Patents

Literature

95results about How to "Play the role of drying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

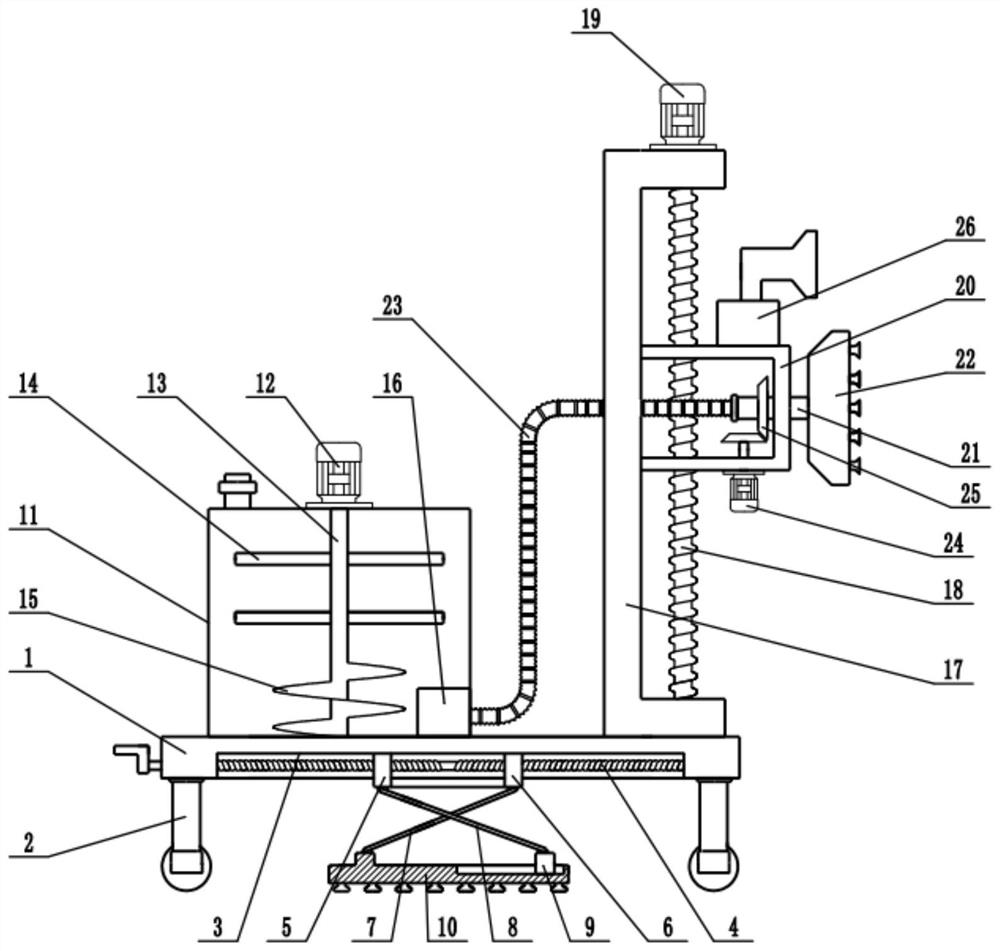

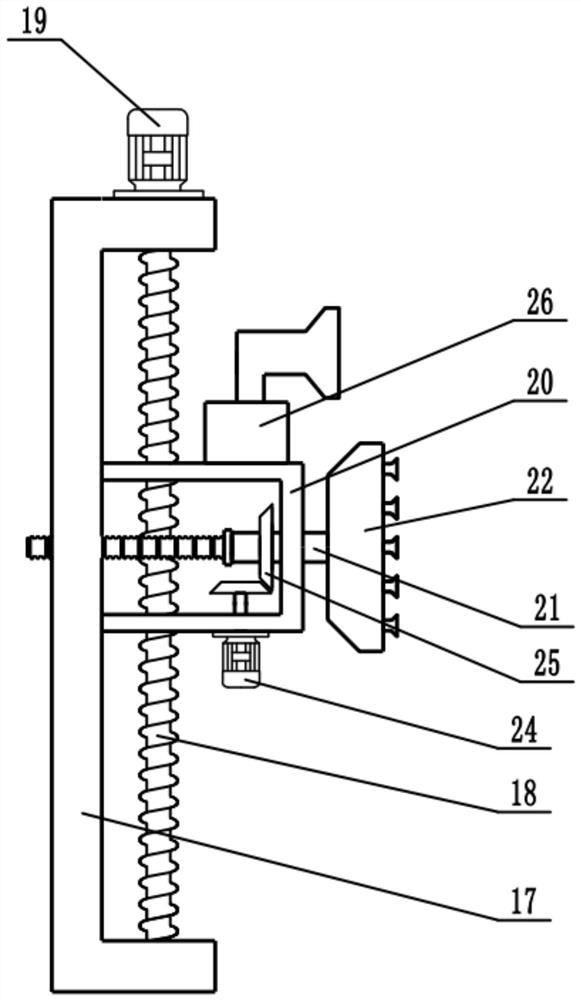

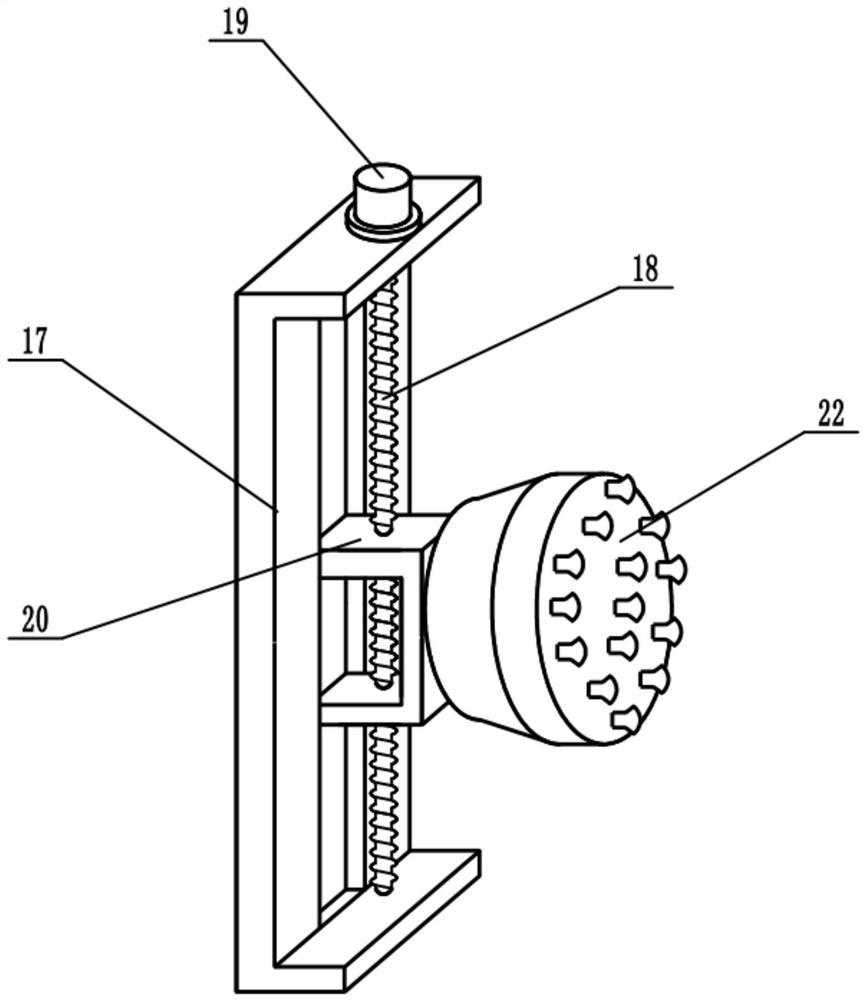

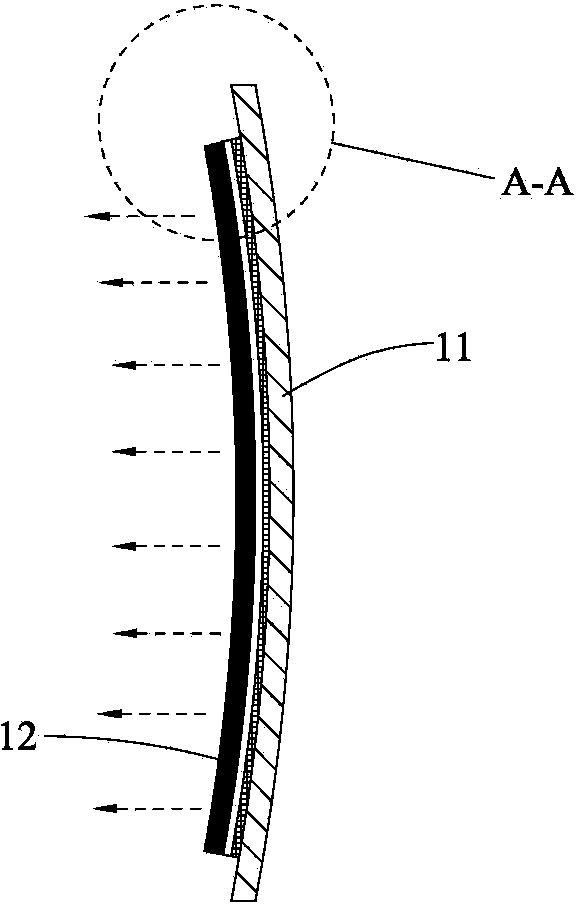

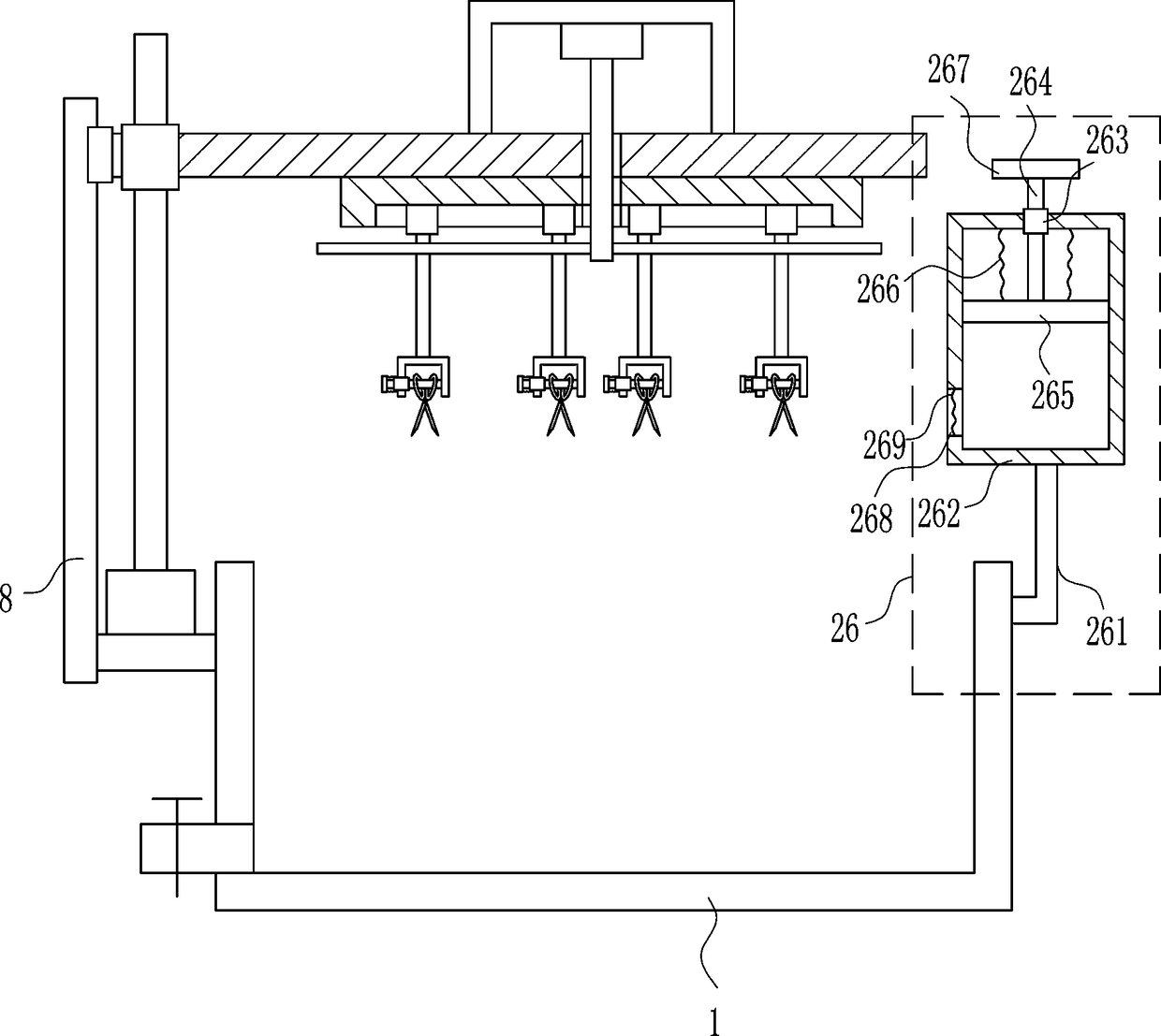

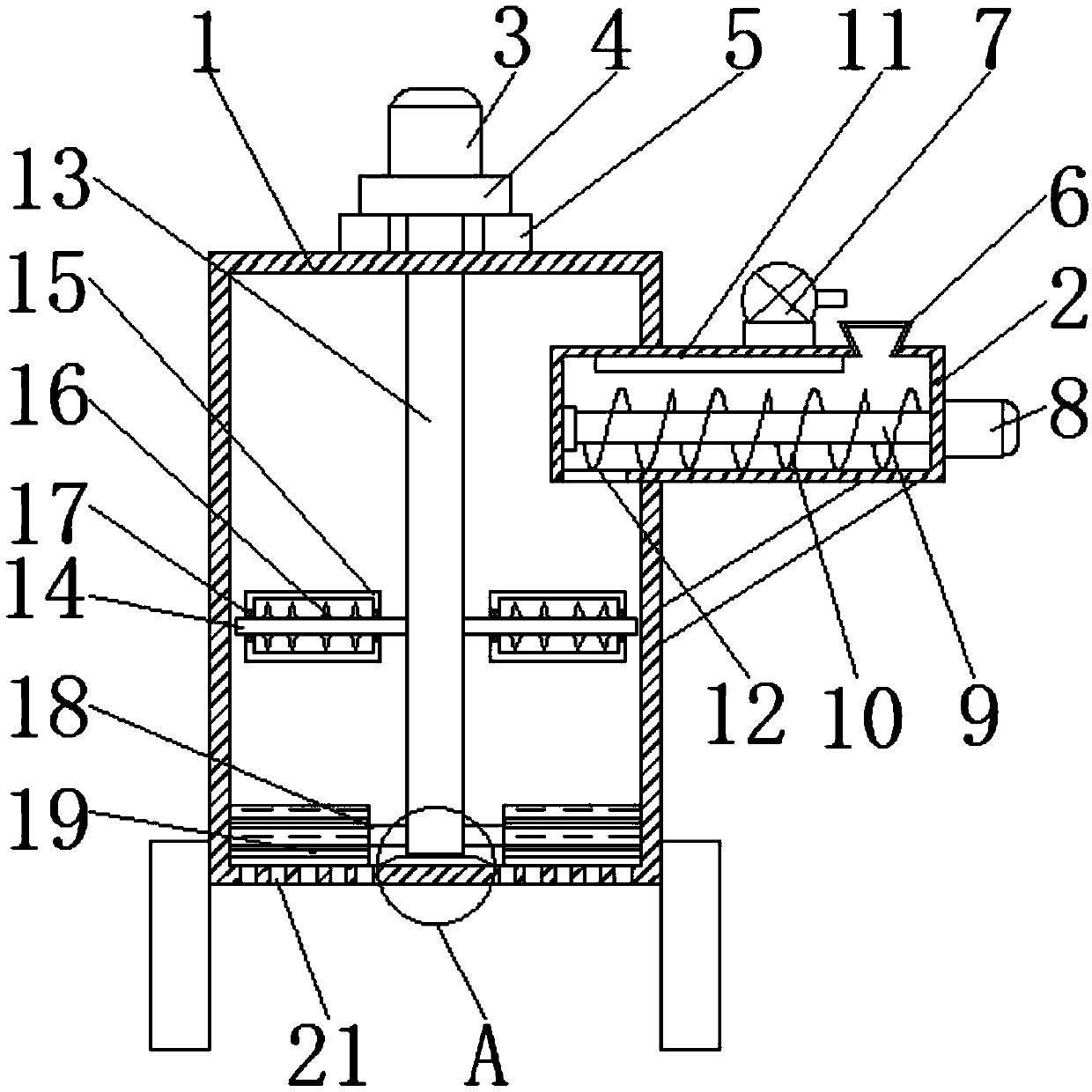

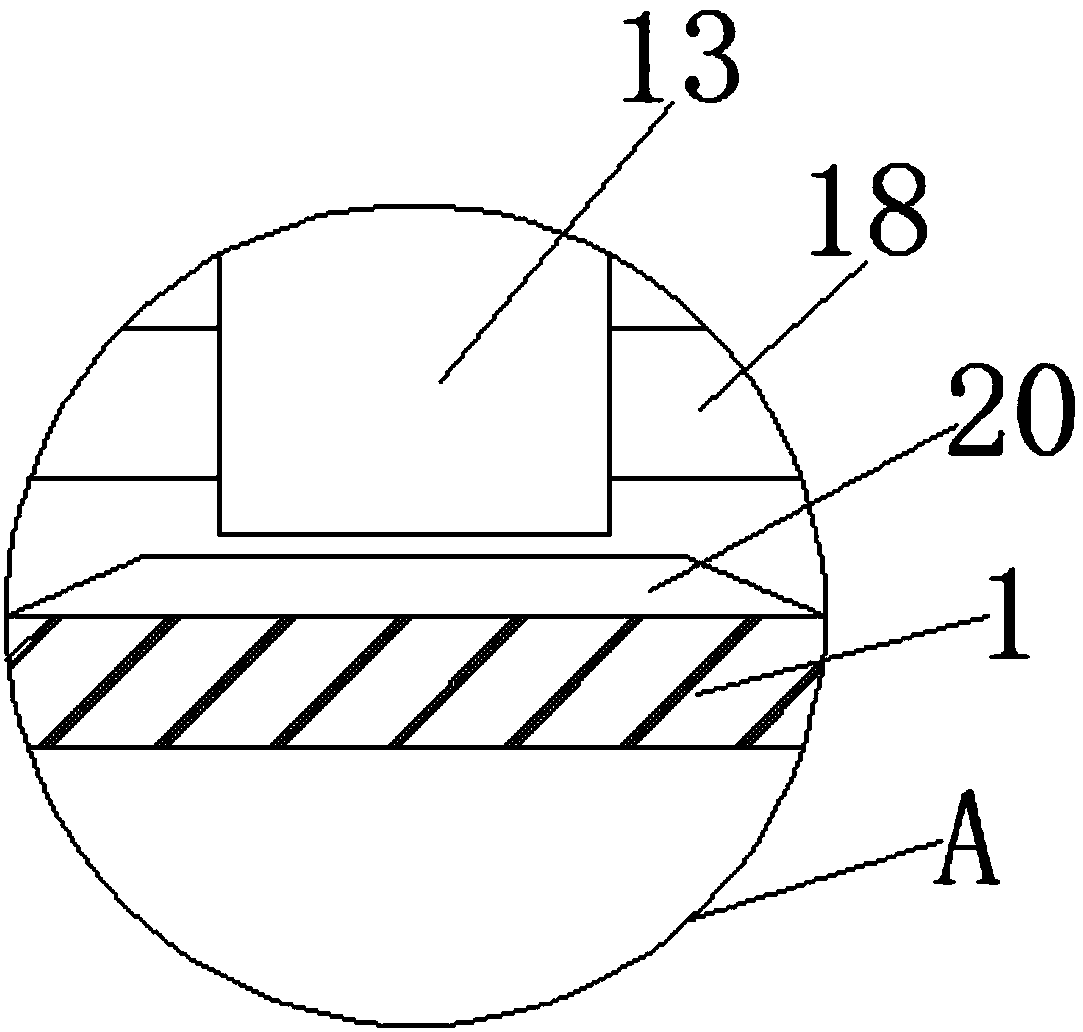

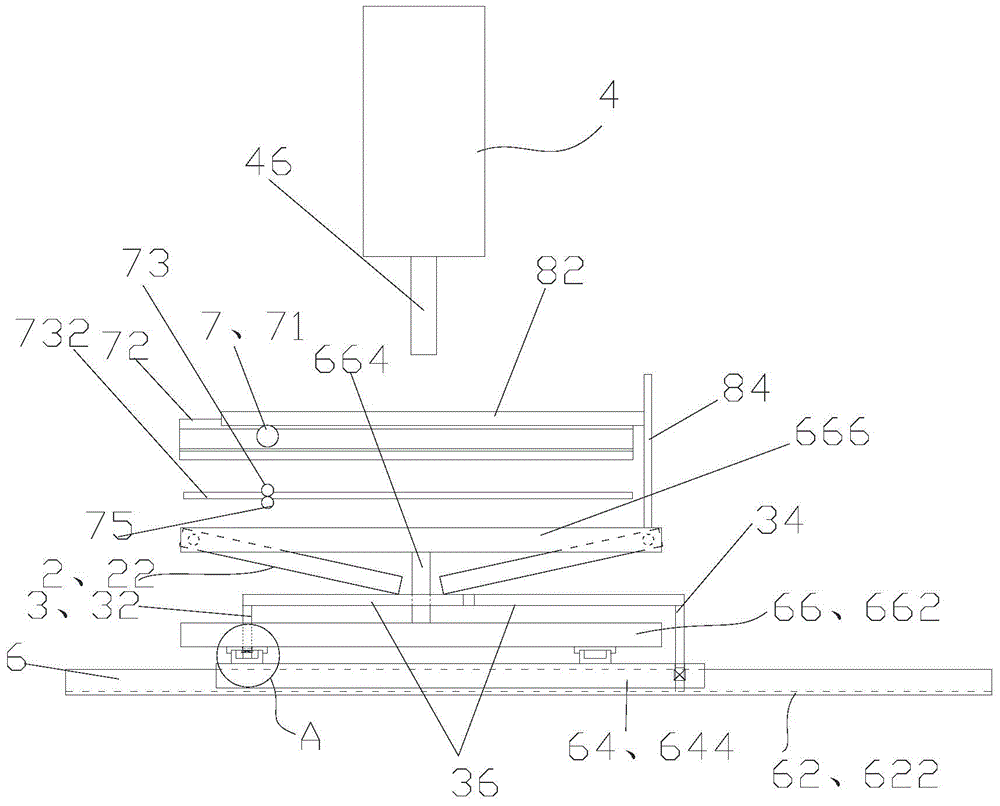

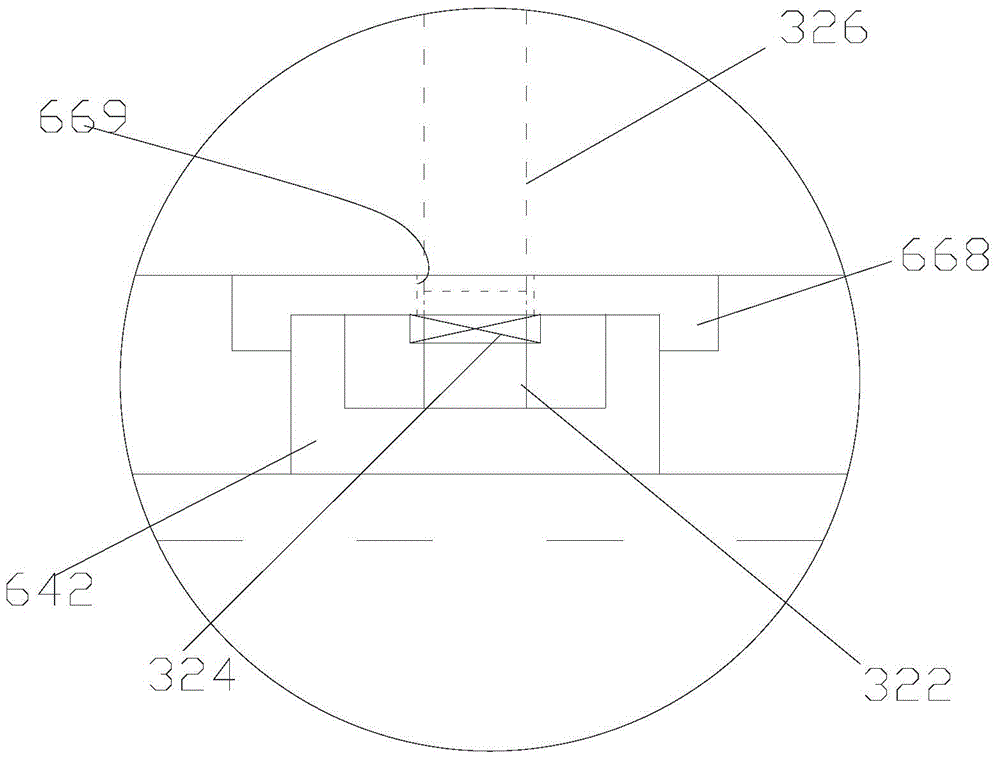

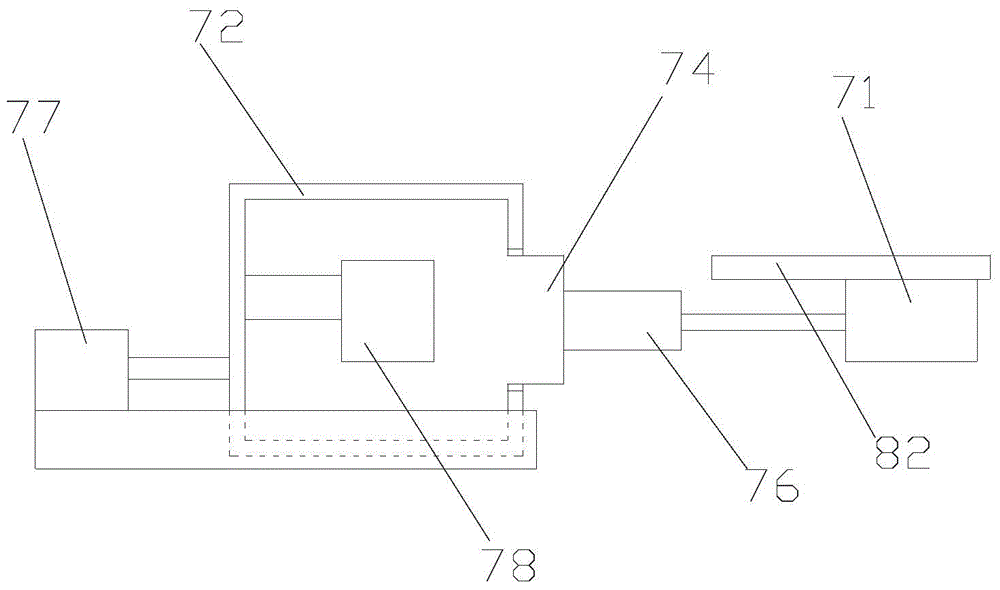

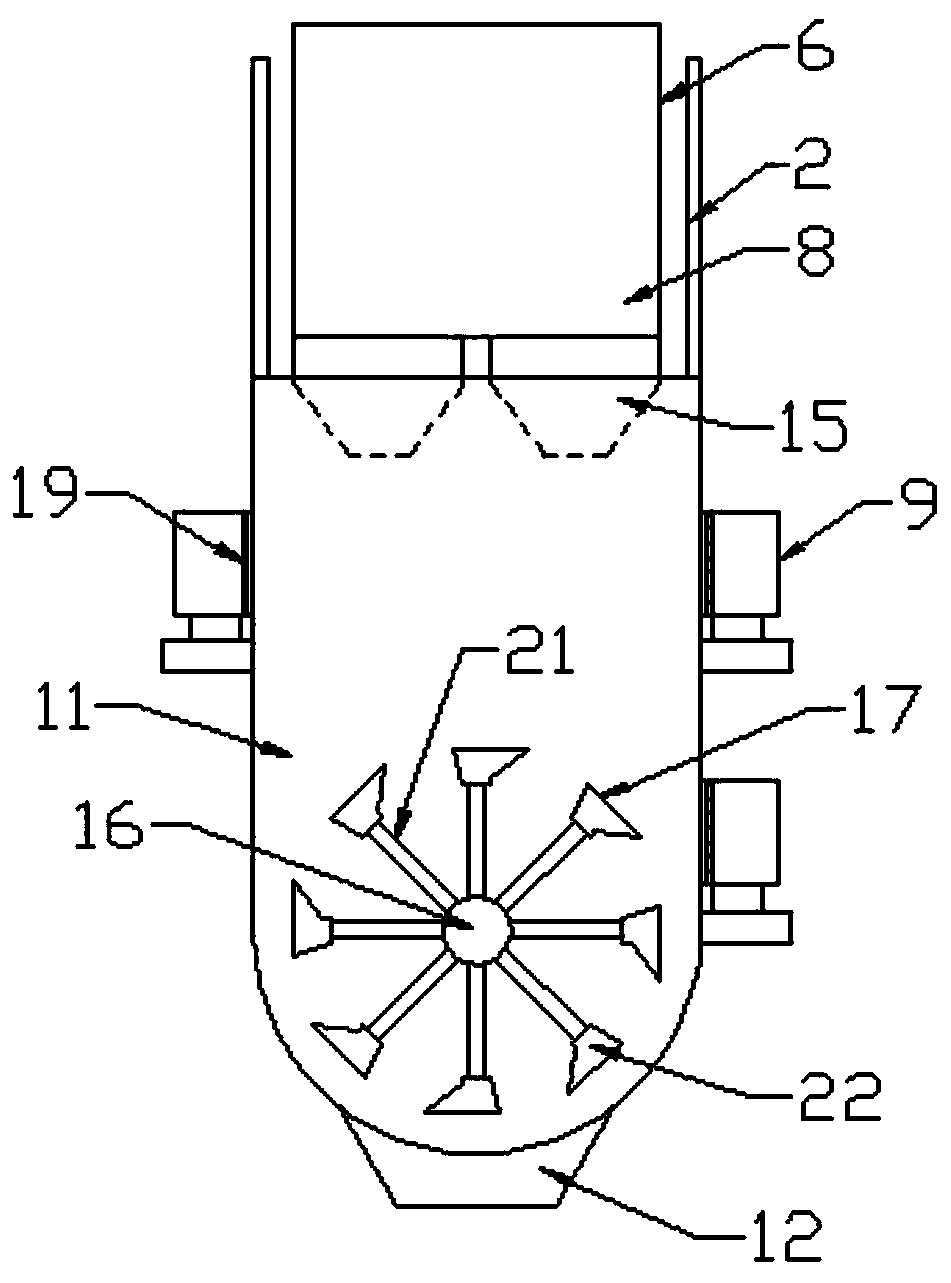

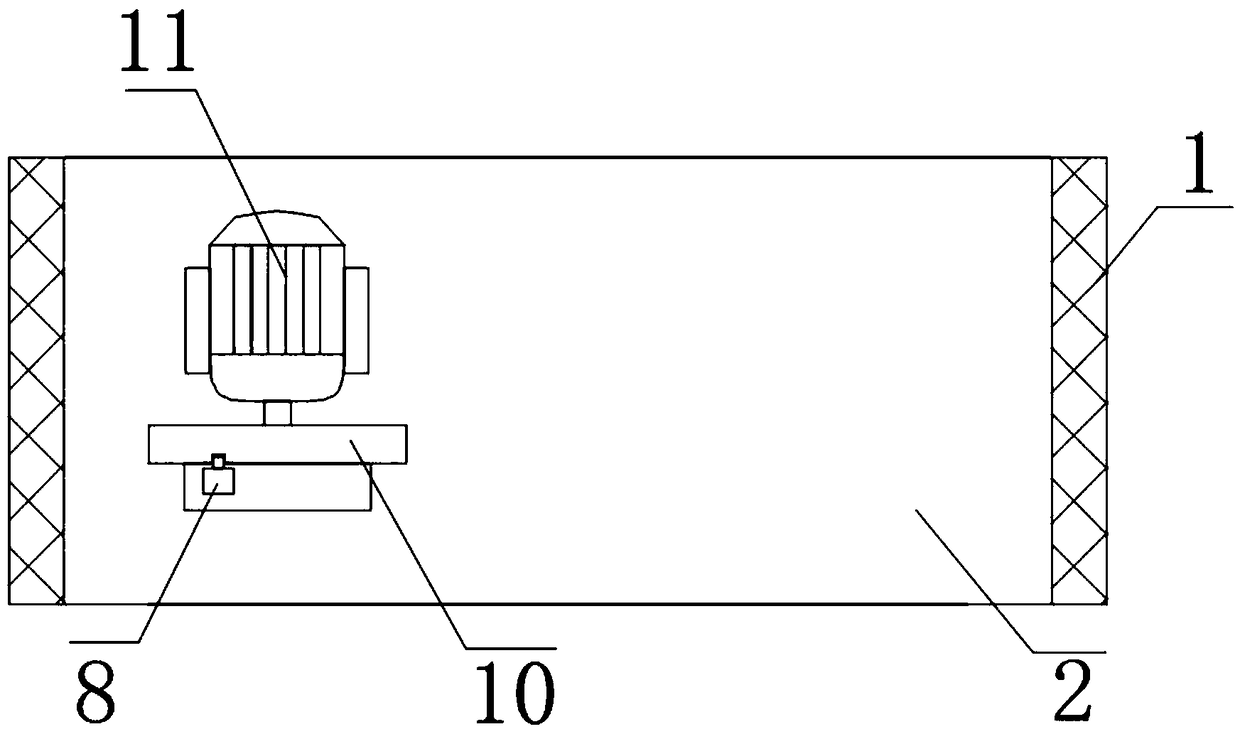

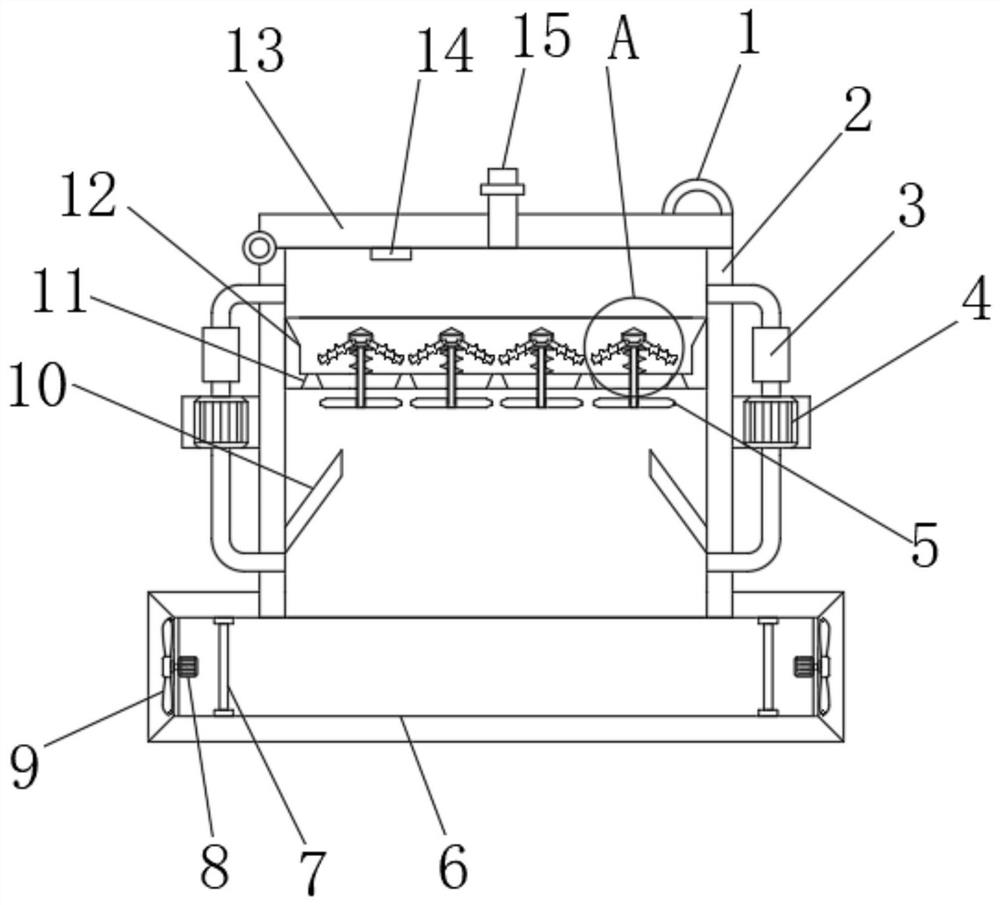

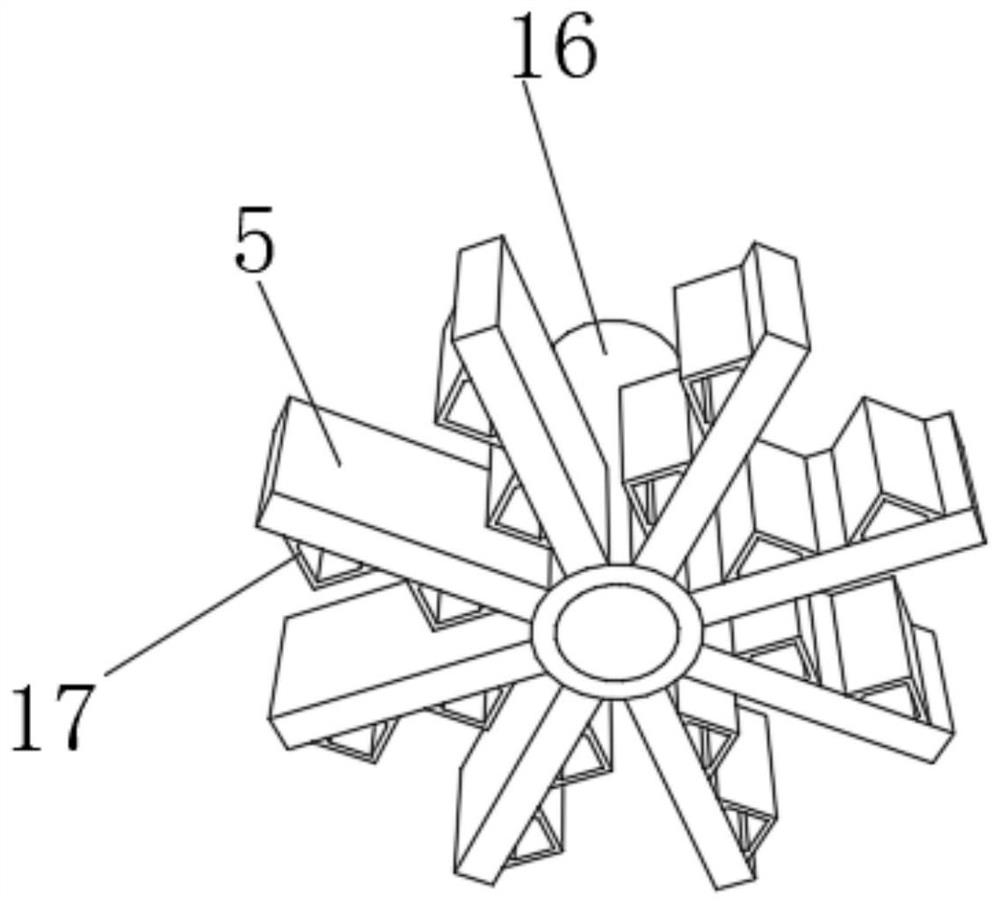

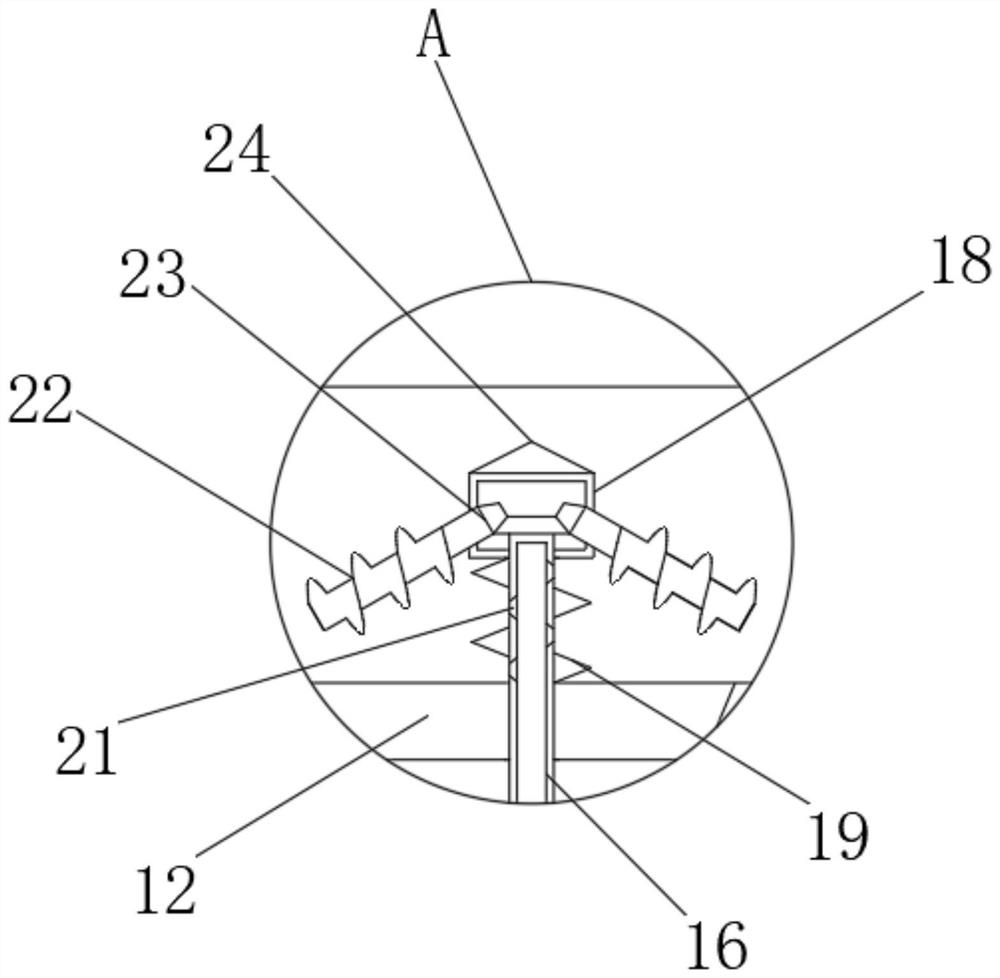

Convenient-to-move wall paint spraying device

InactiveCN111715431AWell mixedPrevent precipitationPretreated surfacesBuilding constructionsSprayerElectric machinery

The invention relates to the field of building equipment, in particular to a convenient-to-move wall paint spraying device. The device comprises a rack, a storage box, a booster pump, a mounting frameand a sprayer. The upper surface of the rack is fixedly connected with the storage box, a stirring mechanism is installed in the storage tank, the bottom of the storage box is also provided with thebooster pump, the upper surface of the rack is fixedly connected with the mounting frame, a lifting lead screw is mounted inside the mounting frame, the interior of the mounting frame is slidably connected with a lifting frame, a hollow rotating shaft penetrates through the lifting frame, and the sprayer is installed at the right end of the hollow rotating shaft. A stabilizing mechanism is mountedat the bottom of the rack. By means of the stabilizing mechanism, the stability of the device is greatly improved, and wall paint spraying is facilitated. Paint is stirred through the stirring mechanism, so that the paint is evenly mixed, and the paint is prevented from being precipitated. The paint in the storage box is conveyed to the sprayer through the booster pump for wall paint spraying. The sprayer is driven by a third motor to rotate, so that the spraying process is more uniform, and the paint spraying efficiency is improved.

