Patents

Literature

91results about How to "Play a role in cleaning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Disinfecting equipment for medical apparatus

InactiveCN106620767ARealize continuous disinfectionImprove work efficiencyChemicalsRadiationDisinfectantUv disinfection

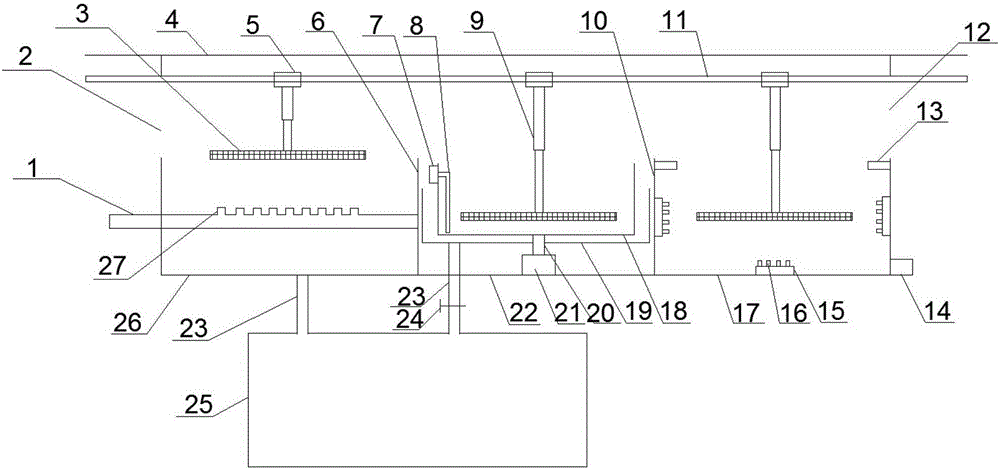

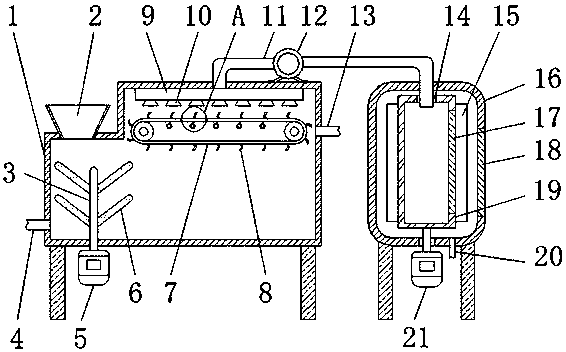

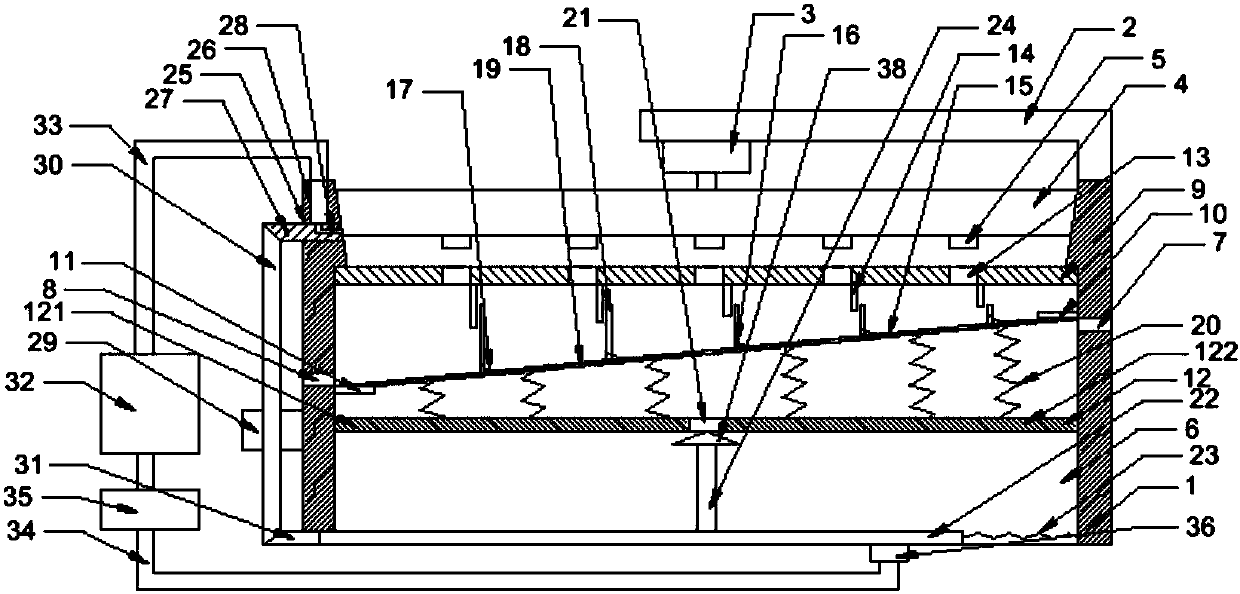

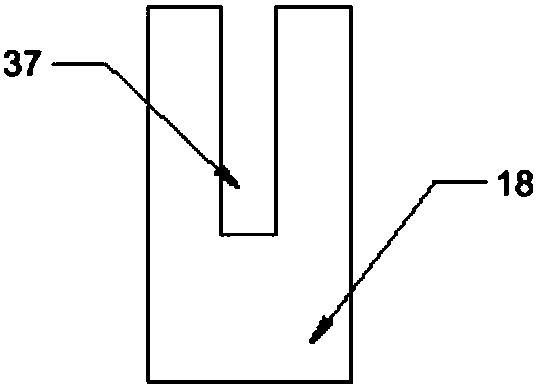

The invention discloses disinfecting equipment for a medical apparatus. The disinfecting equipment comprises a disinfecting box, wherein a first partition board and a second partition board are sequentially arranged in the disinfecting box; by virtue of the first partition board and the second partition board, the disinfecting box is divided into a primary disinfecting chamber, a secondary disinfecting chamber and a tertiary disinfecting chamber; both the first partition board and the second partition board are lower than the disinfecting box; the sidewall, at one side of the primary disinfecting chamber, of the disinfecting box is provided with an inlet; the sidewall, at one side of the tertiary disinfecting chamber, of the disinfecting box is provided with an outlet; a top cap is arranged on the disinfecting box; a sliding rail and sliding blocks which can slide along the sliding rail are fixedly arranged below the top cap; two ends of the sliding rail run out of the disinfecting box from the inlet and the outlet; storage nets are connected to the bottoms of the sliding blocks by virtue of telescopic rods; a disinfectant spraying device is arranged in the primary disinfecting chamber; an ozone water disinfecting device is arranged in the secondary disinfecting chamber; and ultraviolet disinfecting lamps and a drying device are arranged in the tertiary disinfecting chamber. According to the disinfecting equipment provided by the invention, by arranging the plurality of storage nets, the three disinfecting chambers are constantly kept under a working state, so that continuous disinfection is achieved, and working efficiency is improved.

Owner:弘毅天承知识产权股份有限公司

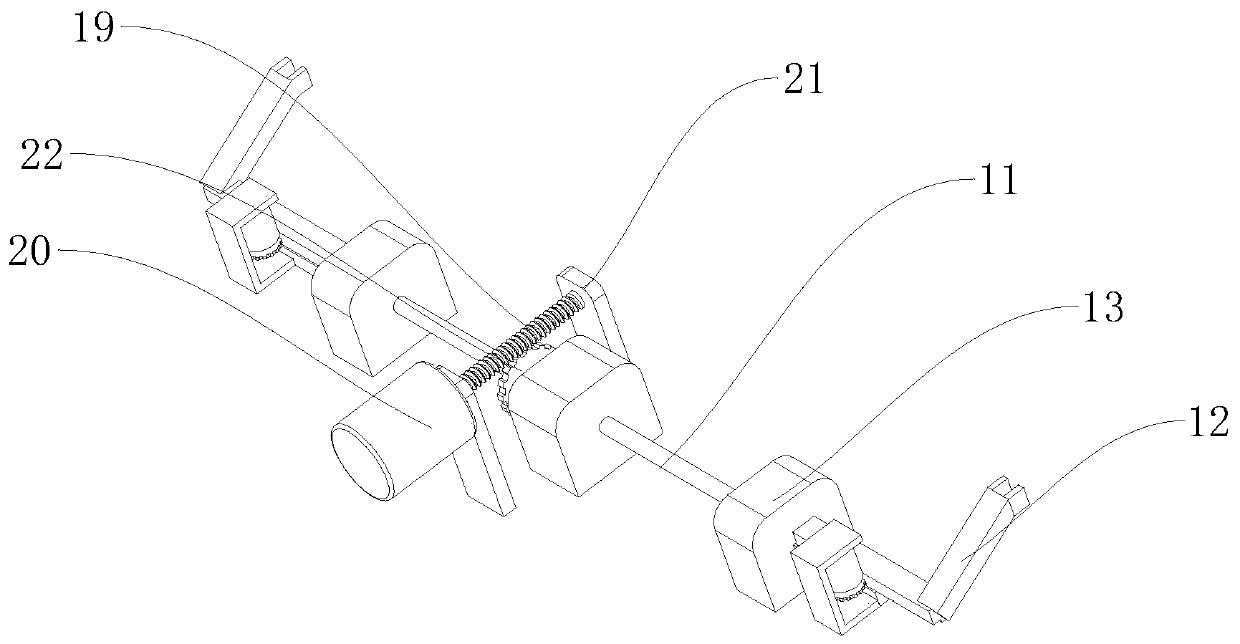

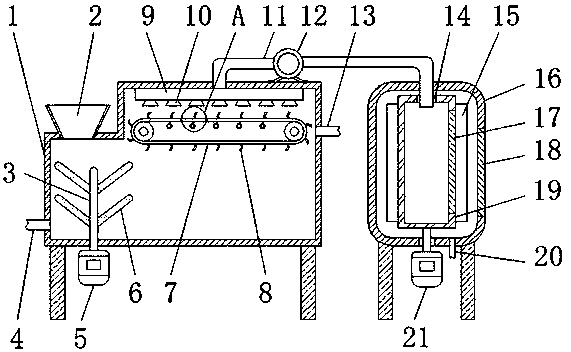

Cleaning equipment and cleaning method for small-pipe diameter pipeline

ActiveCN105537206APlay a role in cleaningLess componentsHollow article cleaningSewageElectrical and Electronics engineering

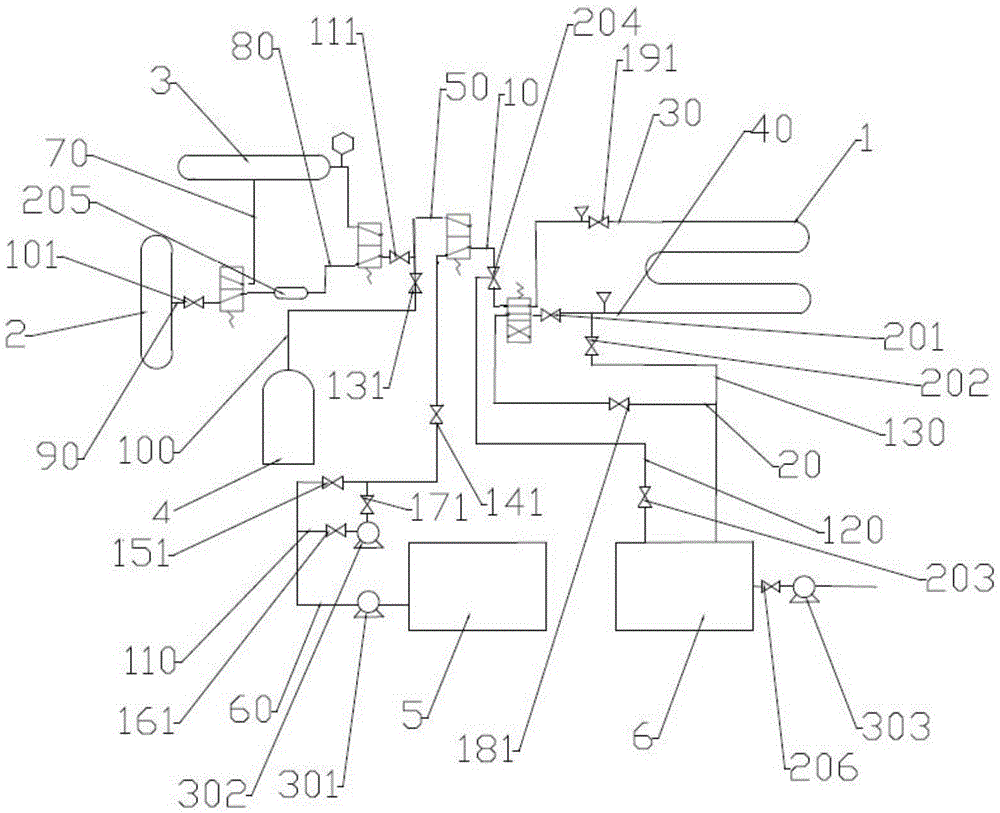

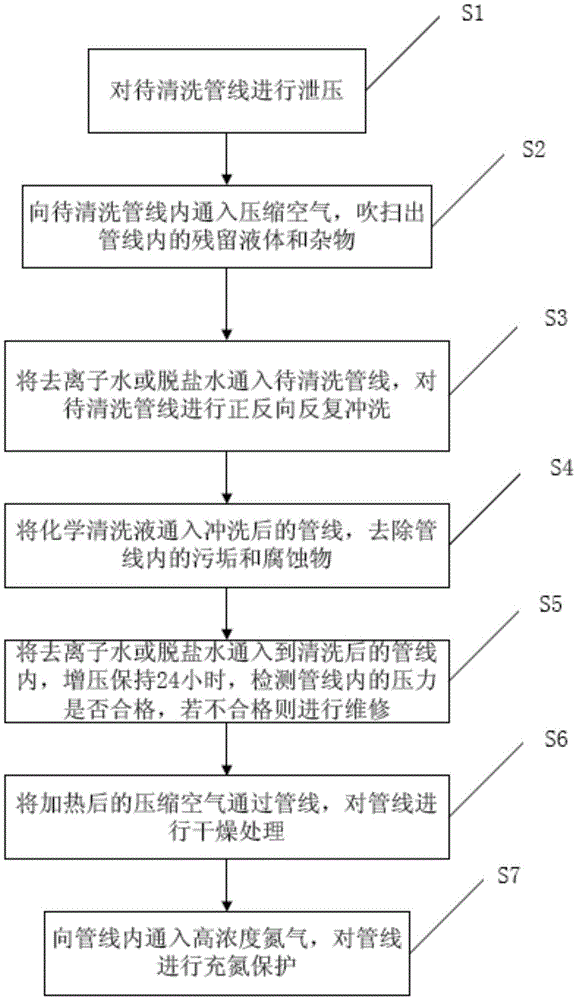

The invention relates to the technical field of pipeline cleaning, in particular to cleaning equipment and a cleaning method for a small-pipe diameter pipeline. The cleaning equipment comprises a pump unit, a first connection pipe, a second connection pipe, a third connection pipe, a fourth connection pipe, a fifth connection pipe, a sixth connection pipe, a first two-inlet one-outlet valve, an air supply device and a four-way reversing valve; the outlet of the first connection pipe selectively communicates with the third connection pipe or the fourth connection pipe through the four-way reversing valve; the second connection pipe is connected with the four-way reversing valve; the third connection pipe and the fourth connection pipe are separately connected with two ends of the to-be-cleaned pipeline; the inlet of the first connection pipe selectively communicates with the outlet of the fifth connection pipe or the outlet of the sixth connection pipe through the first two-inlet one-outlet valve; the inlet of the fifth connection pipe is connected with the air supply device; the inlet of the sixth connection pipe communicates with a cleaning tank; the pump unit is arranged on the sixth connection pipe; and the outlet of the second connection pipecommunicateswith a sewage tank. According to the cleaning equipment, fewer components are adopted; a series of operation of cleaning of the pipeline can be realized; and the operation is simple.

