Biomass gasification method

A biomass and gasification agent technology, applied in the field of biomass gasification, can solve the problems of difficulty in realization, low carbon conversion rate in the system, and high tar content, and achieves the improvement of biomass conversion utilization rate, prolongation of residence time, and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

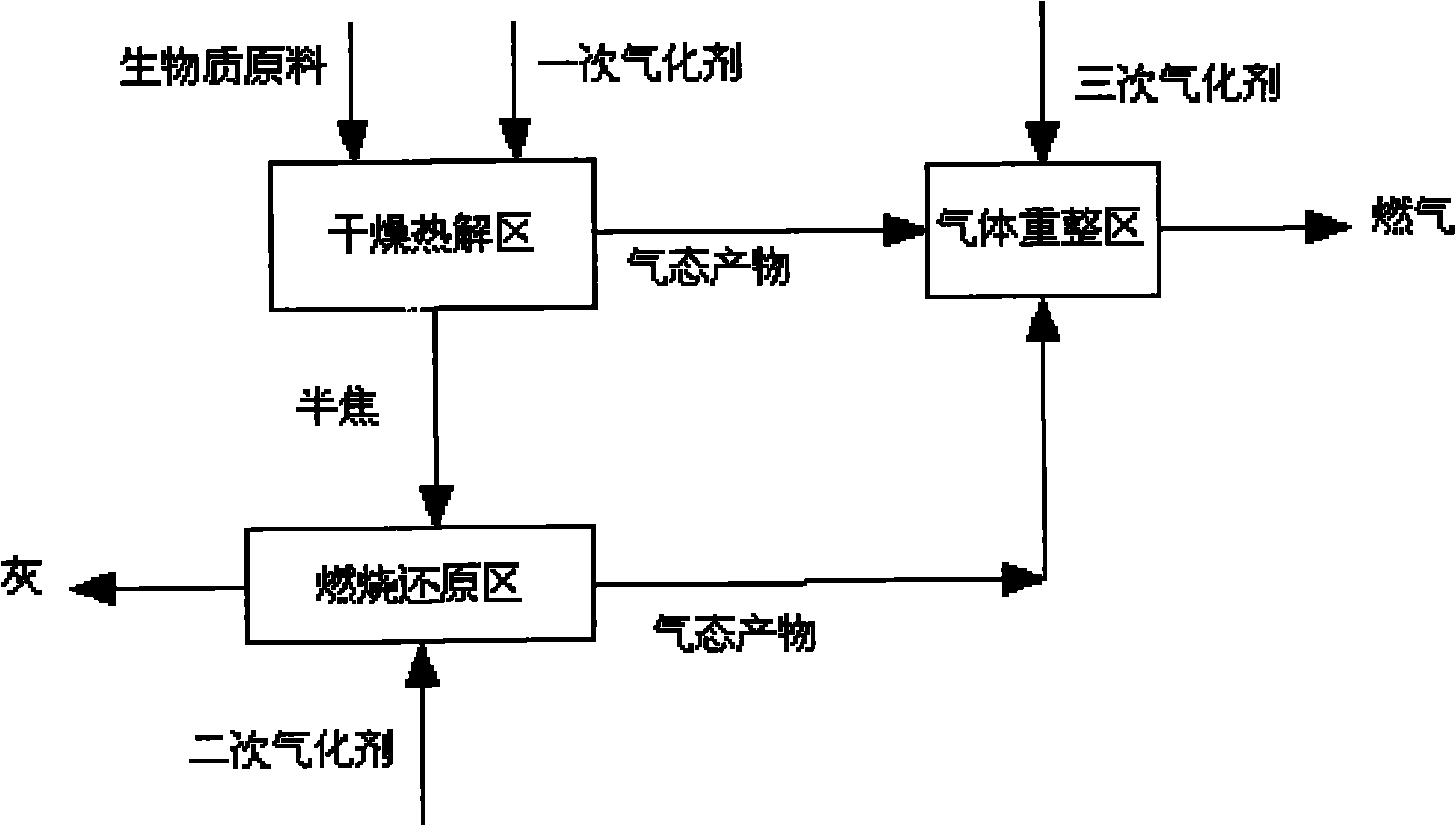

[0039] Such as figure 1 As shown, the three steps of dry pyrolysis, combustion reduction and gas reforming experienced by biomass gasification are relatively separated and carried out step by step. Biomass raw material and primary gasification agent undergo dry pyrolysis and partial gasification reaction under the condition of indirect heating, and semi-coke after pyrolysis and partial gasification undergoes combustion and reduction with secondary gasification agent introduced in the combustion reduction zone The gaseous products after reaction, pyrolysis and partial gasification and the gaseous products produced by combustion reduction are mixed in the gas reforming zone, and then undergo incomplete combustion reaction with the tertiary gasification agent passed in, forming a high temperature zone above 1000 ° C, and realizing tar High temperature enhanced cracking and reforming process of product gas, and finally high-quality product gas with almost no tar is obtained.

