Patents

Literature

113results about How to "Low cracking temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production method of needle coke raw material

ActiveCN101724420AExpand sourceThe method flow is simpleCoking carbonaceous materialsDecompositionCoke rate

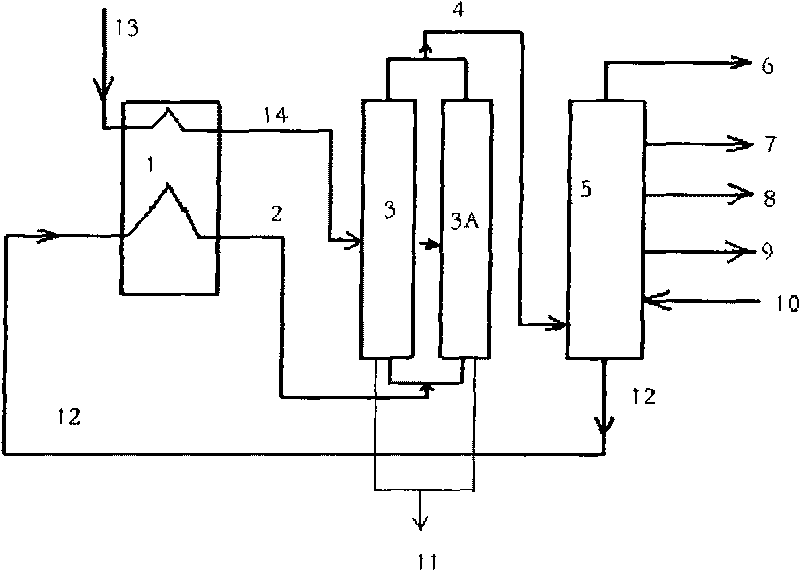

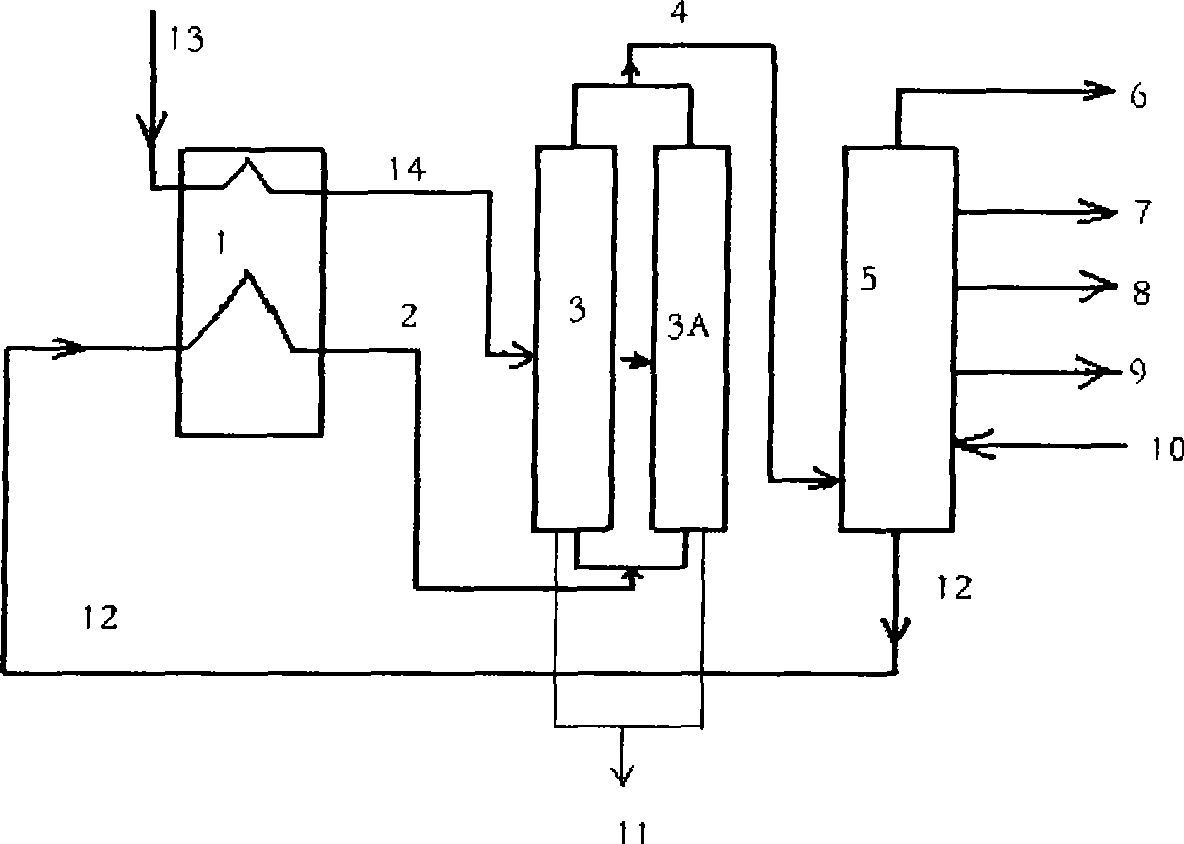

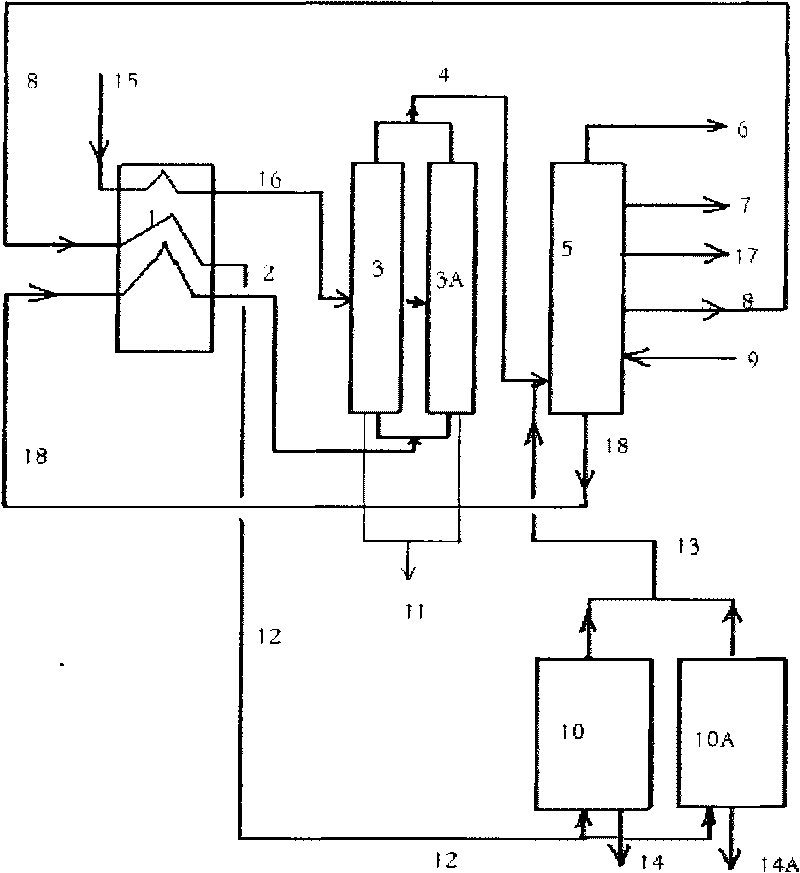

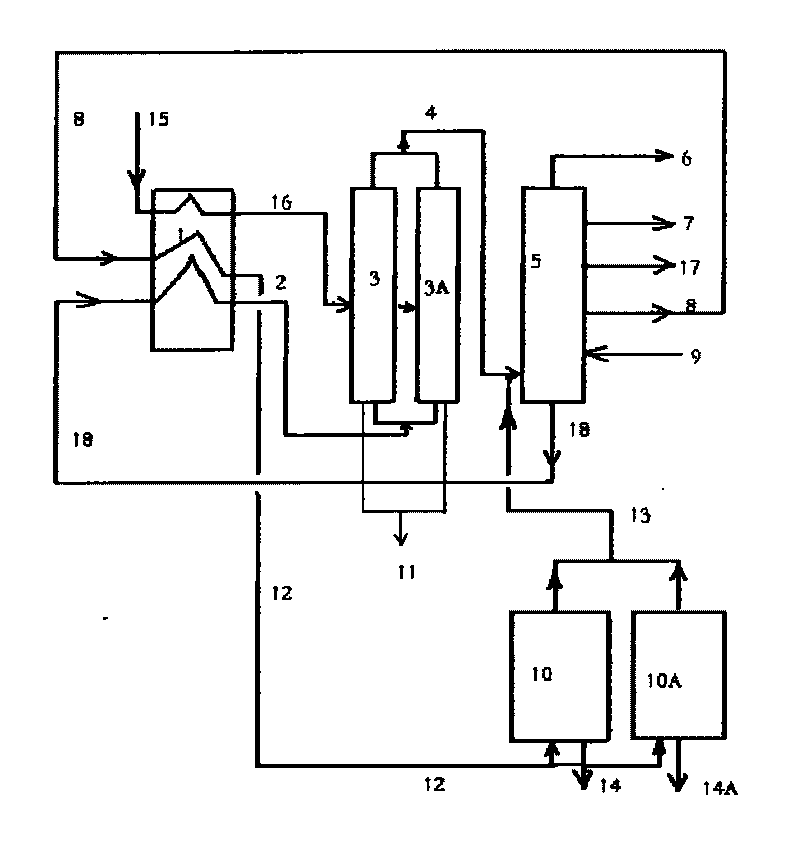

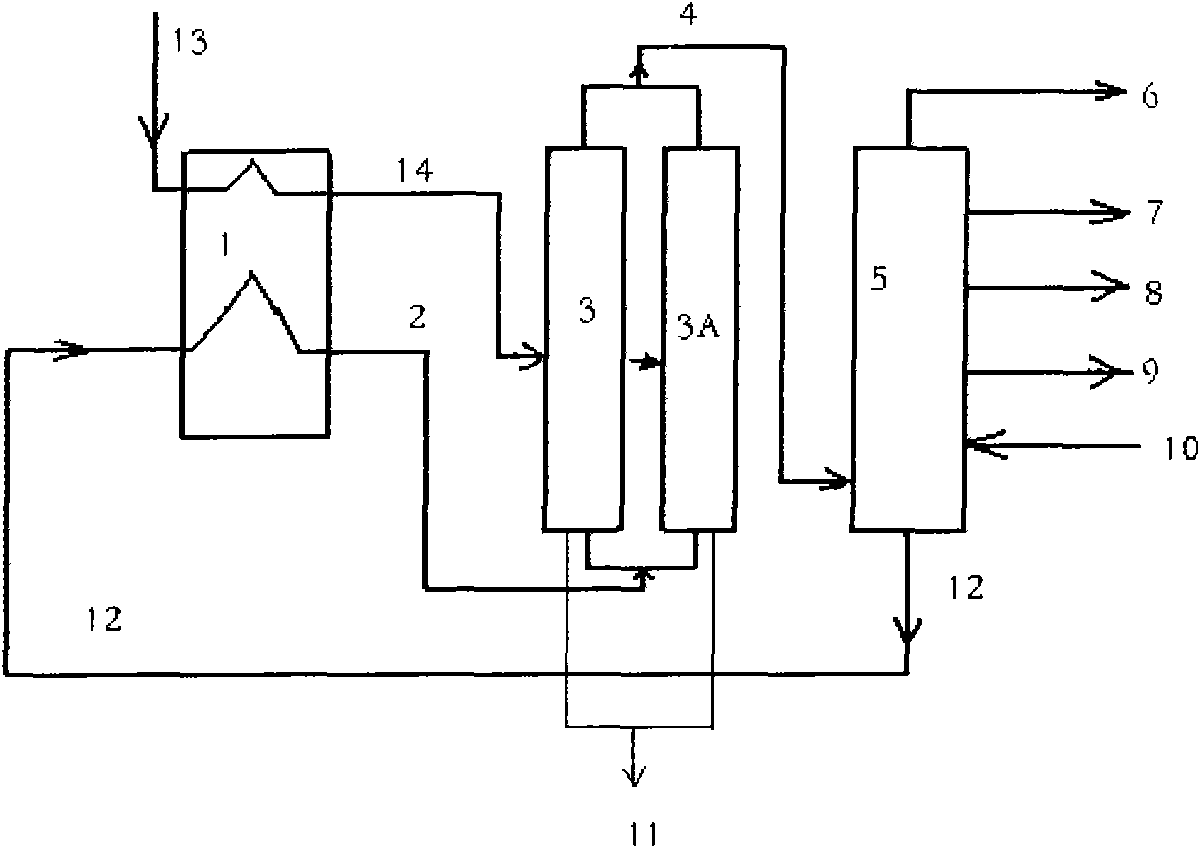

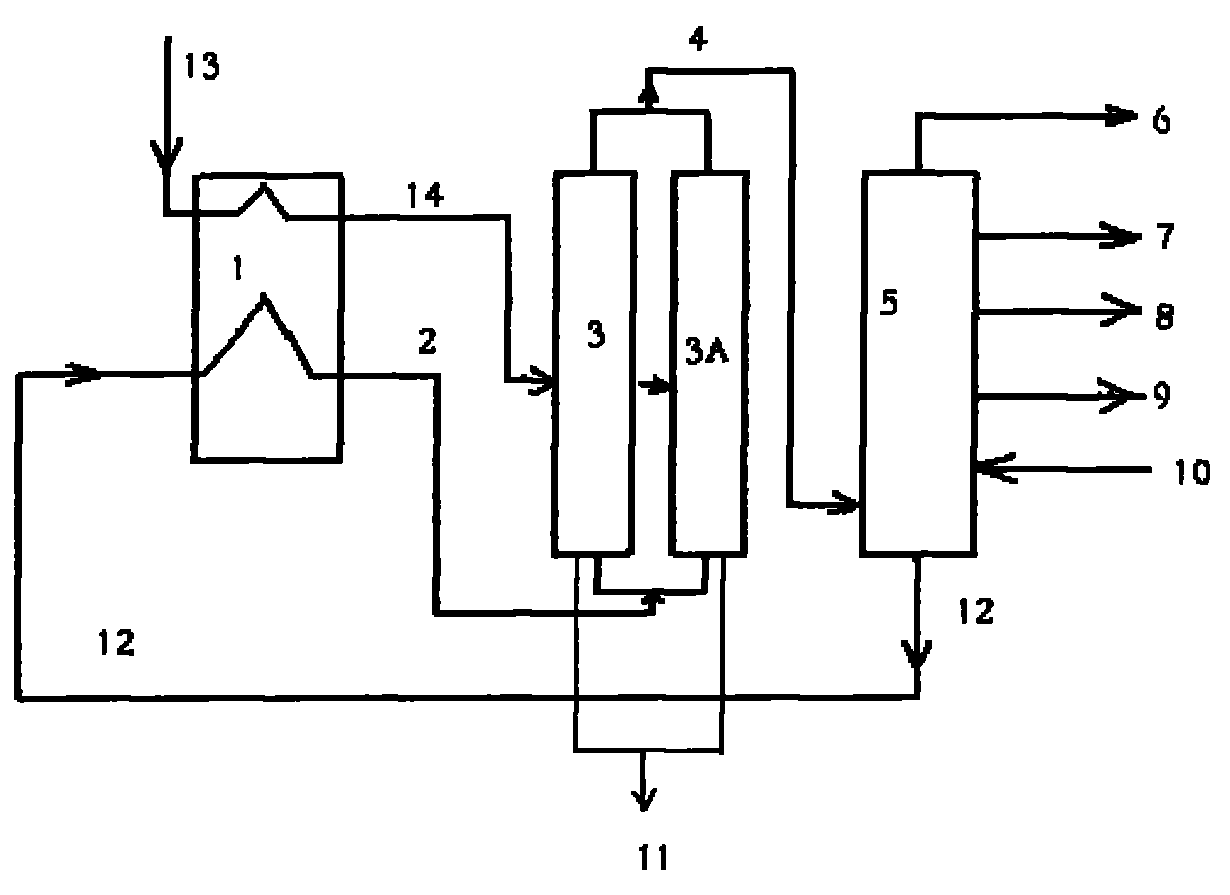

The invention discloses a method of needle coke raw material by using delay coking technique to treat FCC slurry oil and conventional coking raw material. The method comprises: introducing FCC slurry oil with low temperature into a delay coking tower from the upper part inside the tower, leading the introduced FCC slurry oil to be contacted with high temperature oil gas generated by the conventional coking raw material which is introduced into the tower from the bottom and treated by high temperature decomposition, and reacting under the condition of delay coking; and separating the generated oil gas in a coking fractionating tower, and obtaining the needle coke raw material. In the method, as the FCC slurry oil enters into the coking tower at the lower temperature, the decomposition temperature of the conventional coking raw material is lowered, the high temperature decomposition time of the raw material is shortened, the occurrence of secondary reaction is reduced, green coke rate is reduced, the stable operation cycle of a signal tower is prolonged, and light components which have high reaction activity and are not beneficial to producing the needle coke, heavy components with high polymerization activity, and a great deal of impurities such as catalyst powder, heavy metal and the like can be removed. The obtained needle coke has high yield and good properties.

