Patents

Literature

114results about How to "Large deviation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

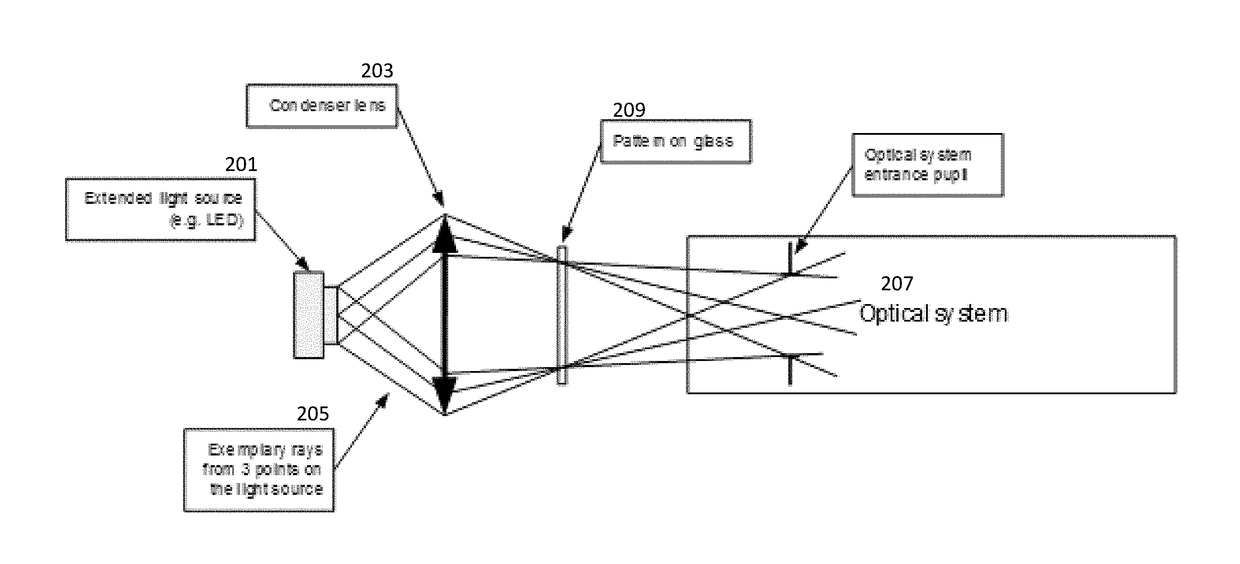

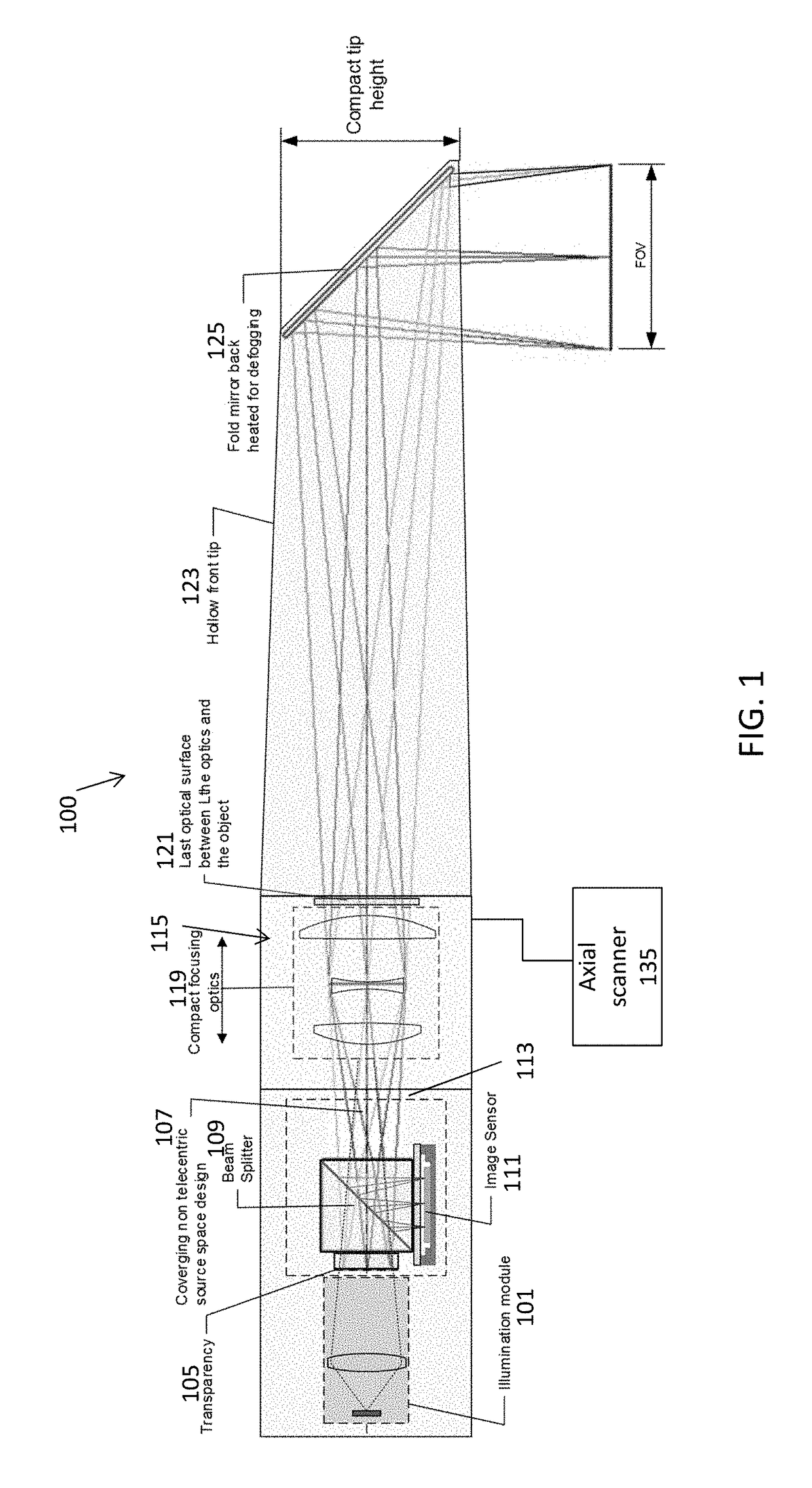

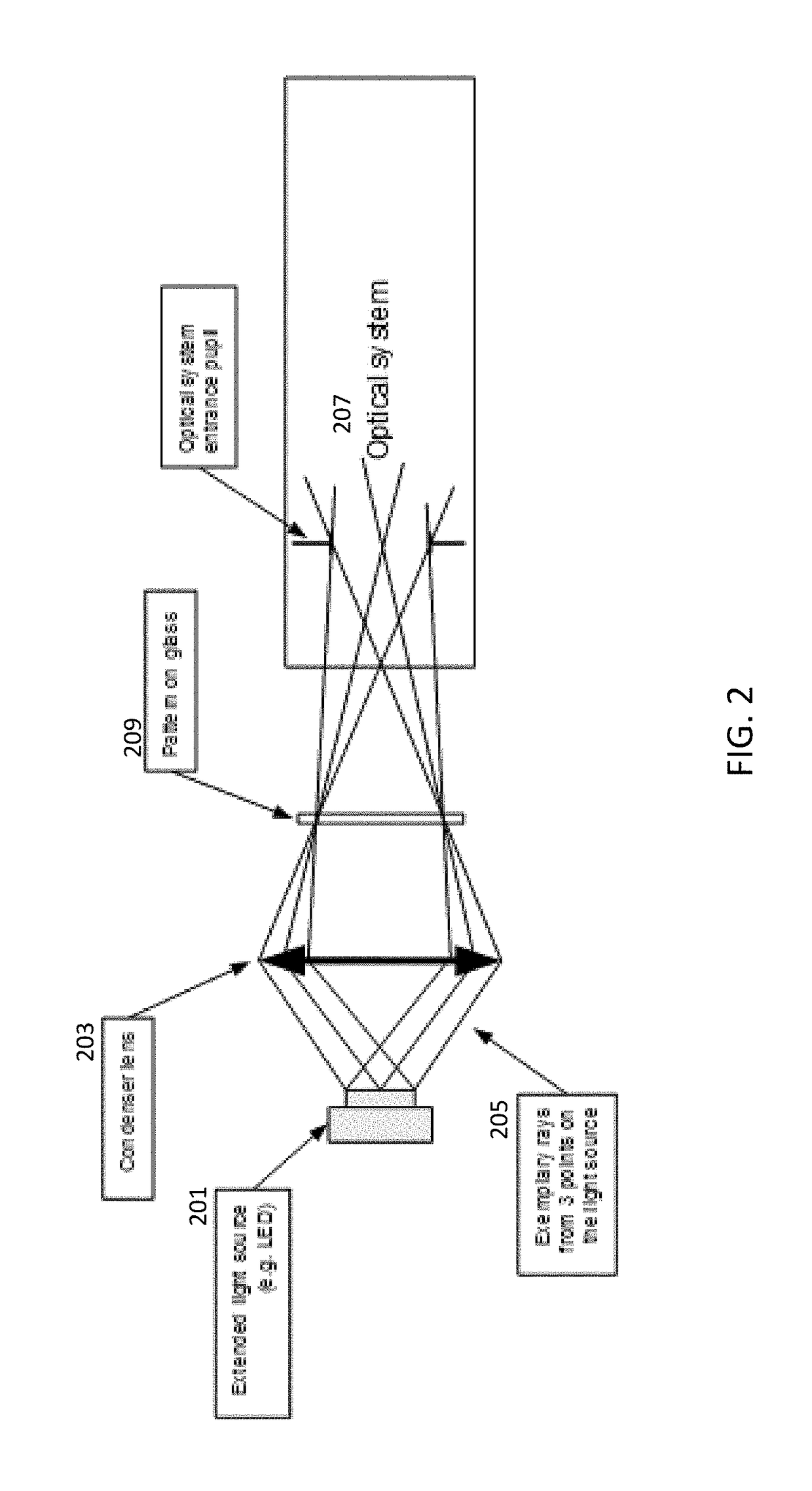

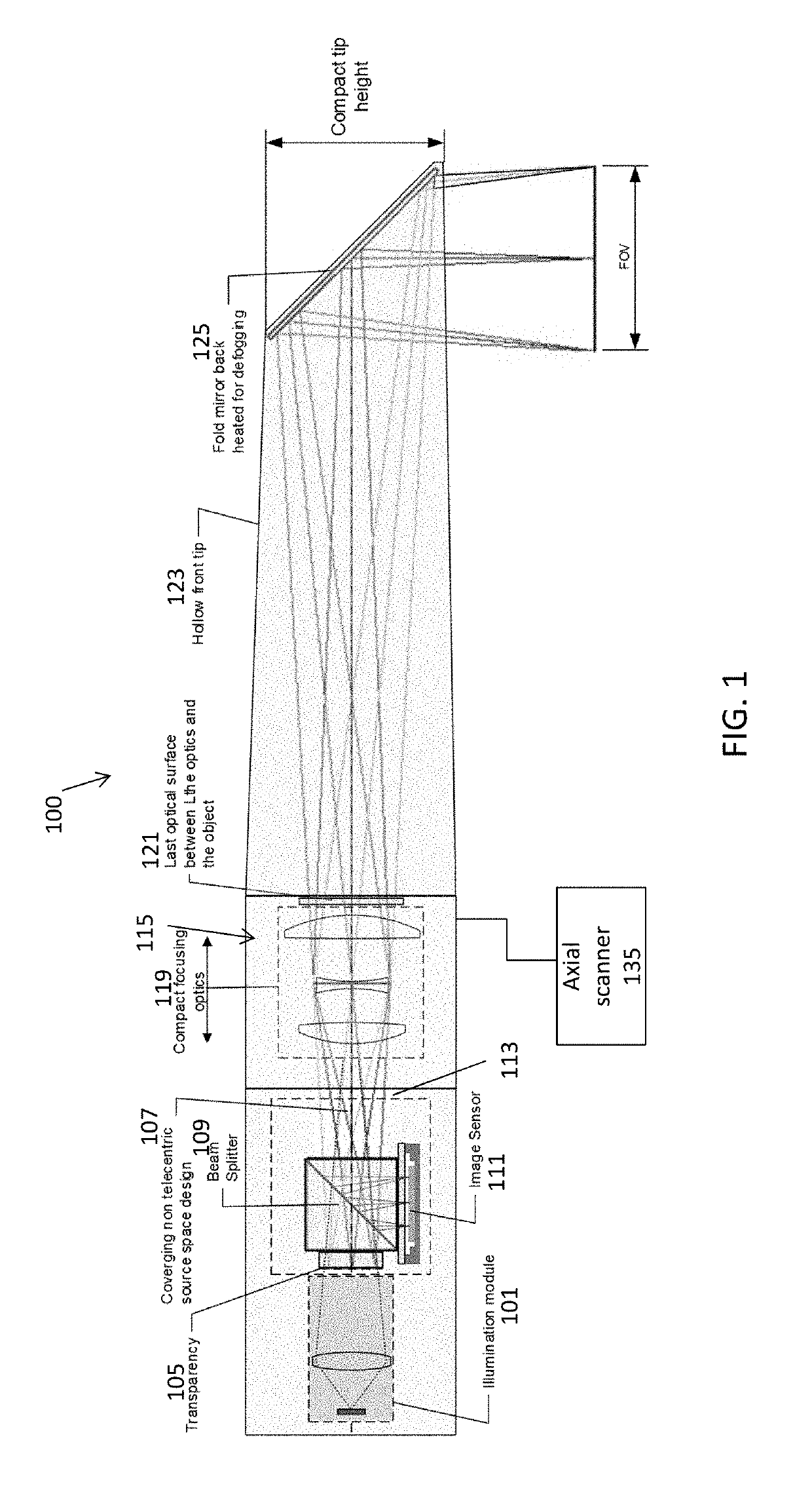

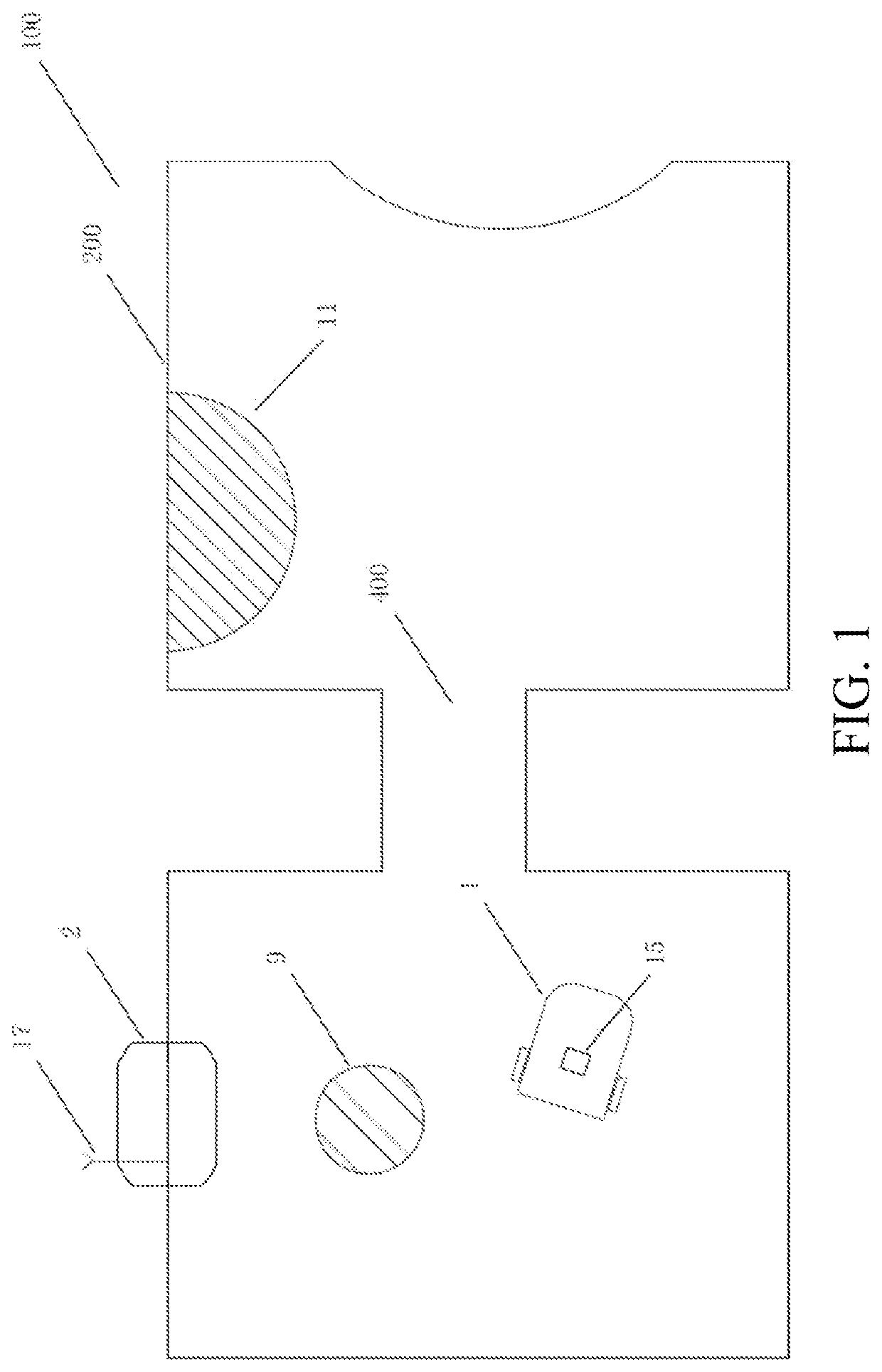

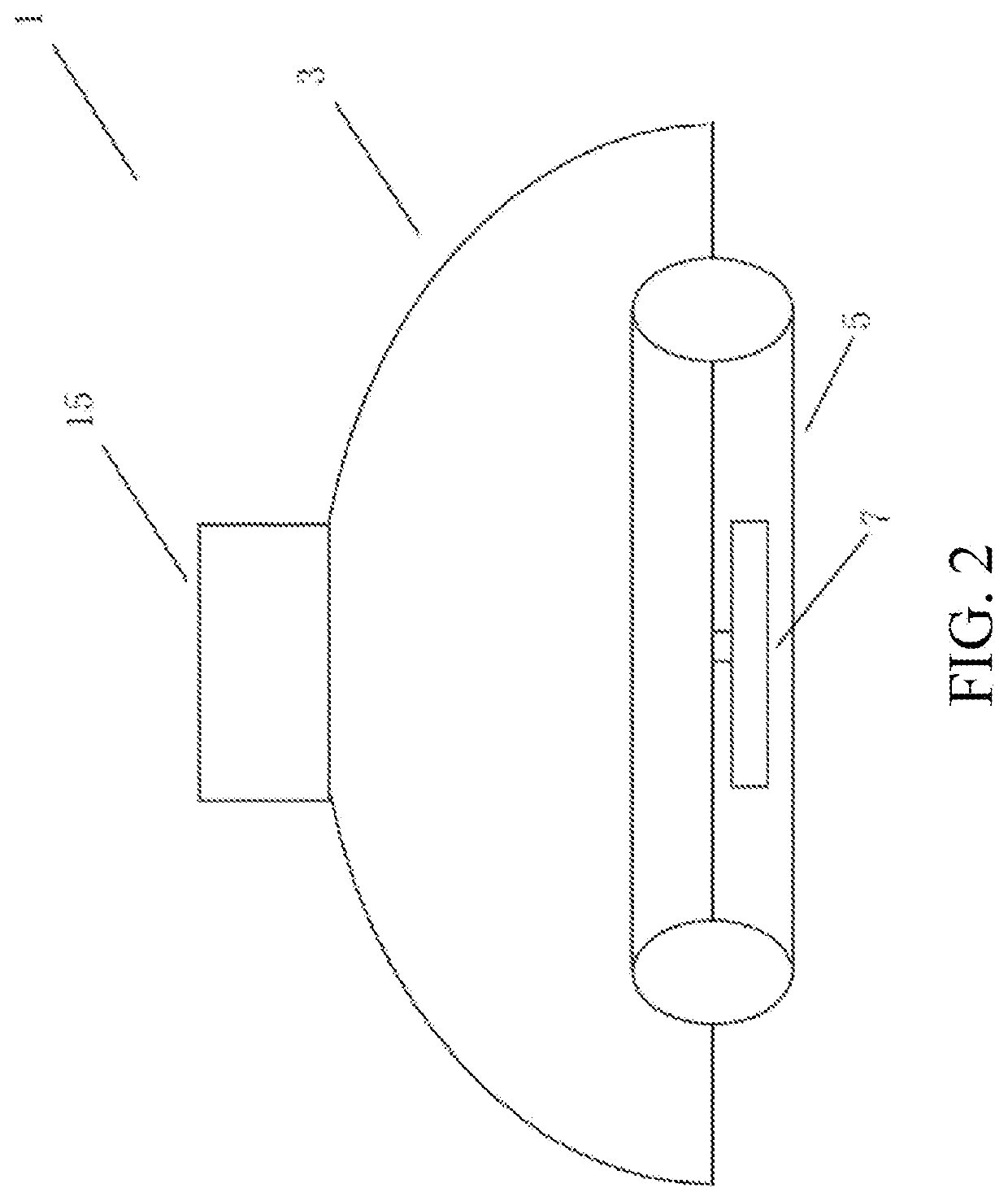

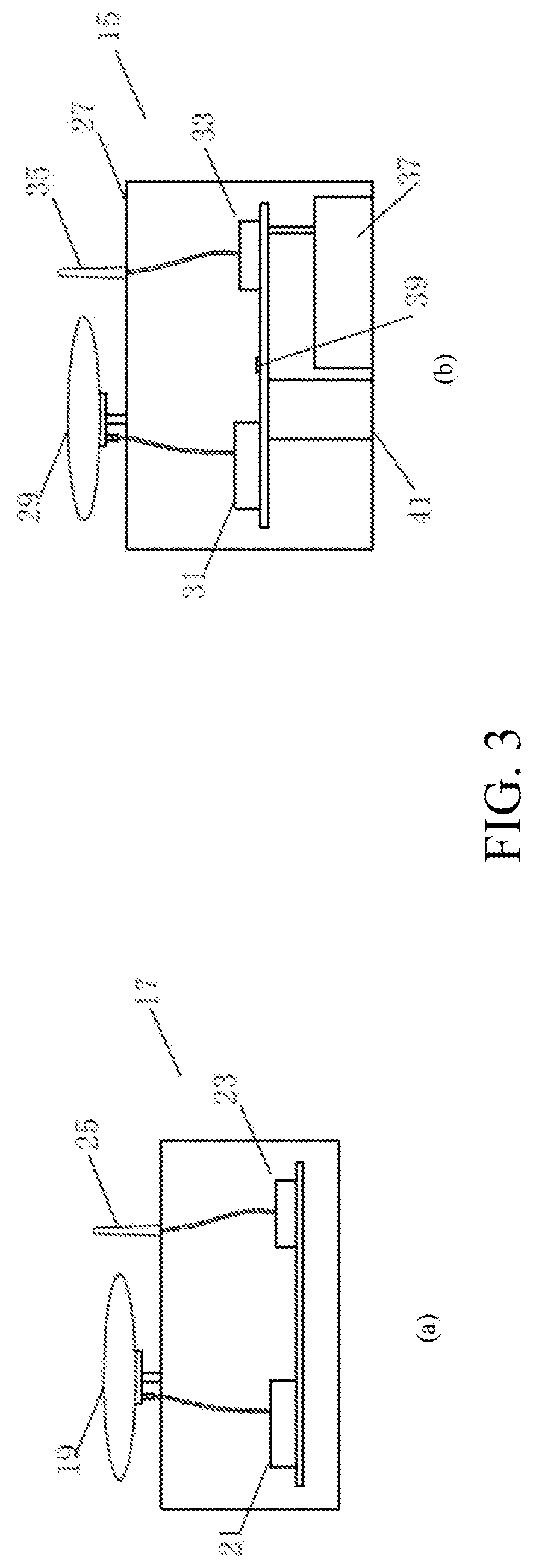

Compact confocal dental scanning apparatus

ActiveUS20180192877A1Reduce speckle noiseSimple transparencyImpression capsOthrodonticsDental scanningOptical axis

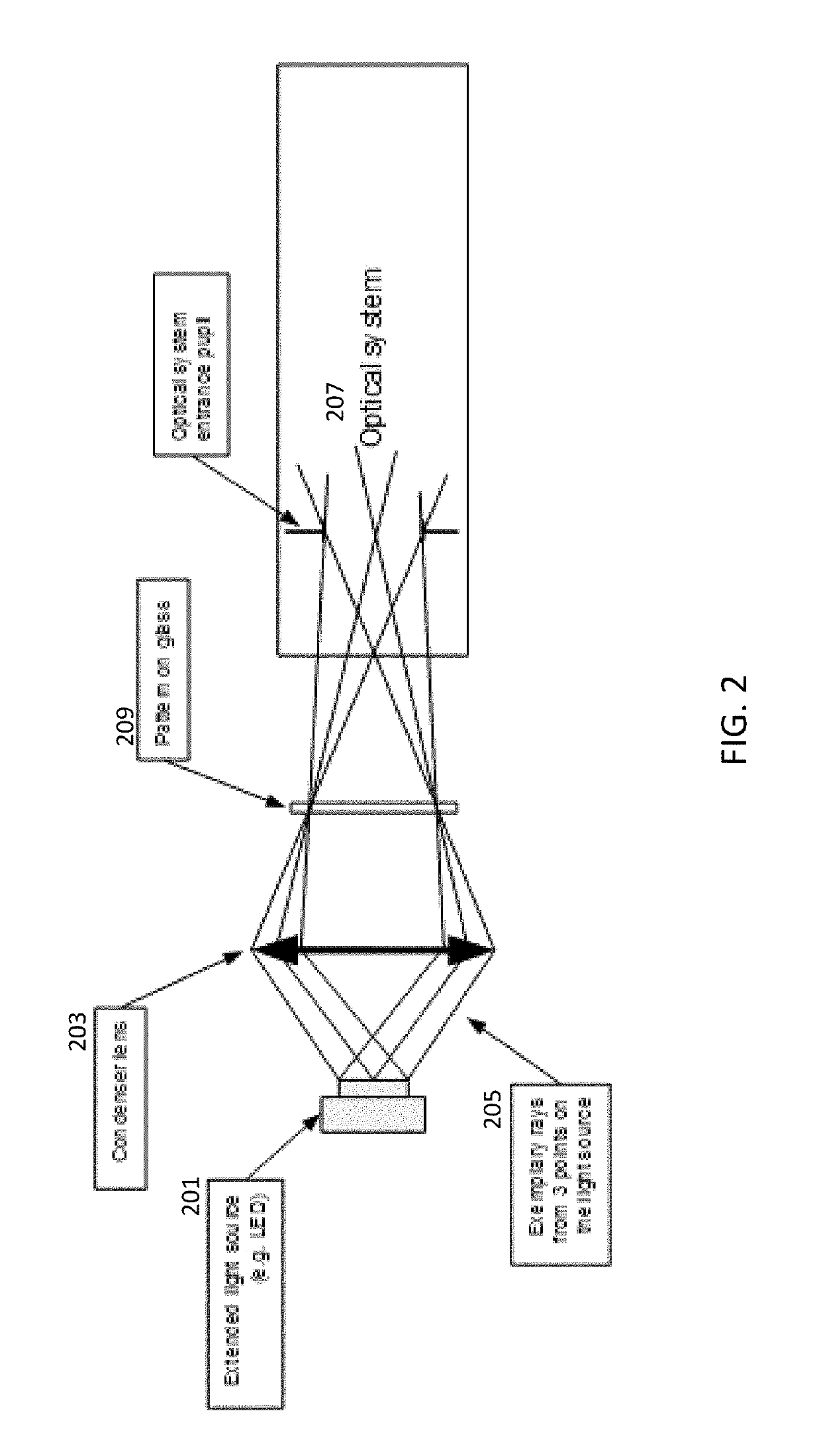

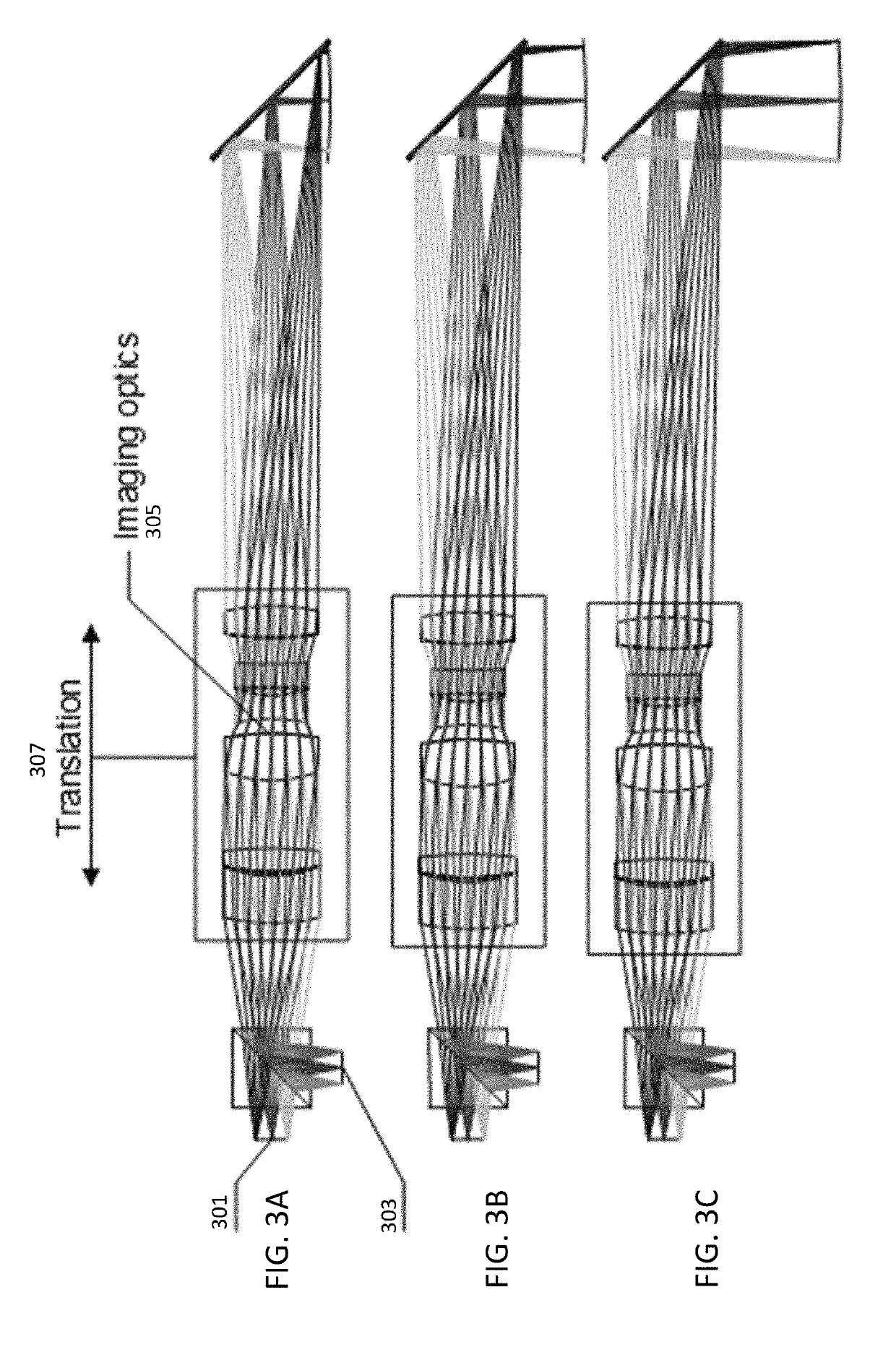

Described herein are apparatuses and methods for confocal 3D scanning. The apparatus can comprise a spatial pattern disposed on a transparent base and a light source configured to provide illumination to the spatial pattern and an optical system comprising projection / imaging optics having one or more lenses and an optical axis. The projecting / imaging optics may be scanned to provide depth scanning by moving along the optical axis.

Owner:ALIGN TECH

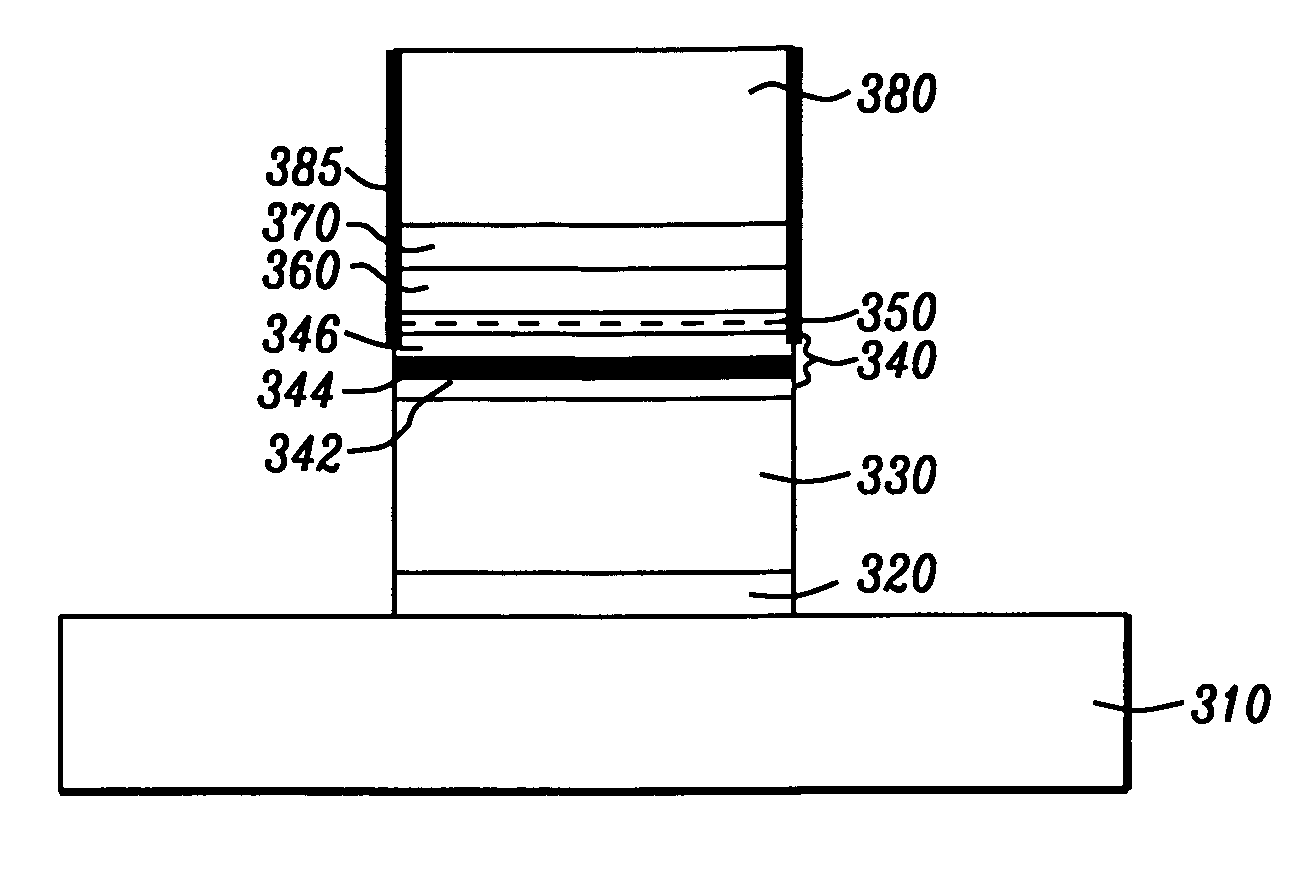

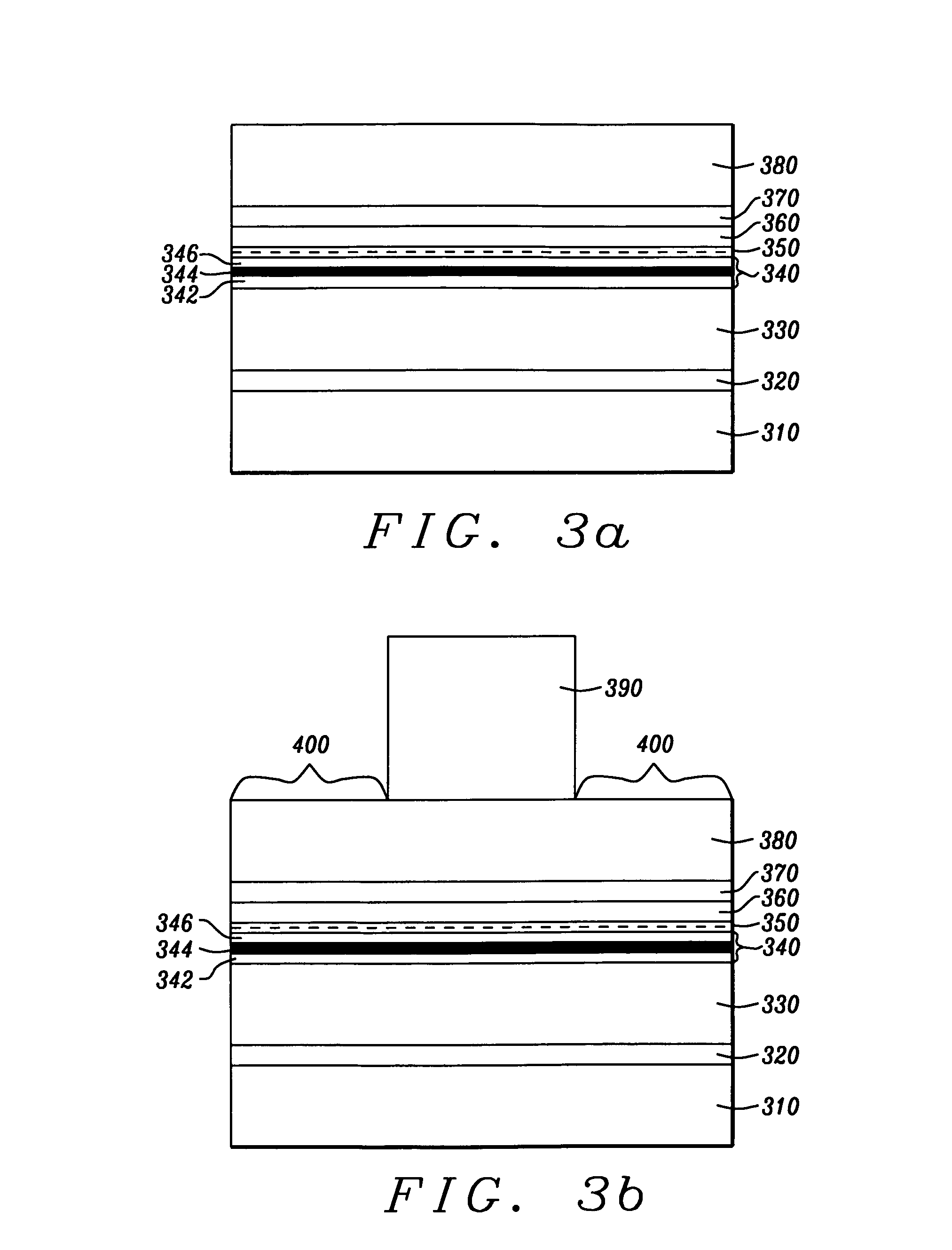

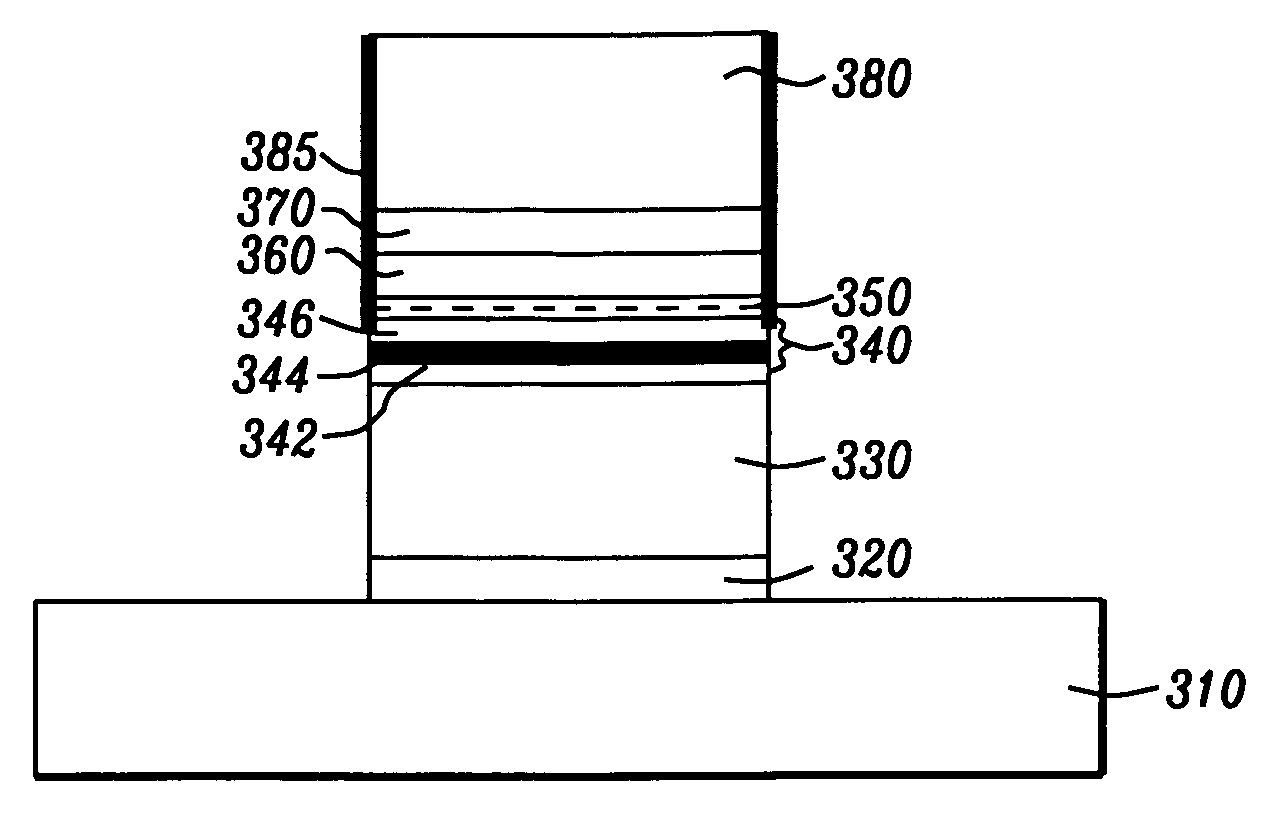

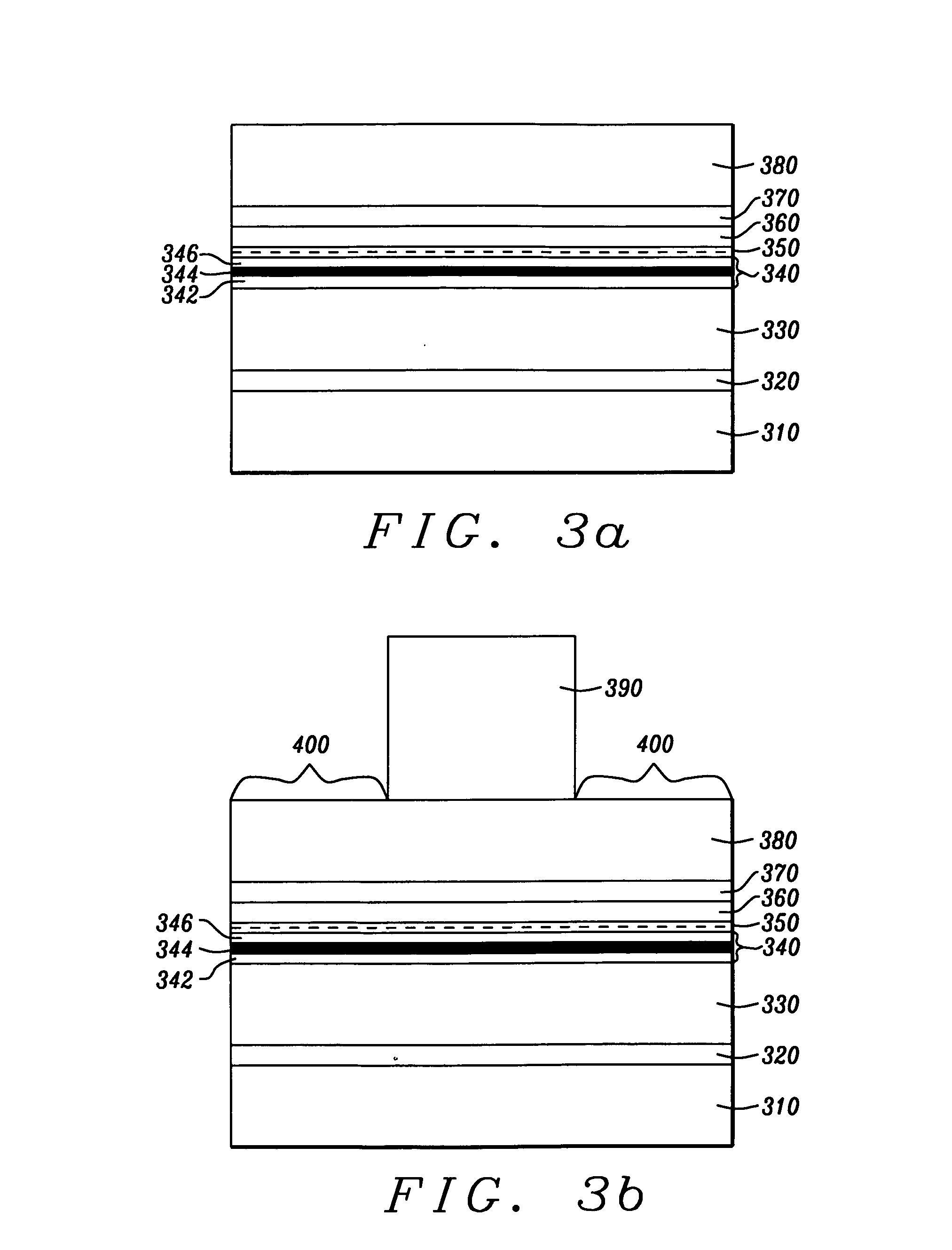

Method of MRAM fabrication with zero electrical shorting

ActiveUS7936027B2Reduces and eliminates electrical shortingLarge deviationMagnetic-field-controlled resistorsSemiconductor/solid-state device manufacturingElectricityHydrogen

