Patents

Literature

88 results about "Paraffin product" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

First of all Paraffin is a gas by product and comes in the form of a wax or a liquid, derived from the petroleum refining process. Paraffin wax is a grey sludge which needs to be bleached & processed before it is deemed suitable to work with.

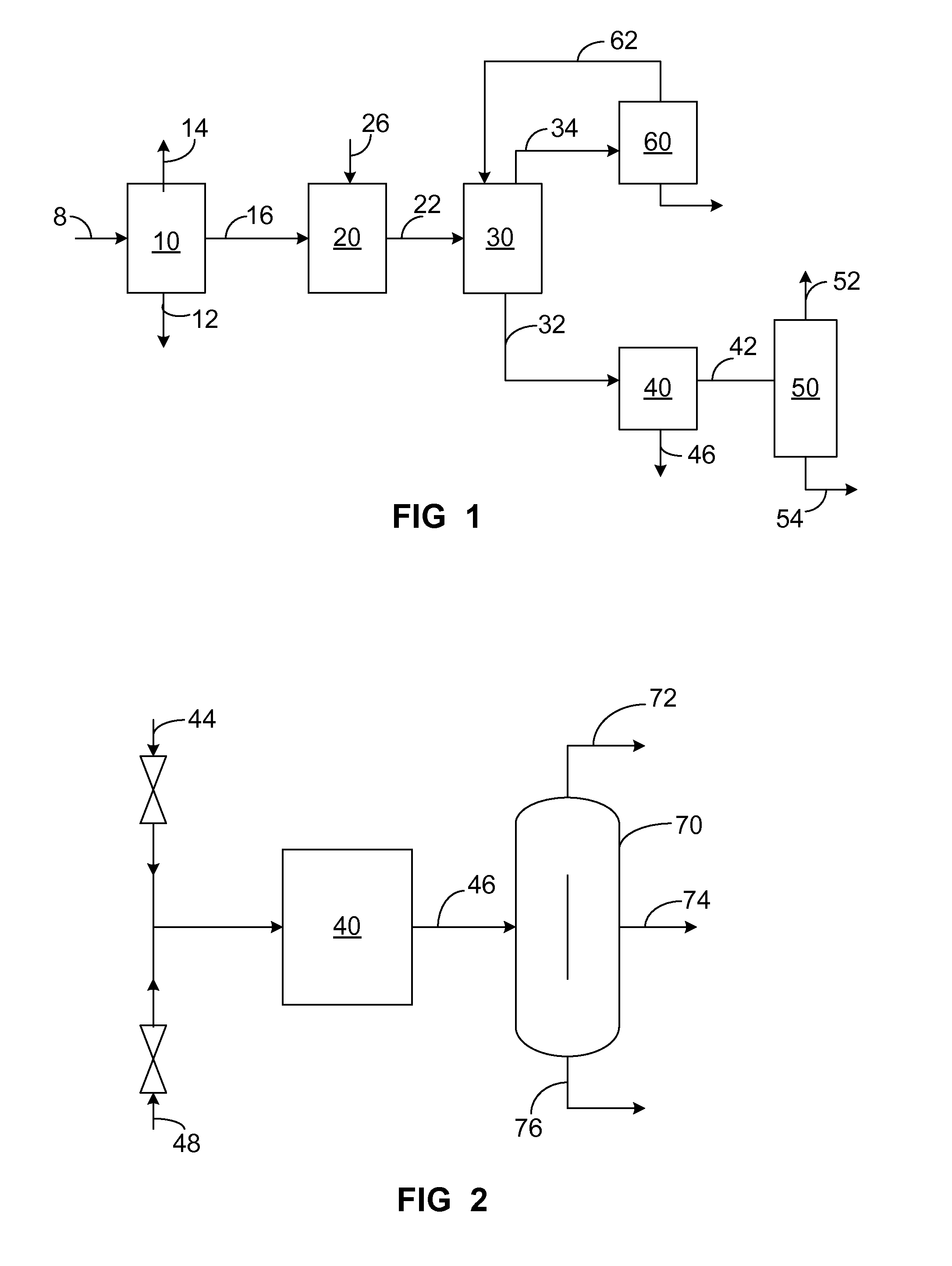

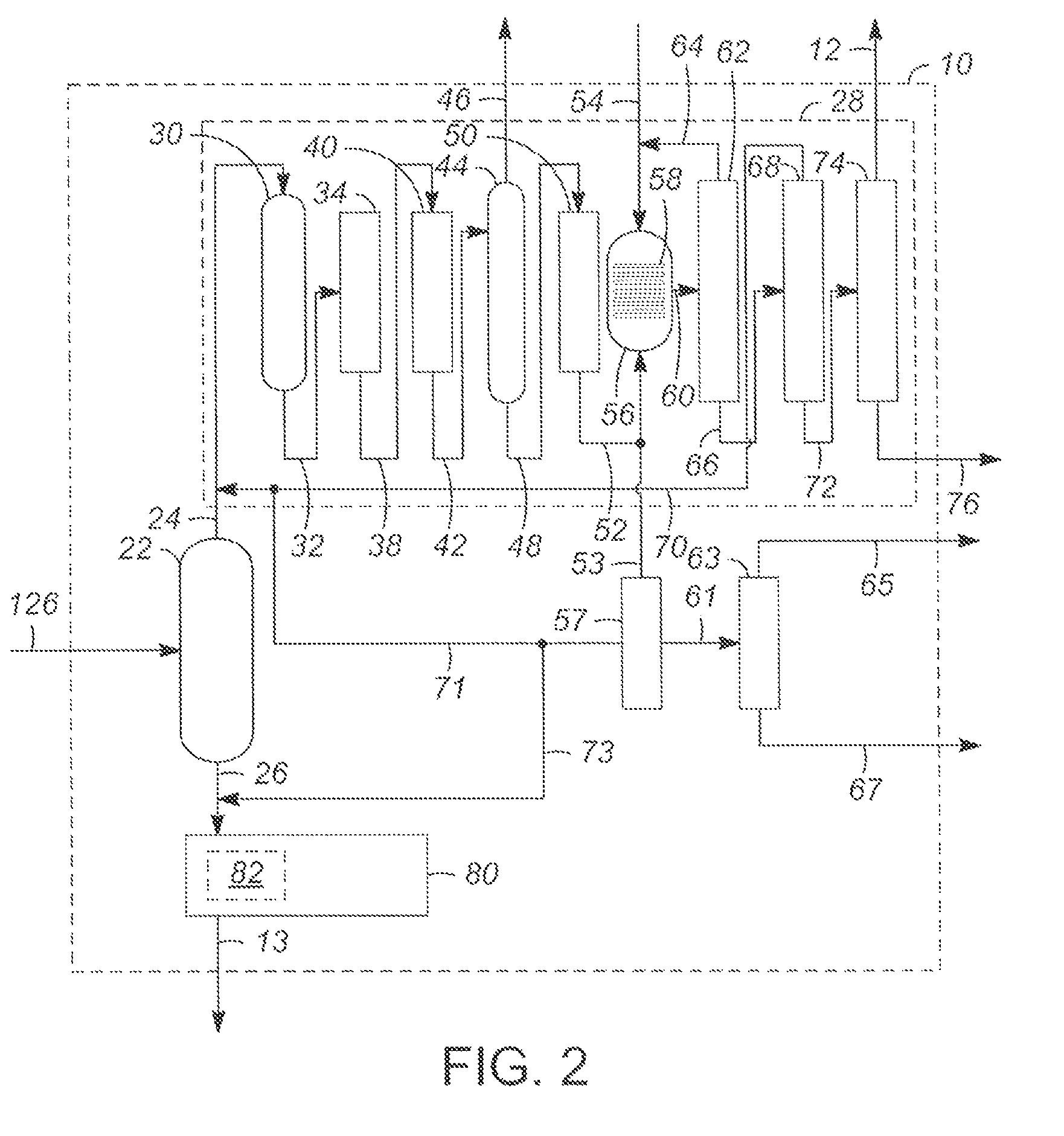

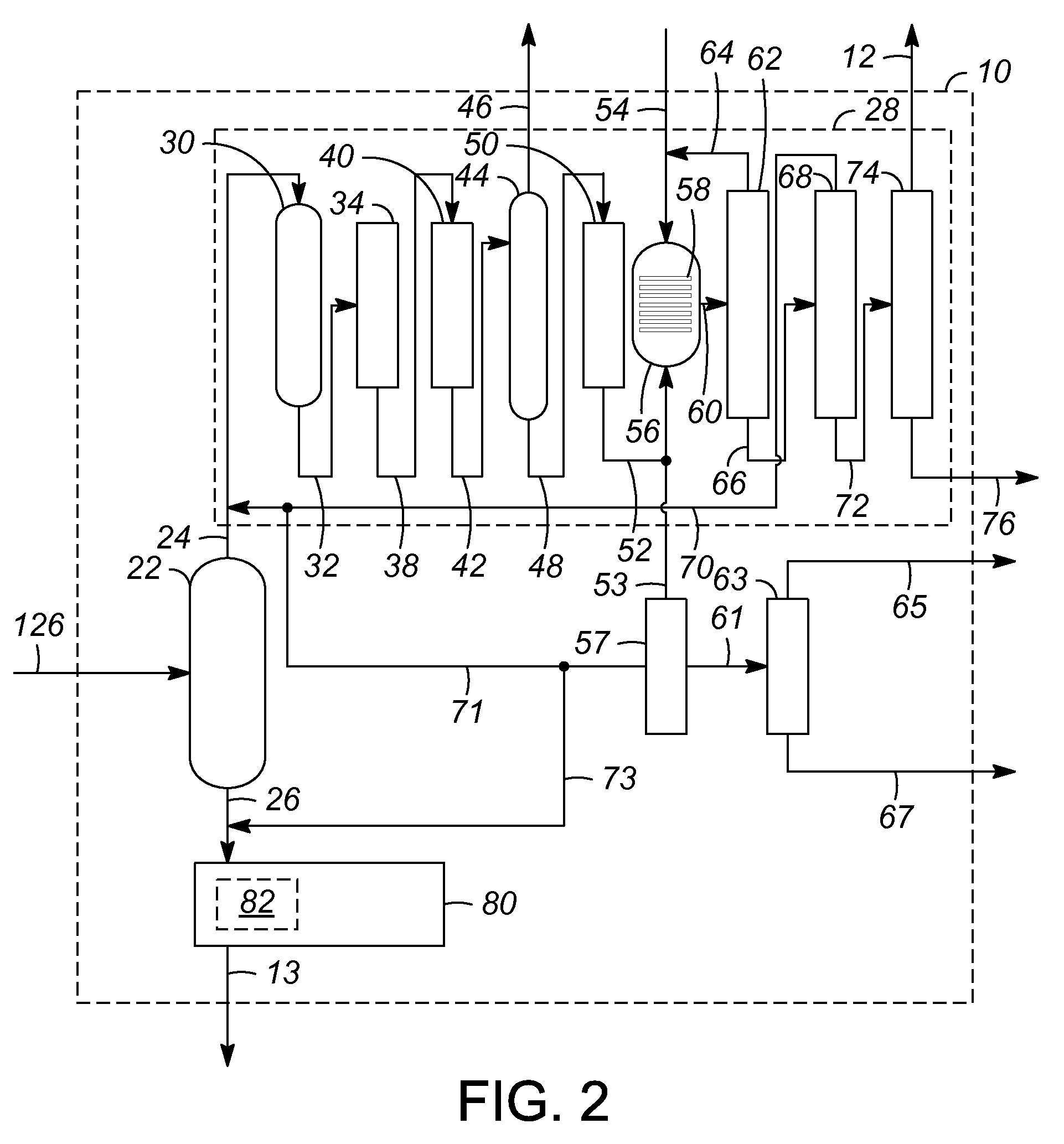

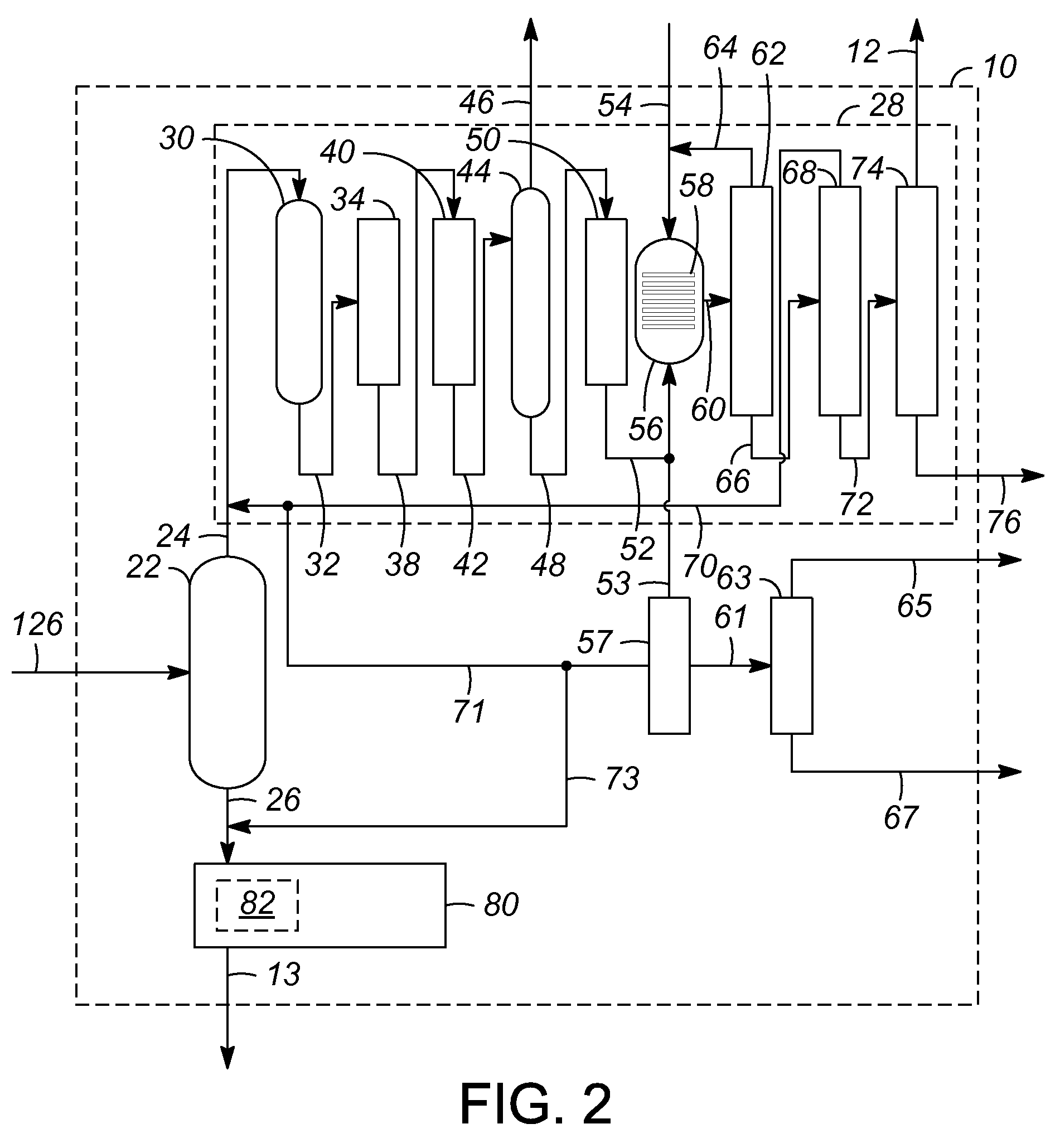

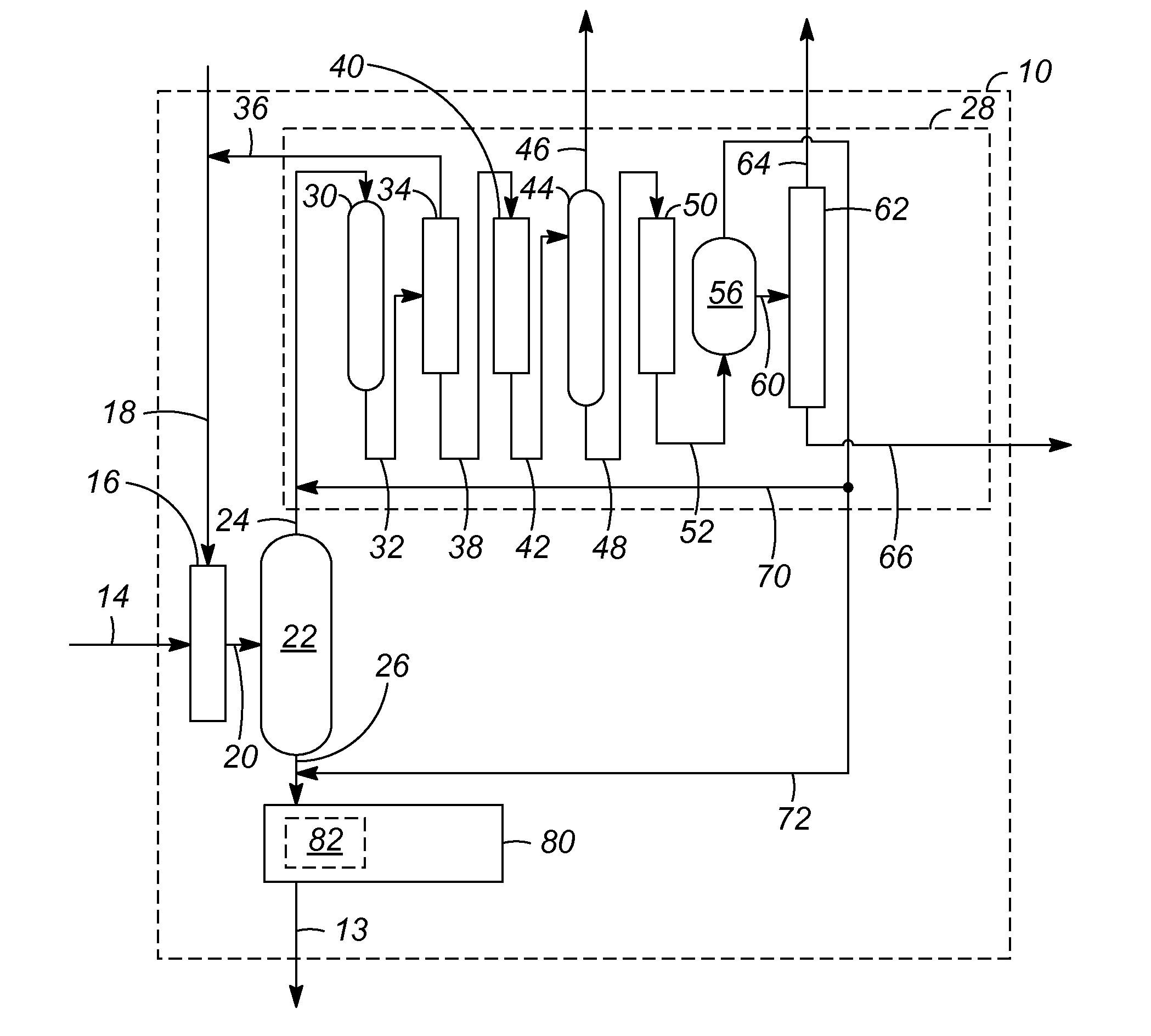

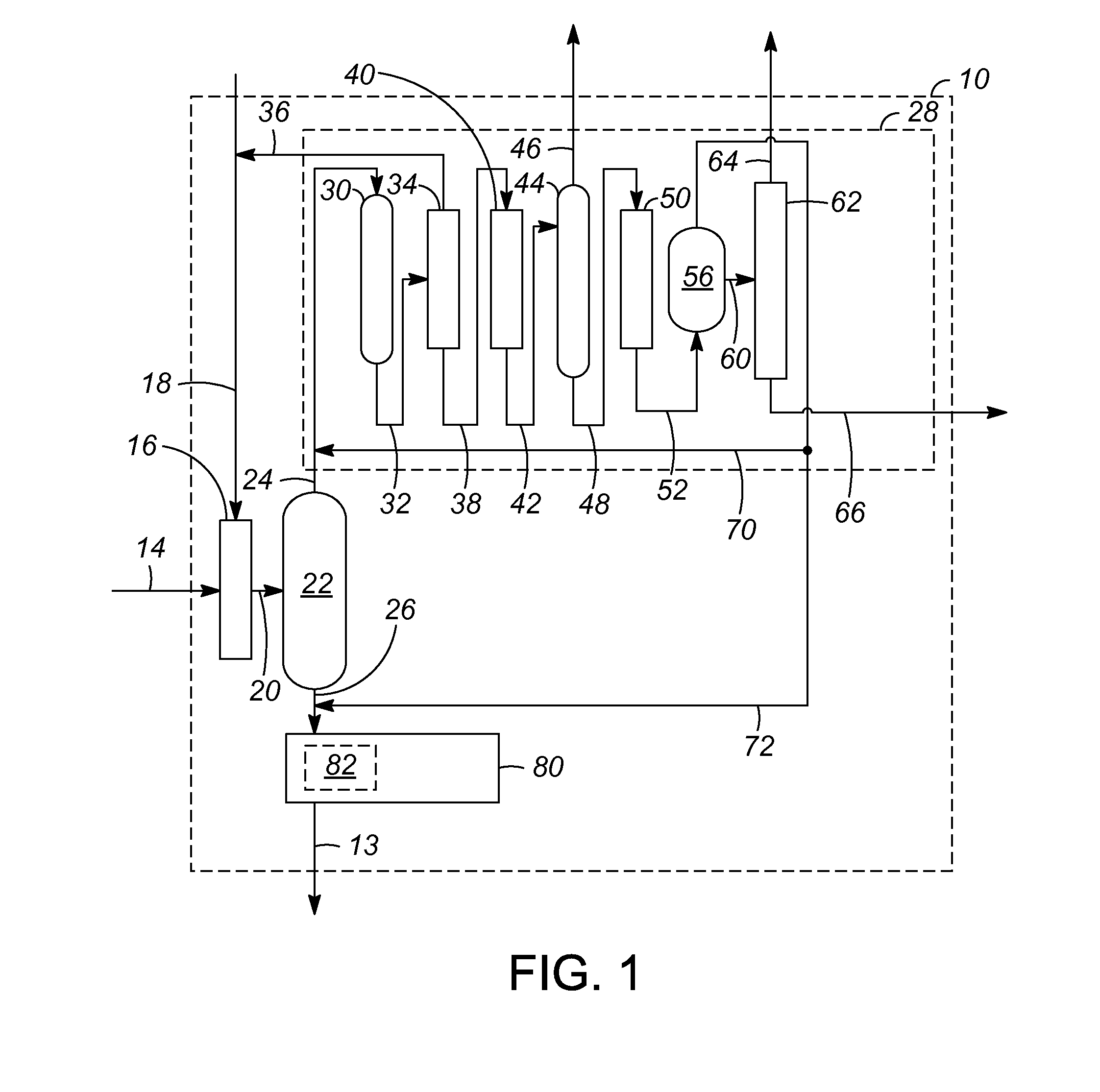

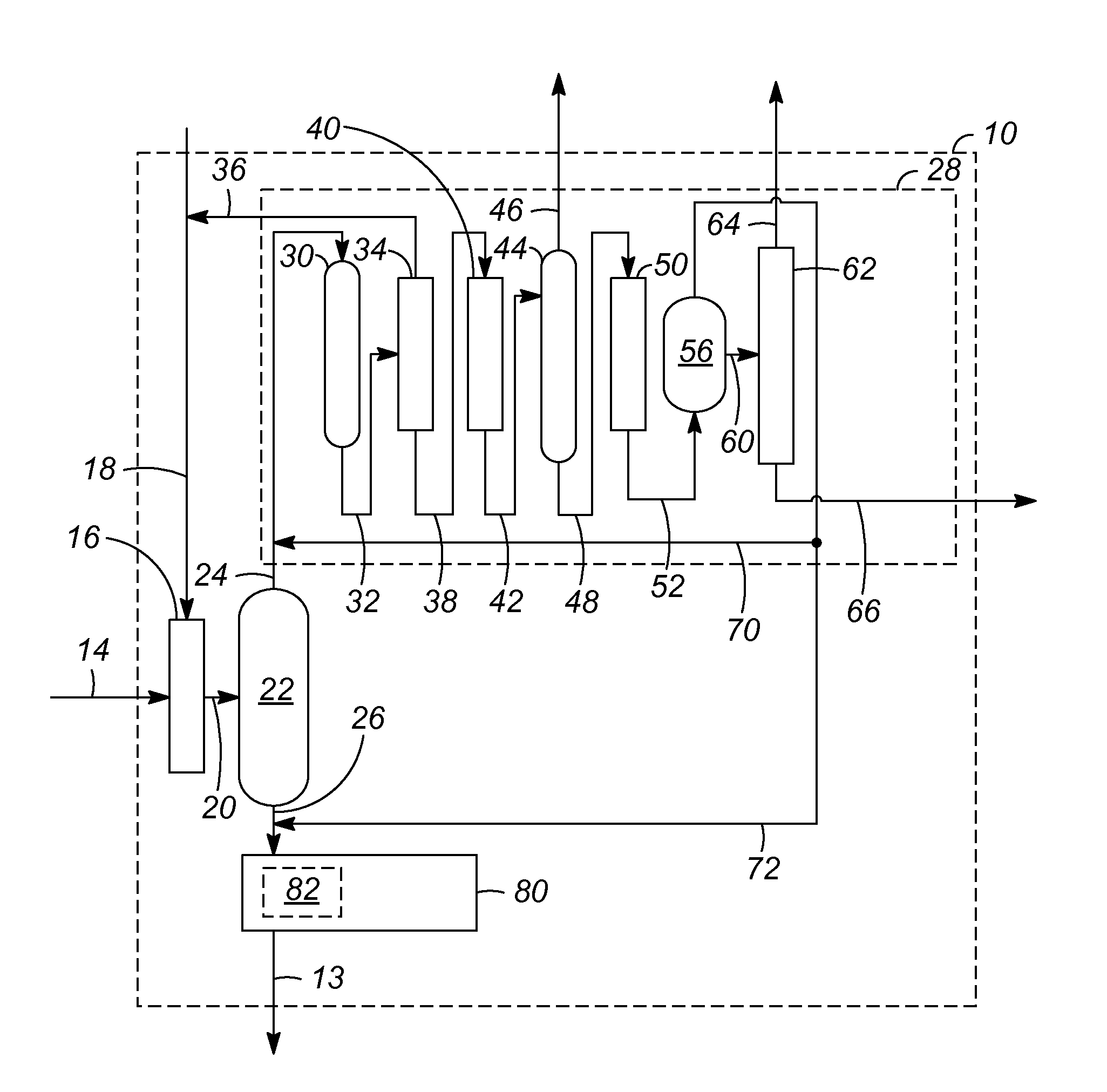

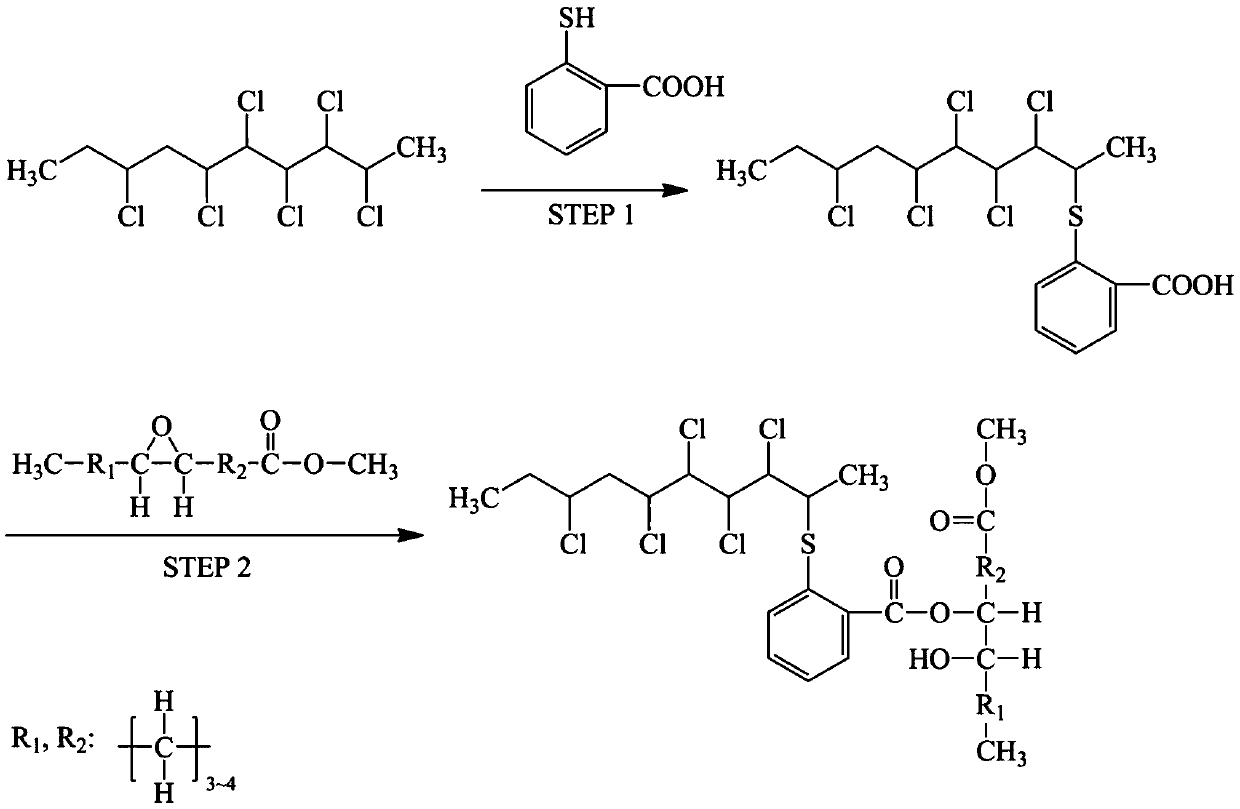

High Purity Heavy Normal Paraffins Utilizing Integrated Systems

InactiveUS20120160742A1High purityReduce pollutantsHydrocarbon distillationTreatment with hydrotreatment processesAlkaneParaffin oils

A process is presented for producing a purified normal paraffin product stream. The process includes passing a hydrocarbon stream having the desired normal paraffins to an adsorption separation system. A process stream generated from the separation system and having the normal paraffins is passed to an adsorption unit for the selective adsorption of aromatic compounds from the process stream, thereby producing a purified product.

