Patents

Literature

30results about How to "Smooth steps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

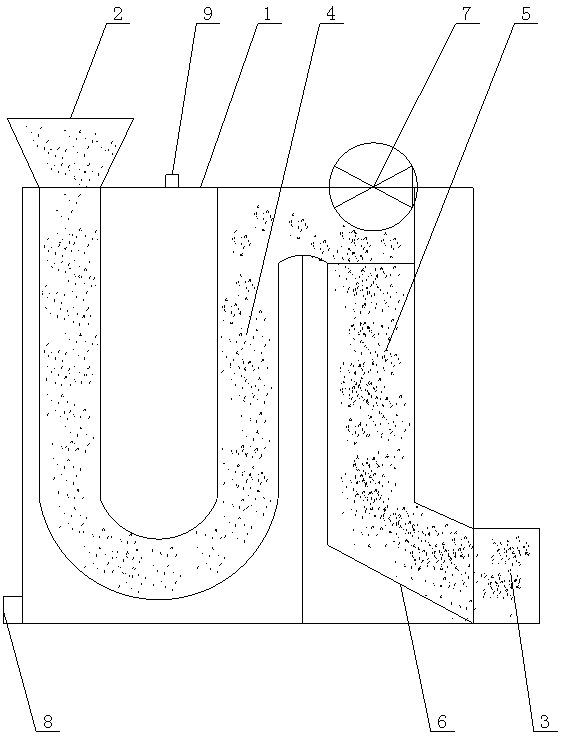

Biomass gasification method

ActiveCN101805638AReduce qualityAchieving directional gasificationCombustible gas productionCombustionMass ratio

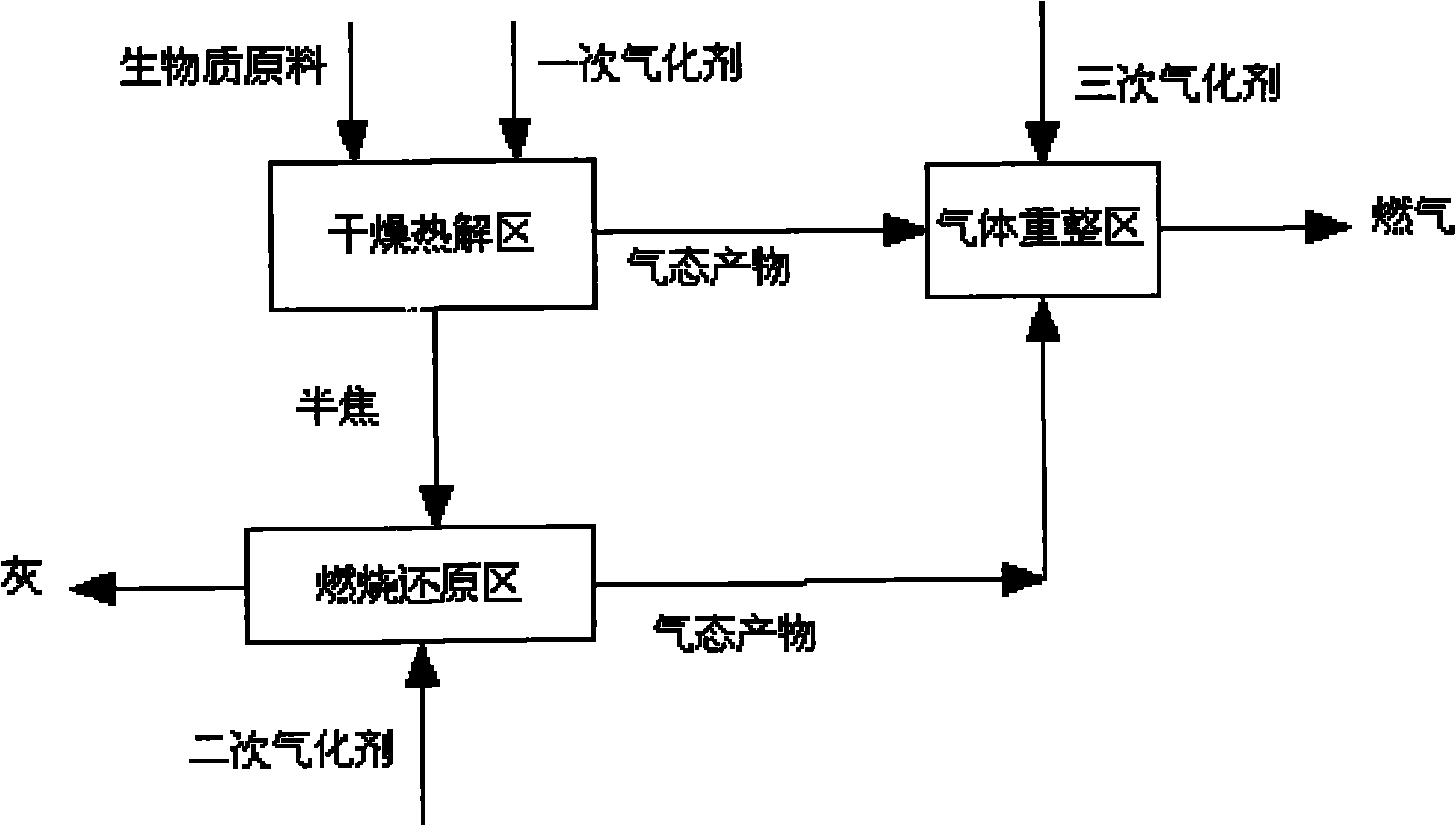

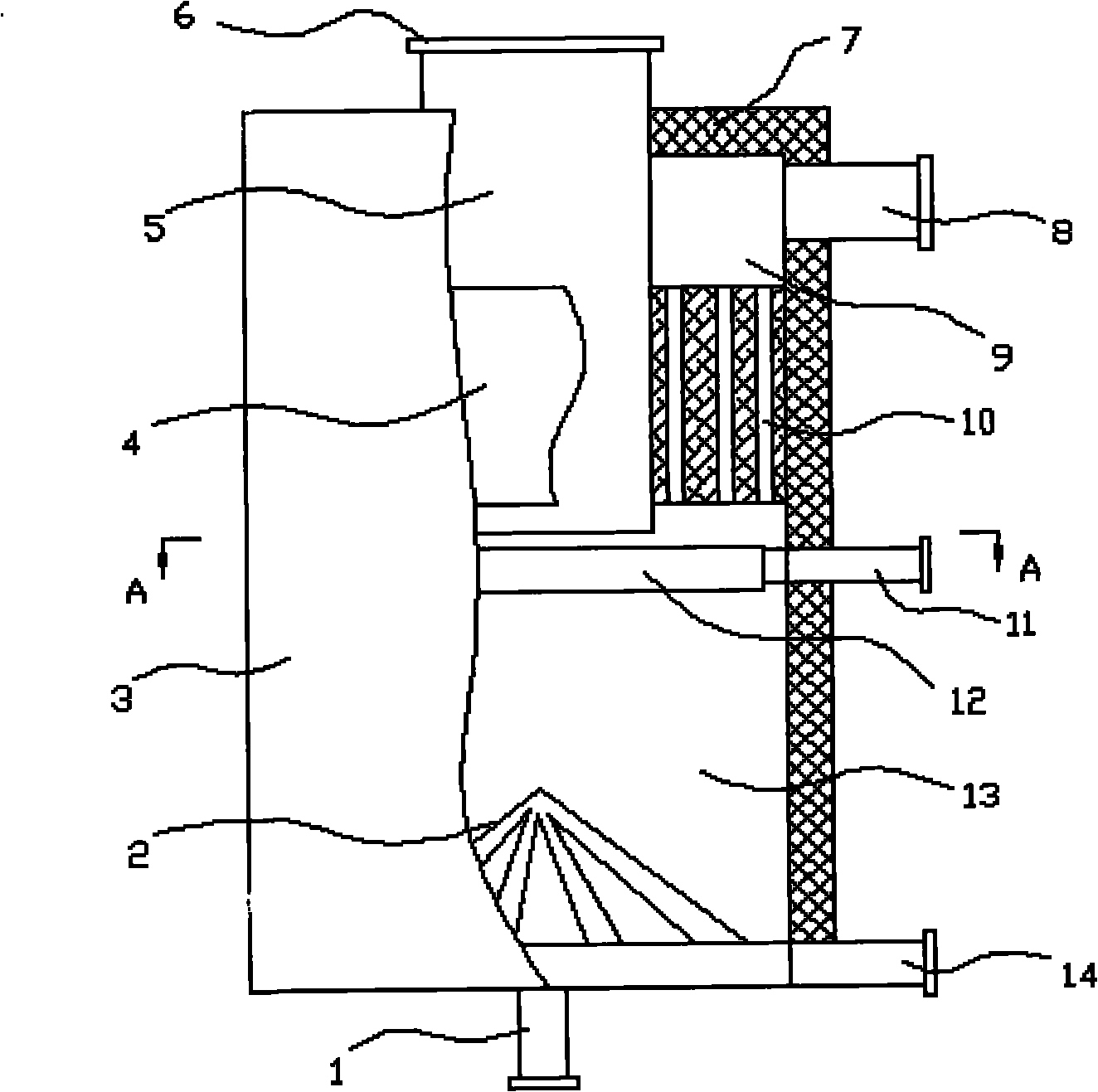

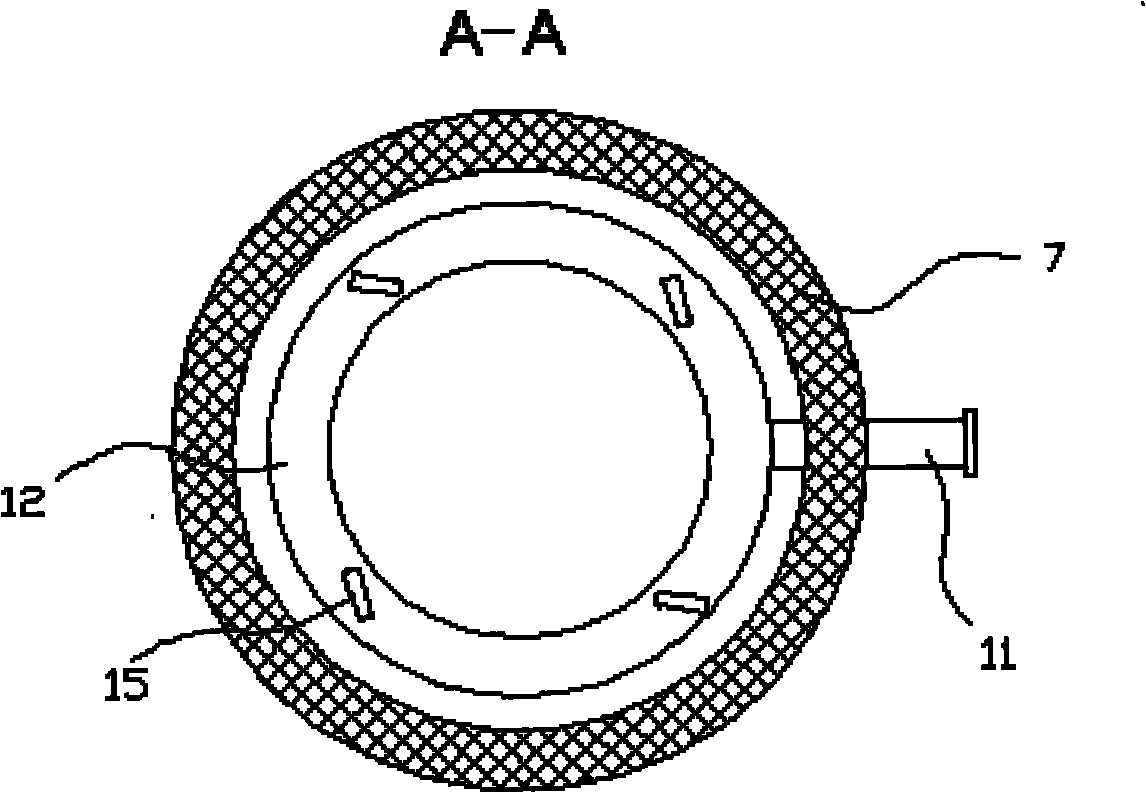

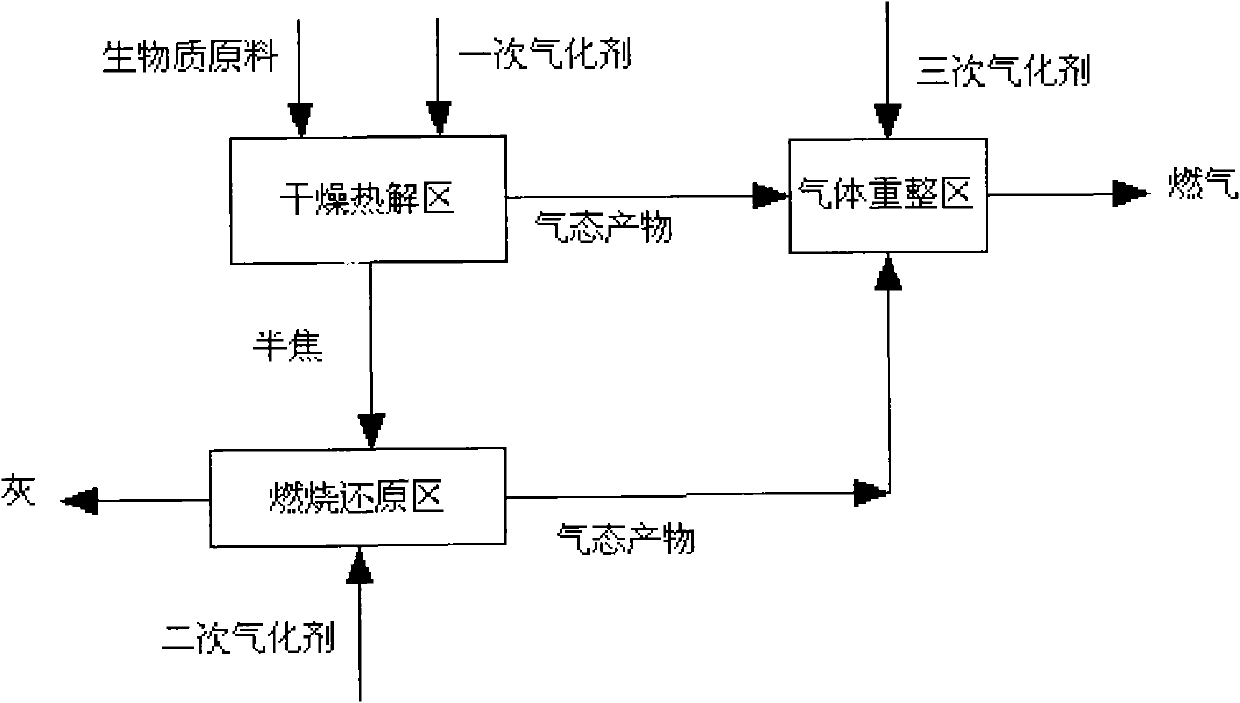

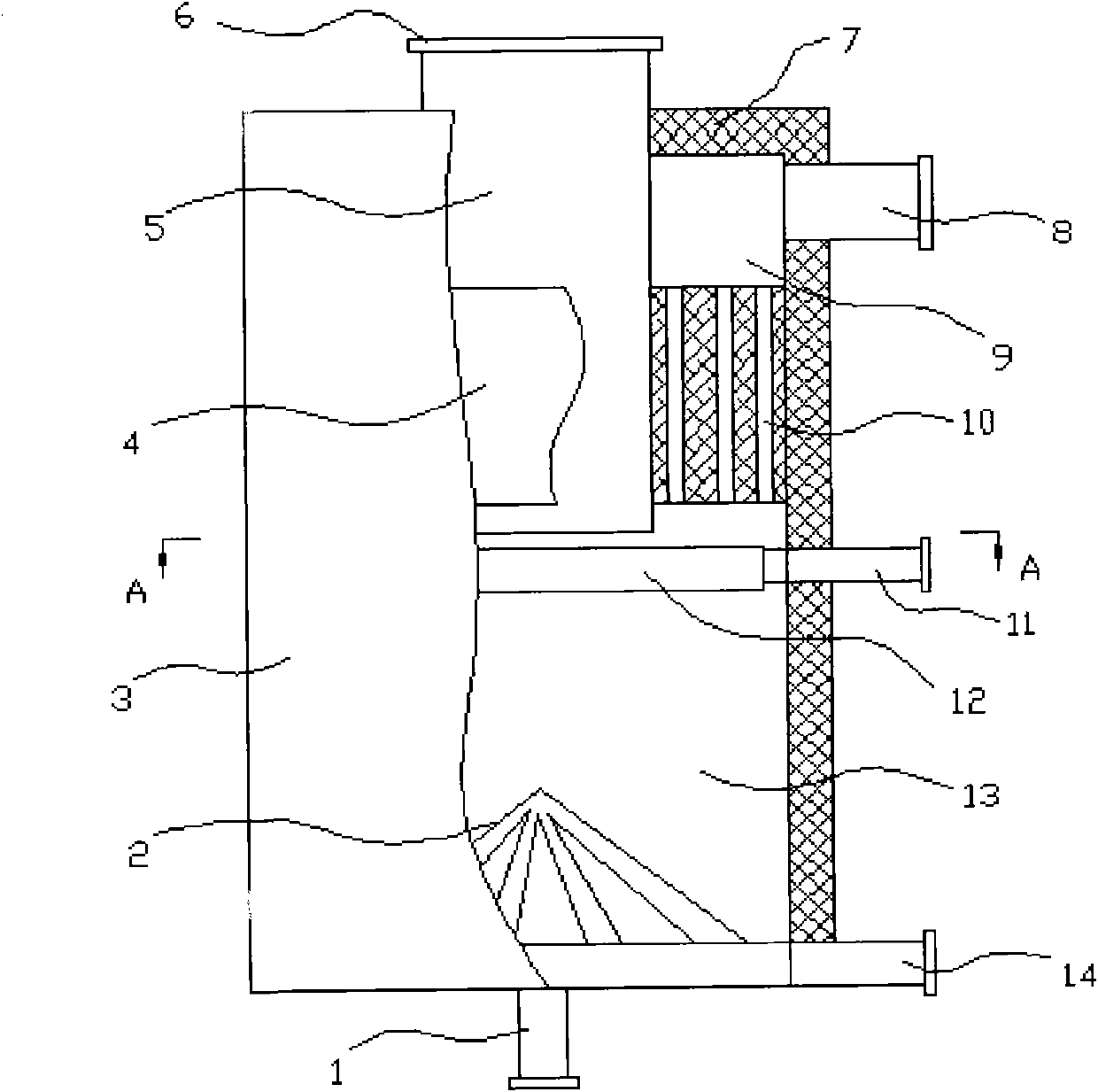

The invention discloses a biomass gasification method. The method requires the steps of drying pyrolysis, combustion deoxidization and gas reforming in the gasification process to be relatively separated and continuously carried out in the same gasification furnace, simultaneously continuously gasification agent is introduced at three points in the whole gasification process and finally the cleanhigh quality product gas is obtained. In the invention, the equivalence ratio of the total gasification agent is 0.2-0.35, and the mass ratio of a first gasification agent, a second gasification agent and a third gasification agent is (0-0.8):(2-3.5):(0.7-1.5). The method controls the temperature and the reaction depth of each subarea in the furnace by controlling the mutual ratio of the biomass materials, the first gasification agent, the second gasification agent and the third gasification agent so as to control the quality of the final product gas. The obtained product gas can be used as the energy or the chemical engineering synthesis raw material gas. The method can generate clean product gas from the biomass, cannot generate secondary pollution and has high carbon conversion rate and simple implementation method.