Owner:TAIWAN SEMICON MFG CO LTD

Method of MRAM fabrication with zero electrical shorting

ActiveUS20090173977A1Reduces and eliminates electrical shortingLarge deviationMagnetic-field-controlled resistorsSolid-state devicesHydrogenEngineering

An MTJ cell without footings and free from electrical short-circuits across a tunneling barrier layer is formed by using a Ta hard mask layer and a combination of etches. A first etch patterns the Ta hard mask, while a second etch uses O2 applied in a single high power process at two successive different power levels. A first power level of between approximately 200 W and 500 W removes BARC, photoresist and Ta residue from the first etch, the second power level, between approximately 400 W and 600 W continues an etch of the stack layers and forms a protective oxide around the etched sides of the stack. Finally, an etch using a carbon, hydrogen and oxygen gas completes the etch while the oxide layer protects the cell from short-circuits across the lateral edges of the barrier layer.

Owner:TAIWAN SEMICON MFG CO LTD

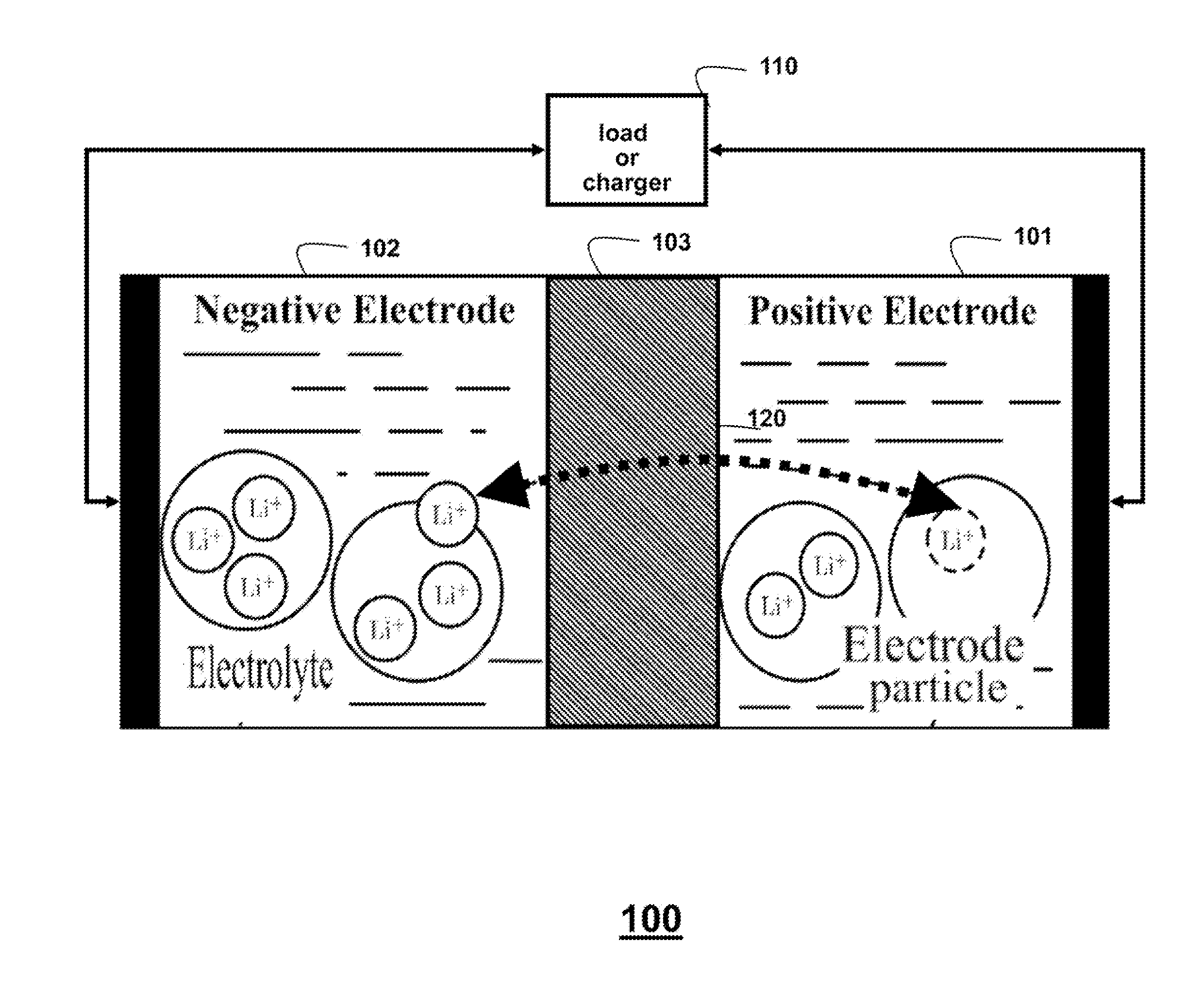

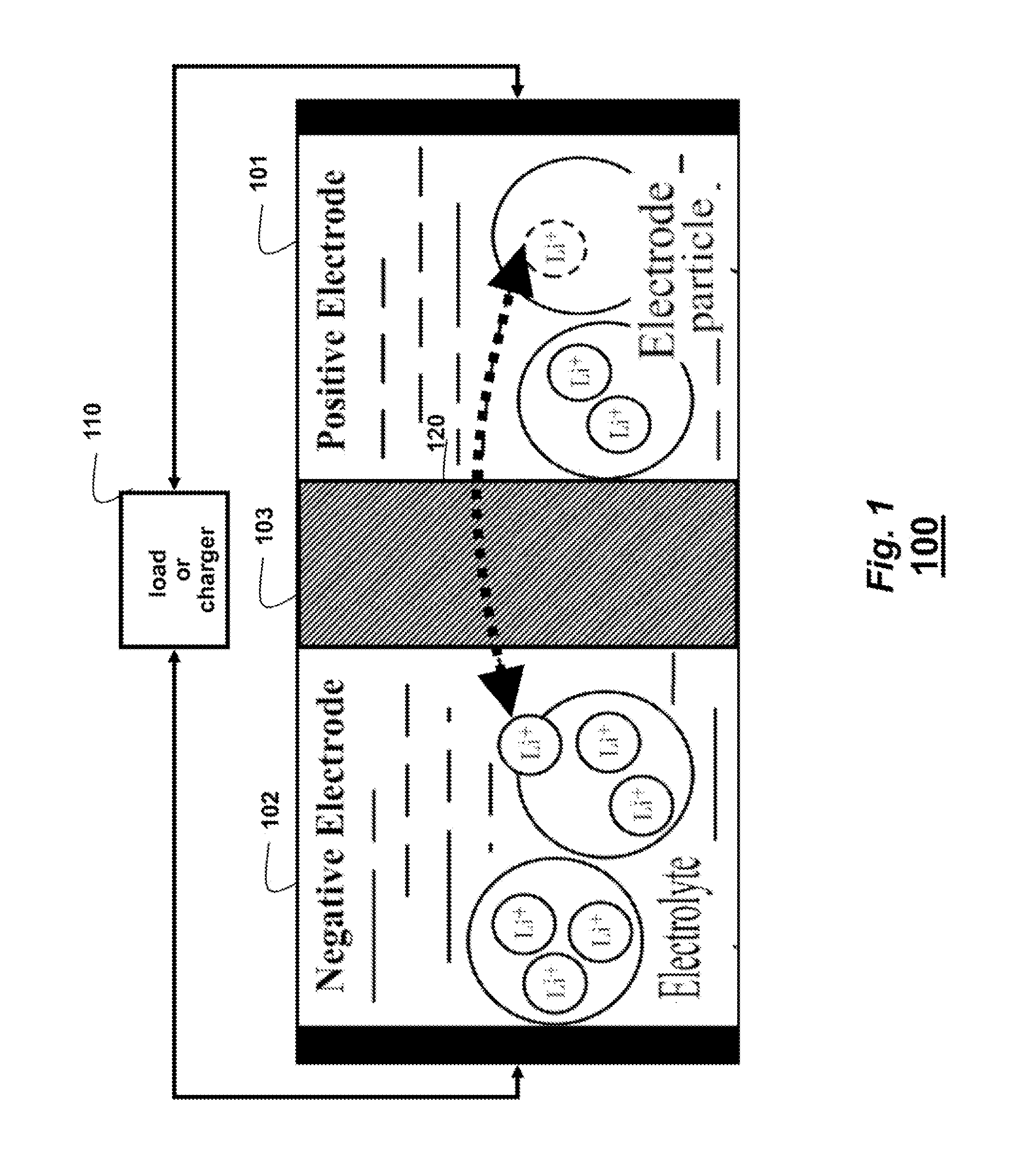

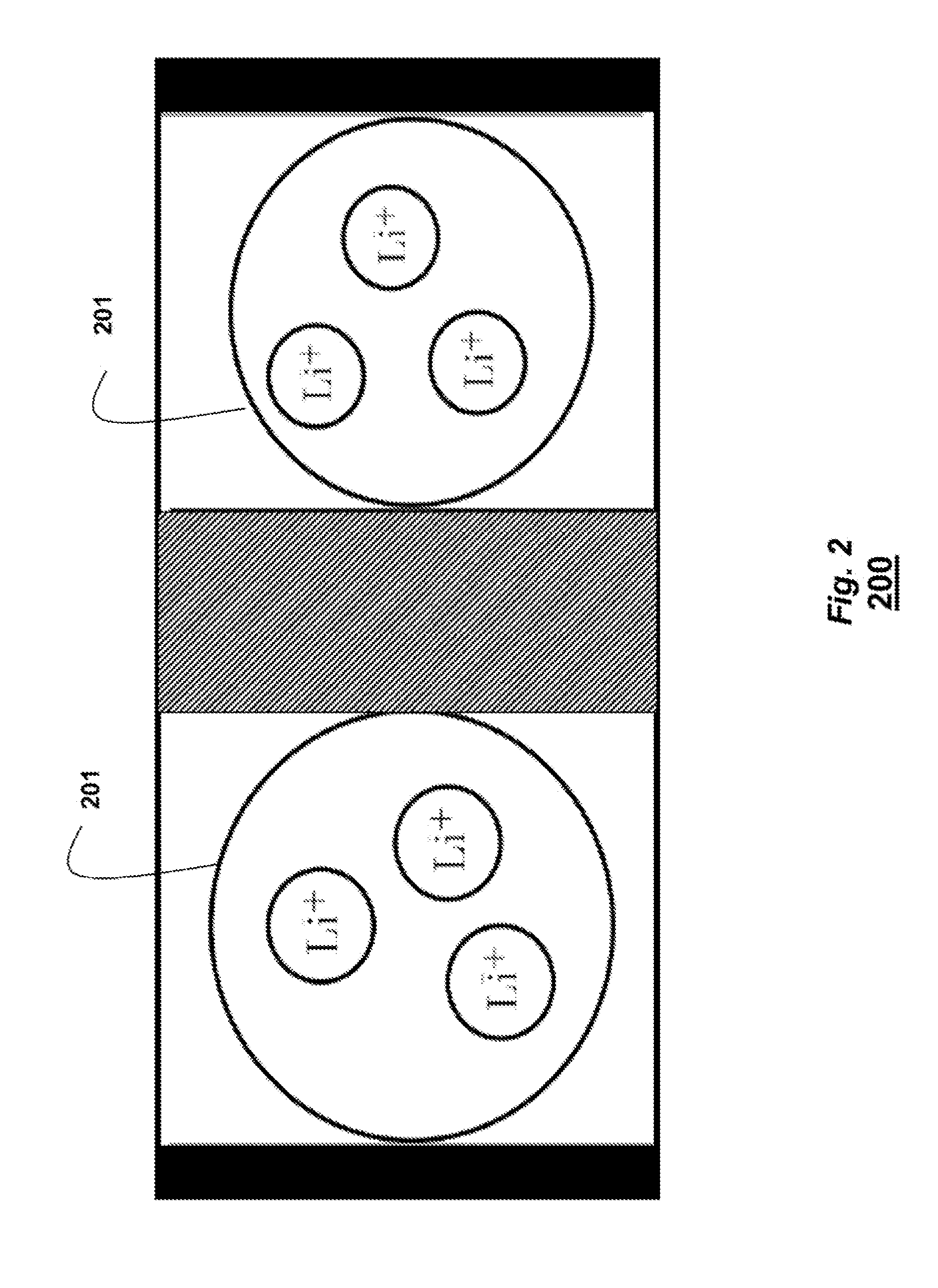

Method for Estimating State of Charge for Lithium-Ion Batteries

InactiveUS20140210418A1Ensure stabilityLarge deviationBatteries circuit arrangementsElectrical testingCharge currentState of charge

A state of charge (SoC) a lithium-ion (Li+) battery is estimated at a time instant by first constructing a model of the Li+ battery based on a single particle operation. The model describes a relationship between the SoC, a charge current, a discharge current, and an output voltage. Using a nonlinear optimization, a function expressing a relationship between the SoC and an open circuit voltage is determined. The relationship is based on off-line measurements of the charge current, the discharge current, and the open-circuit voltage. Then, the SoC and parameters of the model are estimated concurrently, wherein the SoC and the parameters are based on the model, the function, and on-line measurements of the charge current, the discharge current, and the output voltage.

Owner:MITSUBISHI ELECTRIC RES LAB INC

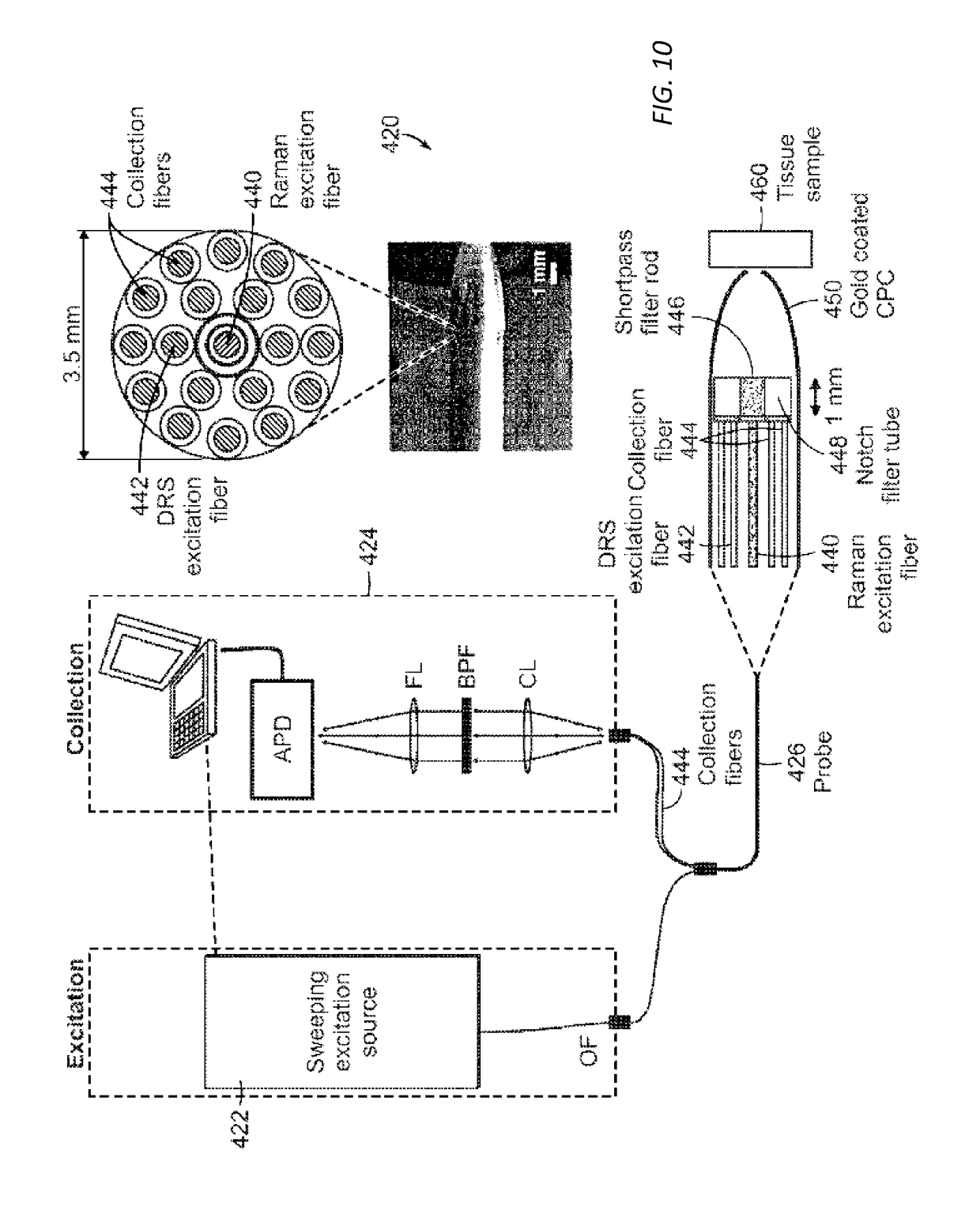

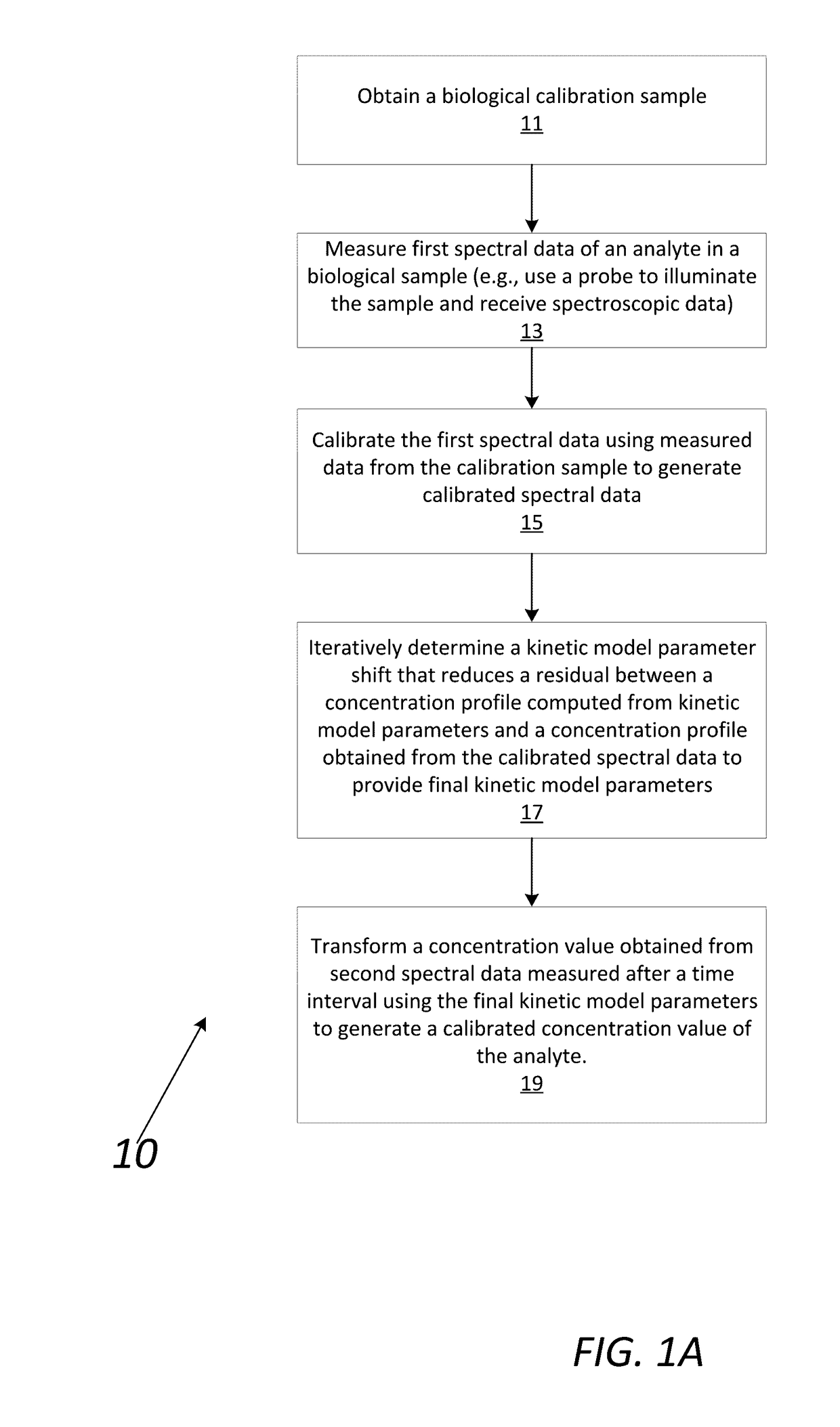

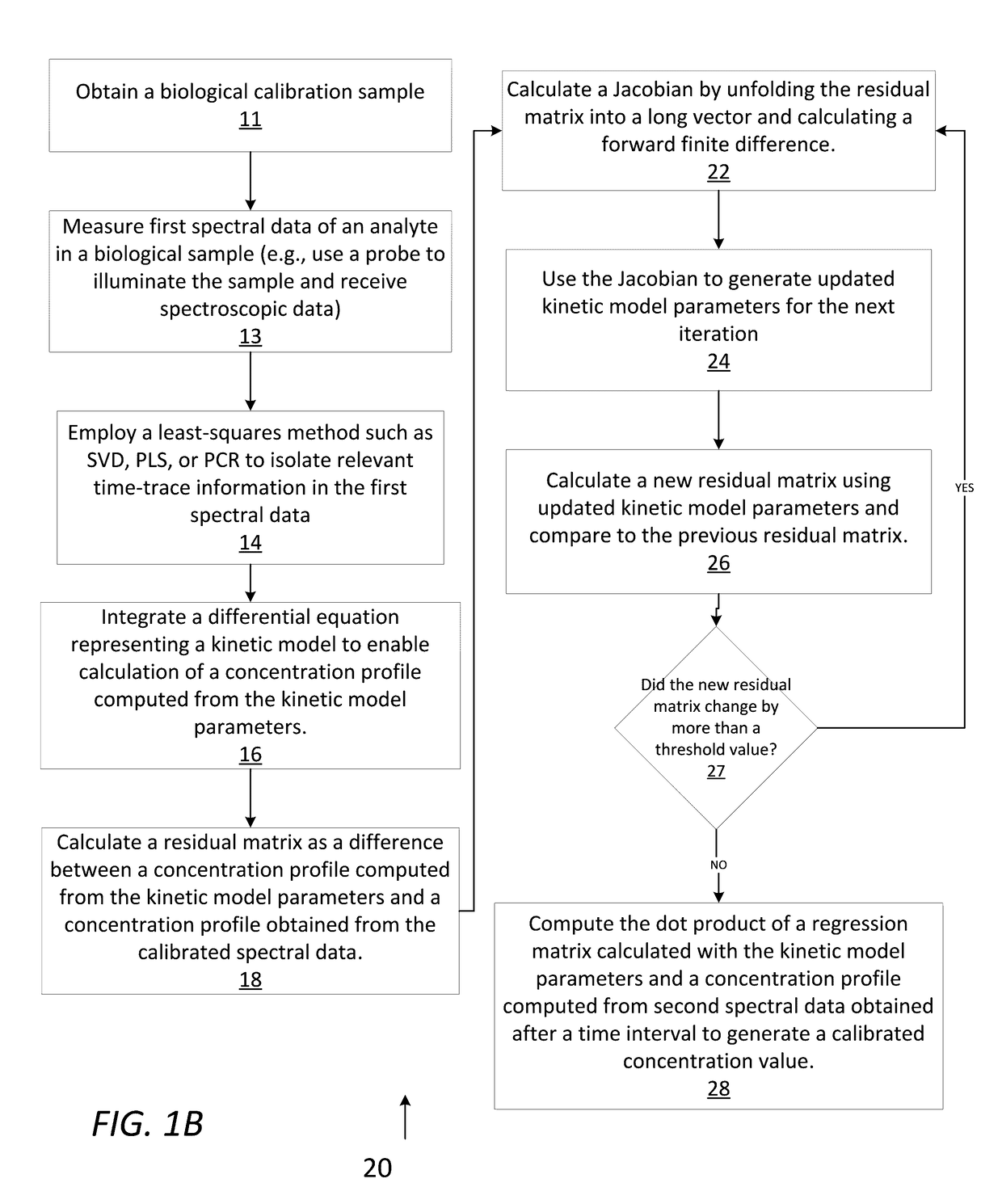

Systems and methods for sampling calibration of non-invasive analyte measurements

InactiveUS20170127983A1Large deviationSurgeryMaterial analysis by optical meansChemical reaction kineticsAnalyte

Systems and methods of the present invention provide a calibration model that requires minimal information compared with prior techniques. These systems and methods represent the first generalized approach for combined treatment of spectroscopic measurements of a dynamic, mass-transfer system with the underlying kinetic model of said system. The technique can be applied to non-invasive glucose monitoring or monitoring of chemical reaction dynamics.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE +1

Compact confocal dental scanning apparatus

ActiveUS10456043B2Assembly toleranceReduce manufacturing costImpression capsOthrodonticsDental scanningOptical axis

Owner:ALIGN TECH

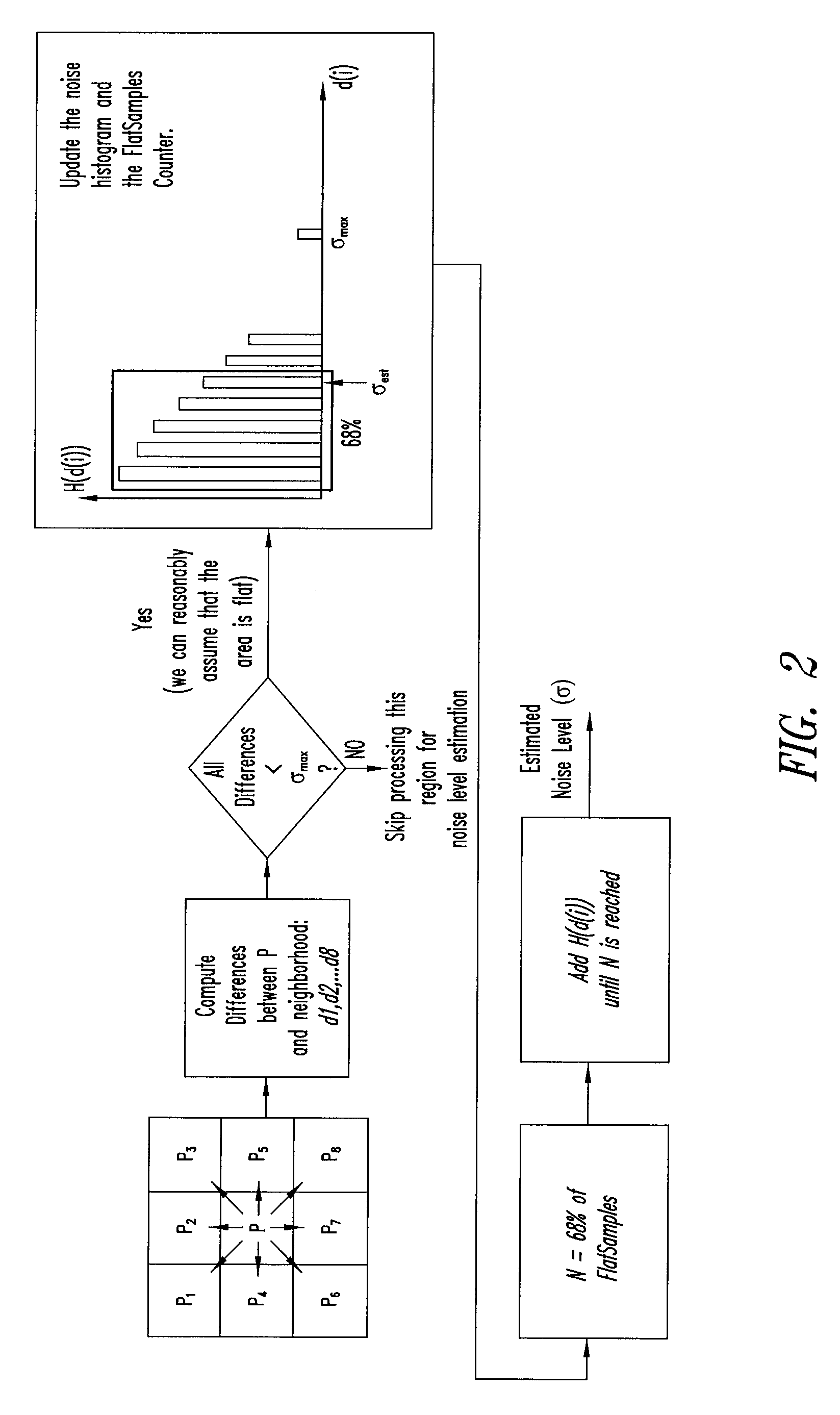

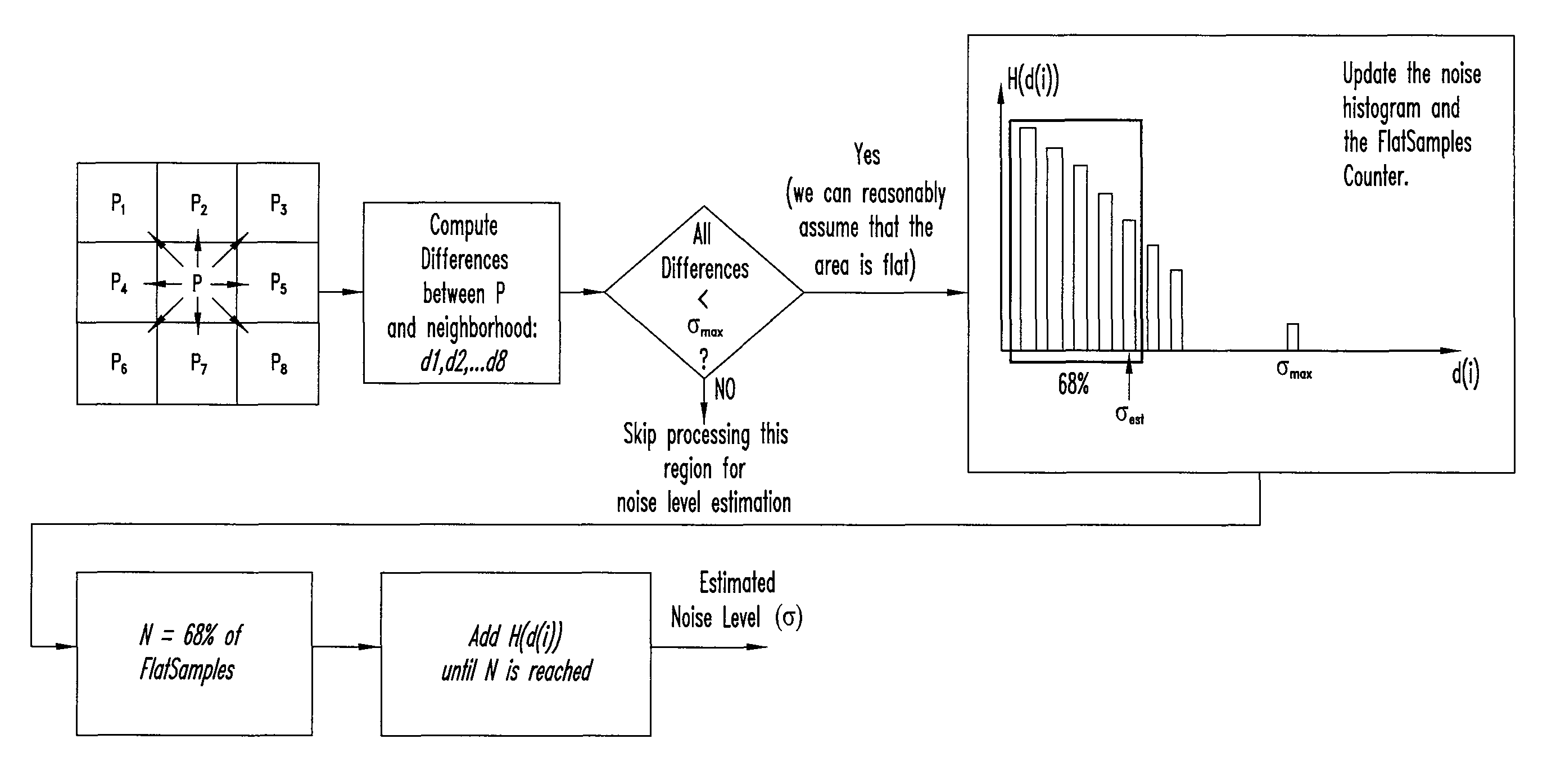

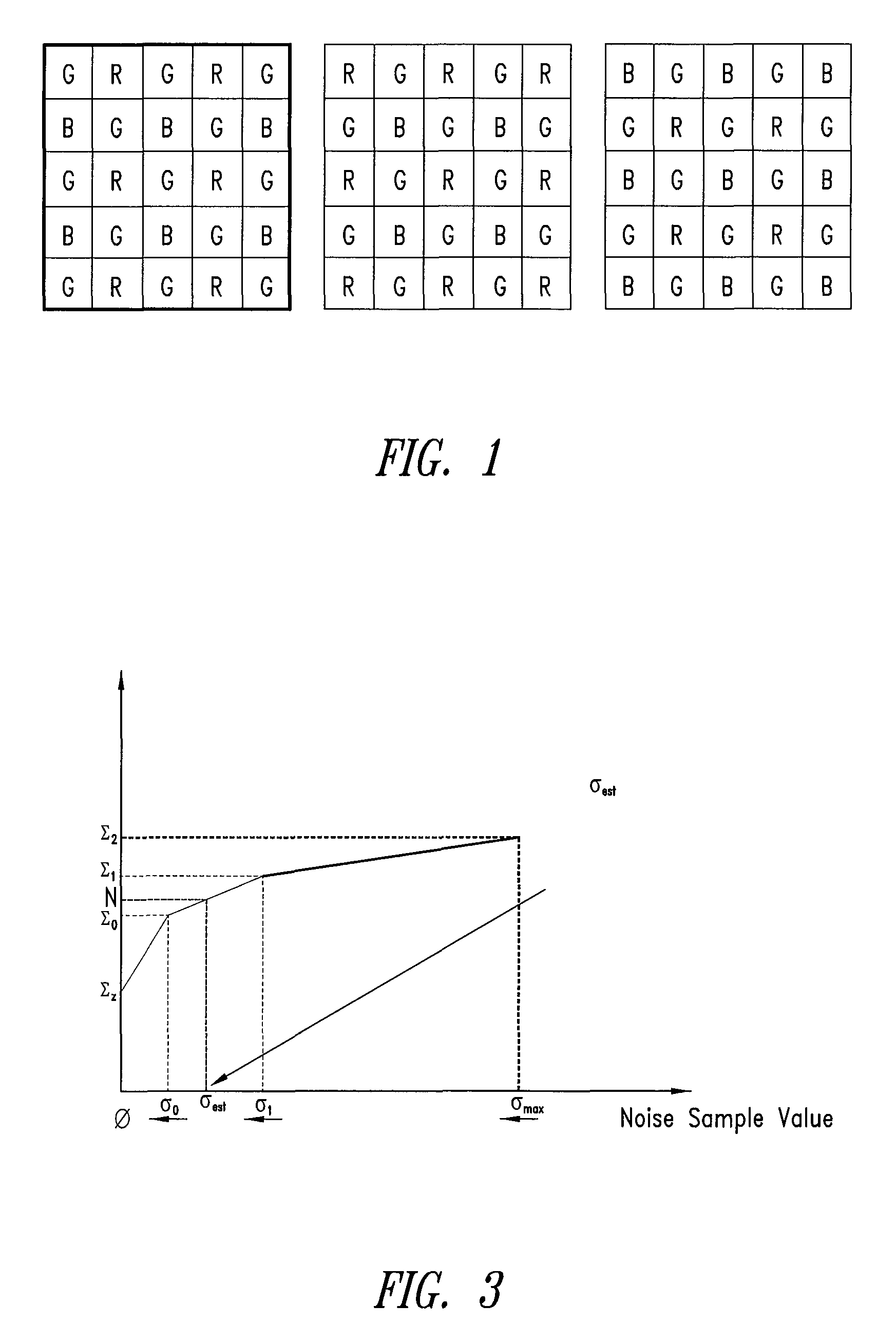

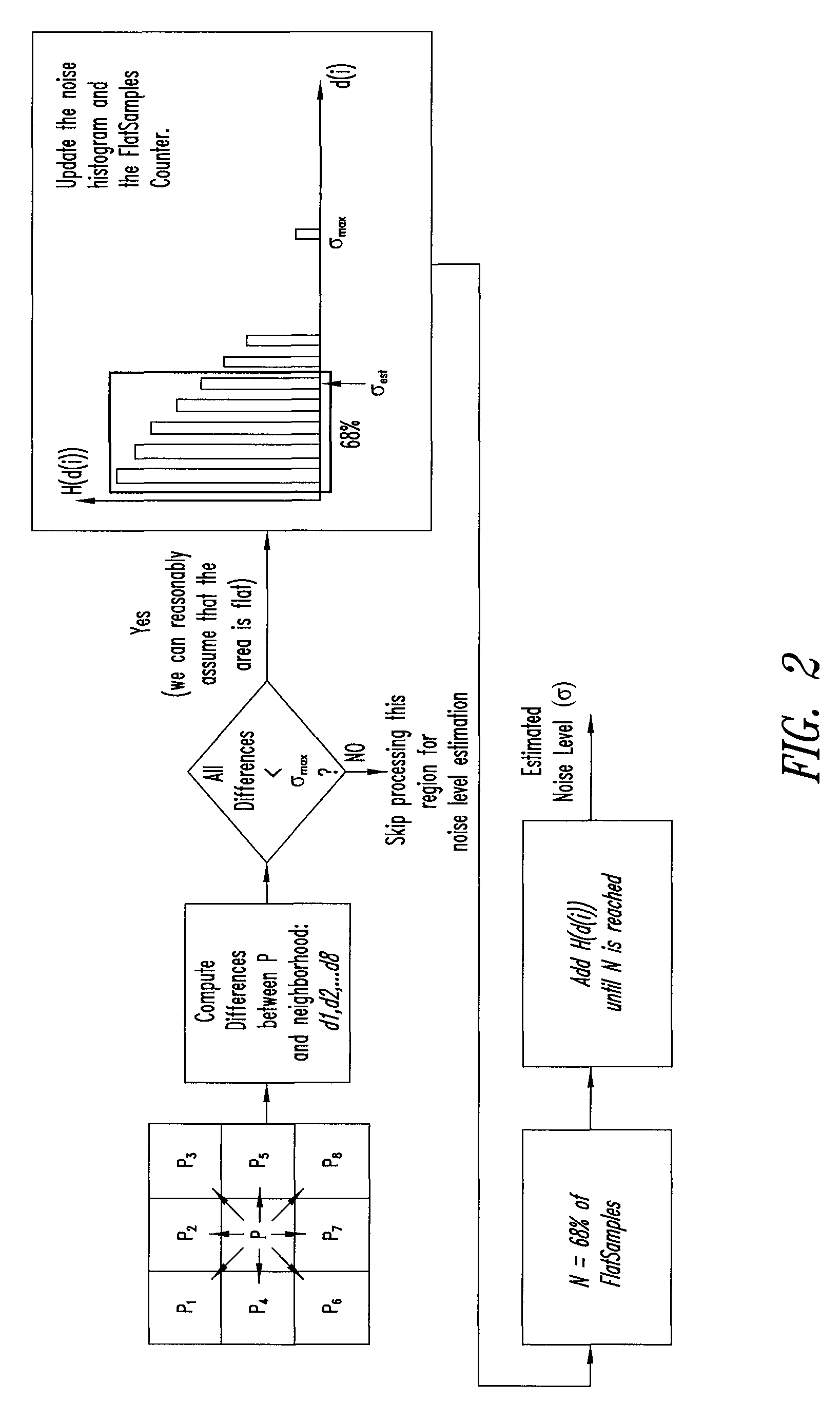

Method and relative device for estimating white gaussian noise that corrupts a digital image