Owner:UOP LLC

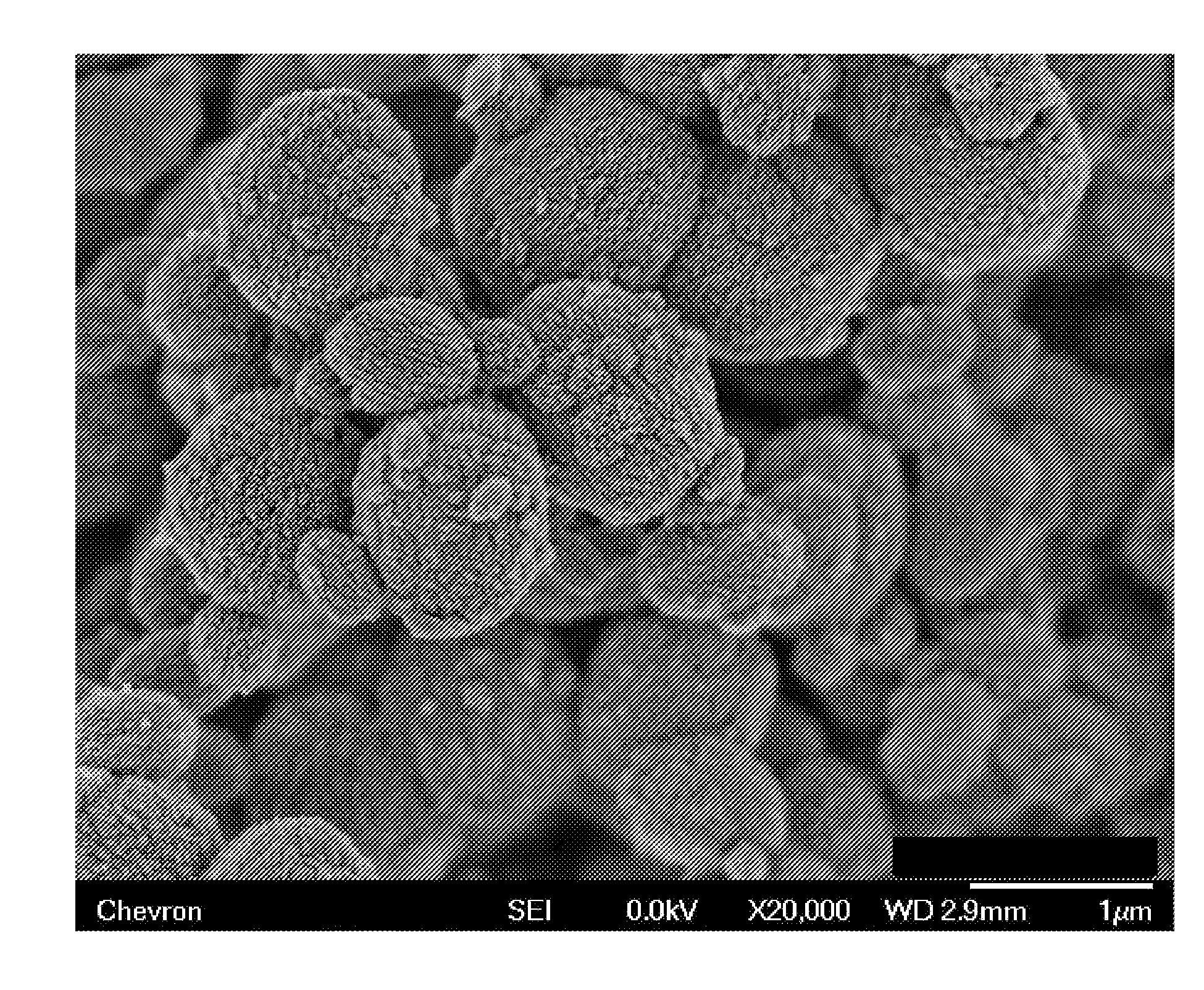

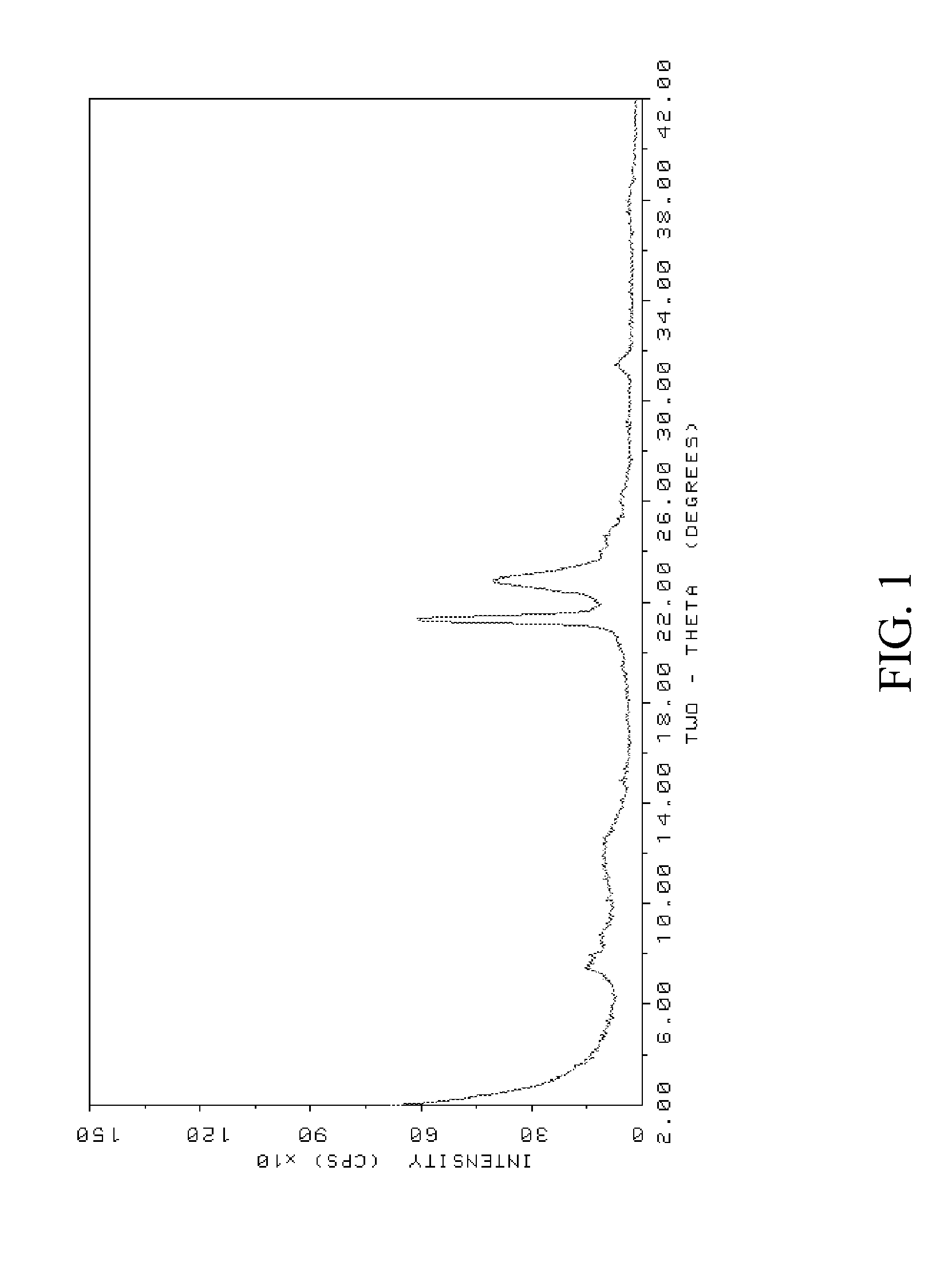

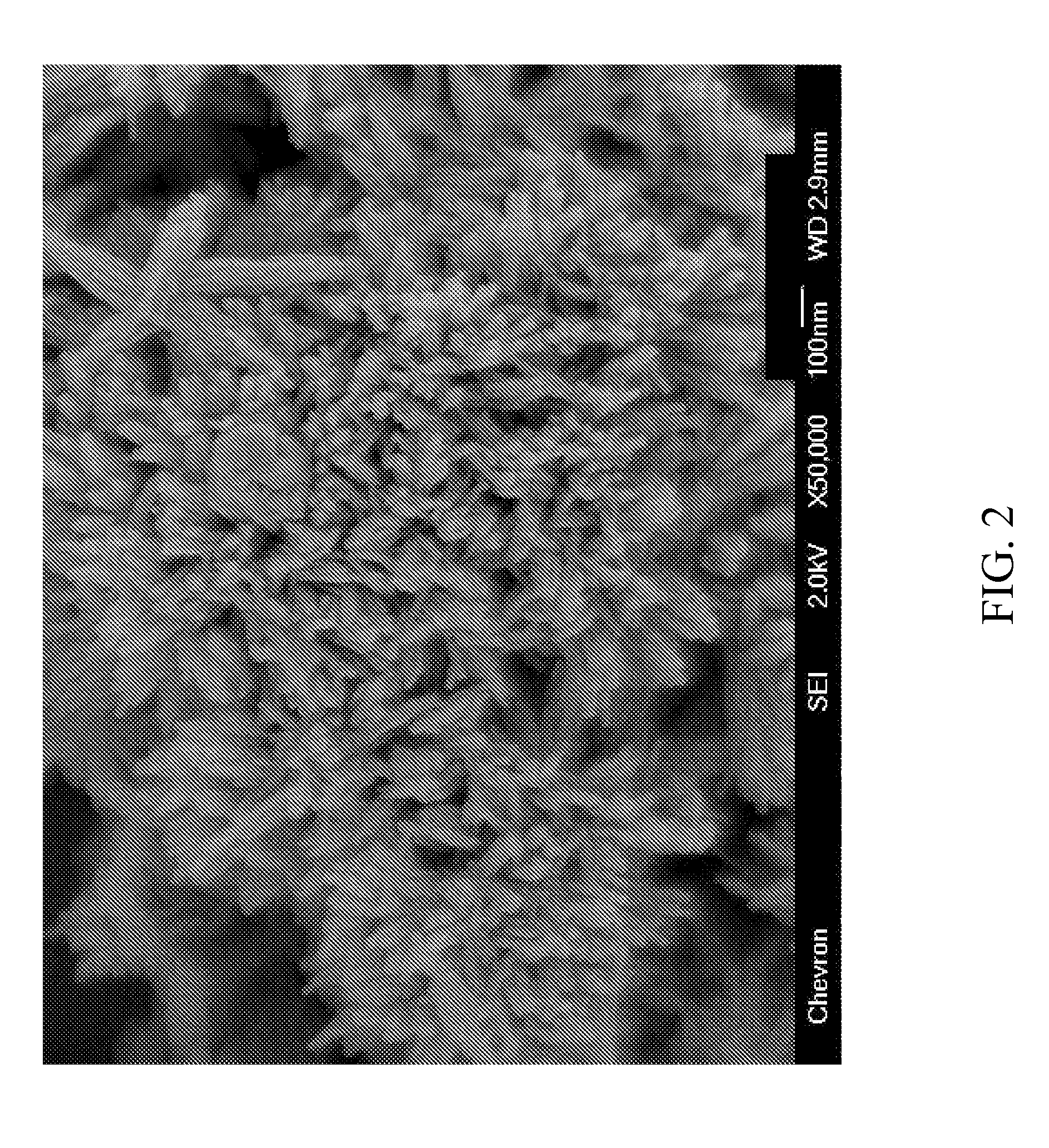

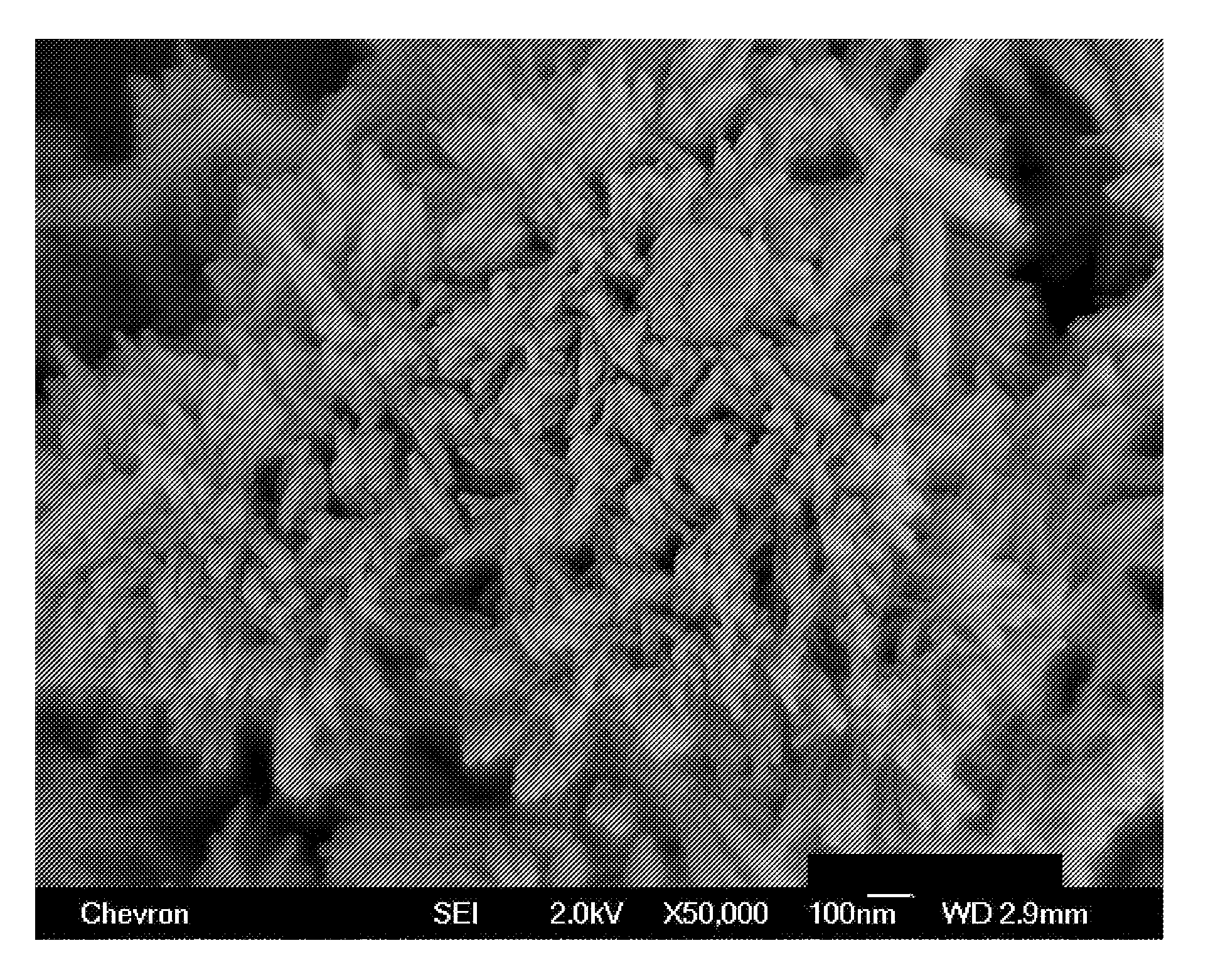

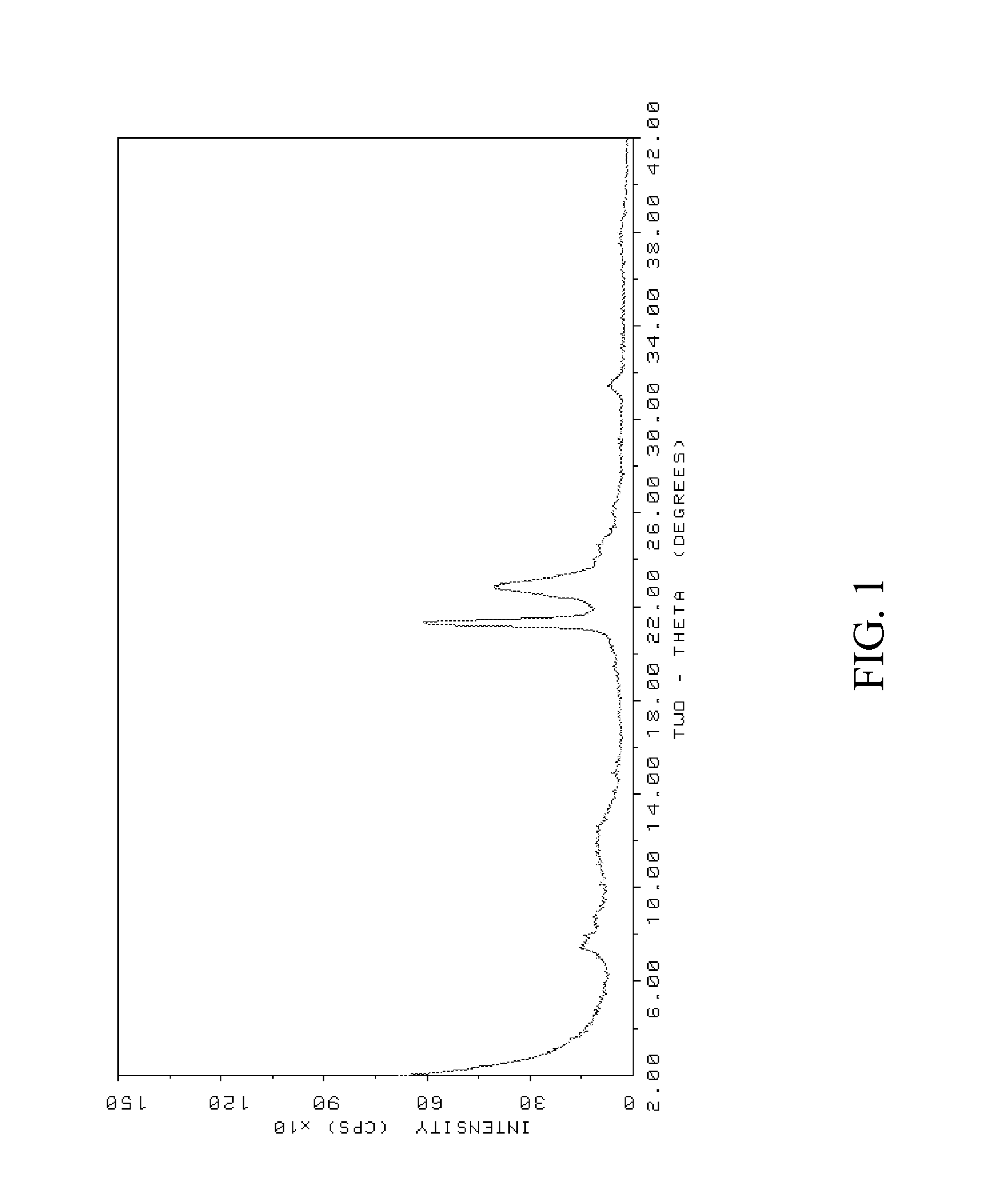

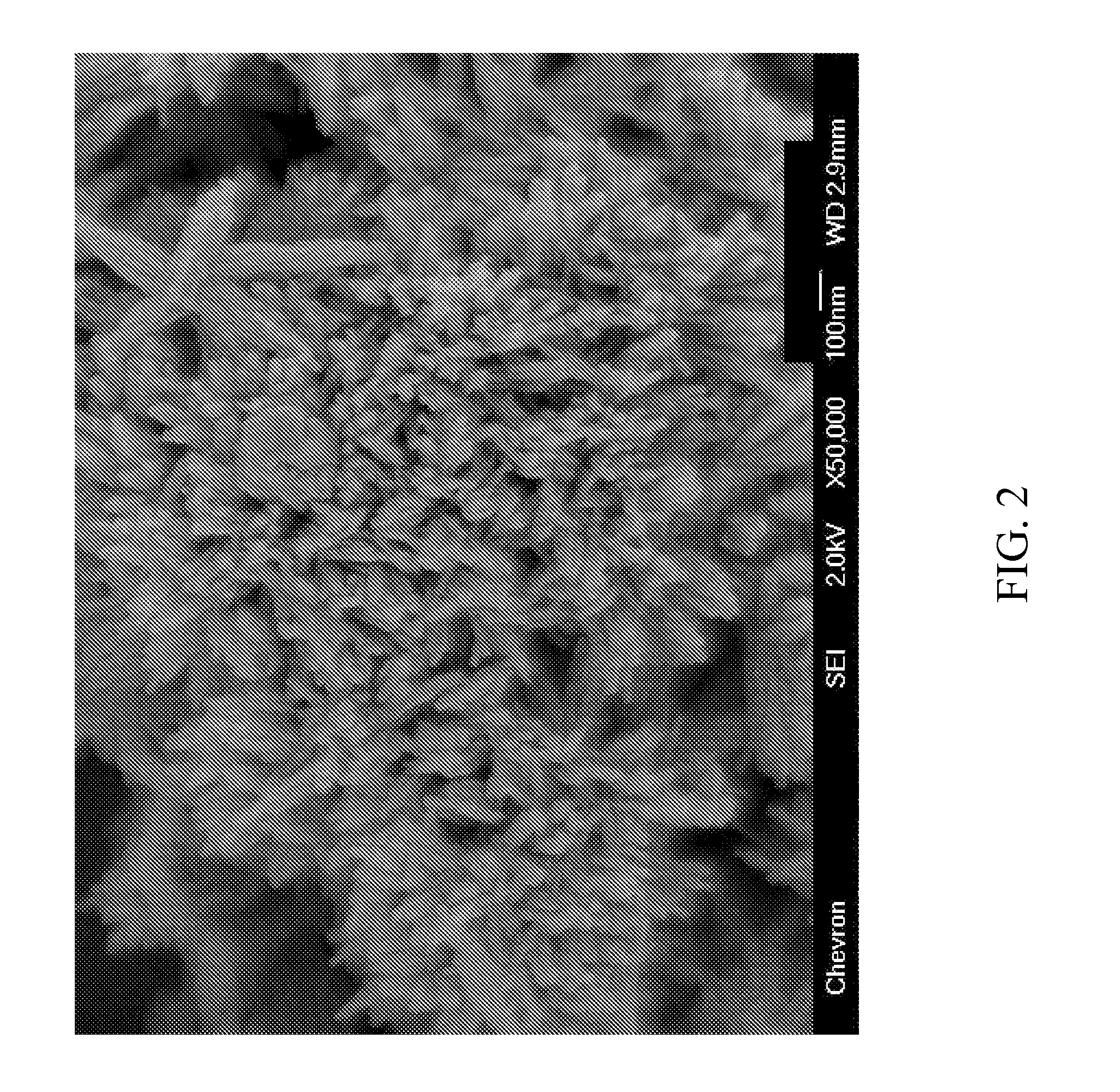

Method for making borosilicate zsm-48 molecular sieves

ActiveUS20110105302A1Reduce molecular weightAluminium compoundsMolecular sieve catalystsMolecular sieveAlkane

The present invention is directed to a borosilicate ZSM-48 molecular sieve having a mole ratio of between 40 and 400 of silicon oxide to boron oxide, synthesized using novel structure directing agents. Also disclosed are processes using a borosilicate ZSM-48 as a catalyst for the selective hydroconversion of heavy normal paraffins into lighter normal paraffin products, with minimal formation of isoparaffins.

Owner:CHEVROU USA INC

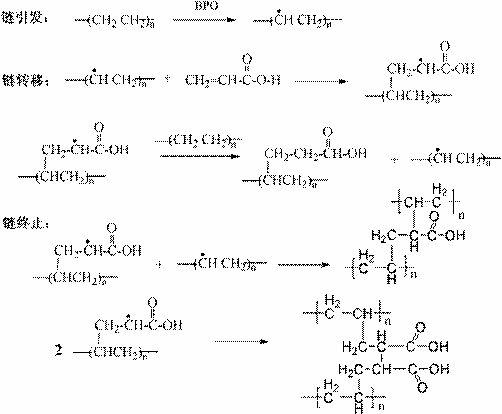

Preparation method and application of modified paraffin capable of being used for spontaneous emulsification

The invention discloses a preparation method and the application of modified paraffin capable of being used for spontaneous emulsification and is characterized in that the method comprises the following steps: a, the modified paraffin is synthesized; under nitrogen protection, 100 portions of No.70 paraffin and 2 to 20 portions of evocating agent are dissolved into a right amount of resolvent, 10 to 50 portions of polar monomer are required, and a reaction lasts for 1 to 3h at the temperature of 85 to 170 DEG C, so as to obtain coarse modified paraffin product, then coarse products are precipitated and separated through the resolvent, suction filtration and repeated washing are performed, and drying is performed until a constant weight is obtained, so as to obtain refined modified paraffin product; and b, spontaneous emulsification paraffin is prepared; and 100 portions of modified paraffin and 5 to 20 portions of emulsifier are melted and uniformly mixed at the temperature of 85 to 100 DEG C, and through cooling forming at room temperature, the spontaneous emulsification paraffin can be obtained. The preparation process of the modified paraffin is simple, and the grafting rate is higher, a paraffin emulsifiable solution prepared by the spontaneous emulsification paraffin has a better stability, is convenient to store and transport, and has a favorable popularization value.

Owner:GUANGDONG YINYANG ENVIRONMENT FRIENDLY NEW MATERIALS CO LTD

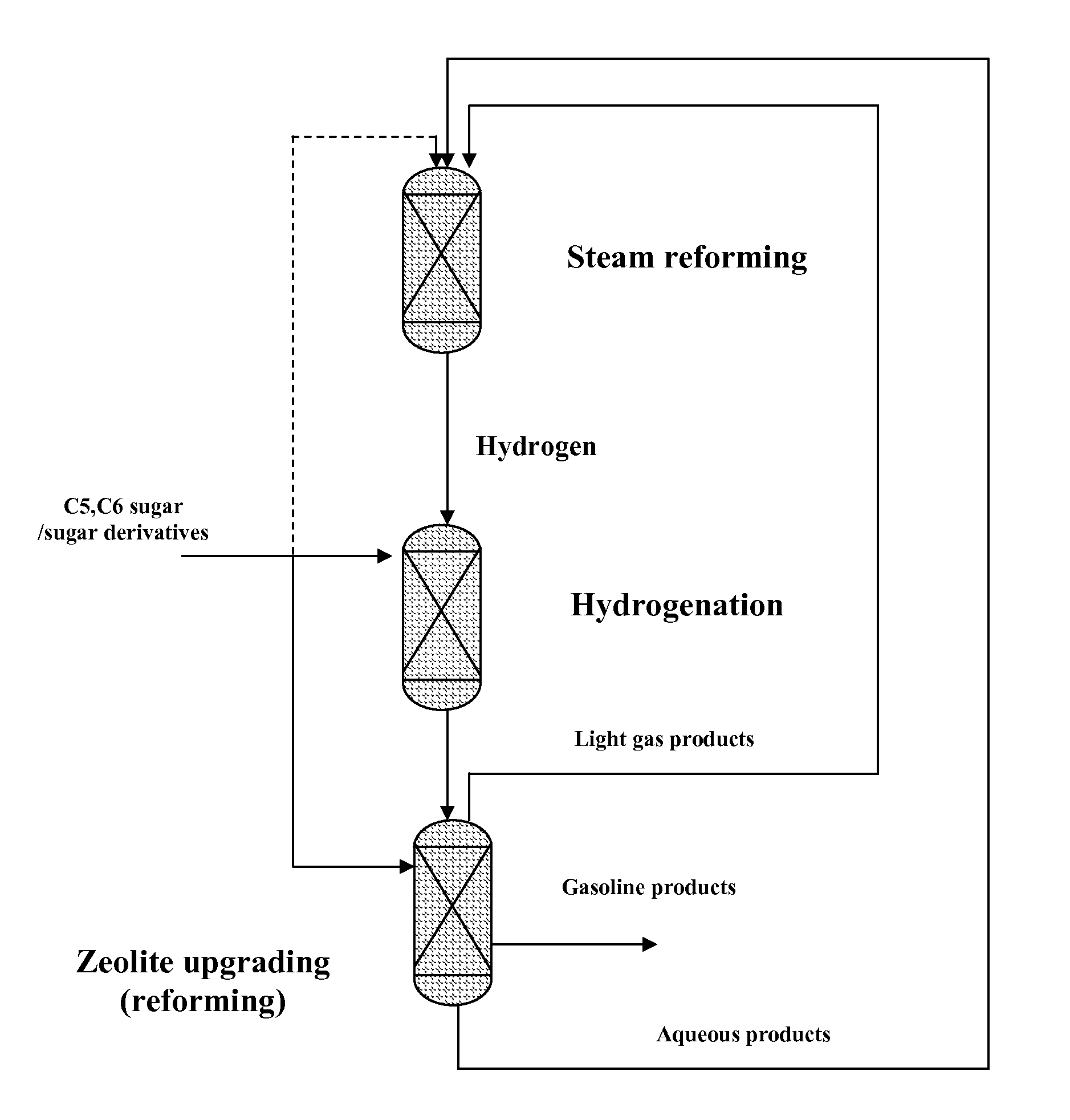

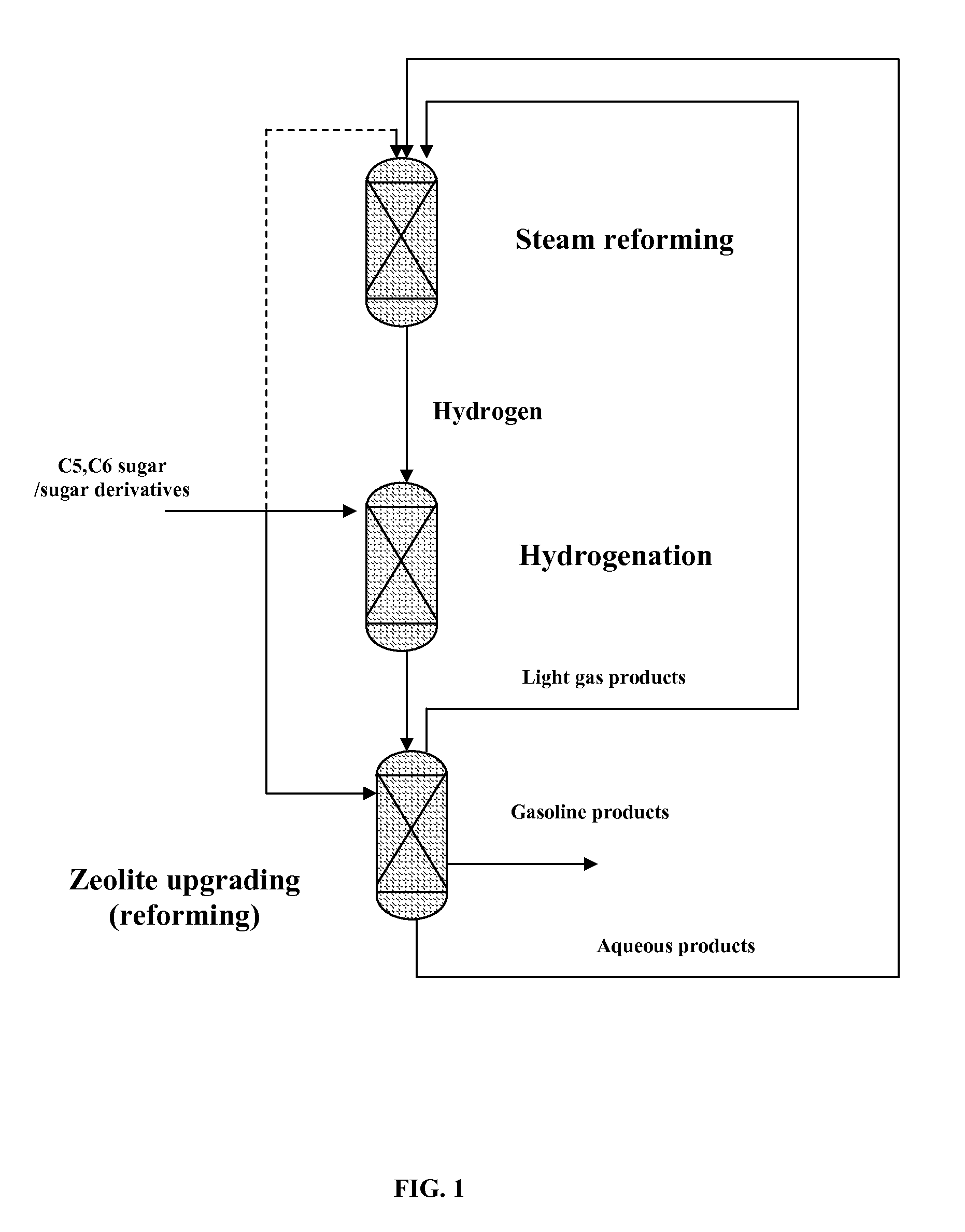

Combination of zeolite upgrading with hydrogenation upgrading to produce renewable gasoline from biomass

ActiveUS20120095274A1Low vapor pressureReduce cokingMolecular sieve catalystsRaney catalystAlkaneParaffin wax

Technologies to convert biomass to liquid hydrocarbon fuels are currently being developed to decrease our carbon footprint and increase use of renewable fuels. Since sugars / sugar derivatives from biomass have high oxygen content and low hydrogen content, coke becomes an issue during zeolite upgrading to liquid hydrocarbon fuels. A self-sustainable process was designed to reduce the coke by co-feeding sugars / sugar derivatives with the paraffin products from hydrogenation of sugars / sugar derivatives. Paraffins without complete conversion result in products with less aromatics and relatively low density compared with the products directly from zeolite upgrading. Thus, the process is more economically favorable.

