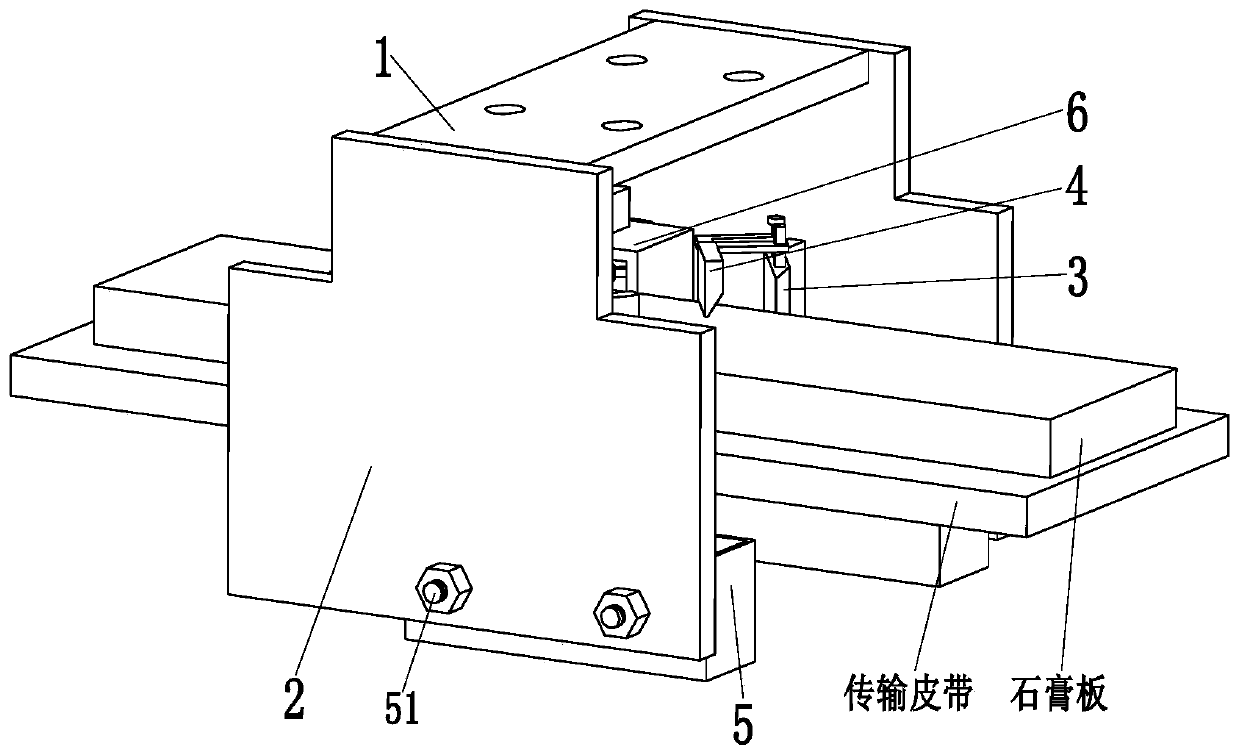

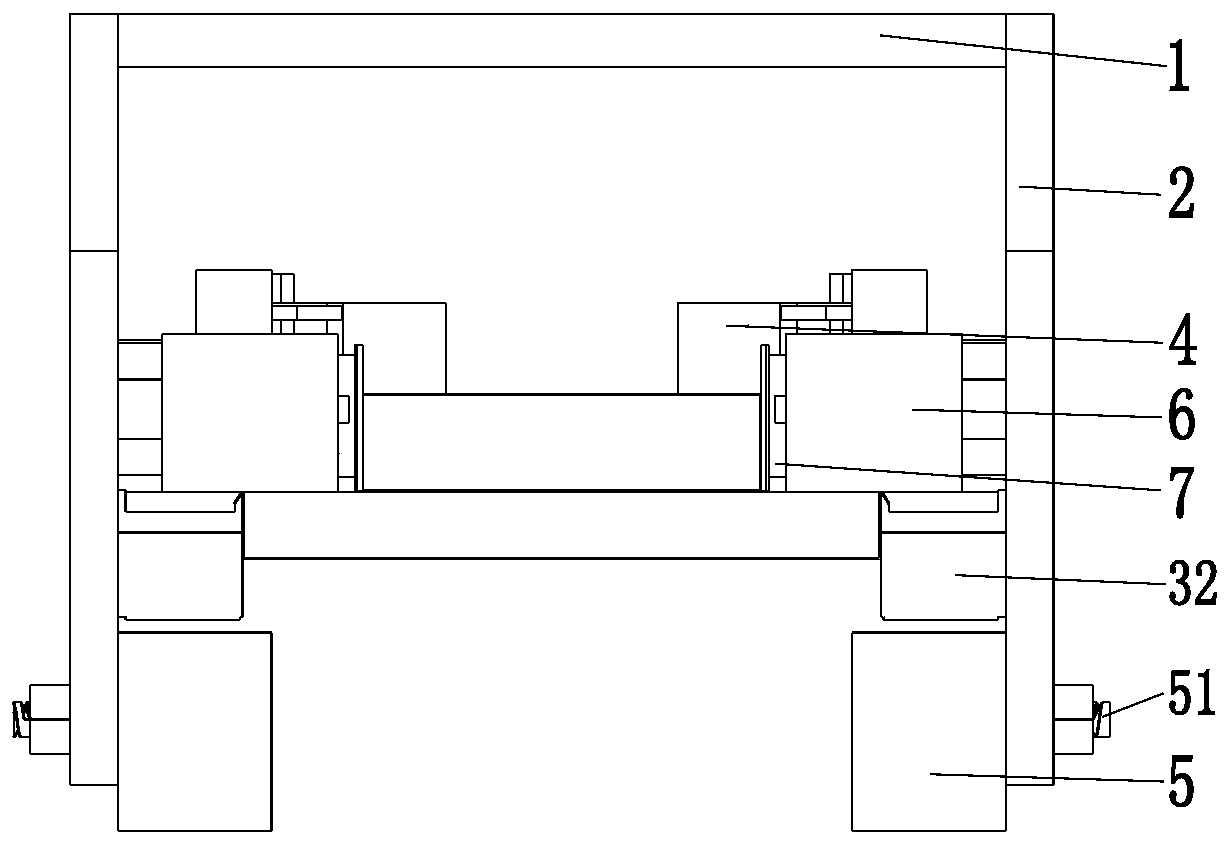

Production and processing technology of decoration material gypsum board

ActiveCN111516104AGood molding effectProcessing effectAuxillary shaping apparatusCompression moldingProcess engineering

The invention relates to a production and processing technology of a decoration material gypsum board. The production and processing technology of the decoration material gypsum board adopts a following gypsum board production and processing device. The gypsum board production and processing device includes a mounting board, a side support board, a scraper bar, a leveling board, a support frame and a leveling mechanism; and the production and processing technology of the decoration material gypsum board adopting the above-mentioned gypsum board production and processing device includes the following steps of: S1, raw material mixing preparation; S2, gypsum board molding and conveying; S3, gypsum board side edge scraping and flattening; S4, gypsum board paving; and S5, dry gypsum board drying. Through the production and processing technology, the problems during existing gypsum board flattening treatment that excess gypsum is squeezed on the upper side surfaces of gypsum boards and a conveying belt when the gypsum boards are smoothed, the molding effect of the gypsum boards are poor due to the gypsum on the upper side surfaces of the gypsum boards, and compression molding of the gypsum boards is affected by the gypsum on the gypsum boards can be solved.

Owner:泰山石膏(邳州)有限公司

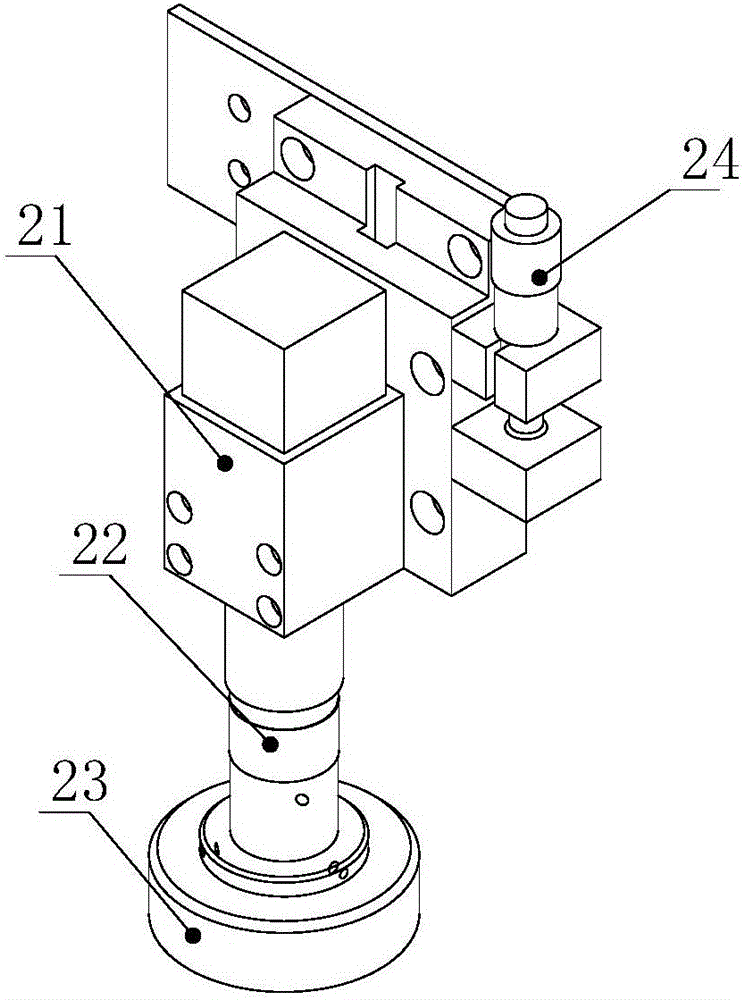

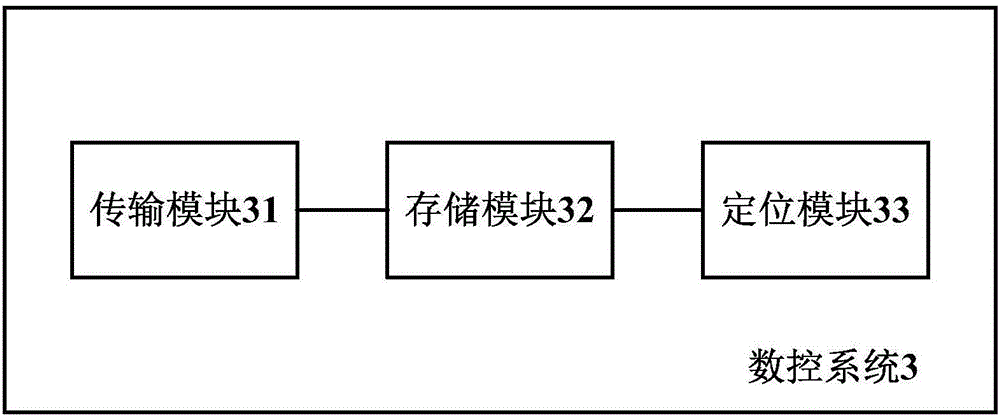

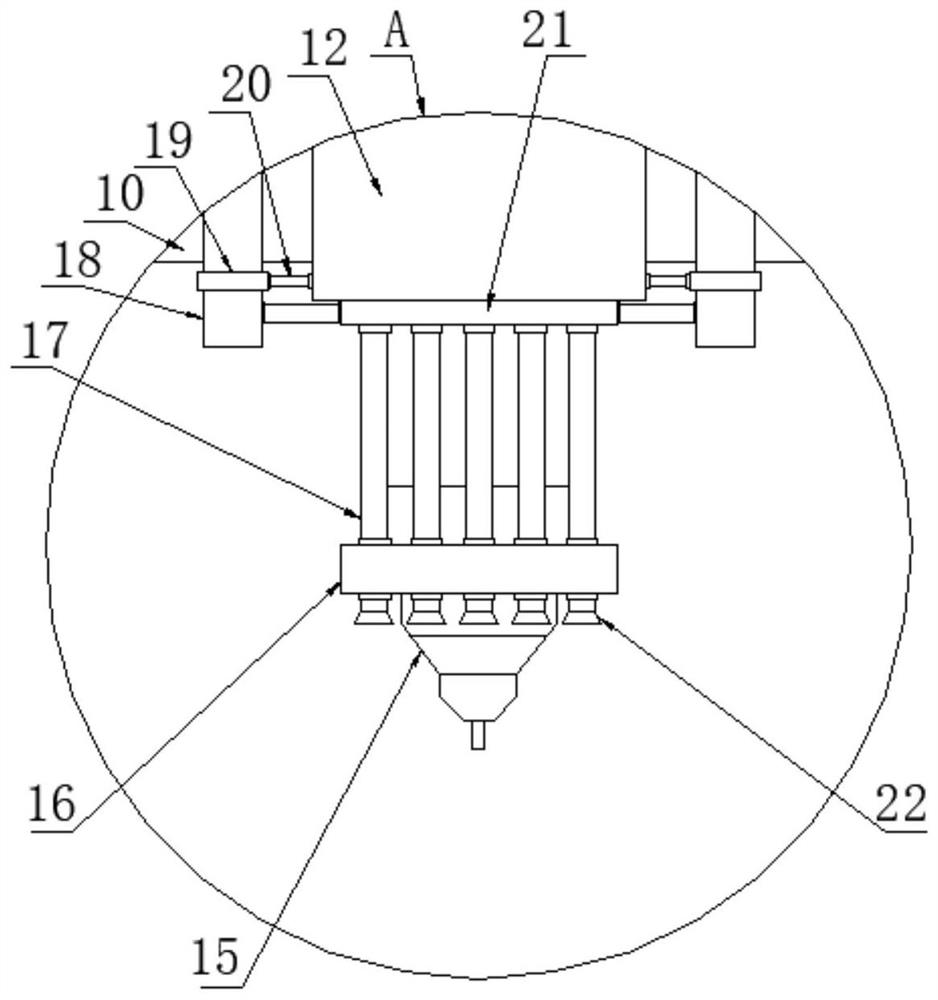

Cutting head with positioning mechanism, cutting device and cutting method

InactiveCN106141454AAccurate transmissionPrecise processingLaser beam welding apparatusCamera lensLaser cutting

The invention discloses a cutting head with a positioning mechanism, a cutting device and a cutting method and relates to the technical field of laser cutting. A visual imaging unit is arranged at a side part of the cutting head; the visual imaging unit comprises a CCD (Charge Coupled Device) camera, a deep focus camera lens and an annular light source, which are connected in sequence from top to bottom; a lifting adjusting device is arranged at the side part of the CCD camera; and the lifting adjusting device is used for adjusting the lifting height of the deep focus camera lens. With the adoption of the cutting head with the positioning mechanism, the cutting device and the cutting method, accurate cutting of parts is realized and the major problem that cutting blanking is difficult is solved.

