Patents

Literature

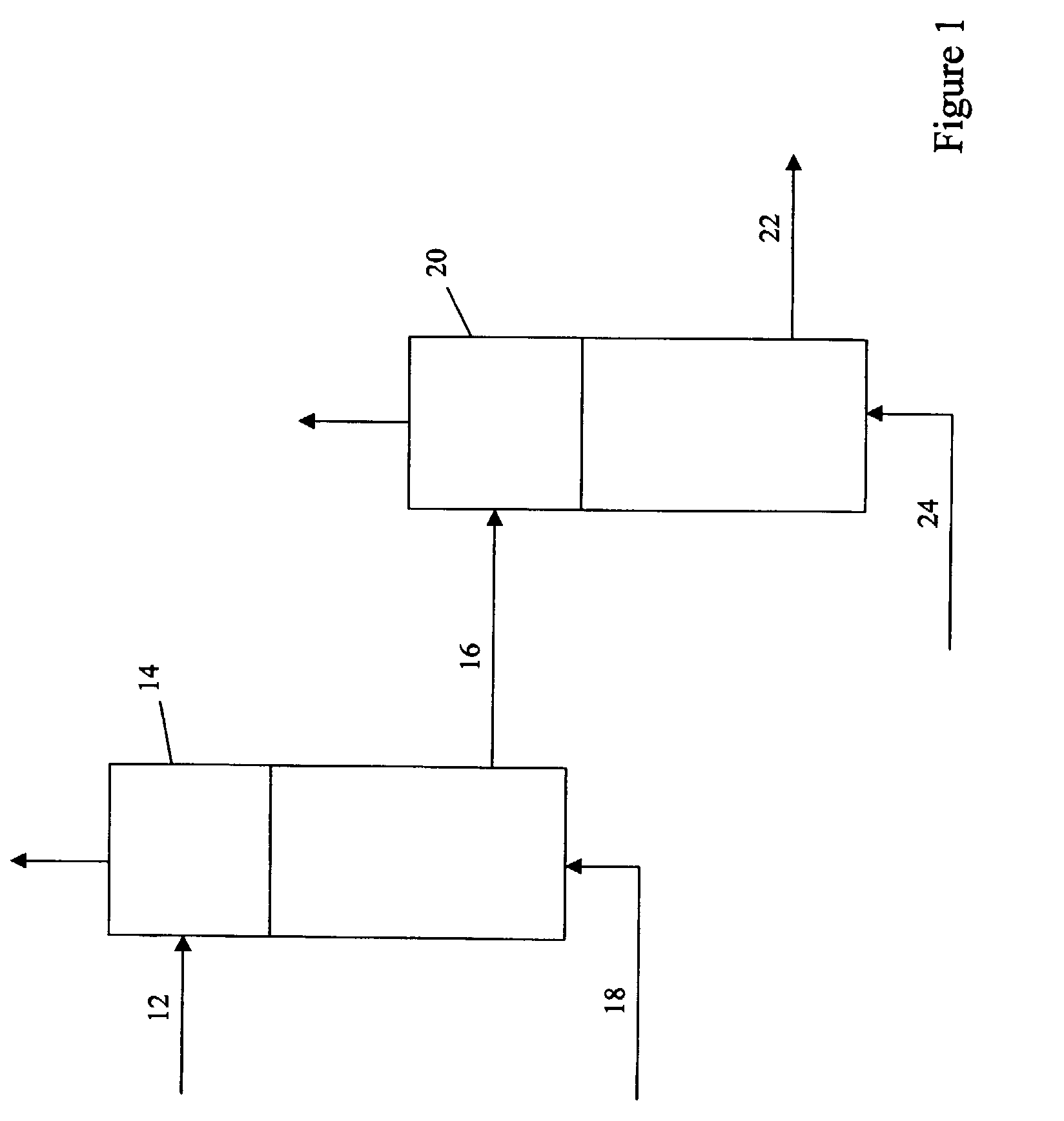

126results about "Hydrocarbon by aliphatic/cycloaliphatic split-off" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

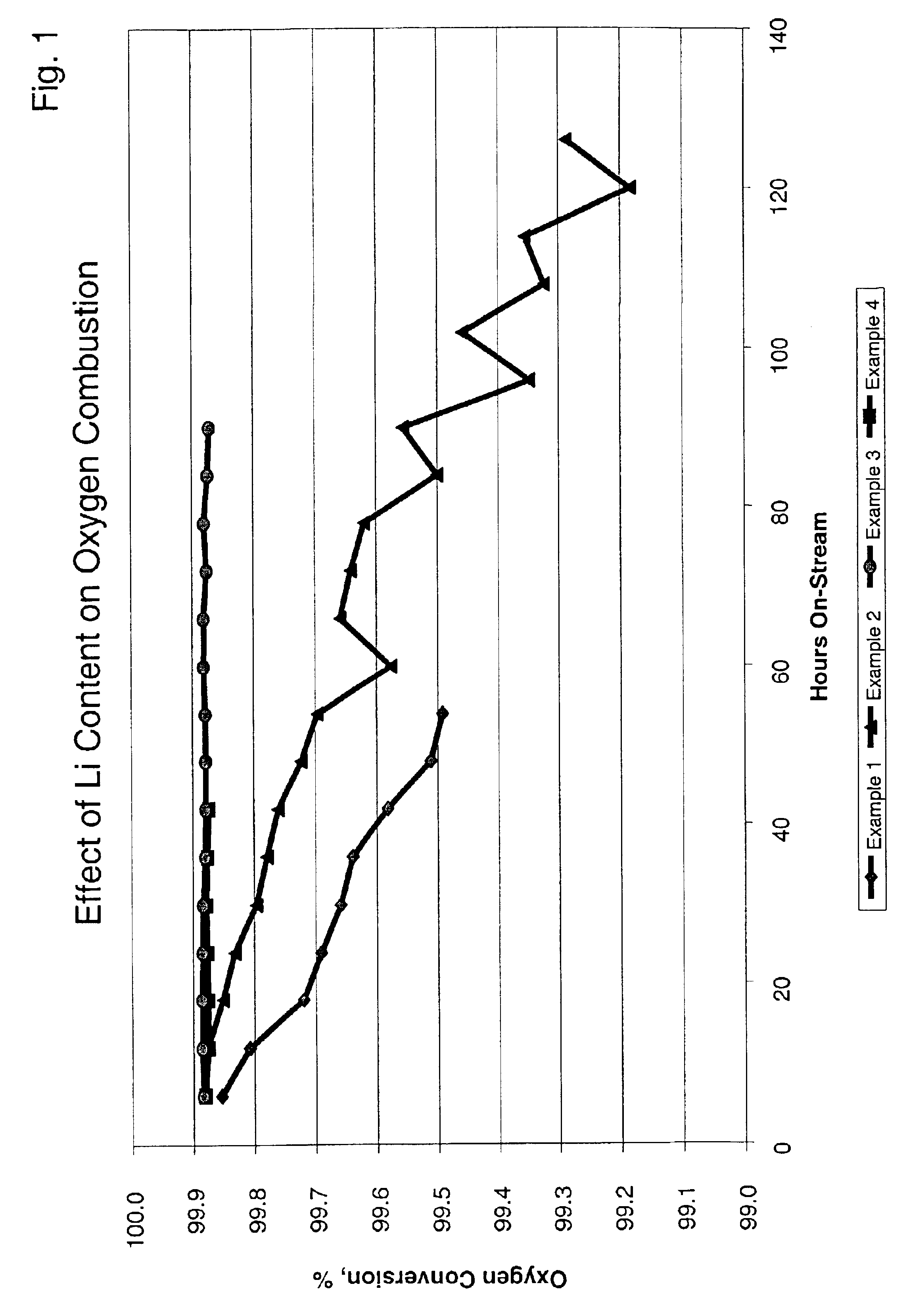

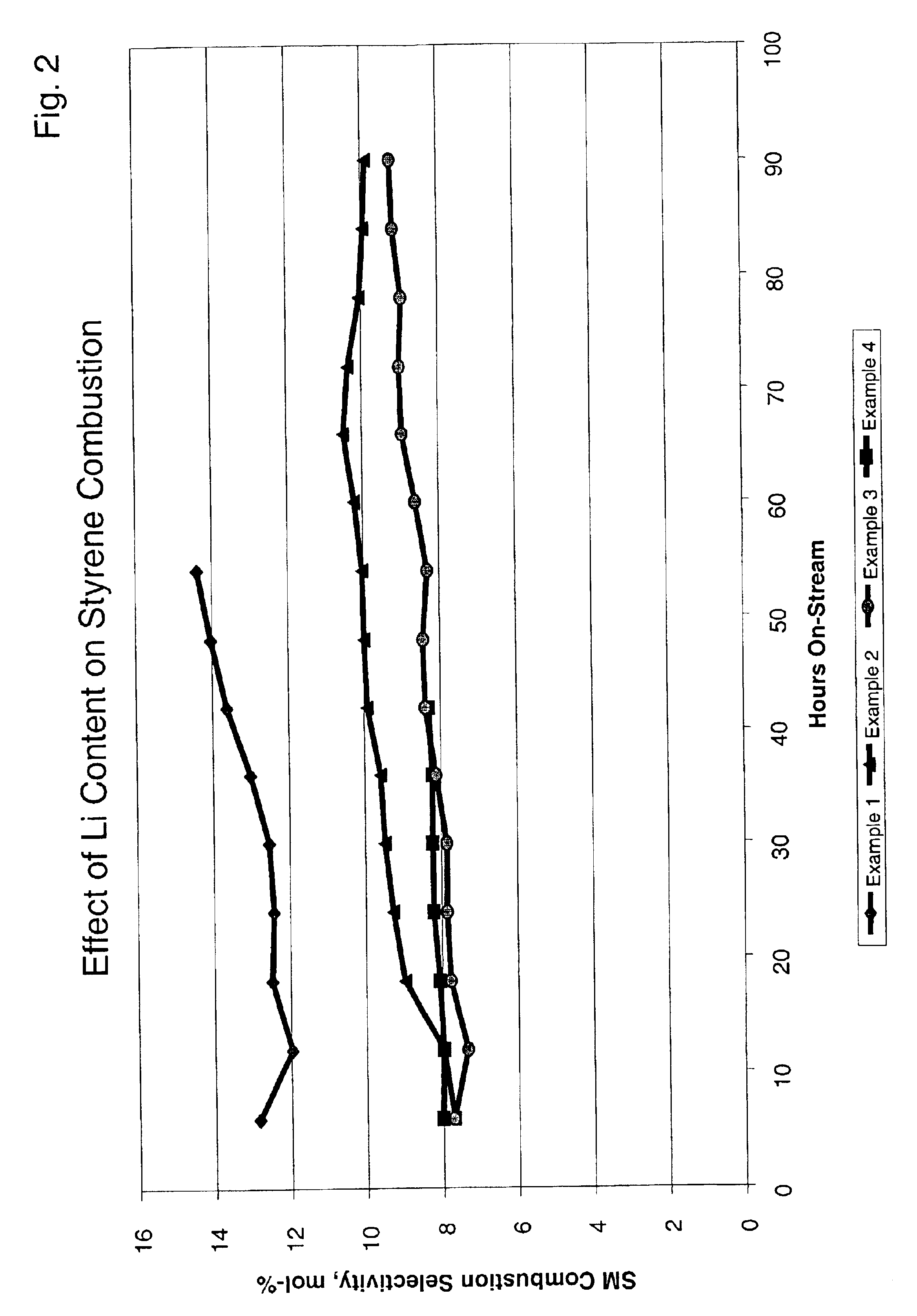

Lithium aluminate layered catalyst and a selective oxidation process using the catalyst

InactiveUS6858769B2Thermal non-catalytic crackingHydrocarbon by isomerisationHydrogenDehydrogenation

A catalyst for the selective oxidation of hydrogen has been developed. It comprises an inert core such as cordierite and an outer layer comprising a lithium aluminate support. The support has dispersed thereon a platinum group metal and a promoter metal, e.g. platinum and tin respectively. This catalyst is particularly effective in the selective oxidation of hydrogen in a dehydrogenation process.