Owner:山东山科环境资源有限公司

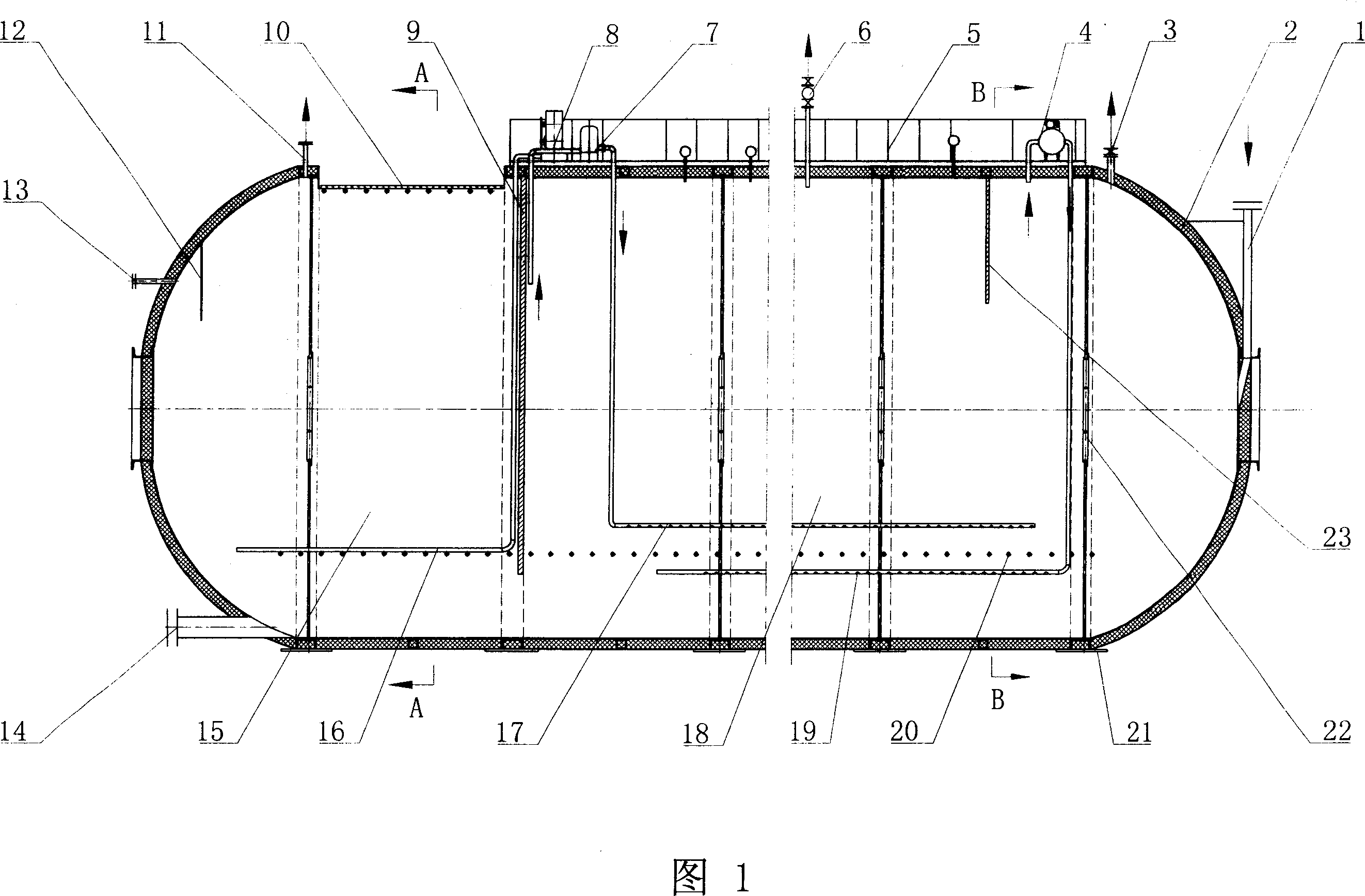

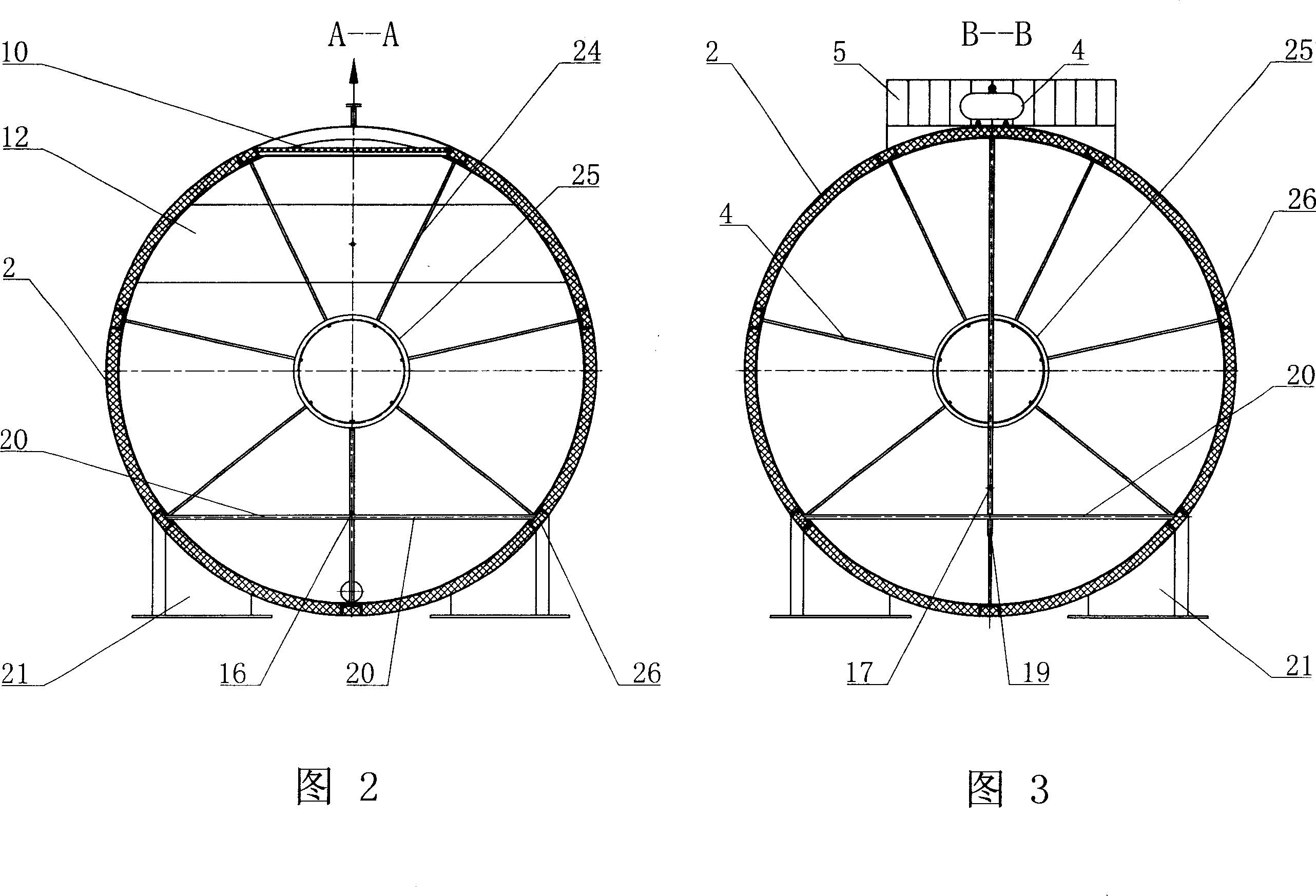

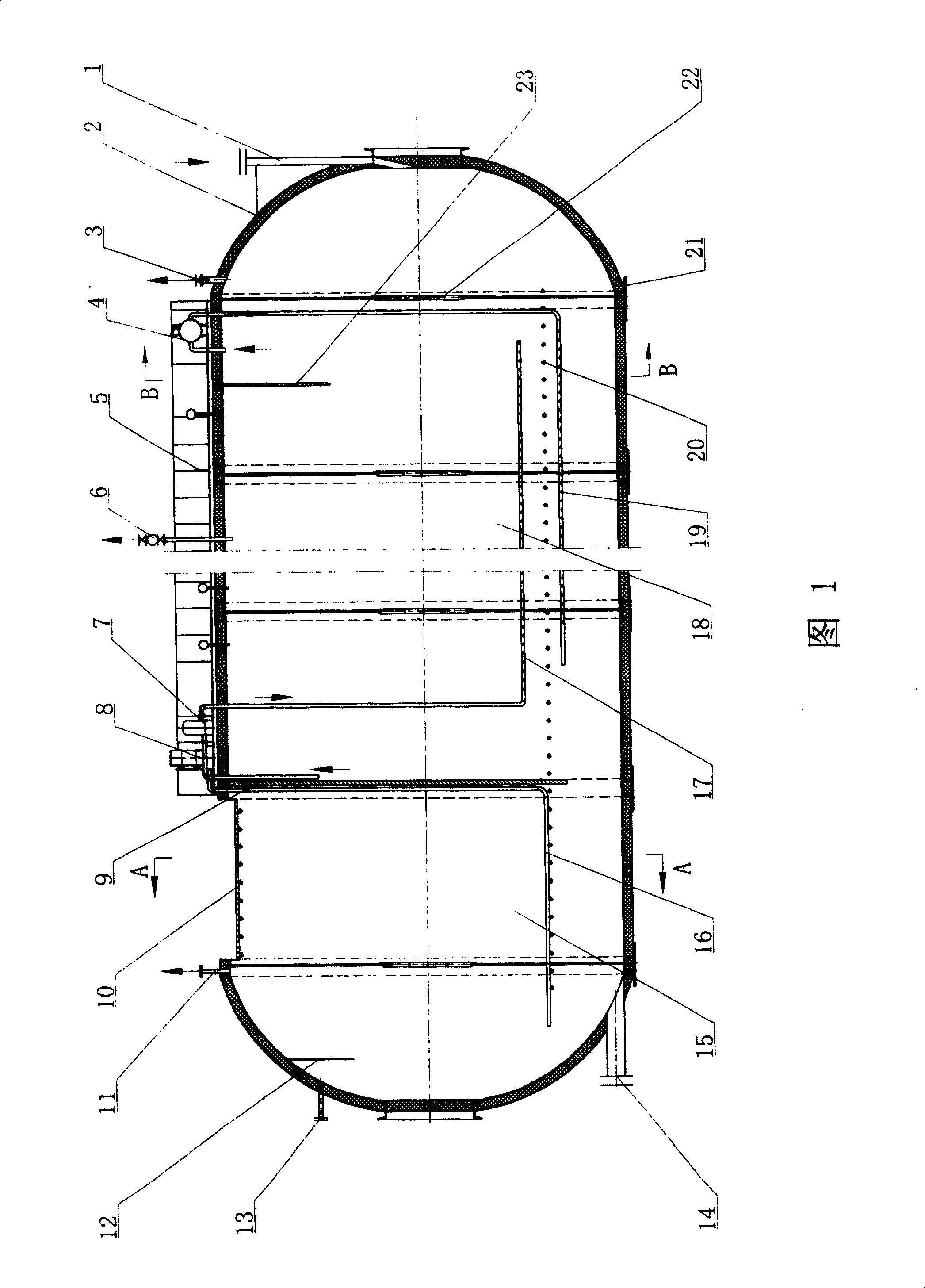

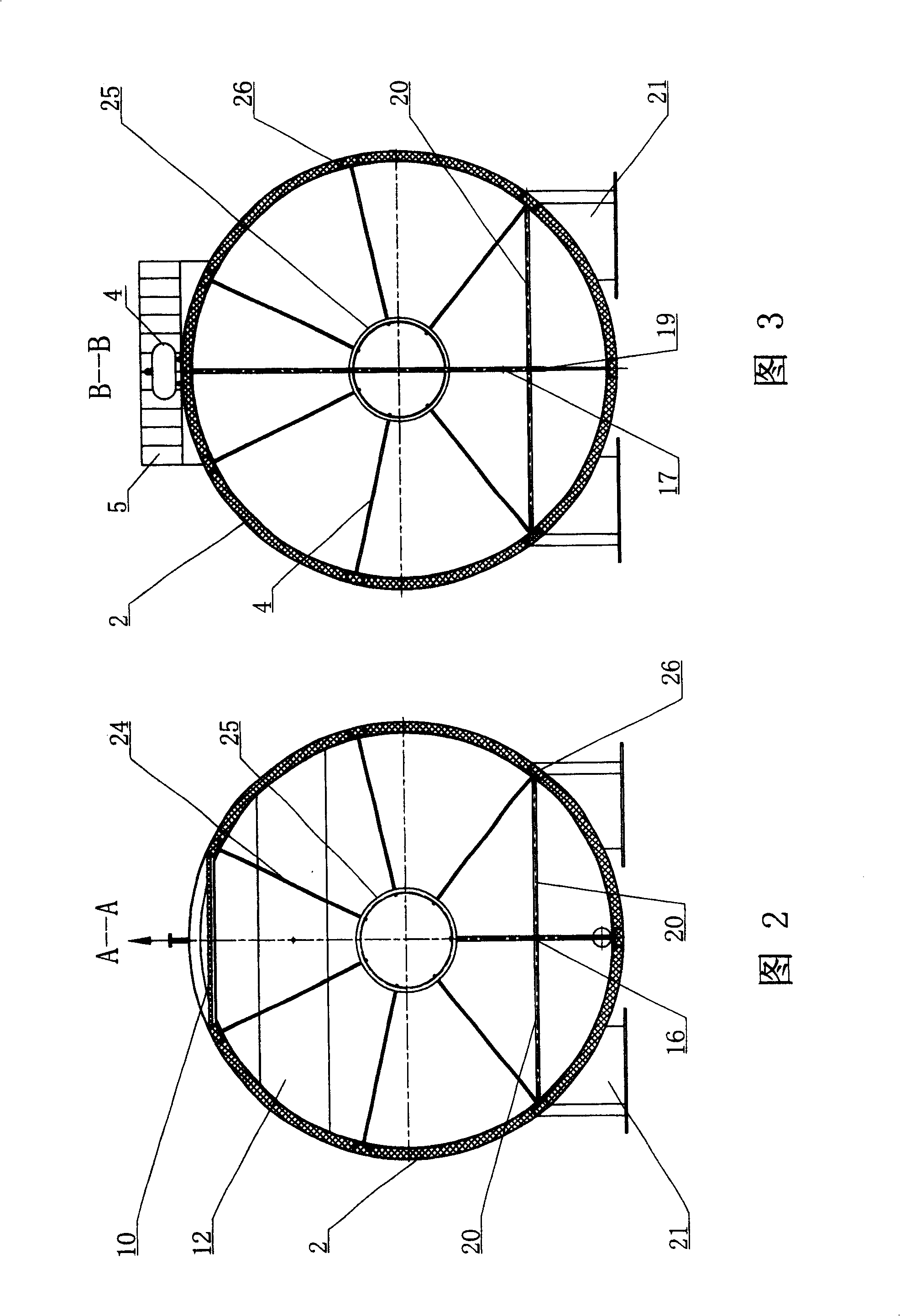

Apparatus for preparing ecological fertilizer using animal-bird feces

InactiveCN101024589AProcess matching is reasonableReasonable processBio-organic fraction processingClimate change adaptationSludgeAnimal feces

The invention relates to a device to make biology fertilizer from livestock dejection. It includes material intake, material outlet, gate valve, marsh gas control valve and jar. The main technology is that: the identity cavity is separated into anaerobic cavity and aerobic cavity, the outlet pipe end of returning pump extending into anaerobic cavity and connecting to gas nozzle, the output end of sludge pump extending into identity anaerobic cavity and connecting to spray pipe, top part of identity aerobic cavity is set light-passing board, and the output end of burst device connects to burst pipe of aerobic pipe. The invention has the advantages of high intention, super thin, electric energy saving, low running cost, and could effectively improve producing efficiency and quality of biology fertilizer.

Owner:辽宁中田干燥设备制造有限公司

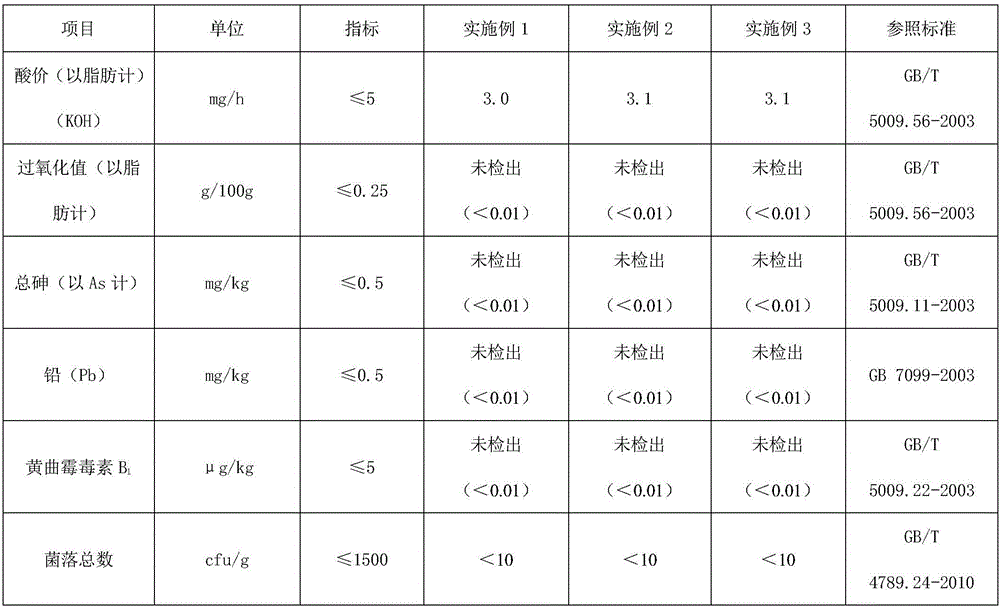

Sandwich doughnut cake and preparation method thereof

InactiveCN105707177AImprove production efficiencyIncrease nutritionDough treatmentBakery productsFlavorVegetable oil

The invention discloses a preparation method for a sandwich doughnut cake, and belongs to the field of preparation of doughnut cakes. The sandwich doughnut cake is prepared from the following raw materials in parts by mass: 22-23 parts of medium-strength wheat flour, 19-22 parts of white granulated sugar, 4-6 parts of water, 18-21 parts of refined vegetable oil, 25-26 parts of fresh eggs, 5-6 parts of corn starch, 1-2 parts of edible salts, 0.5-0.8 part of double-effect baking powder, 0.1-0.2 part of citric acid, 0.05-0.15 part of edible flavor, 2-6 parts of Custard cream, 5-6 parts of coating chocolate, 0.2-0.5 part of chocolate cream, 0.04-0.06 part of a d-sorbitol solution, 0.04-0.05 part of glycerol, 0.04-0.05 part of xanthan gum and 0.10-0.15 part of a cake emulsifier. A preparation method for the sandwich doughnut cake comprises the following steps: preparing the raw materials and mixing the raw materials, fermenting flour pulp, slip-casting and molding the fermented flour pulp, roasting the fermented flour pulp, carrying out core casting on the roasted flour pulp, de-molding and cooling the flour pulp to obtain a cake, forming patterns on the coating of the cake, and packaging and warehousing the cake. The preparation method further comprises preparing coating chocolate. The sandwich doughnut cake adopts various formulas, and is rich in nutrient, is fine in classifying in a preparing process, steps are smooth, and the operation is easier.