Owner:WUHAN TIANQI LASER EQUIP MFG

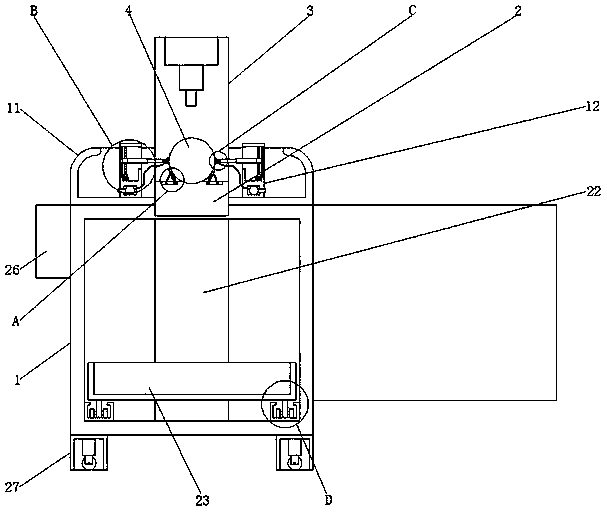

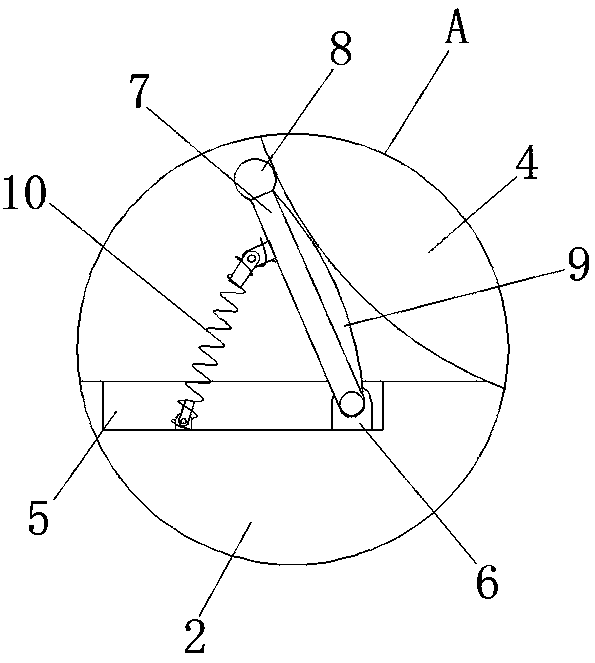

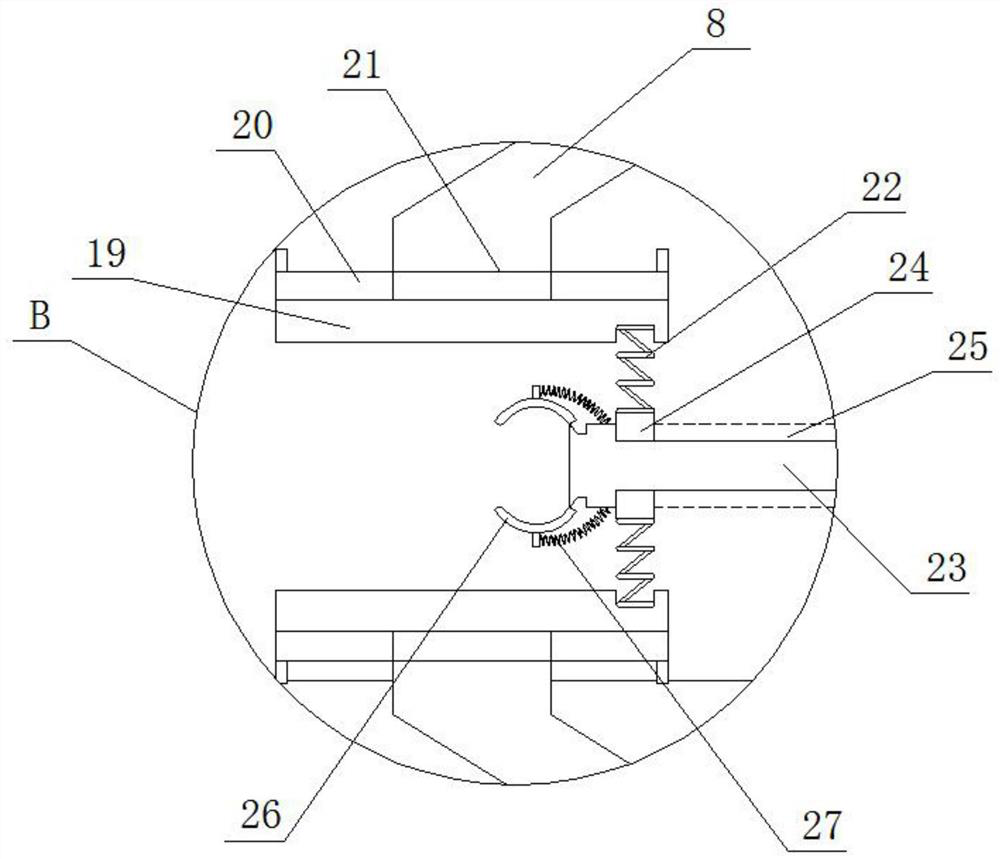

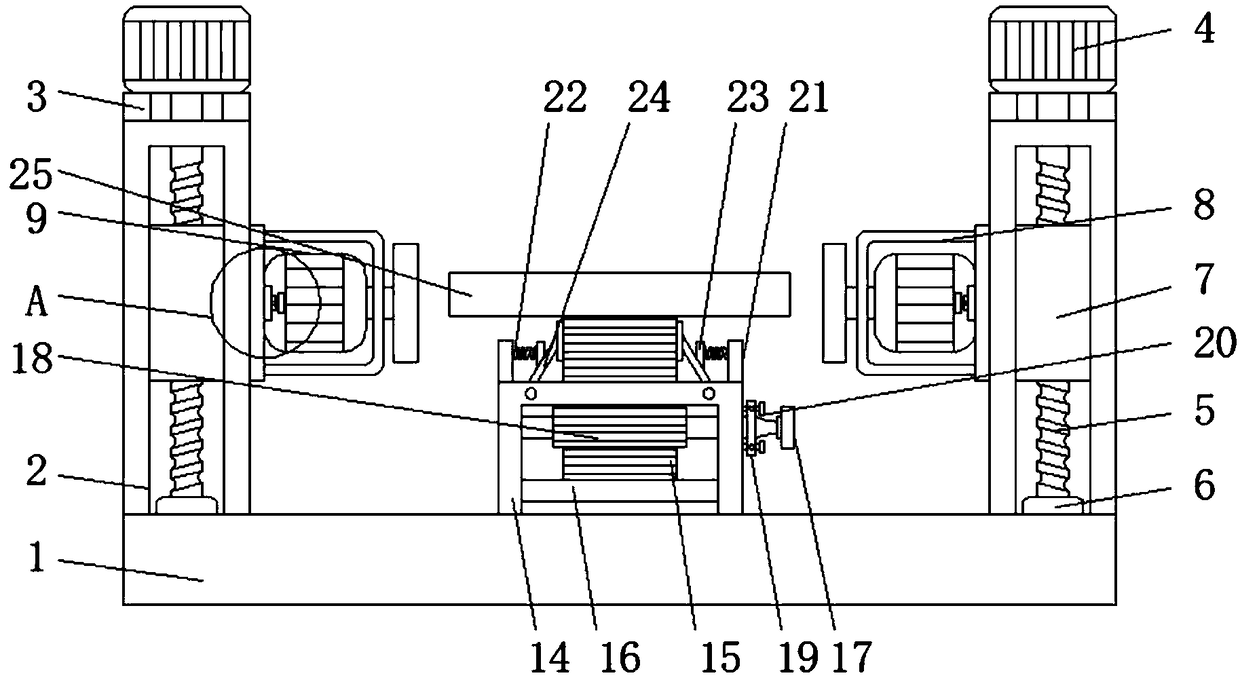

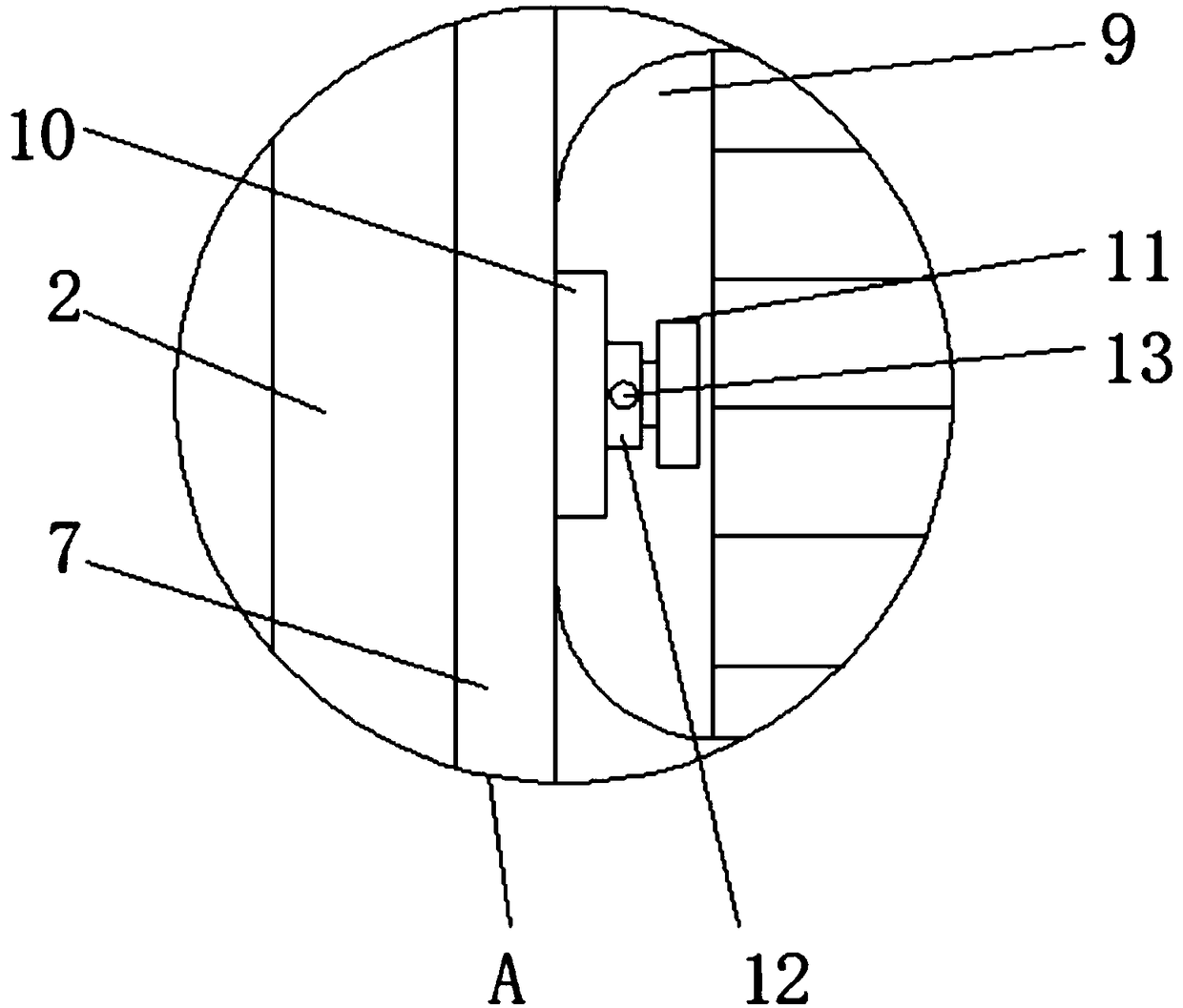

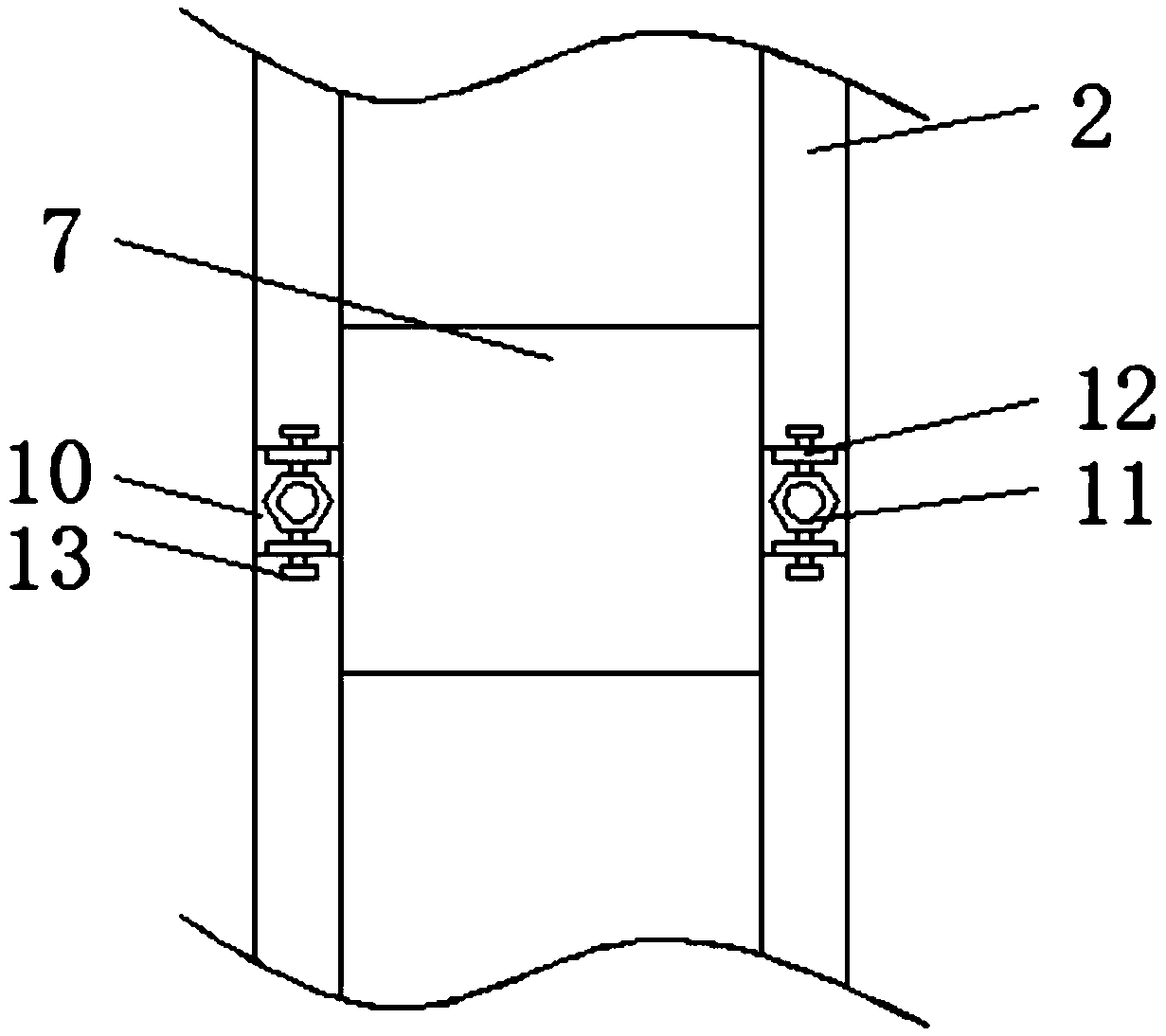

Industrial machine tool for machining circular parts

ActiveCN108655776AProcessing effectRealize the clamping effectPositioning apparatusMetal-working holdersIndustrial machineEngineering

The invention provides an industrial machine tool for machining circular parts and relates to the field of industrial machine tool devices. The industrial machine tool for machining circular parts comprises a shell. A clamping table is embedded in the top of the shell, a machining device is fixedly mounted on the top of the shell and located on the back side of the clamping table, the top of the clamping table is provided with an arc groove, the top of the clamping table is provided with a spherical part, a first groove is formed in the top of the clamping table and located on the periphery ofthe spherical part, and fixing blocks are fixedly mounted on the bottom of the inner wall of the first groove and located on one side of the first groove close to the spherical part. According to theindustrial machine tool for machining circular parts, by the cooperative use of springs and clamping plates, the clamping effect is achieved. Rubber suckers are pushed by electric push rods to be attached to the spherical part, and the air in the rubber suckers are pumped by miniaturized air pumps, so that the clamping effect is improved, and the influence on the machining of the spherical part since the spherical part is loosened during machining is prevented.

Owner:台州越工自动化设备有限公司

Gravel screening device

PendingCN108620233AQuality improvementImprove efficiencySievingUsing liquid separation agentDrive wheelWaste collection

The invention discloses a gravel screening device and belongs to the technical field of screening devices. The gravel screening device is characterized by comprising a discharging outlet, a conveyingbelt and a collection device; the conveying belt is used for screening gravels of different sizes; the conveying belt comprises a driving wheel set and at least one driven wheel; the driving wheel set comprises driving wheels corresponding to the driven wheels one by one; the driving wheels are connected with the driven wheels through two chains; a plurality of supporting rods are arranged symmetrically between the two chains; the supporting rods and the chains are connected through reset springs; the conveying belt is provided with a convex block enabling the supporting rods to rotate towards the outer side of the conveying belt and penetrating through the lower half part of the conveying belt; the discharging outlet is formed in the upper portion of the driving wheel set; and the collection device comprises gravel collection positions below the driven wheels and corresponding to the driven wheels one by one and waste collection positions arranged below the driving wheel set. The gravel screening device has the characteristics of filtering and separating gravels of different grain sizes and preventing the gravels from blocking operation of the conveying belt.

