Patents

Literature

38results about How to "Reduce fly ash" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

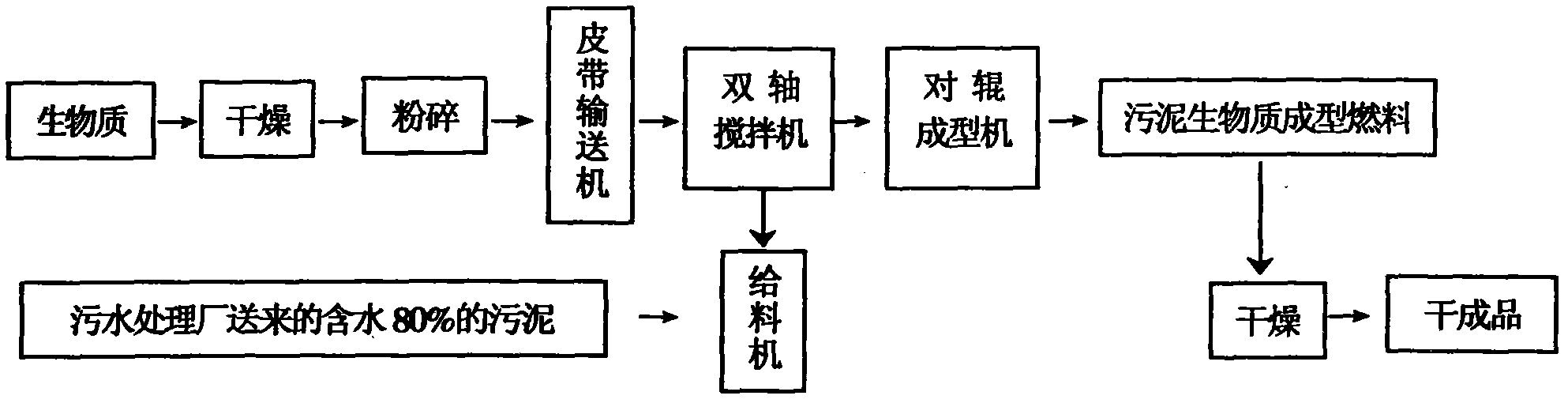

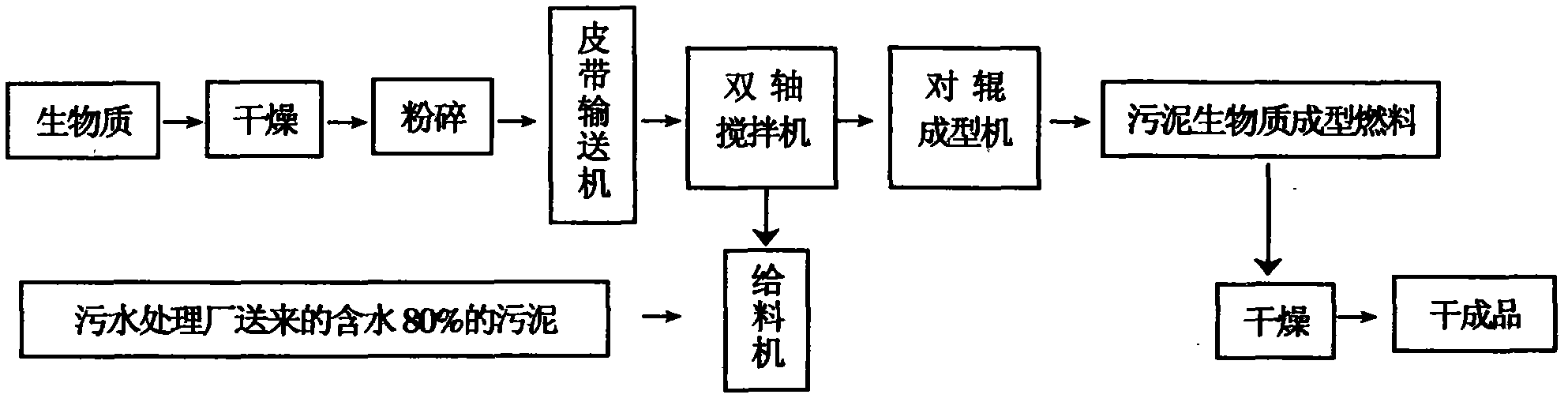

Sludge biomass forming fuel

The invention relates to sludge biomass forming fuel, which belongs to the technical field of renewable energy development and carbon dioxide (CO2) emission reduction. A ring-mould rolling forming machine of the present biomass forming fuel is changed to a roll forming machine, sludge with moisture content of 80 percent in a sewage treatment plant is adopted as a forming caking agent, so the sludge biomass forming fuel can be produced. The yield can be improved by 30 times compared with that of original production technique, the investment and the cost can be reduced by 50 percent, the emission of the CO2 produced by the substituted coal can be reduced by millions of tons, the emission of sulfur dioxide (SO2) is reduced by millions of tons, the sludge can be completely burned, and the biomass waste can be completely utilized. The sludge biomass forming fuel has high yield and good quality and is low in cost; and the forming technique is simple and is easy to popularize and use. The technique also can be used for producing the biomass forming fuel through other caking agents.

Owner:史力

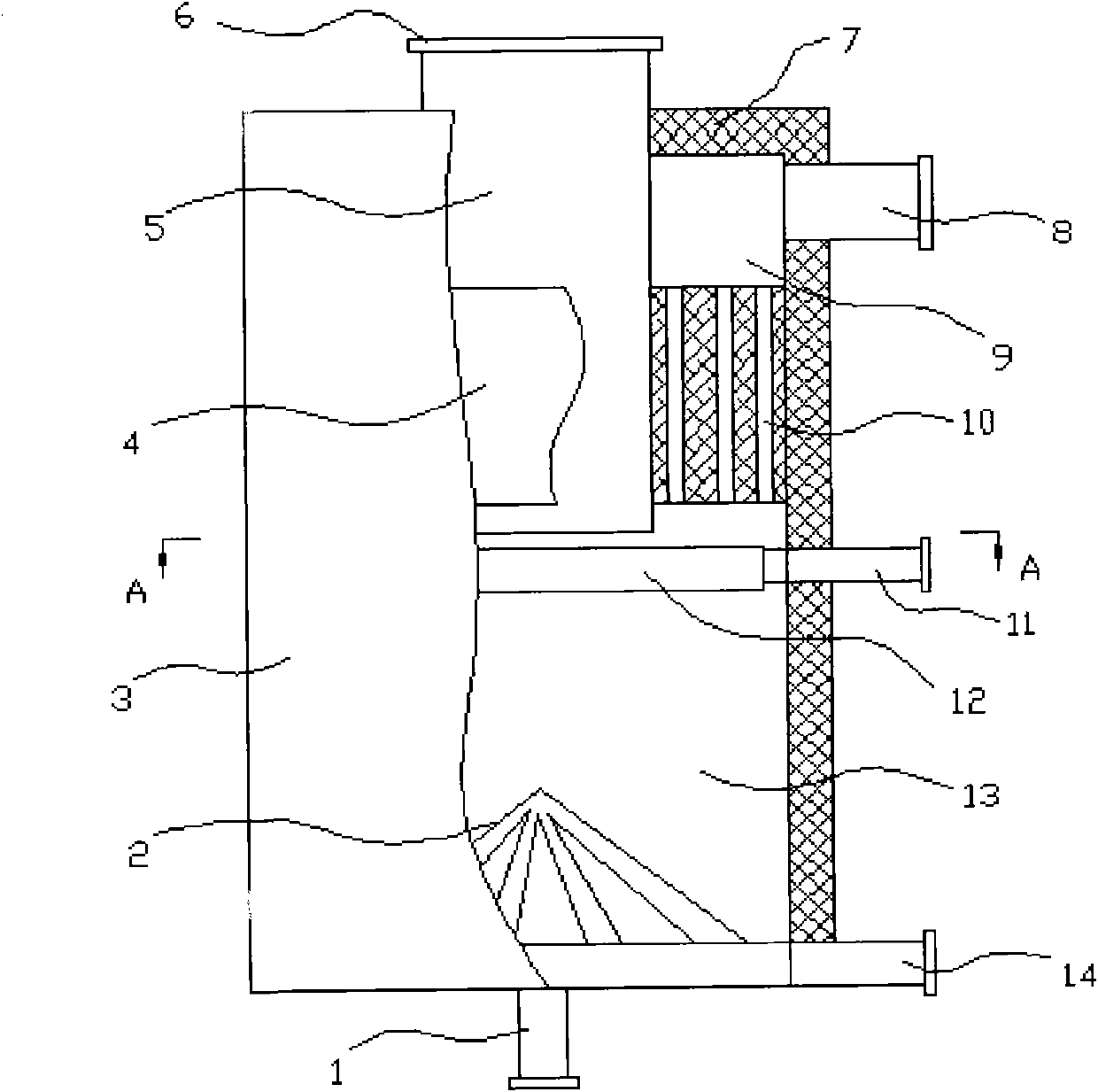

Clean coal gas production method

ActiveCN103725325AEasy to recycleSatisfy the production requirements of the follow-up processGas dust removalGranular/pulverulent flues gasificationProduct gasWater cooling

The invention discloses a clean coal gas production method. The clean coal gas production method is characterized in that the production method comprises the procedures of powdered coal gasification, dedusting in high-temperature segment and indirect cooling. The clean gas production method is composed of high-efficiency coal gas generation, heat recovery, high-temperature dedusting, and ash-free water cooling, therefore, the product gas can meet the requirement of the clean coal gas.

Owner:CHINA CONSTR IND & ENERGY ENG GRP CO LTD

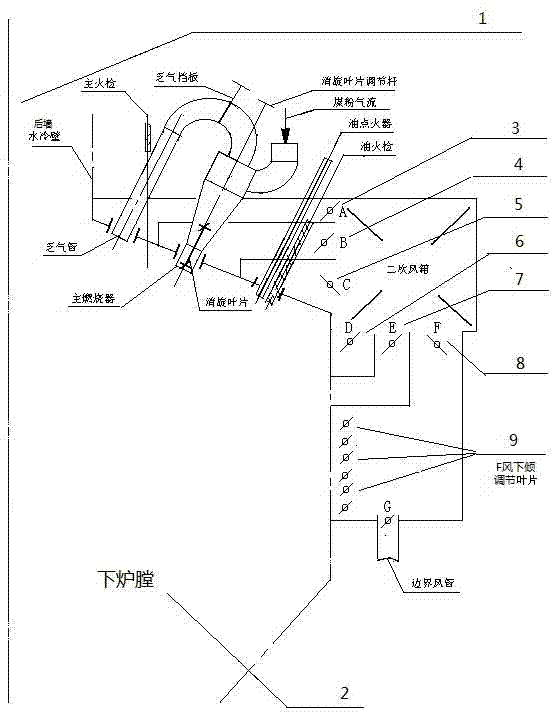

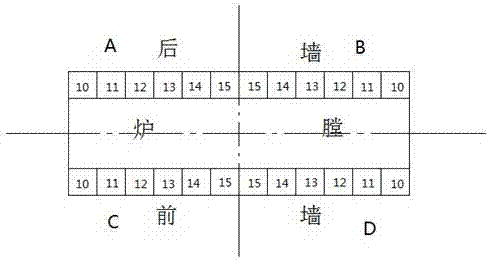

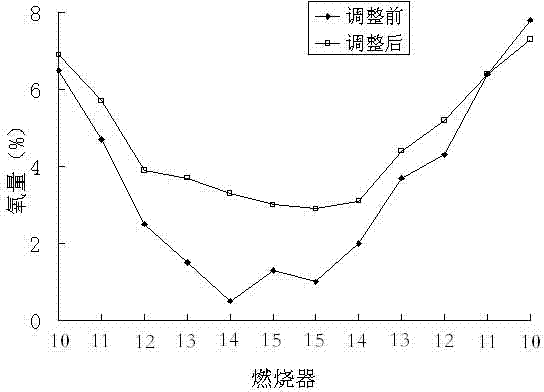

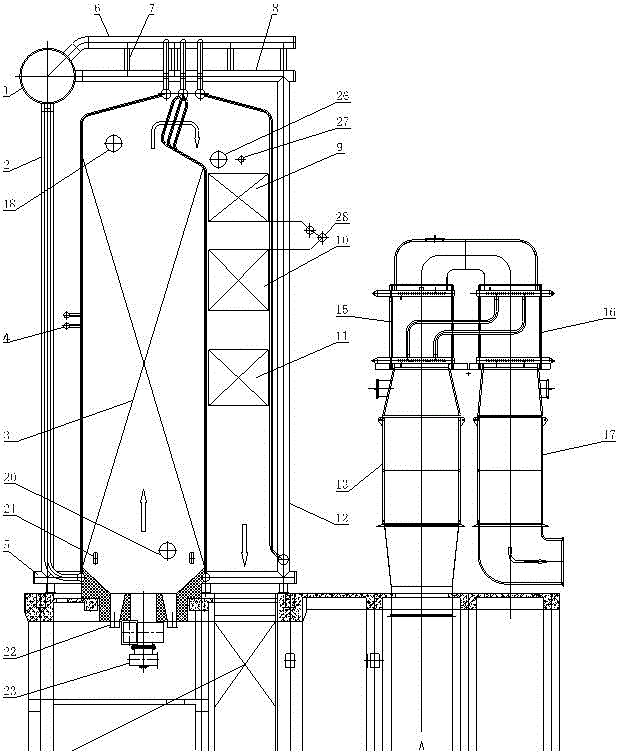

Method for combustion adjustment of W-type flame furnace with under-arch secondary air at adjustable down-dip angle

ActiveCN103672950AImprove stabilityEnhanced downshoot and penetrationAir supply regulationAir doorCoal

The invention discloses a method for combustion adjustment of a W-type flame furnace with under-arch secondary air at an adjustable down-dip angle. The method comprises the steps that when a boiler is normally operated, the angle of an under-arch secondary air adjusting blade is adjusted, so that the air direction of the under-arch secondary air entering a lower furnace hearth is kept in a down-dip state, and the down-dip angle of the under-arch secondary air adjusting blade ranges from 1 degree to 60 degrees; the opening degree of an air door of the under-arch secondary air ranges from 10% to 70% and when the adjusting blade and the air door are adjusted, the adjustment principle that the opening degree in the middle of the furnace hearth is large and the opening degree of the two sides of the furnace hearth is small is adopted; above-arch secondary air is injected into the furnace hearth at the same time, the opening degree of an air door of the above-arch secondary air is adjusted to the range between 0 and 100%, and the adjusting principle that the opening degree of the middle of the furnace hearth is large and the opening degree of the two sides of the furnace hearth is small is adopted. According to the method, the angle of the adjusting blade 9 is adjusted, the under-arch secondary air is kept in a thorough and appropriate down-dip state, and efficient high-temperature smoke backflow is formed in the lower furnace hearth 2, so that the boiler combustion stability is remarkably improved and a high oxygen level needed for thorough-combustion of coal powder is kept.

Owner:ELECTRIC POWER SCI RES INST OF GUIZHOU POWER GRID CO LTD

Coal combustion-supporting hydrogel as well as preparation method and application thereof

The invention discloses a coal combustion-supporting hydrogel as well as a preparation method and application thereof. The coal combustion-supporting hydrogel is prepared through the following steps of: (1) uniformly mixing 30-89% of metal nitrate, 5-60% of potassium chlorate, 1-3% of rare-earth elements, 5-30% of alkali metal hydroxide and 0-20% of sodium silicate, so as to obtain a mixture; (2) dissolving 3% of poly (N-isopropylacrylamide) and 30% of oxydol in water, and uniformly stirring, so as to obtain a solvent; and (3), dissolving the mixture in the solvent, so as to obtain the coal combustion-supporting hydrogel. The coal combustion-supporting hydrogel disclosed by the invention is non-corrosiveness, is stable in property, can be easily adsorbed to the surface of coal powder so as to form a loose porous combustion adjuvant layer, can be directly mixed with coal by virtue of a spraying device, and is convenient in use. By utilizing the coal combustion-supporting hydrogel disclosed by the invention, the desulfurization percent reaches 85%, the standard coal saving rate is 14.6%, the boiler thermal efficiency is improved by 10.6%, the carbon content of slags is reduced by 12.7%, and decoking, smoke abatement and corrosion inhibition reach more than 92%, so that the coal combustion-supporting hydrogel can achieve a combined action of saving coal and reducing the pollutant emission.