Owner:CHINA PETROLEUM & CHEM CORP +1

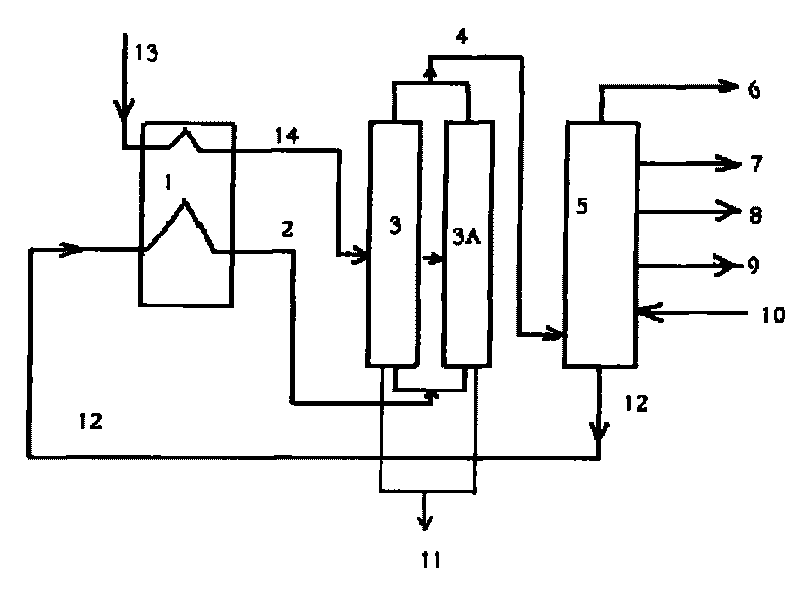

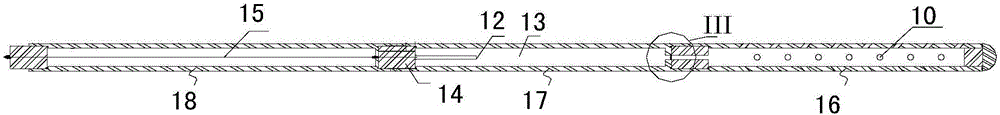

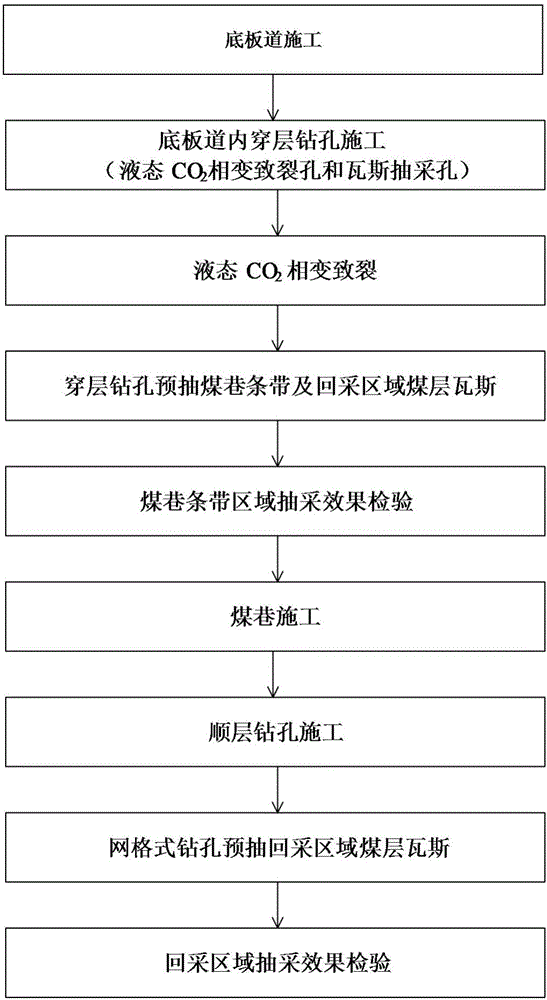

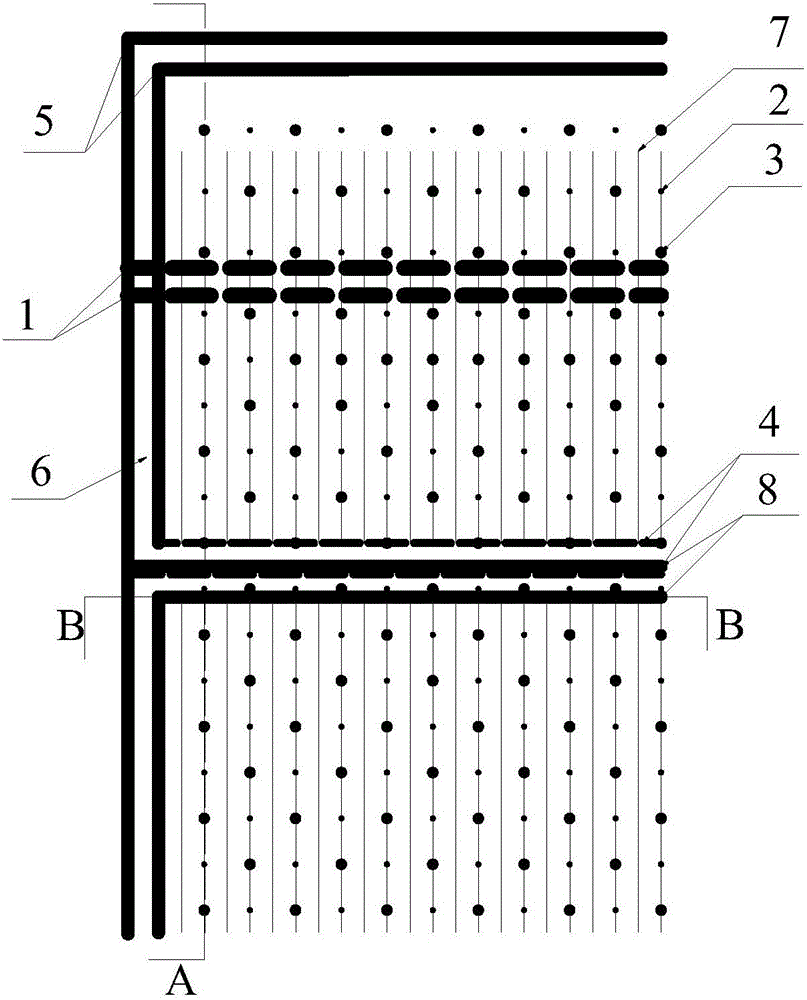

Liquid-phase CO2 phase change cracking permeability-increasing grid type gas extraction method for low-permeable coal seam

ActiveCN106194244AIncrease gas extractionEliminate outstanding hazardsFluid removalGas removalDrill holeProcess engineering

The invention discloses a liquid-phase CO2 phase change cracking permeability-increasing grid type gas extraction method for a low-permeable coal seam. The method comprises the following steps that (1) a bottom board passage is constructed; (2) crossing drilling construction is carried out in the bottom board passage; (3) liquid CO2 phase change cracking is carried out; (4) gas of coal seams of a coal roadway strip and a recovery area is pre-drained with crossing drill holes; (5) the extraction effect of the coal roadway strip area is detected; (6) coal roadway construction is carried out; (7) hole drilling down the seam is carried out; (8) gas of the coal seam in the recovery area is pre-drained with grid type drill holes; and (9) the extraction effect of the recovery area is detected. The method can improve the quantity of drainage of gas of underground coal mine, achieve the purpose of rapidly eliminating danger of outburst for high-gas low-permeable outburst coal seams, prevent coal and gas outburst accidents and guarantee safety production of the underground coal mine.

Owner:CHONGQING UNIV

Use of stannous benzoate as catalyst

ActiveCN1806919AReduce dosageLow cracking temperatureOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsBenzoic acidPolymer science

The invention provides the usage of using the benzoic acid stannous as catalyst. The invention solves the problem that polymerization rate of current catalyst in lactic acid and glycolic acid is slow. The benzoic acid stannous is the catalyst used for preparing low-molecular polymer lactic acid with lactic acid dewatering; benzoic acid stannous is the catalyst used for preparing lactide with low-molecular polymer lactic acid cracking; benzoic acid stannous is the catalyst used for preparing polylactic acid with lactide polymerizing; benzoic acid stannous is the catalyst used for preparing low-molecular polymer glycolic acid with glycolic acid dewatering; benzoic acid stannous is the catalyst used for preparing glycolide with low-molecular polymer glycolic acid cracking; benzoic acid stannous is the catalyst used for preparing poly-glycollide with glycolide polymerizing. The benzoic acid stannous is the catalyst used for polymerizing glycolide, lactide and epsilon-caprolactone. Using the benzoic acid stannous is low content, high productivity, high product purity, low temperature and good repeatability.

Owner:ZHEJIANG HISUN BIOMATERIALS +1

Production method of needle coke raw material

ActiveCN101724420BHigh reactivityExpand sourceThermal non-catalytic crackingCoking carbonaceous materialsCoke rateDecomposition

Owner:CHINA PETROLEUM & CHEM CORP +1

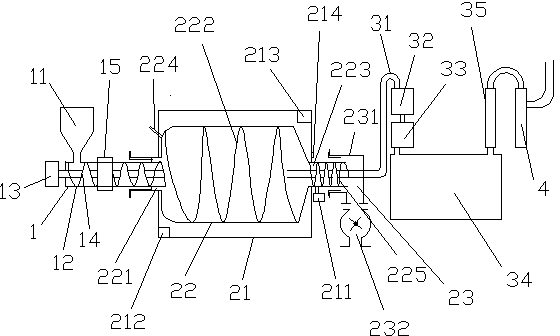

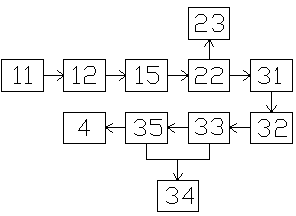

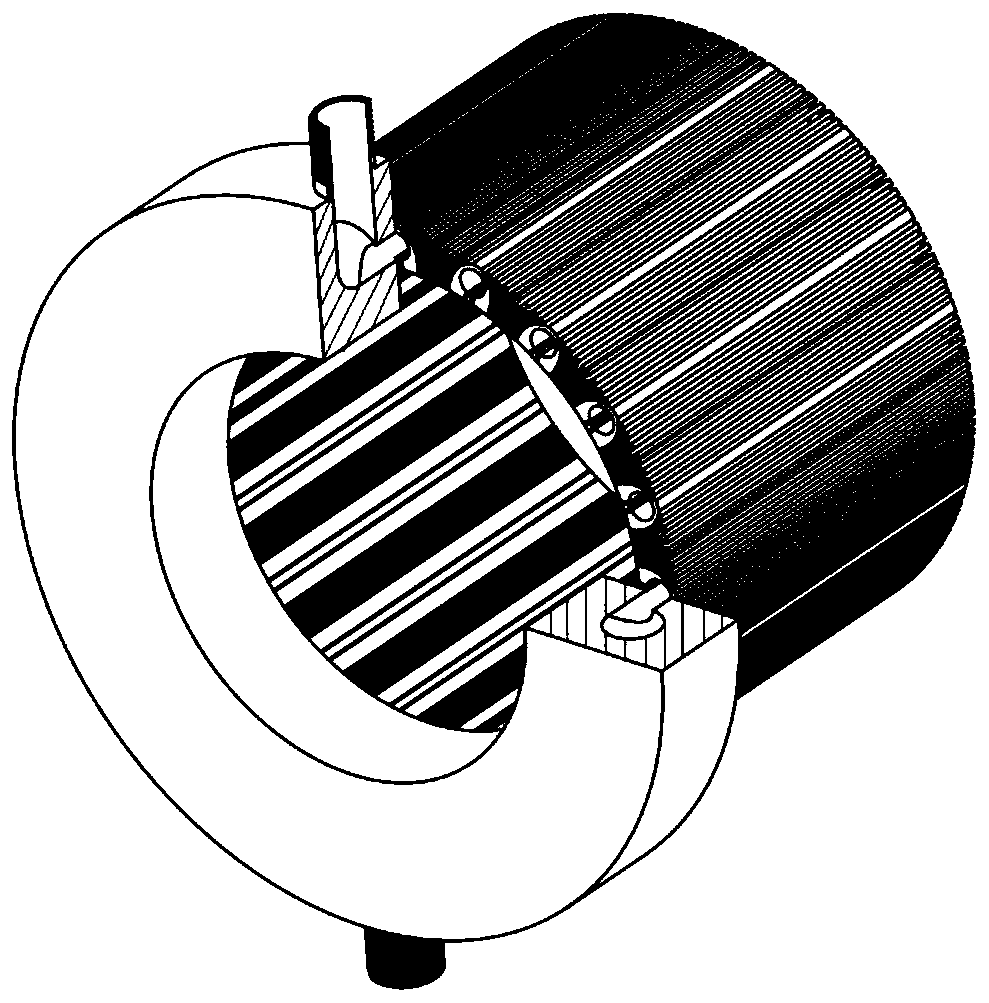

Rotary spiral waste organic glass propelling and continuous splitting decomposition method and device

ActiveCN104211984AGood choiceEmission reductionOrganic compound preparationCarboxylic acid esters preparationDecompositionHearth

The invention relates to a rotary spiral waste organic glass propelling and continuous splitting decomposition method and device and belongs to the field of chemical engineering. The raw material splitting decomposition efficiency and product recovery rate can be improved, and energy consumption and pollutant discharge can be reduced. The device comprises a feeding device, a splitting decomposition device, a condensing device and a waste gas treatment device which are sequentially connected, and further comprises a pressure limiting valve, a residue discharging pipe, a star-shaped valve, a feeding port, guide blades and a discharging port, wherein the pressure limiting valve is used for controlling pressure intensity in a splitting decomposition kettle. The feeding port is movably connected with a feeding pipe. The guide blades are fixedly arranged in the splitting decomposition kettle, and materials are spirally propelled from the feeding port to the discharging port. A hearth is provided with a thermometer. The discharging port is movably connected with the residue discharging pipe, and the residue discharging pipe is connected with the star-shaped valve. The condensing device is connected with the splitting decomposition device through a guide pipe, the guide pipe penetrates through the residue discharging pipe to extend into the discharging port, the guide pipe, a water-cooling device, a storage tank and a copious cooling device are connected in sequence, and the storage tank is arranged at the lower end of the water-cooling device and the lower end of the copious cooling device. The waste gas treatment device is connected with the copious cooling device.

Owner:杭州临安清云环保设备有限公司

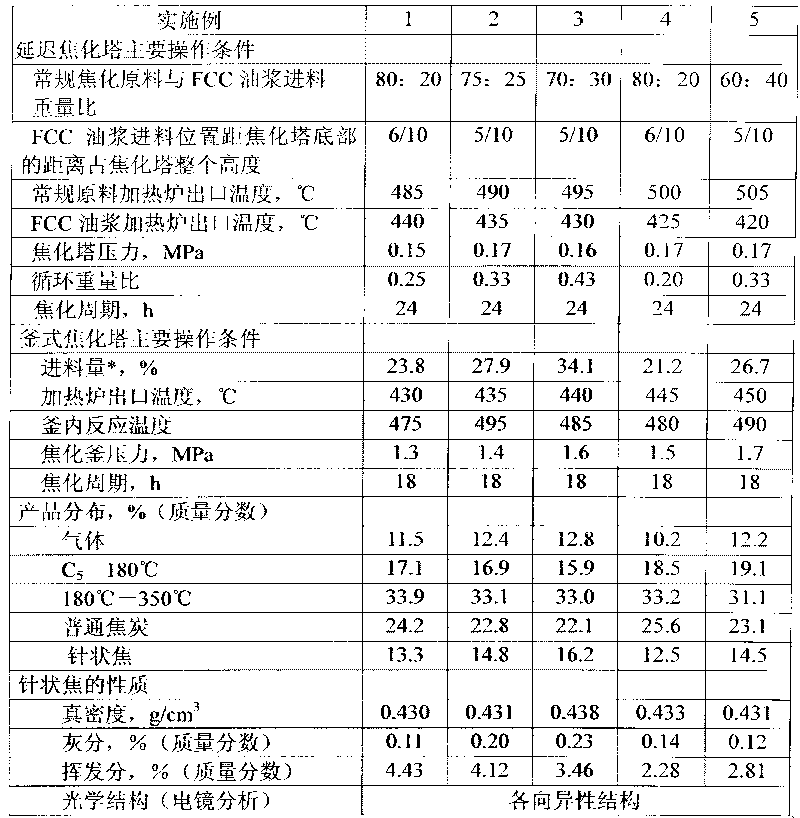

Production method of needle coke

The invention discloses a method for producing needle coke by adopting the technique combining delay coking and kettle-type coking. The method comprises: when treating the conventional coking raw material by using the delay coking technique, introducing FCC slurry oil into a delay coking tower from the upper part inside the tower at the low temperature, and obtaining needle coke raw material by fractionating high temperature oil gas obtained by the reaction; and then, treating the needle coke raw material by using the kettle-type coking technique, and obtaining high quality needle coke. In the method, as the FCC slurry oil is injected into the coking tower at the lower temperature, the decomposition temperature of the conventional coking raw material is lowered, the high temperature decomposition time of the raw material is shortened, the occurrence of secondary reaction is reduced, green coke rate is reduced, the stable operation cycle of a signal tower is prolonged, and light components which have high reaction activity and are not beneficial to producing the needle coke, heavy components with high polymerization activity, and a great deal of impurities such as catalyst powder, heavy metal and the like can be removed. The obtained needle coke has high yield and good quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method and equipment of vacuum catalytic cracking for preparing limonene, fuel oil and carbon black from scrap tire

InactiveCN1760333ANo emissionsDo not pose a hazardPigmenting treatmentPlastic recyclingLiquid productFuel oil

A process for preparing lemon oil extract, fuel oil and carbon black from used tyre by vacuum catalytic cracking includes such steps as proportionally mixing sodium hydroxide and zinc oxide to obtain catalyst, proportionally loading the catalyst and used tyre particles into vacuum catalytic cracking reactor, reacting to obtain gas mixture and carbon black residual in reactor, condensing the gas mixture to obtain the mixture of lemon oil extract, fuel and water, separating, and purifying. Its apparatus is also disclosed.

Owner:广州中科环能科技有限公司

Infrared high shield core-shell structure opacifying agent for SiO2 aerogel and preparation method of opacifying agent

The invention relates to an infrared high shield core-shell structure opacifying agent for SiO2 aerogel and a preparation method of the opacifying agent, and belongs to the field of high temperature heat-insulating materials. The opacifying agent is a TiO2-coated SiC hollow core-shell structure ceramic microsphere, wherein the hollow size theta is 0.8-1.5 mu m, the thickness of a nuclear layer SiC is 0.1-0.2 mu m, and the thickness of a shell layer TiO2 is 0.1-0.3 mu m. The preparation method comprises the following steps: I, sequentially adding butyl titanate, polysilazane and divinyl benzene into fused paraffin, and magnetically stirring to obtain a uniform oil phase; dispersing an emulsifier in deionized water in an ultrasonic condition to obtain a uniform water phase; stirring the water phase and the oil phase at a high speed to uniformly emulsify; installing a condensating device, and carrying out a reaction on the emulsion in an oil bath pan; II, centrifugalizing, cleaning and drying the product obtained in the step I; III, sintering the dried product in an atmosphere furnace; and IV, uniformly mixing the sintered product with the SiO2 aerogel and pressing and forming. The core-shell structure ceramic beads are controllable in size, light in weight and high-temperature resistant, and the core-shell structure opacifying agent can effectively improve the anti-infrared shield performance of the SiO2 aerogel.