Owner:PHILLIPS 66 CO

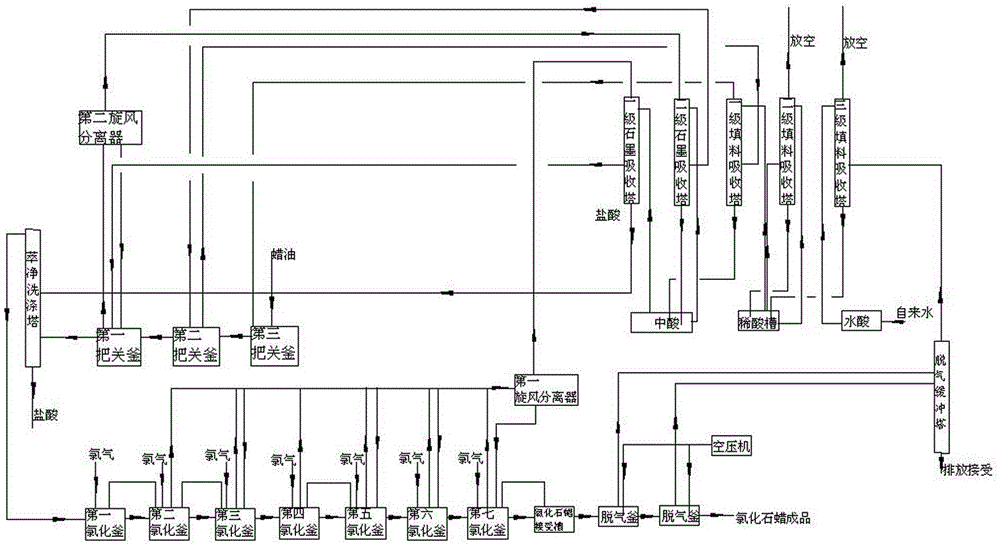

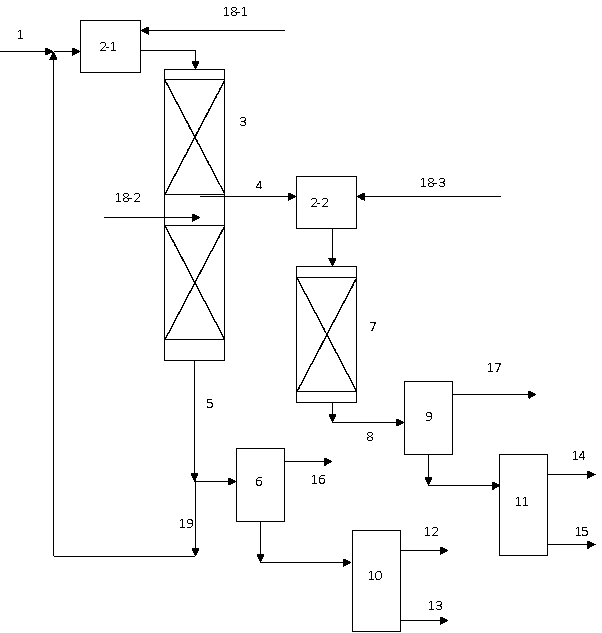

Processing technology for chlorinated paraffin

ActiveCN105296004ASimple processing technologyShort reaction timeDispersed particle separationHalogenated hydrocarbon preparationParaffin oilsEconomic benefits

The invention relates to a processing technology for chlorinated paraffin. A chlorinated paraffin product is obtained by using wax oil and chlorine as raw materials and adopting a seven-stage continuous photo-thermal catalytic chlorination process and a bubbling degassing technology. The processing technology for the chlorinated paraffin, which is disclosed by the invention, comprises the following steps of: liquid chlorine gasification, chlorination and chlorinated tail gas adsorption. The processing technology which is disclosed by the invention is simple, is short in reaction time, and is high in conversion rate; production cost is reduced; economic benefits of enterprises are increased.

Owner:江西塑星材料有限公司

Dual functional catalyst for selective opening of cyclic paraffins and process for using the catalyst

A process for selectively opening cyclic paraffins (naphthenic rings) with substantially no subsequent cracking of the acyclic product has been developed. The process comprises contacting a cyclic paraffin feedstream with a catalyst at ring opening conditions to produce an acyclic paraffin product. The catalyst comprises a Group VIII metal, such as platinum, a modifier component, such as niobium or ytterbium, a molecular sieve, such as UZM-16 and a refractory inorganic oxide such as alumina. The Group VIII metal and modifier component are preferably deposited on the refractory inorganic oxide.

Owner:UOP LLC

Phase-change paraffin preparation method

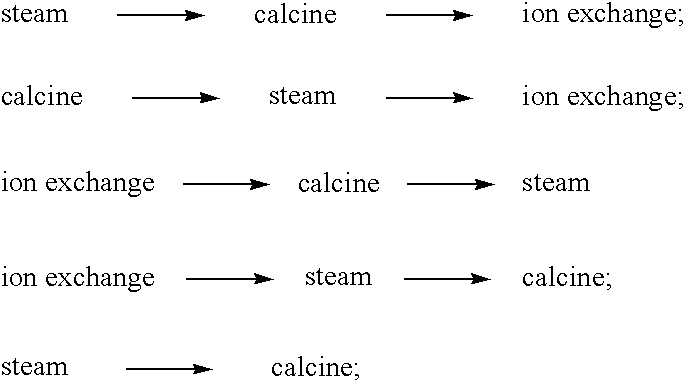

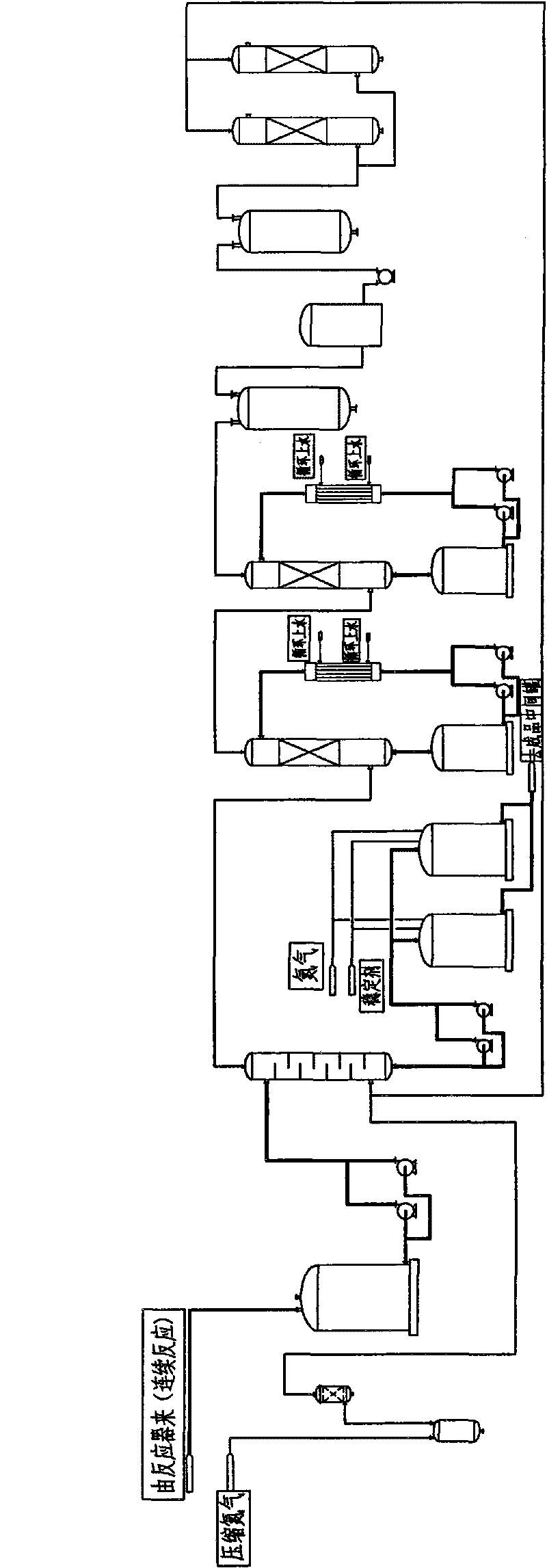

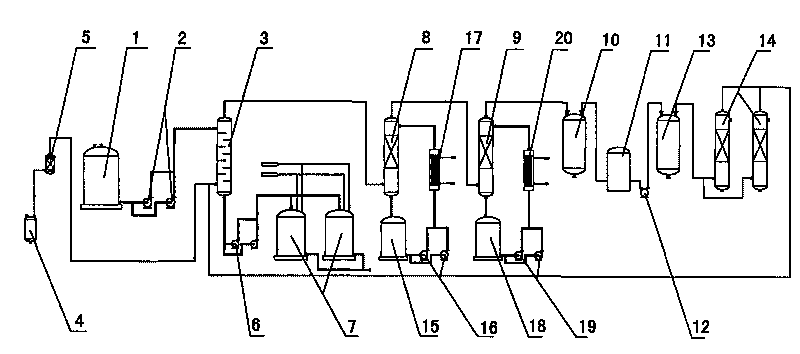

InactiveCN105505331AEfficient steam outReduce pollutionPetroleum wax refiningHeat-exchange elementsPhase change enthalpyHydrogenation reaction

The invention relates to a phase-change paraffin preparation method, and belongs to the technical field of pharmaceutical and chemical engineering. The phase-change paraffin preparation method is simple in technology; by means of the method, demand-based customized production can be achieved, waste can be reduced, cost can be lowered, and economic benefits can be effectively increased. According to the technical scheme, the phase-change paraffin preparation method includes the following steps that coal is subjected to gasification production to obtain synthesis feed gas, the feed gas is subjected to a Fischer-Tropsch synthesis reaction to obtain Fischer-Tropsch synthesis products, the Fischer-Tropsch synthesis products are subjected to a hydrogenation reaction to obtain a wide-fraction mixture, namely, Fischer-Tropsch synthesis paraffin, the Fischer-Tropsch synthesis paraffin is subjected to molecular short steaming and rectification to obtain refined paraffin products with different phase change enthalpy values, and NNO is added to obtain stable phase-change paraffin.