Owner:福建惠家食品有限公司

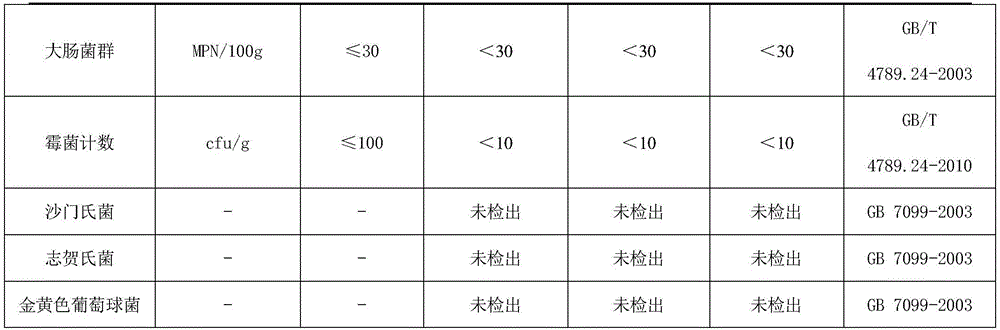

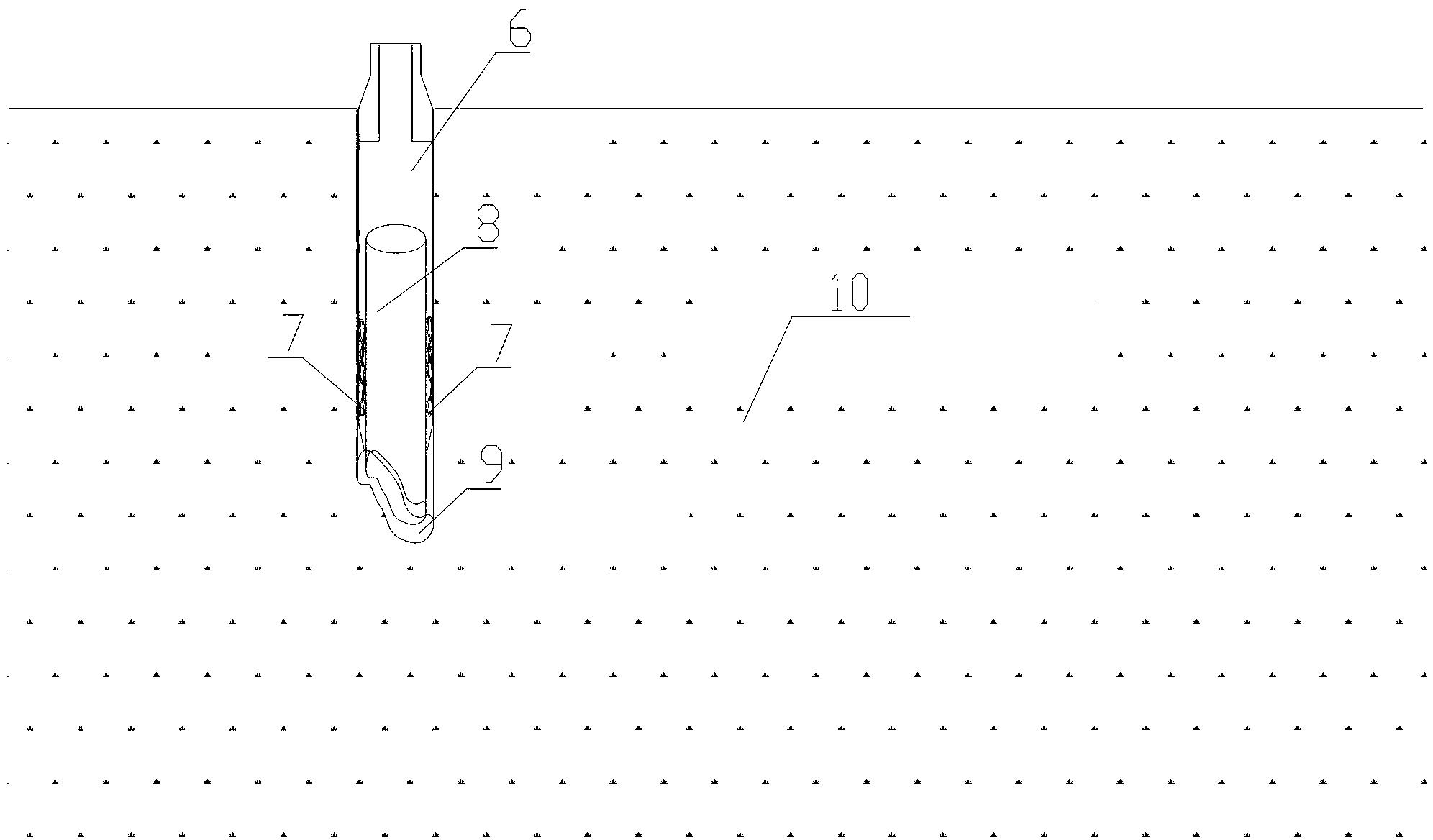

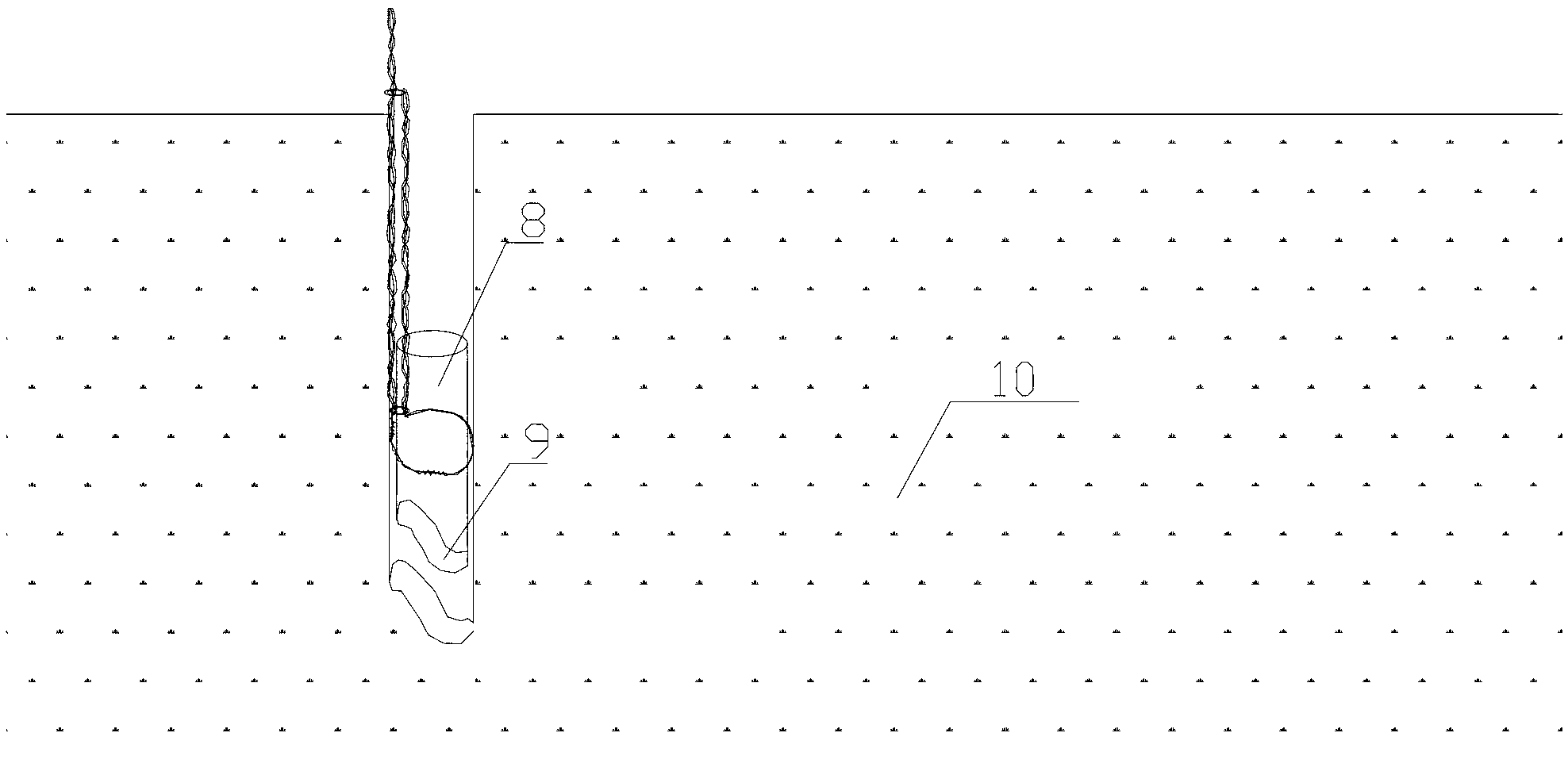

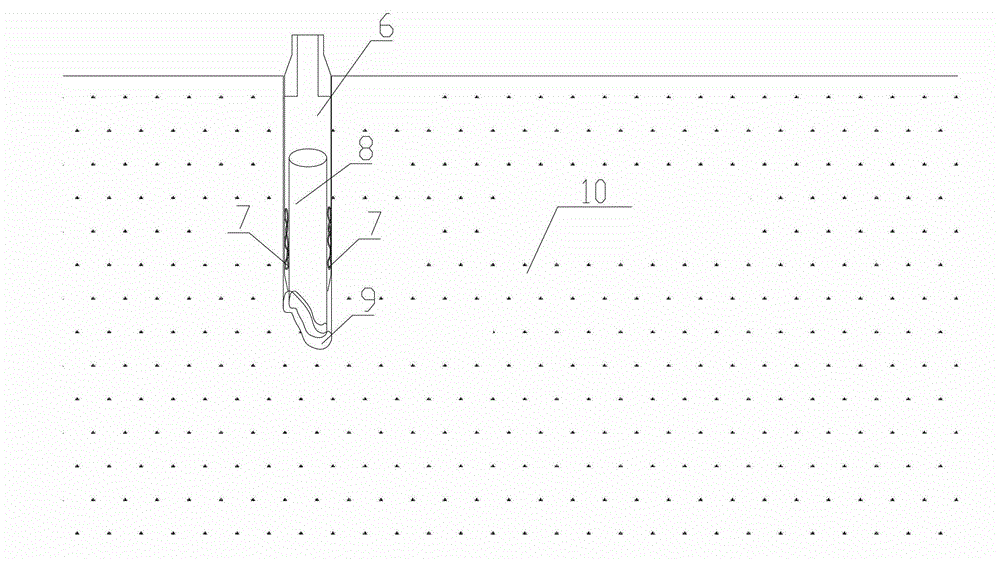

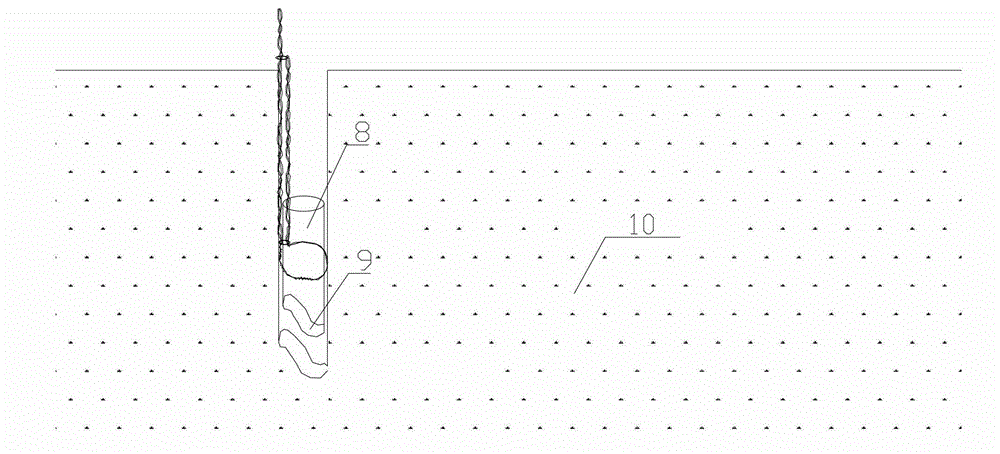

High efficiency coring method for portable drilling machine in integral hard rock

ActiveCN103306623ADamage Fracture RealizationStrong targetingConstructionsCore removalRock coreHigh integrity

The invention relates to a high efficiency coring method for a portable drilling machine in an integral hard rock. The invention solves the technical difficult problems of high wear speed of a drilling tool and low coring rate which are caused by the case that when the portable drilling machine drills in the hard rock with high integrity, the root of a rock core is usually difficult to cut off or is difficult to successfully take out after being cut off. The invention adopts the scheme that the high efficiency coring method comprises the following steps: a, on a superficial layer of the earth surface, where a rock core to be taken is positioned, drilling a blind hole by the drilling machine and clearing away the broken rock core in the blind hole; b, lengthening a drill rod on the drilling machine in the step a and continuously drilling towards the lower layer on the basis of the blind hole; c, lifting up the drilling machine in the step b to form a gap between the inner wall of a hollow drill bit and the rock core; d, filling a filler in the gap in the step c; e, starting the drilling machine to enable the root of the rock core to be broken, shutting down the drilling machine and taking out the drill rod and the hollow drill bit; f, placing in-hole positioning imaging equipment into the blind hole to carry out positioning and recording on a damaged and cracked position of the rock core in the blind hole; g, taking out the in-hole positioning imaging equipment in the blind hole; h, placing deep hole rock core extracting equipment into the blind hole and taking out a rock core sample.

Owner:NANJING UNIV

Flavoring sauce with avicennia marina fruits and production method thereof

ActiveCN104323217AGood for healthCooling bloodFood ingredient functionsFood preparationBiotechnologyAvicennia marina

The invention provides flavoring sauce with avicennia marina fruits, which can maintain rich nutritional ingredients and health-care effect, is convenient in storage and eating and is very scientific and reasonable in processing process. The flavoring sauce comprises the following materials of the avicennia marina fruits, cortex cinnamomi, pepper powder, cardamom, white granulated sugar, onion, garlic, fennel, clove, white vinegar and salt. The invention also discloses a production method of the flavoring sauce with the avicennia marina fruits. The production method comprises the steps of: cleaning, water removing, peeling, soaking, pulping, mixing, cooking, packaging, sterilizing, cooling and storing and the like. A product provided by the invention maintains the original nutritional ingredients of the avicennia marina fruits and is a natural and delicious pollution-free food.

Owner:TONGLING RUIPU PEONY IND DEV

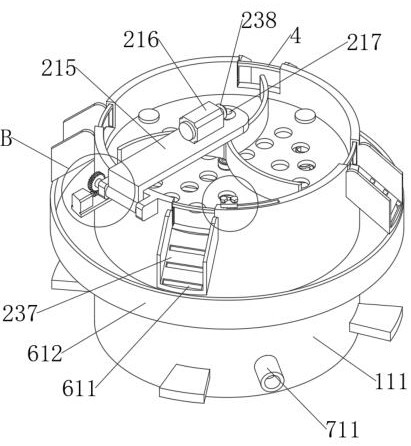

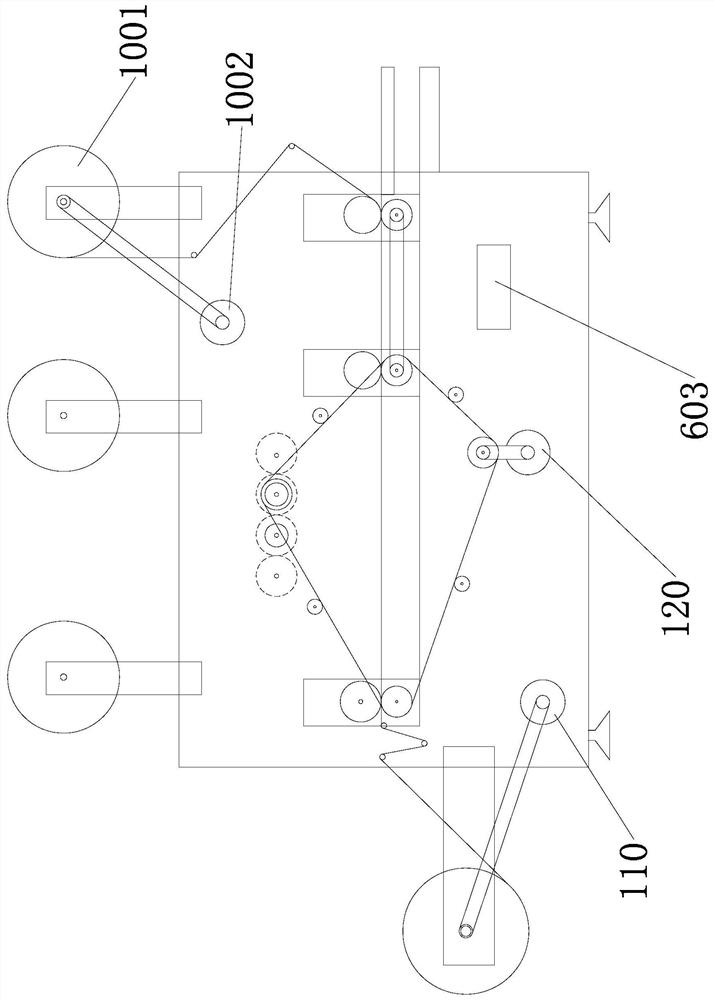

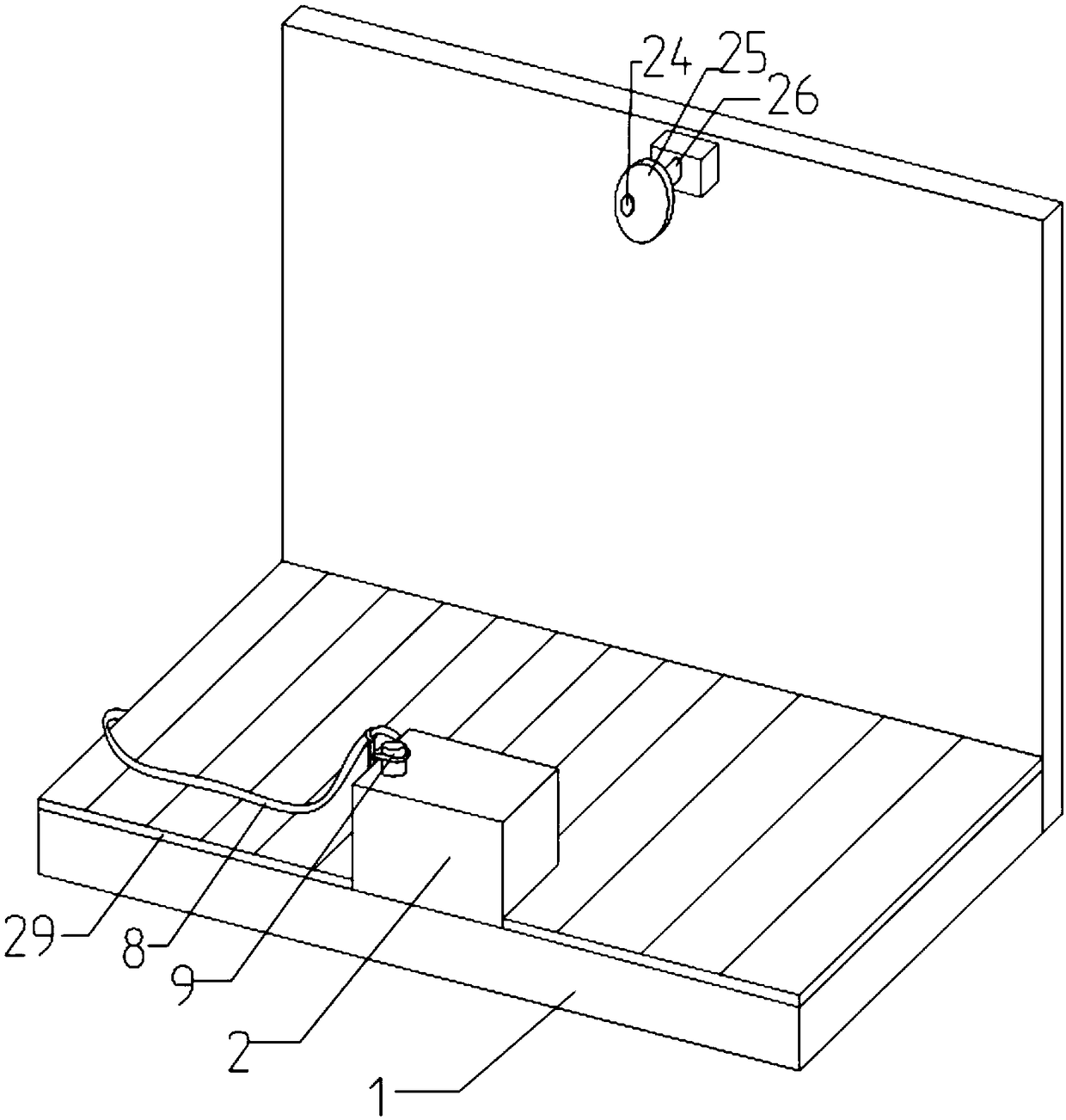

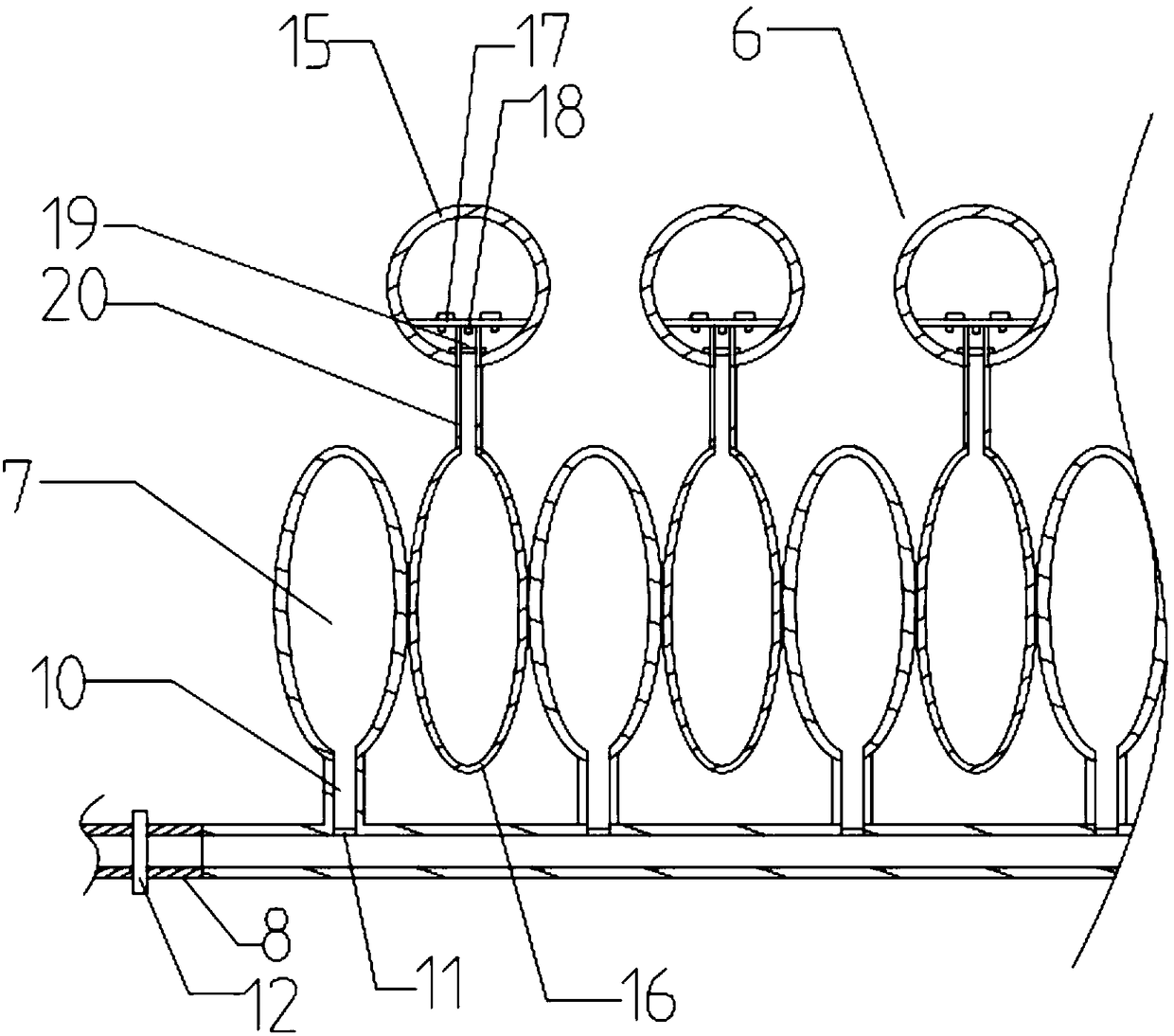

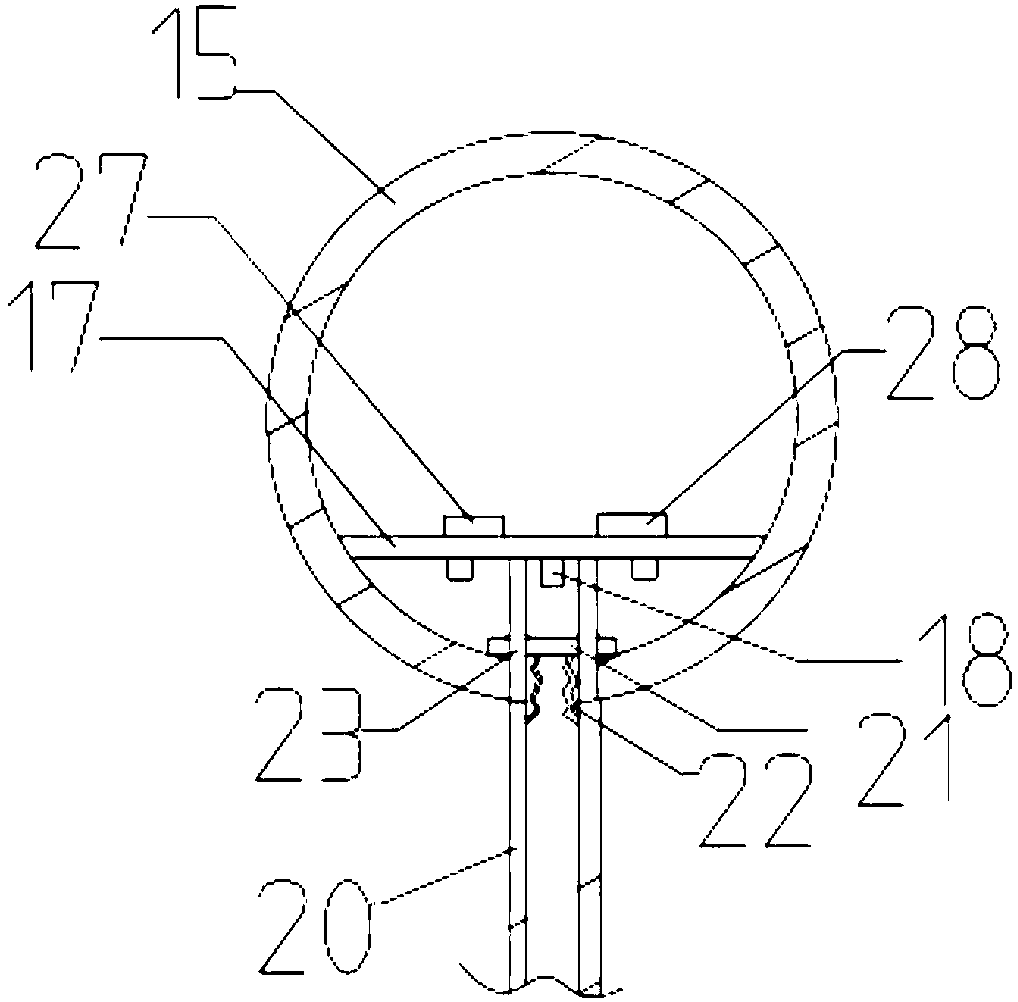

Automatic subdivision loading and transporting equipment for fishing boat

The invention relates to the technical field of subdivision loading and transporting, in particular to fishing boat automatic subdivision loading and transporting equipment which comprises a storage cavity body, and a movable guide discharging mechanism is arranged on the storage cavity body; the movable guide discharging mechanism comprises a fixed mounting rod; a turning mechanism is arranged on one side of the movable guide discharging mechanism, an adjusting protection mechanism is arranged on one side of the interior of the storage cavity body, a movable storage mechanism is arranged on the outer side of the storage cavity body, and a separating mechanism is arranged on one side of the movable storage mechanism. According to the device, a spline shaft rotates to drive a movable guide plate to rotate, and meanwhile, a placement support plate moves, so that fish schools fall from a discharge port in a storage cavity main body and are loaded and transported in different bins, manual operation of workers is not needed, the labor amount of the workers is greatly reduced, meanwhile, due to the fact that the placement support plate ascends automatically, the labor intensity of the workers is reduced, and the working efficiency is improved. And therefore, the fish school placed on the supporting plate can fall down slowly all the time, and the sub-packaging efficiency is greatly improved.