Owner:阁美仕(广东)建材有限公司

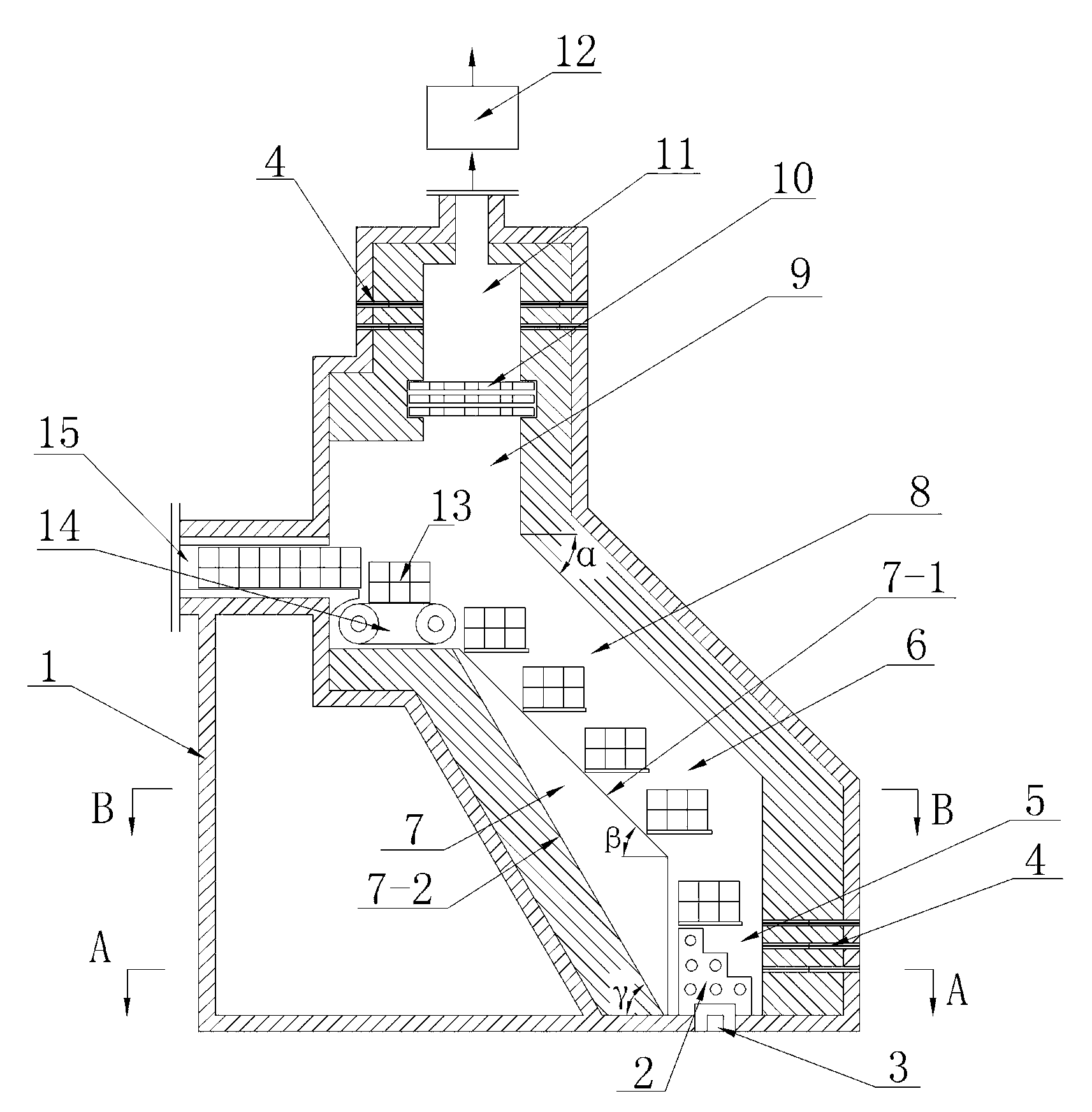

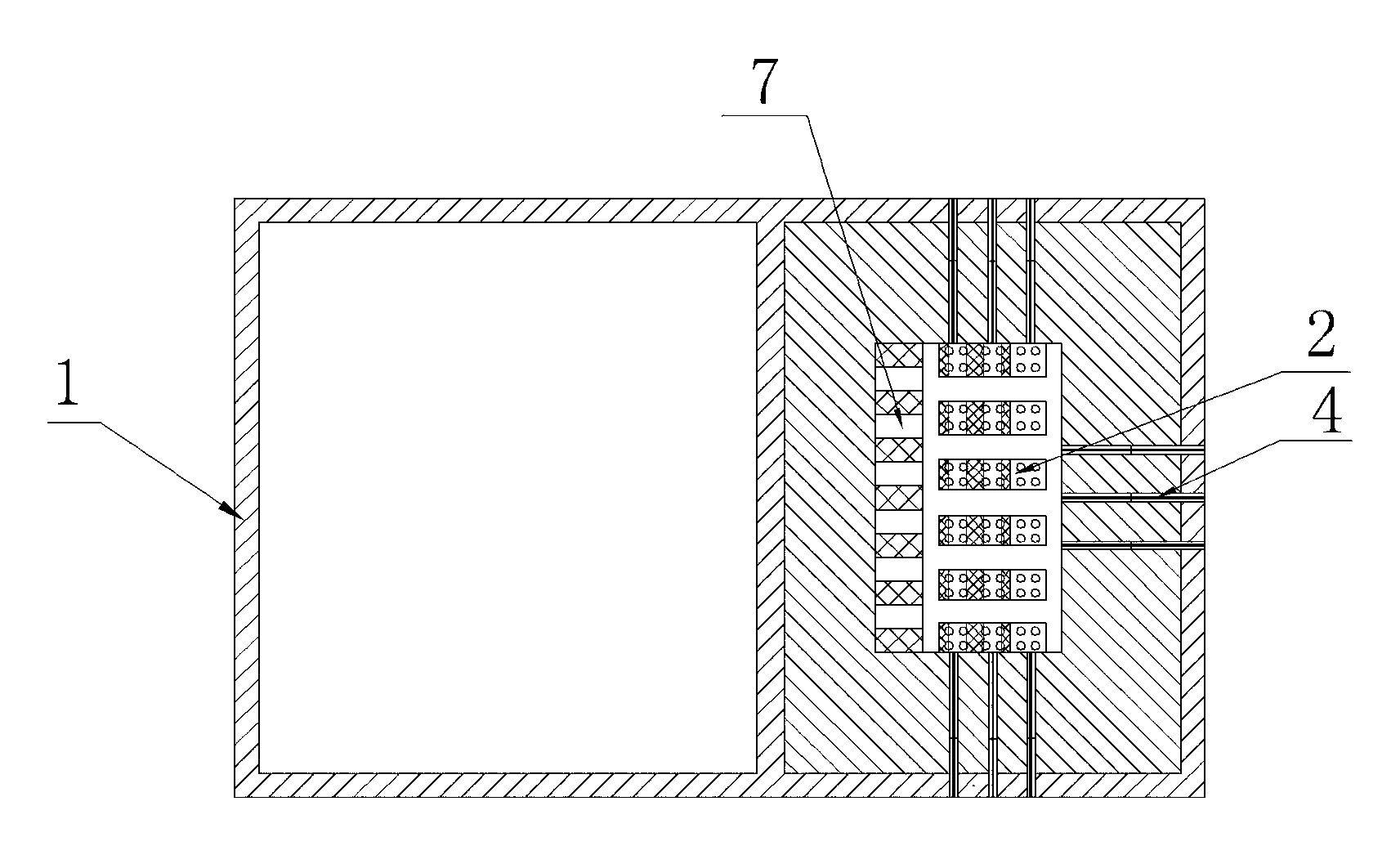

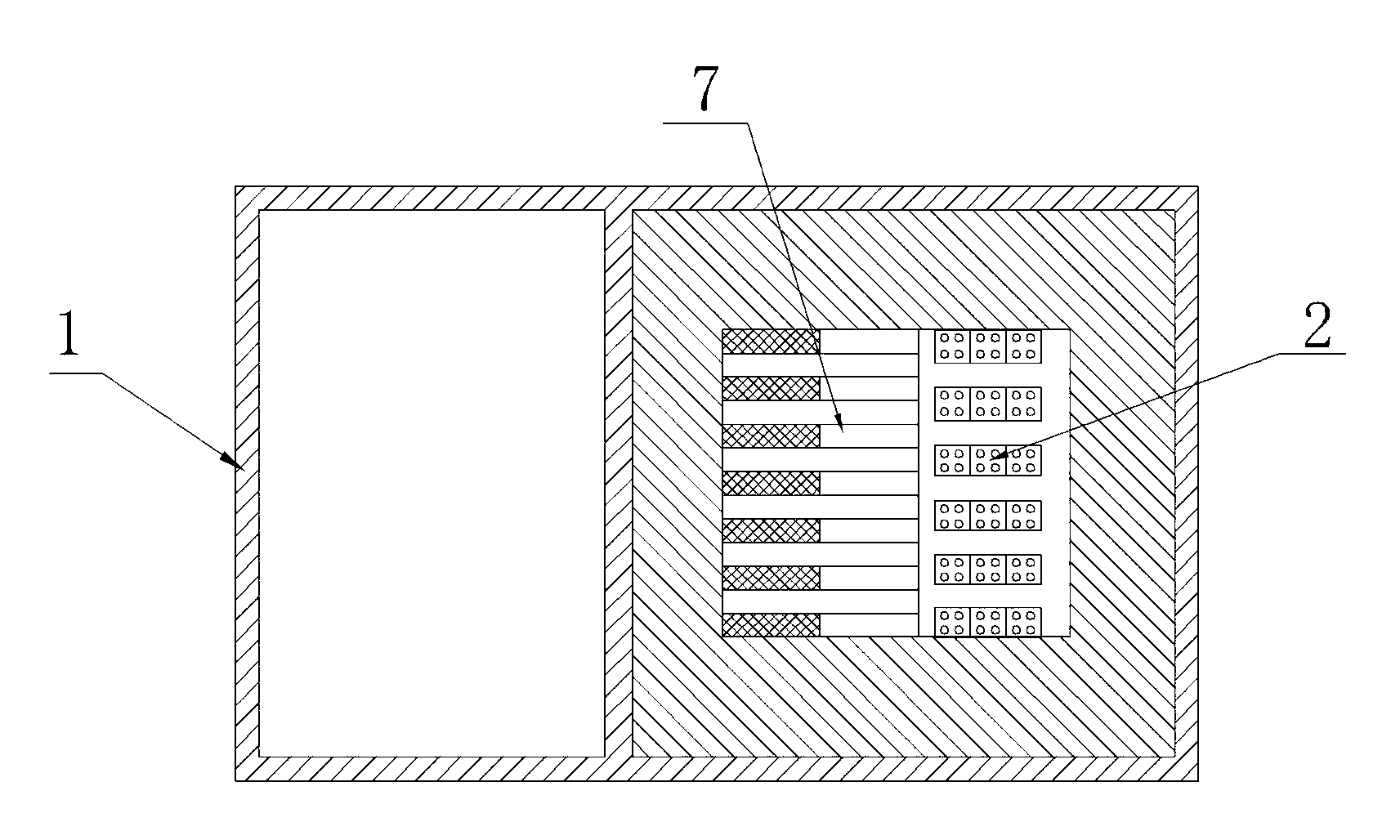

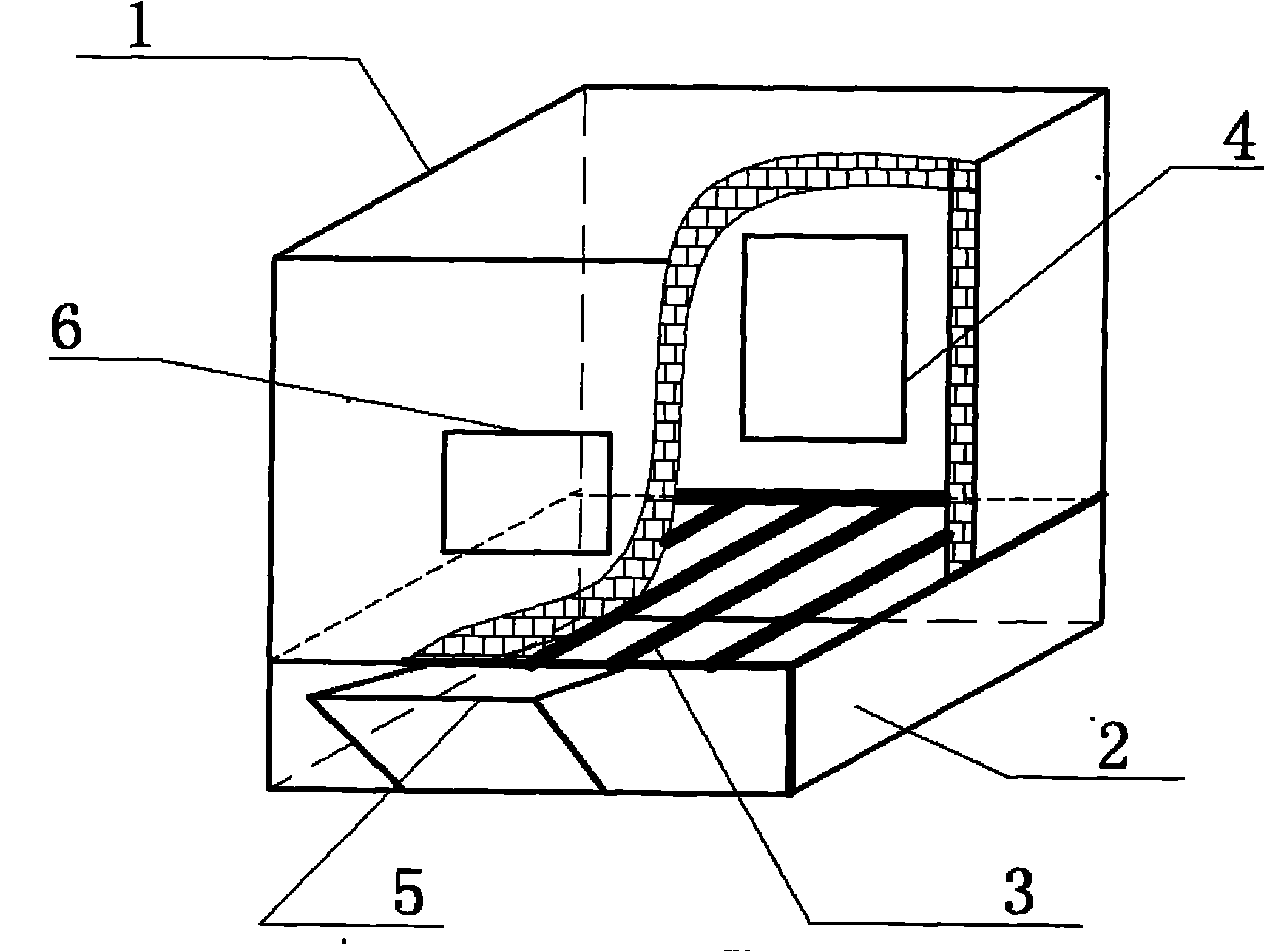

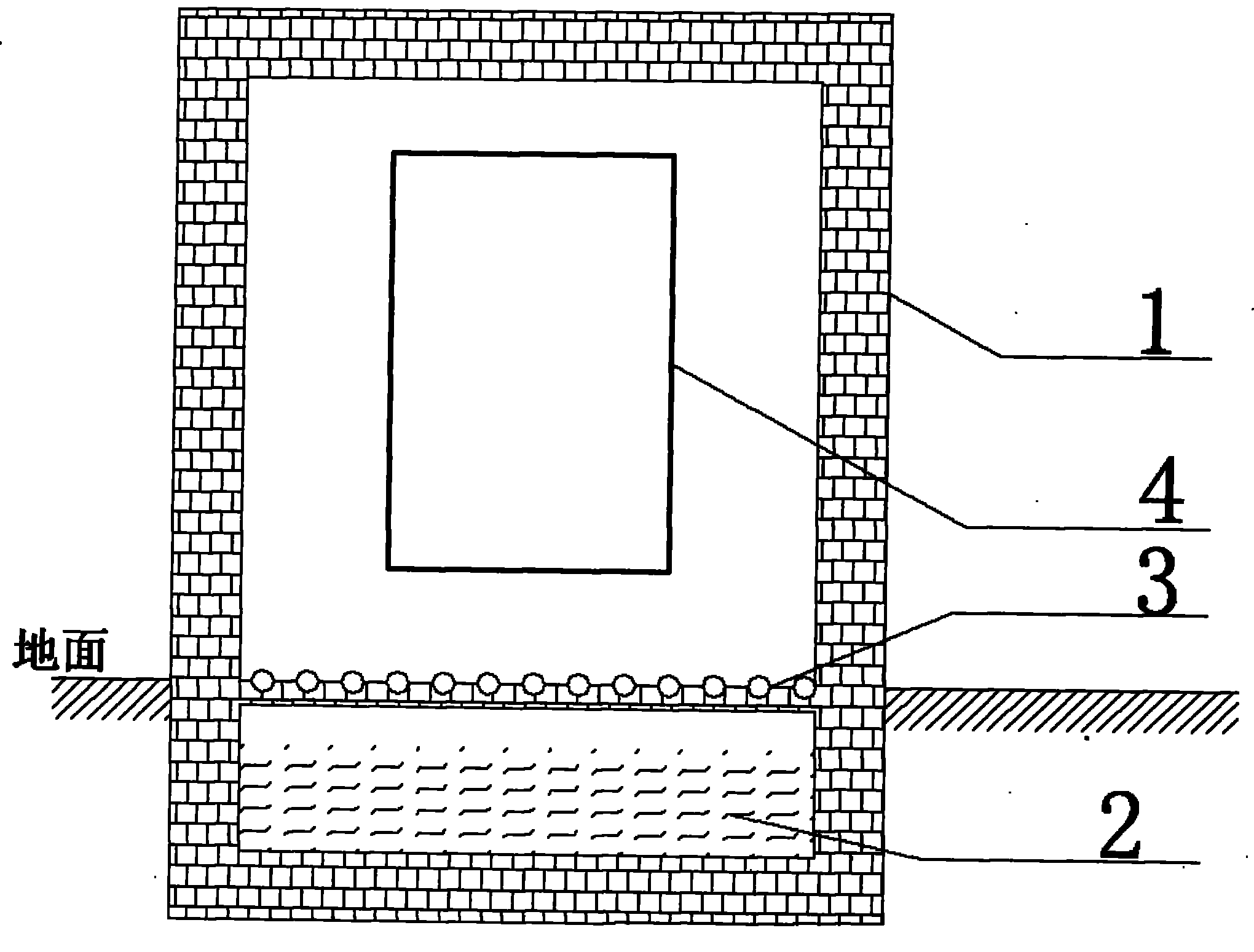

Solid waste incinerator body

InactiveCN102705831AHigh thermal efficiencyReduce productionDirect carbon-dioxide mitigationIndirect carbon-dioxide mitigationBoiler furnaceHearth

The invention provides a solid waste incinerator body. The incinerator body and a hearth of an incinerator are of vertical structures. The hearth is sequentially provided with a drying zone, a pyrolyzing zone and a burning zone from top to bottom, a group of fiery pits are arranged on the inner side of the hearth, a group of spray guns are respectively arranged on the outer side, the left side and the right side of the burning zone, a blocky compressed solid waste inlet is arranged on the outer side of the upper portion of the hearth, a boiler furnace and a draught fan are arranged at the top of the hearth, a group of spray guns are arranged on the side wall of the boiler furnace, the draught fan enables smoke to be discharged out of the incinerator, oxygen enriched gas formed by mixing residual smoke and pure oxygen is led to the third group of spray guns of the burning zone and the group of spray guns of the boiler furnace. The incinerator hearth is small in volume and large in solid waste disposal capacity, and the solid waste incinerator body is rapid in burning speed, good in effect, capable of disposing solid waste of various kinds at the same time, energy-saving, environment-friendly and remarkable in effect.

Owner:袁永扬

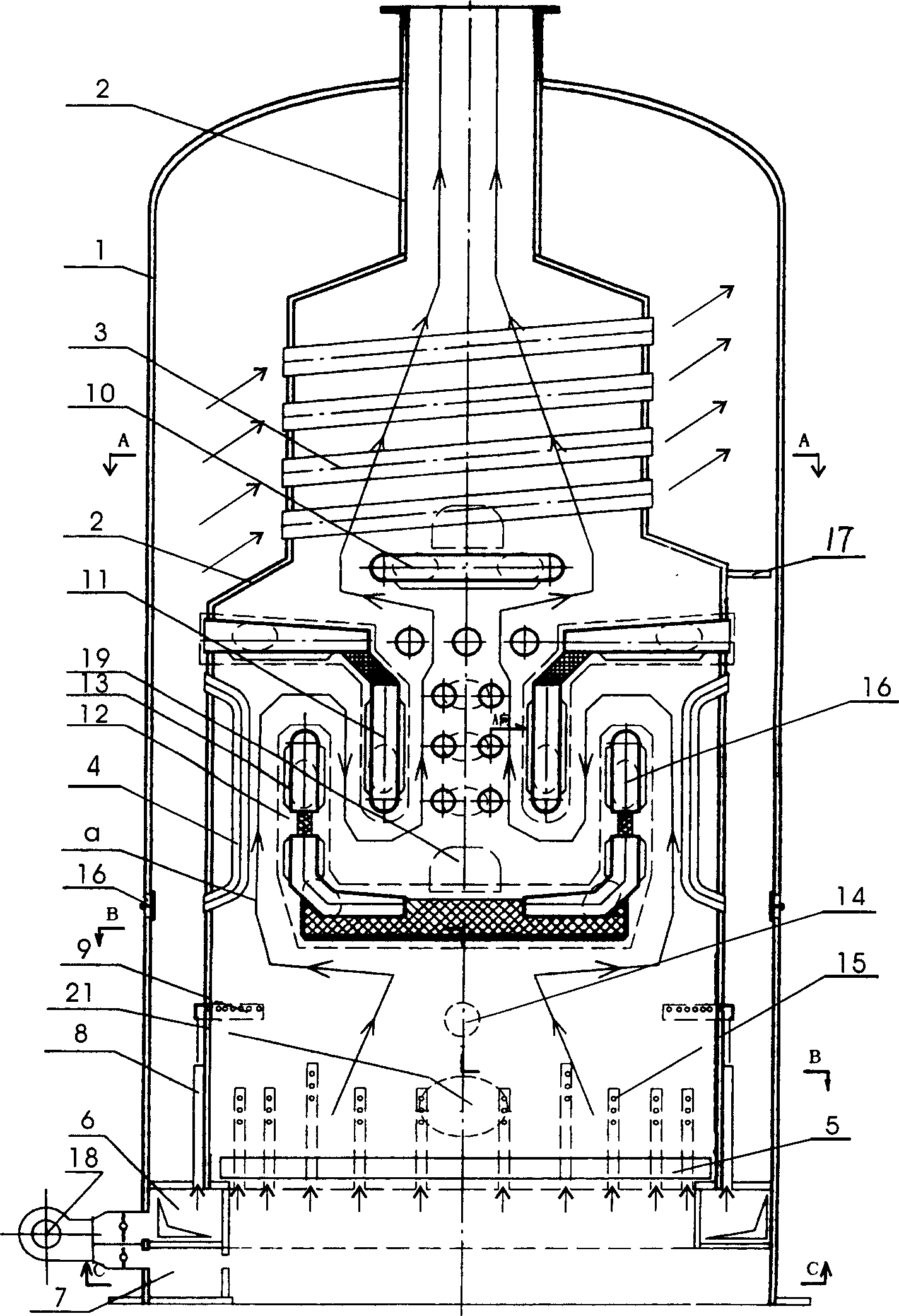

Three return stroke half fire coal, fuel oil and gas-fired smokeless boiler

InactiveCN1670431AEasy to manufactureMaintain stiffnessSolid fuel combustionWater heatersDust controlEngineering

This invention relates to a three return travel half coal, oil and gas fuel smokelessness boiler. It includes boiler external cylinder, inner bag shell, multiple horizontal siphonal areas, water cold wall pipe, and combination furnace arch and fire grate. Its feature is that annular secondary air bellows and arched first air bellows are fixed under fire grate, the secondary air bellow is interconnected to vertical quadric air manifold set along furnace outer wall, semilunar horizontal air pipe is set under arched high temperature fume outlet at both sides of furnace. The combination furnace arch is consisted by yi form up furnace arch, inverse L form middle arch and concave down arch. The three arches are all formed by combination of horizontal cleet water cover and vertical cleet water cover and plugging cleet water cover connecting through fire bricks, and malpositioned in inner bag shell, three return travel flue is formed under up furnace arch. Both sides of up parts of inner bag shell shrink entad to form two segment special form barrel of vertical upright faces. Up part horizontal pipe is put up between two vertical upright faces. Bituminous coal smokelessness burning technique and inner furnace smoke prevention and dust control technique is formed by the boiler in this invention and air distribution burning technique and multifunction furnace arch structure. Coal cleanliness burning smokelessness boiler is formed by the combination of bituminous coal smokelessness burning technique and three return half coal process. Its heat efficiency is high when running longtime, energy saving effect is great, discharging of polluting matter is low, and the oil and gas fuel boiler is achieved.