Owner:UOP LLC

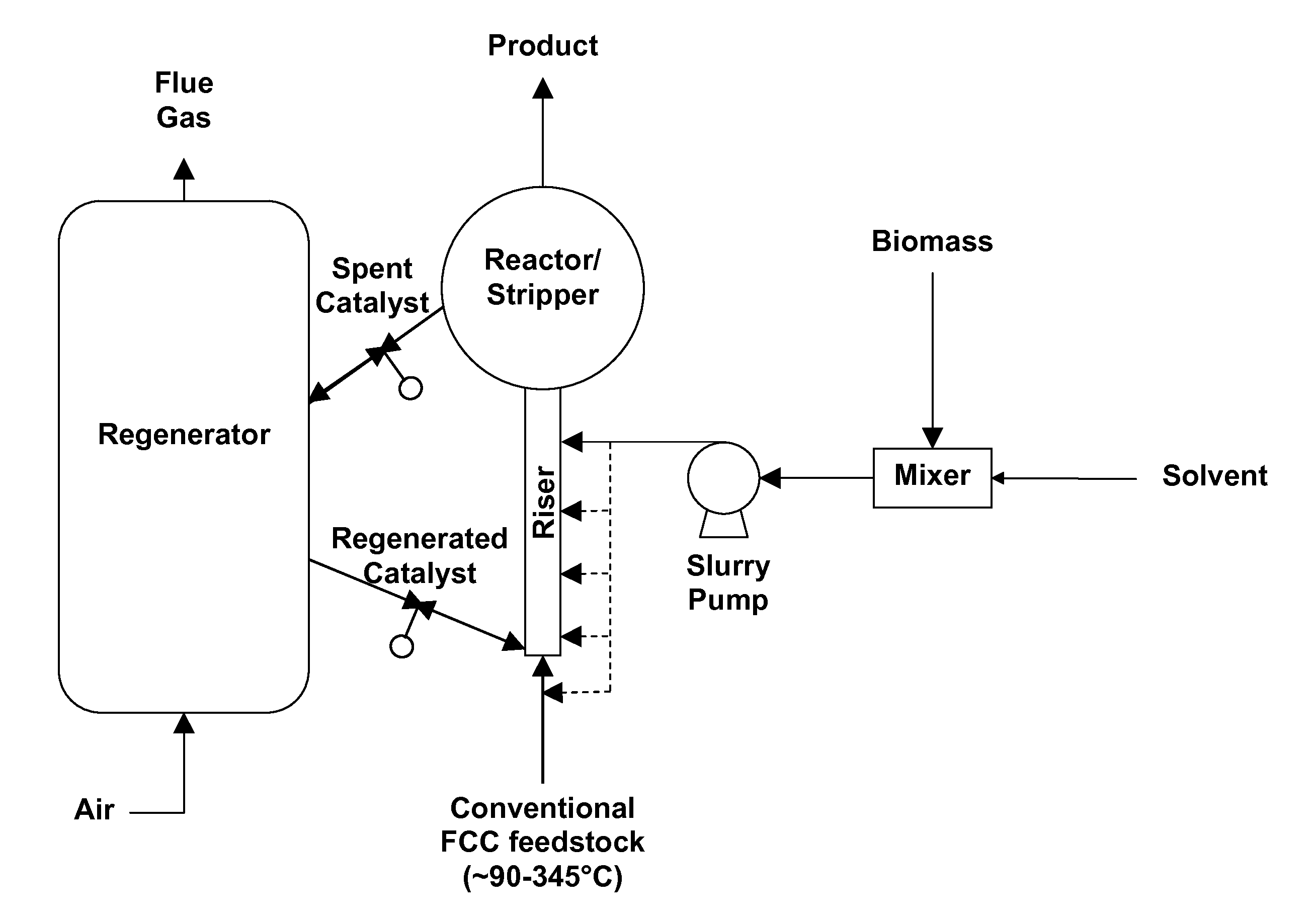

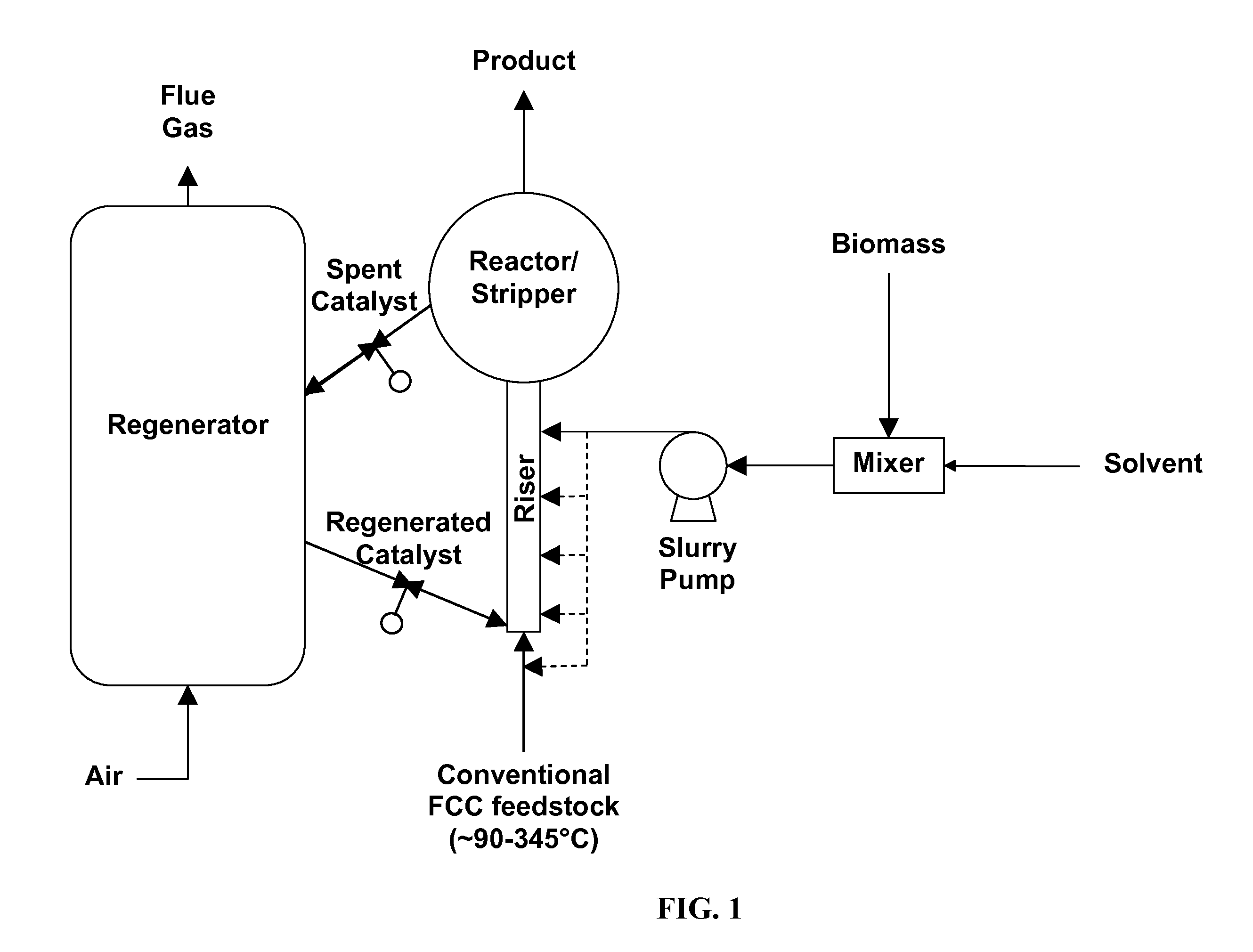

Integrated fcc biomass pyrolysis/upgrading

Owner:PHILLIPS 66 CO

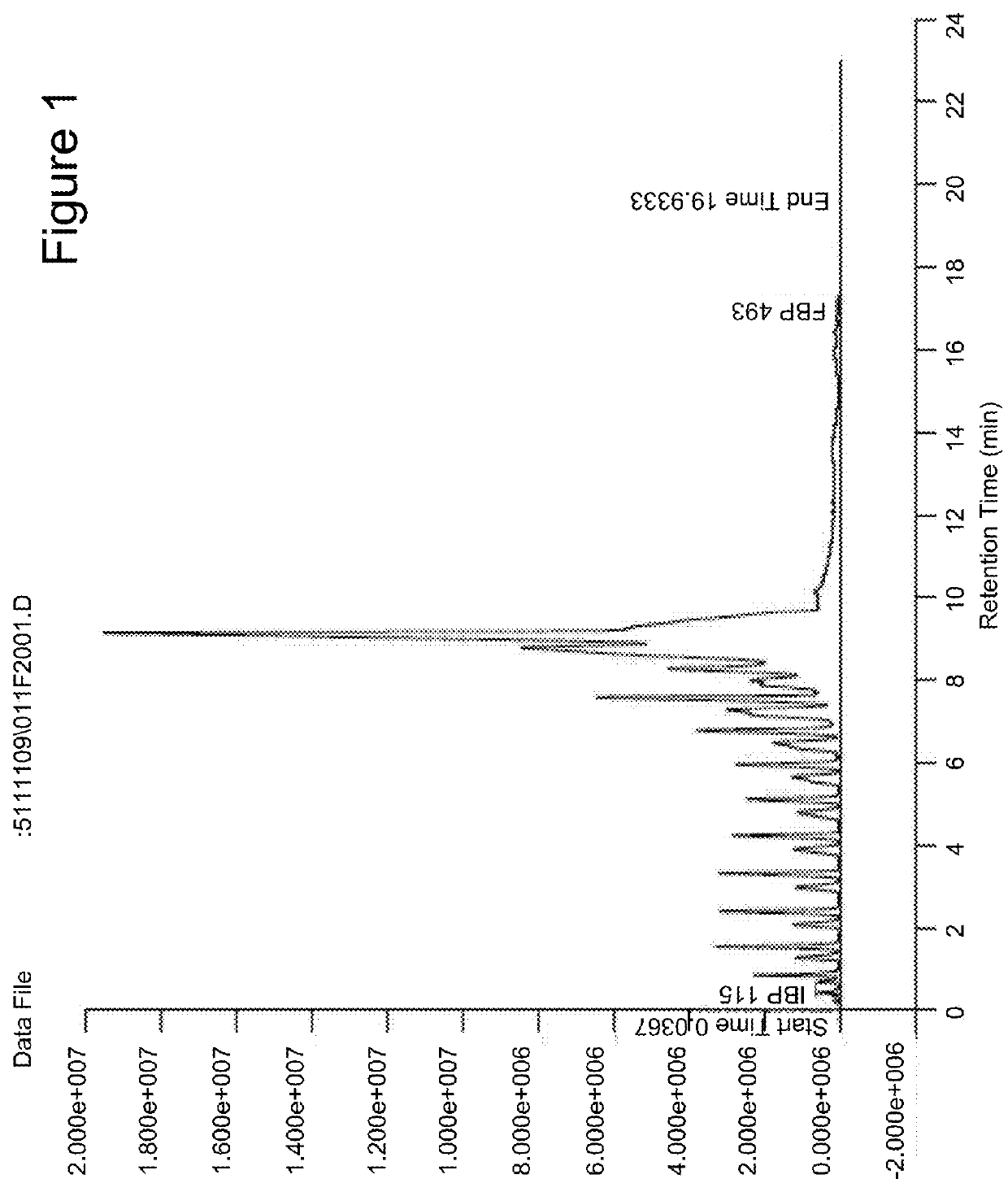

Production of fuels and lube oils from fischer-tropsch wax

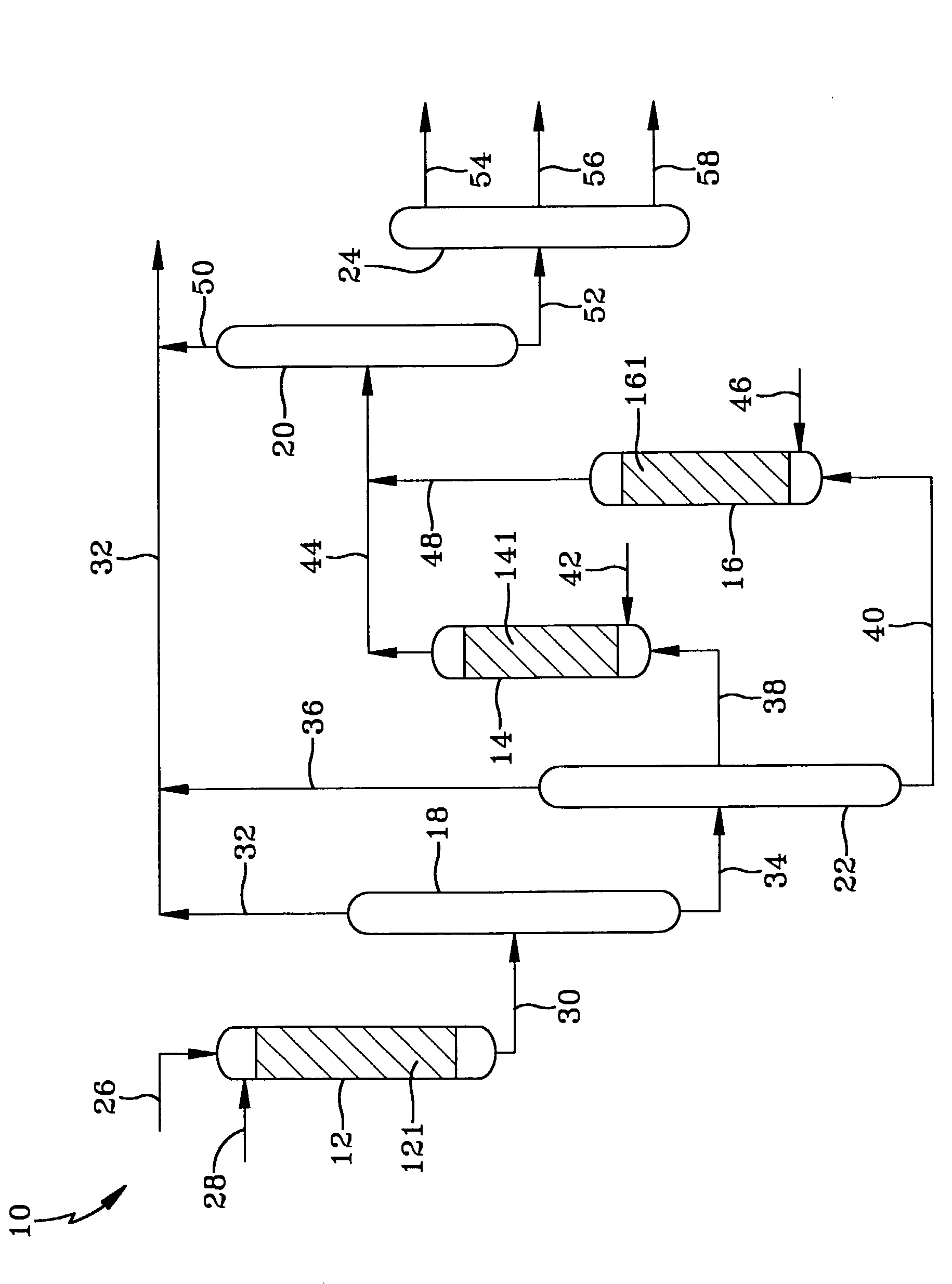

Dewaxed fuel and lubricant base stocks are made by (a) producing a synthesis gas from natural gas, (b) reacting the H2 and CO in the gas in the presence of a cobalt Fischer-Tropsch catalyst, at reaction conditions effective to synthesize a waxy hydrocarbon feed boiling in the fuel and lubricant oil ranges, which is hydrodewaxed in a first stage to produce a dewaxed fuel and a partially dewaxed lubricant fraction. The partially dewaxed lubricant fraction is separated into heavy and lower boiling fractions each of which is separately hydrodewaxed, to produce lubricant base stocks. A hydrodewaxing catalyst comprising a hydrogenation component, binder and solid acid component used to hydrodewax at least one, and preferably at least two of the waxy feed and partially dewaxed heavy and lower boiling lubricant fractions.

Owner:EXXON RES & ENG CO

Hydrocarbon Conversion

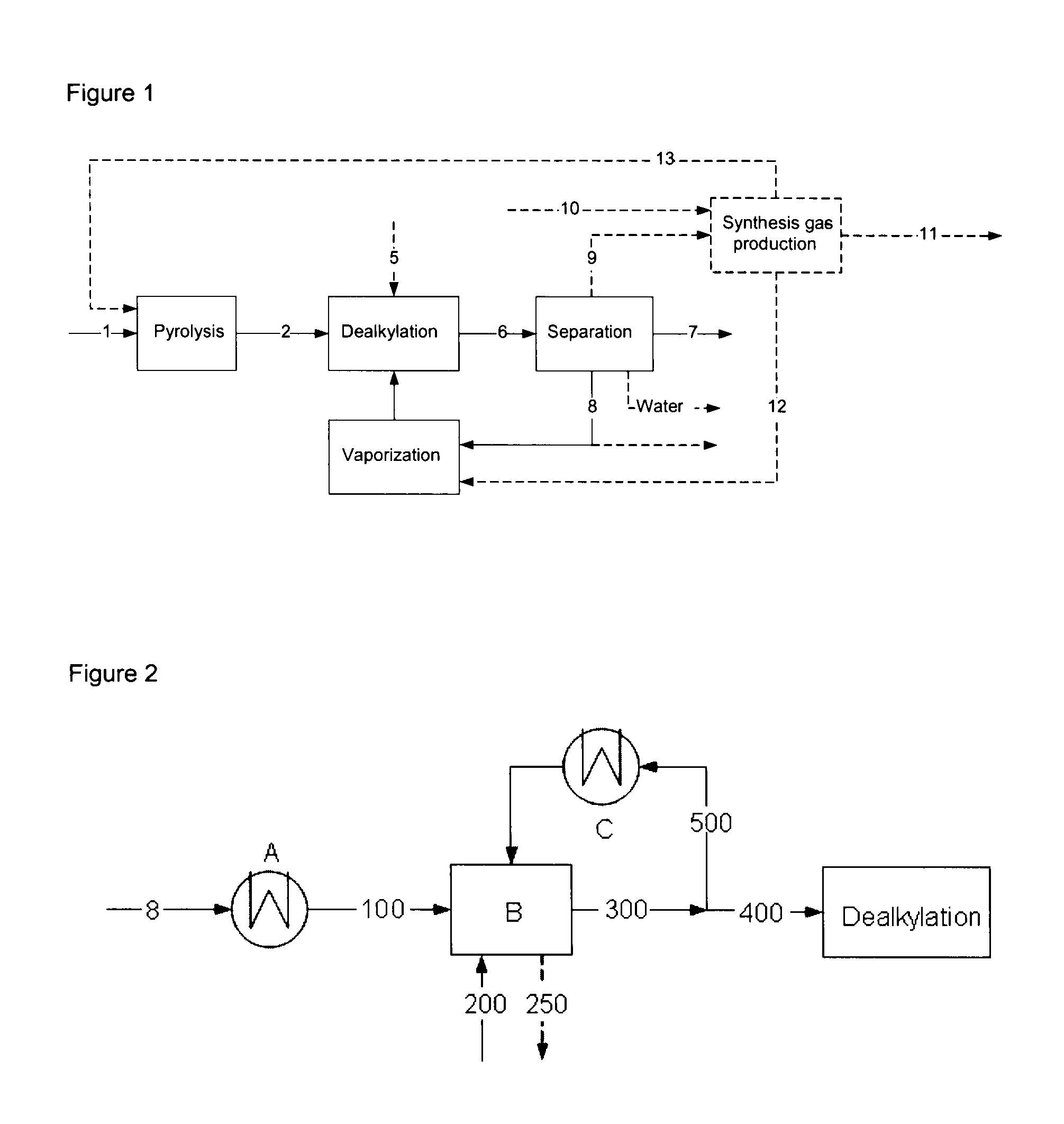

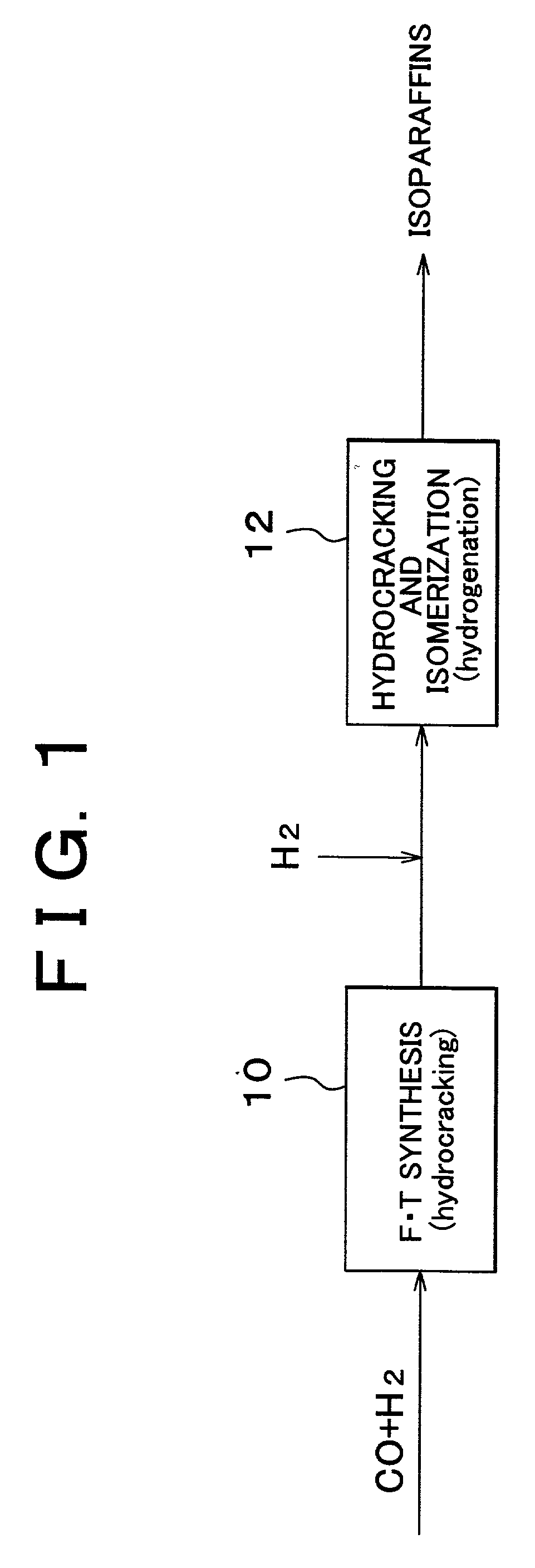

The invention relates to hydrocarbon conversion processes, to equipment useful in such processes, to the products of such hydrocarbon conversion processes and the use thereof, and to the use of energy derived from such processes.

Owner:EXXONMOBIL CHEM PAT INC

Hydrocarbon conversion processes using non-zeolitic molecular sieve catalysts

Hydrocarbon or oxygenate conversion process in which a feedstock is contacted with a non zeolitic molecular sieve which has been treated to remove most, if not all, of the halogen contained in the catalyst. The halogen may be removed by one of several methods. One method includes heating the catalyst in a low moisture environment, followed by contacting the heated catalyst with air and / or steam. Another method includes steam-treating the catalyst at a temperature from 400° C. to 1000° C. The hydrocarbon or oxygenate conversion processes include the conversion of oxygenates to olefins, the conversion of oxygenates and ammonia to alkylamines, the conversion of oxygenates and aromatic compounds to alkylated aromatic compounds, cracking and dewaxing.

Owner:EXXONMOBIL CHEM PAT INC

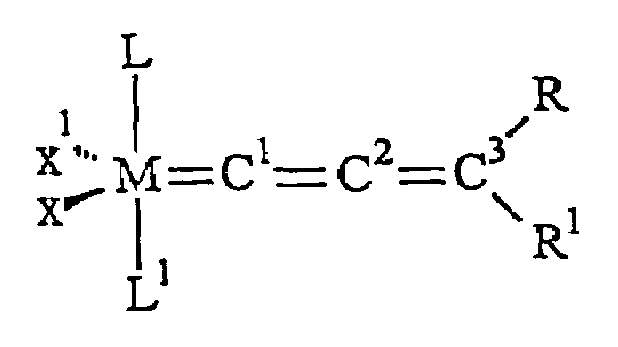

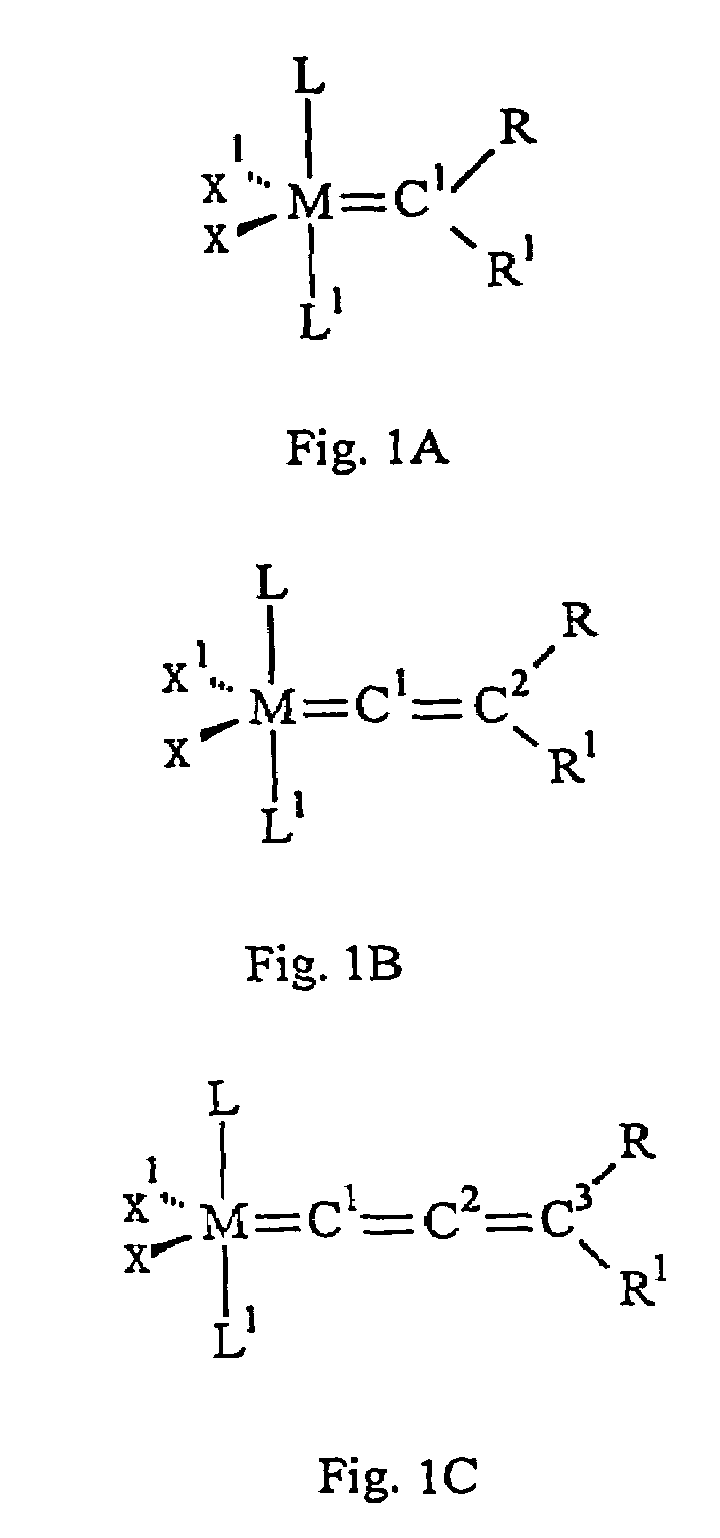

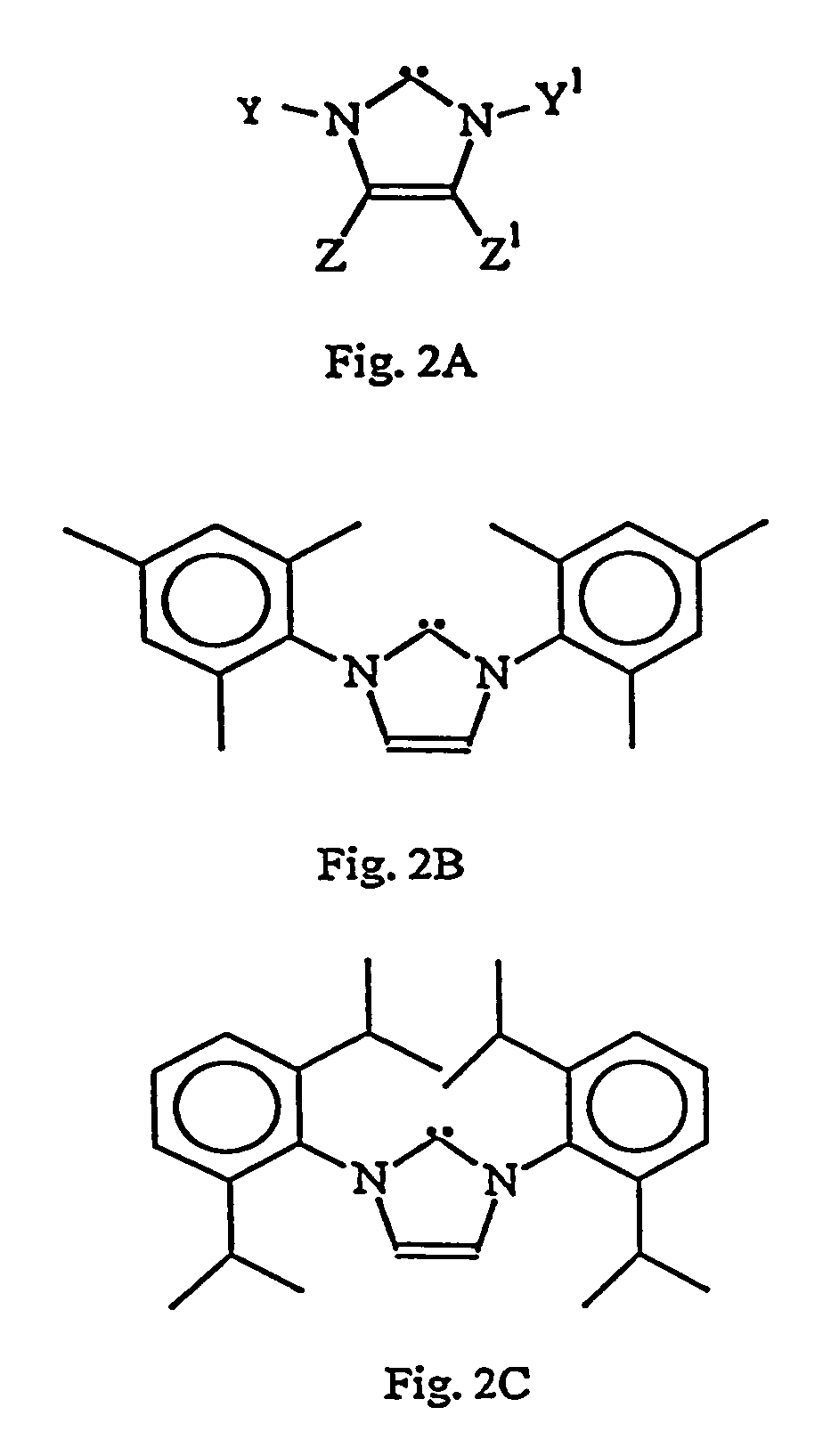

Catalyst complex with carbene ligand

InactiveUS7622590B1Increase response rateEasy to synthesizeHydrocarbon by isomerisationGroup 5/15 element organic compoundsCarbeneAlkene

Catalytic complexes including a metal atom having anionic ligands, at least one nucleophilic carbene ligand, and an alkylidene, vinylidene, or allenylidene ligand. The complexes are highly stable to air, moisture and thermal degradation. The complexes are designed to efficiently carry out a variety of olefin metathesis reactions.

