Methods and apparatuses for co-processing pyrolysis oil

a technology of pyrolysis oil and coprocessing, which is applied in the direction of lighting and heating apparatus, dewatering/demulsification with chemical means, furnaces, etc., can solve the problems of affecting the heat balance of the fcc unit, challenging the processing in the fcc unit, and harming the fcc catalys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011]The following Detailed Description is merely exemplary in nature and is not intended to limit the methods and apparatuses described herein. Furthermore, there is no intention to be bound by any theory presented in the preceding Background or the following detailed description.

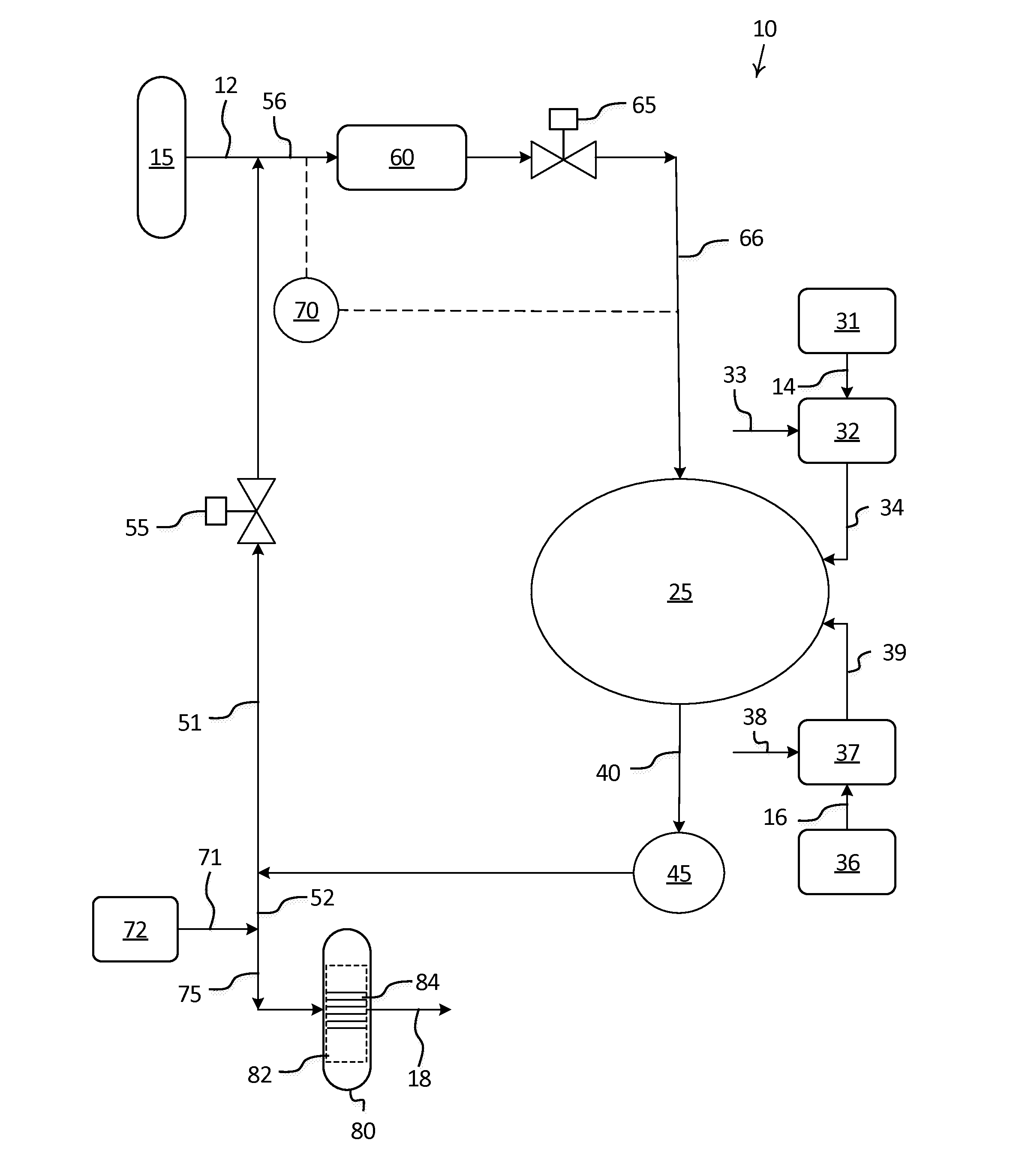

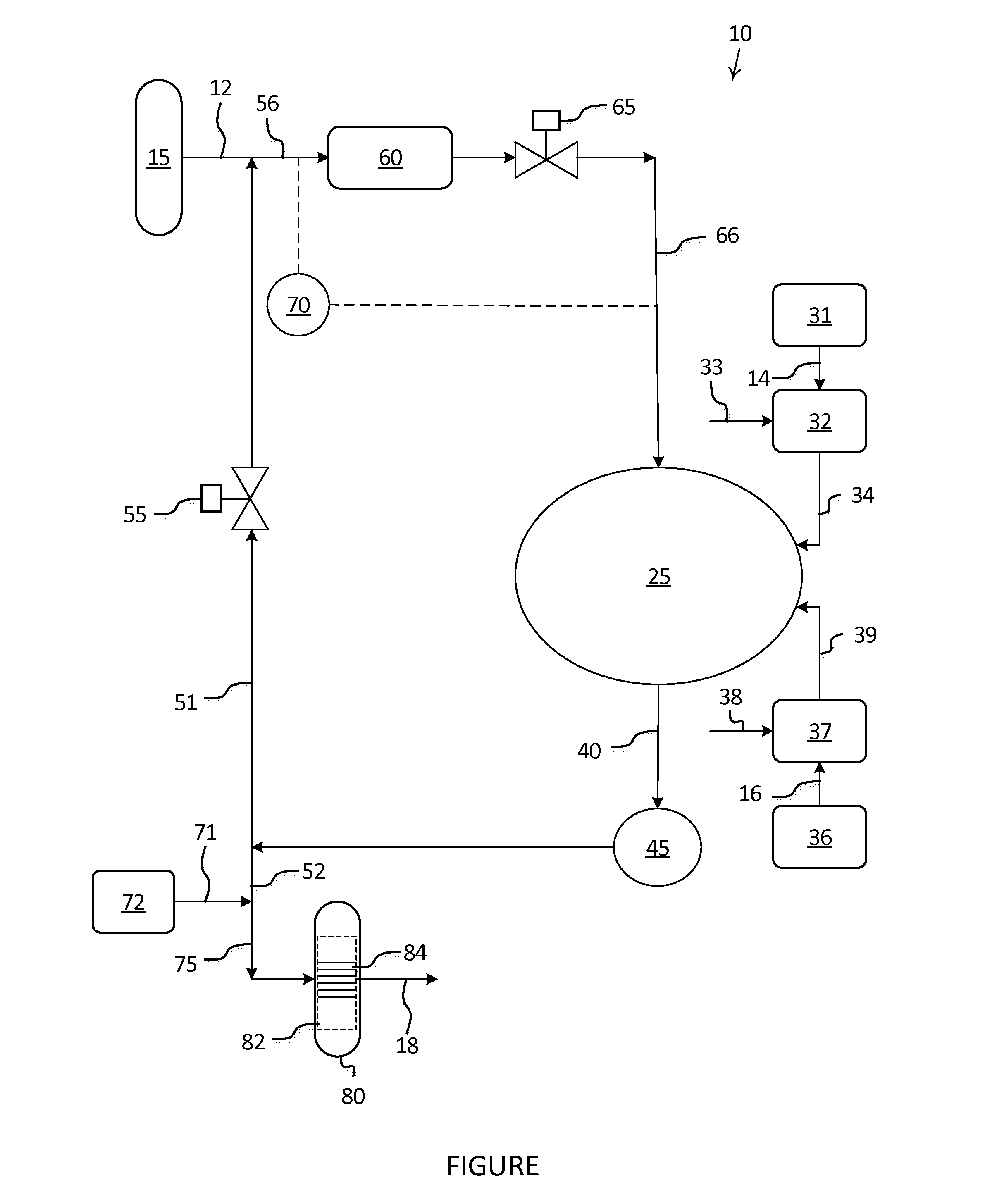

[0012]Various embodiments contemplated herein relate to methods and apparatuses for co-processing pyrolysis oil. Specifically, embodiments herein provide for co-processing pyrolysis oil in an FCC reactor with another stream, such as a hydrocarbon stream and / or a lipid stream. An exemplary process uses a surfactant to form an emulsion from the pyrolysis oil, the hydrocarbon stream, and the surfactant. The emulsion is fed directly into the FCC reactor through conventional means, i.e., no special injection equipment is needed. The FCC reactor converts the emulsion into an FCC product stream including upgraded fuel products. The FCC product stream may be distilled into various streams including naphtha, light...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com