Owner:SHANXI LUAN COAL BASED SYNTHETIC OIL +1

Methods for producing linear alkylbenzenes, paraffins, and olefins from natural oils and kerosene

A method for producing a linear paraffin product from natural oil and kerosene includes providing a first feed stream comprising kerosene, pre-fractionating the first feed stream to produce a heart cut paraffin stream comprising paraffins in a heart cut range, and combining the heart cut paraffin stream with a second feed stream comprising natural oil to form a combined stream. The method further includes deoxygenating the natural oil and fractionating the combined stream to remove paraffins that are heavier than the heart cut range.

Owner:UOP LLC

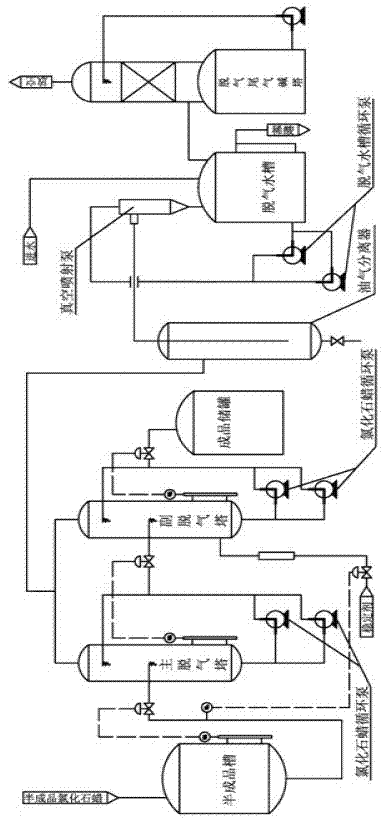

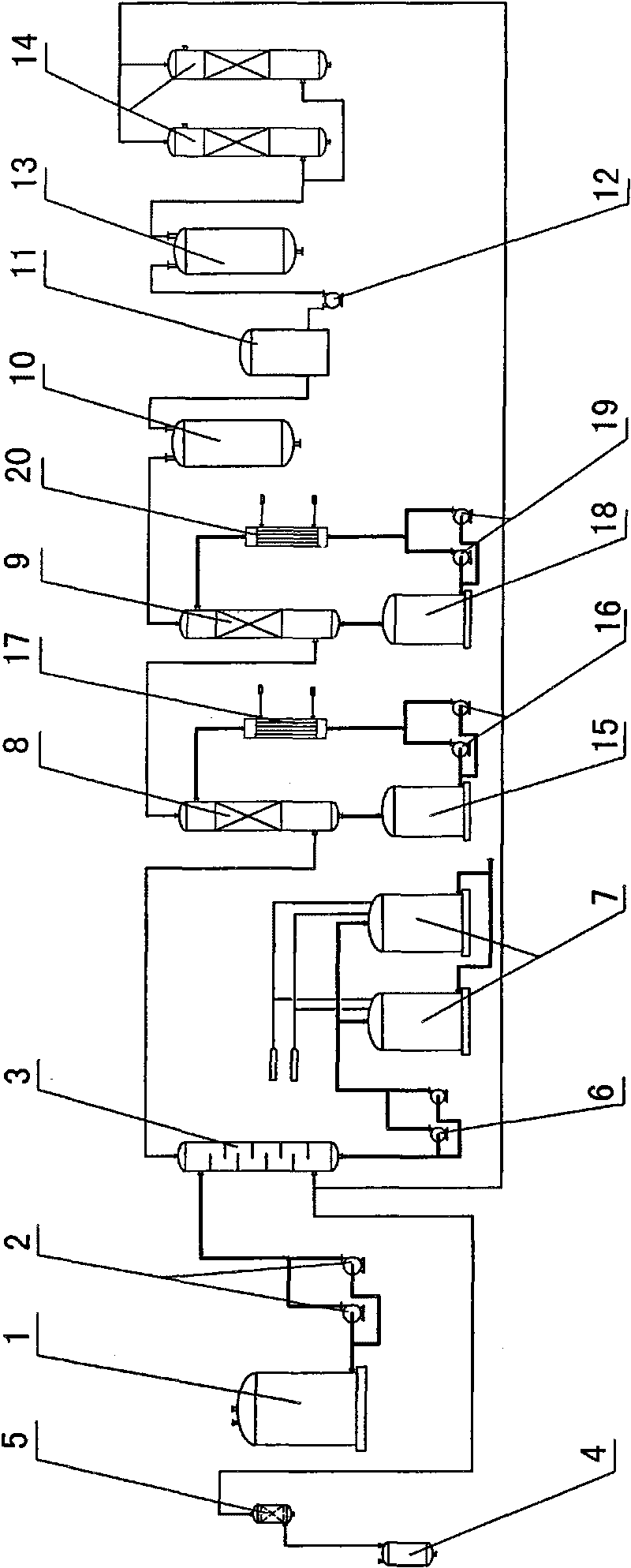

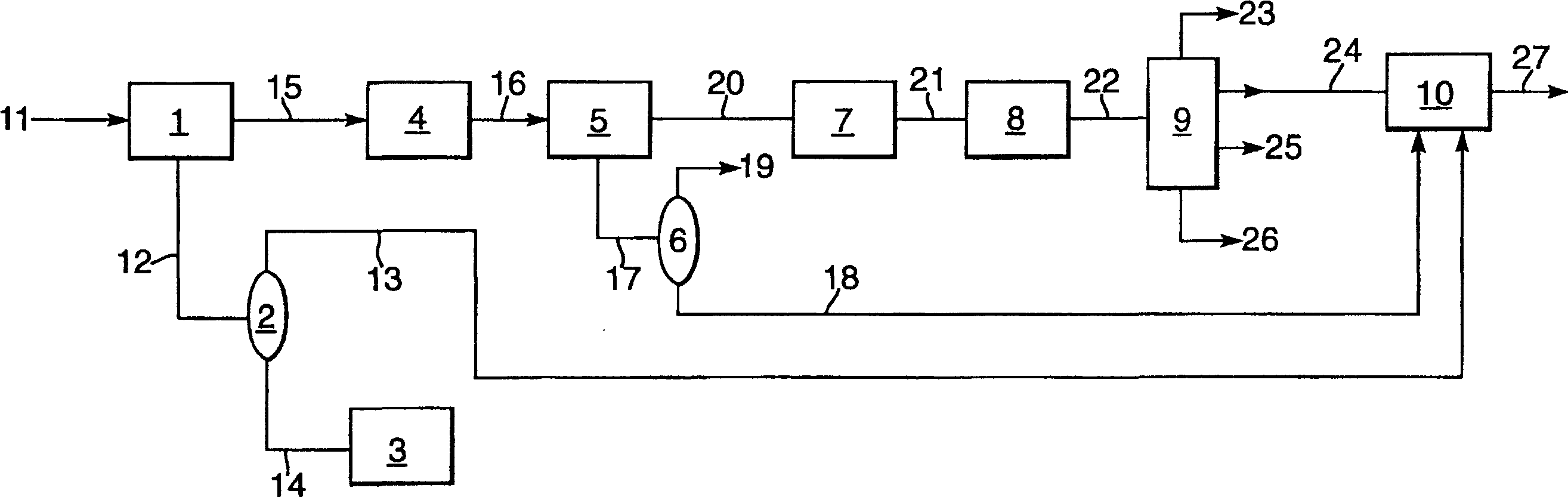

Continuous vacuum degassing process for chlorinated paraffin and device thereof

ActiveCN103170220AShort stayAutomatic addition is safe and environmentally friendlyDispersed particle separationPetroleum chemical modificationEnvironmental resistanceParaffin wax

The invention belongs to the technical field of fine chemical engineering, and relates to a continuous vacuum degassing process for chlorinated paraffin and a device thereof. A semi-finished chlorinated paraffin product is subjected to degassing refining through two degassing towers, namely, after the flow rate of the semi-finished chlorinated paraffin product is controlled by an automatic regulating valve, the semi-finished chlorinated paraffin product is sprayed out from the upper middle part of the main degassing tower, and under the action of vacuum, a large amount of chlorine and hydrogen chloride gas are egressed; after egressed chlorinated paraffin is pressurized by a circulating pump, one part of the chlorinated paraffin is fed into the upper part of the main degassing tower to carry out spray degassing, the other part of the chlorinated paraffin, after subjected to automatic flow-rate adjustment control, is fed into an assistant degassing tower, and through carrying out chlorine and hydrogen chloride gas egressing for twice, another part of the chlorinated paraffin, after subjected to flow-rate control through the automatic regulating valve, is fed into a finished product storage tank. According to the invention, the whole technological process is completely and automatically controlled, simple and convenient to operate, and large in treatment quantity. Compared with other processes, the process disclosed by the invention is low in energy consumption, the staying time of chlorine and hydrogen chloride gas in chlorinated paraffin is short; chlorinated paraffin is not in contact with other process mediums, so that the product quality can be improved; and a stabilizer is automatically added, so that an effect of safety and environmental friendliness is achieved.

Owner:江苏国威化工有限公司

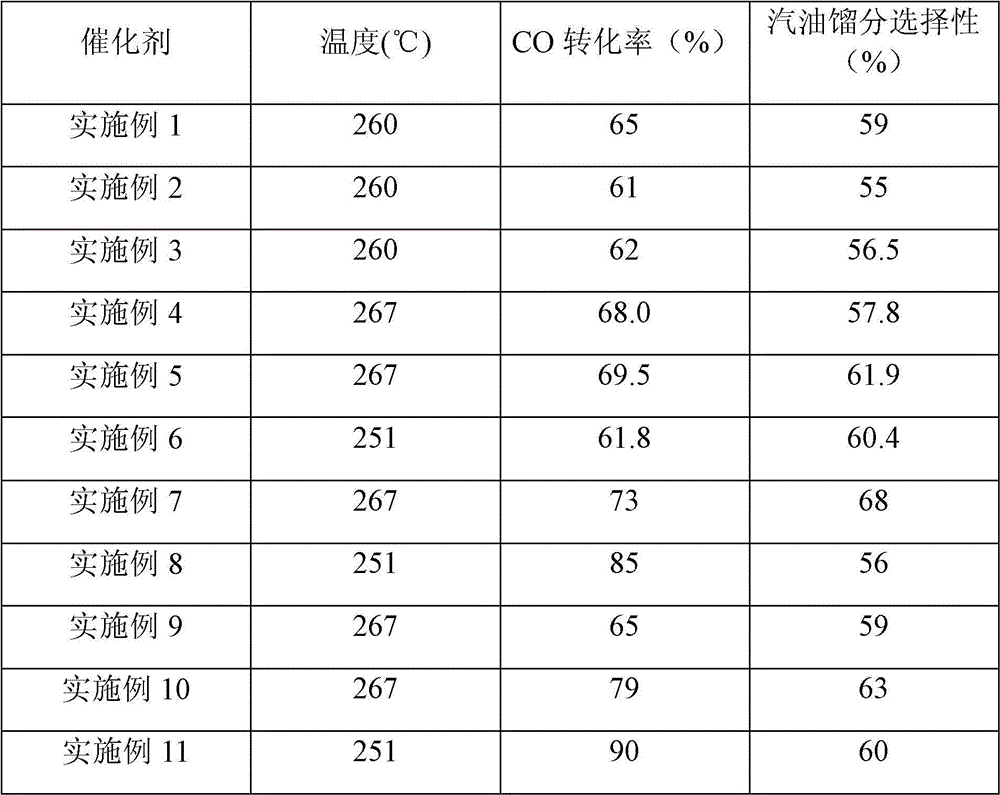

Catalyst for Fischer-Tropsch oriented synthesis for gasoline and method for preparing catalyst

ActiveCN102872905AUniform particlesUniform particle distributionMolecular sieve catalystsLiquid hydrocarbon mixture productionCarbon numberAlkane

The invention discloses a catalyst for Fischer-Tropsch oriented synthesis for gasoline. The catalyst comprises, by weight, from 10% to 50% of metallic cobalt, from 2% to 10% of auxiliaries and the balance molecular sieve carriers. The invention further discloses a method for preparing the catalyst for the Fischer-Tropsch oriented synthesis for the gasoline. The simple two-step impregnation method includes impregnating cobalt salt and auxiliary elements onto the untreated molecular sieve carriers. The method is simple and convenient, and cost is low. The prepared catalyst for Fischer-Tropsch synthetic reaction is high in selectivity to hydrocarbon gasoline fraction with the carbon number ranging from 5 to 12, and the content of isoparaffin is increased. Besides, a product does not contain paraffin products with high carbon numbers, so that a follow-up paraffin catalytic cracking device and the like can be omitted, problems of pipeline blockage and the like are solved, and investment cost and running cost of the devices can be effectively reduced.

Owner:ZHEJIANG UNIV

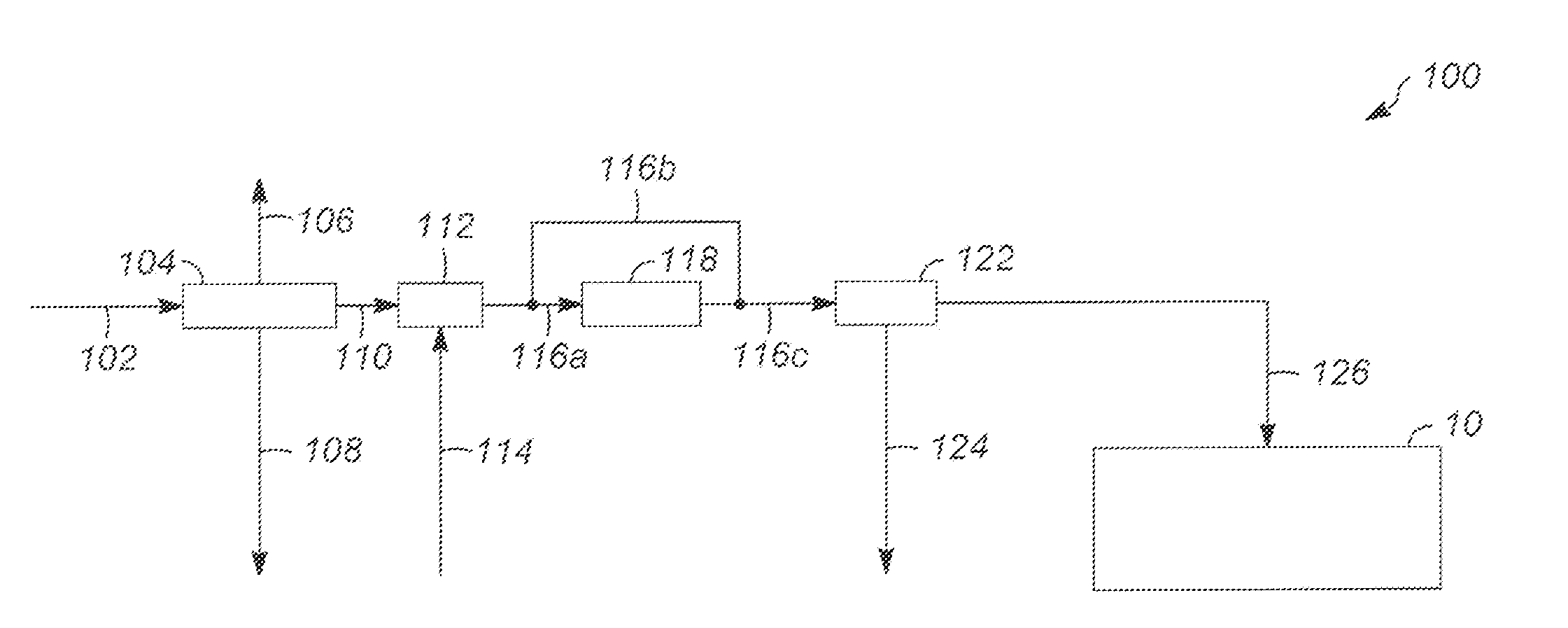

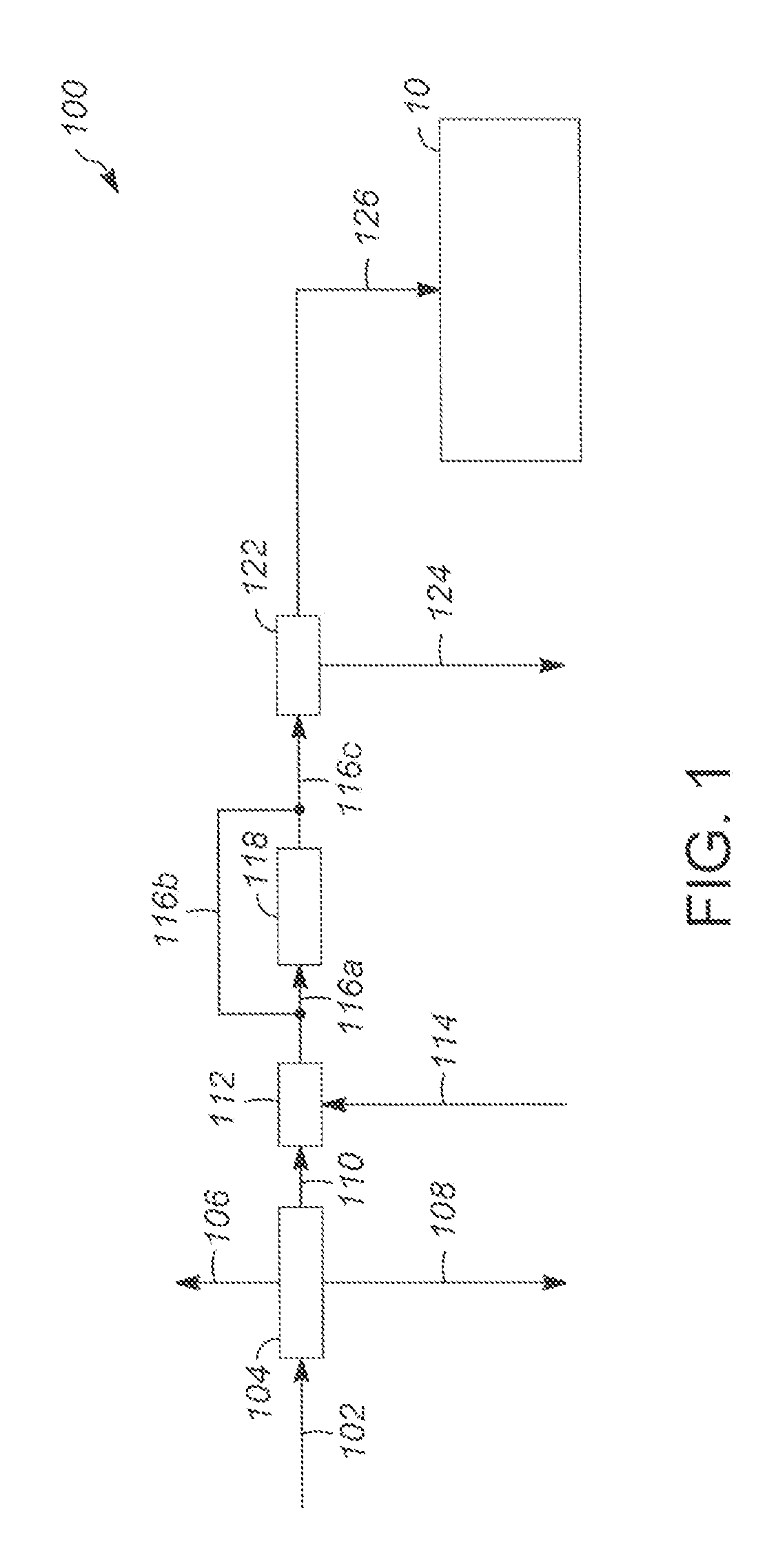

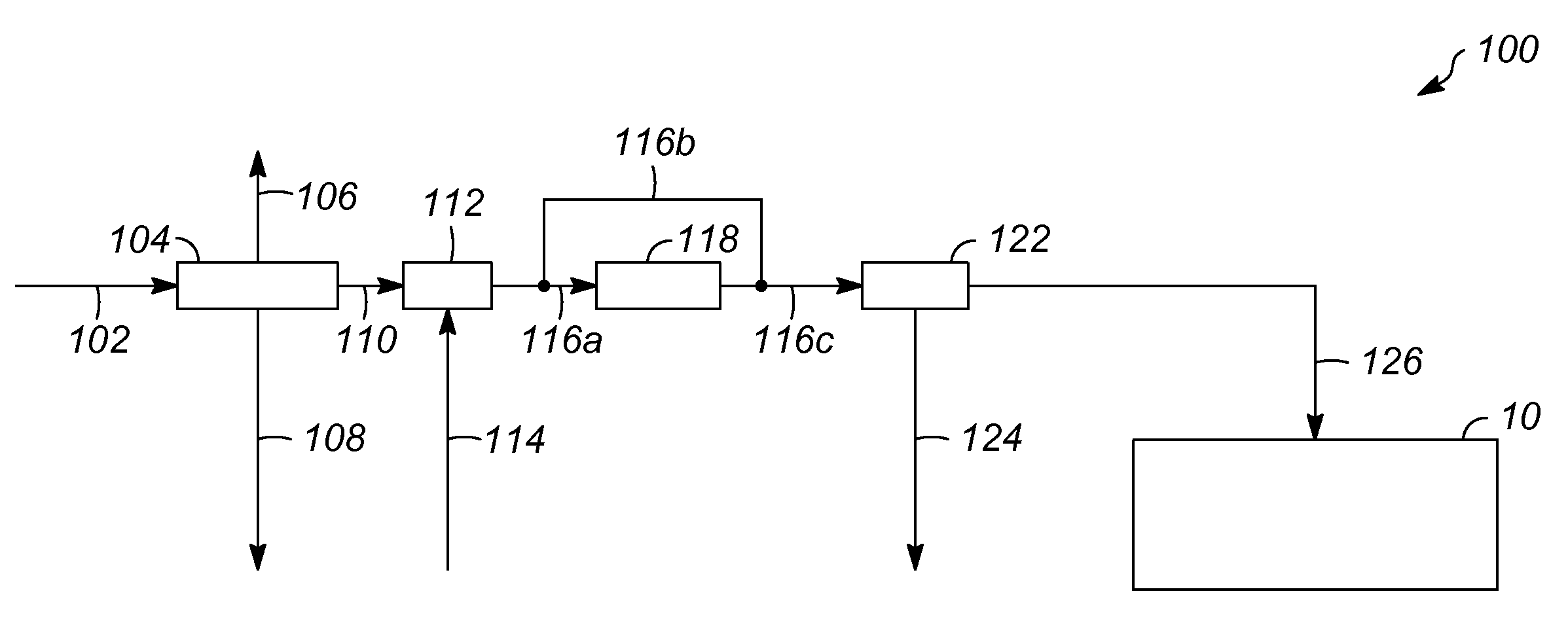

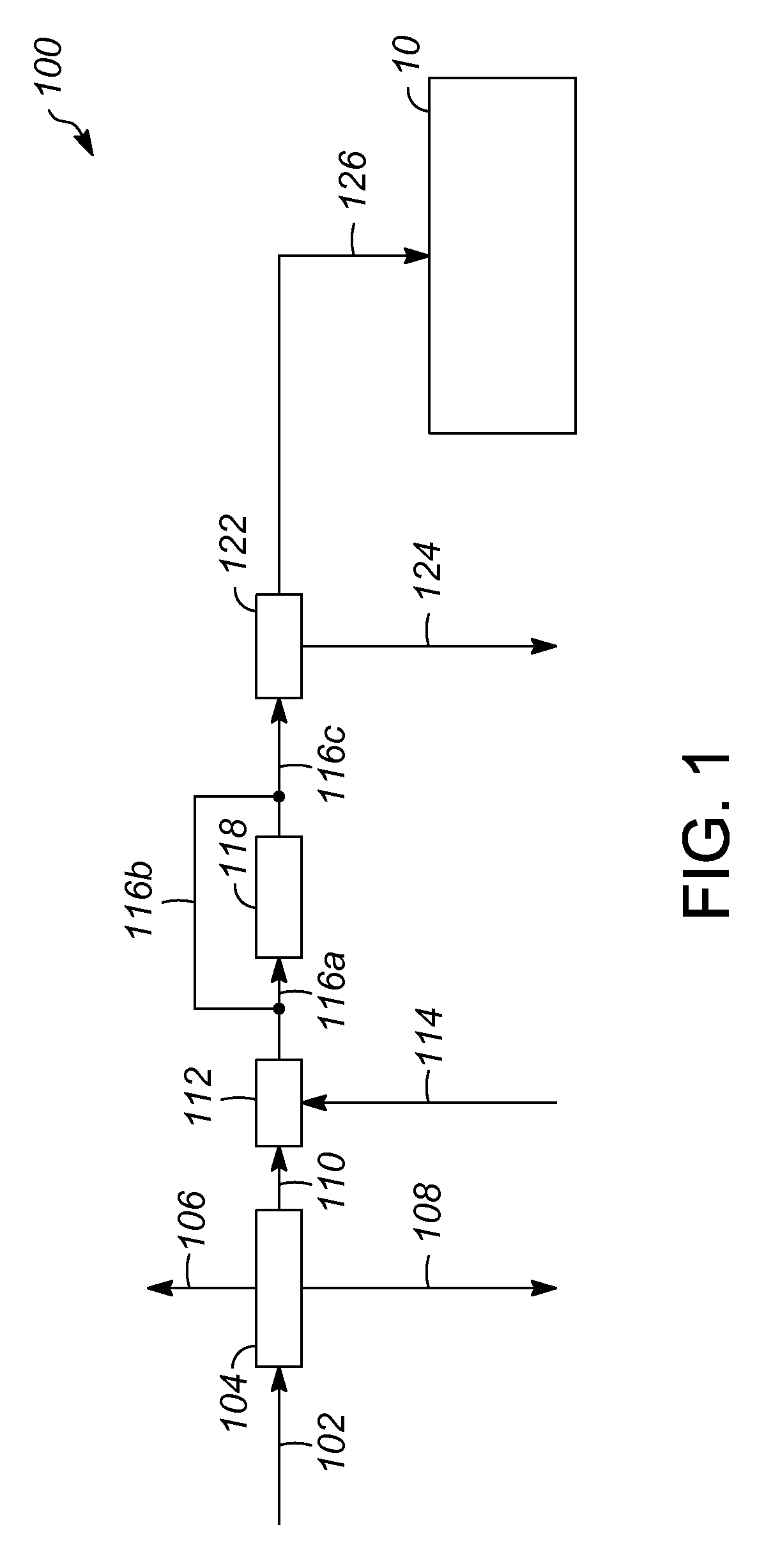

Methods for producing linear alkylbenzenes, paraffins, and olefins from natural oils and kerosene

ActiveUS20130253240A1Distillation purification/separationHydrocarbon from oxygen organic compoundsParaffin waxKerosene

A method for producing a linear paraffin product from natural oil and kerosene includes providing a first feed stream comprising kerosene, pre-fractionating the first feed stream to produce a heart cut paraffin stream comprising paraffins in a heart cut range, and combining the heart cut paraffin stream with a second feed stream comprising natural oil to form a combined stream. The method further includes deoxygenating the natural oil and fractionating the combined stream to remove paraffins that are heavier than the heart cut range.