Owner:MATERIA +1

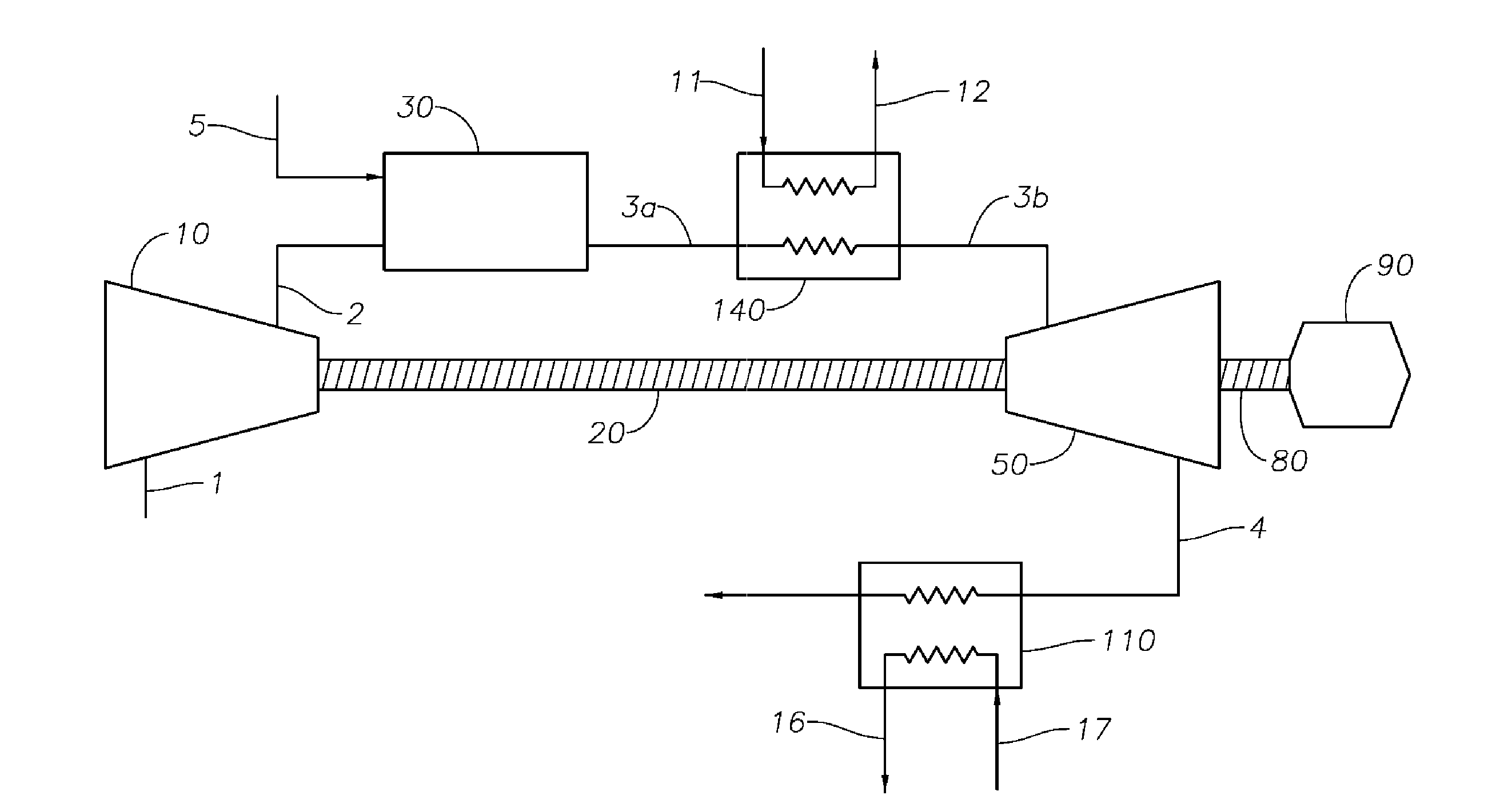

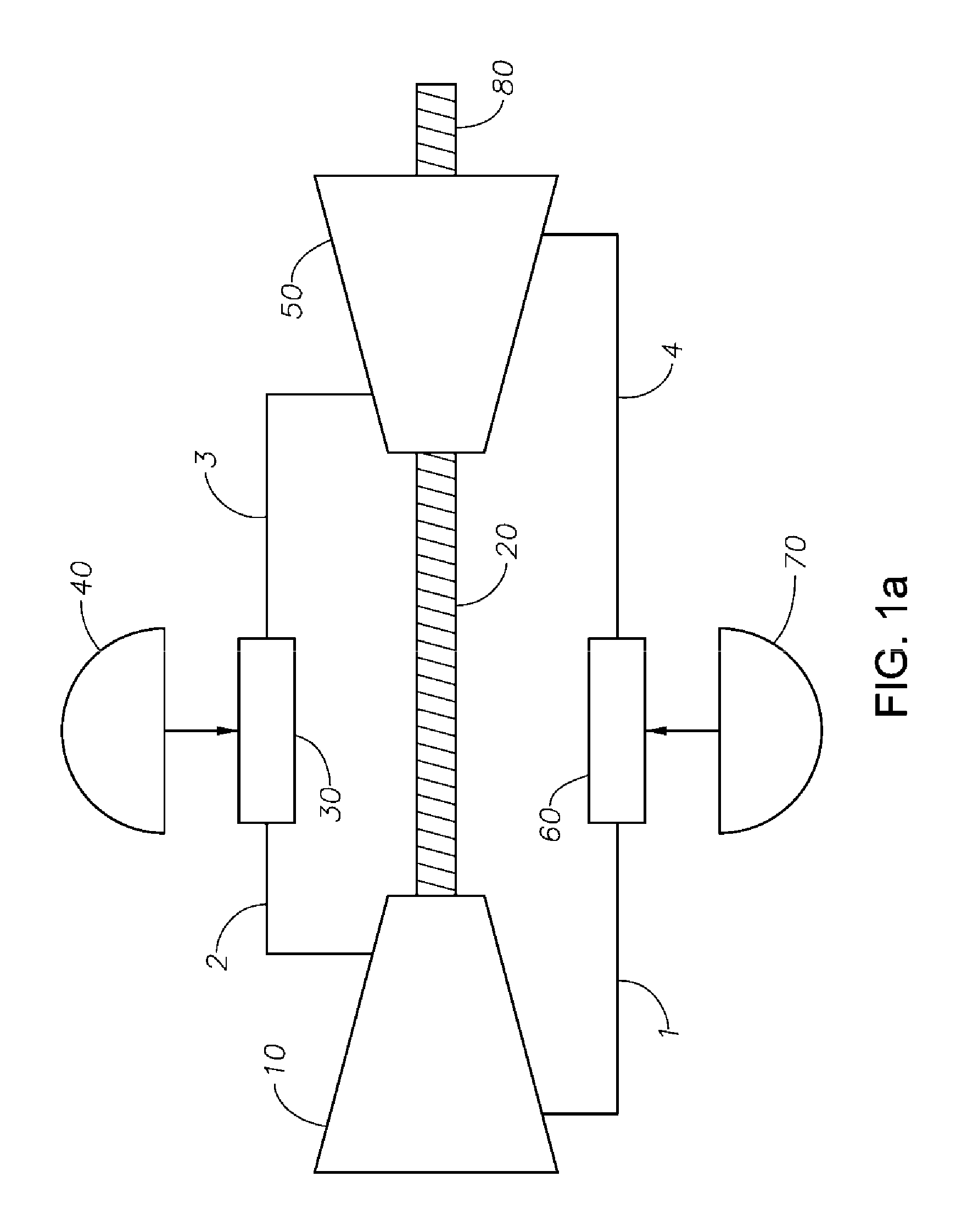

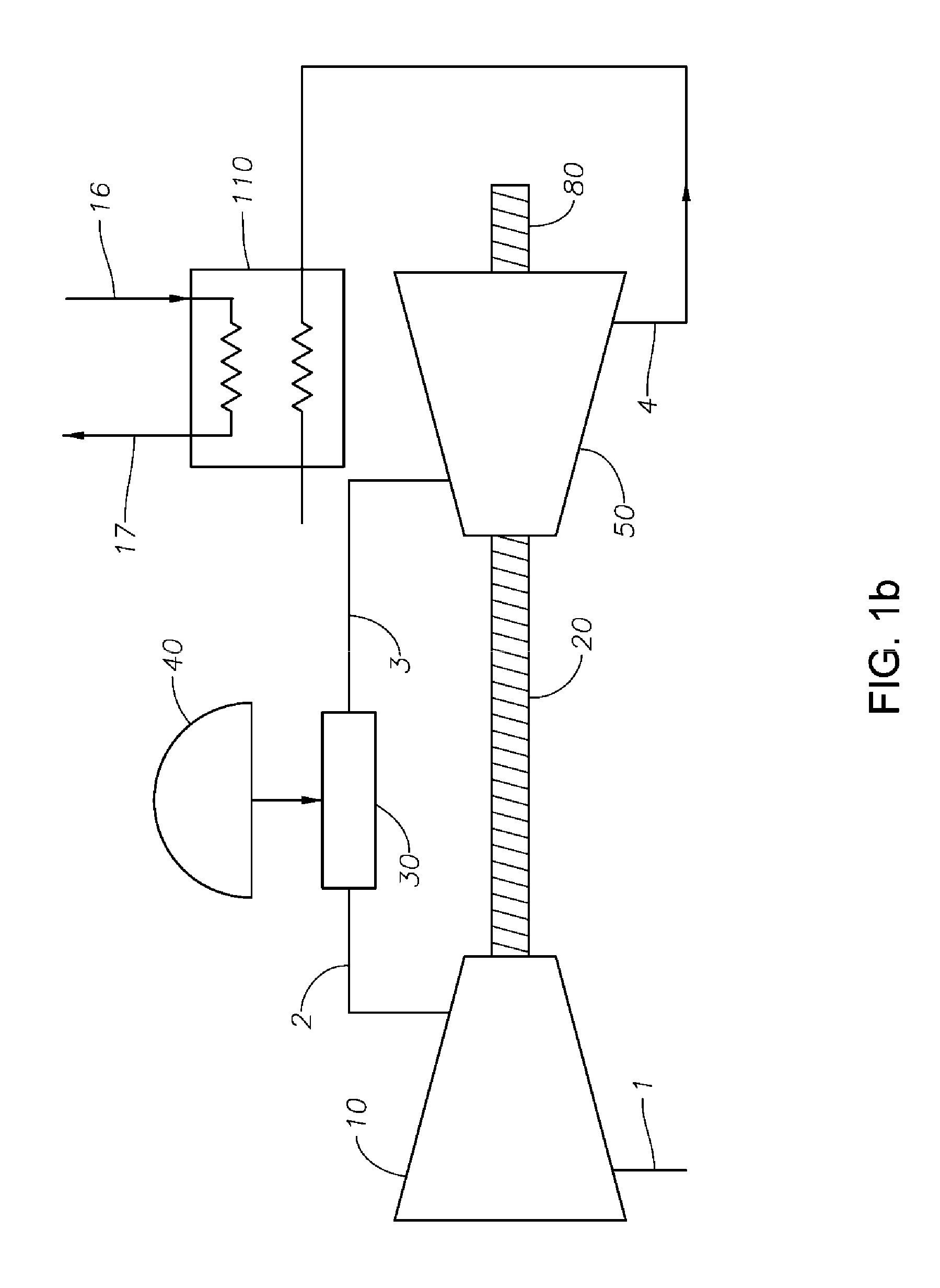

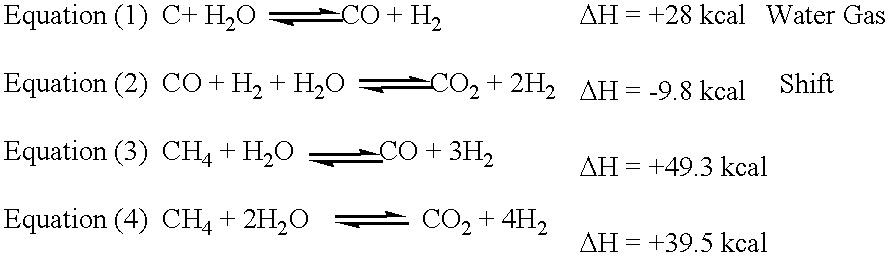

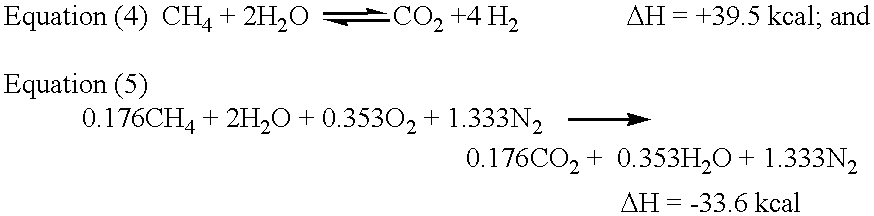

Method and apparatus for total energy fuel conversion systems

InactiveUS6350394B1Thermal non-catalytic crackingInternal combustion piston enginesPeak loadElectric power

An independent and conserved source of fuel and / or power comprises a top stage rocket engine firing up to 5000 F. at very high pressures, delivering jet flows up to transonic velocities into a near adiabatic tunnel for mixing in general and / or for transforming reactants introduced to suit specific objectives. The related compression is supplied by an independent prime mover which compresses its exhaust and other recoverable fluids. Low grade flows, thereby upgraded in temperature and pressure, are adiabatically contained, are further upgraded in the tunnel to become part of the prescribed fuel for export at the tunnel ends; or fuel to be fired in a prime mover for electric or other power, or hydrogen for chemical use. Expansion turbines for this purpose are relieved of the load used to compress the excess air in standard gas turbines thus increasing export power. A portion of the expansion turbine's exhaust becomes part of recoverable fluids. When oxygen is used instead of air, the gases through turbines are nitrogen-free with more heat capacity reducing turbine inlet temperatures for the same power. When reactant transformation is specified, the larger water vapor content in the cycle enhances the water gas / shift autothermally for ammonia and / or power and alternatively for pyrolysis cracking for olefins and diolefins. Further, staging rocket engine reactors increases efficiency in boilers and steam turbines; and staging can produce sponge iron and / or iron carbide as well as expansion turbine power and fuel cells for peak and off-peak loads.

Owner:EGT ENTERPRISES

Hydroprocessing Microalgal Oils

InactiveUS20140305031A1Low costImprove efficiencyHydrocarbon by isomerisationHydrocarbon purification/separationChemical treatmentAlkaline hydrolysis

Owner:TERRAVIA HLDG INC

Production of fuels and lube oils from fischer-tropsch wax

ActiveUS7132042B2Low pour pointHigh product yieldHydrocarbon by hydrogenationCatalytic naphtha reformingWaxBoiling point

Dewaxed fuel and lubricant base stocks are made by (a) producing a synthesis gas from natural gas, (b) reacting the H2 and CO in the gas in the presence of a cobalt Fischer-Tropsch catalyst, at reaction conditions effective to synthesize a waxy hydrocarbon feed boiling in the fuel and lubricant oil ranges, which is hydrodewaxed in a first stage to produce a dewaxed fuel and a partially dewaxed lubricant fraction. The partially dewaxed lubricant fraction is separated into heavy and lower boiling fractions each of which is separately hydrodewaxed, to produce lubricant base stocks. A hydrodewaxing catalyst comprising a hydrogenation component, binder and solid acid component used to hydrodewax at least one, and preferably at least two of the waxy feed and partially dewaxed heavy and lower boiling lubricant fractions.

Owner:EXXON RES & ENG CO

Process for producing high RON gasoline using CFI Zeolite

ActiveUS7037422B2Promote recoveryIncreased RONHydrocarbon by hydrogenationChemical industryNaphthaGasoline

A process for producing a high RON naphtha which comprises contacting a hydrocarbon feed stream comprising a mixture of the isomers of C5 and C6 paraffins with a CFI zeolite, such as CIT-5, in an adsorption zone, whereby the branched isomers of the C5 and C6 paraffins are preferentially adsorbed by the CFI zeolite as compared to the straight chain isomers, and recovering a naphtha product from the adsorption zone having a higher RON than the hydrocarbon feed stream, also including a hydroisomerization process and a hydrocracking process.

Owner:CHEVROU USA INC

Cracking C5+ Paraffins to Increase Light Olefin Production

A process for increasing the light olefin production from light paraffins is presented. The process includes separating paraffins from olefin streams and separately processing the paraffins.