Owner:衡阳泰源商砼有限公司

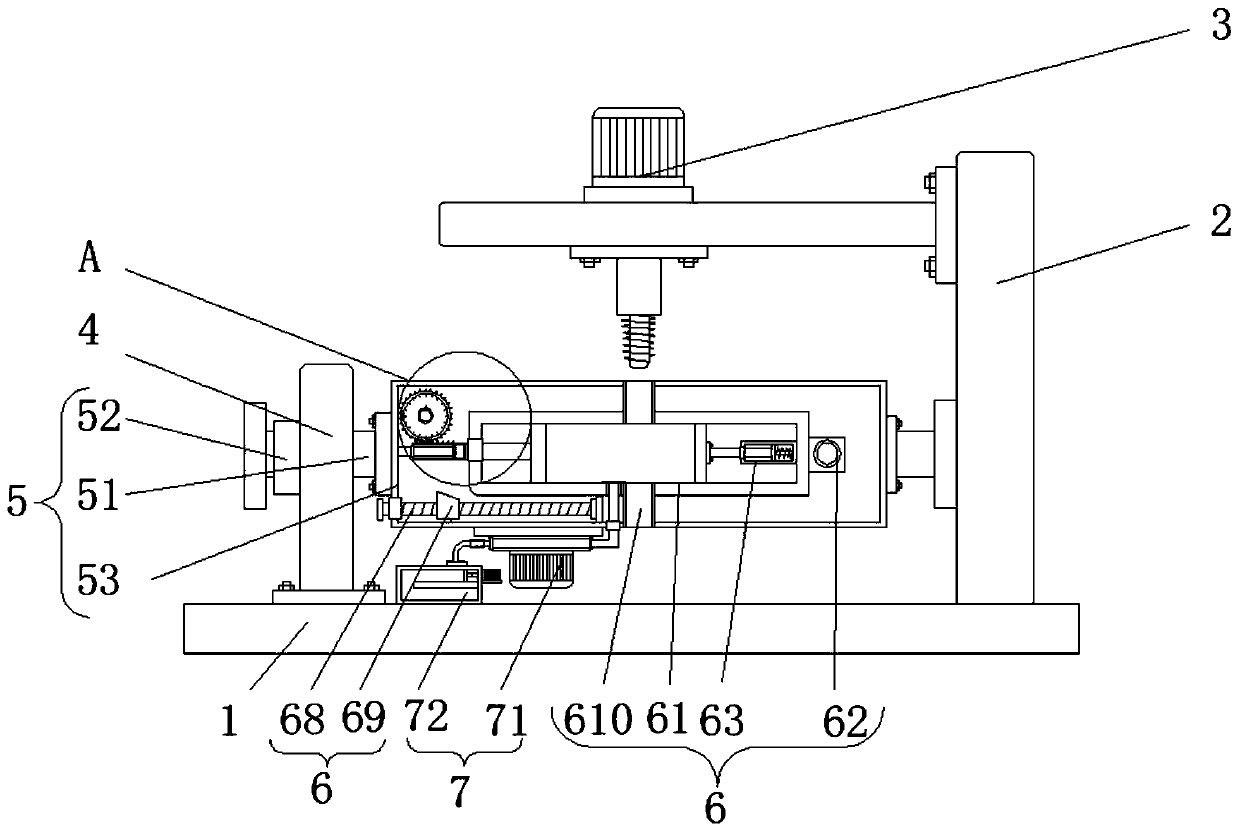

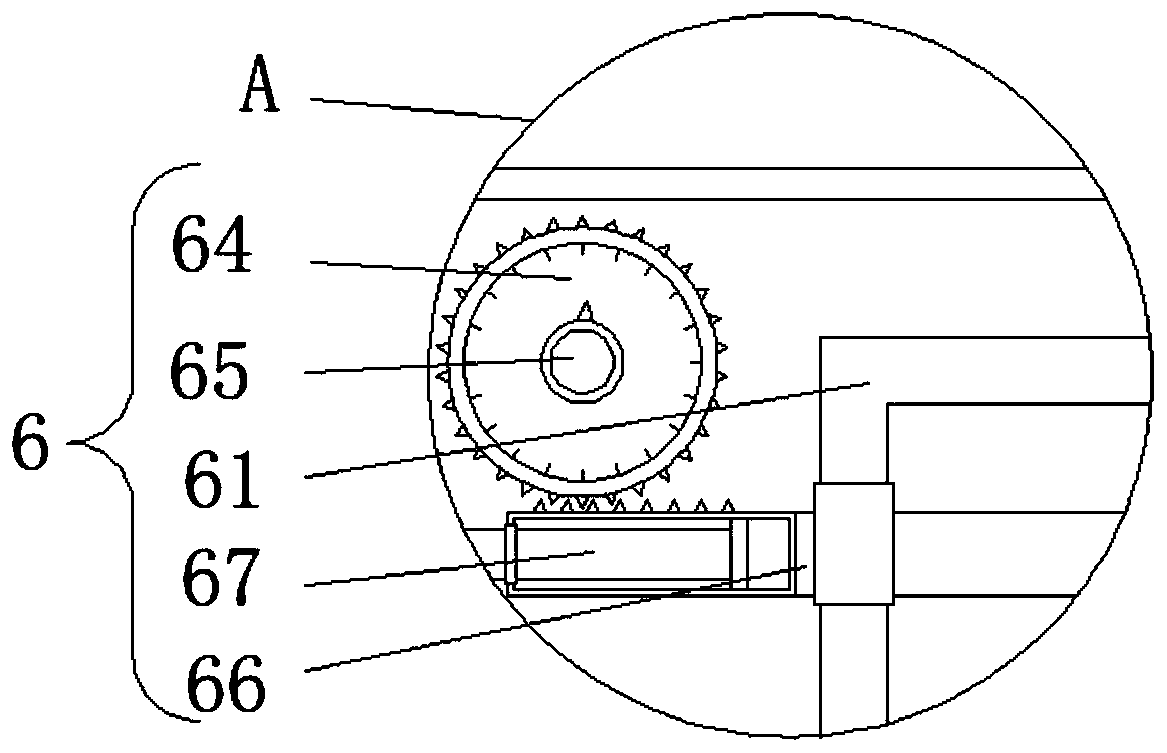

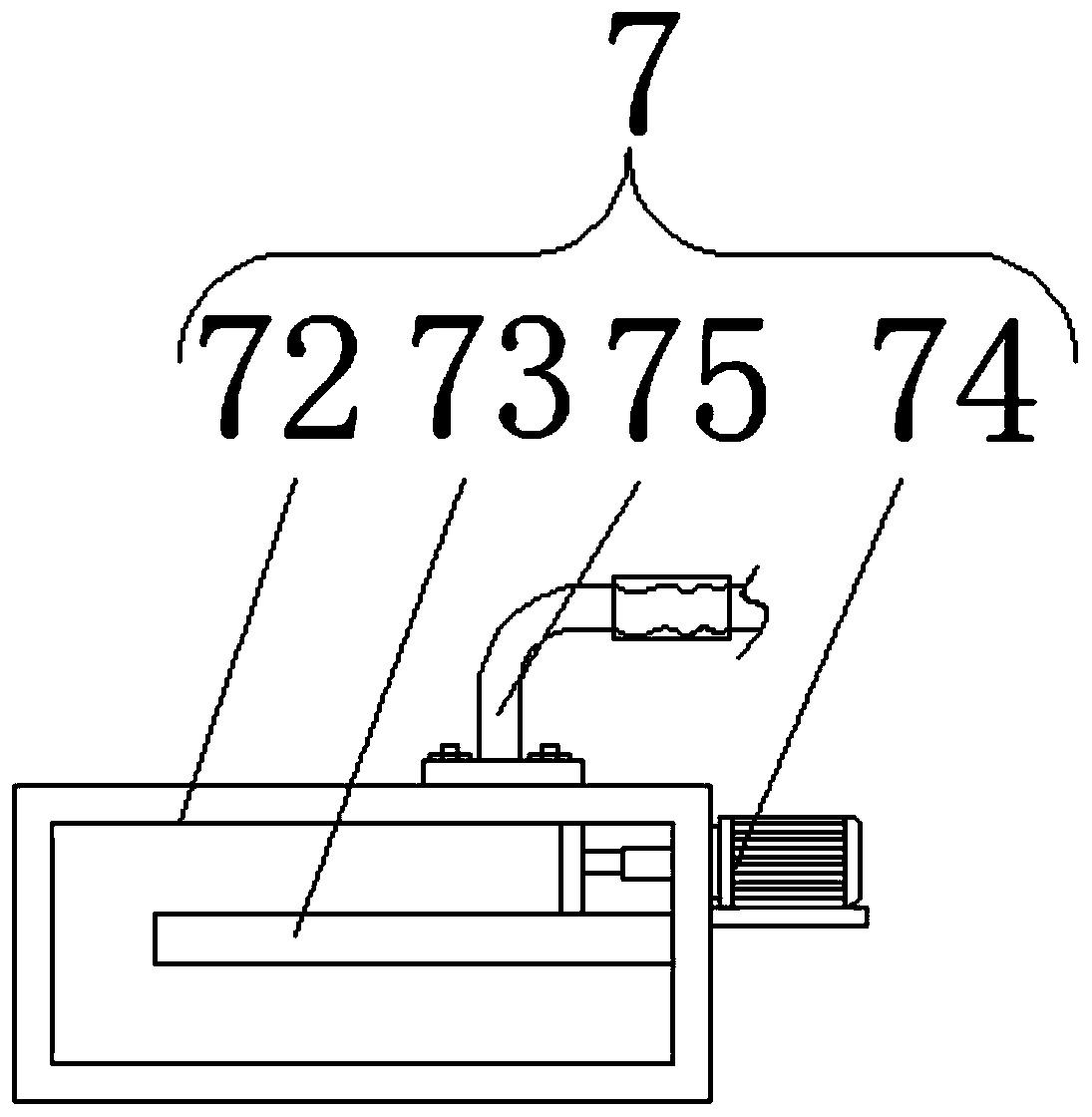

Deep hole device used for electronic lock machining

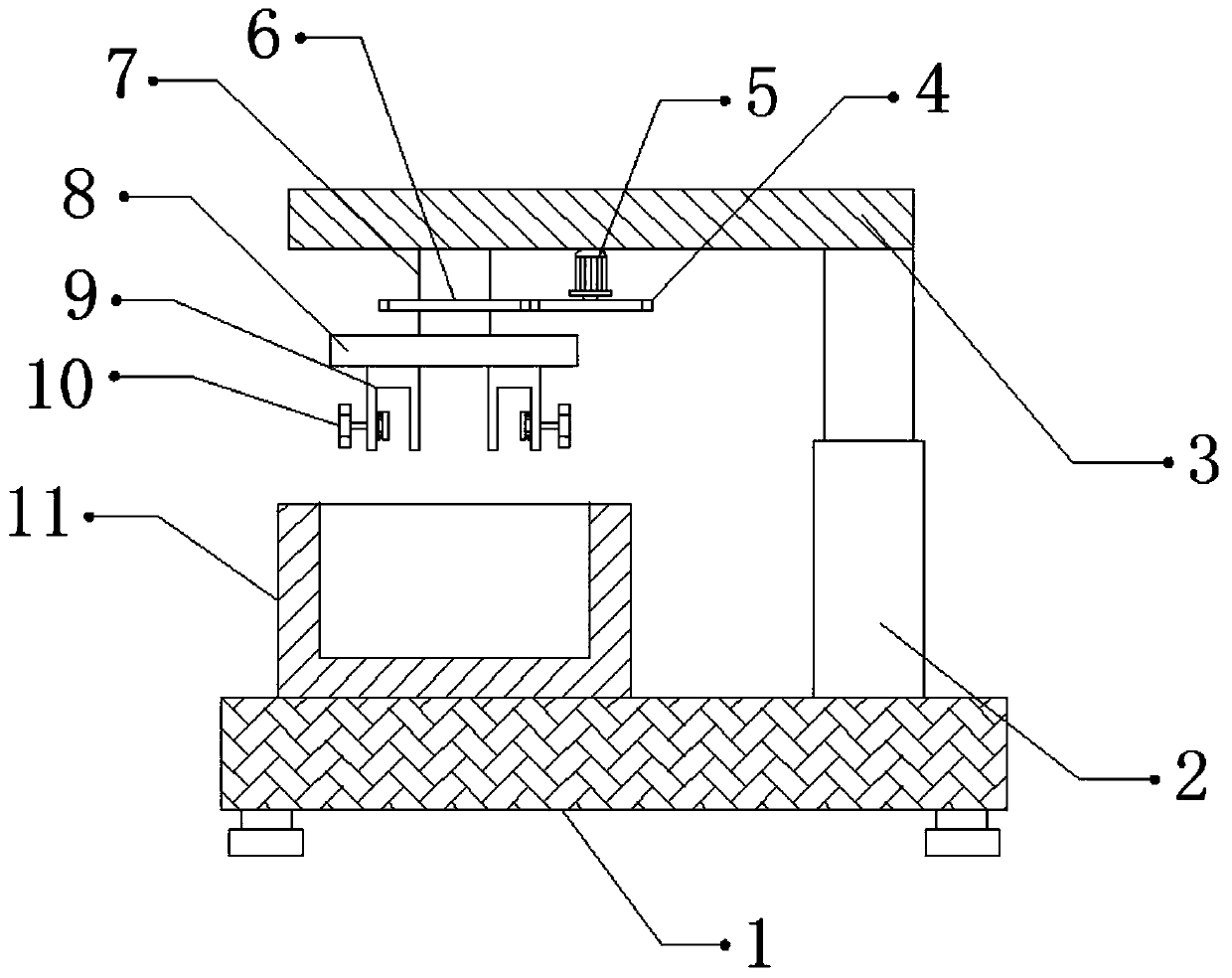

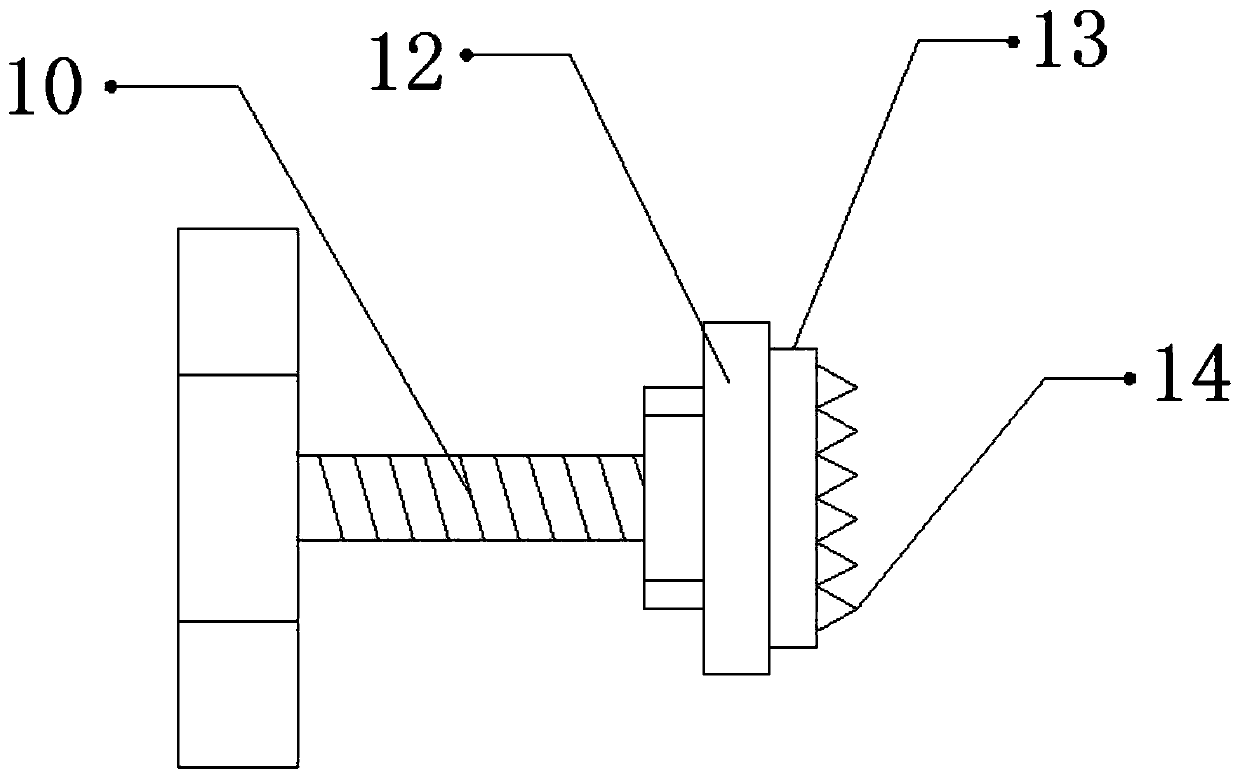

ActiveCN110170680AIncreased versatilityQuickly adjust the workpiece positionLarge fixed membersPositioning apparatusEngineeringDeep hole

The invention provides a deep hole device used for electronic lock machining and relates to the technical field of deep hole devices. The deep hole device comprises a base. A supporting pillar is fixed to the top of the base, and a drilling device is fixedly installed on the top of the supporting pillar. A stand column is fixedly installed at the position, located on one side of the supporting pillar, of the top of the base, and a rotating structure is fixedly installed on one side of the outer surface of the stand column. An adjusting structure is fixedly installed in the rotating structure,and an impurity removing device is fixedly installed at the position, located below the rotating structure, of the top of the base. According to the deep hole device used for electronic lock machining, the inclined angle of a carrying table can be adjusted by controlling motion of a nut block, a matched inclined hole can be formed in a punching manner, and multifunctionality of the deep hole device is improved; meanwhile, due to the cooperation of a gear, a first clamp and a second clamp, the effect of rapidly adjusting the position of a workpiece can be achieved, the phenomenon that people stretch hands to the position below a machining machine for manual adjustment is avoided, the work efficiency and the safety performance of workers are improved, and meanwhile the labor intensity of theworkers is lowered.

Owner:FUYANG WANRUI ELECTRONICS LOCKS CO LTD

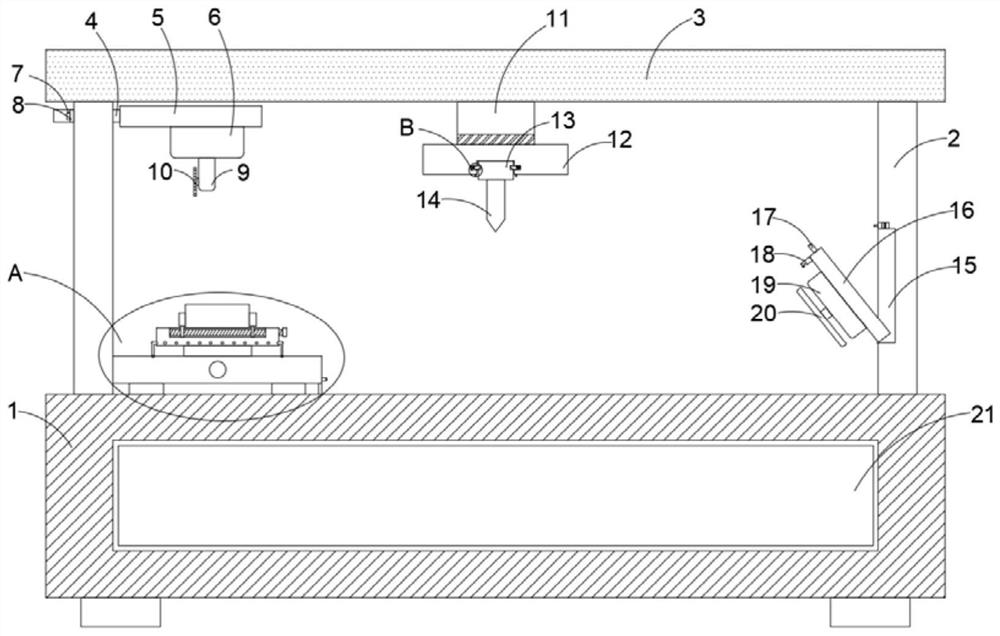

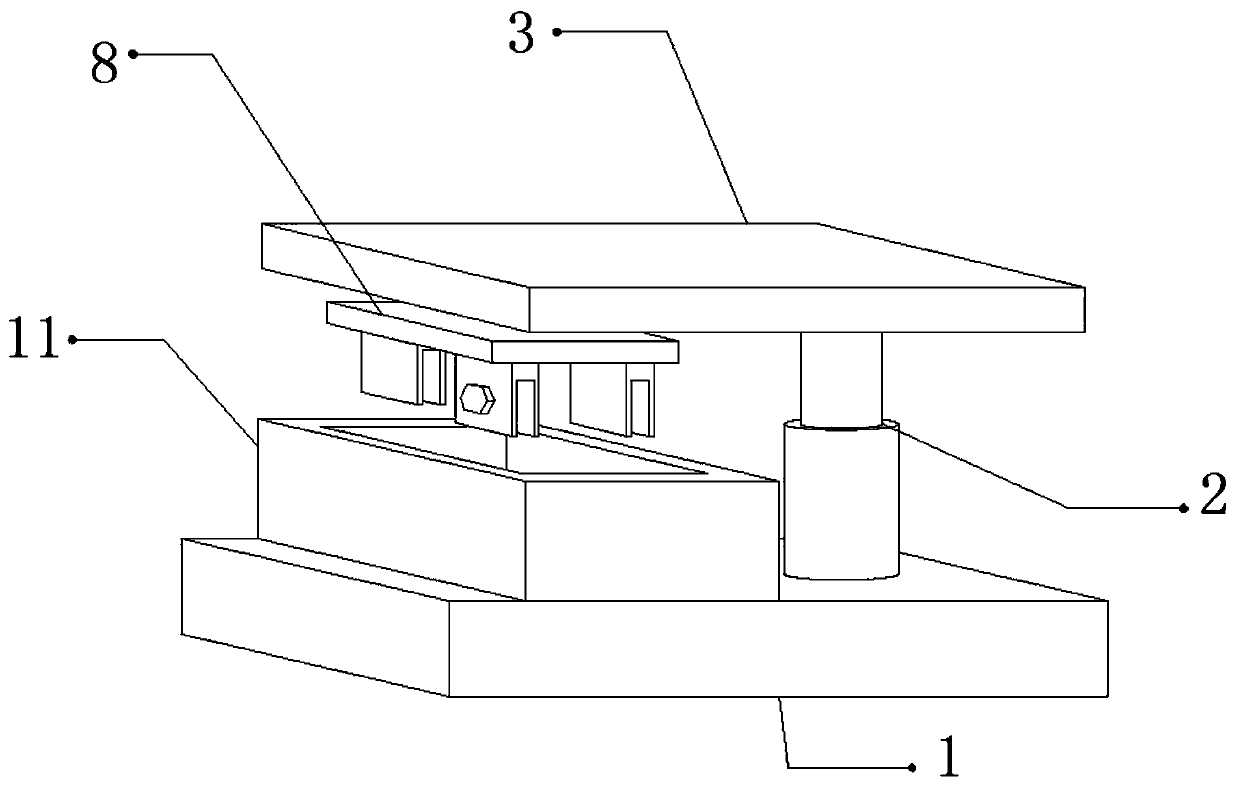

Multifunctional agricultural machinery machining workbench

InactiveCN111633435AAchieve blockingAchieve regulationOther manufacturing equipments/toolsLarge fixed membersAgricultural machineryMachining

The invention discloses a multifunctional agricultural machinery machining workbench. The multifunctional agricultural machinery machining workbench comprises a workbench body, two supporting plates are symmetrically and fixedly arranged on the workbench body, a top plate is fixedly arranged on the two supporting plates, a workpiece is arranged on the workbench body, a material clamping mechanismcorresponding to the workpiece is arranged on the workbench body, a cutting mechanism corresponding to the workpiece is arranged on the supporting plate on one side, a polishing mechanism corresponding to the workpiece is arranged on the supporting plate on the other side, a waste groove is formed in the side wall of the workbench body, a waste box is arranged in the waste groove in a sliding mode, an opening communicating with the waste groove is formed in the upper wall of the workbench body, and the opening corresponds to the waste box. According to the multifunctional agricultural machinery machining workbench, the workpiece of agricultural machinery can be cut, drilled and polished, multiple functions are integrated, so that the production efficiency of the agricultural machinery is greatly improved, the workpiece can be moved, rotated and fixed according to needs, and the machining is facilitated.

Owner:山东硕达通机械设备有限公司

High-stability fixing clamp for machining

ActiveCN112894656AImprove stabilityEasy to processWork holdersCleaning using toolsStructural engineeringMachining

The invention provides a high-stability fixing clamp for machining. The fixing clamp comprises a base, a moving plate, an adjusting plate, a storage box, an upper supporting rod, a lower supporting rod, a fixing plate, a clamping plate, a fixing rod, a cleaning plate and a clamping rod, wherein a base sliding groove is formed in the center of the top of the base, a screw rod is rotationally installed in the base sliding groove, a bottom hand wheel is welded to one end of the screw rod, the moving plate is movably installed on the screw rod through a sliding block, the sliding block is movably installed in the base sliding groove, and the adjusting plate is movably installed on one side of the top of the base through a rotating shaft. According to the high-stability fixing clamp for machining, the clamping length of a workpiece can be adjusted through the clamping plate and the fixing rod according to the specification of the workpiece, the stability of the clamp can be improved through the combined action of an arc-shaped clamping plate, the fixing rod and the clamping plate, the workpiece with the smaller specification can be conveniently machined through adjustment of the adjusting plate, and the workpiece machining efficiency can be improved.

