Anaerobic cracking treatment device for household garbage

A technology for pyrolysis treatment and domestic waste, which is applied in special forms of dry distillation, petroleum industry, coke oven, etc., and can solve the problems of not meeting the requirements of the living environment of residents, water pollution of landfill leachate, and serious neighbor avoidance effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

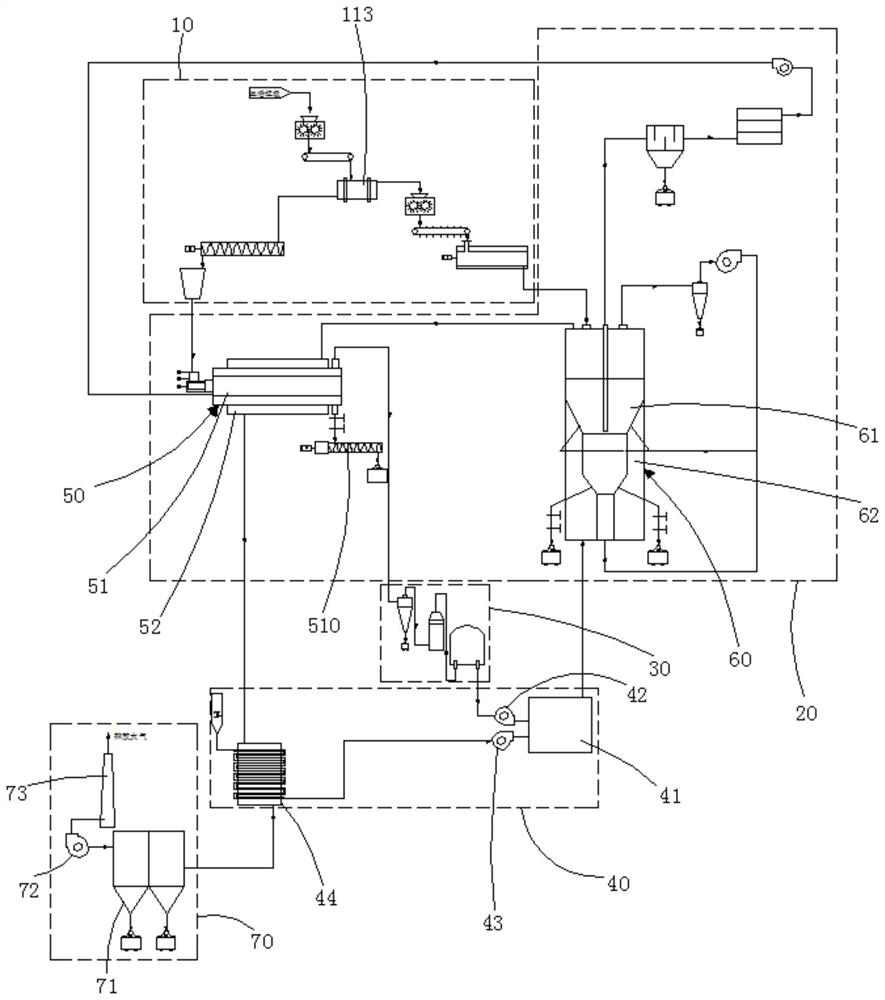

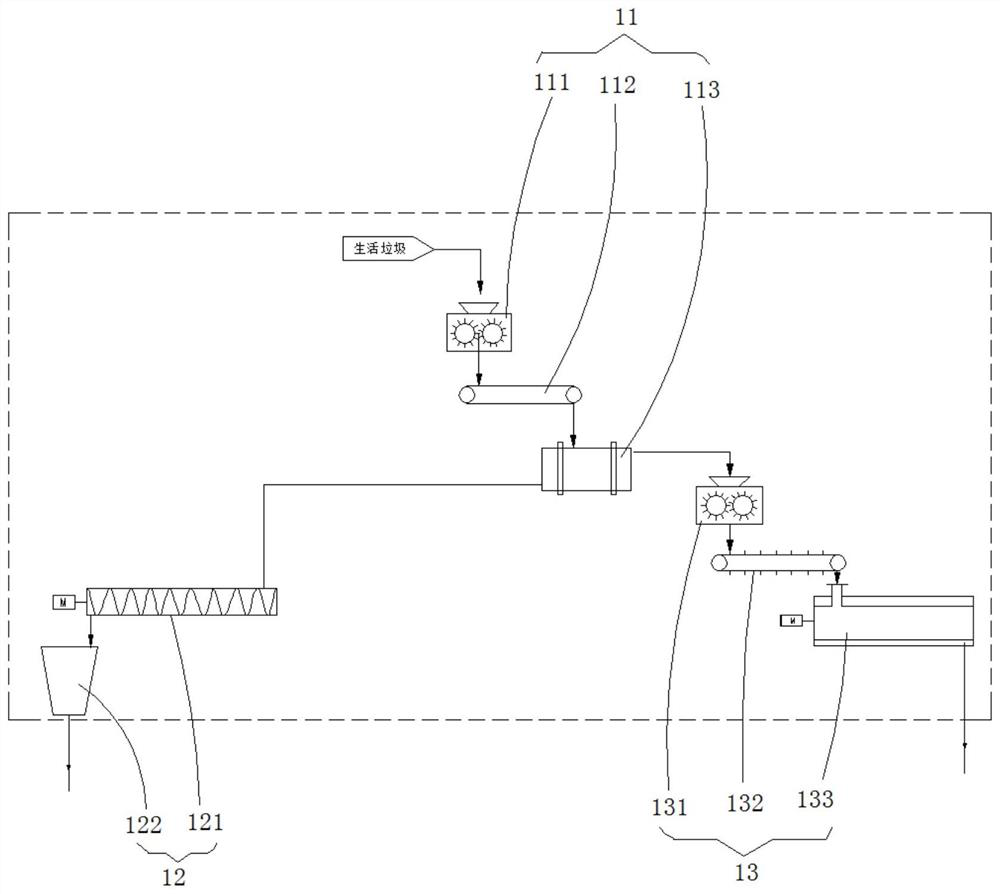

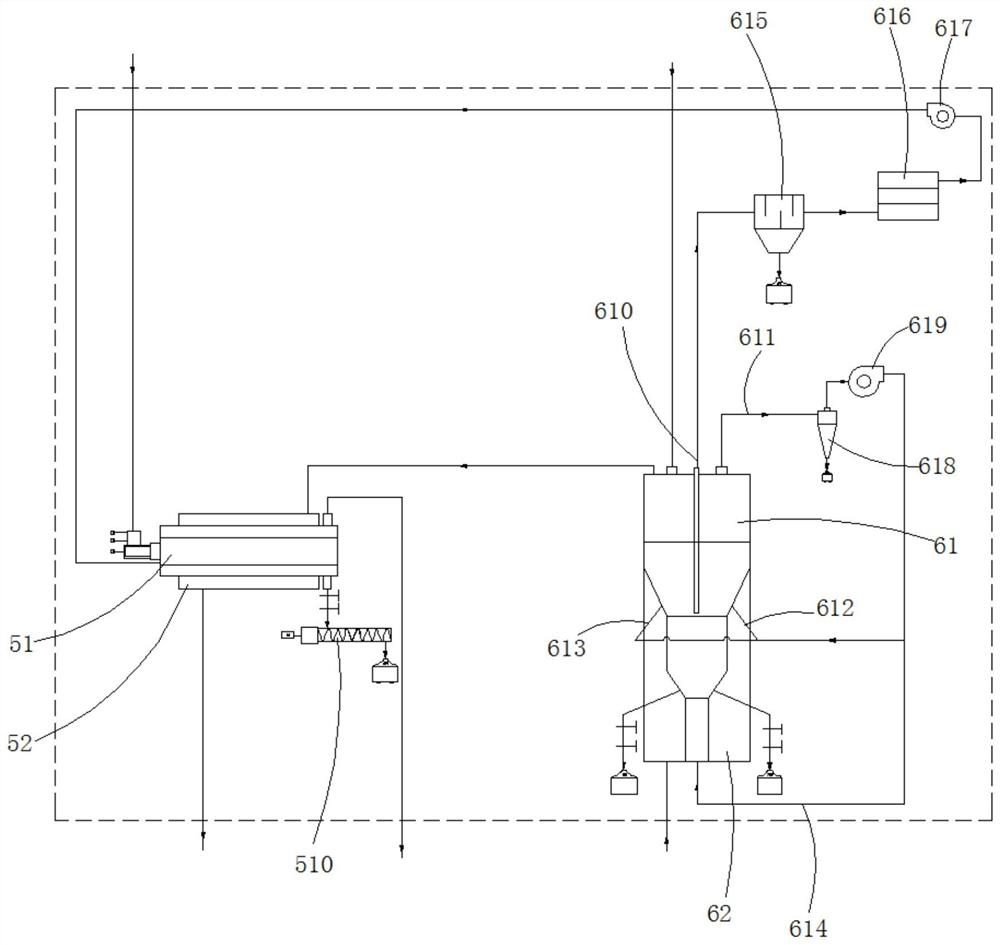

[0030] see figure 1 , is a schematic diagram of the process flow of an anaerobic cracking treatment device for domestic waste in a preferred embodiment of the present invention, which adopts anaerobic cracking technology to perform pyrolysis treatment on domestic waste, and the anaerobic cracking treatment device for domestic waste includes feeding System 10, carbonization and cracking system 20, cracking gas purification system 30 and combustion system 40, feeding system 10 is used to pretreat raw materials, and is divided into first material and second material; carbonization and cracking system 20 is used to feed system 10 The raw materials conveyed are subjected to pyrolysis treatment; the carbonization and cracking system 20 includes a carbonization furnace 50 for processing the first material and a cracking furnace 60 for processing the second mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com