Household garbage treatment method

A domestic garbage and treatment method technology, applied in the direction of combustion method, steam generation method using heat carrier, recovery of liquid hydrocarbon mixture, etc., can solve problems such as energy waste, and achieve the effects of reducing the total amount, reducing fly ash, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

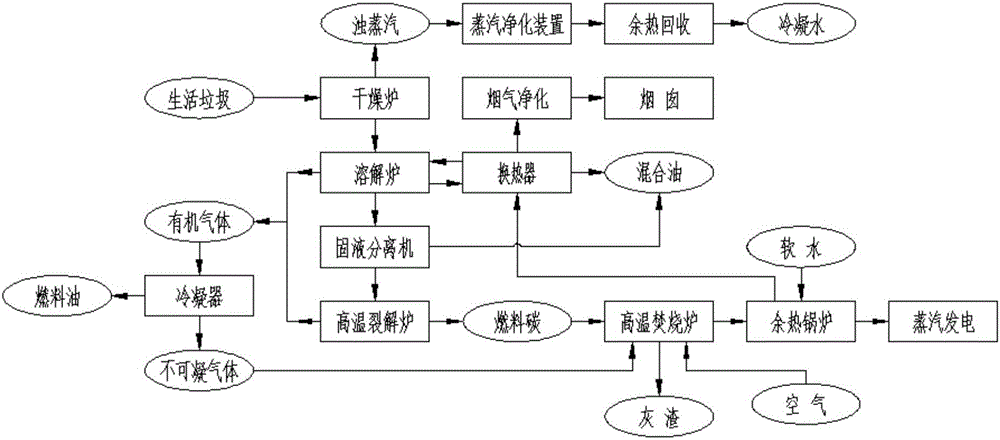

[0038] A kind of domestic refuse processing method of embodiment one, such as figure 1 shown, including the following steps,

[0039]S1. Put the garbage into the dissolving furnace, feed the dissolving oil into the dissolving furnace, and the dissolving oil dissolves the organic matter in the garbage into the dissolving oil to form a mixed oil, and collects the volatilized organic gas;

[0040] S2. Send the above solid-liquid mixture into a solid-liquid separator for solid-liquid separation to obtain the remaining mixed oil and residual solid.

[0041] S3. Send the residual solid produced in step S2 into a pyrolysis furnace for pyrolysis to obtain fuel carbon and organic gas.

[0042] S4. The fuel carbon in step S3 is sent into the incinerator, and air is introduced into the incinerator to obtain heat and high-temperature waste gas. The heat is used to supplement the heat of the cracking furnace and maintain the stability of the pyrolysis temperature in the pyrolysis furnace....

Embodiment 2

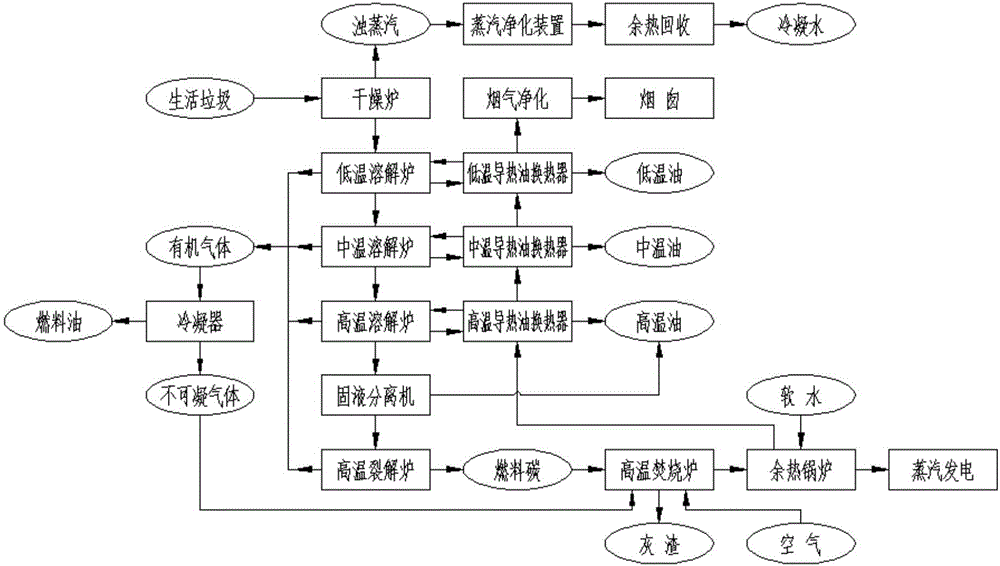

[0056] Such as figure 2 As shown, the domestic waste disposal method comprises the following steps:

[0057] S1. Put the garbage into the melting furnace, first feed low-temperature dissolved oil into the melting furnace, and the low-temperature dissolved oil dissolves the organic matter in the garbage into the low-temperature dissolved oil to form a low-temperature mixed oil, and collects volatile organic gases;

[0058] After the low-temperature mixed oil is discharged into the low-temperature heat exchanger for heating, the low-temperature mixed oil is returned to the melting furnace, and after a certain period of time, the low-temperature mixed oil in the melting furnace is discharged to the low-temperature heat exchanger and another melting furnace , and during the cycle, collect the organic gas produced.

[0059] Then feed the medium-temperature dissolved oil into the dissolution furnace, which dissolves the organic matter in the garbage into the medium-temperature dis...

Embodiment 3

[0078]In this embodiment, on the basis of Embodiment 1 or Embodiment 2, domestic waste is sent to the drying furnace intermittently after preliminary sorting and crushing to dry, and the dried waste and turbid steam are obtained, and the dried waste is sent into In the dissolution furnace, the turbid steam is sent to the steam purification device for purification. Waste heat recovery is performed on the steam purified by the steam purification device to obtain a product including condensed water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com