Owner:胡海军

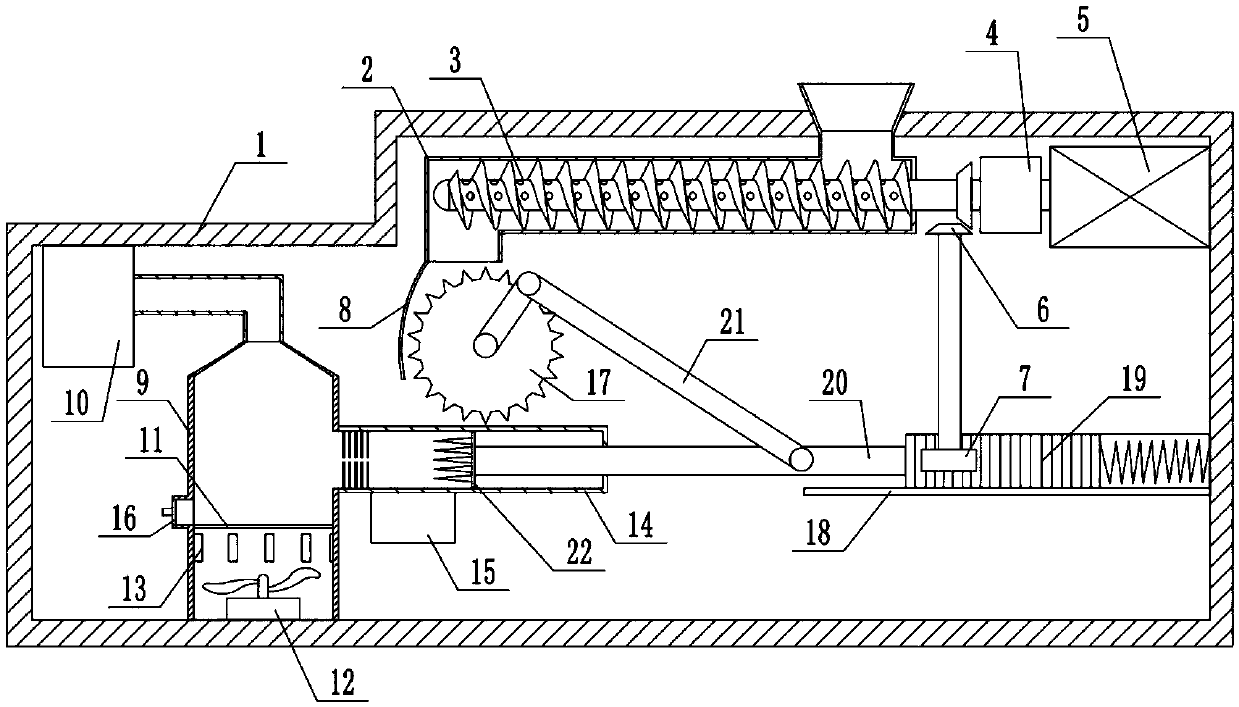

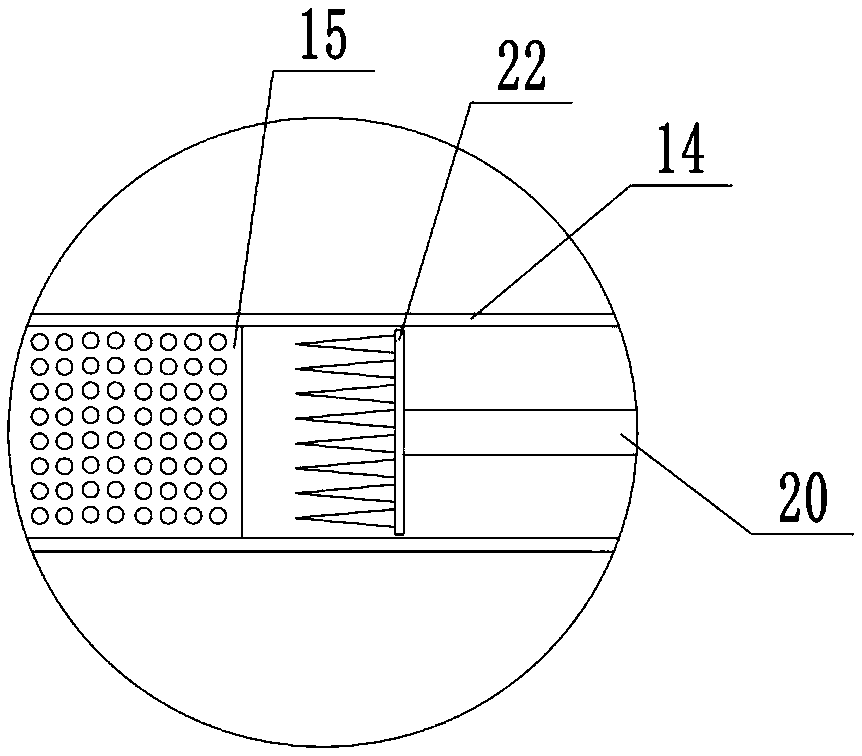

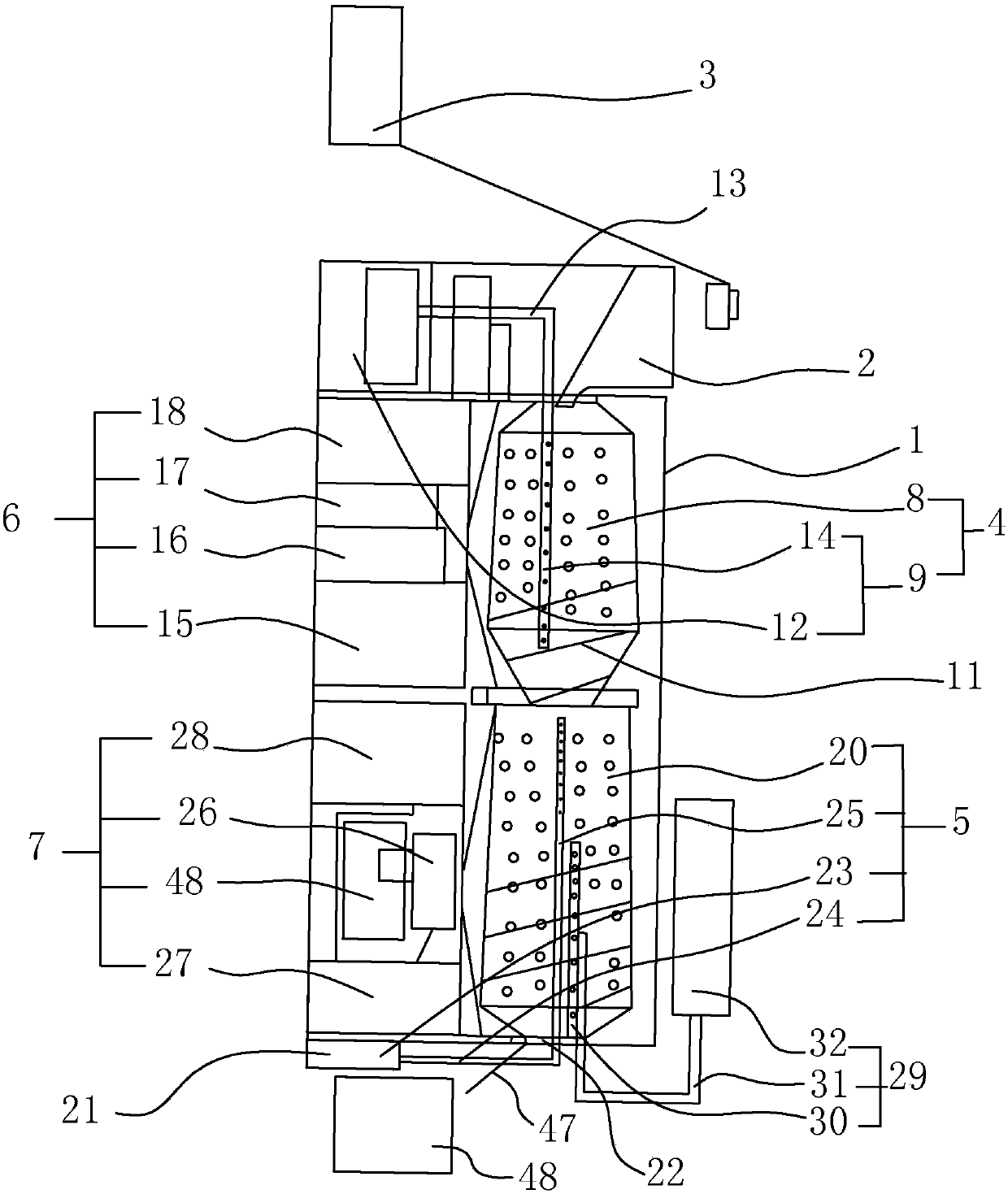

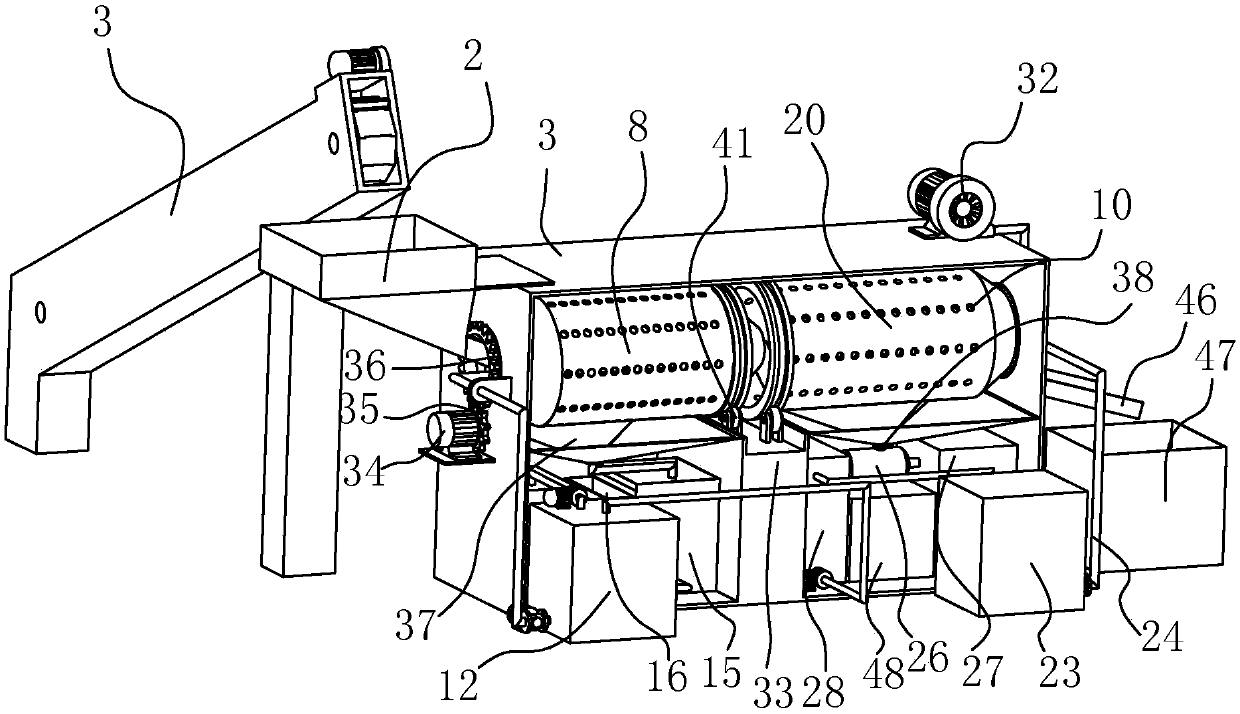

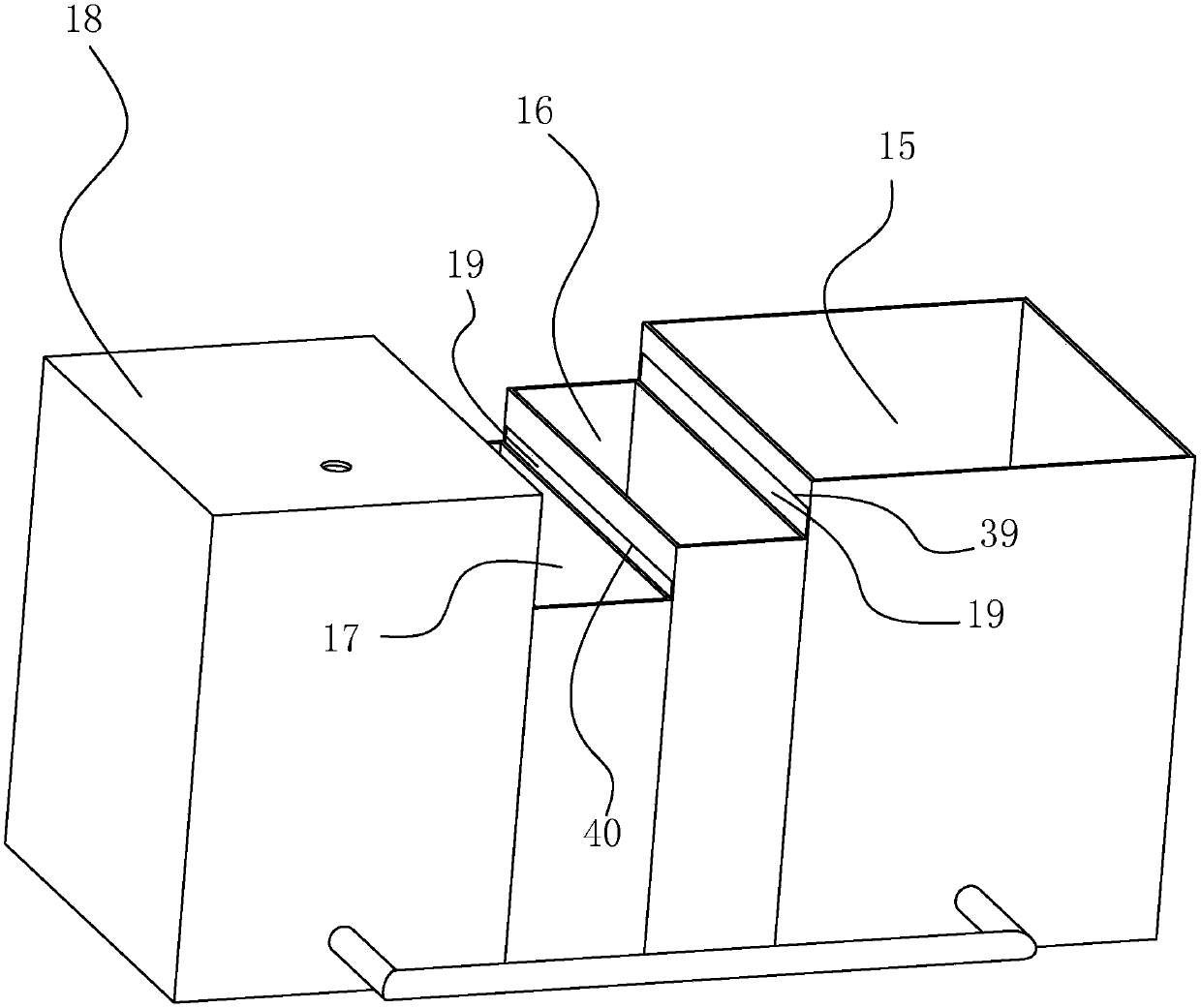

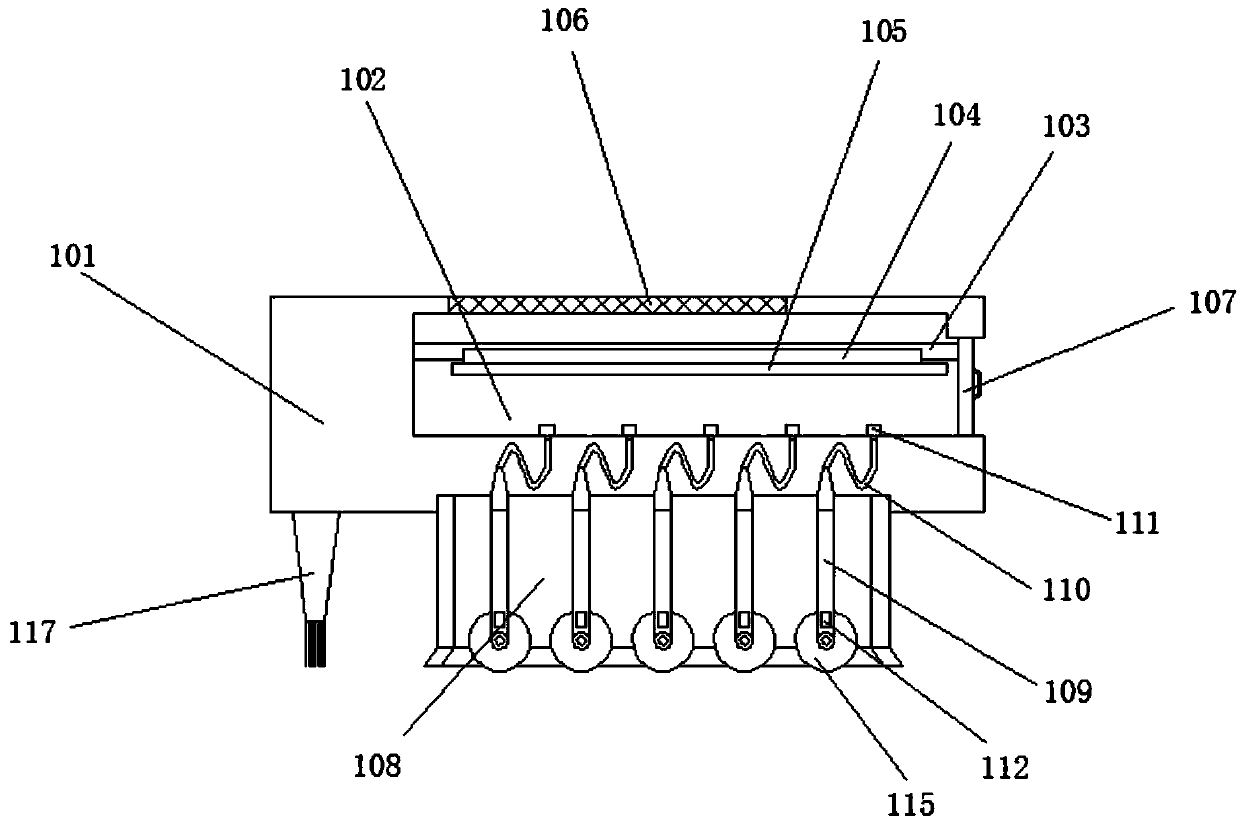

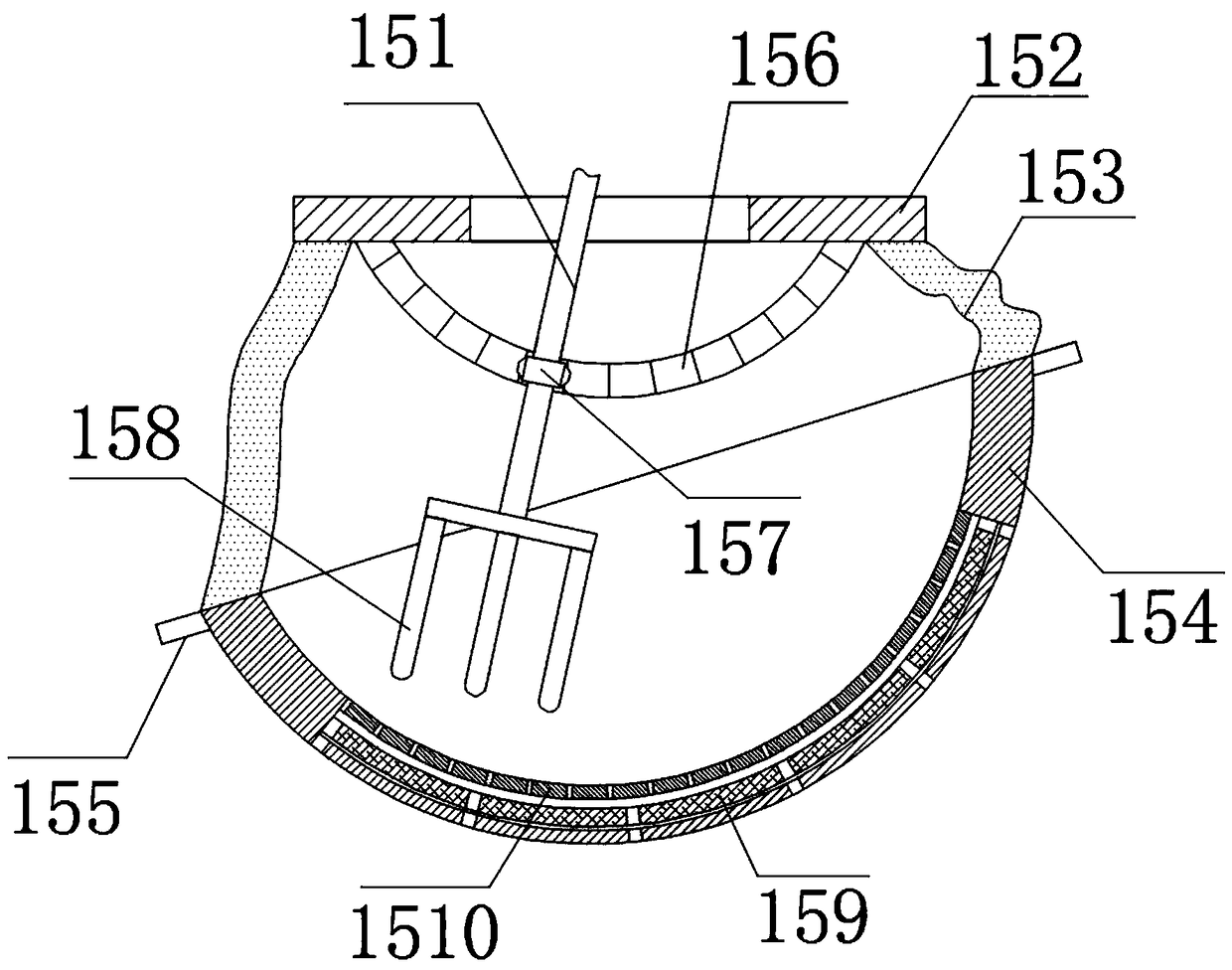

Cotton seed separating device

InactiveCN109652862AEasy to separatePrevent flutteringVegetable fibre separation from seedsFiberWood splinter

The invention relates to the field of textile, and discloses a cotton seed separating device which comprises a body. The inside of the body is provided with a feeding port, a feeding pipe, an operation barrel, a pressuring roller and a sliding rail, a screw rod is arranged in the feeding pipe and provided with a chamber, a through hole, a first bevel gear, a steamer and a motor, the first bevel gear is engaged with a second bevel gear, the second bevel gear is coaxially connected with an incomplete gear, a baffle plate is fixedly connected at the tail end of the feeding pipe, a conveying pipeis fixedly connected at the top of the operation barrel and connected with a treatment box, an air feeding plate, a plurality of heating pipes and a fan are arranged in the operation barrel, air outlet holes are densely formed in the air feeding plate, a separating tank is arranged on the operation barrel, a brush is arranged in a separating box, a collecting box is communicated with the bottom ofthe separating box, a rack and a spring are arranged in a guide rail, a pushing rod and a connecting rod mechanism are arranged on the rack, a needle plate is arranged on the pushing rod, iron splinters are densely distributed on the needle plate. By the aid of the technical scheme, the separating device solves the problems of low quality of cotton fibers separated by a ginning machine and more cotton dust in the prior art.

Owner:象山平悦环保科技有限公司

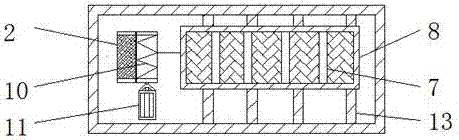

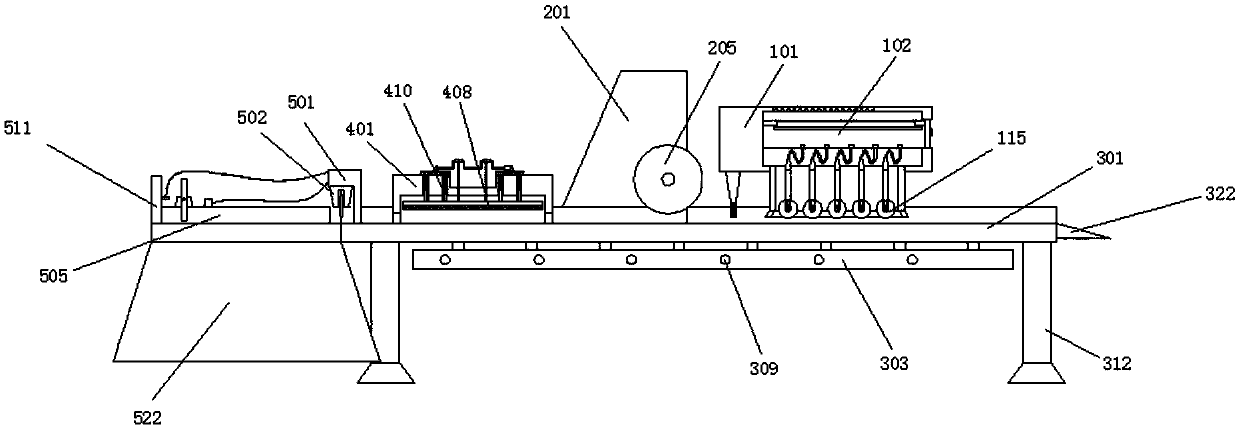

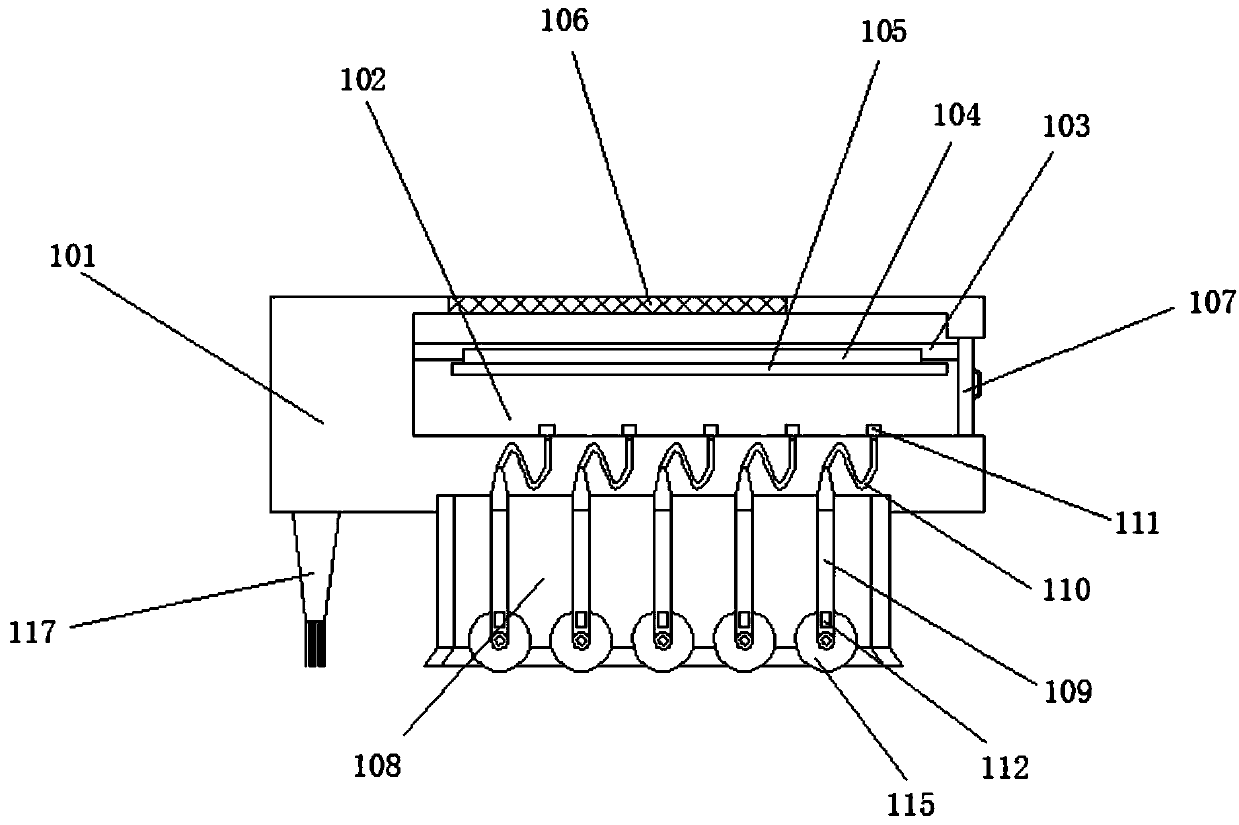

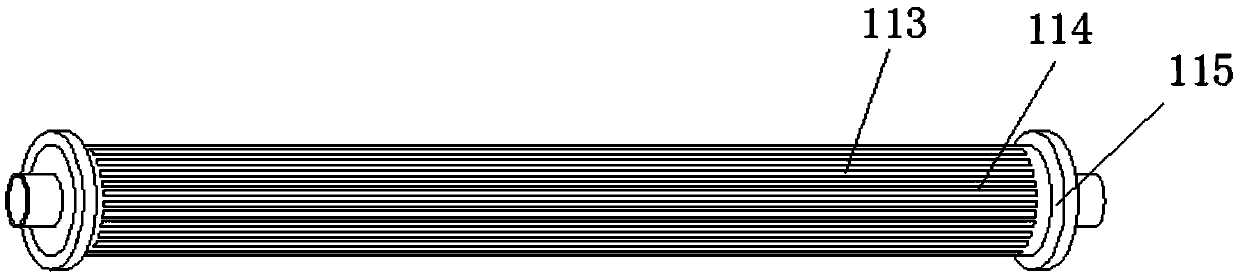

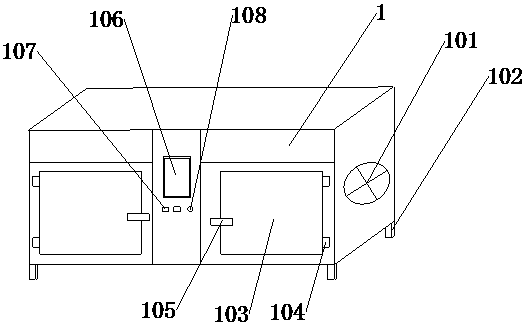

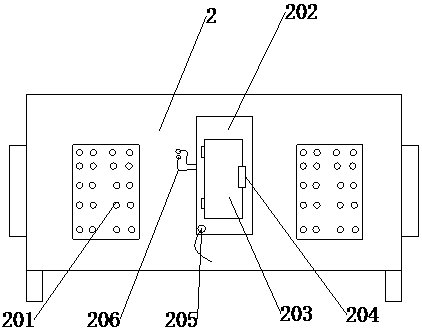

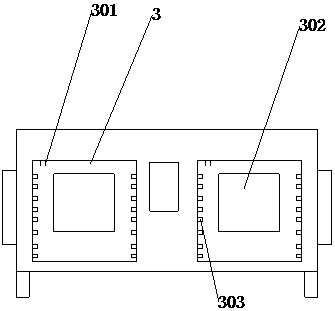

Environment-friendly automatic rivet nut cleaning system

PendingCN107755349AHigh degree of automationLabor savingDrying gas arrangementsCleaning using liquidsProcess engineeringIndustrial engineering

Owner:海宁瑞贝特科技股份有限公司

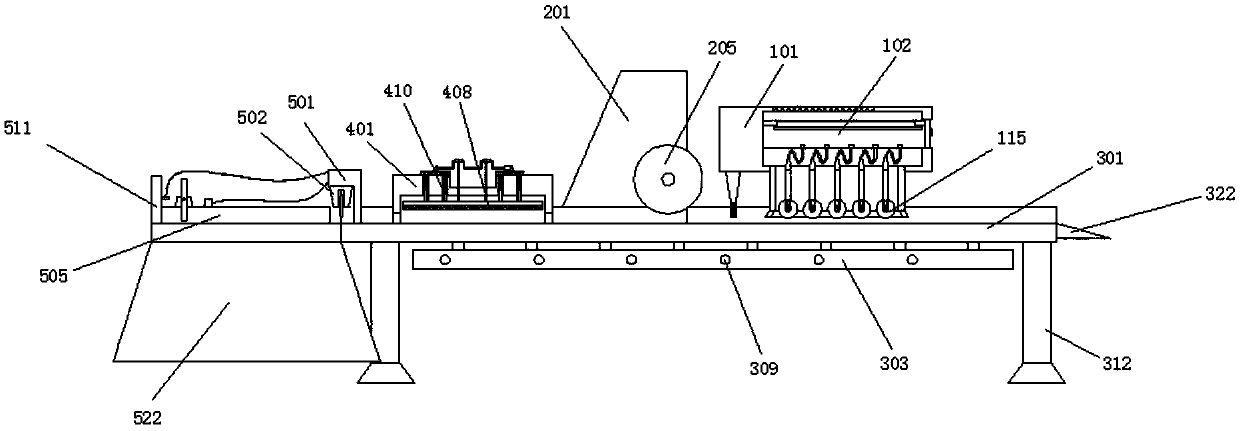

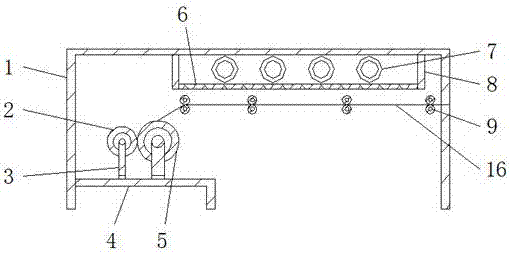

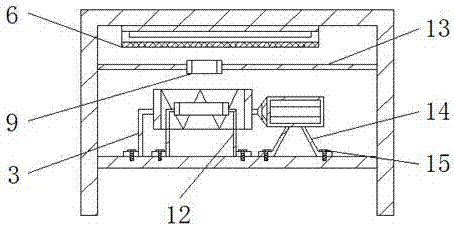

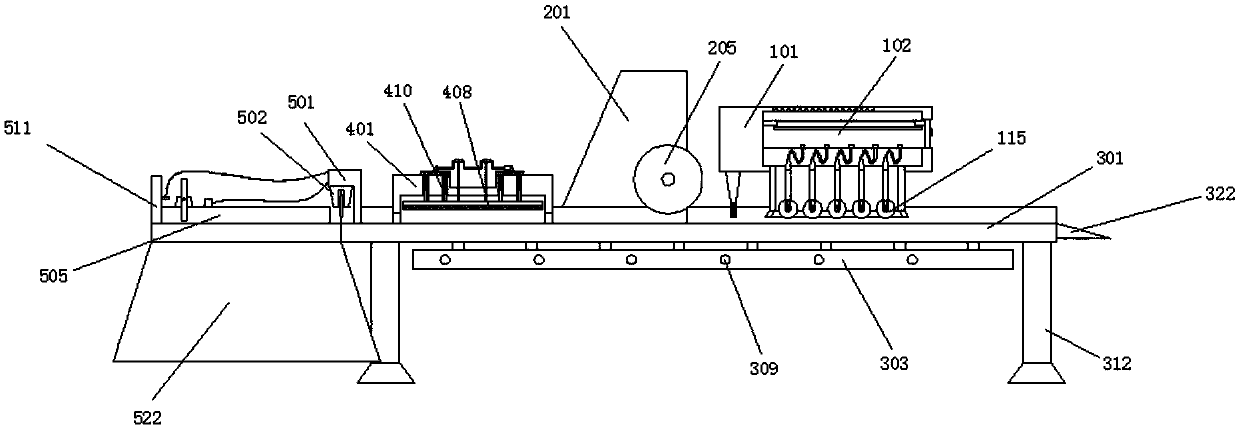

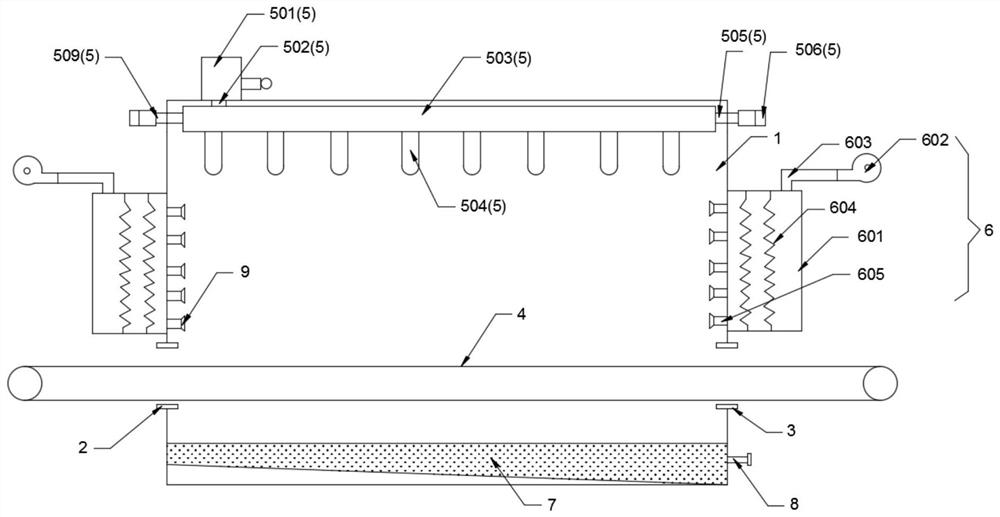

Adjustable positioning conveying table for plastic extruding plate machining device

InactiveCN109573540AStable deliveryReduce frictional resistanceRotary pressesConveyor partsPrinting inkEngineering

The invention discloses an adjustable positioning conveying table for a plastic extruding plate machining device. The adjustable positioning conveying table comprises a conveying table body, and a dust removal cavity, a printing table, a drying bin and a beam frame are sequentially and fixedly installed on the top side of the conveying table body from right to left; a clamping and positioning mechanism is arranged on the conveying table body, a cutting knife rest is movably installed on the lower side of the beam frame, and an automatic discharging mechanism is fixedly installed on the left side of the conveying table body. According to the adjustable positioning conveying table, the surface of the plastic extruding plate can be subjected to dust removal treatment, the printing ink is prevented from being printed onto dust during printing, and therefore the printing effect is influenced; a printing roller can be adjusted and rotated, the distance and the position of printing can be changed, and then a printing pattern is changed, and the effect of air drying during printing is achieved; redundant ink of the corrugated board can be adsorbed and cleaned through adsorption cotton after the printing, meanwhile, hot air plays a role in drying the surface, the automatic quantitative automatic cutting and discharging are realized, the full-automatic machining operation is simple and accurate, the manual labor is reduced, and the adjustable positioning conveying table is easy to popularize and apply.