ActiveUS20080085060A1Quickly calculate standard deviationLarge deviationImage enhancementImage analysisPattern recognitionDigital image

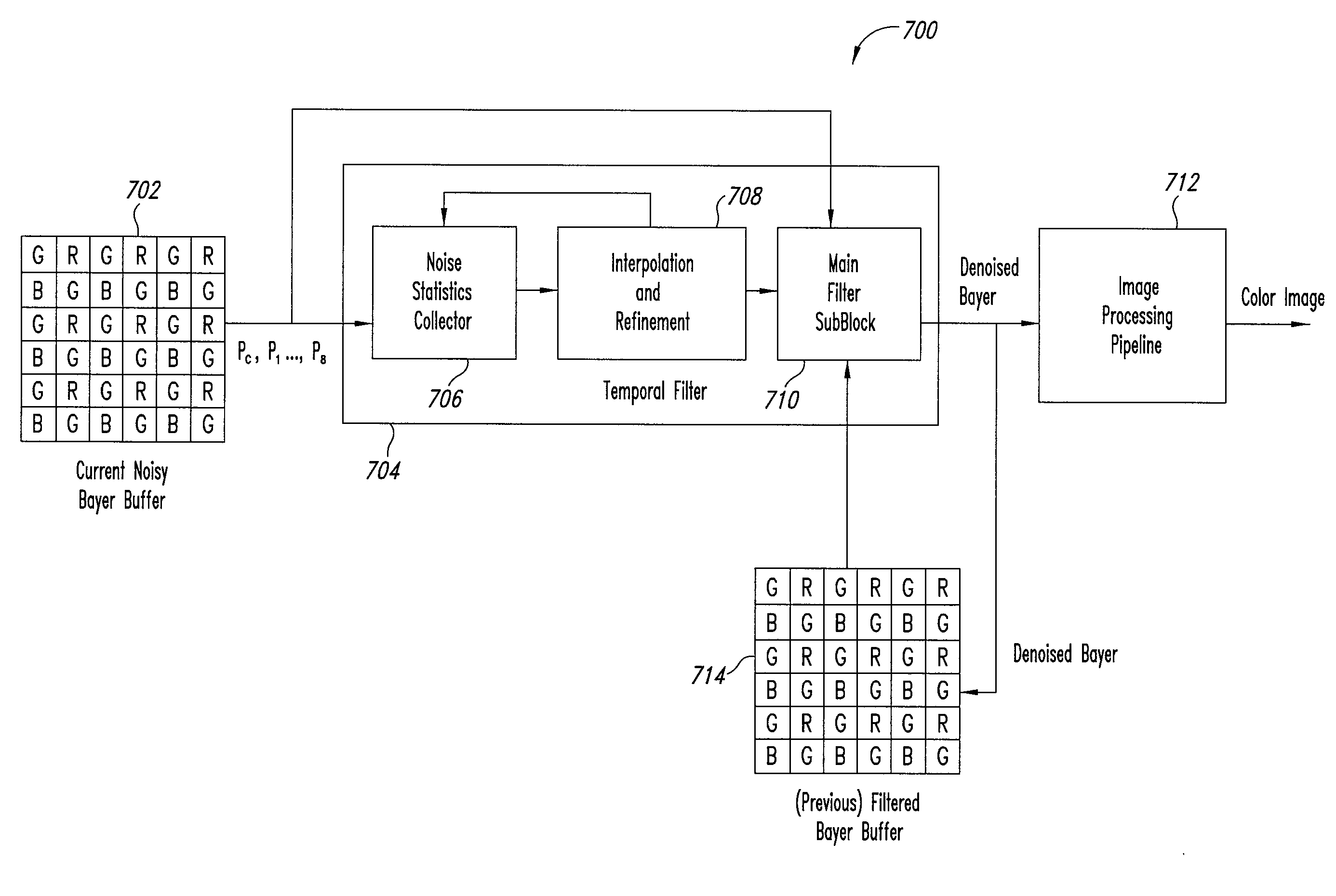

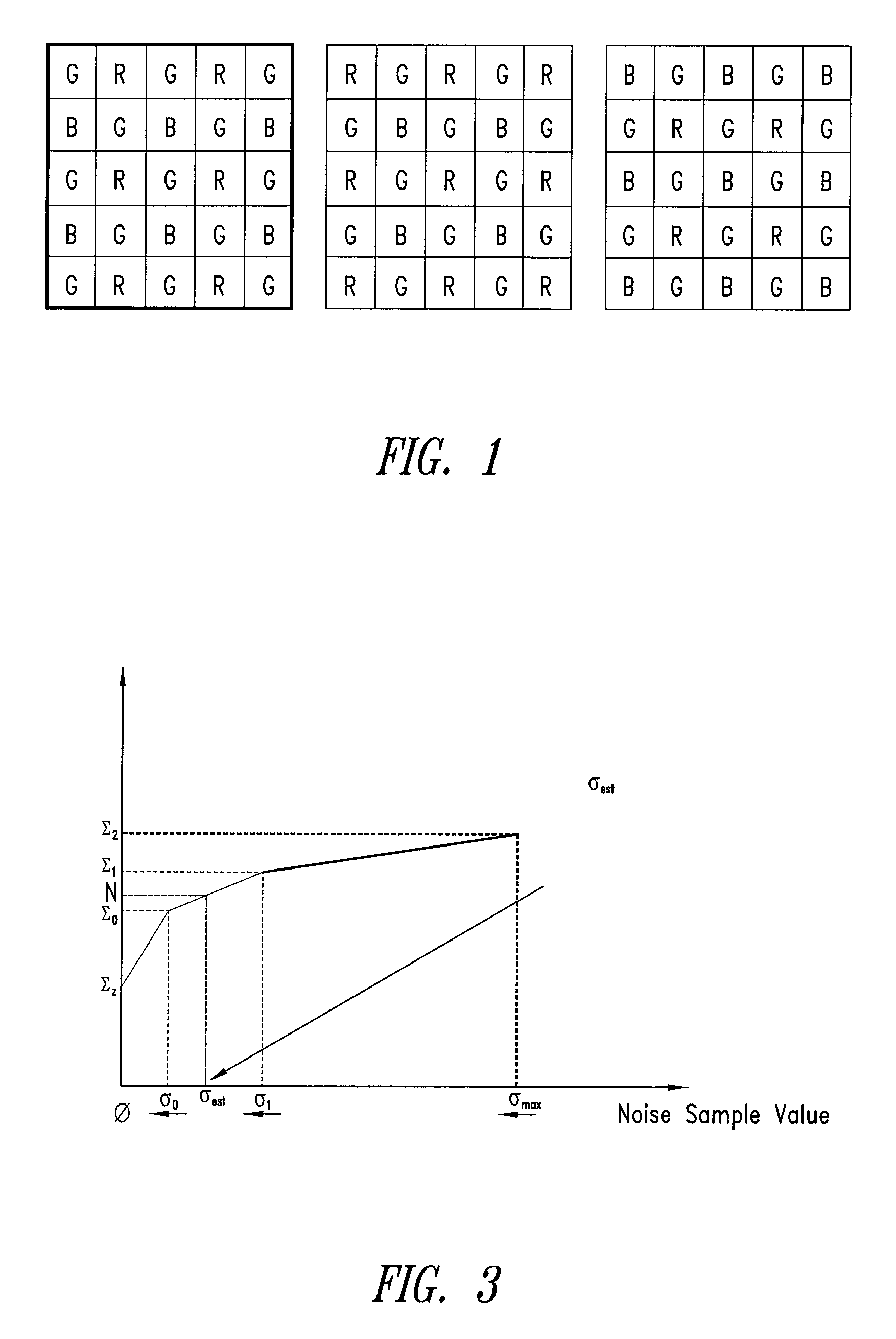

A method for estimating the white Gaussian noise level that corrupts a digital image by discriminating homogeneous blocks from blocks containing a textured area and skipping these last blocks when evaluating the noise standard deviation.

Owner:STMICROELECTRONICS SRL +1

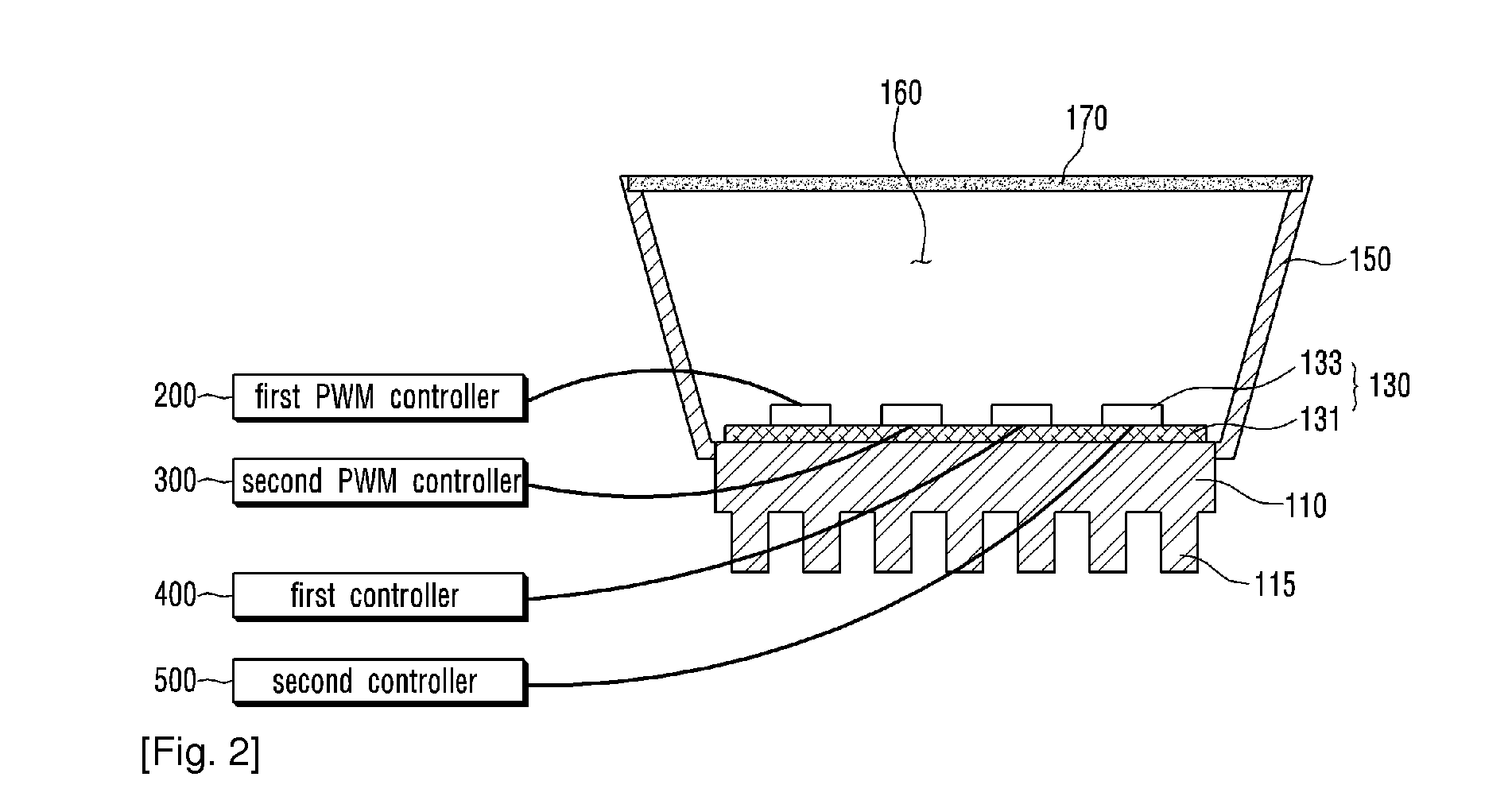

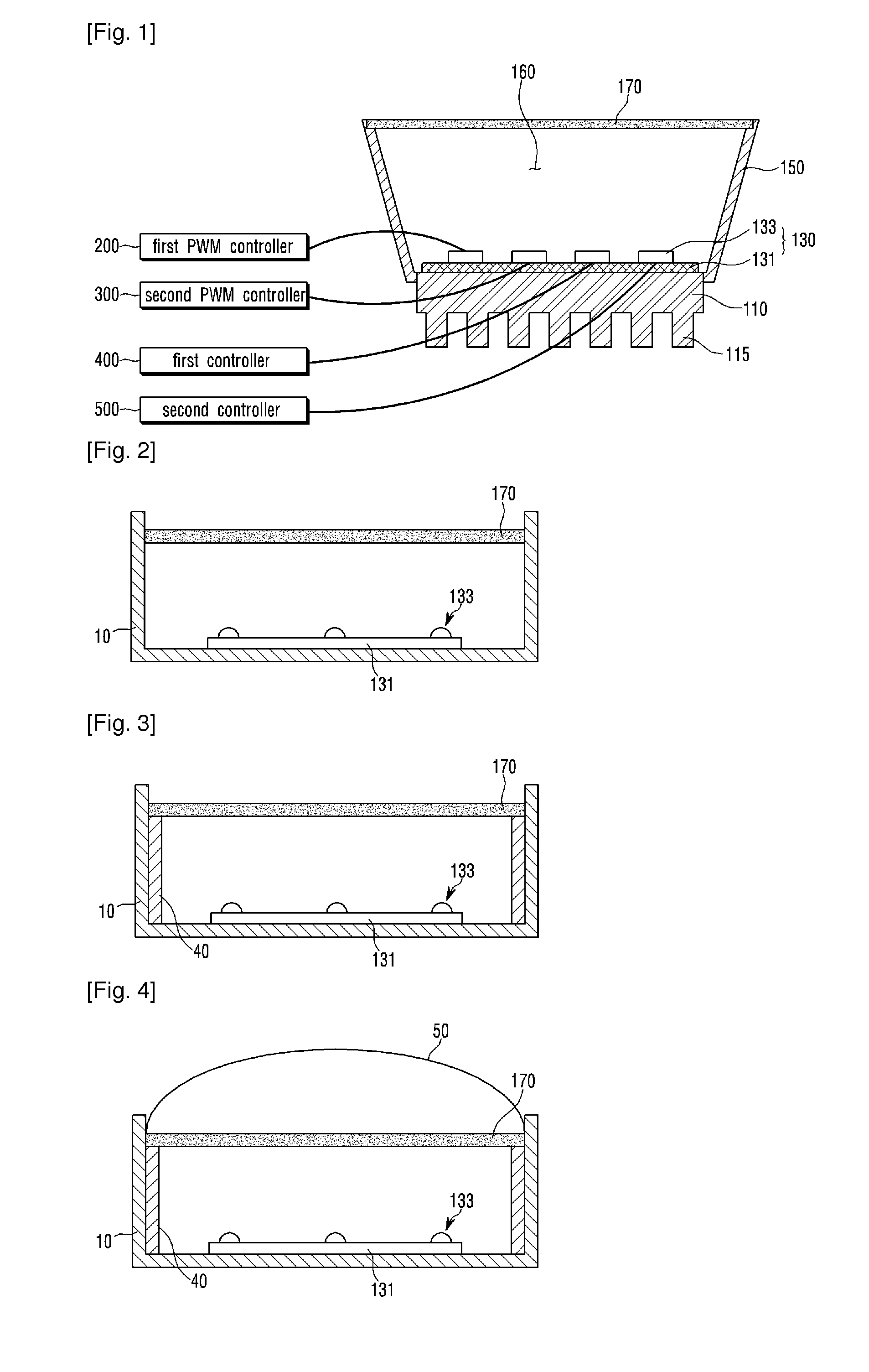

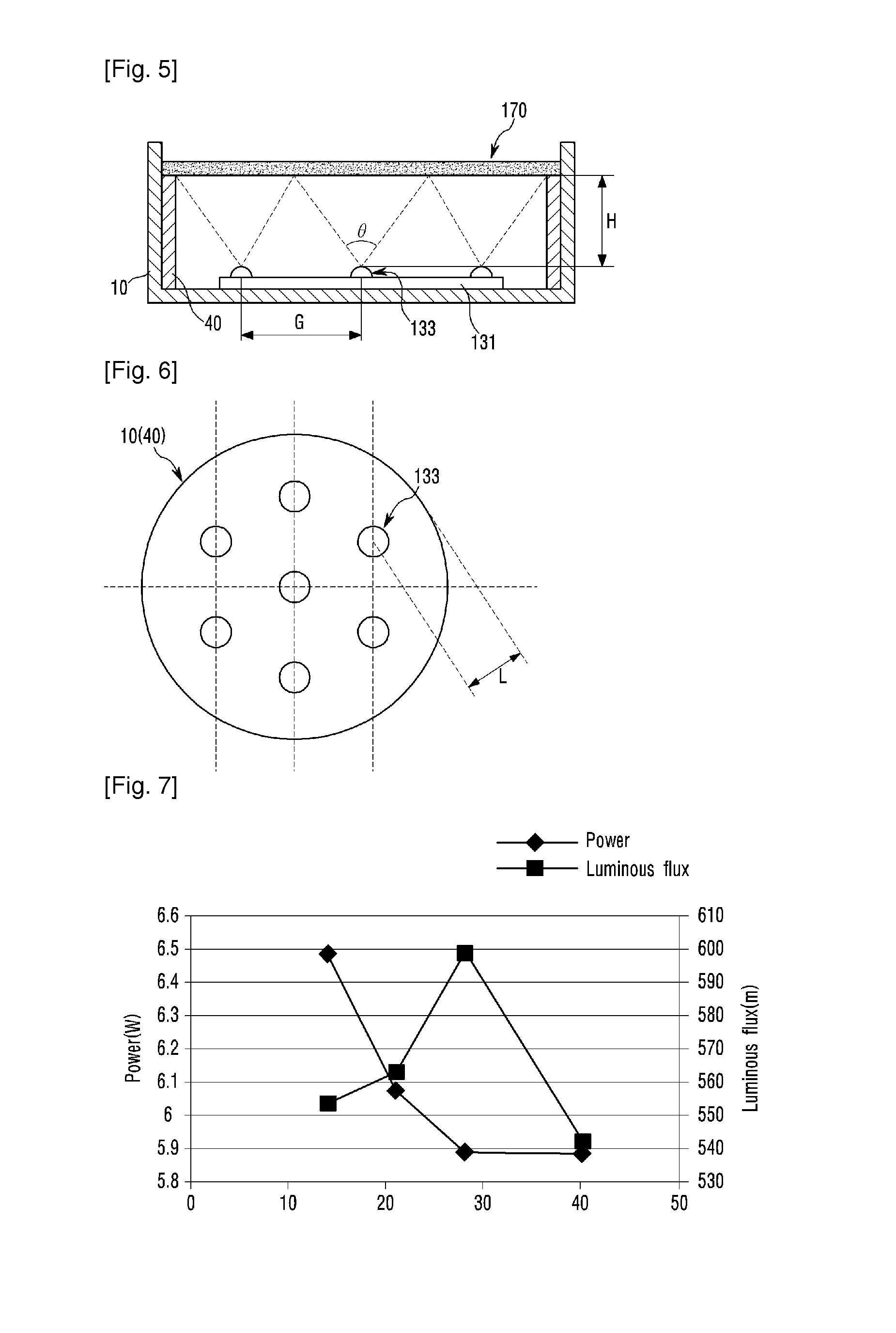

Lighting device and lighting control method

InactiveUS20140246990A1Good colorImprove efficiencyLight source combinationsElectrical apparatusBlack-body radiationEffect light

A lighting device may be provided that includes: a first to a fourth light emitting devices which are disposed on a substrate a first and a second pulse width modulation controllers which perform a pulse width modulation on currents applied to the first and the second light emitting devices respectively; and a first and a second controllers which control respectively currents applied to the third and the fourth light emitting devices having color temperatures different from those of the first and the second light emitting devices, wherein an (x, y) coordinate, which is determined by the mixture of the lights emitted from the first to the fourth light emitting devices and is located within a 1931 CIE chromaticity diagram, is moved onto a black body radiation curve within the 1931 CIE chromaticity diagram through the pulse width modulation of the first and the second pulse width modulation controllers and the control of the first and the second controllers.

Owner:LG INNOTEK CO LTD

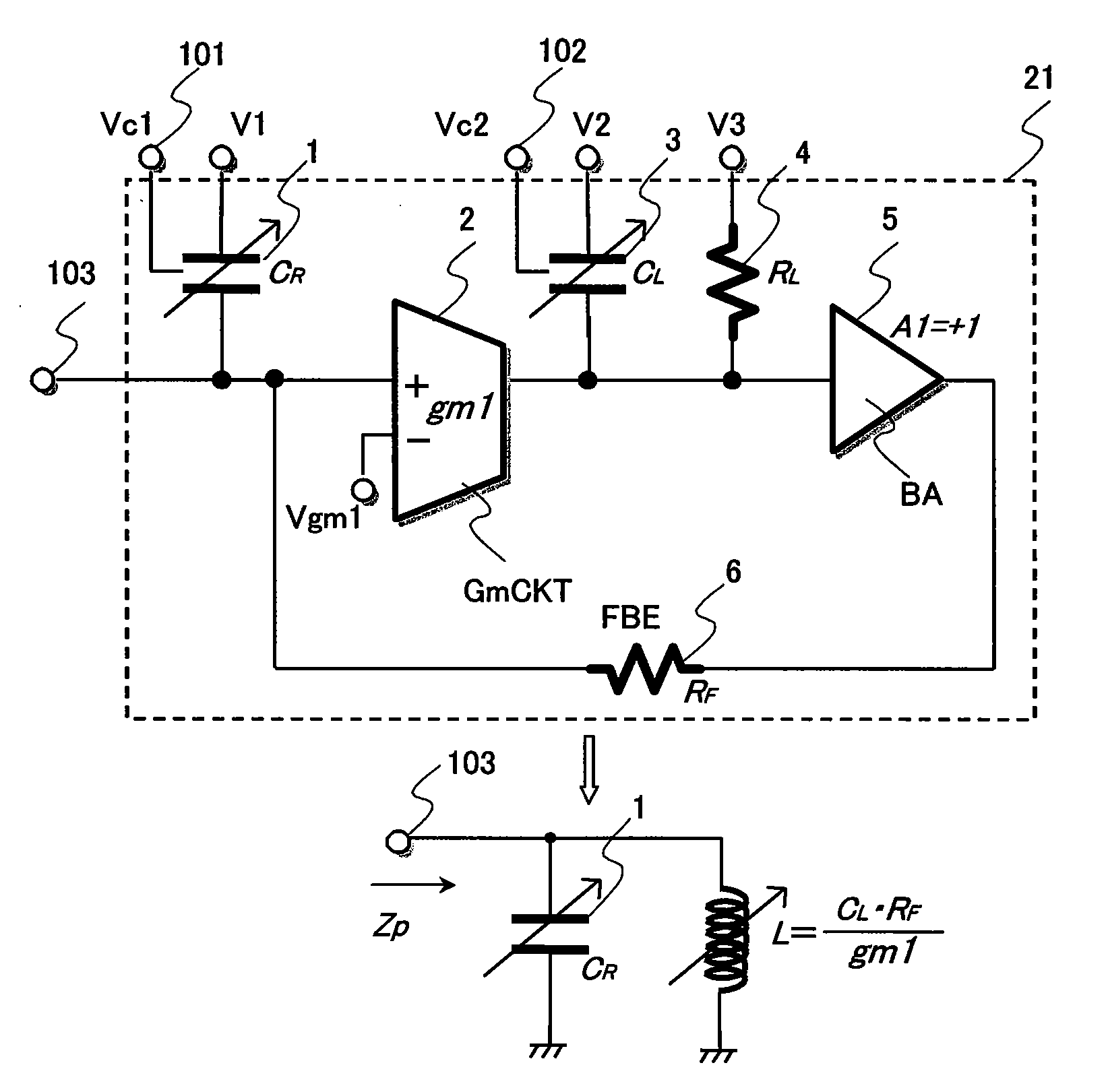

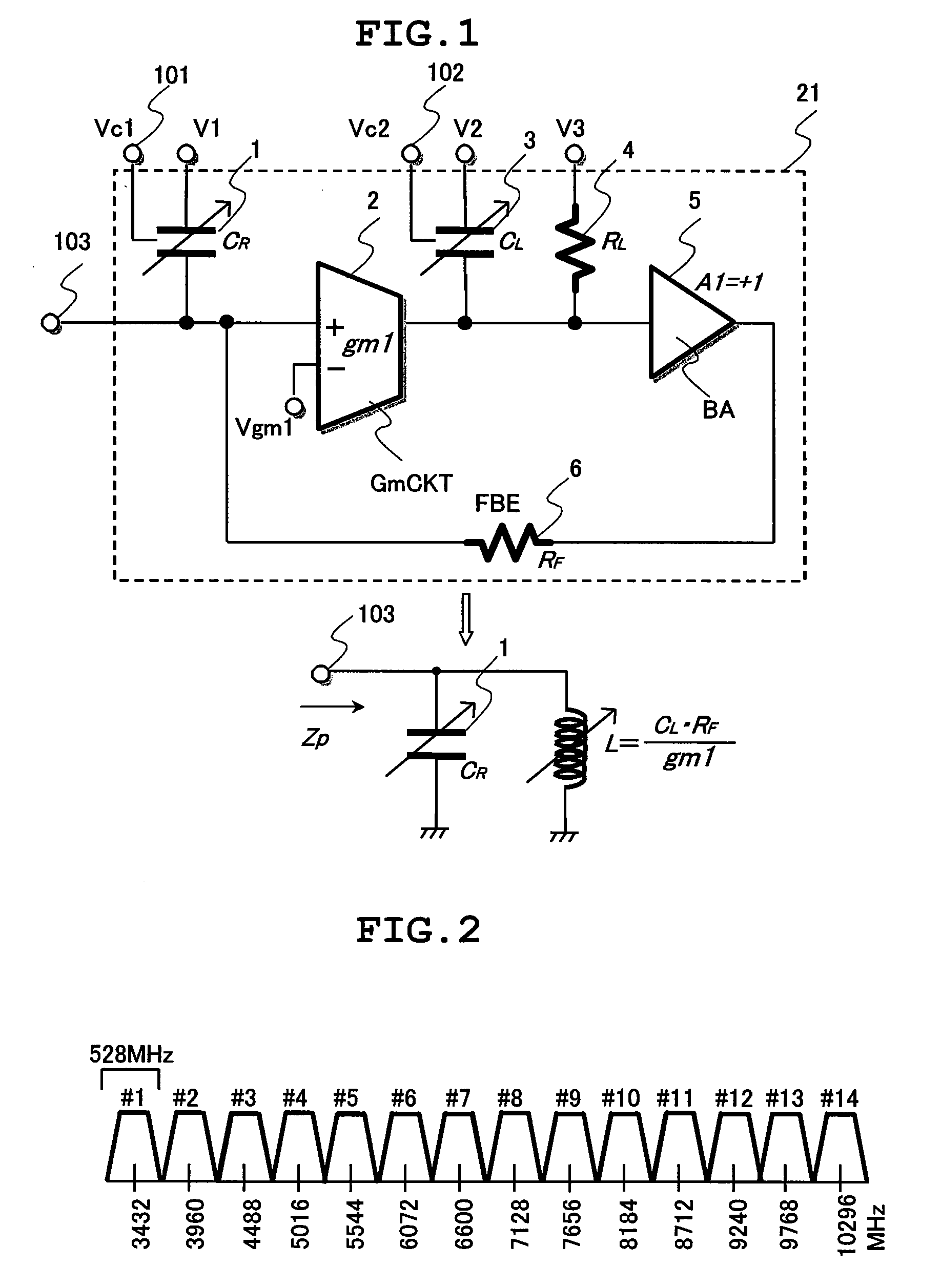

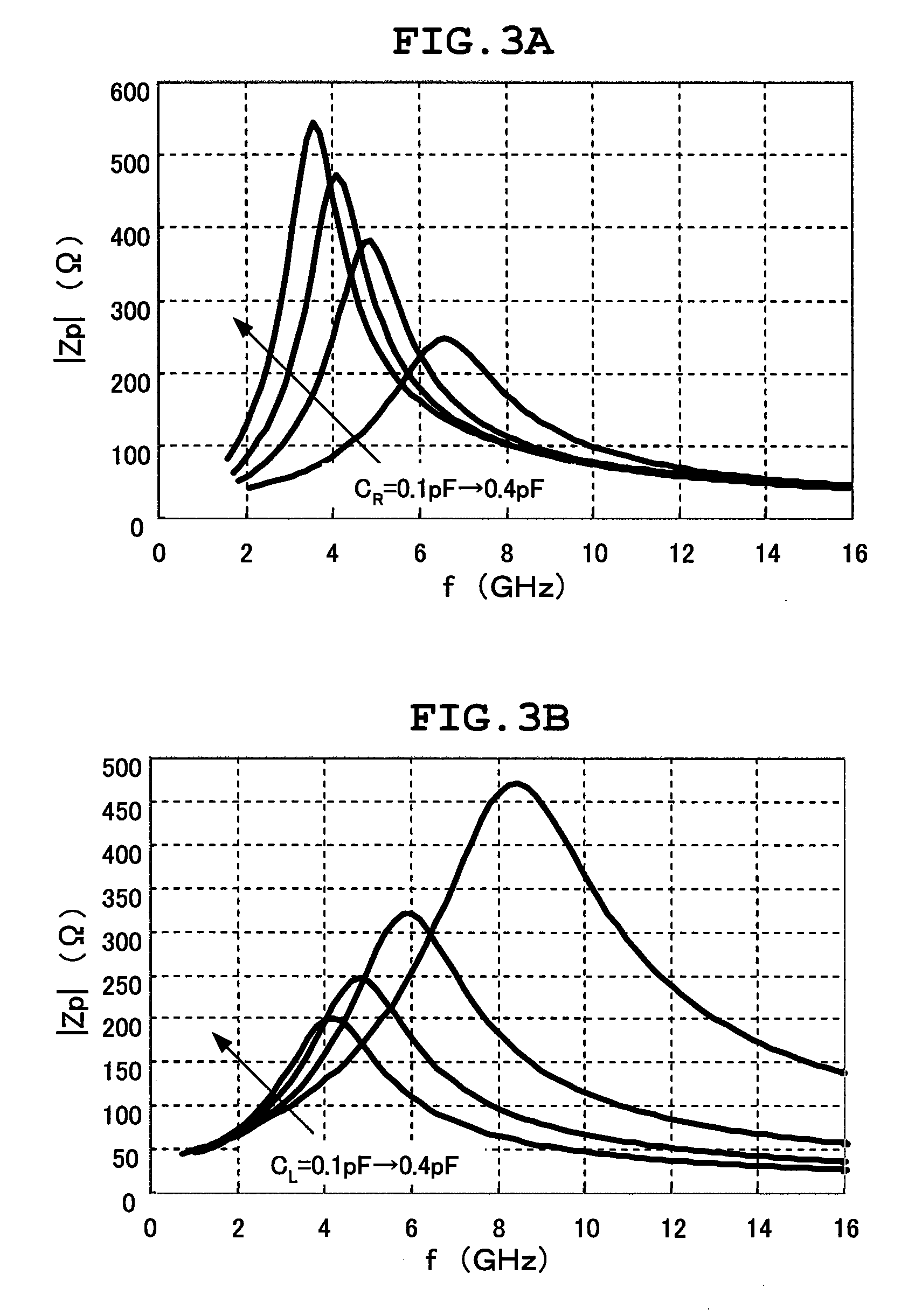

Active resonant circuit with resonant-frequency tunability

The present invention is directed to provide a low-power-consumption wide-range RF signal processing unit having a small chip occupation area. A semiconductor integrated circuit has, on a semiconductor chip, a resonant circuit including a first capacitor having a capacitance which can be controlled by a first control signal of a first control terminal, and a gyrator for equivalently emulating an inductor by including a second capacitor having a capacitance which can be controlled by a second control signal of a second control terminal. The capacitance and the inductor form a parallel resonant circuit. At the time of changing parallel resonant frequency, the capacitances of the first and second capacitors are coordinately changed. The parallel resonant circuit is suitable for an active load which is connected to an output node of an amplifier.