Owner:畲顺元

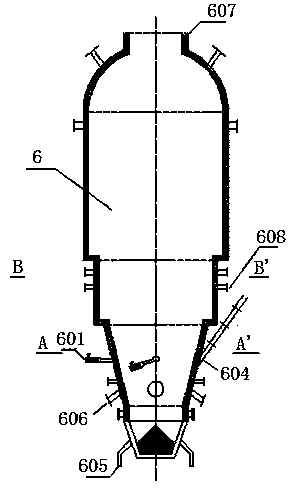

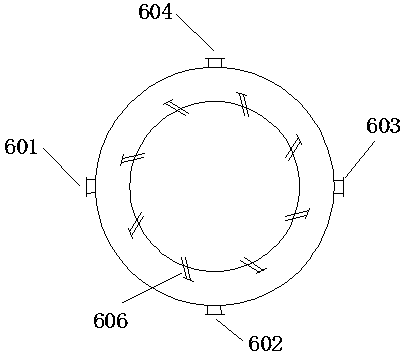

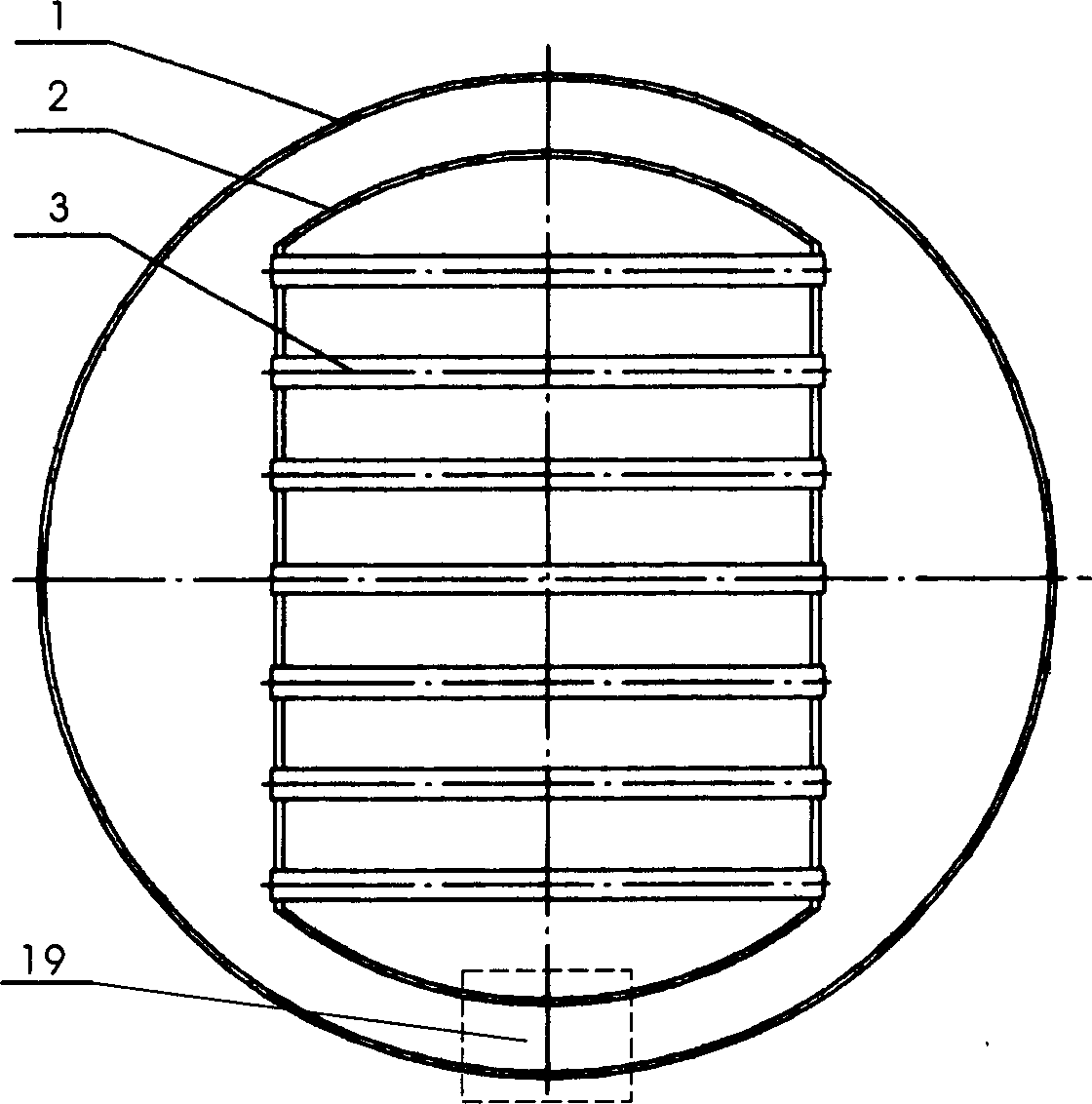

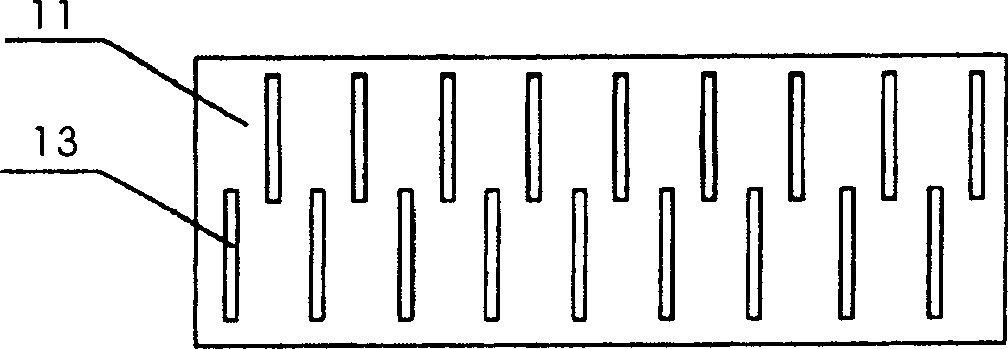

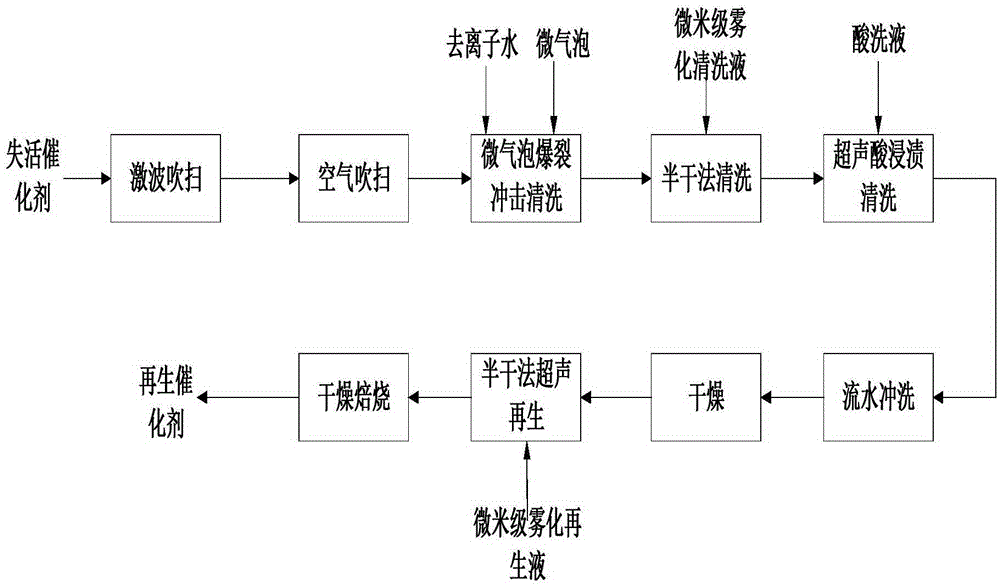

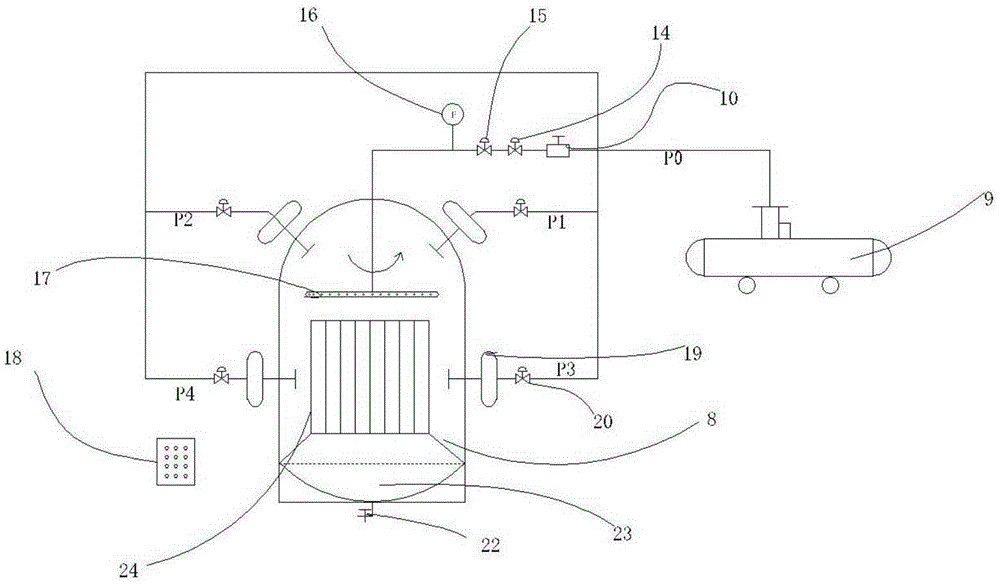

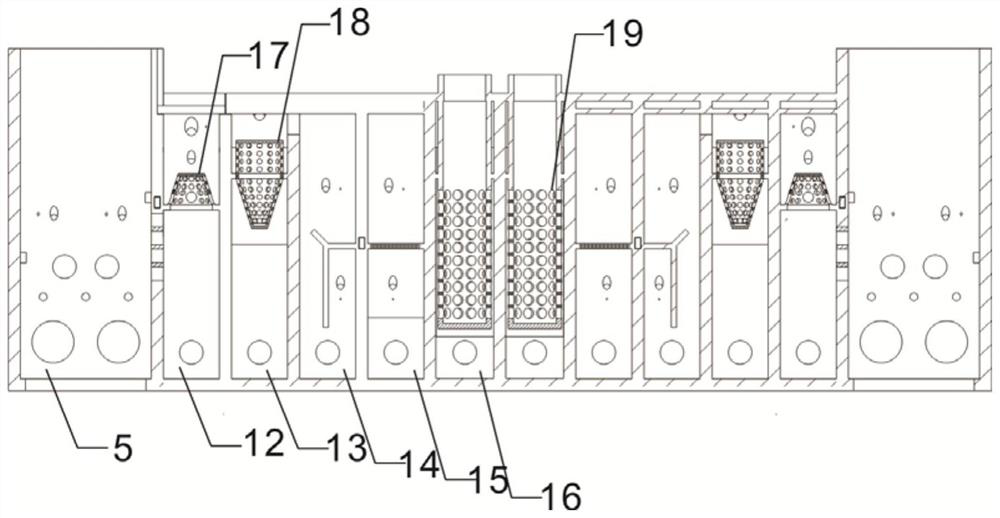

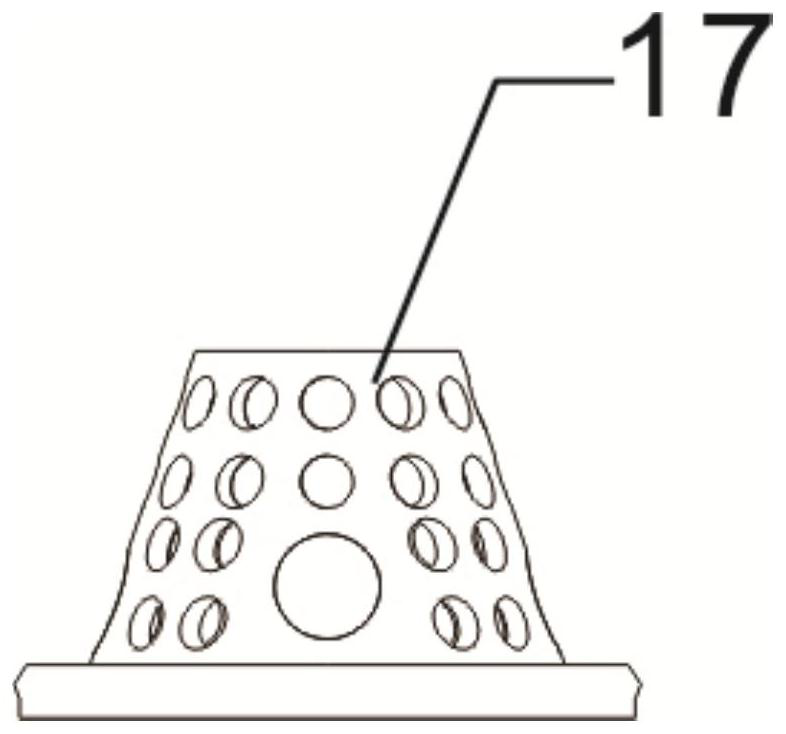

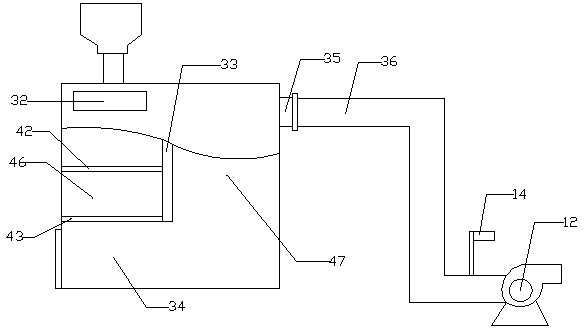

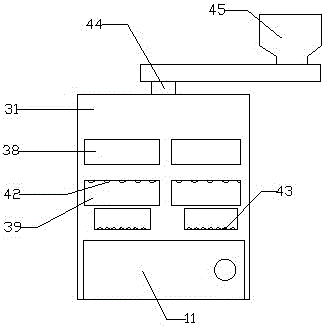

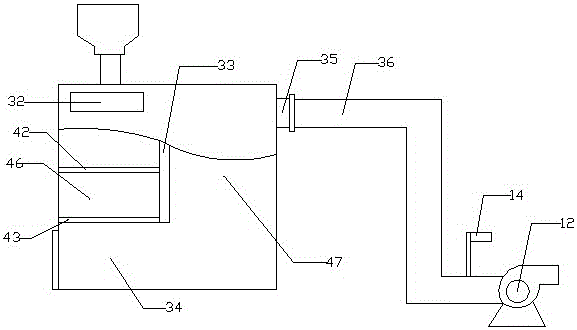

Deactivated SCR denitration catalyst purging device, activation device and regeneration system and corresponding methods

InactiveCN105381716AAchieve activationAchieve regenerationDispersed particle separationCatalyst regeneration/reactivationEngineeringBiological activation

The present invention relates to a deactivated SCR denitration catalyst purging device, an activation device and a regeneration system and corresponding methods, the activation device includes a regeneration main body tank, an ultrasonic atomization device, a catalyst rotating turntable and a micro negative pressure suction device; and the regeneration system includes the purging device, a cleaning device, a first drying device and the activation device which are connected in turn. The regeneration system can achieve deactivated catalyst regeneration, and compared with the normal regeneration process, the process is more thorough in purging and more complete in cleaning, also greatly improves the utilization ratio of a cleaning solution and a regeneration solution, and maximizes recovery of surface and pore structure of a deactivated catalyst.

Owner:FUJIAN ZIJIN ENVIRONMENT ENG TECH +1

High-efficiency fuel coal catalyst

InactiveCN101269339BHigh thermal efficiencyHas a defocusing effectSolid fuelsMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementAdditive ingredient

The invention discloses a coal-fired catalyst with high efficiency, the coal-fired catalyst essentially comprises the following components in accordance with the mass percentage content: 20 to 40 percent of potassium salt, 10 to 25 percent of industrial grade sodium chloride, 15 to 30 percent of quicklime, 9 to 15 percent of bauxite, 1 to 4 percent of rare earth elements, and 0.1 to 1 percent of ferric oxide, wherein, the main ingredients of the invention are monovalent and divalent alkali metal salts, bauxite and rare earth elements. The coal-fired catalyst has catalytic combustion, sulfur fixing and improvement of the properties of coal combustion, and therefore, the coal-fired catalyst plays a comprehensive role of coal conservation and emission reduction of pollutants, and is suitablefor a variety of large-scale civic or industrial coal-fired boilers. The catalyst has simple use, adequate raw materials supply, simple preparation, low price, stable performance and pollution-free for the environment, therefore, the catalyst as an ideal coal-fired catalyst has obvious social and economic benefits.

Owner:袁柏安

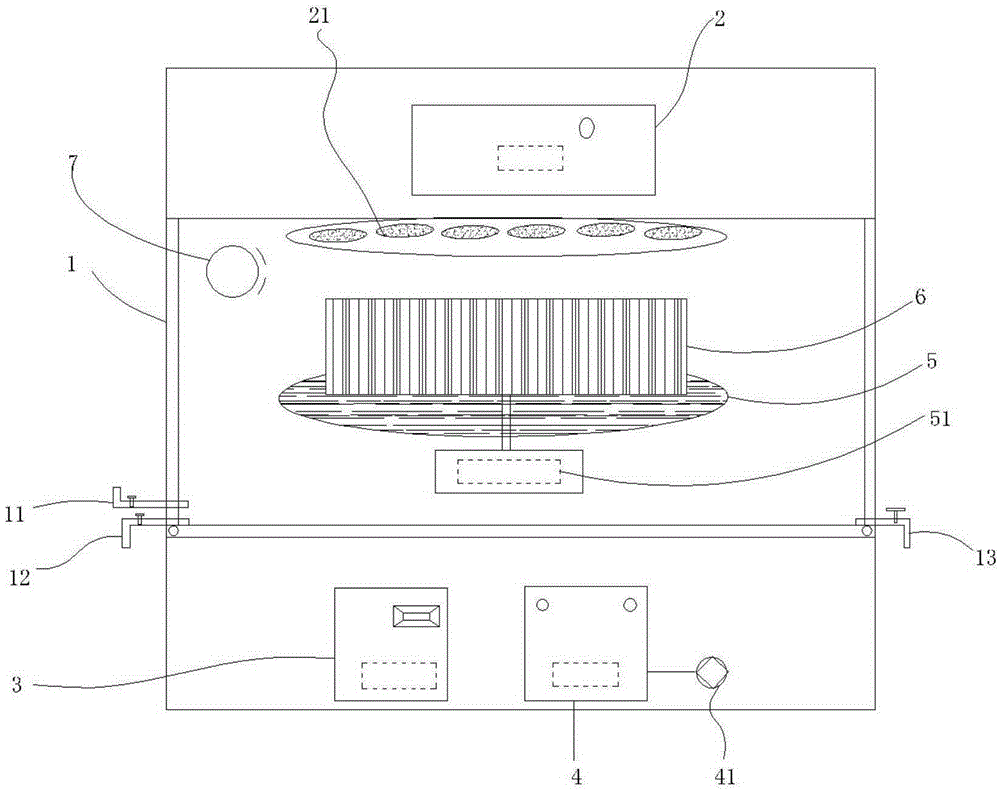

Sacrificial offering incinerator provided with smoke cleaning system

PendingCN109751607AExtend discharge timeImprove combustionCombination devicesIncinerator apparatusCombustion chamberCombustor

A sacrificial offering incinerator provided with a smoke cleaning system comprises a crushing bin, an incinerator body, a quenching tower, a spraying tower, a cloth bag dust remover and a chimney which are sequentially connected through pipelines, wherein the incinerator body comprises a main combustion chamber, a re-combustion chamber and a board baffle; the board baffle is arranged between the main combustion chamber and the re-combustion chamber; a combustor and an air inlet are arranged on the inner wall of the main combustion chamber; sacrificial offerings are crushed through the crushingbin and then are fed into the incinerator body; air is supplied through the air inlet, and fuel is injected through the combustor; the sacrificial offerings are fully combusted in the main combustionchamber; smoke enters the re-combustion chamber for further combusting and is completely decomposed; the combusted smoke is cooled through the quenching tower and then enters the spraying tower for depickling and washing; the smoke is subjected to dust removing by the cloth bag dust remover; and the cleaned gas is exhausted into atmosphere through the chimney. The sacrificial offering incineratoris capable of performing multi-stage cleaning treatment, including dust removing, smell removing, and harmful substance removing; and the sacrificial offering incinerator has the characteristics of being high in combustion efficiency, and good in cleaning effect.