Owner:南通澳洋船务有限公司

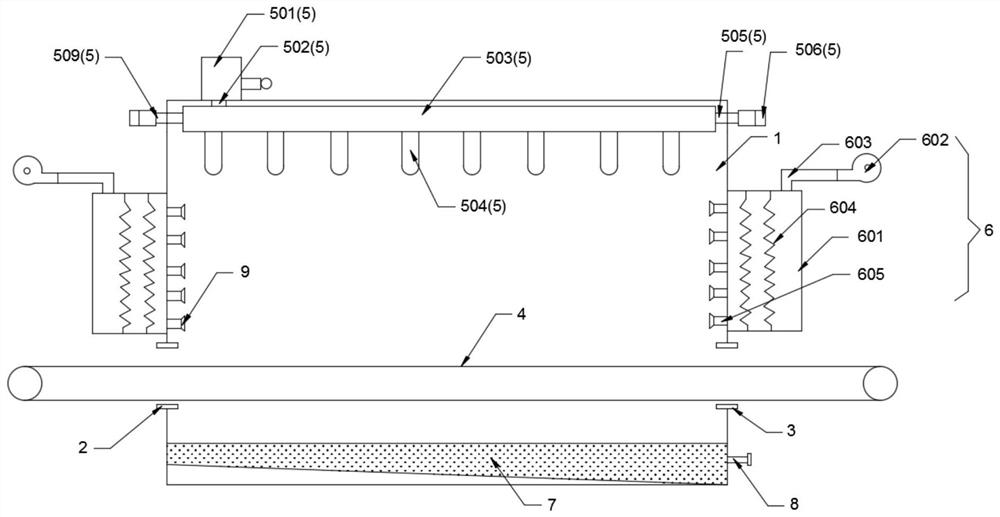

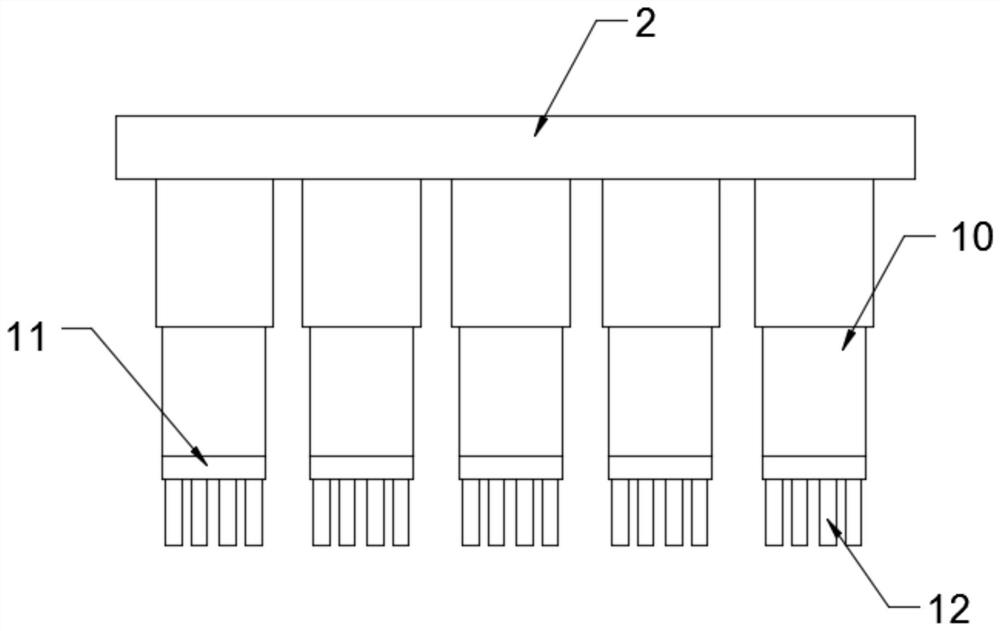

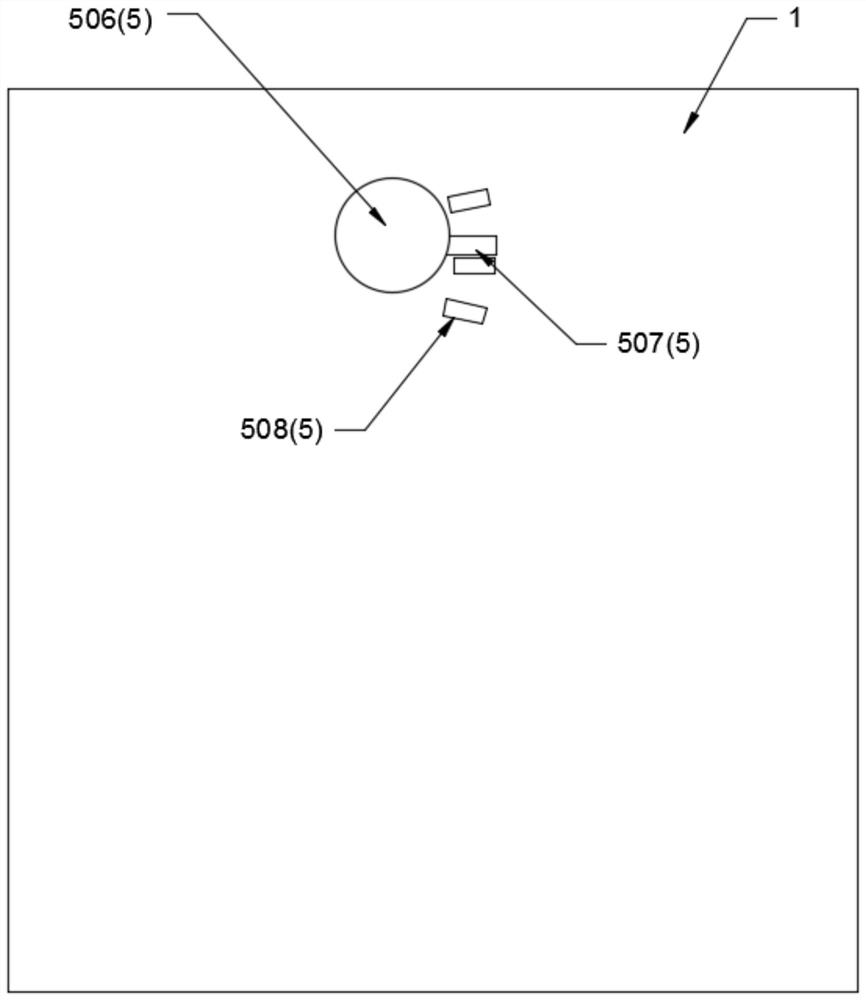

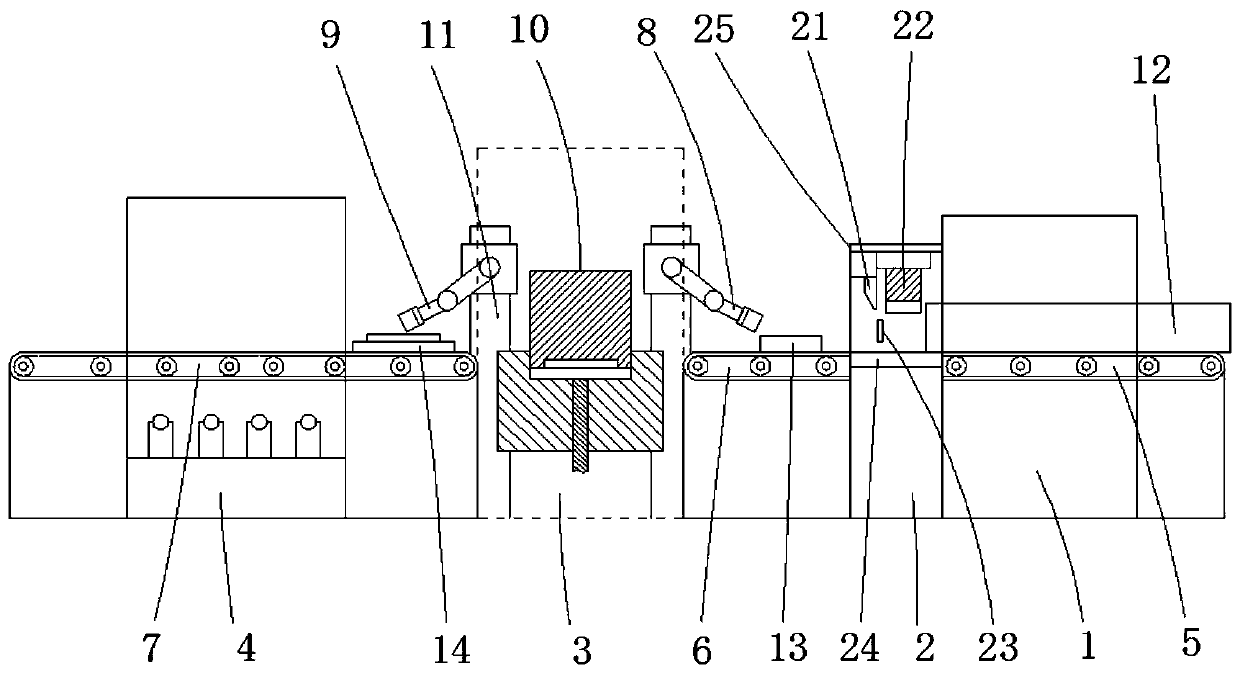

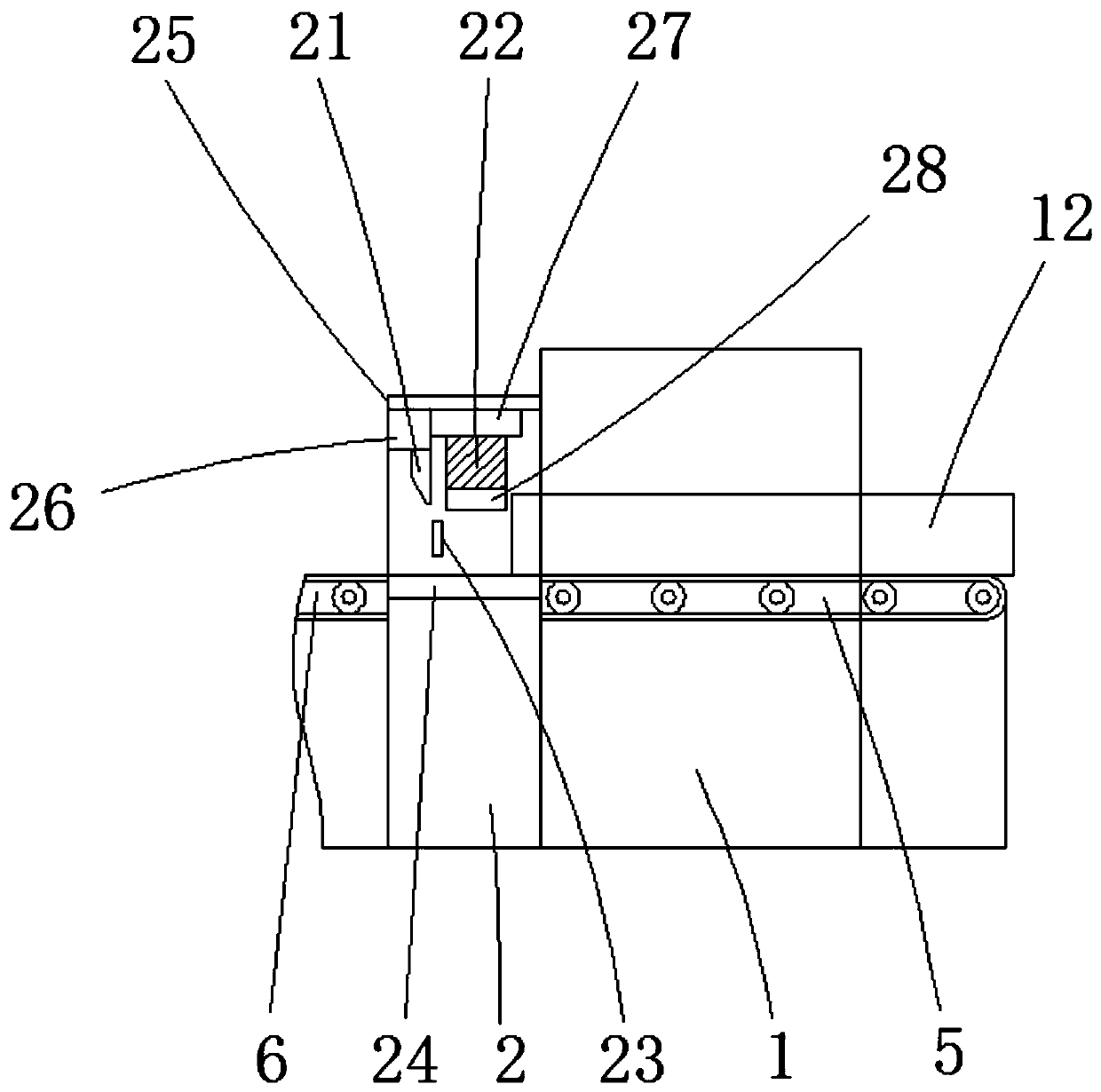

Paint spraying device and method for furniture processing

InactiveCN112317172ASmooth stepsPracticalPretreated surfacesCleaning using toolsMetallurgyAir blower

The invention discloses a paint spraying device and method for furniture processing. The paint spraying device comprises a paint spraying chamber, a paint spraying inlet, a paint spraying outlet, a conveying belt, a paint spraying assembly, drying assemblies, a paint collecting tank and a paint discharging port; the paint spraying inlet is formed in the lower portion of one side of the paint spraying chamber, and the paint spraying outlet is formed in the lower portion of the other side of the paint spraying chamber; one end of the conveying belt penetrates through the paint spraying inlet andextends out of the paint spraying outlet, the paint spraying assembly is arranged on the upper portion in the paint spraying chamber, the drying assemblies are arranged on the outer walls of the twosides of the paint spraying chamber, each drying assembly comprises a drying shell, an air blower, an air inlet pipe, a heating wire and an air outlet pipe, the paint collecting tank is arranged belowthe paint spraying chamber, and the paint discharging port is formed in the rear end of the paint collecting tank. According to the paint spraying device and method for furniture processing, throughmutual cooperation of all the components, furniture is firstly cleaned before paint spraying, then paint spraying and drying are conducted, the steps are smooth, and the practicability is high.

Owner:湖南新宝峰家具制品有限公司

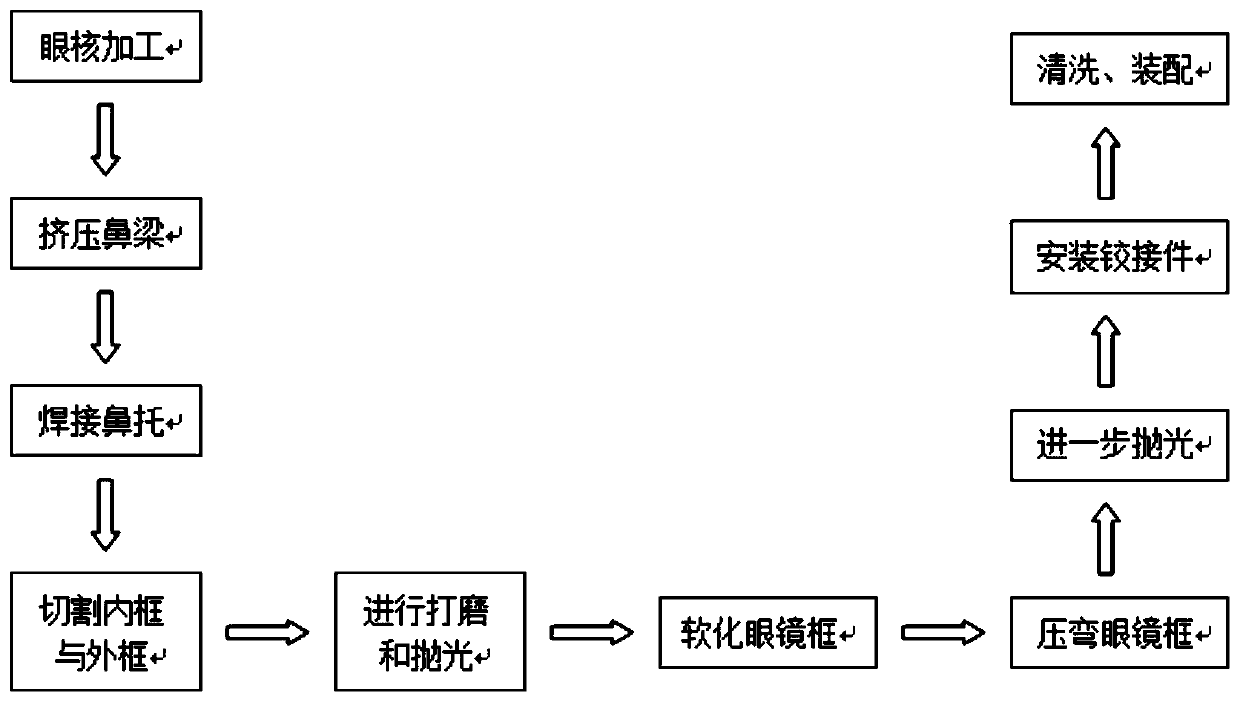

Processing process for glasses

ActiveCN110978466AReduce the probability of occurrenceSmooth stepsSpectales/gogglesCleaning using liquidsNasal bridgeEyewear

The invention relates to a processing process for glasses which comprises a glasses frame and glasses legs hinged with the two sides of the glasses frame. The processing process comprises the following steps: step I of placing a glasses frame board into a hole cutting machine, and cutting out an eye pattern through the hole cutting machine; step II of placing the glasses frame board obtained in the step I into a nose press, heating the middle part of glasses frame board, putting the glasses frame board into a mould to extrude and form, and cutting out a groove of a nose; step III of placing the glasses frame board obtained in the step II into a splicing machine, and welding and splicing a nose frame with the glasses frame board; and step IV of putting the glasses frame board obtained in the step III into a dual-channel fully-automatic board fancy type machine, and cutting and processing the outer frame and the inner frame of the glasses frame, thereby obtaining a semi-finished productof the glasses frame. The processing process has the beneficial effects of effectively improving working efficiency, being capable of meeting daily production needs, being suitable for large-batch production, being high in degree of automation, and reducing the cost.