Owner:RENESAS ELECTRONICS CORP

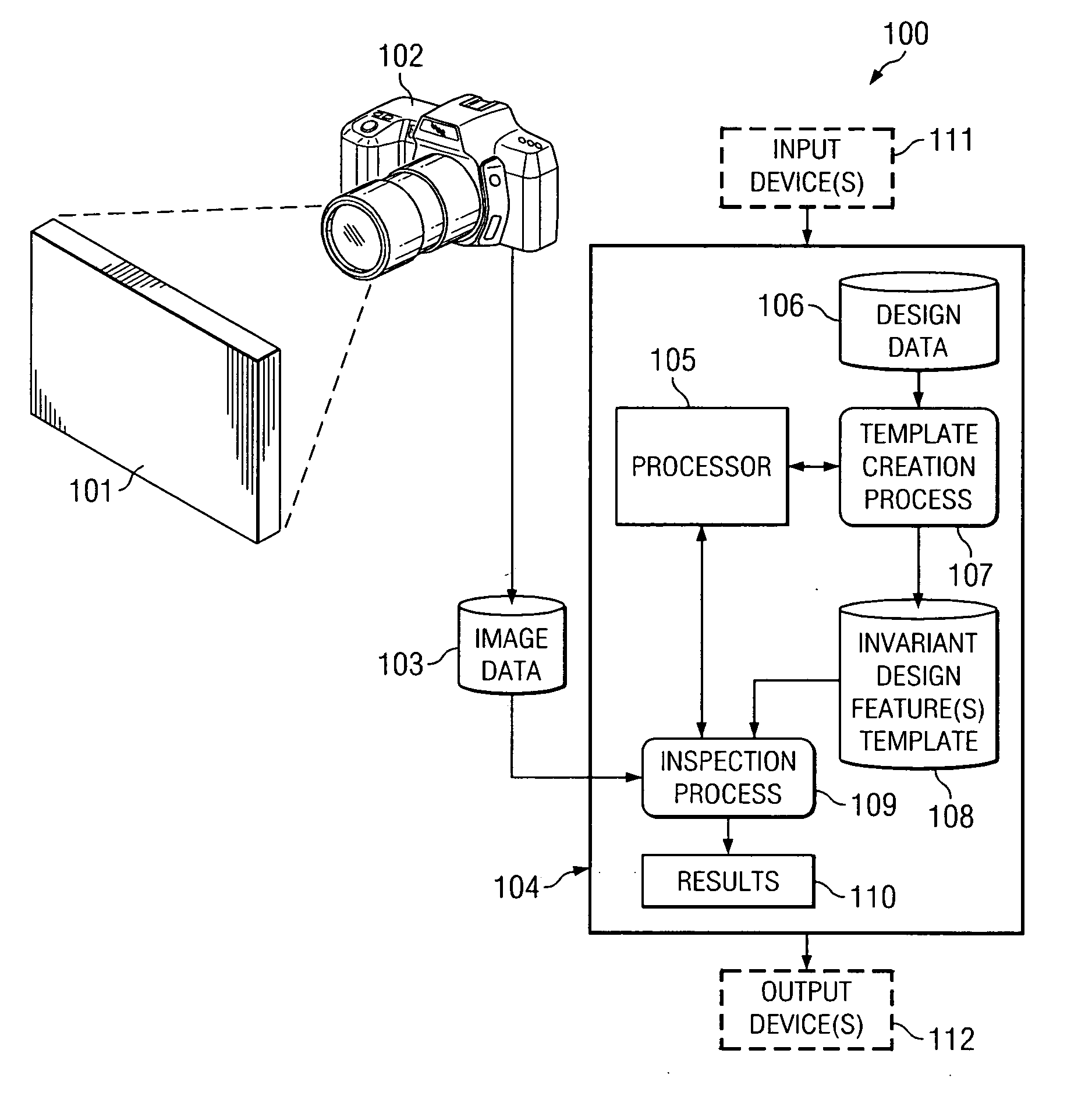

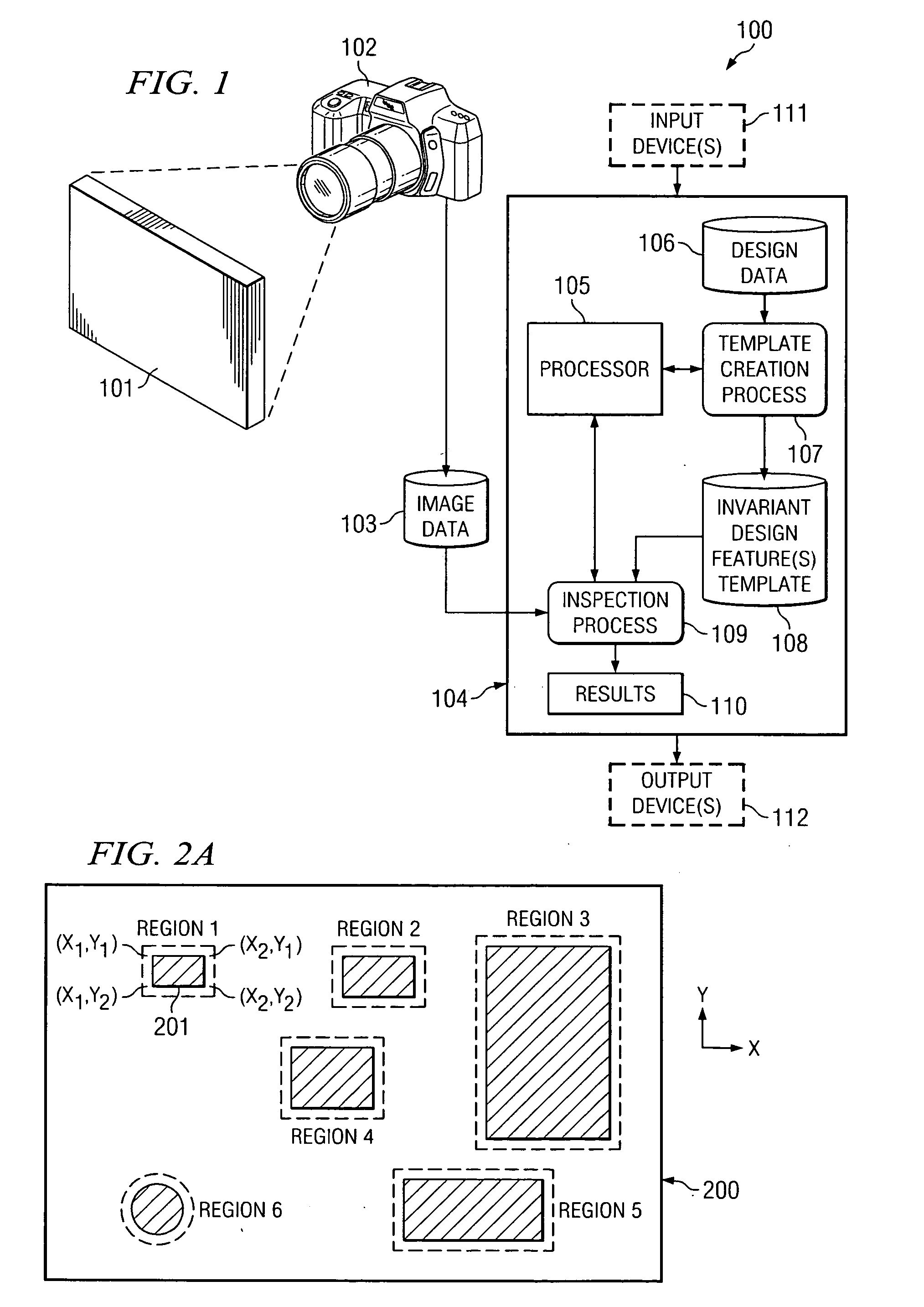

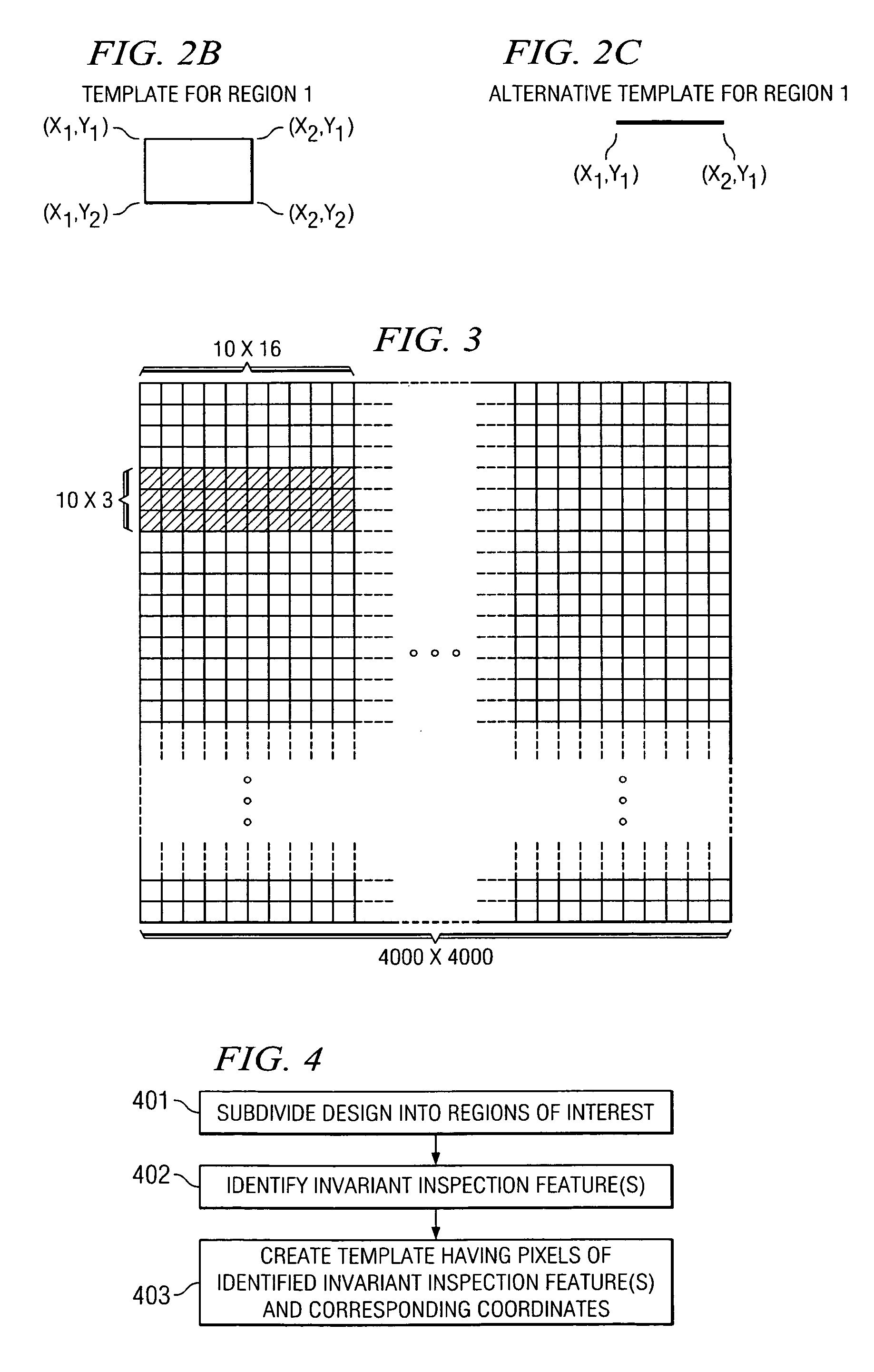

System and method for performing automated optical inspection of objects

InactiveUS20050281452A1Improve efficiencyReduce in quantityImage enhancementImage analysisBrightness perceptionAutomated optical inspection

A system and method for performing optical inspection are provided. At least one “invariant feature” of an object design is determined, and such invariant feature is used in inspecting objects having the corresponding design. An “invariant feature” is a feature that is invariant certain transformations occurring in a captured image of an object under inspection, such as brightness, color, and / or other transformations in the captured image. Accordingly, an inspection template may comprise information corresponding to at least one pre-selected invariant feature of an object's design. In certain embodiments, the template is a shape description of a feature that provides an intrinsic invariance to a specified set of basic transformations. Accordingly, the amount of pixel values stored in a template may be minimized, which minimizes the number of pixel comparisons made between a captured image of the object under inspection and the inspection template during the inspection analysis.

Owner:AGILENT TECH INC

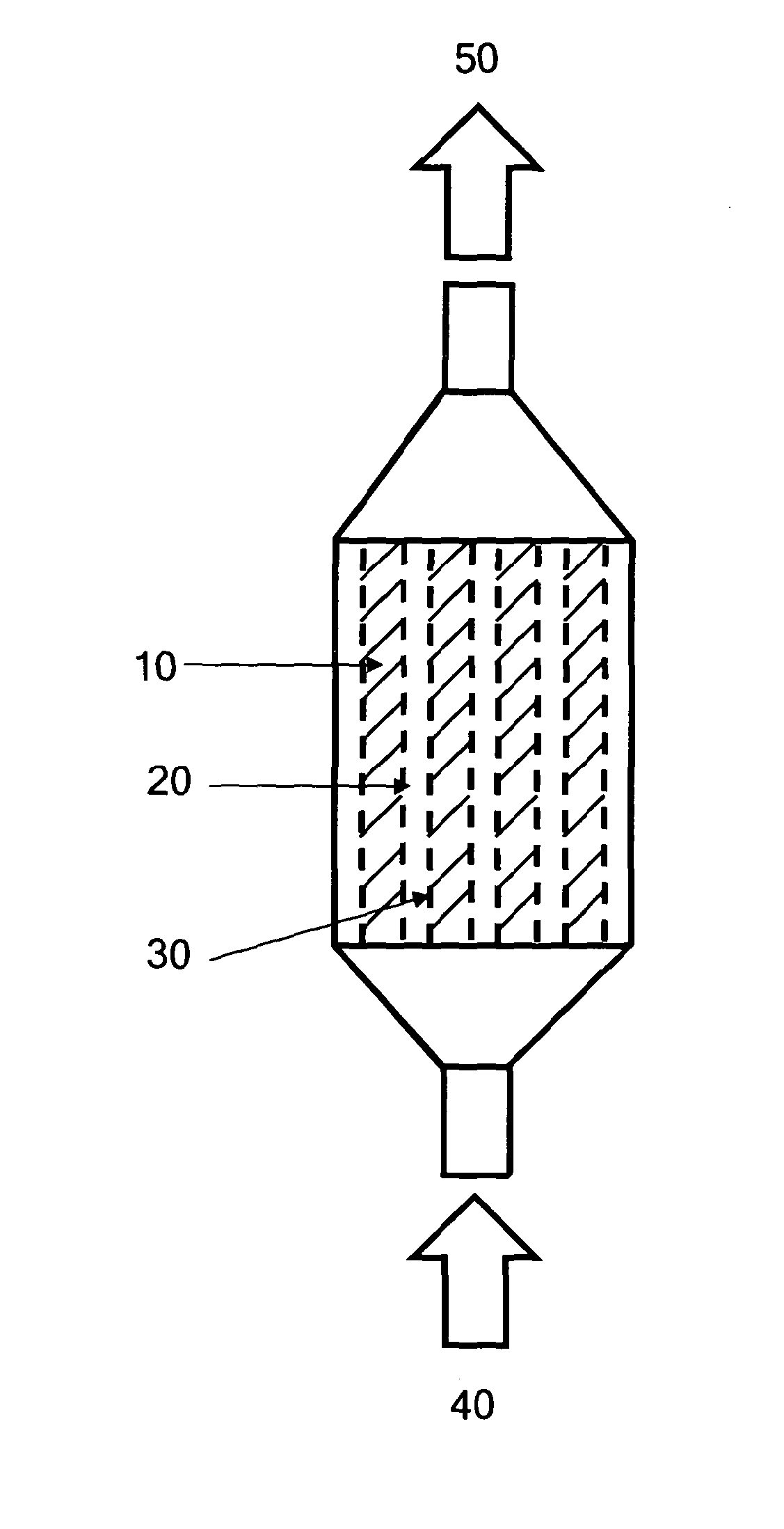

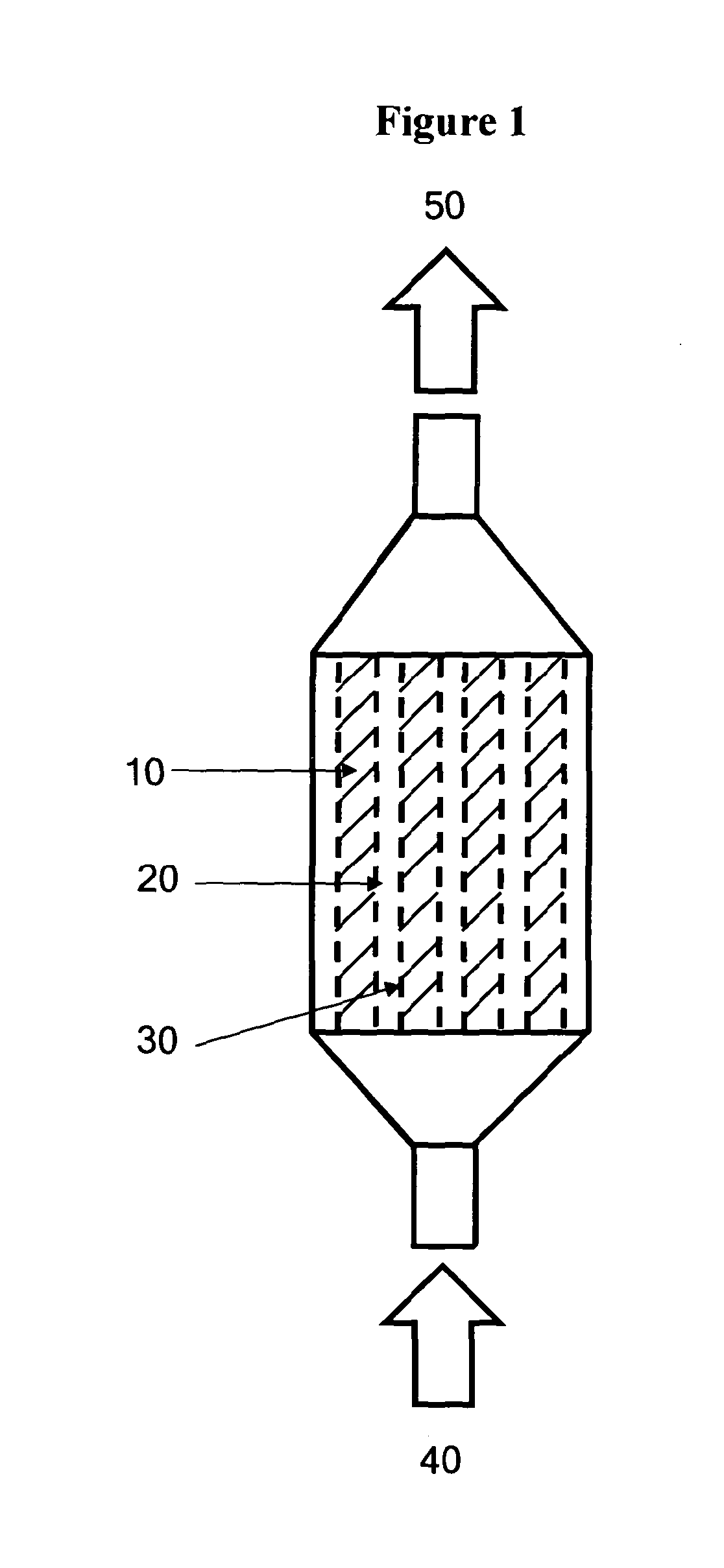

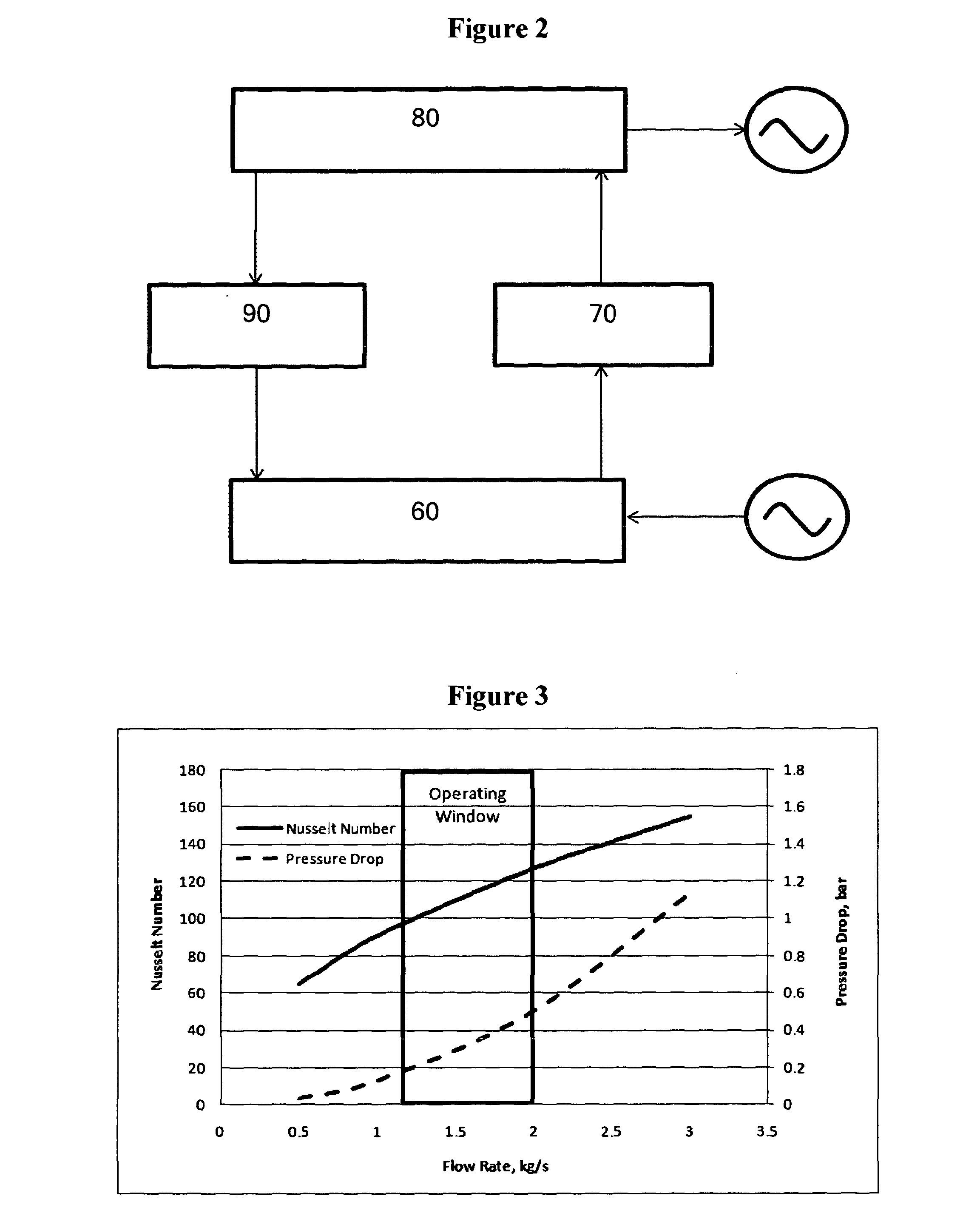

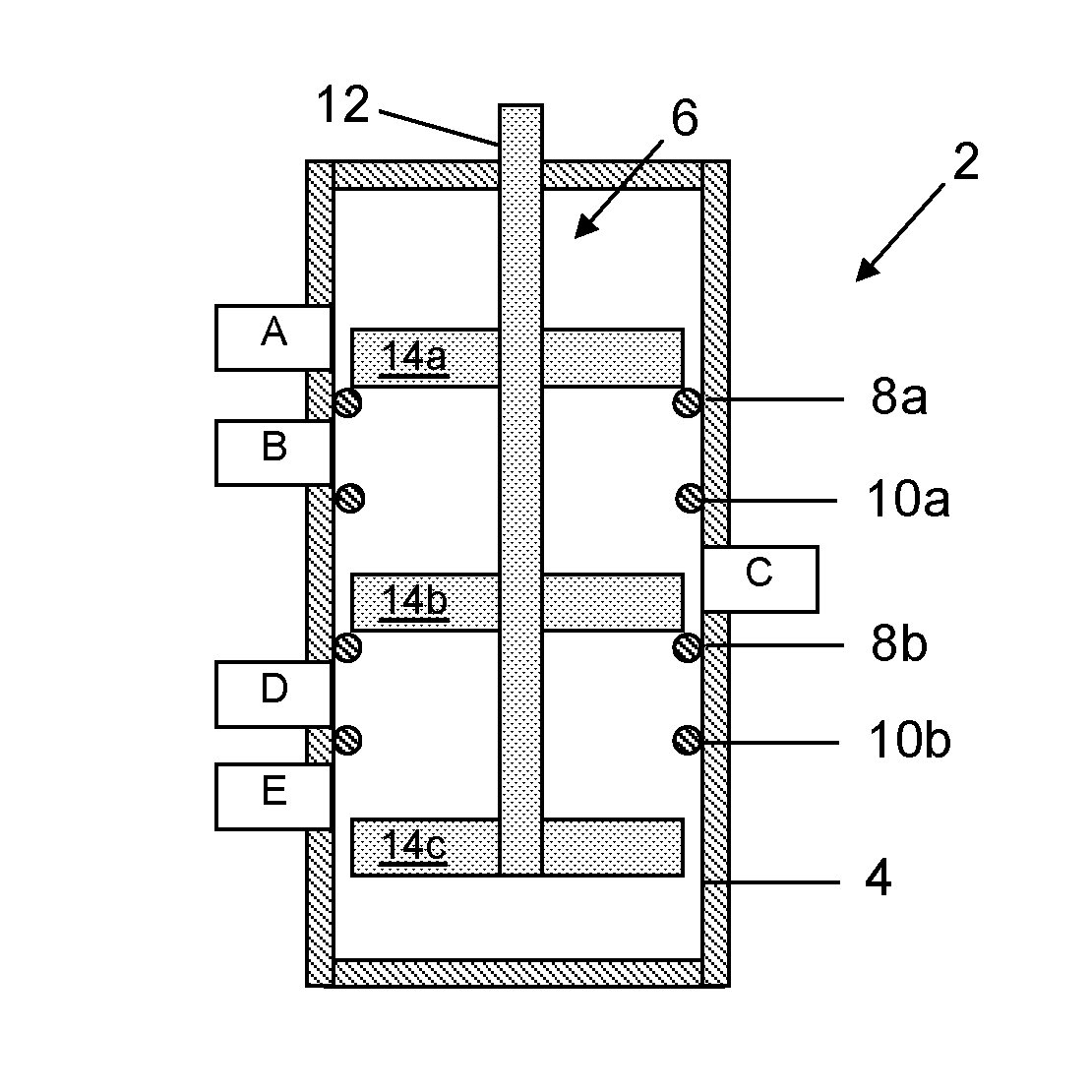

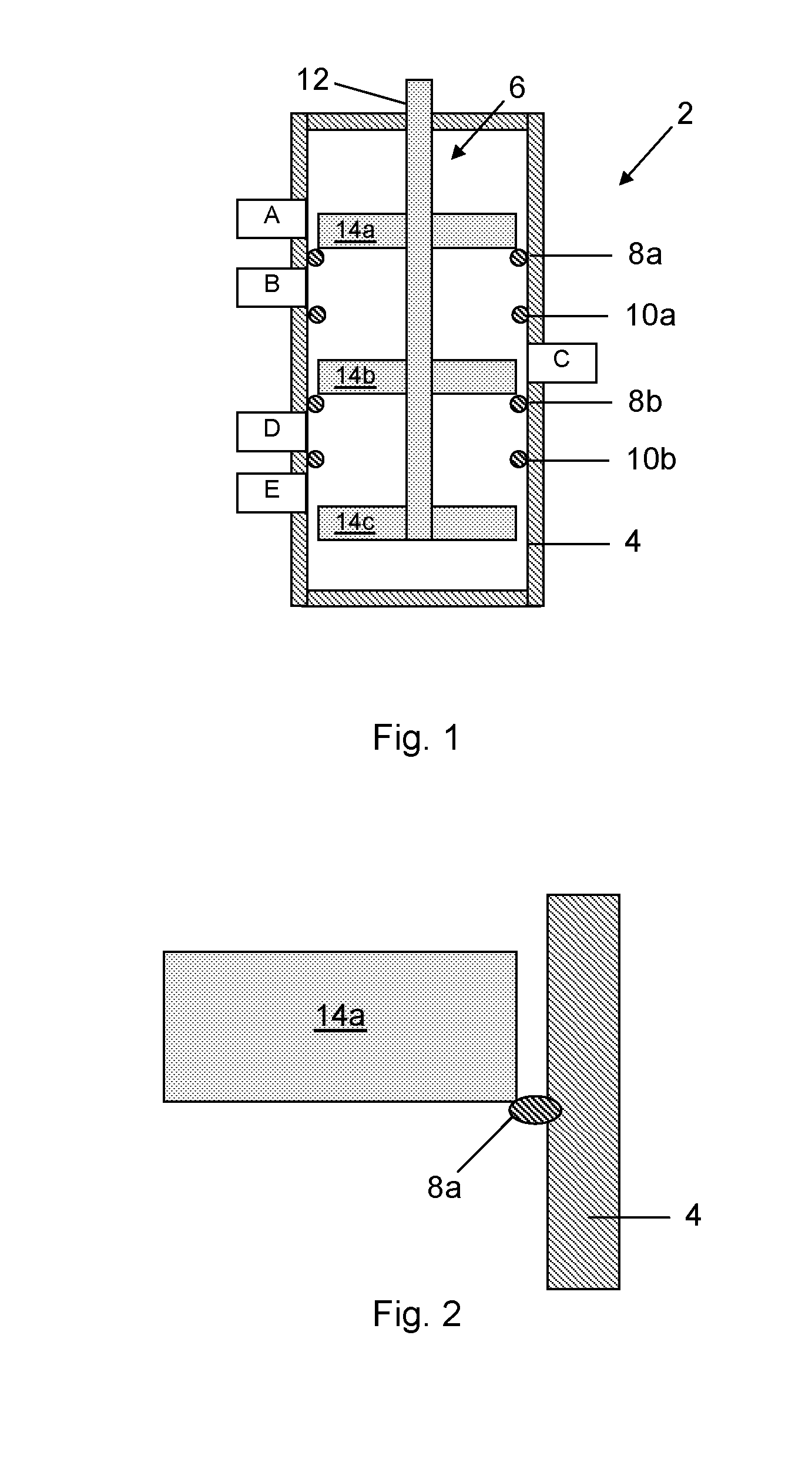

Method and apparatus for storing thermal energy

ActiveUS20130240171A1Maximizes thermal efficiencyDifferent flow rateHeat storage plantsHeat exchange apparatusThermal energyCharge and discharge

Methods and apparatus for storing thermal energy are disclosed. The thermal energy may be hot or cold. The methods and apparatus allow the thermal store to be charged and discharged at different rates. The methods and apparatus also allow the thermal store to be charged and discharged with multiple and / or interrupted phases.

Owner:HIGHVIEW ENTERPRISES LTD

Dividing method for working region of self-moving device, dividing apparatus, and electronic device

InactiveUS20190346848A1High positioning accuracyReduce biasAutonomous decision making processElectric testing/monitoringMobile deviceComputer science

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

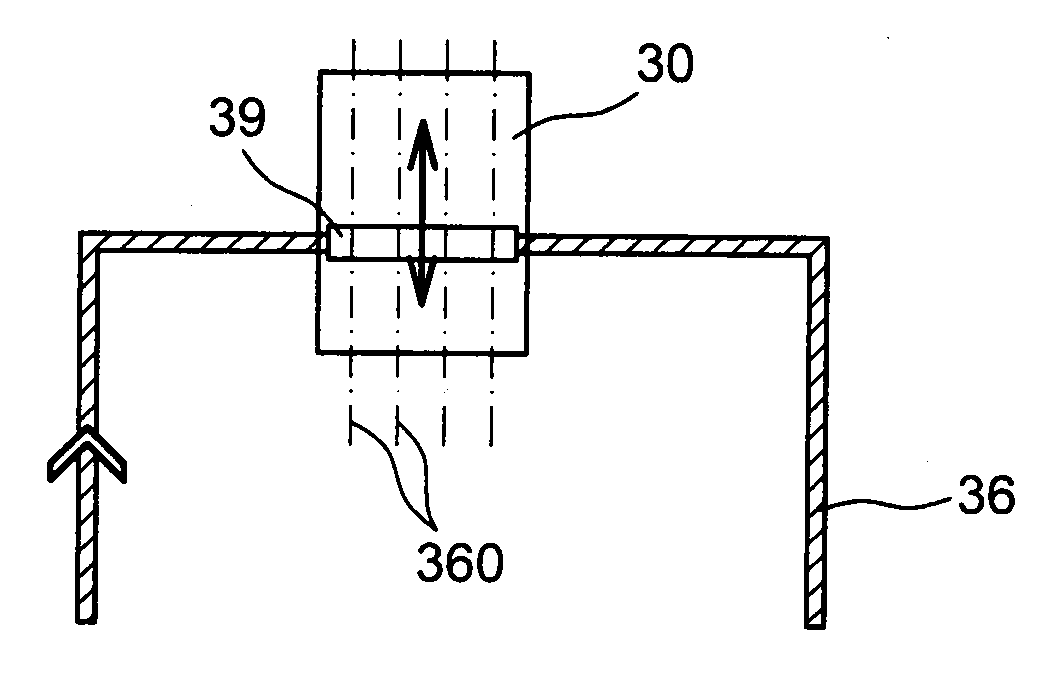

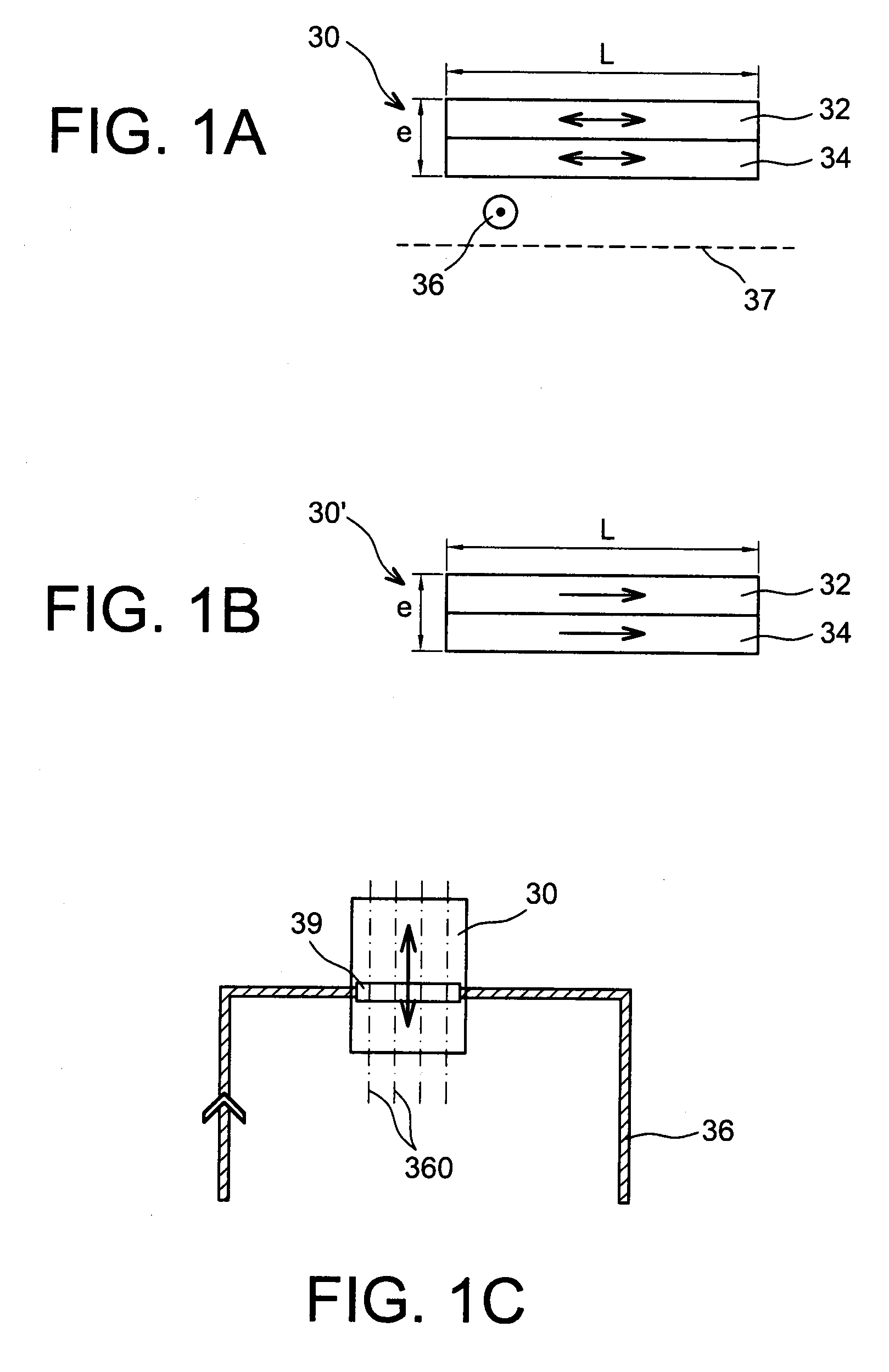

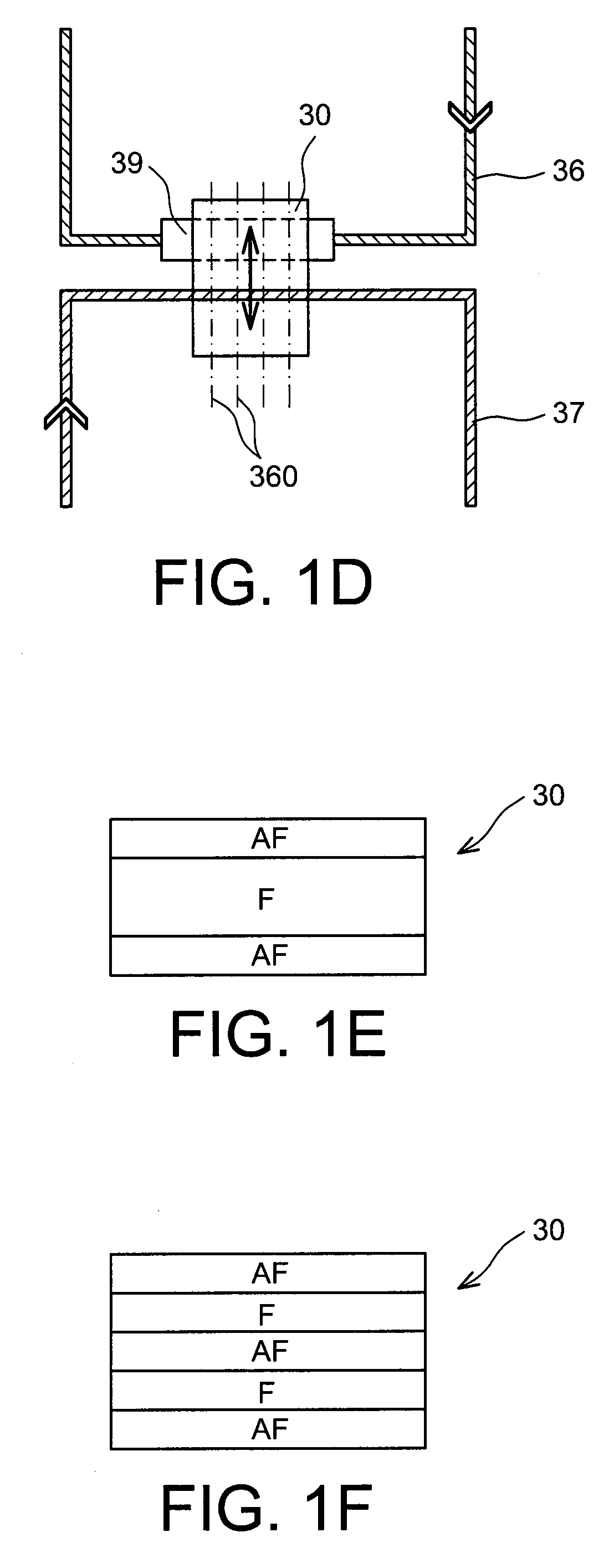

Magnetic nano-resonator

ActiveUS20090289747A1Movement can be detectedWide amplitudeMagnetic measurementsImpedence networksEngineeringResonator

A nano-resonator device comprising at least one fixed element and at least one mobile element with respect to the fixed element, first electromagnetic means, integrated or fixed on the fixed element, and second electromagnetic means, integrated or fixed on the mobile element, to generate an oscillating movement of the mobile element.

Owner:EDISON WELDING INSTITUTE INC +1

GC-IRMS direct measurement method for hydrogen sulfide sulfur isotope in mixed gas

InactiveCN101936964ASimple and fast operationLess sample volumeComponent separationSmall sampleGas phase

The invention relates to a GC-IRMS direct measurement method for hydrogen sulfide sulfur isotope in mixed gas, which comprises the steps of: firstly, by utilizing a gas chromatogram-stable isotope ratio mass spectrum combined instrument with I s o d a t N T 2.0 software, carrying out the magnetic field control so that an intermediate receiving cup receives ions with the receiving charge-to-mass ratio of 35, which are 35H2S, and correspondingly, receiving cups on two sides respectively receive ions with charge-to-mass ratios of 34 and 36, which are 34H2S and 36H2S, and recording a numerical value of a magnetic filed at the moment; then correcting the instrument by H2S reference gas; secondly, injecting a plurality of gas samples containing 1-5ml H2S into a gas chromatograph in the instrument, and meanwhile obtaining gas chromatograms of 36H2S, 35H2S and 34H2S and gas chromatograms of ratios of 36H2S / 34H2S and 35H2S / 34H2S; finally, processing obtained data to gain a value of hydrogen sulfide sulfur isotope in a mixed gas sample. The GC-IRMS direct measurement method has the characteristics of simpleness, rapidness, accuracy and small sample consumption, and does not need sample preparation and correction of interference isotopes.