Owner:民政部一零一研究所 +1

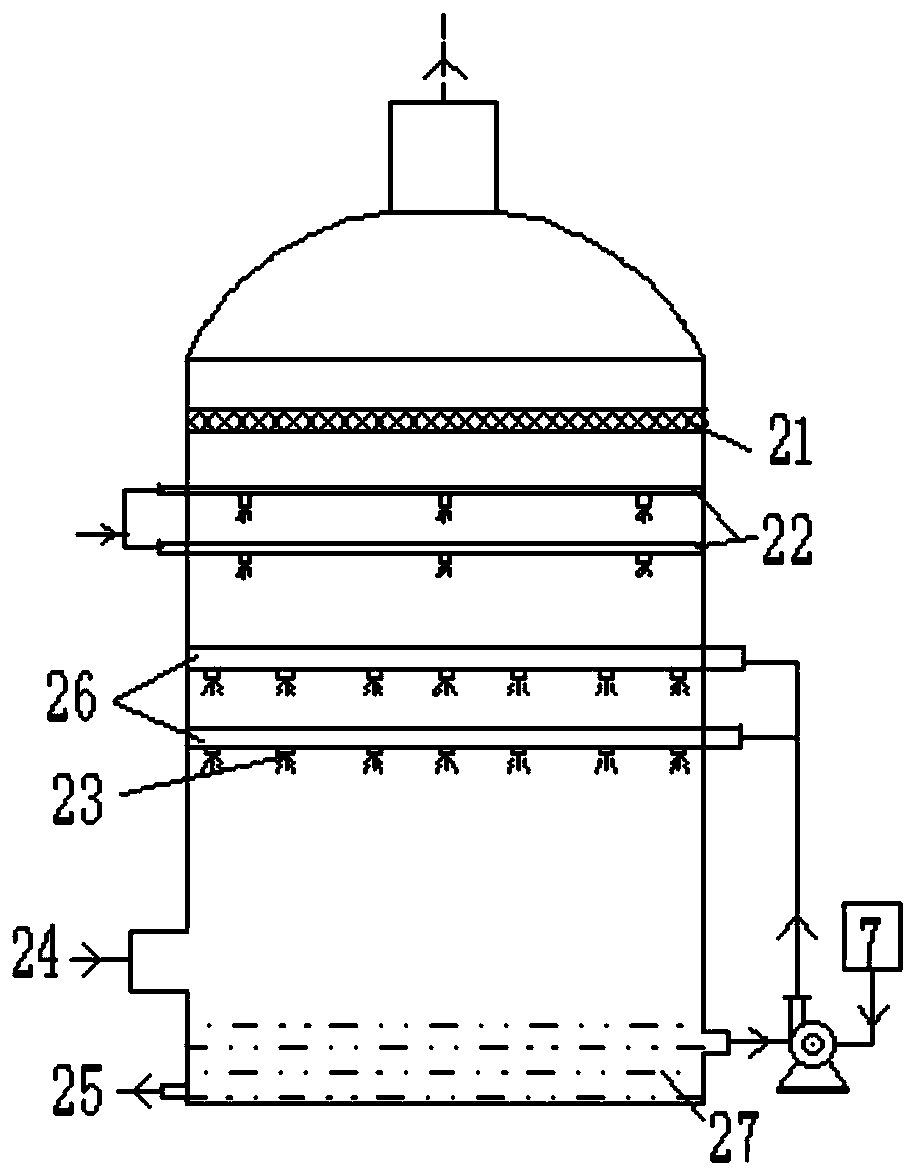

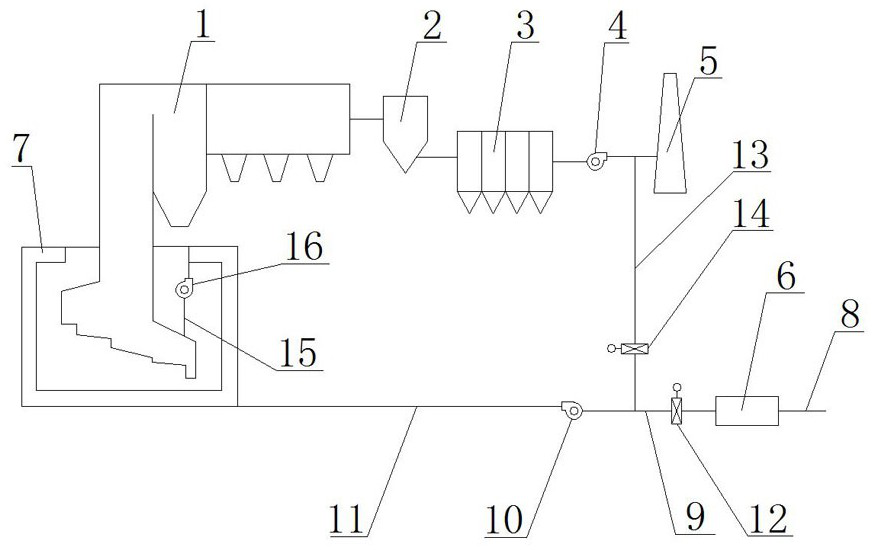

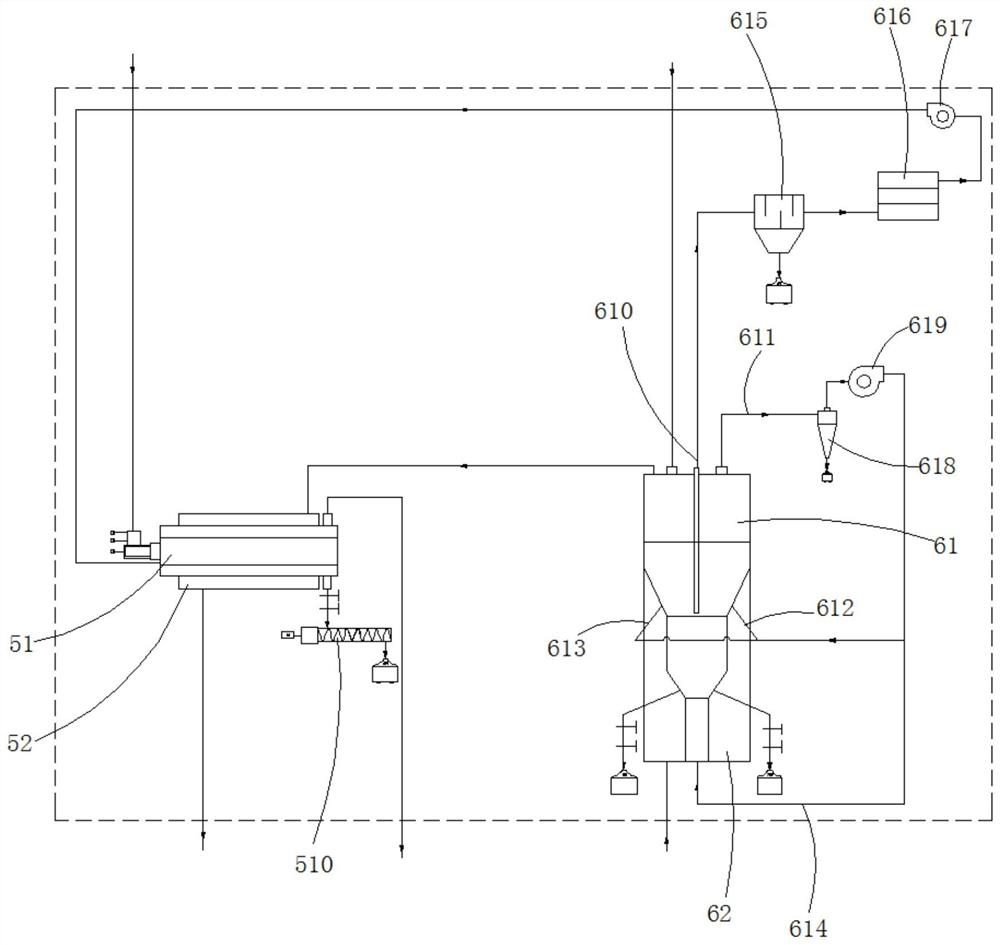

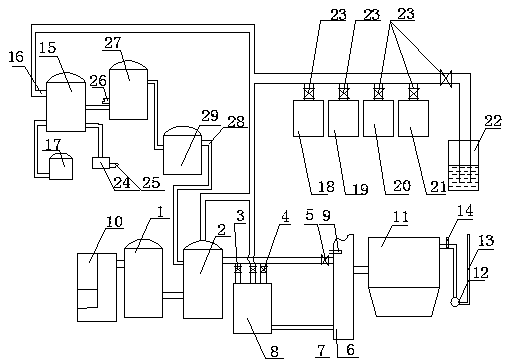

Flue gas recirculation system of household garbage incineration power plant

PendingCN113280351AIncreased inert gas contentSuppress generationEmission preventionIndirect carbon-dioxide mitigationAir preheaterInert gas

The invention discloses a flue gas recirculation system of a household garbage incineration power plant. The flue gas recirculation system comprises an incinerator, a reaction tower, a dust remover, an induced draft fan, a chimney and an air preheater, a flue gas outlet of the incinerator is connected with an inlet of the reaction tower, an outlet of the reaction tower is connected with one end of the dust remover, and the other end of the dust remover is connected with one end of the induced draft fan. The other end of the induced draft fan is connected with the chimney, air is introduced into one end of the air preheater, and the other end of the air preheater and the other end of the induced draft fan are connected with a secondary air chamber of the incinerator. According to the flue gas recirculation system of the household garbage incineration power plant, recycled flue gas replaces part of secondary air, so that the content of inert gas in a combustion area is increased, the flue gas absorbs heat, the concentration of oxygen is reduced, the flue gas and combustion-supporting air spread and combust in a high-temperature and low-oxygen atmosphere, the flame volume is multiplied, a local high-temperature area is reduced, temperature distribution is more uniform, generation of thermal NOx is inhibited, the coking problem of a hearth can be solved, and the heat efficiency and the generating capacity are improved.

Owner:CHINA TIANYING +1

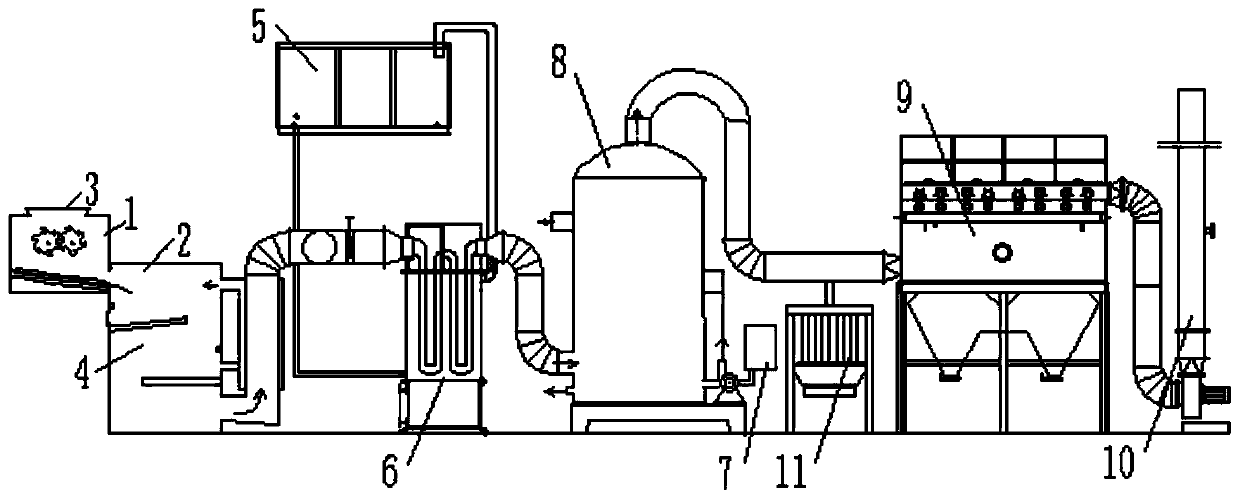

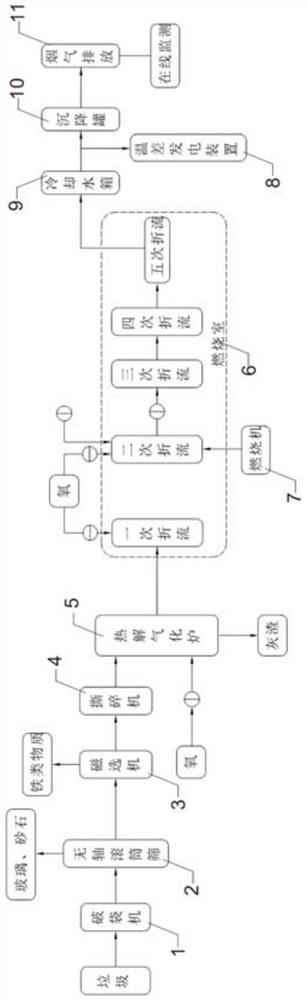

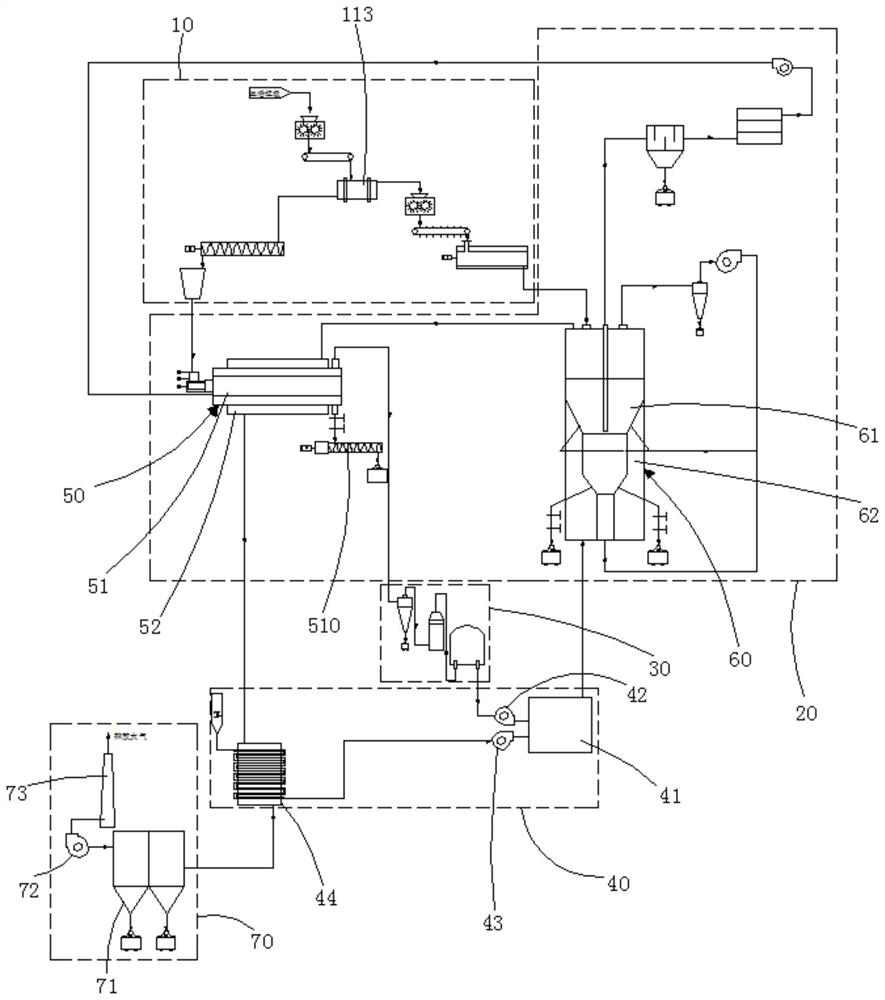

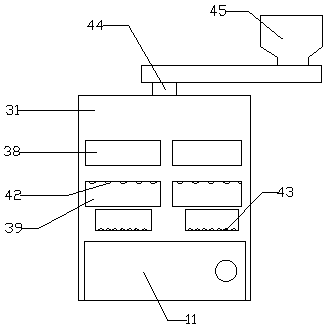

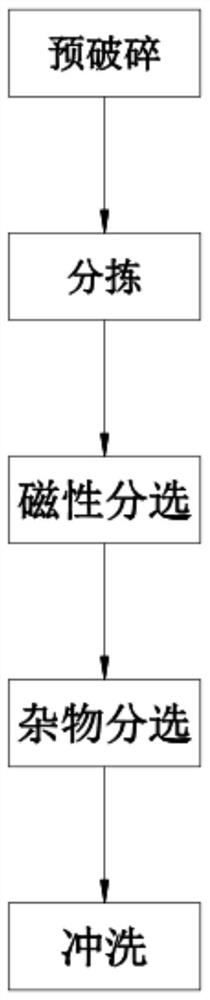

Innocent treatment device for domestic waste and method

ActiveCN112161273AReduce generationImprove resource utilizationIncinerator apparatusGenerators/motorsCombustion chamberFlue gas

The invention discloses an innocent treatment device for domestic waste and a method. The device comprises a bag breaking machine, a shaftless drum screen, a magnetic separator and a shredder, whereinthe shredder is connected to a stock bin of a pyrolysis gasification furnace, the pyrolysis gasification furnace is connected to a high-temperature combustion chamber, the high-temperature combustionchamber is connected to a cooling water tank, the cooling water tank is connected to a settling tank through a draft fan and a connecting pipeline, a thermoelectric generation device is arranged on the connecting pipeline, and the settling tank is connected to a flue gas emission device; and the innocent treatment device for the domestic waste further comprises a control device, and temperature sensors and pressure sensors are arranged at all positions. The invention further comprises a method for conducting innocent treatment on the biochemical waste by adopting the device. According to thedevice and the method, the innocent, reducing and recycling treatment of the domestic waste can be achieved, the power generation utilization is conducted, the finally-effluent flue gas can reach theemission standard, and the problems that an existing waste treatment method is large in environmental pollution, low in resource utilization rate, high in treatment cost and the like are effectively solved.

