Preparation method and application of modified paraffin capable of being used for spontaneous emulsification

A self-emulsifying and paraffin wax technology, applied in the field of chemical products, can solve the problems of few patents for the preparation of modified paraffin wax, and achieve the effects of excellent water solubility, cheap raw materials, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] A kind of preparation method and application of the modified paraffin that can be used for self-emulsification of the present invention, it comprises the steps:

[0021] a. Synthesis of modified paraffin: under the protection of nitrogen, dissolve 100 parts of 70# paraffin, 2-20 parts of initiator in an appropriate amount of solvent, 10-50 parts of polar monomer, and react at 85-170 °C for 1- After 3 hours, the crude product of modified paraffin was obtained, and the crude product was precipitated and separated with a solvent, filtered by suction, washed several times, and dried to constant weight to obtain a refined product of modified paraffin;

[0022] b. Preparation of self-emulsifying paraffin: take 100 parts of modified paraffin and 5-20 parts of emulsifier, melt and mix them uniformly at 85-100°C, cool and shape at room temperature, and obtain self-emulsifying paraffin.

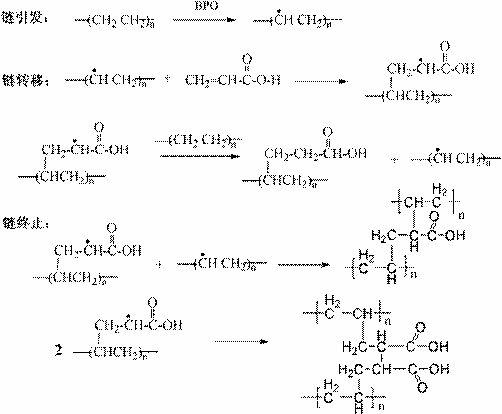

[0023] The preparation of described modified paraffin, reaction principle is as follows:

...

Embodiment 1

[0026] A self-emulsifying paraffin of the present invention is prepared by self-made modified paraffin, and the production formula is composed of the following component proportions (parts by weight):

[0027] (1) Synthesis of modified paraffin: Under nitrogen protection, dissolve 100 parts of 70# paraffin, 5 parts of initiator in 25 parts of acetone, 30 parts of polar monomer, and react at 160-170 °C for 1-2 hours. The crude product of modified paraffin is obtained, and the crude product is precipitated and separated with acetone, filtered with suction, washed several times, and dried to constant weight to obtain a refined product of modified paraffin.

[0028] (2) Preparation of self-emulsifying paraffin: Take 100 parts of modified paraffin and 12 parts of emulsifier, melt and mix them uniformly at 85-100°C, cool and shape at room temperature, and obtain self-emulsifying paraffin.

Embodiment 2

[0030] Under the protection of nitrogen, dissolve 100 parts of 70# paraffin, 9 parts of initiator in 45 parts of acetone, and 30 parts of polar monomer, and react at 160-170 ° C for 1-2 hours to obtain the crude modified paraffin product. The crude product was precipitated and separated with acetone, filtered with suction, washed several times, and dried to constant weight to obtain a refined product of modified paraffin. Then follow step (2) to prepare self-emulsifying paraffin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com