Embodiment 2

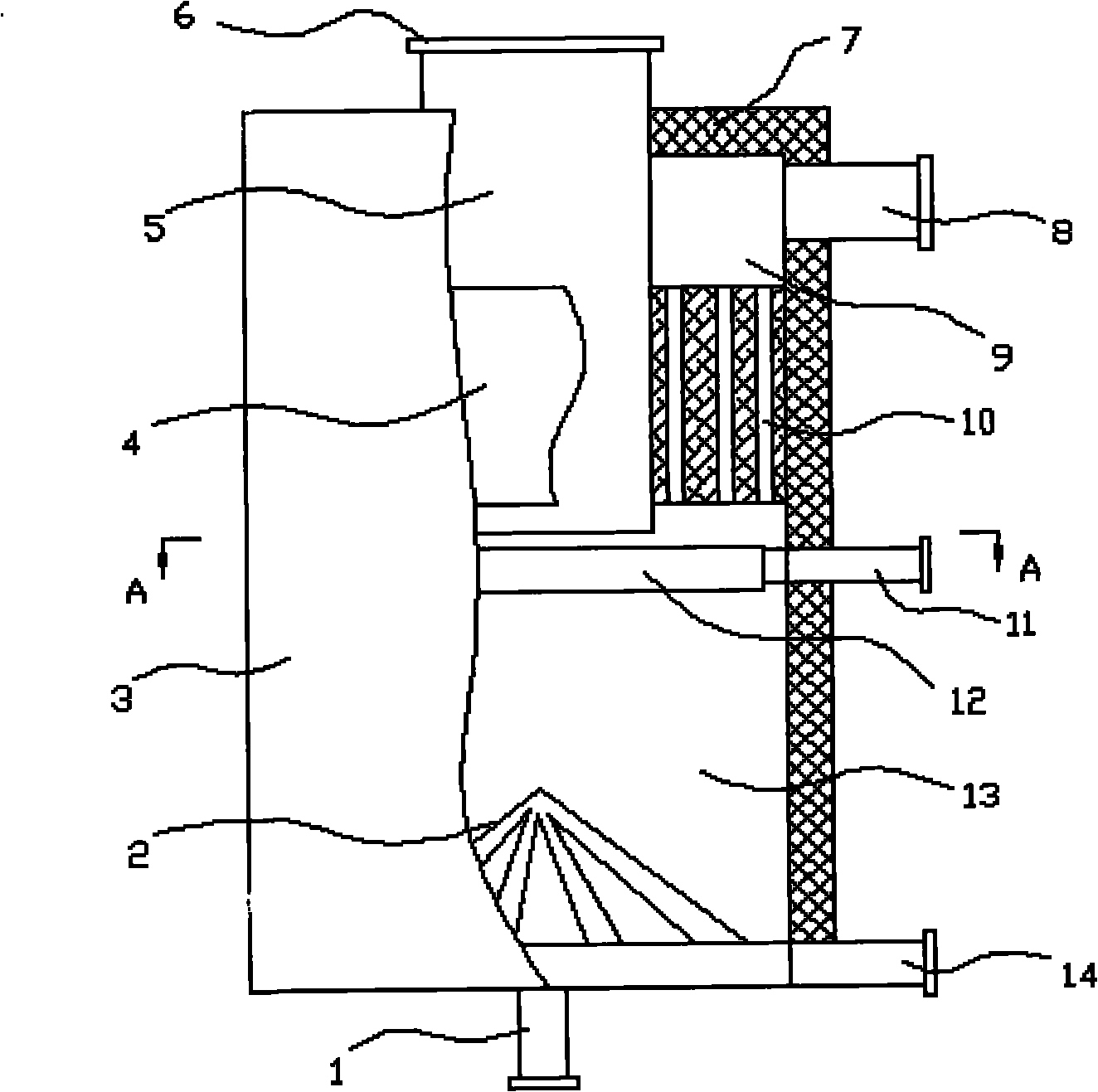

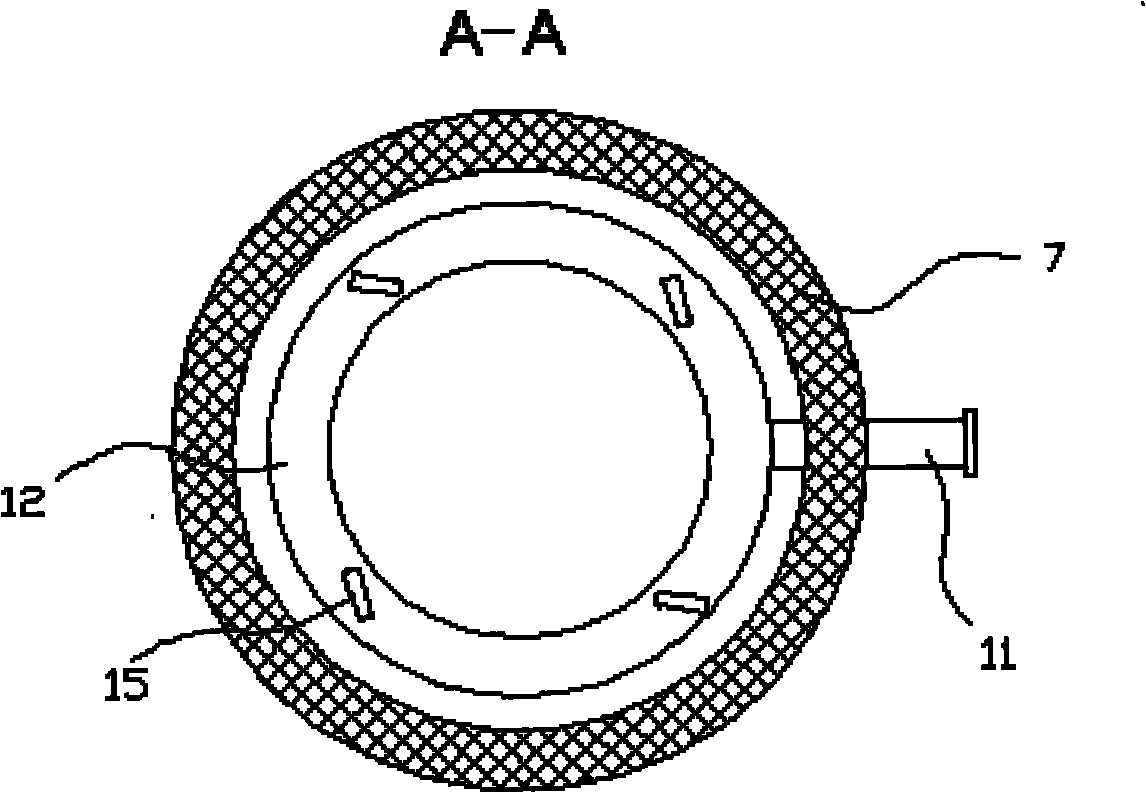

[0041] Such as figure 2 As shown, the biomass gasification furnace of this program includes a furnace body 3 with an insulating layer 7, a raw material inlet 6, a product gas outlet 8 and a gasification agent inlet are arranged on the furnace body 3, and a fire grate 2 is arranged at the bottom of the furnace body 3 And ash outlet 13, this scheme is to have the pyrolysis tube 5 of steel cylindrical cylinder coaxially with furnace body 3 on described furnace body 3, the upper opening end of this pyrolysis tube 5 is raw material inlet 6, and height Out of the upper top of the furnace body 3 , the lower open end of the pyrolysis cylinder 5 is located in the middle of the furnace body 3 . There is an annular gas reformer 4 between the periphery of the pyrolysis cylinder 5 and the inner wall of the furnace body 3. The position of the gas reformer 4 is in the middle and lower part of the pyrolysis cylinder 5. The gas reformer 4 It is made of high-temperature-resistant materials, an...

Embodiment 3

[0046] Such as figure 2 As shown, in the absence of a primary gasification agent, only the biomass raw material is fed into the pyrolysis cylinder (5) through the raw material inlet and the primary gasification agent inlet (6), and passed through the gas reformer (4) at a temperature above 1000°C The high-temperature gas is heated, and dry pyrolysis occurs; the pyrolyzed solid product semi-coke enters the combustion chamber (13), falls on the grate (2), and is combined with the gasification gas entering from the secondary gasification agent inlet (1). The combustion and reduction reaction of the agent occurs, and the solid residue after the reaction is discharged from the furnace body through the ash outlet (14); the gaseous matter produced by pyrolysis in the pyrolysis cylinder (5) and the semi-coke in the combustion chamber (13) are The gaseous substances produced by combustion and reduction are mixed with the gasification agent ejected from the gasification agent inlet (11)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com