Owner:北京蓝星清洗有限公司

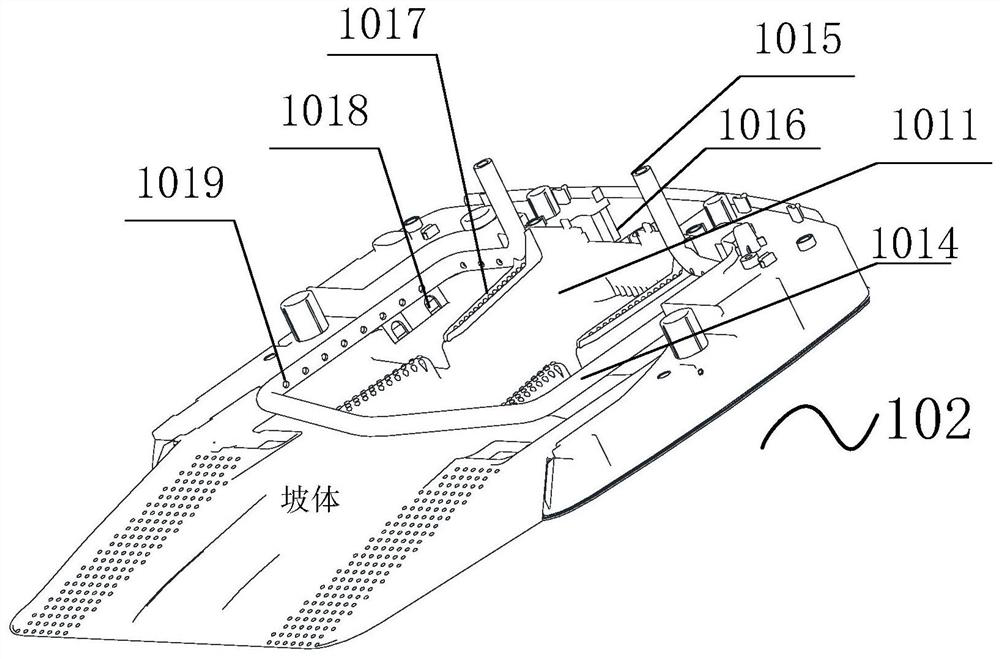

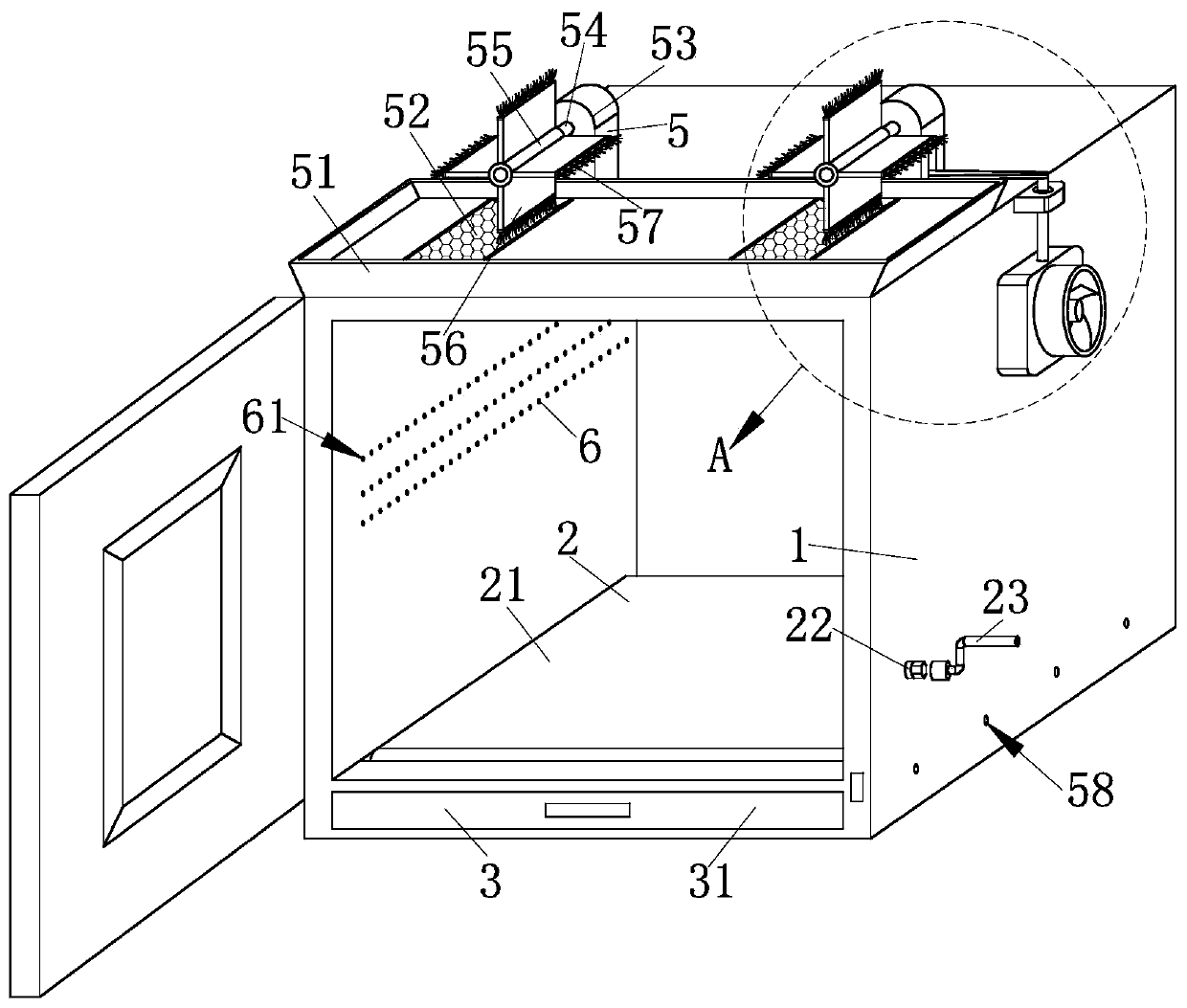

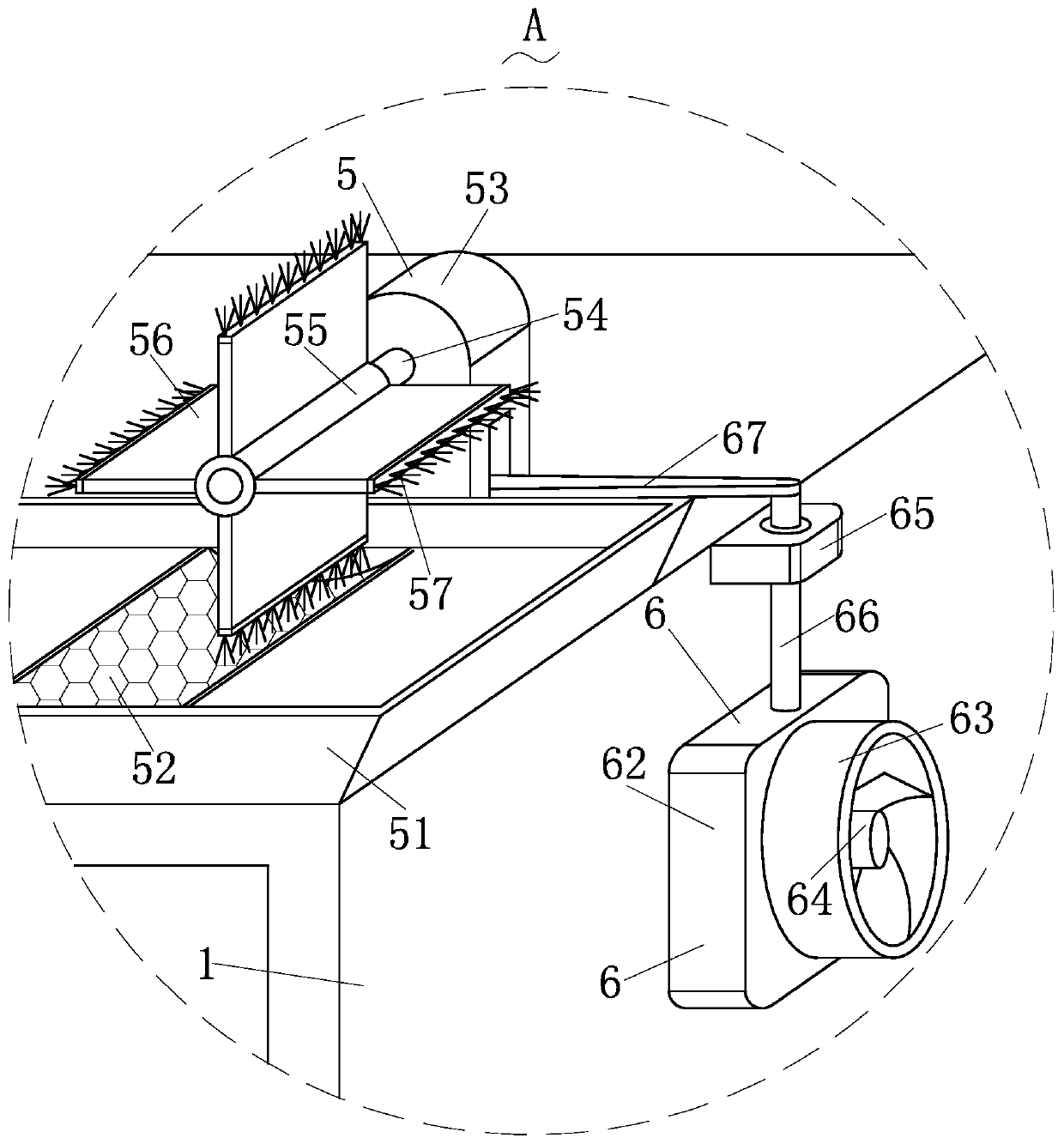

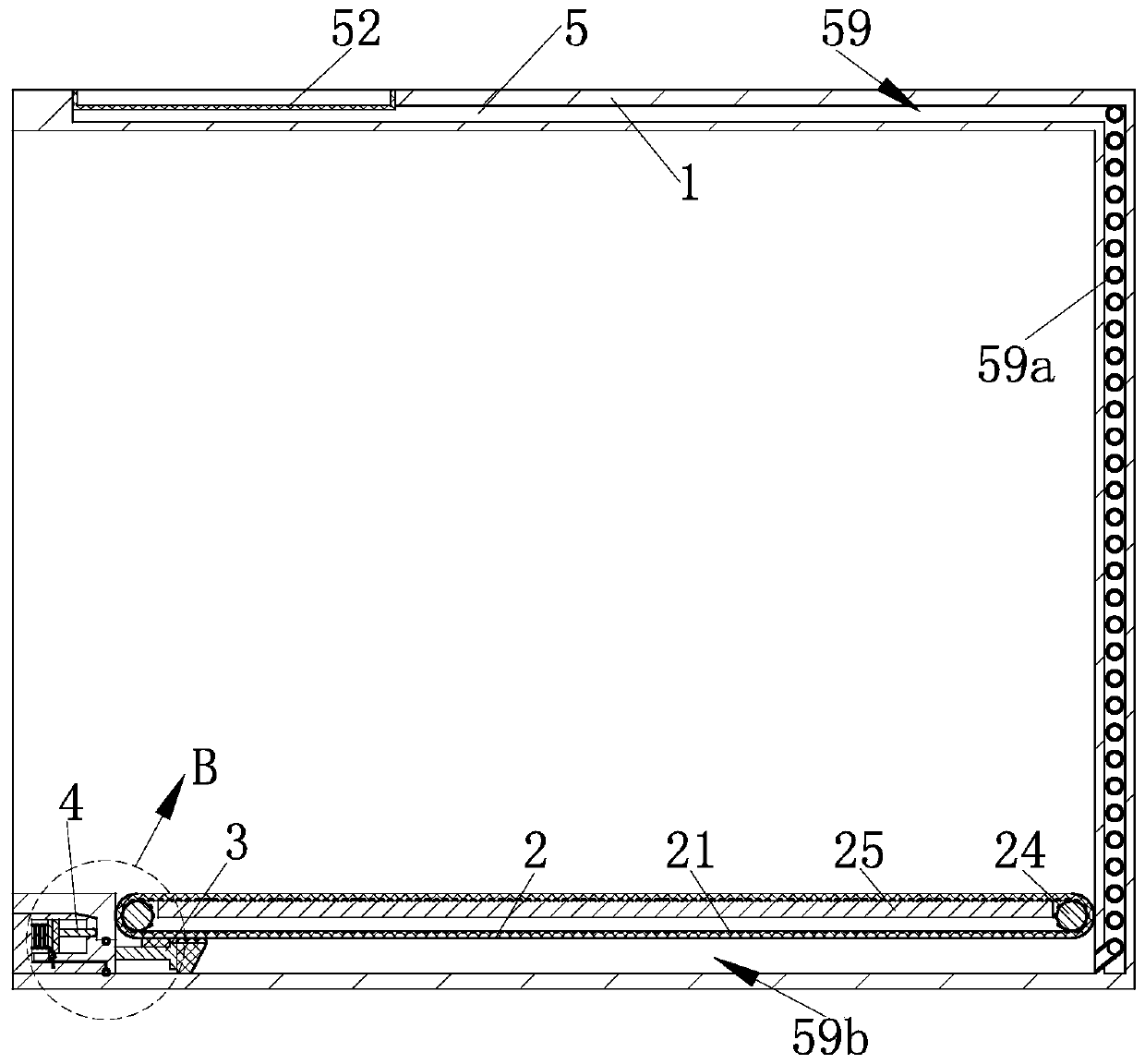

Protective device for electrical equipment

ActiveCN108262270APlay a role in cleaningGuaranteed power generation efficiencyFouling preventionPhotovoltaicsExtreme weatherElectric power

The invention discloses a protective device for electrical equipment, and relates to the technical field of electrical equipment. The protective device comprises a fixed base, a row brush and a springroller shutter, the row brush can slide along lower guide columns arranged on the fixed base, and the spring roller shutter can slide along upper guide columns arranged on the fixed base. A solar panel is cleaned by the row brush arranged on the fixed base in which the solar panel is installed, so that the problem that the generating efficiency is affected due to the fact that the solar panel iscovered with sand, dust and accumulated snow in present is solved. By using the spring roller shutter to cover the solar panel, the problem that the surface of the solar panel is easily damaged by extreme weather such as hail and sand storm is solved. The solar panel is washed by rainwater collected through a water tank, the cleanliness of the surface of the solar panel is further guaranteed, andthe generating efficiency maintains to be maximized.

Owner:江苏欧普电力科技有限公司

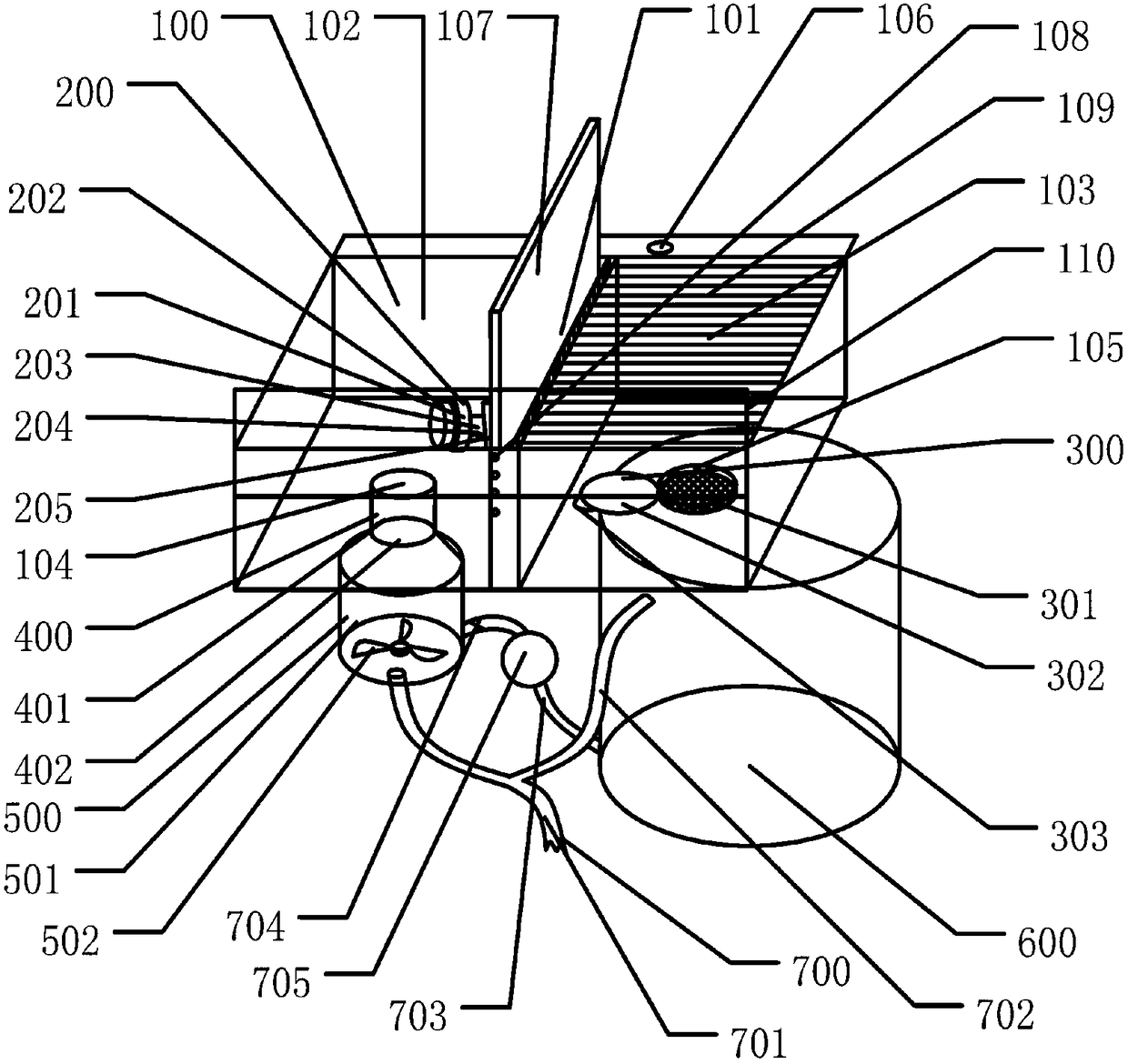

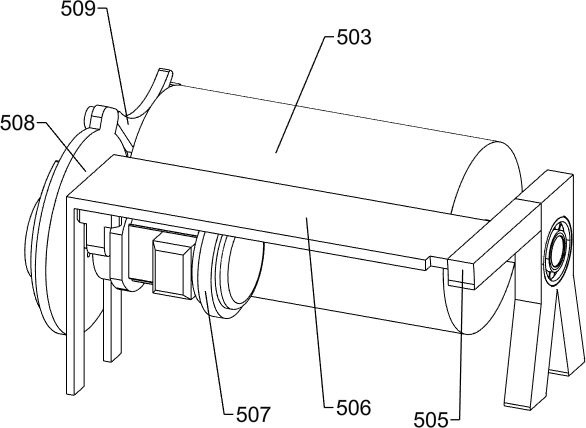

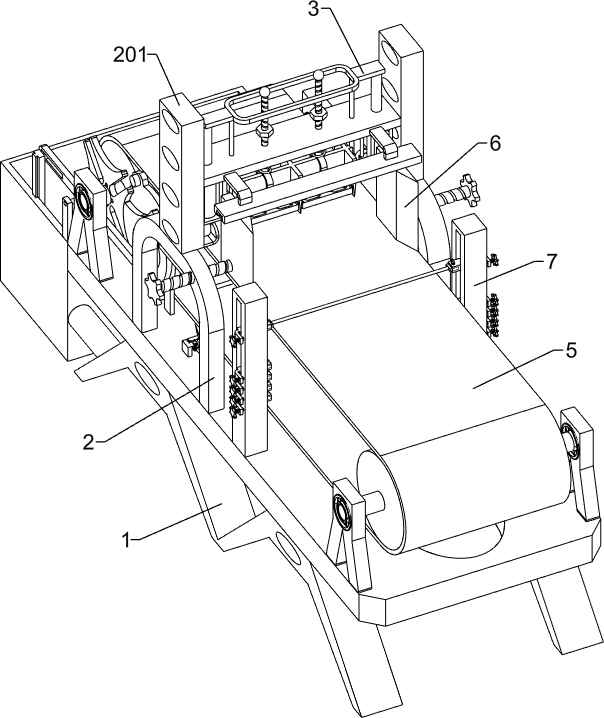

Cleaning and drying device conveniently removing impurities for down feather production and processing

ActiveCN108168222AFacilitate subsequent processingProcessing effectDrying solid materials without heatWool fibre washing/scouringEngineeringWater pipe

The invention discloses a cleaning and drying device conveniently removing impurities for down feather production and processing. The cleaning and drying device includes a cleaning device, a water inlet pipe, a stirring rod, a transmission belt, a suction opening, a fan, a first water outlet, a protective cover, a protective door, an air-tight door, a spin-dry revolving drum, a second air hose anda blowpipe; the upper of the cleaning device is provided with a feed inlet, the lower of the feed inlet is provided with a rotating rod, the water inlet pipe is located below the left side of the cleaning device, and the cleaning device is internally connected with a first motor through the rotating rod; and the stirring rod is located at the outer side of the rotating rod, the second air hose isarranged in the transmission belt which is provided with through holes, and the through holes are connected with scraping plates. According to the cleaning and drying device conveniently removing theimpurities for the down feather production and processing, the cleaning device is arranged to clean down feather, subsequent processing can be prevented from affection due to impurities in the down feather, and the cleaning of the down feather is facilitated.

Owner:ZHANJIANG ZIJIN DOWN PROD

Anti-scaling agent and preparation method thereof

InactiveCN106833576AInhibition formationEfficient formationDrilling compositionSurface-active agentsSolvent

The invention relates to an anti-scaling agent and a preparation method thereof. The anti-scaling agent comprises the following components by weight percent: 15.0%-20.0% of a barium sulfate anti-scaling agent, 0.10%-0.30% of a wetting inversion agent, 0.10%-0.30% of a surface active agent, 10.0%-15.0% of a mutual solvent, 10.0%-15.0% of a chelating agent and the balance of water. After the anti-scaling agent provided by the invention is injected, the deep part of the ground layer can be cleaned; the back flow is not required; the construction process is simple. The anti-scaling agent provided by the invention has the advantages of wide raw material source, low cost, stable product performance, long service life and long-term storage and use.