Owner:LANZHOU CENT FOR OIL & GAS RESOURCES INST OF GEOLOGY & GEOPHYSICS CAS

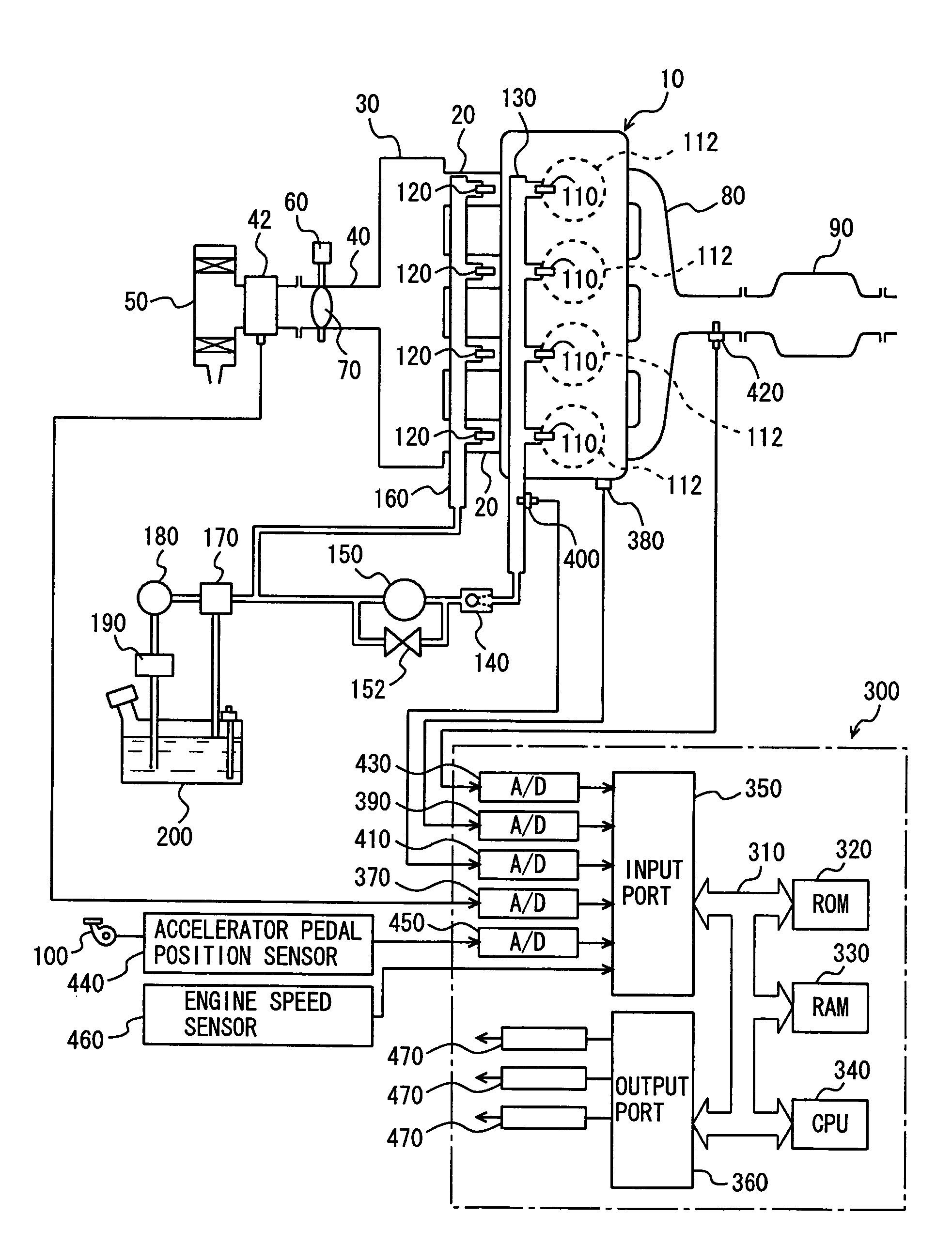

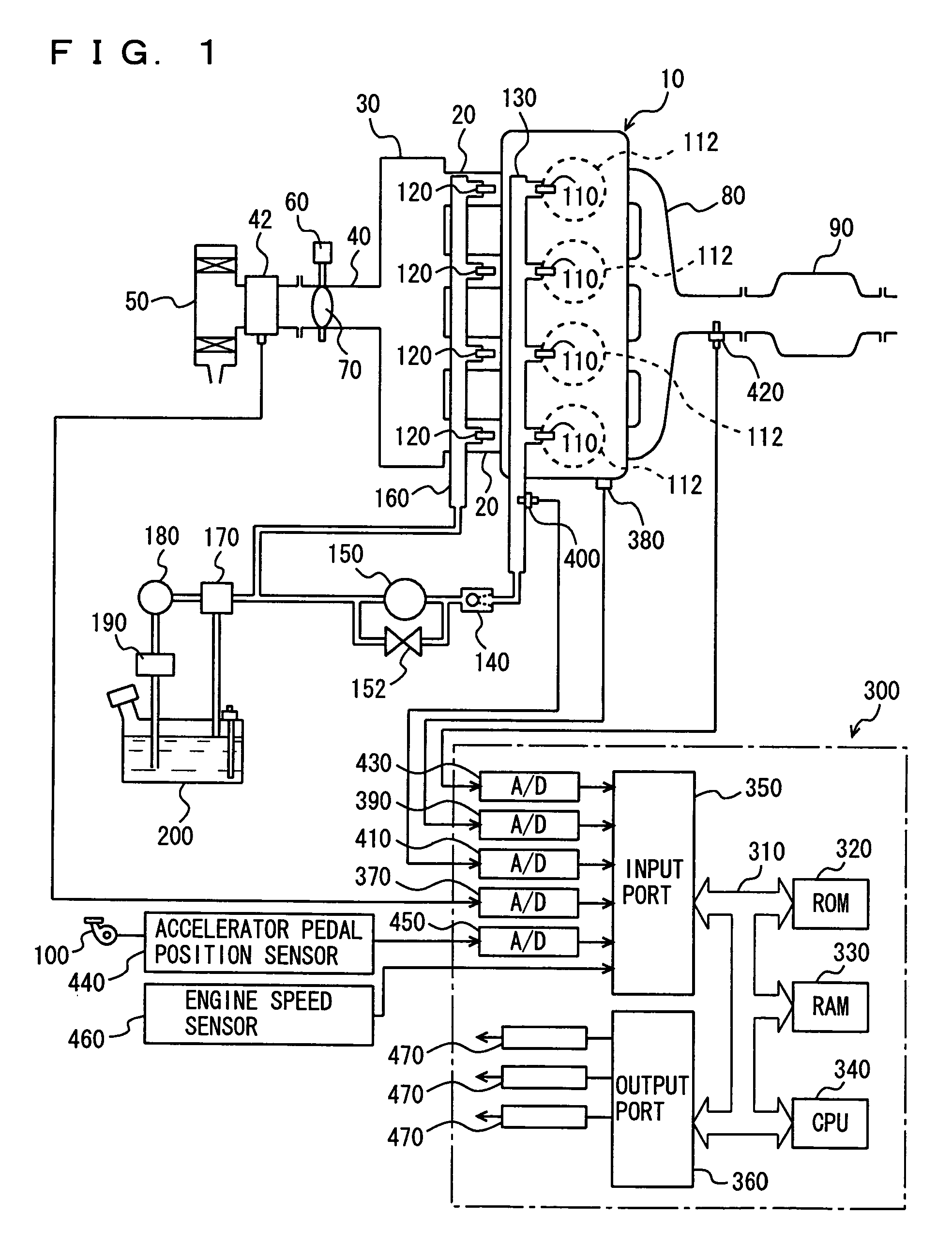

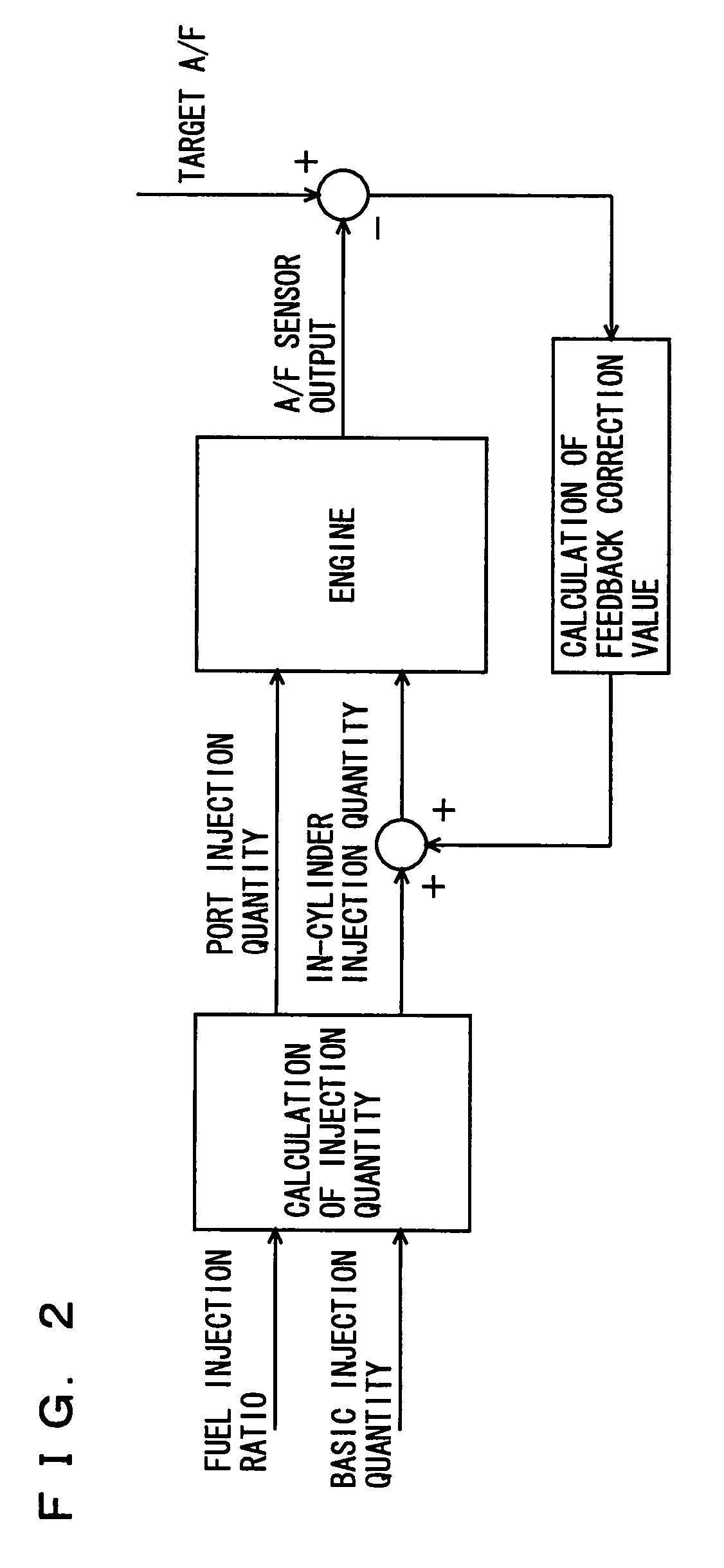

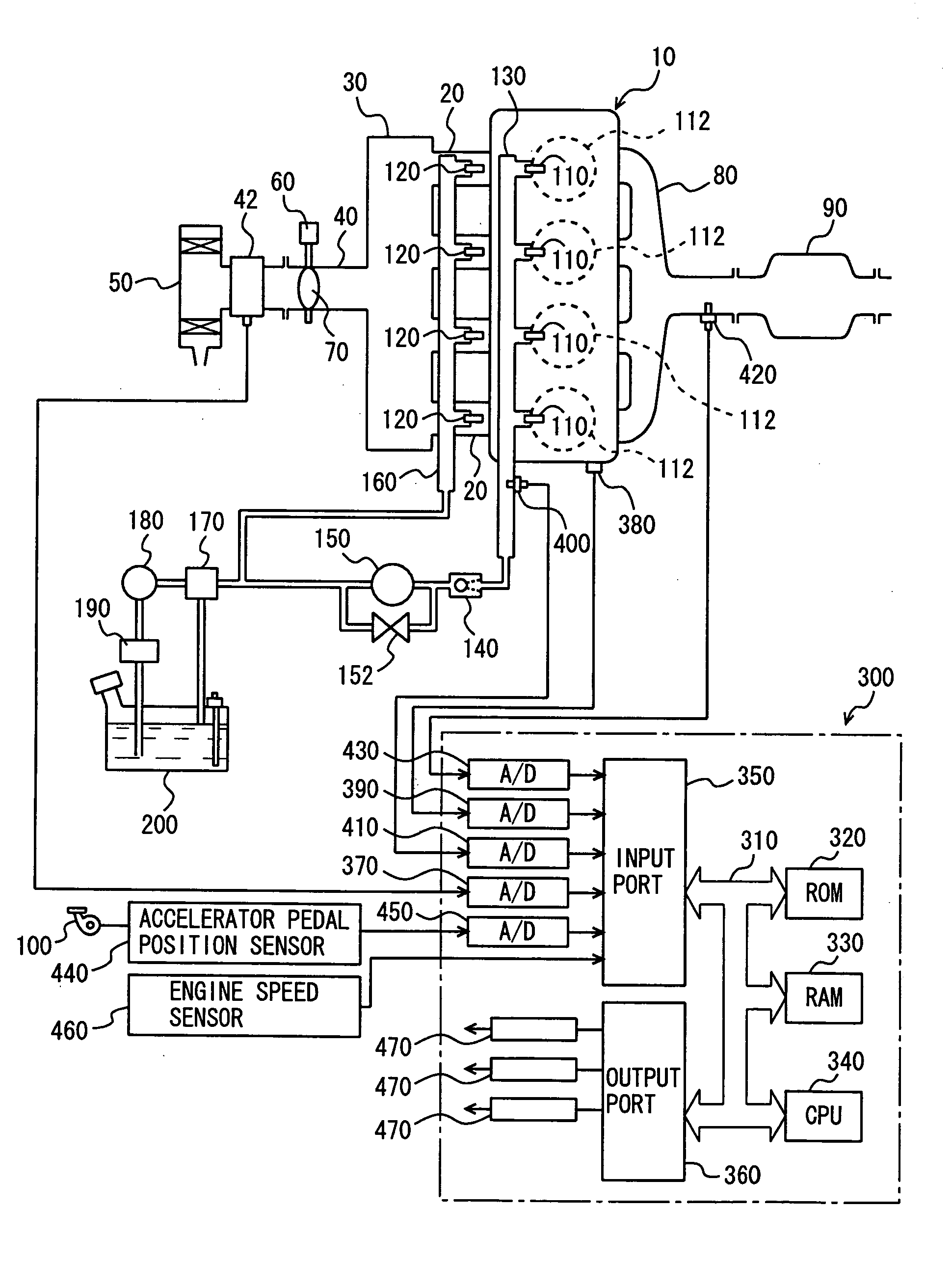

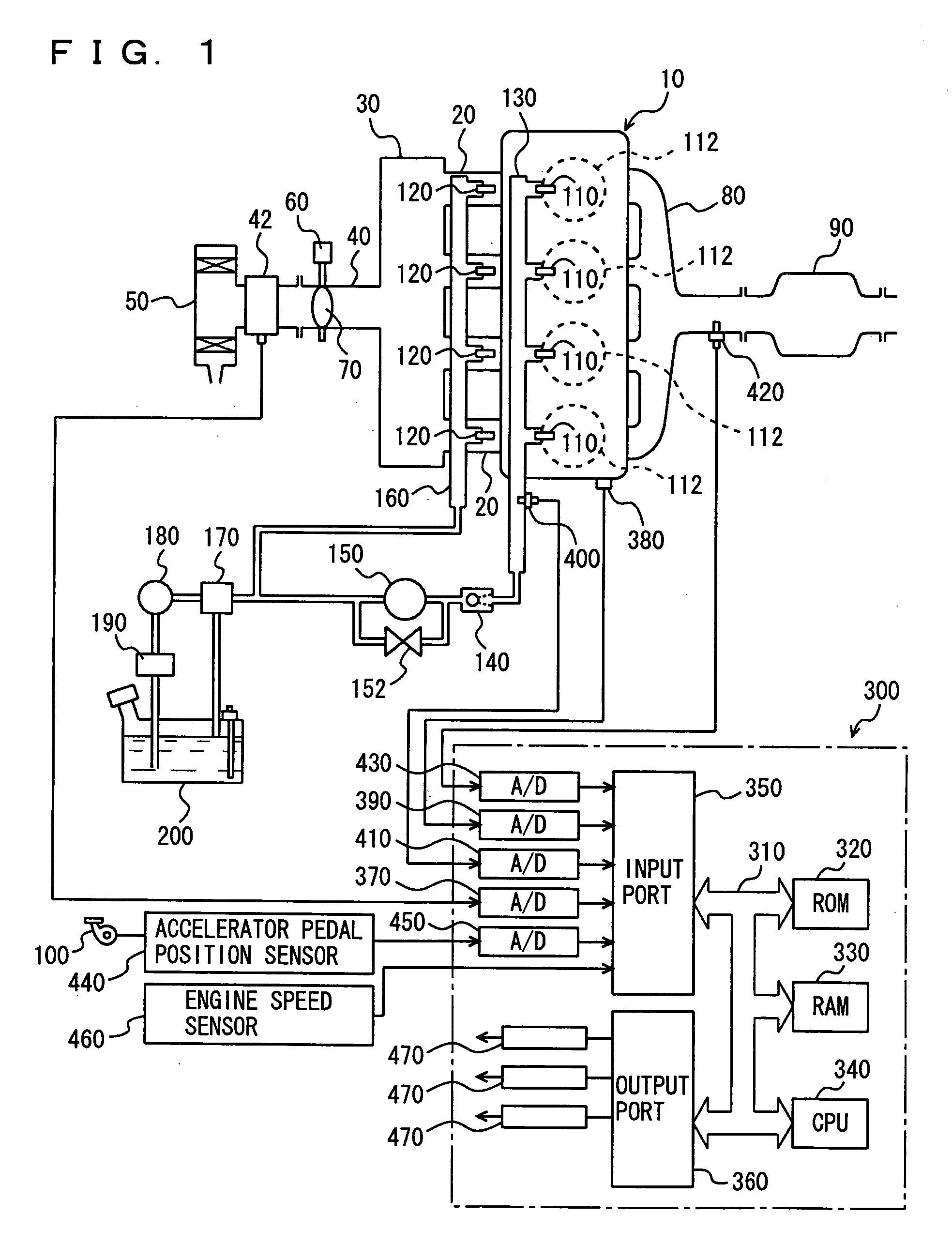

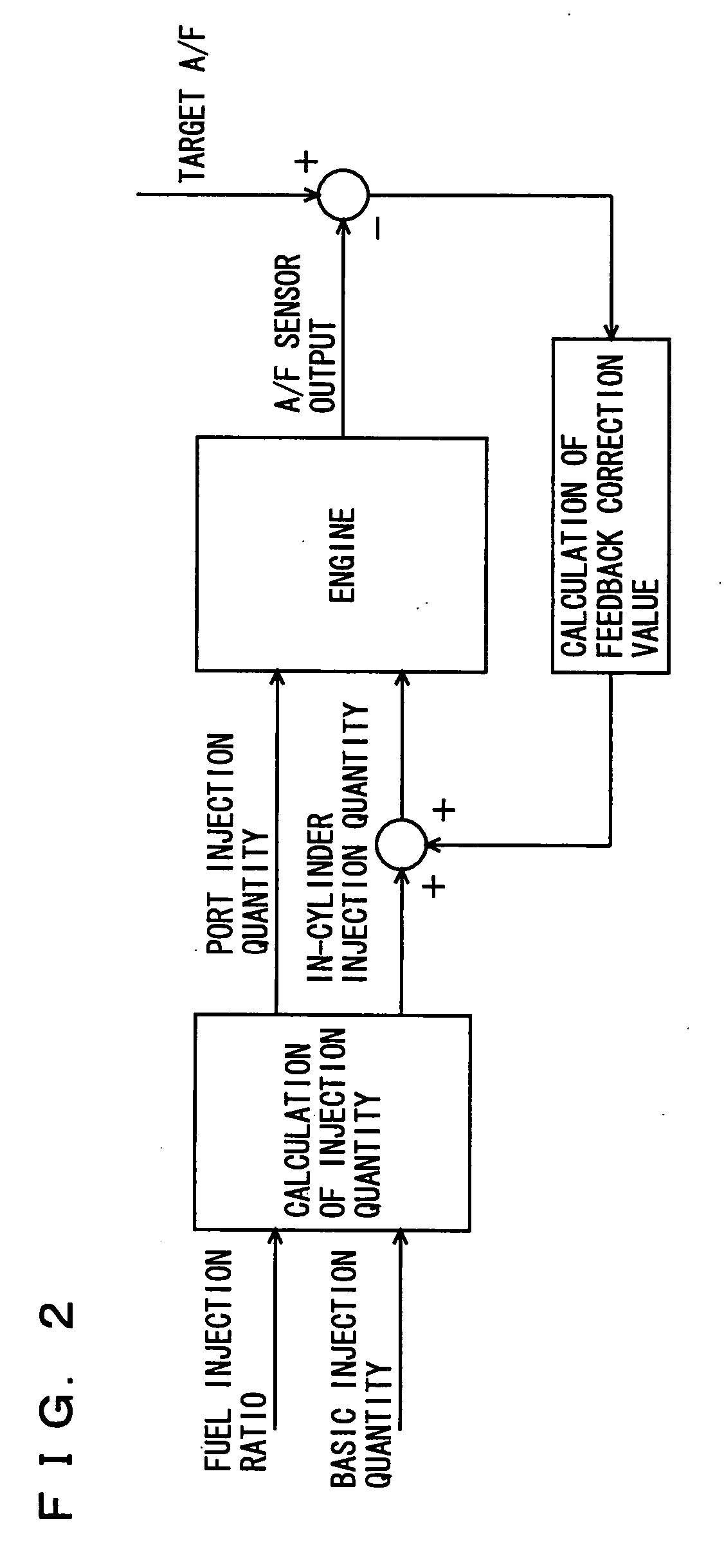

Control apparatus for internal combustion engine

InactiveUS7334569B2Improve responseHigh gainElectrical controlCombustion enginesExternal combustion engineControl theory

An air-fuel ratio feedback system is configured to calculate the deviation between a target air-fuel ratio and an air-fuel ratio sensor value, multiplying a proportional gain by the calculated deviation to obtain a feedback correction value, and add the calculated feedback correction value to the in-cylinder injection quantity of an in-cylinder injector that is obtained by multiplying the fuel injection ratio of the in-cylinder injector by the basic fuel injection quantity. The calculated feedback correction value is not added to the port injection quantity of the intake manifold cylinder.

Owner:TOYOTA JIDOSHA KK

Control apparatus for internal combustion engine

InactiveUS20060207566A1Improve responseHigh gainElectrical controlCombustion enginesControl theoryInlet manifold

An air-fuel ratio feedback system is configured to calculate the deviation between a target air-fuel ratio and an air-fuel ratio sensor value, multiplying a proportional gain by the calculated deviation to obtain a feedback correction value, and add the calculated feedback correction value to the in-cylinder injection quantity of an in-cylinder injector that is obtained by multiplying the fuel injection ratio of the in-cylinder injector by the basic fuel injection quantity. The calculated feedback correction value is not added to the port injection quantity of the intake manifold cylinder.

Owner:TOYOTA JIDOSHA KK

Method and relative device for estimating white gaussian noise that corrupts a digital image

ActiveUS8224109B2Quickly calculate standard deviationLarge deviationImage enhancementTelevision system detailsPattern recognitionDigital image

A method for estimating the white Gaussian noise level that corrupts a digital image by discriminating homogeneous blocks from blocks containing a textured area and skipping these last blocks when evaluating the noise standard deviation.

Owner:STMICROELECTRONICS SRL +1

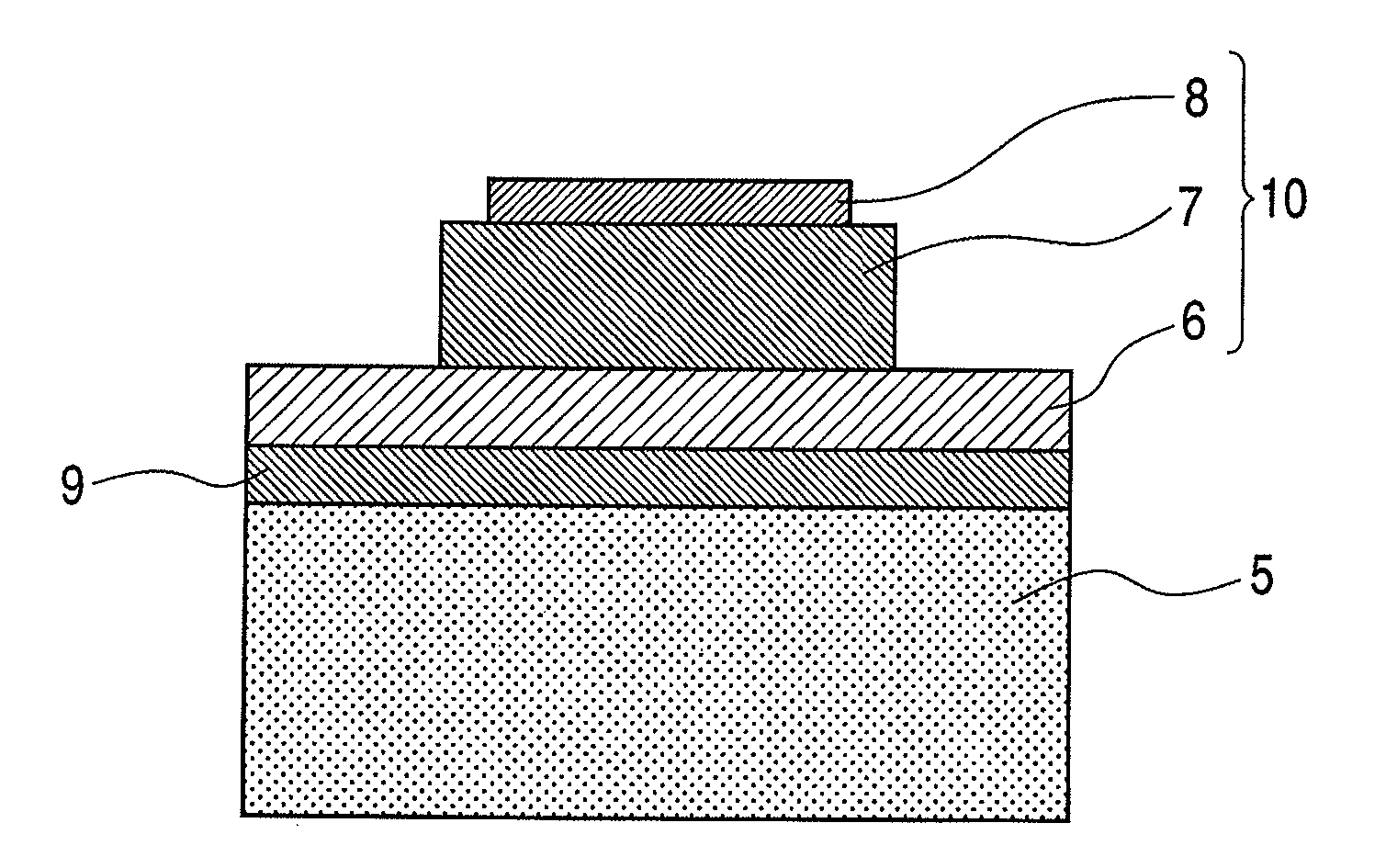

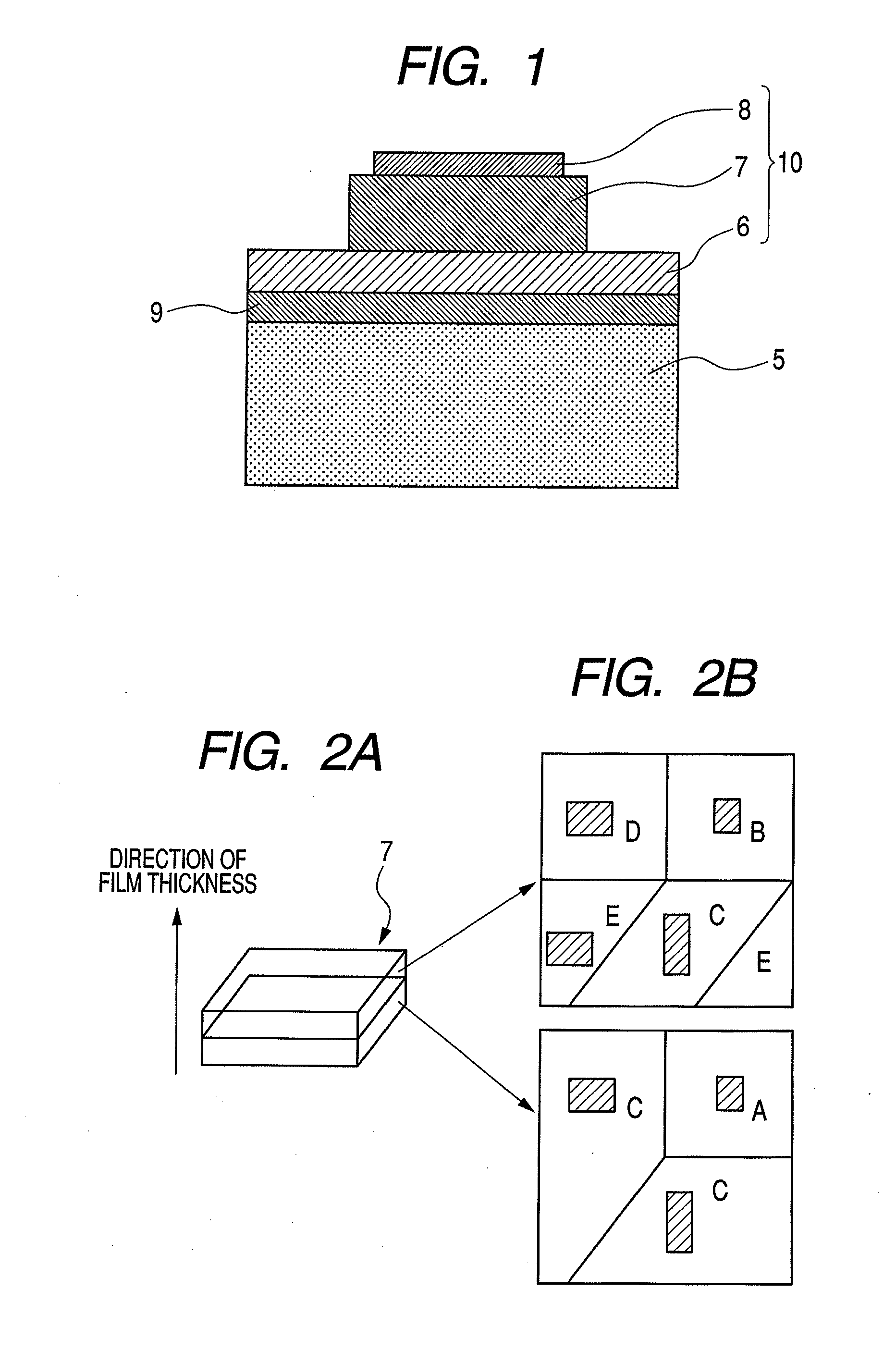

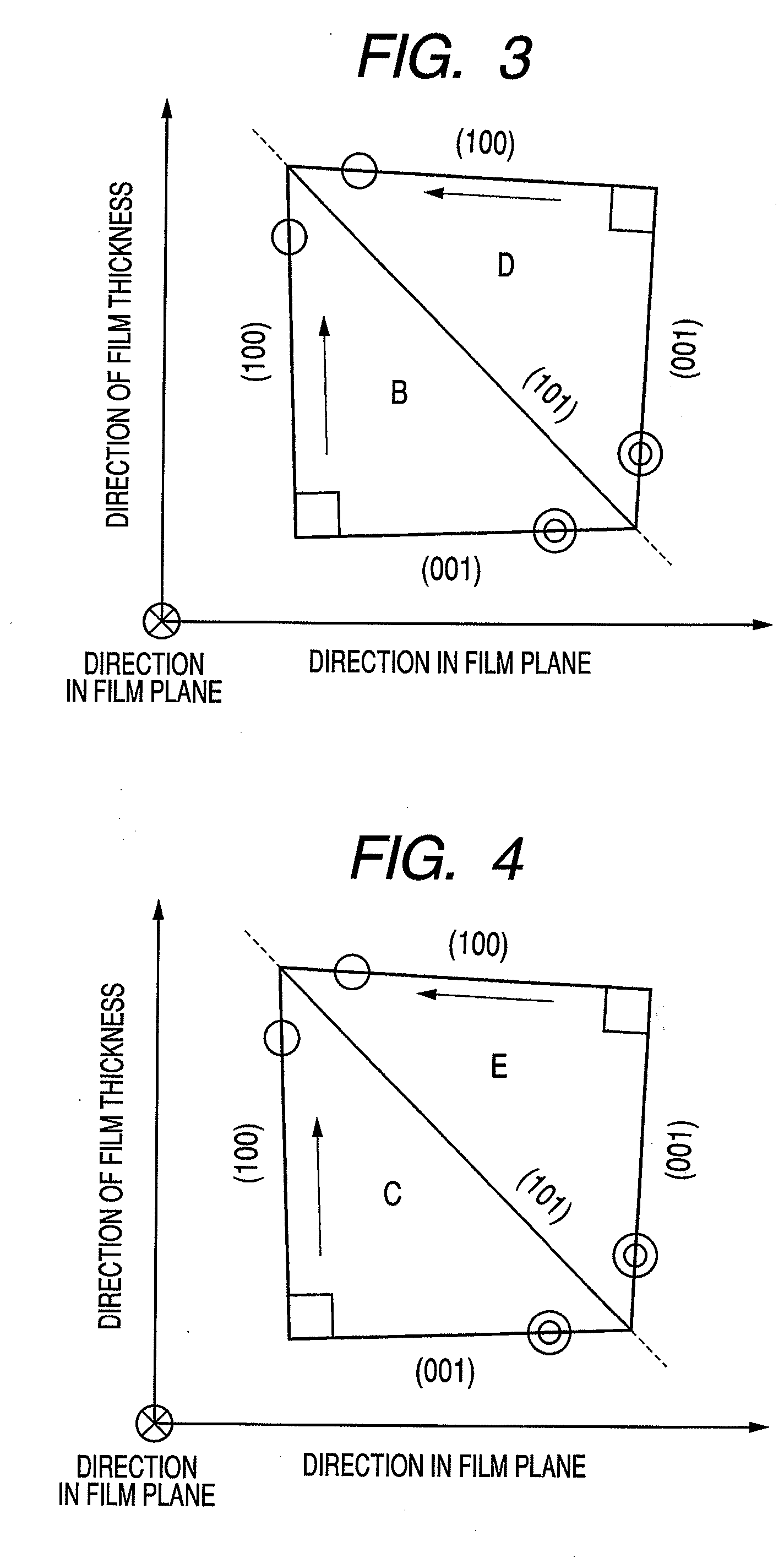

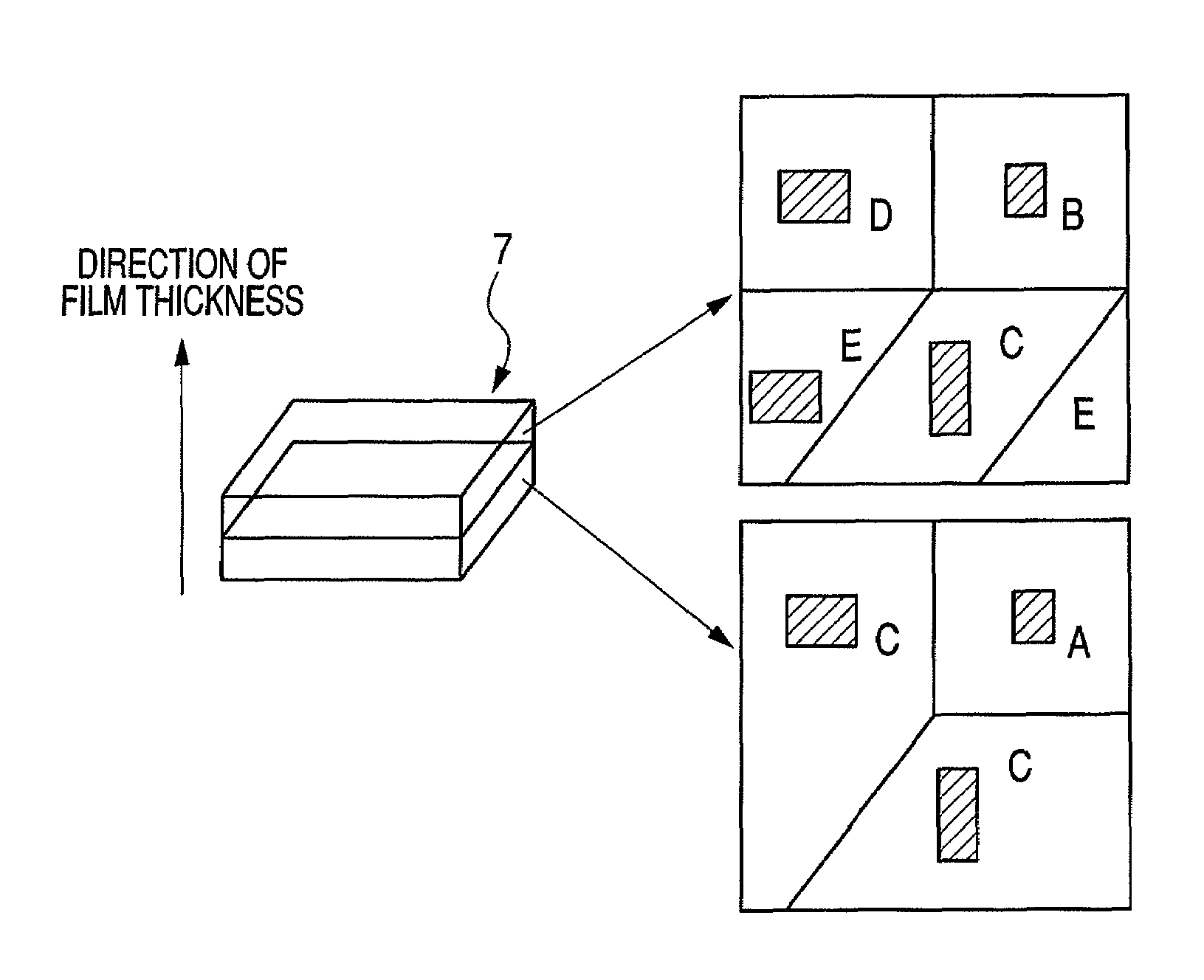

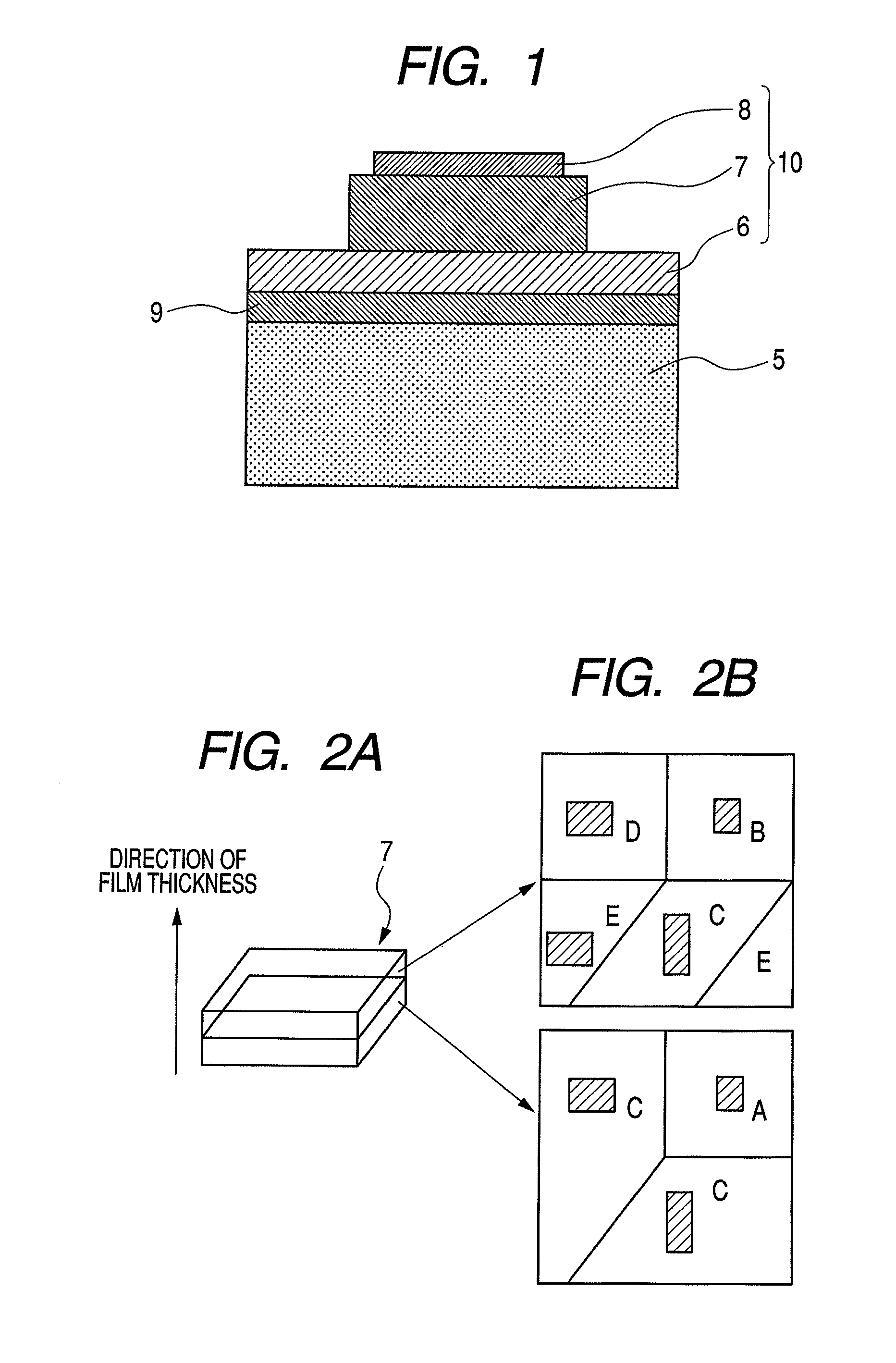

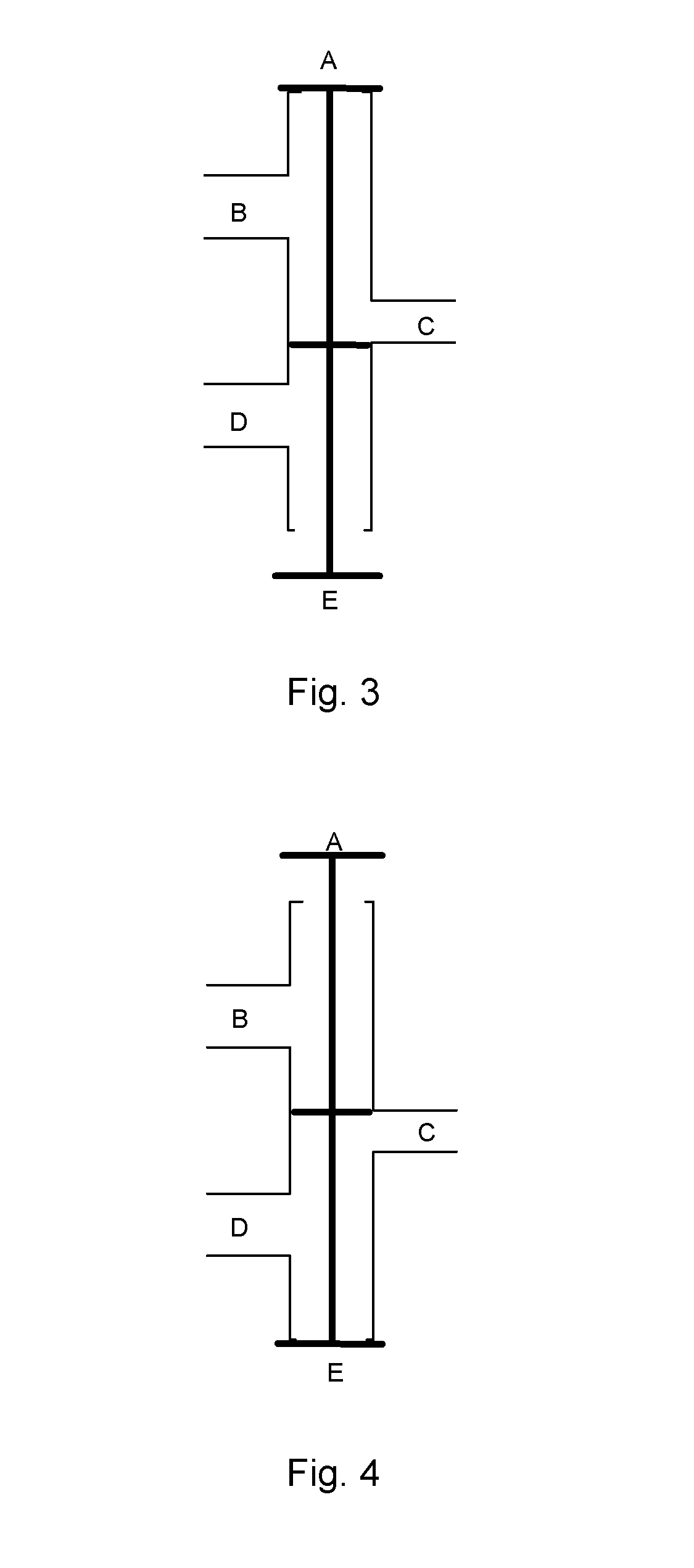

Piezoelectric member, piezoelectric element, and liquid discharge head and liquid discharge apparatus utilizing piezoelectric element

