Garbage incineration smoke gas dry process treatment method and garbage incineration smoke gas dry process treatment device

A technology of dry treatment and waste incineration, which is applied in the direction of combustion methods, separation methods, chemical instruments and methods, etc., which can solve the problems of indiscriminate air supply, low utilization rate of heat energy, insufficient combustion, etc., to prevent low-temperature corrosion and high-temperature Injury, preheating cost savings, effects of flue gas resistance reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The technical solutions of the present invention will be described in detail below through specific examples.

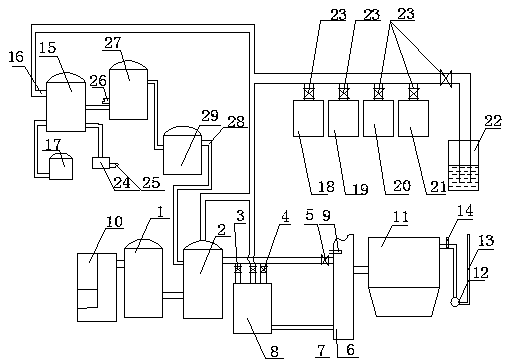

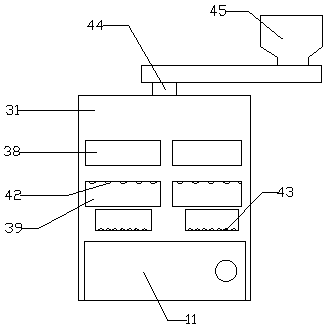

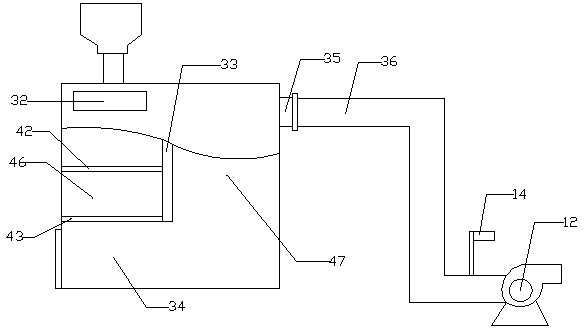

[0050] A dry treatment method for waste incineration flue gas, the steps are as follows: put the waste to be treated into the preheated incinerator for primary combustion, and at the same time add calcium oxide through the top, and then the flue gas goes down through the grate and enters the secondary combustion chamber After secondary combustion, the burned flue gas enters the main heat exchanger from the flue gas outlet for heat exchange and cooling; after the flue gas passes through the main heat exchanger for heat exchange and cooling, it enters the flue gas constant temperature adjustment device; through the constant temperature adjustment of the flue gas , keep the flue gas temperature at 150-250°C, and then carry out bag dust removal on the flue gas through the purification integrated device, fixed bed activated carbon adsorption and purification up to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com