Owner:四川明日得投资管理咨询有限责任公司

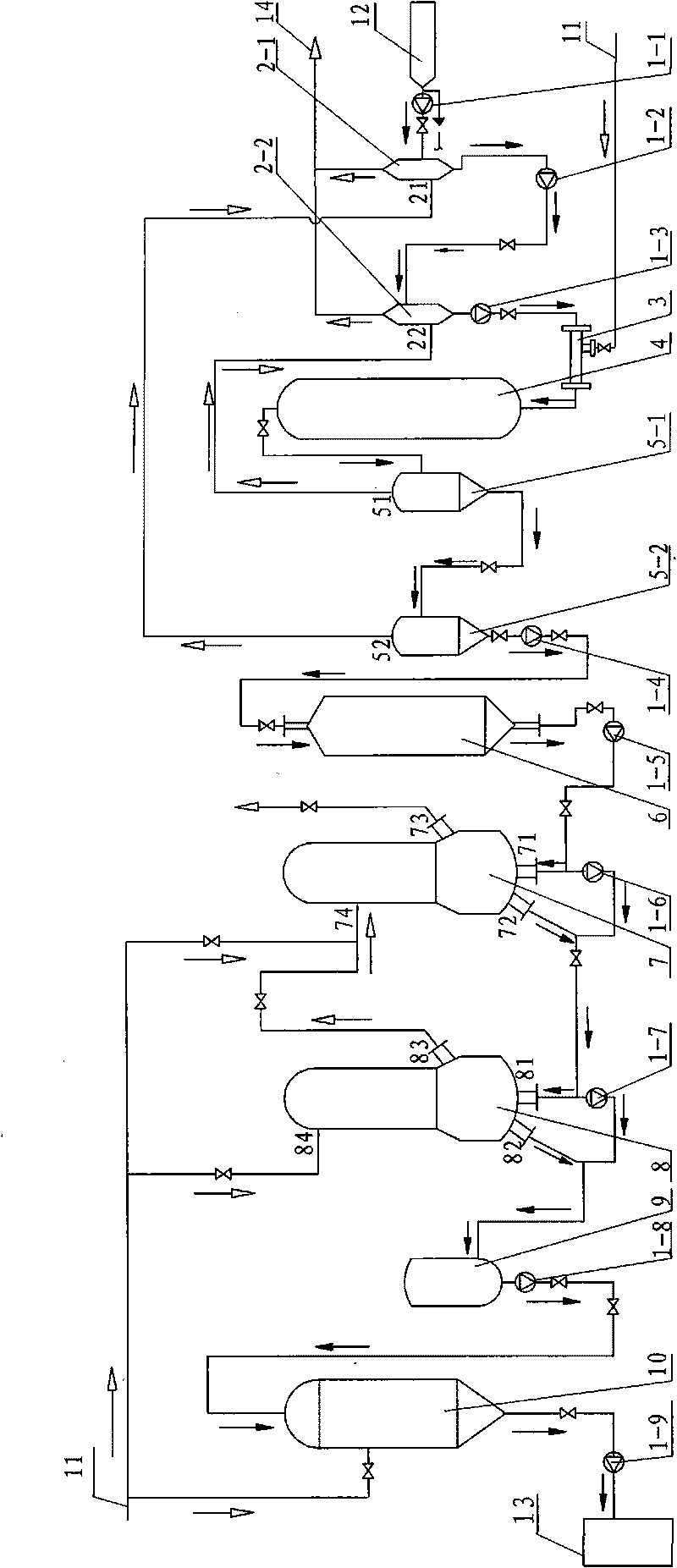

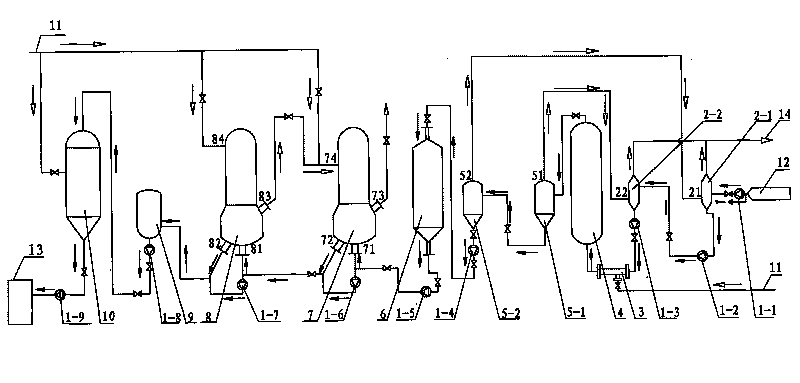

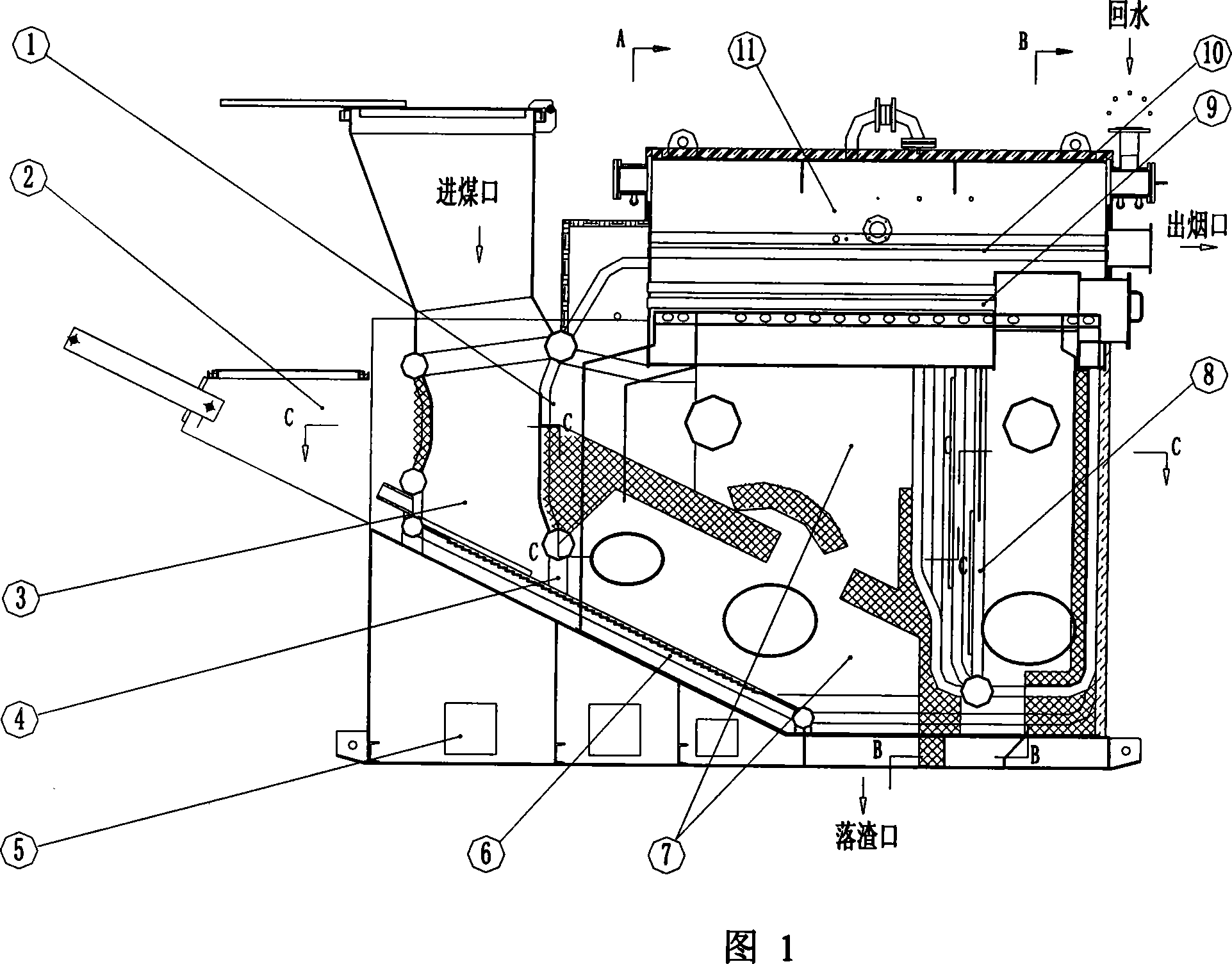

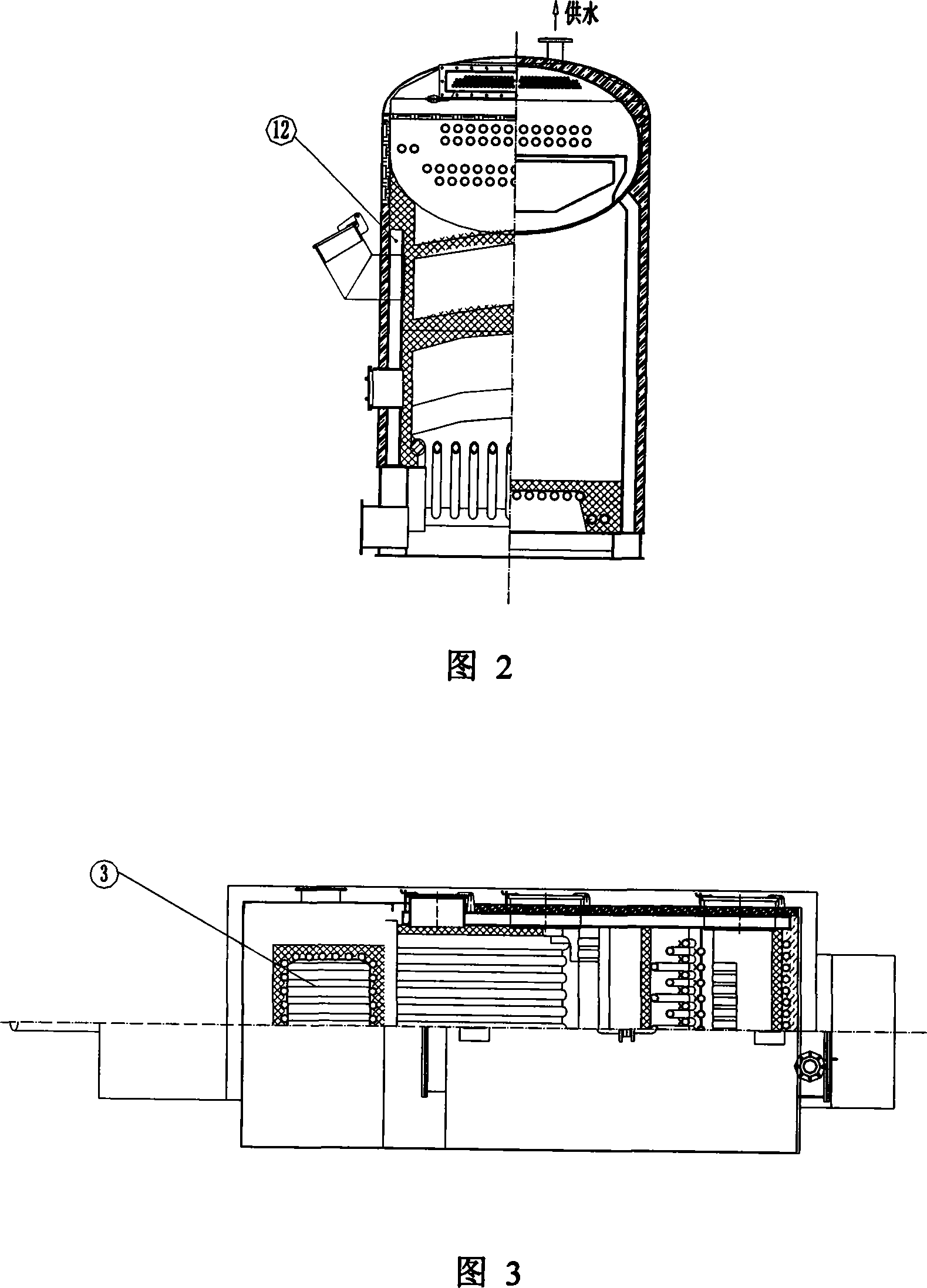

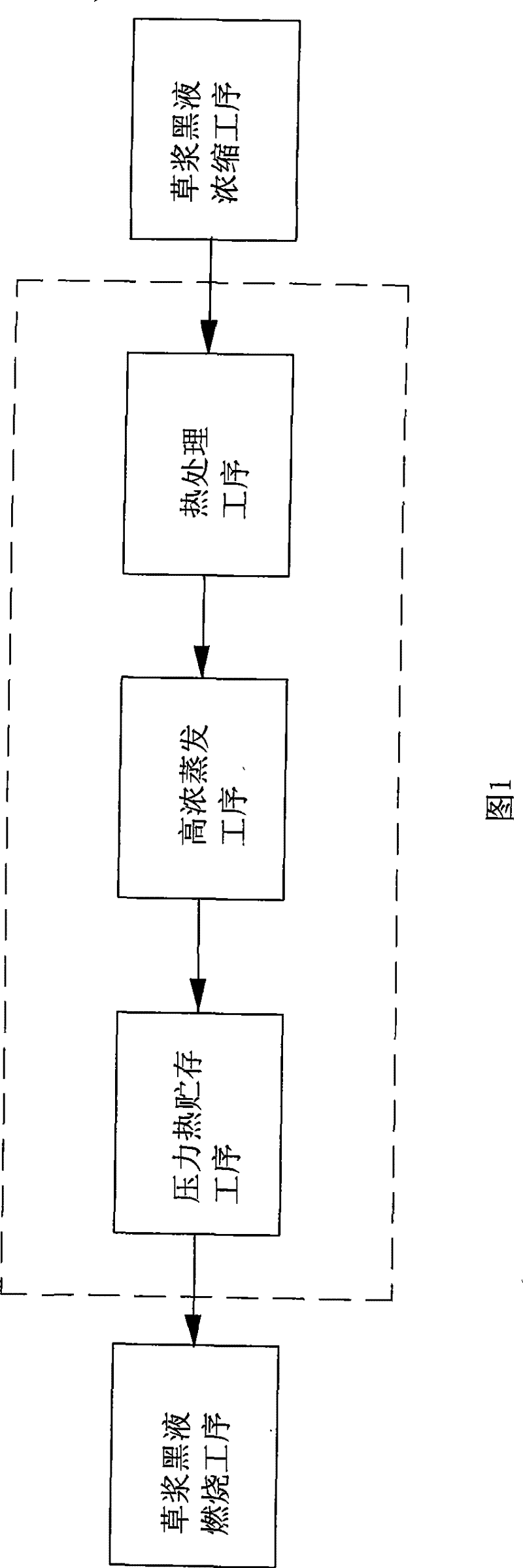

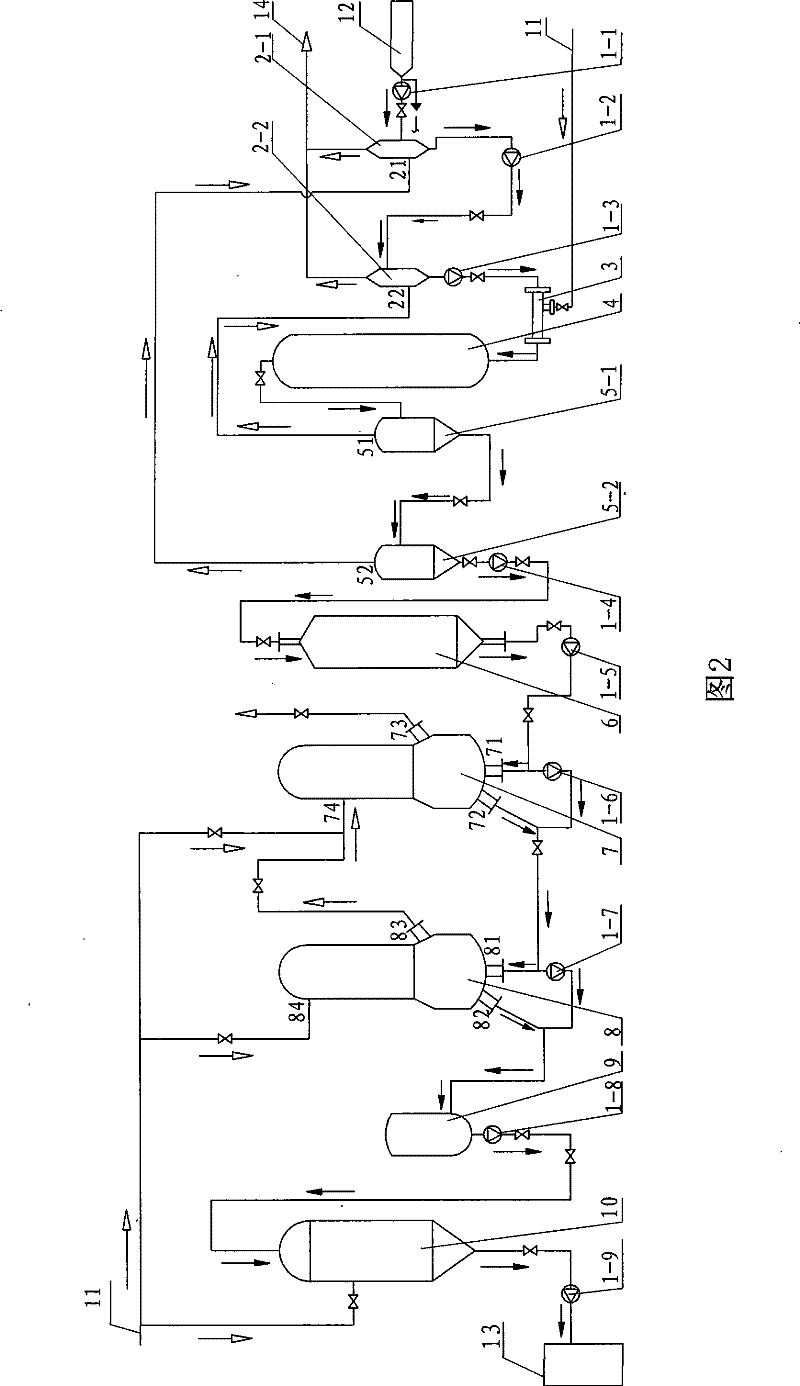

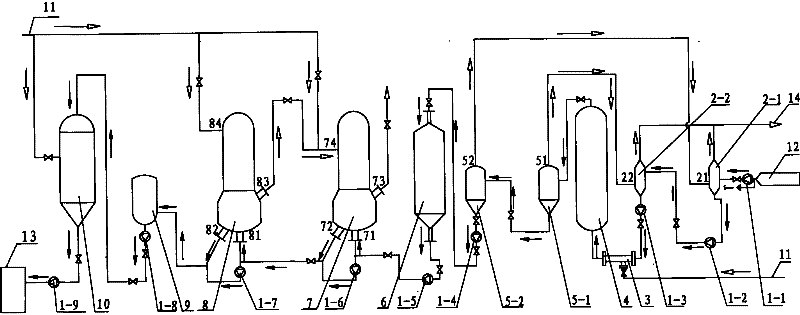

Process and equipment for improving concentration of straw pulping black liquor by alkali method

ActiveCN101736639ALow investment costIncrease concentrationSpent liquor concentrationChemistryEvaporator

The invention relates to a process and equipment for improving the concentration of straw pulping black liquor by an alkali method. The process is characterized by being arranged between a condensing procedure and a burning procedure of the conventional process for alkali recovery of straw pulp by the alkali method and comprising: (1) a step of heat treatment, in which the final pressure of the black liquor is 1.0 to 1.2MPa and the temperature is between 175 and 180 DEG C, so that the polymerized sugar in high molecular weight is decomposed; (2) a step of high-concentration vaporization, in which the final concentration of the black liquor is 55 to 65 percent; and (3) a step of pressurized heat storage, in which the equipment mainly comprises a pre-pressurizing pump, a preheater, a heat mixer, a final pressure pressurizing pump, a heat processor, a flash evaporator, a concentrated black liquor storage tank, A and B vaporization thickeners, E and F circulating / conveying pumps, and a final concentration black liquor pressure storage tank. The process and the equipment have the advantages that: the energy is saved and the energy consumption is reduced; the straw pulping black liquor is good in atomizing dispersibility, is easily burned and does not block an air inlet; the corrosion of the device is reduced; on a basis of the original straw pulp alkali recovery process, the process and the equipment are just added and the original process can be normally operated, so that the energy saving investment cost is lowered.

Owner:天津晟成环境技术发展有限公司

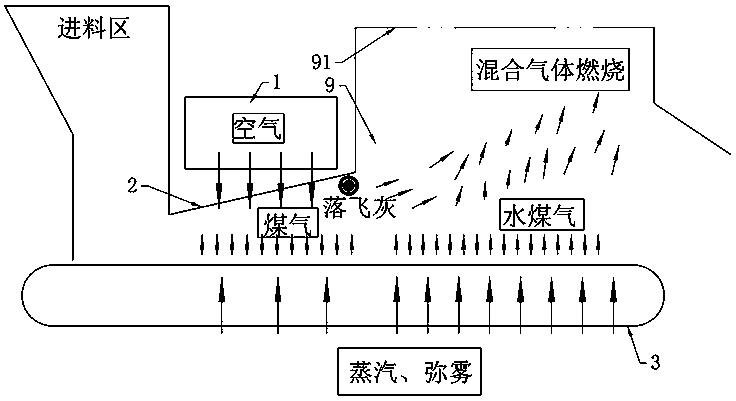

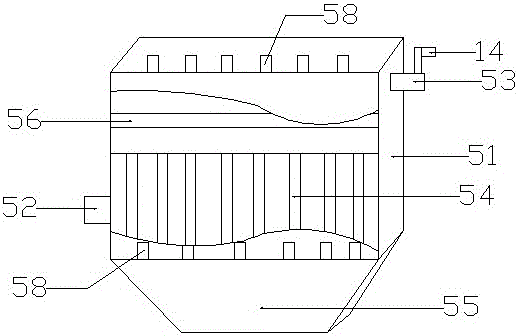

High-efficient combustion furnace with self-steam-supplying combustion-supporting function

InactiveCN102338373AImprove combustion efficiencyLow costSolid fuel combustionNon-combustible gases/liquids supplySlagEngineering

The invention relates to a high-efficient combustion furnace with a steam-self-supplying combustion-supporting function, which comprises two main parts of a furnace body and a water tank, wherein the pitch between a grate and the water level in the water tank is 10-500mm, the burned-out coal slags or other solid substances fall into the water tank from the grate, a part of the water contacted with the slags can be immediately heated by the high-temperature slags to be boiled, the produced steam can rise into the combustion furnace, then enters a hearth by a very short travel, and then reacts with coal to produce coal gas, and the water has the combustion-supporting function. In addition, in the structure, the fly ash can be furthest reduced, so that a small combustion furnace can achieve the effect of clean operation with low cost.

Owner:肖建选

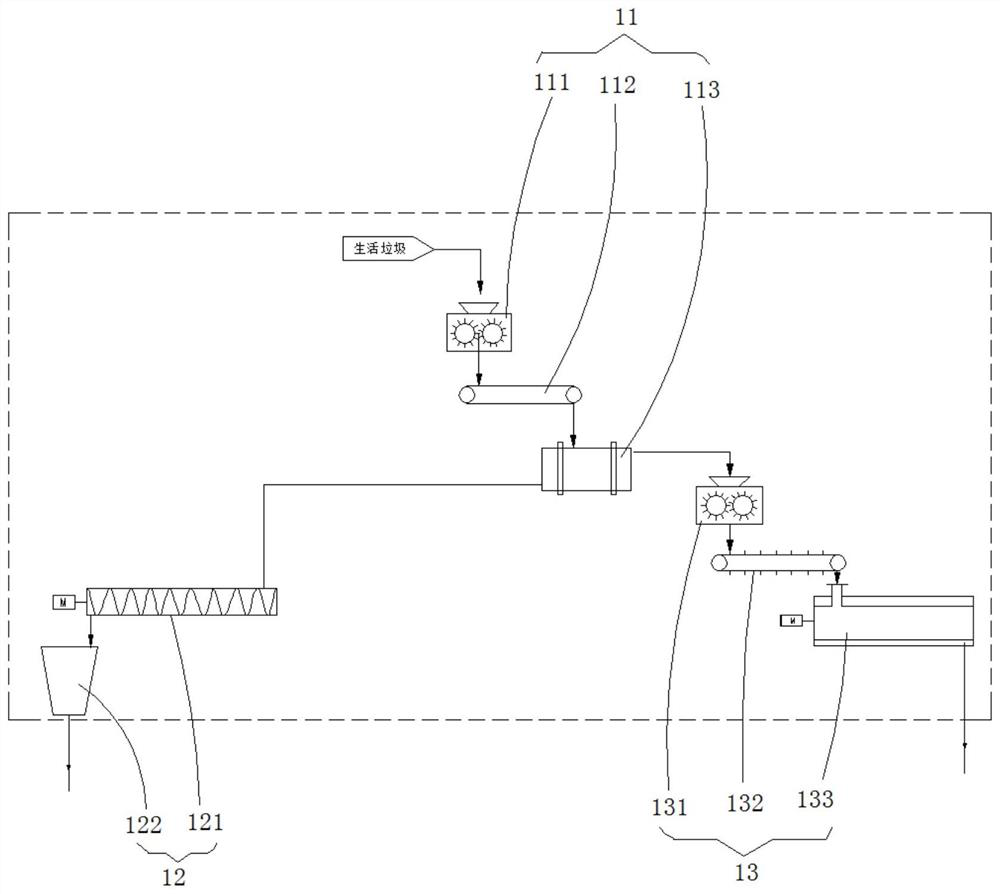

Anaerobic cracking treatment device for household garbage

PendingCN111826176ARealize comprehensive utilizationEnvironmental protectionDirect heating destructive distillationSpecial form destructive distillationCombustion systemThermodynamics

The invention discloses an anaerobic cracking treatment device for household garbage. The device comprises: a feeding system, which is used for pretreating raw materials and dividing the raw materialsinto a first material and a second material; a carbonization cracking system, which is used for carrying out pyrolysis treatment on the raw materials conveyed by the feeding system, and comprises a carbonization furnace and a cracking furnace, wherein the carbonization furnace comprises a carbonization part and a carbonization heating jacket, and the cracking furnace comprises a cracking part anda cracking heating jacket; a cracking gas purification system, which is used for purifying gas generated by the carbonization furnace and the cracking furnace; and a combustion system, which is usedfor providing heat required by reaction for the carbonization furnace and the cracking furnace by the gas purified by the cracking gas purification system. The household garbage is divided into two parts to be treated, each part of the household garbage is subjected to pyrolysis treatment in an anaerobic cracking mode, the cracked product can be recycled, and comprehensive utilization of resourcesis achieved.

Owner:GUANGZHOU WEIGANG ENVIRONMENT TECH CO LTD

A formula of biocarbon and a biocarbon production process

A formula of biocarbon and a biocarbon production process are provided. The formula comprises gangue, yellow waste, potassium nitrate, sodium nitrate, borax, efficient plant particles and water. The production process includes smashing the gangue and the yellow waste into powder having a size of 30 meshes, stirring uniformly, adding the potassium nitrate, the sodium nitrate, the borax and the efficient plant particles, stirring the materials, adding the water, fully mixing, performing cold press molding, and drying to obtain a finished product. The product can be fully combusted, reduces fly ash, and reduces slag heat loss. By detection, 50-60% of the discharging amount of smoke dust is reduced, 50-70% of coal is saved, the heat efficiency is increased by 70-90%, the SO2 content in flue gas is reduced by 40-70%, and the sulfur fixation rate can be more than 50%. Combustion structures and working conditions are changed. The product saves energy, reduces environment pollution, is low in cost and high in benefit, and can be widely used as industrial or household fuel.