Owner:UOP LLC

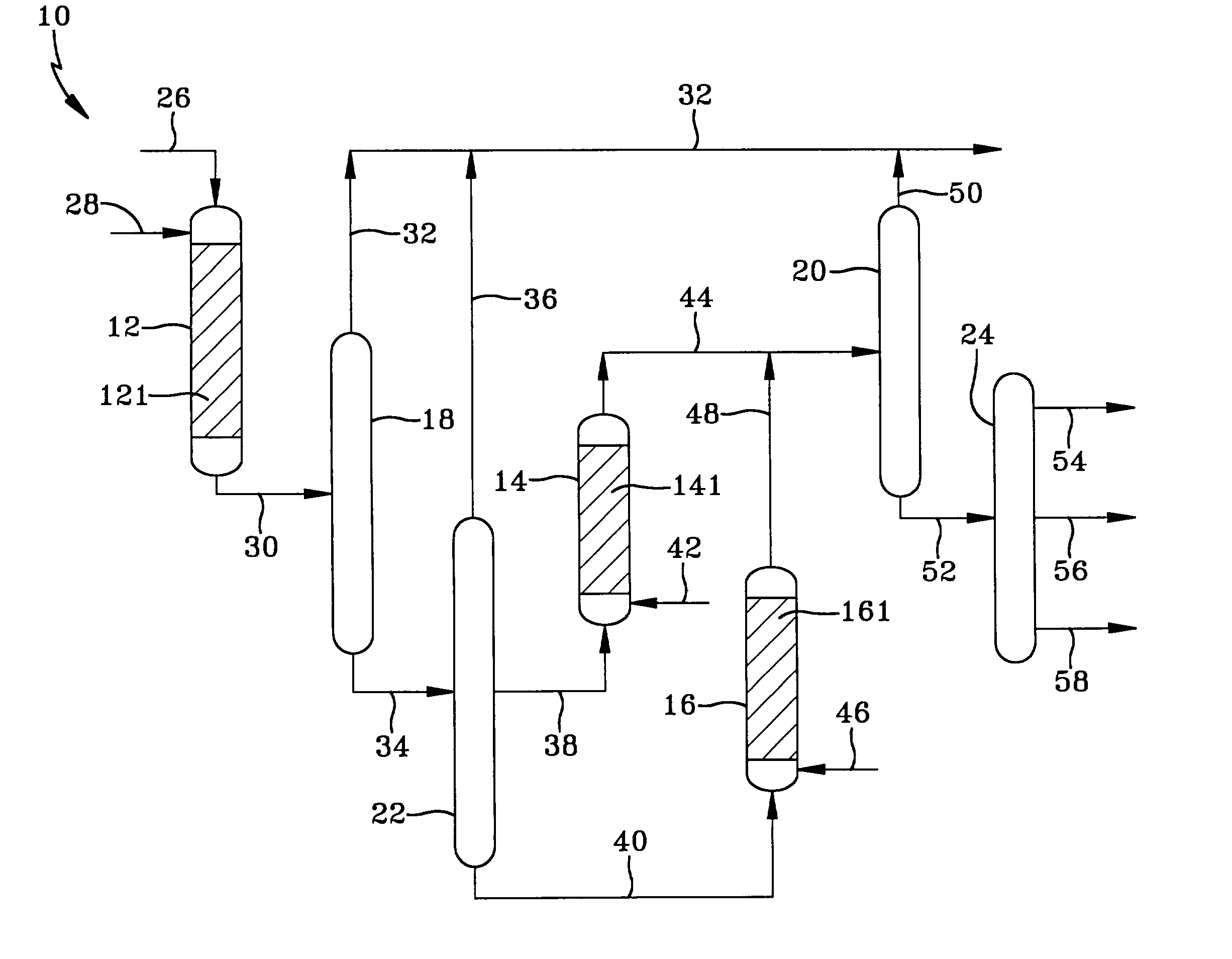

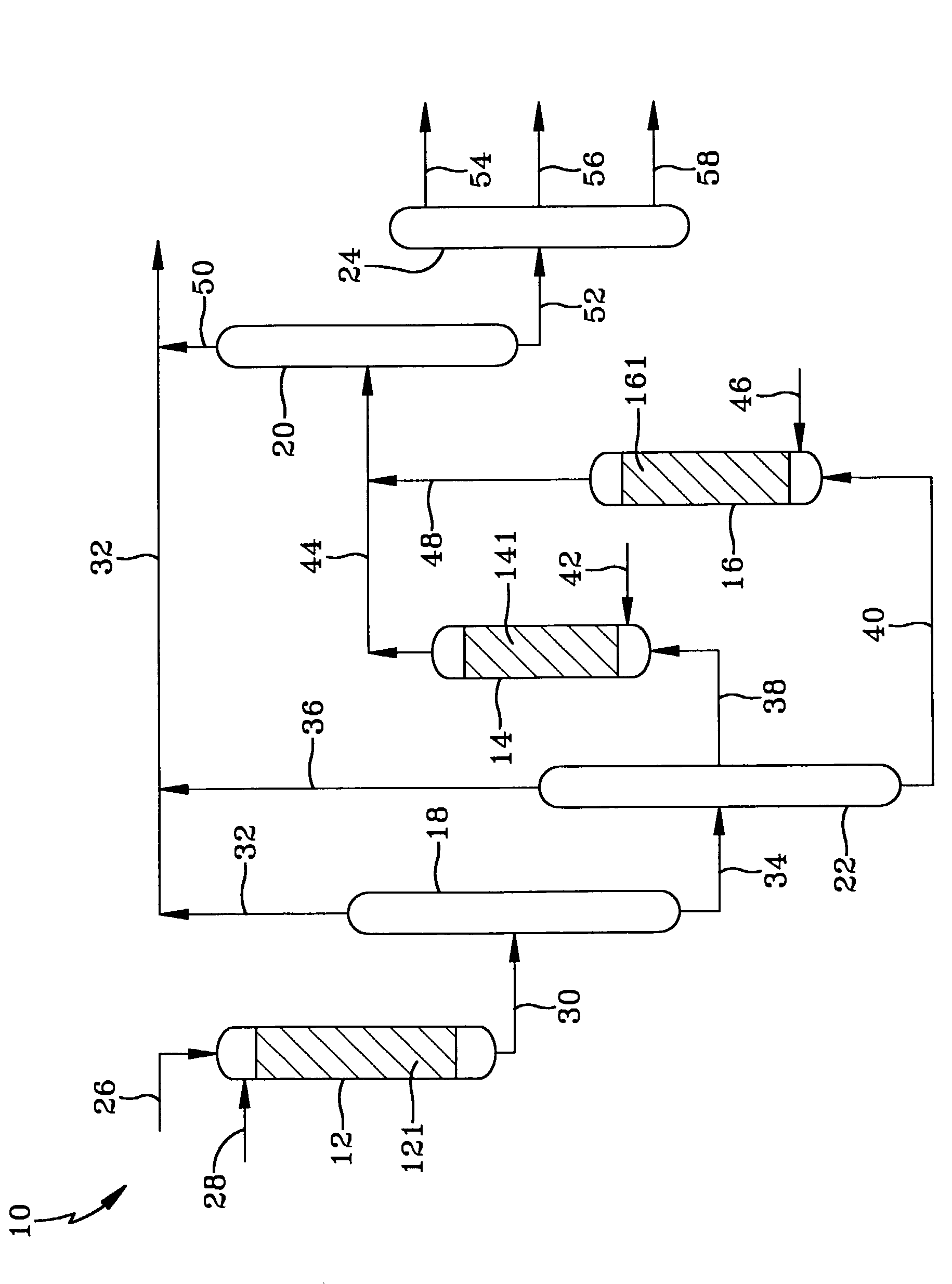

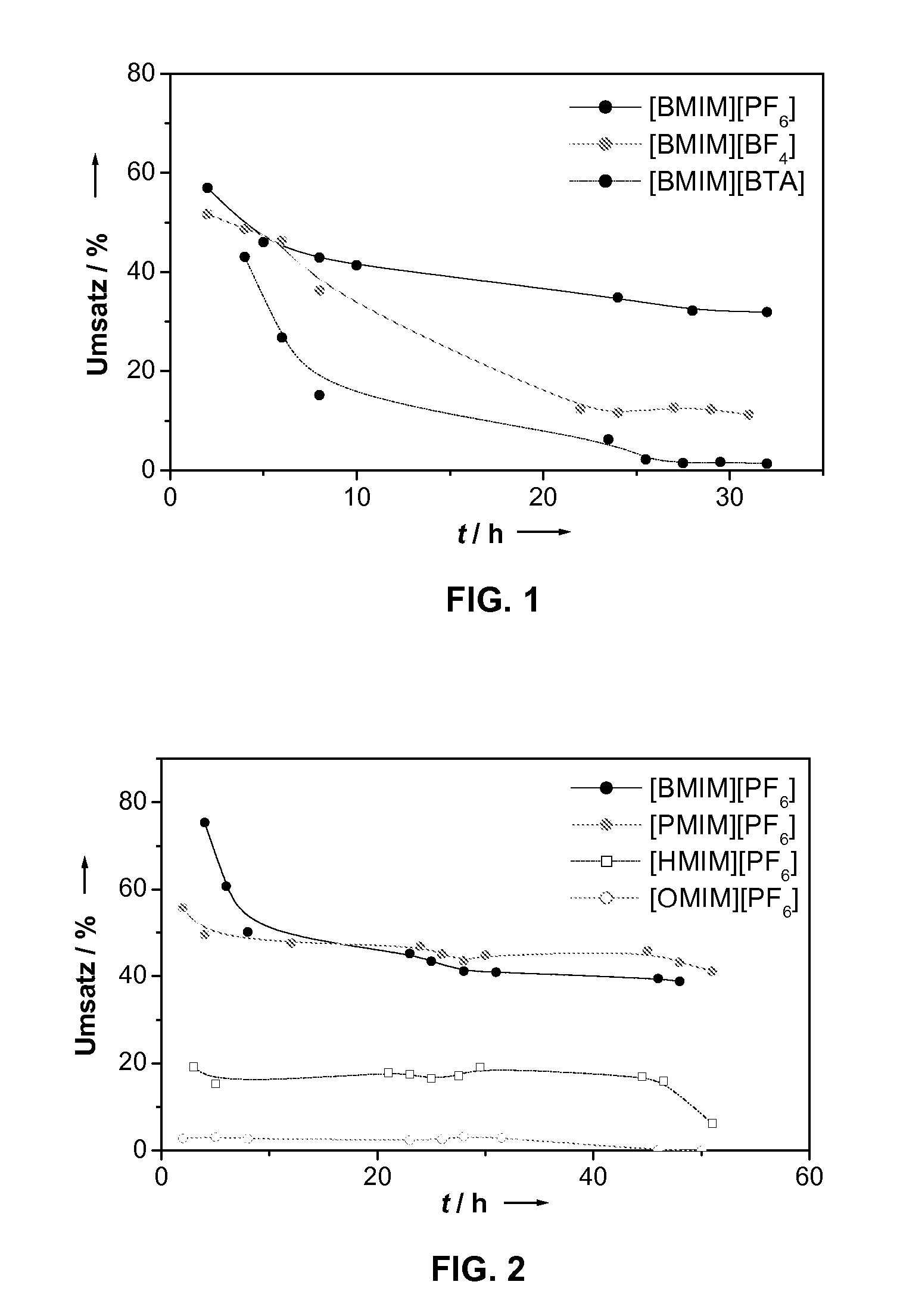

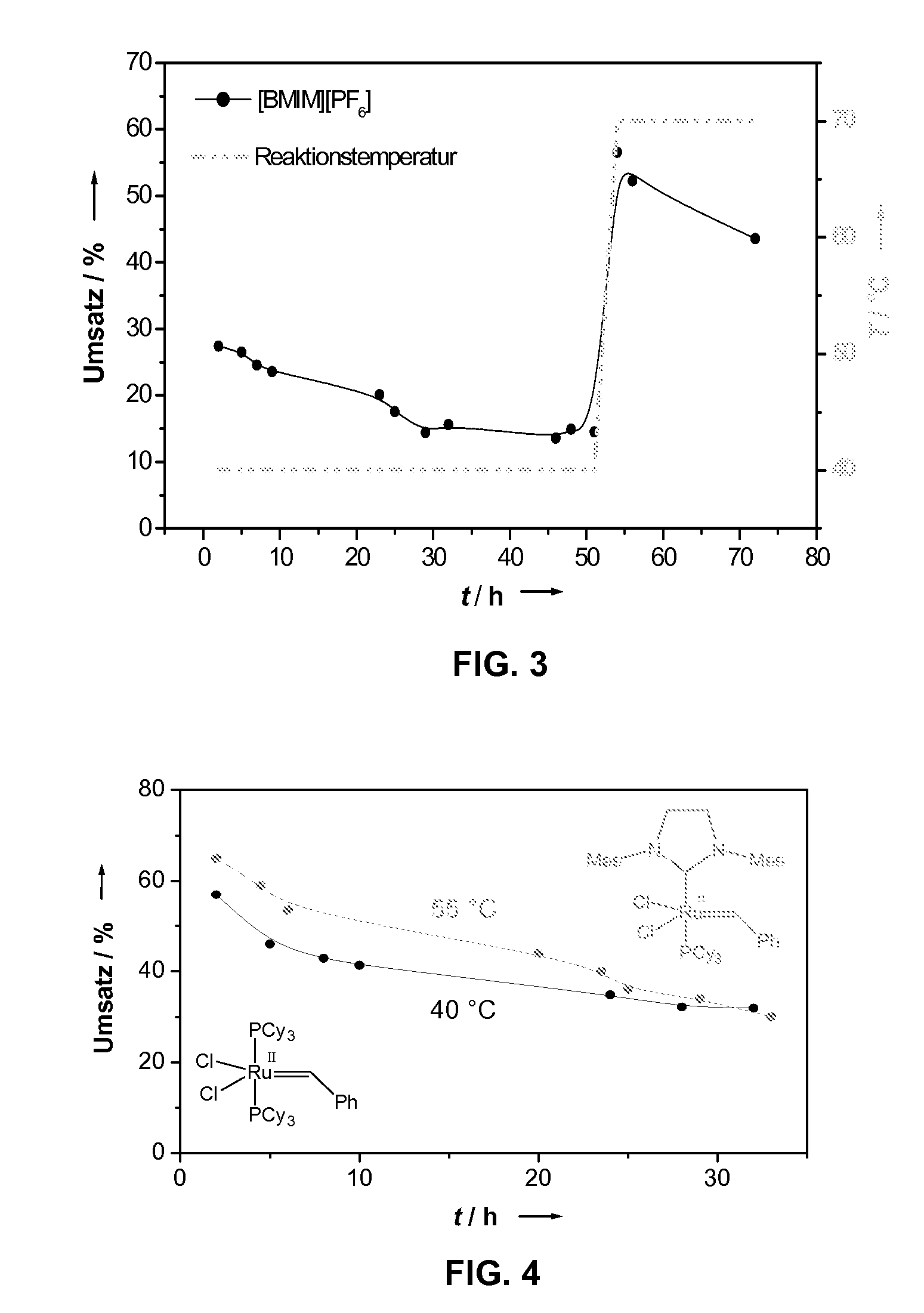

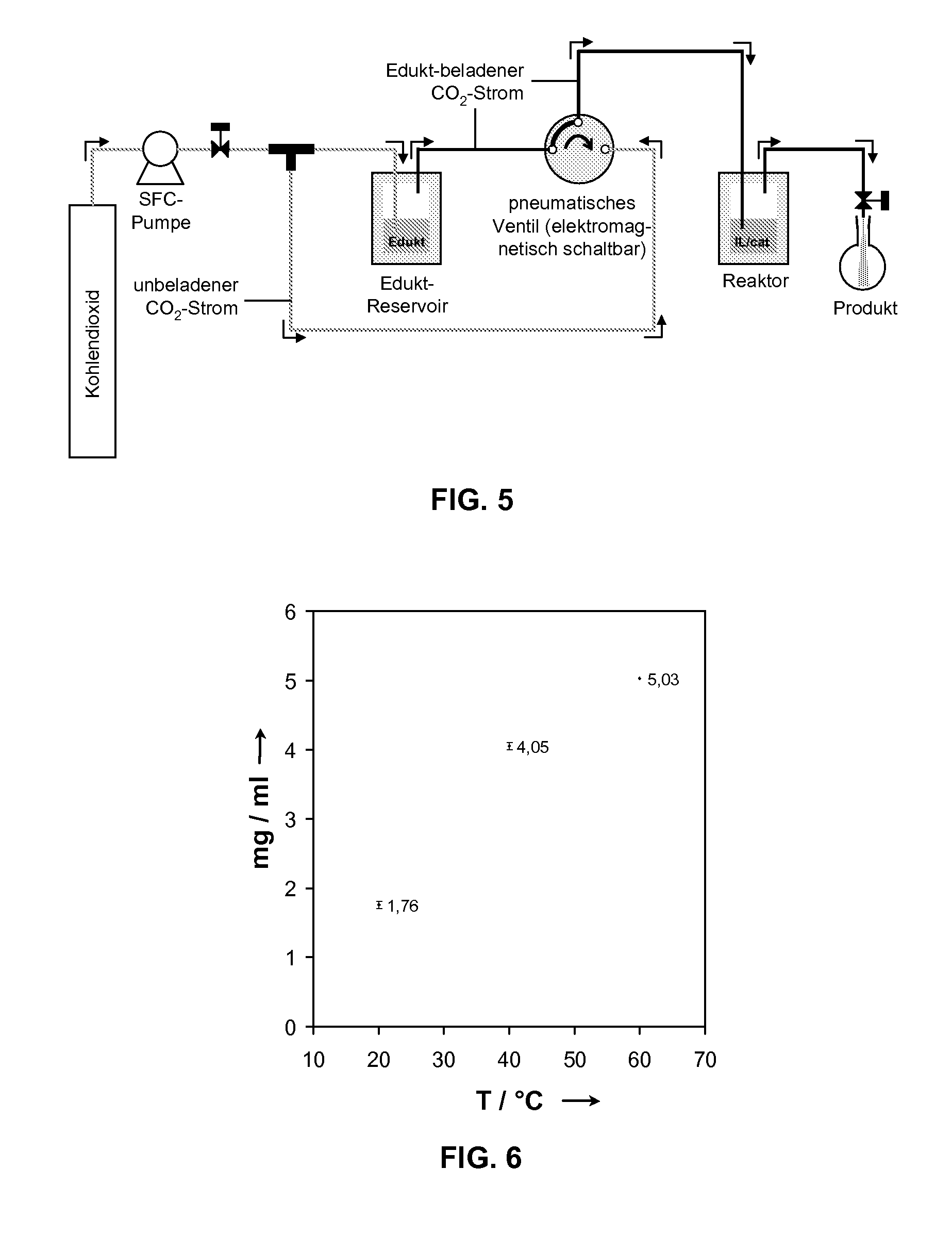

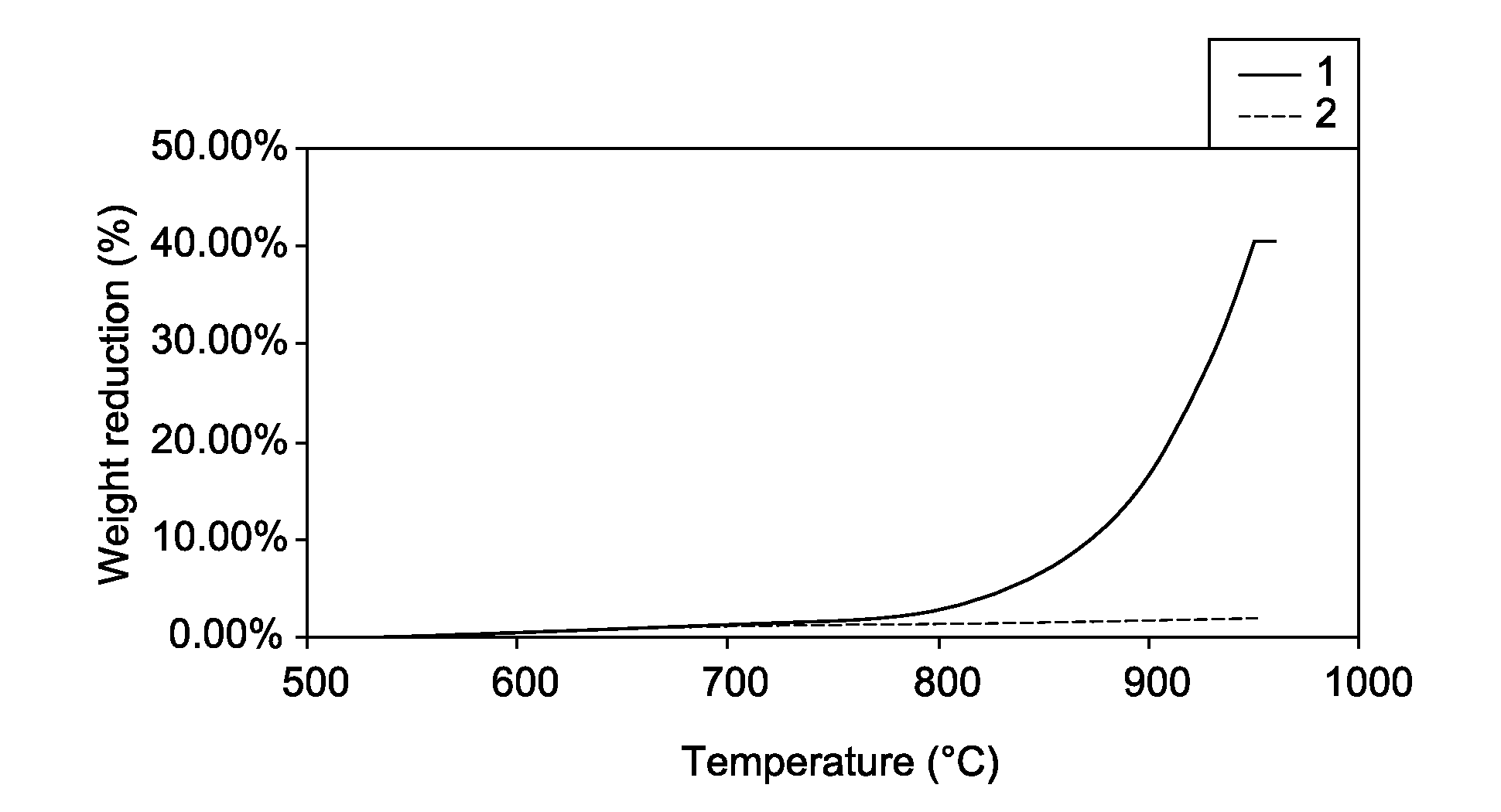

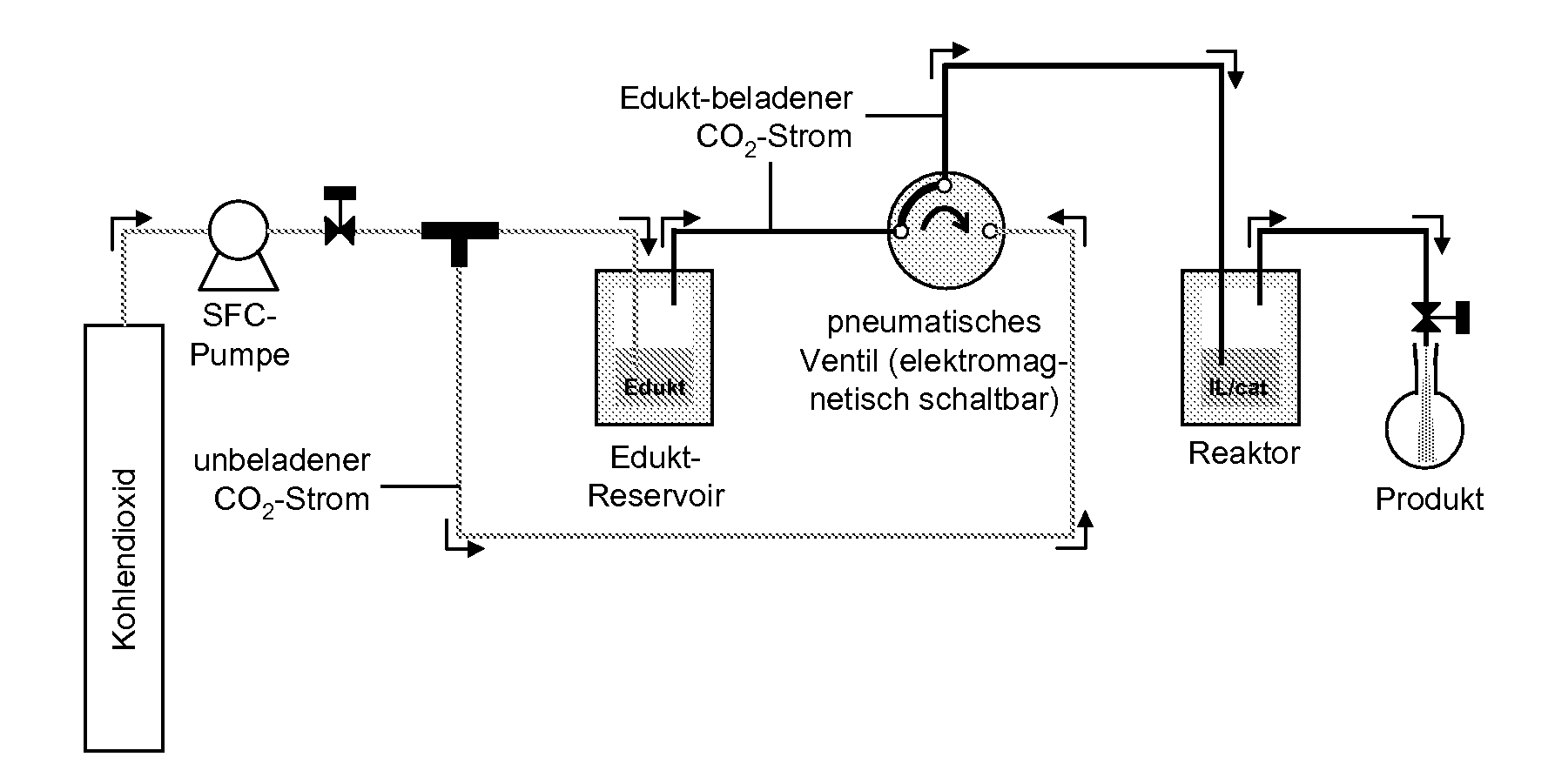

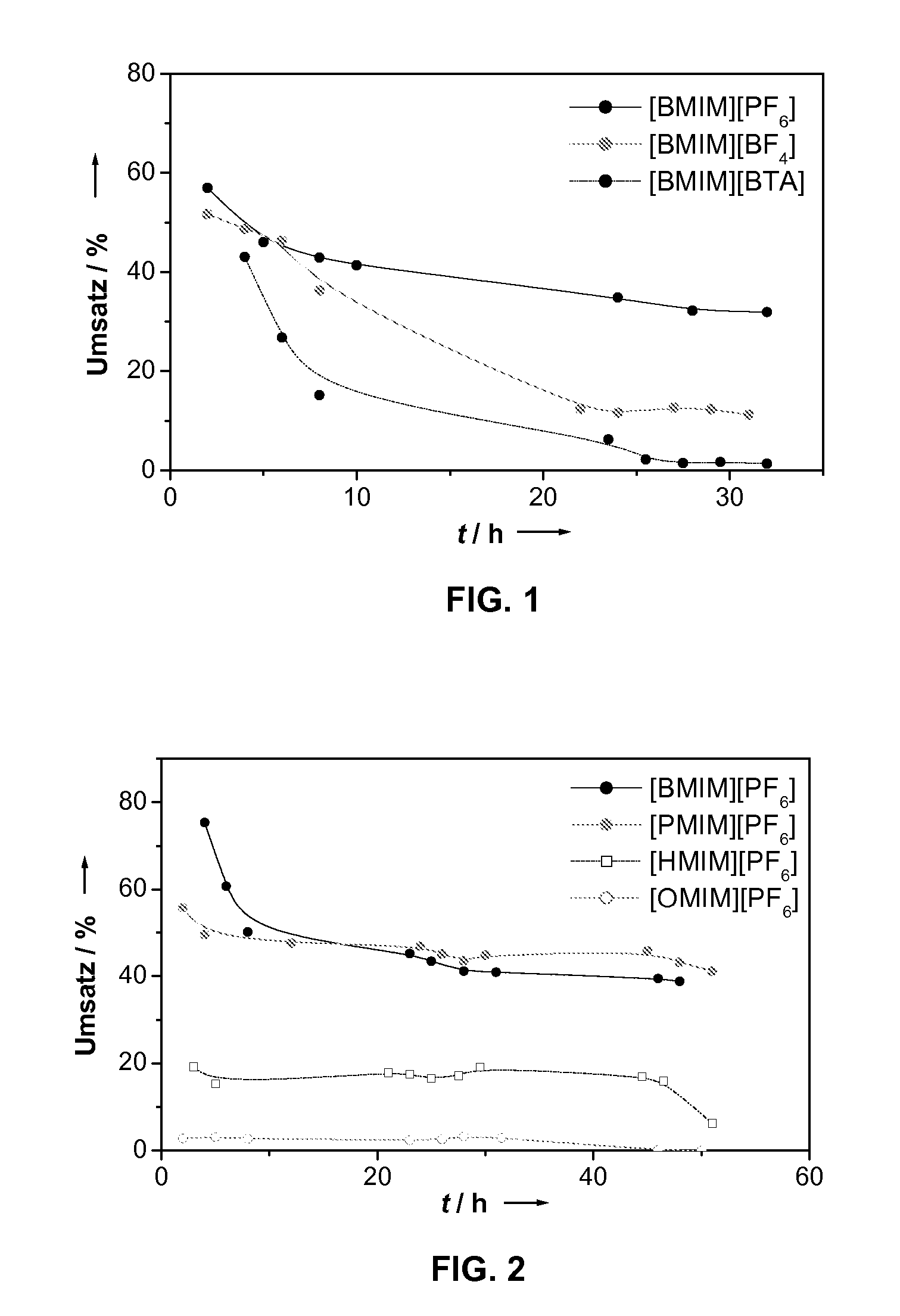

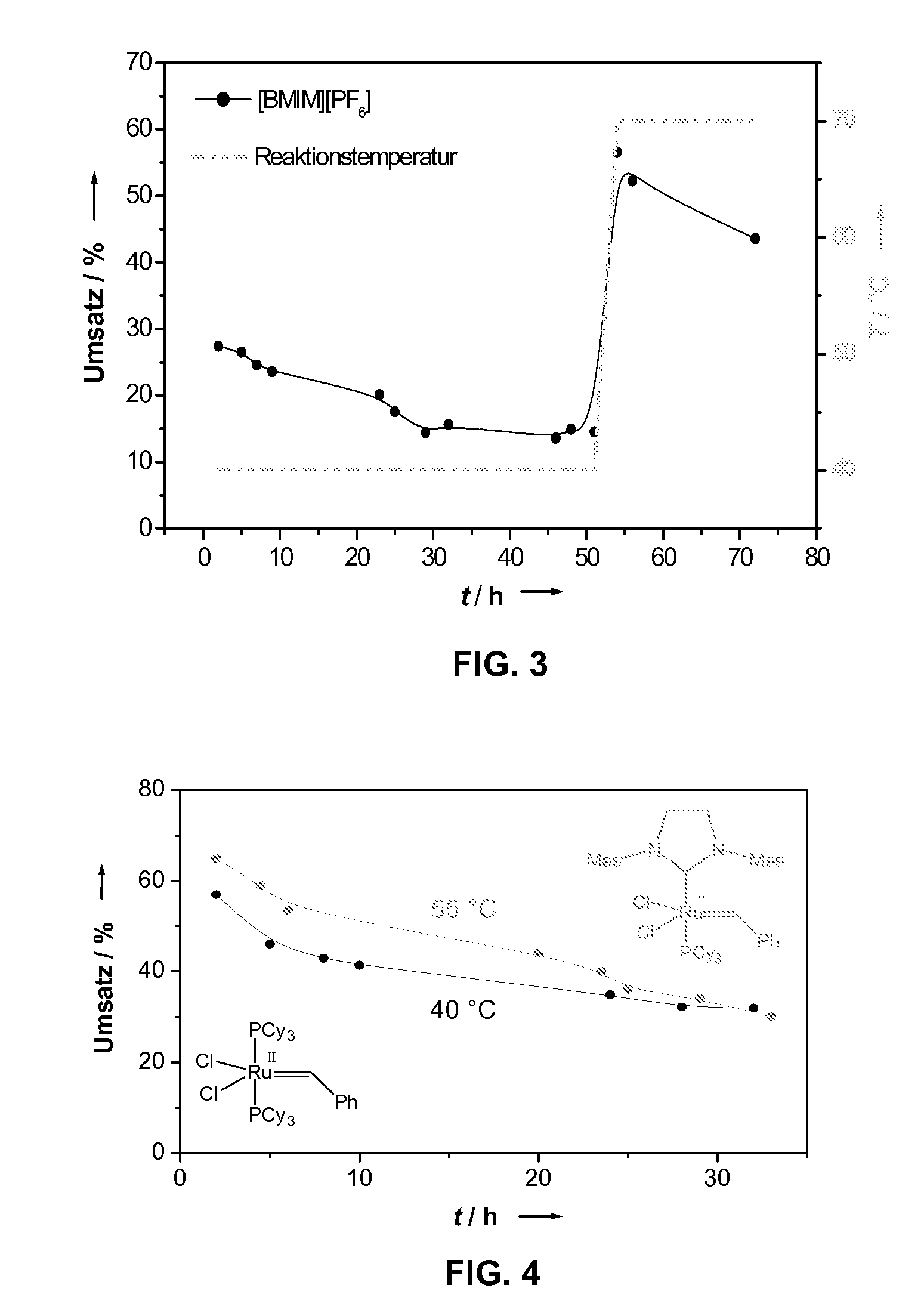

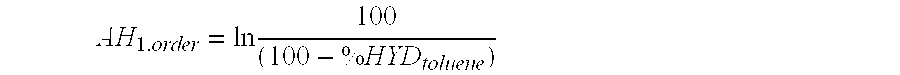

Process for continuous ringclosing metathesis in compressed carbondioxide

InactiveUS7482501B2Hydrocarbon by isomerisationGroup 8/9/10/18 element organic compoundsRing-closing metathesisSolvent

The present invention relates to a process for carrying out olefin ring-closing metathesis (RCM) wherein compressed carbon dioxide (gaseous, liquid or supercritical) acts as solvent for the liquid or solid reactant and the products obtained therefrom, while additionally one or more ionic liquids are introduced as the 2nd phase in which homogeneous olefin metathesis catalysts are immobilised.