Owner:新乡市亚联重工有限公司

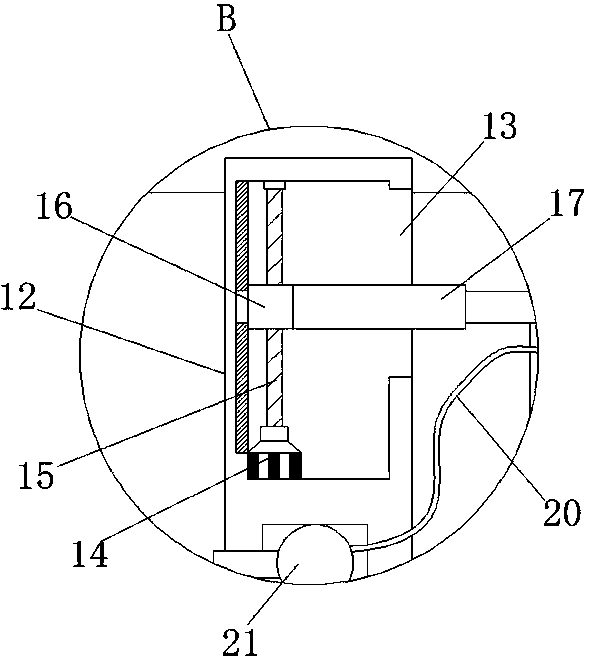

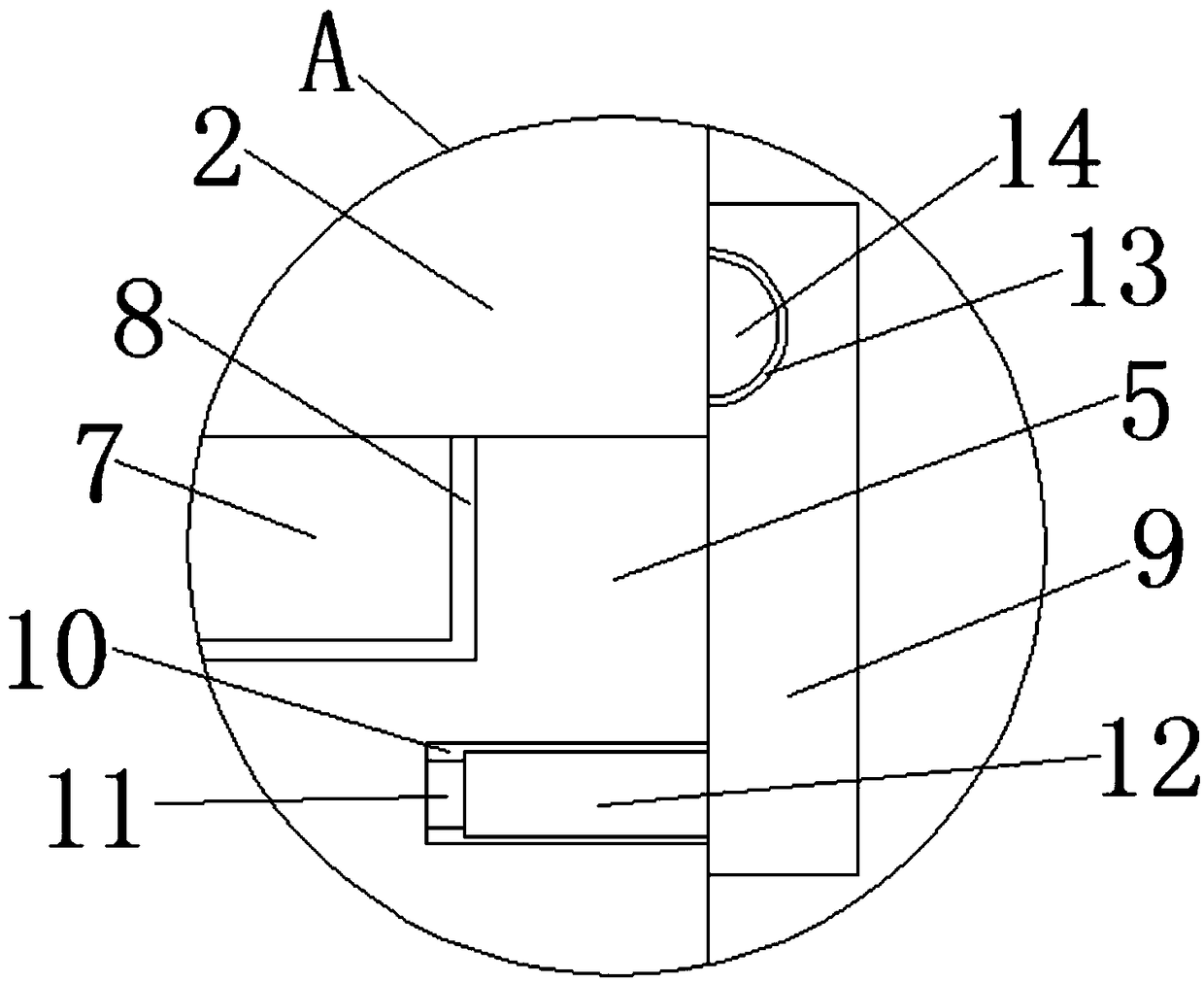

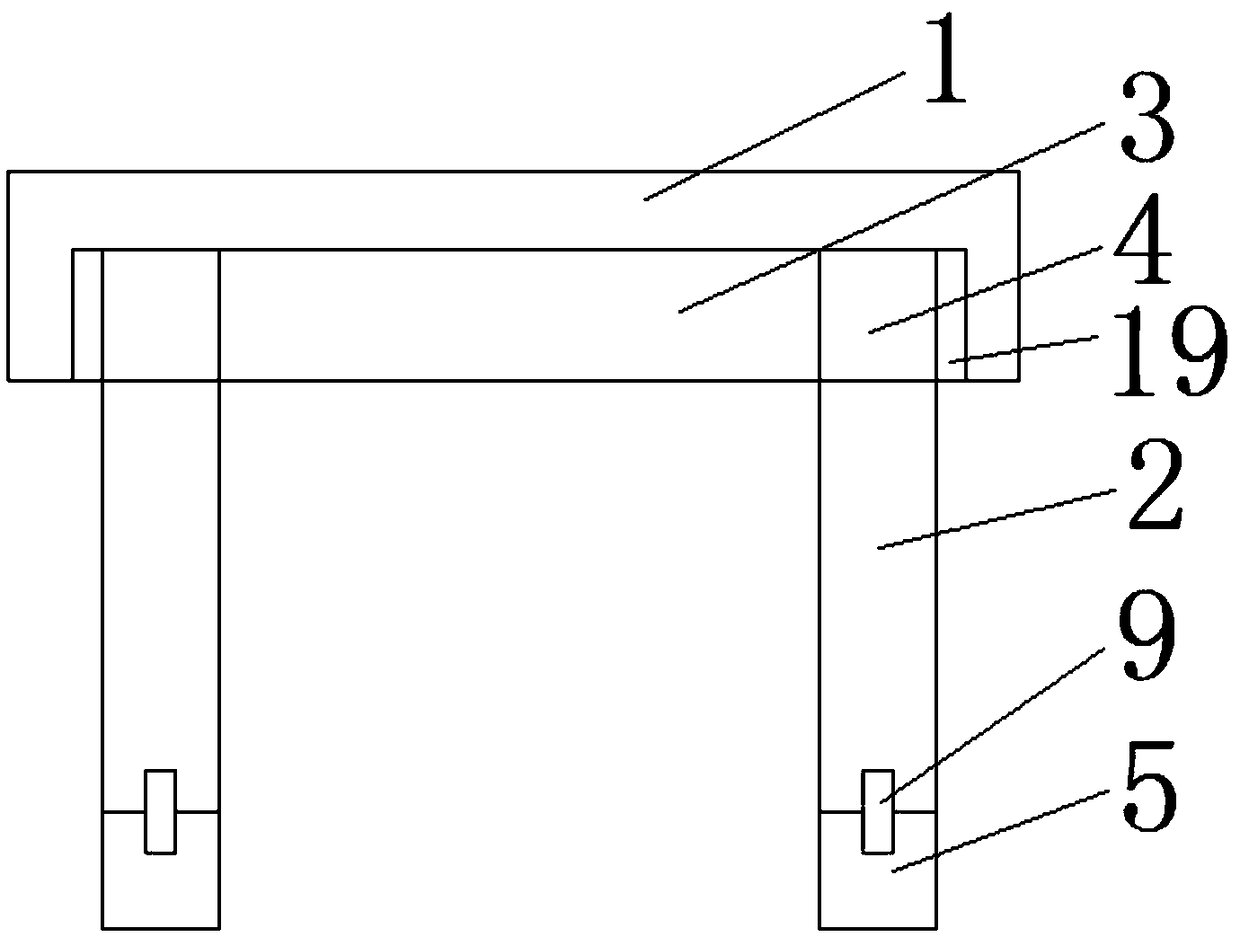

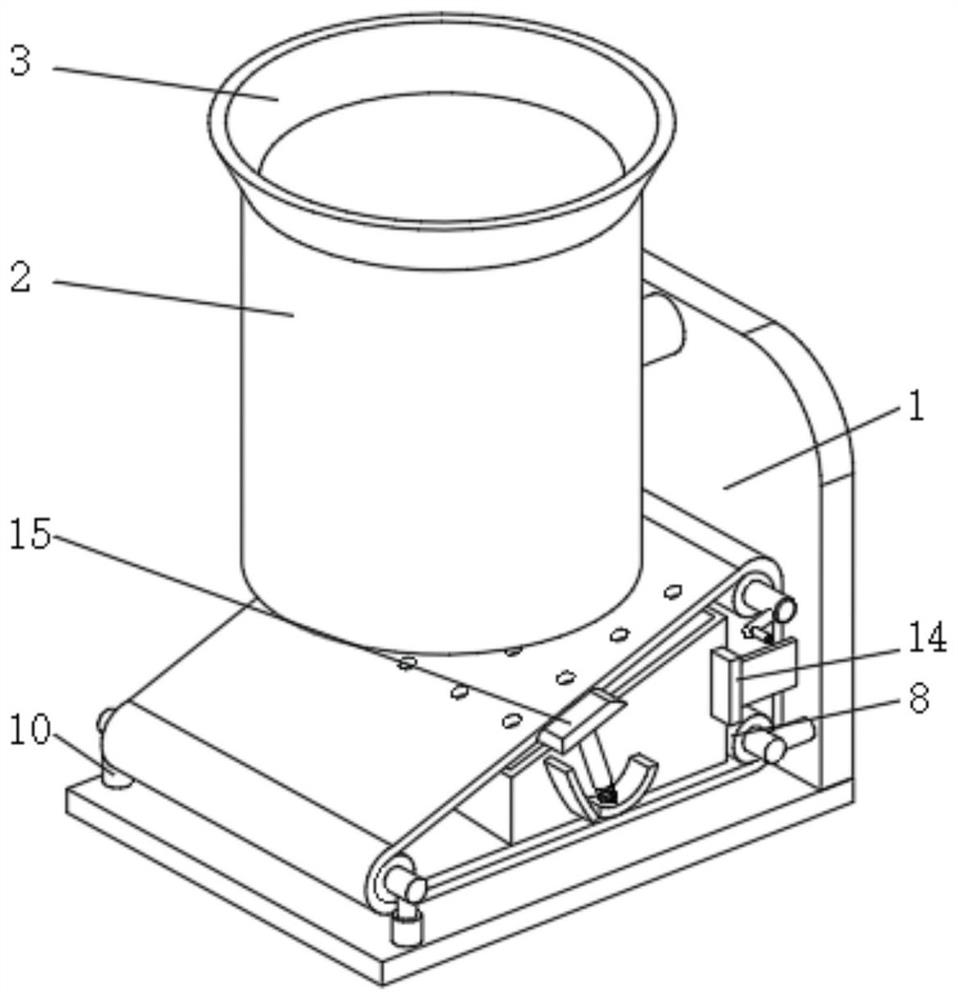

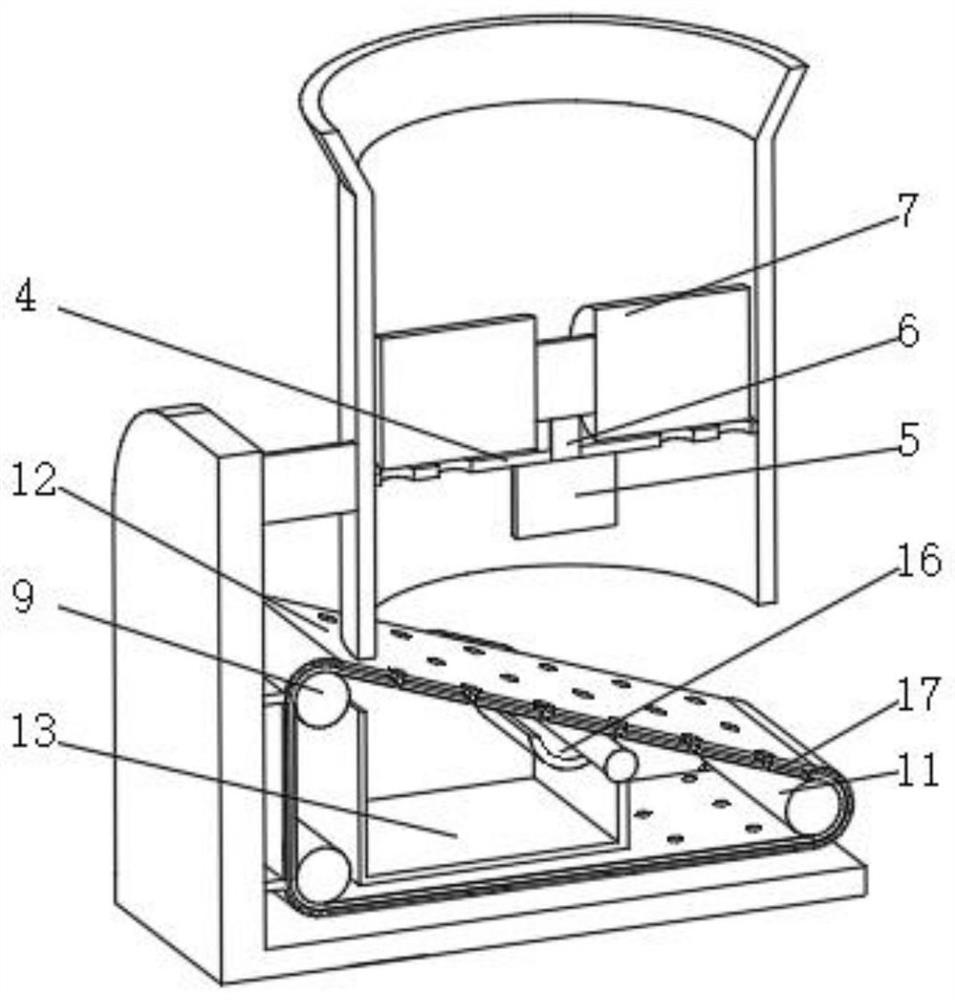

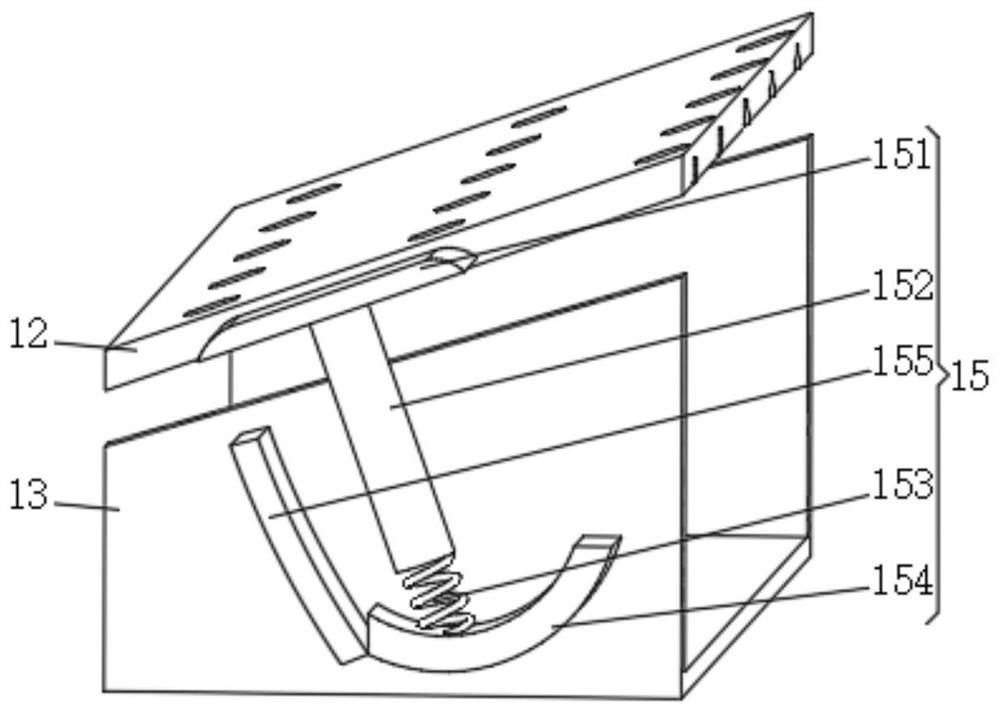

A cleaning and drying device for down production and processing that is convenient for removing impurities

ActiveCN108168222BFacilitate subsequent processingProcessing effectDrying solid materials without heatWool fibre washing/scouringTransmission beltElectric machinery

The invention discloses a cleaning and drying device conveniently removing impurities for down feather production and processing. The cleaning and drying device includes a cleaning device, a water inlet pipe, a stirring rod, a transmission belt, a suction opening, a fan, a first water outlet, a protective cover, a protective door, an air-tight door, a spin-dry revolving drum, a second air hose anda blowpipe; the upper of the cleaning device is provided with a feed inlet, the lower of the feed inlet is provided with a rotating rod, the water inlet pipe is located below the left side of the cleaning device, and the cleaning device is internally connected with a first motor through the rotating rod; and the stirring rod is located at the outer side of the rotating rod, the second air hose isarranged in the transmission belt which is provided with through holes, and the through holes are connected with scraping plates. According to the cleaning and drying device conveniently removing theimpurities for the down feather production and processing, the cleaning device is arranged to clean down feather, subsequent processing can be prevented from affection due to impurities in the down feather, and the cleaning of the down feather is facilitated.

Owner:ZHANJIANG ZIJIN DOWN PROD

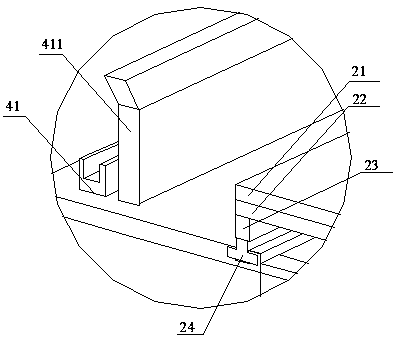

Plate adjusting and locking mechanism

InactiveCN108748756ATranslational teleportation implementationEfficient and accurate processingMulti-purpose machinesWorking accessoriesLocking mechanismEngineering

The invention discloses a plate adjusting and locking mechanism, belonging to the field of construction material processing machinery and equipment. A guide plate mechanism and a clamping plate mechanism are vertically and fixedly arranged on the two sides of the upper part of a fixed base respectively, and the two ends of a guide plate roller are rotationally connected with the upper ends of guide plate supports on the two sides of the upper part of the fixed base respectively. The output end of a lifting cylinder is fixedly connected with upper end of a lifting rack. The clamping plate mechanism comprises a clamping plate support, an adjusting support, a lifting support, a rotary clamping plate and a locking mechanism. The lifting support is horizontally arranged on the lower side of theadjusting support, and lifting guide rods are vertically and fixedly arranged on the two sides of the upper part of the lifting support respectively and are arranged on the adjusting support in a sliding mode along a vertical direction. The middle parts of the two sides of the rotary clamping plate are respectively hinged with a rotary support seat, and the locking mechanism is horizontally and fixedly arranged on the upper side of the adjusting support. The plate adjusting and locking mechanism has a reasonable structural design, can stably and accurately convey a plate, can also conveniently and efficiently adjust the oblique angle of the plate, thereby meeting the needs of processing and use.