Owner:TIANJIN CHENGJIAN UNIV

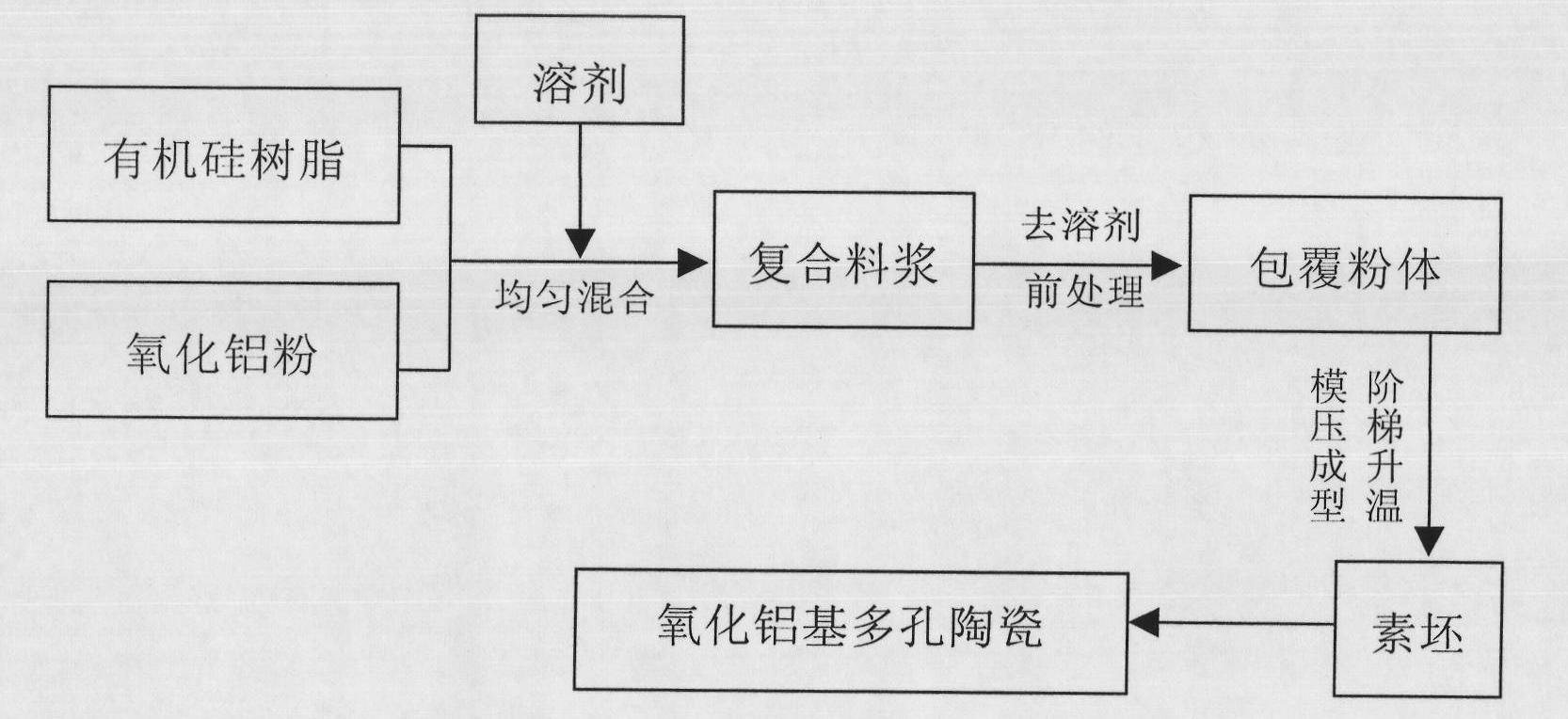

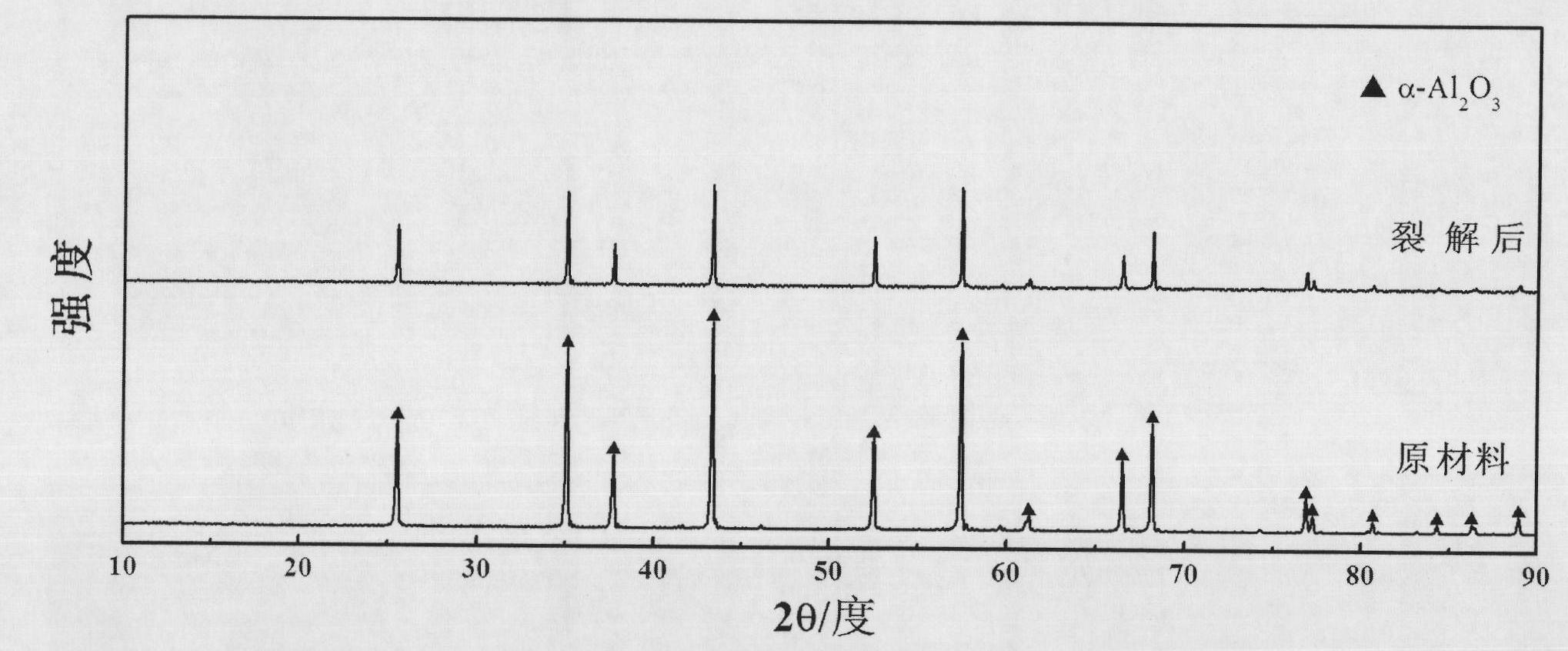

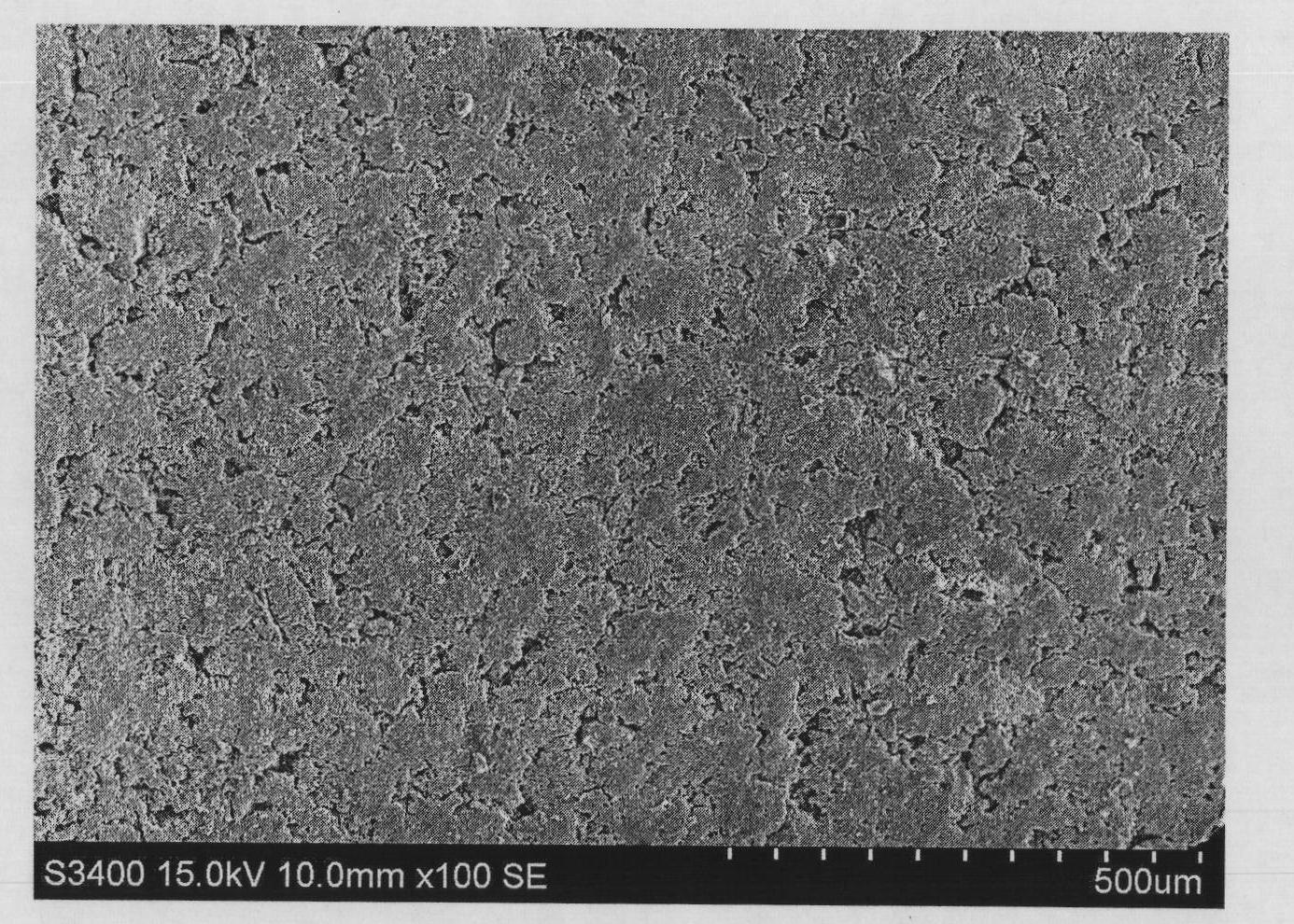

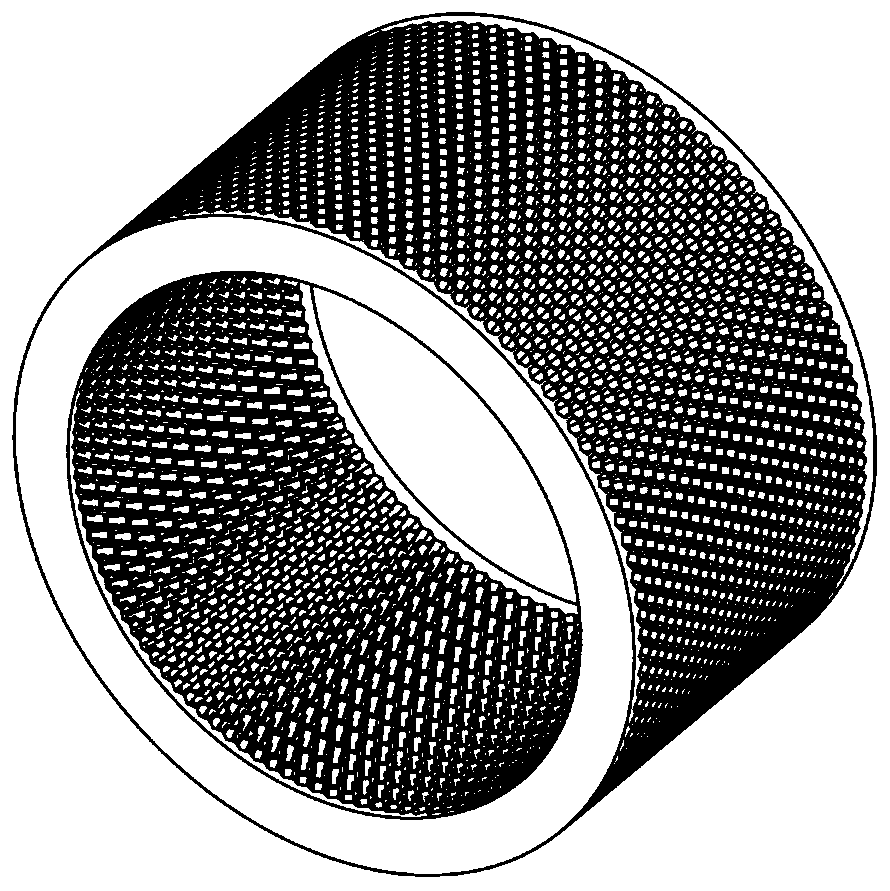

Preparation method of alumina oxide matrix porous ceramic material

InactiveCN101792327ATo achieve the purpose of making holesControllable opening/closingCeramicwareProcess systemsOxide ceramic

The invention provides a preparation method of an alumina oxide matrix porous ceramic material, which specifically comprises the following steps: uniformly mixing silicone with alumina oxide ceramic powder according to the volume ratio of 1:1-4:1; treating the mixed powder at a temperature of 100-150 DEG C for 3 to 24 hours to evaporate a solvent, and removing free water of the silicone to obtain the alumina oxide ceramic coating powder; after grinding and screening, forming the alumina oxide ceramic coating powder by adopting a step heating molding process system to obtain biscuit samples; and pyrolyzing the biscuit at a temperature of 800-1200 DEG C under the protection of inert atmosphere, controlling the reaction rate between 100 DEG C / hour and 300 DEG C / hour, the holding time being 1-10 hours, and obtaining the alumina oxide matrix porous ceramic material. The invention has low pyrolysis temperature, good repeatability and low cost, and the prepared alumina oxide matrix porous ceramic material has uniform pore distribution, small pore size, higher porosity, higher mechanical strength and other excellent performances.

Owner:WUHAN UNIV OF TECH

Recovery method of silicone rubber

InactiveCN103626796AEvenly heatedIncrease heat transfer rateSilicon organic compoundsRecovery methodCircular economy

The invention relates to a recovery method of silicone rubber by alkali solvent cracking. In a high temperature resistant inert solvent medium, an alkaline compound is employed to carry on cracking on silicone rubber. The cracking products are subjected to separation and purification to obtain organic siloxane ring monomers and silica. The method does not generate new wastes, and is consistent with the requirements of circular economy.