Owner:温州坤腾光学有限公司

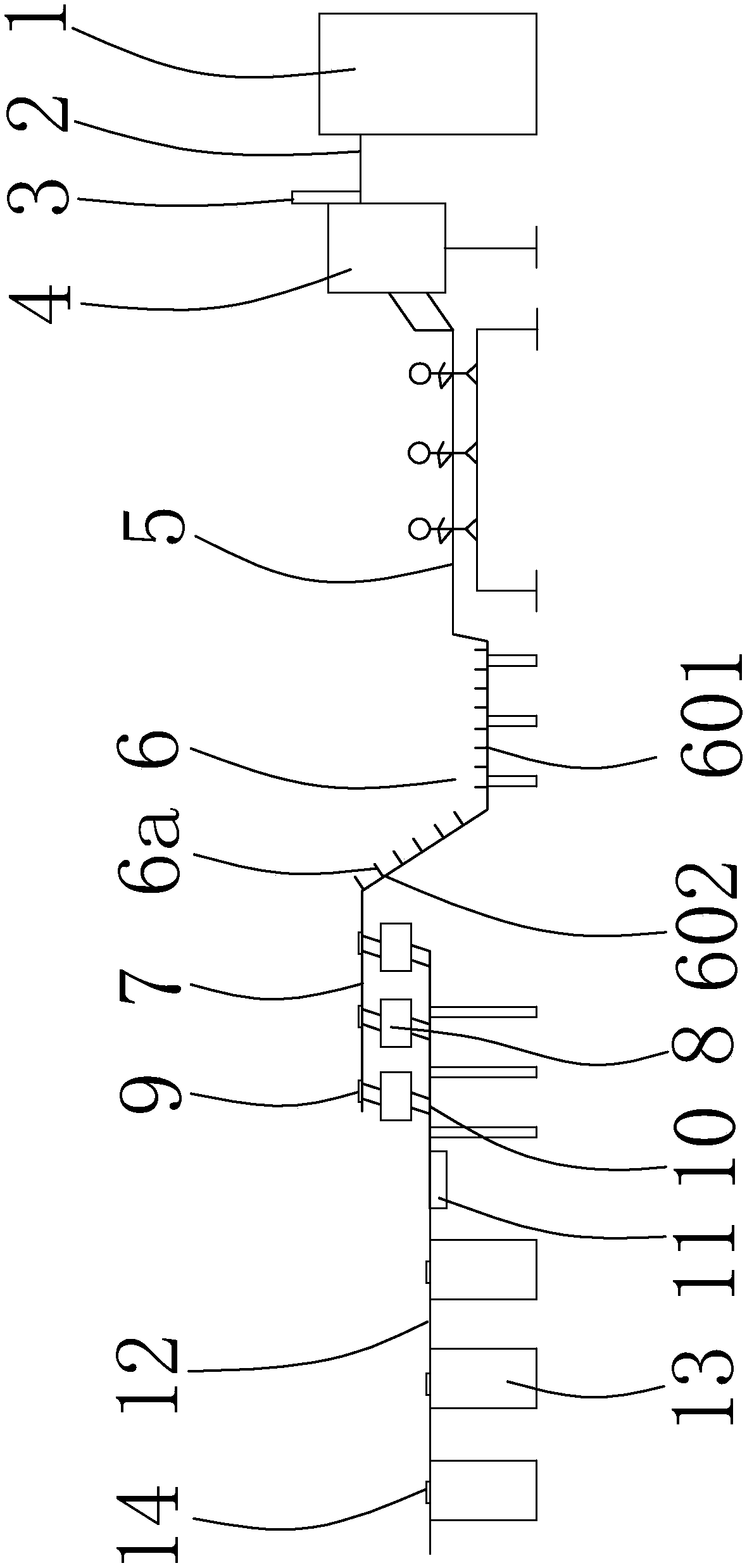

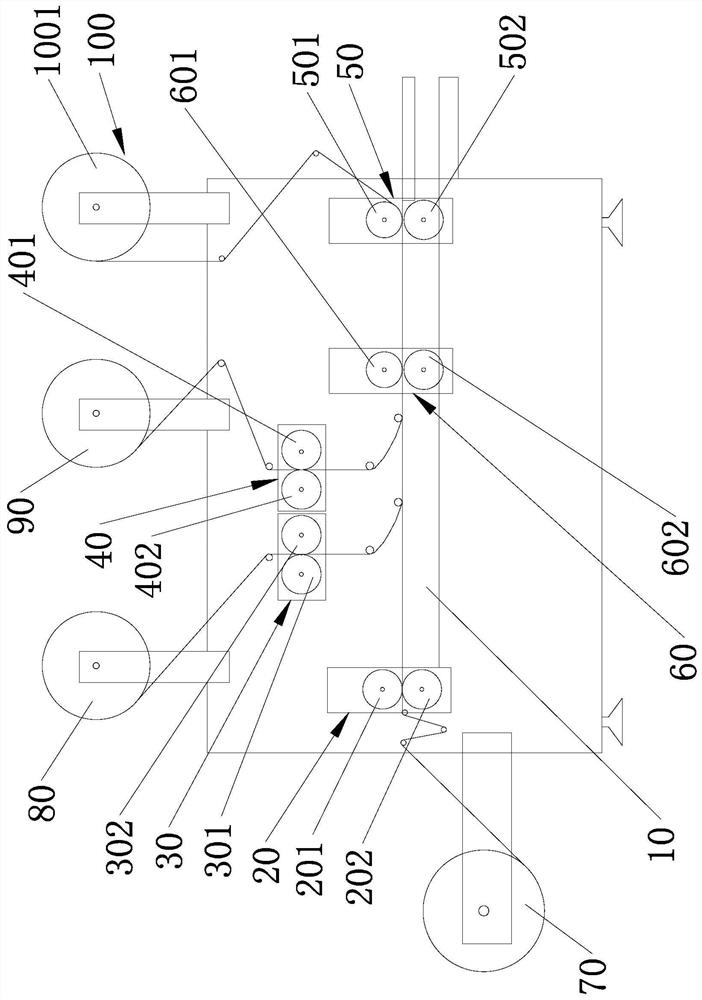

Front-end automatic treatment assembly line for fresh live fish

PendingCN107549278AGuaranteed freshReduce labor intensityFish washing/descalingControl engineeringConveyor belt

The invention relates to a front-end automatic treatment assembly line for fresh live fish. The front-end automatic treatment assembly line comprises a pre-storage device, a first conveyor belt, a first gate mechanism, a weight calculation device, a blood storage tank, a second conveyor belt and a third conveyor belt which are connected in sequence, wherein a plurality of scaling rollers are arranged beside the third conveyor belt; a second gate mechanism is arranged at a communicating part of each scaling roller and the third conveyor belt; a common fourth conveyor belt is arranged at the outlet of the plurality of scaling rollers; the tail end of the fourth conveyor belt is sequentially connected with a weighing machine and a fifth conveyor belt; a plurality of containers are arranged beside the fifth conveyor belt; and a third gate mechanism is arranged at a communicating part of each container and the fifth conveyor belt. According to the front-end automatic treatment assembly linefor fresh live fish disclosed by the invention, the front-end automatic treatment of killing fishes, removing scales and weight classification can be completed on a large scale, the steps are coherent, the labor intensity of operators is reduced, the operating efficiency is improved, and fish products are kept fresh; and moreover, the front-end automatic treatment assembly line disclosed by the invention is suitable for pretreatment of various fishes, and the operating range is wide.

Owner:SHENZHEN ALLIED AQUATIC PROD DEV LTD +1

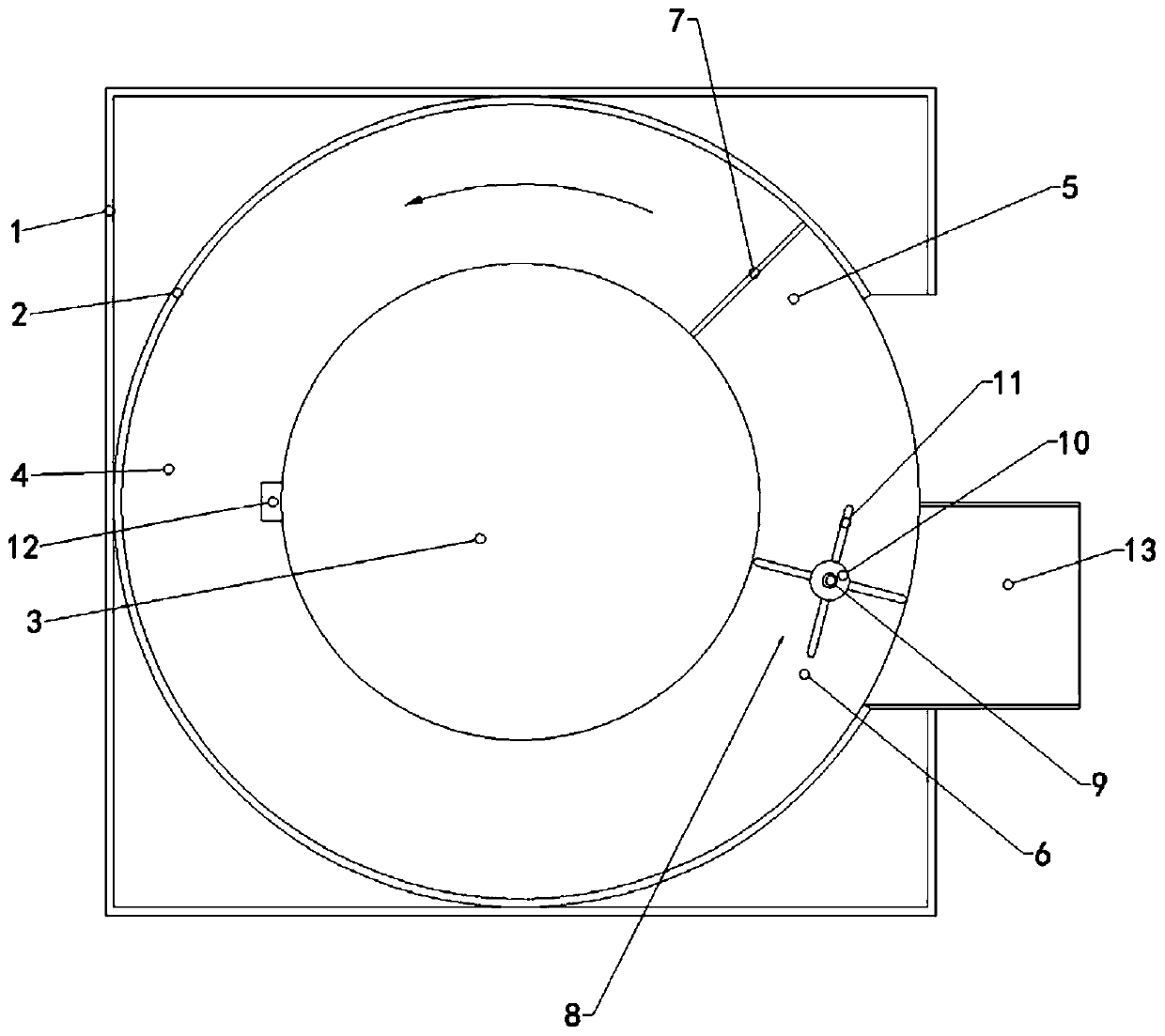

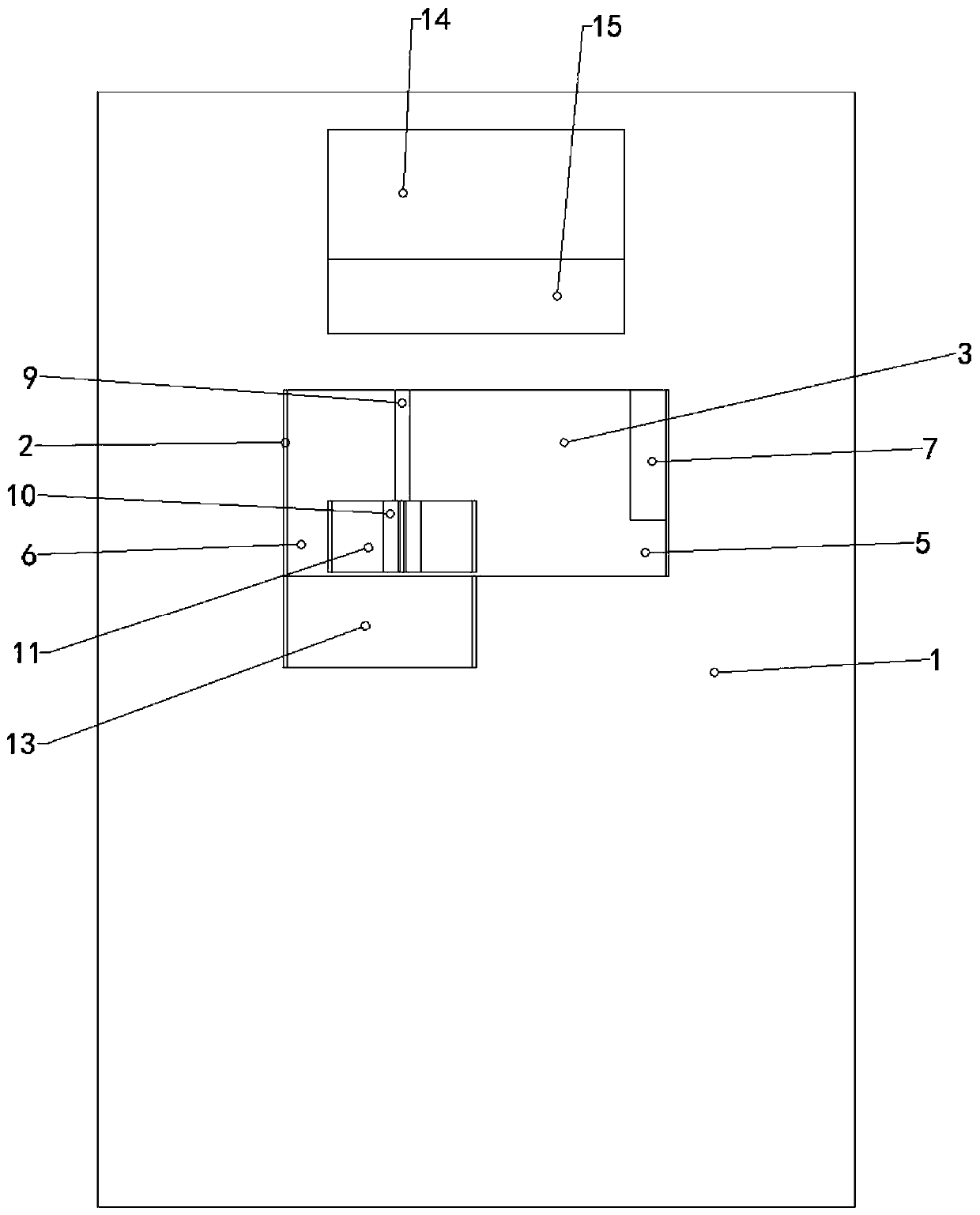

Automatic bolt conveying device for high-altitude construction operation machine

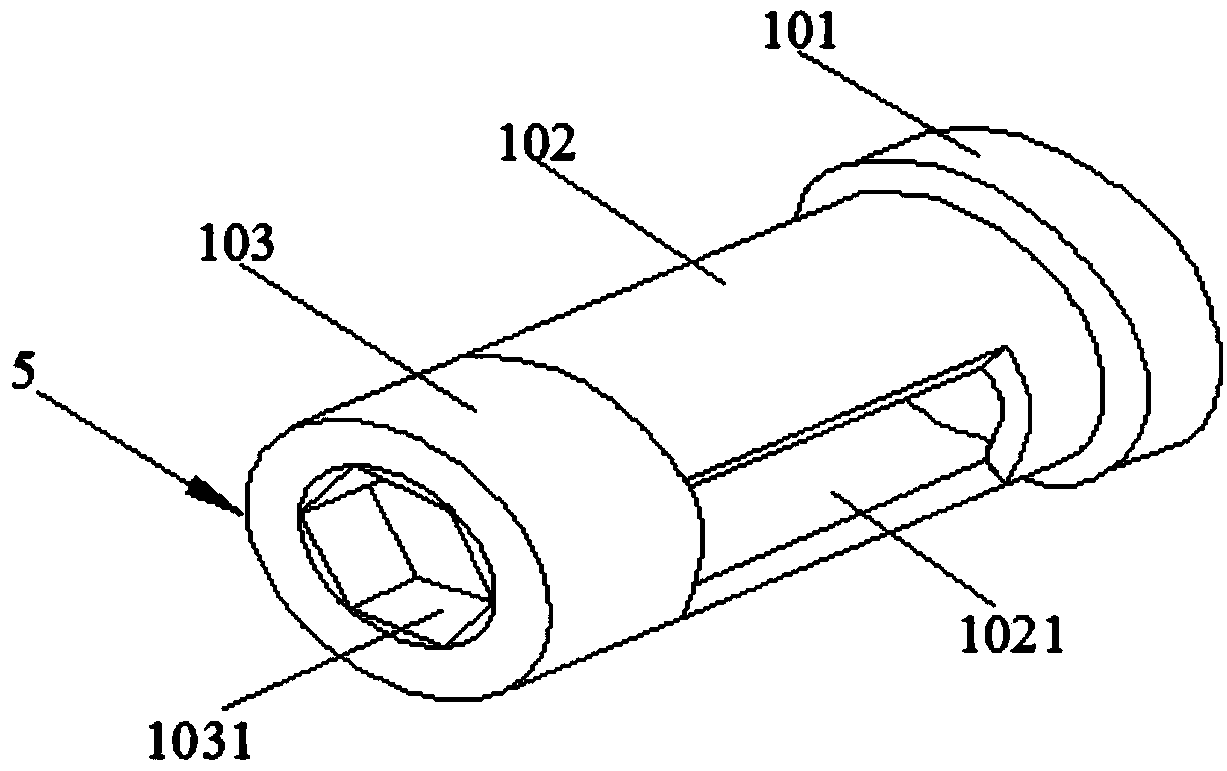

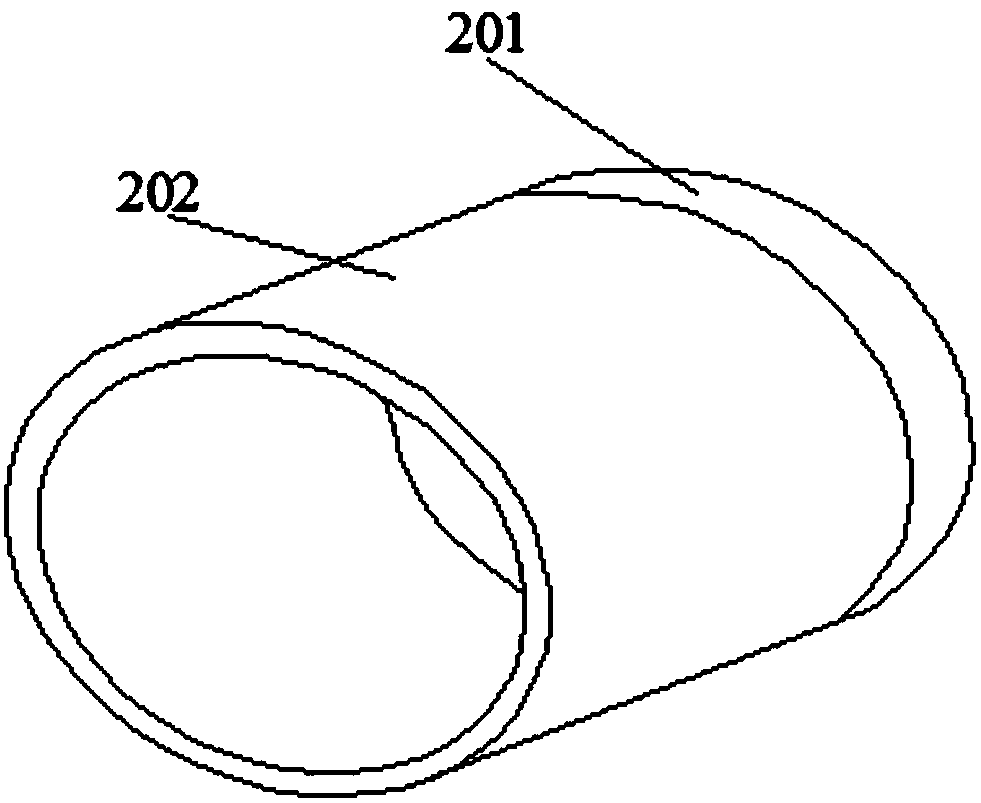

ActiveCN113460574ARealize mechanized transportationAchieve loadingConveyorsBuilding material handlingMaterial resourcesMachine

The invention provides an automatic bolt conveying device for a high-altitude construction operation machine, the automatic bolt conveying device comprises a support, a track drum rotatably connected to the support and a driving mechanism arranged on the support, the track drum is sleeved with a bolt conveying track, and the driving mechanism drives the track drum to drive a bolt conveying belt to rotate. Bolts are conveyed through the bolt conveying track, and automatic conveying of the bolts is achieved. The bolts are unloaded through a push-out mechanism, the unloaded bolts are obtained through a socket spanner, so that automatic conveying of the bolts can be achieved, consumption of manpower and material resources is reduced, the defect that the operation machine moves back and forth in the air and needs to be manually filled with the bolts is overcome, and the construction period is shortened.