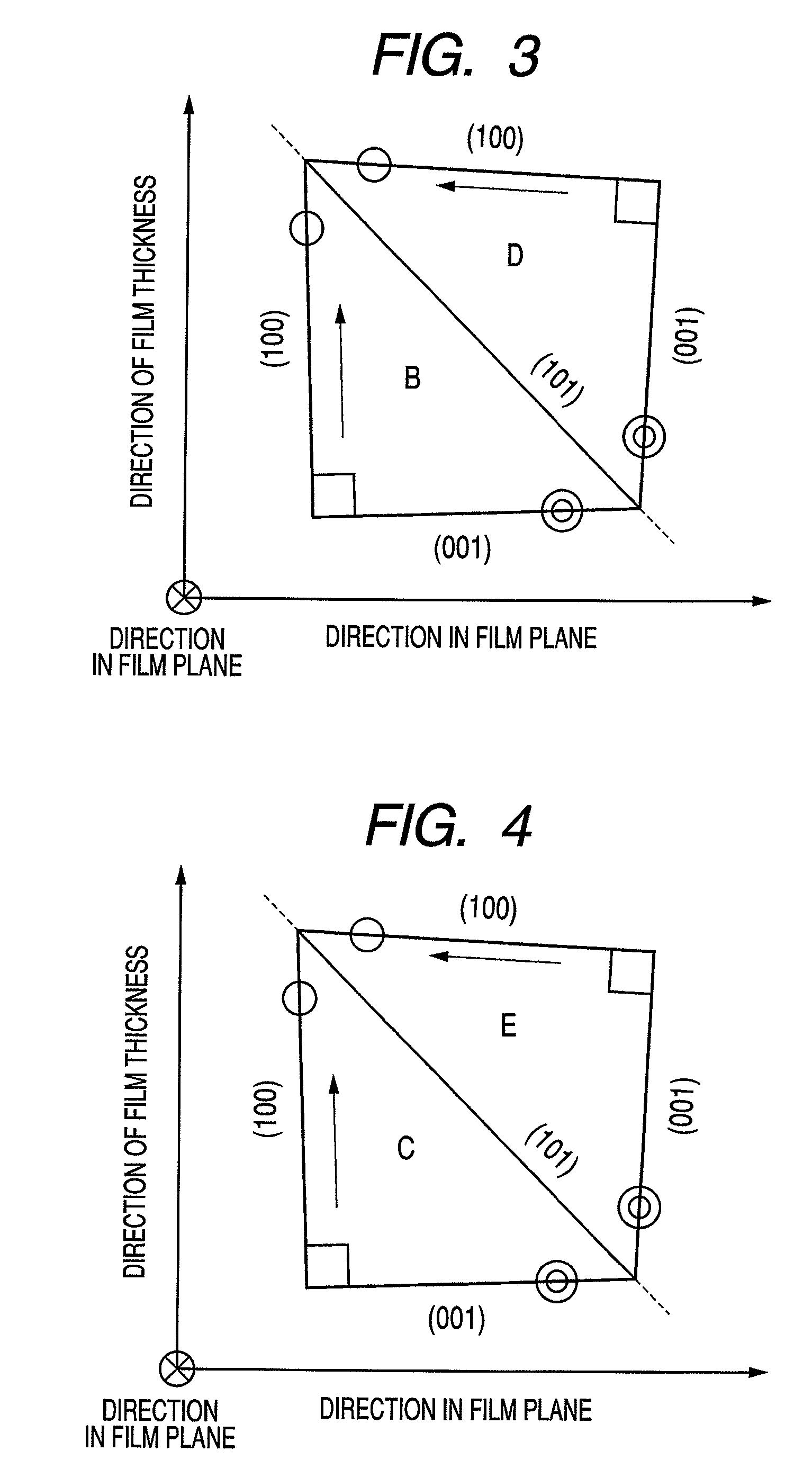

ActiveUS20080211881A1Excellent piezoelectric propertiesPrevent peelingPiezoelectric/electrostrictive device manufacture/assemblyInking apparatusCrystal structureAngular deviation

The invention provides a piezoelectric film having a large piezoelectric property, and a piezoelectric element, a liquid discharge head and a liquid discharge apparatus utilizing the same. The piezoelectric film is formed by an epitaxial oxide of <100> orientation having at least a tetragonal crystal structure, in which the oxide is a perovskite type composite oxide represented by a general formula ABO3 and contains at least domains C, D and E of [100] orientation having mutual deviation in crystal direction, where the angular deviation between [100] directions in domains C and D, in domains D and E, in domains C and E and in domains D and E are respectively 5° or less, 5° or less, 0.3° or less, and 0.3° or more, and the angular deviation between [001] directions in domains C and E and in domains D and E are respectively 1.0° or more, and 1.0° or more.

Owner:CANON KK

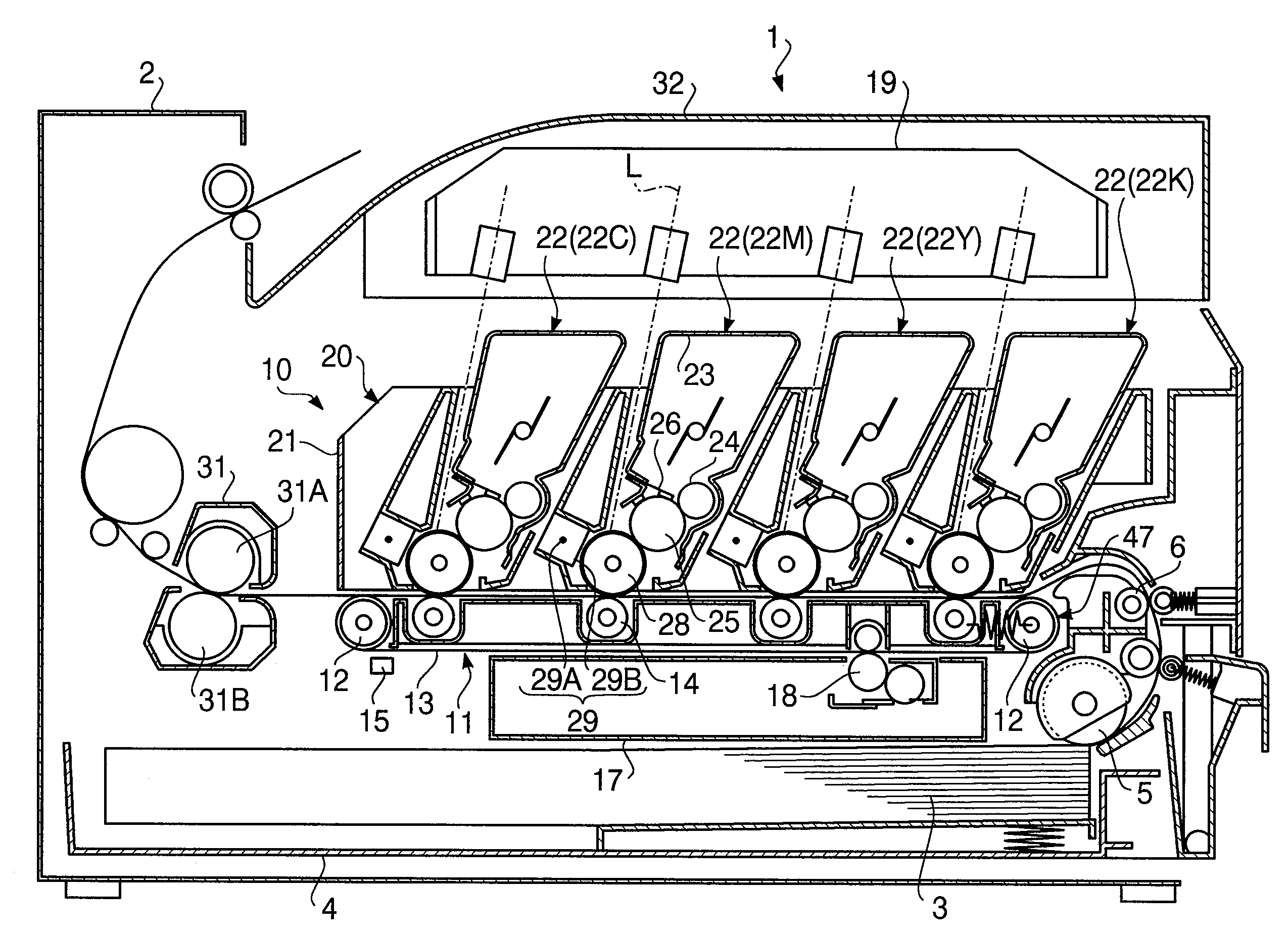

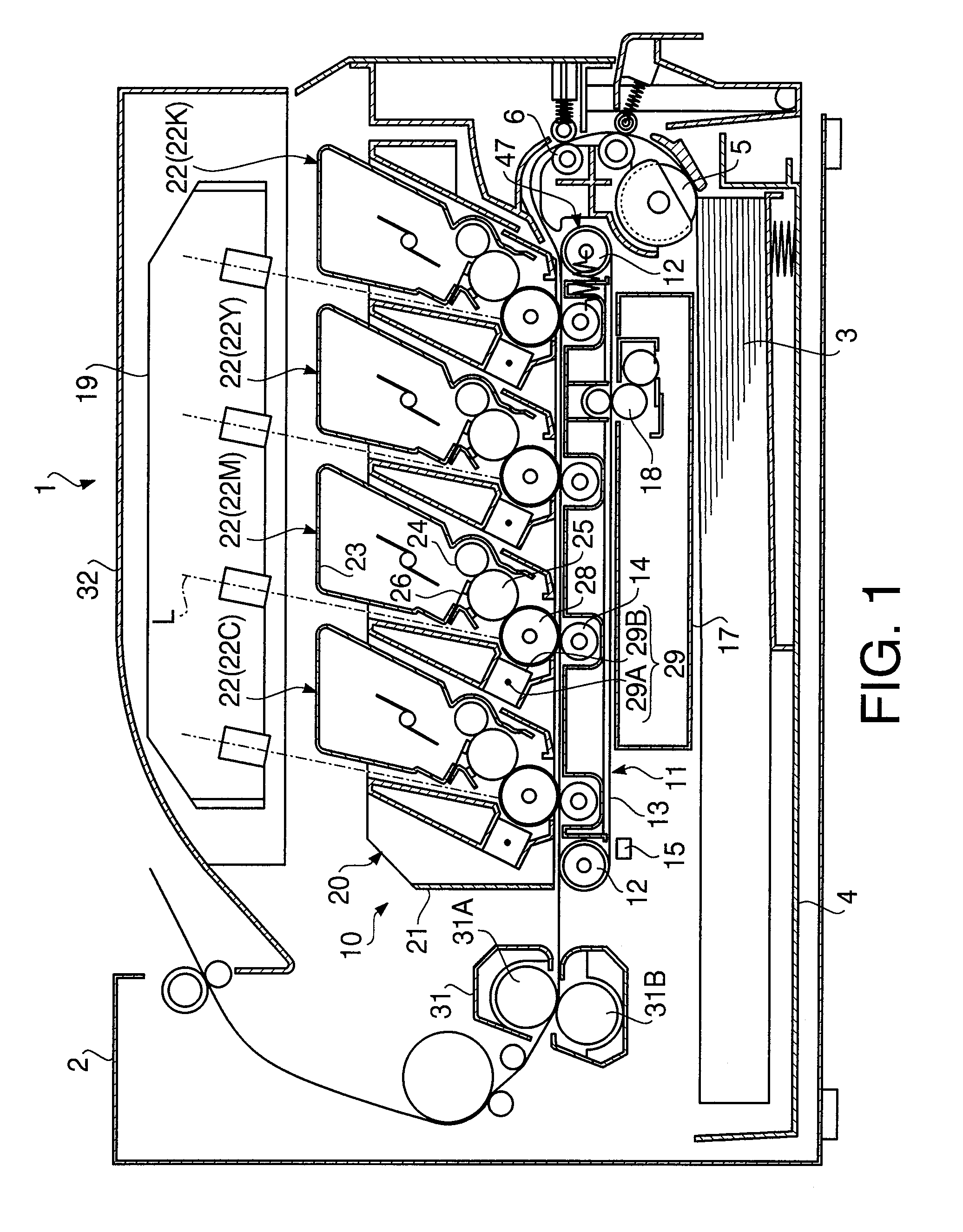

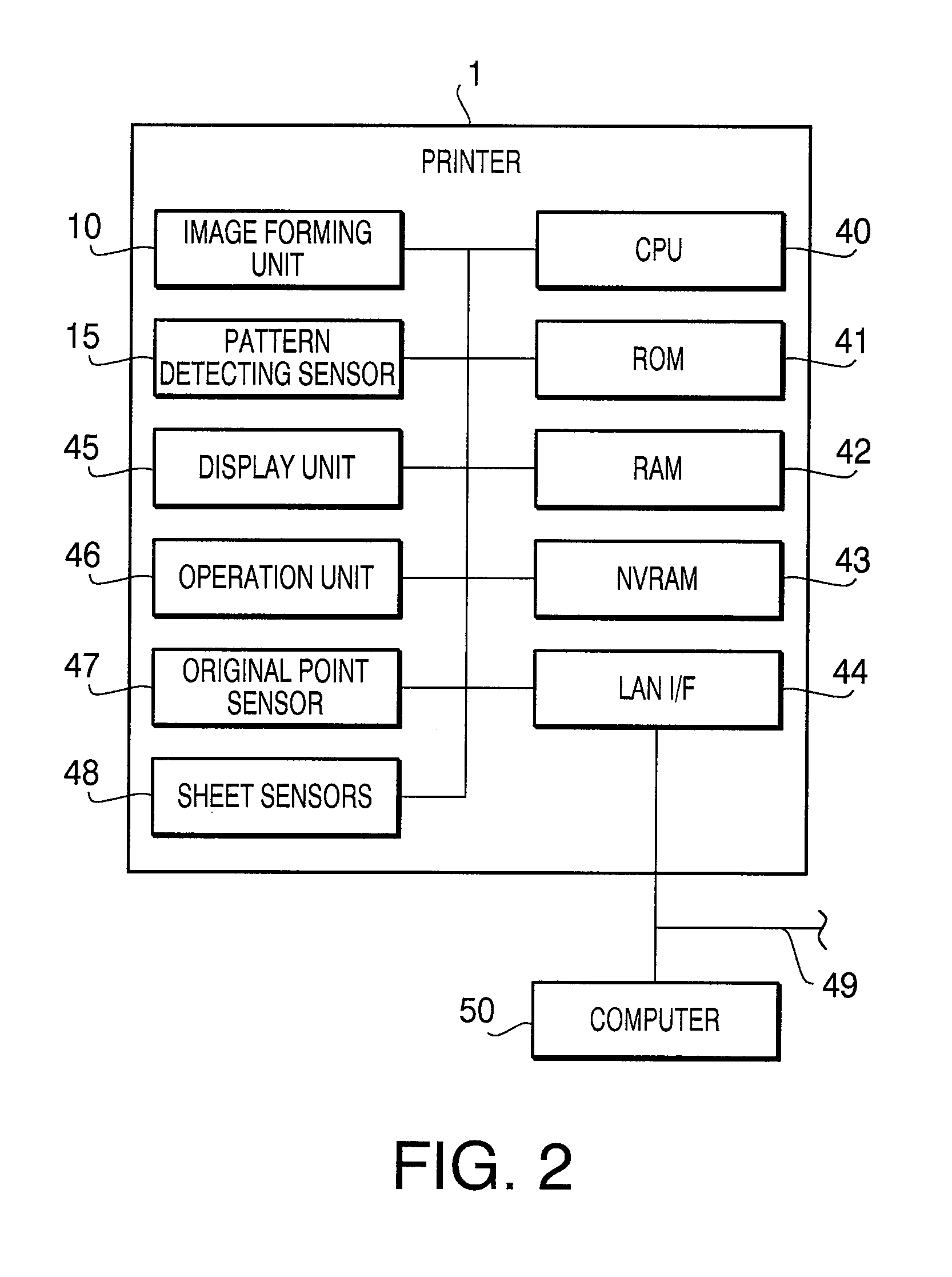

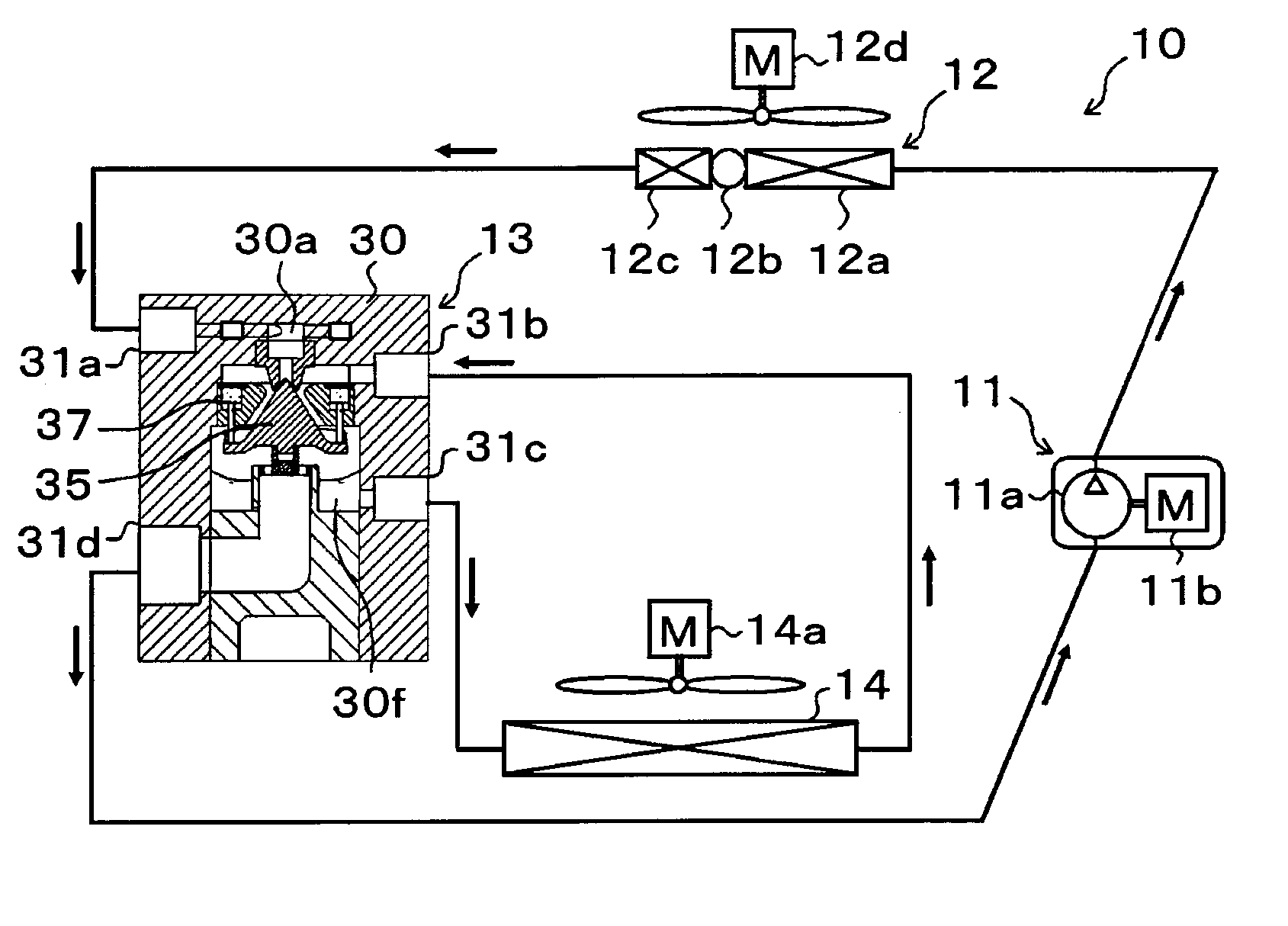

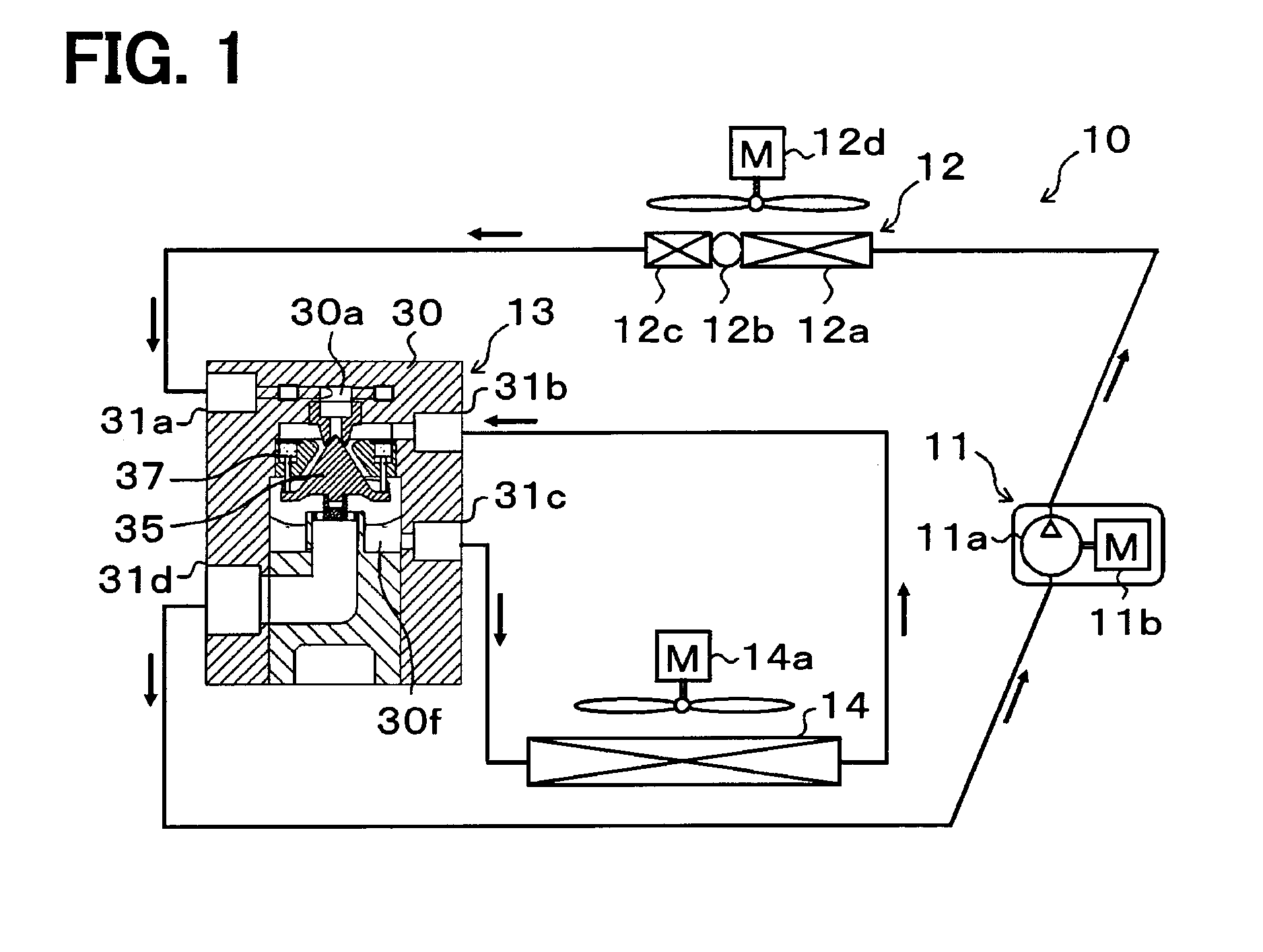

Image Forming Device, and Method and Computer Readable Medium Therefor

ActiveUS20090091773A1Securing of qualitySecure image qualityVisual presentationElectrographic process apparatusImage formationComputer science

An image forming device includes a rotational body carrying a sheet thereon, the rotational body including first regions defined thereon that begin with respective different phases on the rotational body, a forming unit forming an image on one of the rotational body and the sheet carried on the rotational body, a storage unit storing thereon information regarding positional deviations of images formed within each of the first regions, a region specifying unit that determines a variation of the positional deviations of the images within each of the first regions based upon the information stored and specifies one of the first regions based upon the determined variation, and a control unit controlling the forming unit to form an intended image of which an image forming position is corrected based upon the information stored, in the first region specified on the rotational body.

Owner:BROTHER KOGYO KK

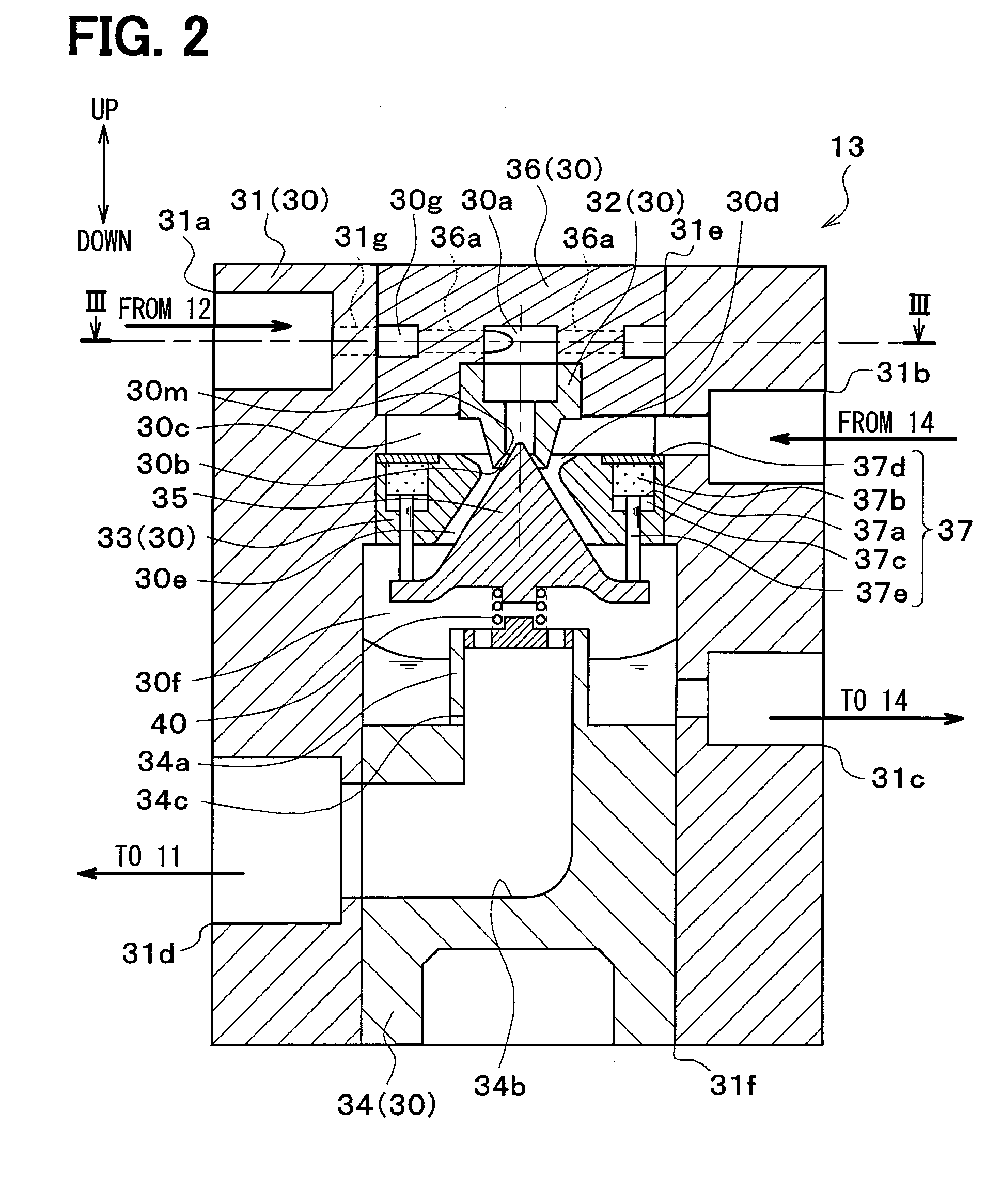

Ejector

InactiveUS20160169566A1Suppress large deviationImproves efficiency of nozzleCompression machines with non-reversible cycleJet pumpsRefrigerantPhysics

An approximately conical passage-forming member is disposed inside a body in which a swirling space for swirling a refrigerant is formed, and an ejector defines therein a nozzle passage that functions as a nozzle for depressurizing a refrigerant that has flowed out from the swirling space between an inner circumferential surface of the body and the passage-forming member, and a diffuser passage that pressurizes a mixed refrigerant obtained from a refrigerant sprayed from the nozzle passage and a refrigerant drawn from a suction-passage. A plurality of driving passages through which a refrigerant is introduced from a distribution space to the swirling space are formed in the body. In this case, the driving passages are formed in a manner such that a refrigerant flowing in from each driving passage into the swirling space flows along an outer circumference of the swirling space and flows in directions different from each other. Accordingly, nozzle efficiency is sufficiently improved.

Owner:DENSO CORP

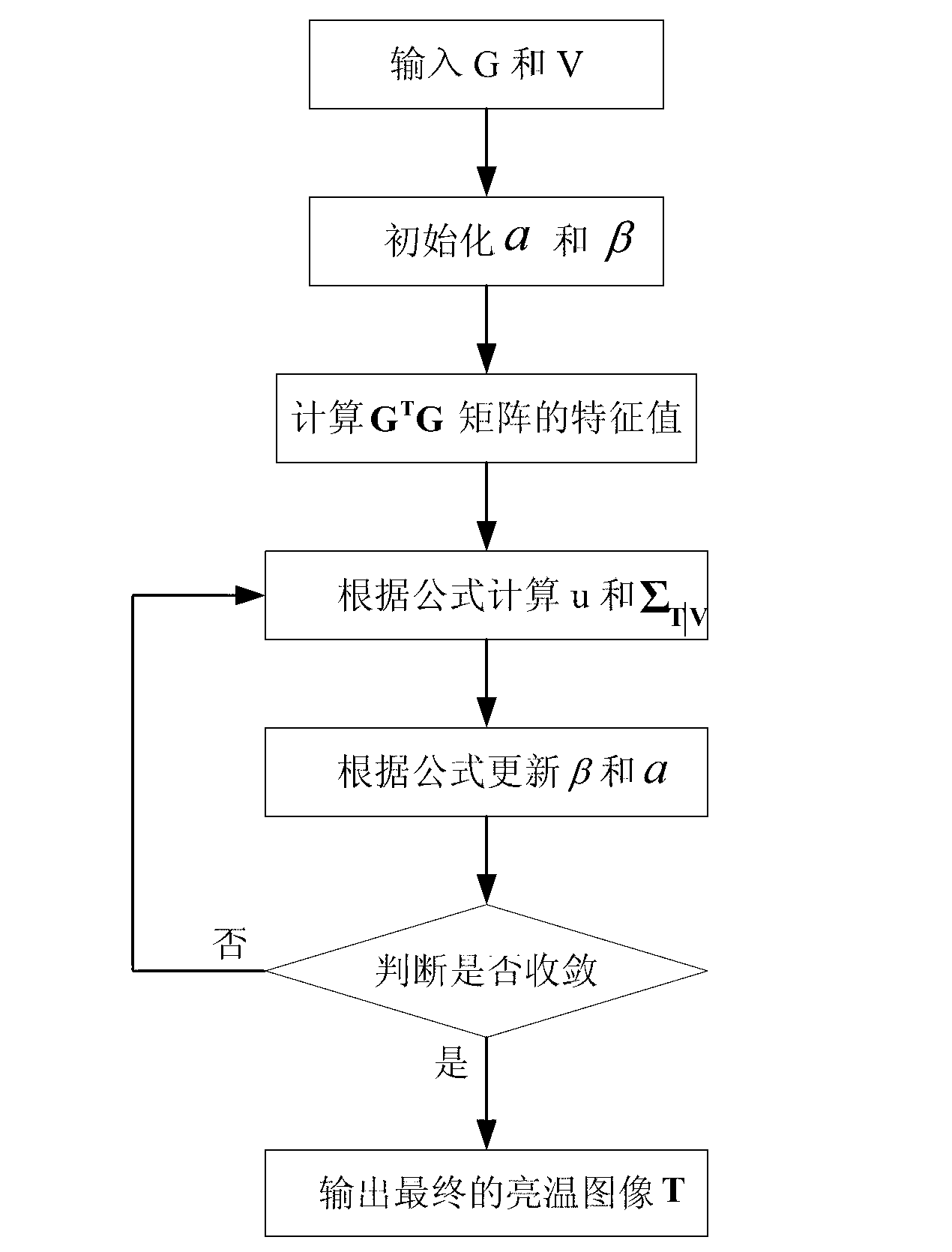

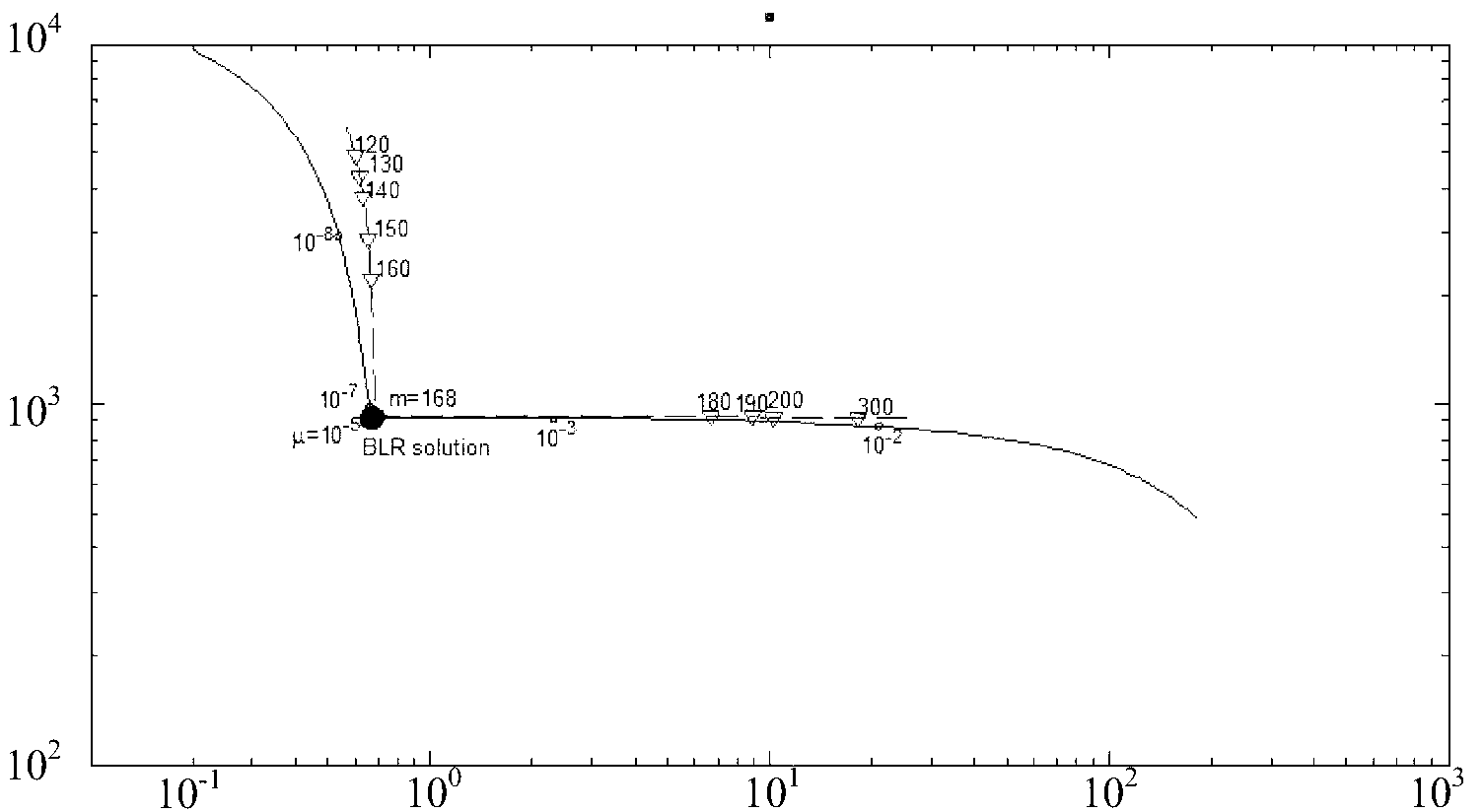

Synthetic aperture interferometric radiometer image inversion method

InactiveCN102914774AReduce computational complexityLarge deviationRadio wave reradiation/reflectionRadiometerBrightness temperature

The invention discloses a synthetic aperture interferometric radiometer image inversion method, which comprises the following steps: obtaining the probability measure initial value beta of visibility and the probability measure initial value ai of different pixels i according to the visibility data V of a target scene and the impact response matrix G of an interferometric radiometer; calculating the characteristic value lambda i of a GTG (grey to grey) matrix; calculating the mean value mu of a posterior probability and the variance sigma T|V of the posterior probability; updating beta and alpha; judging whether the probability measure updating value beta new of the visibility and a probability measure updating value alpha new are simultaneously restrained or not; if so, substituting the probability measure updating value beta new of the visibility, the probability measure updating value alpha new, the mean value mu of a posterior probability and the variance sigmaT|V of the posterior probability into a formula p (T|G, anew, beta new)=N(T|u, sigma T|V) to obtain brightness temperature image distribution T; and if not, returning to further calculate mu and sigma T|V. According to the synthetic aperture interferometric radiometer image inversion method disclosed by the invention, the computation complexity for obtaining an optimal model can be effectively lowered, an inversion result with small variance and deviation is obtained, influence on an inversion result by the noise is reduced, the resolution ratio of the inversion image is effectively improved, and the synthetic aperture interferometric radiometer image inversion method is a synthetic aperture image inversion method which can automatically select the optimal model.