Owner:杨晓林

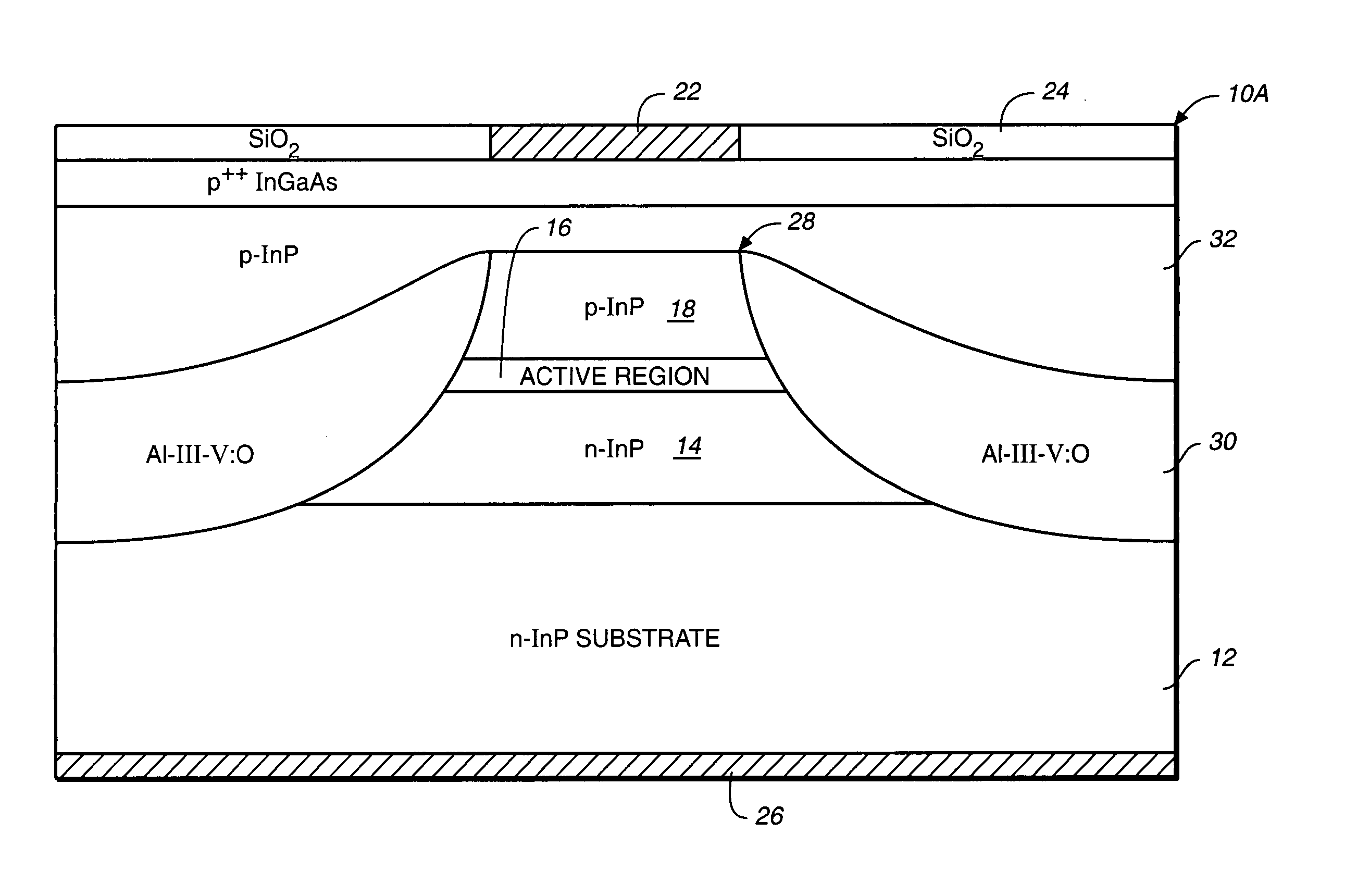

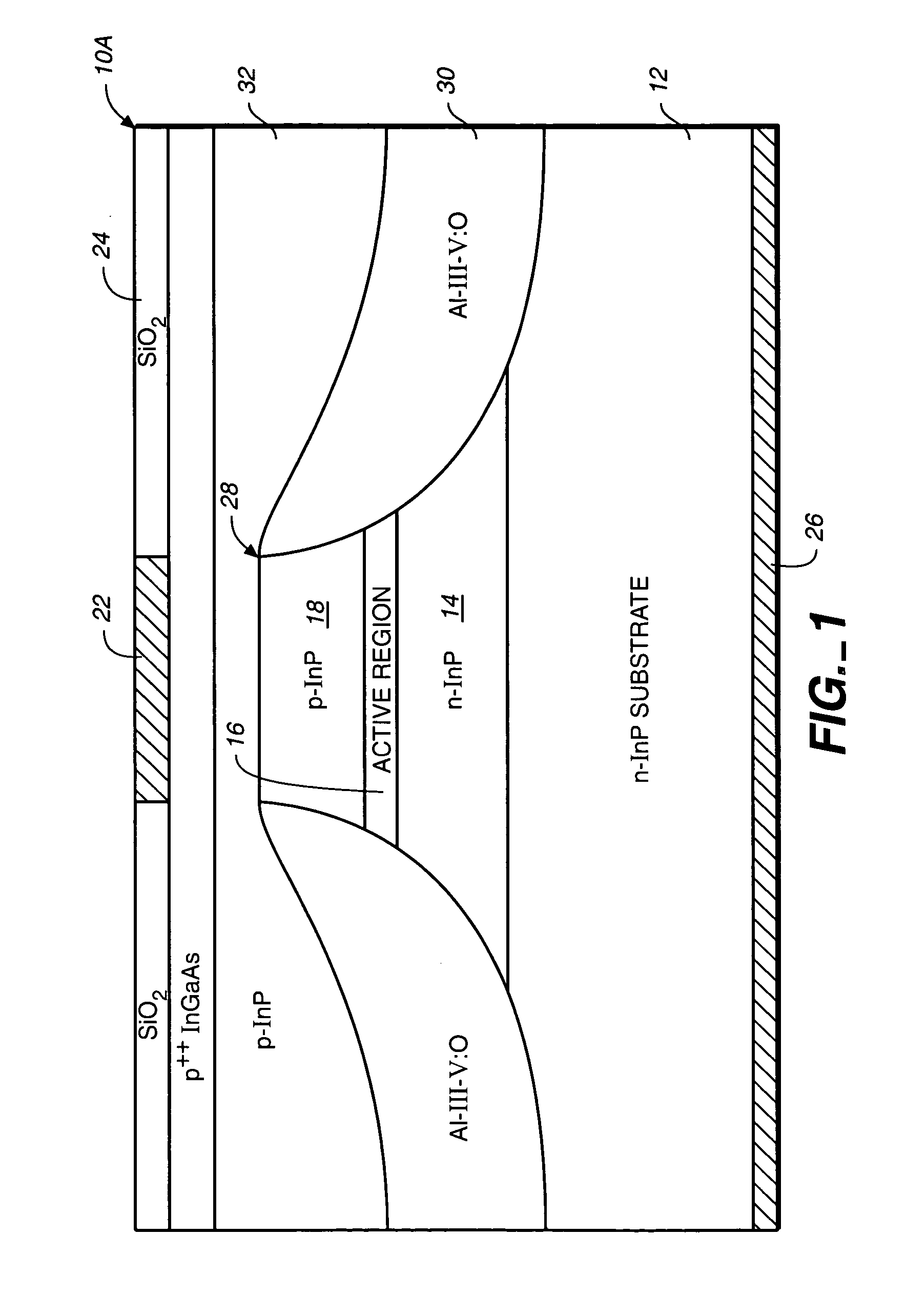

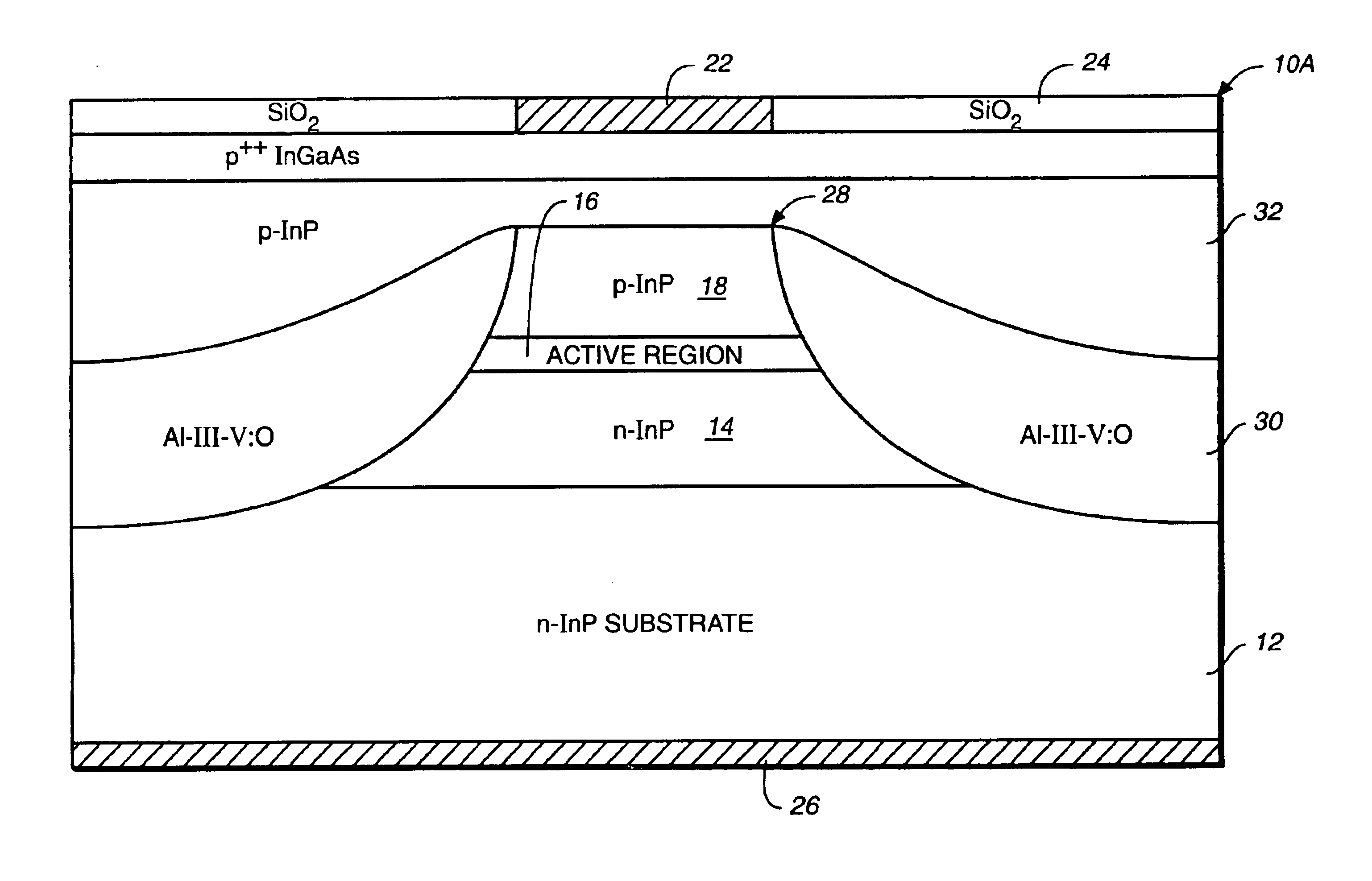

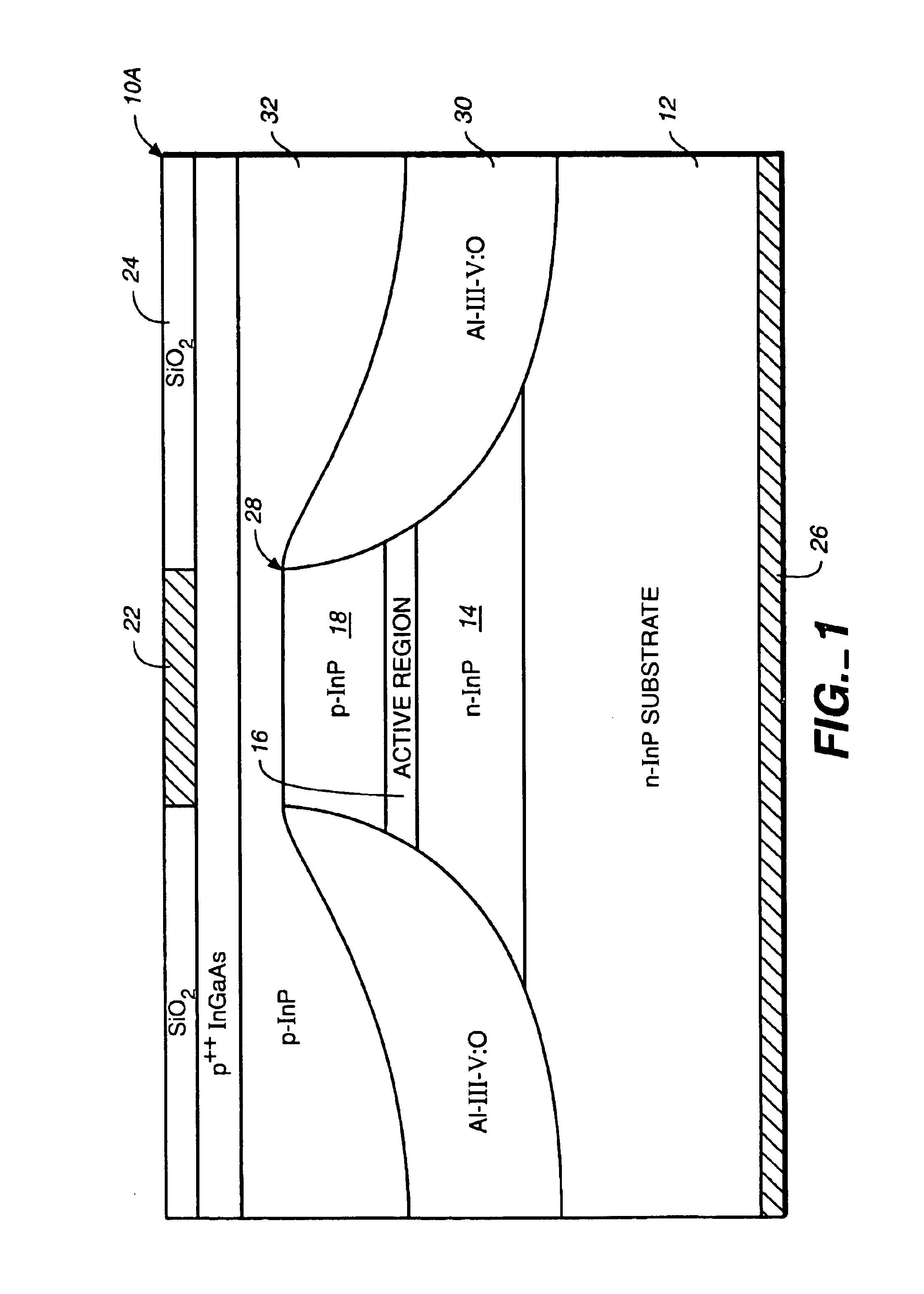

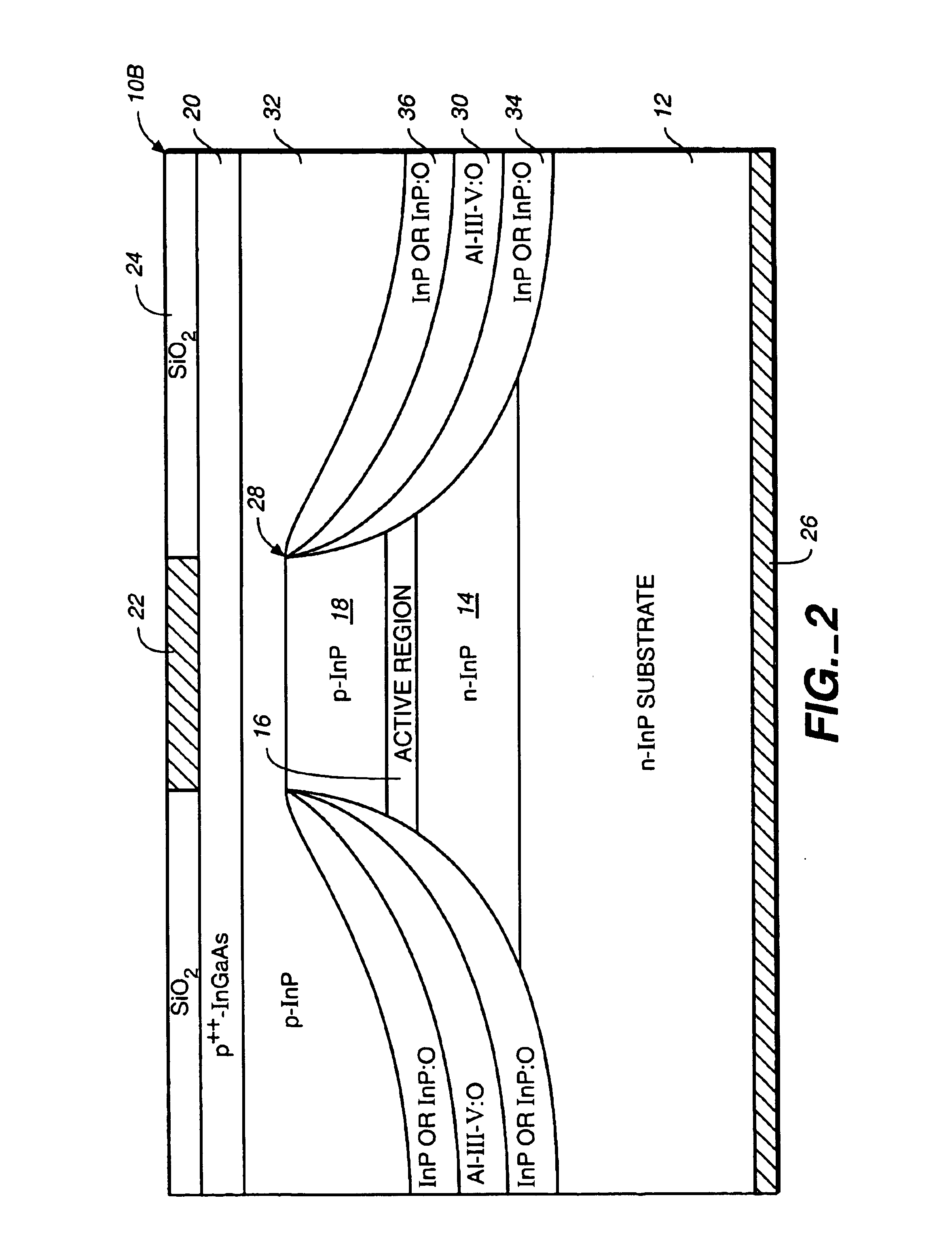

Oxygen-doped al-containing current blocking layers in active semiconductor devices in photonic integrated circuits (PICs)

InactiveUS20050040415A1Low cracking temperaturePrevent indiffusionOptical wave guidanceNanoopticsDevice materialImpurity doping

In photonic integrated circuits (PICs) having at least one active semiconductor device, such as, a buried heterostructure semiconductor laser, LED, modulator, photodiode, heterojunction bipolar transistor, field effect transistor or other active device, a plurality of semiconductor layers are formed on a substrate with one of the layers being an active region. A current channel is formed through this active region defined by current blocking layers formed on adjacent sides of a designated active region channel where the blocking layers substantially confine the current through the channel. The blocking layers are characterized by being an aluminum-containing Group III-V compound, i.e., an Al-III-V layer, intentionally doped with oxygen from an oxide source. Also, wet oxide process or a deposited oxide source may be used to laterally form a native oxide of the Al-III-V layer. An example of a material system for this invention useful at optical telecommunication wavelengths is InGaAsP / InP where the Al-III-V layer comprises InAlAs:O or InAlAs:O:Fe. Other materials for the blocking layers may be InAlGaAs or alternating layers or alternating monolayers of AlAs / InAs. Thus, the O-doped blocking layers may be undoped, impurity doped or co-doped with Fe.

Owner:INFINERA CORP

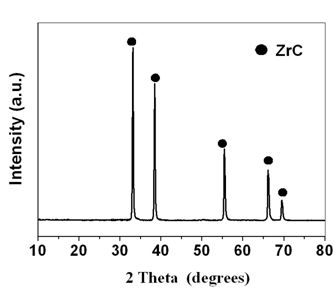

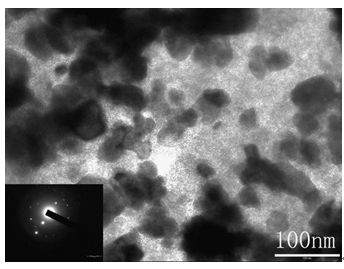

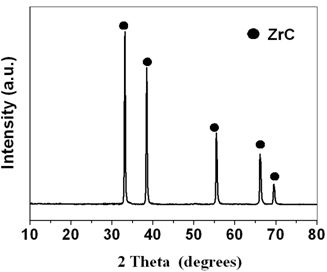

Synthetic method of superhigh temperature resistant zirconium carbide ceramic precursor

A synthetic method of a superhigh temperature resistant zirconium carbide ceramic precursor belongs to preparation methods of ceramic precursors. The synthetic method includes firstly, dissolving 6.44g zirconium oxychloride in 50 mL absolute methanol, stirring the mixture at a room temperature for dissolving, subjecting the mixture to ice bath for cooling, dropwise adding 2.4g-3.47g saligenin, finally dropwise adding 4.24g triethylamine at a dropping speed of 1 droplet per second, and subjecting the mixture to magnetic stirring in the process of the dropping adding; after the dropping adding, removing the ice bath and stirring the mixture at a room temperature for 4 hours; then subjecting the mixture to rotary evaporation for 10 minutes to evaporate solvents, adding 50 mL tetrahydrofuran, stirring the mixture at a room temperature for 2 hours, and performing suction filtration to remove a precipitation of triethylamine hydrochloride; subjecting the mixture to rotary evaporation for 15 minutes to evaporate the solvents of colatuie, adding 100 mL hexyl hydride, stirring the mixture at a room temperature for 12-48 hours, performing filtration to obtain a pale yellow precipitation, and subjecting the pale yellow precipitation to vacuum drying for three hours to obtain the zirconium carbide ceramic precursor. The synthetic method of the superhigh temperature resistant zirconium carbide ceramic precursor has the advantages that the even dispersing of modular zirconium components in precursor reins is achieved, the solidification group saligenin are contained in the ceramic precursor so that crosslinking solidification is facilitated, the synthesis temperature is low, the reaction speed is rapid, and the toxicity of solvents is small.

Owner:CHINA UNIV OF MINING & TECH

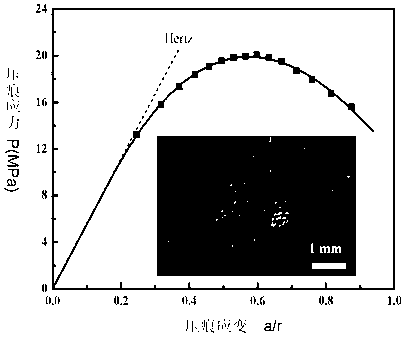

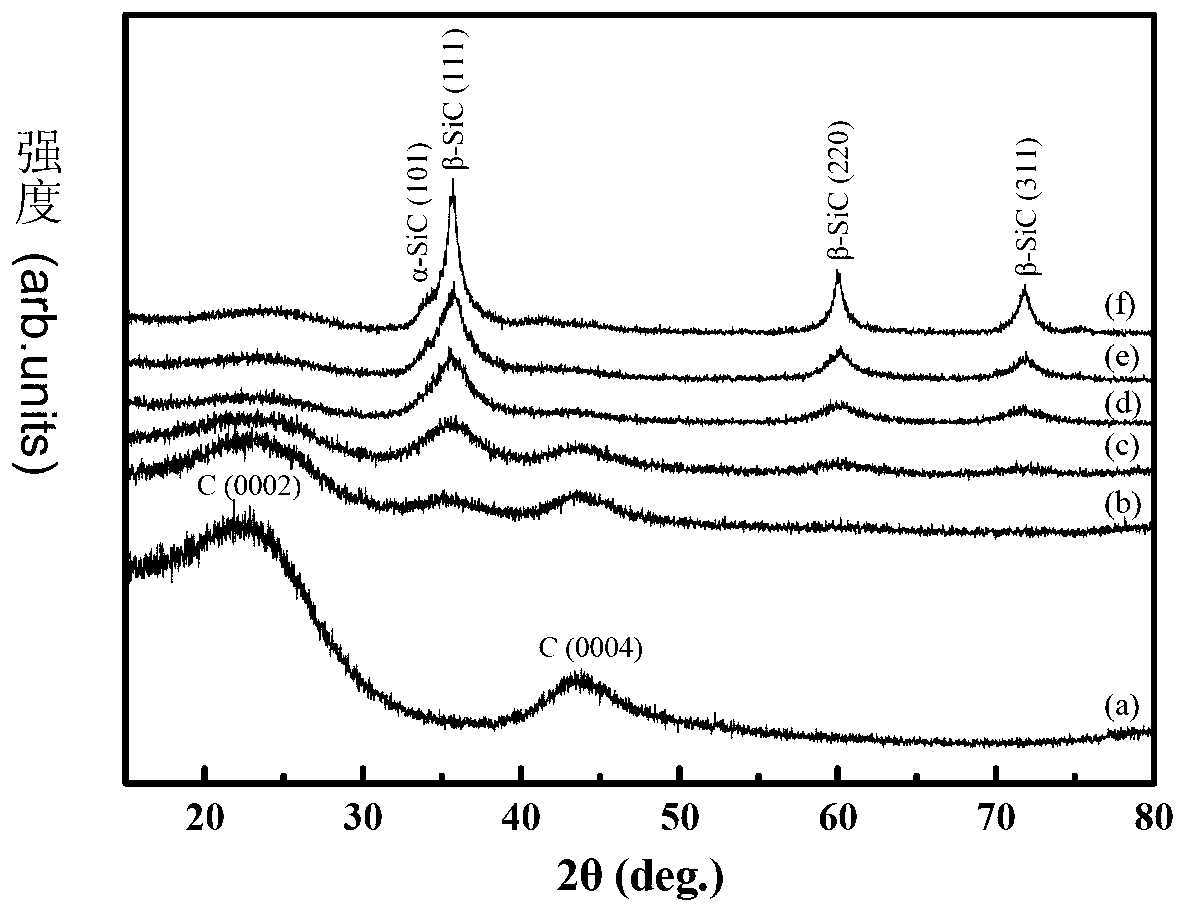

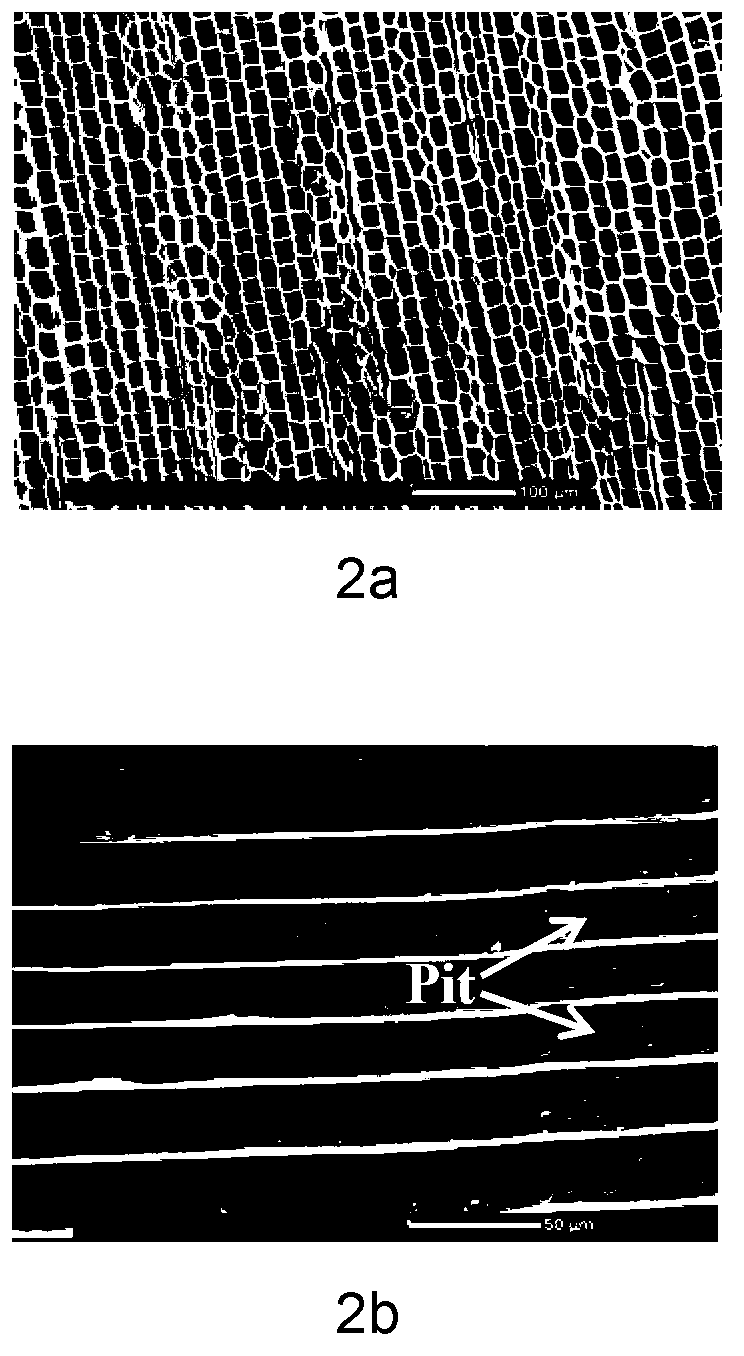

Preparation method of high-strength anti-contact-damage porous SiC

ActiveCN103319194AThe porous structure is not damagedUndamaged shapeCeramicwareMetallurgyHydrogen atmosphere