Owner:张帼威

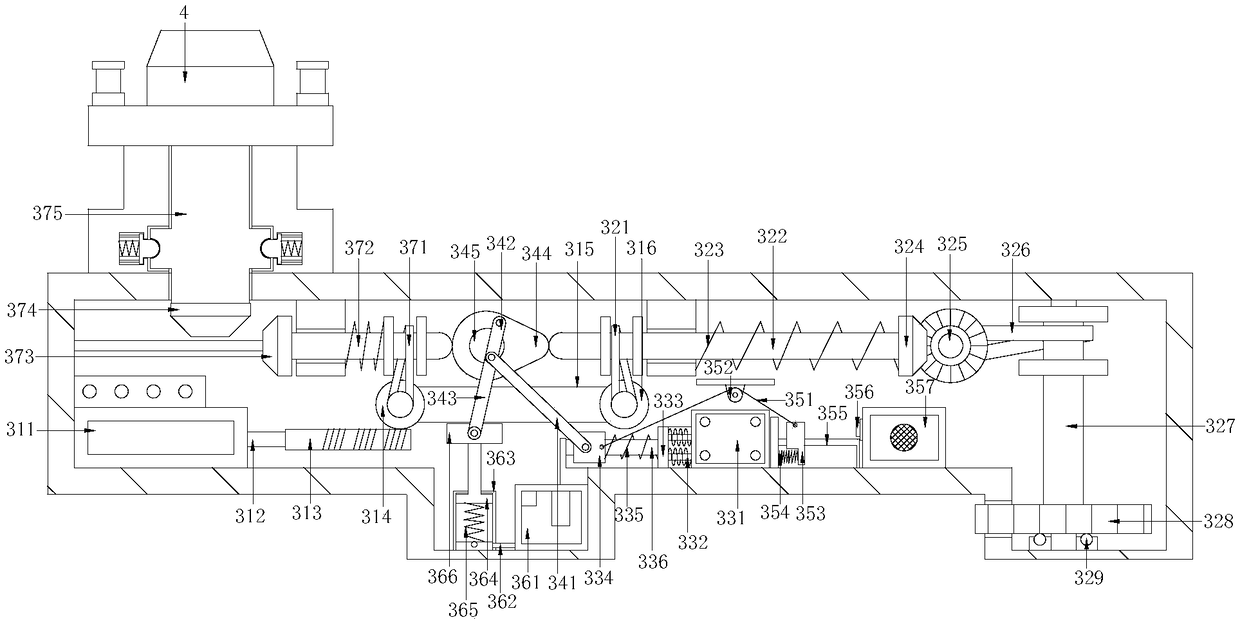

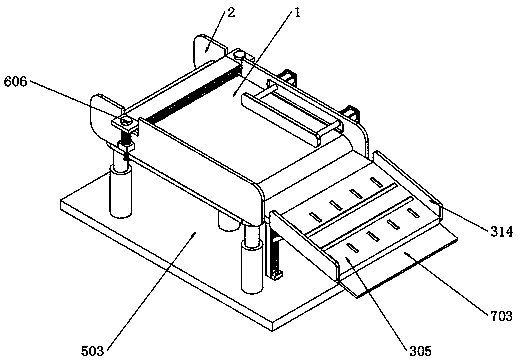

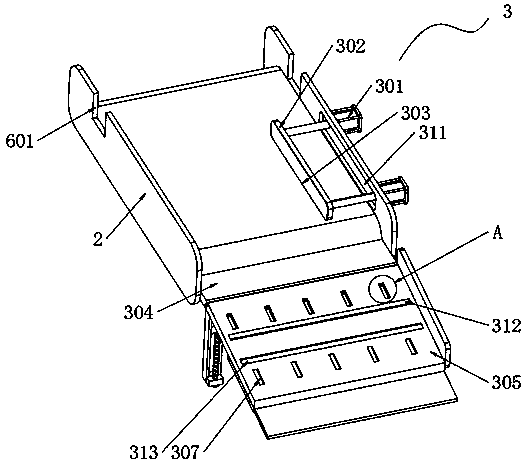

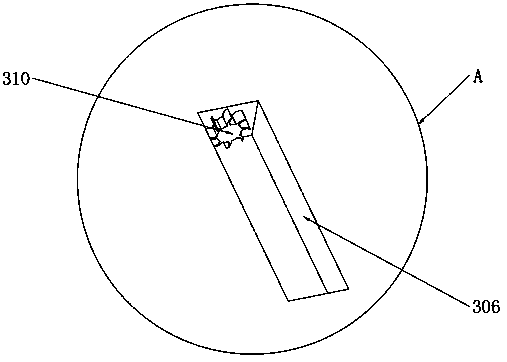

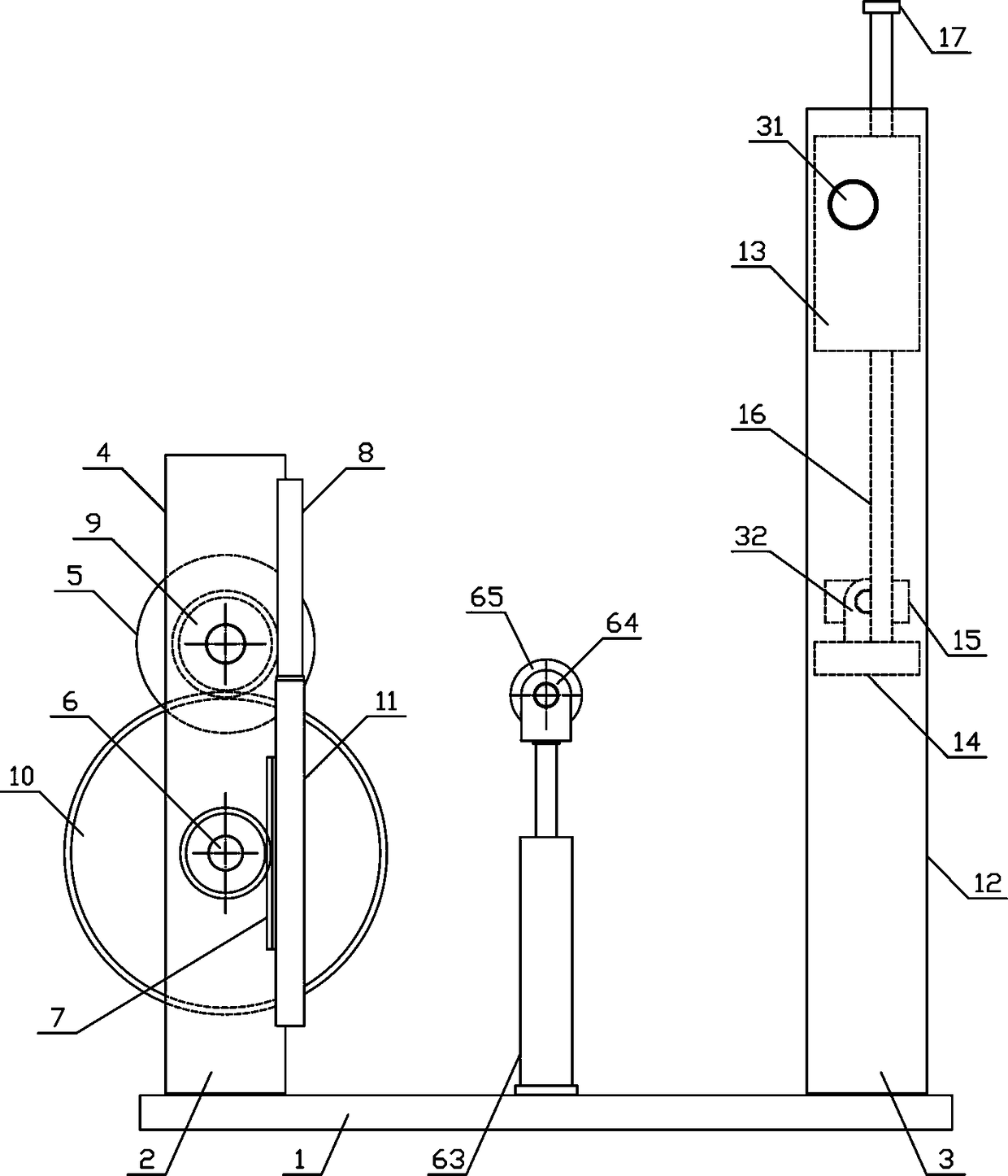

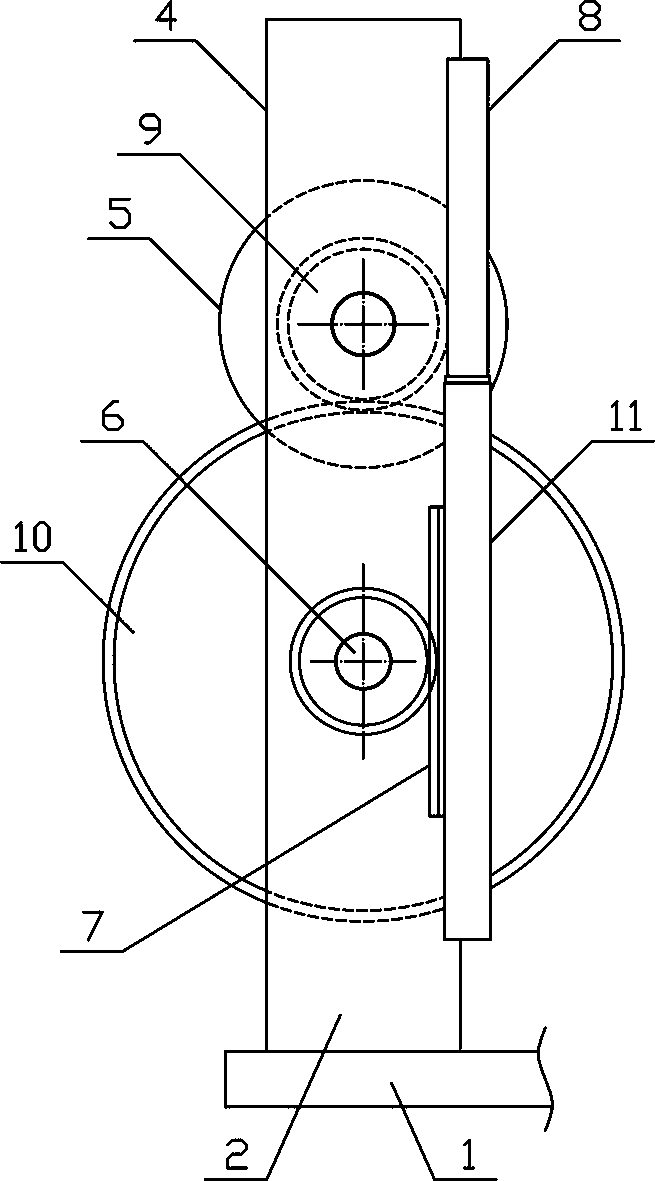

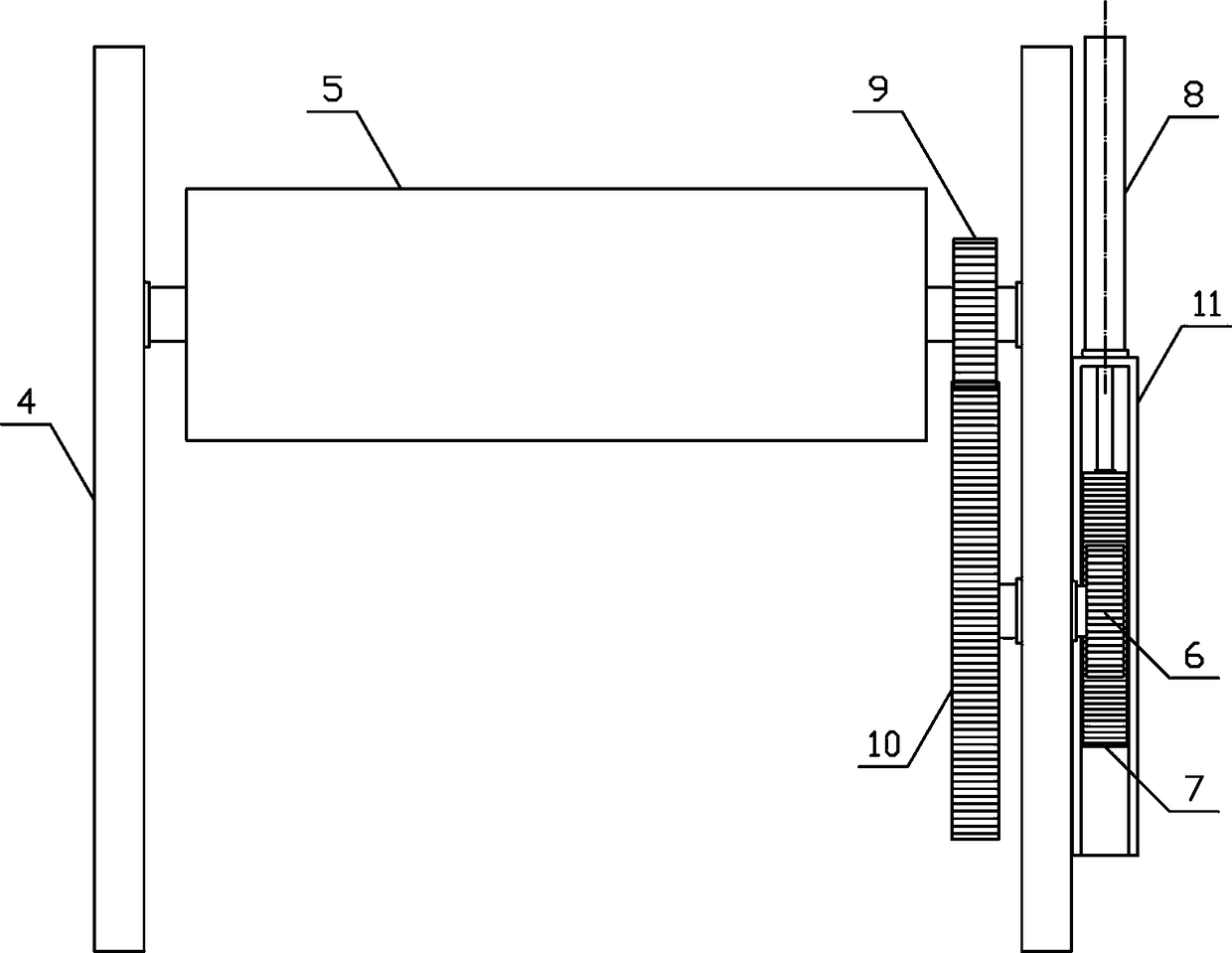

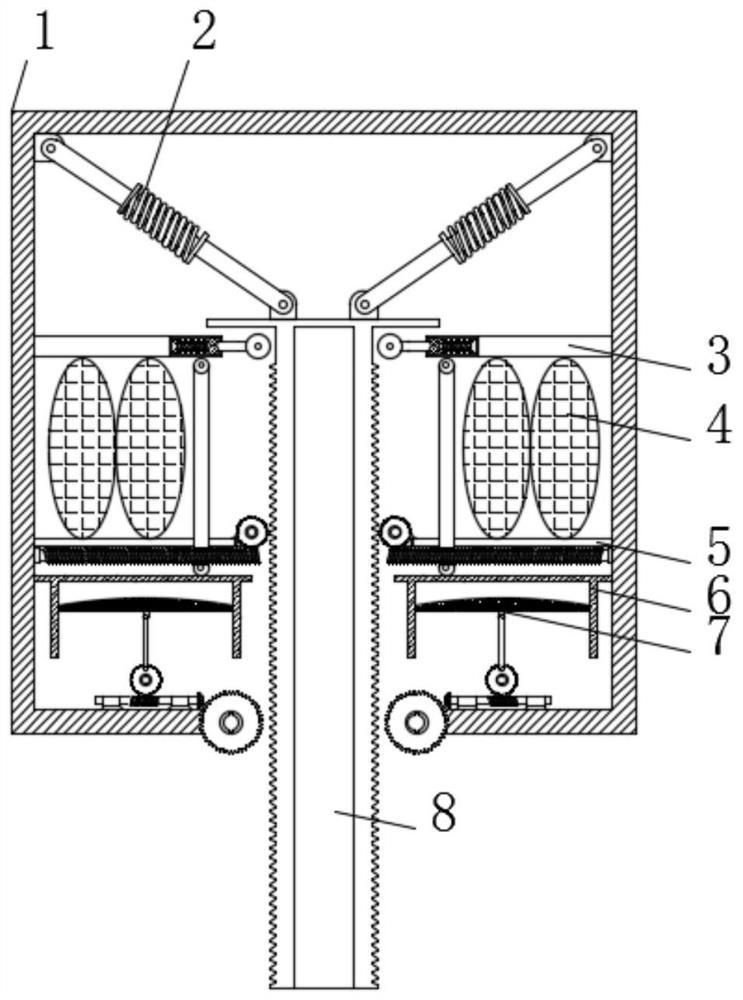

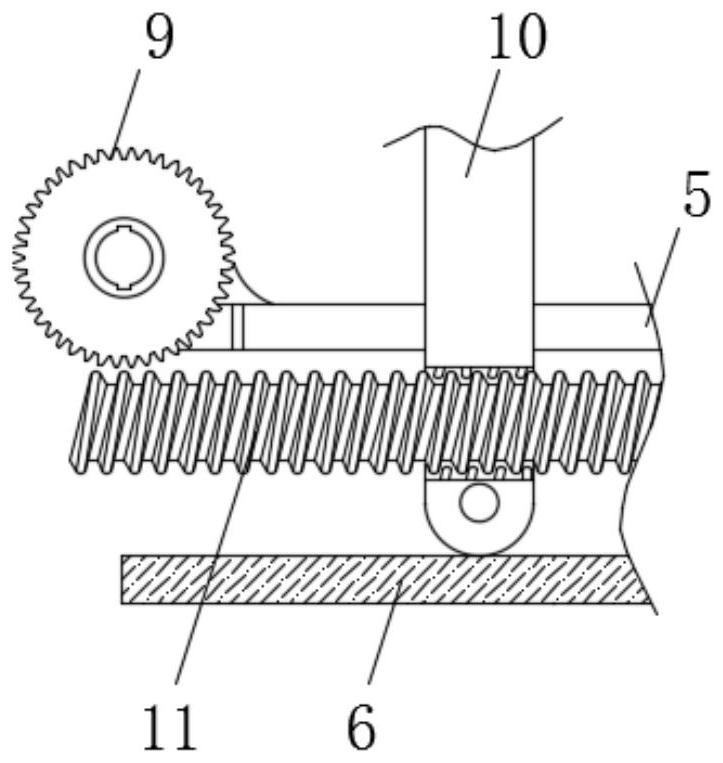

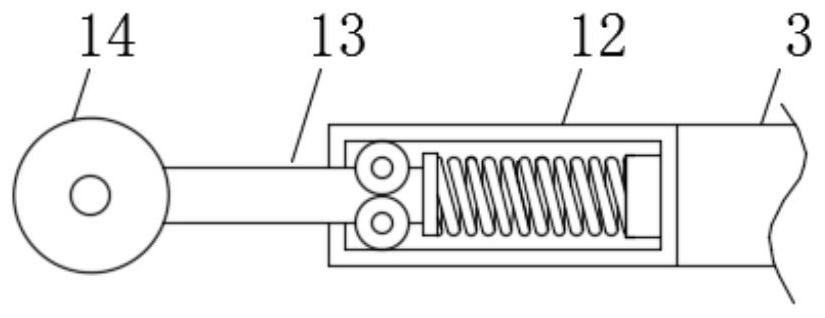

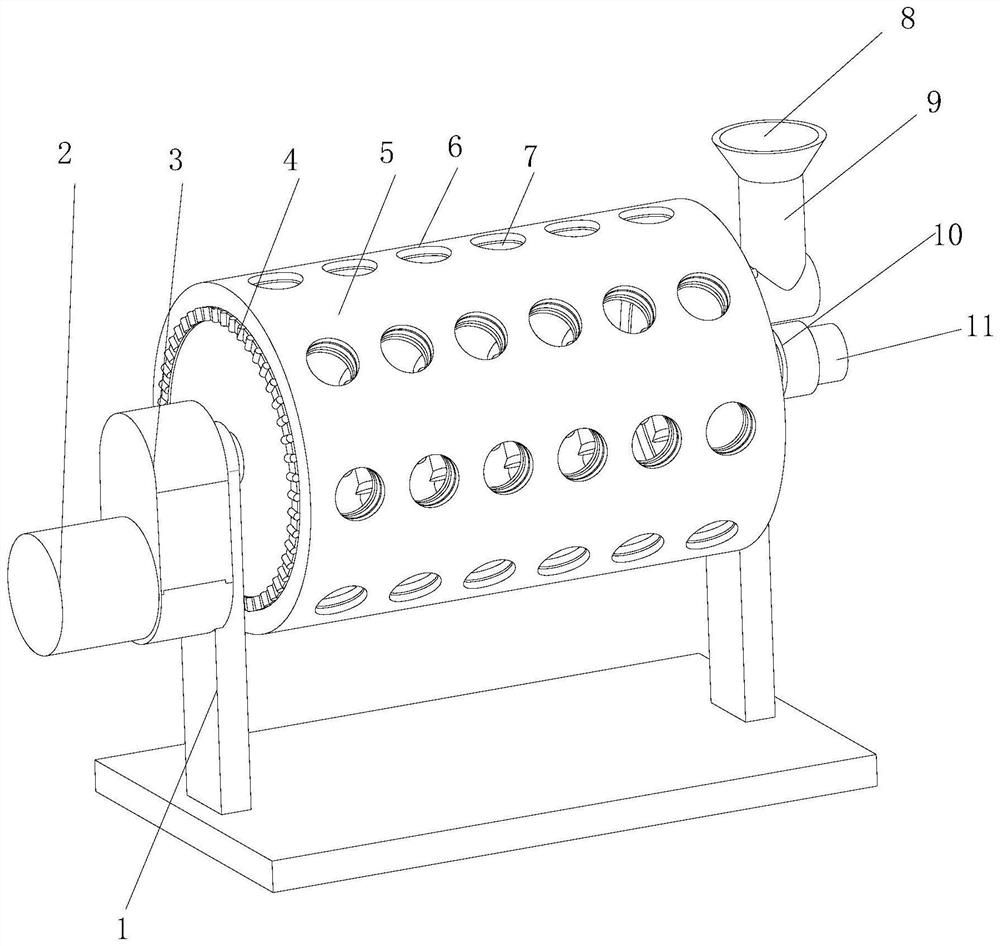

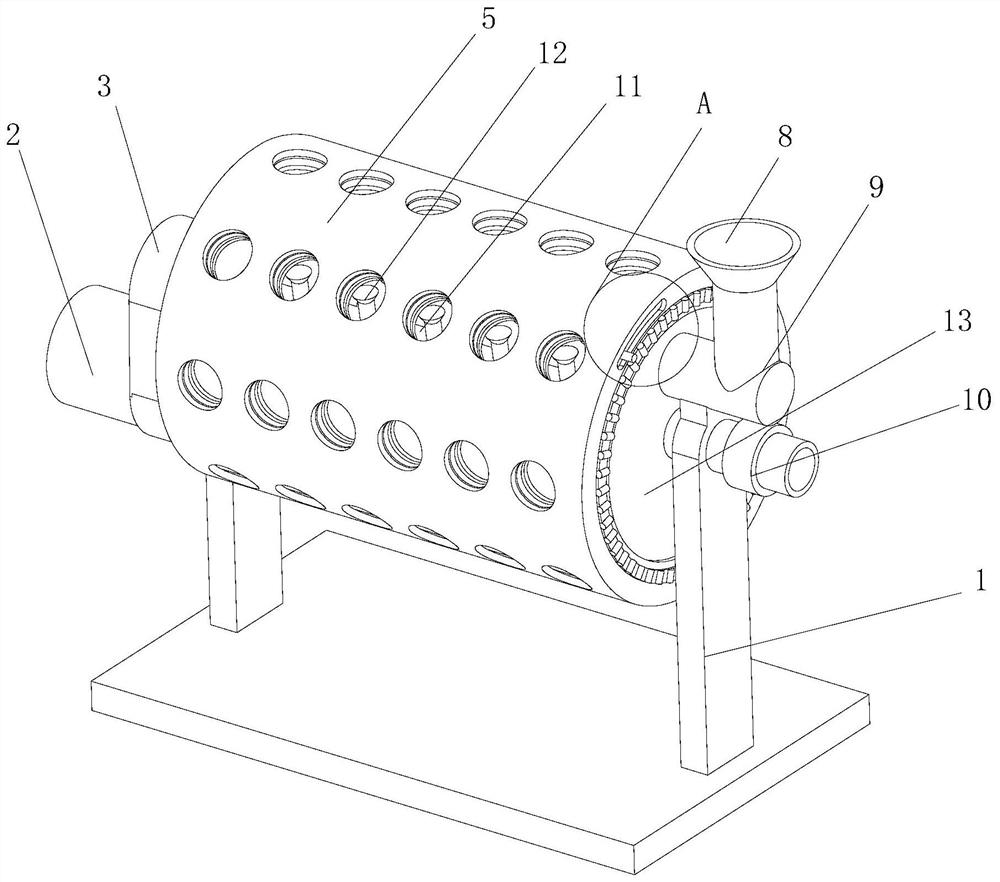

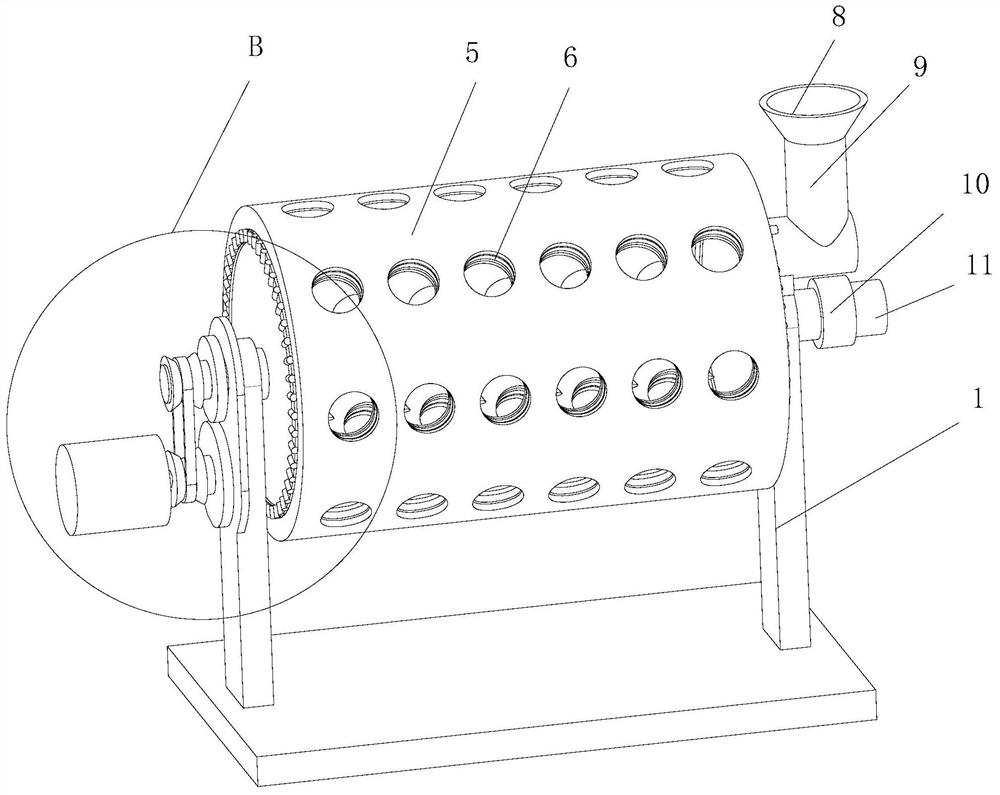

Mask processing raw material feeding system

InactiveCN112108066AProcessing effectFacilitate subsequent processingTransportation and packagingMixer accessoriesManufacturing engineeringMechanical engineering

The invention relates to the technical field of feeding equipment, in particular to a mask processing raw material feeding system which has the advantage of processing mask processing raw materials into a round shape for feeding and comprises a supporting and discharging assembly, a forming assembly, a driving assembly, a discharging assembly, a stirring assembly and a discharging assembly. The forming assembly is rotationally connected to the supporting and discharging assembly. The driving assembly is fixedly connected to the supporting and discharging assembly, the forming assembly and thedriving assembly are in meshing transmission, the discharging assembly is connected to the supporting and discharging assembly, the driving assembly and the discharging assembly are in meshing transmission, the stirring assembly is fixedly connected to the discharging assembly, and the discharging assembly is rotationally connected to the stirring assembly.

Owner:田忠泉

Workpiece cutting device with waste recovering function

InactiveCN110216496AProcessing effectImprove securitySingle direction vortexShearing machinesEngineeringSupport surface

The invention discloses a workpiece cutting device with waste recovering function. The device comprises a supporting mechanism, a workpiece conveying platform and a cutting mechanism, wherein a pair of mutually parallel supporting surfaces is arranged on the top surface of the supporting mechanism; a waste collecting groove is embedded between the supporting surfaces and is positioned under the workpiece conveying platform in the conveying direction; and a powder recovering mechanism is arranged at one side of the workpiece conveying platform. According to the device, the powder collecting groove and the powder recovering mechanism are matched with each other to efficiently recover residues, powder or wasted edges produced in use process, so that the board processing cannot be influenced by blockage of an edge cutting machine.

Owner:HEFEI YAKELI NEW BUILDING MATERIAL CO LTD

Probe clamping equipment for scanning probe machining

InactiveCN111957652AProcessing effectIncrease productivityDrying gas arrangementsCleaning using liquidsElectrolytic agentGas cylinder

The invention relates to the technical field of probes, in particular to probe clamping equipment for scanning probe machining. The probe clamping equipment comprises a shell. The bottom end of the lower surface of the shell is rotationally connected with first worm wheels. The positions, located in the middles of the first worm wheels, of the lower surface of the shell are in sliding connection with a clamping block. The upper surface of the clamping block is rotationally connected with spring supporting rods. The clamping block is driven by a probe to slide downwards in the shell, then the first worm wheels engaged with the clamping block are driven to rotate synchronously in the process that the clamping block slides downwards, and then second worm wheels above worms are driven to do circular motion; pistons are pulled through connecting rods to slide up and down in gas cylinders; when the pistons slide up and down in the gas cylinders, gas in the gas cylinders is subjected to suction motion, then a gas pipe is connected with a water box to push out water in the water box, the surface of the probe is cleaned, and electrolytes on the surface of the probe are thoroughly cleaned away; and electrolytes are prevented from influencing the next machining of the probe, and the production efficiency of the probe is improved.