Owner:PETROCHINA CO LTD

Sweet potato washing device

InactiveCN105852163AIncrease frictionGood cleaning effectFood treatmentBody right sideAgricultural engineering

Owner:ANHUI LONGWANGSHAN AGRI CO LTD

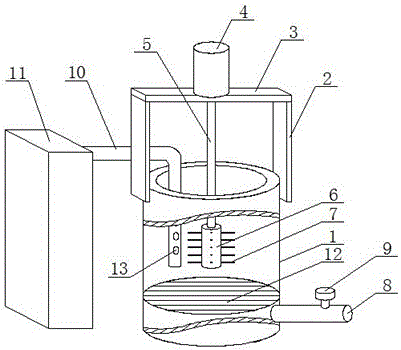

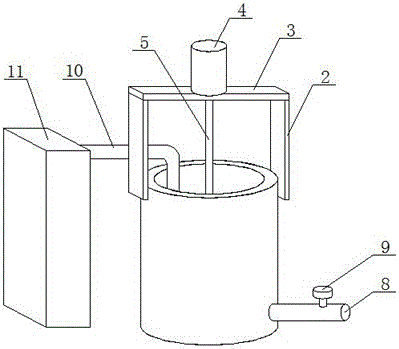

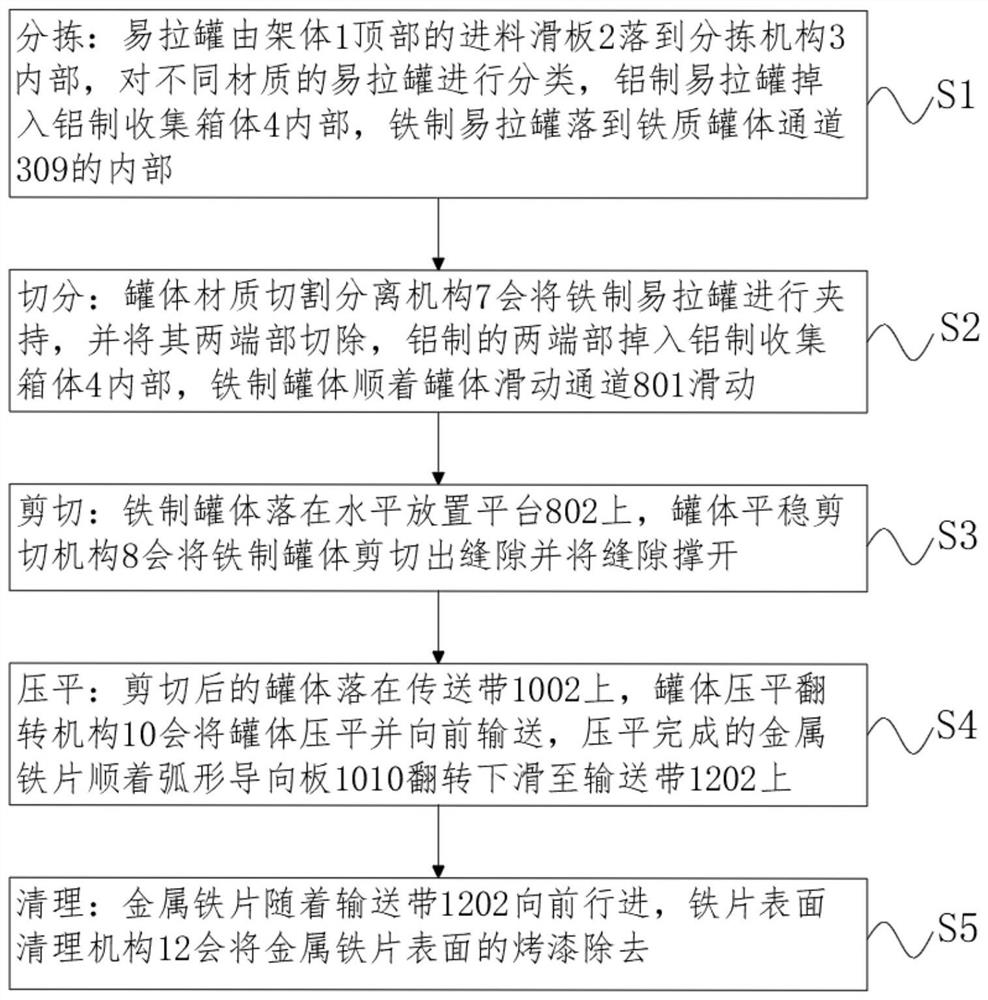

Zip-top can recycling method

PendingCN112157114AScientific and reasonable structureEasy to useTransportation and packagingSolid waste disposalStructural engineeringMechanical engineering

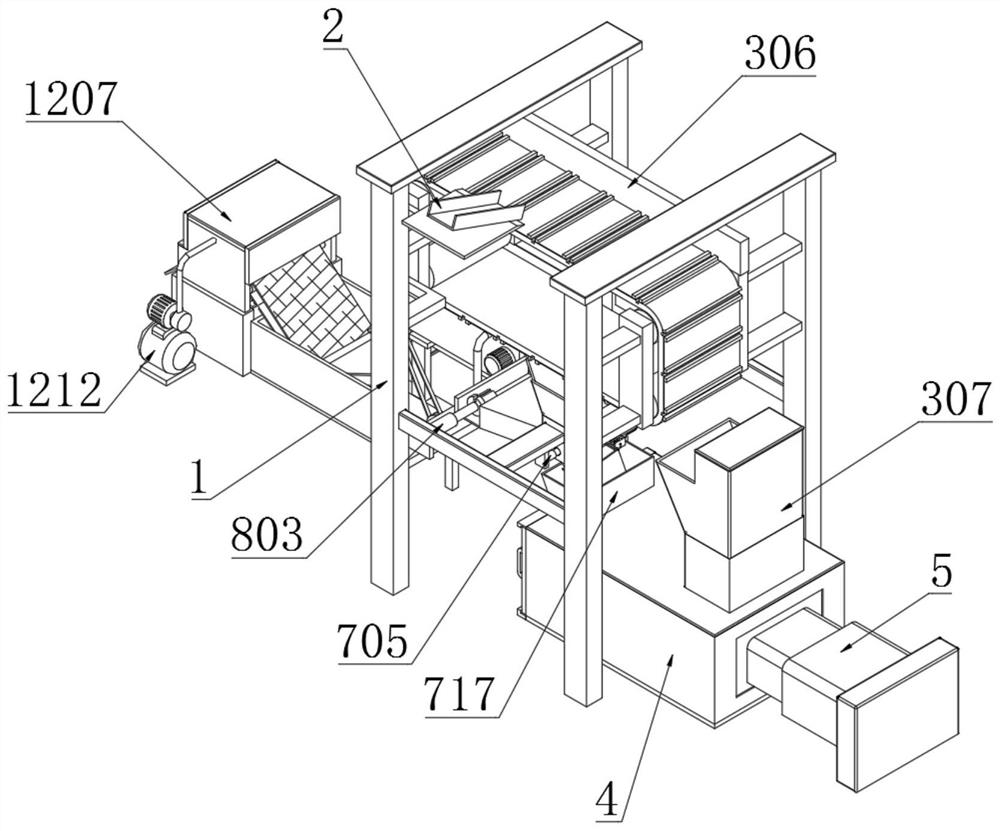

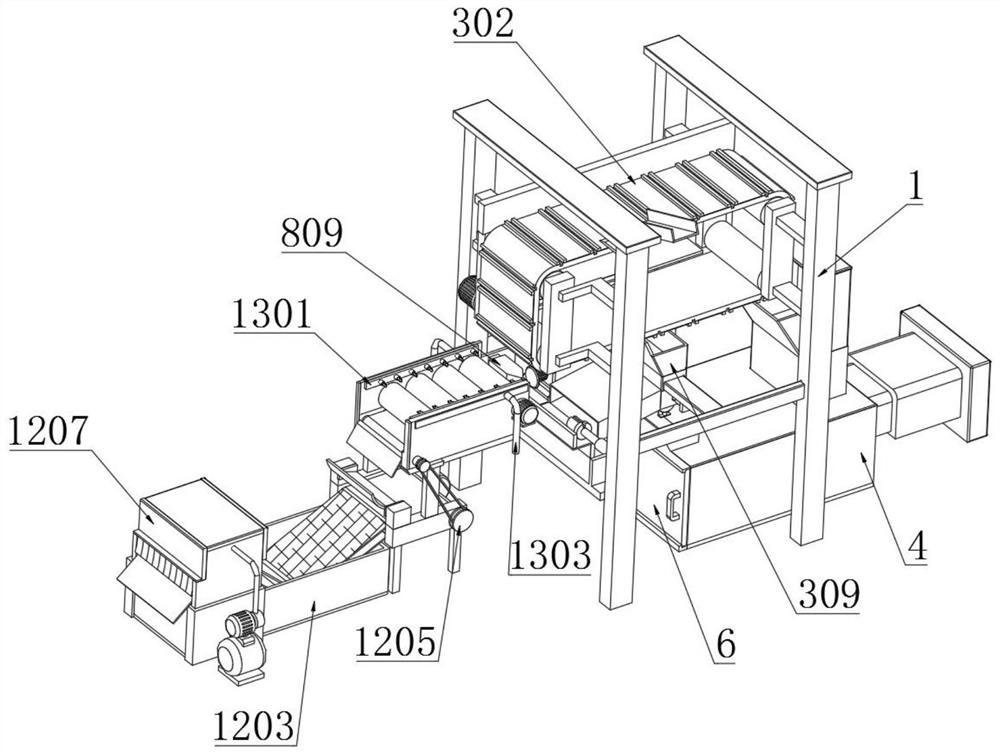

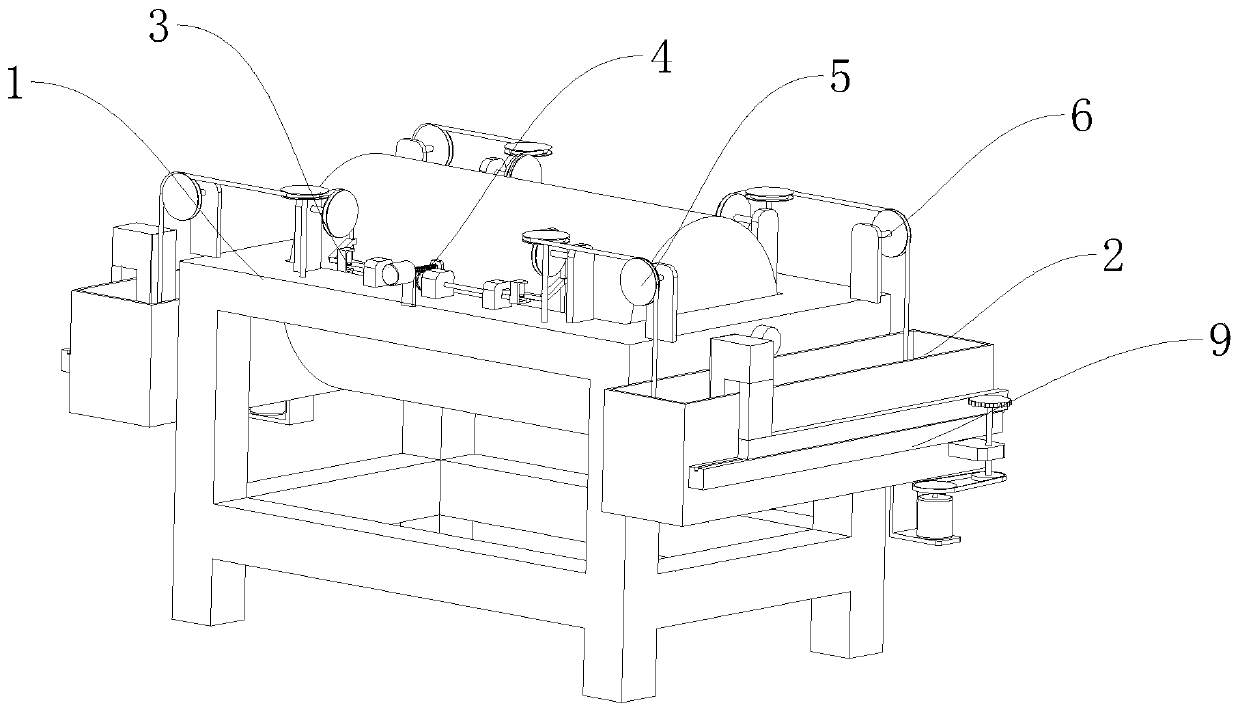

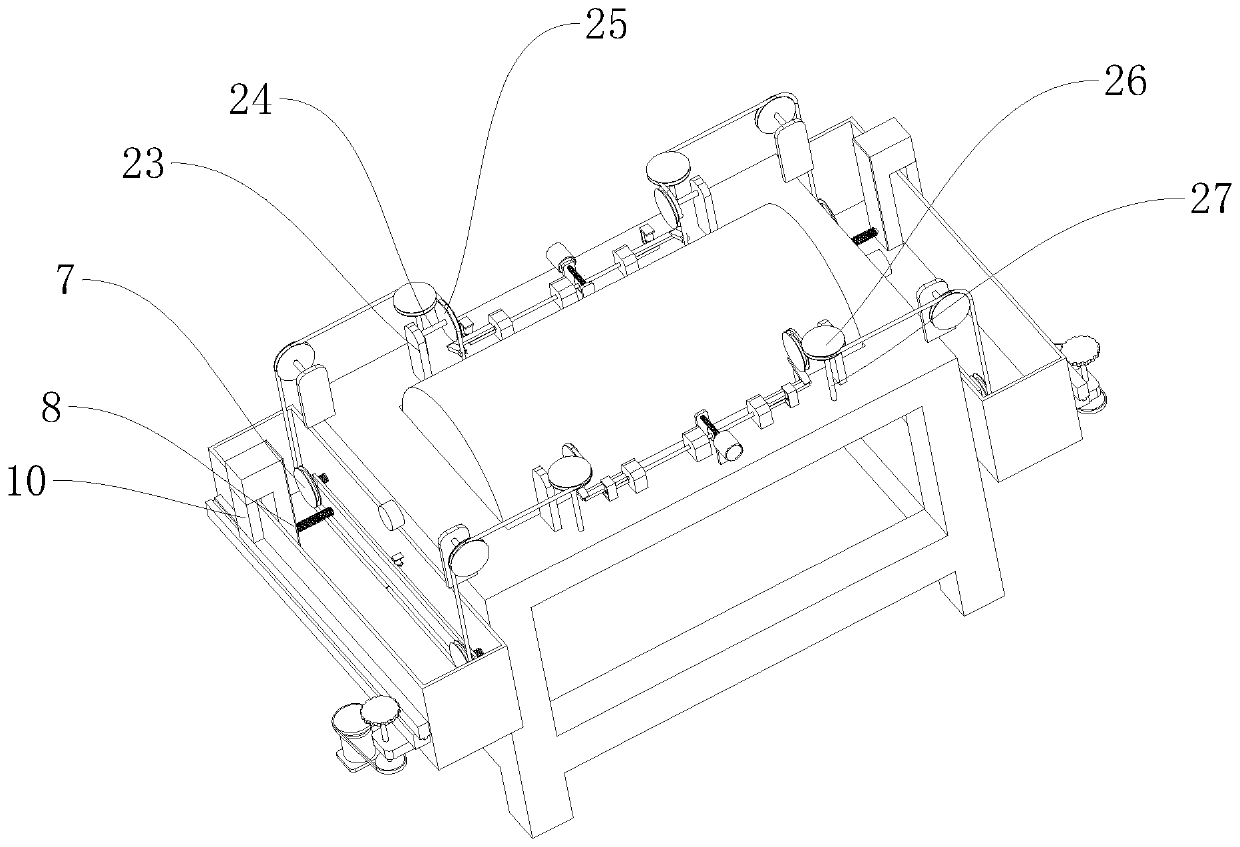

The invention discloses a zip-top can recycling method which comprises the following steps: sorting: zip-top cans fall into a sorting mechanism from a feeding plate at the top of a frame body, the zip-top cans made of different materials are classified, aluminum zip-top cans fall into an aluminum collecting box body, and iron zip-top cans fall into an iron can body channel; cutting: a can body material cutting and separating mechanism can clamp the iron zip-top cans and cut off two ends of the iron zip-top cans, the two aluminum ends fall into the aluminum collecting box body, and iron can bodies slide along a can body sliding channel; shearing: the iron can bodies fall onto a horizontal placing platform, and a stable can body shearing mechanism shears each iron can body to form a gap andexpands the gap; and flattening: the sheared can bodies fall on a conveying belt, a can body flattening and overturning mechanism flattens the can bodies and conveys the can bodies forwards, and flattened iron sheets overturn and slide down to the conveying belt along an arc-shaped guide plate.

Owner:秦金铭

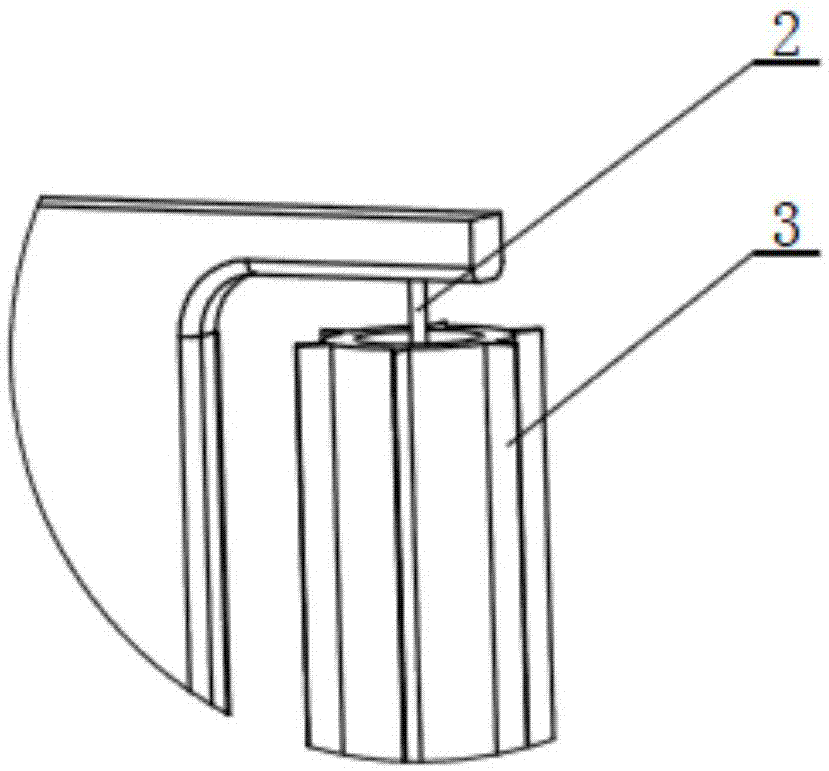

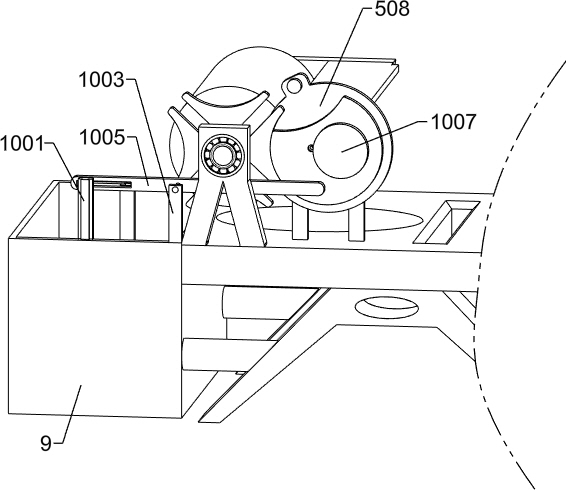

Sealing ring dynamic cleaning device for copper foil electrolytic production

ActiveCN109939993APlay a role in cleaningEasy to cleanCleaning using toolsCleaning using liquidsElectrolysisEngineering