Owner:UOP LLC

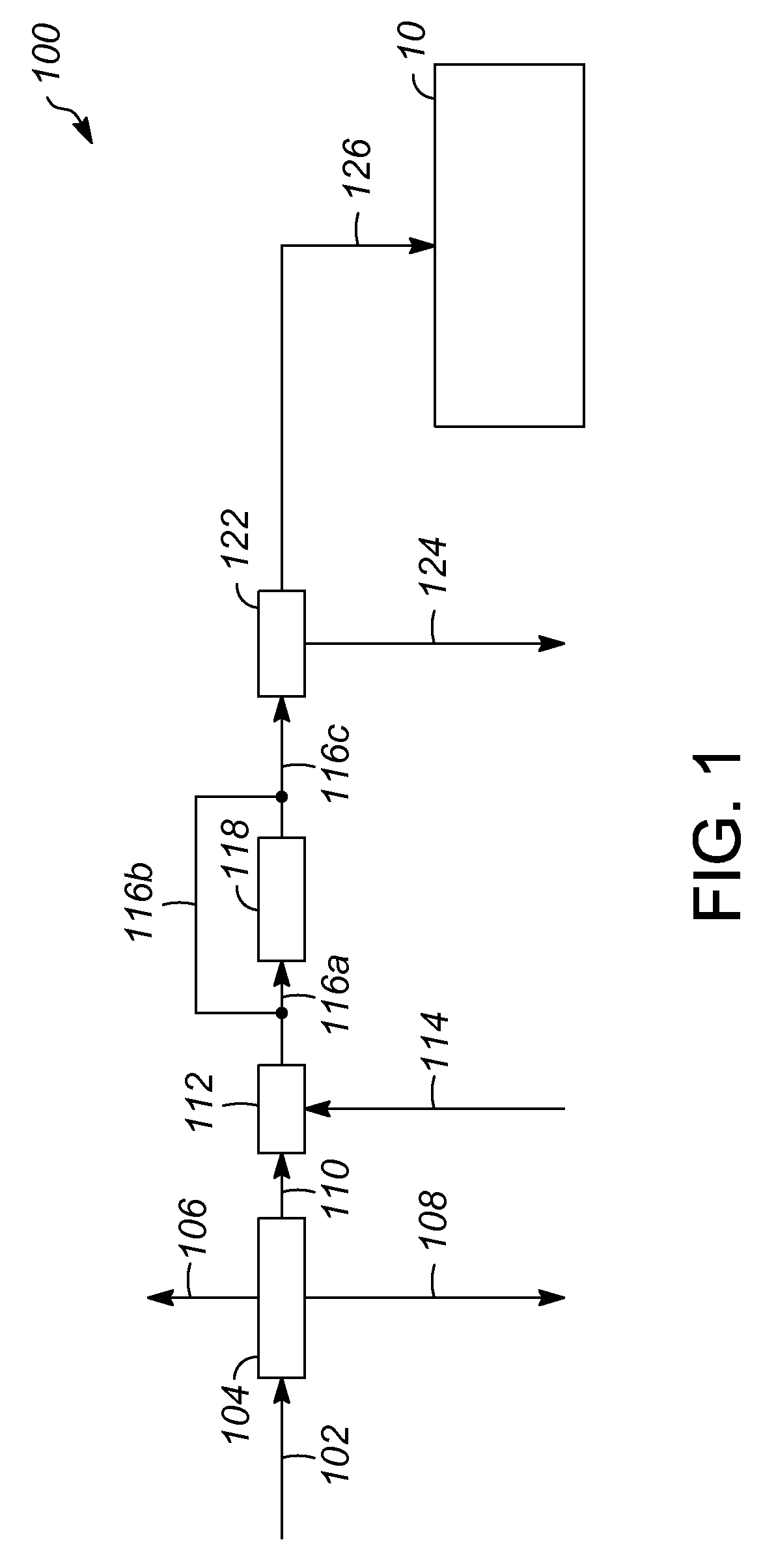

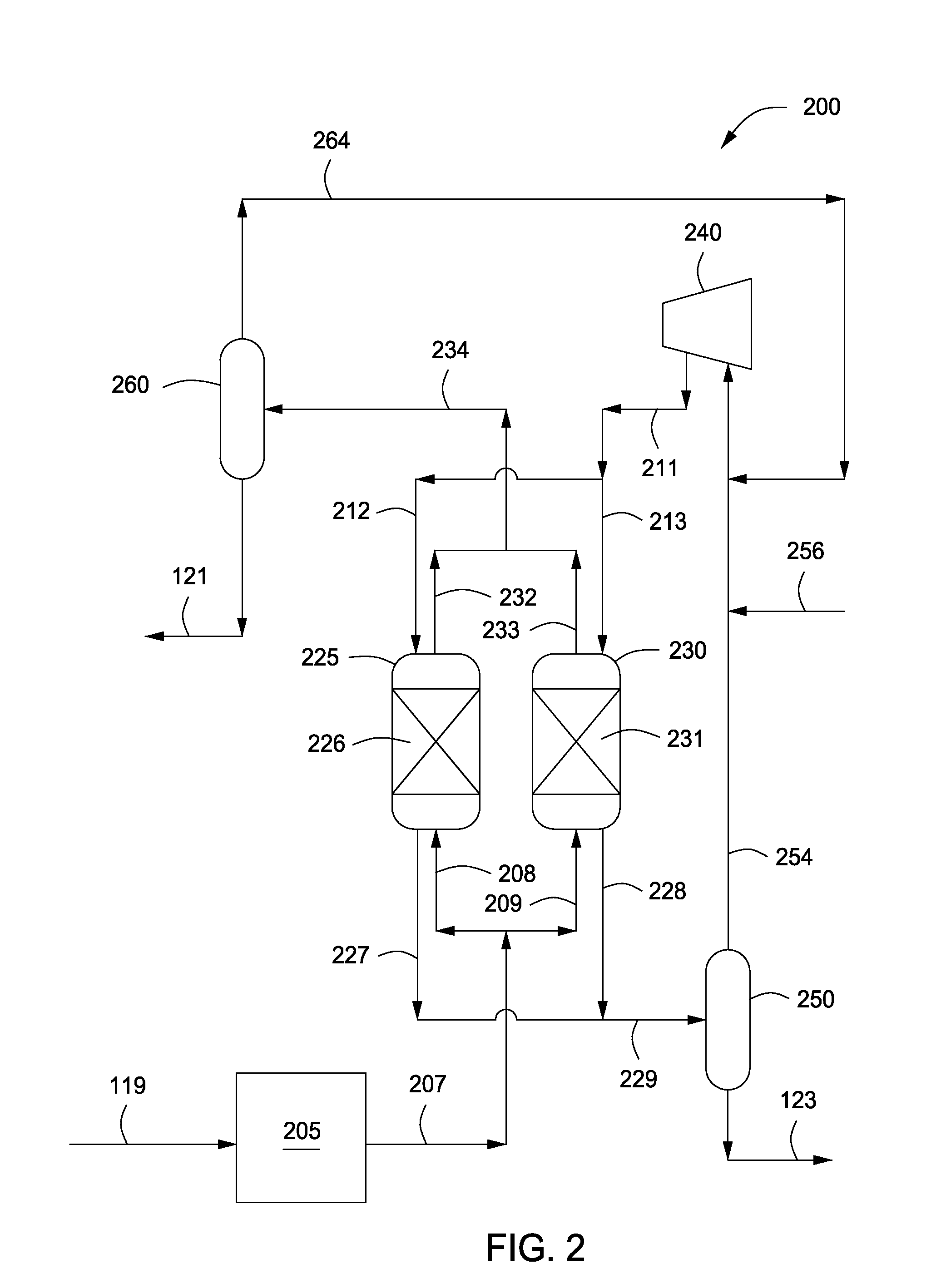

Systems and Methods for Producing N-Paraffins From Low Value Feedstocks

InactiveUS20100116711A1Treatment with hydrotreatment processesHydrocarbon oils refiningAlkaneKerosene

Systems and methods for producing n-paraffins are provided. The method can include hydroprocessing at least a portion of a kerosene fraction recovered from a thermally cracked hydrocarbon product to produce a hydroprocessed kerosene product comprising n-paraffins. The n-paraffins can be separated from the hydroprocessed kerosene product to produce an n-paraffins product.

Owner:KELLOGG BROWN & ROOT LLC

Method for recycling paraffin from polytetrafluoroethylene resin kettle-cleaning material

ActiveCN108239299AGuaranteed washing qualityEasy to controlPetroleum wax refiningPlastic recyclingParaffin waxParaffin oils

The invention provides a method for recycling paraffin from a polytetrafluoroethylene resin kettle-cleaning material. The method comprises the following steps: (1) adding the polytetrafluoroethylene resin kettle-cleaning material and water into a reaction kettle, heating until the polytetrafluoroethylene resin kettle-cleaning material is melted, and stirring, so as to finish washing; (2) standingthe washed material in the kettle for layering, adding a rough paraffin mixture on an upper layer into a dryer, and drying for dehydration; and (3) filtering: filtering the material dried and dehydrated in the step (2), so as to obtain paraffin. Separated polytetrafluoroethylene resin can be used as a common industrial product and can be widely applied to various fields and emerging industries innational economy, and the separated paraffin can be used as a civilian product. The method is applied to the recycling of paraffin from the kettle-cleaning material in the production process of the polytetrafluoroethylene resin and has the characteristics that the process is simple, the control is easy, and the purity of the paraffin product is high, and the like.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

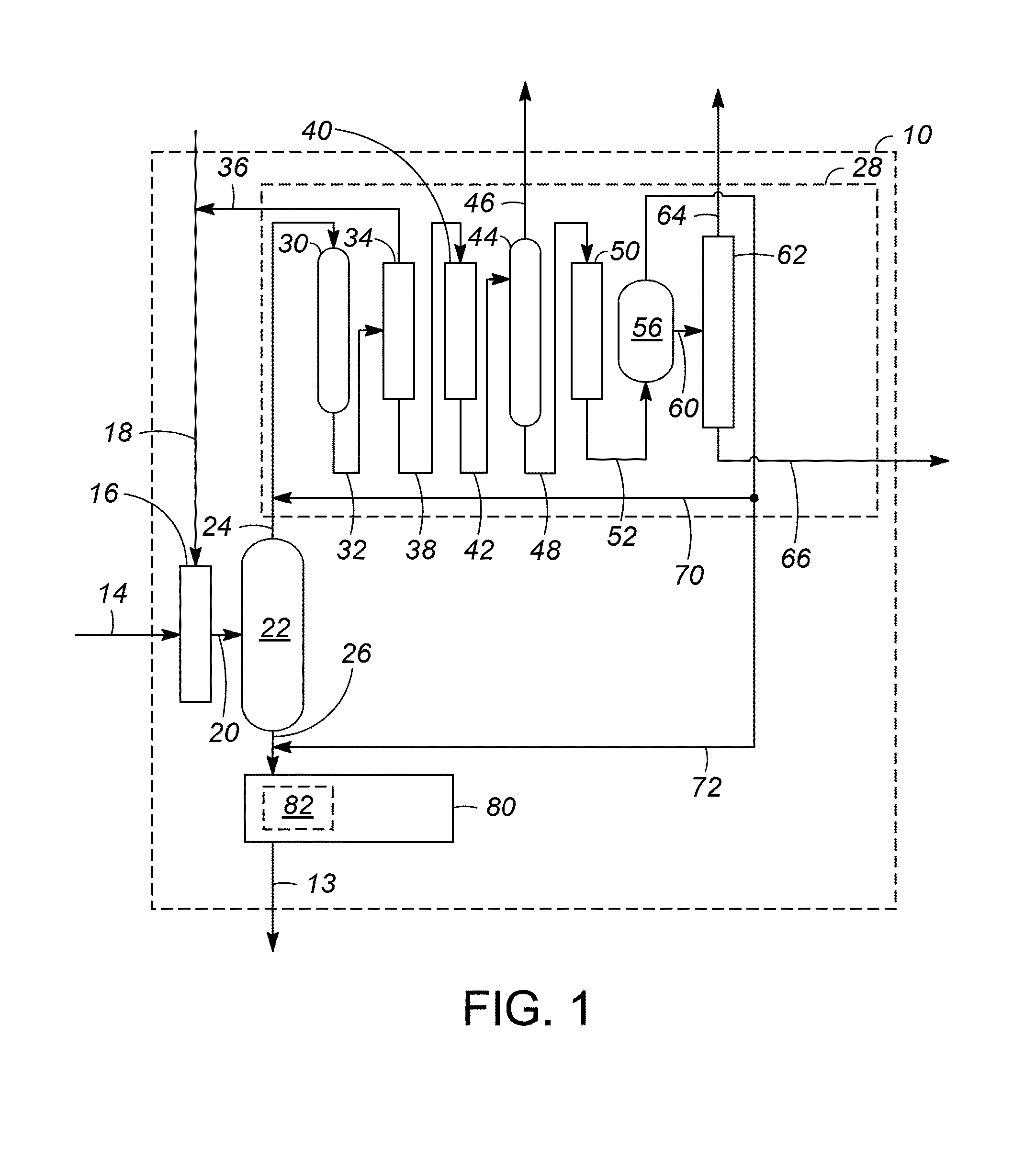

Methods for producing linear paraffins and olefins from natural oils

InactiveUS20130253243A1Hydrocarbon from oxygen organic compoundsLiquid hydrocarbon mixture productionAlkaneParaffin wax

A method for producing a linear paraffin includes providing a natural oil in a feed stream, deoxygenating the natural oil to form a stream comprising paraffins, purifying the stream comprising paraffins to form a purified stream comprising paraffins, and separating a first fraction of paraffin product from the purified stream comprising paraffins. A method for producing a linear olefin includes providing a natural oil in a feed stream, deoxygenating the natural oil to form a stream comprising paraffins, dehydrogenating the stream comprising paraffins to form a stream comprising olefins, purifying the stream comprising olefins to form a purified stream comprising olefins, and separating a first fraction of olefin product from the purified stream comprising olefins.

Owner:UOP LLC

Granule-based wax sweating method

ActiveCN109810725AIncrease heat transfer areaIncreased flow poresPetroleum wax recoveryParaffin waxWarm water

A granule-based wax sweating method comprises the following steps: (1) filling water to the bottom part of a sweating device; (2) heating paraffin to a liquid state, adding sweating granules, and thenadding the mixture in the sweating device; (3) cooling the paraffin to be 10 to 20 DEG C lower than a melting point at the speed of 1 to 4 DEG C / h; (4) releasing the water, pumping warm water to a sweating tank, heating at the speed of 0.5 to 2 DEG C / h, and collecting the paraffin which can sweat at different melting points; (5) melting the paraffin after finishing heating, and enabling a moltenhigh-melting-point paraffin product to flow into an intermediate tank; (6) blowing residual sweating granules and the last one distillate in the sweating tank by using steam, filtering and separatingthe sweating granules and the distillate, and recycling the sweating granules. According to the granule-based wax sweating method disclosed by the invention, the compaction density of sweating raw materials is reduced, outflow of oil content and low-melting-point wax can be facilitated, the fluidity of sweating liquid is improved, and the separation effect is multiplied; meanwhile, the yield of asweating product is higher, a wax melting range is narrower, a wax product is concentrated in molecular weight, and the enthalpy value of a product is higher.

Owner:上海焦耳蜡业有限公司

N-paraffin selective hydroconversion process using borosilicate ZSM-48 molecular sieves

ActiveUS20110100872A1Reduce molecular weightMolecular sieve catalystsCatalyst activation/preparationAlkaneMolecular sieve

The present invention is directed to processes using a borosilicate ZSM-48 as a catalyst for the selective hydroconversion of heavy normal paraffins into lighter normal paraffin products, with minimal formation of isoparaffins. The borosilicate ZSM-48 molecular sieve has a mole ratio of between 40 and 400 of silicon oxide to boron oxide, synthesized using novel structure directing agents.

Owner:CHEVROU USA INC

Continuous stripping process and device for chlorinated paraffin

ActiveCN101760242AIncrease profitAchieve recyclingPetroleum chemical modificationBuffer tankWater vapor

The invention discloses a continuous stripping process for chlorinated paraffin, which comprises the following steps: transferring coarse chlorinated paraffin into a chlorinated paraffin buffer tank and delivering the coarse chlorinated paraffin to a chlorinated paraffin stripping tower to perform stripping by the nitrogen; delivering the chlorinated paraffin to a chlorinated paraffin intermediate tank, adding a stabilizer to perform mixing treatment, and delivering the treated chlorinated paraffin to a finished product intermediate tank; after the stripping, delivering the nitrogen to an acidic filter tower and an alkaline tower to allow the nitrogen to be absorbed; and delivering the nitrogen to a nitrogen drying tower to dry the nitrogen. The invention also discloses a continuous stripping device for chlorinated paraffin, which comprises the chlorinated paraffin buffer tank, a chlorinated paraffin intermediate pump, a chlorinated paraffin stripping tower, a chlorinated paraffin stripping pump, the chlorinated paraffin intermediate tank, the acidic filer tower, the alkaline filter tower, an alkaline vapor capturer, a nitrogen gas cabinet, a nitrogen compressor, a water vapor capturer, the nitrogen drying tower and the like. The process and method can perform continuous modification for refining the chlorinated paraffin product, improve the automation of production, realize the recycling of the nitrogen and improve the utilization rate of energy.