The invention relates to a preparation method of high-strength anti-contact-damage porous SiC, which comprises the following steps: (1) carbonizing wood at 600-1100 DEG C in an inert gas or hydrogen atmosphere for 1-6 hours; (2) carrying out dipping treatment on the carbonized wood in liquid polycarbosilane in a vacuum environment to obtain a carbon template; (3) curing the carbon template subjected to dipping treatment at 180-250 DEG C for 1-5 hours; and (4) carrying out high-temperature treatment on the cured carbon template in an inert gas or hydrogen atmosphere or in a vacuum environment to obtain the porous SiC ceramic. The method provided by the invention can reserve the porous structure in the wood template, so that the porous SiC can still have high compression strength under the condition of high porosity and also have excellent anti-contact-damage capacity.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Catalyst used in low-temperature removal of hydrogen chloride from dichloroethane for preparation of vinyl chloride, and preparation method and application thereof

ActiveCN105983428AExtend your lifeLow cracking temperaturePreparation by hydrogen halide split-offPhysical/chemical process catalystsEthane DichlorideInert gas

The invention discloses a catalyst used in low-temperature removal of hydrogen chloride from dichloroethane for preparation of vinyl chloride, and a preparation method and application thereof. The preparation method for the catalyst comprises the following steps: (1) subjecting a precursor, a solvent and active carbon to stirring and impregnation at 30 to 100 DEG C for 1 to 12 h and then evaporating the solvent to dryness; and (2) putting a product of the step (1) into a heating furnace, carrying out heating to 300 to 1000 DEG C in an inert gas atmosphere at a heating rate of 1 to 10 DEG C / min, maintaining the product at the temperature for 0.5 to 6 h and then cooling the product to room temperature. With the catalyst provided by the invention, pyrolysis temperature of dichloroethane is greatly reduced, so energy consumption is reduced, carbon formation and coking of a reactor are alleviated, and the service life of the catalyst is prolonged; and in catalysis of removal of hydrogen chloride from dichloroethane for preparation of vinyl chloride, the pyrolysis conversion rate of dichloroethane is 91%, produced vinyl chloride has selectivity of 99.5% or above, and the activity of the catalyst has no obvious change in the reaction having lasted for 180 h.

Owner:TIANJIN UNIV

Oxygen-doped Al-containing current blocking layers in active semiconductor devices

InactiveUS6891202B2High resistivityEasy to controlOptical wave guidanceLaser detailsHeterojunctionImpurity doping

Owner:INFINERA CORP

Method for preparing biologic oil from blue algae in catalytic cracking mode in vacuum

InactiveCN103773589AReduce pollutionSimple processFatty-oils/fats productionEutrophicationHydrotalcite

The invention discloses a method for preparing biologic oil from blue algae in a catalytic cracking mode in vacuum. The biologic oil is prepared by taking blue alga powder as a raw material and a composite metal oxide which takes hydrotalcite as a precursor as a catalyst in the catalytic cracking mode in vacuum. The method takes the composite metal oxide as the catalyst, so that the preparation is simple to carry out; by applying the prepared catalyst to blue alga cracking, the yield of the biologic oil can be effectively improved; moreover, as the metal oxide can absorb the moisture in the blue algae, the quality of the biologic oil is improved. The method disclosed by the invention is simple, the blue algae which is the chief culprit of eutrophication to a water body is taken as the raw material, the waste is turned into wealth, and the environment pollution is alleviated.

Owner:SOUTHEAST UNIV +1

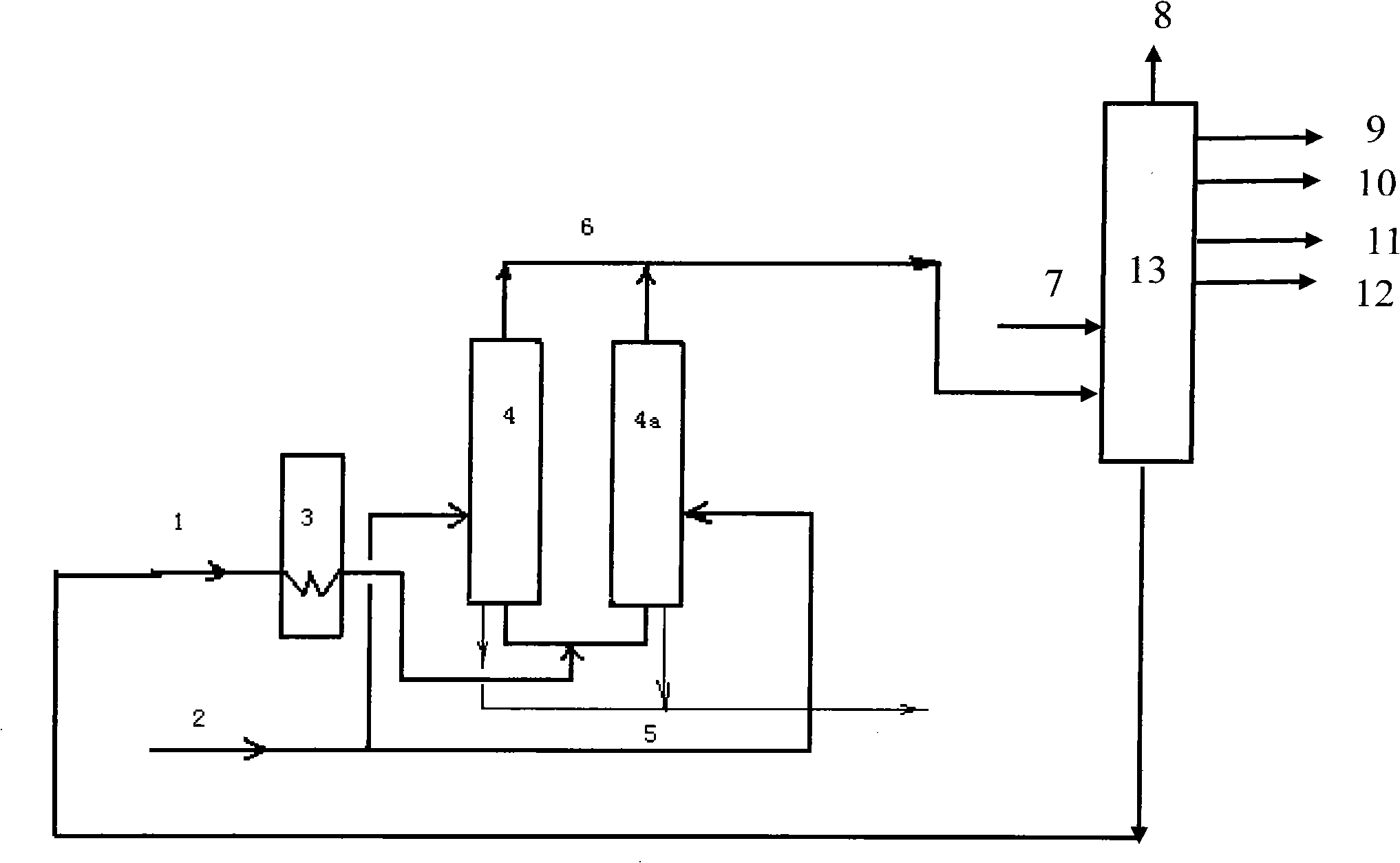

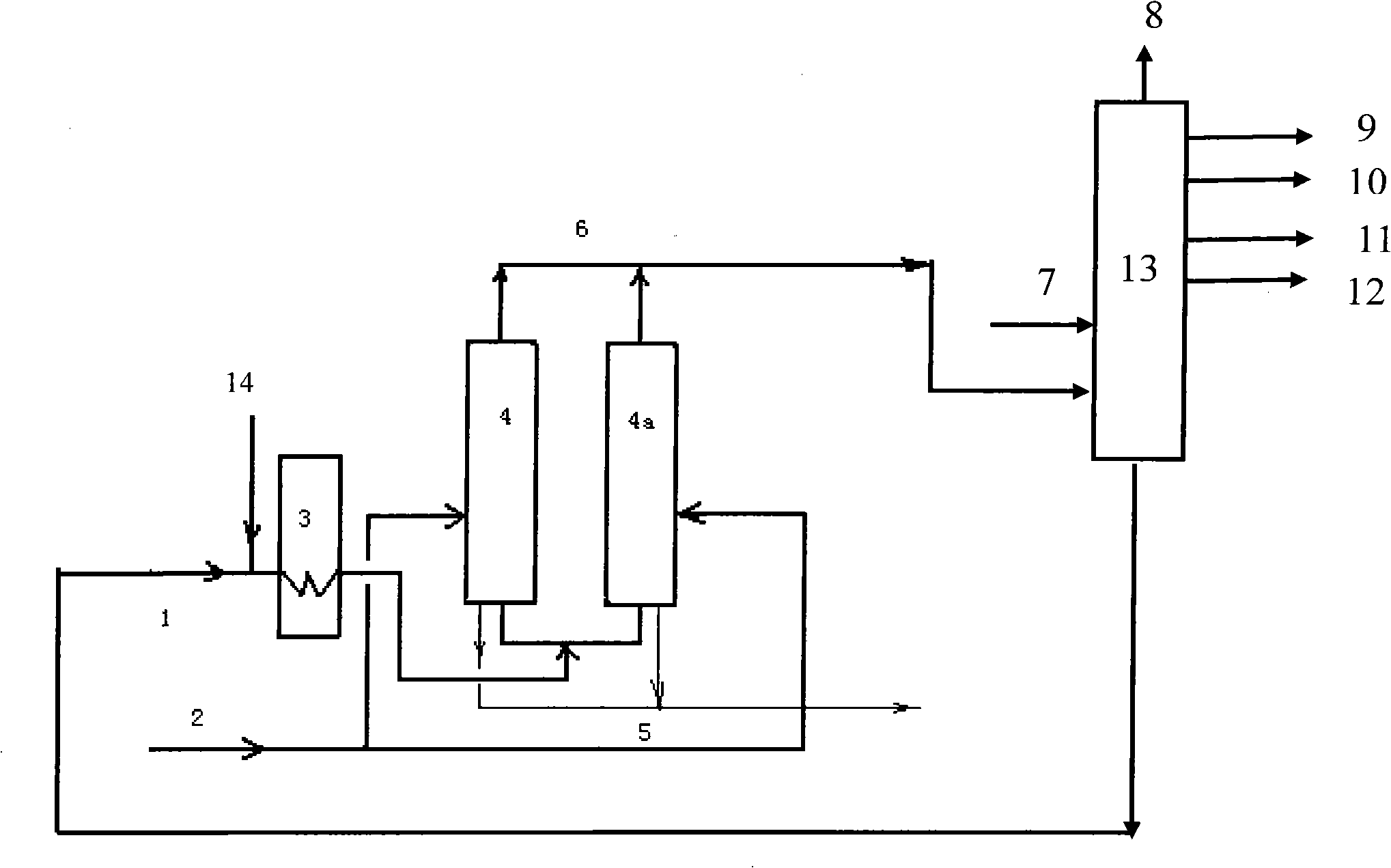

Coking method for processing highly acid crude oil

ActiveCN101280213AReduce corrosionCorrosion is reduced or even avoidedThermal non-catalytic crackingTowerCorrosion

The invention discloses a method of processing highly-acidic crude oil through the delayed coking process; the method includes that the low temperature highly-acidic crude oil is fed from the middle-lower part and the high temperature low-acidic coking raw material is fed from the bottom; the high temperature oil gas generated by the high temperature cracking of the low-acidic coking raw material is mixed with the low temperature highly-acidic crude oil so that the highly-acidic crude oil is enabled to realize the purpose of the deacidification through the pyrolysis deacidification under high temperature; meanwhile, the cracking temperature of the low-acidic coking raw material is lowered; the high temperature cracking time of the conventional raw materials; thereby, the coking yield is reduced and the stable operation period of the single tower is prolonged; besides, the preheating temperature of the highly-acidic crude oil can avoid the strong corrosion stage of the acid; the corrosion on the heating device caused by the acid can be reduced or avoided when the temperature is even lower than the corrosion temperature.

Owner:CHINA PETROLEUM & CHEM CORP +1

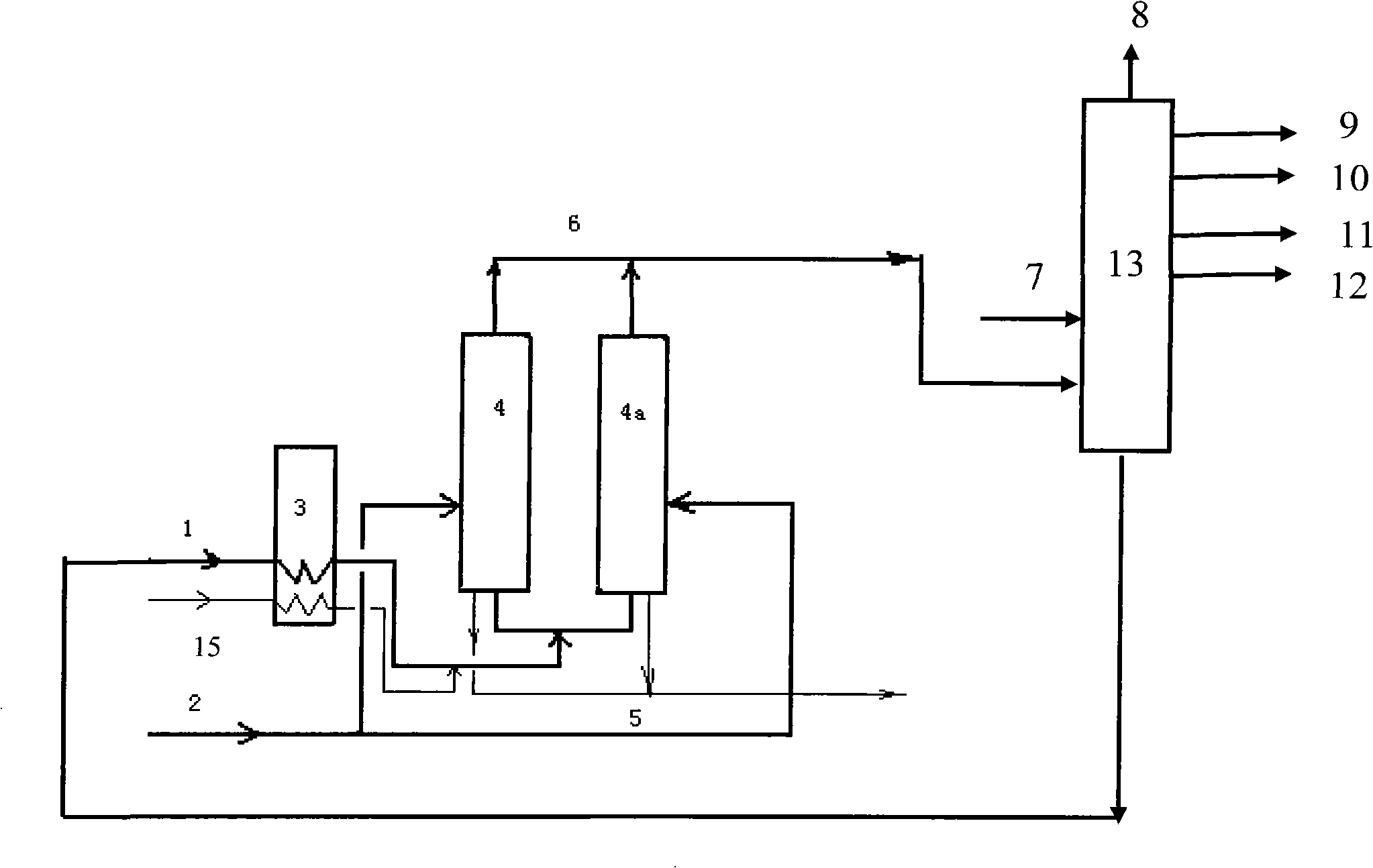

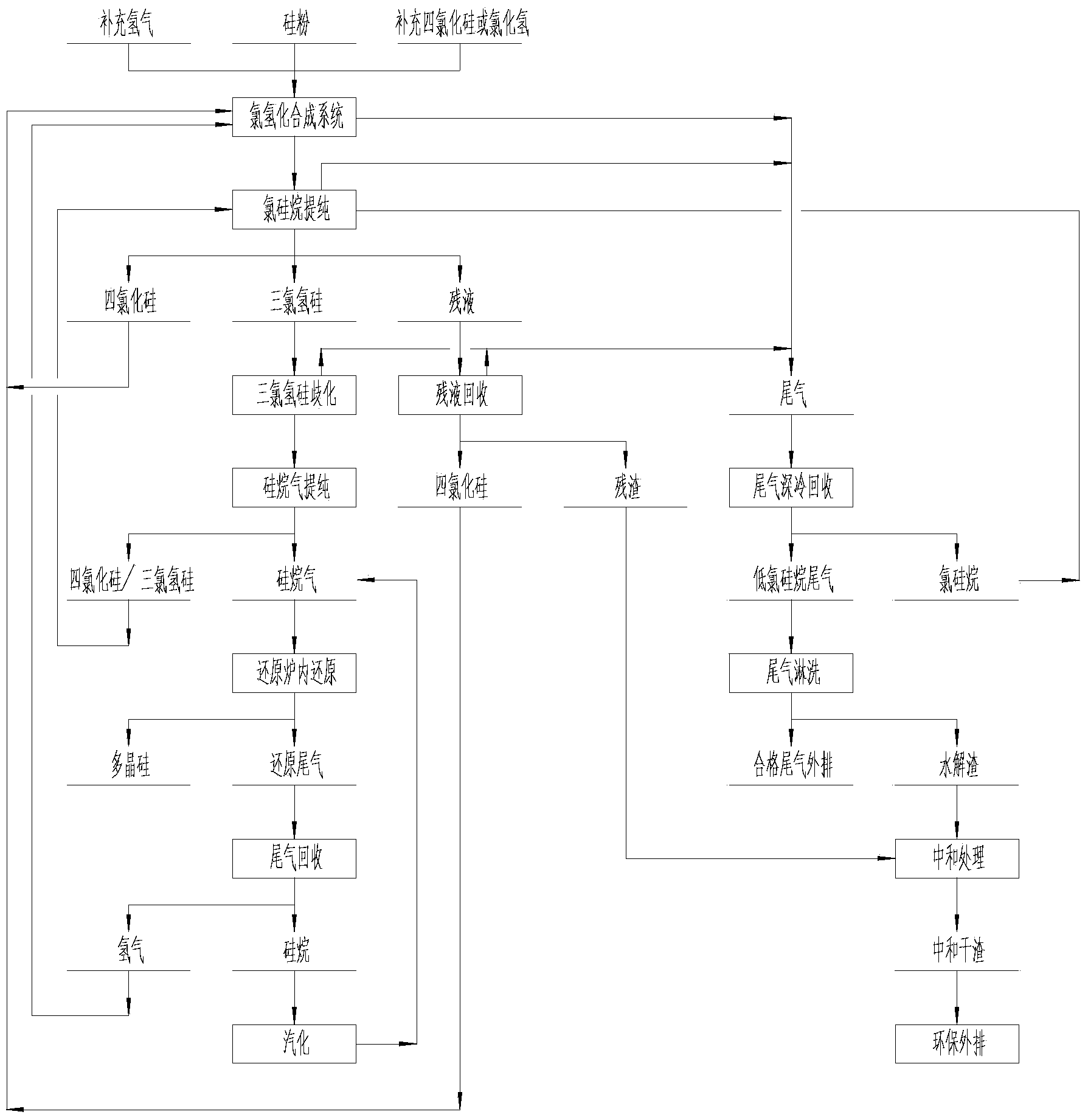

Equipment for purifying trichlorosilane

ActiveCN103449448AImprove efficiencyReduce manufacturing costHalogenated silanesTowerPolycrystalline silicon

The invention discloses equipment for purifying trichlorosilane. The equipment is a first rectifying and purifying device and used for conducting first rectifying and purifying treatment on trichlorosilane so as to obtain purified trichlorosilane and first rectifying residual liquid, wherein the first rectifying and purifying device consists of a first rectifying tower, a second rectifying tower and a third rectifying tower which are connected in series, the rectifying of the first rectifying tower is conducted at the temperature of 60-100DEG C and the pressure of 0.2MPa according to the reflux ratio of (10-50):1; the rectifying of the second rectifying tower is conducted at the temperature of 100-140DEG C and the pressure of 0.5MPa according to the reflux ratio of (20-50):1; the rectifying of the third rectifying tower is conducted at the temperature of 60-80DEG C and the pressure of 0.2MPa according to the reflux ratio of (20-50):1. The equipment can be utilized for effectively purifying the trichlorosilane, and is simple, safe, energy-saving and environment-friendly and low-cost in technique, the purity of the purified trichlorosilane is high, the purified trichlorosilane can be effectively utilized for producing polycrystalline silicon, and the produced waste liquor can be recycled.