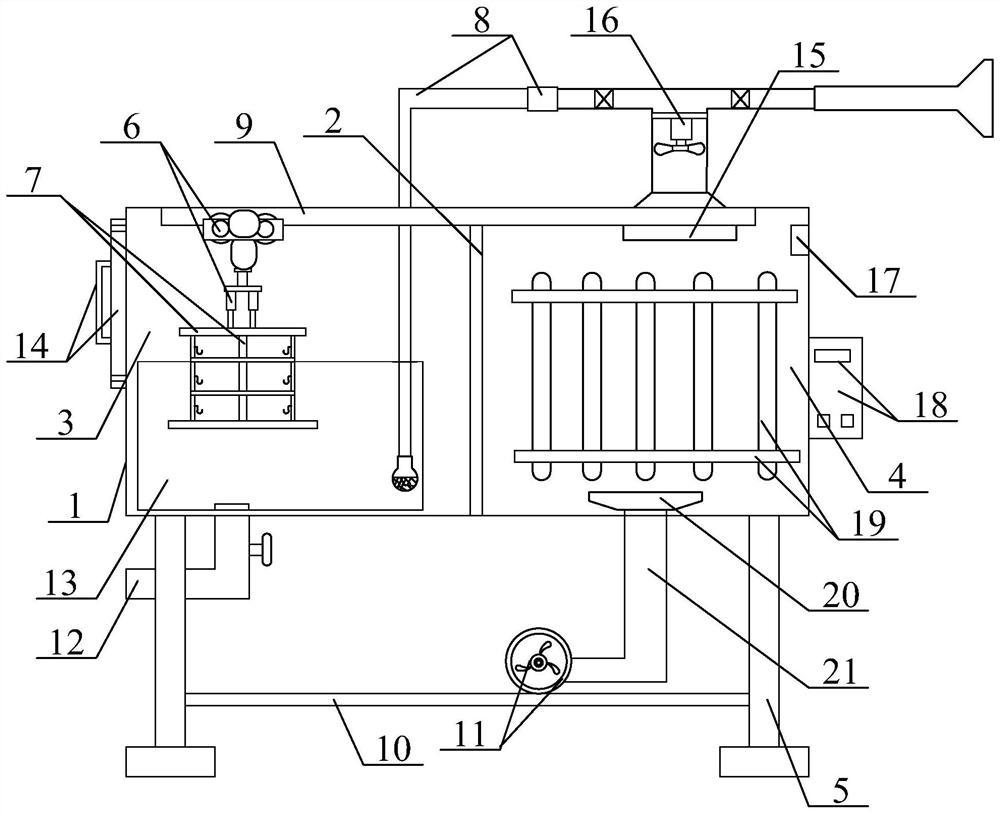

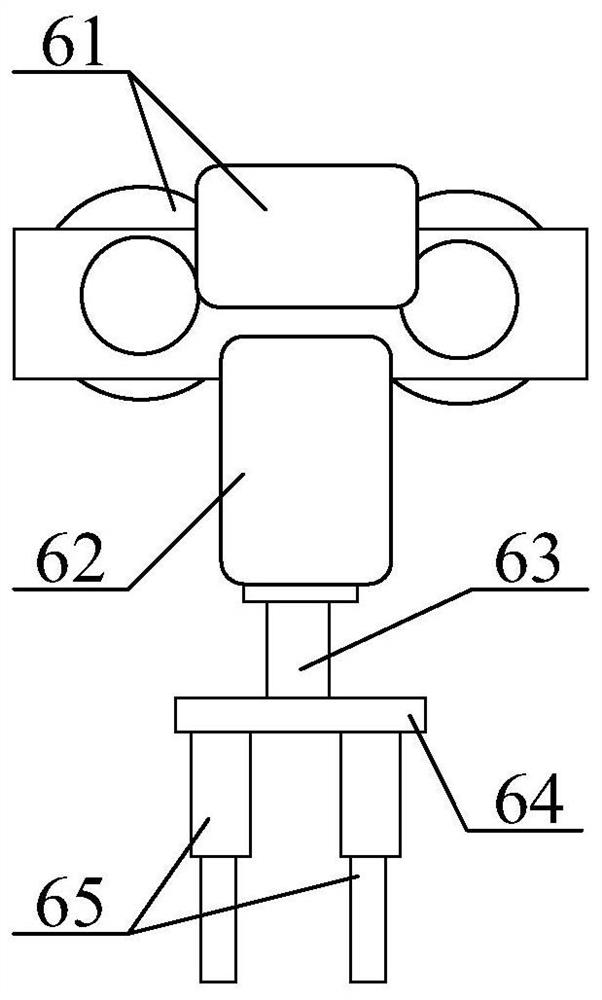

The invention relates to the technical field of electrolytic copper foil production equipment, in particular to a sealing ring dynamic cleaning device for electrolytic copper foil production. The sealing ring dynamic cleaning device for electrolytic copper foil production comprises a guide wheel assembly, a cleaning device and a workbench, wherein a plurality of guide sealing rings are arranged onthe guide wheel assembly; the two sides of the workbench are each provided with a cleaning water tank; the two sides of the workbench are provided with pressing devices for pressing and attaching thesealing rings on a cathode roller; the two sides of the workbench are further provided with driving assemblies for driving the pressing devices to rotate; the guide wheel assembly is arranged at a side portion of each pressing device; a leading-in wheel is arranged on one side above each cleaning water tank; a leading-out wheel is arranged on the other side of each cleaning water tank; the cleaning device comprises cleaning components and horizontal moving components, wherein the horizontal moving component is arranged on the side wall of each cleaning water tank; an output end of each horizontal moving component is vertically provided with a mounting rod; the cleaning component is mounted on each mounting rod; and an output end of each cleaning component extends into each cleaning watertank. According to the sealing ring dynamic cleaning device, the sealing rings are cleaned efficiently.

Owner:赣州逸豪新材料股份有限公司

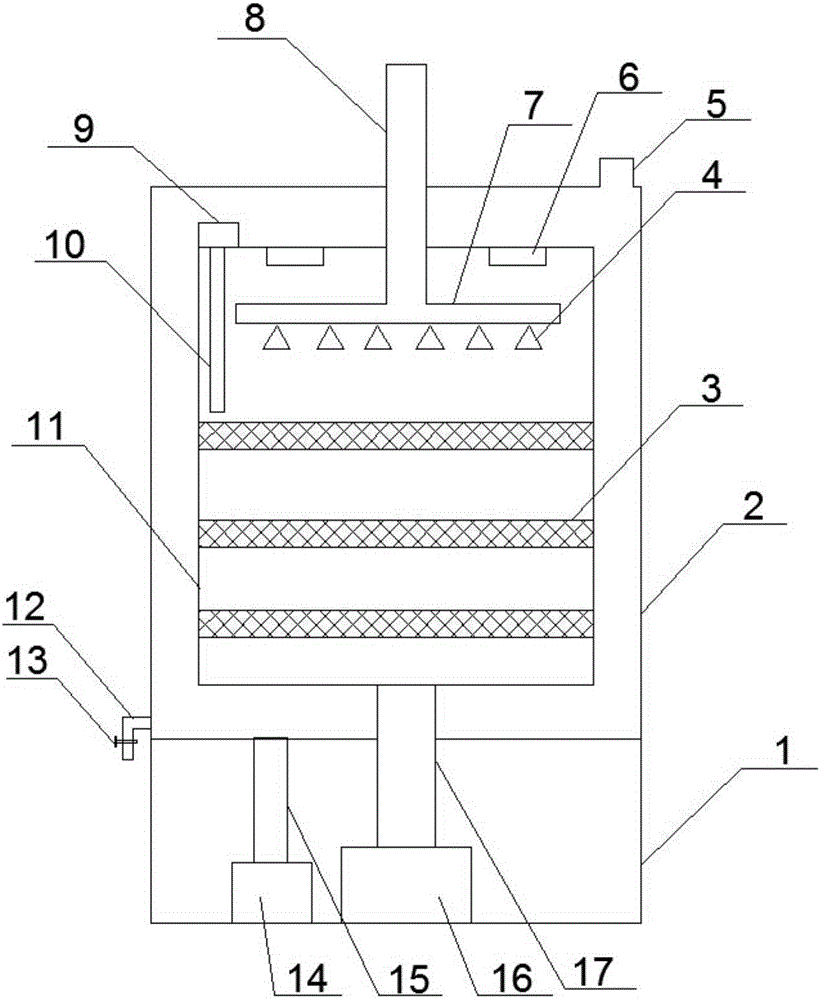

Preparing of compound organic blocking remover and application of compound organic blocking remover to low-permeability oil field

InactiveCN110066649APlay a role in cleaningInhibit swellingCleaning apparatusDrilling compositionCompound organicOrganic acid

The invention discloses a compound organic blocking remover which is composed of body liquid and protection liquid. The body liquid is composed of organic acid, a surfactant and an anti-scaling agent.The protection liquid is composed of an anticrustator, an anti-swelling agent and water. During preparing and using, all the components are evenly mixed according to the mass percentages of the formula; the compound organic blocking remover is diluted with water and injected and reversely discharged separately in use, so the blocking removal aim can be realized. When the liquid gradually enters ashaft bottom, the temperature gradually rises, and diffusion is intensified; in an oil well, organic matter, bacteria blocking removers and the anti-swelling agent are added to the oil well at the same time in cooperation with the organic blocking remover, and stratum clay swelling and clay fine migration are restrained. The surfactant has a cleaning effect on the oil well; by adding the protection liquid, the corrosion of a solution to devices and pipelines is relieved.

Owner:陕西一诺油气工程技术服务有限公司

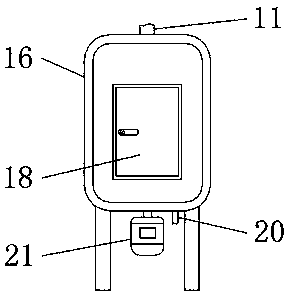

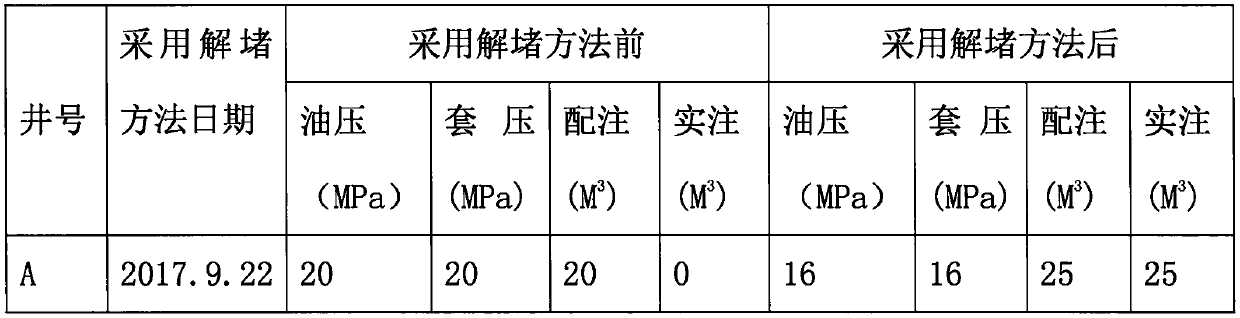

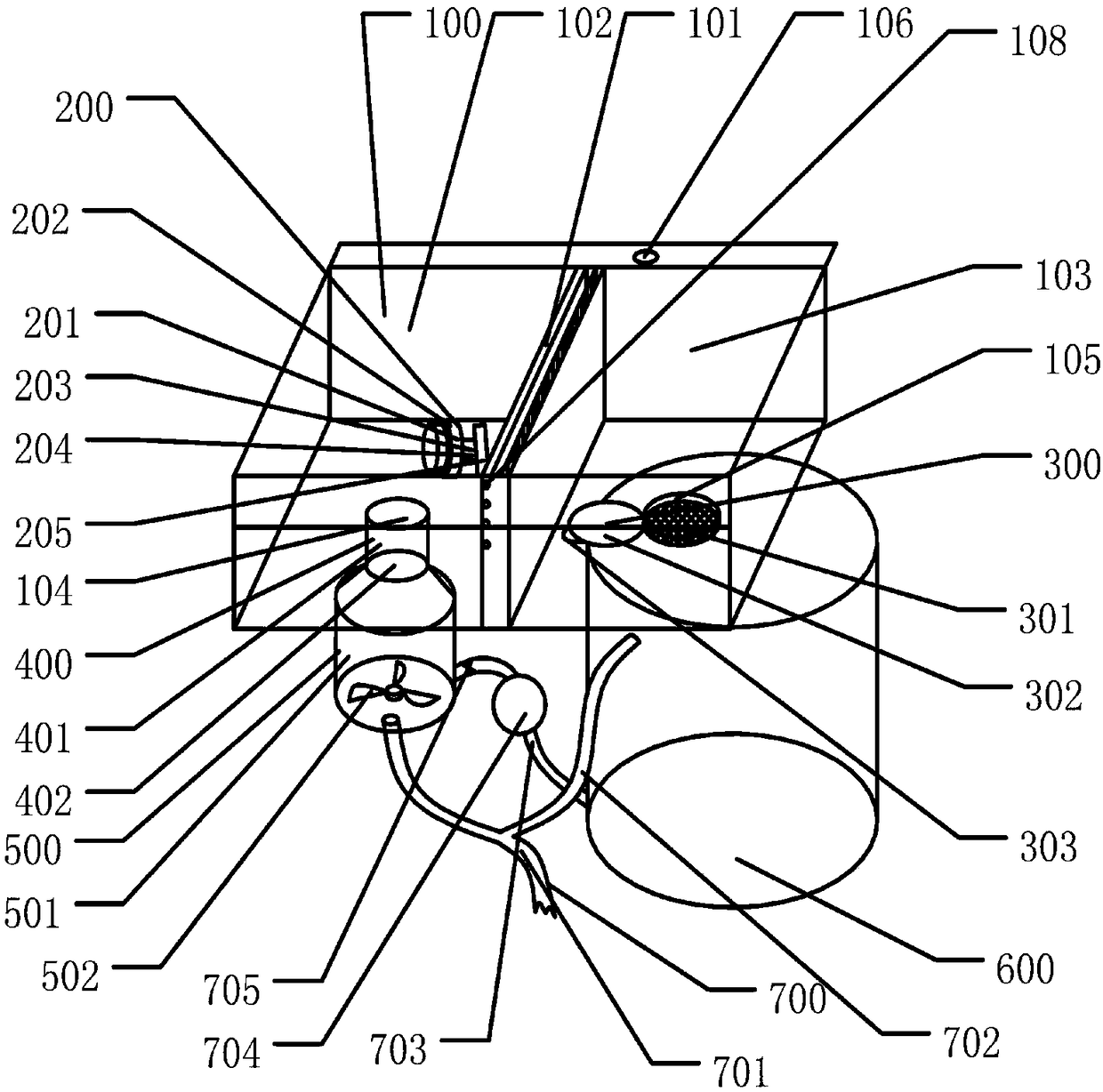

Disinfection device

InactiveCN106729833ASolve incomplete disinfectionSpray evenlyLavatory sanitoryHeatOzone generatorMedical equipment

The invention provides a disinfection device. The disinfection device comprises a disinfection box, wherein the disinfection box comprises a disinfection tank and a base which are arranged up and down; the disinfection tank is internally provided with a screen frame; the bottom of the screen frame is connected with a rotary shaft; the rotary shaft penetrates through the bottom of the disinfection tank and is in transmission connection with a motor arranged in the base; the screen frame is internally provided with an object placement screen; a disinfection solution spraying pipe is arranged above the object placement screen; the disinfection solution spraying pipe is communicated with an external disinfection solution through a disinfection solution feeding pipe; the disinfection solution feeding pipe and the rotary shaft are located on the same axis; an ozone generator is arranged on the outer surface of the top of the screen frame; the ozone generator is connected with a gas conveying pipe; one end, far away from the ozone generator, of the gas conveying pipe stretches into the screen frame; an ultraviolet disinfection lamp is arranged on the inner surface of the top of the screen frame; a water injection hole is further formed in the top of the disinfection tank; a drying device is further arranged in the disinfection box. According to the disinfection device, medical equipment is disinfected for a plurality of times through disinfection liquid, ozone water and ultraviolet disinfection and is completely disinfected; the problems that a disinfection manner of an existing disinfection device is single and the disinfection is not complete are solved.

Owner:弘毅天承知识产权股份有限公司

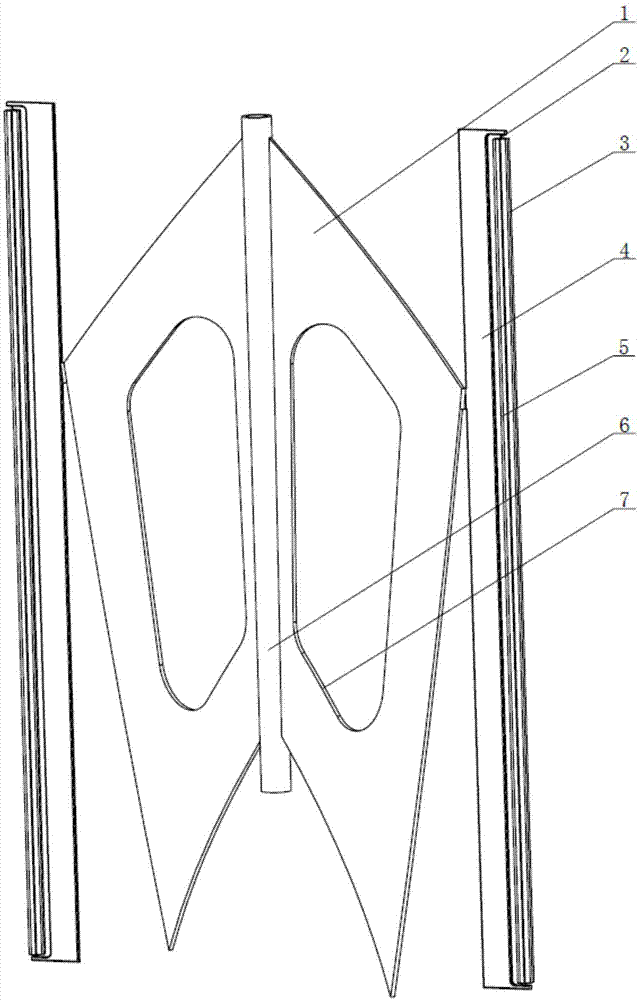

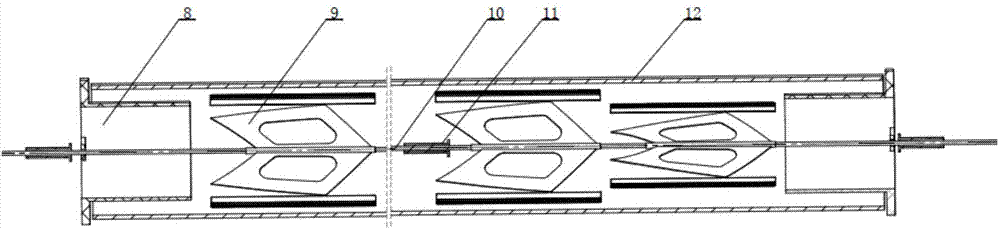

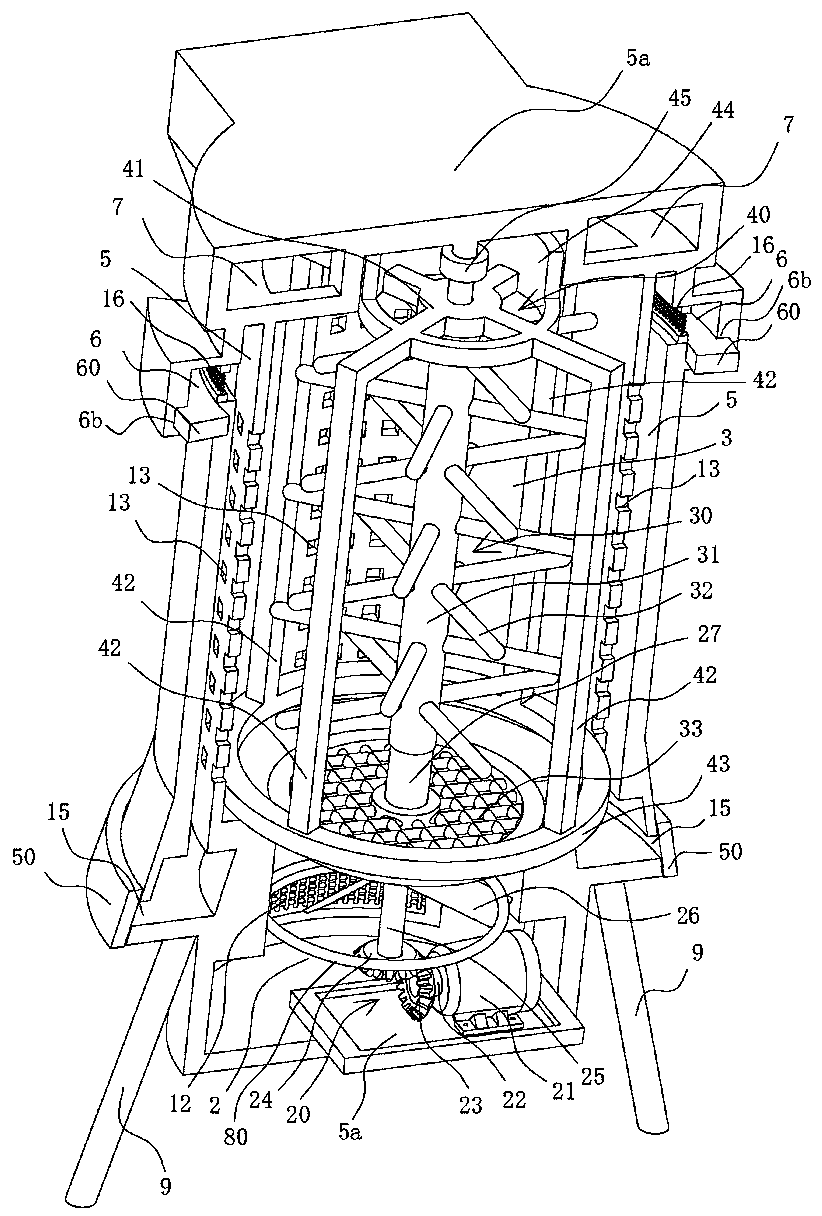

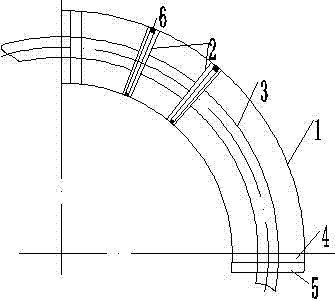

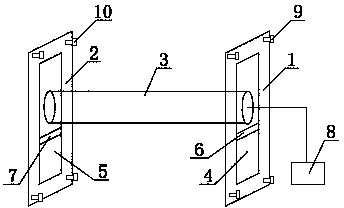

Inner turbulent flow dirt cleaning rotor of heat exchanging pipe

ActiveCN103673746ADelay or block initiationIncreased turbulenceRotary device cleaningAerospace engineering