Owner:张磊

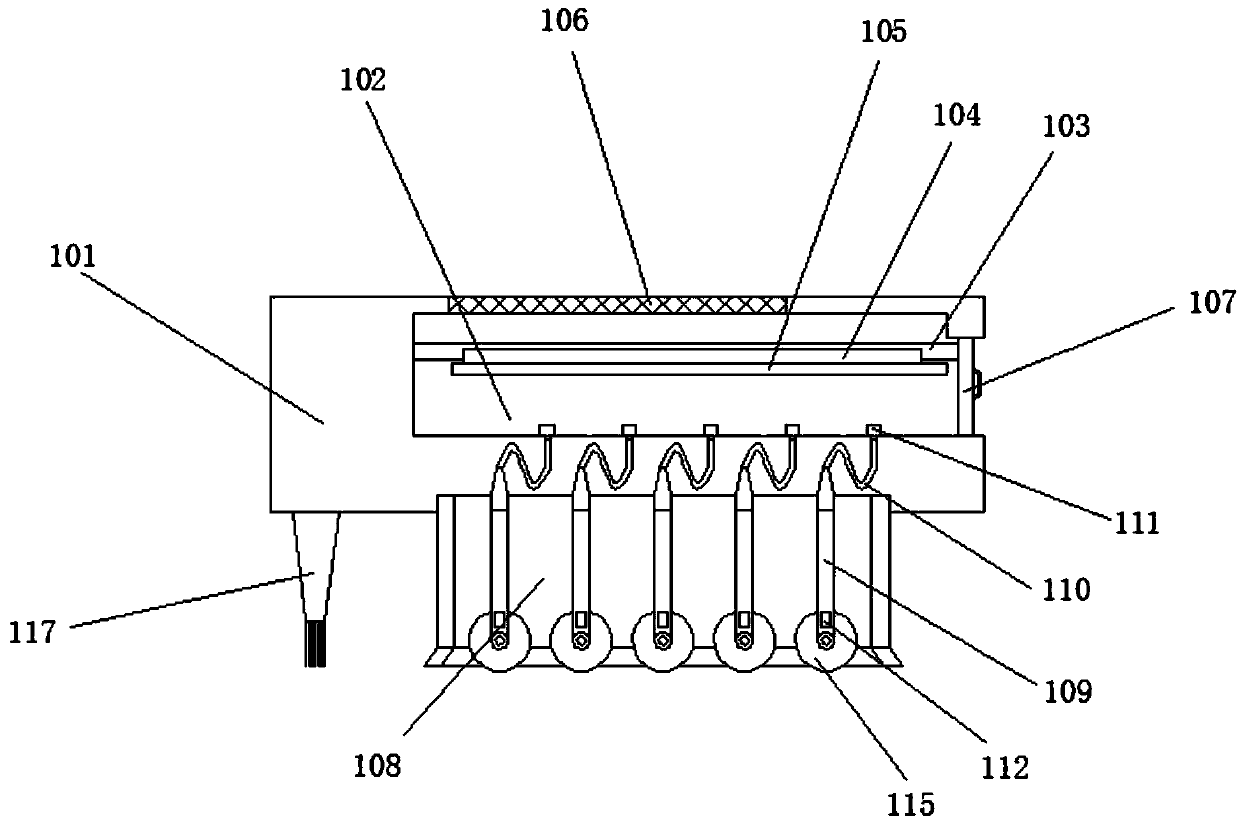

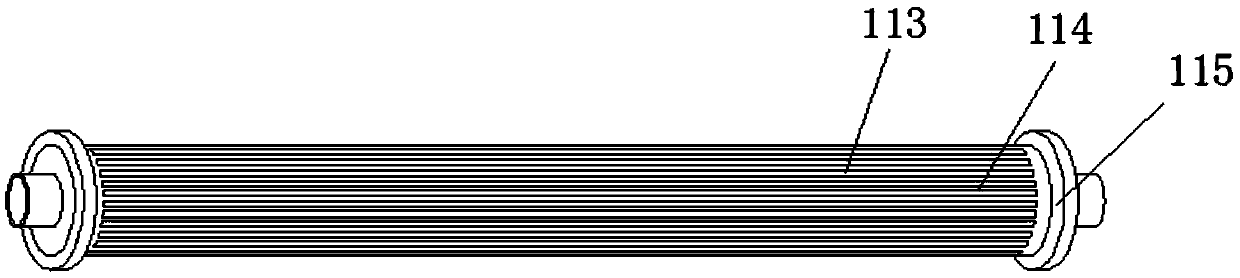

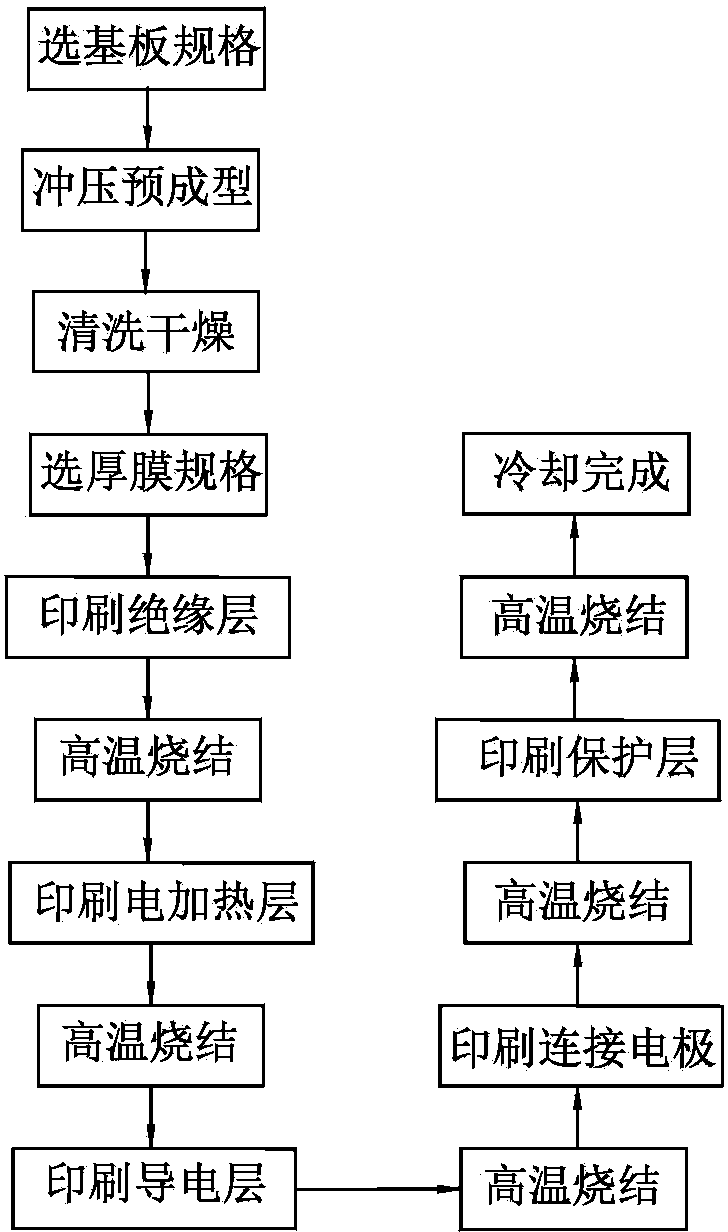

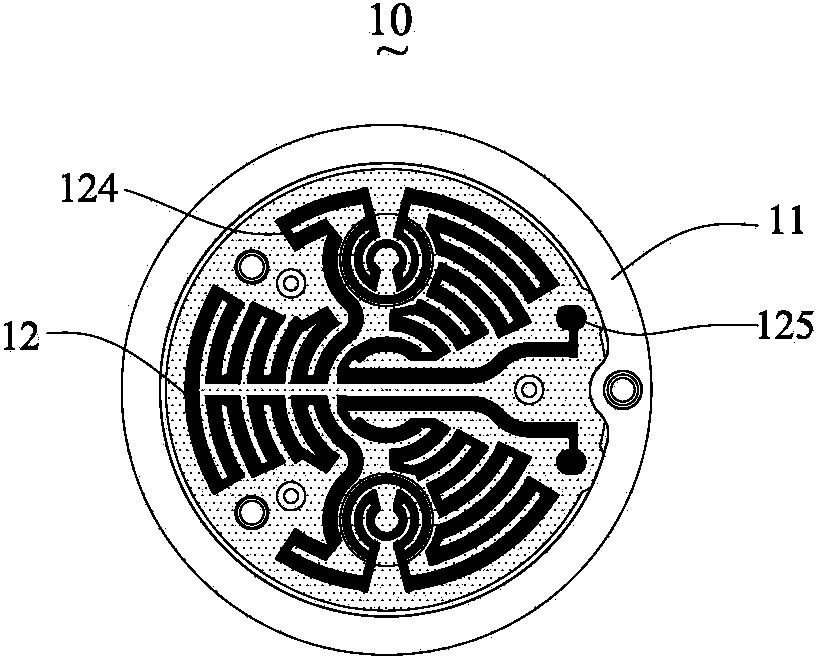

Processing method of thick film heating device, thick film heating container and equipment

ActiveCN103415092APlay the role of dryingAvoid the risk of low yieldBeverage vesselsOhmic-resistance heatingHome applianceComposite material

Owner:JOYOUNG CO LTD

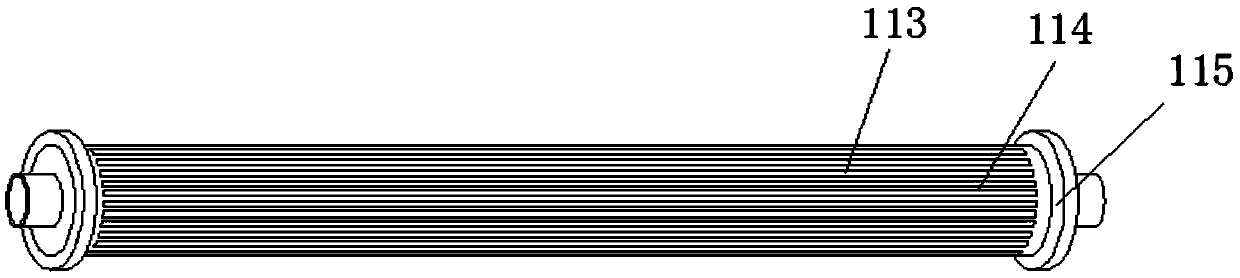

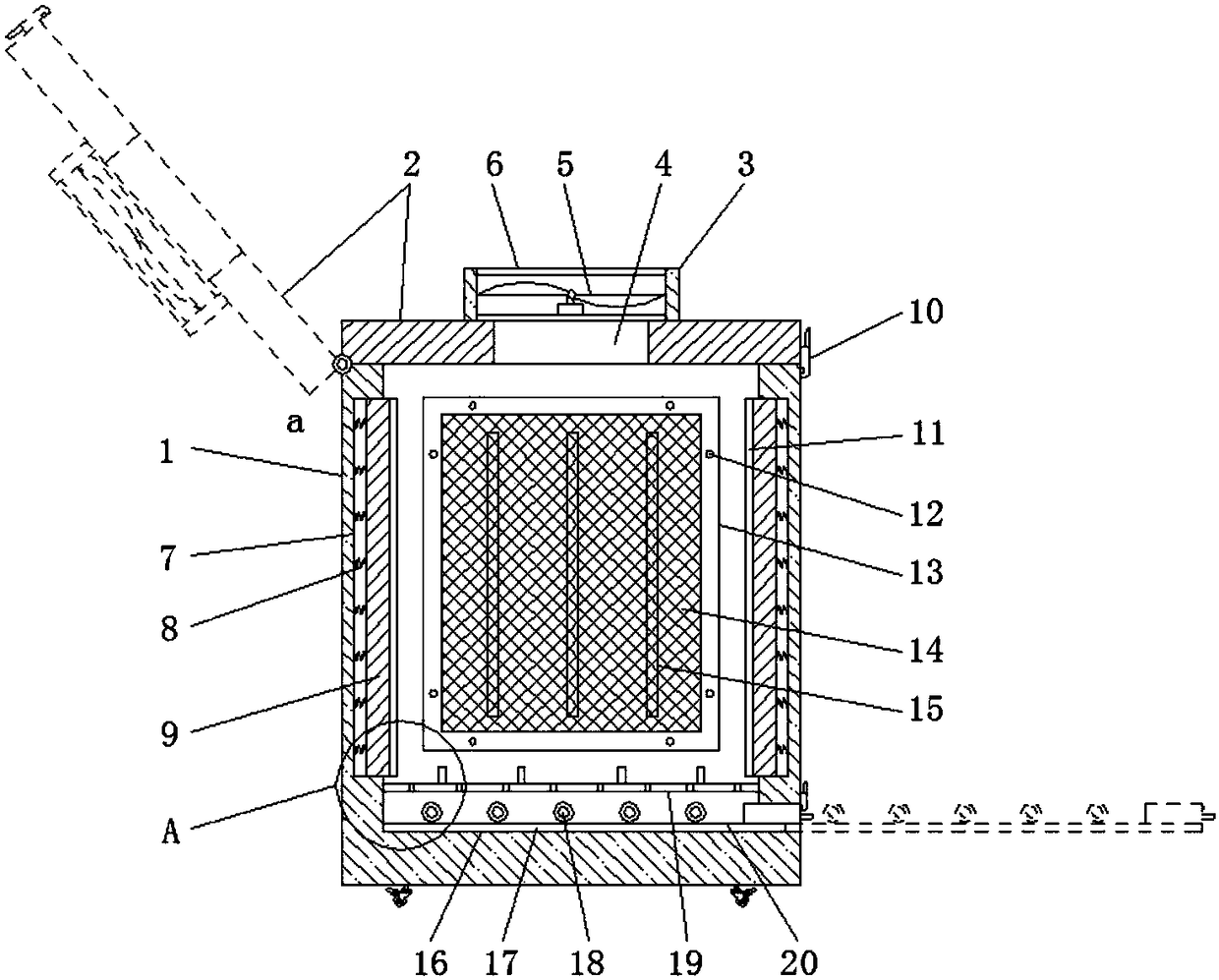

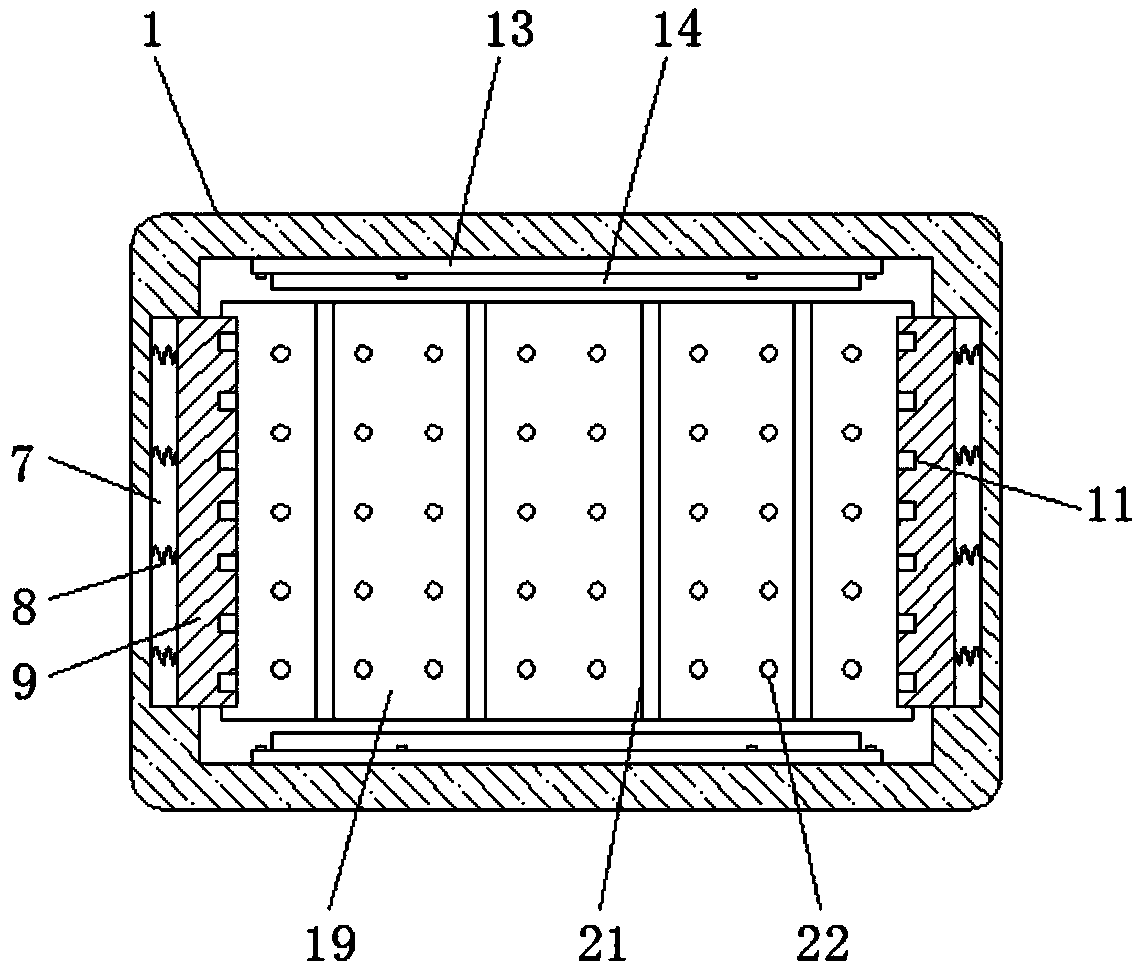

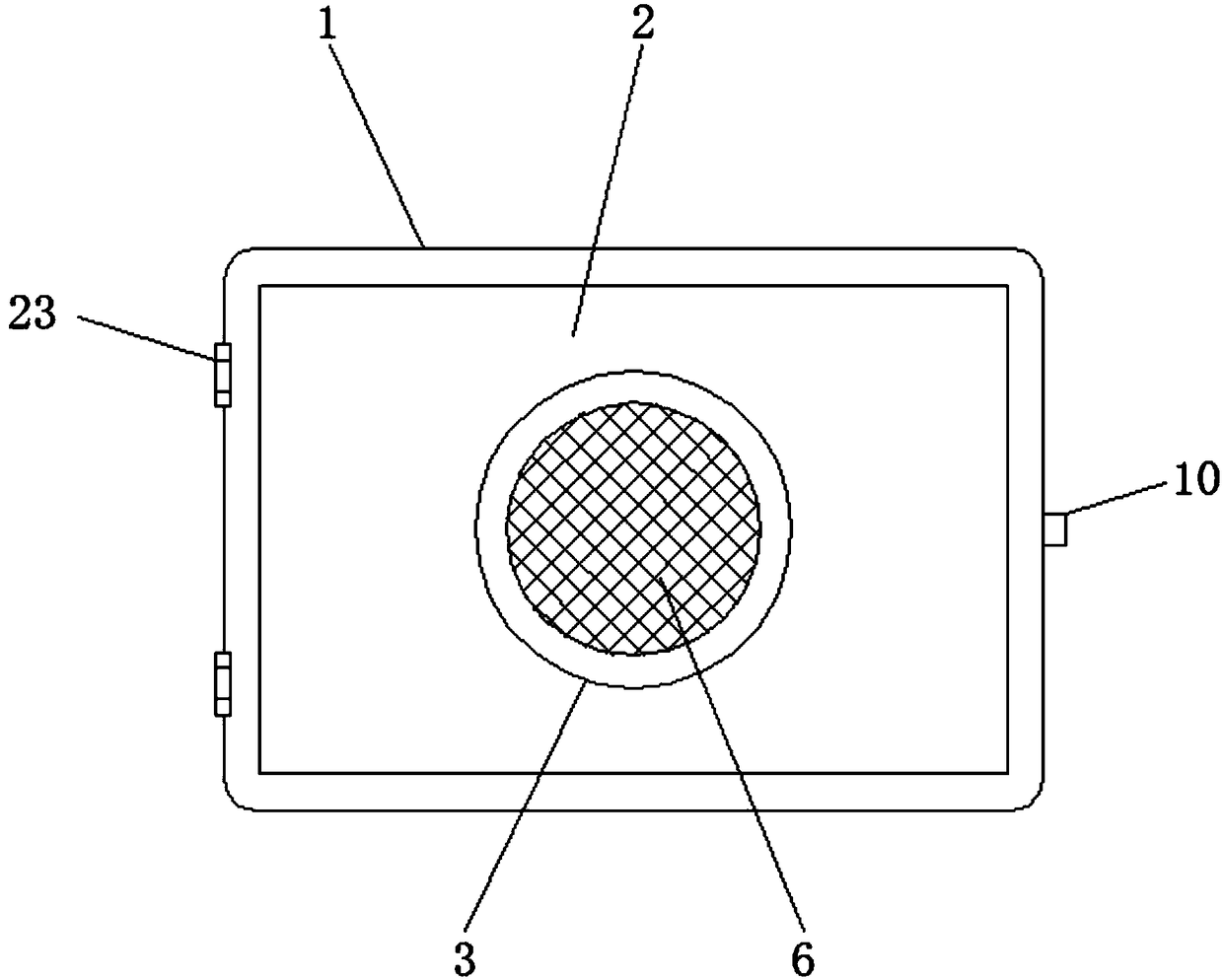

Colored spun yarn drying and collecting device

The invention discloses a colored spun yarn drying and collecting device which comprises a collecting device bracket, a yarn collecting cylinder, a driving cylinder and a motor, wherein the upper part of the collecting device bracket is connected with a fixing bracket through fixing bolts I; the lower end of the fixing bracket is connected with a protective screen plate through fixing bolts II; the interior of the collecting device bracket is connected with supporting rods; supporting drums are mounted on the supporting rods; the yarn collecting cylinder is mounted at the upper end of a first bracket; the driving cylinder is fixed at the upper end of a second bracket; a yarn guiding groove is formed in the outer surface of the driving cylinder; and yarn is arranged on the yarn guiding groove. According to the colored spun yarn drying and collecting device, the arranged yarn collecting cylinder has a collecting effect on the yarn; the arranged protective screen plate has a protective effect on drying lamp tubes, so that the drying lamp tubes can be protected from damage caused by external objects; and the arranged drying lamp tubes have a drying effect on the yarn, so that the working environment can be protected from pollution caused by incompletely dried yarn and the influence on the yarn quality can be avoided.