Owner:沈祥青

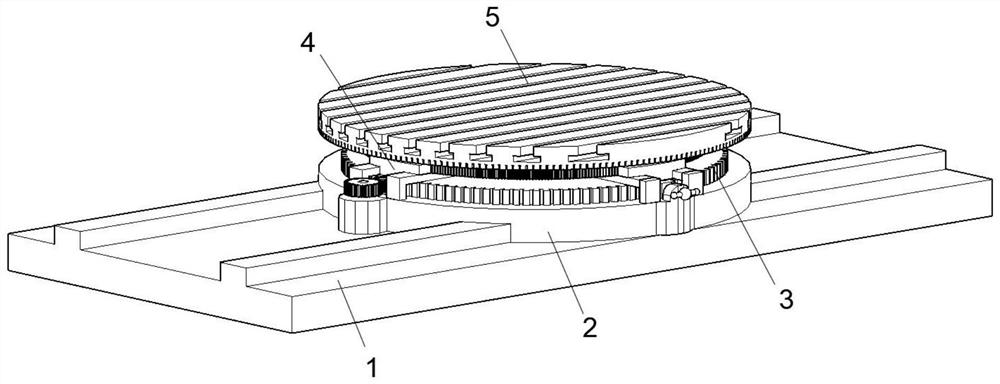

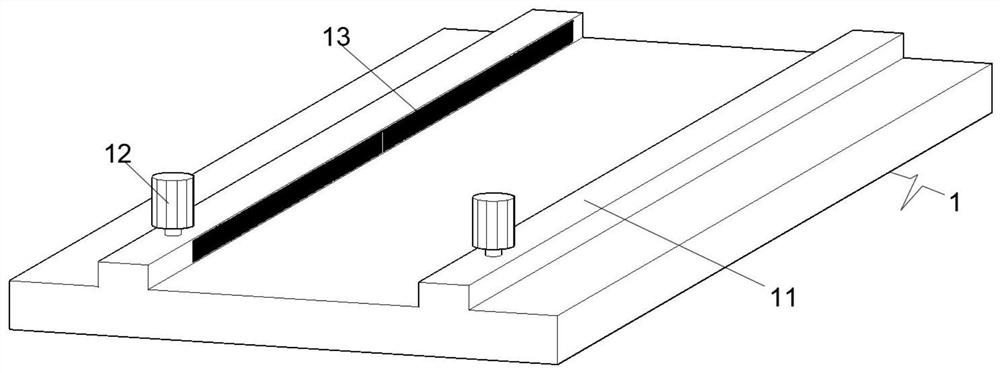

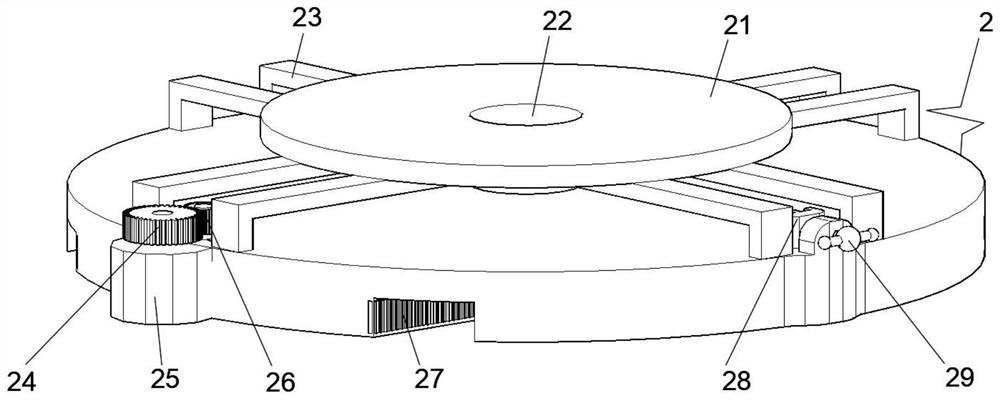

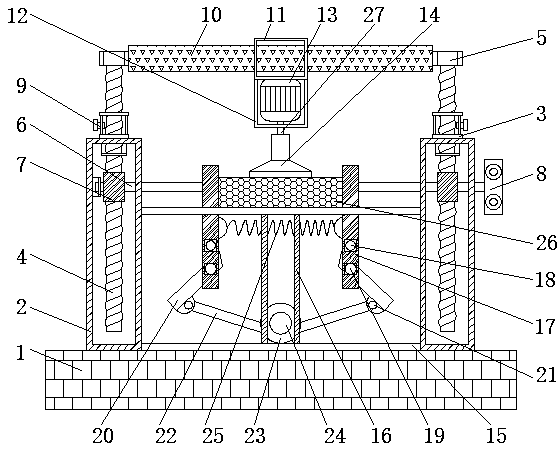

Automatic horizontal milling and boring machine

PendingCN111823053ASmooth lateral movementPlay a restrictive rolePrecision positioning equipmentBoring/drilling machinesElectric machineryEngineering

The invention relates to the technical field of milling and boring machine equipment, in particular to an automatic horizontal milling and boring machine. The automatic horizontal milling and boring machine comprises a base, a baes plate, an adjusting plate, positioning blocks and a machining table, wherein the base plate is movably engaged with the top face of the base, the adjusting plate is movably clamped to the center of the top of the base plate, and the positioning blocks are movably clamped to the edge of the top face of the base plate; and the machining table is rotationally installedin the center of the top face of the base plate, guide rails are symmetrically arranged on the top face of the base, chains are movably installed in the side faces of the guide rails, and a first driving motor is fixedly installed on the edge of one end of the top of each guide rail. By controlling rotation of the adjusting plate, the four sets of positioning blocks can position the machining table, so that the machining table is conveniently rotated to change the machining angle of a workpiece, repeated mounting and dismounting of a clamp are avoided, and the machining efficiency of the workpiece is improved.

Owner:杨安龙

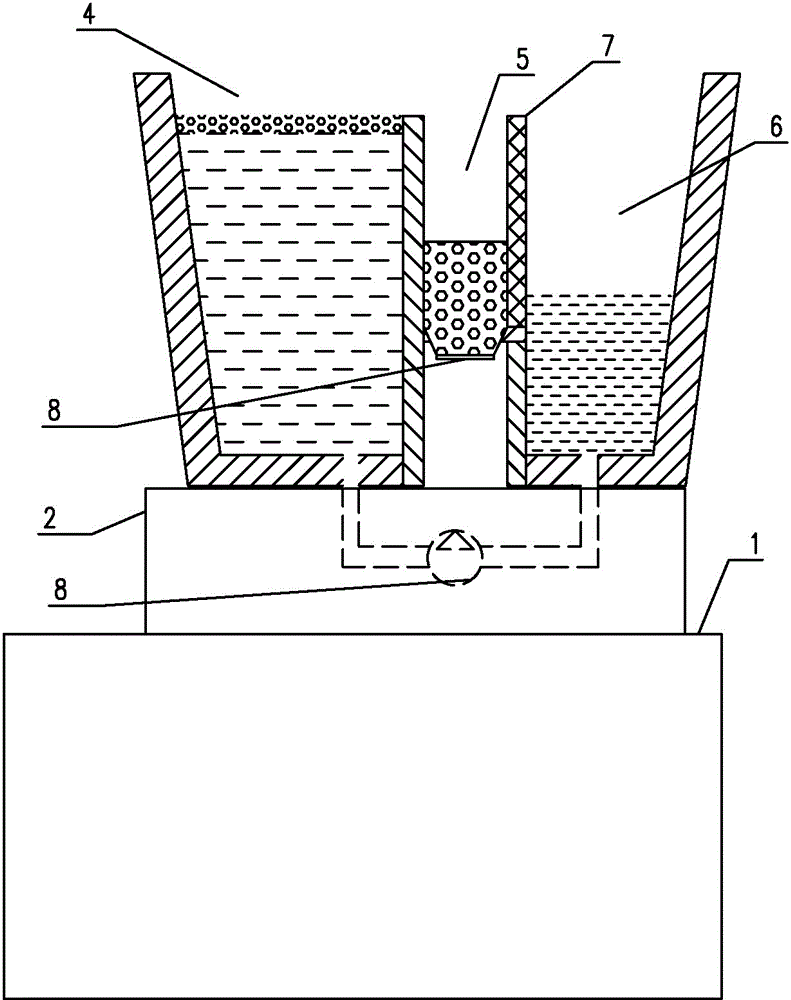

Electrical discharge machining device

InactiveCN104439569AStable quantityEasy to cleanElectrical-based auxillary apparatusCorrosionMachine tool

The invention relates to the field of electrical discharge machining, in particular to an electrical discharge machining device. The electrical discharge machining device comprises a machine tool and a working table located on the machine tool. An electrode bath is arranged on the working table and comprises a bath body, two longitudinal partition plates are arranged in the bath body to divide the bath body into a working bath body, a particulate matter collecting bath body and a liquid storage bath body, the particulate matter collecting bath body is located between the working bath body and the liquid storage bath body, and the partition plate between the particulate matter collecting bath body and the working bath body is lower than the bath wall of the electrode bath body; a filtering film is arranged on the partition plate between the particulate matter collecting bath body and the liquid storage bath body, the bottom of the particulate matter collecting bath body is higher than the bottom of the working bath body and the bottom of the liquid storage bath body, and a communicating pipe is further arranged between the working bath body and the liquid storage bath body and provided with a hydraulic pump; electrical discharge machining liquid is arranged in the working bath body, and the liquid level of the electrical discharge machining liquid is the same as the partition plates in height; the liquid level of the electrical discharge machining liquid in the liquid storage bath body is not higher than the bottom of the particulate matter collecting bath body. By means of the technical scheme, the electrical discharge machining device has the advantage that electric corrosion particular matter can be conveniently removed.

Owner:CHONGQING SHUAICHANG MACHINE MFG

Hardware non-standard part cutting equipment

The invention relates to the technical field of hardware processing, and discloses hardware non-standard part cutting equipment. The hardware non-standard part cutting equipment comprises a supportingplate, wherein the top of the supporting plate is fixedly equipped with a supporting barrel; the top of the supporting barrel is fixedly equipped with a supporting block; the top of the supporting block is fixedly connected with a motor positioned above the supporting plate; and the side surface of the motor is fixedly connected with a lead screw; and one end of the lead screw penetrates throughand extends into the supporting barrel. According to the hardware non-standard part cutting equipment disclosed by the invention, the supporting barrel is used for supporting the motor and is also used for protecting the lead screw, and prevents a positioning plate from shaking during movement; the supporting block is utilized, so that the lead screw is prevented from being stressed to shake backand forth in use; a case is utilized to prevent fragments from entering the cutting equipment while the cutting equipment cuts an object; and the problem that use of the cutting equipment is affectedas the cutting equipment has faults as a result of long-time use is avoided.

Owner:邱会奇

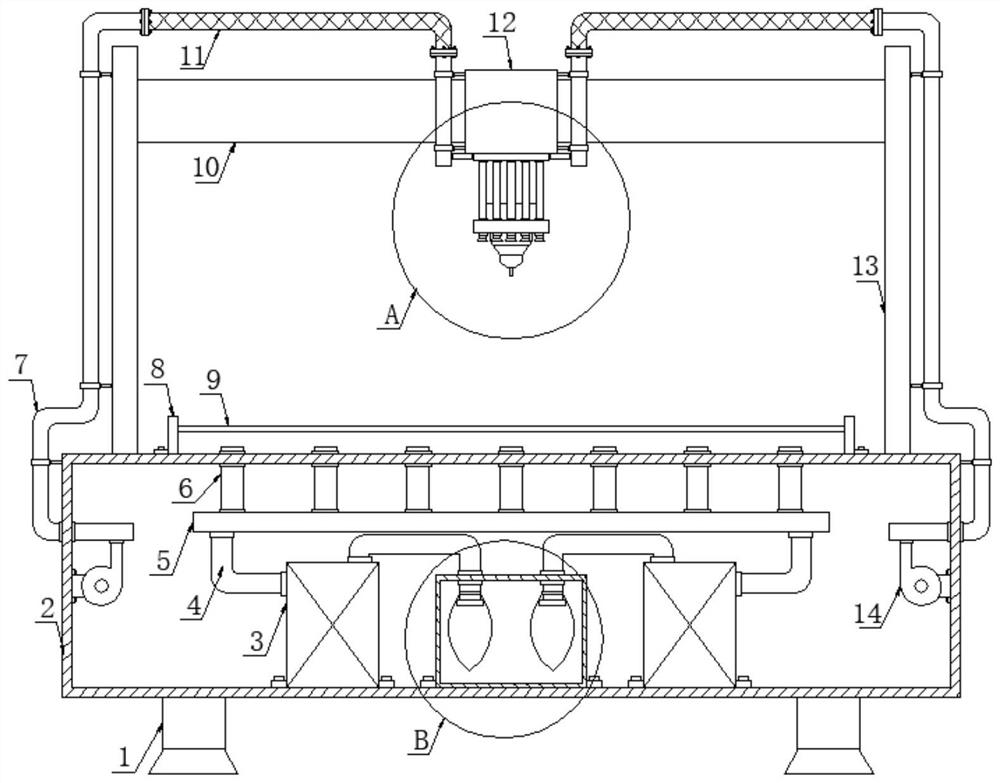

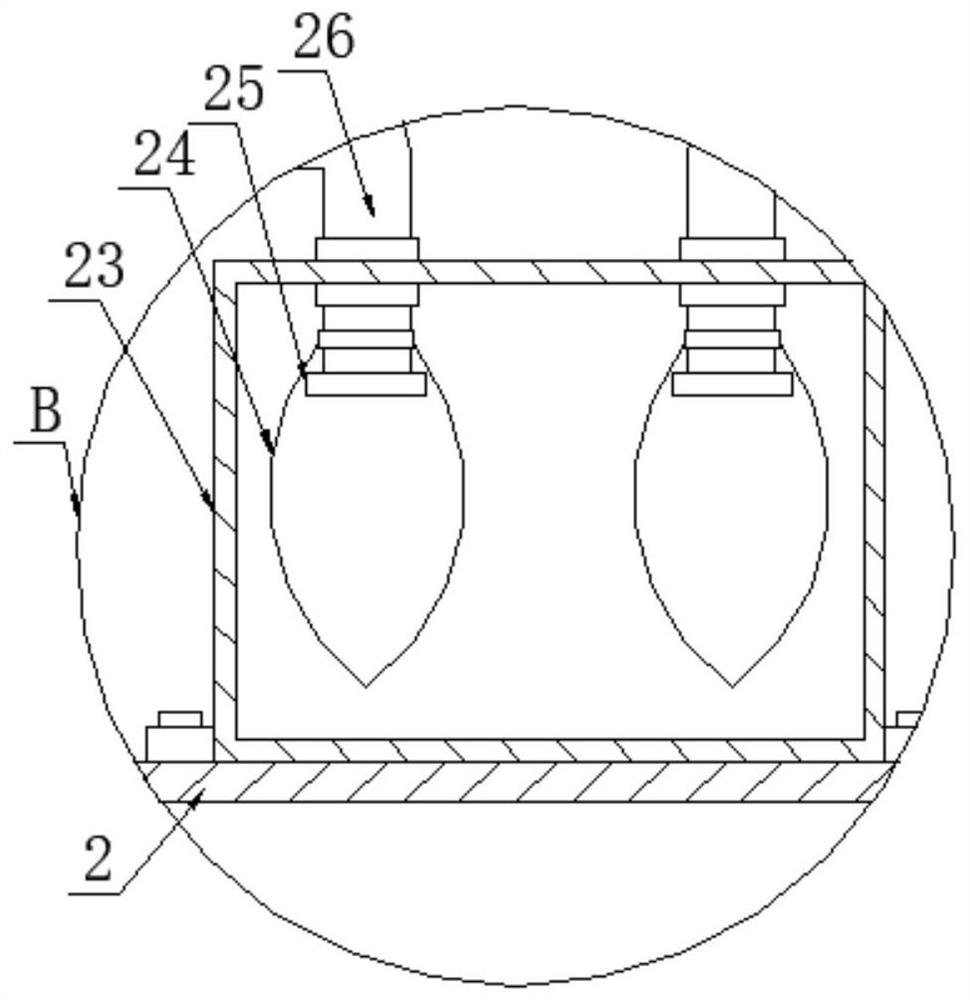

Lamp production and processing device

ActiveCN113369363AAvoid contactPrevent adhesionFouling preventionHollow articlesPhysicsElectric machinery

The invention belongs to the technical field of lamp production, and particularly relates to a lamp production and processing device. The lamp production and processing device comprises two mounting plates, a spinning mechanism is arranged between supporting plates on the left side and the right side of the lower mounting plate, the two mounting plates are vertically distributed and form a 90-degree angle, a motor is assembled at one end of each screw in a transmission mode, abutting mechanisms matched with the spinning mechanism are assembled on the left side and the right side of a sliding plate, each shielding mechanism comprises a rotating rod, two torsional springs, two shielding covers and shielding cloth, each supporting plate is provided with a mounting cavity, the rotating rods are rotationally assembled in the mounting cavities, the two torsional springs are arranged in the two shielding covers respectively and assembled with the rotating rod, the shielding cloth is fixedly connected with the middle of the rotating rod, the other end of the shielding cloth extends out of the mounting cavity through an extension opening, the shielding cloth of the lower shielding mechanism extends out of the mounting cavity and is fixedly connected with the upper mounting plate, the shielding cloth of the upper shielding mechanism extends out of the mounting cavity and is fixedly connected with the sliding plate, and the end, extending out of the mounting cavity, of the shielding cloth is located over a sliding groove.

Owner:中山市莱利灯饰股份有限公司

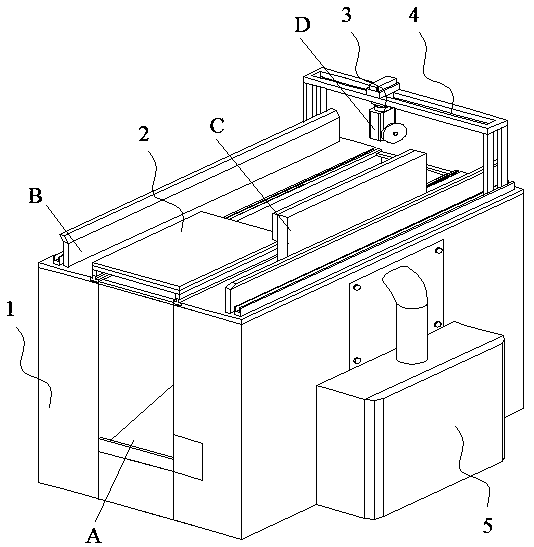

Quick-cooling type laser processing device facilitating continuous production and processing method thereof

InactiveCN112496567AEffective coolingAvoid temperature overloadLaser beam welding apparatusLaser processingEngineering

The invention discloses a quick-cooling type laser processing device facilitating continuous production in the technical field of laser processing. The quick-cooling type laser processing device comprises a box body, two sets of side plates, a mounting frame body, a transmission frame and a laser cutting head, wherein the two sets of side plates are symmetrically arranged on the top end surface ofthe box body in a left-right mode, and the two sets of side plates are fixedly connected with the box body; the mounting frame body is arranged between the two sets of side plates, and the transmission frame is arranged on the mounting frame body; the laser cutting head is arranged on the bottom end surface of the transmission frame, and an air blowing device which is movably connected is arranged outside the laser cutting head; and two sets of fixing plates which are detachably connected through bolts are symmetrically arranged at the center of the top end of the box body in a left-right mode, a grid plate is fixedly connected between the two sets of fixing plates, and an air suction device is arranged below the grid plate. The quick-cooling type laser processing device aims to solve theproblem that parts need to be cooled for a long time.