Owner:魏文彬

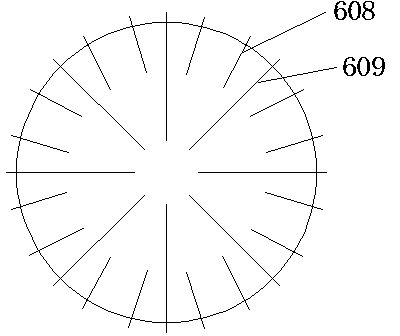

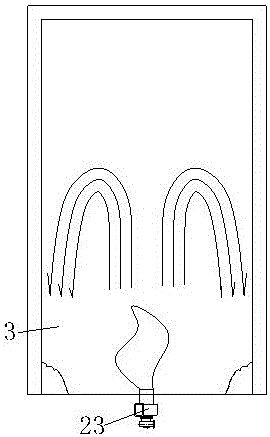

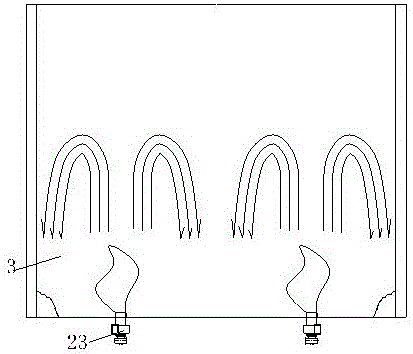

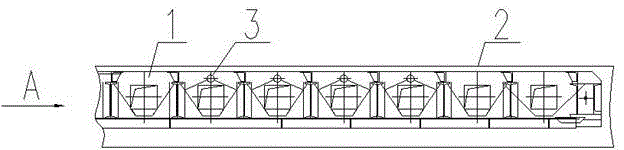

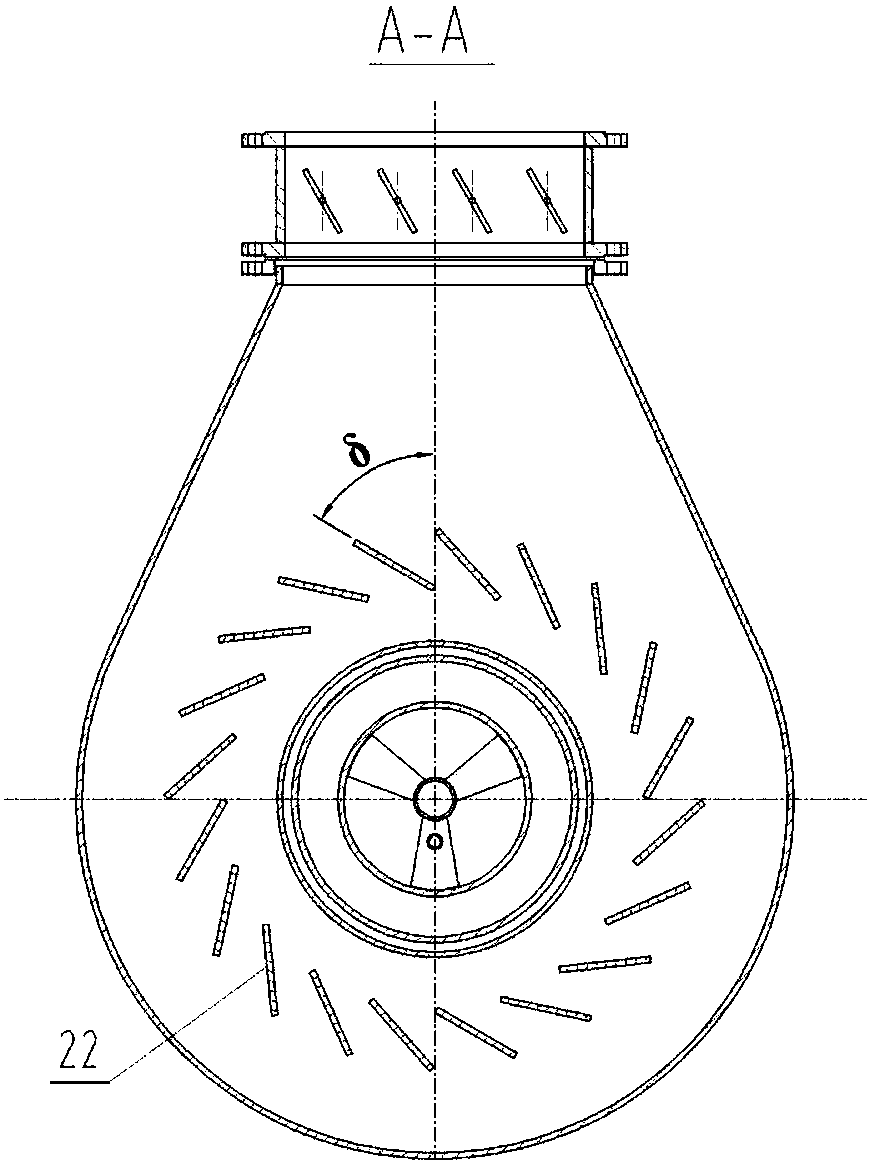

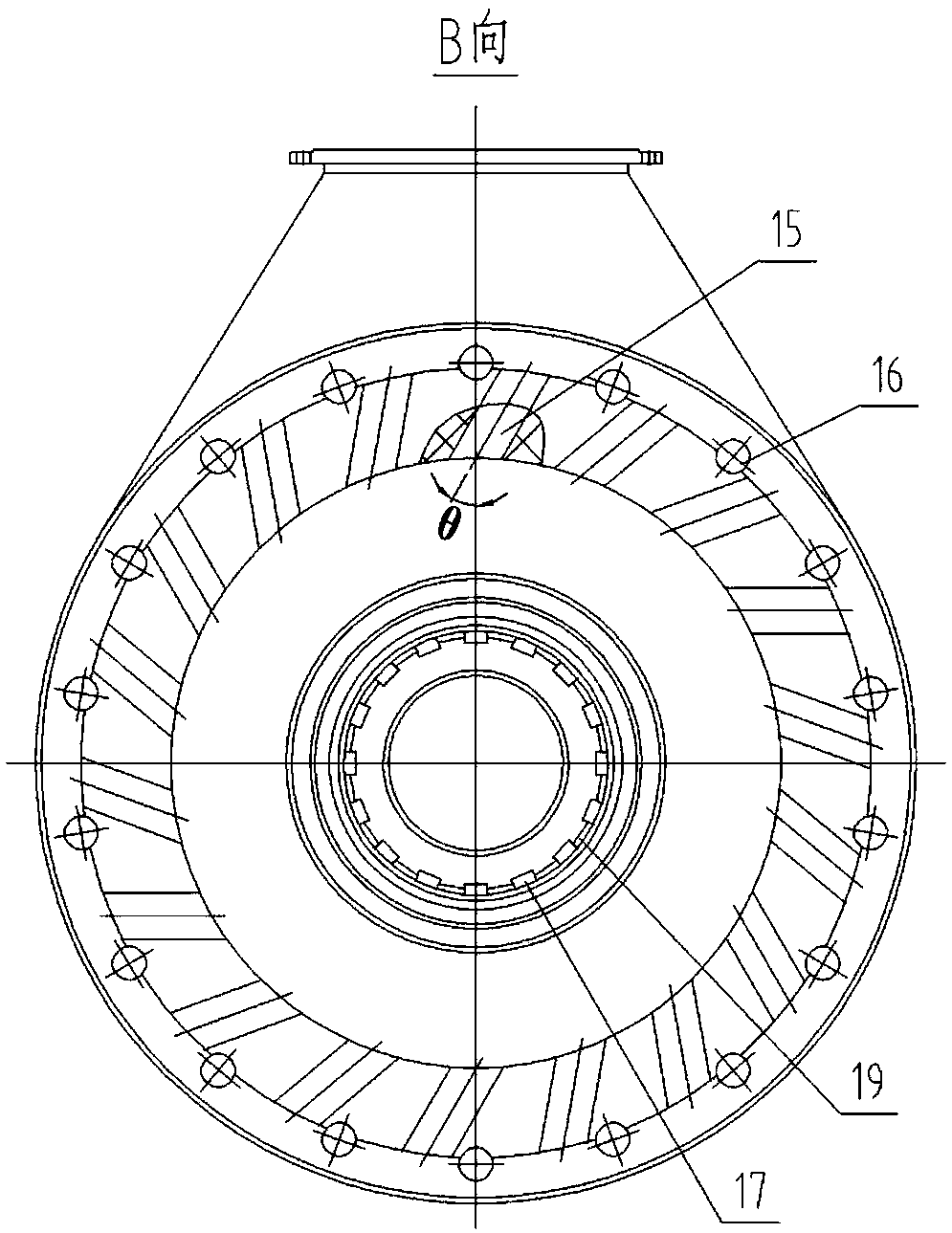

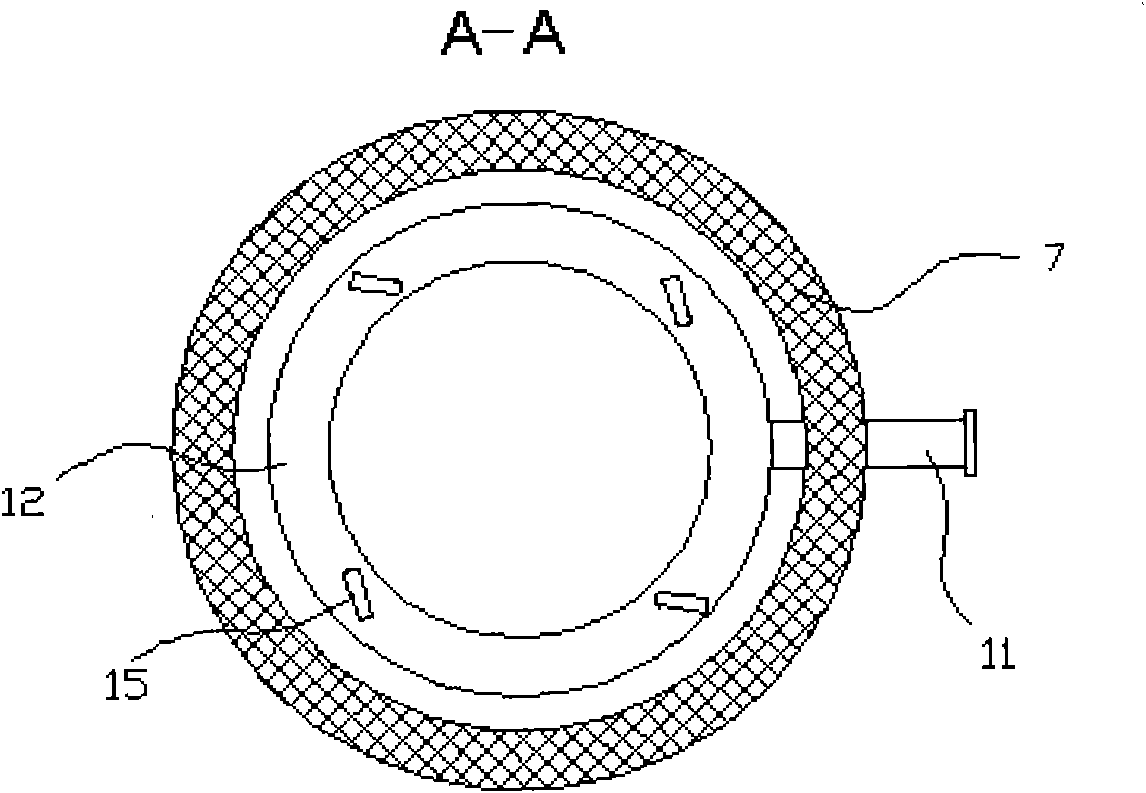

Coal powder boiler

InactiveCN106168375AReduce fly ashCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorHearth

The invention relates to the mechanical field, in particular to a pulverized coal boiler. The present invention provides a pulverized coal boiler, which includes a furnace and burners for burning pulverized coal, the number of the burners is even, the burners are evenly located at the bottom of the furnace, and the burners are inclined towards the center of the furnace . In the pulverized coal boiler of the present invention, the number of the burners is even, the burners are evenly located at the bottom of the furnace, and the burners are inclined towards the center of the furnace. Burners inclined towards the center of the furnace, most of the ash produced by combustion moves towards the center of the furnace or towards the bottom of the furnace. Since a pair of burners are symmetrical to each other, the airflow of the two burners is balanced in the center of the furnace, so the ash The ash falls from near the center of the hearth as the inertia decreases. Therefore, the pulverized coal boiler of the present invention can reduce the fly ash attached to the side wall of the furnace or accumulated at the bottom of the furnace close to the side wall of the furnace.

Owner:HANGZHOU JUNENG BOILER

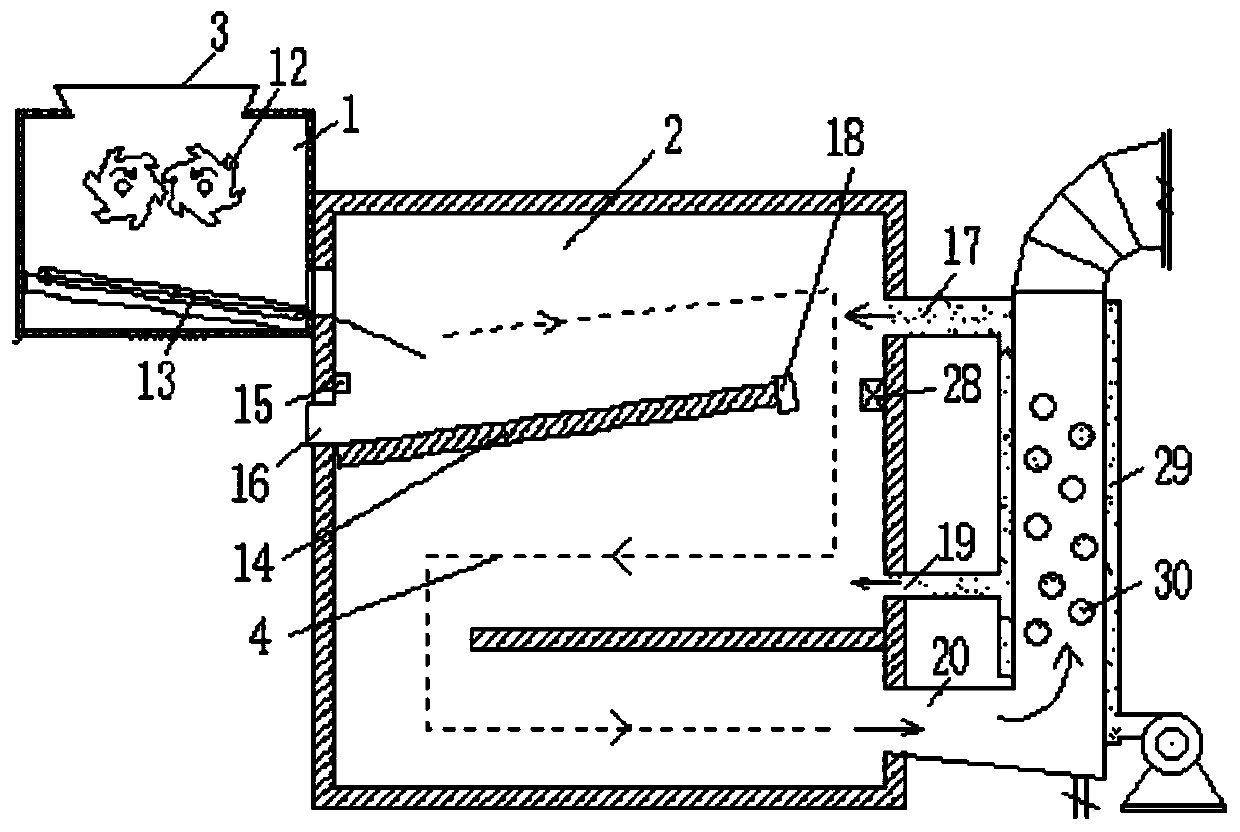

Garbage incineration smoke gas dry process treatment method and garbage incineration smoke gas dry process treatment device

InactiveCN104214780ADecompose thoroughlyImprove adsorption capacityDispersed particle filtrationMultistage water/sewage treatmentActivated carbonCombustion chamber

The invention belongs to the technical field of garbage incineration treatment, and particularly relates to a garbage incineration smoke gas dry process treatment method and a garbage incineration smoke gas dry process treatment device. Garbage to be treated is put into a preheated incineration furnace to be subjected to primary combustion, meanwhile, calcium oxide is added through the top, next, smoke gas descends to enter a secondary combustion chamber through a fire grate to be subjected to secondary combustion, and then, the combusted smoke gas is subjected to heat exchange to 150 to 250 DEG C from a smoke gas outlet (the temperature is properly higher than the dew point corrosion temperature and lower than the acceptable maximum temperature of subsequent smoke gas treatment equipment such as dust removal equipment and fans); then, the smoke gas is subjected to cloth bag dust removal and fixed bed activated carbon adsorption purification, after standards are reached, the smoke gas is led to a chimney through a draught fan to be exhausted, and in addition, material supply and air supply are controlled, so that the oxygen content in the exhausted smoke gas is in a reasonable interval being 5 to 13 percent.

Owner:王惠生

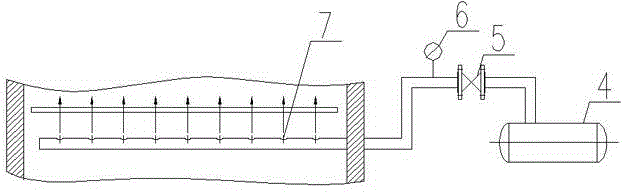

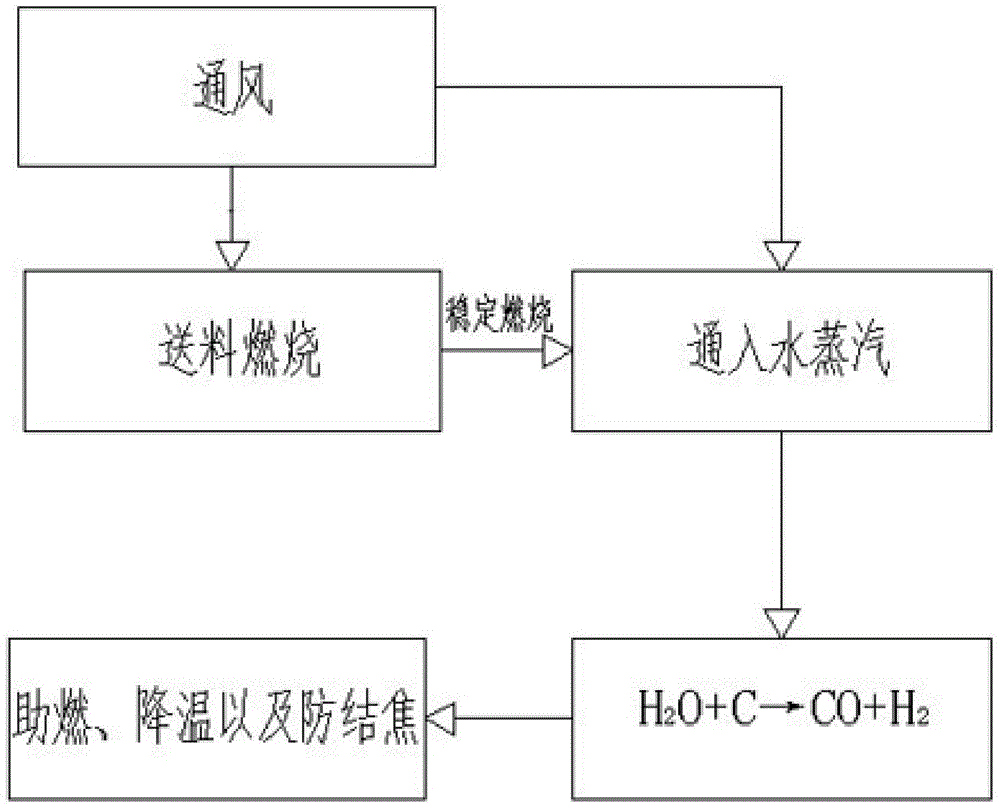

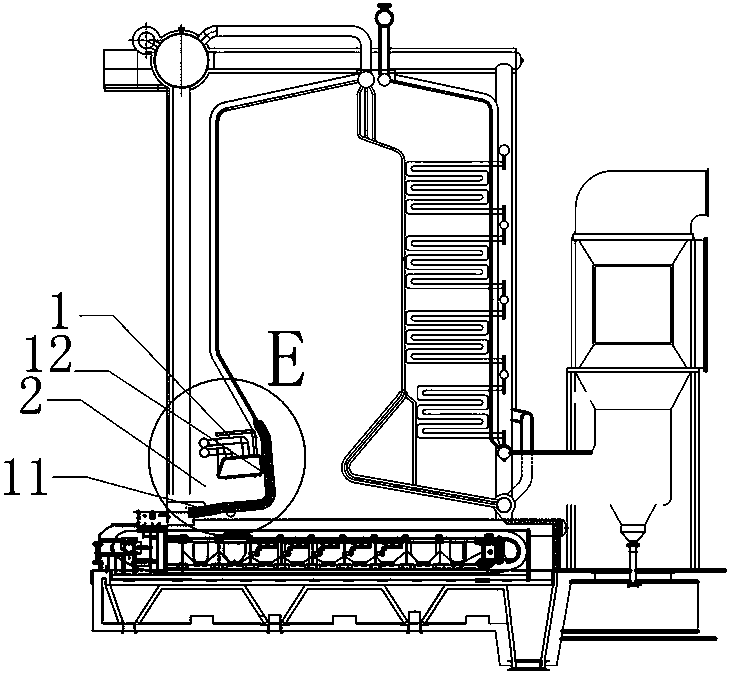

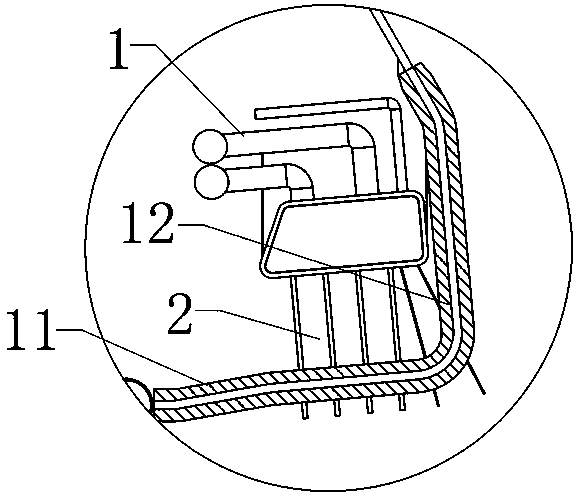

Boiler capable of preventing biomass coking

InactiveCN105003909ALower combustion temperatureReduce the temperatureSolid fuel combustionNon-combustible gases/liquids supplyEngineeringBiomass boiler

The invention discloses a boiler capable of preventing biomass coking. The boiler comprises an air distribution chamber, a chain grate stoker, a steam conveying pipe, a steam manifold, a reducing valve, a pressure gage and steam outlet holes; the air distribution chamber is arranged below the chain grate stoker, and the steam conveying pipe is arranged at the position, above an air distribution bend, of the air distribution chamber, and is fixed to an inclined lateral wallboard of the air distribution chamber through a support; the steam conveying pipe is connected with the steam manifold through the reducing valve; the pressure gage is further installed at the position, in front of the air distribution chamber, of the steam conveying pipe and is located at the front end of the reducing valve; and the steam outlet holes are arranged at the positions, located inside the air distribution chamber, on the steam conveying pipe and face a main burning area of the chain grate stoker, and steam can rapidly reach portions needing to be cooled. The boiler capable of preventing biomass coking includes two steps of feeding burning and steam leading in. According to the method, the air distribution chamber is combined with steam conveying, the structure is compact, using is simple and convenient, biomass burning coking is effectively prevented, the burn-off rate is improved, the cost is reduced, and the method is suitable for industrial production.