Owner:响水县天盈纺织有限公司

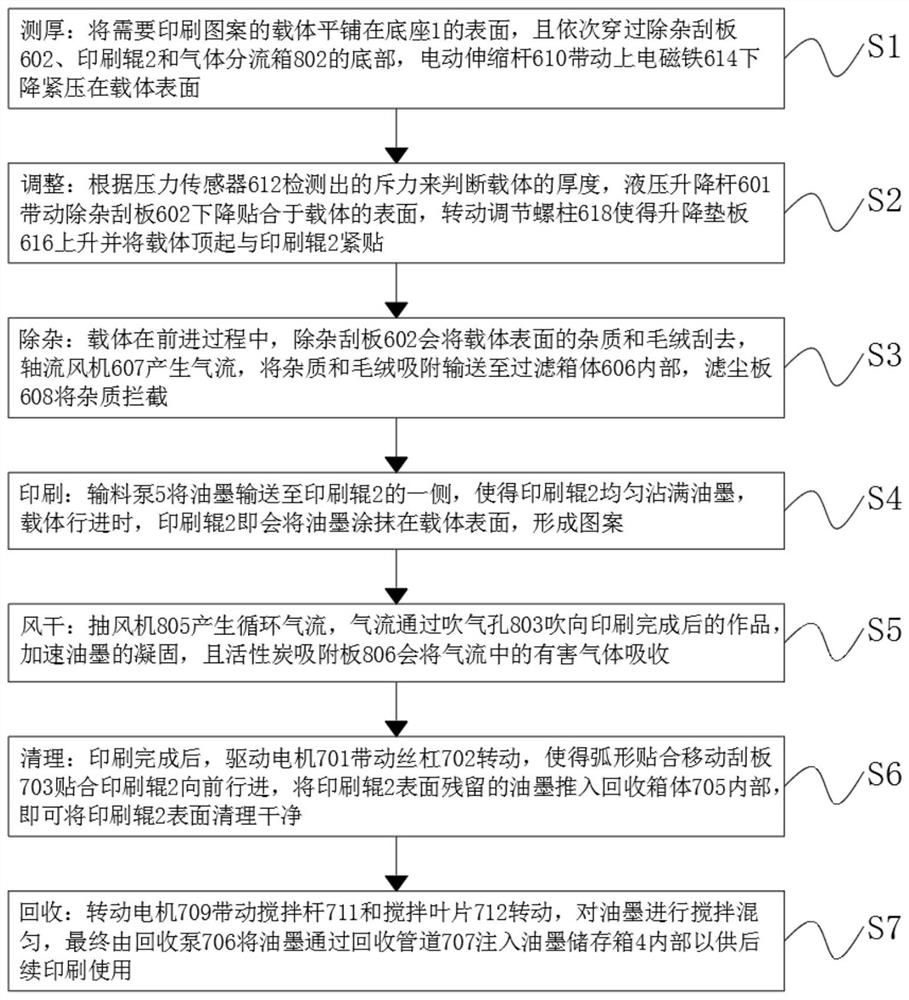

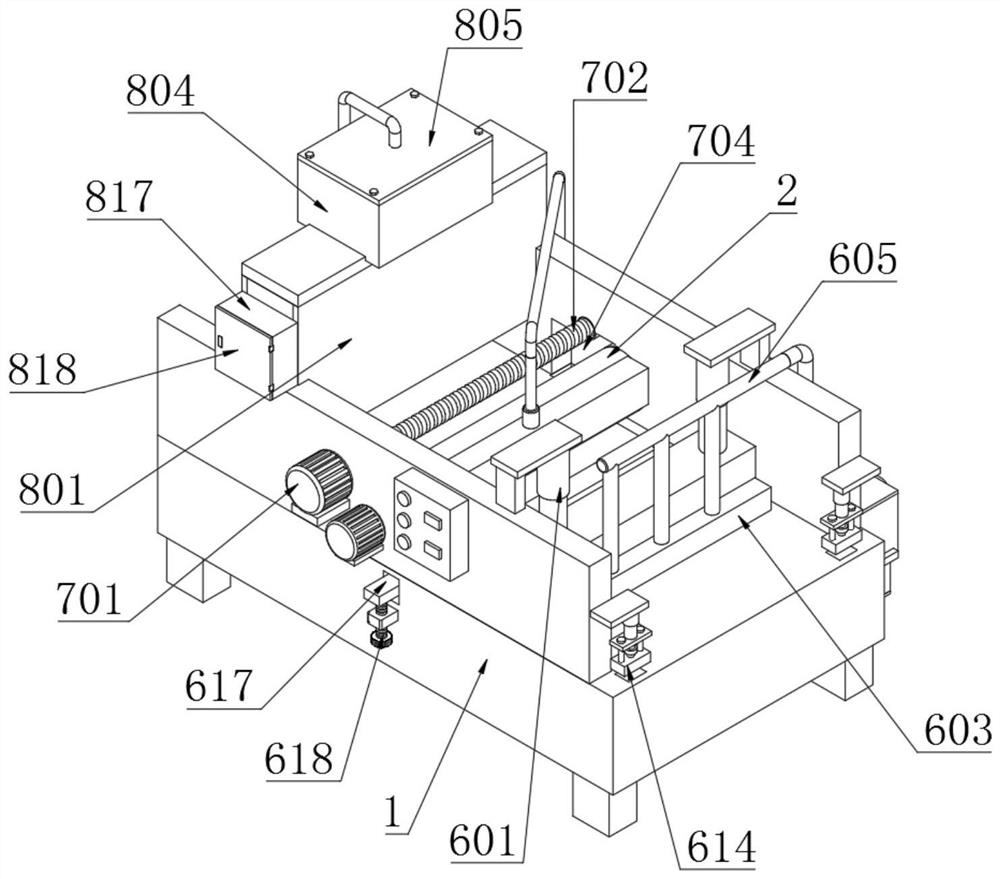

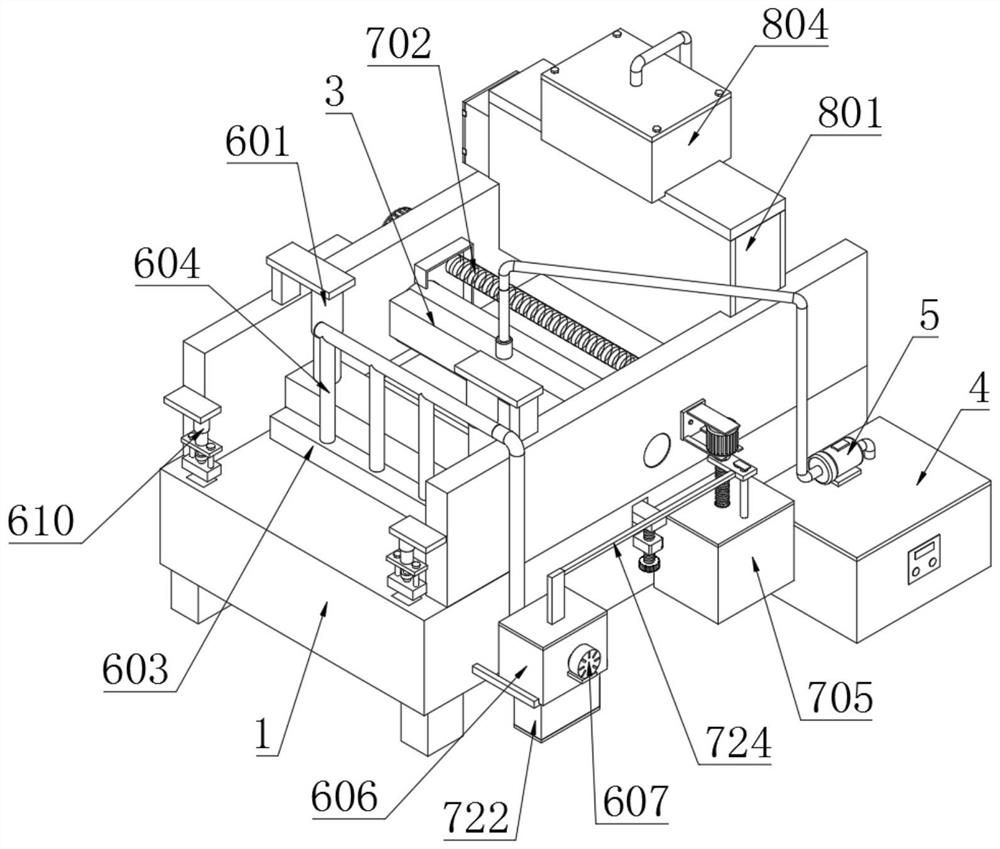

Environment-friendly green printing method

PendingCN114083895AScientific and reasonable structureSafe to useDispersed particle filtrationRotary stirring mixersPaper sheetPrinting ink

The invention discloses an environment-friendly green printing method which comprises the steps: impurity removal: in the advancing process of carriers, an impurity removal scraper can scrape impurities and plush on the surfaces of the carriers, an axial flow fan generates airflow, the impurities and the plush are adsorbed and conveyed into a filtering box body, and a dust filtering plate intercepts the impurities. The carriers such as paper, cloth or plastic used for printing can penetrate through the bottom end of the impurity removal scraper when moving forwards along the base, and the impurity removal scraper can conduct scraping and impurity removal treatment on the surfaces of the carriers, so that the plush and impurities adhering to the surfaces of the carriers in the production and transportation process are removed, the surfaces of the carriers are kept clean and flat, the situation that printing ink cannot be normally bonded to the surfaces of the carriers due to impurities and plush residues, and consequently printed patterns have flaws is avoided, it is ensured that printed works are kept complete, airflow is generated through an axial flow fan, the airflow flows upwards to directly suck and adsorb the plush and impurities scraped during impurity removal into a long-strip-shaped box body, and one side of the impurity removal scraper is always kept clean.

Owner:陈彩莲

Polymethyl methacrylate micropore diaphragm

InactiveCN103396579AEffective control of morphologyPlay the role of "drying"Cell component detailsBulk chemical productionPolymethyl methacrylateLithium-ion battery

The invention discloses a polymethyl methacrylate micropore diaphragm which is mainly applied to a lithium ion battery. The micropore diaphragm is prepared by a supercritical fluid phase separation method.

Owner:HANGZHOU INST OF ADVANCED MATERIAL BEIJING UNIV OF CHEM TECH

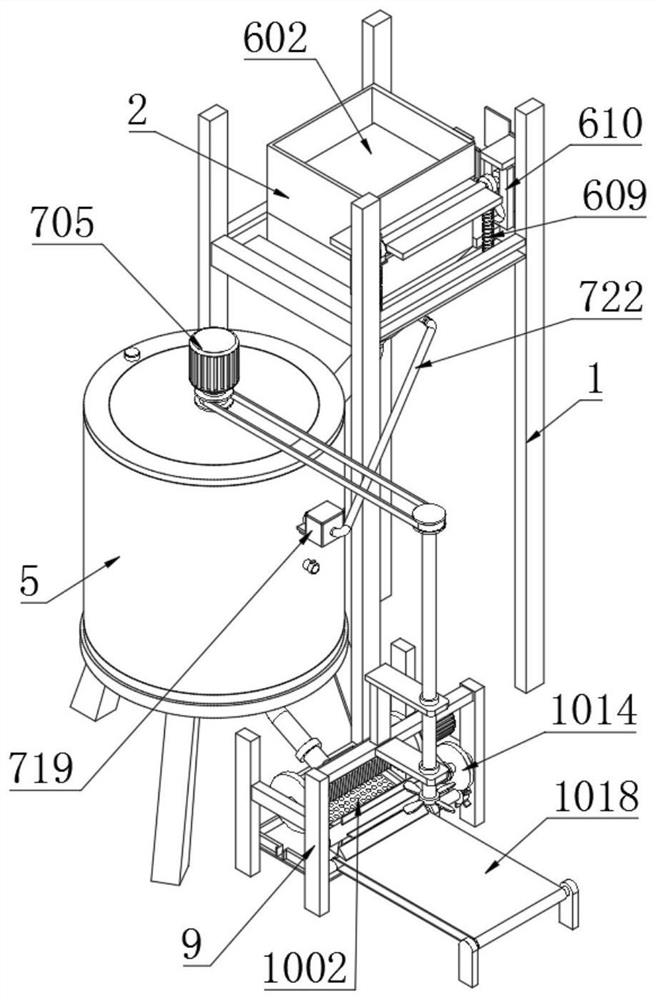

Raw material drying discharging machine capable of conducting measuring

InactiveCN109051851AEasy to useOut shortcutDrying gas arrangementsDrying solid materialsAir heaterElectromagnetic valve

The invention discloses a raw material drying discharging machine capable of conducting measuring. The raw material drying discharging machine comprises a material storage box. A feeding pipe is installed on the left side of the material storage box. A hydraulic machine is installed below the feeding pipe. The output end of the hydraulic machine is connected with a pressure sensor through an L-shaped pull rod. The right lower end of the material storage box is connected with the upper end of the left side of a conveying pipe through the feeding pipe. A motor is installed at the left end of theconveying pipe, and the output end of the motor is connected with the left end of a rotating rod. An air heater is installed at the upper end of the middle portion of the conveying pipe, and a discharging pipe is installed on the lower side of the right end of the conveying pipe. By means of the raw material drying discharging machine, due to the fact that a vibration motor, the pressure sensor,the L-shaped pull rod, the hydraulic machine, a controller, the air heater and an electromagnetic valve are arranged, the problems that material accumulation is likely to happen to a spiral discharging tail end in an airtight environment, measuring cannot be conducted when the discharging machine is used, raw materials are humid during discharging, the accumulation phenomenon happens, drying cannot be conducted, and normal use of the discharging machine is affected are solved.