Owner:王华根

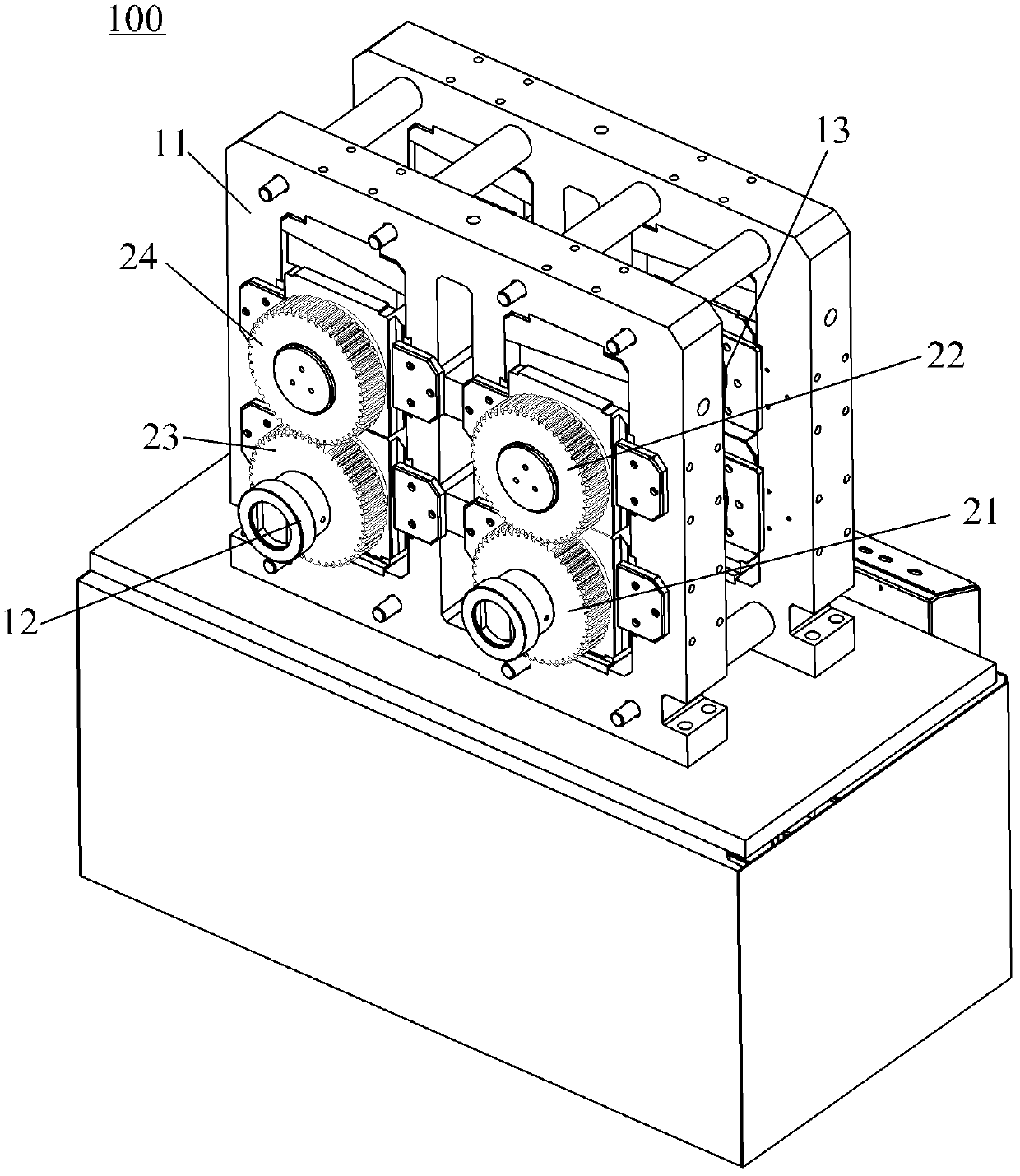

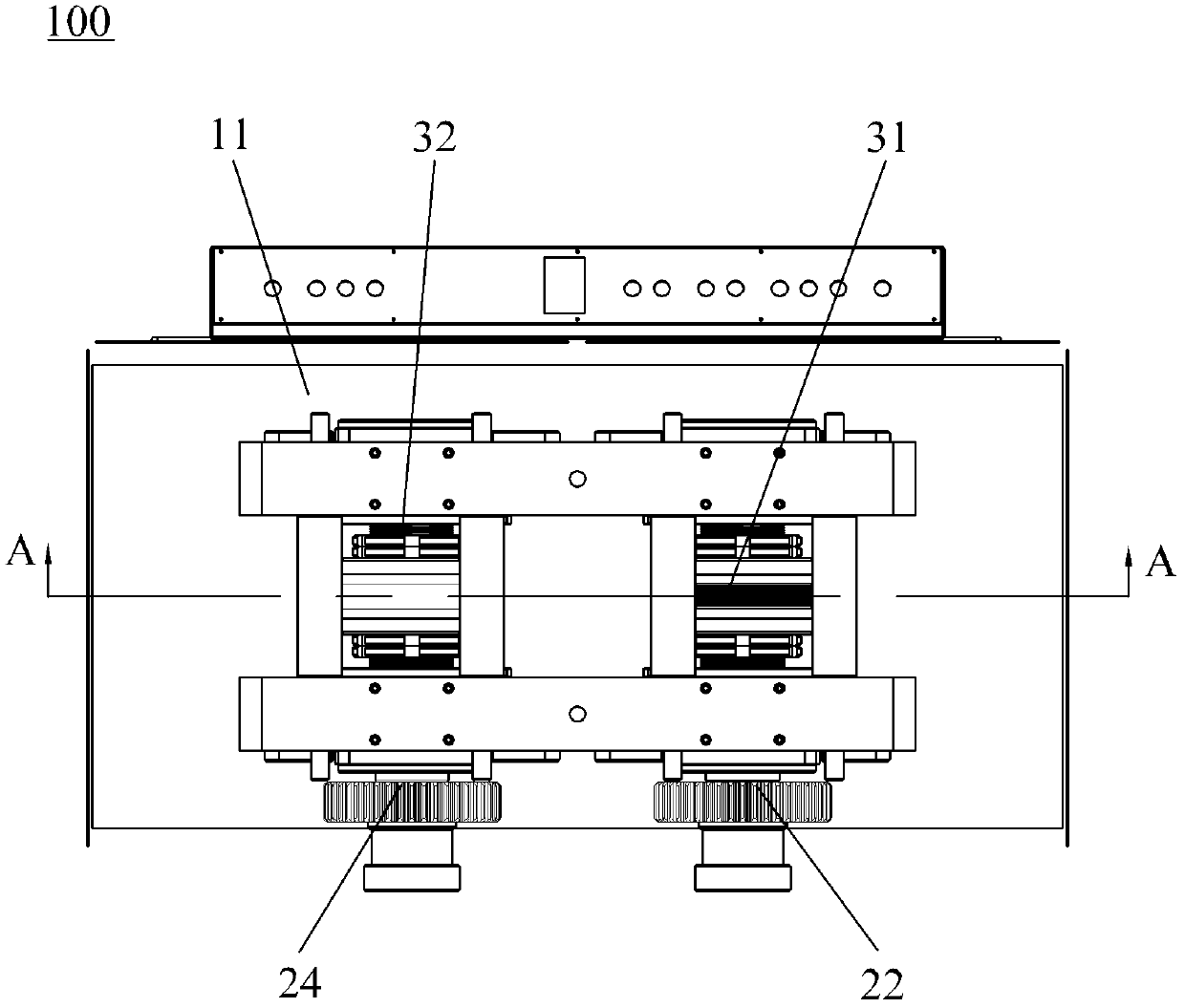

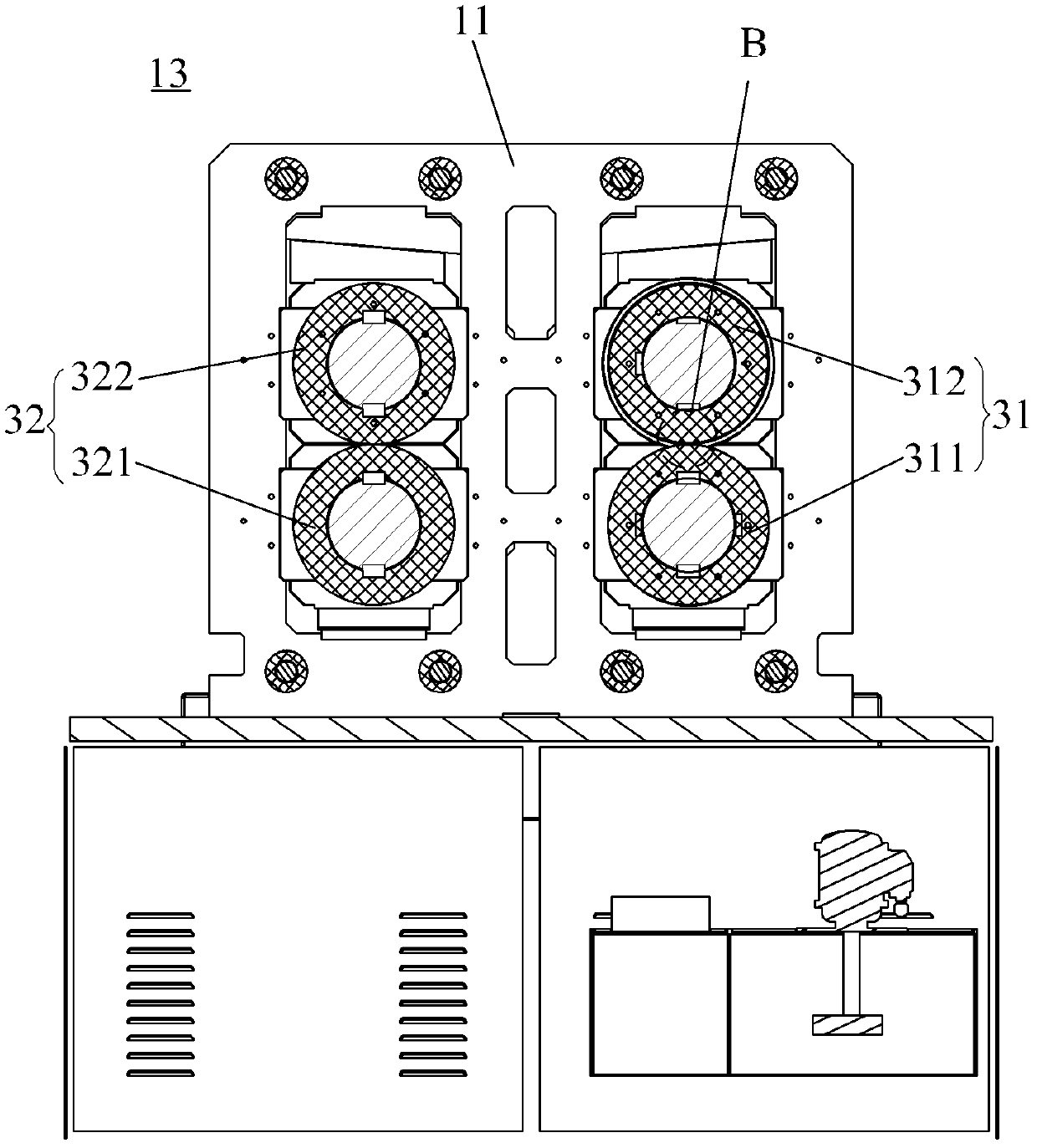

Technology for processing blank of paper shredding blade and processing device of technology

The invention discloses a technology for processing a blank of a paper shredding blade. The technology is used for processing a metal material strap into a strap blank of the paper shredding blade, and comprises the steps as follows: 1), the metal material strap is provided; and (2), the metal material strap is processed with a rolling technology, so that the strap blank with unchanged width is formed; a plurality of concave pits and separation walls for separating the concave pits are formed in one side surface of the strap blank; and the separation walls are strip-shaped and staggered mutually, so that the side surface is net-shaped. Compared with the prior art, the processed strap blank not only is high in strength, but also saves materials. Besides, the invention further discloses a processing device of the blank of the corresponding paper shredding blade.

Owner:肇庆精锐电器五金有限公司

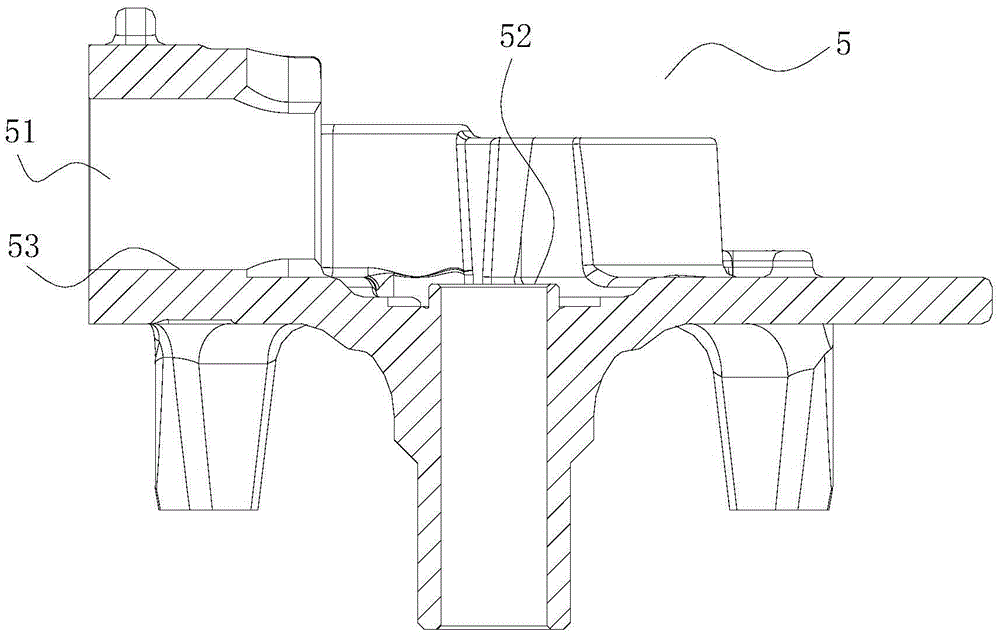

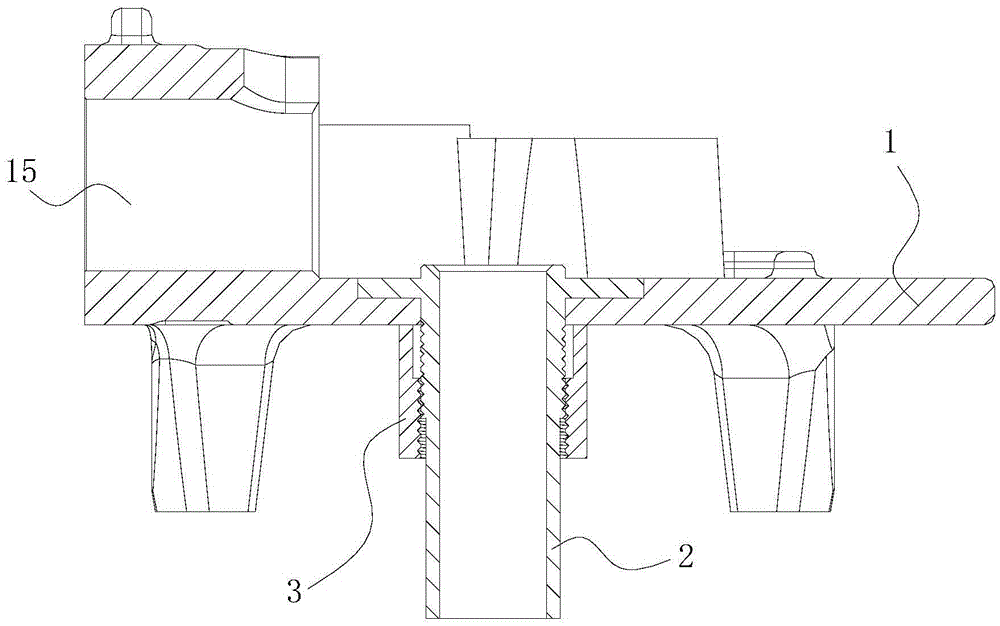

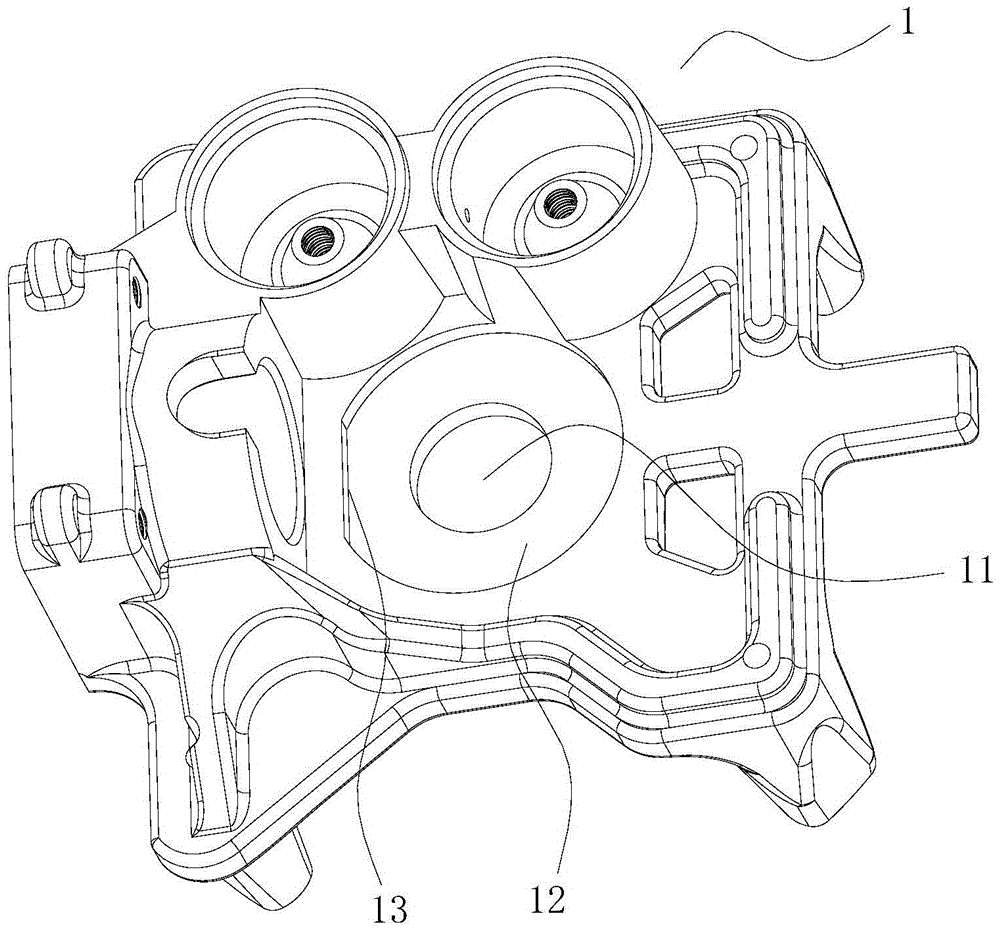

Cylinder seat, compressor and machining method for cylinder seat

ActiveCN105673456AImprove stressAvoid affecting processingCompressorPositive displacement pump componentsStress concentrationEngineering

The invention discloses a cylinder seat, a compressor and a machining method for the cylinder seat, and belongs to the field of compressors and parts thereof. The compressor is designed for solving the problem that force bearing conditions of existing devices are unreasonable. The cylinder seat comprises a base and a detachable bearing. A bearing hole is formed in the base, and the detachable bearing is detachably installed in the bearing hole. The compressor comprises the cylinder seat. According to the machining method for the cylinder seat, the detachable bearing is detached from the base for finish machining of a cylinder hole. The cylinder seat can shorten the force arm length L1, improve the force bearing conditions of the bearing, and reduce stress concentration. According to the compressor, the force bearing conditions of the bearing are improved, and the reliability of the compressor is improved. According to the machining method for the cylinder seat, the machining process of the cylinder hole is simplified, the force arm length L1 is shortened as much as possible, and the force bearing conditions of the bearing are improved.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

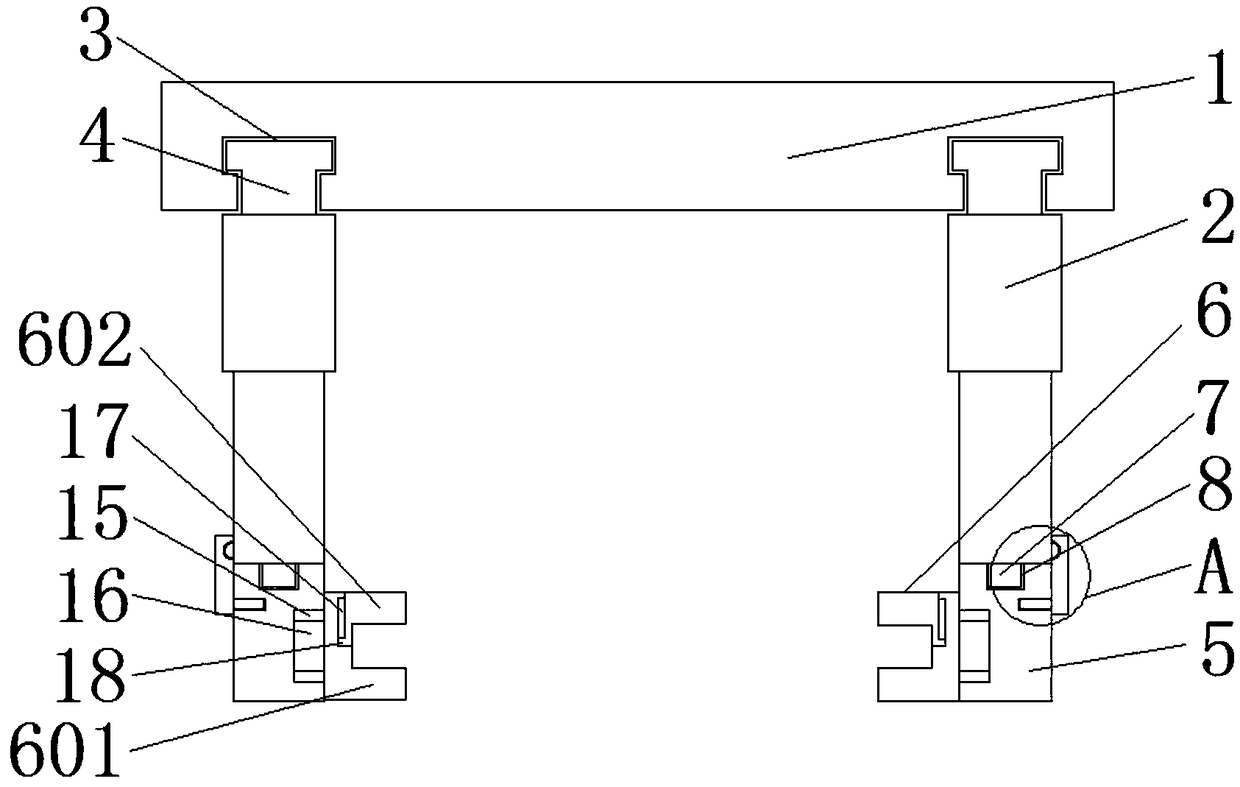

Plate processing hoisting device

The invention discloses a plate processing hoisting device, and relates to the technical field of plate processing. The plate processing hoisting device comprises a top plate, two dies of the lower end of the top plate are movably connected with lifting rods, first slide ways are arranged in two sides of the bottom of the top plate, first slide blocks are slidably connected in the first slide ways, the bottom ends of the first slide blocks are fixedly connected with the tops of the lifting rods, a connecting block is movably mounted at the lower end of every lifting rod, a gripper is movably connected at one side of every connecting block, and a projection is fixedly mounted at the middle part of the bottom end of every lifting rod. The plate processing hoisting device has the advantages of convenience in lifting for hoisting, stability in running, convenience in adjustment, realization of adjustment and fixation according to the widths of different plates, convenience in use, firmnessin fixation, avoiding of influences of shaking on plate processing, increase of the production efficiency, convenience in connection and fixation, detachability, convenience in replacement of the grippers, avoiding of influences of wearing caused by long-time use on the use effect, buffer reduction, wearing avoiding, and prolongation of the service life.