Owner:CHINA CONSTR SENVENTH ENG BUREAU INSTALLATION ENG

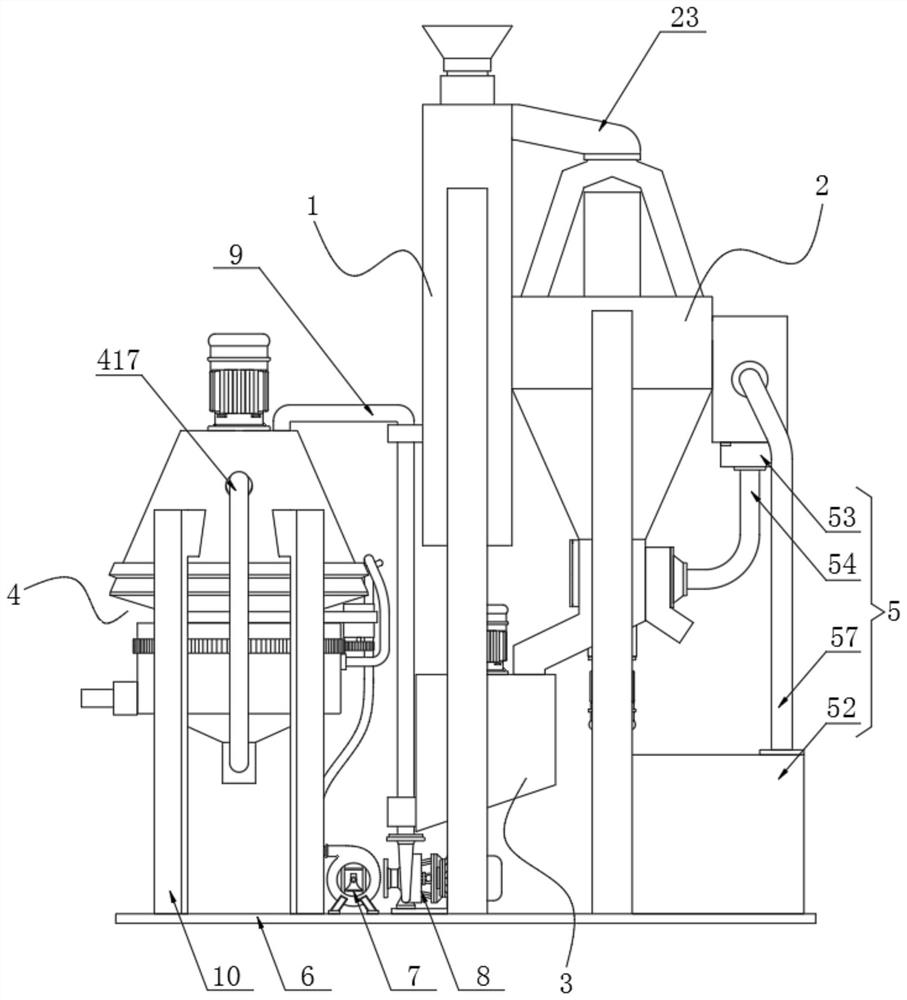

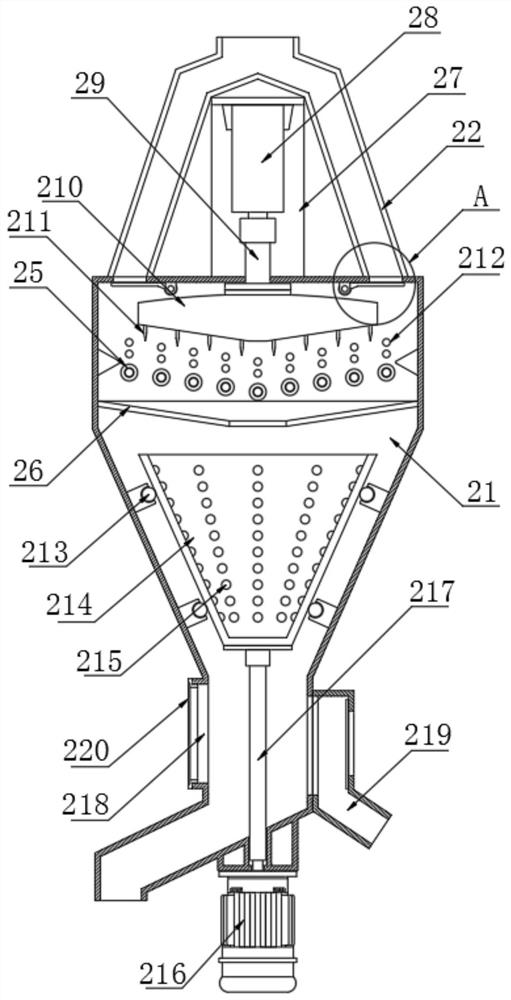

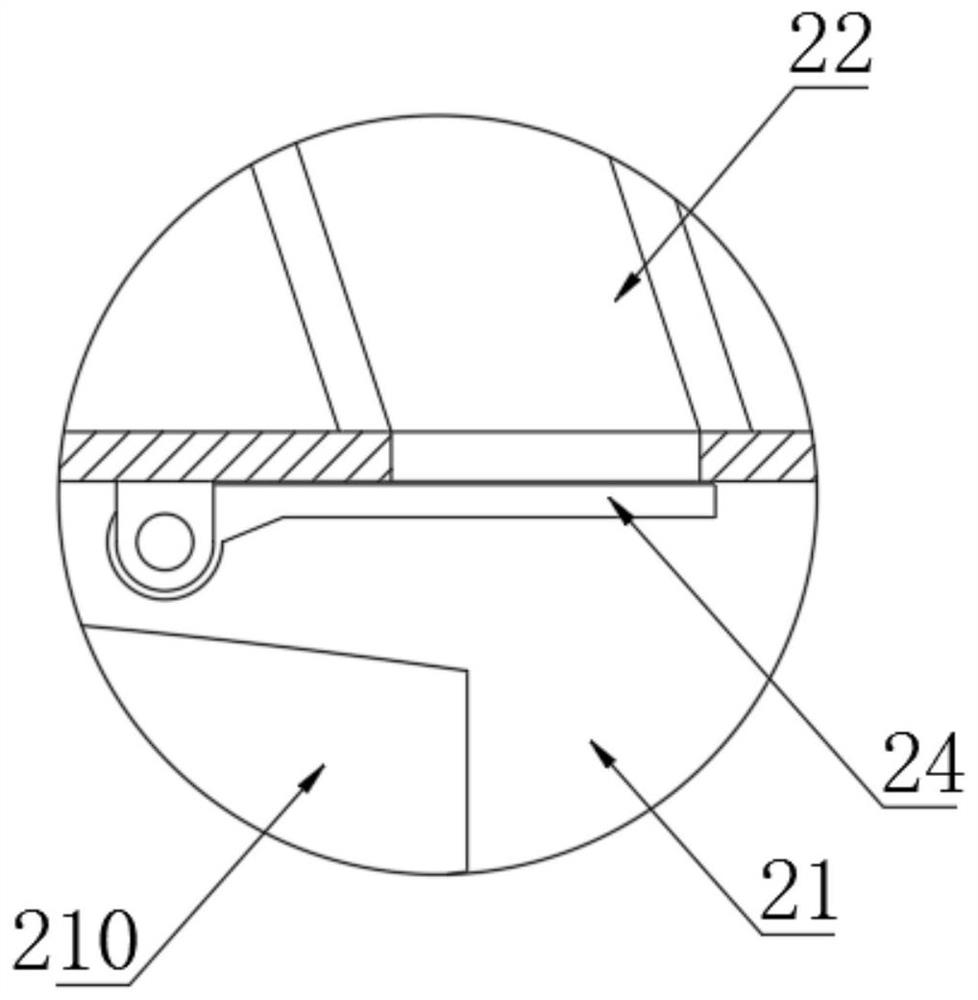

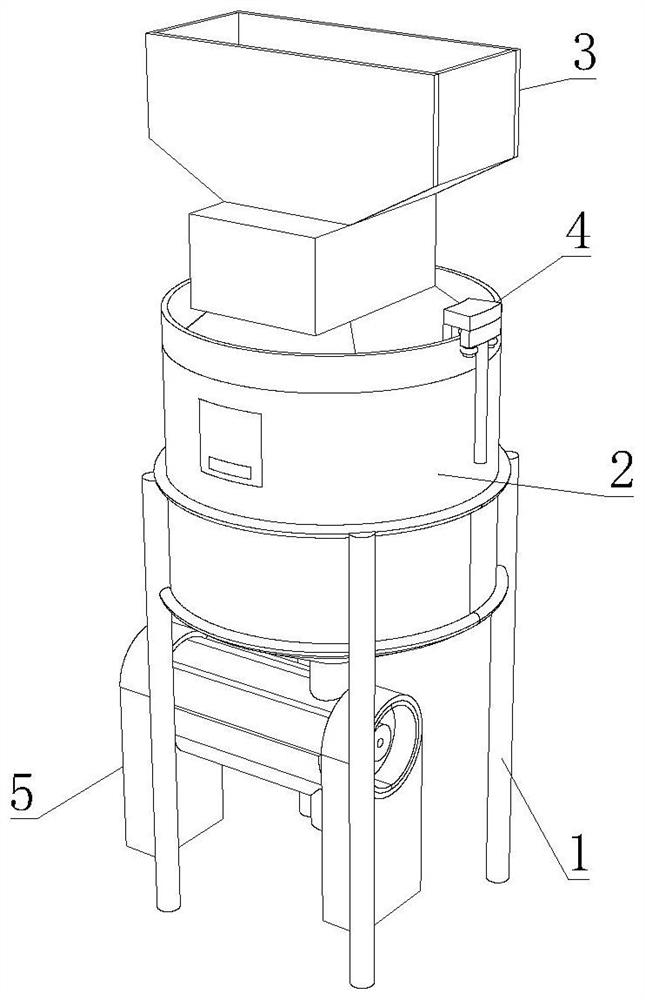

High-utilization-rate chestnut juice production system

The invention discloses a high-utilization-rate chestnut juice production system. The system comprises a heating mechanism, a cooling separation mechanism, a grinding mechanism, a centrifugal separation mechanism, a condensation mechanism and a base, and the heating mechanism, the cooling separation mechanism, the grinding mechanism and the centrifugal separation mechanism are fixedly connected tothe top of the base through a rack. The invention relates to the technical field of food production. According to the high-utilization-rate chestnut juice production system, a rotating pipe is arranged to block heated Chinese chestnuts, and then a rear side cold air inlet is used for directly blowing cold air for rapid cooling, so that chestnut shells burst. A lifting cylinder is used for pressing a blade downwards to cut off the Chinese chestnuts. By utilizing a subsequent high-speed rotating separation cylinder and a silica gel convex block in the separation cylinder, the pulp-shell separation can be realized on the premise of keeping the chestnut pulp relatively complete, and the skins of the chestnuts can be removed, so that skin chippings and fluff are prevented from being mixed in the later grinding and filtering process, the product quality is ensured, the overall steps are coherent, continuous processing can be realized, and the processing efficiency is high.

Owner:赵连计

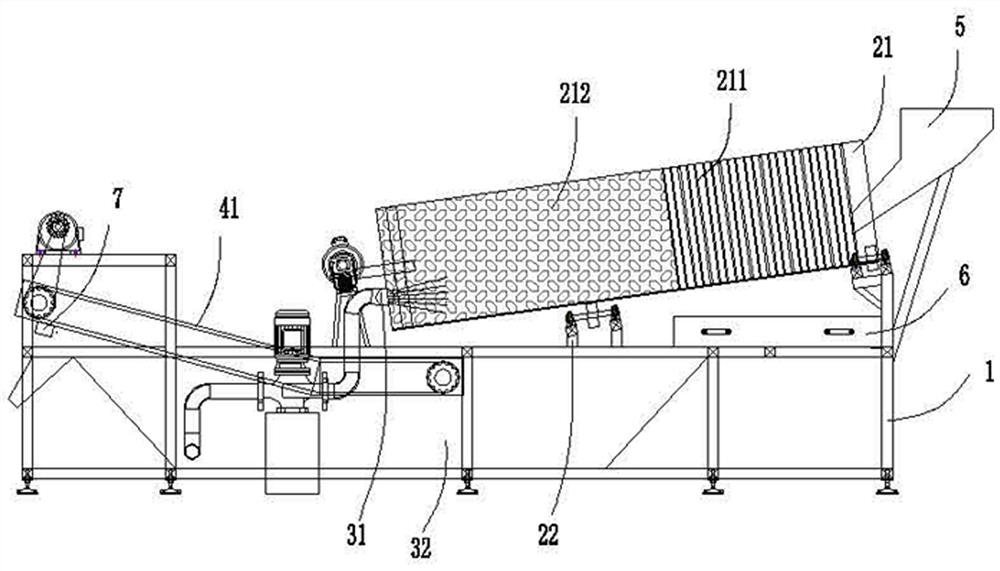

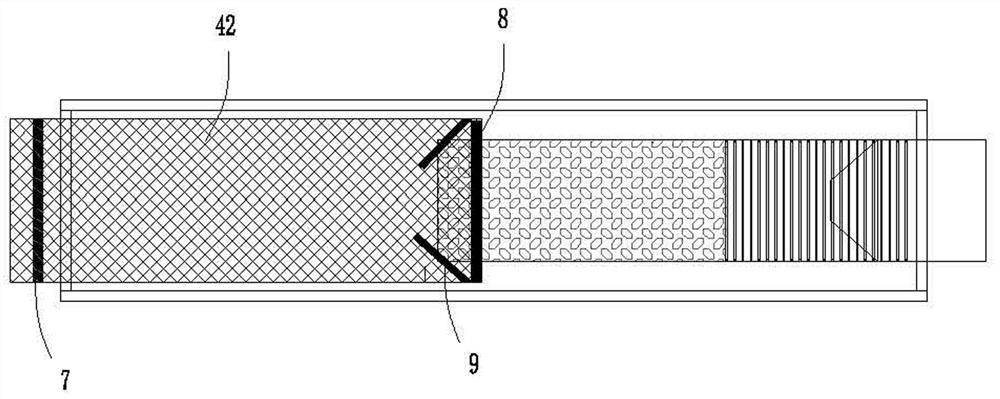

Cleaning machine

The invention relates to the technical field of material cleaning and discloses a cleaning machine. The cleaning machine comprises a machine frame, a rotary drum device, a water supply device and a conveying device, wherein the rotary drum device, the water supply device and the conveying device are arranged on the machine frame; and the rotary drum device comprises a rotary drum for receiving and cleaning materials and a rotating mechanism for driving the rotary drum to rotate, screen openings are distributed in the rotary drum, the water supply device comprises a sprayer arranged at a material outlet end of the rotary drum, the conveying device comprises a conveying chain for conveying materials falling from the outlet end of the rotary drum from the machine frame, and a head end of the conveying chain is arranged below the rotary drum. According to the cleaning machine, overall steps, i.e., charging, incoming-material broken slag filtering, flushing and conveying-from-the-machine-frame are cohesive and can be completed fully automatically, and the efficiency of cleaning is high; and the rotary drum is designed with screen openings of two kinds of different forms, an incoming material is firstly subjected to slag filtering by annular screen openings and then is subjected to water flushing at independent screen openings, and thus, the cleaning effect can be guaranteed relatively greatly.

Owner:HUNAN DASANXIANG TEA OIL CO LTD

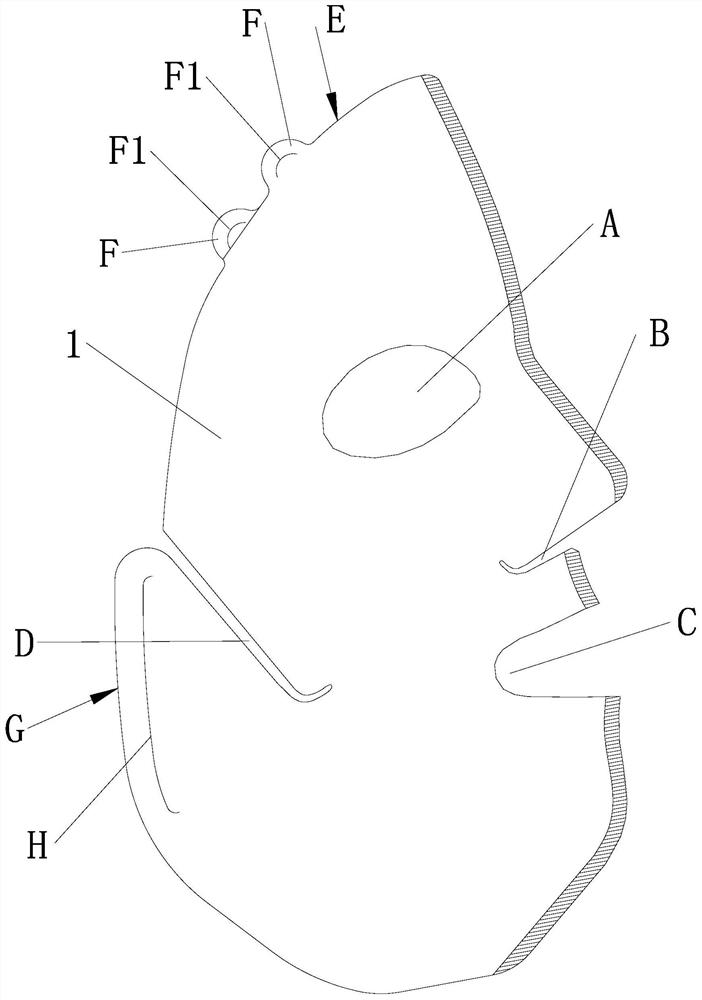

Ear hanging type three-dimensional mask sheet as well as production equipment and manufacturing method thereof

PendingCN112826749AEasy to useReasonable structureCosmetic preparationsToilet preparationsUltrasonic weldingEngineering

An ear-hanging type three-dimensional facial mask sheet comprises an upper facial mask cloth layer and a lower facial mask cloth layer which correspond to the contours of the two sides of the human face and the lower jaw, and a middle PP film bonding layer which is clamped between the upper facial mask cloth layer and the lower facial mask cloth layer in the three-dimensional bending direction of the center line of the human face and used for ultrasonic welding. The upper layer mask cloth and the lower layer mask cloth are respectively provided with eye holes, nose end kerfs which are obliquely cut along the end surfaces of the nose holes, lip exposure notches and ear line upper edge kerfs which are downwards inclined; the upper facial mask cloth layer and the lower facial mask cloth layer are provided with ear grip positions for conveniently opening the upper facial mask cloth layer and the lower facial mask cloth layer on the upper edge behind the mask above the kerfon the ear line; the ear grip positions of the upperfacial mask cloth layer and the lowerfacial mask cloth layer are mutually staggered; ear hanging notches are formed in the lower edges, close to the ear lines, behind the facial masks along the kerfs, of the upper facial mask cloth layer and the lower facial mask cloth layer. The three-dimensional facial mask sheet material is more convenient and more humanized to use, and the facial mask made of the three-dimensional facial mask sheet material can be more comprehensively attached to the face so as to achieve an all-around facial beautifying effect. The three-dimensional mask sheet production equipment adopts ultrasonic welding and is high in production efficiency.

Owner:爱丽姿(广东)日用品有限公司

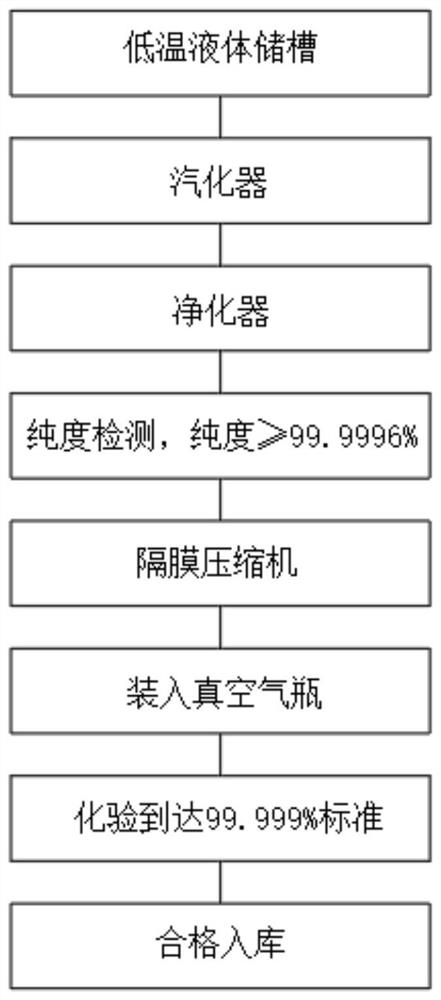

Low-energy-consumption preparation method for preparing argon and nitrogen gases

PendingCN113562708AAchieving Purity RequirementsMeet needsNitrogen purification/separationSemi-permeable membranesLiquid argonGas cylinder

The invention discloses a low-energy-consumption preparation method for preparing argon and nitrogen gases, which comprises the following steps: 1) feeding a liquid substance with the purity of 99.99% in a low-temperature liquid storage tank into a vaporizer for vaporizing, and purifying the vaporized gas in a purifier, wherein the liquid substance is one of liquid argon or liquid nitrogen; (2) enabling the gas treated by the purifier to pass through an impurity remover and then to be subjected to purity detection, after the purity detection is qualified, feeding the gas into a diaphragm compressor to be pressurized by 0mpa-15mpa, and filling the gas into a vacuum gas bottle, wherein a composite film is arranged in a shell of the impurity remover; and (3) carrying out qualification test on the gas filled in the vacuum gas bottle, and sending the qualified gas to a warehouse for storage. By adopting the method for producing the argon and nitrogen gases disclosed by the invention, the requirements of the market on the argon and nitrogen gases can be met, and the requirements on the purity of the argon and nitrogen gases can be met while the yield is ensured, so that the purity of the argon and nitrogen gases reaches 99.9996% or above.

Owner:云南安锋气体有限公司

A rapid forging and hot cutting production system and its working method

ActiveCN108262433BGuaranteed temperatureIncrease productivityForging/hammering/pressing machinesHandling devicesThermal insulationEngineering

Owner:JIANGSU BAOJIE FORGING

Apparatus for preparing ecological fertilizer using animal-bird feces

InactiveCN100447113CProcess matching is reasonableReasonable processBio-organic fraction processingClimate change adaptationSludgeAnimal feces

The invention relates to a device to make biology fertilizer from livestock dejection. It includes material intake, material outlet, gate valve, marsh gas control valve and jar. The main technology is that: the identity cavity is separated into anaerobic cavity and aerobic cavity, the outlet pipe end of returning pump extending into anaerobic cavity and connecting to gas nozzle, the output end of sludge pump extending into identity anaerobic cavity and connecting to spray pipe, top part of identity aerobic cavity is set light-passing board, and the output end of burst device connects to burst pipe of aerobic pipe. The invention has the advantages of high intention, super thin, electric energy saving, low running cost, and could effectively improve producing efficiency and quality of biology fertilizer.

Owner:辽宁中田干燥设备制造有限公司

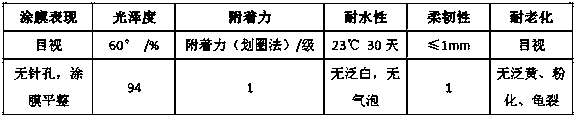

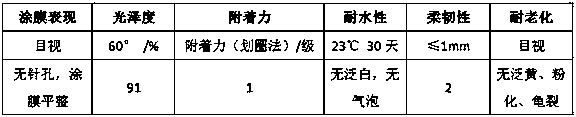

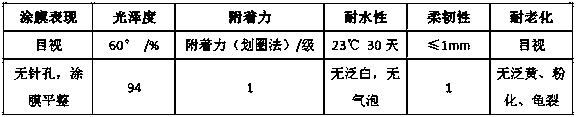

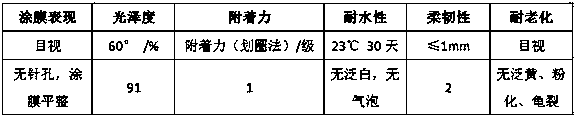

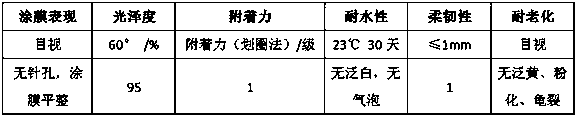

Preparation method of water-soluble acrylic resin for reflection film

The invention discloses a preparation method of water-soluble acrylic resin for a reflection film. The water-soluble acrylic resin is prepared from the following raw materials in parts by weight: methyl methacrylate, ethyl acrylate, lauryl methacrylate, hydroxyethyl methylacrylate, acrylic acid, 1-ethyoxyl-2 propyl alcohol, dimethylethanolamine, deionized water and benzoperoxide through the following preparation steps of preparing a mixed solution A, feeding the mixed solution A into a reaction container to react, performing stirring, and continuously inputting nitrogen gas; stopping the nitrogen gas input, and raising and maintaining the temperature; preparing and dripping a mixed solution B, and after the dripping completion, maintaining the temperature; preparing and dripping a mixed solution C, and after the dripping completion, maintaining the temperature; preparing a mixed solution D, performing high-speed stirring dispersion, turning off a machine, and pouring out the materialsto obtain the transparent water-soluble acrylic resin for the reflection film. The water-soluble acrylic resin obtained by the invention has the advantages of good water resistance, intensity and elongation balance; and when the water-soluble acrylic resin is applied to the reflection film production, a reverse adhesion phenomenon and sudden and violent bubbling cannot easily occur in the coating,so that the appearance is full and flat.