Owner:LUXI IND EQUIP

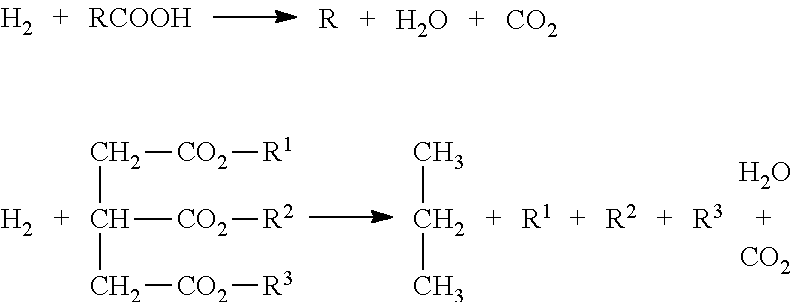

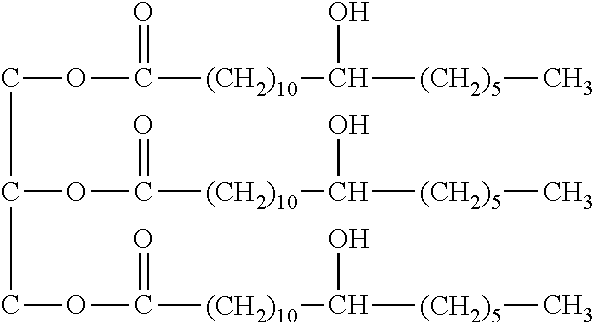

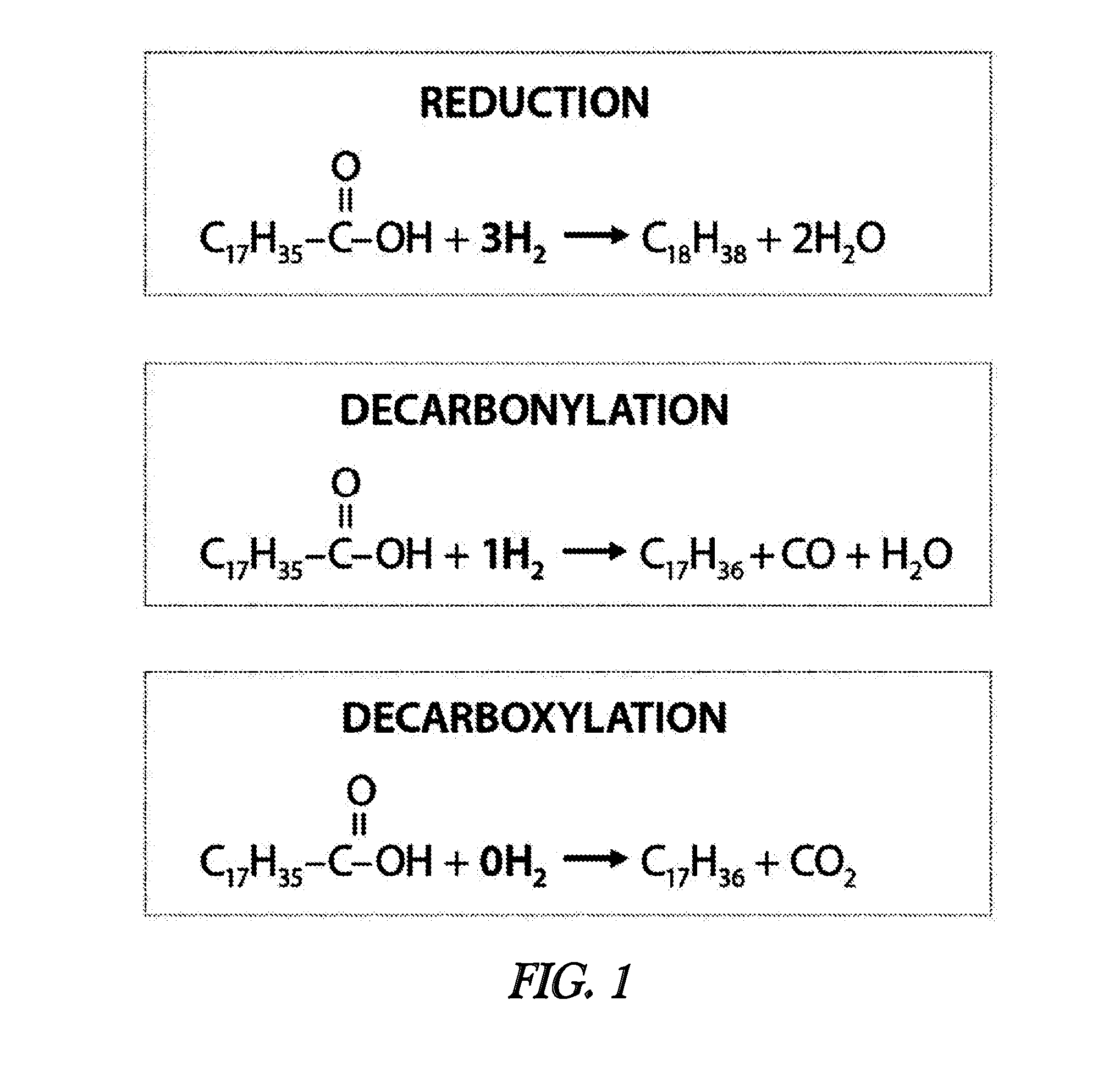

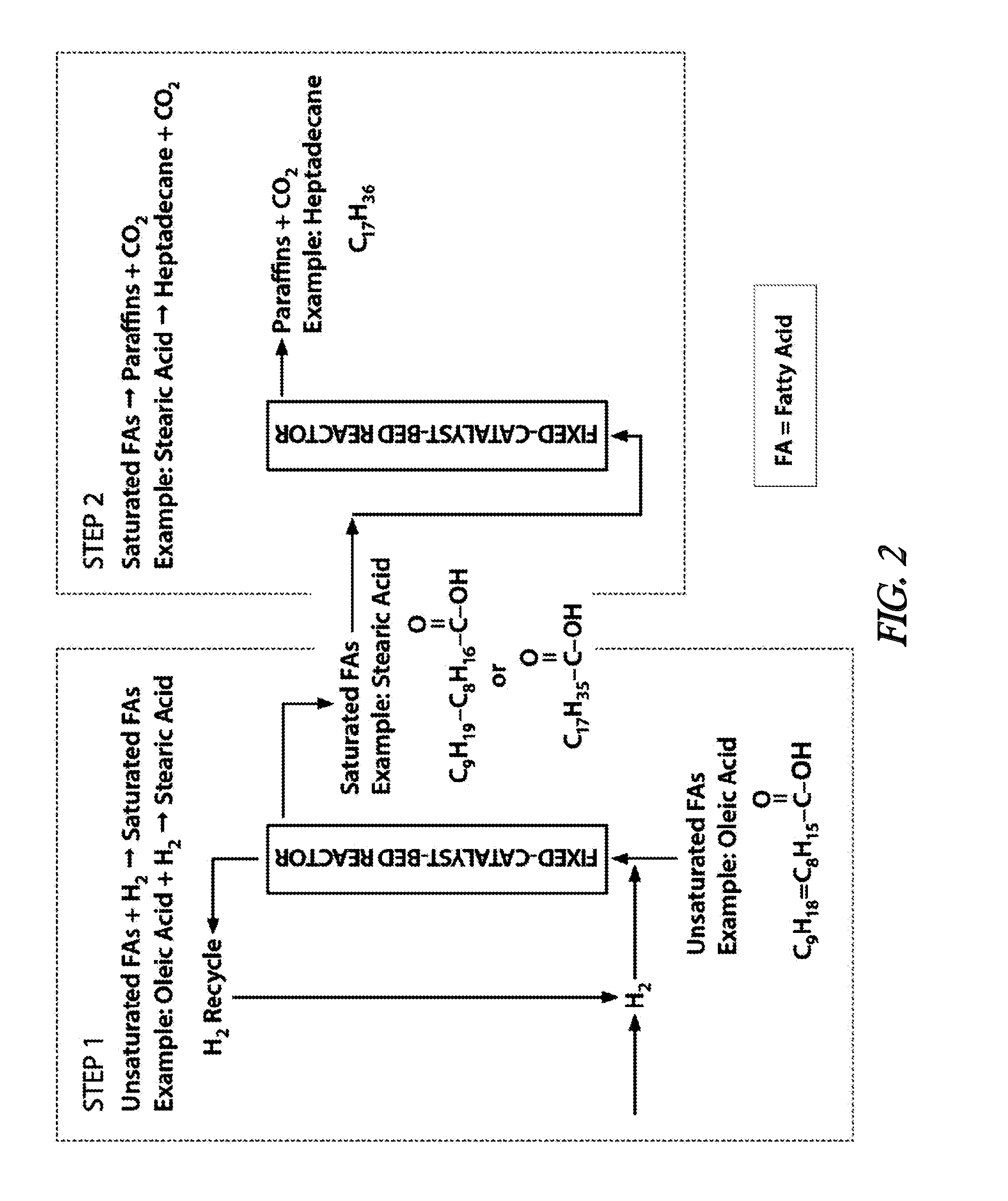

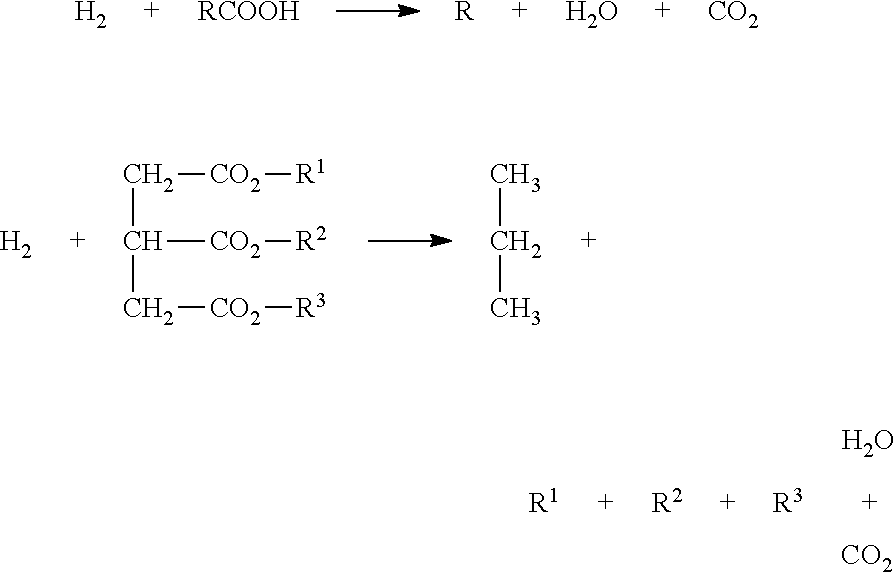

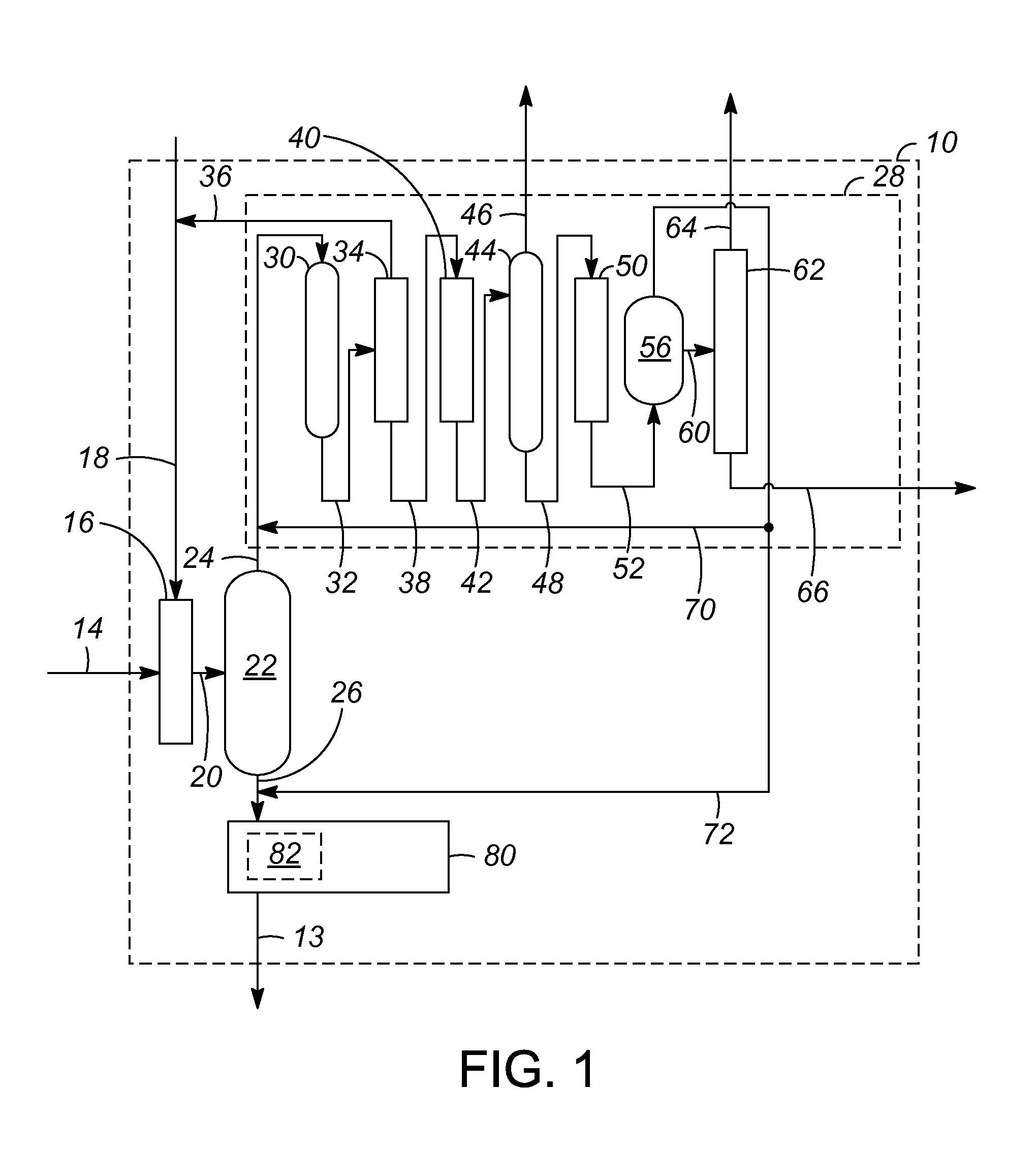

Process for low-hydrogen-consumption conversion of renewable feedstocks to alkanes

A process relating to the manufacture of hydrocarbons, particularly paraffins / alkanes, from fatty acid feedstocks. More specifically, a process relating to the manufacture of paraffins / alkanes from fatty acid feedstocks comprising an olefinic bond saturation followed by a deoxygenation process carried out using decarboxylation achieving a maximum feedstock conversion to a paraffin product while consuming a minimum amount of hydrogen.

Owner:ENERGY & ENVIRONMENTAL RES CENT FOUNDATIO

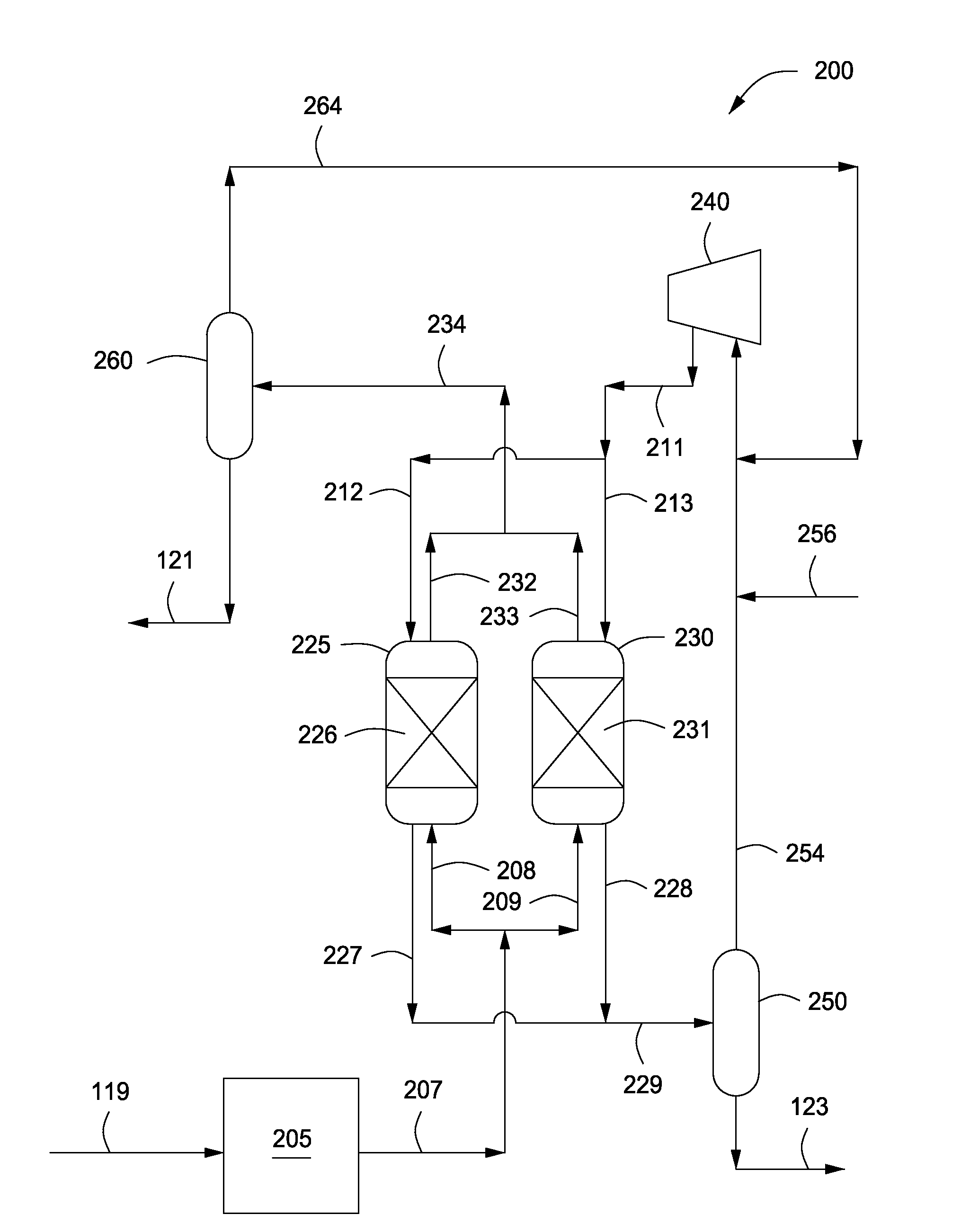

Methods for producing linear alkylbenzenes, paraffins, and olefins from natural oils and kerosene

InactiveUS20130253241A1Distillation purification/separationHydrocarbon from oxygen organic compoundsParaffin waxKerosene

A method for producing a linear paraffin product from natural oil and kerosene includes providing a first feed stream comprising kerosene, pre-fractionating the first feed stream to produce a heart cut paraffin stream comprising paraffins in a heart cut range, and combining the heart cut paraffin stream with a second feed stream comprising natural oil to form a combined stream. The method further includes deoxygenating the natural oil and fractionating the combined stream to remove paraffins that are heavier than the heart cut range.