Owner:BOEHRINGER INGELHEIM INT GMBH +1

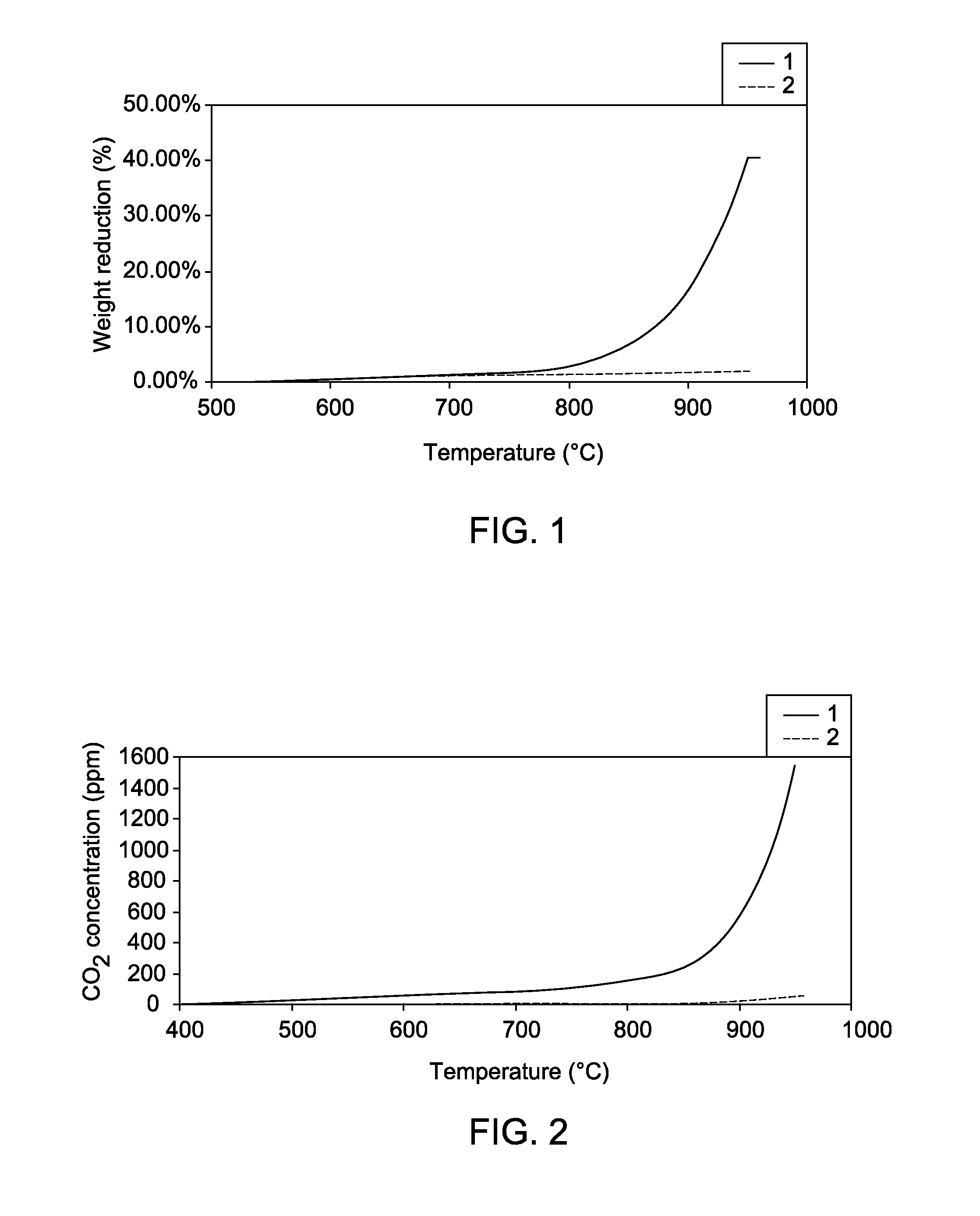

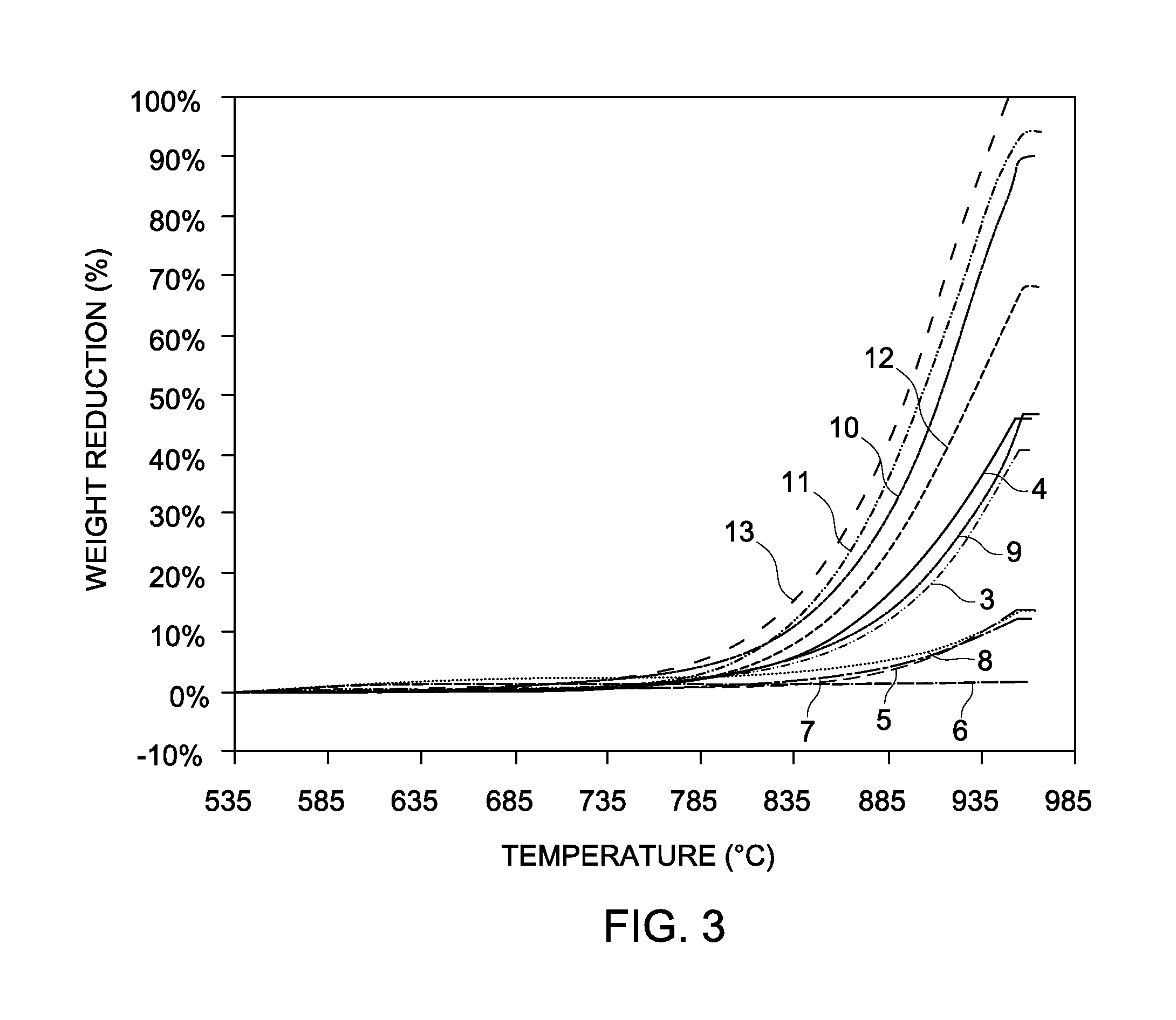

Method and reactor for cracking hydrocarbon

ActiveUS20110295051A1Reduces and eliminates build-upThermal non-catalytic crackingHydrocarbon oil cracking processIndiumCerium

A method for cracking hydrocarbon, comprises: providing steam and hydrocarbon; and feeding steam and hydrocarbon into a reactor accessible to hydrocarbon and comprising a perovskite material of formula AaBbCcDdO3-δ, wherein 0<a<1.2, 0≦b≦1.2, 0.9<a+b≦1.2, 0<c<1.2, 0≦d≦1.2, 0.9<c+d≦1.2, −0.5<δ<0.5; A is selected from calcium, strontium, barium, and any combination thereof; B is selected from lithium, sodium, potassium, rubidium and any combination thereof; C is selected from cerium, zirconium, antimony, praseodymium, titanium, chromium, manganese, ferrum, cobalt, nickel, gallium, tin, terbium and any combination thereof; and D is selected from lanthanum, cerium, praseodymium, neodymium, promethium, samarium, europium, gadolinium, terbium, dysprosium, holmium, ebium, thulium, ytterbium, lutetium, scandium, titanium, vanadium, chromium, manganese, ferrum, cobalt, nickel, copper, zinc, yttrium, zirconium, niobium, molybdenum, technetium, ruthenium, rhodium, palladium, silver, cadmium, hafnium, tantalum, tungsten, rhenium, osmium, iridium, platinum, gold, gallium, indium, tin, antimony and any combination thereof.

Owner:BL TECH INC

Process for preparing at least one low molecular weight aromatic material of value from a lignin-comprising starting material

InactiveUS20110275868A1Reduce molecular weightLiquid hydrocarbon mixture productionHydrocarbonsPolymer scienceBiomass

Owner:BASF AG

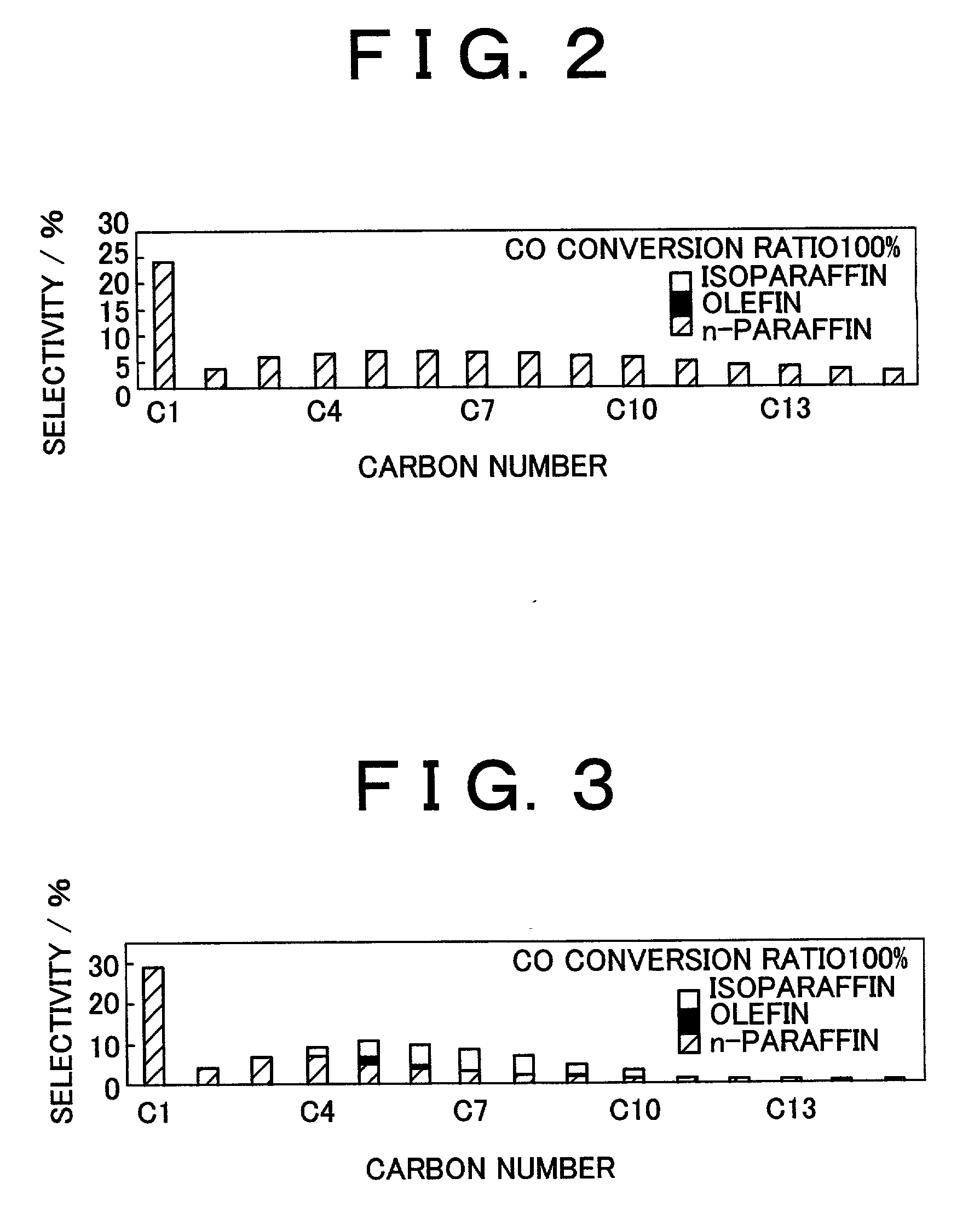

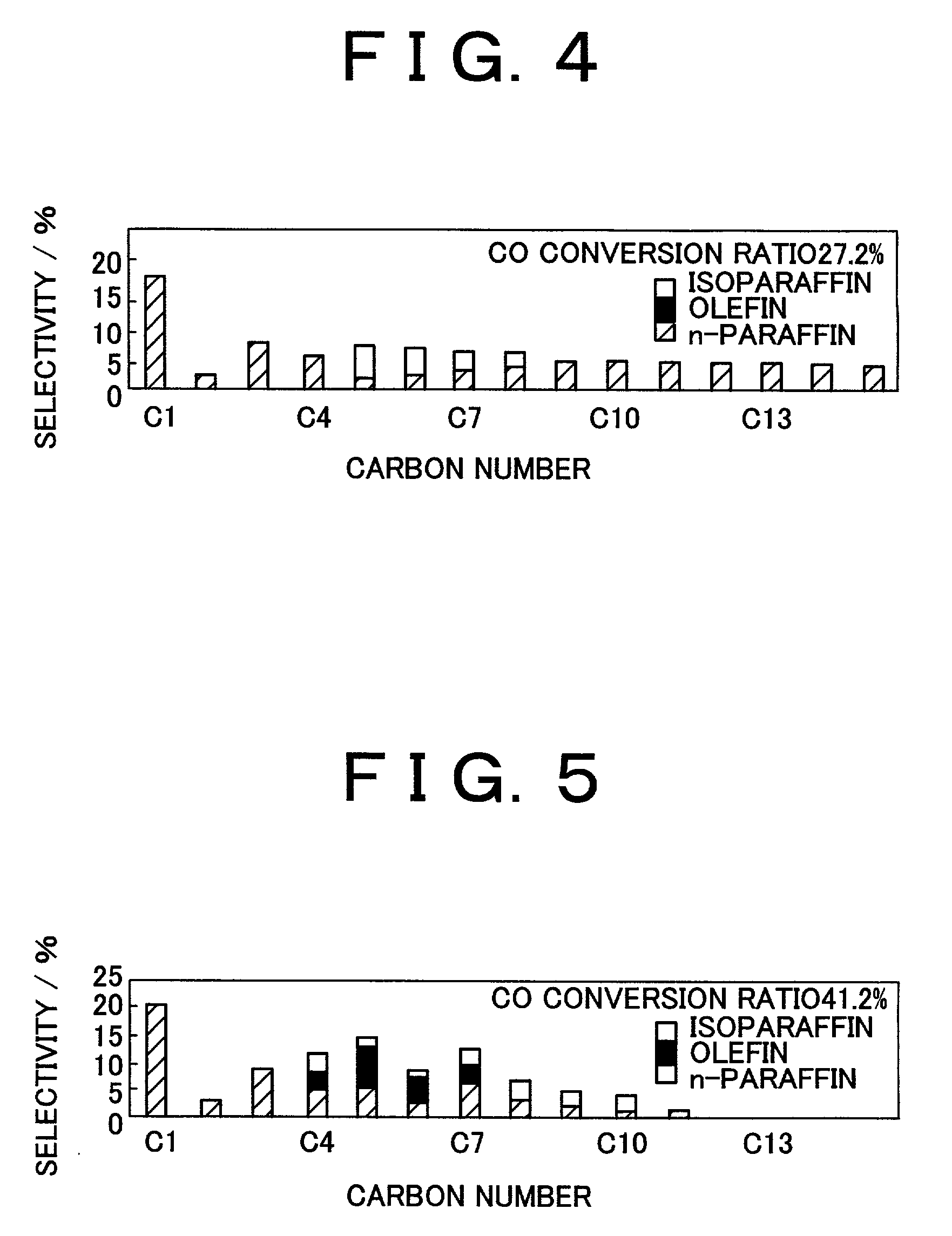

Process for synthesis of lower isoparaffins from synthesis gas

A process for synthesis of lower isoparaffins from synthesis gas that is a mixture of hydrogen and carbon monoxide, wherein straight chain hydrocarbons are synthesized while isoparaffins and isoolefins are also produced through decomposition of hydrocarbons having a higher carbon number by use of a solid acid catalyst in the first stage, and isoparaffins are synthesized in the second stage. The straight chain hydrocarbons are produced by contacting the synthesis gas with a Fischer-Tropsch synthesis catalyst that is mixed with a solid acid catalyst for mainly hydrocracking long chain hydrocarbons. The isoparaffins are produced by contacting the straight chain hydrocarbons synthesized in the first stage, with a mixture of a hydrogenation catalyst for hydrogenating olefins and a solid acid catalyst for hydrocracking and isomerizing the straight chain hydrocarbons.

Owner:TOYOTA JIDOSHA KK +1

Process for preparing molecular sieve beads

A process for preparing beads of various compositions has been developed. The process involves preparing a reaction mixture of sources of framework elements of a molecular sieve. The reaction mixture can optionally contain molecular sieve seeds. Additional sources of the framework elements are added to give a concentration above the critical supersaturation limit thereby forming beads. Depending on the composition of the reaction mixture and the reaction conditions one can obtain beads which are substantially amorphous, to beads that are substantially crystalline molecular sieve. These beads in turn can be further processed to deposit a molecular sieve layer onto the beads.