The invention discloses an inner turbulent flow dirt cleaning rotor of a heat exchanging pipe, and the inner turbulent flow dirt cleaning rotor can clean and prevent dirt and strengthen heat transferring. The inner turbulent flow dirt cleaning rotor mainly comprises inner blades, outer blades and a center shaft. The inner blades are connected with the outer blades. The inner turbulent flow dirt cleaning rotor is characterized in that the inner blades are connected with the center shaft and are in a spiral shape, and the inner blades are provided with through holes; the outer blades are in a straight plate shape, the outer portions of the outer blades are provided with cylindrical rollers with the outer surfaces making contact with the inner wall of the heat exchanging pipe, center shafts of the cylindrical rollers are fixed to the outer blades, and the cylindrical rollers rotate around the center shafts of the corresponding cylindrical rollers; gaps are reserved between the inner blades and the outer blades. When the rotor rotates, the cylindrical rollers rotate along the inner wall of the pipe, strip-shaped protrusions on the cylindrical rollers have the function of extruding and cutting the dirt on the pipe wall, promote the dirt to be peeled off the heat exchanging pipe wall, and have the function of cleaning the dirt. For the cleaned heat exchanging pipe, the rotor can postpone the starting stage of the dirt when rotating, the inner blades have the turbulent flow function on liquid, the turbulence degree of the liquid inside the pipe is increased, and the effect of strengthening heat transferring is achieved.

Owner:BEIJING UNIV OF CHEM TECH

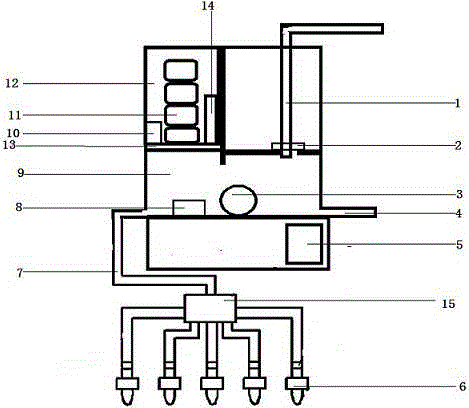

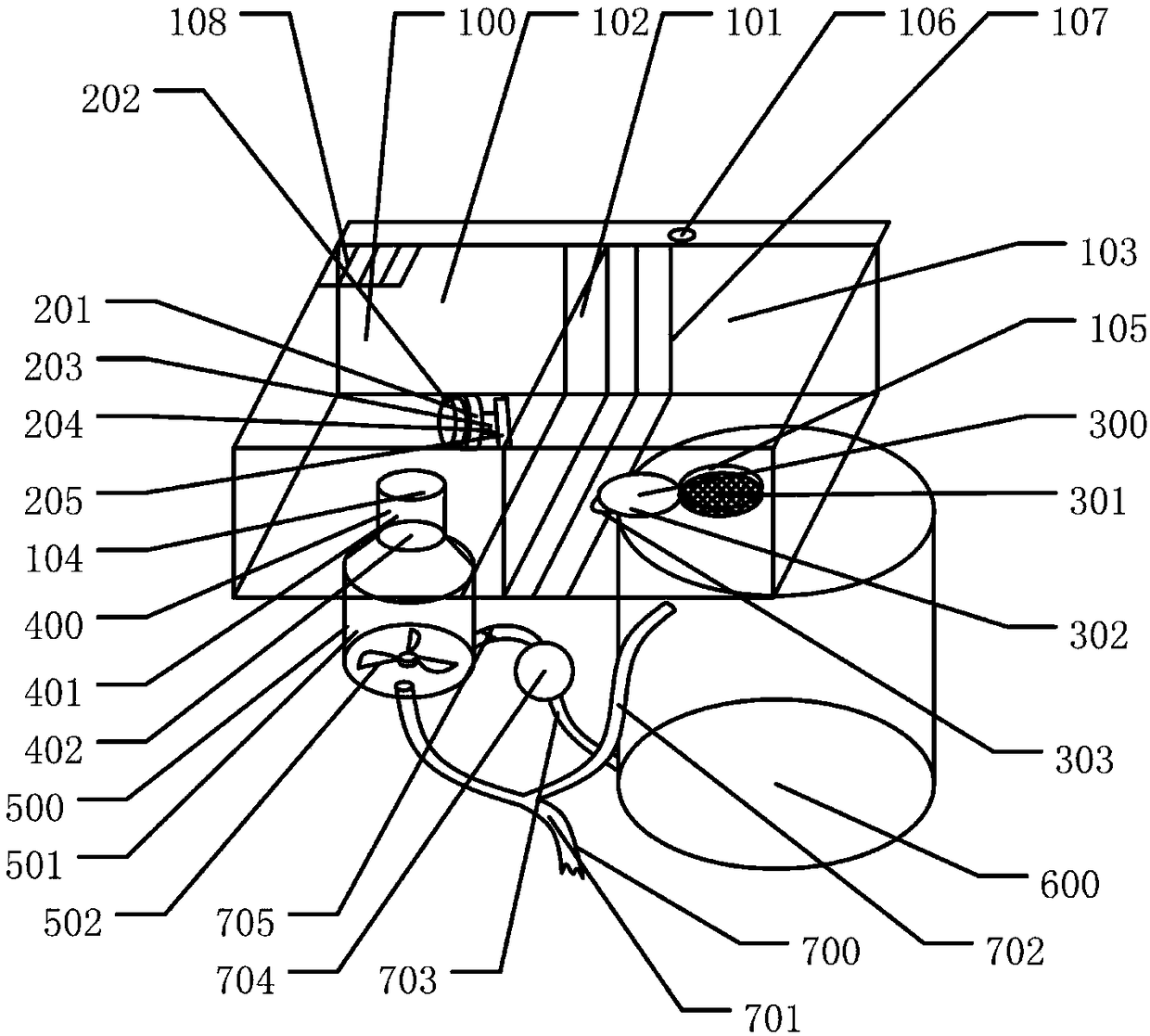

Full-automatic milk feeder for newborn livestock

InactiveCN105165647AInhibition of reproductionEnsure safetyAnimal feeding devicesAnimal feedLivestock

The invention relates to the field of animal feed, specifically to a full-automatic milk feeder for newborn livestock. The full-automatic milk feeder for the newborn livestock is composed of a feed box, a stirring box and a feeding unit, wherein the feed box is located above the stirring box, and the feed box and the stirring box are connected via a movable plate; the interior of the stirring box is provided with a stirring unit; and the feeding unit comprises a feeding pipeline and a feeding mouth, and a valve is arranged between the feeding pipeline and the feeding mouth. The full-automatic milk feeder for the newborn livestock provided by the invention realizes full-automatic feeding and does not need manual-stirring of materials; meanwhile, the milk feeder has the advantages of automatic batching, fixed-time feeding and automatic cleaning, so true full automation is achieved; material resources, human resources and financial resources are saved; bacterial reproduction is inhibited; and safety of liquid milk for the newborn livestock is guaranteed.

Owner:江苏盛大生物科技有限公司

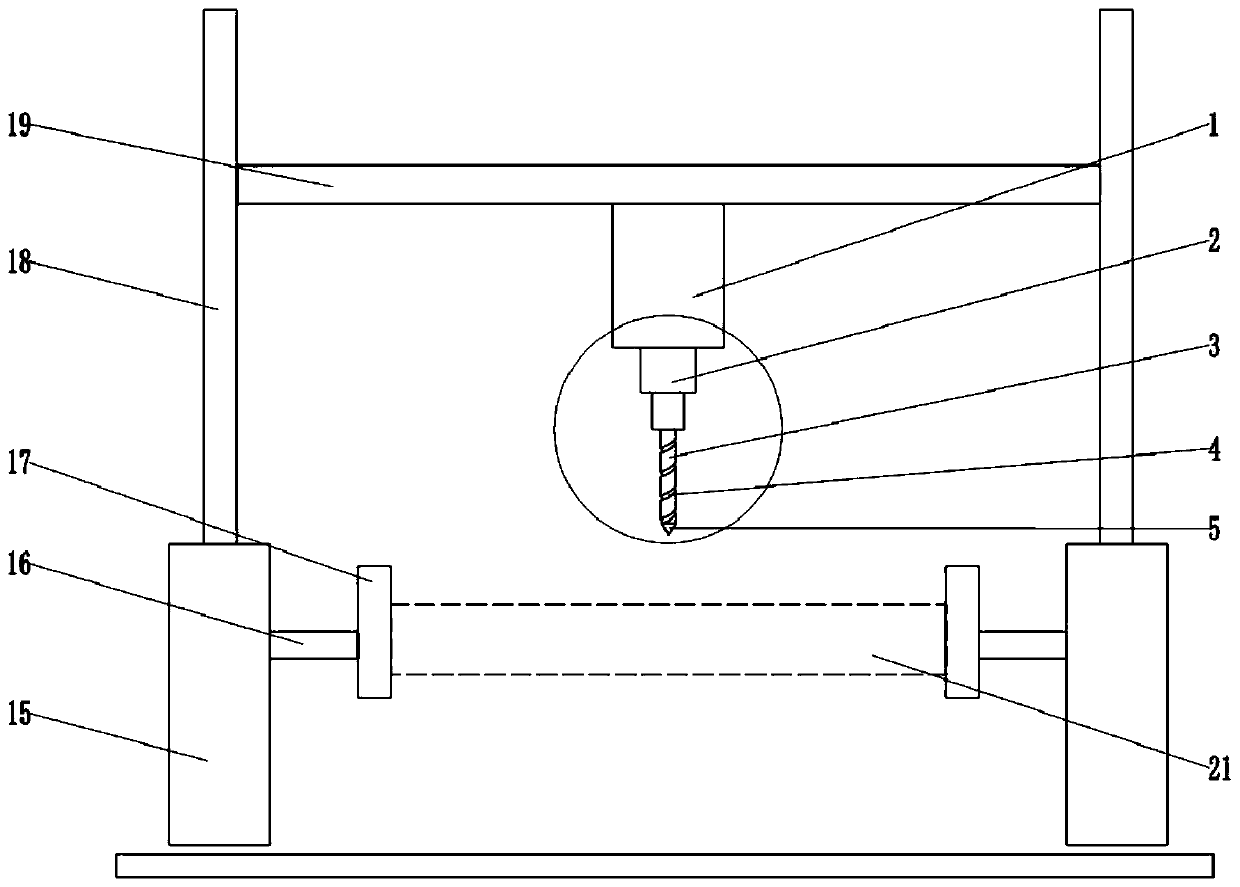

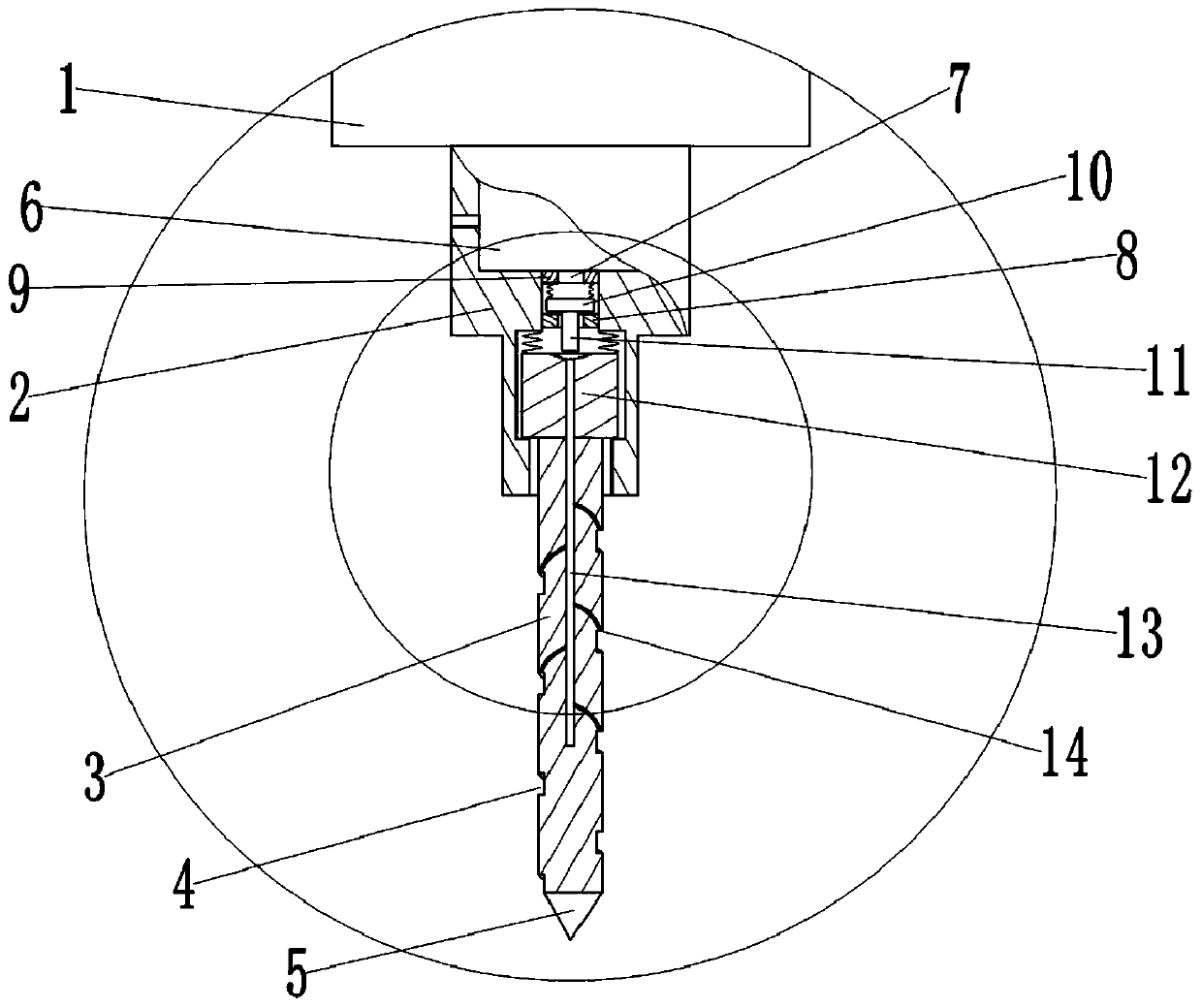

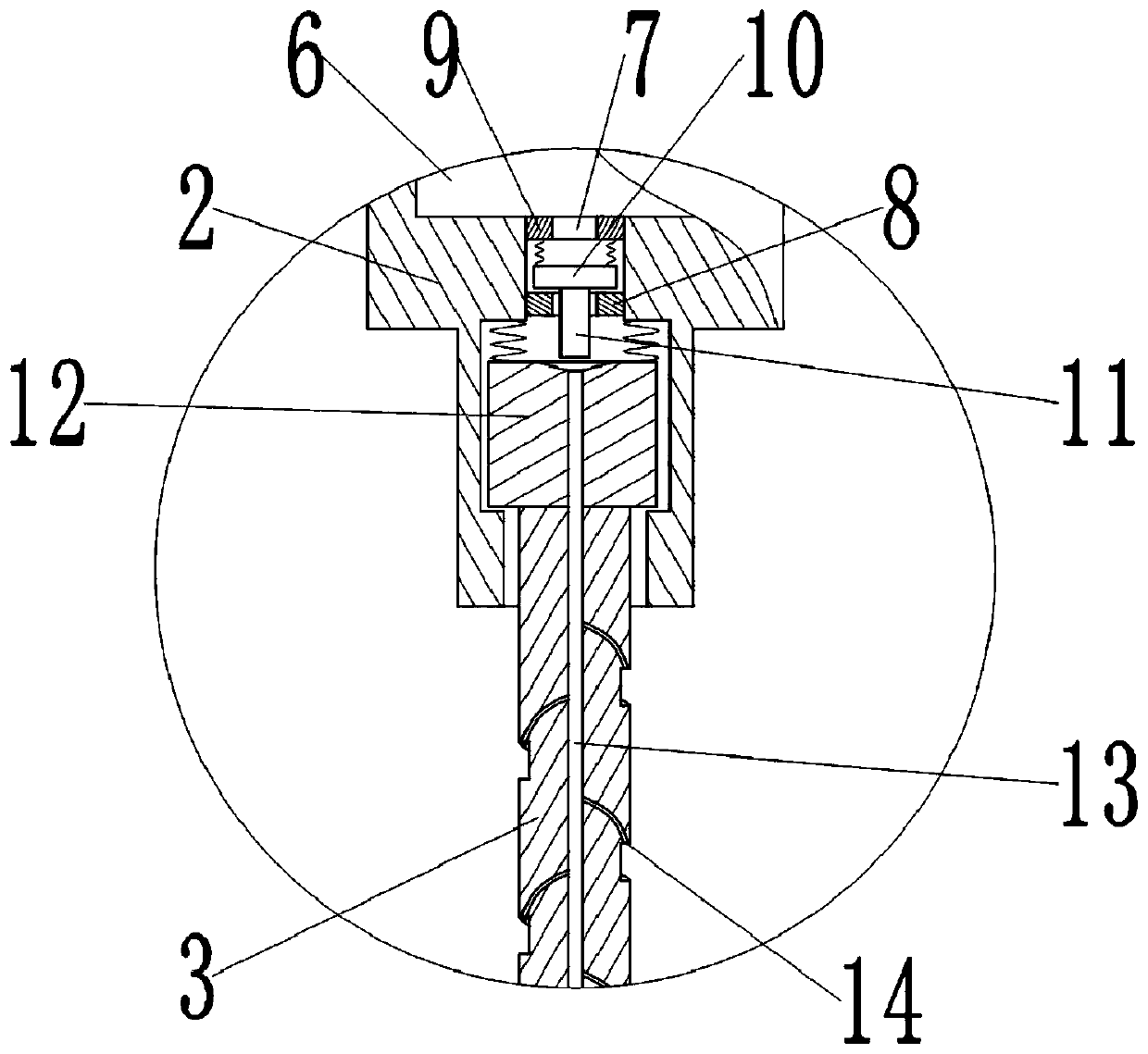

Punching process of wood tray special-shaped hole

ActiveCN110682369AEasy to replaceReduce maintenance costsStationary drilling machinesEngine lubricationPunchingStructural engineering

The invention relates to the technical field of a wood punching process, in particular to a punching process of a wood tray special-shaped hole. The process comprises the steps of ruling, punching device preparing, anvil hole punching and drilling. When a punching device is prepared, a drill bit on the punching device is smeared with cooling lubricating liquid, and the drill bit is lubricated andcooled. According to the scheme, the technical problems that in the prior art, when a drill bit is used, the cooling lubricating liquid needs to be smeared in advance can be solved.