Owner:浙江龙游道明光学有限公司

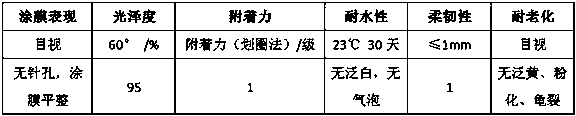

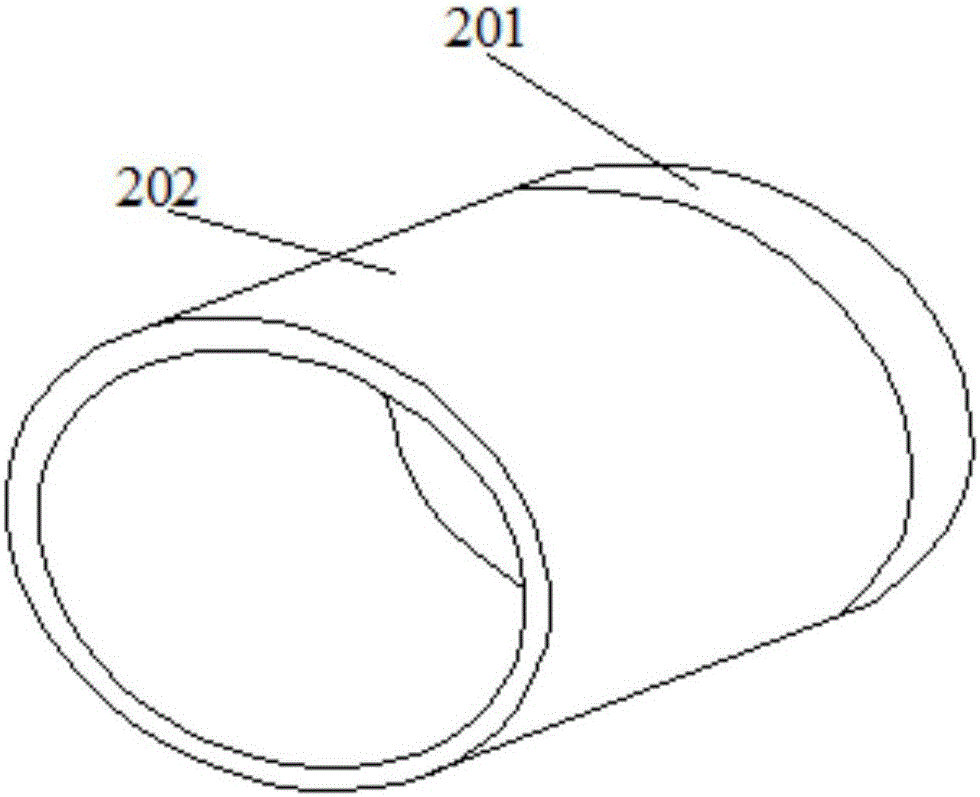

Organic fertilizer drying equipment

InactiveCN103411411AImprove securitySimple structureDrying solid materialsDrying machinesOrganic manureEngineering

The invention discloses organic fertilizer drying equipment. The organic fertilizer drying equipment comprises a barrel and is characterized in that a material inlet is formed in one side of the top of the barrel, a material outlet is formed in one side of the bottom of the barrel, a conveying pipeline is arranged inside the barrel, and inclines downwards from the material inlet side to the material outlet side, the top of the conveying pipeline is connected with the material inlet, the bottom of the conveying pipeline is connected with the material outlet, an upper conveying pipeline partition plate is arranged on the upper side of the conveying pipeline, a lower conveying pipeline partition plate is arranged on the lower side of the conveying pipeline, draught fans are arranged at the bottom inside the barrel, and steam outlets are formed in the top of the barrel. The organic fertilizer drying equipment has the advantages that the whole structure is simple, the steps are continuous, the manpower is not needed, the mechanical safety is greatly improved, the drying efficiency is high, and the structure is simple.

Owner:庄丽强

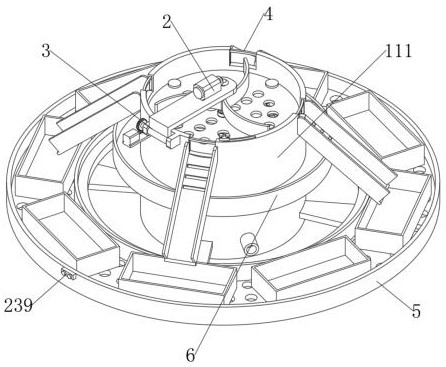

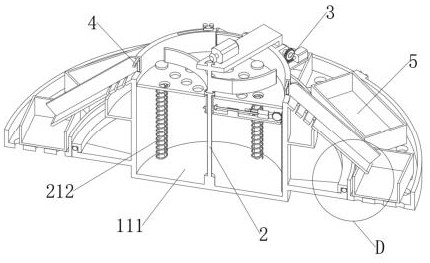

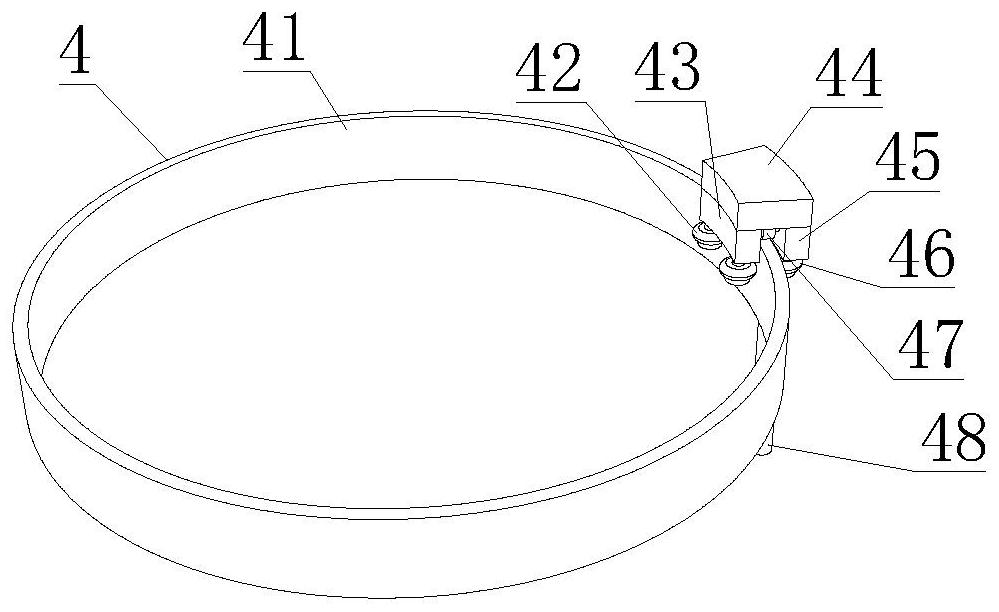

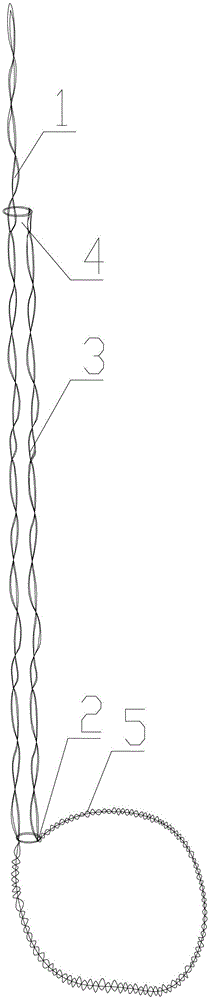

A kind of multifunctional climbing device for distribution network of power supply company and its assembling method and using method

ActiveCN112274878BImprove versatilityLarge clamping rangeClimbingControl engineeringDistribution networks

Owner:STATE GRID SHANDONG ELECTRIC POWER CO BOXING POWER SUPPLY CO

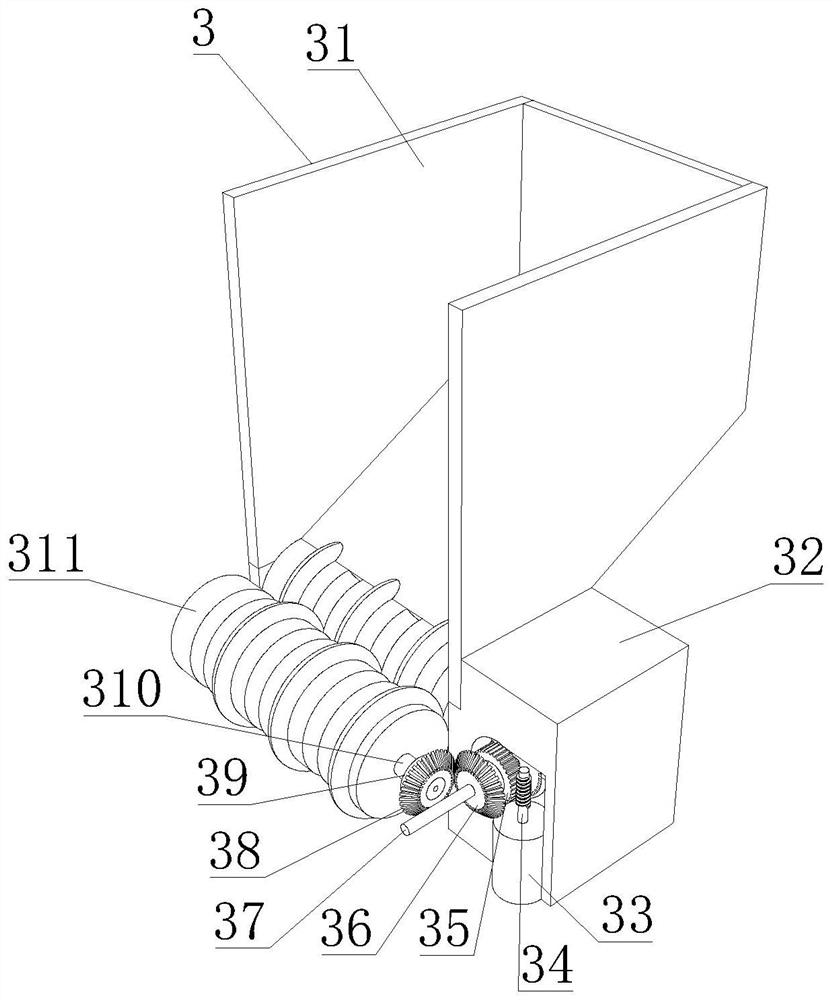

Plant extract extraction equipment based on cosmetic production

PendingCN114832430AGrind fullyHigh extraction conversion rateEnergy based chemical/physical/physico-chemical processesSolid solvent extractionPlant fibreAgricultural engineering

The invention discloses plant extract extraction equipment based on cosmetic production, and relates to the technical field of plant extract extraction.The plant extract extraction equipment comprises a supporting frame, an extraction tank is fixedly connected to the inner side of the supporting frame, and an ultrasonic extraction mechanism is fixedly connected to the upper side of the extraction tank; the ultrasonic extraction mechanism comprises an ultrasonic generator and a rolling mechanism, the upper side of the extraction tank is fixedly connected with a grinding mechanism, the grinding mechanism comprises a grinding wheel, and the lower side of the extraction tank is fixedly connected with a filtering mechanism. According to the plant raw material grinding device, small sections of plant raw materials are placed in the feeding bin, the first servo motor is started to work to drive the lead screw to rotate, the grinding wheels rotate after a series of transmission, the grinding wheels on the two sides rotate in a coupled mode, the plant raw materials are ground, and the problems that plant fibers are too large, and the effective conversion rate is low are solved; the method solves the problem that a part of target substances exist in the residues, and achieves the effects of fully grinding the plant raw materials and improving the extraction conversion rate.

Owner:连六胜

A high-efficiency coring method for portable drilling rigs in intact hard rock

ActiveCN103306623BDamage Fracture RealizationStrong targetingConstructionsCore removalRock coreEngineering

The invention relates to a high efficiency coring method for a portable drilling machine in an integral hard rock. The invention solves the technical difficult problems of high wear speed of a drilling tool and low coring rate which are caused by the case that when the portable drilling machine drills in the hard rock with high integrity, the root of a rock core is usually difficult to cut off or is difficult to successfully take out after being cut off. The invention adopts the scheme that the high efficiency coring method comprises the following steps: a, on a superficial layer of the earth surface, where a rock core to be taken is positioned, drilling a blind hole by the drilling machine and clearing away the broken rock core in the blind hole; b, lengthening a drill rod on the drilling machine in the step a and continuously drilling towards the lower layer on the basis of the blind hole; c, lifting up the drilling machine in the step b to form a gap between the inner wall of a hollow drill bit and the rock core; d, filling a filler in the gap in the step c; e, starting the drilling machine to enable the root of the rock core to be broken, shutting down the drilling machine and taking out the drill rod and the hollow drill bit; f, placing in-hole positioning imaging equipment into the blind hole to carry out positioning and recording on a damaged and cracked position of the rock core in the blind hole; g, taking out the in-hole positioning imaging equipment in the blind hole; h, placing deep hole rock core extracting equipment into the blind hole and taking out a rock core sample.

Owner:NANJING UNIV

A kind of preparation method of reflective film water-soluble acrylic resin

The invention discloses a preparation method of water-soluble acrylic resin for a reflection film. The water-soluble acrylic resin is prepared from the following raw materials in parts by weight: methyl methacrylate, ethyl acrylate, lauryl methacrylate, hydroxyethyl methylacrylate, acrylic acid, 1-ethyoxyl-2 propyl alcohol, dimethylethanolamine, deionized water and benzoperoxide through the following preparation steps of preparing a mixed solution A, feeding the mixed solution A into a reaction container to react, performing stirring, and continuously inputting nitrogen gas; stopping the nitrogen gas input, and raising and maintaining the temperature; preparing and dripping a mixed solution B, and after the dripping completion, maintaining the temperature; preparing and dripping a mixed solution C, and after the dripping completion, maintaining the temperature; preparing a mixed solution D, performing high-speed stirring dispersion, turning off a machine, and pouring out the materialsto obtain the transparent water-soluble acrylic resin for the reflection film. The water-soluble acrylic resin obtained by the invention has the advantages of good water resistance, intensity and elongation balance; and when the water-soluble acrylic resin is applied to the reflection film production, a reverse adhesion phenomenon and sudden and violent bubbling cannot easily occur in the coating,so that the appearance is full and flat.