Owner:青岛青义锅炉有限公司

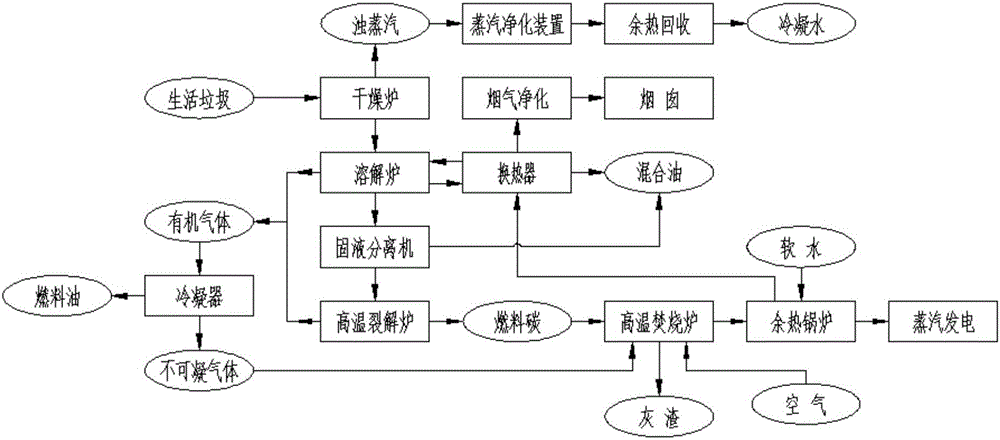

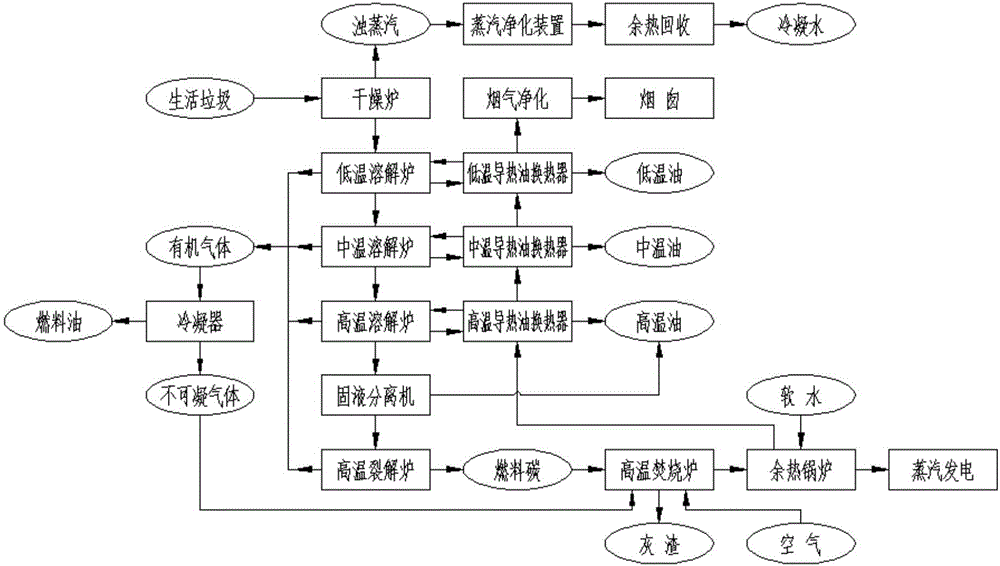

Household garbage treatment method

InactiveCN106287733AReduce heatReduce consumptionLiquid hydrocarbon mixture recoveryIncinerator apparatusOil and greaseOrganic matter

The invention relates to the technical field of garbage treatment, in particular to a household garbage treatment method. The method comprises following steps that garbage is fed into a dissolving furnace, dissolving oil is led into the dissolving furnace, organic matter in garbage is dissolved into dissolving oil and / or grease generated through heating and decomposing of the organic matter through dissolving oil is blended into the dissolving oil to form mixed oil, and volatile organic gas is collected; a solid-liquid mixture is fed into a solid-liquid separator to be subject to solid-liquid separation, and remaining mixed oil and residual solids are obtained; the generated residual solids are fed into a cracking furnace to be subject to high-temperature cracking, and fuel carbon and organic gas are obtained; the technical problem that when an existing product carries out pyrolysis on household garbage, the pyrolysis temperature higher than the garbage resistant to high temperature is adopted to carry out pyrolysis on the garbage resistant to low temperature, and energy is wasted is solved, and the household garbage treatment method can reduce energy consumption during household garbage pyrolysis.

Owner:THERMONERGY HIGH TECH CO LTD

Environmental-protection energy-saving emission-reduction synthetic smokeless coal

InactiveCN102559326AExtended burn timeHigh thermal efficiencyBiofuelsSolid fuelsEngineeringHigh pressure

The invention provides environmental-protection energy-saving emission-reduction synthetic smokeless coal, which belongs to the field of environmental-protection energy sources, uses rice husks as main raw materials to replace the existing coal, and can achieve energy conservation, environment protection and enough heat value. The environmental-protection energy-saving emission-reduction synthetic smokeless coal comprises parts by weight, main materials of rice husk particles and smokeless coal particles and auxiliary materials of corn starch. The environmental-protection energy-saving emission-reduction synthetic smokeless coal is high strength briquette molded by high pressure, is compact in texture, cannot crack automatically in a combustion process, is small in fly ash, restructures and changes structures, performances and properties of the coal, and can achieve maximum efficiency. The environmental-protection energy-saving emission-reduction synthetic smokeless coal has the advantages of being rapid in ignition, capable of prolonging combustion time of the coal, improving thermal efficiency and saving the coal, free of pollution and smoke, capable of achieving the purposes of dust removal combustion supporting and desulfuration, convenient to use, safe and reliable, easy to store and capable of being applied to industrial power coal and civil life coal widely.

Owner:GILIN HAOXIN IMPORT&EXPORT

Energy-saving and environmentally-friendly chain furnace

InactiveCN108730961ASimple structureEasy to useSolid fuel combustionCombustion apparatusCombustionCoal conversion

The invention discloses an energy-saving and environmentally-friendly chain furnace which comprises a gasification device and a fly ash unit; the gasification device is arranged at the upper part of afire gate, blows combustion-supporting air to the fire gate from top to bottom and is arranged at a front arch, an open chamber for accommodating the purification device is formed in the front arch,and the gasification device blows the combustion-supporting air to the fire gate from top to bottom; the fly ash unit is positioned in a position at the rear end of the front arch and is used for blowing fly ash into a furnace body, so that coal and the fly ash in the chain furnace are fully burned, therefore, the coal conversion efficiency is higher, the waste of coal resources cannot be caused,and the pollution caused by harmful gas produced by insufficient combustion of the coal to an environment is reduced; the chain furnace is simple in structure and convenient to use, thereby being an energy-saving, efficient and environmentally-friendly novel chain furnace.

Owner:刘振亮

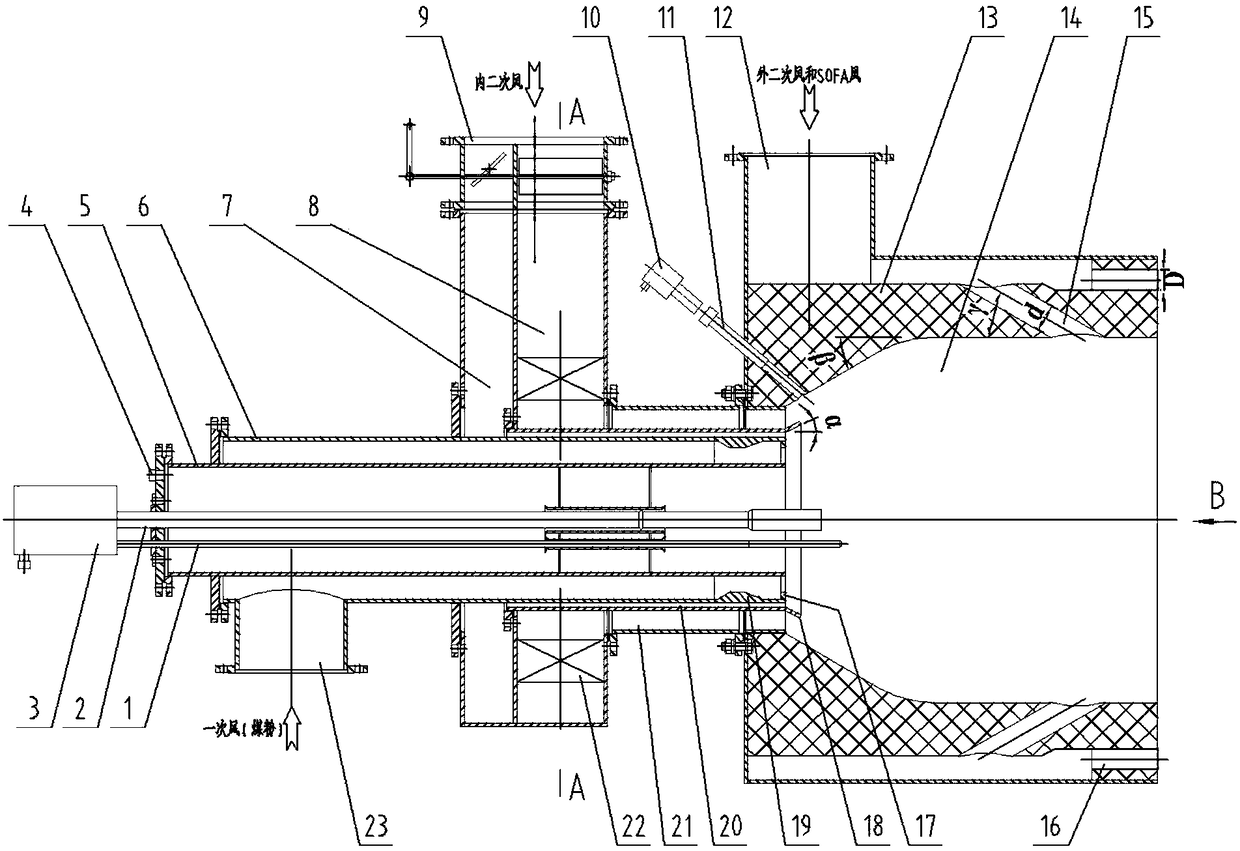

A high-temperature flue gas recirculation pre-combustion low NOx burner equipped with sofa

ActiveCN106287667BRealize the separation of thick and lightReduce oxygen concentrationSolid fuel combustionAir/fuel supply for combustionRefluxCyclone

The invention discloses a high temperature flue gas recirculation precombustion type low NOx combustor provided with SOFA. The combustor comprises a precombustion chamber, wherein a middle core tube is arranged at one side of the inlet of the precombustion chamber, an external secondary air and SOFA air sleeve is arranged on the precombustion chamber, a plurality of external secondary air spray holes are formed in the side wall of the precombustion chamber, and a plurality of SOFA air direct flow spray holes are formed in the outer side of the shell of the precombustion chamber; the inlet of a cyclone internal secondary air sleeve is communicated with a cyclone internal secondary air passage, and the outlet is communicated with the precombustion chamber. According to the invention, the coal dust low temperature precombustion technology is adopted, coal dust is carried by primary air to enter the precombustion chamber, and pre-combusts under the reducing atmosphere of the precombusiton chamber. Internal secondary air is divided into two paths by a flap valve and mainly functions in disturbing and mixing, and different internal secondary air cyclone strengths can be formed by adjusting the opening of a cyclone internal secondary air regulating valve and a direct flow internal secondary air regulating valve. The combustor disclosed by the invention can effectively reduce emission of NOx, is good in flame stability and contributes to the reduction of NOx pollutant emission of thermal power enterprises.

Owner:XI AN JIAOTONG UNIV

Method and device for dry treatment of waste incineration flue gas

InactiveCN104214780BDecompose thoroughlyImprove adsorption capacityDispersed particle filtrationMultistage water/sewage treatmentCombustion chamberFixed bed

The invention belongs to the technical field of garbage incineration treatment, and particularly relates to a garbage incineration smoke gas dry process treatment method and a garbage incineration smoke gas dry process treatment device. Garbage to be treated is put into a preheated incineration furnace to be subjected to primary combustion, meanwhile, calcium oxide is added through the top, next, smoke gas descends to enter a secondary combustion chamber through a fire grate to be subjected to secondary combustion, and then, the combusted smoke gas is subjected to heat exchange to 150 to 250 DEG C from a smoke gas outlet (the temperature is properly higher than the dew point corrosion temperature and lower than the acceptable maximum temperature of subsequent smoke gas treatment equipment such as dust removal equipment and fans); then, the smoke gas is subjected to cloth bag dust removal and fixed bed activated carbon adsorption purification, after standards are reached, the smoke gas is led to a chimney through a draught fan to be exhausted, and in addition, material supply and air supply are controlled, so that the oxygen content in the exhausted smoke gas is in a reasonable interval being 5 to 13 percent.

Owner:王惠生

Clean-burning coal vacuum boiler

InactiveCN101178172ABurn fullyImprove combustion efficiencyWater-tube boilersCombustion chamberAtmospheric air

The invention relates to a clean coal-burning vacuum boiler, belonging to the technical filed of a vacuum boiler. The invention comprises a boiler body, a drum and a grate. The drum is arranged at the upper part of the boiler body and the grate is arranged at the lower part of the boiler. A burning chamber is arranged at the middle part of the boiler body. The invention is characterized in that the front part of the burning chamber of the boiler body is provided with a gas generation chamber; the upper part of the gas generation chamber is provided with a gas outlet; the gas outlet is communicated with the upper part of the burning chamber; the gas generation chamber is communicated with the lower part of the burning chamber and is provided with a fixed grate; an exit of the burning chamber is provided with a dedusting water-cooling pipe bank; and the two sides of the burning chamber are provided with a boiler lateral water-cooling tank. The invention has the advantages of increasing the coal burning efficiency, saving the energy resource, realizing smoke eliminating and dust removing effects, decreasing the atmosphere environmental pollution, economy and environmental protection, etc. The invention can be widely used in the coal-burning vacuum boiler industry.

Owner:天津天大胜远冷暖设备有限公司

Technology and equipment for increasing concentration of soda straw pulp black liquor

ActiveCN101736639BLow viscosityIncrease concentrationSpent liquor concentrationBlack liquorProcess engineering

The invention relates to a process and equipment for increasing the concentration of soda straw pulp black liquor, which is characterized in that the process is set between the concentration process and the combustion process of the traditional soda straw pulp alkali recovery process, steps: (1) heat treatment, the final pressure of black liquor is 1.0 ~1.2Mpa, temperature 175℃-180℃, to decompose high molecular weight polysaccharides in black liquor; (2) high-concentration evaporation, black liquor reaches a final concentration of 55% to 65%; (3) pressure heat storage; Booster pump, pre-heater, thermal mixer, final pressure booster pump, heat processor, flash evaporator, thick black liquor storage tank, A, B evaporation thickener, E, F circulation / delivery pump, final thick black hydraulic pressure The power storage tank constitutes. The advantages of the present invention are: energy saving and consumption reduction; straw pulp black liquor has good atomization dispersibility, is easy to burn, and does not block the air inlet; reduces device corrosion; only needs to add the process and technology provided by the present invention on the basis of the original straw pulp alkali recovery process. The equipment can run normally, reducing the investment cost of energy-saving transformation.

Owner:天津晟成环境技术发展有限公司

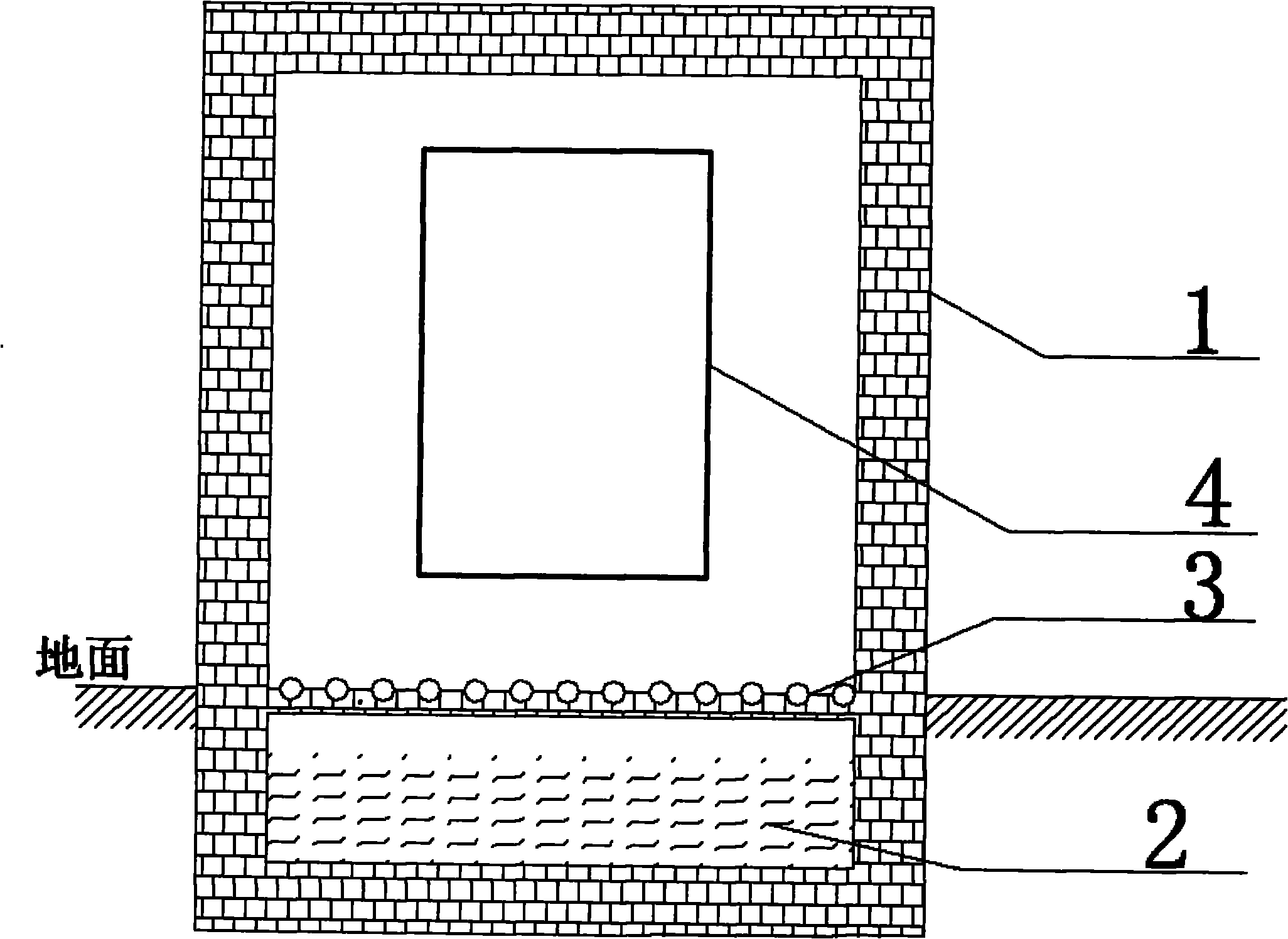

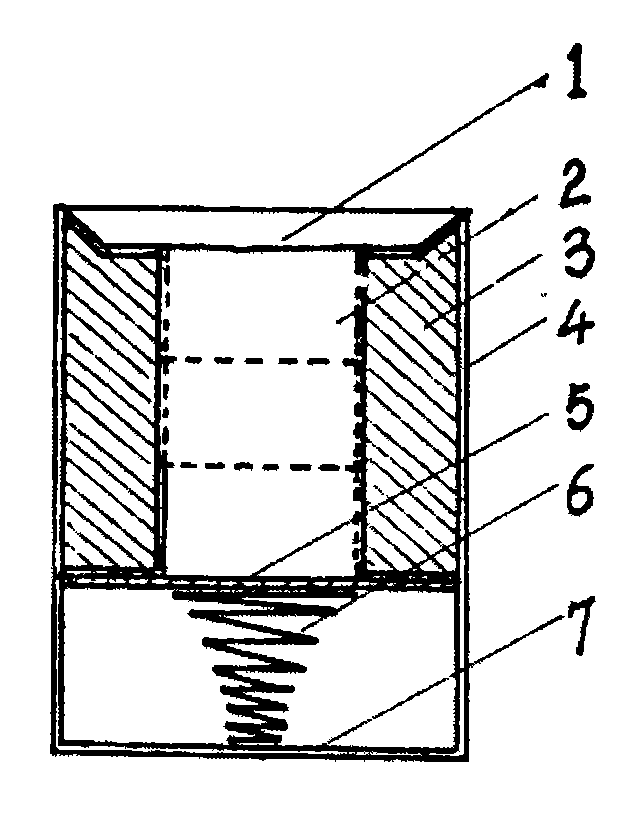

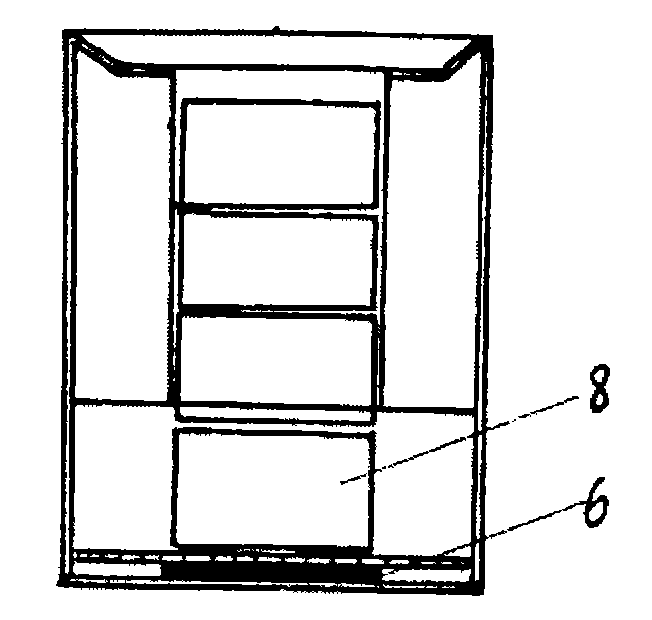

Briquette furnace

InactiveCN101586813AEasy to operateReduce fly ashDomestic stoves or rangesLighting and heating apparatusHeat lossesBriquette

The invention discloses a briquette furnace and aims at providing a novel technical proposal of the briquette furnace. The briquette furnace can discharge a cinder briquette from an ash outlet of the furnace, has relatively easy operation action, and reduces fly ash and heat loss. The briquette furnace consists of a furnace shell, a furnace wall, a furnace grate and a tower-shaped reed. The furnace grate is not fixedly connected with the furnace shell, and a compression spring is arranged between the furnace grate and the furnace bottom.