Owner:HUAZHONG UNIV OF SCI & TECH

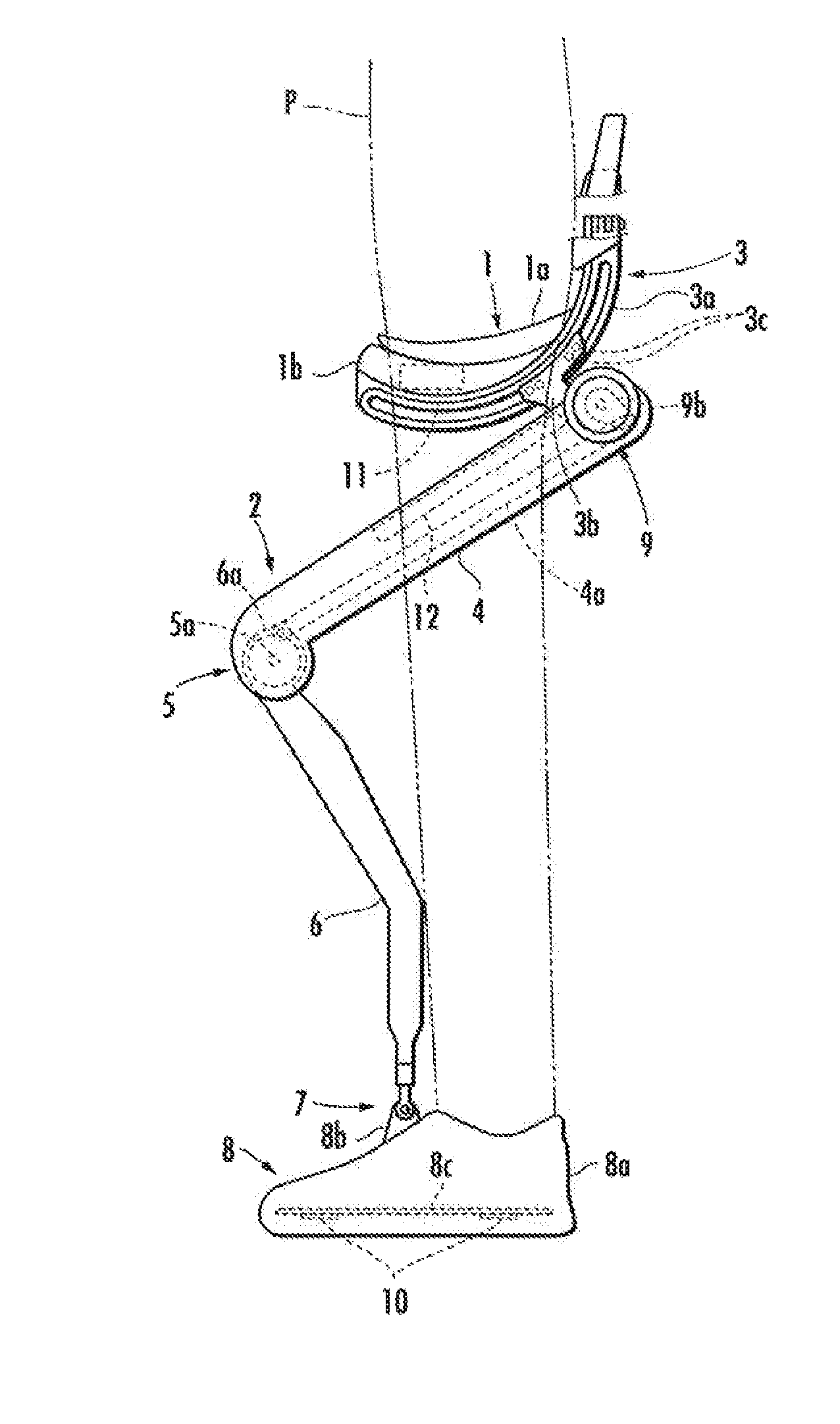

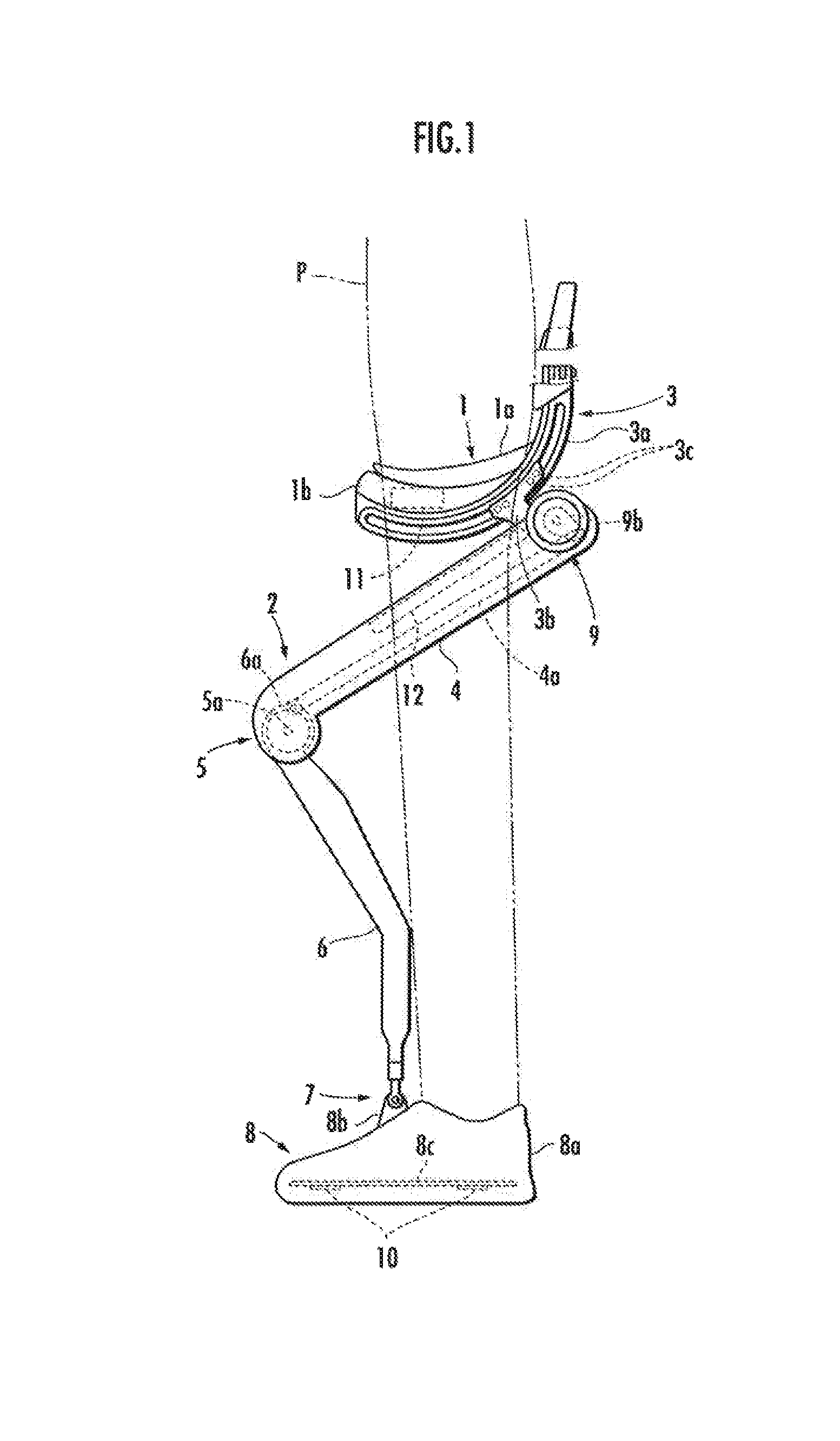

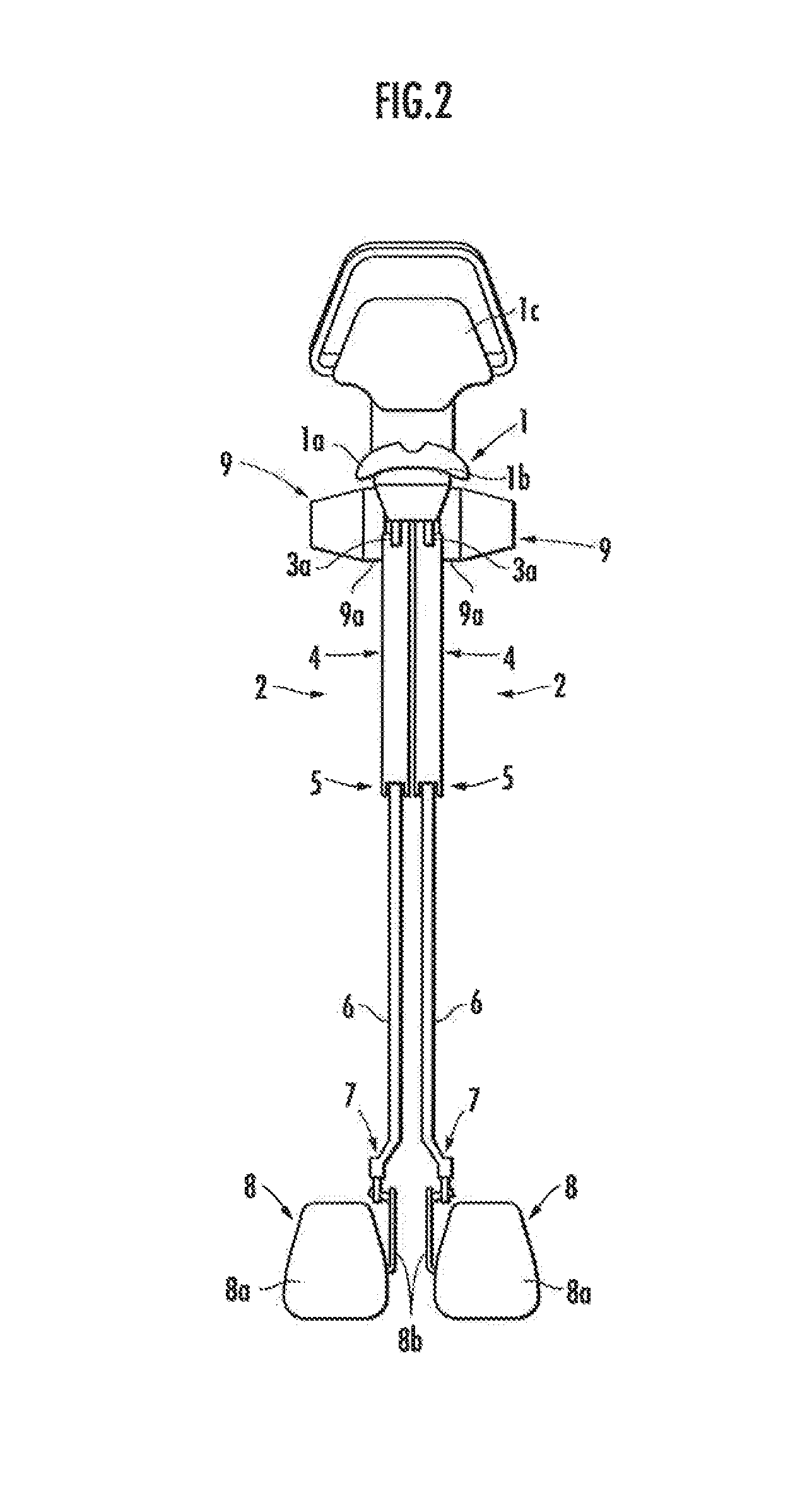

Walking assist device

ActiveUS20150374513A1Large deviationNon-surgical orthopedic devicesArtificial legsState variableEngineering

Provided is a walking assist device independent of a deviation of a bending / stretching state between user's legs and applying a force to a user in a direction intended by the user. The walking assist device performs control so that the larger the deviation of a value of a bending / stretching state variable representing the bending / stretching state of each of a pair of right and left legs of a user P is, the larger the deviation between the assist forces Fr and Fl acting on the user P from each of the leg links 2 is.

Owner:HONDA MOTOR CO LTD

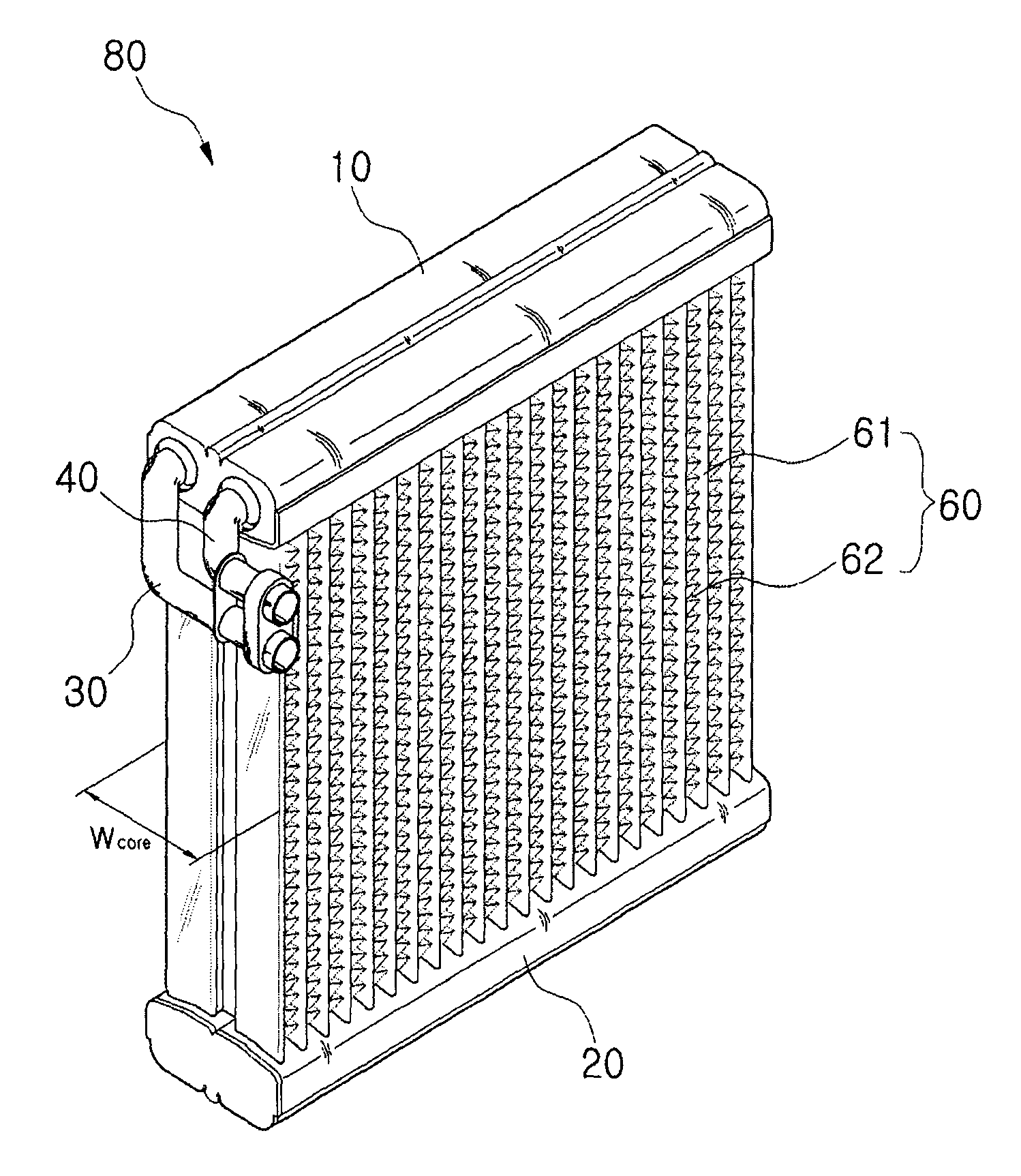

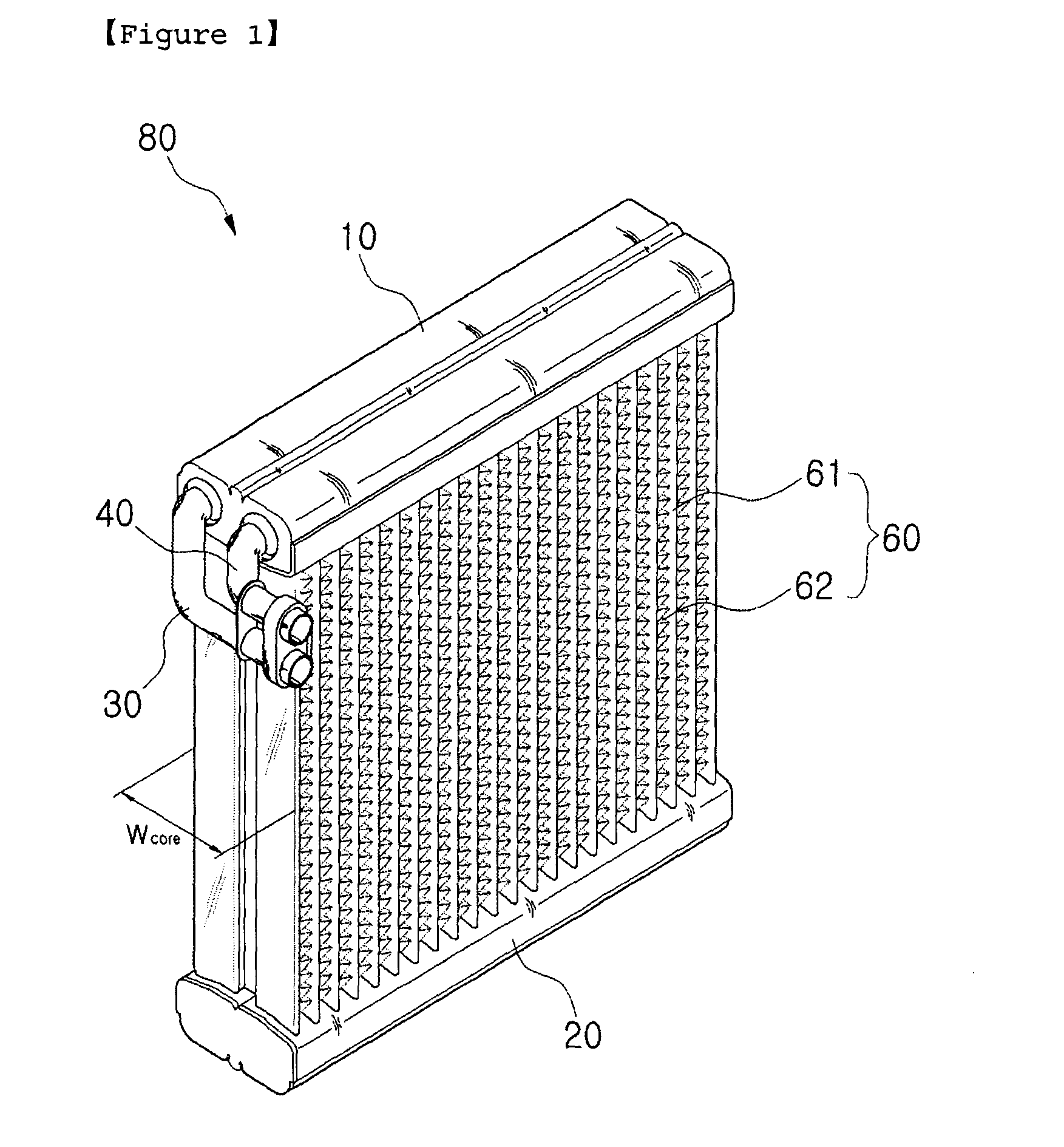

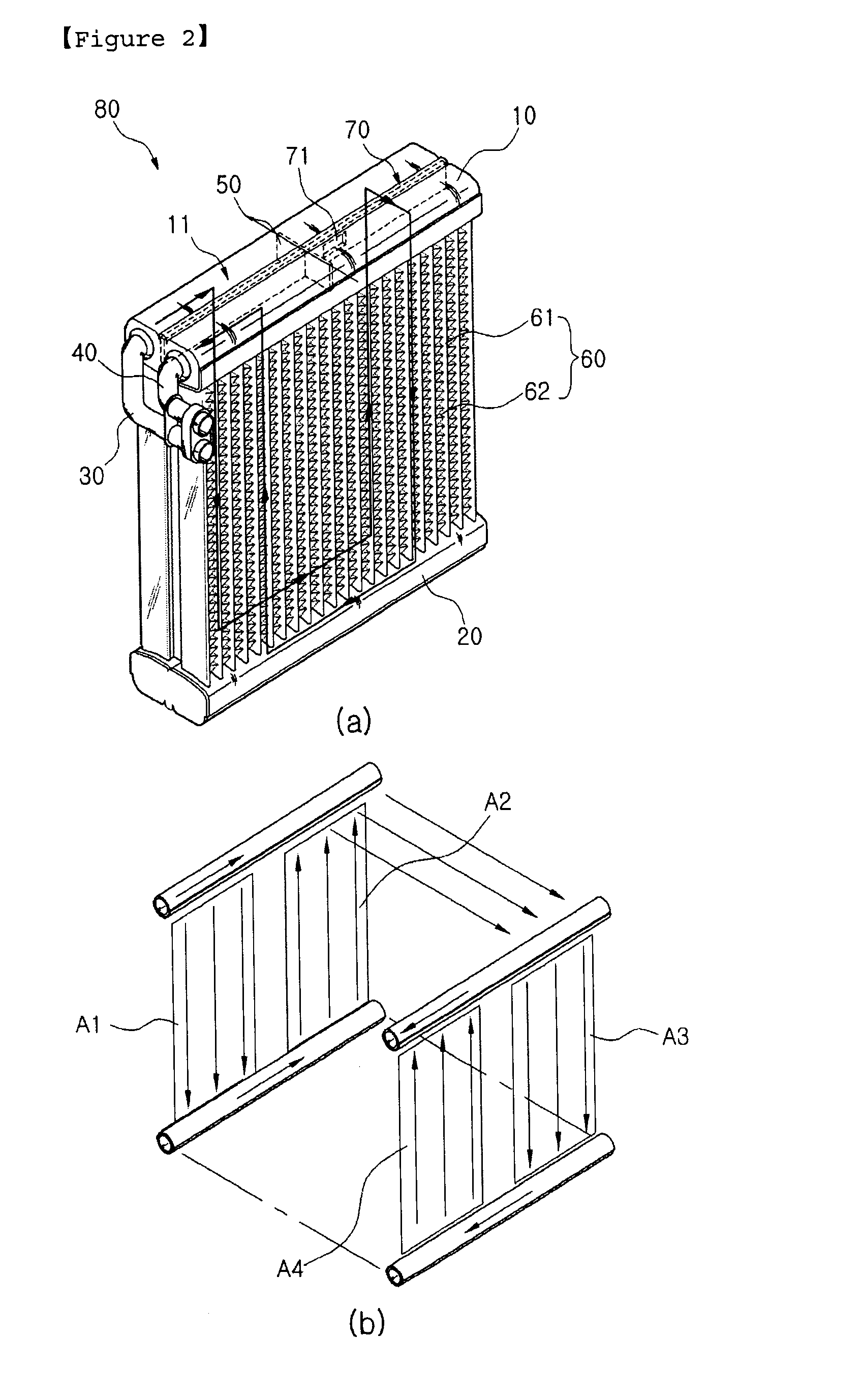

Evaporator

ActiveUS20100243223A1Maximizing heat radiation amountMaximum temperature deviationEvaporators/condensersVehicle heating/cooling devicesEngineeringRefrigerant

The present invention relates to an evaporator, and more particularly, to an evaporator which can restrict a surface area of a communication hole with respect to a cross sectional area of a compartment and a surface area of a tube with respect to a surface area of a fin, thereby providing a dimensional extent for maximizing the heat exchange efficiency. Therefore, by optimizing a relation between the surface area of the communication portion and the surface area of the compartment of the first header tank and dimensions for each surface area and the heights of the tube and fin, the present invention provides a dimensional extent for maximizing the heat radiation amount, reducing the maximum temperature deviation of the core portion and allowing the refrigerant and air to be smoothly flowed, thereby maximizing the heat exchange efficiency.

Owner:HANON SYST

Piezoelectric member, piezoelectric element, and liquid discharge head and liquid discharge apparatus utilizing piezoelectric element

ActiveUS7622852B2Excellent piezoelectric propertiesPrevent peelingPiezoelectric/electrostrictive device manufacture/assemblyInking apparatusCrystal structureAngular deviation

The invention provides a piezoelectric film having a large piezoelectric property, and a piezoelectric element, a liquid discharge head and a liquid discharge apparatus utilizing the same. The piezoelectric film is formed by an epitaxial oxide of <100> orientation having at least a tetragonal crystal structure, in which the oxide is a perovskite type composite oxide represented by a general formula ABO3 and contains at least domains C, D and E of [100] orientation having mutual deviation in crystal direction, where the angular deviation between [100] directions in domains C and D, in domains D and E, in domains C and E and in domains D and E are respectively 5° or less, 5° or less, 0.3° or less, and 0.3° or more, and the angular deviation between [001] directions in domains C and E and in domains D and E are respectively 1.0° or more, and 1.0° or more.

Owner:CANON KK

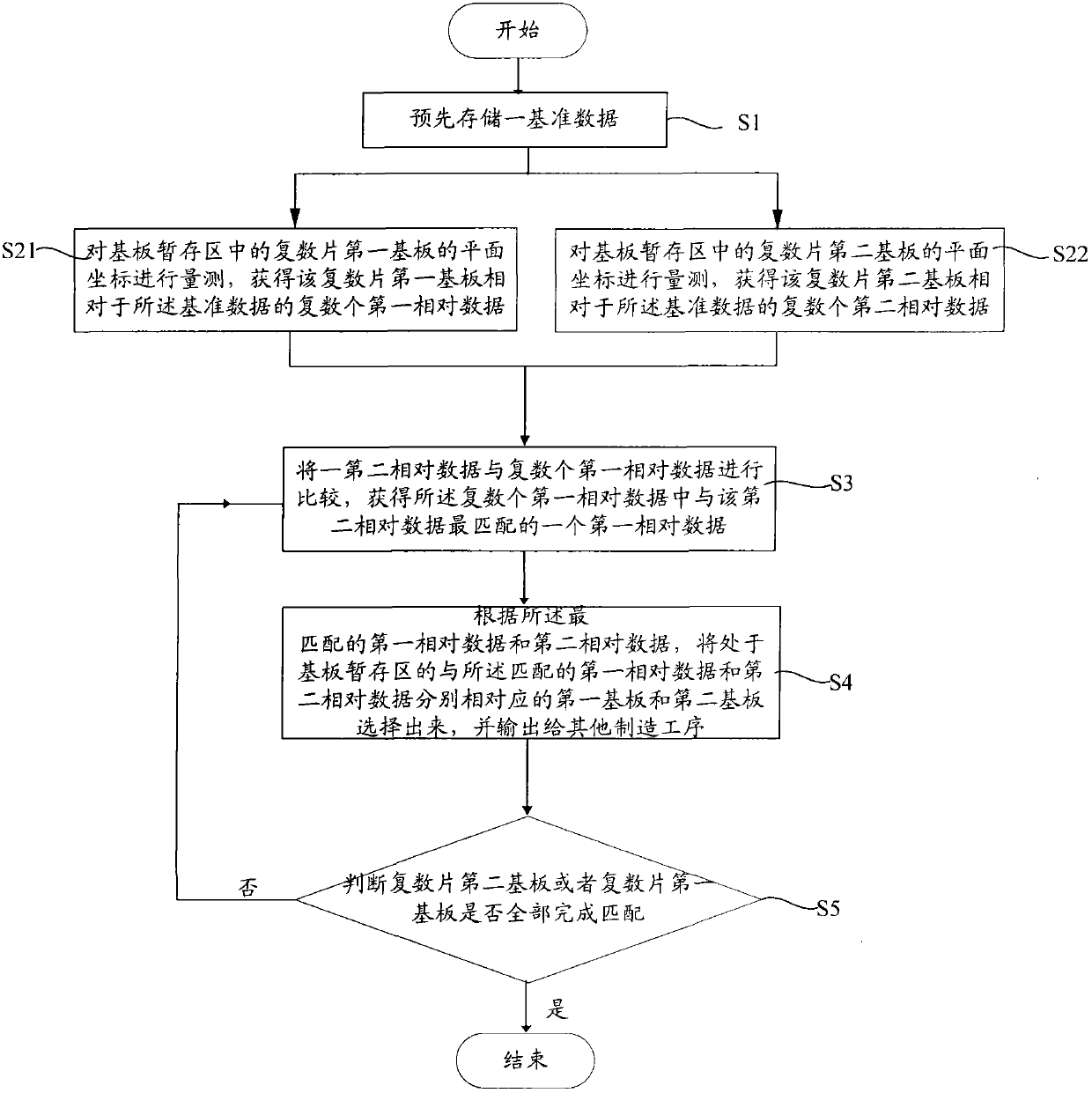

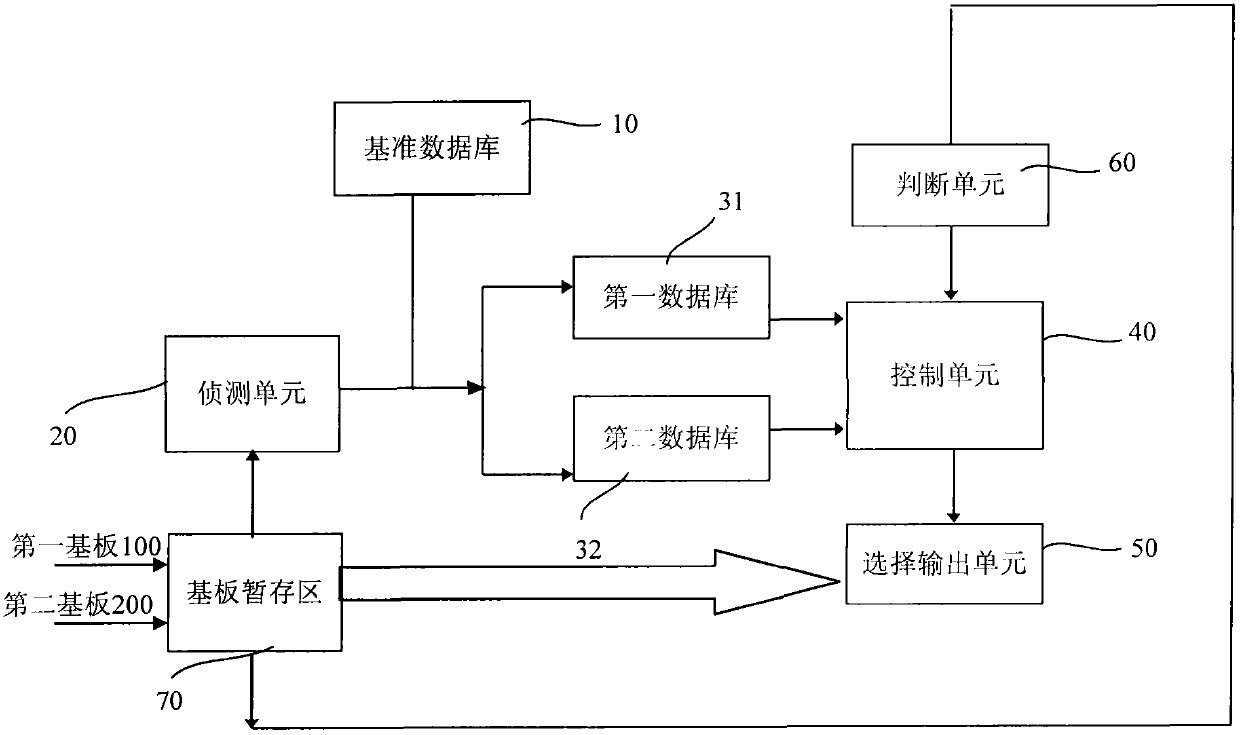

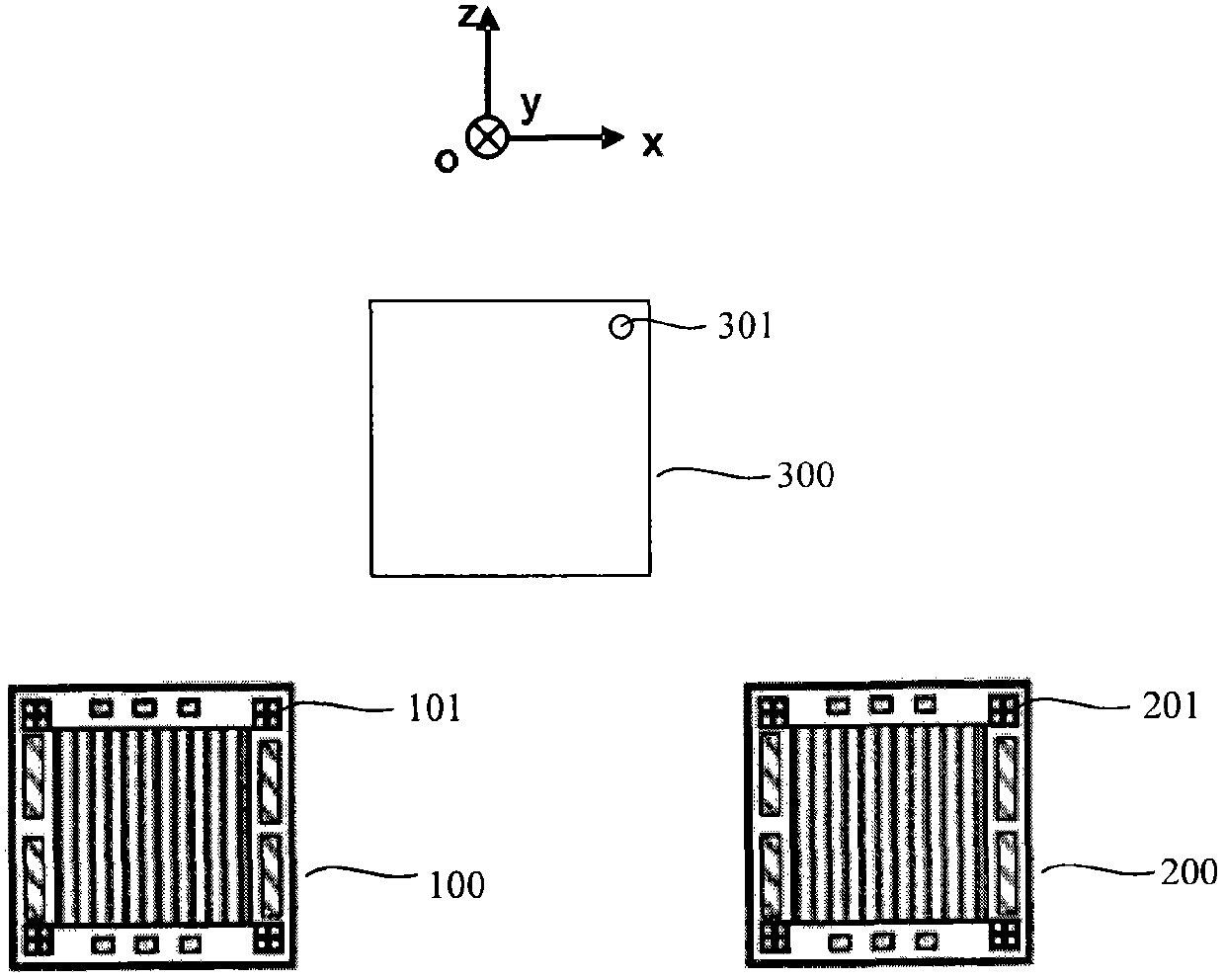

Aligning and matching system and method for liquid crystal display panel

ActiveCN102004350ALarge deviationReduce bad situationsNon-linear opticsReference databaseLiquid-crystal display

The invention provides an aligning and matching system for a liquid crystal display panel. The system comprises a substrate temporary storage region, a reference database, a detection unit, a first database, a second database, a control unit and a selection and output unit, wherein the detection unit measures first relative data and second relative data, relative to reference data in the reference database, of the first substrate and the second substrate in the liquid crystal display panel; the control unit matches the first relative data with the second relative data and acquires the first relative data and the second relative data which are matched with each other best; and the selection and output unit selects the first substrate and the second substrate, respectively corresponding to the first relative data and the second relative data which are matched with each other best, in the substrate temporary storage region according to the first relative data and the second relative data which are matched with each other best, and outputs the selected first substrate and the selected second substrate to other manufacturing processes. The invention also provides an aligning and matching method for the liquid crystal display panel. By using the system and the method, the alignment accuracy of the first substrate and the second substrate of the liquid crystal display panel are improved.