Owner:UOP LLC

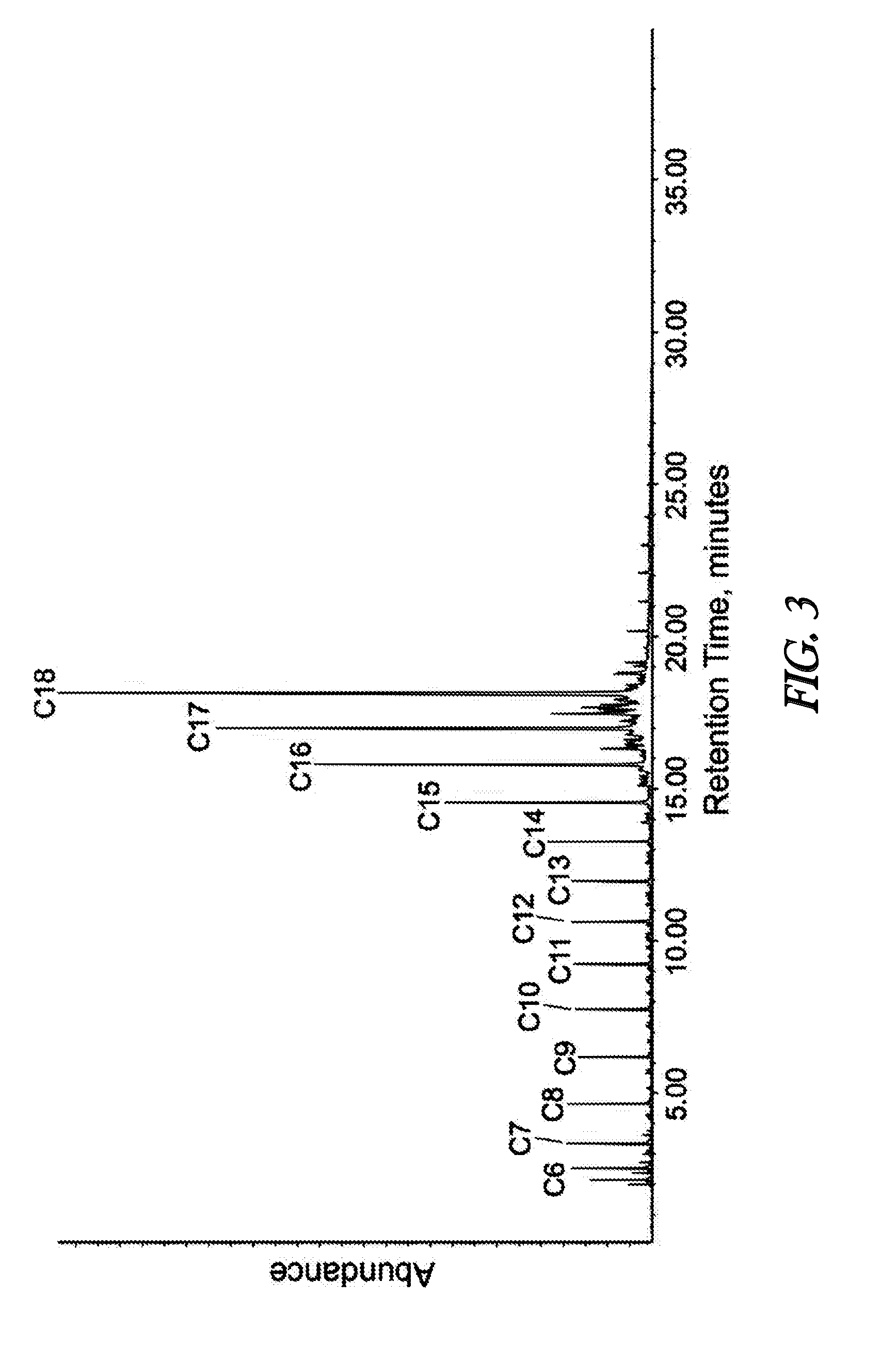

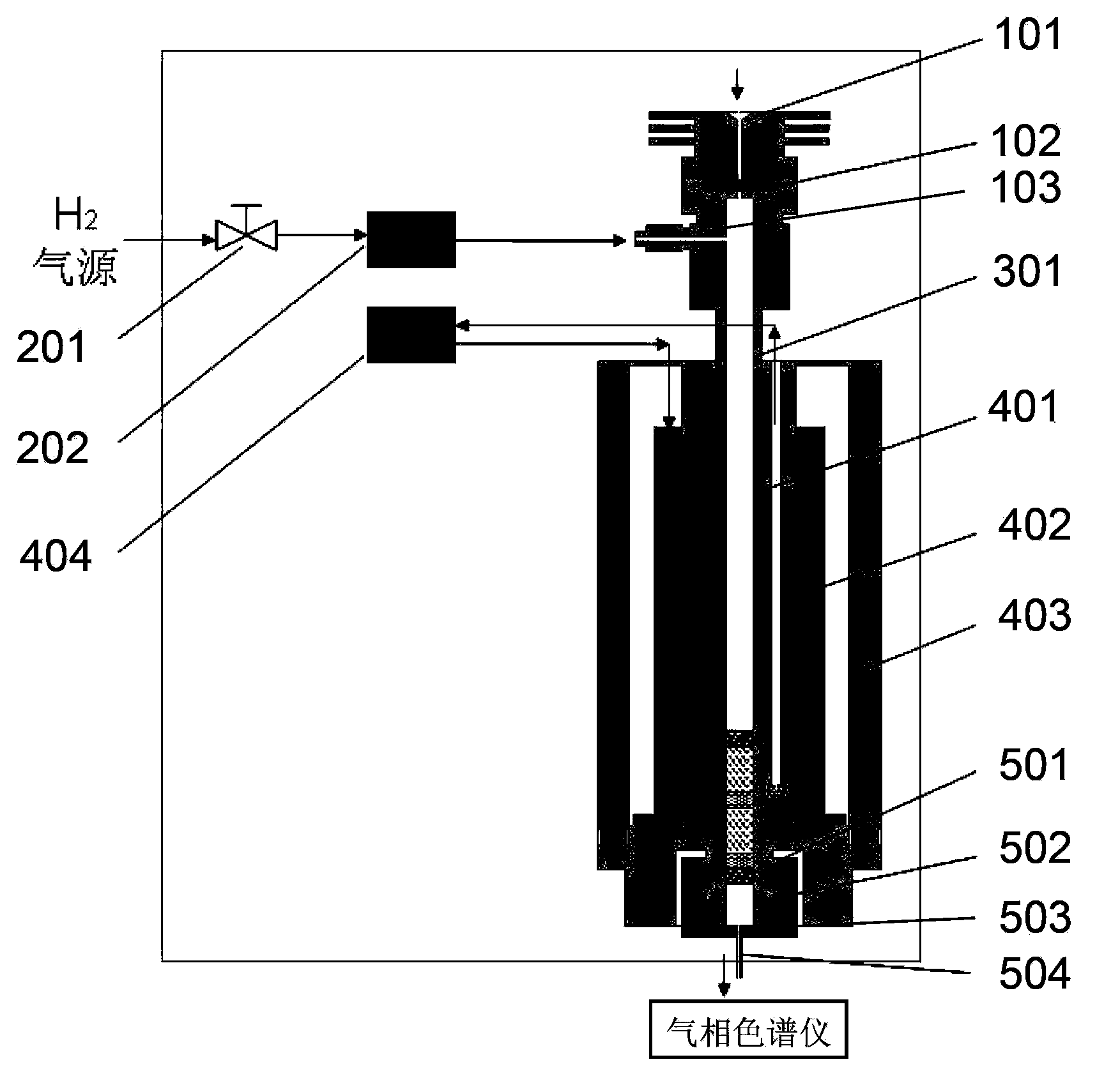

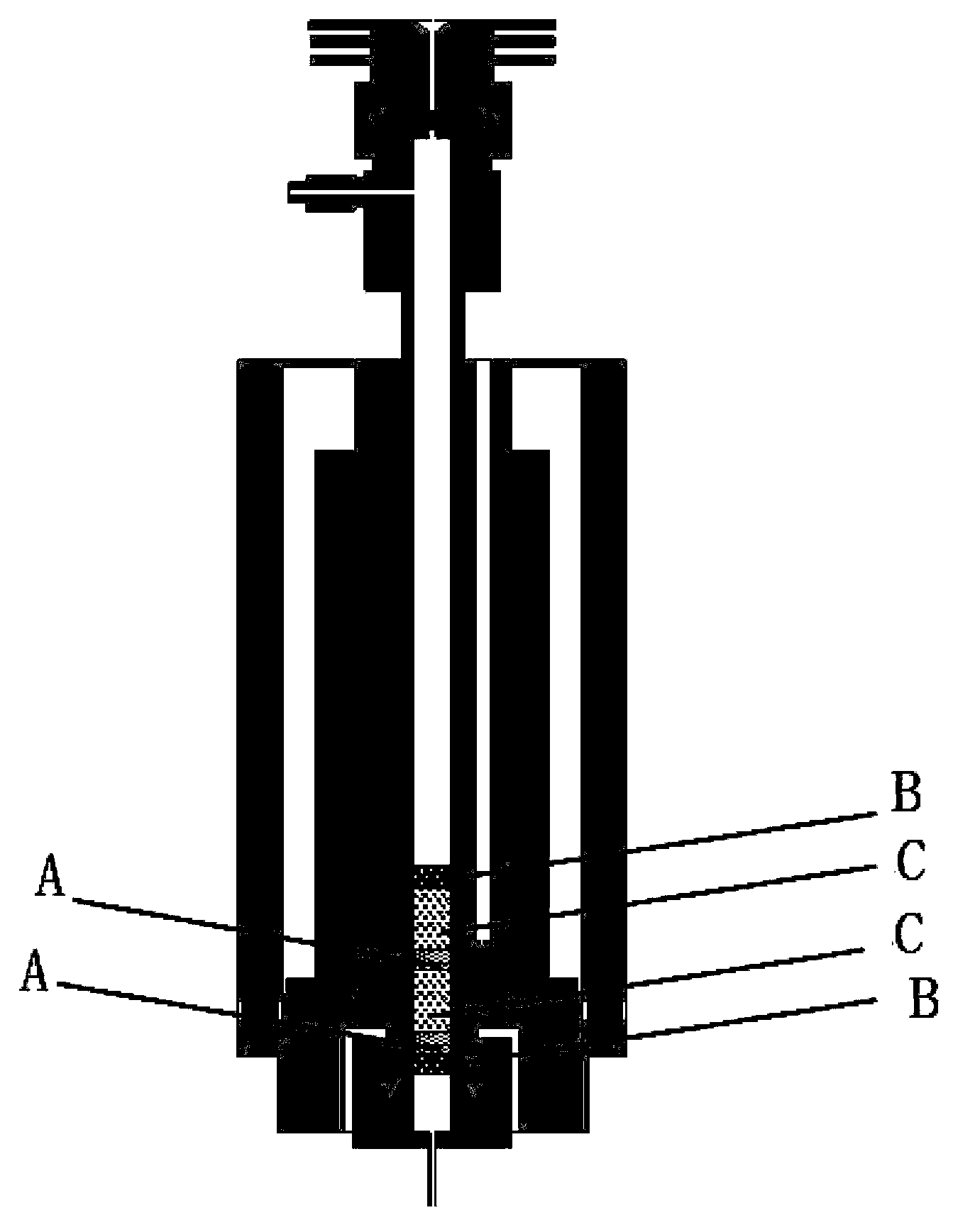

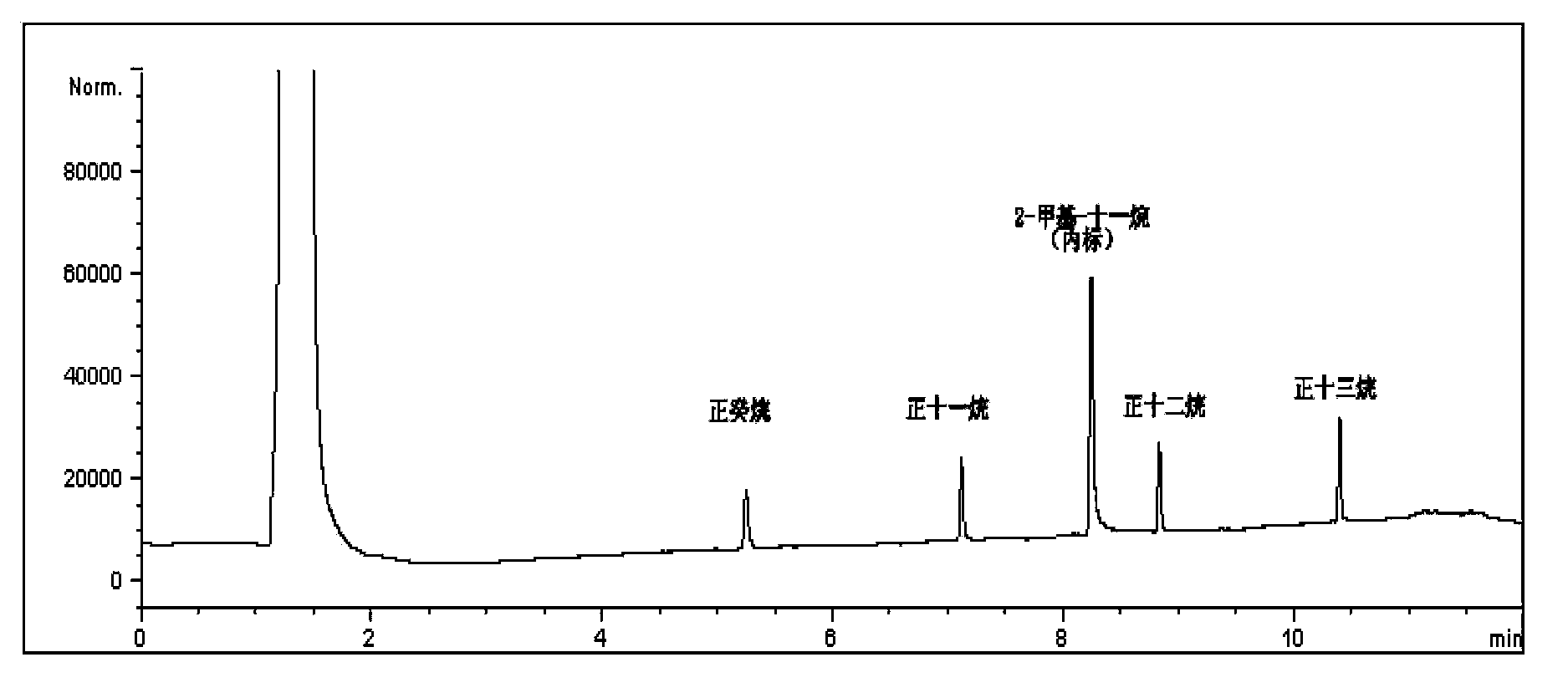

Short-chain chlorinated paraffin online hydrogenation unit combined with gas chromatograph and application thereof

ActiveCN103837623AAvoid interferenceImprove conversion efficiencyComponent separationData acquisitionChlorinated paraffins

The invention relates to a short-chain chlorinated paraffin online hydrogenation unit combined with a gas chromatograph and a use method thereof. The short-chain chlorinated paraffin online hydrogenation unit comprises a sample feeding part, a carrier gas supplying part and a pressure controlling part, a catalysis dechlorinating and hydrogenating reaction part which is connected with the carrier gas supplying part and provided with a heating element, a temperature control part used for performing temperature control and regulation on the catalysis dechlorinating and hydrogenating reaction part, and an interface part connected with the gas chromatograph. An online catalysis dechlorinating and hydrogenating device is connected with a commercial gas chromatograph, and is used for performing data acquisition and analysis. The short-chain chlorinated paraffin online hydrogenation unit is used for performing online catalysis dechlorinating and hydrogenating on short-chain chlorinated paraffin, and has the advantages of accuracy in quantification, simple spectrum analysis, high analysis speed, low experimental cost, less health hazard, convenience in operation, and the like. The short-chain chlorinated paraffin online hydrogenation unit is suitable for routine laboratory analysis of the short-chain chlorinated paraffin in a chlorinated paraffin product.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

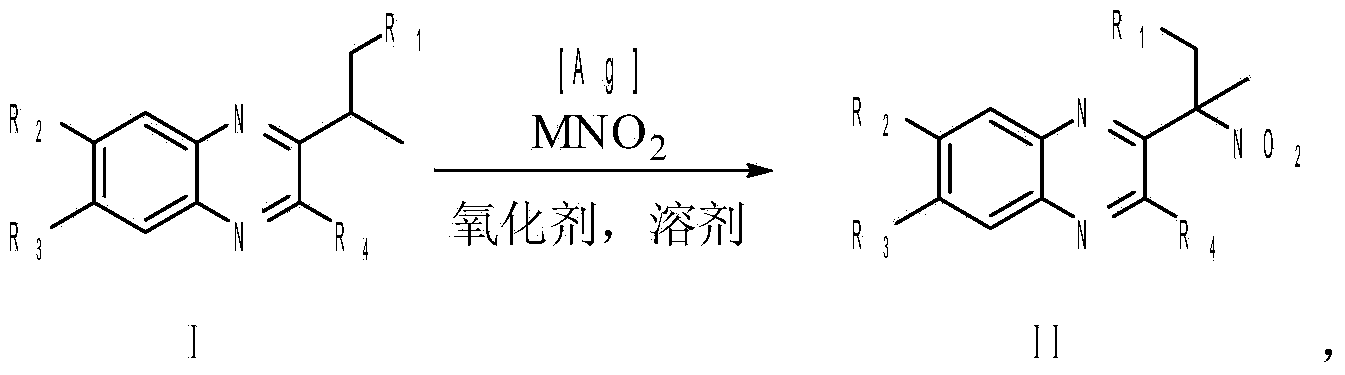

Nitration method of quinoxaline substituted alkane

The invention relates to a synthesis method of an organic compound, and provides a nitration method of quinoxaline substituted alkane in order to solve the problems that a conventional nitration method is high in energy consumption, a high-purity nitro-paraffin product is difficult to obtain and the actual application of the high-purity nitro-paraffin product is limited. The nitration method comprises the steps as follows: 2-quinoxaline substituted alkane, a catalyst, a nitration reagent, an oxidant and a reaction solvent are sequentially added in a sealed pressure-resistant container, a mixture is heated and reacts under the pressure of 1 bar-10 bar for 6-72 hours in oil bath at the temperature of 50 DEG C-150 DEG C, and quinoxaline substituted alkane is obtained. With the adoption of the method, the required nitration product is obtained under the relative mild condition through very high selectivity, and the phenomenon of high probability of carbon-carbon bond rupture witha traditional method is avoided.

Owner:临沭县益兴供汽维修服务有限公司

Methods for producing linear paraffins and olefins from natural oils

A method for producing a linear paraffin includes providing a natural oil in a feed stream, deoxygenating the natural oil to form a stream comprising paraffins, purifying the stream comprising paraffins to form a purified stream comprising paraffins, and separating a first fraction of paraffin product from the purified stream comprising paraffins. A method for producing a linear olefin includes providing a natural oil in a feed stream, deoxygenating the natural oil to form a stream comprising paraffins, dehydrogenating the stream comprising paraffins to form a stream comprising olefins, purifying the stream comprising olefins to form a purified stream comprising olefins, and separating a first fraction of olefin product from the purified stream comprising olefins.

Owner:BOZZANO ANDREA G +1

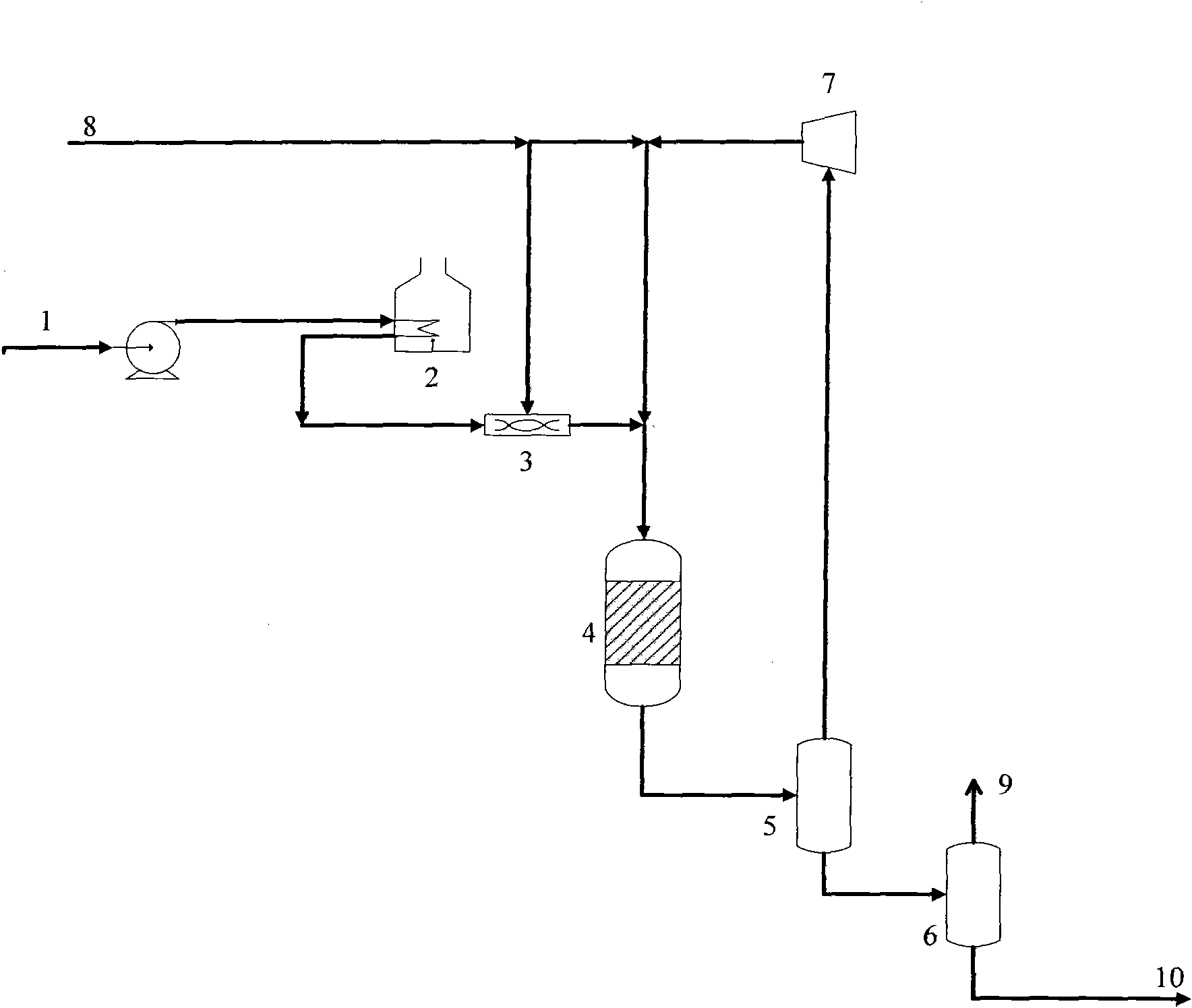

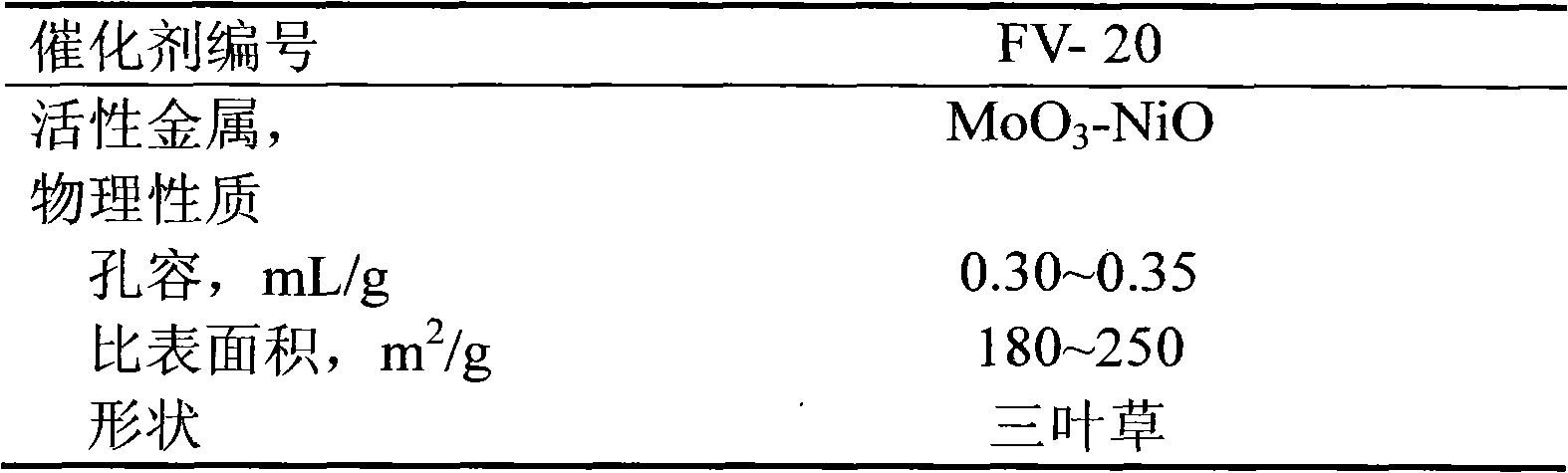

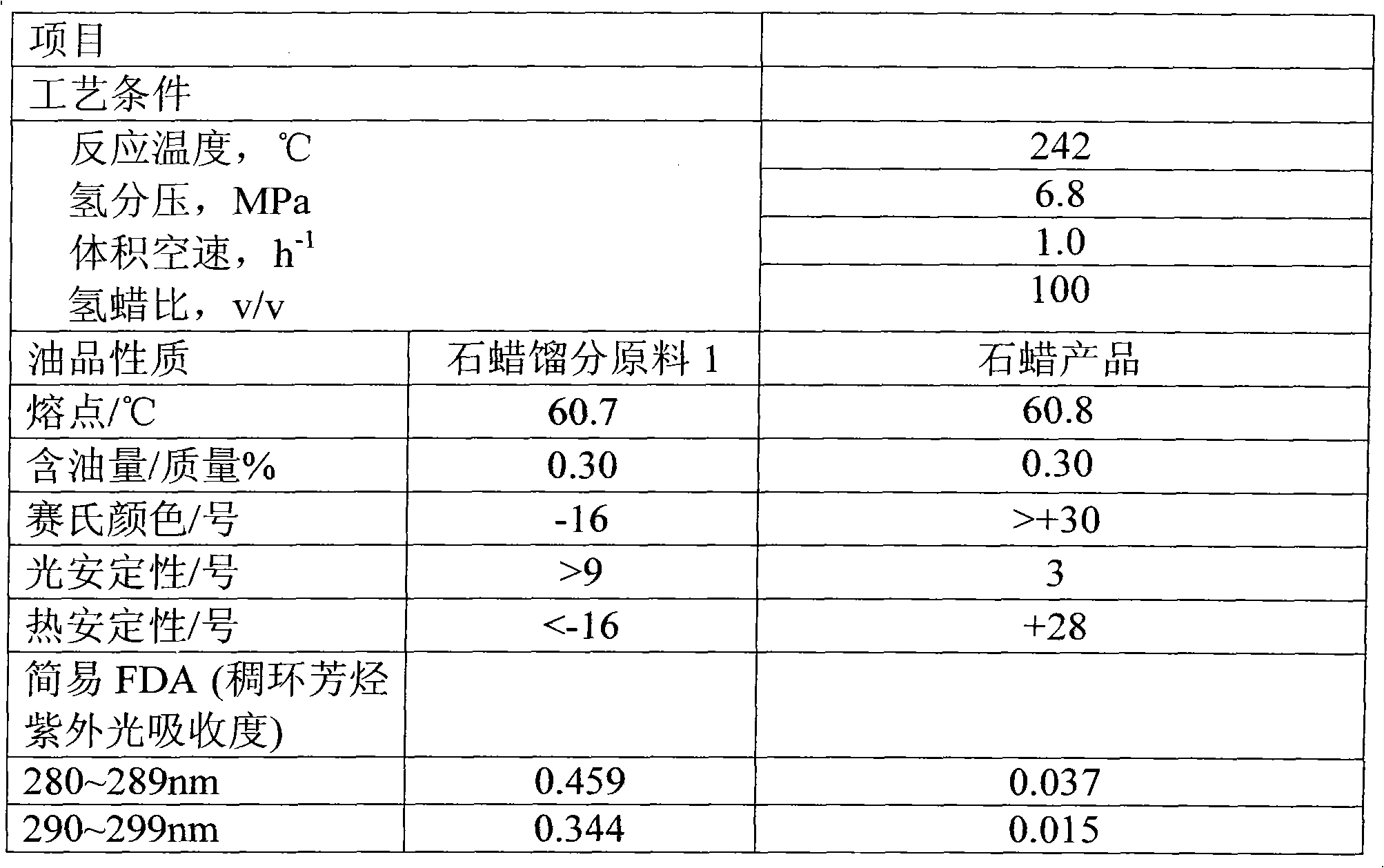

Hydrogenated modification method for petroleum wax substance

InactiveCN101942341AImprove solubilityQuick responsePetroleum wax refiningParaffin waxHydrogenation reaction

The invention relates to a hydrogenated modification method for a petroleum wax substance, which comprises the following steps of: fully mixing the petroleum wax substance serving as a raw material and hydrogen in a gas-liquid mixer through a heating furnace, then making the mixture contact a hydrogenation catalyst in a low hydrogen-wax volume ratio under mild process condition, and performing the conventional hydrogenation reaction. Compared with the conventional hydrogenation process, the method can achieve the same effect as the conventional refining under the mild process condition. The method can produce high-quality paraffin products of various brands, and has the advantages of simple process flow, stable operation, good product property and capabilities of reducing the energy consumption of a device, improving the product yield and newly building a hydrogenation device or reforming an old device.

Owner:FUSHUN RES INST OF PETROLEUM & PETROCHEMICALS SINOPEC CORP

Methods for producing linear paraffins and olefins from natural oils

A method for producing a linear paraffin includes providing a natural oil in a feed stream, deoxygenating the natural oil to form a stream comprising paraffins, purifying the stream comprising paraffins to form a purified stream comprising paraffins, and separating a first fraction of paraffin product from the purified stream comprising paraffins. A method for producing a linear olefin includes providing a natural oil in a feed stream, deoxygenating the natural oil to form a stream comprising paraffins, dehydrogenating the stream comprising paraffins to form a stream comprising olefins, purifying the stream comprising olefins to form a purified stream comprising olefins, and separating a first fraction of olefin product from the purified stream comprising olefins.

Owner:BOZZANO ANDREA G +1

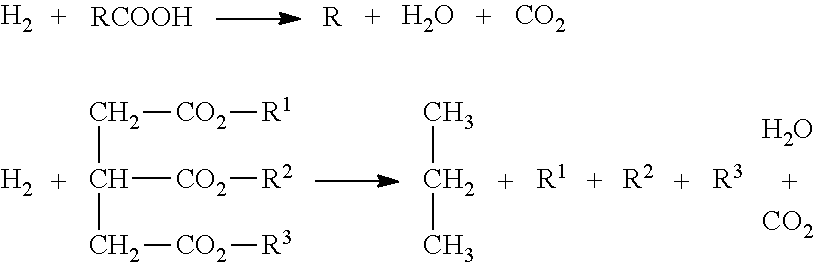

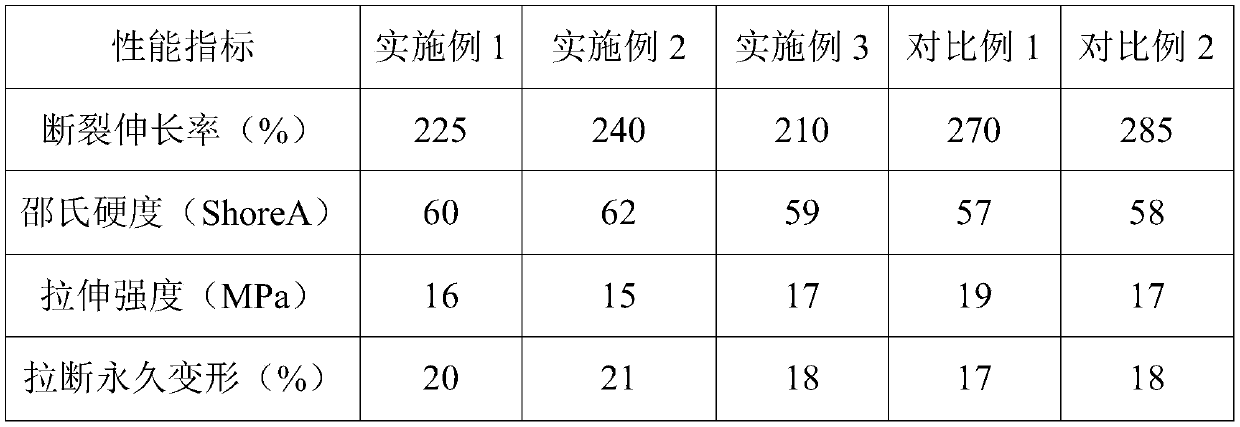

Modified chlorinated paraffin, preparation method and application thereof

ActiveCN110144242AImprove flexibilityImprove efficiencyPetroleum chemical modificationEpoxyThiosalicylic acid

The invention discloses a preparation method of modified chlorinated paraffin, which comprises the following steps: dissolving chlorinated paraffin in a solvent, adding thiosalicylic acid and potassium carbonate, reacting at 50-100 DEG C under the protection of nitrogen, pouring that reactants into an ethanol solution, and performing vacuum drying to obtain a transparent liquid; dissolving the clear liquid in a solvent and adjusting the pH to 4-5, pouring into ethanol to extract, vacuum drying to obtain thiosalicylic acid modified chlorinated paraffin product; adding the chlorinated paraffin modified by thiosalicylic acid into solvent, then adding epoxy fatty acid methyl ester and N,N-dimethyl formamide, performing reflux reaction at 50-80 DEG C, pouring into ethanol to extract, vacuum drying to obtain modified chlorinated paraffin. The invention also discloses a modified chlorinated paraffin. The invention also discloses the application of a modified chlorinated paraffin in a plasticizer. The modified chlorinated paraffin prepared by the invention is environmentally friendly, has good compatibility with organic substances and good plasticizing effect, and can improve the deficiency of the traditional chlorinated paraffin.