Owner:重庆涛扬建材有限公司

Cotton drying machine

ActiveCN111023750AQuality improvementEvenly heatedDrying gas arrangementsDrying solid materialsAgricultural engineeringStructural engineering

The invention discloses a cotton drying machine. The cotton drying machine structurally comprises a machine box, wherein supporting legs are arranged under the machine box; a power cavity is formed inone end of the machine box, a coil capable of heating after being electrified is arranged in the power cavity, a power mechanism is arranged at one end of the power cavity, a drying cavity is connected to one end of the power cavity, first holes are formed in the inner wall of the drying cavity, and a beating mechanism is arranged in the drying cavity; an impurity cavity is formed outside the drying cavity, exhaust cavities are formed at the upper part of the impurity cavity, sliding grooves are formed in the exhaust cavities, external sliding rails are arranged at one ends of the sliding grooves, and first baffles are arranged in the sliding rails; and a discharging opening and a feeding opening are formed in the upper portion of the machine box, and a turning cover is arranged on the feeding opening. The cotton drying machine has the beneficial effects that the beating mechanism can stir cotton, so that heating is more evenly, the drying efficiency is improved; the beating mechanismcan also beat caked cotton lumps after water absorption, so that cotton is separated, meanwhile, the cotton is fluffed out, and the cotton quality is improved; and cotton discharging is controlled bymanually controlling opening and closing of exhaust holes, and the cotton can be discharged from the discharging opening only under the condition that the cotton is completely dry and fluffy.

Owner:济南龙茂源纺织品有限公司

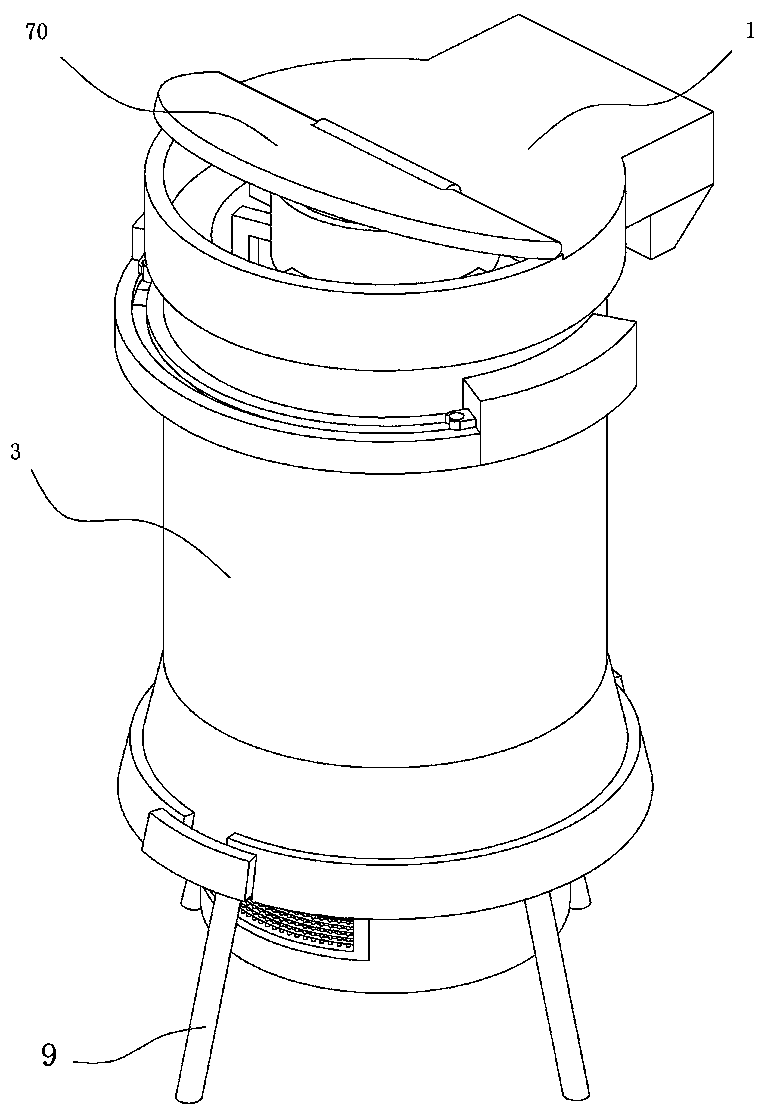

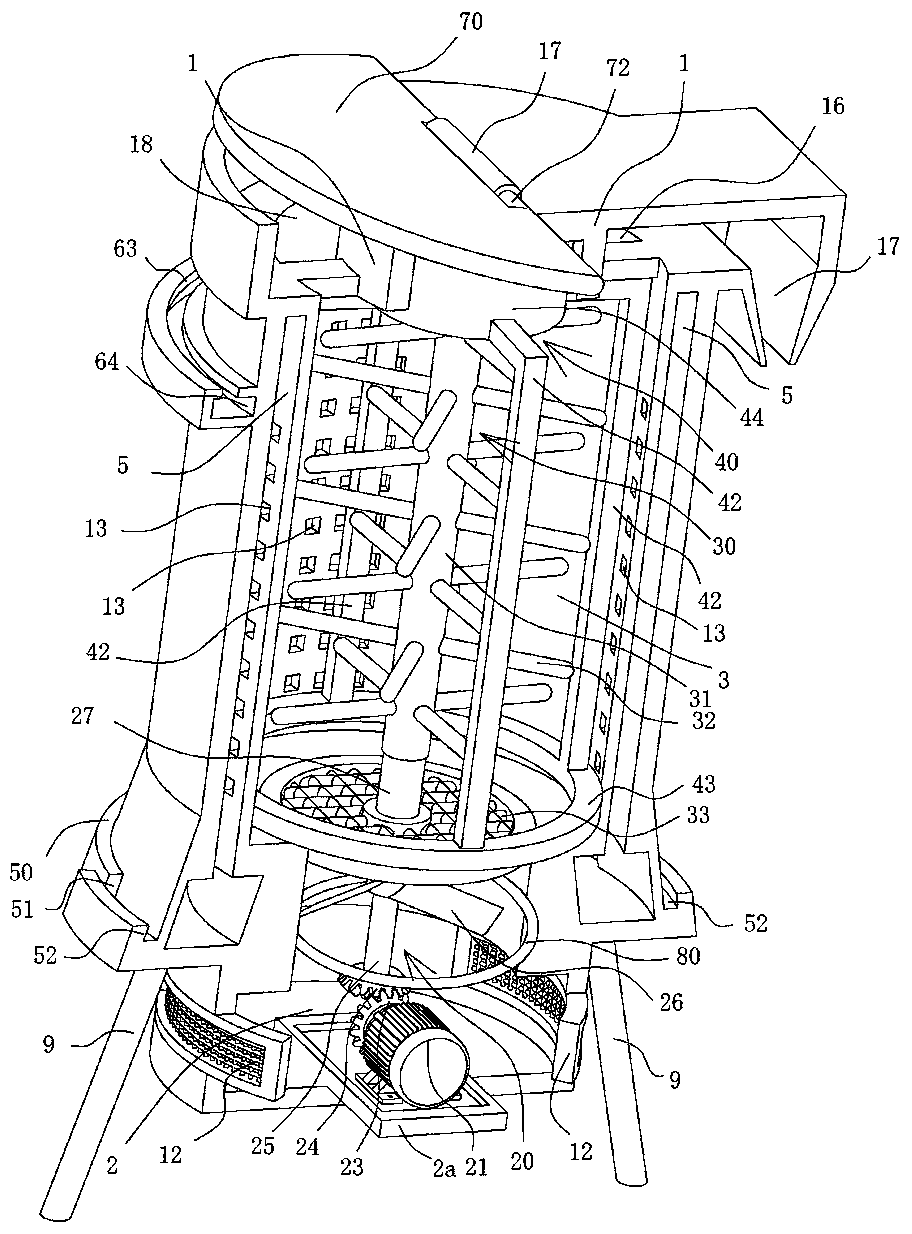

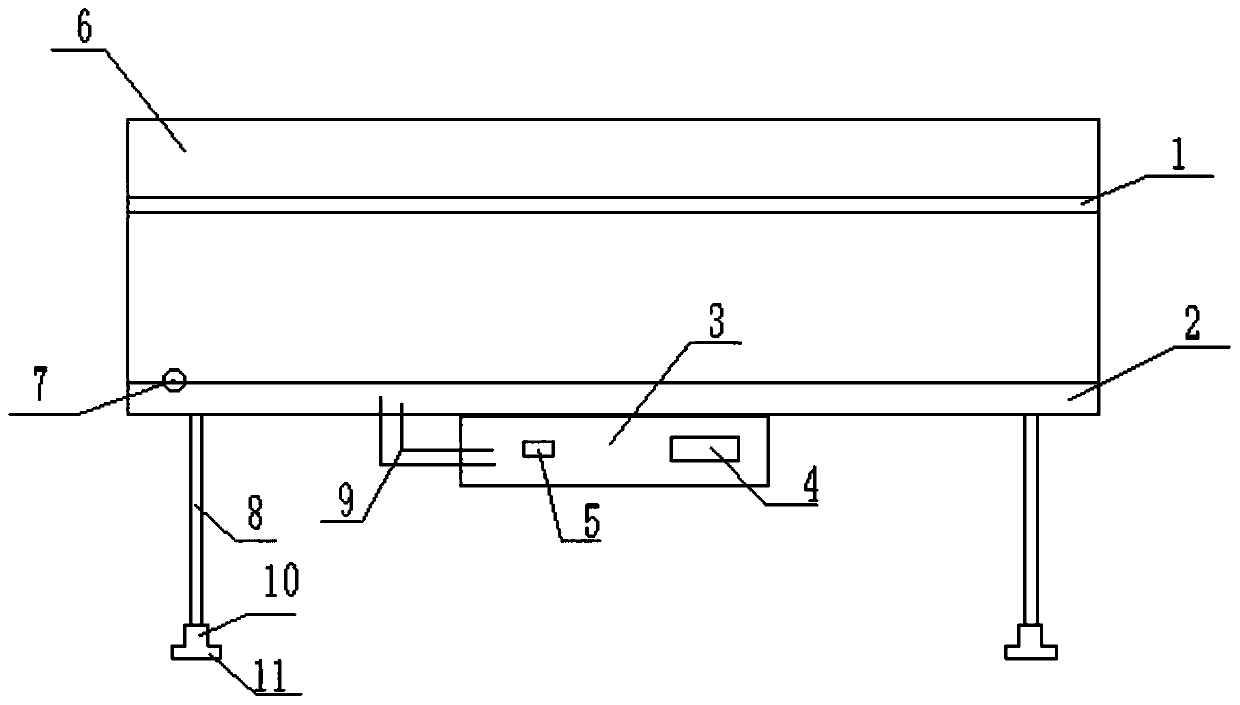

Multifunctional intelligent cleaning pool

ActiveCN108240019AGuaranteed service lifeAvoid accumulationDomestic plumbingKitchen equipmentWater storageWater saving

The invention discloses a multifunctional intelligent cleaning pool. The multifunctional intelligent cleaning pool comprises a cleaning pool, a storage tank, a whipping device, a water saving system and a control device, wherein a separating plate is arranged in the cleaning pool, the separating plate separates the cleaning pool into a first cleaning area and a second cleaning area; a first wateroutlet and a second water outlet are respectively formed in the bottoms of the inner sides of the first cleaning area and the second cleaning area; the storage tank is arranged below the first water outlet, the storage tank comprises a tank body and a base plate which is arranged at the bottom of the tank body and is movably connected in a liftable and rotatable manner; the whipping device is arranged at the bottom of the storage tank, and the whipping device is communicated with a drainage pipeline by virtue of liquid; and the water saving system comprises a water storage barrel and the drainage pipeline, and the water storage barrel is connected below the second water outlet by virtue of the drainage pipeline. The multifunctional intelligent cleaning pool disclosed by the invention has the advantages that an independent cleaning area can be formed, water is prevented from spilling out of the cleaning area, secondary cleaning water is utilized, waste of water resource is reduced, highpressure washing guarantees service life of a whipping blade, whipping efficiency is improved, and blockage of a sewer pipeline is avoided.

Owner:合肥源康信息科技有限公司

A cleaning and drying device for down production and processing that is convenient for removing impurities

ActiveCN108168222BFacilitate subsequent processingProcessing effectDrying solid materials without heatWool fibre washing/scouringTransmission beltElectric machinery

The invention discloses a cleaning and drying device conveniently removing impurities for down feather production and processing. The cleaning and drying device includes a cleaning device, a water inlet pipe, a stirring rod, a transmission belt, a suction opening, a fan, a first water outlet, a protective cover, a protective door, an air-tight door, a spin-dry revolving drum, a second air hose anda blowpipe; the upper of the cleaning device is provided with a feed inlet, the lower of the feed inlet is provided with a rotating rod, the water inlet pipe is located below the left side of the cleaning device, and the cleaning device is internally connected with a first motor through the rotating rod; and the stirring rod is located at the outer side of the rotating rod, the second air hose isarranged in the transmission belt which is provided with through holes, and the through holes are connected with scraping plates. According to the cleaning and drying device conveniently removing theimpurities for the down feather production and processing, the cleaning device is arranged to clean down feather, subsequent processing can be prevented from affection due to impurities in the down feather, and the cleaning of the down feather is facilitated.

Owner:ZHANJIANG ZIJIN DOWN PROD

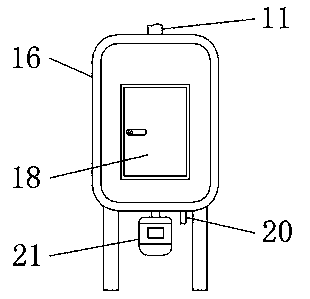

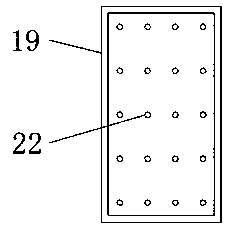

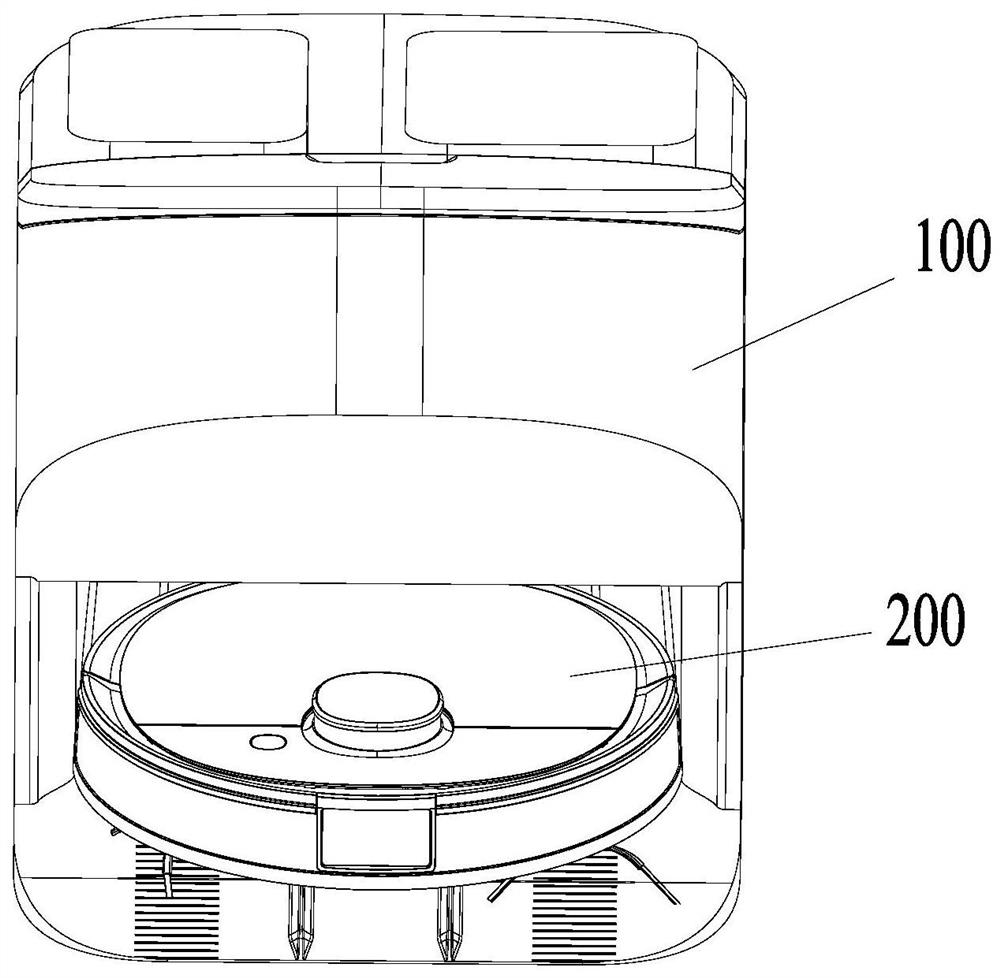

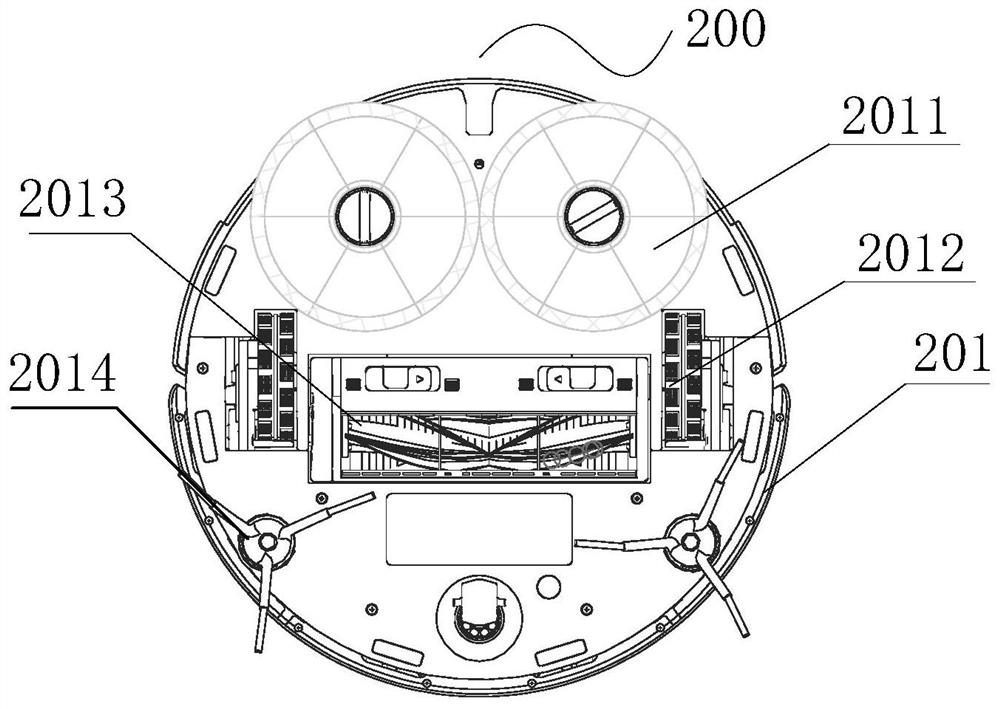

Workstation and working method thereof

ActiveCN113729579APlay a role in cleaningImprove user experienceCarpet cleanersFloor cleanersEngineeringProcess engineering

The embodiment of the invention discloses a workstation and a working method thereof. The workstation comprises a workstation body, a containing cavity is formed in the lower portion of the workstation body, and a cleaning tank is formed in the bottom of the containing cavity; a first liquid storage barrel and a second liquid storage barrel are arranged above the containing cavity, wherein the first liquid storage barrel is communicated with a first water outlet pipeline; the first water outlet pipeline extends to the cleaning tank and is communicated with a second water outlet pipeline arranged along the side wall of the cleaning tank; a plurality of water outlets capable of discharging water towards the bottom of the cleaning tank are formed in the second water outlet pipeline so as to convey liquid in the first liquid storage barrel into the cleaning tank; the second liquid storage barrel communicates with a water pumping pipeline, and the water pumping pipeline extends into the cleaning tank and is used for pumping liquid in the cleaning tank into the second liquid storage barrel. According to the technical scheme, the bottom of the cleaning tank can be cleaned, the two hands of a user are liberated, and the cleaning efficiency and the use experience of the user are improved.