Owner:CHINA ENFI ENGINEERING CORPORATION

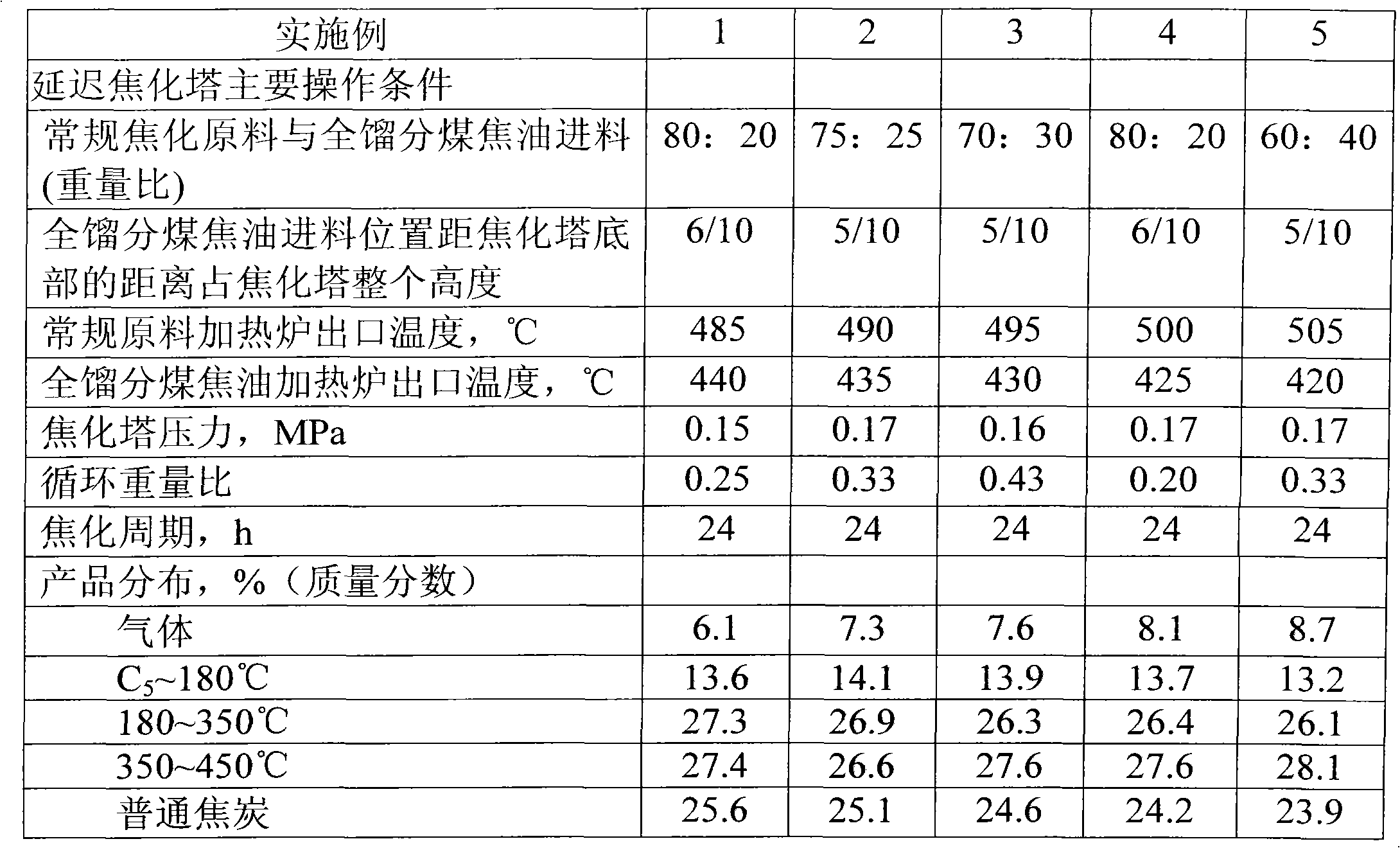

Method for producing needle coke raw material by using delayed coking process

ActiveCN102041013AExpand sourceThe method flow is simpleCoking carbonaceous materialsGeneration rateDesorption

The invention discloses a method for producing a needle coke raw material by using a delayed coking process. In the method, full-range coal tar is imported to the top and the middle and a high-temperature conventional coking raw material is imported to the bottom; the high-temperature oil gas generated by the conventional coking raw material via high-temperature cracking is mixed with the full-range coal tar with lower temperature at the top and the middle of a reactor so that the full-range coal tar can crack hydrocarbon molecules with high reaction activity at a proper high temperature to achieve the aim of desorption; for the full-range coal tar, under the condition of the delayed coking process, asphaltene and partial colloid are condensed to form coke which is deposited in a coking tower so as to remove the components going against the production of the needle coke; furthermore, by means of the injection of the low-temperature full-range coal tar, the cracking temperature of the conventional coking raw material is reduced, the high-temperature cracking time of the conventional raw material is shortened, the secondary reaction is decreased, the coke generation rate is reduced and the stable operation period of a single tower is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

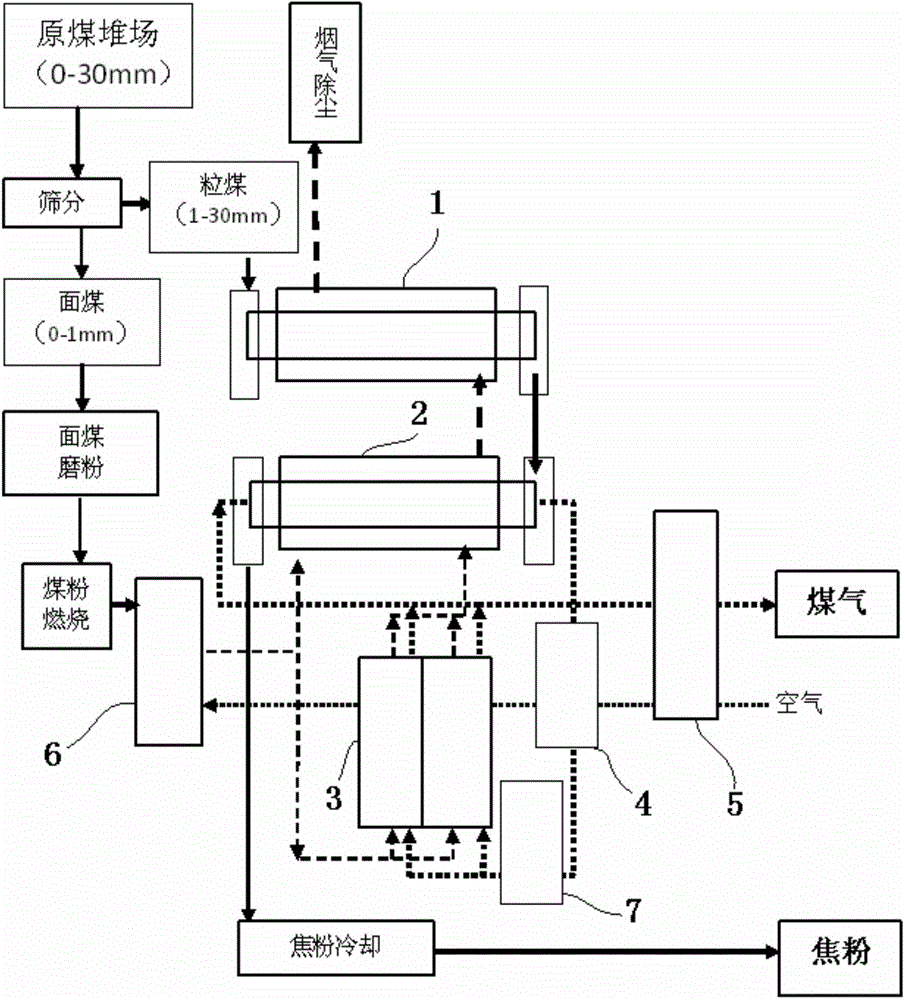

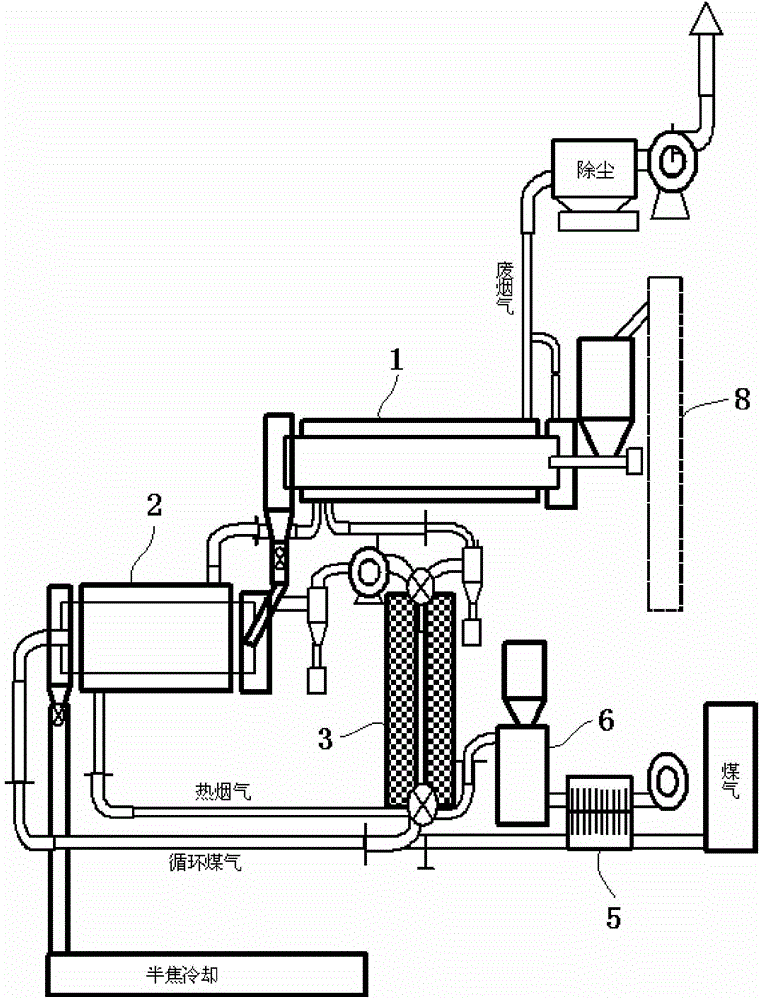

Method and device for producing coal gas by pulverized coal pyrolysis

InactiveCN103980951APlay a filtering roleEasy to transportIndirect and direct heating destructive distillationGas purification by catalytic conversionWater vaporProcess engineering

The invention relates to a method and device for producing a coal gas by pulverized coal pyrolysis. The coal gas production method disclosed by the invention comprises the following step: with an unpurified raw gas which is obtained from raw coal by dry distillation pyrolysis as a raw material, producing the high-quality coal gas inside a regenerative chamber in a pyrolysis manner. The device disclosed by the invention comprises a raw coal drying oven, a dry distillation furnace, a regenerative chamber for pyrolyzing the raw gas, and a hot blast heater for supplying heat. The raw gas is pyrolyzed to produce the coal gas, water vapor in the raw gas reacts with coke powder to produce a water gas, and meanwhile tar is cracked into the coal gas, so as to serve multiple purposes. The method and device disclosed by the invention have the advantages of low energy consumption, low investment, high calorific value of the gas, low semicoke ash and low coal quality transformation cost.