Owner:芜湖佩林郁松计量科技有限公司

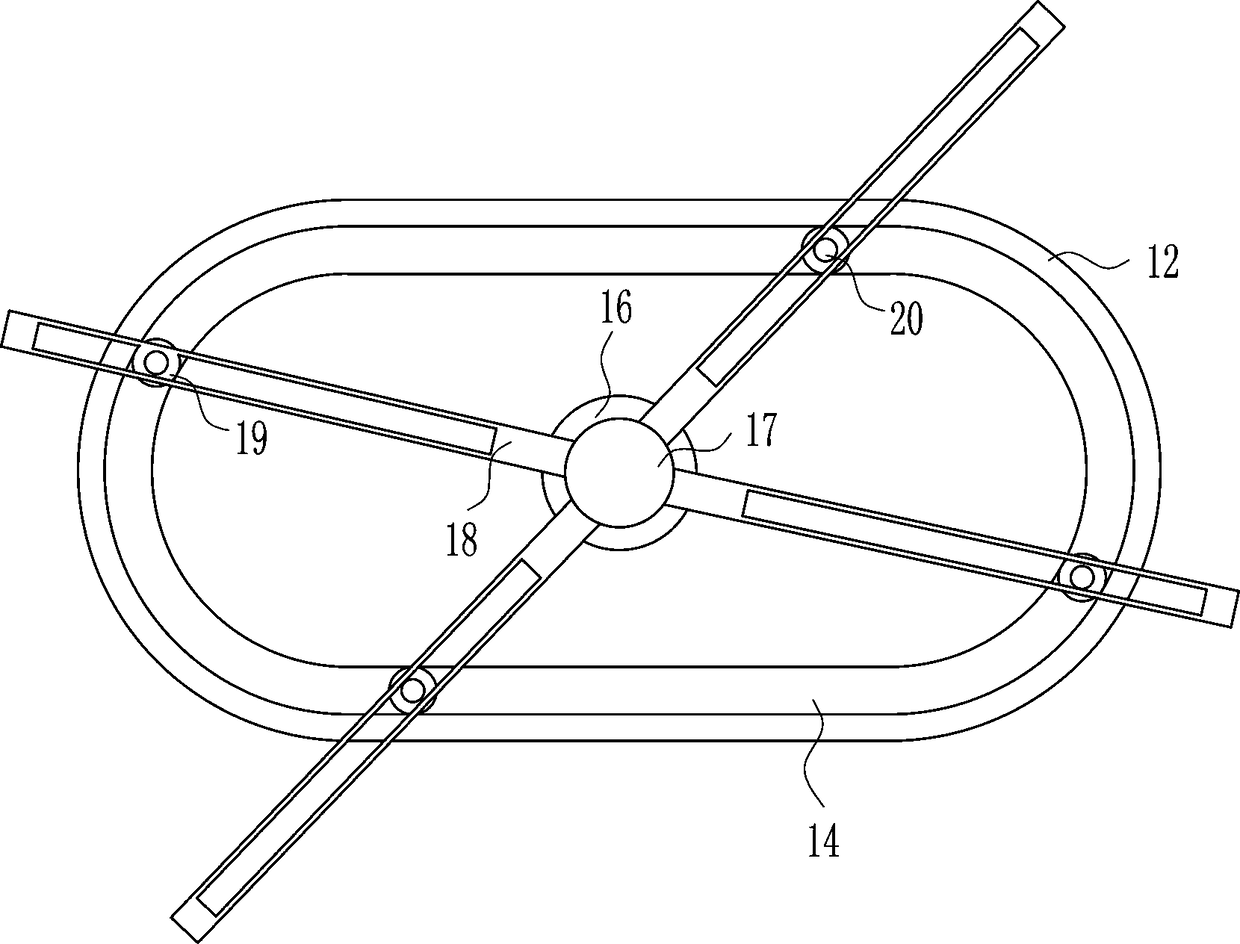

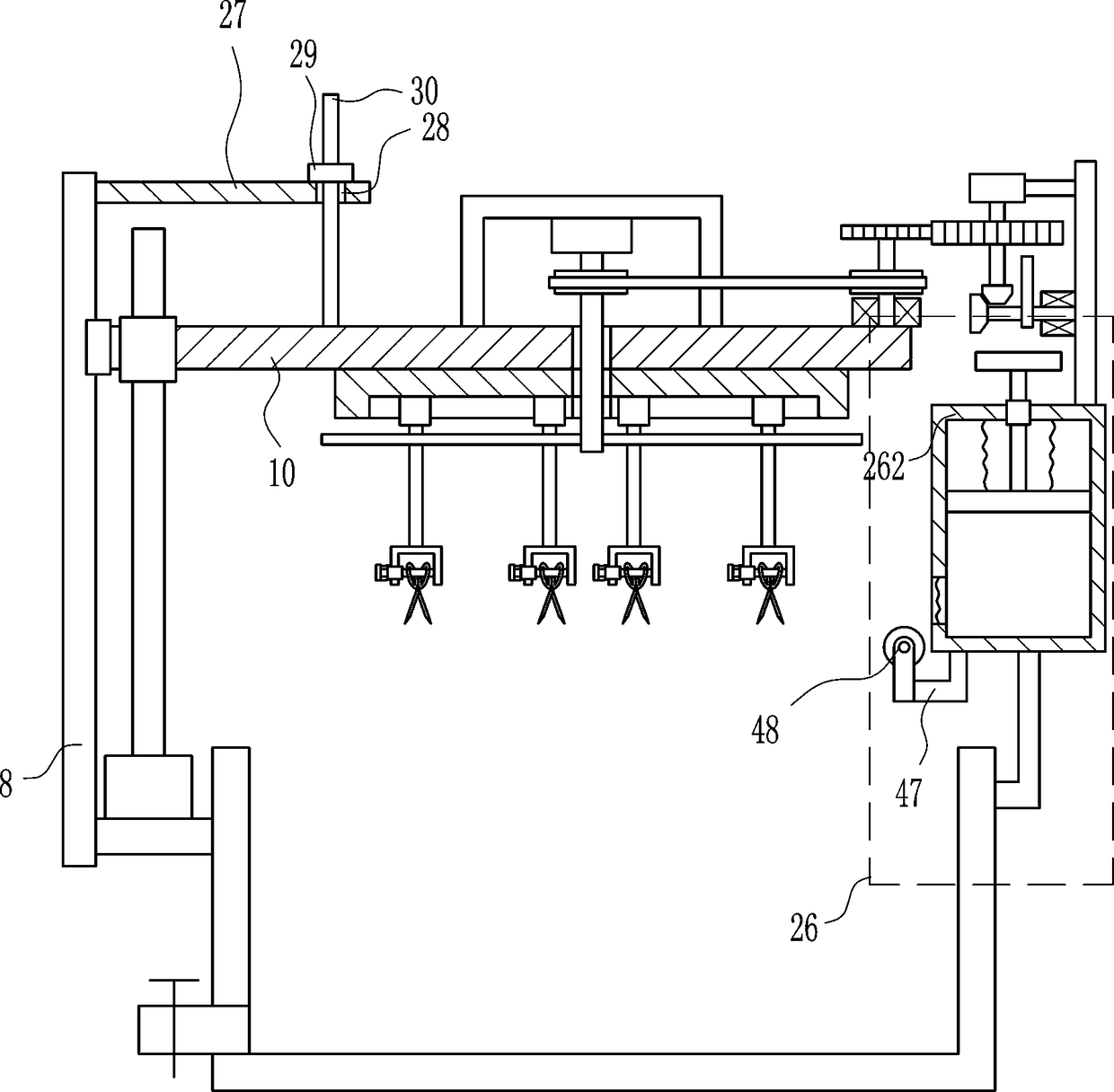

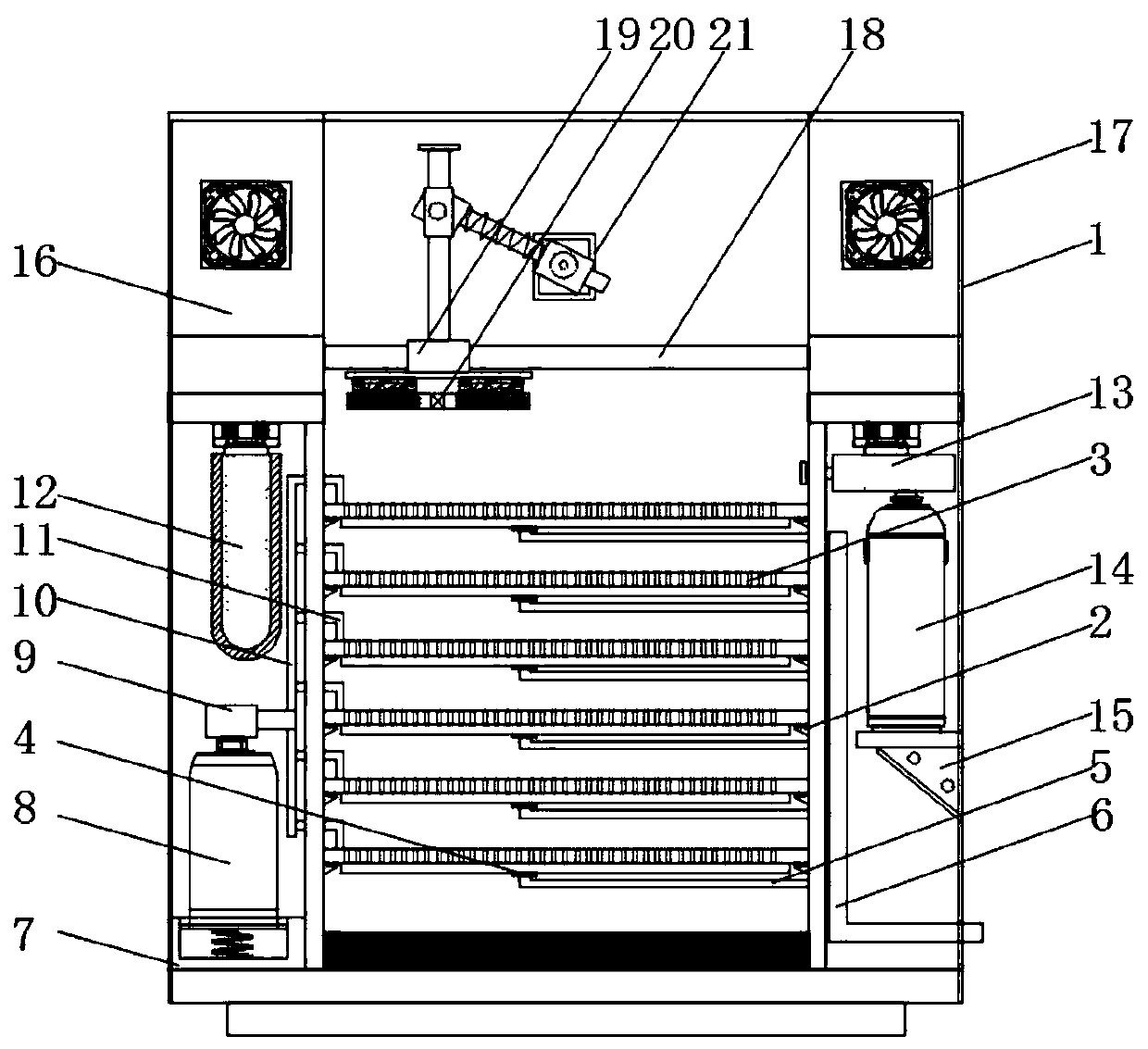

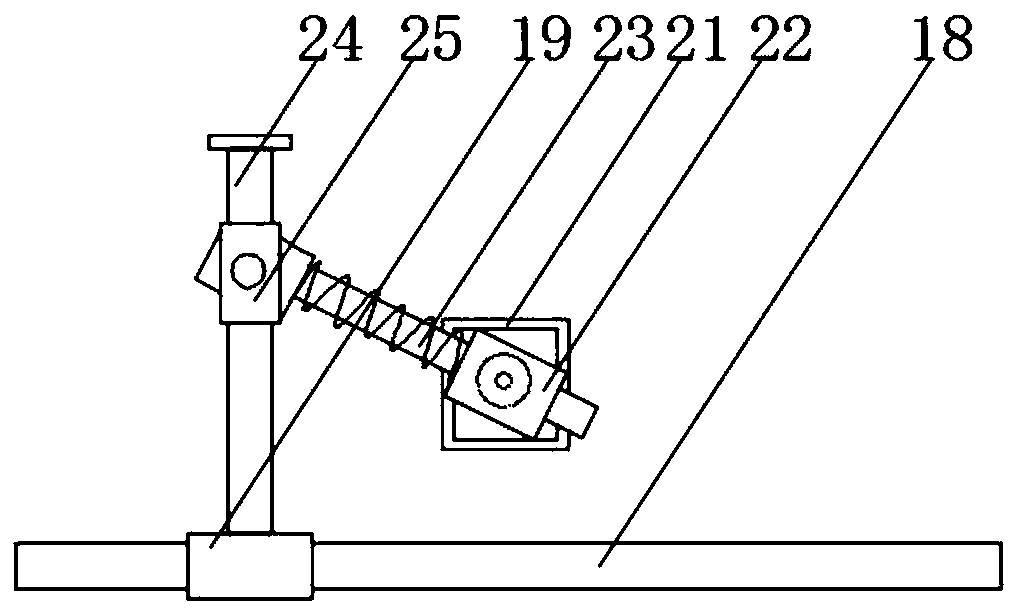

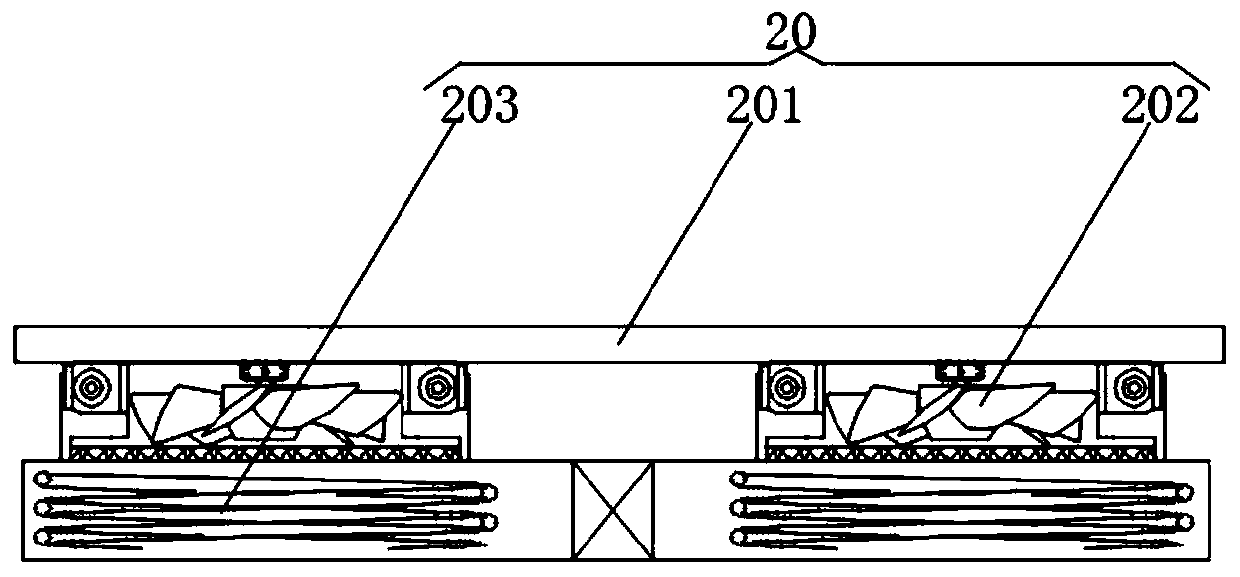

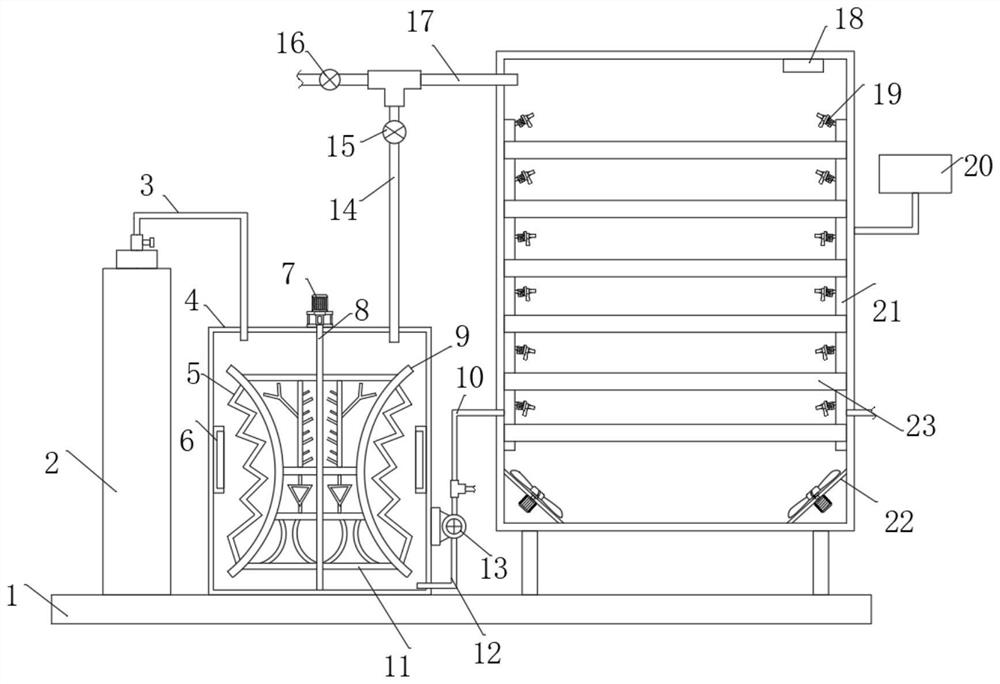

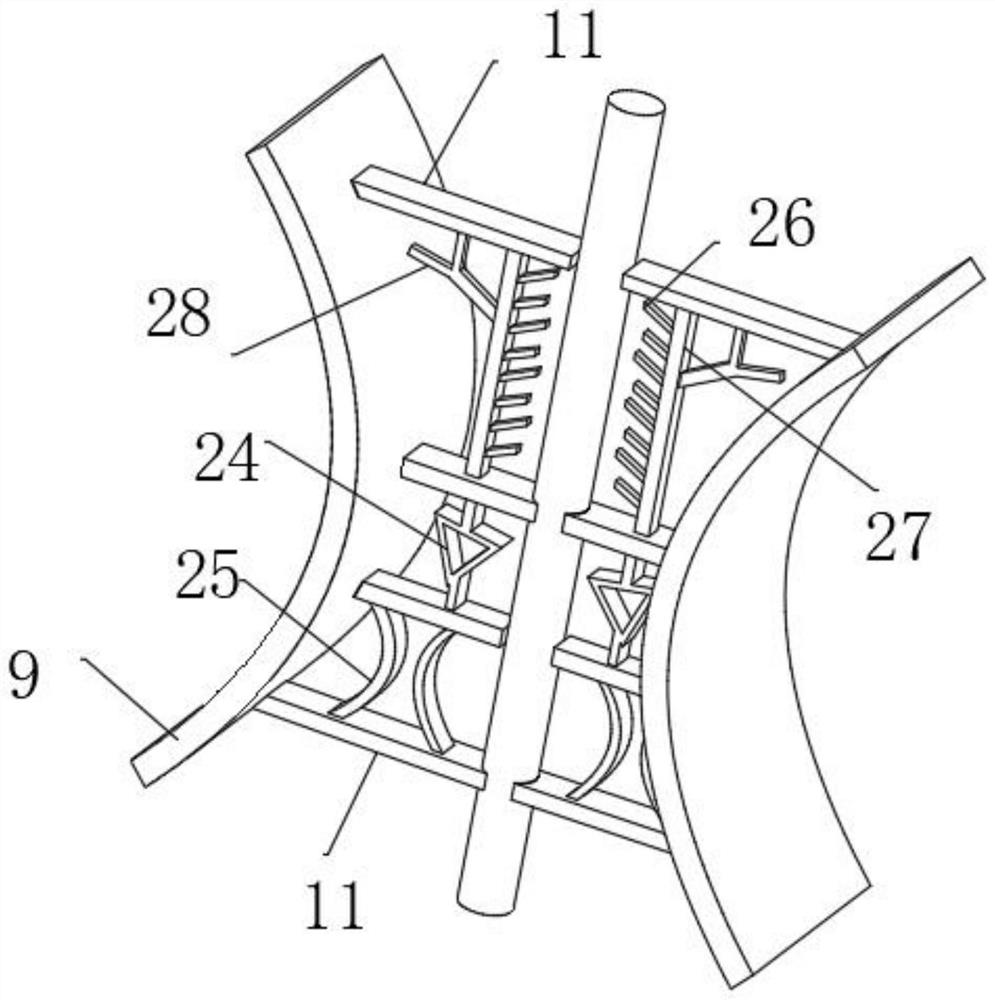

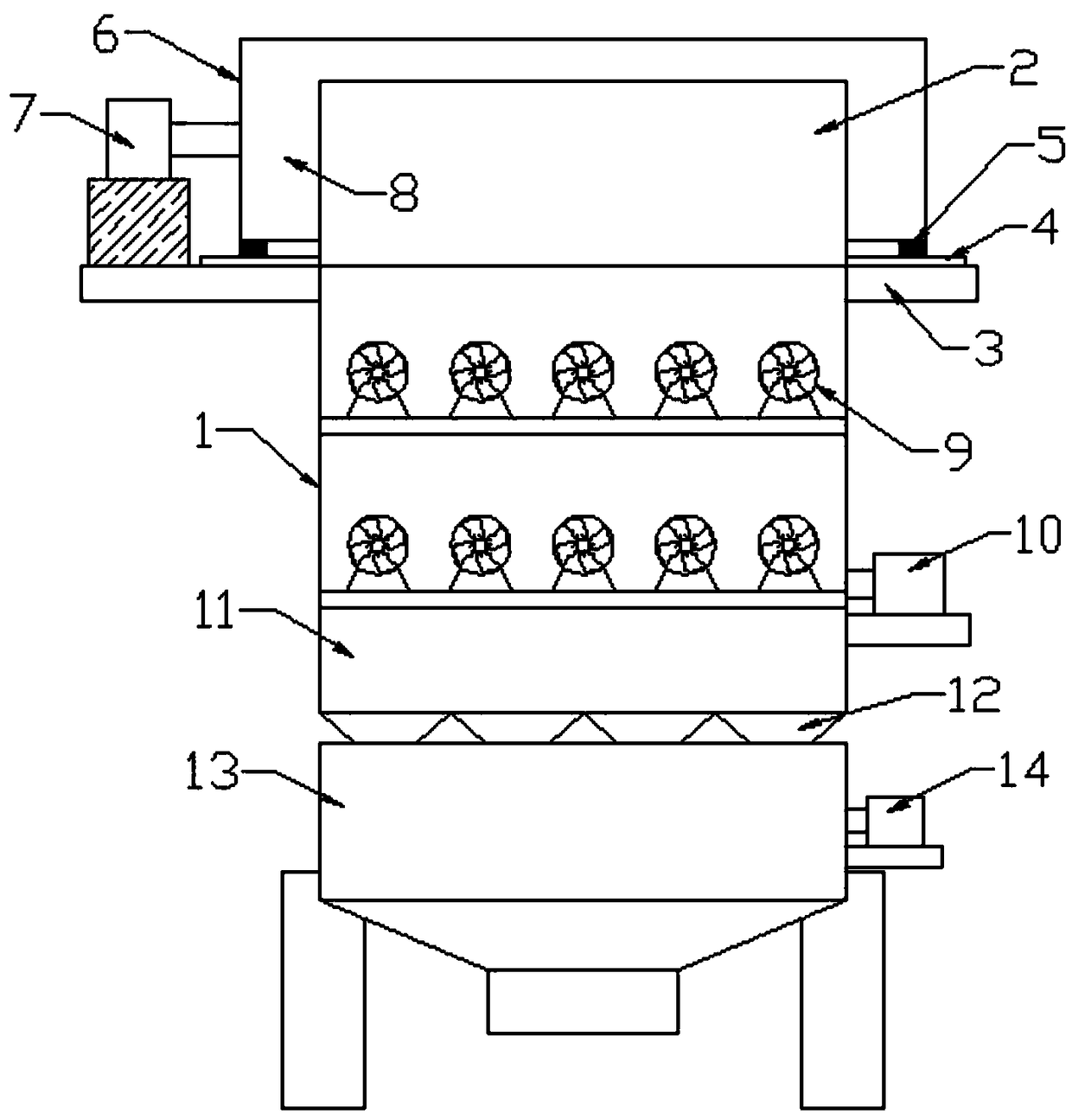

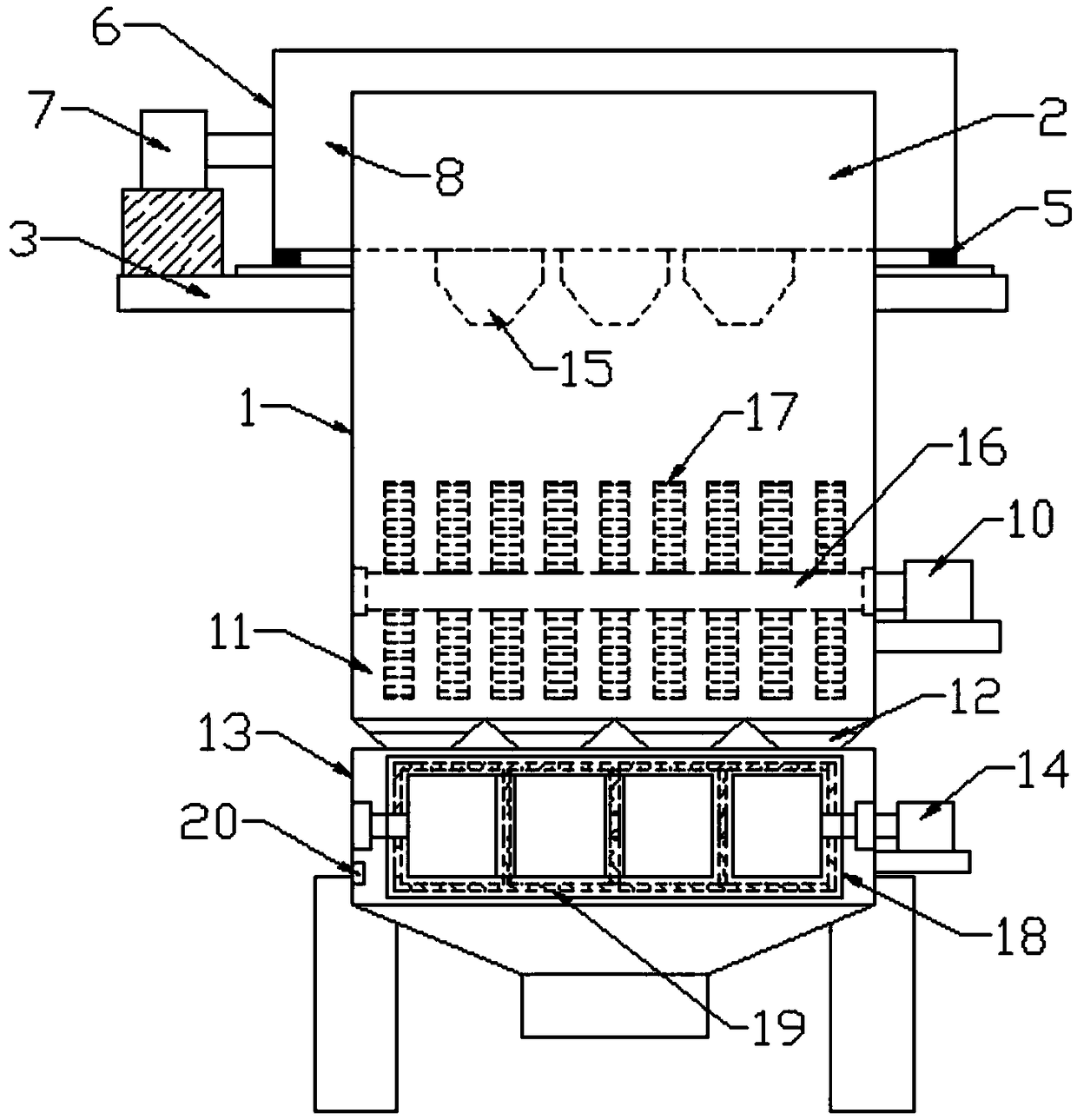

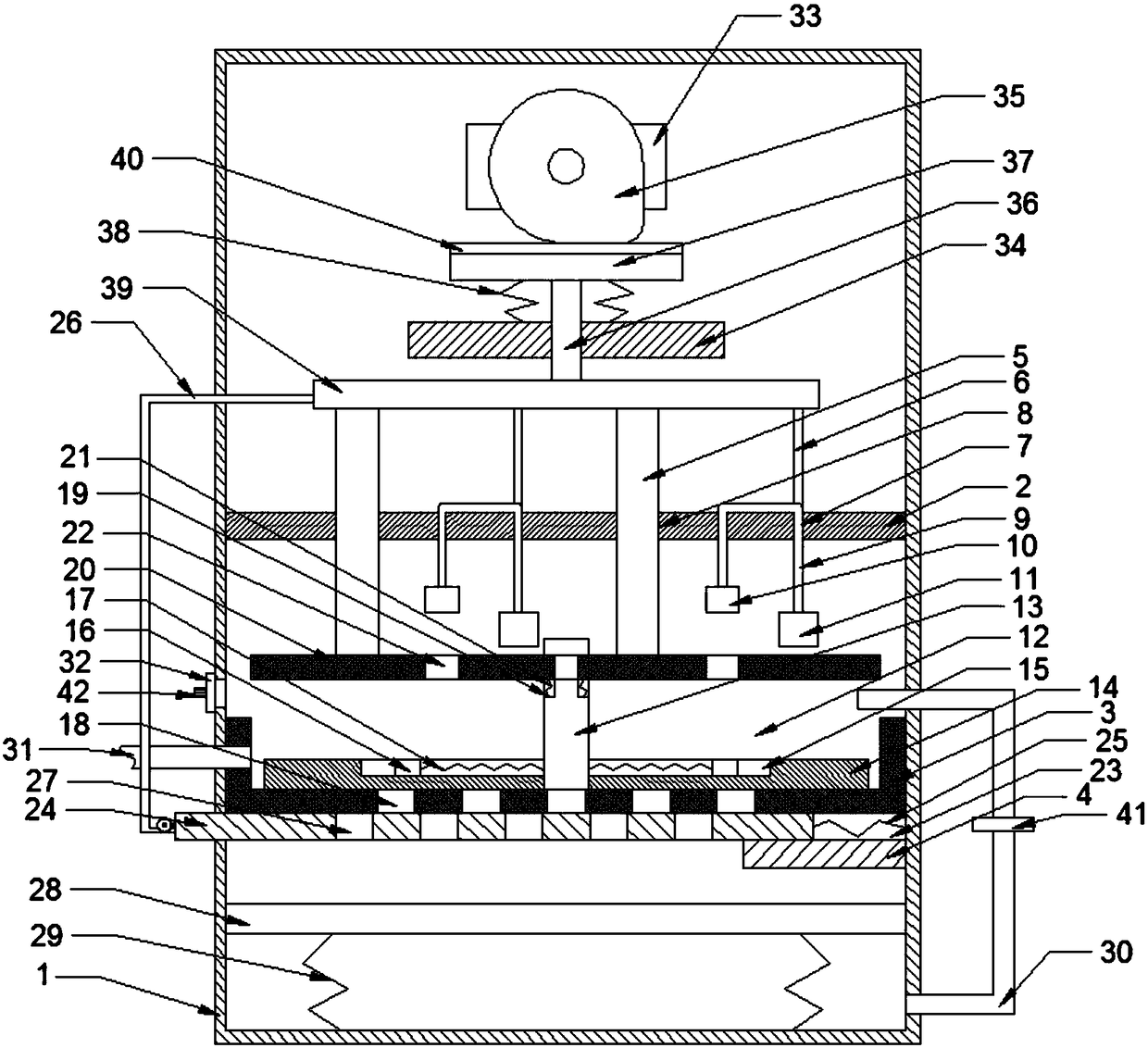

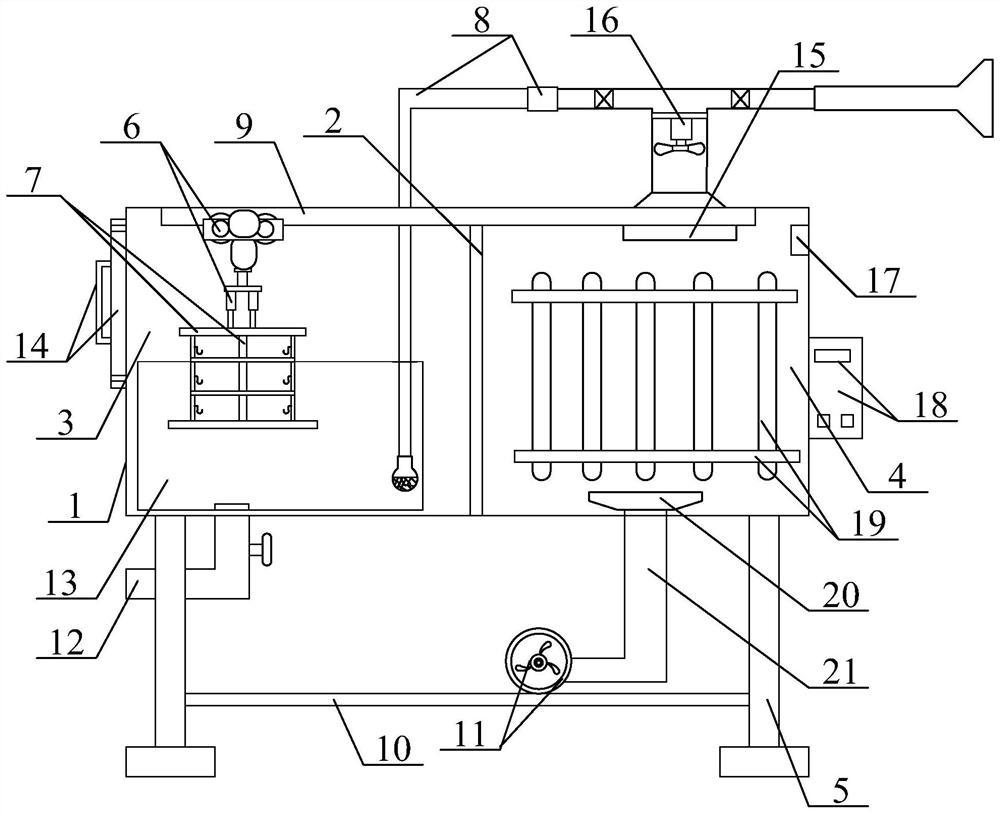

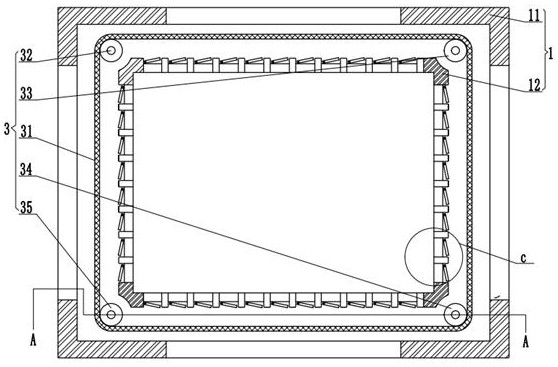

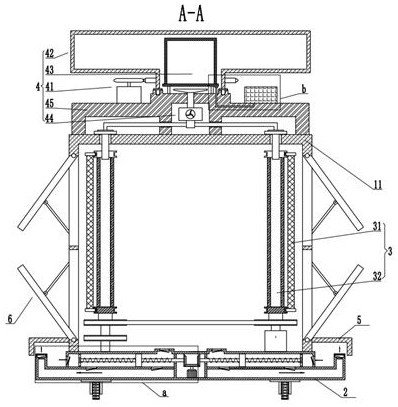

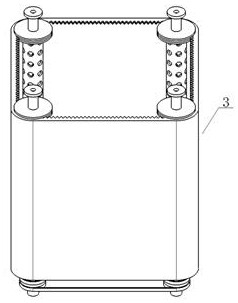

Medical device cleaning equipment for preventing mutual collision

ActiveCN108889701APlay the role of dryingAvoid colliding with each otherDrying gas arrangementsCleaning using liquidsWater leakageMedical device

The invention relates to medical device cleaning equipment, in particular to the medical device cleaning equipment for preventing mutual collision. The object of the invention is to provide the medical device cleaning equipment for preventing the mutual collision which prevents medical devices from colliding with each other during cleaning and conducts air-drying on the medical devices after cleaning. According to the technical scheme, the medical device cleaning equipment for preventing the mutual collision comprises a cleaning frame, a water leakage pipe, a valve, a first connecting plate, afirst motor, a first screw rod, a first nut, a sliding rail, a first sliding block, a second connecting plate, an elliptical plate and the like; the lower portion of the left side of the cleaning frame is provided with the water leakage pipe, the water leakage pipe is communicated with the cleaning frame, and the water leakage pipe is provided with the valve. The equipment achieves the effect ofpreventing the medical devices from colliding with each other during the cleaning and air-drying the medical devices after the cleaning. The equipment allows the medical devices to maintain a certaindistance from each other by the arrangement of a first rotating rod and a shape returning rod, thereby avoiding collision with each other during the cleaning process.