Owner:ECOVACS ROBOTICS (SUZHOU ) CO LTD

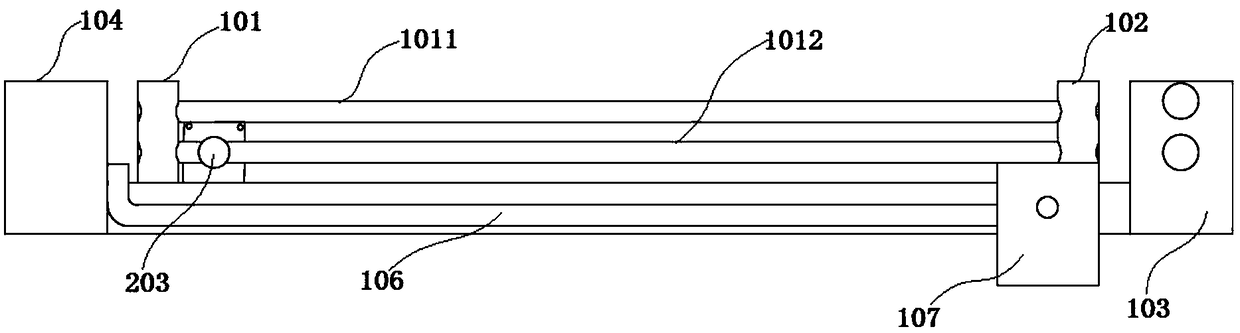

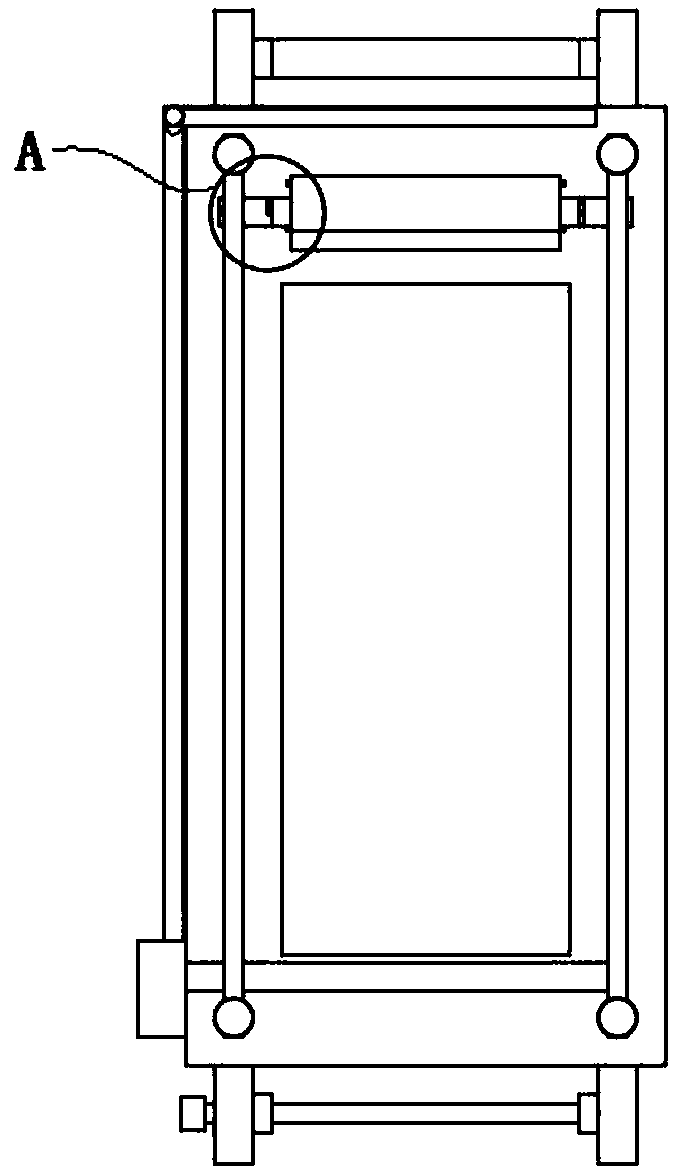

Pneumatic cylinder for controlling valve rod

InactiveCN106855147ASave energySave installation spaceOperating means/releasing devices for valvesPlungersControl valvesCylinder block

The invention discloses a pneumatic cylinder for controlling a valve rod. A piston is installed in a cylinder body, cylinder covers are installed at the two ends of the cylinder body, the piston is provided with two piston columns, the circle centers of one end faces of the two piston columns are connected through a connecting rod, the circle centers of the other end faces of the two piston columns are provided with piston rods respectively, the two piston rods penetrate through the cylinder covers at the two ends of the cylinder body respectively, and air inflow nozzles and air exhaust nozzles are arranged on the end faces of the cylinder covers. Dustproof covers are installed outside the cylinder covers, the dustproof covers are installed on the cylinder body, and the center liens of the cylinder body, the piston and the piston rods are arc lines. The pneumatic cylinder for controlling the valve rod is simple in structure, more reliable, small in size and convenient to install, and is provided with one cylinder body and the double piston rods, and by means of the pneumatic cylinder, more energy is saved, and more manufacturing cost is reduced.

Owner:王翔

5G test shielding box

InactiveCN111257657AClean and comprehensivePlay a supporting roleElectromagentic field characteristicsStructural waterWater flow

The invention relates to the field of 5G test shielding devices, in particular to a 5G test shielding box which comprises a box body, a rotating structure, a cleaning structure, a sealing structure, awater cooling structure and an anti-blocking structure. By arranging the rotating structure, the ground in the box body can be moved, a cleaning structure is arranged, the ground in the box body canbe comprehensively cleaned, and therefore, dust on the ground in the box body is prevented from influencing the test precision, the cleaning structure can also act on the sealing structure while performing installation work, by adopting seal arrangement, a gap between the cleaning structure and the bottom end of the box body can be filled to increase the sealing effect, the situation that water atthe bottom end of the box body flows out is avoided, normal work of the cleaning structure is guaranteed, it can be kept that water exists at the bottom end of the box body all the time to cool the interior of the box body, and rainwater can be collected and cool the interior of the box body by installing the water cooling structure at the top end of the box body.

Owner:浙江新铭智能科技有限公司

Roller brush

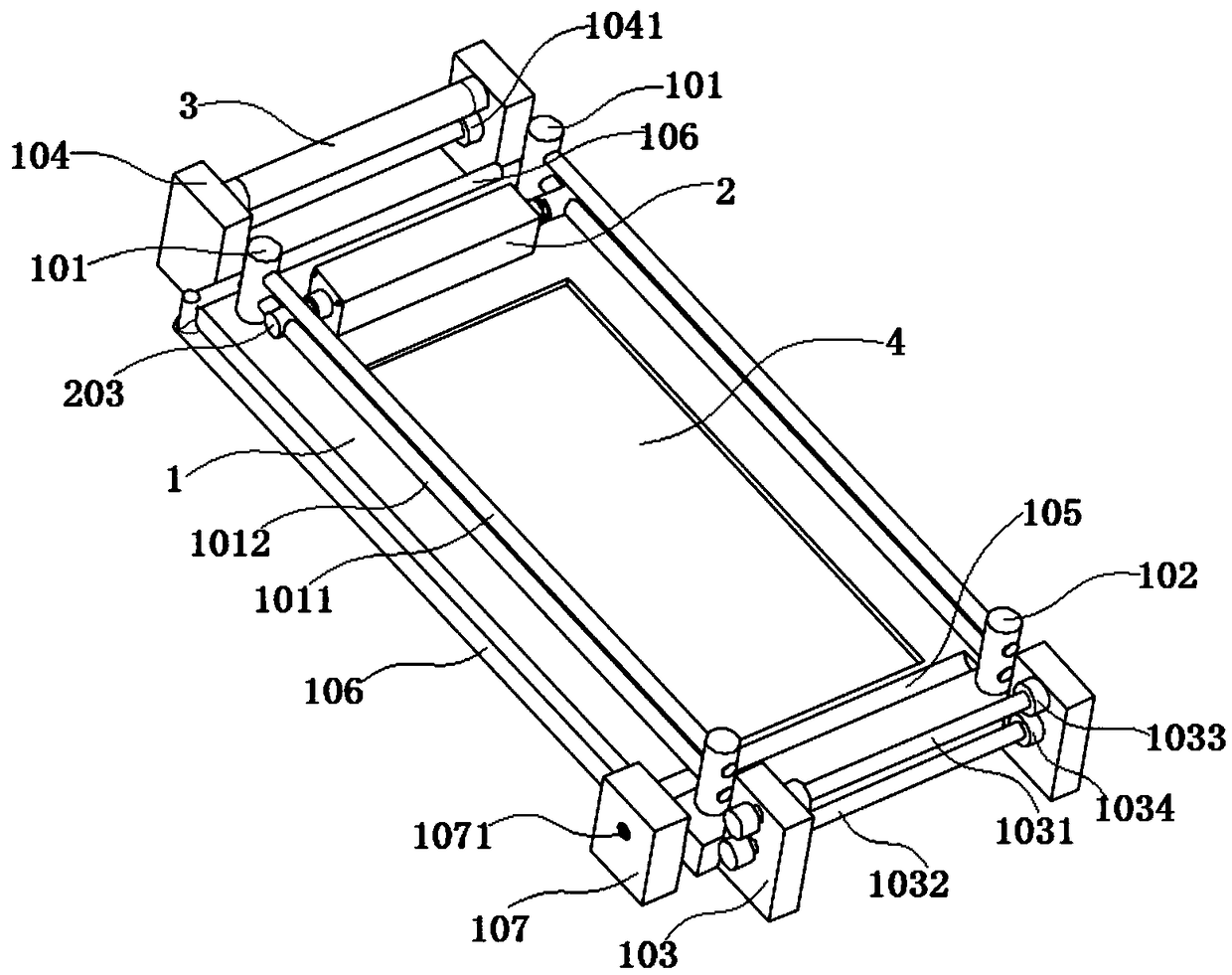

The invention discloses a roller brush. The roller brush comprises a first installation plate and a second installation plate which are made of metal materials, wherein a roller brush body is arranged between the first installation plate and the second installation plate, a first gear groove is formed in the first installation plate, a first gear pin is arranged in the first gear groove, a second gear groove is formed in the second installation plate, a second gear pin is arranged in the second gear groove, one end of the roller brush body is arranged on the first gear pin, the other end of the roller brush body is arranged on the second gear pin, and the roller brush body is connected with a driving motor used for controlling the roller brush body to rotate. The roller brush is simple in structure, convenient to use and adjustable in height.

Owner:赛音

Carbon deposit cleaning agent for automobile engine

InactiveCN106916657ARapid and efficient penetrationFast cleaningAnionic surface-active compoundsSurface-active non-soap compounds and soap mixture detergentsCombustion chamberPhosphate

The invention relates to a cleaning agent, specifically to a carbon deposit cleaning agent for an automobile engine. The carbon deposit cleaning agent is composed of the following materials in parts by weight: 45 to 55 parts of solvent naphtha, 15 to 20 parts of alkyl polyoxyethylene ether, 45 to 55 parts of ethanol, 5 to 8 parts of disodium cocoyl monoethanolamide sulfosuccinate DMSS, 15 to 25 parts of monoethanolamine, 15 to 25 parts of monolauryl alcohol phosphate acid ester MAP, 8 to 12 parts of polyisobutylene amine, 5 to 10 parts of sodium alkyl sulfate, 3 to 5 parts of sec-alkyl sodium sulfate, 15 to 25 parts of methacrylic acid, 3 to 5 parts of sodium alkylnaphthalenesulfonate, 5 to 8 parts of igepon T, 5 to 8 parts of diethyl ether, 3 to 5 parts of alkyl polyoxyethylene ether, 15 to 25 parts of petroleum ether, 1 to 3 parts of sodium lignosulfonate and 25 to 45 parts of ethyl acetate. The carbon deposit cleaning agent for an engine provided by the invention can quickly and efficiently permeate into the interior of carbon deposits of the engine and acts with the carbon deposits, thereby exerting an effect of cleaning. The carbon deposit cleaning agent can thoroughly clean the carbon deposits in a combustion chamber, and the carbon deposits may not agglomerate and can be directly discharged out of the engine, so secondary cleaning of the combustion chamber is not needed; the difficulty of cleaning operation is reduced; and hours of work for repair and maintenance are saved.

Owner:青岛城轨交通装备科技有限公司

Bean curd dicing device with knife sticking prevention function for food processing

InactiveCN113400401ARealize automatic cuttingAvoid stickingMetal working apparatusEngineeringMechanical engineering

The invention relates to the technical field of food processing, in particular to a bean curd dicing device with a knife sticking prevention function for food processing. Aiming at the defects in the prior art, the invention provides the bean curd dicing device with the knife sticking prevention function for food processing, which is used for preventing knife sticking and collecting bean curd blocks. According to the technical scheme, the bean curd dicing device with the knife sticking preventing function for food processing comprises a supporting table, first supports, first fixing plates, a dicing mechanism and a fixing mechanism, wherein the first supports are fixedly connected to the two sides of the top of the supporting table correspondingly, the first fixing plates are fixedly connected to the upper sides of the two first supports correspondingly, a dicing mechanism is fixedly connected between the two first fixing plates, and a fixing mechanism is arranged on the dicing mechanism in a sliding mode. Bean curd can be fixed through a limiting plate, and meanwhile the situation that the bean curd sticks to a cutter during processing, and consequently the surface of the bean curd is damaged is prevented.

Owner:钟满香

Park seat

InactiveCN111053385ARealize the heating effectEasy to dryStoolsBeach chairsThermodynamicsSpray nozzle

The embodiment of the invention provides a park seat. A temperature sensor is used for detecting the surface temperature of the park seat in real time, a controller regulates and controls an air heating box in terms of generating hot air according to the information of the temperature sensor, and the hot air is transmitted into a gas pipe in a seat cushion through a gas pipeline, so that a heatingeffect on the seat cushion is realized. A chair back is provided with a rainwater storage tank, the controller utilizes a programmed program to open the electric control spray nozzle according to requirements, the electric control spray nozzle is connected to the rainwater storage tank through a water pipe, the electric control spray nozzle sprays rainwater to clean the surface of the seat cushion, the rainwater inevitably reduces the surface temperature of the seat, an air heating box is started again to rapidly dry rainwater on the seat surface, and a cleaning effect is achieved.

Owner:西安帝凡合赢科技发展有限公司

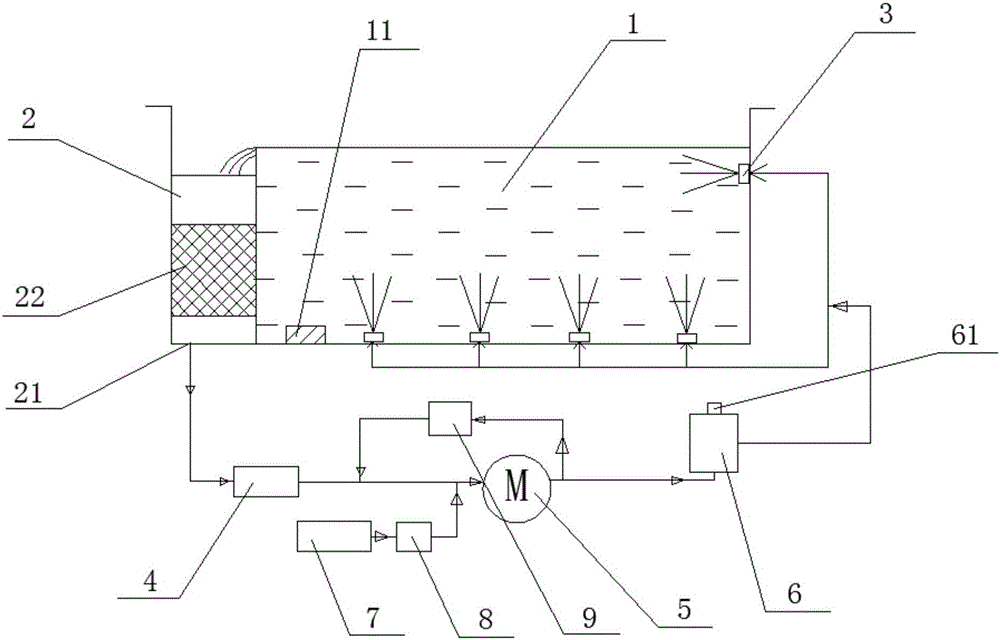

Fruit and vegetable washing machine capable of cyclic washing

InactiveCN106037538APlay a role in cleaningEasy to cleanWater/sewage treatment by irradiationSpecific water treatment objectivesOzone generatorActivated carbon filtration

The invention provides a fruit and vegetable cleaning machine capable of cyclic cleaning, comprising a cleaning pool and a processing pool with a common pool wall on one side, cleaning nozzles are arranged on the bottom and side walls of the cleaning pool, and the upper and bottom parts of the processing pool pass through activated carbon filters Separation, the bottom of the treatment tank is provided with a drain, the drain is connected to the ultraviolet sterilizer through a pipeline, the ultraviolet sterilizer is connected to the water inlet of the water pump, the water outlet of the water pump is connected to the water inlet of the air-water mixer, and the air-water is stirred The upper part of the device is provided with an air release valve, and the outlet of the air-water mixer is connected to the water inlet of each cleaning nozzle through a pipeline. It also includes an ozone generator and a one-way jet valve. The ozone generator is connected through a one-way jet valve. to the water inlet of the sump pump. The beneficial effect is that the cleaned waste water can be recovered and purified into clean water, and the clean water can be circulated and supplied to the cleaning nozzle to form a recycling cycle without wasting water resources, and has strong flushing ability and good cleaning effect.

Owner:素膳美(天津)食品科技有限公司

Nutritional rice processing production process

InactiveCN112121879AQuality improvementPlay a role in cleaningGrain millingAgricultural engineeringWhite rice

The invention relates to the technical field of grains, in particular to a nutritional rice processing production process. The nutritional rice processing production process comprises the following steps that S1, dust raising is carried out, specifically, paddy is extracted through an elevator, the paddy is conveyed to a transverse air duct, and the paddy is subjected to dust raising treatment; S2, impurities are removed; S3, drying is carried out; S4, rice hulling is carried out, specifically, paddy rice is hulled through a rice huller, the paddy and brown rice are separated by adopting a paddy and brown rice separator, the separated paddy is hulled again, and rice milling is carried out on the brown rice; S5, rice milling is carried out, specifically, the brown rice is fed into a rice mill, and surface shells of the brown rice is removed to obtain rice; S6, polishing is carried out, specifically, white rice is put into a polishing machine to be polished; S7, screening is carried out,and specifically, a screening device is adopted for carrying out screening treatment on the rice to screen embryo rice and the white rice out; and S8, packaging is carried out, specifically, the screened embryo rice and the screened white rice are separately put into packaging bags, drying bags are put into the packaging bags, and then warehousing is carried out. The nutritional rice processing production process has the characteristic of being beneficial to rice processing quality.