Owner:ANHUI XINGXIN CHEM TECH

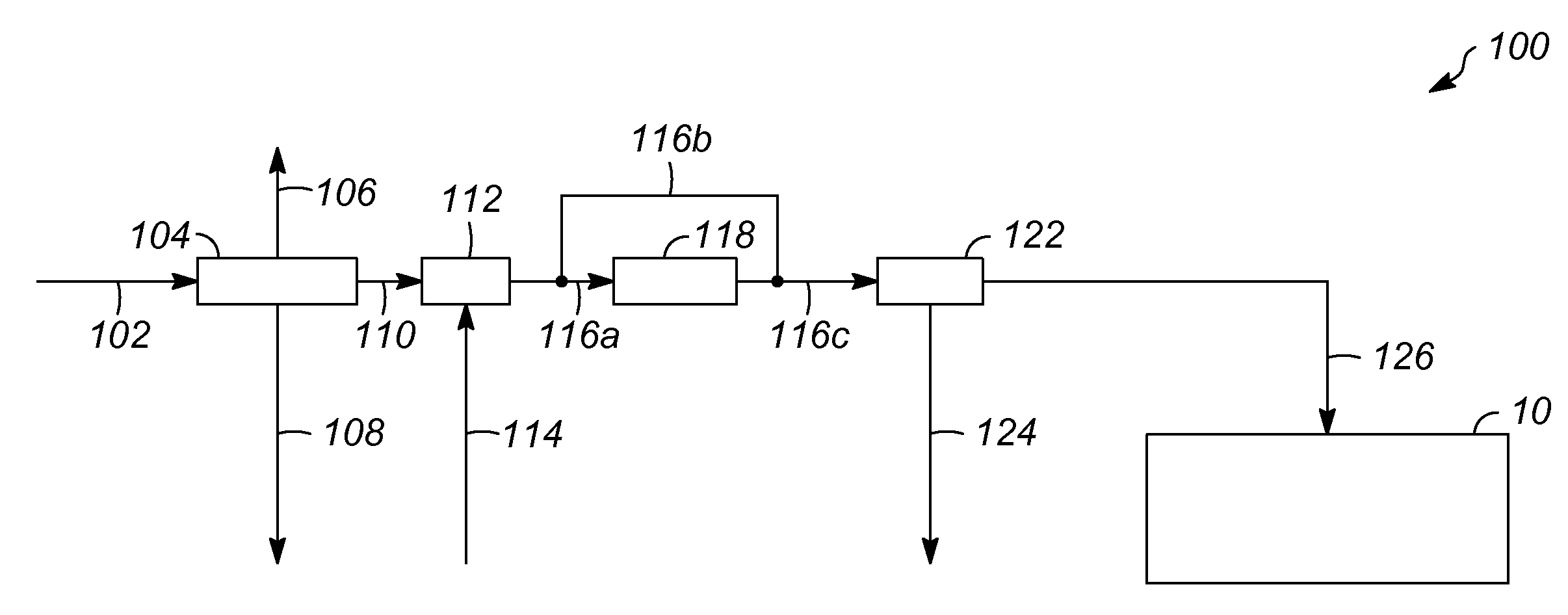

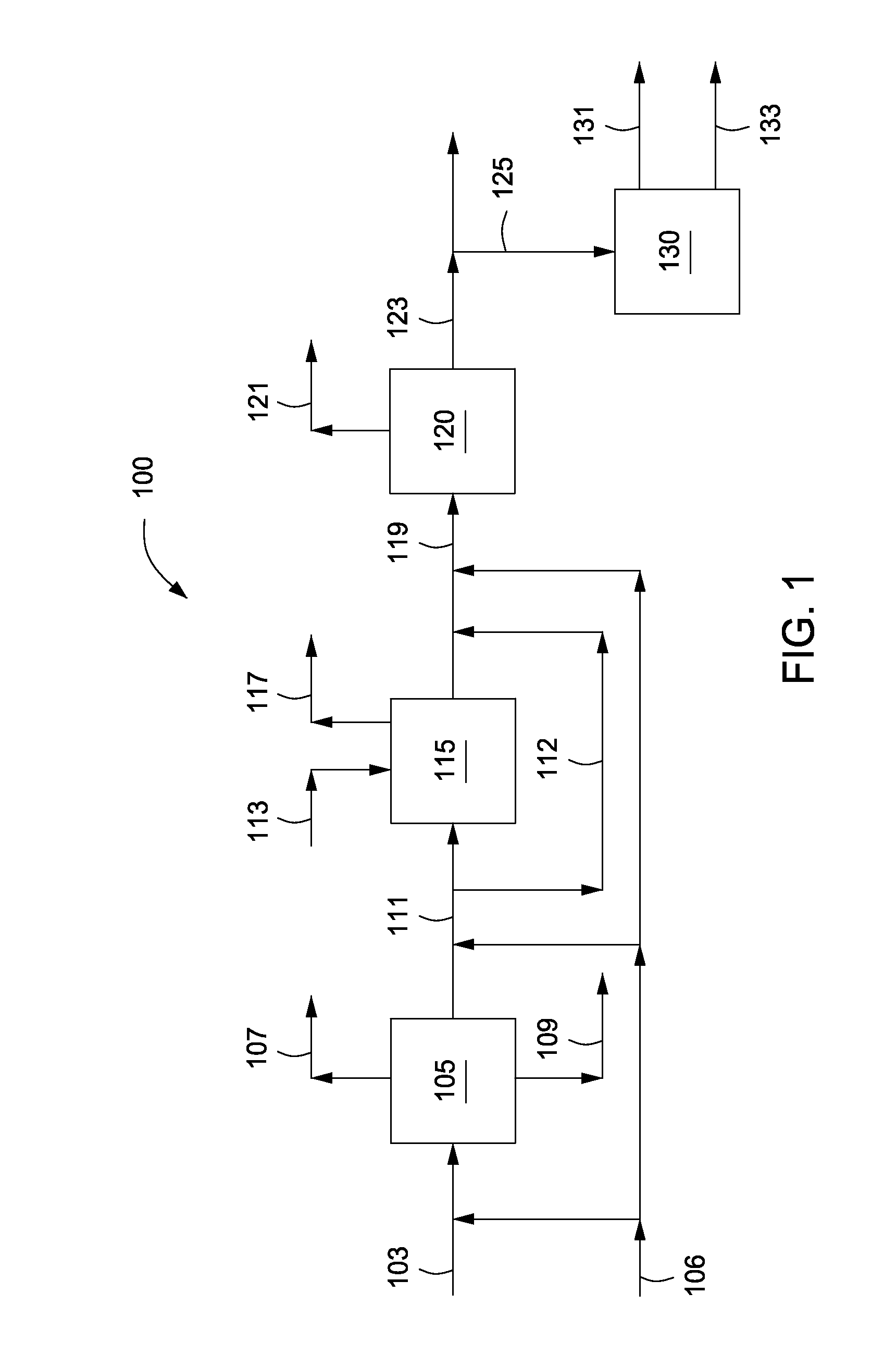

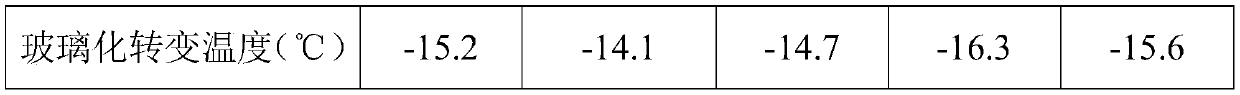

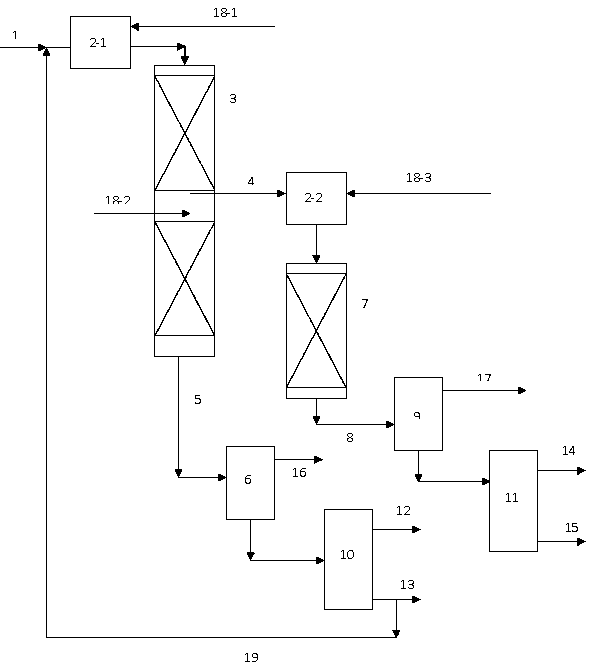

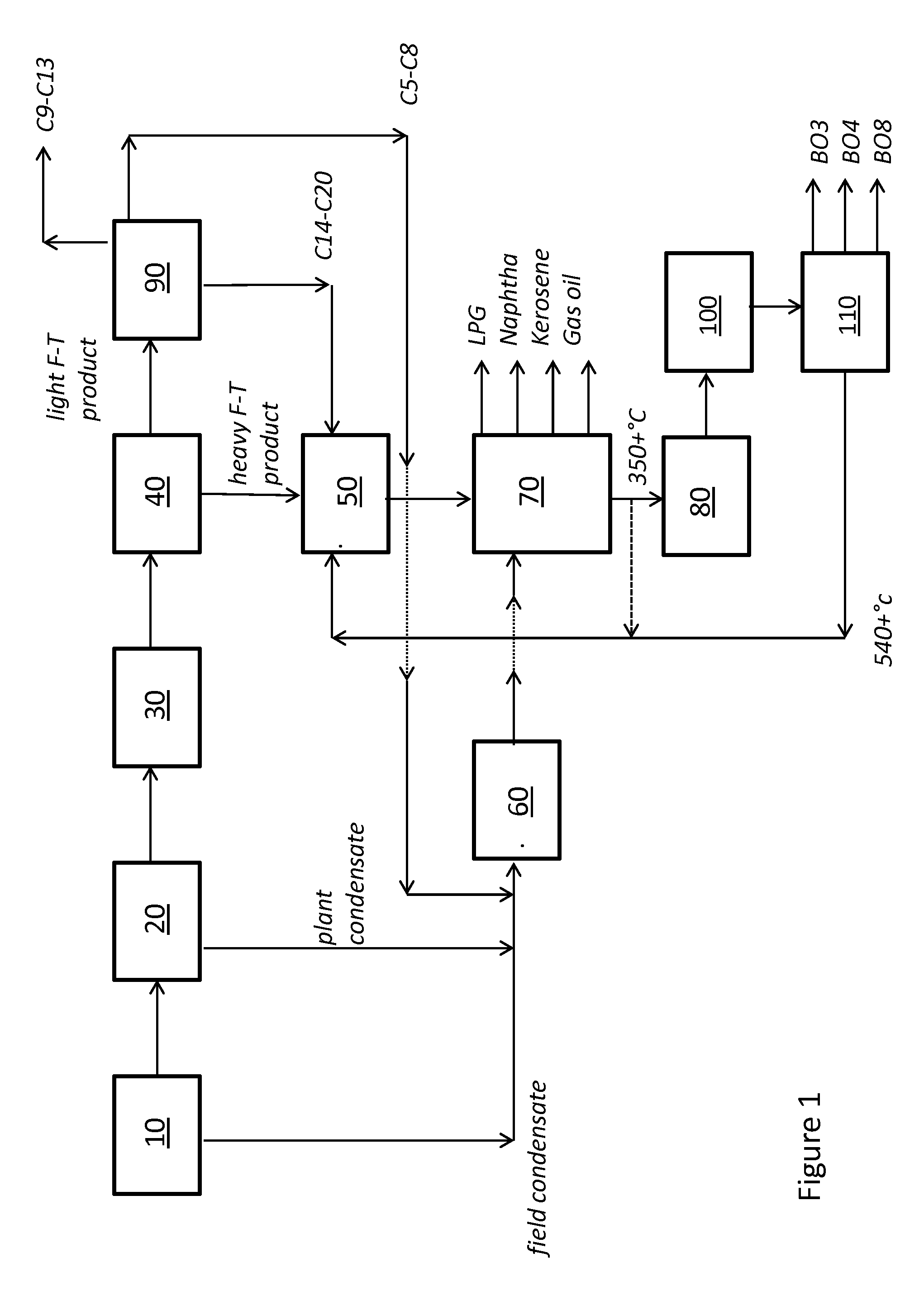

Integrated gas-to-liquid condensate process

InactiveUS20150322351A1Improved GTL performanceIncrease productionHydrogenHydrocarbon oil crackingParaffin waxHydrogen

A process to prepare middle distillates products is provided. The process includes providing and separating a feed stream into a natural gas feed stream and a condensate feed stream; preparing a mixture of carbon monoxide and hydrogen from the natural gas feed stream; preparing a paraffin product stream by performing a Fischer-Tropsch reaction using the carbon monoxide and hydrogen; separating the paraffin product stream to obtain heavy Fischer-Tropsch and light Fischer-Tropsch product streams; hydrogenating and separating the light Fischer-Tropsch product stream to obtain first, second and third hydrogenated paraffinic product fractions; subjecting the heavy Fischer-Tropsch product stream, the third hydrogenated paraffin product fraction and the condensate stream to hydrocracking / hydroisomerization to obtain an isomerised Fischer-Tropsch product stream; combining the isomerised Fischer-Tropsch product stream with the first hydrogenated paraffin product fraction to provide a distillate feed stream and distilling the distillate feed stream to provide isolated middle distillate products.

Owner:SHELL OIL CO

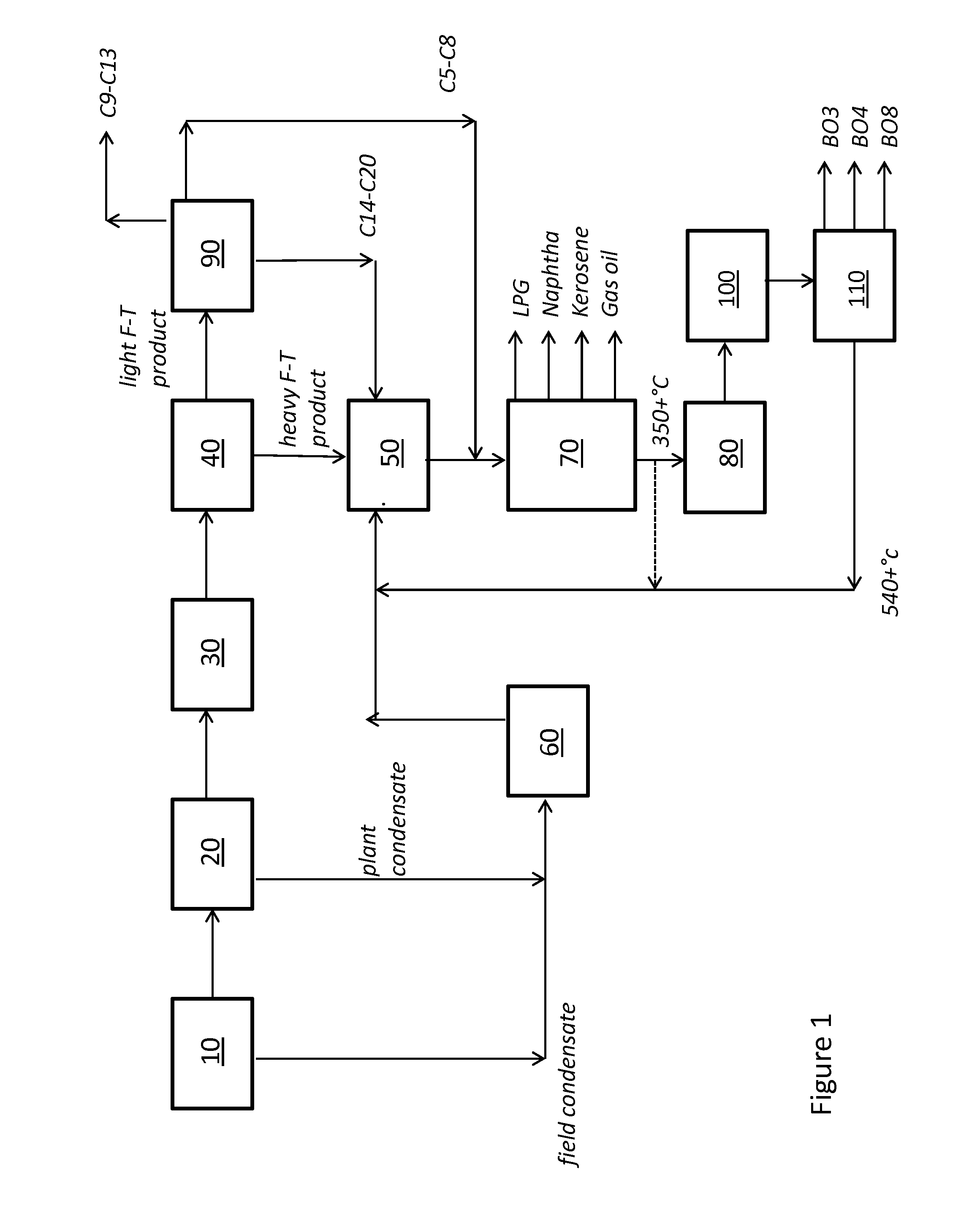

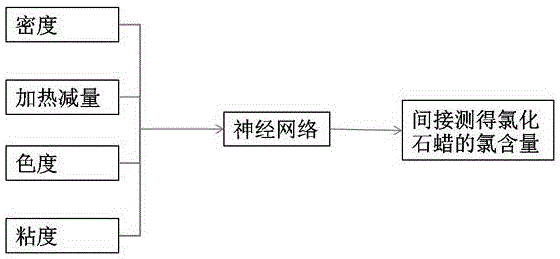

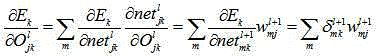

BP neural network-based chlorinated paraffin chlorinity indirect detection method

ActiveCN105158408AAvoid tedious pre-processingAvoid recyclingBiological neural network modelsMaterial analysisData setChlorinated paraffins

The invention discloses a BP neural network-based algorithm model-based chlorinated paraffin chlorinity indirect detection method. The method comprises carrying out sampling measurement on densities, heating losses, chroma values, viscosities and chlorinities of a series of chlorinated paraffin products, building an artificial neural network training set by the measurement results, carrying out training on the written artificial neural network by density, heating loss, chroma and viscosity as an input data set and chlorinity as an output data set, and continuously adjusting network parameters so that a good mapping relationship of the input and output is built. When the network training result reaches the standard, a function expression of chlorinity, heating loss, chroma and viscosity of chlorinated paraffin is obtained. Through measurement of density, chroma, viscosity and heating loss of a chlorinated paraffin product with unknown chlorinity, chlorinity of the chlorinated paraffin product is determined indirectly. Through indirect determination of chlorinated paraffin chlorinity by combination of easily determined physical quantity determination and an artificial neural network, complicated pretreatment processes of the traditional determination method such as mercurimetry are effectively avoided, treatment and recovery of the determined waste liquid is avoided and damage to the environment is reduced.

Owner:ANHUI XINGXIN CHEM TECH +1

Process to make a sulphur containing steam cracker feedstock

InactiveCN1648112AIncrease in sizeFew facilitiesHydrogenHydrocarbon from carbon oxidesAlkaneProcess engineering

Owner:SHELL INT RES MAATSCHAPPIJ BV

Flexible paraffin liquid phase hydrogenation process

ActiveCN109988608AEffective distributionFlexible productionPetroleum wax refiningTreatment with hydrotreatment processesParaffin waxIsomerization

The invention discloses a flexible paraffin liquid phase hydrogenation process. A paraffin raw material and circulating oil enter a liquid-phase hydrofining reactor under a liquid-phase hydrogenationcondition; the material passing through an upper hydrofining catalyst bed layer is divided into two streams; one material stream is extracted out of the liquid-phase hydrofining reactor from the middle of the bed layer, and fed into a liquid-phase hydroisomerization reactor for isomerization reaction; the other material stream continues flowing downward to pass through a lower hydrofining catalystbed layer; and an obtained hydrofining reaction material and an obtained hydroisomerization reaction material are subjected to gas-liquid separation and fractionation separately to obtain paraffin products with different specifications. The invention provides the hydrogenation process for simultaneously producing more than two paraffin products with different specifications on one set of liquid-phase hydrogenation process equipment for the first time, heat carried by a part of hydrofined materials can be fully utilized, and coupling operation of the liquid-phase hydrofining reactor and the liquid-phase hydroisomerization reactor is realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

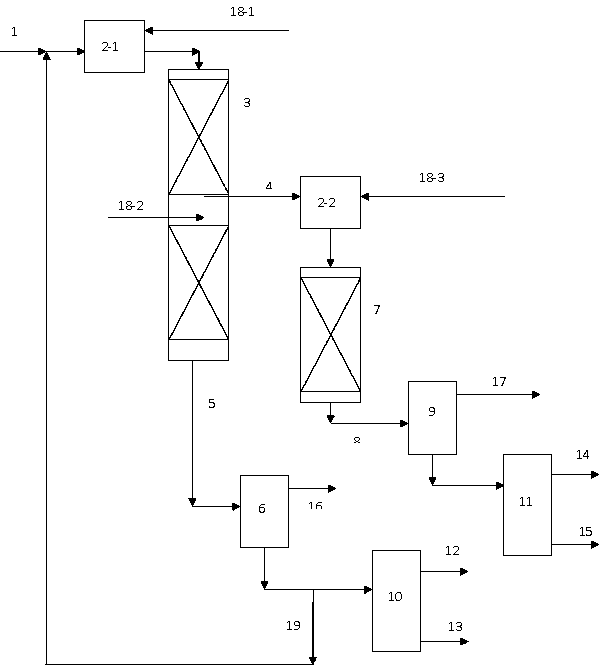

Integrated gas-to-liquids condensate process

InactiveUS20150337212A1Increase productionOptimal utilisationHydrogenHydrocarbon purification/separationParaffin waxHydrogen

Provided is a process to prepare middle distillates products. The process includes providing and separating a feed stream into a natural gas feed stream and a condensate feed stream; preparing a mixture of carbon monoxide and hydrogen from the natural gas stream; preparing a paraffin product stream by performing a Fischer-Tropsch reaction using carbon monoxide and hydrogen; separating the paraffin product stream to obtain heavy Fischer-Tropsch and light Fischer-Tropsch product streams; separating the light Fischer-Tropsch product to obtain first, second, and third paraffinic product fractions; subjecting the heavy Fischer-Tropsch product stream to a hydrocracking / hydroisomerization step to obtain an isomerised Fischer-Tropsch product stream; hydrotreating the condensate feed stream and the first product fraction to obtain a hydrotreated product stream; combining the isomerised Fischer-Tropsch product stream with the hydrotreated product stream to provide a distillate feed stream; and performing a distillation step on the distillate feed stream to isolate middle distillate products.

Owner:SHELL OIL CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com