Owner:宋明明 +1

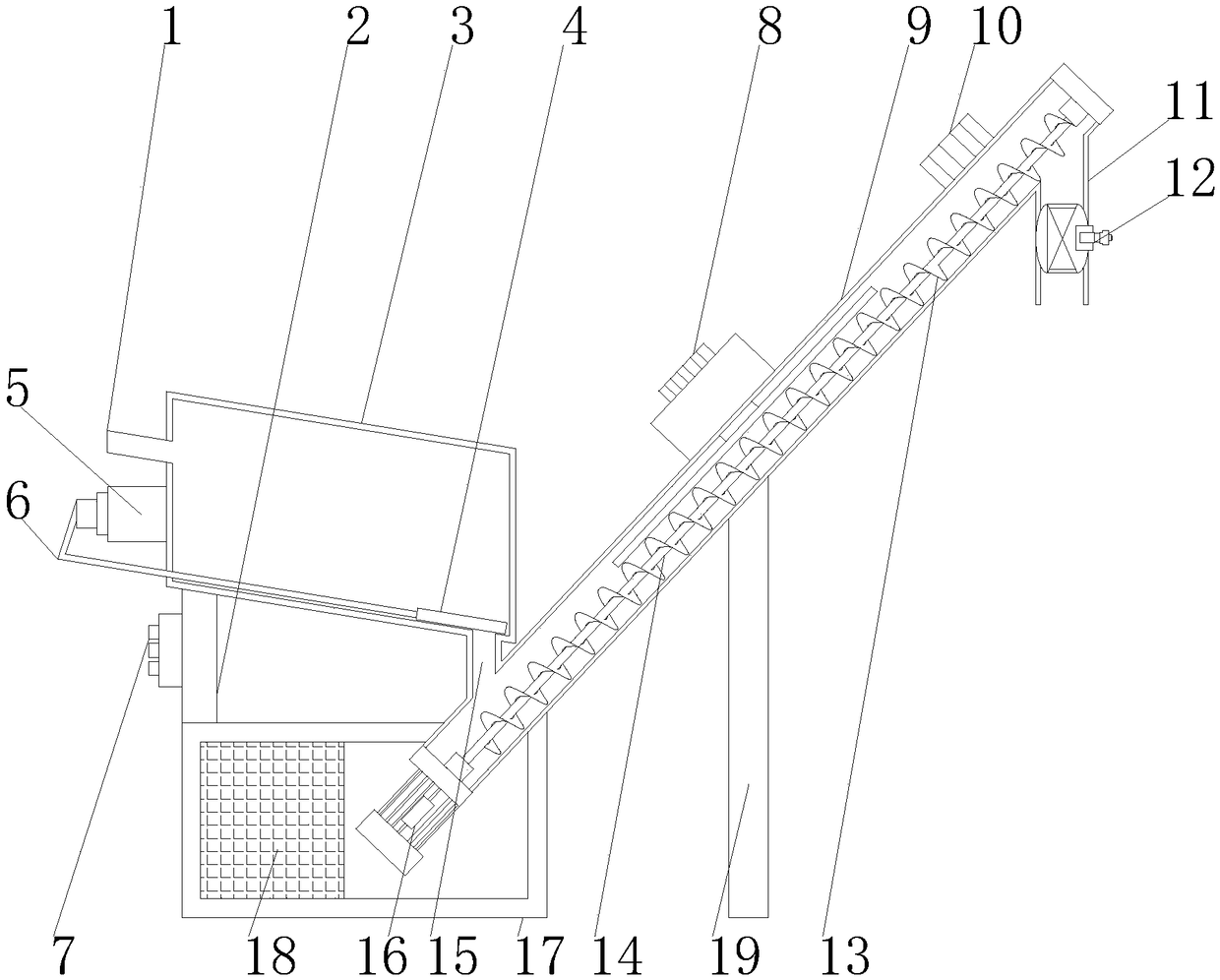

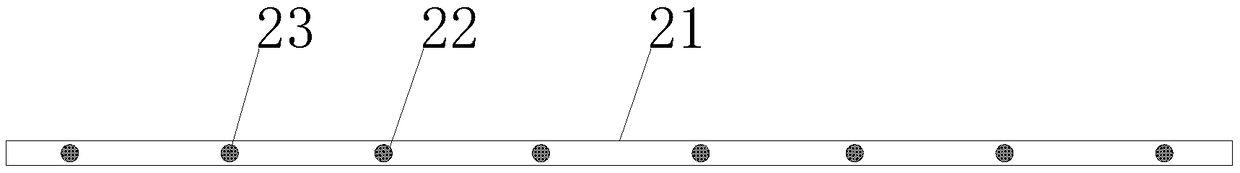

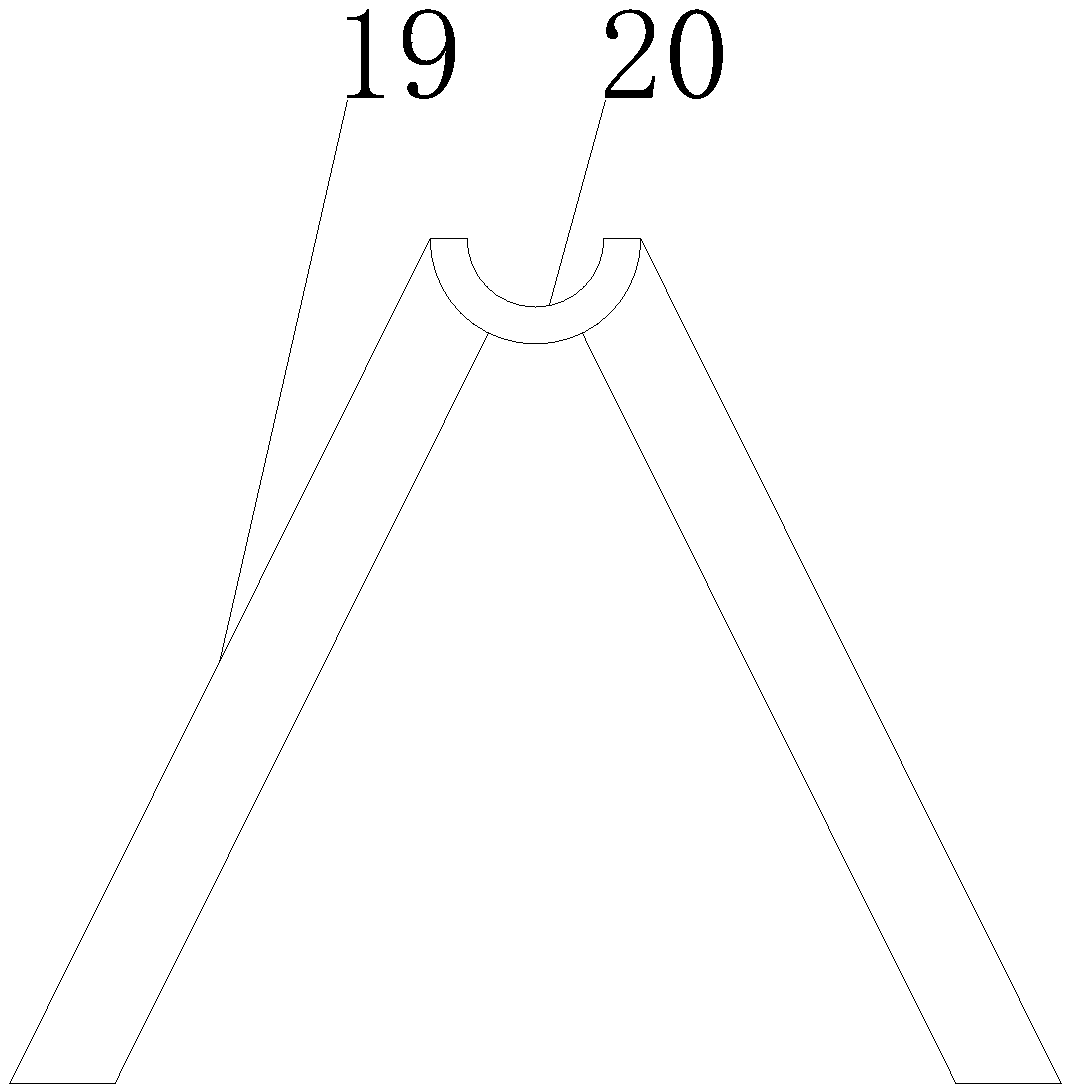

Straw particle forming device

InactiveCN107901184APlay the role of cutting and crushing againInto the uniformTransportation and packagingRotary stirring mixersEngineeringScrew conveyor

Owner:建始惠万农生物科技有限公司

Tissue inspection and disinfection treatment device

InactiveCN111001018APrecise and careful disinfectionAvoid cross infectionLavatory sanitoryHeatDisinfectantEnvironmental engineering

The invention discloses a tissue inspection and disinfection treatment device which comprises a disinfection box. A supporting rack is arranged in the disinfection box. Disinfection placement tables are placed on the inner side of the supporting rack. Discharge electromagnetic valves are arranged at the bottoms of the disinfection placement tables. Disinfectant discharge pipes are mounted at the bottoms of the disinfection placement tables. The disinfectant discharge pipes are installed below the discharge electromagnetic valves. A discharge header pipe is arranged on the right side of the interior of the disinfection box, and the disinfectant discharge pipes are communicated with the discharge header pipe. A disinfectant bottle mounting base is arranged at the bottom of the left side of the inner side of the disinfection box. The invention relates to the technical field of inspection and disinfection. According to the tissue inspection and disinfection treatment device, the purpose ofcomprehensive disinfection through disinfectant, ultraviolet rays and ozone is achieved, and disinfection treatment can be conducted more accurately and carefully; residual objects on the surfaces ofthe objects can be soaked and disinfected due to the fact that the disinfectant conducts disinfection in advance in the disinfection process; and the disinfection placement tables are independently placed, and cross infection can be avoided.

Owner:齐杰玉

Electrostatic dust removal mechanism for extruded sheet processing device

InactiveCN109551883AReduce frictional resistanceBetter and smoother deliveryRotary pressesPrinting press partsAutomatic processingPrinting ink

The invention discloses an electrostatic dust removal mechanism for an extruded sheet processing device. The electrostatic dust removal mechanism comprises a conveying table, wherein a dust removal cavity, a printing table, a drying bin and a beam frame are fixedly installed on the top side of the conveying table from right to left in sequence; a clamping and positioning mechanism is arranged on the conveying table; a cutting tool rest is movably installed on the lower side of the beam frame; and an automatic part discharging mechanism is fixedly installed on the left side of the conveying table. The electrostatic dust removal mechanism can carry out dust removal treatment on the surface of an extruded sheet, the situation that the printing effect is affected due to printing ink is printedon dust during printing is avoided, a printing roller can be adjusted and can be adjusted in a rotating mode, the distance and position of printing can be changed so as to change printing patterns, the function of air drying is achieved at the same time of printing, after printing is carried out, excess printing ink of corrugated cardboards can be adsorbed clean through adsorption cotton, meanwhile, the surface is dried through hot air, automatic quantitative automatic cutting and part discharging are realized, the full-automatic processing operation is simple and accurate, the labor force isgreatly reduced, and the electrostatic dust removal mechanism is easy to popularize and apply.

Owner:张磊

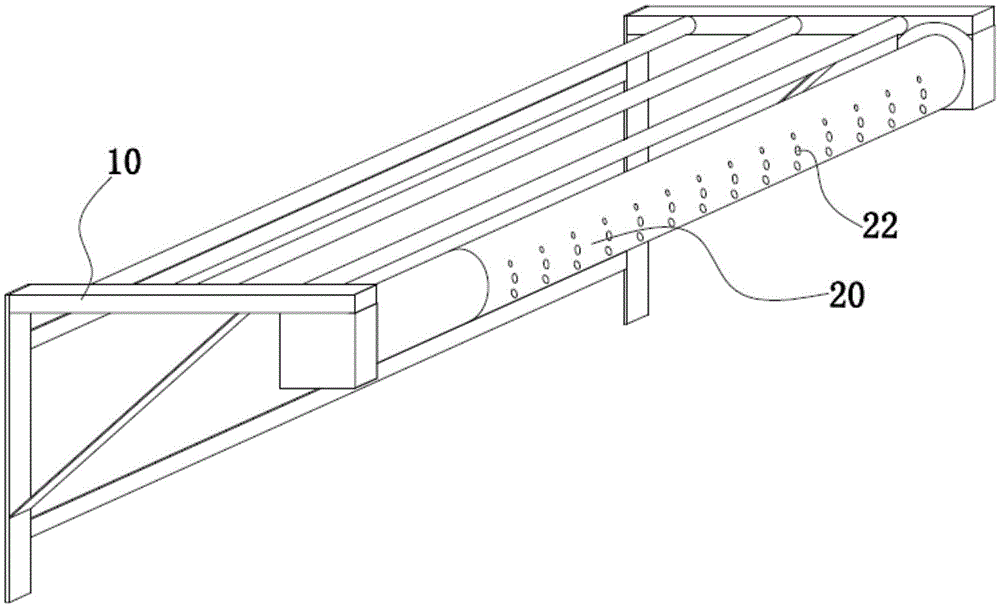

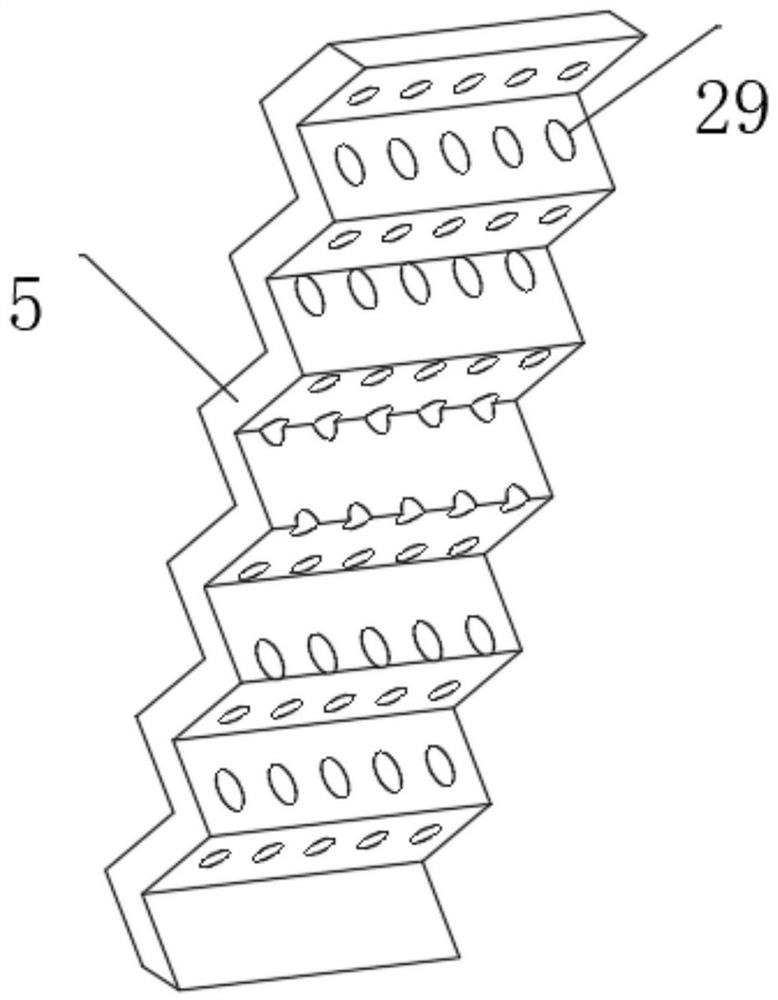

Towel rack with air drying function

InactiveCN105615751AKeep clean and hygienicWith blower air drying functionDomestic applicationsEngineeringAir drying

The invention relates to a towel rack and discloses a towel rack with an air drying function to solve the problem that an existing towel is difficult to air dry after using.The towel rack comprises a support used to be mounted on a wall and that is provided with at least one transversely arranged airing rod, and is characterized in that the airing rod is in the shape of a hollow tube, the peripheral wall of the airing rod is provided with a plurality of air outlets, a blower is disposed in the airing rod, and a flow of air blown by the blower is out of the air outlets in the wall of the airing rod.In the invention, the blower in the airing rod blows the flow of air from the air outlets of the airing rod to a wet towel hung on the airing rod, thus air drying the towel and inhibiting growth of germs.

Owner:柳州市金旭节能科技有限公司

Hot-drying ink absorbing mechanism used after printing and used for plastic extruding plate processing device

InactiveCN109551886AStable deliveryReduce frictional resistanceRotary pressesPrinting press partsEngineeringPrinting ink

The invention discloses a hot-drying ink absorbing mechanism used after printing and used for a plastic extruding plate processing device. The hot-drying ink absorbing mechanism comprises a conveyingtable, a dust removal cavity, a printing table, a drying bin and a beam frame are sequentially and fixedly installed on the top side of the conveying table from right to left, a clamping and positioning mechanism is arranged on the conveying table, a cutting knife rest is movably arranged on the lower side of the beam frame, and an automatic discharging mechanism is fixedly installed on the left side of the conveying table. According to the hot-drying ink absorbing mechanism used after printing and used for the plastic extruding plate processing device, the surface of an plastic extruding plate can be subjected to dust removal treatment, so that printing ink is prevented from being printed onto dust during printing, and then the printing effect is prevented from being influenced; a printing roller can be adjusted, can be adjusted in a rotating mode, and can change the distance and the position of printing so as to change a printing pattern; and the effect of air drying during printingis also achieved, the redundant printing ink of a corrugated board can be adsorbed and cleared through adsorption cotton after printing, meanwhile, a drying effect on the surface is achieved through hot air, and automatic quantitation and automatic cutting and discharging are realized, so that the full-automatic machining operation is simple and accurate, moreover, the manual labor is reduced, andthe then the hot-drying ink absorbing mechanism is easy to popularize and apply.

Owner:张磊

Lithium ion battery with polymethyl methacrylate micropore diaphragm

InactiveCN103396567AEffective control of morphologyPlay the role of "drying"Cell component detailsBulk chemical productionPhysical chemistryLithium-ion battery

The invention discloses a lithium ion battery with a polymethyl methacrylate micropore diaphragm. The micropore diaphragm is prepared by a supercritical fluid phase separation method.

Owner:HANGZHOU INST OF ADVANCED MATERIAL BEIJING UNIV OF CHEM TECH

Rapid drying device for dried bamboo shoots

The invention discloses a quick drying device for dried bamboo shoots, which comprises a device main body. The bottom of the device main body is provided with a base, and the base and the device main body are tightly welded. The left and right sides of the front end of the device main body are provided with drying box doors. The door is movably connected with the main body of the device. There is a connection end on the right side of the drying box door, and the connecting end is tightly welded with the drying box door. There is a handle on the left side of the drying box door, and the handle is closely attached to the drying box door. combine. Compared with ordinary dried bamboo shoots drying equipment, this kind of dried bamboo shoots quick drying device is equipped with two drying box assemblies inside the main body of the device, and the two drying boxes The components can operate independently, which can effectively dry a small amount or a large amount of dried bamboo shoots. There are receiving ends on the left and right sides of the drying box components, through which the inside of the drying box can be layered. Effect.

Owner:广西华竹生物科技有限公司

Nitrogen adjusting device for semiconductor oven

InactiveCN111947446APrevent oxidationImprove drying effectDrying gas arrangementsPhysicsSpray nozzle

The invention belongs to the technical field of semiconductor ovens, particularly relates to a nitrogen adjusting device for a semiconductor oven, and provides the following scheme for solving the problem that nitrogen is not heated. The nitrogen adjusting device comprises a base plate, a nitrogen cylinder, a heating box and a drying box are arranged on an outer wall of the top of the base plate,an electronic air pump is arranged on an outer wall of one side of the heating box, a same third guide roller is arranged at an input end of the electronic air pump and an inner wall of one side of the heating box, a same first guide pipe is arranged at an output end of the nitrogen cylinder and an inner wall of the top of the heating box, and heaters are arranged on two sides of the inner walls of the heating box. According to the device, the heater, the electronic air pump, the heating box, an air injection disc, a spraying nozzle, a fifth guide pipe, a fourth guide pipe, a first electromagnetic valve and a second electromagnetic valve are provided, and when a semiconductor is dried, the heater and the electronic air pump are started, and heated nitrogen is guided into the drying box sothat the semiconductor can be dried and the semiconductor can be prevented from being oxidized.

Owner:JILIN AGRICULTURAL UNIV

Lithium ion battery with polyvinylidene fluoride-hexafluoropropylene microporous membrane

InactiveCN103367674AEffective control of morphologyPlay the role of "drying"Cell component detailsHexafluoropropylenePhysical chemistry

The invention provides a lithium ion battery with a polyvinylidene fluoride-hexafluoropropylene microporous membrane. The microporous membrane is prepared by a supercritical fluid phase separation method.

Owner:HANGZHOU INST OF ADVANCED MATERIAL BEIJING UNIV OF CHEM TECH

Printing equipment with self-cleaning function

InactiveCN105082751AClean in timeStable supportScreen printersPrinting press partsEngineeringSelf cleaning

The invention relates to printing equipment with a self-cleaning function. The printing equipment comprises a workbench for bearing a printing part to be processed and a scraper mechanism arranged above the workbench. A lifting strike-through plate is further arranged between the workbench and the scraper mechanism. The workbench is arranged on a supporting frame and comprises two split plates which are in shaft connection with the supporting frame. A cleaning mechanism is arranged on the lower portion of the strike-through plate and comprises a cleaning roller arranged at the lower end of the strike-through plate, and the cleaning roller can move transversely. The printing equipment with the self-cleaning function is provided with the lifting strike-through plate, the cleaning mechanism is arranged on the lower portion of the strike-through plate, and therefore the strike-through plate can be conveniently cleaned in time, and the printing quality is guaranteed. The mode of the supporting frame and the two split plates in shaft connection with the supporting frame is especially designed for the workbench, so that stable supporting to the printing part is guaranteed, and dirt which is removed from the upper portion can also be conveniently discharged.

Owner:SUZHOU ENOUXI INTELLIGENT TECH CO LTD

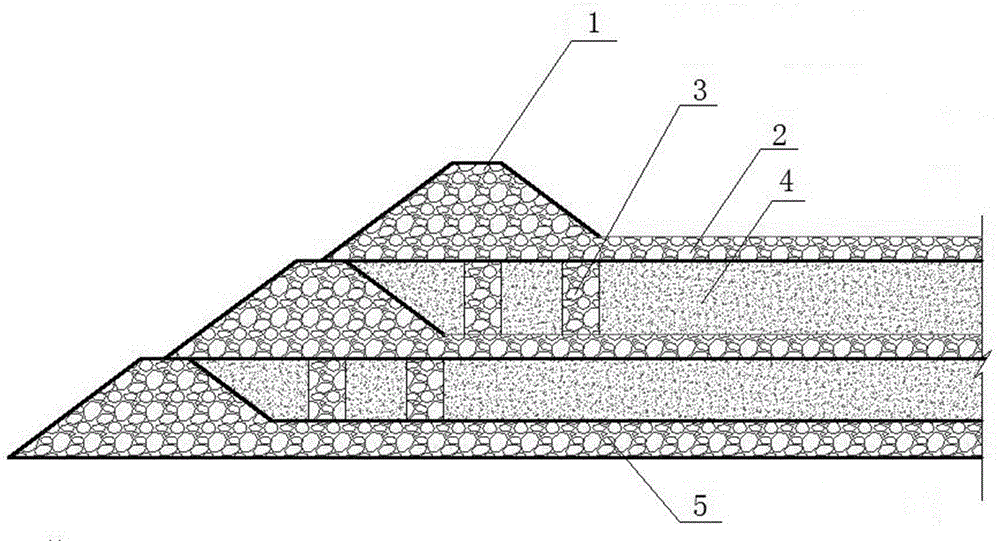

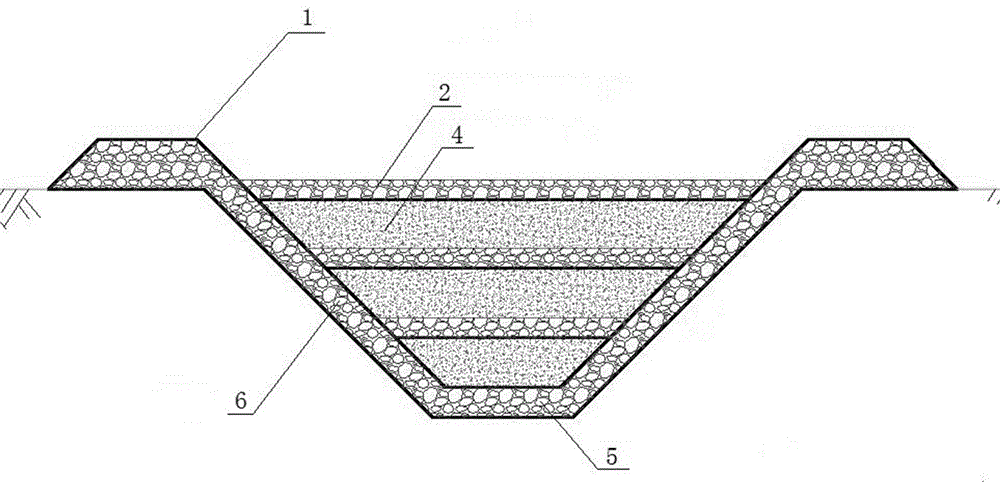

A kind of sludge-coal gangue co-landfilling process

InactiveCN104801530BSolving the Difficulty of LandfillingEfficient use ofSludge treatment by de-watering/drying/thickeningSolid waste disposalSludgeEnvironmental quality

The invention relates to a process for landfill of sludge and coal gangue together. The process comprises the following steps: (1) performing half-dry pretreatment on dewatered sludge; (2) performing pre-crushing treatment on coal gangue, and screening; (3) performing landfill of the sludge and the coal gangue which are subjected to pretreatment together. During landfill, the sludge and the coal gangue are laid at intervals by adopting a layered laying method, and the sludge in the half-dry state is supported under the distance separation action of the coal gangue, so that time and space for secondary drying of the sludge in a coal gangue field are provided. Aiming at plains and valleys, different sludge landfill processes such as 'stacked on the plains' or 'valley type' can be adopted respectively. According to the process, the landfill of sludge and coal gangue can be taken into consideration comprehensively, and not only is the problem of sludge landfill solved, but also the effective use of the coal gangue field is promoted; through adoption of the process, the environmental quality of a coal-producing area is improved, contribution to promotion of social and economic sustainable development is made, and the implementation operability is high.

Owner:吉晋兰

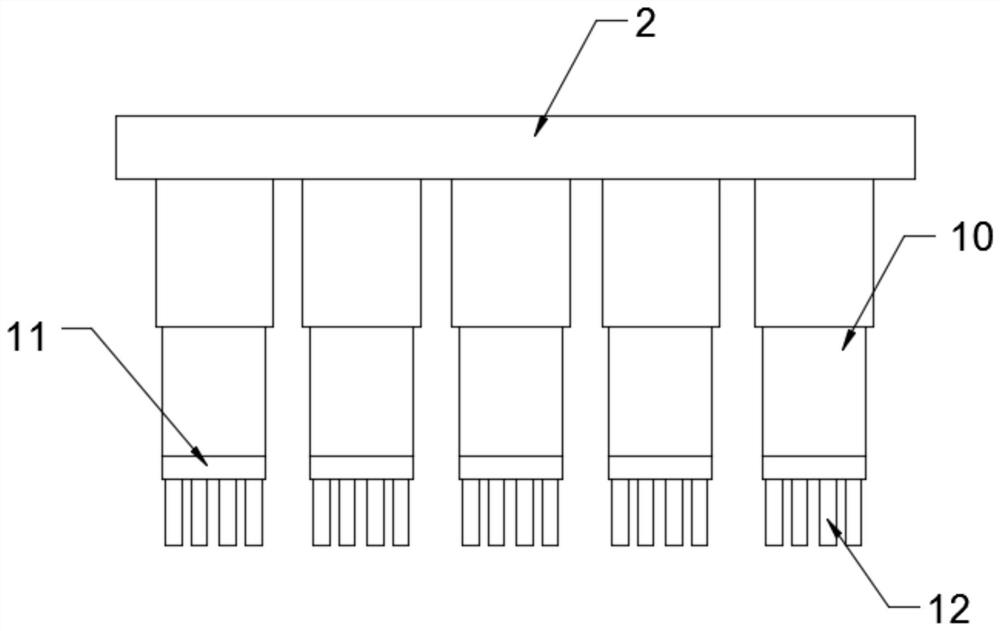

Glutinous rice drying device

InactiveCN109452361ASpeed up entryPlay the role of dryingSeed preservation by dryingHeat resistanceEngineering

The invention discloses a glutinous rice drying device. The device comprises a dryer, the interior of the dryer comprises a first drying bin and a second drying bin, the top end of the first drying bin is provided with a glutinous rice inlet, a movable feeding mechanism is arranged above the glutinous rice inlet, the movable feeding mechanism comprises a storage bin and a plurality of feeding pipeorifices welded on the lower end face of the storage bin, a heating cavity is formed in a plate of each feeding pipe orifice, a plurality of groups of heating resistance wires are arranged in the heating cavity, sliding blocks are arranged at two ends of the lower end face of the storage bin, supporting plates are welded on both ends of a glutinous rice inlet of the dryer, the upper end surface of each supporting plates is provided with a sliding rail, the movable feeding mechanism moves along the sliding rail through a sliding block, one end, far from the dryer, of the upper end surface of one supporting plate is provided with an air cylinder, and the tail end of the piston rod of the air cylinder is fixed on the outer side wall of the storage bin. The device can improve the drying efficiency through step-by-step drying.