Owner:湖州亚信科技孵化有限公司

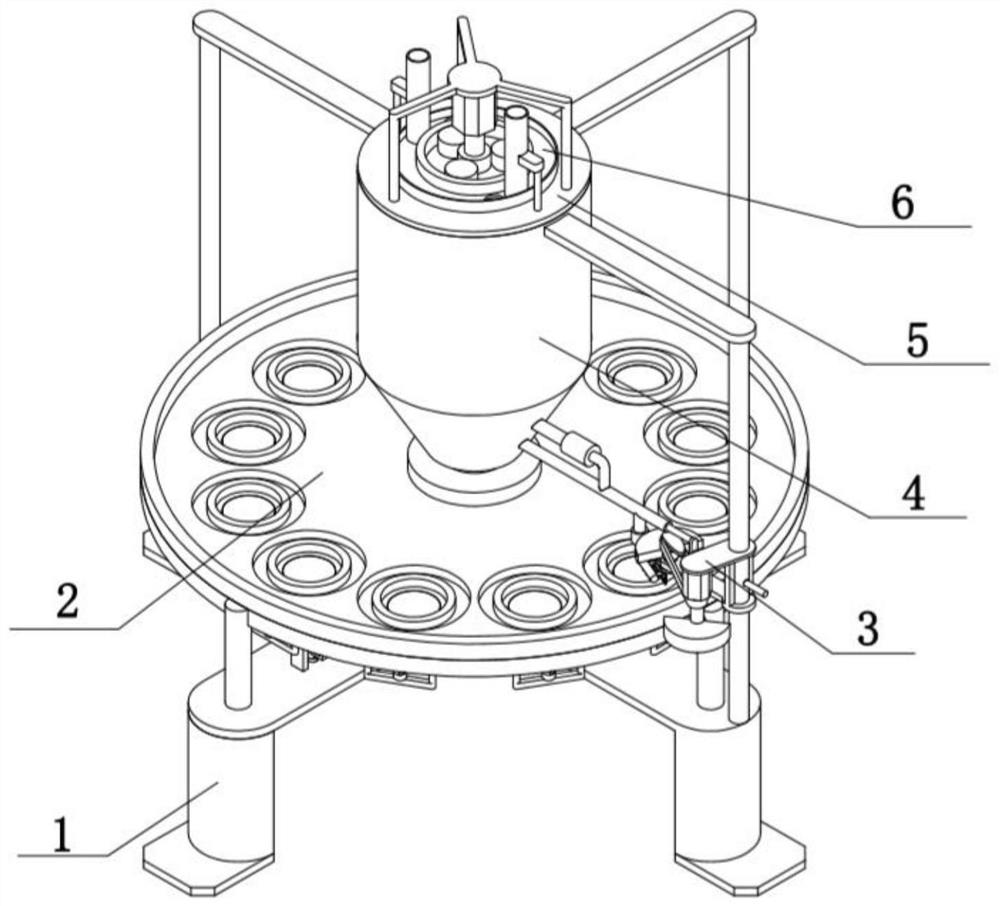

Biomass fuel processing and forming device

InactiveCN113663899ATo achieve the purpose of cleaningMake full use of structural featuresSievingScreeningElectric machineEngineering

The invention discloses a biomass fuel processing and forming device, and relates to the technical field of biomass energy. The biomass fuel processing and forming device comprises a base, one side of the base is fixedly connected with a forming cylinder through a fixing column, the top of the forming cylinder communicates with a feeding cylinder, the inner wall of the forming cylinder is fixedly connected with a fixing plate, forming holes are evenly formed in one side of the fixing plate, a driving motor is fixedly connected to the bottom of the fixing plate, an output shaft of the driving motor is rotationally connected with a rotating rod, one end of the rotating rod penetrates through the fixing plate and is fixedly connected with a pressing wheel, a first driven roller is rotationally connected to one side of the base through a rotating seat, and the side, close to the driven roller, of the base is rotationally connected with a driving roller through a rotating seat, and one side of the base is connected with a second driven roller through a hydraulic rod. According to the biomass fuel processing and forming device, the purpose of collecting formed and unformed straw particles in a classified mode is achieved, and the forming rate of finished products and the utilization rate of waste are guaranteed.

Owner:淮北特旭信息科技有限公司

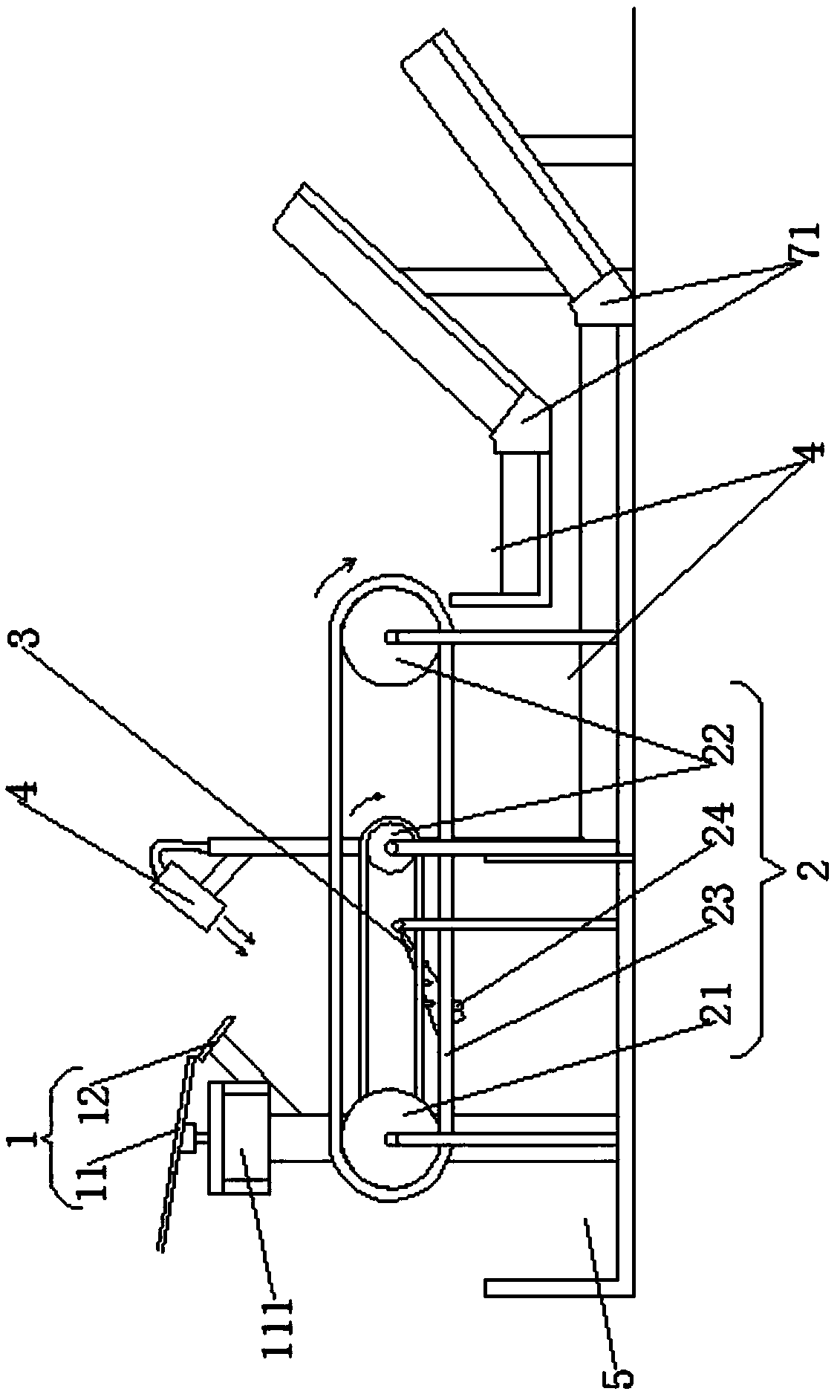

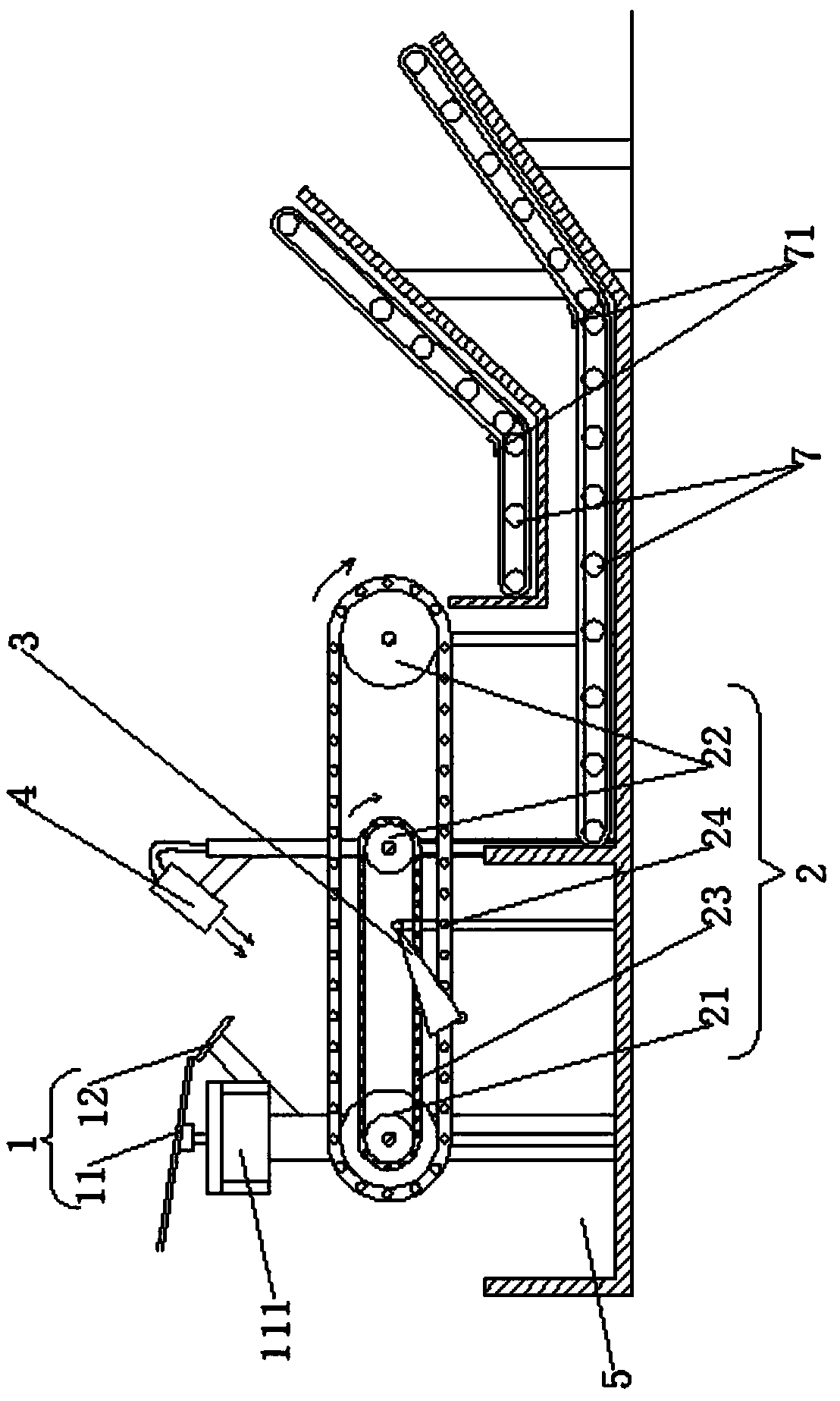

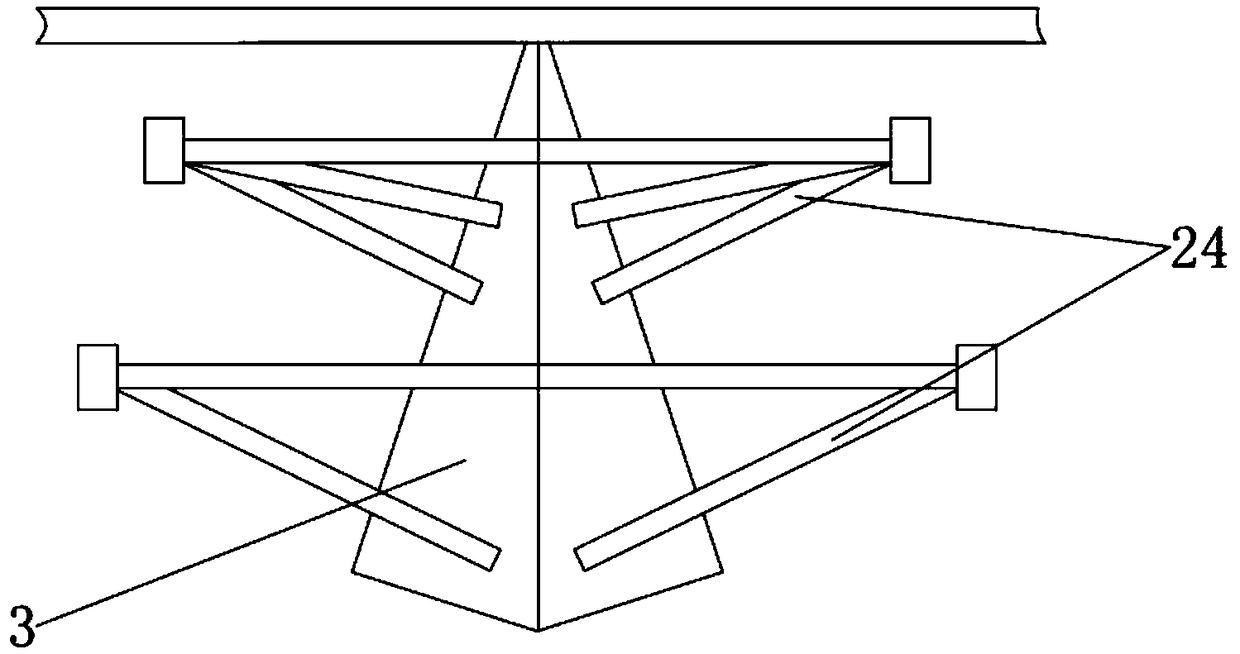

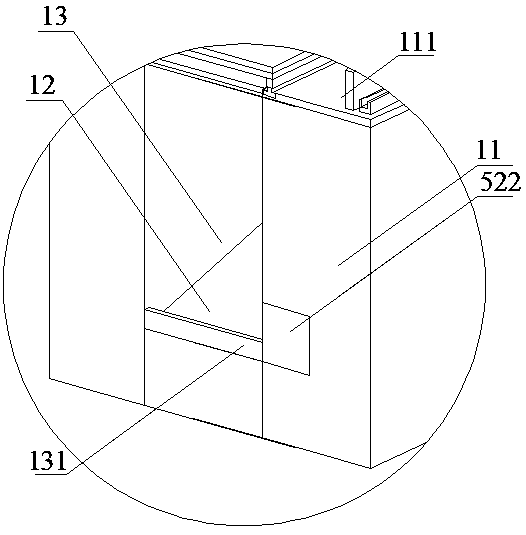

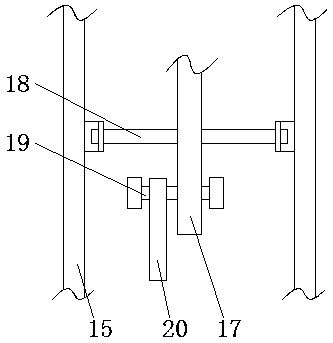

Chain type lifting mechanism for boards

InactiveCN108946109AReasonable structural designImprove the efficiency of lifting adjustmentConveyor partsLocking mechanismChain type

The invention discloses a chain type lifting mechanism for boards and belongs to the field of building material machining mechanical devices. According to the chain type lifting mechanism for the boards, an adjusting support is vertically and fixedly arranged above a board clamping support, a lifting support is horizontally arranged below the adjusting support, the two sides of the upper side of the lifting support are vertically and fixedly provided with lifting guide rods, the lifting guide rods are arranged on the adjusting support in the vertical direction in a sliding manner, a front board pulling chain and a back board pulling chain are fixed to the two sides of the upper side of the lifting support correspondingly, a board pulling air cylinder is horizontally and fixedly arranged onone side of the upper side of the board clamping support, the output end of the board pulling air cylinder is fixedly connected with the middle of one side of a horizontal movement adjusting plate, arotational clamping plate is horizontally arranged on the upper side of the lifting support, the middle portions of the two sides of the rotational clamping plate are hinged to rotational support seats correspondingly, and a locking mechanism is horizontally and fixedly arranged on the upper side of the adjusting support. The chain type lifting mechanism for the boards is reasonable in structuraldesign and capable of firmly clamping and fixing the ends of the boards and conveniently, rapidly and stably adjusting the inclination angle of each board and meets the machining and use demands.

Owner:张帼威

Surface coating device for automobile body pillar machining

InactiveCN110355046AIncrease frictionEasy to fixPretreated surfacesCoatingsEngineeringCentrifugal force

The invention discloses a surface coating device for automobile body pillar machining. The surface coating device comprises a fixing seat, wherein an electric telescopic rod is fixed on one side of the outer wall of the top of the fixing seat, a supporting plate is fixed on the outer wall of the top of the electric telescopic rod, a rotating rod is rotationally connected to one side of the outer wall of the bottom of the supporting plate through a bearing, a fixing plate is fixed on the outer wall of the bottom of the rotating rod, a U-shaped frame is fixed on the outer wall of the bottom of the fixing plate, a threaded hole is formed in the outer wall of one side of the U-shaped frame, the inner wall of the threaded hole is in threaded connection with a fixing bolt, the fixing bolt is connected with a clamping plate through a nut, and a protective pad is glued on the outer wall of one side of the clamping plate. According to the device, the phenomenon that a pillar falls off from theU-shaped frame due to centrifugal force generated during rotation so as to affect coating of the pillar is prevented, the influence on pillar machining due to the fact that the surface of the pillar is not coated uniformly is avoided, and the problem that the device is inconvenient to clean due to the fact that coating liquid drips on the device can be prevented.

Owner:十堰市寅云实业有限公司

Processing technology of sauce

InactiveCN108157883ASolve the technical problem of unstable sour tasteProcessing effectFood ingredient as taste affecting agentLipidic food ingredientsAdditive ingredientBroad beans

The invention provides a processing technology of a sauce. The processing technology comprises the following steps of preparing materials; weighing soybean oil, a thick broad-bean sauce, a chili sauce, tomato paste, minced fresh ginger, minced garlic, chili powder, a seafood sauce, anhydrous citric acid, a dark soy sauce, fresh hot juice, white sugar, chicken powder and water according to an ingredient list; stir-frying materials; according to technology requirements, frying ginger and garlic to generate fragrance, frying the chili sauce and the tomato paste to generate fragrance, adding the chili powder, and performing frying to generate red oil; performing seasoning; adding the water, the seafood sauce, the citric acid, the dark soy sauce, the fresh hot juice, the white sugar and the chicken powder for seasoning; packaging finished products; and performing sterilization. The sauce produced by the technology disclosed by the invention is balanced and outstanding in acid, sweet and hottaste, and red bright in oil juice.

Owner:安徽兆味源食品科技有限公司

Polishing device for marble processing

InactiveCN108381320AImprove practicalityProcessing effectGrinding carriagesGrinding work supportsEngineeringMechanical engineering

The invention relates to the technical field of marble processing, and discloses a polishing device for marble processing. The polishing device comprises a base, sleeve boxes are fixedly installed onthe two sides of the top of the base, the two sleeve boxes are symmetrical with respect to the center of the base, fixing boxes are fixedly installed on the tops of the sleeve boxes, lead screws are movably connected to inner cavities of the sleeve boxes in a sleeved manner, the other ends of the lead screws sequentially penetrate the sleeve boxes and the fixing boxes and extend to the exteriors of the top ends of the fixing boxes, connecting blocks are fixedly connected to the ends, located outside the fixing boxes, of the lead screws, and a rotating shaft is movably connected between the twosleeve boxes in a sleeved manner. By means of the polishing device for marble processing, a bolt is screwed, a handle is rotated, transmission fit between the rotating shaft and the lead screws is used, a polishing disc moves up and down, the distance between the polishing disc and a working table is adjusted, the polishing device can be used for polishing marble with different heights, and practicability of the polishing device is improved.

Owner:郑州博钰特超硬材料制品有限公司

Rapid soil removing device for earthworm breeding

InactiveCN112154978AQuick removalProcessing effectAnimal husbandryAgricultural scienceMechanical engineering

The invention relates to the technical field of earthworm breeding, and discloses a rapid soil removing device for earthworm breeding. The device comprises supporting legs, outer rods are arranged inside the supporting legs; an outer box is fixedly connected with the surfaces of the outer rods; and first leaking holes are formed in the surfaces of the outer box. According to the rapid soil removing device for earthworm breeding, a motor is started to drive a second concave gear to rotate, then a chain drives a first concave gear and a water pipe to rotate, then the water pipe is made to rotatereversely, meanwhile, a second gear drives a first gear to rotate, the outer rods and the outer box are made to rotate, and forward rotation is conducted. Therefore, earthworms can be conveniently separated from the soil, and the earthworms are processed, the soil of the earthworm processing process is reduced, so that bacterium breeding is prevented, the effect after cleaning is improved, the cleanness and tidiness of the earthworms are guaranteed, and the influence on later processing of the earthworms due to incomplete cleaning is avoided.

Owner:李延平

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com