Owner:宁夏铭泽农业科技有限公司

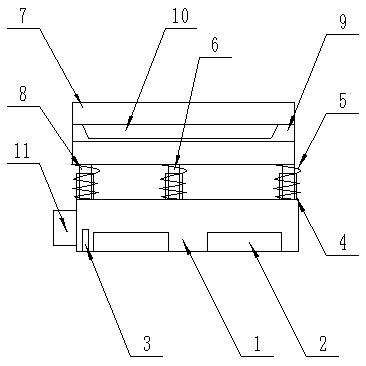

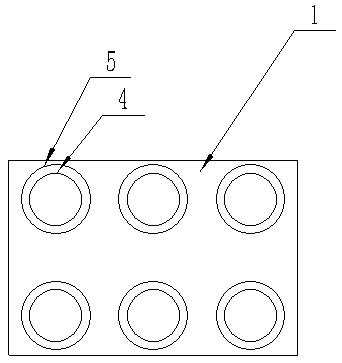

Ink jetting device for plastic products

The invention discloses an ink jetting device for plastic products. The ink jetting device comprises a processing table, the processing table is provided with a supporting arm, the supporting arm is provided with an air cylinder, the air cylinder is provided with a lifting plate, and the bottom of the lifting plate is detachably connected with a plurality of spraying heads; the processing table isinternally provided with a processing chamber for allowing the lifting plate to extend into, and the two sides of the processing table are correspondingly provided with an inlet and an outlet; the processing chamber is sequentially provided with a supporting plate, an upper limiting plate, a lower limiting plate and a splitter plate from top to bottom; a plurality of through holes are formed in the supporting plate, an elastic iron sheet is arranged between the upper limiting plate and the lower limiting plate, a plurality of storage grooves are formed in the elastic iron sheet, and a rockerarm is hinged to each storage groove, and a first spring is arranged between each rocker arm and the corresponding storage groove; and a sponge block is arranged on each rocker arm, a plurality of leaking holes are further formed in the elastic iron sheet, a plurality of second springs are arranged on the splitter plate, and a splitter hole is further formed in the splitter plate. The scheme of the ink jetting device for the plastic products mainly solves the problem that residual ink affects the appearance of the products after the brushing of current plastic products is finished.

Owner:宁波江北文增新材料科技有限公司

Cleaning and drying device for textile products

InactiveCN112359528APlay a role in cleaningPlay the role of dryingLiquid/gas/vapor treatment machines driving mechanismsLiquid/gas/vapor removal by gas jetsElectric machineProcess engineering

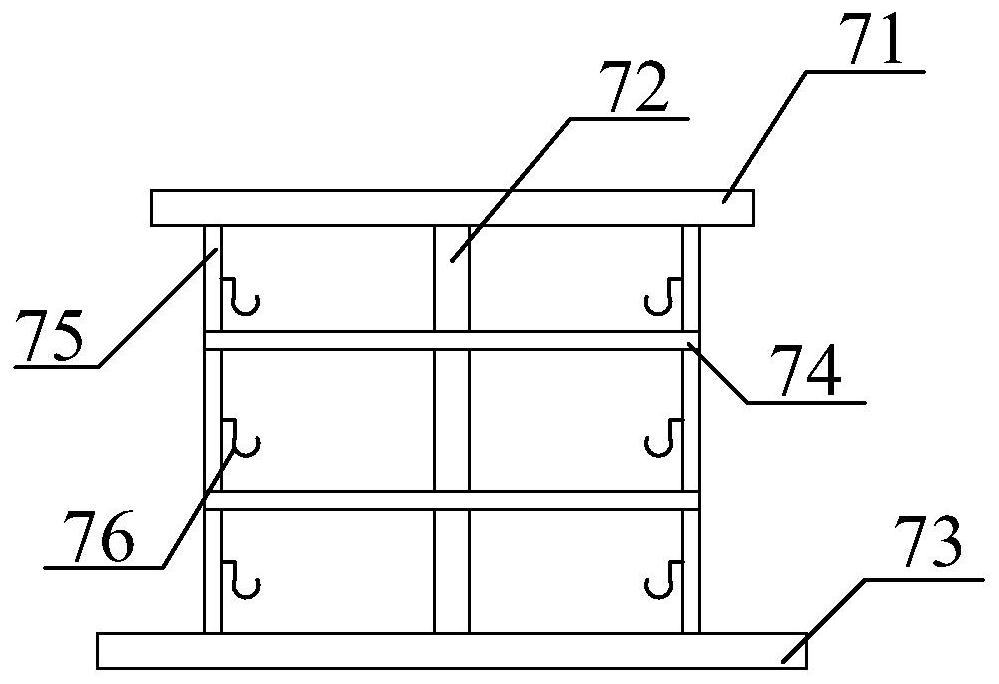

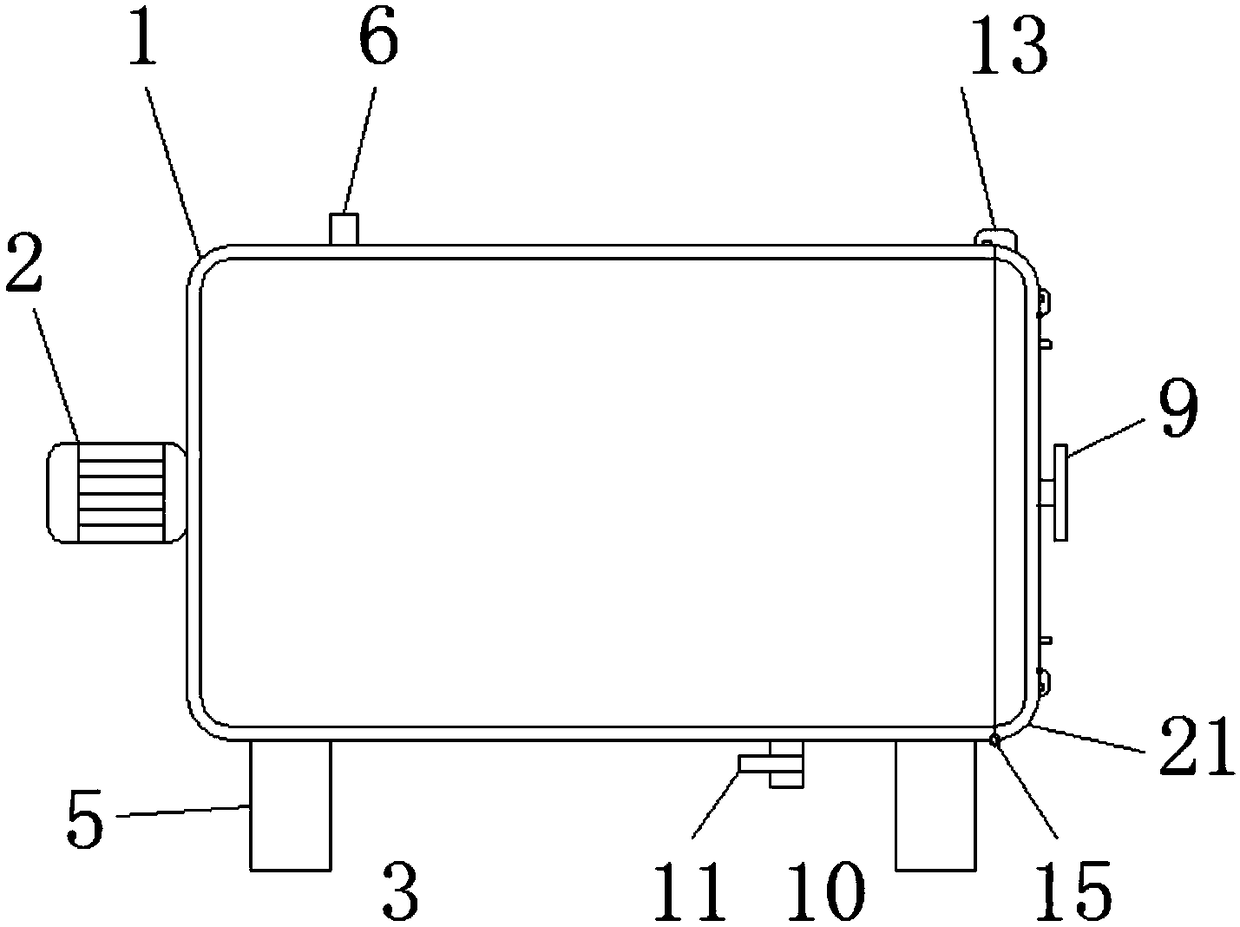

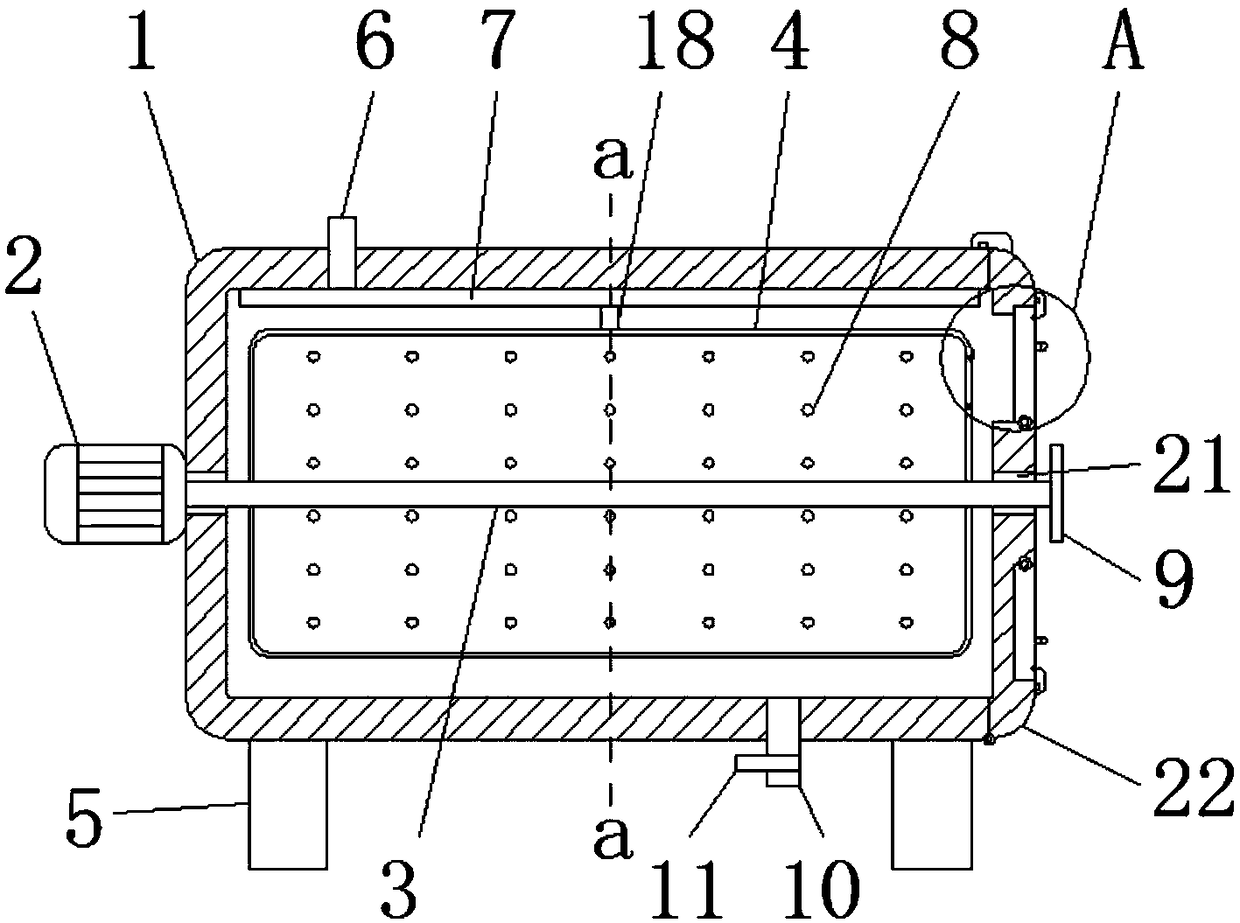

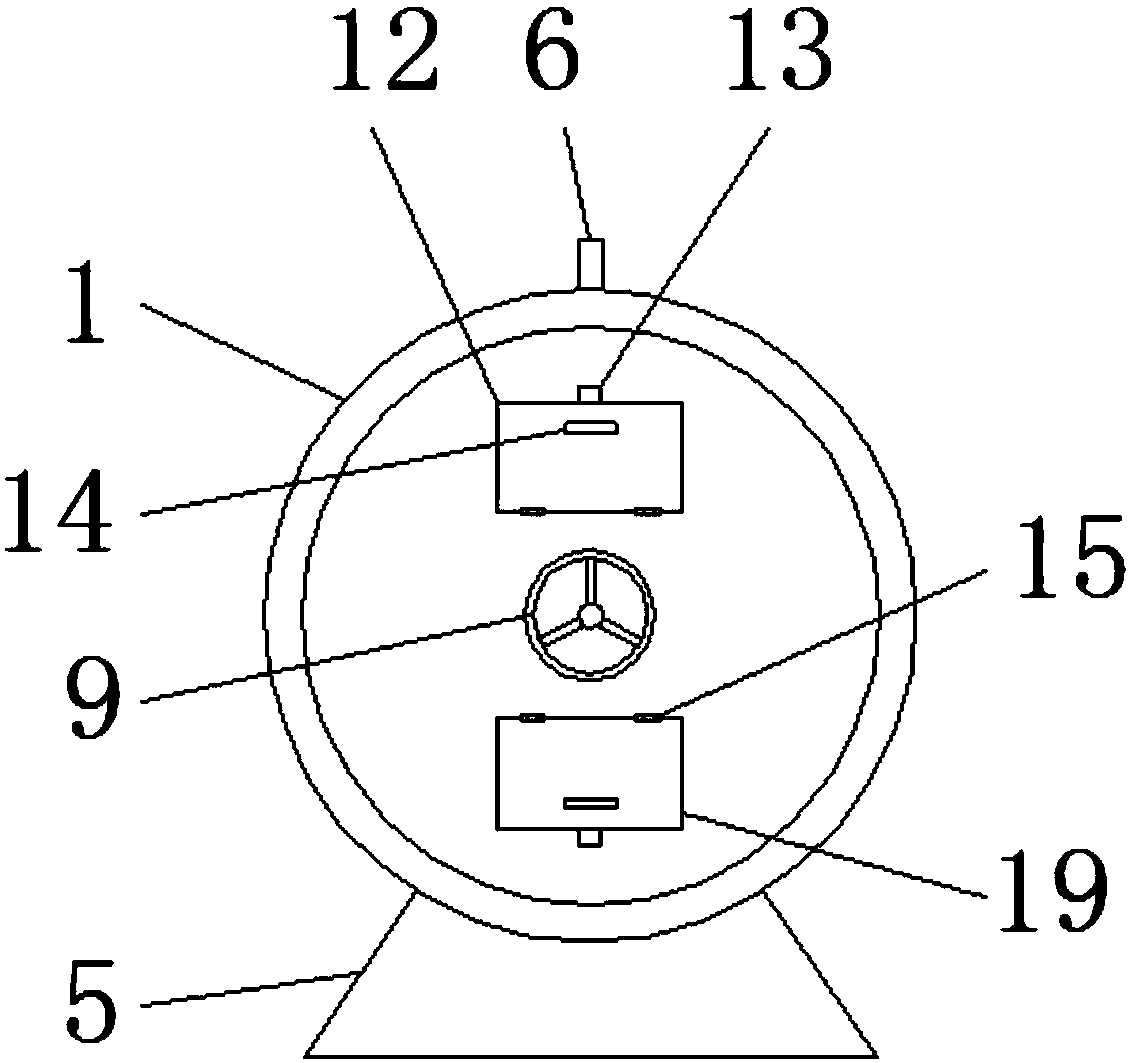

The invention provides a cleaning and drying device for textile products. The cleaning and drying device comprises a cleaning and drying integrated box, an electric door, a cleaning chamber, a dryingchamber, a supporting column, an immersion type cleaning driving hanging plate assembly, a textile product fixing frame assembly, a steam flow dividing guide pipe assembly, a rail, a transverse supporting plate, an air blower, a waste discharging pipe, a cleaning box, a manual door, an air collecting hood, an exhaust fan, a temperature sensor, a control box, an electric heating pipe, an air outletcover and a wind guide pipe. According to the cleaning and drying device, the textile products needing to be cleaned and dried are hung on hooks or fixed to protective pieces and connecting rods; thetextile product fixing frame assembly with the textile products is immersed into the cleaning box, a rotating motor is started to rotate, so that the cleaning effect is achieved, and after stirring and cleaning are completed, the textile product fixing frame assembly is lifted out to rotate, and thus the spin-drying effect is achieved; and the rail is specifically an annular rail, cleaning and drying operation can be conducted at the same time, and the cleaning and drying efficiency is improved.

Owner:邵阳市昌兴实业有限公司

Food fermentation tank with solid-liquid separation function

InactiveCN108384705AWith solid-liquid separation functionPlay a role in cleaningBioreactor/fermenter combinationsBiological substance pretreatmentsAgricultural engineeringFermentation

The invention discloses a food fermentation tank with a solid-liquid separation function. The tank comprises a fermentation tank body, a base, a top spraying pipe, a water through hole, a rotating wheel, a drainage pipe, a handle, a water spraying opening, a connecting pipe and a second sealing door; a stirrer is arranged on the left side of the fermentation tank body, the base is welded to the lower end of the fermentation tank body, the top spraying pipe is arranged at the upper portion inside the fermentation tank body, the water through hole runs through the outer wall of a mixing tank, the rotating wheel is arranged at the right side of a fermentation tank door through a stirring shaft, the drainage pipe is arranged below the fermentation tank body, the handle is arranged on the outerside of the first sealing door, and the water spraying opening is formed below the top spraying pipe. According to the food fermentation tank with the solid-liquid separation function, the water through hole is formed in the outer wall of the mixing tank, water can be added into the mixing tank and water inside the mixing tank can be drained conveniently, and fermented solid and fermented water inside the mixing tank can be separated conveniently.

Owner:江西省食品发酵研究所

Water-saving intelligent cleaning pool

ActiveCN108301467AGuaranteed service lifeAvoid accumulationDomestic plumbingWater storageWater saving

The invention discloses a water-saving intelligent cleaning pool which comprises a cleaning pool, a storage tank, a stirring device, a water-saving system and a control device, wherein a detachable partition plate is arranged in the cleaning pool; the cleaning pool is partitioned into a first cleaning area and a second cleaning area by the partition plate; a first water outlet and a second water outlet are respectively formed in bottom ends of the inner sides of the first cleaning area and the second cleaning area; the storage tank is arranged below the first water outlet and comprises a tankbody and a bottom plate; the bottom plate is liftable and is movably connected to the bottom of the tank body in a rotatable manner; the stirring device is arranged at the bottom end of the storage tank and communicated with the interior of the storage tank; the water-saving system comprises a water storage barrel and a drainage pipeline arranged below the second water outlet; the drainage pipeline comprises a first pipeline and a second pipeline; the first pipeline is in liquid communication with a sewer line and the water storage barrel; the second pipeline is in liquid communication with the shell and the water storage barrel. According to the water-saving intelligent cleaning pool disclosed by the invention, waste of water resources is reduced, the service life of stirring blades is ensured, the stirring efficiency is improved, and blockage of the sewer line is avoided.

Owner:平邑现代中药产业园有限公司

Glasses case

InactiveCN107692452APlay a role in cleaningEasy to operateOther accessoriesSurface mountingEngineering

Owner:陕西再造故乡文化发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com