Owner:UOP LLC

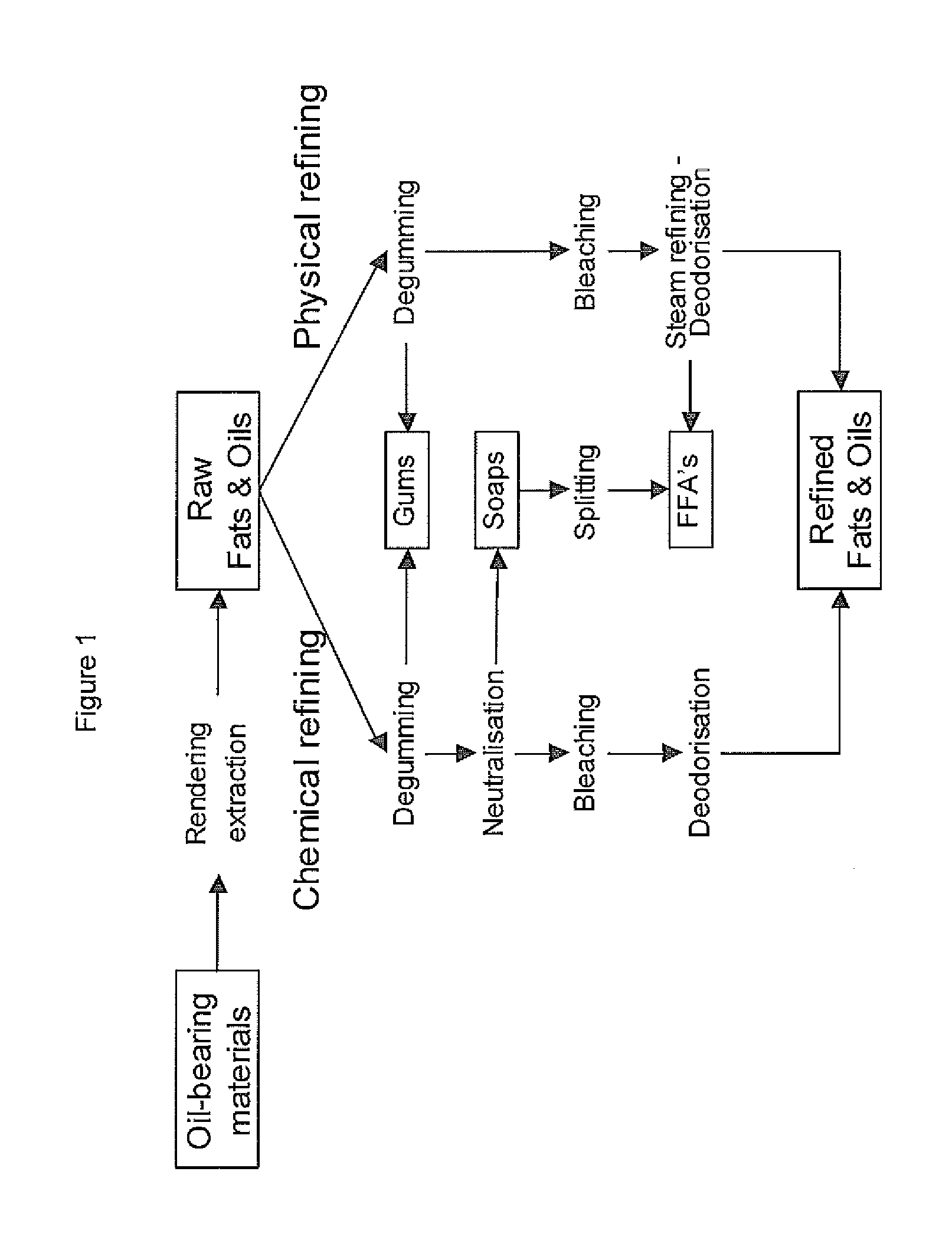

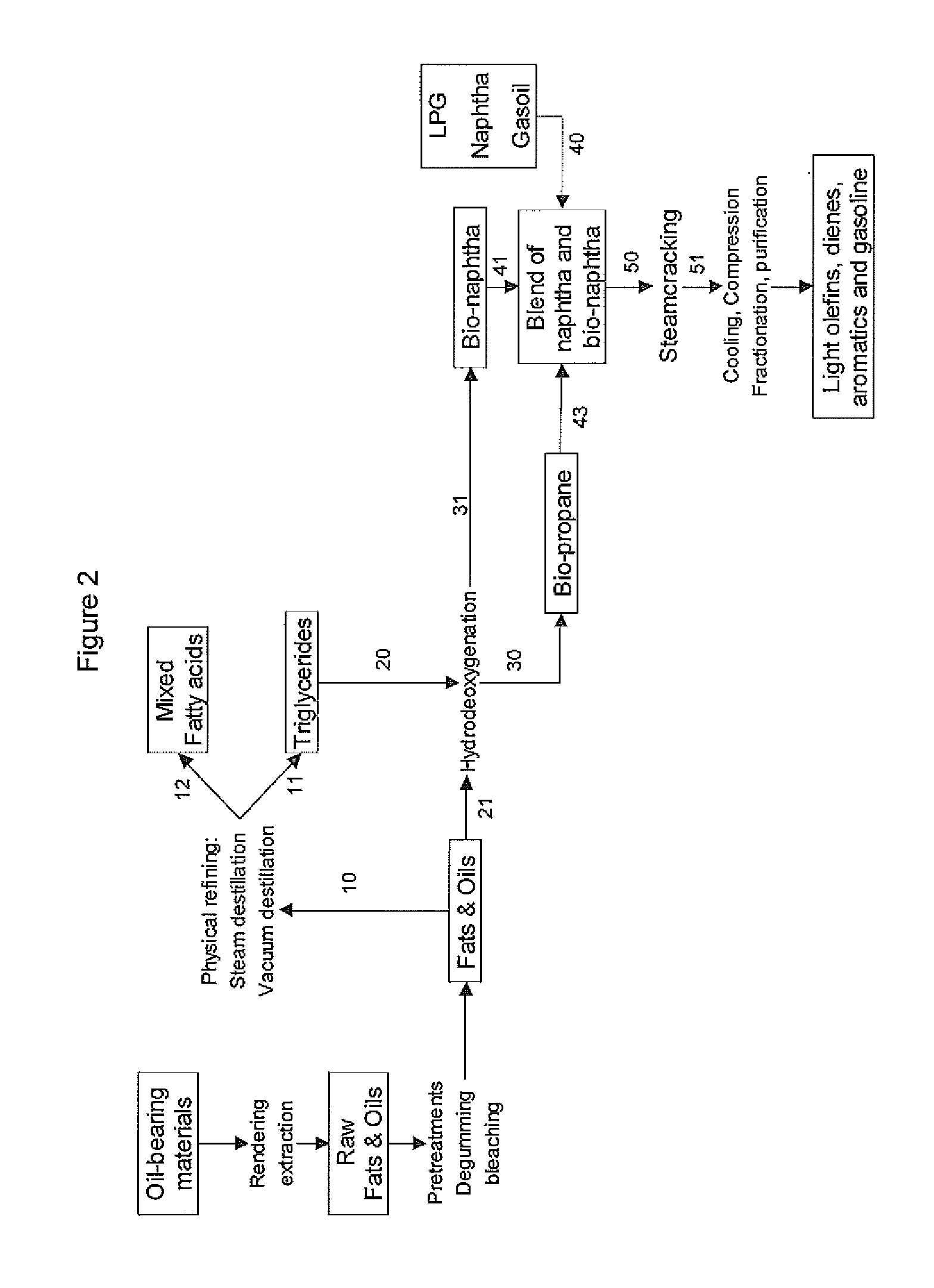

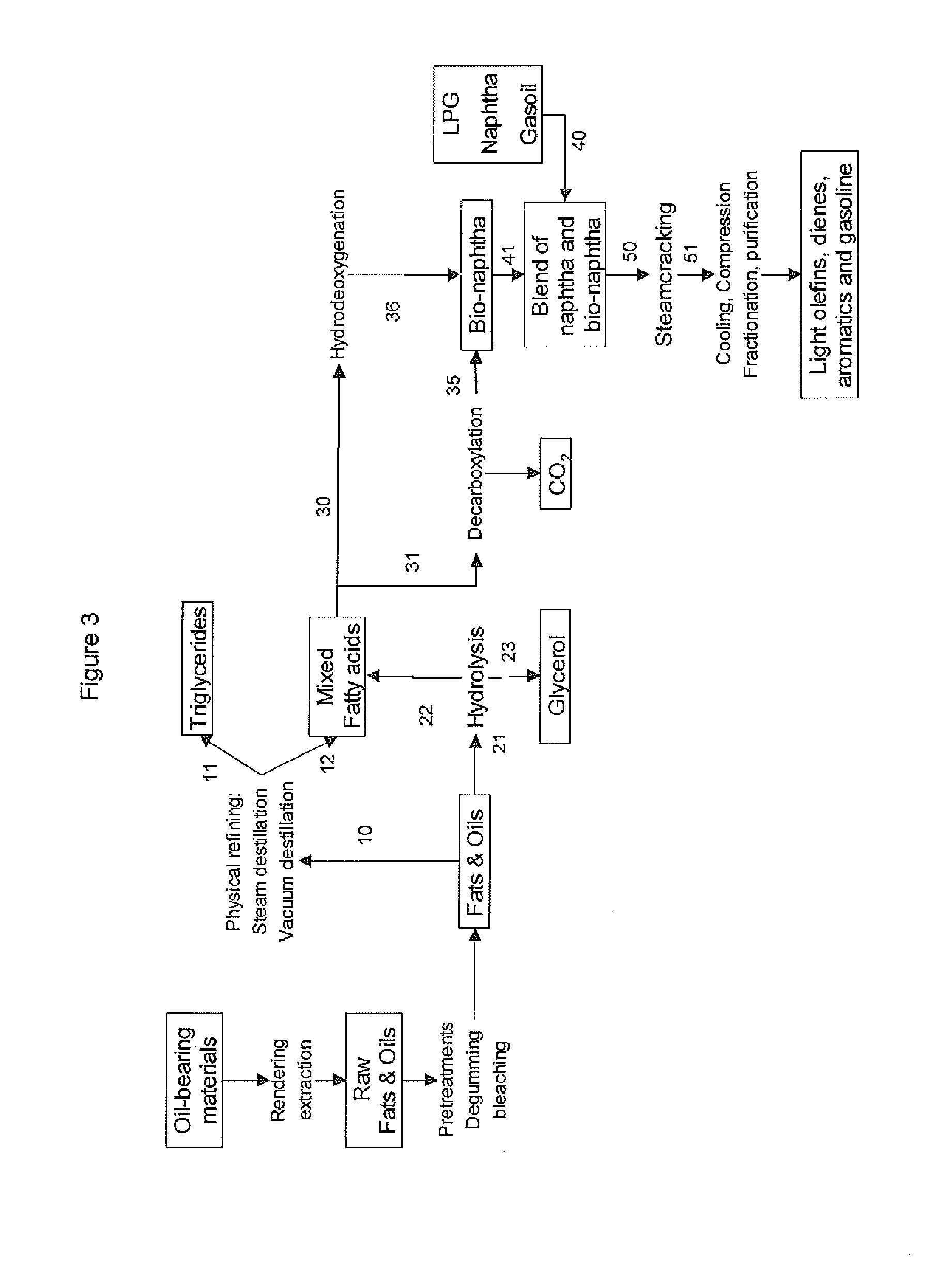

Process for the production of bio-naphtha from complex mixtures of natural occurring fats and oils

InactiveUS20120157728A1Good water solubilityImprove responseThermal non-catalytic crackingFatty oils/acids recovery from wasteParaffin waxNaphtha

A process for making a bio-naphtha and optionally bio-propane from a complex mixture of natural occurring fats & oils, whereinsaid complex mixture is subjected to a refining treatment for removing the major part of non-triglyceride and non-fatty acid components, thereby obtaining refined fats & oils;said refined fats & oils are transformed into linear or substantially linear paraffin's as the bio-naphtha by an hydrodeoxygenationor from said refined fats & oils are obtained fatty acids that are transformed into linear or substantially linear paraffin's as the bio-naphtha by hydrodeoxygenation or decarboxylation of the free fatty acidsor from said refined fats & oils are obtained fatty acids soaps that are transformed into linear or substantially linear paraffin's as the bio-naphtha by decarboxylation of the soaps.

Owner:TOTAL RES & TECH FELUY

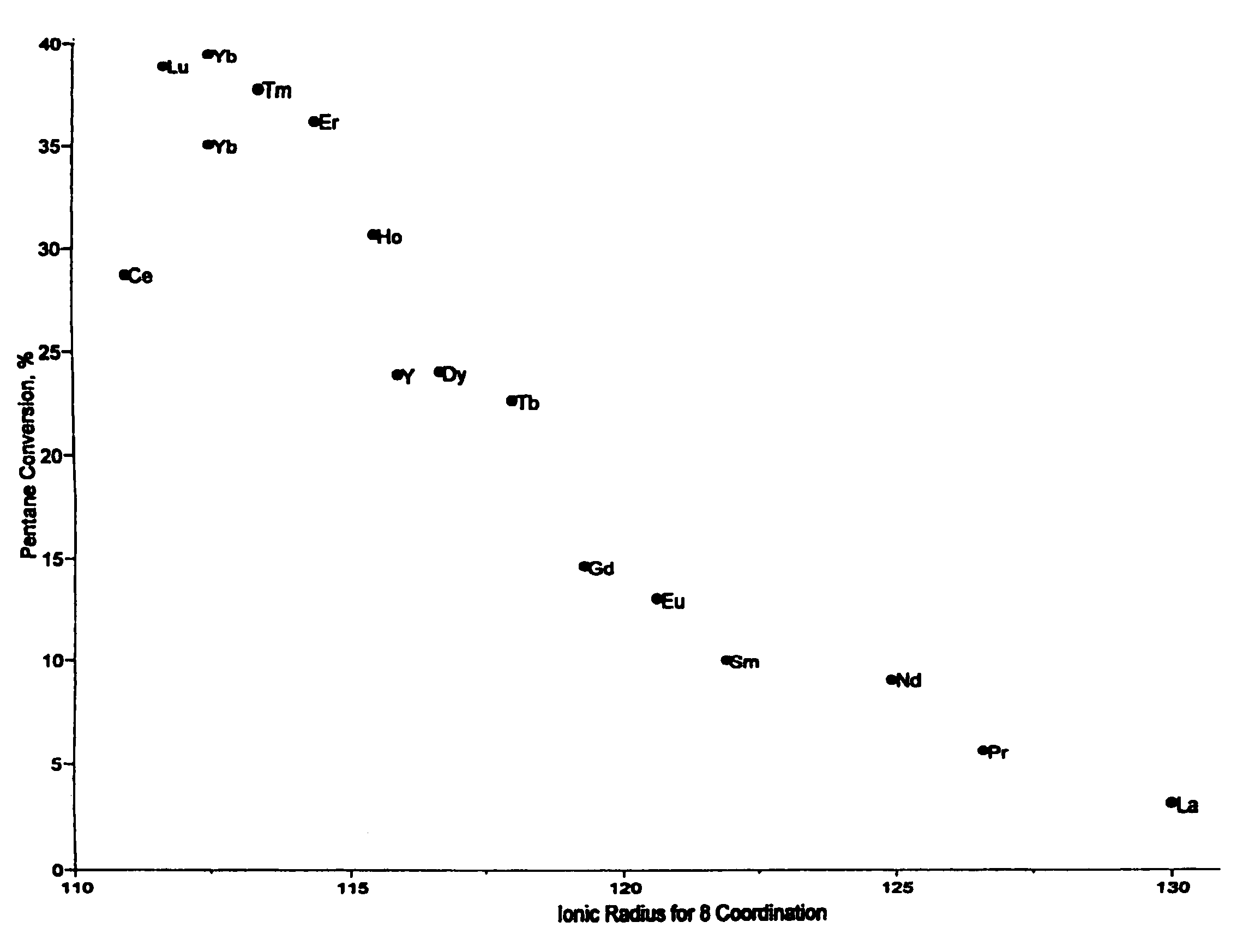

High-activity isomerization catalyst and process

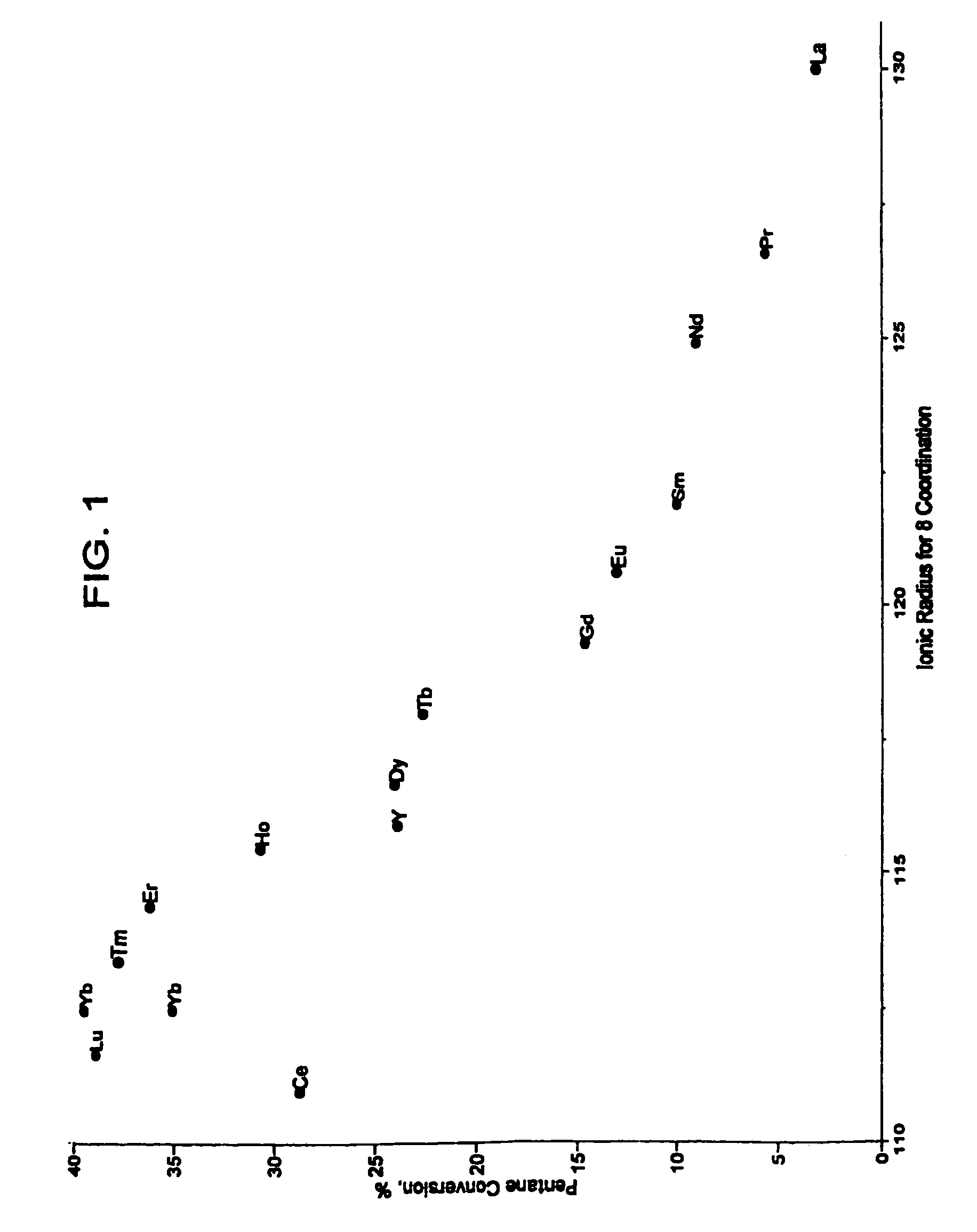

InactiveUS7015175B2Improve performanceImprove stabilityHydrocarbon by isomerisationCatalytic crackingAlkaneIsomerization

A catalyst and process is disclosed to selectively upgrade a paraffinic feedstock to obtain an isoparaffin-rich product for blending into gasoline. The catalyst comprises a support of a sulfated oxide or hydroxide of a Group IVB (IUPAC 4) metal, a first component of at least one lanthanide element or yttrium component, which is preferably ytterbium, and at least one platinum-group metal component which is preferably platinum and a refractory-oxide binder having at least one platinum-group metal component dispersed thereon.

Owner:UOP LLC

Process for the isomerization of xylenes and catalyst therefor

InactiveUS20070060470A1Easy to prepareLow net naphtheneMolecular sieve catalystsCatalyst activation/preparationMolecular sievePlatinum

Catalysts of certain combinations of platinum, tin, acidic molecular sieve and aluminum phosphate binder achieve the isomerization and dealkylation activities characteristic of platinum-containing catalysts yet enjoy the low net C6 naphthenes make properties.