Owner:CHANGAN UNIV

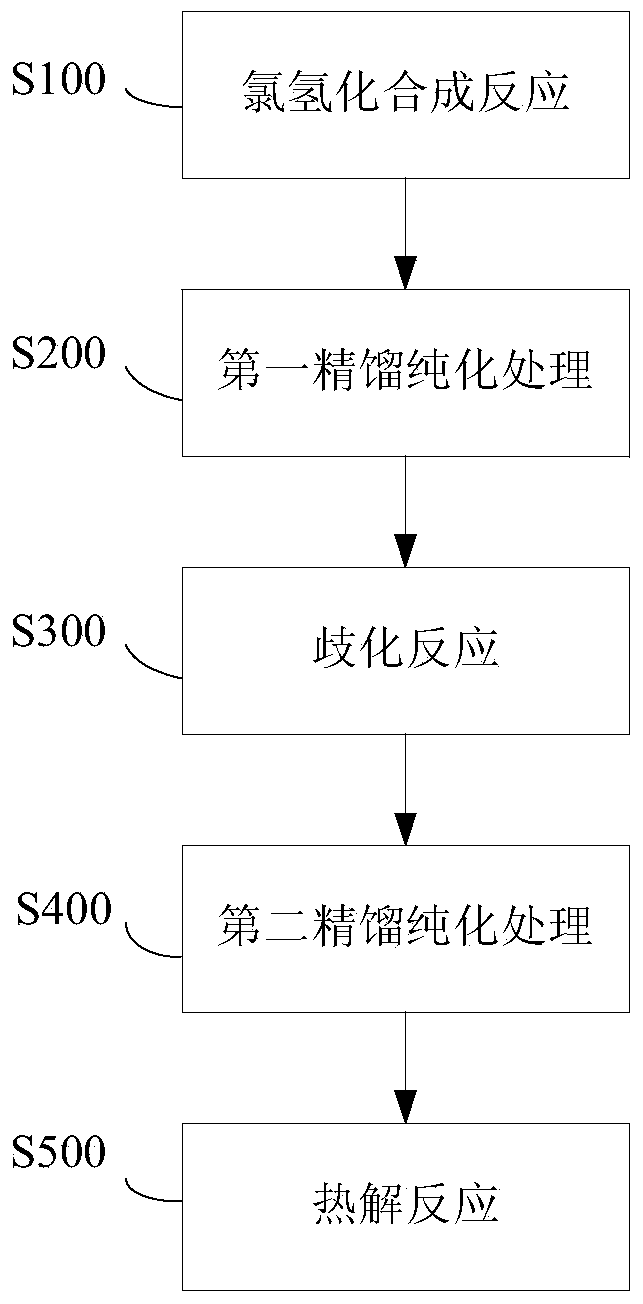

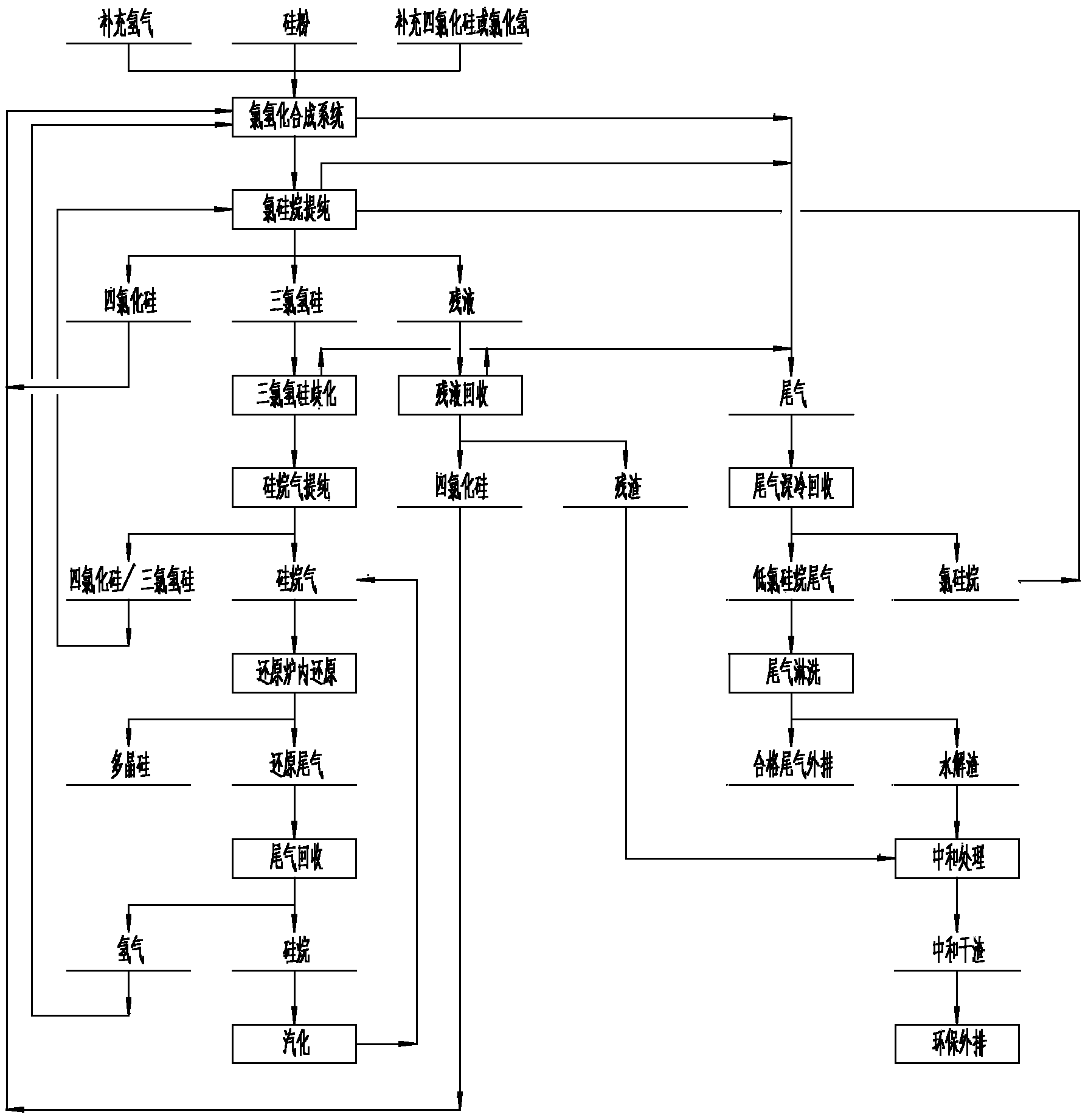

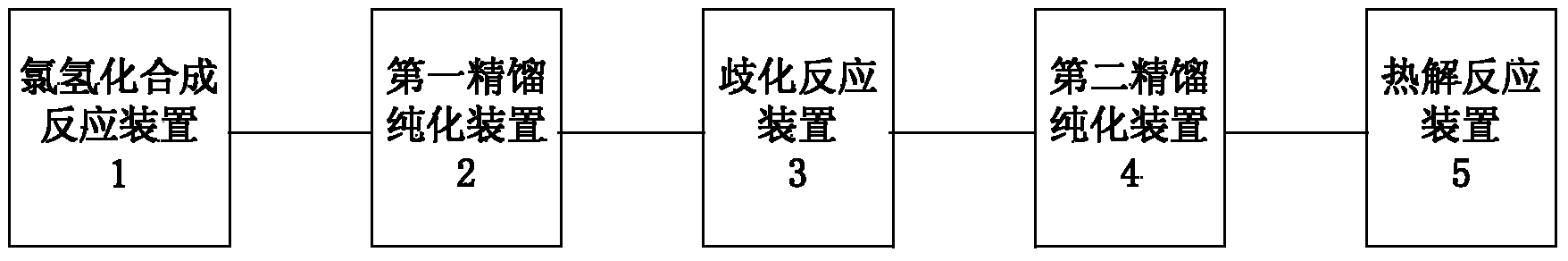

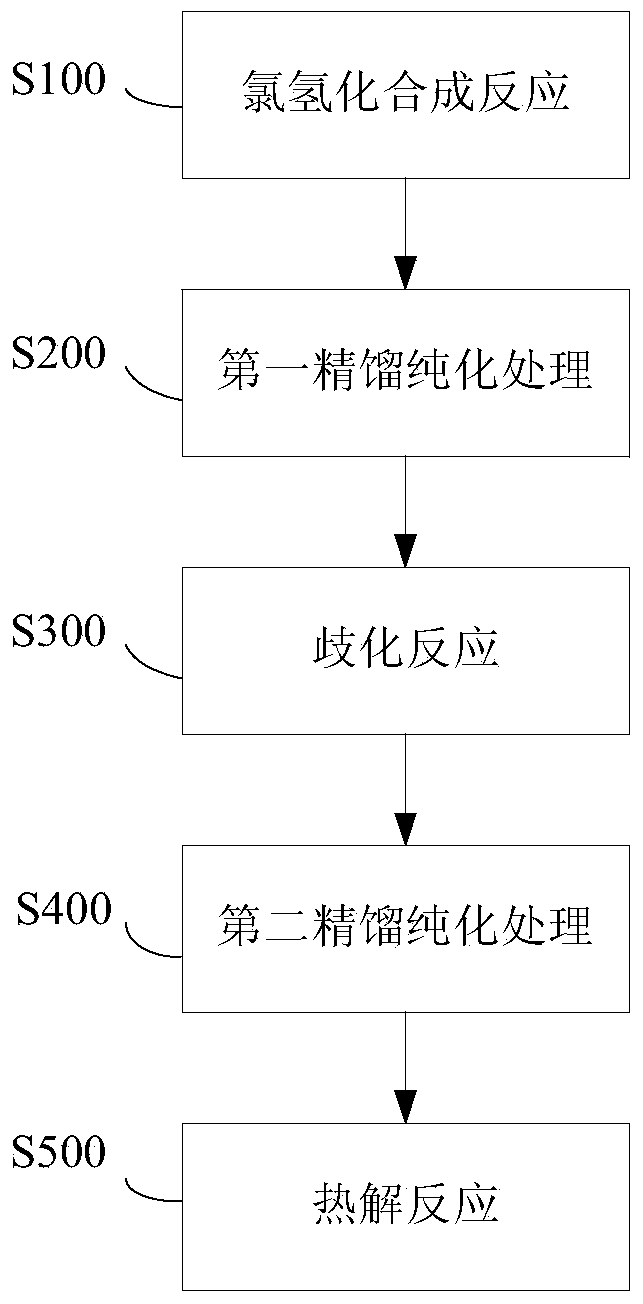

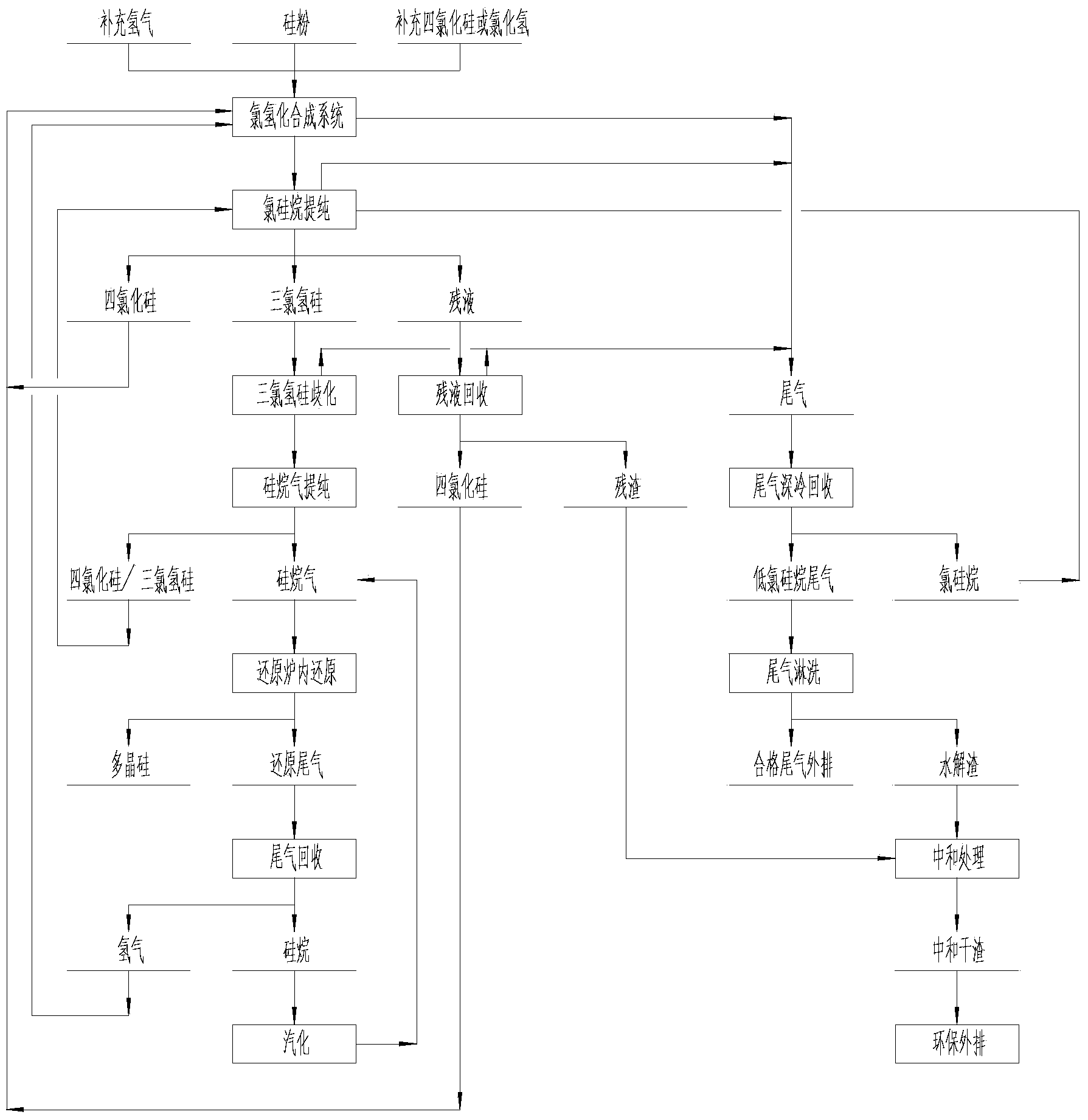

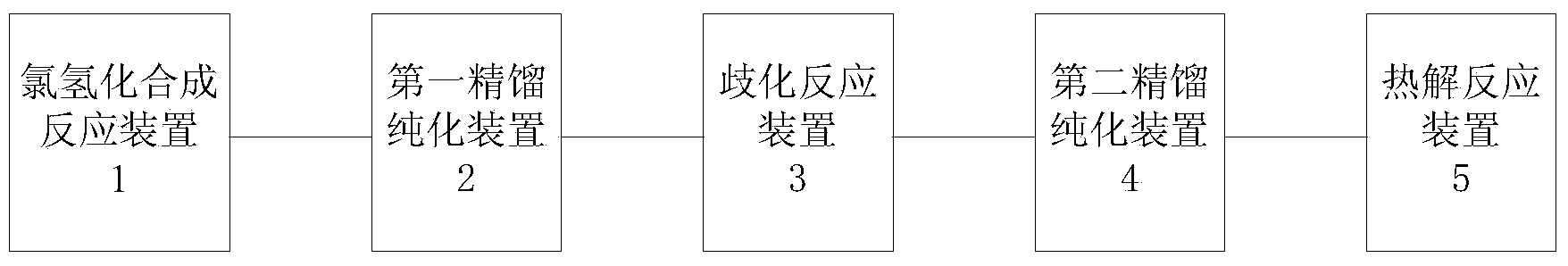

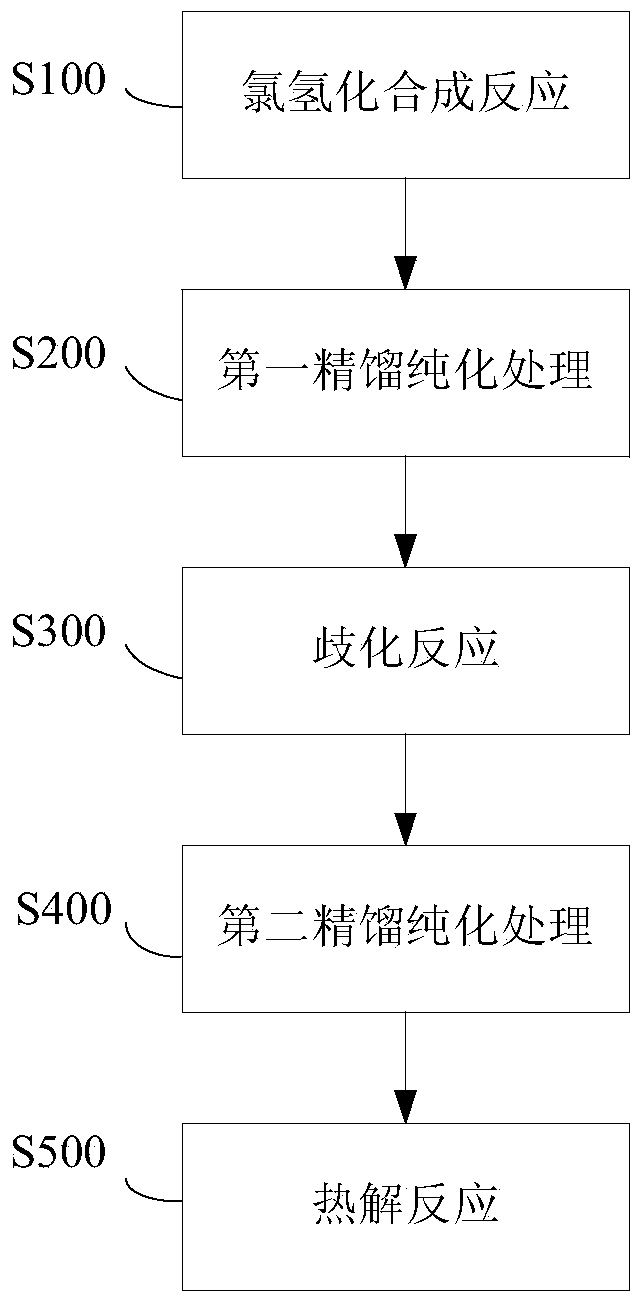

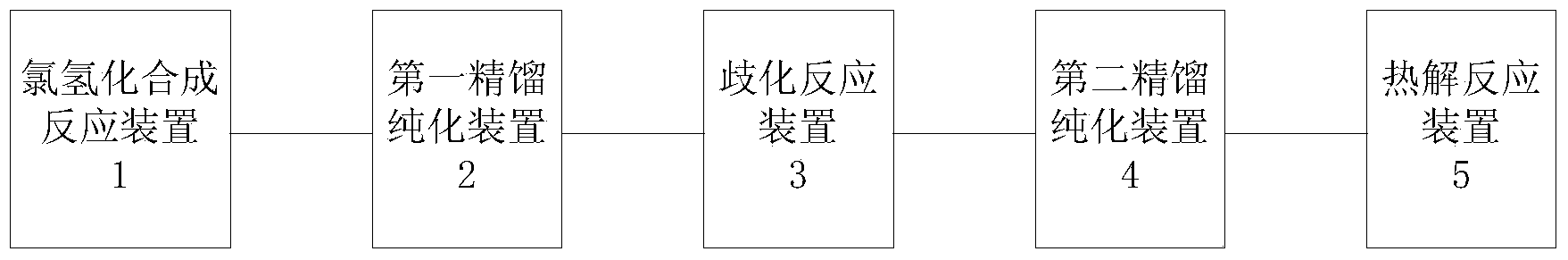

Equipment for preparing polycrystalline silicon

ActiveCN103449440ASafe and stable process systemSimple processSiliconSilicon tetrachlorideDisproportionation

The invention discloses equipment for preparing polycrystalline silicon. The equipment comprises a chlorhydrogenation synthetic reaction device which is used for carrying out chlorhydrogenation synthetic reaction on silicon powder, hydrogen gas and at least one of chlorine hydride and silicon tetrachloride, a first rectification purification device which is used for carrying out first rectification purification treatment on chlorhydrogenation synthetic reaction products containing trichlorosilane, a disproportionation reaction device which is used for carrying out disproportionation reaction on trichlorosilane, a second rectification purification device which is used for carrying out second rectification purification treatment on disproportionation reaction products, and a pyrolytic reaction device which is used for carrying out pyrolytic reaction on silicane gas to obtain the polycrystalline silicon. The equipment is utilized to prepare electronic-grade polycrystalline silicon effectively, and the technology involving the equipment is simple and safe, has energy-saving and environment-friendly effects and is low in cost, the purity of the produced polycrystalline silicon is high, generated tail gas and waste residues can meet the environment-protection requirement, and the technology is applied to cleaner production of the electronic-grade polycrystalline silicon.

Owner:CHINA ENFI ENGINEERING CORPORATION +1

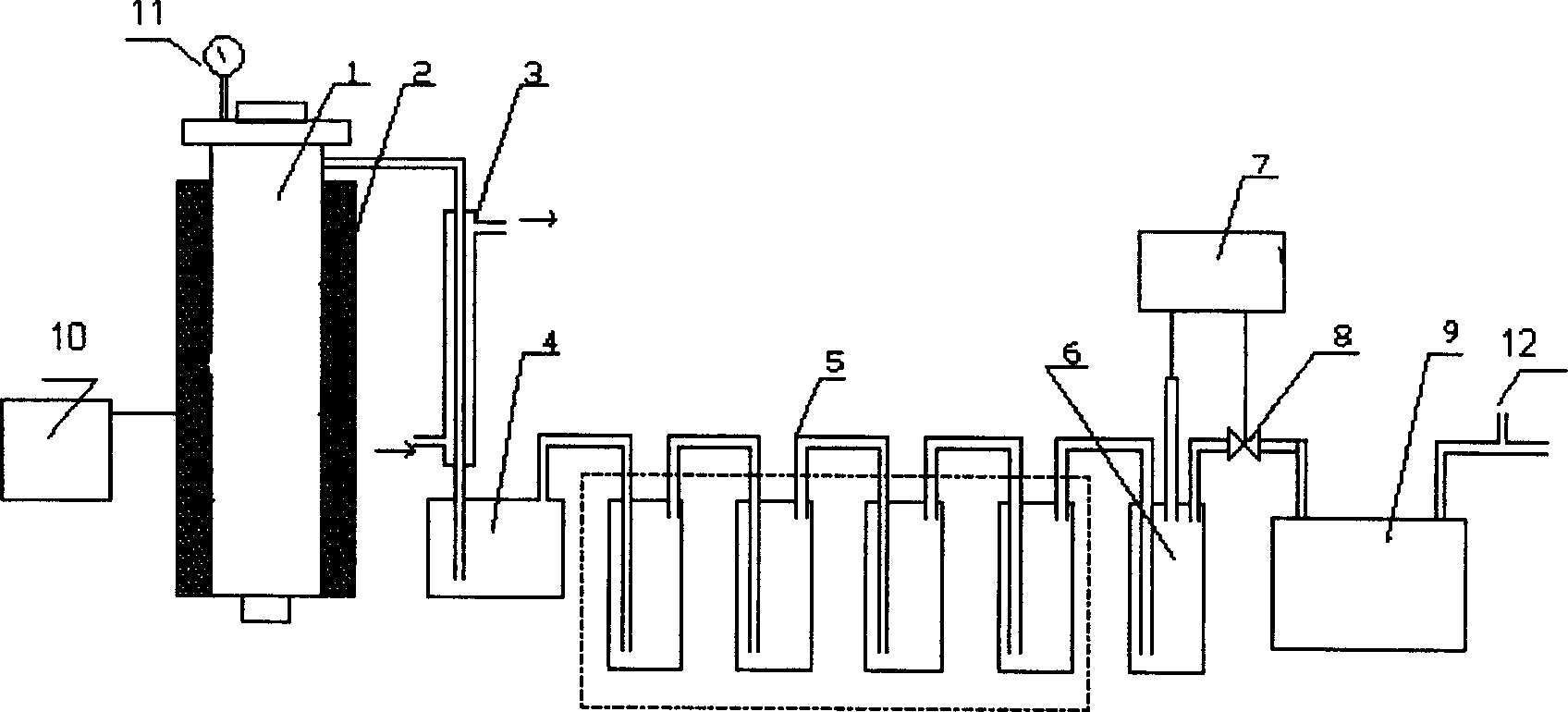

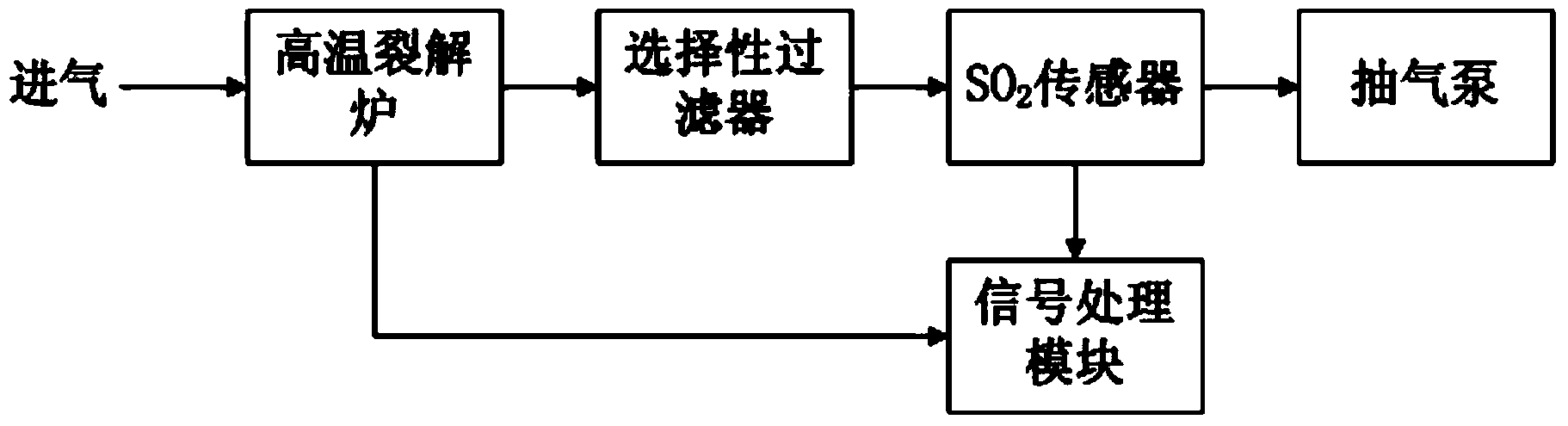

System for detecting sulfur hexafluoride

ActiveCN103675206AStrong output signalLow cracking temperatureMaterial analysisLower limitElectricity

The invention discloses a system for detecting sulfur hexafluoride, and belongs to the technical field of detection of sulfur hexafluoride. The system comprises a high-temperature cracking furnace, a selective filter, an SO2 sensor, an air pump and a signal processing module, wherein an air inflow sensor is arranged at an air inlet of the high-temperature cracking furnace; the high-temperature cracking furnace, the selective filter, the SO2 sensor and the air pump are connected sequentially through pipelines; the SO2 sensor is electrically connected with the signal processing module; and the air inflow sensor in the high-temperature cracking furnace is electrically connected with the signal processing module. According to the system, the concentration of SO2 produced by the system is high, interference gas is little, a catalyst is not required to be used, the operability is high, the cost is low, the analysis precision is high, and the lower limit of detection is low.