Owner:颍上县迪沟米业有限公司

Cleaning mechanism for textiles

InactiveCN108505247AAchieve cleaningPlay the role of dryingLiquid/gas/vapor removalLiquid/gas/vapor fabric treatmentEngineeringTextile

The invention discloses a cleaning mechanism for textiles. The cleaning mechanism for textiles comprises a box, and a vertical reciprocating mechanism, a first fixed plate and a second fixed plate arearranged in the box; a plurality of pushing rods and first steel wires are arranged on the vertical reciprocating mechanism; a plurality of guiding holes are formed in the first fixed plate, and second steel wires are slidingly connected in the two adjacent guiding holes; the two ends of each second steel wire are each provided with an impact block and a balance weight; the second steel wires arefixedly connected with the first steel wires; a fixed shaft is rotationally connected on the second fixed plate, a plurality of blades are circumferentially arranged on the fixed shaft, each blade isprovided with a sliding groove, rubbing blocks are slidingly connected in the sliding grooves, and first springs are arranged between the rubbing blocks and the sliding grooves; an annular groove isformed in the fixed shaft, a vertical plate is slidingly connected in the annular groove, and a second spring is arranged between the vertical plate and the annular groove; a plurality of second through holes are formed in the vertical plate. By means of the cleaning mechanism for textiles in the technical scheme, the problem that the efficiency of the current cleaning mode of textiles is low is mainly solved.

Owner:NINGBO WENZE TEXTILE CO LTD

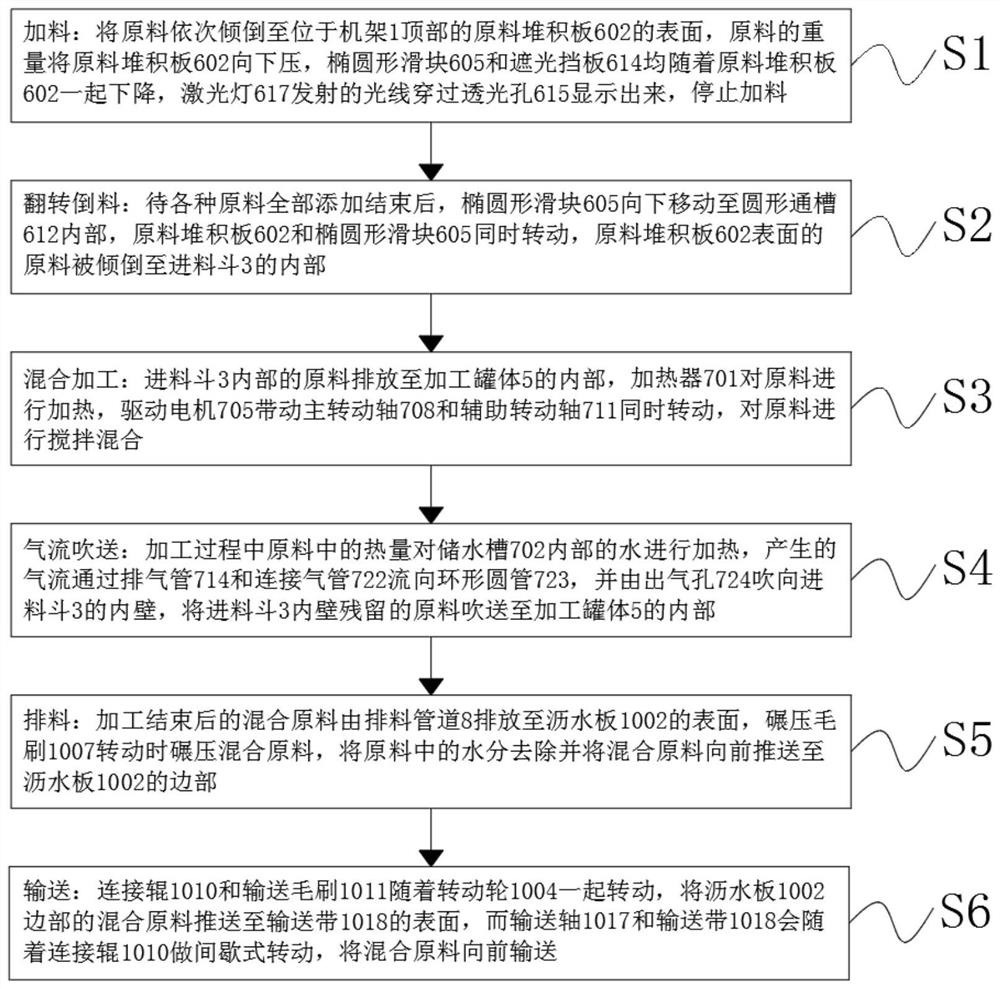

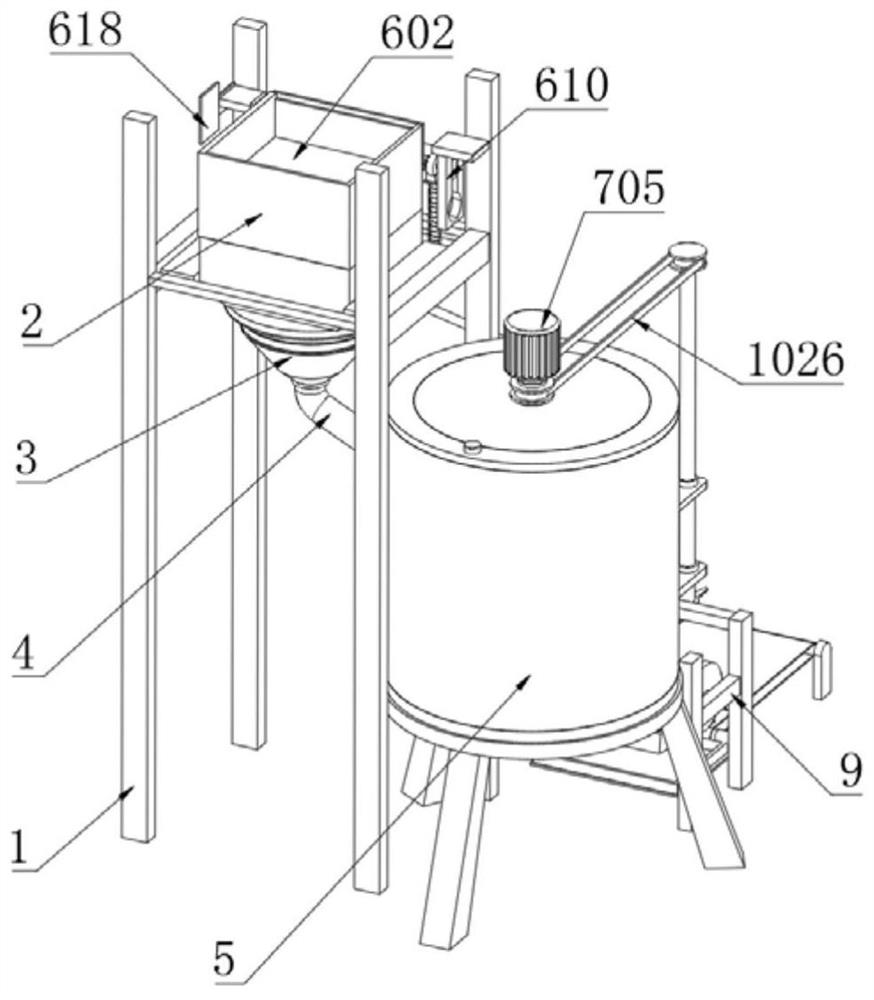

Preparation method of degradable straw raw material PLA (polylactic acid)

ActiveCN113198347AScientific and reasonable structureEasy to useRotary stirring mixersTransportation and packagingLaser lightLight hole

The invention discloses a preparation method of a degradable straw raw material PLA (polylactic acid), which comprises the following steps: feeding: sequentially pouring raw materials to the surface of a raw material stacking plate, pressing the raw material stacking plate downwards by the weight of the raw materials, descending an oval sliding block and a shading baffle along with the raw material stacking plate, and stopping feeding when light emitted by a laser lamp penetrates through a light hole to be displayed; and overturning and material pouring: after all the raw materials are added, enabling the oval sliding block to move downwards into a circular through groove, rotating the raw material stacking plate and the oval sliding block at the same time, and pouring the raw materials on the surface of the raw material stacking plate into a feeding hopper. Raw materials and auxiliaries which need to be added are sequentially placed on the raw material stacking plate, the raw material stacking plate can be pressed downwards by the weight of the raw materials, so that an extrusion spring is compressed, the oval sliding block slides downwards along a sliding groove all the time, the oval sliding block is clamped in the sliding groove, a rotating shaft is limited and cannot rotate, and therefore, the raw material stacking plate cannot turn over.

Owner:东莞市锐泽创艺新材料有限公司

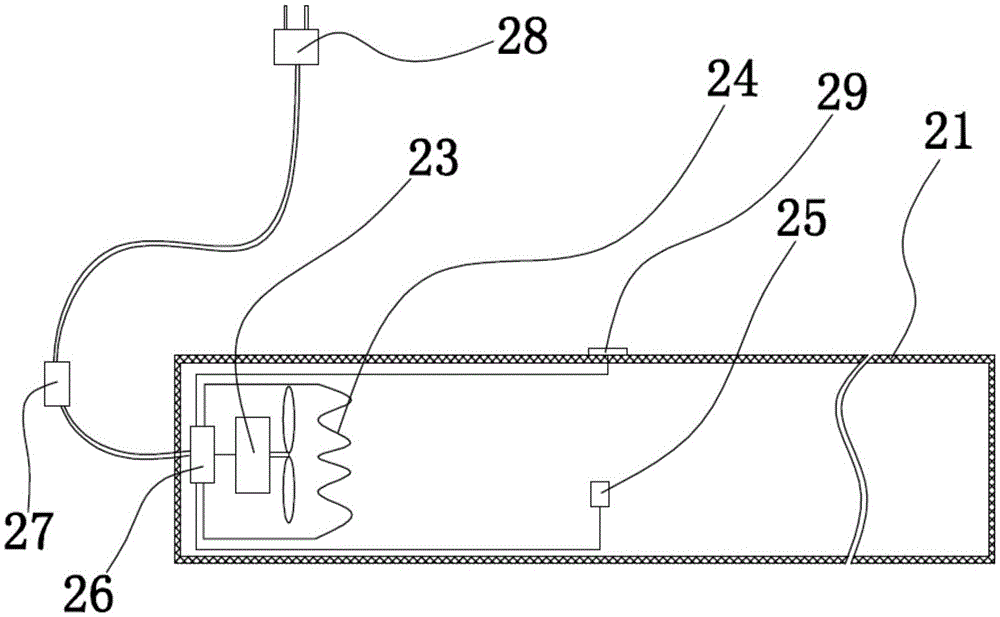

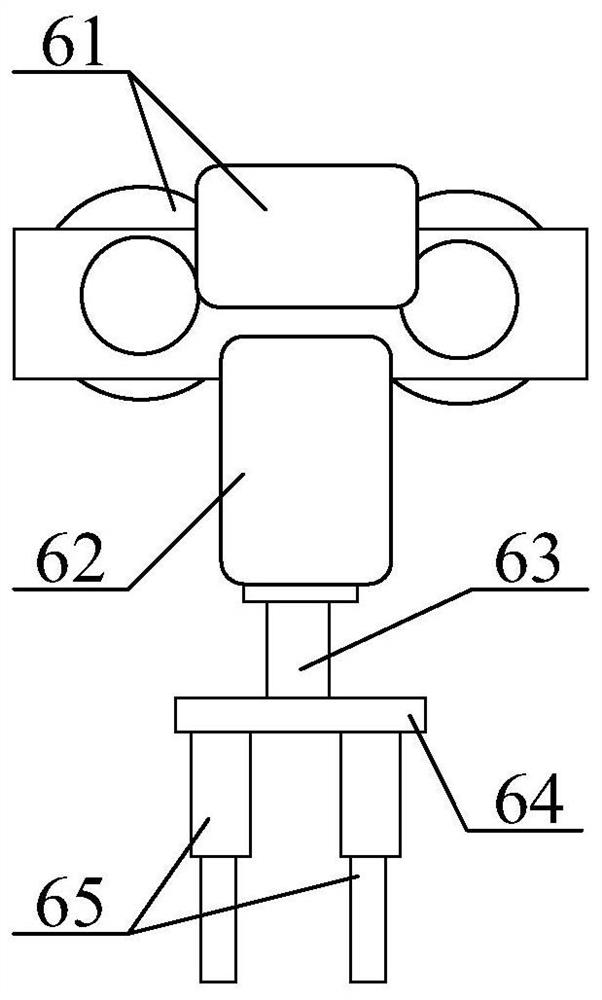

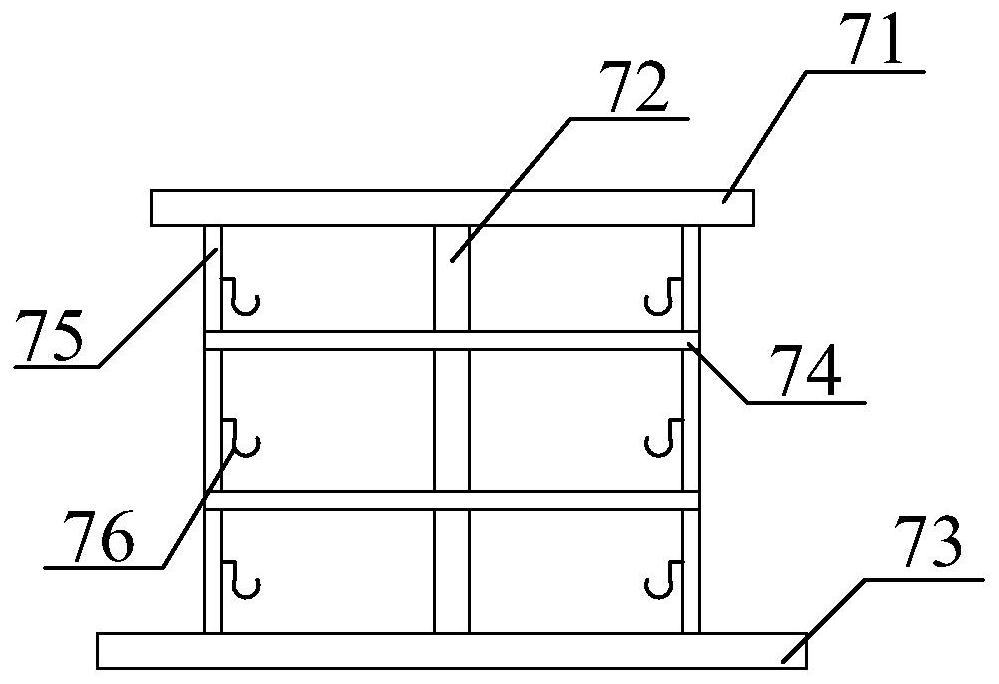

Cleaning and drying device for textile products

InactiveCN112359528APlay a role in cleaningPlay the role of dryingLiquid/gas/vapor treatment machines driving mechanismsLiquid/gas/vapor removal by gas jetsElectric machineProcess engineering

The invention provides a cleaning and drying device for textile products. The cleaning and drying device comprises a cleaning and drying integrated box, an electric door, a cleaning chamber, a dryingchamber, a supporting column, an immersion type cleaning driving hanging plate assembly, a textile product fixing frame assembly, a steam flow dividing guide pipe assembly, a rail, a transverse supporting plate, an air blower, a waste discharging pipe, a cleaning box, a manual door, an air collecting hood, an exhaust fan, a temperature sensor, a control box, an electric heating pipe, an air outletcover and a wind guide pipe. According to the cleaning and drying device, the textile products needing to be cleaned and dried are hung on hooks or fixed to protective pieces and connecting rods; thetextile product fixing frame assembly with the textile products is immersed into the cleaning box, a rotating motor is started to rotate, so that the cleaning effect is achieved, and after stirring and cleaning are completed, the textile product fixing frame assembly is lifted out to rotate, and thus the spin-drying effect is achieved; and the rail is specifically an annular rail, cleaning and drying operation can be conducted at the same time, and the cleaning and drying efficiency is improved.

Owner:邵阳市昌兴实业有限公司

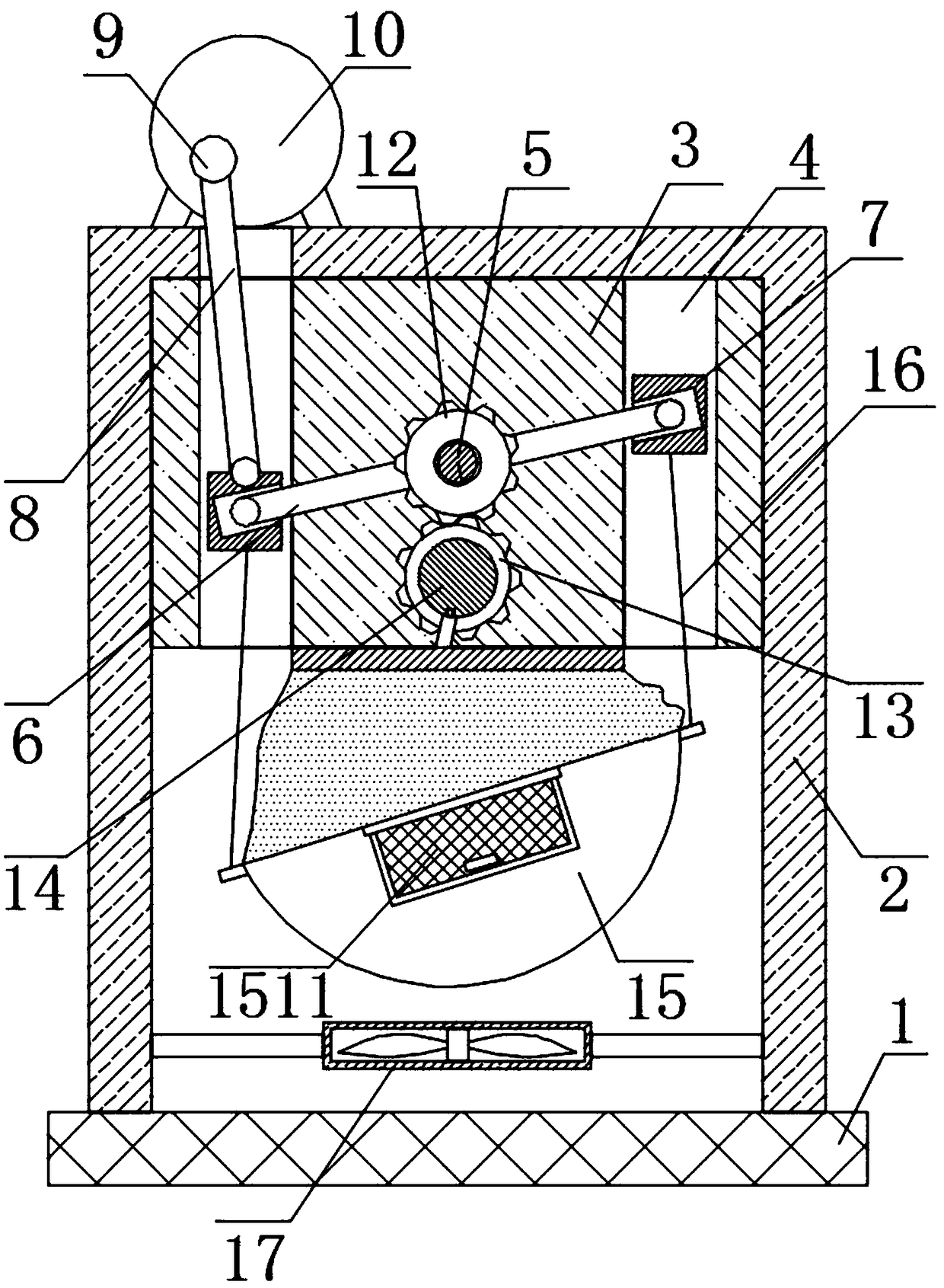

Drying device capable of conveniently and stably placing printed finished products

PendingCN108407451AEasy and stable placementEasy to placePrinting press partsPulp and paper industryExhaust pipe

The invention discloses a drying device capable of conveniently and stably placing printed finished products. The drying device comprises a drying device main body, an exhaust pipe, a protective net,placing grooves, jacking plates, a fixing frame, a protective plate, a sliding groove, second drying lamps, a drying bottom plate and drying holes. A fixed cover plate is connected with the upper partof the drying device main body through a fixed lock catch and rotating hinges, the exhaust pipe is arranged above a heat dissipation opening, the placing grooves are formed in the left and right sides inside the drying device main body, the drying bottom plate is arranged above the second drying lamps, and the drying holes are formed in the drying bottom plate. According to the drying device capable of conveniently and stably placing the printed finished products, the printed finished products inside the drying device main body can be fixed to facilitate stable placement of the printed finished products inside the drying device main body, and first drying lamps and the second drying lamps are arranged on the inner side and the bottom of the drying device main body correspondingly, so thatdrying of the printed finished products is speeded up.

Owner:JIANGXI SHUANGLIN COLOR PRINTING PACKAGING CO LTD

Efficient water removing device for tea processing

The invention provides an efficient water removing device for tea processing. The efficient water removing device comprises a base, a U-shaped frame connected to the upper end of the base, a connecting plate connected to the inner top wall of the U-shaped frame, two sliding chutes symmetrically formed on the connecting plate and sliding blocks sliding in the sliding chutes; wherein both the two sliding blocks are connected with fixed blocks in a sliding way; the two fixed blocks are hinged at the two ends of a rotating bar; the center of the rotating bar is fixedly spliced with a rotating shaft; the rotating shaft is connected to the front side wall of the connecting plate in a rotational way; the sliding block positioned on the left side is hinged with a connecting rod; and the upper endof the connecting rod passes through a first rectangular through hole formed in the top wall of the U-shaped frame for being hinged on a rotating block. The invention overcomes the deficiencies of theprior art, is reasonable in design and compact in structure, and solves the problems of the prior water removing process that the efficiency is low, the labor intensity is high and the water removingoperation is not uniform. The invention also provides a drying device for reducing the moisture in the tea, thereby improving the quality of the tea and having strong practicability.

Owner:潜山市槎水茶桑专业合作社

Paint spraying device and method for furniture processing

InactiveCN112317172ASmooth stepsPracticalPretreated surfacesCleaning using toolsMetallurgyAir blower

The invention discloses a paint spraying device and method for furniture processing. The paint spraying device comprises a paint spraying chamber, a paint spraying inlet, a paint spraying outlet, a conveying belt, a paint spraying assembly, drying assemblies, a paint collecting tank and a paint discharging port; the paint spraying inlet is formed in the lower portion of one side of the paint spraying chamber, and the paint spraying outlet is formed in the lower portion of the other side of the paint spraying chamber; one end of the conveying belt penetrates through the paint spraying inlet andextends out of the paint spraying outlet, the paint spraying assembly is arranged on the upper portion in the paint spraying chamber, the drying assemblies are arranged on the outer walls of the twosides of the paint spraying chamber, each drying assembly comprises a drying shell, an air blower, an air inlet pipe, a heating wire and an air outlet pipe, the paint collecting tank is arranged belowthe paint spraying chamber, and the paint discharging port is formed in the rear end of the paint collecting tank. According to the paint spraying device and method for furniture processing, throughmutual cooperation of all the components, furniture is firstly cleaned before paint spraying, then paint spraying and drying are conducted, the steps are smooth, and the practicability is high.

Owner:湖南新宝峰家具制品有限公司

Combined power distribution cabinet with moisture-proof function

ActiveCN114069448AGood moisture-proof effectAvoid wasting time and effortSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsDamp proofingElectrical and Electronics engineering

The invention relates to the technical field of power distribution cabinets, and provides a combined power distribution cabinet with a moisture-proof function. The cabinet comprises a power distribution cabinet frame and a dehumidification mechanism, and is characterized in that the power distribution cabinet frame comprises an outer side frame, an inner side frame and a base, the bottoms of the outer side frame and the inner side frame are both mounted on the base, cavity is formed between the outer side frame and the inner side frame, a dehumidification mechanism is installed in the cavity and comprises a water absorption cotton net, a first rotating pipe, a second rotating pipe, a third rotating pipe and a fourth rotating pipe, rotating discs are installed at the two ends of the first rotating pipe, the two ends of the second rotating pipe, the two ends of the third rotating pipe and the two ends of the fourth rotating pipe correspondingly, the water absorption cotton net is installed on the rotating discs, an annular batten is installed on the water absorption cotton net, a plurality of first gear teeth are evenly arranged on the annular batten, a first circular guide rail is arranged on the rotating disc, second gear teeth are evenly arranged in the first circular guide rail, the annular batten is located in the first circular guide rail, and the first gear teeth are connected with the second gear teeth in a meshed mode.

Owner:常州东皓电气有限公司

Cereal drying device for agricultural production

InactiveCN111721085AEasy to dryDry evenlyDrying gas arrangementsDrying chambers/containersAgricultural scienceAgricultural engineering

The invention belongs to the technical field of drying devices, and particularly relates to a cereal drying device for agricultural production. In order to solve the problem that drying for cereals atmiddle and lower layers in a drying process is relatively poor, drying is not even sufficiently, and drying quality is affected as a drying device in the prior art adopts an assembly line drying mode, the invention discloses the following scheme: the cereal drying device comprises a drying box, wherein inner walls of two sides of the drying box are fixedly provided with the same drying slot through bolts; mounting holes which are distributed at equal distance are formed in the bottom outer wall of the drying slot; inner walls of the mounting holes are connected to rotary tubes through bearings; and bottom ends of outer walls of the rotary tubes are fixedly provided with rotary plates which are distributed in an annular mode at equal distance through bolts. Spiral rods and triangular blocks which are alternatively arranged drive cereals in the drying slot to turn over, and rising hot gas can enter the drying slot along a gas outlet and a trapezoidal hole, so that evaporation of water in the cereals is accelerated to achieve the drying effect, the cereals are dried better, drying is even and drying quality is improved.

Owner:烟台农丰农业科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com