Owner:UOP LLC

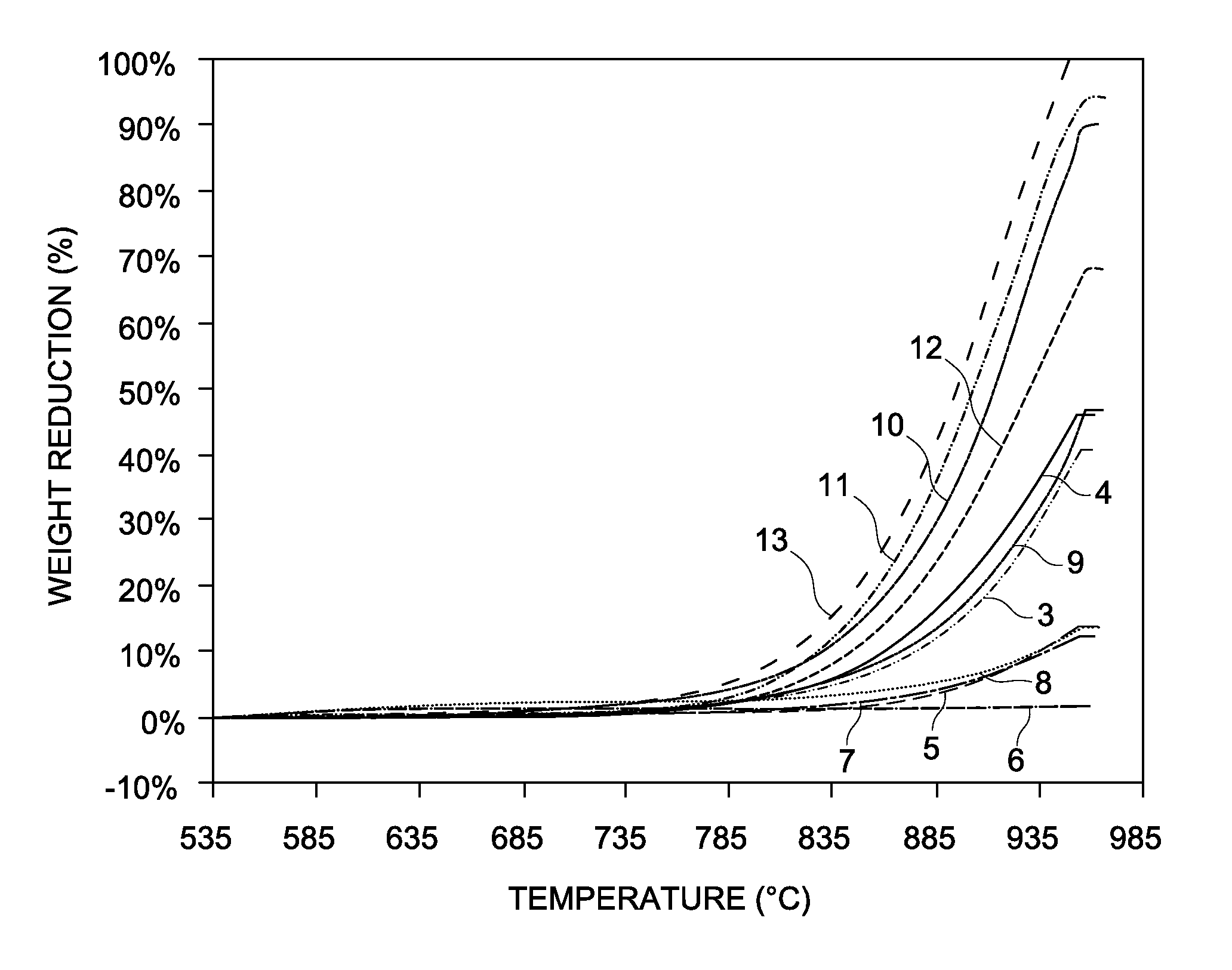

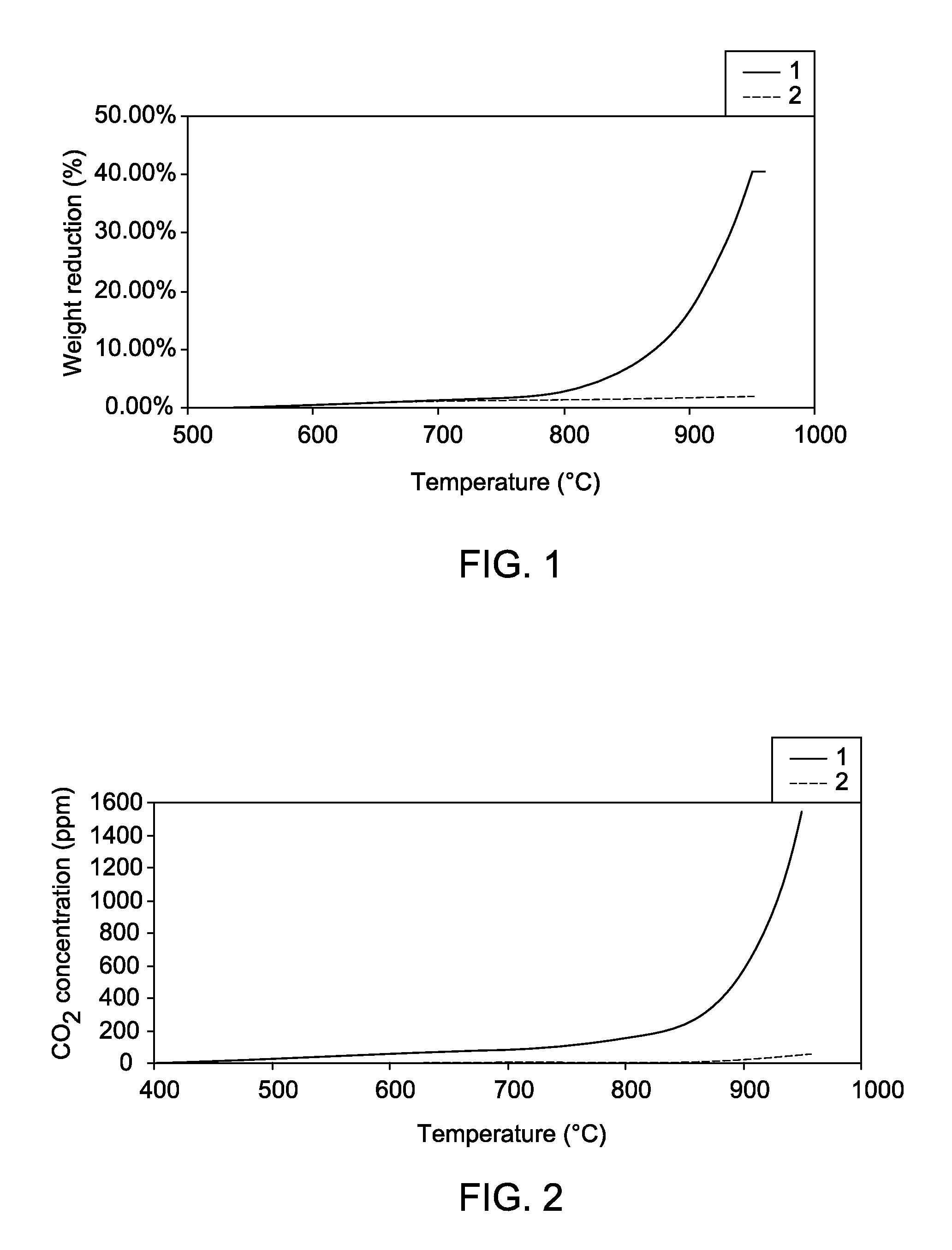

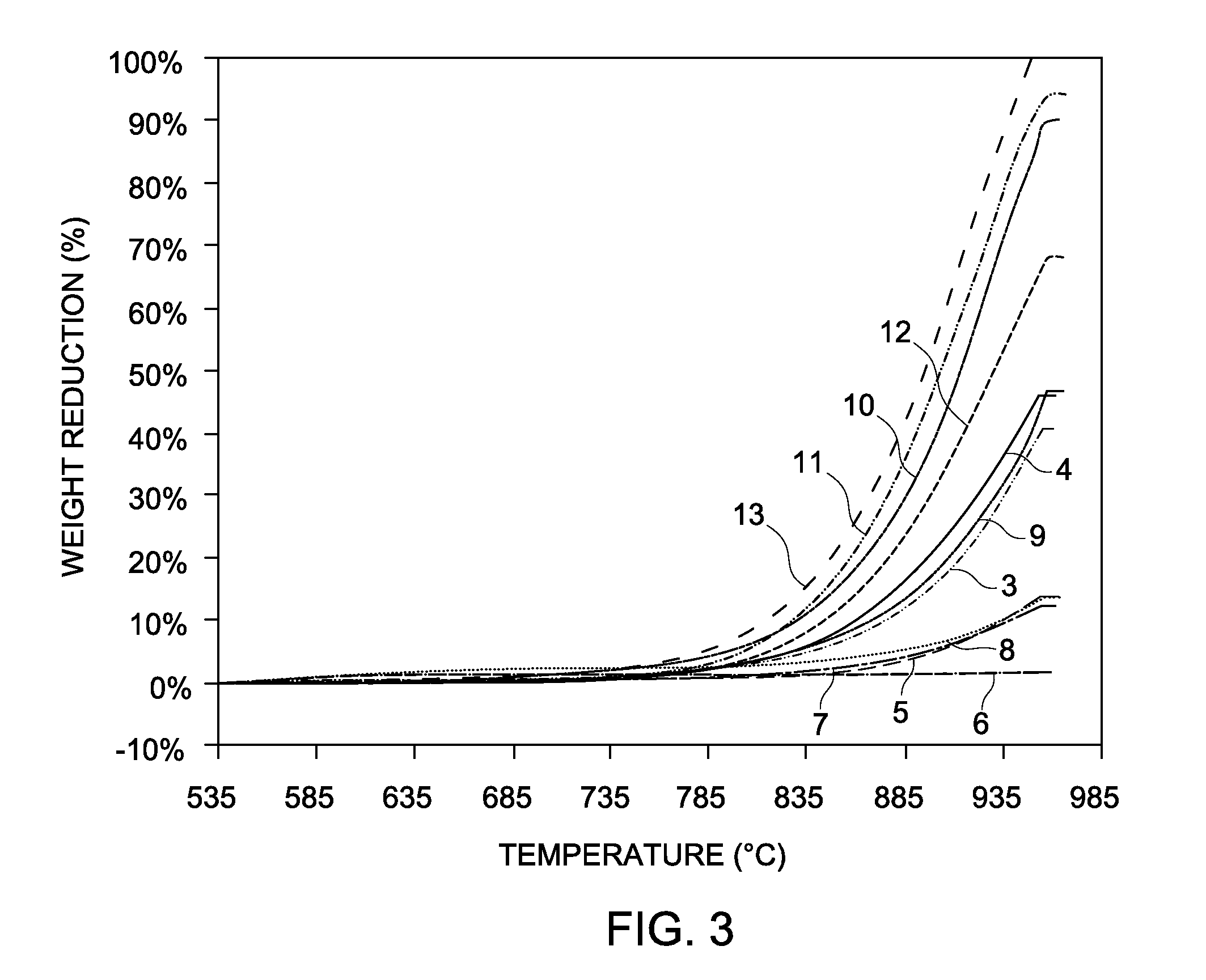

Method and reactor for cracking hydrocarbon

ActiveUS9499747B2Reduces and eliminates build-upThermal non-catalytic crackingHydrocarbon by dehydrogenationIndiumHafnium

A method for cracking hydrocarbon, comprises: providing steam and hydrocarbon; and feeding steam and hydrocarbon into a reactor accessible to hydrocarbon and comprising a perovskite material of formula AaBbCcDdO3-δ, wherein 0<a<1.2, 0≦b≦1.2, 0.9<a+b≦1.2, 0<c<1.2, 0≦d≦1.2, 0.9<c+d≦1.2, −0.5<δ<0.5; A is selected from calcium, strontium, barium, and any combination thereof; B is selected from lithium, sodium, potassium, rubidium and any combination thereof; C is selected from cerium, zirconium, antimony, praseodymium, titanium, chromium, manganese, ferrum, cobalt, nickel, gallium, tin, terbium and any combination thereof; and D is selected from lanthanum, cerium, praseodymium, neodymium, promethium, samarium, europium, gadolinium, terbium, dysprosium, holmium, ebium, thulium, ytterbium, lutetium, scandium, titanium, vanadium, chromium, manganese, ferrum, cobalt, nickel, copper, zinc, yttrium, zirconium, niobium, molybdenum, technetium, ruthenium, rhodium, palladium, silver, cadmium, hafnium, tantalum, tungsten, rhenium, osmium, iridium, platinum, gold, gallium, indium, tin, antimony and any combination thereof.