Owner:浙江龙游道明光学有限公司

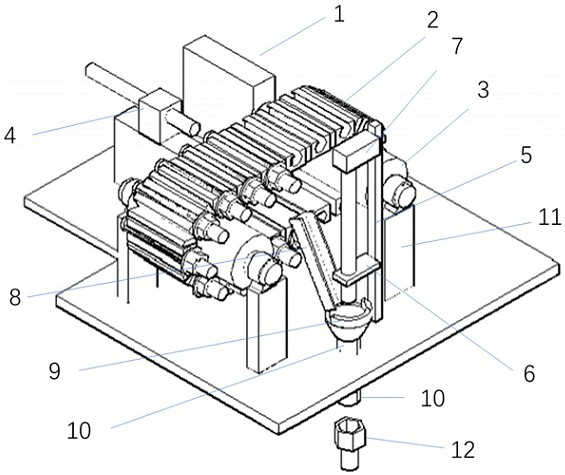

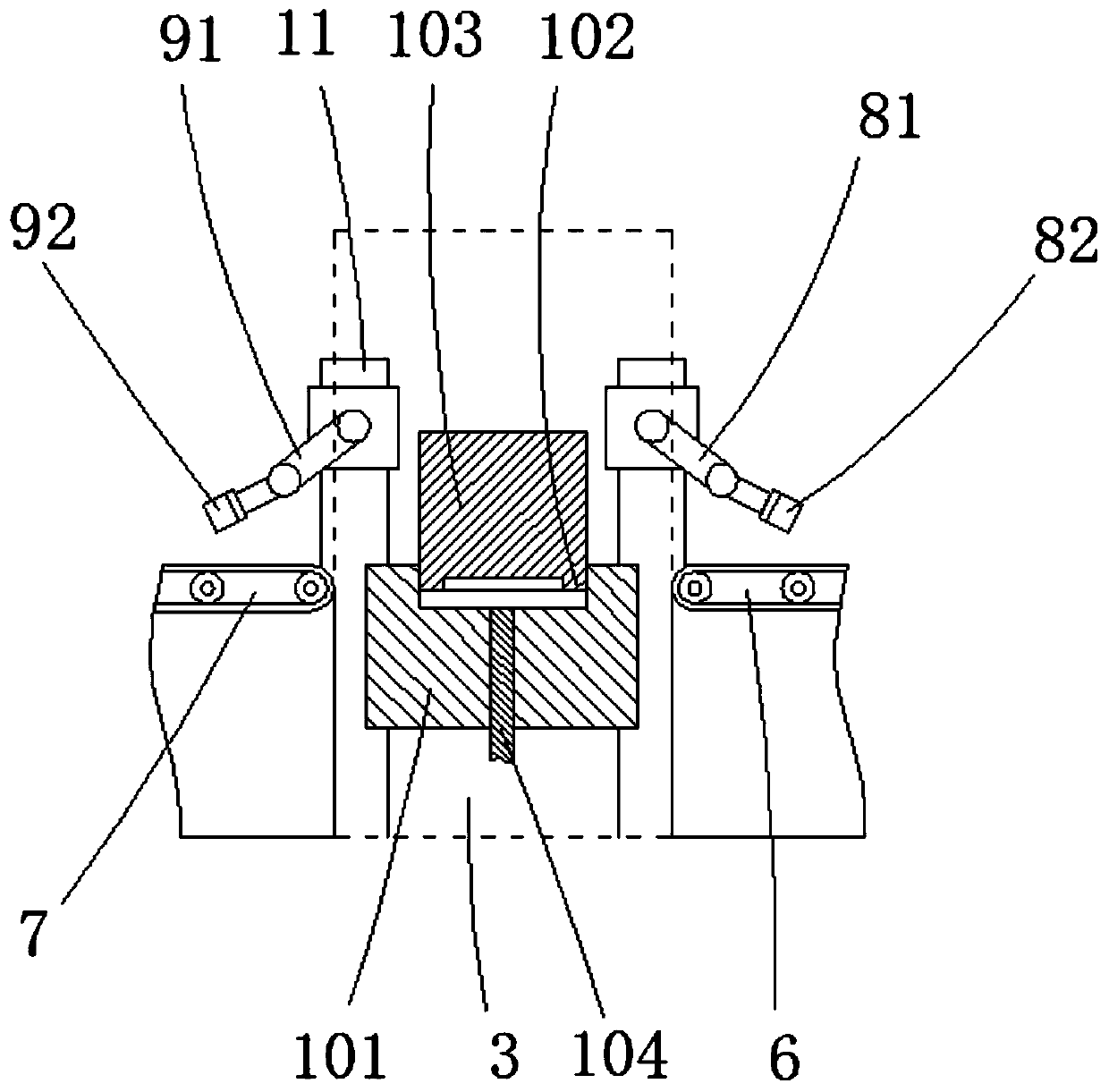

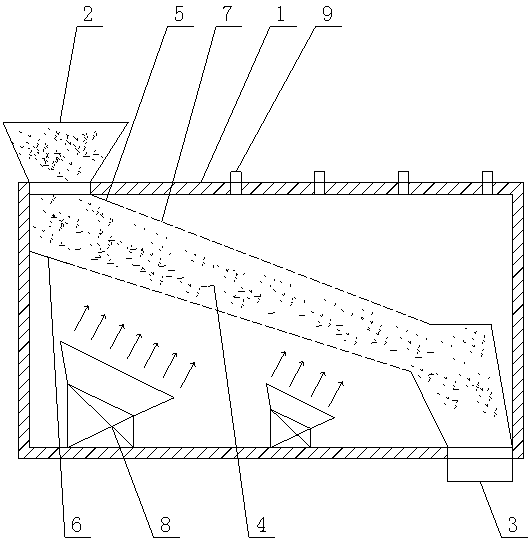

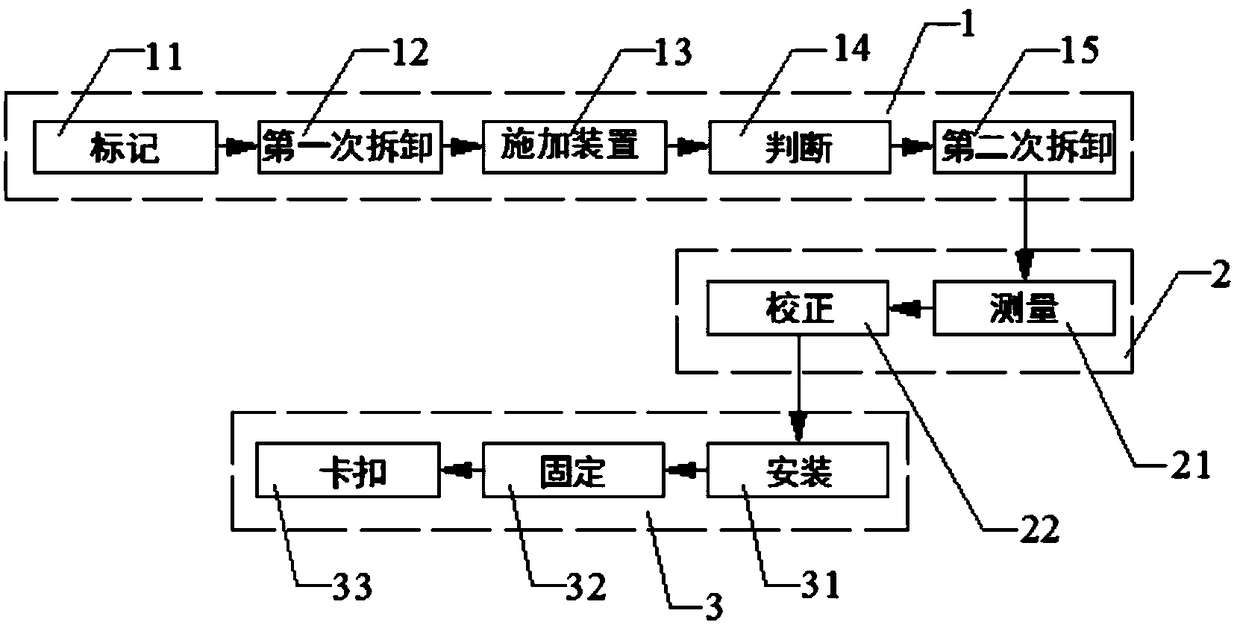

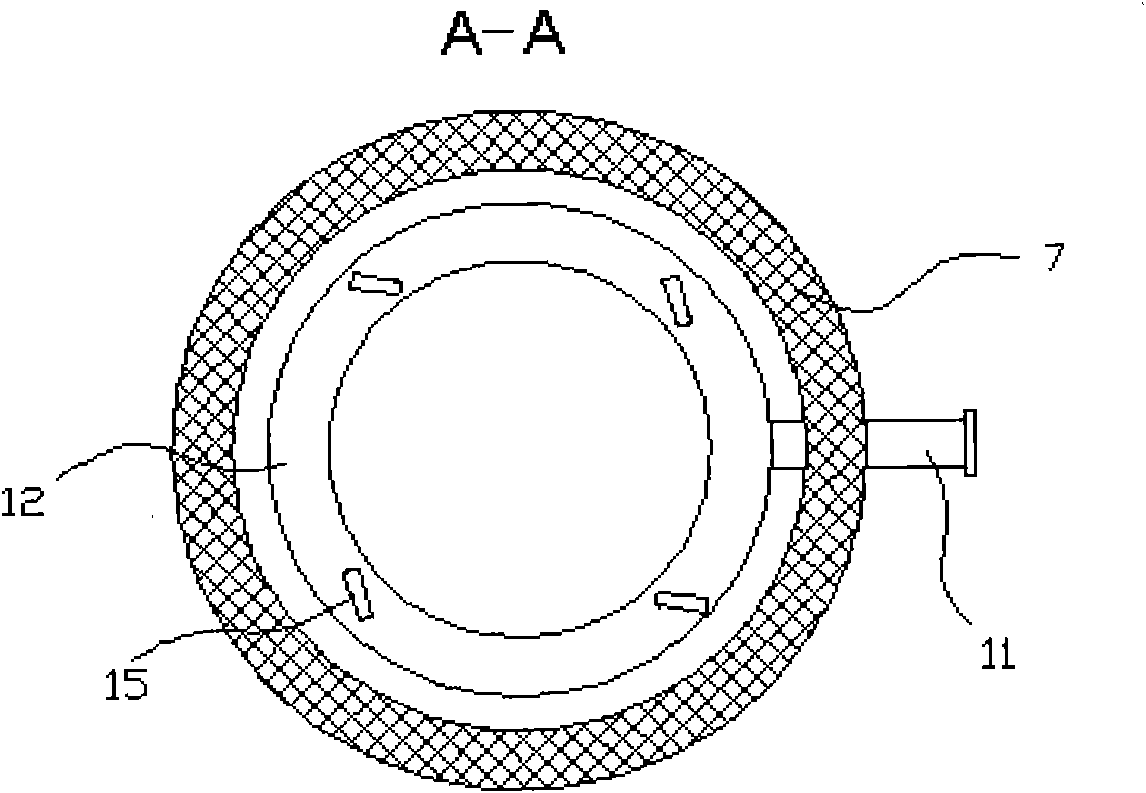

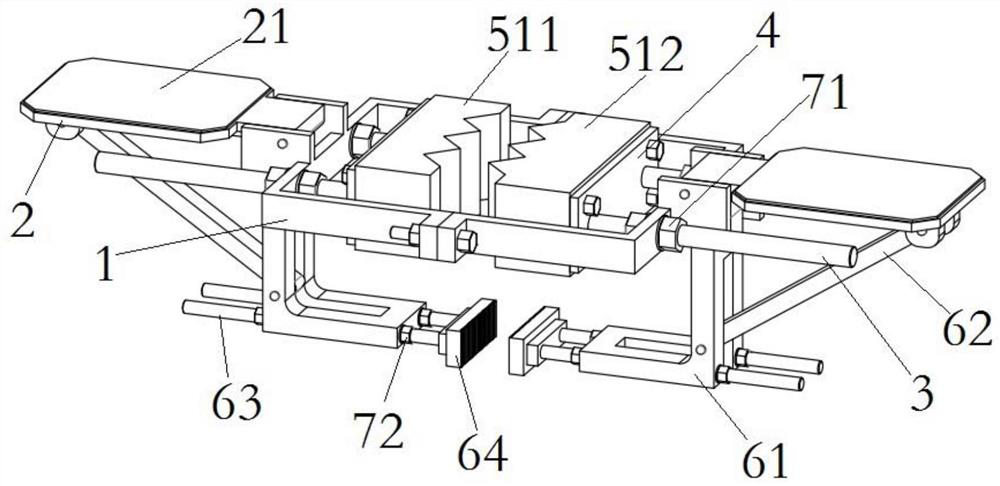

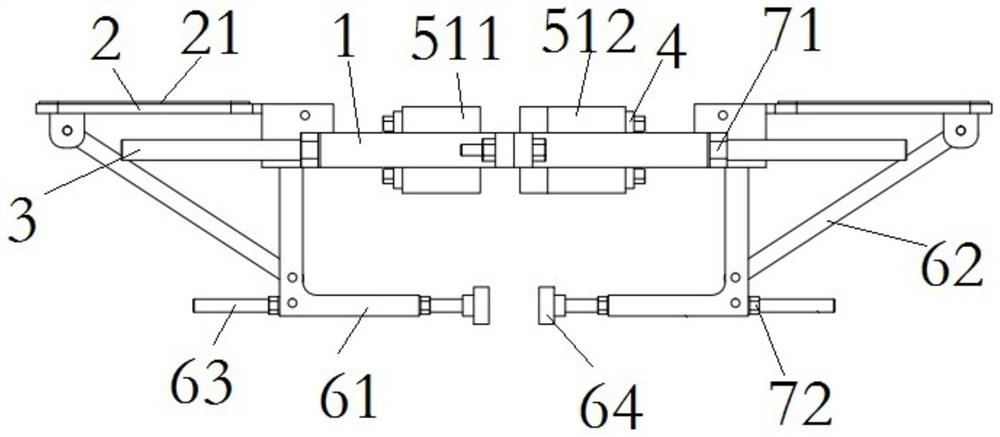

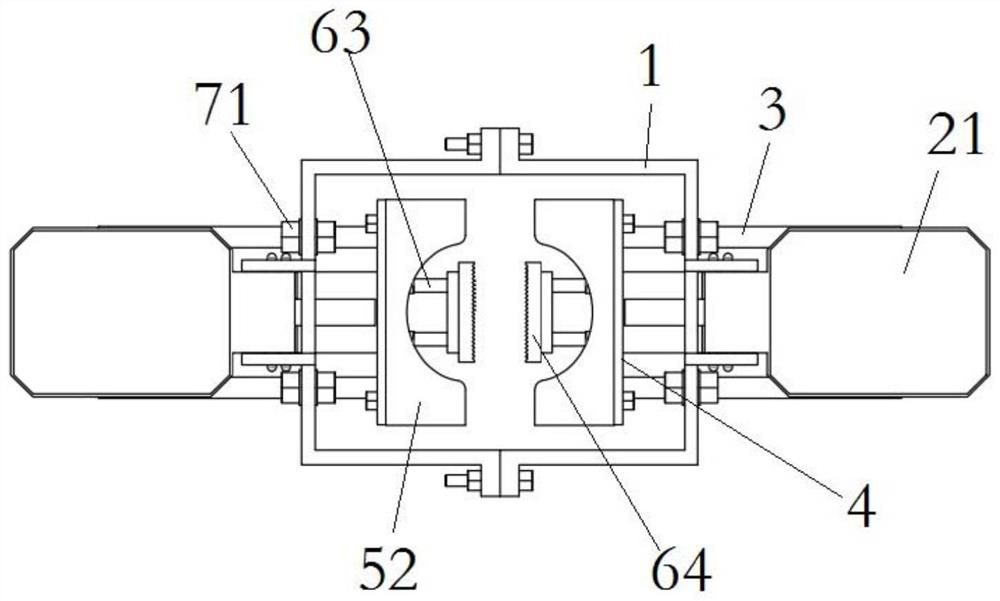

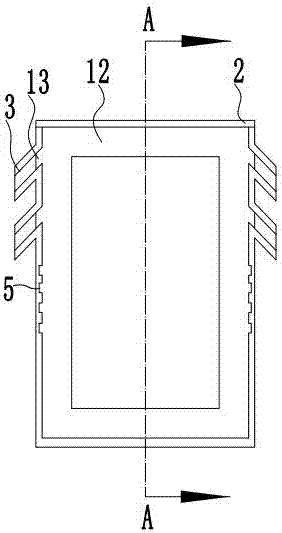

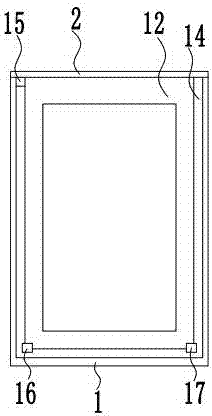

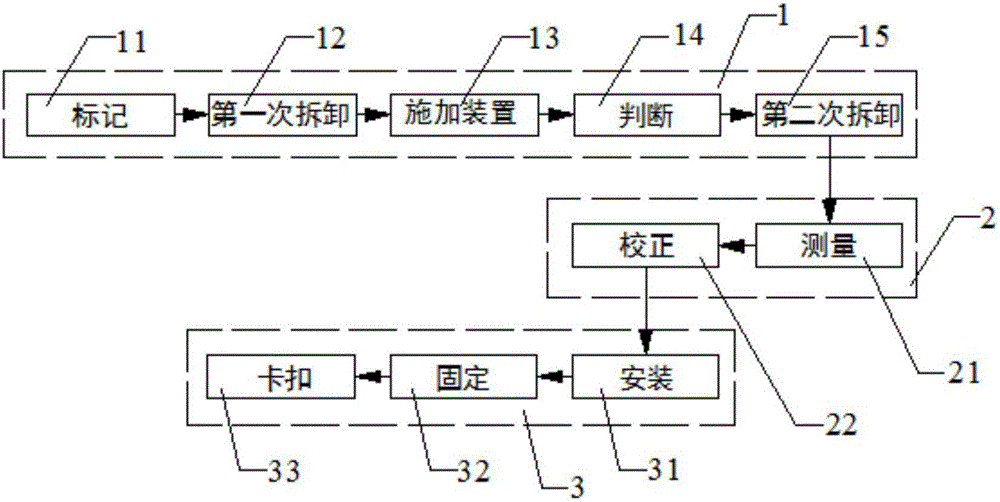

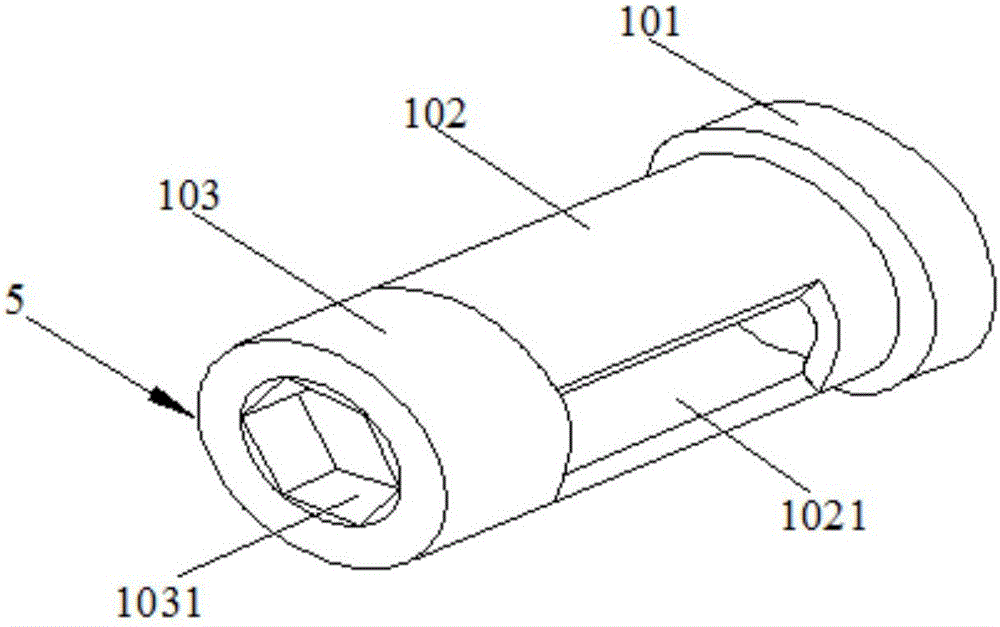

A method and device for replacing outer rotor motor bearings

ActiveCN105896835BAvoid deformationEasy to installManufacturing dynamo-electric machinesControl theoryWork time

The invention discloses a method and device for replacing an external rotor motor bearing. The method comprises steps of disassembly, detection and assembly, wherein the step of disassembly comprises steps of marking, first disassembly, device applying, judgment and secondary disassembly. By the method, the problems of easy damage of a part, time consumption and high cost during the replacement and adjustment processes of the motor bearing are solved. The method also comprises the step of replacing an end cover protection device during the replacement process, the problems of cable damage and end cover deformation during end cover disassembly are prevented, the motor bearing is rapidly replaced, the cable is prevented from being damaged by press, and the working time of the motor is prolonged; with the adoption of the device, the external rotor motor bearing part is more in contact, the bearing is difficult to damage and deform, and a guarantee is provided for easy replacement of the motor bearing.

Owner:HAINAN JINHAI PULP & PAPER

Biomass gasification method

ActiveCN101805638BImprove conversion utilizationControl gas compositionCombustible gas productionCombustionMass ratio

The invention discloses a biomass gasification method. The method requires the steps of drying pyrolysis, combustion deoxidization and gas reforming in the gasification process to be relatively separated and continuously carried out in the same gasification furnace, simultaneously continuously gasification agent is introduced at three points in the whole gasification process and finally the cleanhigh quality product gas is obtained. In the invention, the equivalence ratio of the total gasification agent is 0.2-0.35, and the mass ratio of a first gasification agent, a second gasification agent and a third gasification agent is (0-0.8):(2-3.5):(0.7-1.5). The method controls the temperature and the reaction depth of each subarea in the furnace by controlling the mutual ratio of the biomass materials, the first gasification agent, the second gasification agent and the third gasification agent so as to control the quality of the final product gas. The obtained product gas can be used as the energy or the chemical engineering synthesis raw material gas. The method can generate clean product gas from the biomass, cannot generate secondary pollution and has high carbon conversion rate and simple implementation method.

Owner:山东山科环境资源有限公司

A kind of seasoning Amaranth fruit jam and its production method

ActiveCN104323217BGood for healthCooling bloodFood ingredient functionsFood preparationBiotechnologyAvicennia marina

Owner:TONGLING RUIPU PEONY IND DEV

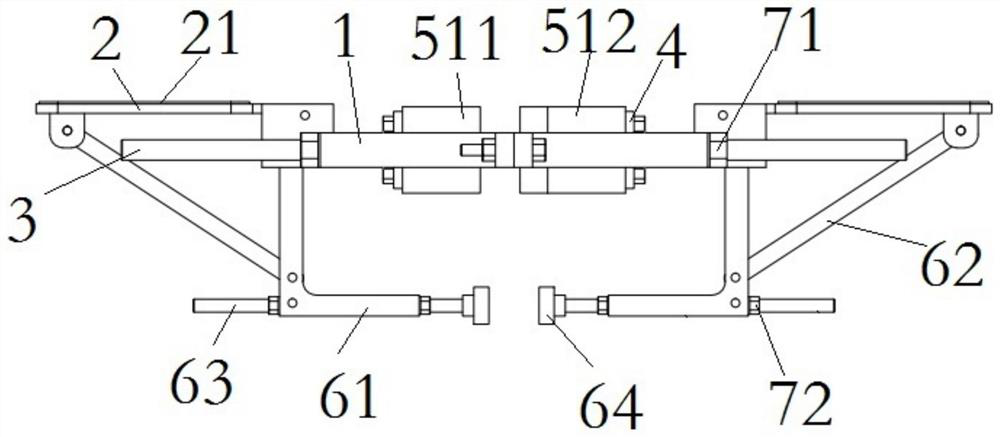

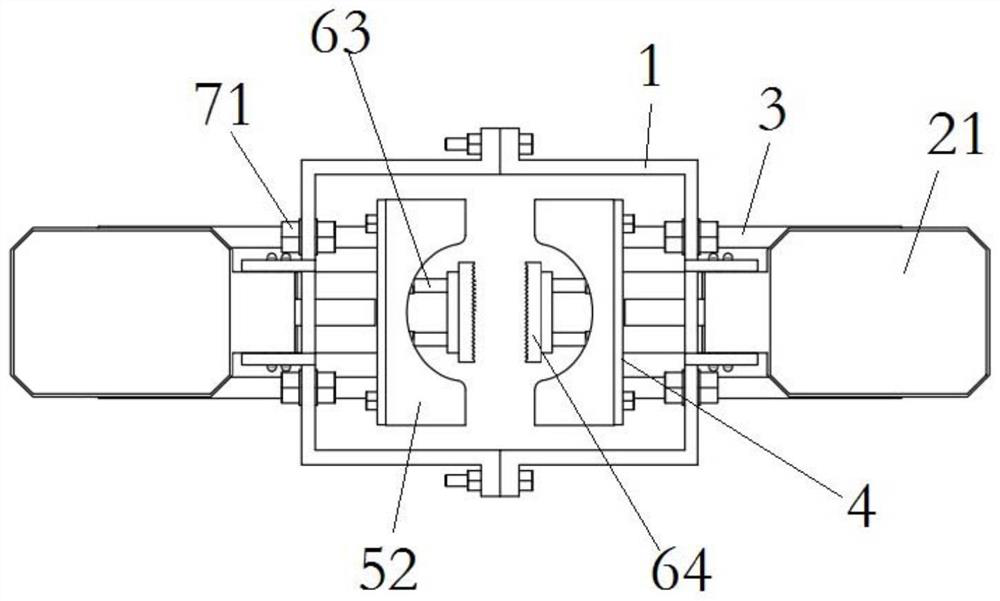

Multifunctional climbing device for distribution network of power supply company, and assembling method and using method thereof

ActiveCN112274878AImprove versatilityLarge clamping rangeClimbingIndustrial engineeringDistribution networks

The invention provides a multifunctional climbing device for a distribution network of a power supply company, and an assembling method and a using method thereof. According to the technical scheme, the multifunctional climbing device for the distribution network of the power supply company comprises two racks which are oppositely arranged and connected through bolts, detachable and replaceable clamping mechanisms are arranged on the racks, pedals connected through shafts are arranged at the tail ends of the racks, and auxiliary supporting mechanisms are arranged at the bottoms of the racks. The clamping mechanism can be disassembled, assembled and replaced so as to meet different working requirements, meanwhile, the supporting mechanism can share stress of the clamping mechanism so as toimprove the safety of the device, and meanwhile, the assembling method provided by the invention is simple and smooth in step, high in logicality and convenient to operate; and the using method is firm in clamping and convenient to adjust.

Owner:STATE GRID SHANDONG ELECTRIC POWER CO BOXING POWER SUPPLY CO

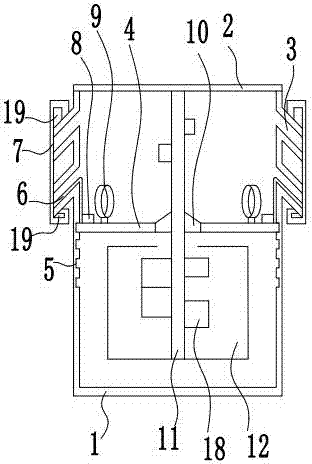

Automatic monitoring device for teaching

The invention discloses an automatic monitoring device for teaching. The automatic monitoring device comprises a motor arranged on a platform wall, a camera driven by the motor to rotate and a foot pad arranged on the platform surface; the motor is internally provided with a first microcontroller used for controlling the motor to rotate and a first bluetooth module connected with the first microcontroller; the foot pad comprises a plurality of air bags arranged at intervals and hydraulic bags containing clean water; a circuit board is arranged in a first ball bag and is provided with a touch switch, a second microcontroller storing the rotating angle and a second bluetooth module connected with the second microcontroller to be used for communication with the first bluetooth module, and thesecond microcontroller and the second bluetooth module are connected with the touch switch in series; the first ball bag is provided with an elastic block capable of pressing the touch switch; and all hydraulic bags communicate with each other, and one side of the foot mat is provided with a water outlet pipe communicating with the hydraulic bags. By means of the automatic monitoring device, orienteering rotation for monitoring can be achieved along with walking of a teacher.

Owner:重庆靖帛天域科技发展有限公司

Manufacturing method for quick-cooling computer case

ActiveCN107122018AEasy to insertEasy to installDigital processing power distributionElectricityCooling effect

The invention discloses a manufacturing method for a quick-cooling computer case. The method comprises the following steps of 1, welding a case body; 2, arranging baffles; 3, digging the case body; 4, arranging a circulating pipe; 5, arranging a condensing bag; 6, filling the condensing bag with a condensing liquid; 7, folding the condensing bag; 8, mounting a mainboard; 9, electrically connecting the baffles with the mainboard, and mounting fans, blowing air to the mainboard, on the baffles on two sides of the mainboard; and 10, casting a cover fastened to the top end of the case body through a metal plate, and fastening the cover to the top end of the case body, thereby finishing the manufacturing of the quick-cooling computer case. The quick-cooling computer case manufactured with the method is good in cooling effect.

Owner:江苏质数科技有限公司

Method and device for replacing external rotor motor bearing

ActiveCN105896835AAvoid deformationEasy to installManufacturing dynamo-electric machinesControl theoryWork time

The invention discloses a method and device for replacing an external rotor motor bearing. The method comprises steps of disassembly, detection and assembly, wherein the step of disassembly comprises steps of marking, first disassembly, device applying, judgment and secondary disassembly. By the method, the problems of easy damage of a part, time consumption and high cost during the replacement and adjustment processes of the motor bearing are solved. The method also comprises the step of replacing an end cover protection device during the replacement process, the problems of cable damage and end cover deformation during end cover disassembly are prevented, the motor bearing is rapidly replaced, the cable is prevented from being damaged by press, and the working time of the motor is prolonged; with the adoption of the device, the external rotor motor bearing part is more in contact, the bearing is difficult to damage and deform, and a guarantee is provided for easy replacement of the motor bearing.

Owner:HAINAN JINHAI PULP & PAPER

Fertilizer drying device with U-shaped conveying pipe for conveying

InactiveCN103411405AImprove securitySimple structureDrying machines with progressive movementsHeating arrangementEngineeringFertilizer

The invention discloses a fertilizer drying device with a U-shaped conveying pipe for conveying. The fertilizer drying device comprises a barrel body, the top of the barrel body is provided with a feed port, one side at the bottom of the barrel body is provided with a discharge port, a U-shaped conveying pipe is arranged in the barrel body, one end of the U-shaped conveying pipe is connected with the feed port, and the other end of the U-shaped conveying pipe is connected with the top of a discharge port pipeline, the bottom of the discharge port pipeline is connected with the discharge port, an induced draft fan is arranged between the discharge port pipeline and the U-shaped conveying pipe, the side at the bottom of the barrel body far away from the discharge port is provided with a heat source inlet, and the top of the barrel body is provided with a heat source outlet. The fertilizer drying device disclosed by the invention has the advantages of being simple in integral structure, coherent in steps, convenient for operation, low in investment and cost, high in drying efficiency, and convenient for promotion and use, and the security of the machine is greatly improved.

Owner:庄丽强

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com