Owner:718TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Equipment for preparing trichlorosilane

The invention discloses equipment for preparing trichlorosilane. The equipment comprises a hydrochlorination synthesis reaction device, and a first distillation purification device, wherein the hydrochlorination synthesis reaction device is used for carrying out hydrochlorination synthesis reaction on ganister sand, hydrogen and at least one material selected from hydrogen chloride and silicon tetrachloride, so as to obtain a hydrochlorination synthesis reaction product containing the trichlorosilane; the first distillation purification device is used for carrying out first distillation purification treatment on the hydrochlorination synthesis reaction product containing the trichlorosilane, so as to obtain the trichlorosilane and first refined raffinate. By using the equipment, the trichlorosilane can be effectively prepared; the process related to the equipment is simple, safe, energy-saving and environment-friendly, low in cost, and high in purity of produced trichlorosilane; the generated tail gas and waste residue can be recycled, so as to achieve the environmental requirements.

Owner:CHINA ENFI ENGINEERING CORPORATION

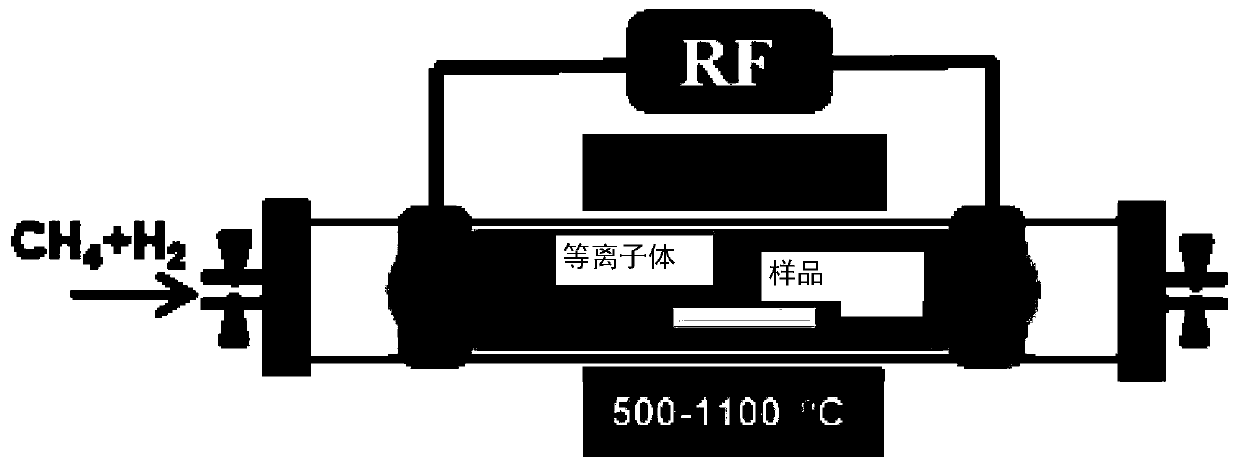

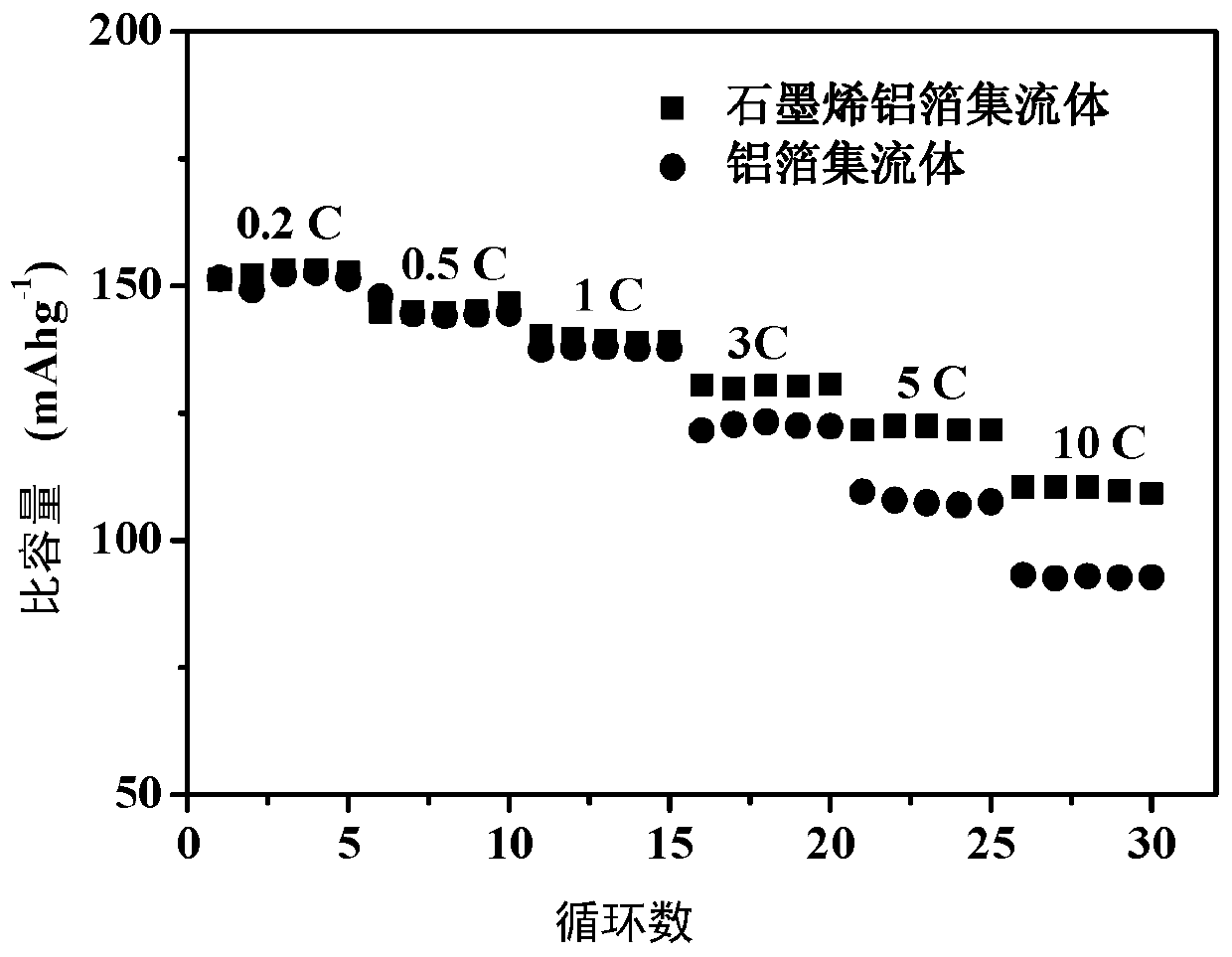

Graphene modification current collector prepared by employing plasma-assisted chemical vapor deposition and preparation method thereof

InactiveCN109950544AImprove power performanceLower internal resistanceElectrode carriers/collectorsSecondary cellsInternal resistancePower performance

The present invention relates to a graphene modification current collector prepared by employing plasma-assisted chemical vapor deposition and a preparation method thereof. The graphene modification current collector comprises a substrate and a grapheme thin film having a three-dimensional continuous structure formed by mutual connection of grapheme nanosheets vertically grown at the surface of the substrate. The graphene modification current collector can effectively reduce the internal resistance of an electrode and can improve the high-power performance of the battery.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI +1

Method for chemical gas-phase permeation compaction of carbon/carbon composite material

The invention discloses a method for the chemical gas-phase permeation compaction of a carbon / carbon composite material. The method comprises the following steps: putting a porous carbon fibre prefabricated body into a vacuum deposition furnace, vacuumizing the vacuum deposition furnace, keeping the vacuum, then setting furnace pressure and furnace temperature, introducing natural gas or the mixedgas of the natural gas and acetylene as a gas precursor body, keeping the gas precursor body being remained in the vacuum deposition furnace and carrying out isothermal isopiestic chemical gas-phasecompacting processing, wherein the volume ratio of the natural gas to the acetylene is 4-9:1. The invention has simple technology, low cost, high carbon deposition efficiency and large permeation depth, is not easy to generate an incrustation on the surface of the carbon / carbon composite material and is beneficial to shortening the compaction period of the carbon / carbon composite material.

Owner:XIAN CHAOMA SCI TECH

Method for extraction and purification of plasmid DNA and its preparation process

InactiveCN1546516AImproved cracking temperatureIncrease productionSugar derivativesFermentationPurification methodsDNA extraction

Method for extraction and purification of plasmid DNA from prokaryotes and its preparation process, wherein the process comprises the steps of prokaryote bacterium liquid concentration, splitting thalline, and plasmid DNA purification.

Owner:CHINA AGRI UNIV

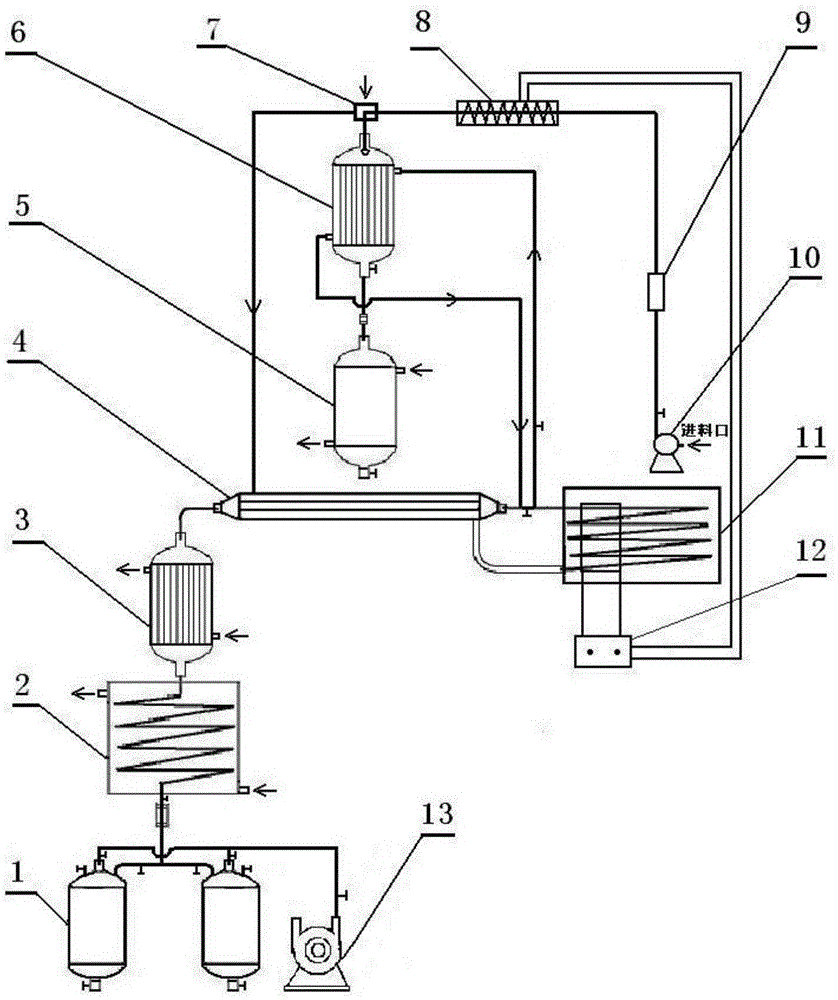

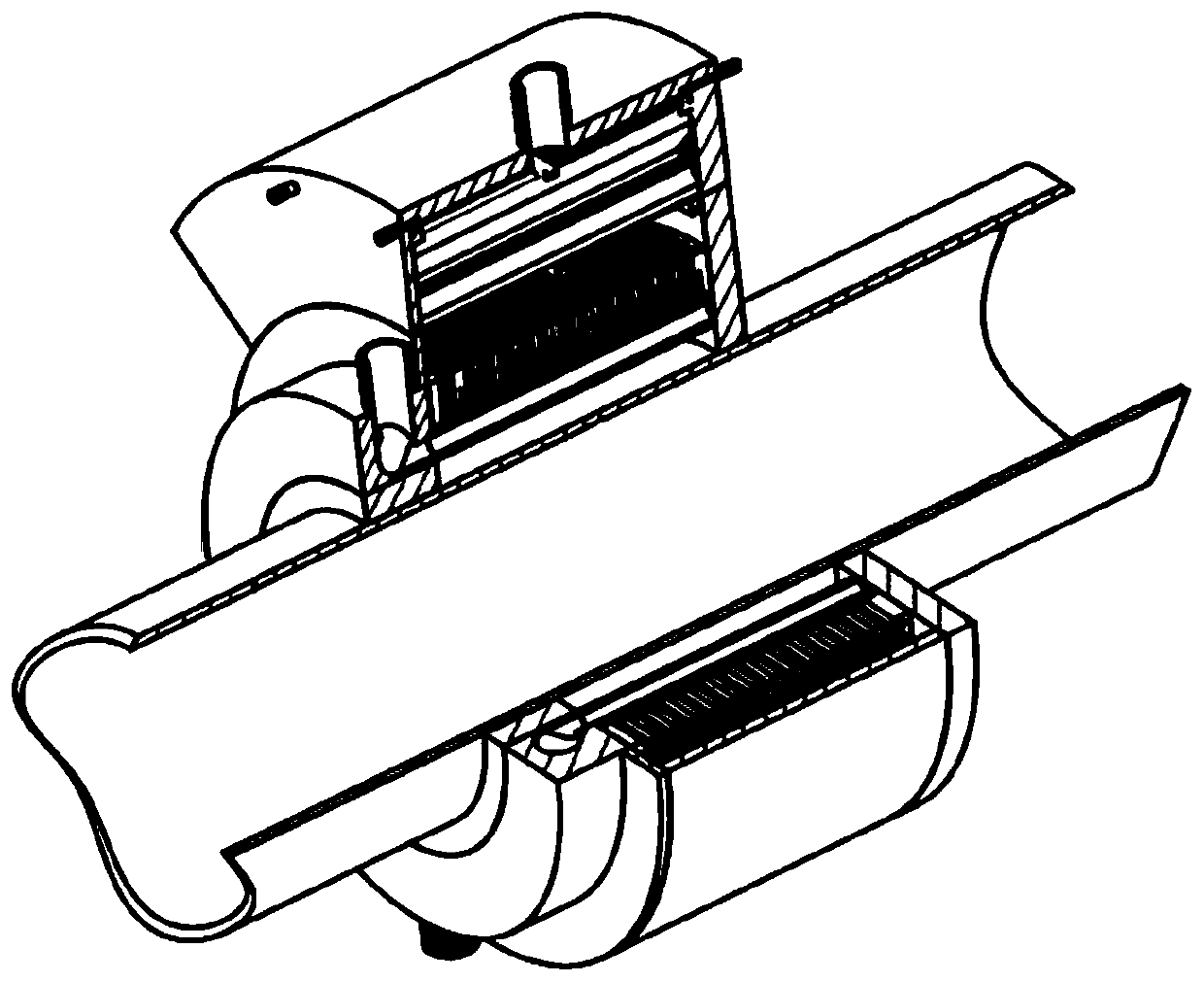

Apparatus for continuously cracking beta-pinene to produce laurene

ActiveCN105481632ASave energyRapid coolingHydrocarbon by isomerisationChemical industryEngineeringGuide tube

The invention discloses an apparatus for continuously cracking beta-pinene to produce laurene. The apparatus comprises a charging pump, a vaporizer, a cracker, a heat exchanger, a cooler and a product collector which are sequentially connected; the charging port of the charging pump is connected with a raw material tank, the discharging port of the charging pump is connected with the upper end of the vaporizer through a guide tube, a nonvolatile matter collector is connected below the vaporizer, a gas mixing chamber is arranged above the vaporizer, the heat conduction material inlet and the heat conduction material outlet of the vaporizer are respectively connected with an eduction tube in front of and behind the eduction tube valve of the cracker, the gas mixing chamber is connected with the heat conduction material inlet of the heat exchanger, the heat conduction material outlet of the heat exchanger is connected with the charging port of the cracker, the charging port of the heat exchanger is connected with the discharging port of the cracker through a valve, and the heat exchanger is connected with the product collector. The apparatus has the advantages of low energy consumption, high reaction efficiency, uniform heating, low cost, high laurene output and realization of continuous cracking production of laurene.

Owner:GUANGXI BEILIU ZHAOZHOU FOREST PROD

A nitrogen-modified catalyst for preparing vinyl chloride and its preparation method

ActiveCN104289254BSimple preparation processLow costPreparation by hydrogen halide split-offOrganic-compounds/hydrides/coordination-complexes catalystsBarium saltEthane Dichloride

The invention discloses a nitrogen-modified catalyst applied to preparation of vinyl chloride and a preparation method of the nitrogen-modified catalyst. According to the nitrogen-modified catalyst, active carbon is used as a carrier, wherein the nitrogen-modified catalyst comprises a metal salt loaded compound and a nitrogen-containing compound; according to the total mass of the catalyst, the mass percentage of the metal salt compound is 0.01-10%, and the mass percentage of the nitrogen-containing compound is 0.01-10%. The metal salt compound is strontium salt or barium salt or mixture of the strontium salt and the barium salt; the nitrogen-containing compound is selected from at least one of guanidine hydrochloride, acetamidine hydrochloride, acrylamide, urea, methanesulfonamide and cyanoacetamide. The nitrogen-modified catalyst is applied to reaction of preparing vinyl chloride by catalytic cracking of 1,2-dichloroethane; not only is the cracking temperature reduced, and also the nitrogen-modified catalyst is high in conversion rate of 1,2-dichloroethane and selectivity of vinyl chloride, and is efficient, and has energy-saving and environment-friendly effects.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

Efficient self-adaptation catalytic cracking device suitable for regenerative cooling detonation combustion chamber

InactiveCN110319457AImprove cooling efficiencyHigh stability detonationExplosive combustion chamberDetonationCombustion chamber

The invention provides an efficient self-adaptation catalytic cracking device suitable for a regenerative cooling detonation combustion chamber. On the basis of the regeneration cooling scheme, the device comprises a bottom-layer heat exchange layer, a middle-layer catalytic cracking layer, a top-layer gas-liquid separation layer and a device fixing structure. By utilization of a radial fuel jetting port and an expansion outlet channel evenly distributed in the circumferential direction of the heat exchange layer in an interphase manner are utilized for achieving uniform heating and flowing speed reduction of fuel, and accordingly, a large amount of micromolecule gas-state fuel is generated in a middle-layer honeycomb-shaped catalytic cracking layer coated with an efficient catalyst, wherein the micromolecule gas-state fuel is excellent in detonation performance and narrow in component kind range. Through an adaptively-adjusted N-shaped baffle plate structure in the gas-liquid separation layer, fuel oil liquid drops unfavorable to detonation and combustion in products can be effectively separated and split. The device can achieve efficient fuel splitting, mixed gas-state fuel withhigh explosion performance is continuously obtained; and in addition, the device can sufficiently utilize physical and chemical heat sink of the fuel, and the cooling efficiency of the detonation combustion chamber is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Method for generating myrcene by cracking beta-pinene

InactiveCN104151124ALow cracking temperatureReduce energy consumptionHydrocarbon by aliphatic/cycloaliphatic split-offNitrogenVaporization

The invention discloses a method for producing myrcene by cracking beta-pinene. The method comprises the following steps: vaporizing a beta-pinene mixture of which the beta-pinene content is over 95 percent in vacuum; mixing nitrogen with gas generated after vaporization of the beta-pinene mixture in a ratio of 1:1-5; preheating mixed gas obtained by mixing; performing a cracking reaction on the preheated gas through a cracking tube; and performing two-stage cooling on a cracking product to form liquid, wherein a catalyst layer is arranged on the inner wall of the cracking tube; the temperature of the cracking tube is 350-500 DEG C; the vacuum degree in vacuum vaporization is between -0.075MPa and -0.098MPa; the vaporization temperature is 80-110 DEG C; the mixing temperature is 90-120 DEG C; and the preheating temperature is 120-250 DEG C. Through adoption of the method, the problems of high production energy consumption and low yield in the conventional myrcene can be solved.

Owner:WUZHOU SONGHUA AROMATIC CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com