Cylinder seat, compressor and machining method for cylinder seat

A processing method and technology for a cylinder block, applied in the field of compressors, can solve the problem that the length of the lever arm cannot be further shortened, and achieve the effects of reducing the length L1 of the lever arm, simplifying the processing process, and reducing stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

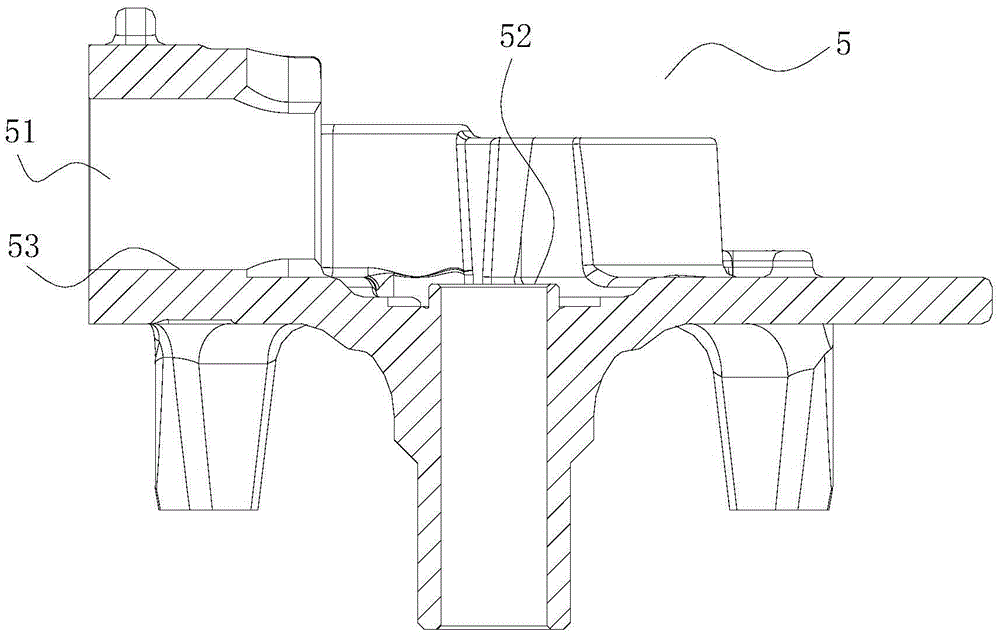

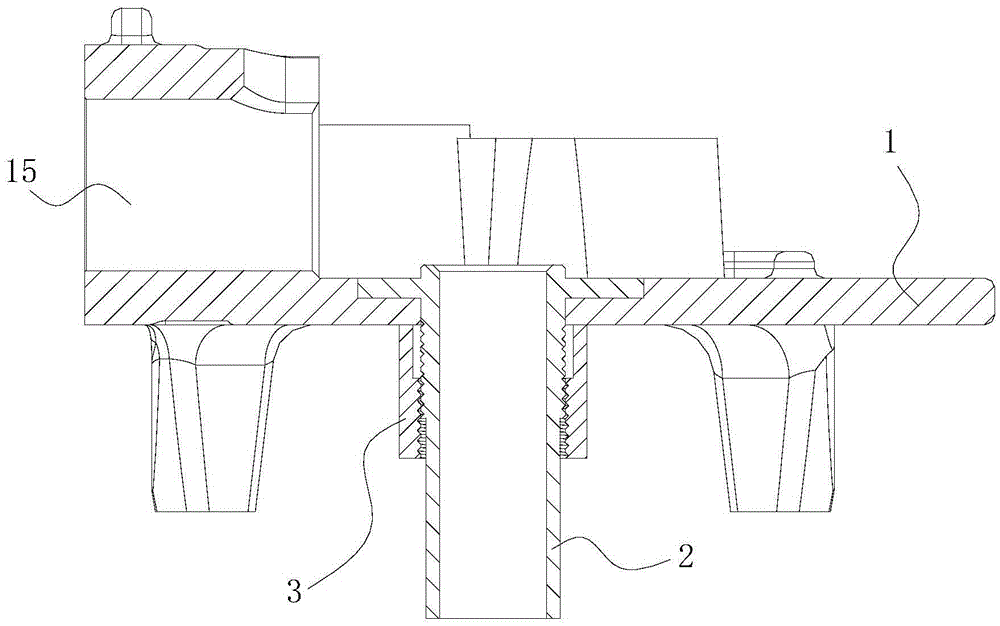

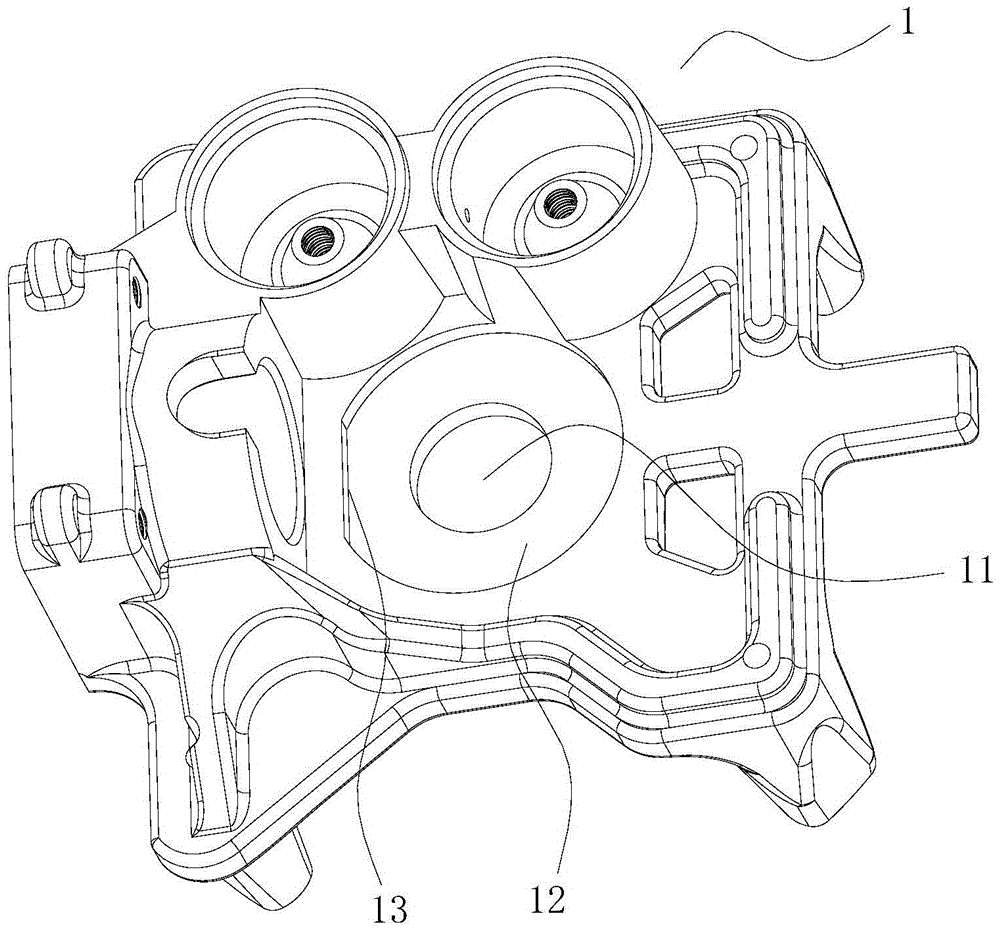

[0039] The preferred embodiment discloses a cylinder block. like Figure 2 to Figure 7 As shown, the cylinder block includes a base 1 and a detachable bearing 2, the base 1 is provided with a bearing hole 11, and the detachable bearing 2 is detachably installed in the bearing hole 11.

[0040] The processing method of the structural cylinder block is basically the same as the existing method, the difference is that the method includes the following steps:

[0041] Step 1. Processing and forming the detachable bearing 2 and the base 1 respectively, and then installing the detachable bearing 2 on the base 1 for semi-finishing. The detachable bearing 2 and the base 1 are integrally installed and processed together to ensure the verticality of the cylinder bore 15 and the shaft hole 24 of the cylinder block.

[0042] Step 2, dismantling the detachable bearing 2 from the base 1, and finishing the cylinder bore 15.

[0043] Step 3. Install the detachable bearing 2 on the base 1 a...

Embodiment 2

[0055] This preferred embodiment discloses a compressor, including various cylinder blocks as described in the first preferred embodiment. The processing of the cylinder seat is more convenient, the force of the whole compressor is more reasonable, and the reliability is higher.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com