Continuous vacuum degassing process for chlorinated paraffin and device thereof

A chlorinated paraffin and vacuum degassing technology, which is applied in the fields of petrochemical modification, chemical instruments and methods, and separation of dispersed particles, can solve the problems of difficult operation, high labor intensity, uneconomical, etc., and achieve simple and convenient operation, The effect of improving product quality and short residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

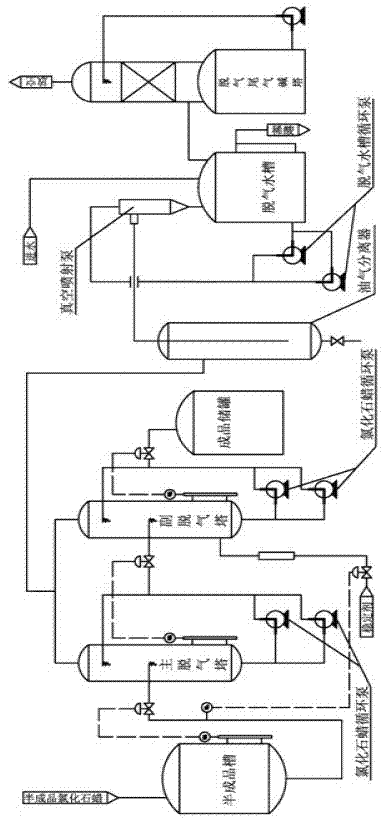

[0017] Example: as attached figure 1 As shown, it mainly includes the main degassing tower and the auxiliary degassing tower. The chlorinated paraffin semi-finished product tank is connected to the main degassing tower through an automatic regulating valve, and the lower part of the main degassing tower is connected to the auxiliary degassing tower through a chlorinated paraffin circulation pump and an automatic regulating valve. Tower; the lower part of the auxiliary degassing tower is connected to the finished product storage tank through the chlorinated paraffin circulation pump; the upper part of the main degassing tower and the auxiliary degassing tower are connected to the oil-gas separator, degassing water tank, degassing water tank circulating pump, vacuum jet pump and Degassing tail gas alkali absorption tower.

[0018] In the embodiment, the chlorinated paraffin semi-finished tank is made of glass fiber reinforced plastic, and a liquid level transmitter is installed,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com