Owner:BL TECH INC

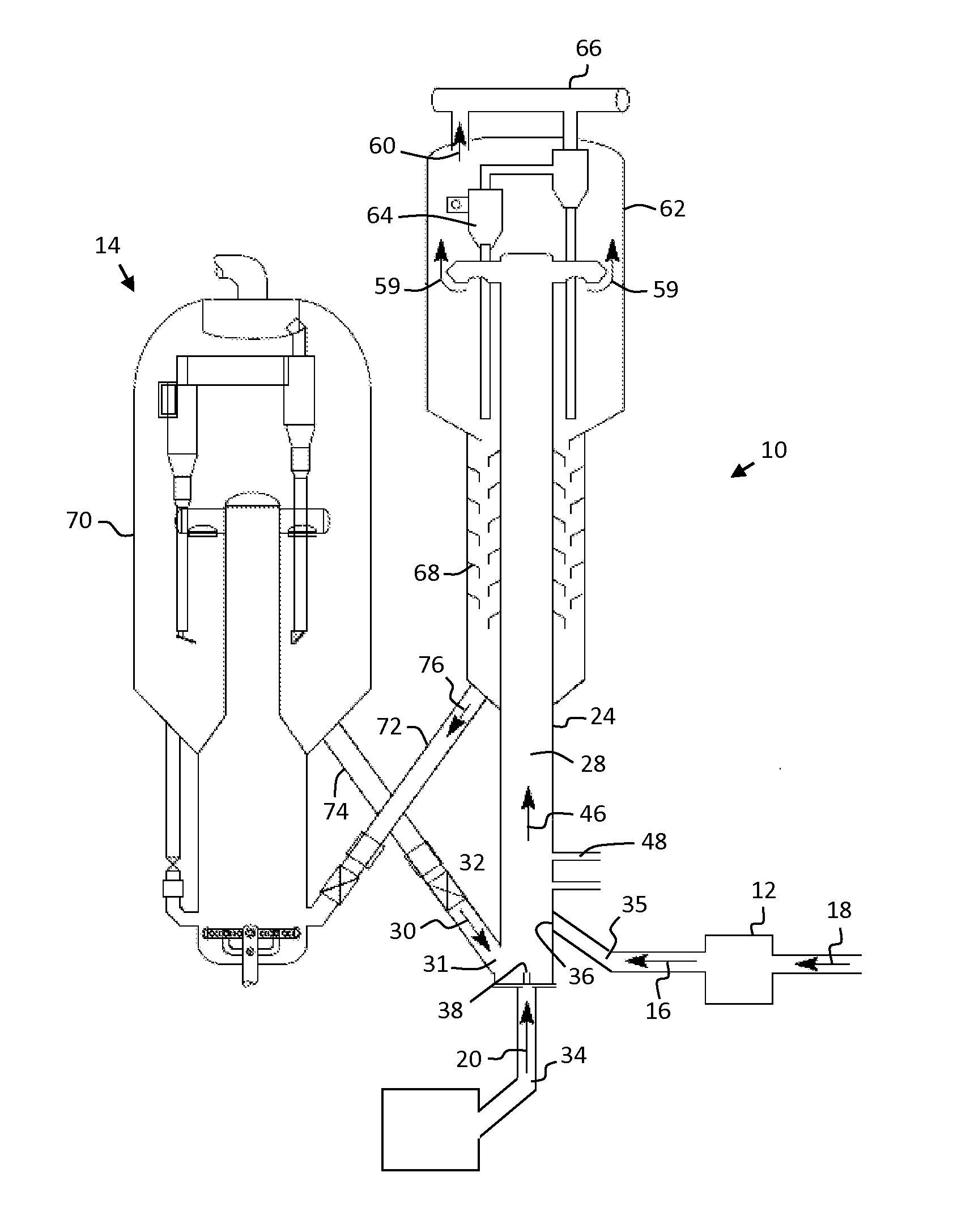

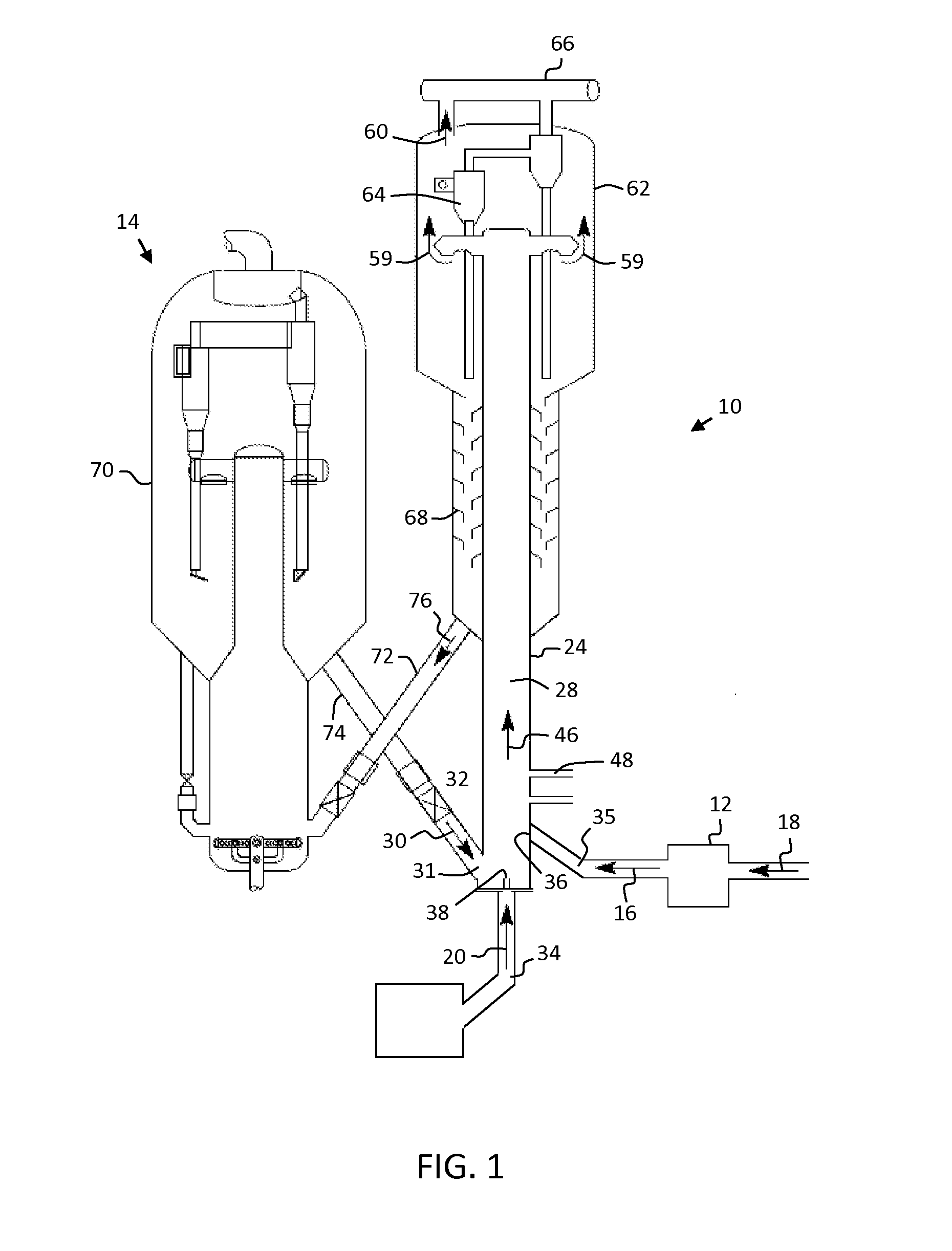

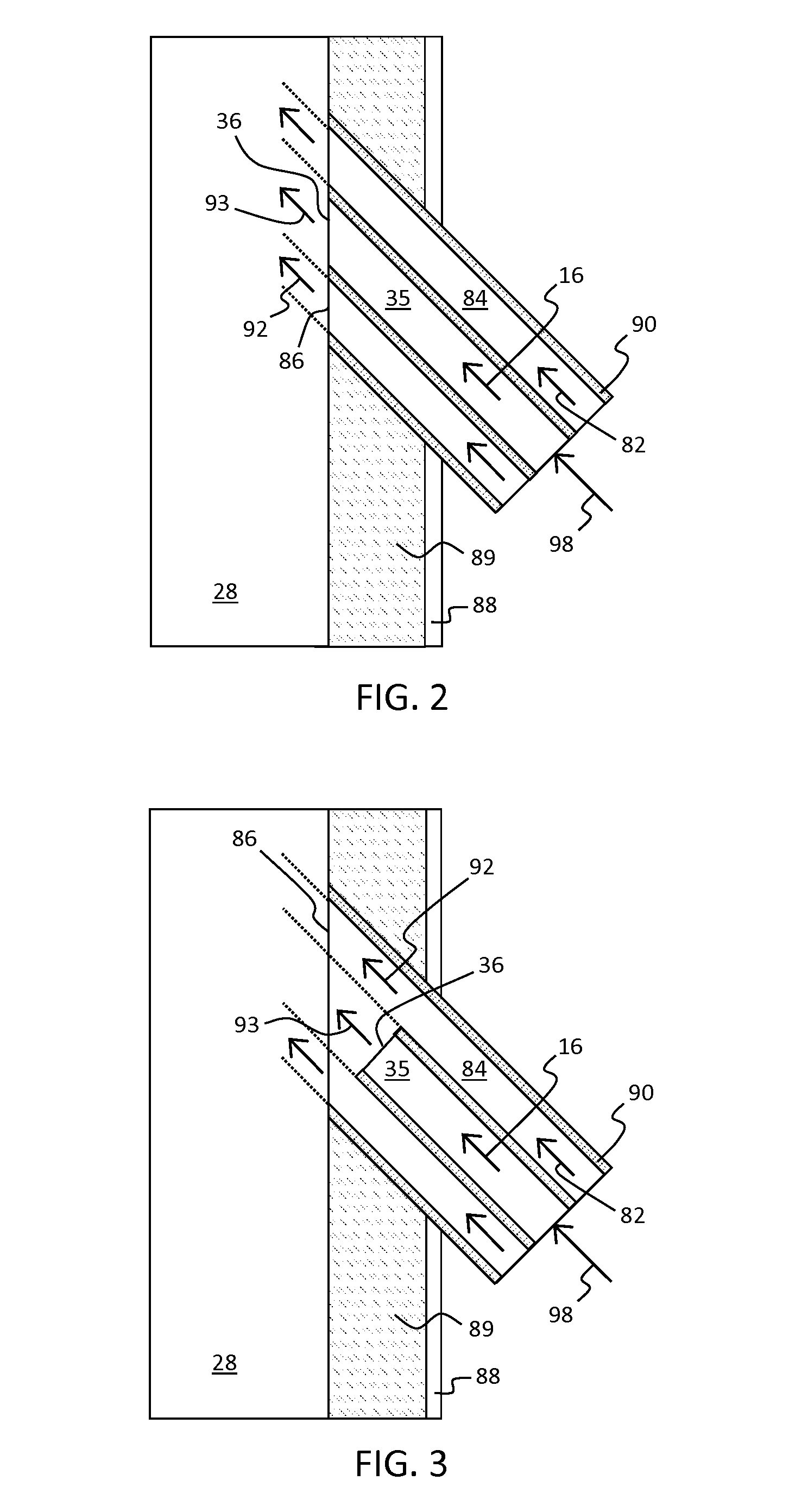

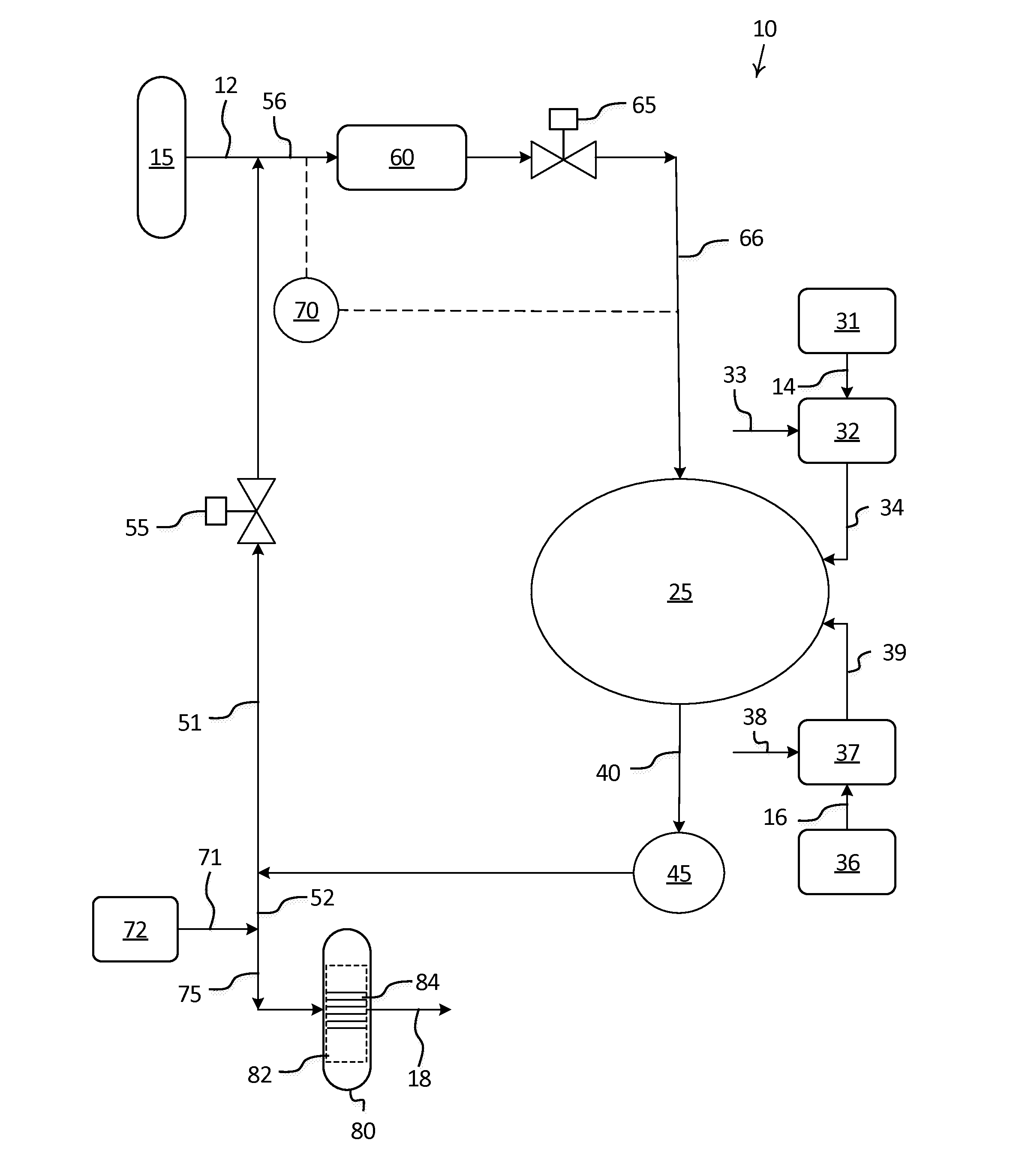

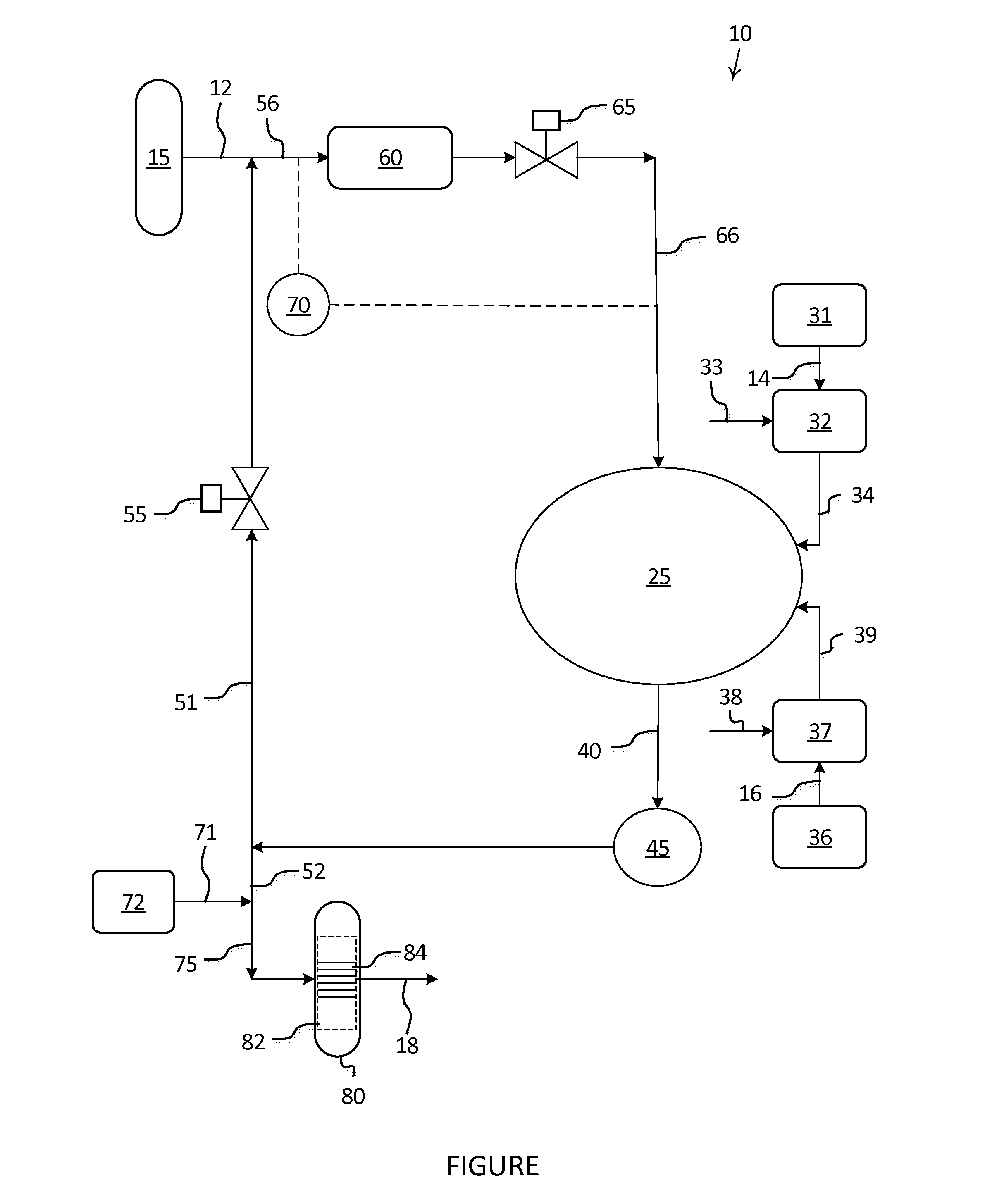

Fcc units, apparatuses and methods for processing pyrolysis oil and hydrocarbon streams

Fluid catalytic cracking (FCC) units, apparatuses, and methods for catalytically cracking a mixture of a pyrolysis oil stream and a hydrocarbon stream are provided herein. In an embodiment, an FCC unit includes a reaction chamber suitable for contacting a pyrolysis oil, a hydrocarbon, and a catalyst. The FCC unit includes a coolant conduit having an coolant outlet in communication with the reaction chamber and suitable for introducing a coolant stream through the coolant outlet into the reaction chamber. The FCC unit further includes a pyrolysis oil conduit including a pyrolysis oil outlet positioned within the coolant conduit and suitable for injecting the pyrolysis oil through the pyrolysis oil outlet into the reaction chamber.

Owner:UOP LLC

Catalyst compositions comprising small size molecular sieves crystals deposited on a porous material

ActiveUS20160136625A1Increase surface areaHigh activityCatalytic crackingCatalytic naphtha reformingMolecular sievePore diameter

A catalyst composition contains an inorganic porous material with pore diameters of at least 2 nm and of crystals of molecular sieve. The crystals of molecular sieve have an average diameter, measured by scanning electron microscopy, not bigger than 50 nm. The catalyst composition has a concentration of acid sites ranges from 50 to 1200 μmol / g measured by TPD NH3 adsorption. An XRD pattern of the catalyst composition is the same as an XRD pattern of the inorganic porous material.

Owner:TOTAL RES & TECH FELUY +1

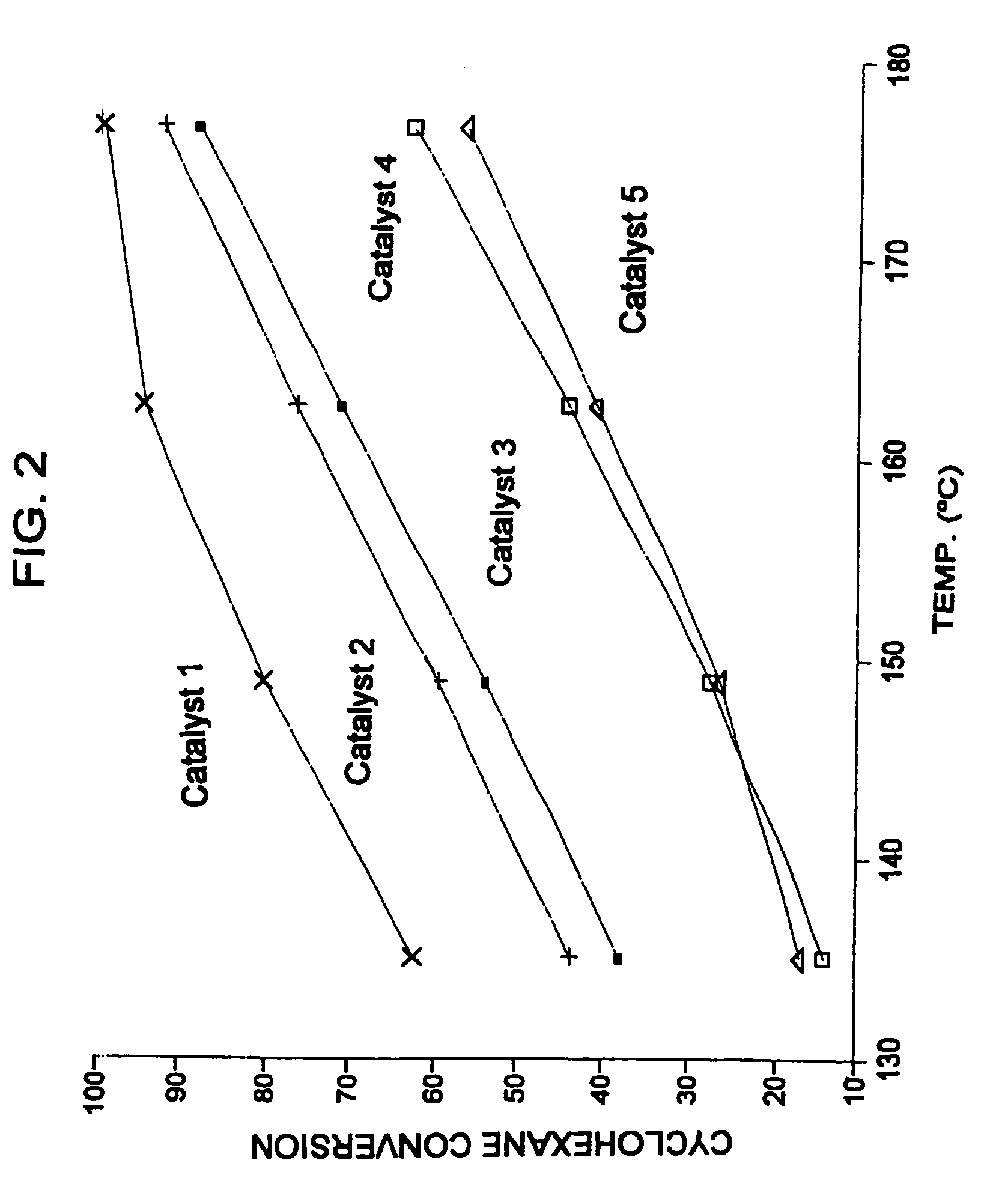

Dual functional catalyst for selective opening of cyclic paraffins and process for using the catalyst

A catalyst for selectively opening cyclic paraffins has been developed. The catalyst comprises a Group VIII metal, such as platinum, a modifier component, such as niobium or ytterbium, a molecular sieve, such as UZM-16 and a refractory inorganic oxide such as alumina. The Group VIII metal and modifier component are preferably deposited on the refractory inorganic oxide. A process for using the catalyst is also disclosed.

Owner:UOP LLC

Dual functional catalyst for selective opening of cyclic paraffins and process for using the catalyst

A process for selectively opening cyclic paraffins (naphthenic rings) with substantially no subsequent cracking of the acyclic product has been developed. The process comprises contacting a cyclic paraffin feedstream with a catalyst at ring opening conditions to produce an acyclic paraffin product. The catalyst comprises a Group VIII metal, such as platinum, a modifier component, such as niobium or ytterbium, a molecular sieve, such as UZM-16 and a refractory inorganic oxide such as alumina. The Group VIII metal and modifier component are preferably deposited on the refractory inorganic oxide.

Owner:UOP LLC

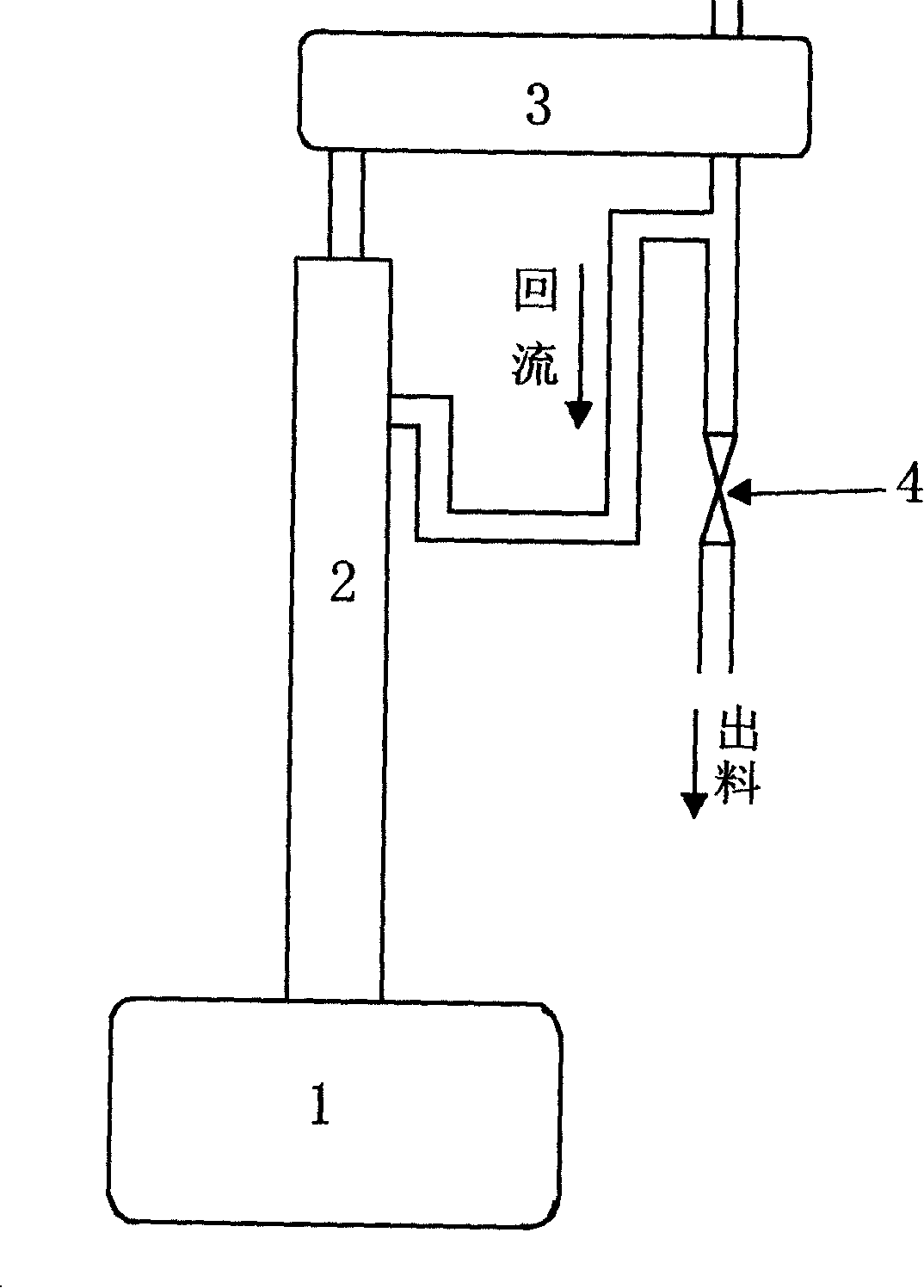

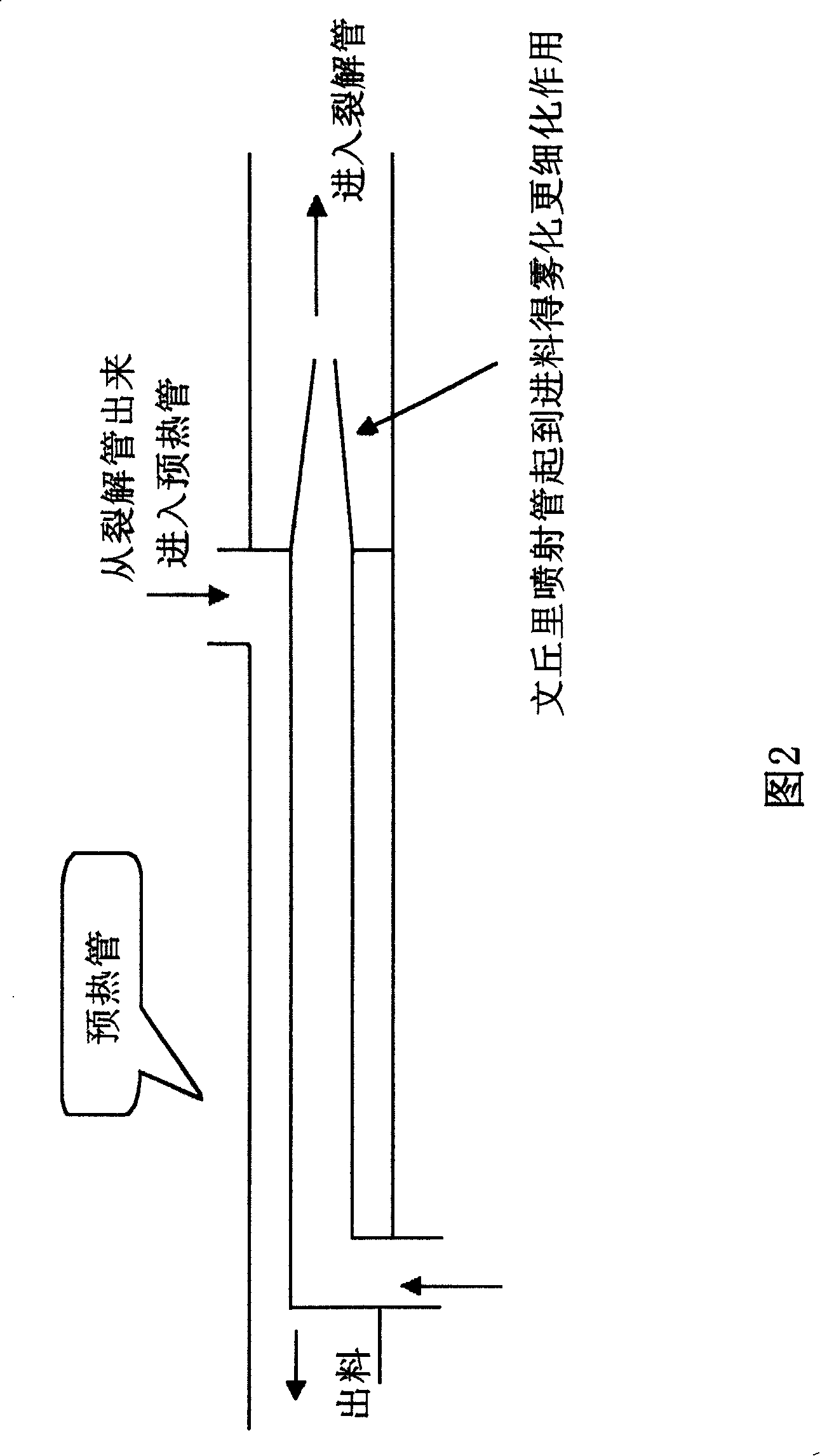

Technique for synthesizing dihydromyrcenol

InactiveCN101239885AHigh yieldReduce manufacturing costOxygen-containing compound preparationOrganic compound preparationNickel catalystHydrogen

The invention discloses a dihydromyrcenol synthesis process in which stainless steel plate rectification technology is used to increase the product content; a skeleton nickel catalyst is prepared by hydrogen-filling and washing during catalyst activation so as to improve the activity of the catalyst; and the atomization and aerification effect is solved by mounting a Venturi adjutage during the schizolysis. The dihydromyrcenol synthesized by the process has high purity, good aroma, increased yield during the preparation, and reduced cost.

Owner:ZHEJIANG DONGPING PERFUME

Methods and apparatuses for co-processing pyrolysis oil

InactiveUS20160168481A1Dewatering/demulsification with chemical meansCatalytic crackingEmulsionReaction zone

Methods for co-processing pyrolysis oil streams and fuel processing apparatuses are provided. In one example, a method for co-processing a pyrolysis oil stream and a hydrocarbon stream is provided. The method includes mixing the pyrolysis oil stream and the hydrocarbon stream with a surfactant to form an emulsion. The method introduces the emulsion to a reaction zone in an fluid catalytic cracking (FCC) unit. The method includes contacting the emulsion with a catalyst in the reaction zone to form an FCC product stream.

Owner:UOP LLC

Process for Continuous Ringclosing Metathesis in Compressed Carbondioxide

InactiveUS20060252951A1Hydrocarbon by isomerisationGroup 8/9/10/18 element organic compoundsRing-closing metathesisSolvent

The present invention relates to a process for carrying out olefin ring-closing metathesis (RCM) wherein compressed carbon dioxide (gaseous, liquid or supercritical) acts as solvent for the liquid or solid reactant and the products obtained therefrom, while additionally one or more ionic liquids are introduced as the 2nd phase in which homogeneous olefin metathesis catalysts are immobilised.

Owner:BOEHRINGER INGELHEIM INT GMBH +1

Process for the preparation of a catalyst based on molybdenum for use in hydrotreatment or in hydrocracking

ActiveUS20140323780A1High activityGood dispersionCatalytic crackingHydrocarbon by hydrogenationDimerPtru catalyst

The invention concerns a process for the preparation of a catalyst for carrying out hydrogenation reactions in hydrotreatment and hydrocracking processes. Said catalyst is prepared from at least one mononuclear precursor based on molybdenum (Mo), in its monomeric or dimeric form, having at least one Mo═O or Mo—OR bond or at least one Mo═S or Mo—SR bond where [R═CxHy where x≧1 and (x−1)≦y≦(2x+1) or R═Si(OR′)3 or R═Si(R′)3 where R′═Cx′Hy′ where x′≧1 and (x′−1)≦y′≦(2x′+1)], and optionally from at least one promoter element from group VIII. Said precursors are deposited onto an oxide support which is suitable for the process in which it is used, said catalyst being dried at a temperature of less than 200° C. then advantageously being sulphurized before being deployed in said process.

Owner:INST FR DU PETROLE

Process for the isomerization of xylenes and catalyst therefor

InactiveUS20070060779A1Low net naphtheneHigh activityHydrocarbon by isomerisationMolecular sieve catalystsMolecular sievePlatinum

Catalysts of certain combinations of platinum, tin, acidic molecular sieve and aluminum phosphate binder achieve the isomerization and dealkylation activities characteristic of platinum-containing catalysts yet enjoy the low net C6 naphthenes make properties.

Owner:UOP LLC

Method for preparing cyclopentene and cyclopentane by depolymerizing and hydrogenating dicyclopentadiene

InactiveCN104151125AImprove conversion utilizationHigh selectivityHydrocarbon by aliphatic/cycloaliphatic split-offCyclopenteneDepolymerization

The invention discloses a method for preparing cyclopentene and cyclopentane by depolymerizing and hydrogenating dicyclopentadiene, which comprises the following steps: 1) depolymerization reaction: adding heat-conducting oil into a heat-conducting layer of a thermal decomposer and a reboiler, heating to 260-300 DEG C, and adding a dicyclopentadiene / heat-conducting oil mixture into the thermal decomposer, wherein the dicyclopentadiene is heated and vaporized in the thermal decomposer and depolymerized into cyclopentadiene, and the cyclopentadiene enters a rectifying column; and 2) hydrogenation reaction: carrying out catalytic hydrogenation reaction twice respectively in a primary hydrogenation kettle and a secondary hydrogenation kettle, wherein Raney nickel is used as a reaction catalyst. In the preparation method, the twice hydrogenation process is adopted, and the time, pressure and temperature of each hydrogenation reaction are controlled to control and adjust the cyclopentene / cyclopentane proportion in the product.

Owner:ZHEJIANG ALPHARM CHEM TECH

Popular searches

Refining to change hydrocarbon structural skeleton Water Hydrocarbon from saturated and unsaturated hydrocarbon addition Hydrocarbon by hydrocarbon cracking Hydrocarbon oils treatment products Dispersed particle separation Hydrocarbon oil cracking Metal/metal-oxides/metal-hydroxide catalysts Liquid-gas reaction processes Treatment with hydrotreatment processes

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com