Owner:KUSN INFOVISION OPTOELECTRONICS

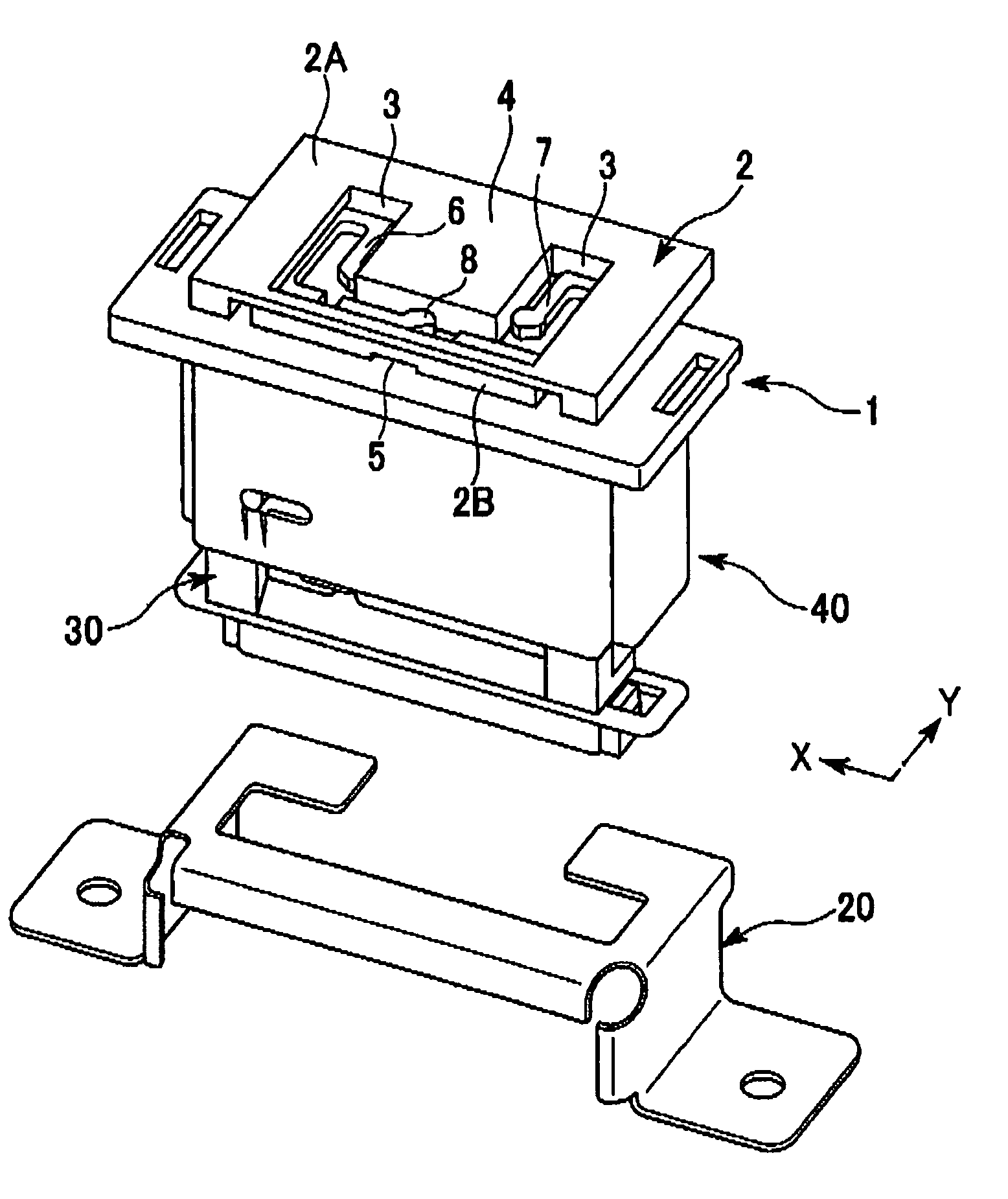

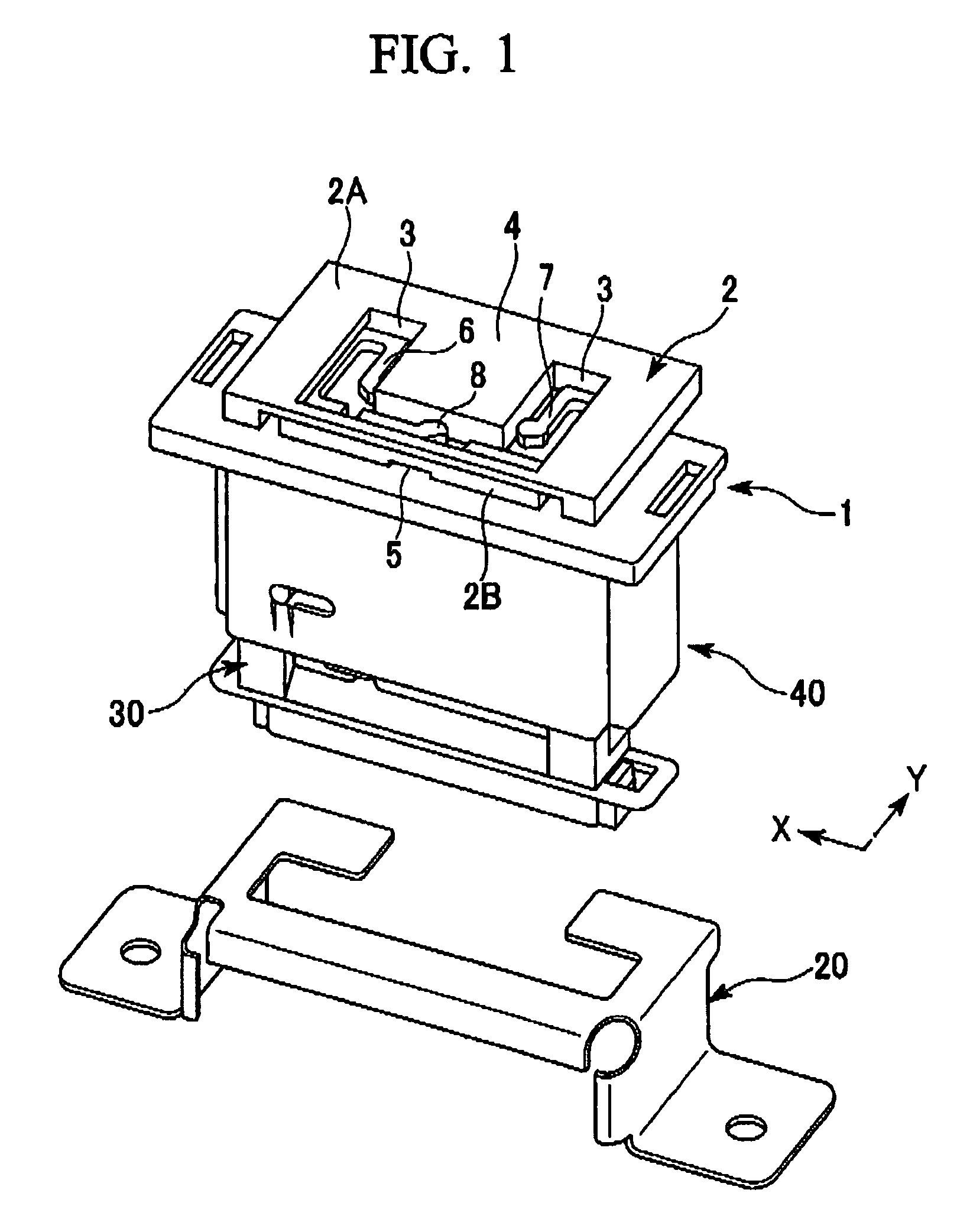

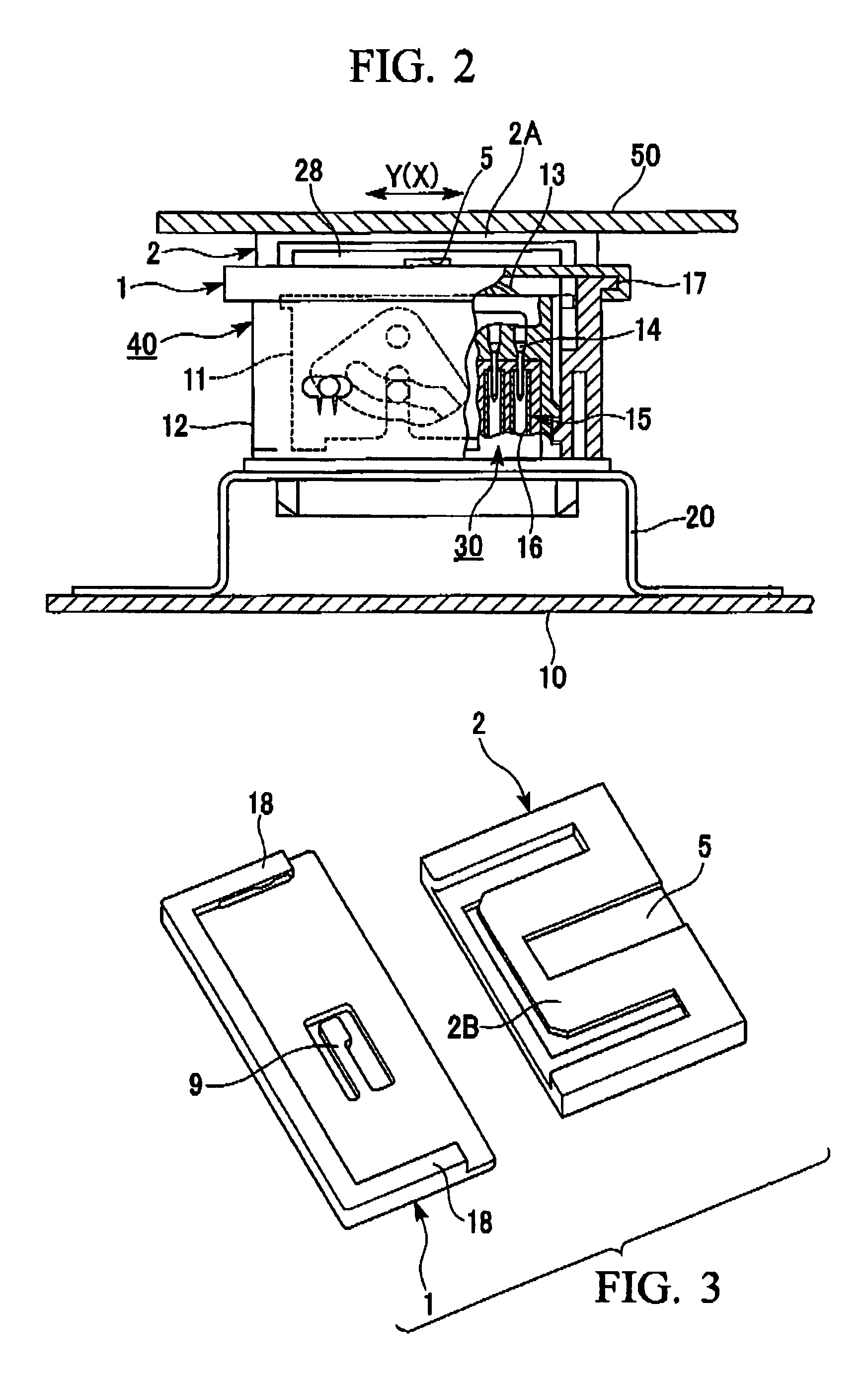

Self-aligning connector

InactiveUS7390207B2Large deviationDownsizableVehicle connectorsIncorrect coupling preventionEngineeringSlide plate

A self-aligning connector, comprising: a female connector which is adapted to include at least one electrical component and to be optionally secured to one securing portion; a male connector connectable to the female connector, the male connector being adapted to include at least one electrical component and to be optionally secured to another securing portion; and at least one connector cover and at least one slide plate, which are disposed between the one securing portion and the another securing portion; wherein the at least one connector cover includes a plurality of resilient pawls, which has distal ends located in the vicinity of a connector cover center portion in front-rear and left-right directions in the plane of the at least one connector cover; wherein the at least one slide plate includes a receiving portion in which resilient pawls are inserted and engaged; and wherein the resilient pawls absorb deviations in the front-rear and left-right directions occurring at the time of connecting the female and the male connectors to properly align the female and the male connectors.

Owner:THE FUJIKURA CABLE WORKS LTD

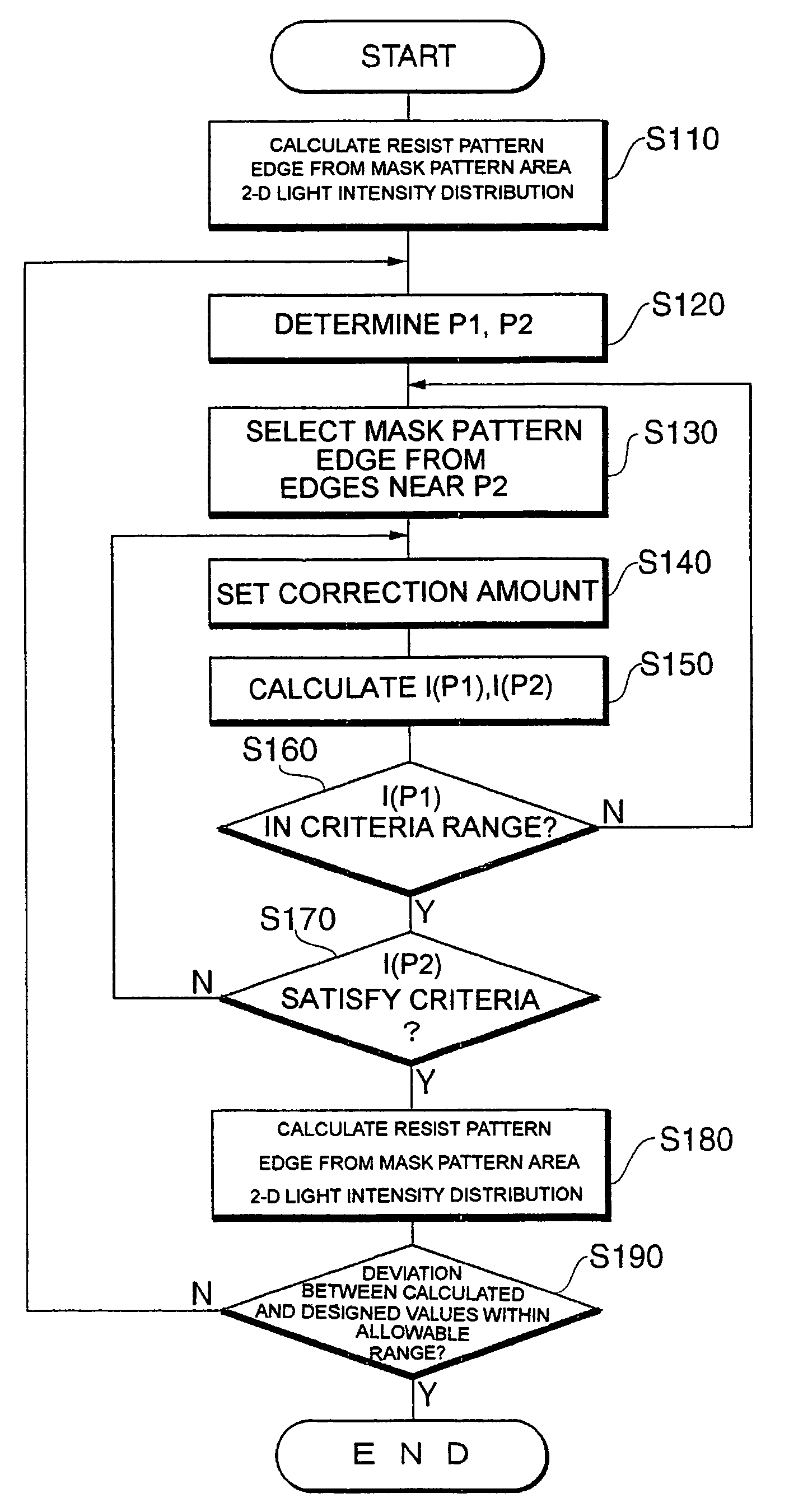

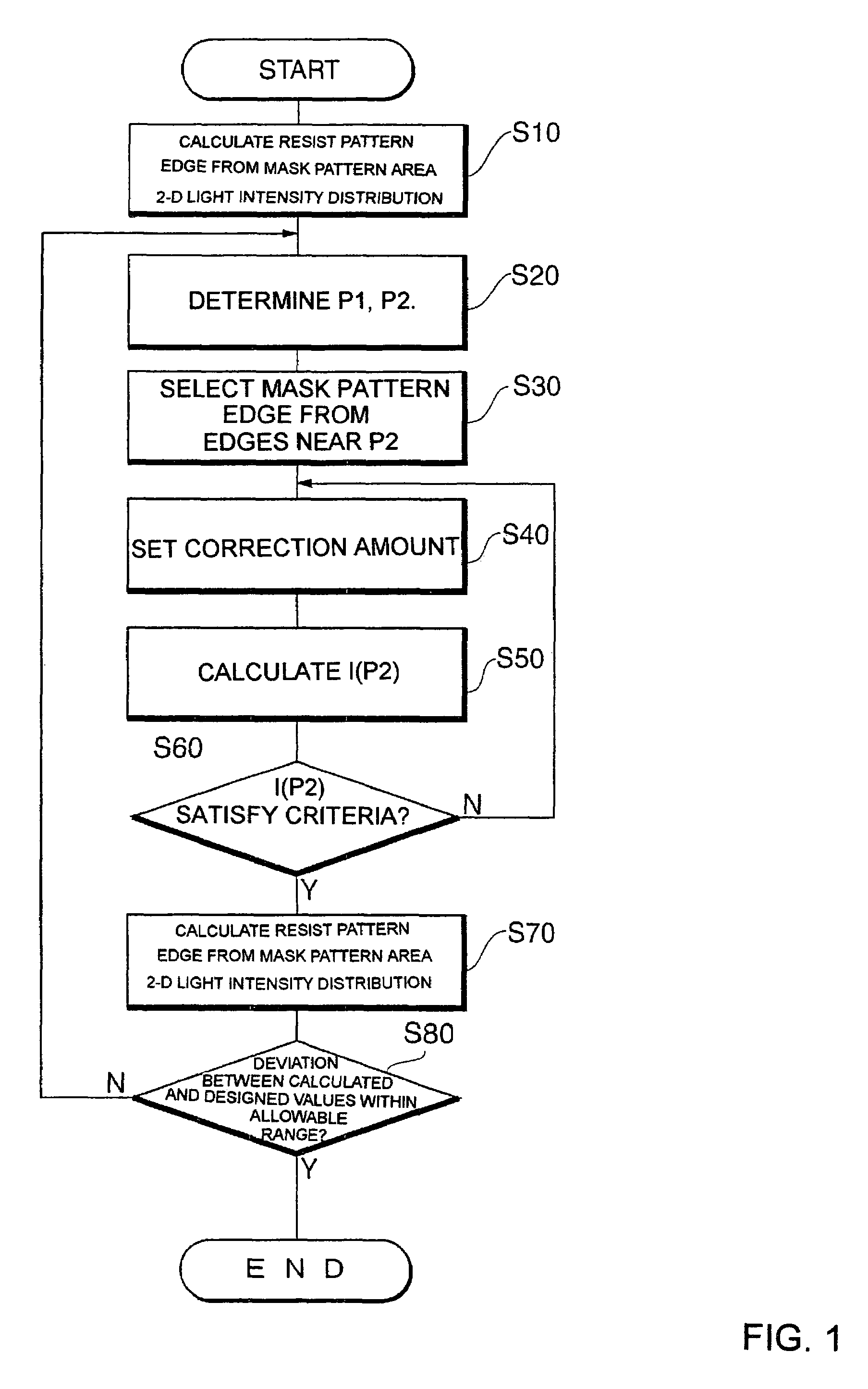

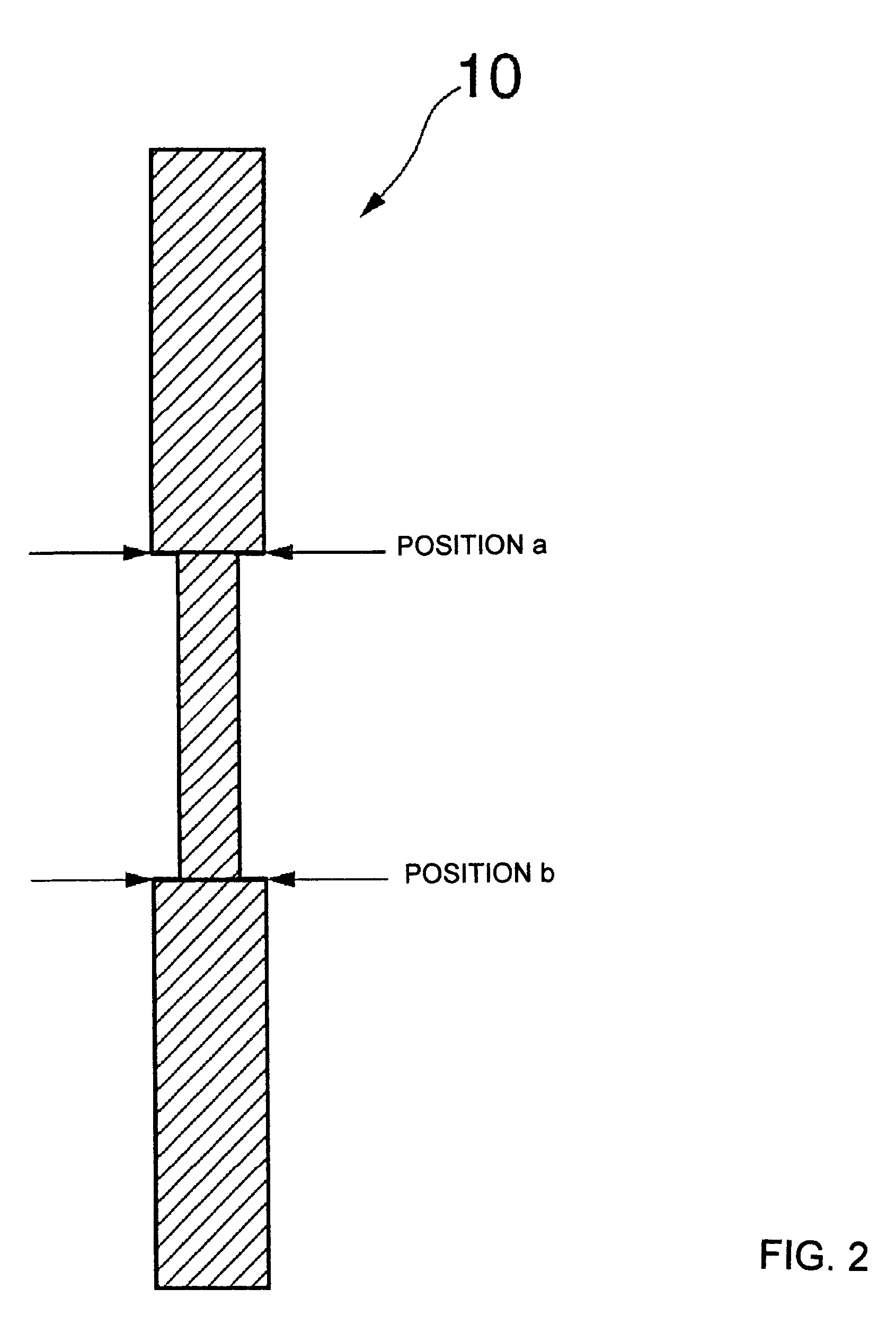

Method of correcting mask pattern

InactiveUS7459243B2Without deteriorating work efficiencyReduce processing timeOriginals for photomechanical treatmentFilm packagingClosest pointPoint light

A mask pattern correcting method is comprised of a before-correction pattern edge defining step for defining an edge of a mask pattern, a deviated position setting step for setting a close point and a isolated point based on the deviation between the pattern edges of the mask pattern and the design pattern, an edge selecting step for correcting an edge located within specified distance from the isolated point, and selecting a mask pattern edge that will have smaller variation of the close point light intensity and larger variation of isolated point light intensity by the correction, a correcting step for correcting an edge to be corrected such that the isolated point light intensity after correction satisfies a criterion for correction, an after-correction pattern edge defining step for defining a pattern edge of the corrected mask pattern, and an end determining step for ending correction when the deviation between the defined after-correction pattern edge and the edge of the design pattern is within a specified criteria for determining ending correction.

Owner:LAPIS SEMICON CO LTD

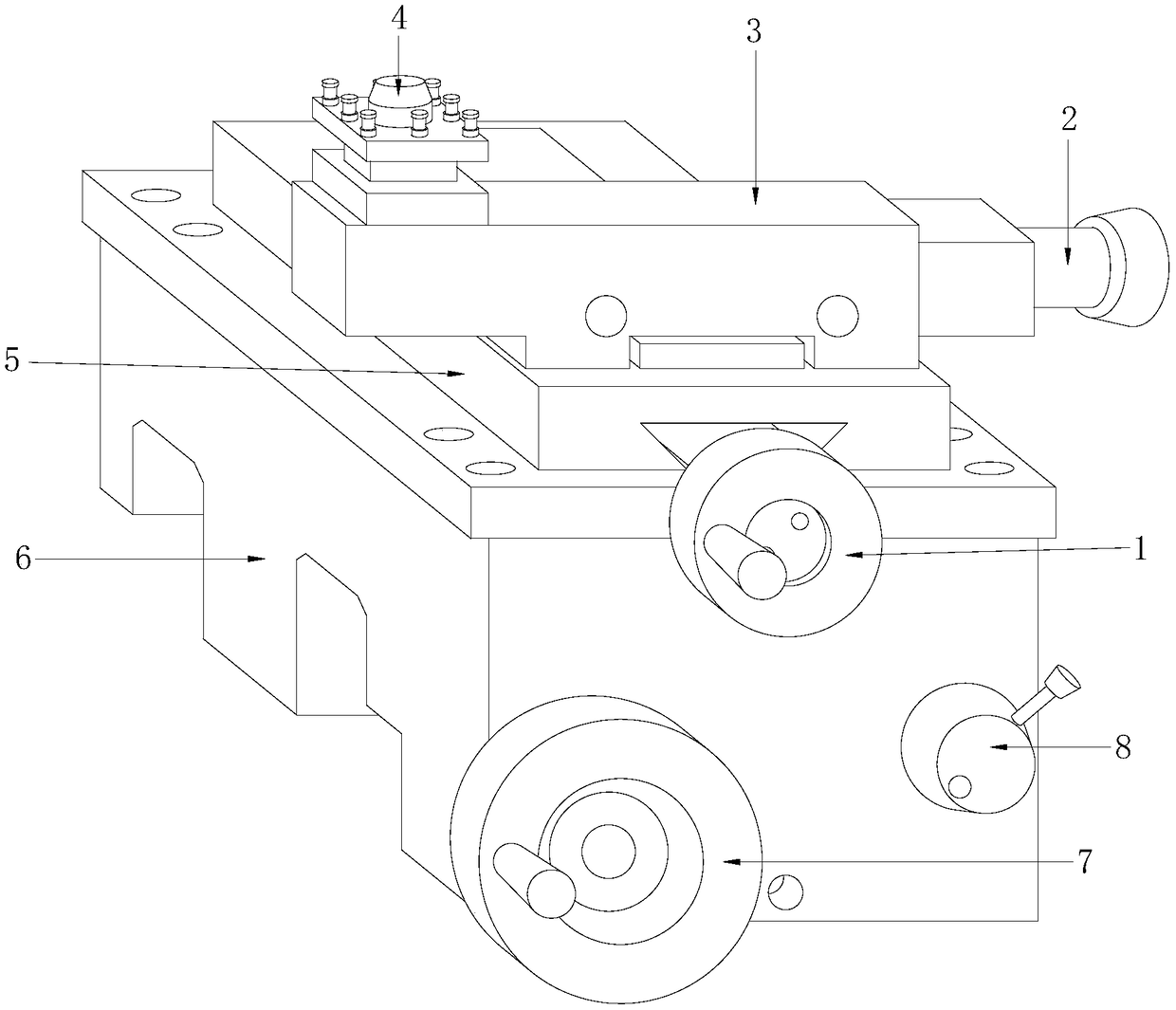

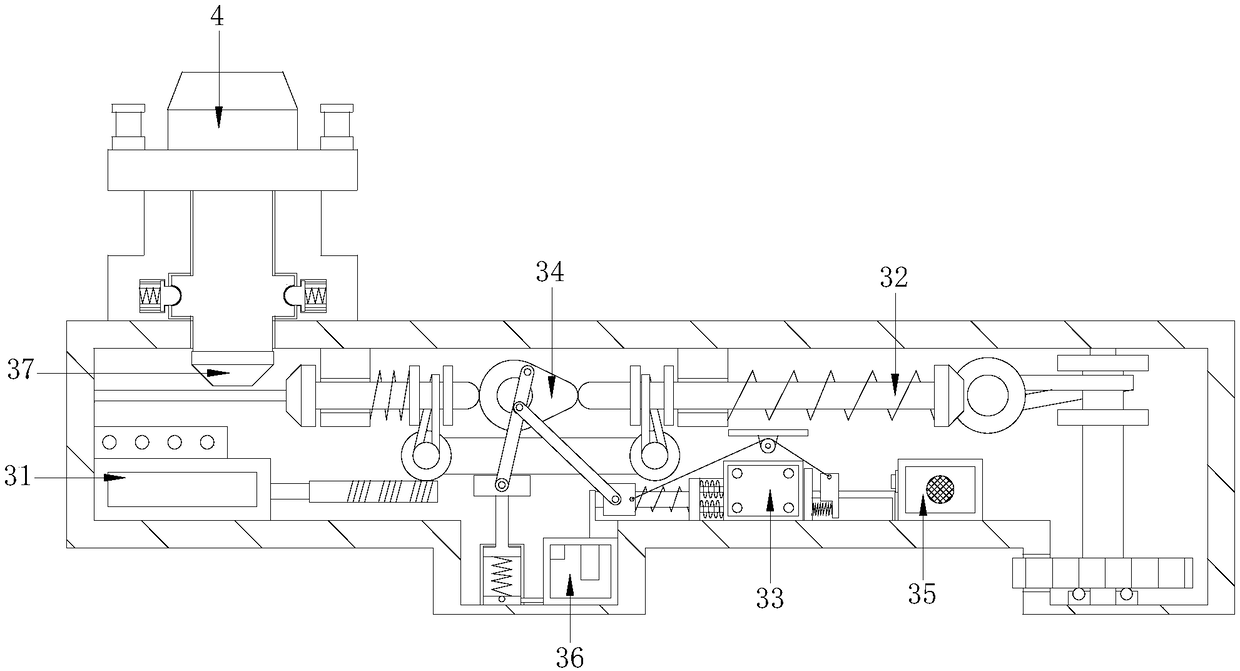

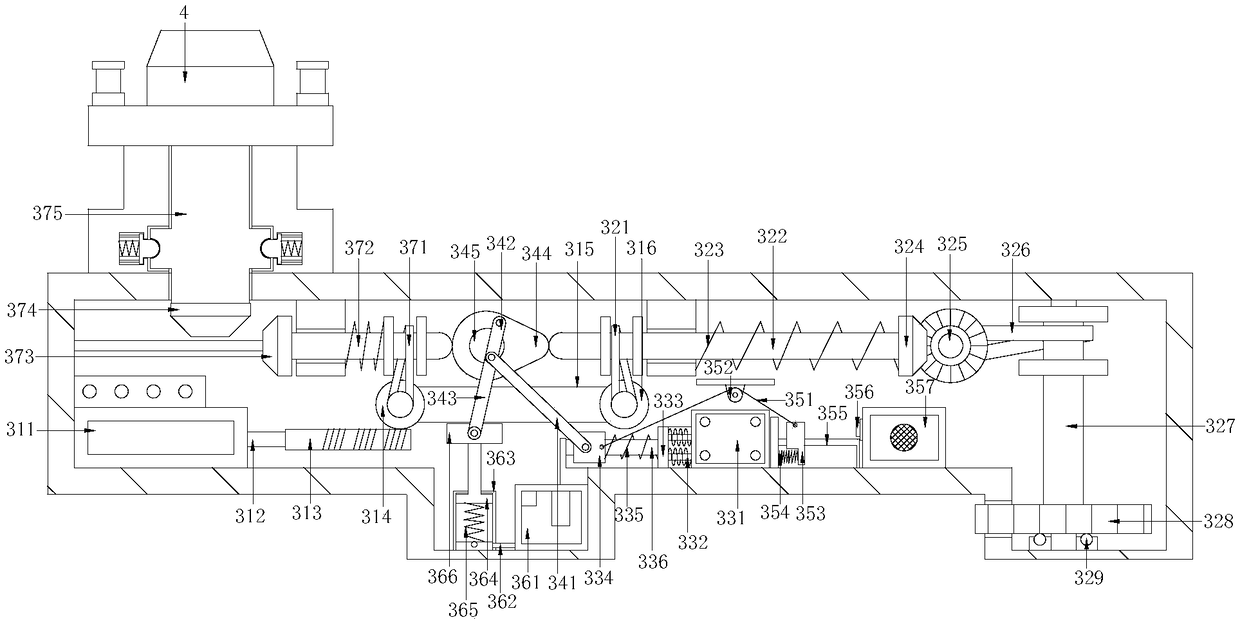

Feeding mechanism for lathe

InactiveCN108856742ATimely processingLarge deviationAutomatic control devicesAuxillary equipmentEngineeringMachining

The invention discloses a feeding mechanism for a lathe. The feeding mechanism structurally comprises a manually-adjusted feeding rotary disc, a tapping tube, a turning and feeding cutter replacementdevice of an automatic-stop anti-collision cutter, a turning cutter rack, a feeding guide rail plate, a cutting depth movement device, a cutting depth adjusting rotary disc and a position locking valve, wherein the manually-adjusted feeding rotary disc is mounted at the direct front end of the cutting depth movement device and is connected with the cutting depth movement device in an embedding manner; the tapping tube is positioned on the right side of the turning and feeding cutter replacement device of the automatic-stop anti-collision cutter and is connected with the turning and feeding cutter replacement device of the automatic-stop anti-collision cutter in an electric welding manner; the turning cutter rack is mounted on the upper surface of the turning and feeding cutter replacementdevice of the automatic-stop anti-collision cutter. According to the feeding mechanism disclosed by the invention, while machining and feeding of the cutter and adapting and replacement of the cutterare controlled, cutter collision caused by over-large feeding quantity can be stopped in time so as to be protected, and therefore, abrasion of cutter edges of the cutter is avoided while chipping andbreaking of the cutter can be prevented at the same time so as to avoid influence of machining of workpieces; meanwhile, an alarm is started to prompt working personnel to maintain the cutter, so that the phenomenon that deviation of molded workpieces is large when the cutter edge is broken and is then machined is avoided.

Owner:黄红兵

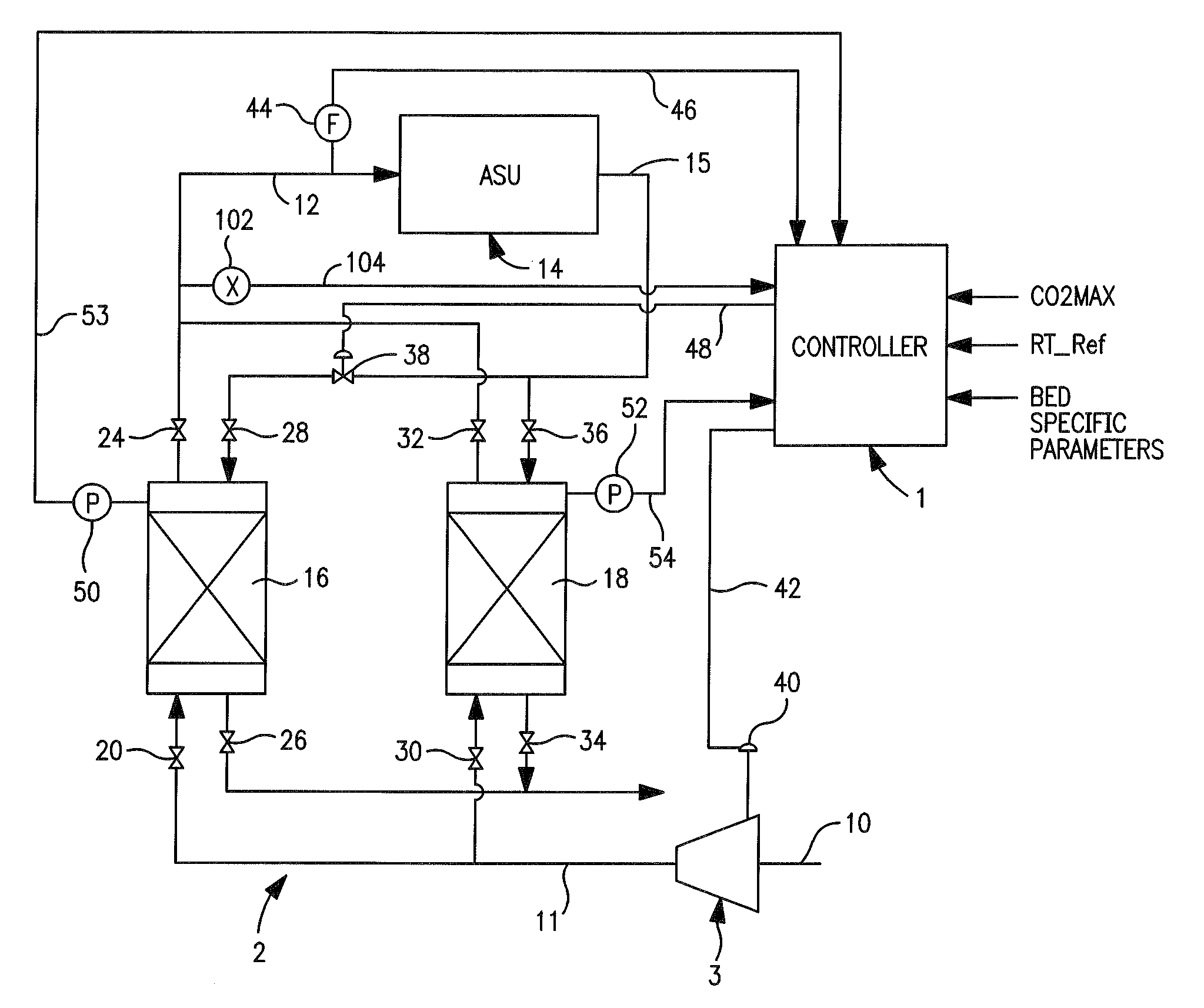

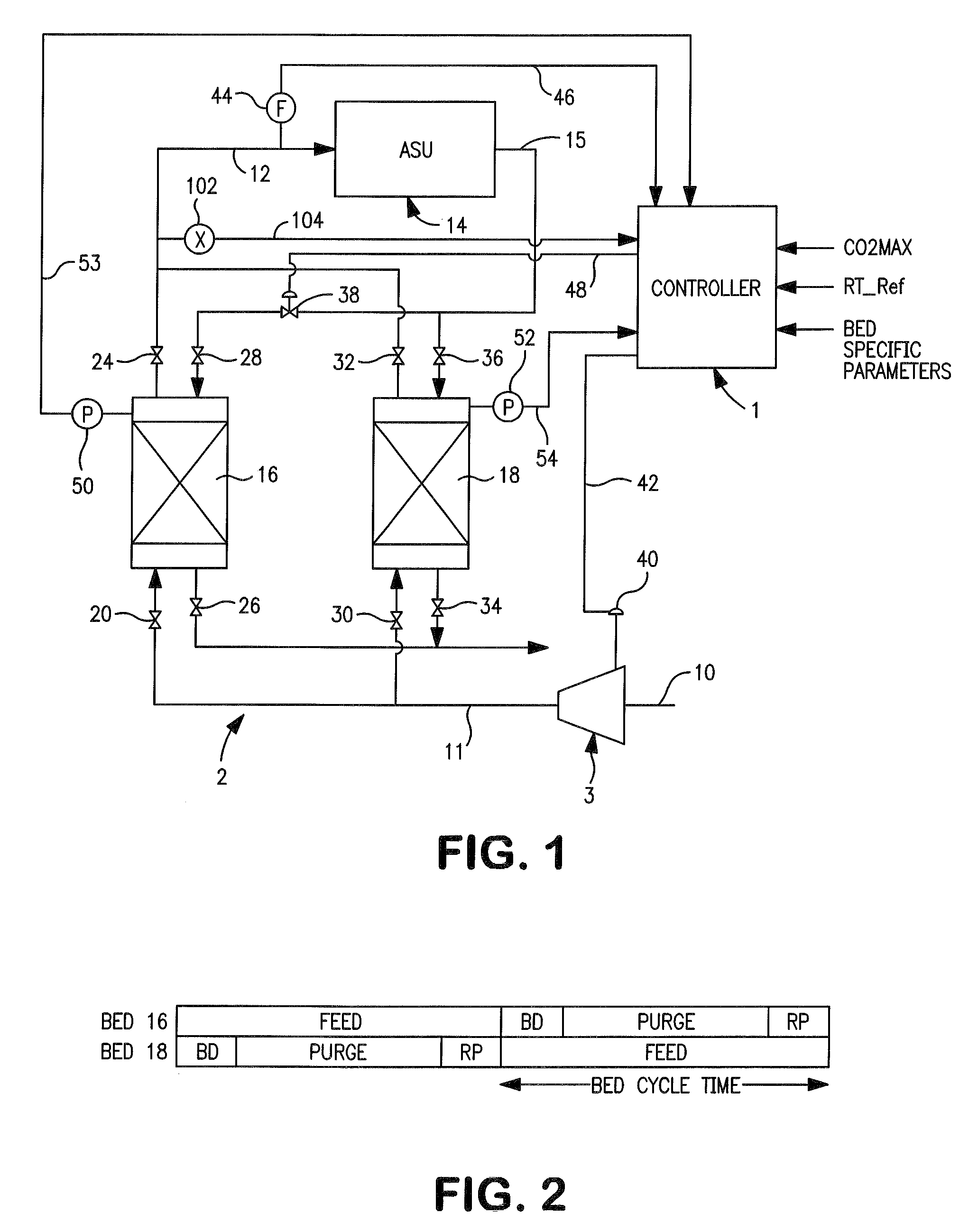

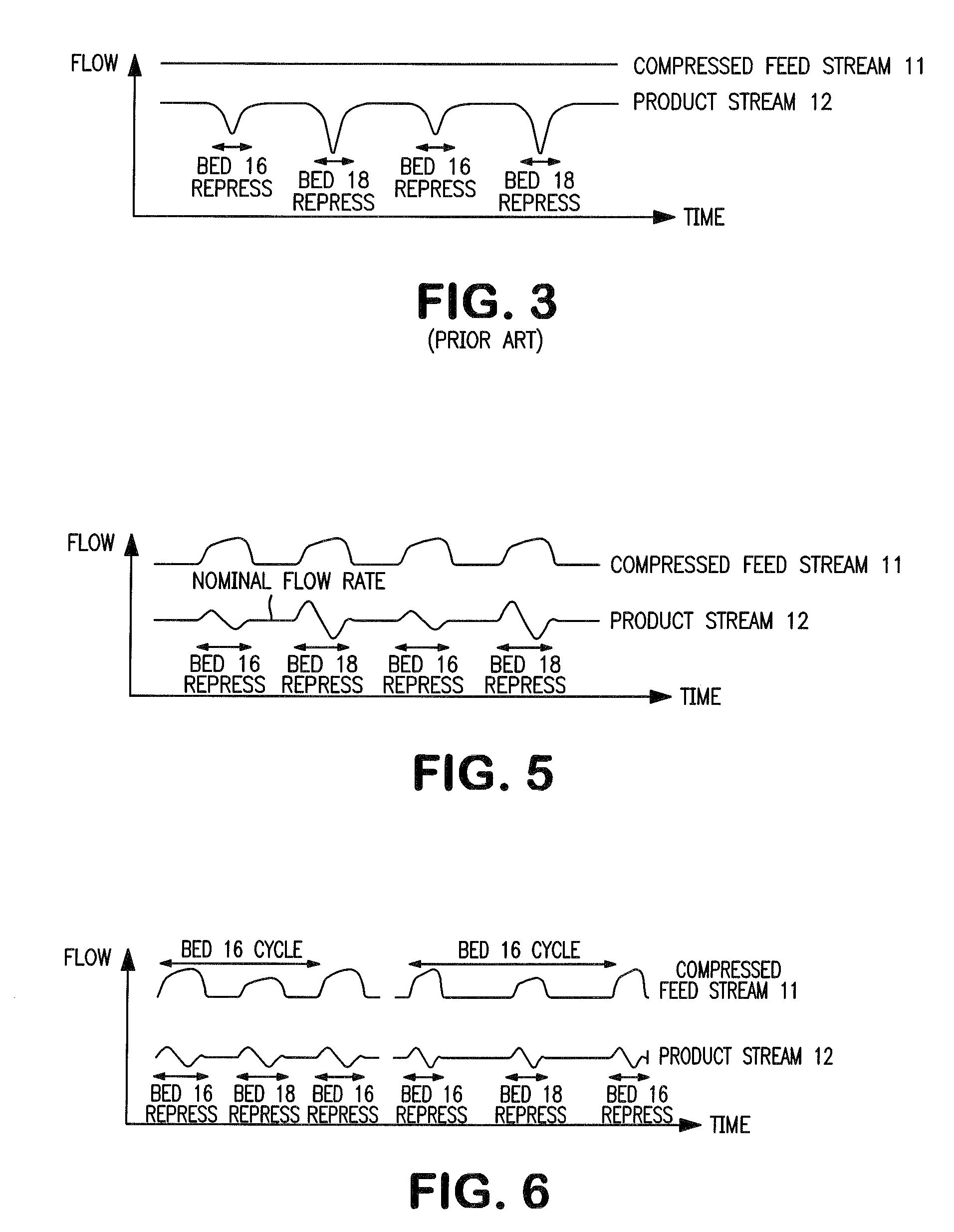

Adsorbent bed repressurization control method

InactiveUS7789939B2Minimize timeExtend cycle timeSolidificationGas treatmentStream flowProcess engineering

A method for controlling an adsorption unit and associated compressor that adjusts the flow rate of a compressed feed stream produced by the compressor so that it increases from a nominal flow rate and then decreased back to the nominal flow rate. The increase and decrease of the feed stream flow rate are controlled in accordance with increase and decrease rate functions of adsorbent bed pressure ratio between off-line and on-line adsorbent beds and a triggering pressure ratio at which the feed flow rate decreases. Each of the increase and decrease rate functions is tuned to produce a similar response in the flow of a product stream produced by the adsorption unit. Additionally, repressurization time is controlled by driving it toward a target value that allows the purge stage of regeneration to be maximized and therefore, the degree to which each of the adsorbent beds is regenerated.

Owner:PRAXAIR TECH INC

A valve

ActiveUS20160001033A1Restrict movementPrevent movementRespiratorsDiaphragm valvesEngineeringVALVE PORT

Owner:KONINKLJIJKE PHILIPS NV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com