Owner:陈烁

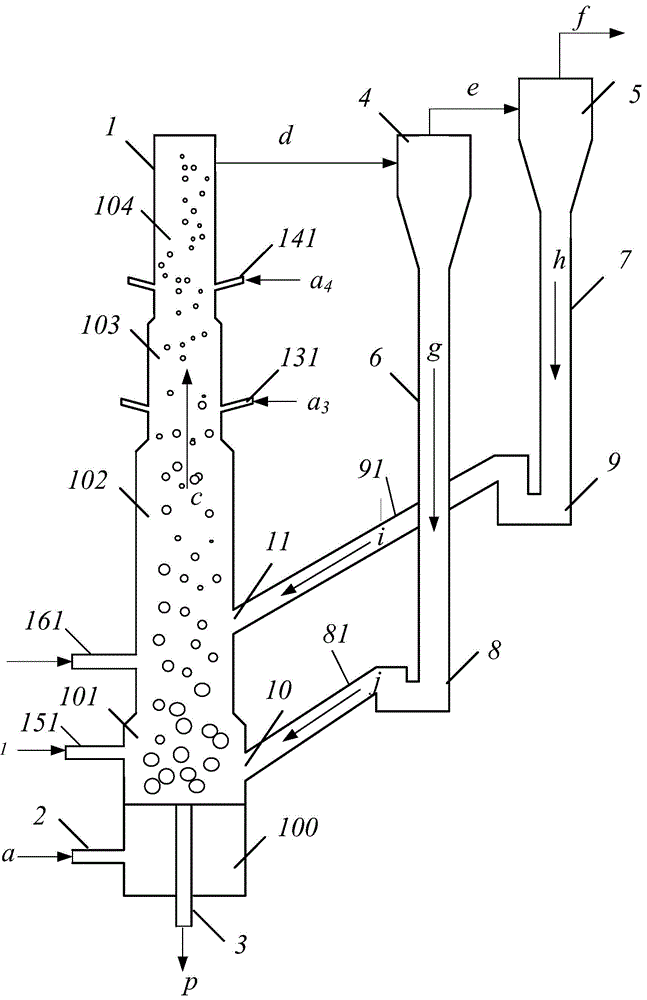

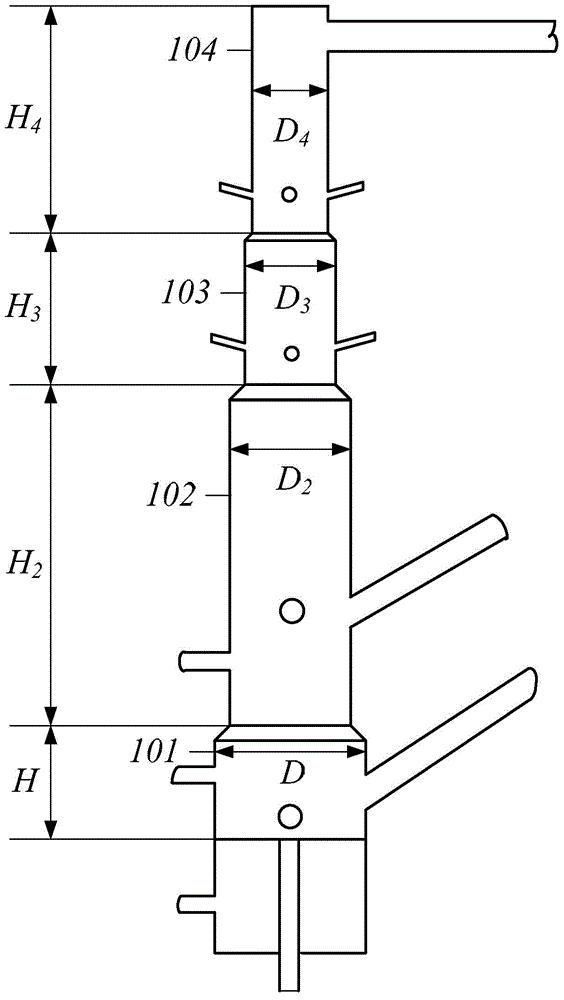

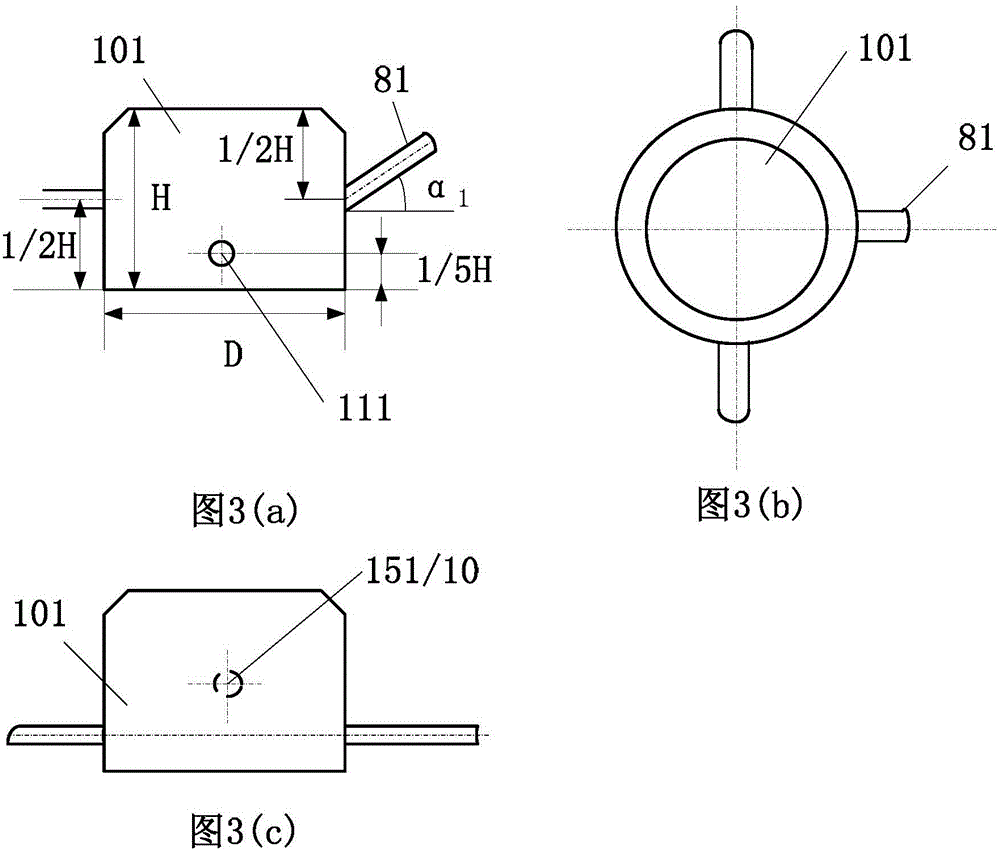

Multi-stage gas distribution high-temperature coal gasification device and method

ActiveCN103740409BIncrease gas-solid mixingMaintain medium and high temperature conditionsCombined combustion mitigationGranular/pulverulent flues gasificationHigh carbonReaction temperature

The invention discloses a multi-stage gas distribution high-temperature coal gasification device and a multi-stage gas distribution high-temperature coal gasification method. According to the device, an oxygen-enriched combustion section, a mixed gasification section, a gasification temperature-rise section and a gasification lifting section are arranged in a gasification reactor from bottom to top and are respectively provided with an independent gasifying agent, so that different reaction conditions of coal in each section are realized, the oxygen-enriched combustion section performs oxygen-enriched combustion on fuel to release heat so as to provide most of the heat needed by a gasification reaction, and the mixed gasification section, the gasification temperature-rise section and the gasification lifting section respectively perform different degrees of combustion and gasification reactions. During multi-stage gas distribution, gas is distributed according to the reaction characteristics of each section, the consumption of oxygen is greatly reduced, and high reaction temperature is kept in the gasification reactor; meanwhile, the temperature is uniformly distributed in the gasification reactor, and gasification with high gasification efficiency, high carbon conversion rate and low pollution is realized.

Owner:SOUTHEAST UNIV

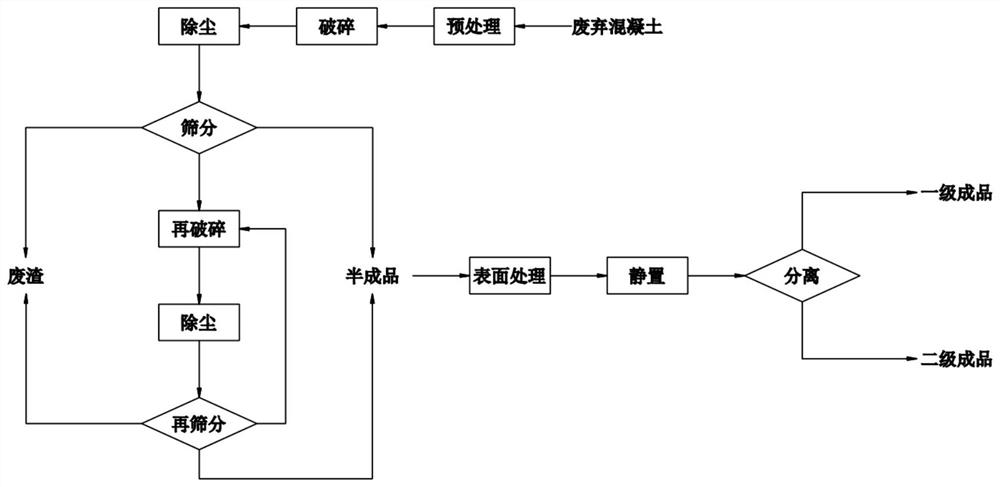

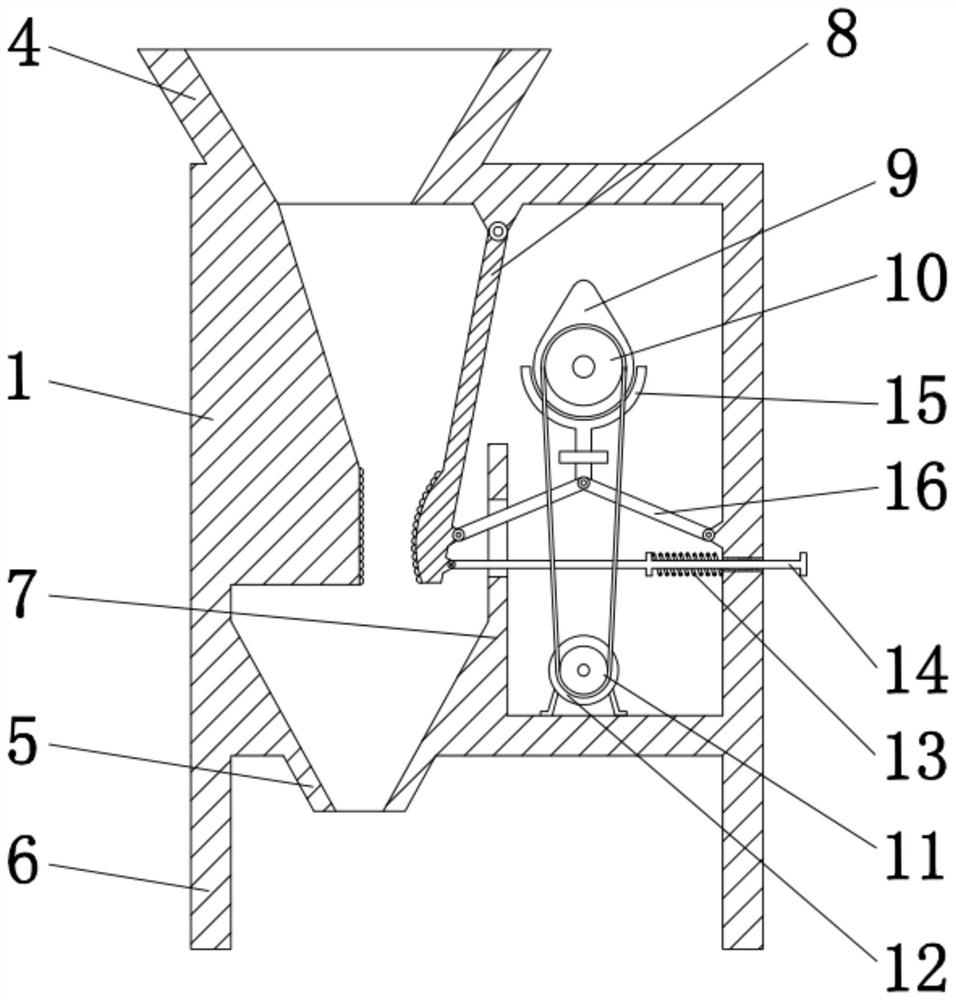

A kind of waste concrete coarse aggregate preparation method

ActiveCN110756325BHigh densityLow water absorptionSolid waste managementGrain treatmentsDust controlEngineering

The invention relates to the field of recycled aggregates, in particular to a waste concrete coarse aggregate preparation device and method comprising a crushing box, a dust removal tank and a immersion pool. The outer wall of the bottom of the box is welded with a hopper, the inner wall of the bottom of the crushing box is connected with a motor through bolts, and the output shaft of the motor is connected with a driving pulley through a flat key, and the inner wall of one side of the crushing box rotates A cam is connected, and a driven pulley is welded on one side of the outer wall of the cam, the driving pulley and the driven pulley are connected through a belt drive, and a push plate is slidably connected to one side of the inner wall of the crushing box, and the push plate is Two push rods are rotationally connected on the bottom outer wall of the board. The beneficial effect of the present invention is that, by performing surface treatment on the cleaned finished coarse aggregate, the density of the coarse aggregate is effectively increased, so that the strength of the coarse aggregate is improved, shrinkage and creep are reduced, and the durability is greatly improved.

Owner:滁州市富邦新型建材有限公司

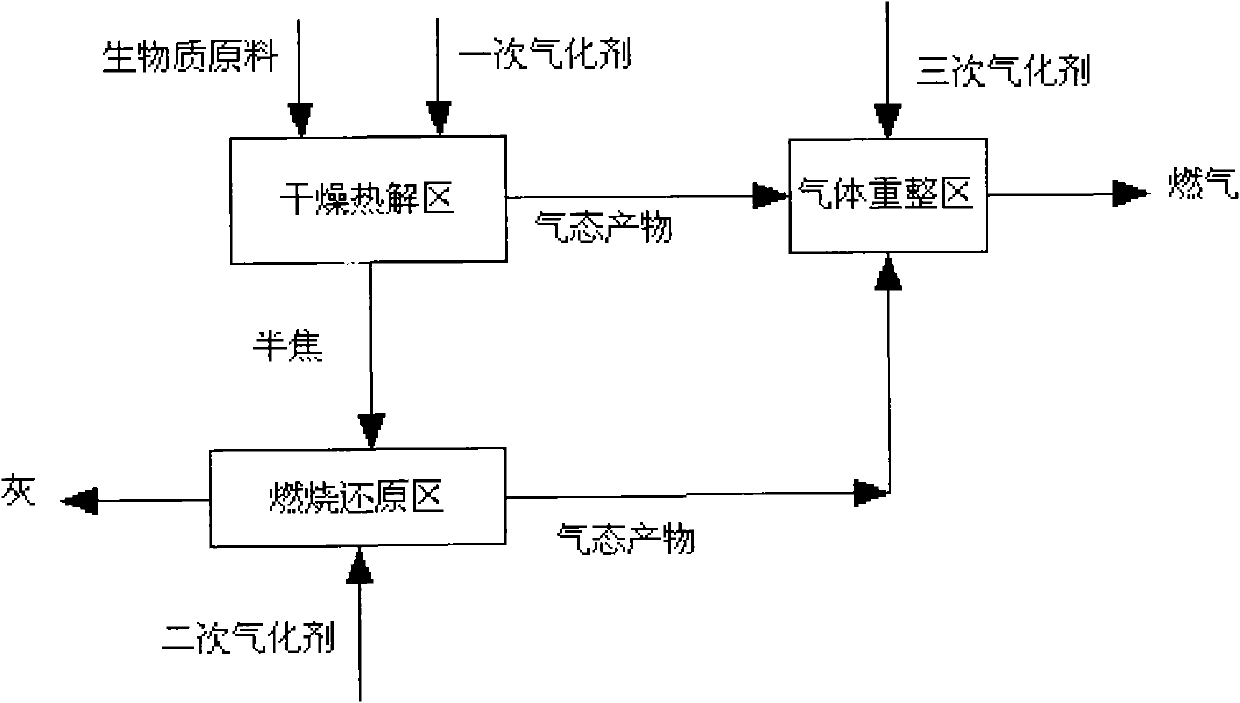

Biomass gasification method

ActiveCN101805638BImprove conversion utilizationControl gas compositionCombustible gas productionCombustionMass ratio

The invention discloses a biomass gasification method. The method requires the steps of drying pyrolysis, combustion deoxidization and gas reforming in the gasification process to be relatively separated and continuously carried out in the same gasification furnace, simultaneously continuously gasification agent is introduced at three points in the whole gasification process and finally the cleanhigh quality product gas is obtained. In the invention, the equivalence ratio of the total gasification agent is 0.2-0.35, and the mass ratio of a first gasification agent, a second gasification agent and a third gasification agent is (0-0.8):(2-3.5):(0.7-1.5). The method controls the temperature and the reaction depth of each subarea in the furnace by controlling the mutual ratio of the biomass materials, the first gasification agent, the second gasification agent and the third gasification agent so as to control the quality of the final product gas. The obtained product gas can be used as the energy or the chemical engineering synthesis raw material gas. The method can generate clean product gas from the biomass, cannot generate secondary pollution and has high carbon conversion rate and simple implementation method.

Owner:山东山科环境资源有限公司

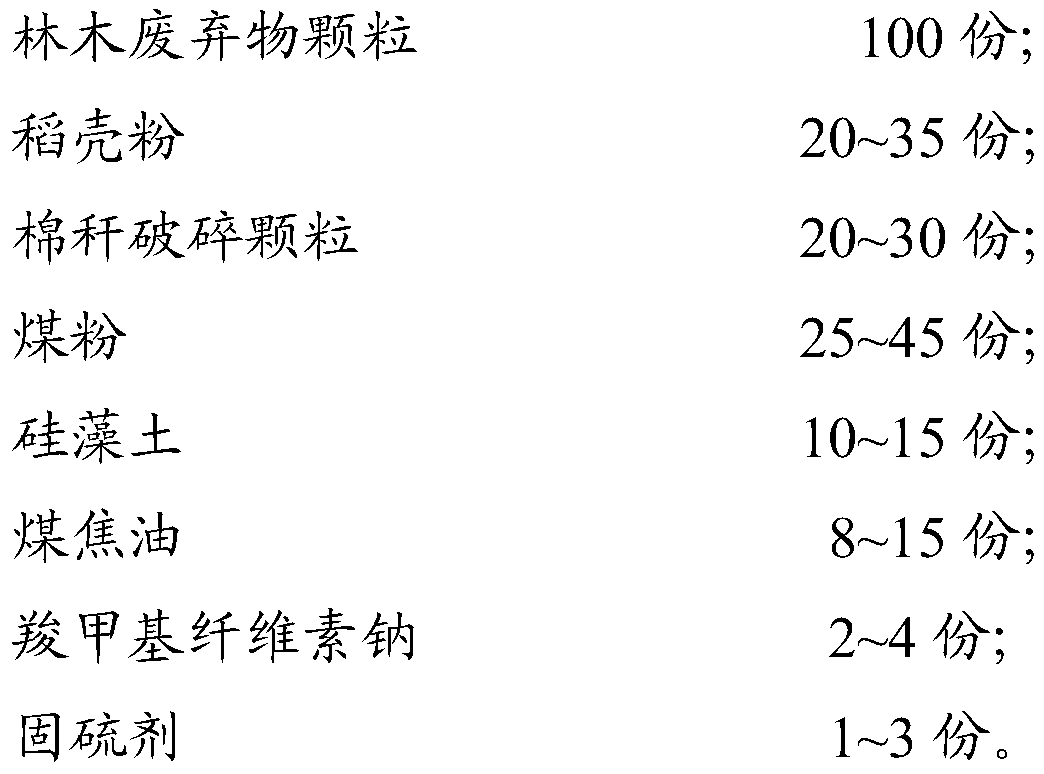

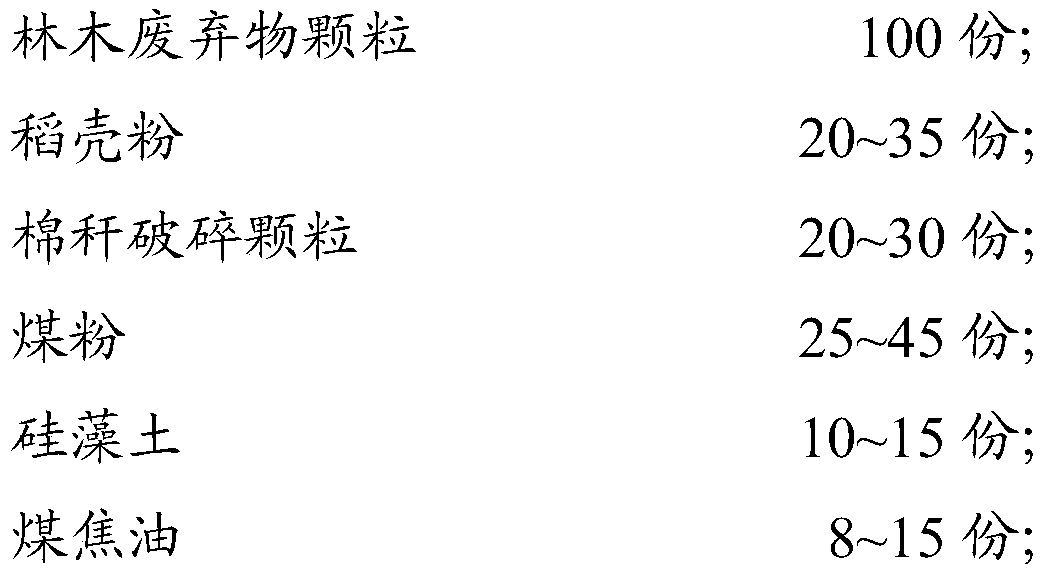

Biomass briquette fuel and preparation method thereof

The invention provides a biomass briquette fuel and a preparation method thereof, and belongs to the technical field of energy fuels. The biomass briquette fuel is prepared from, by mass, 100 parts offorest waste particles, 20-35 parts of rice hull powder, 20-30 parts of crushed cotton stalk particles, 25-45 parts of pulverized coal, 10-15 parts of diatomite, 8-15 parts of coal tar, 2-4 parts ofsodium carboxymethyl cellulose and 1-3 parts of a sulfur fixing agent. The biomass briquette fuel prepared from the components in proportion can be fully combusted, also has a high combustion heat value of 5150-5236 Kcal / kg, and does not generate sulfur dioxide gas or fly ash.

Owner:河南腾博兴环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com