Process to make a sulphur containing steam cracker feedstock

A cracker and steam technology, which is applied in chemical instruments and methods, preparation of liquid hydrocarbon mixtures, catalytic conversion of impurities, gas purification, etc., to achieve the effect of saving oil depot facilities and increasing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

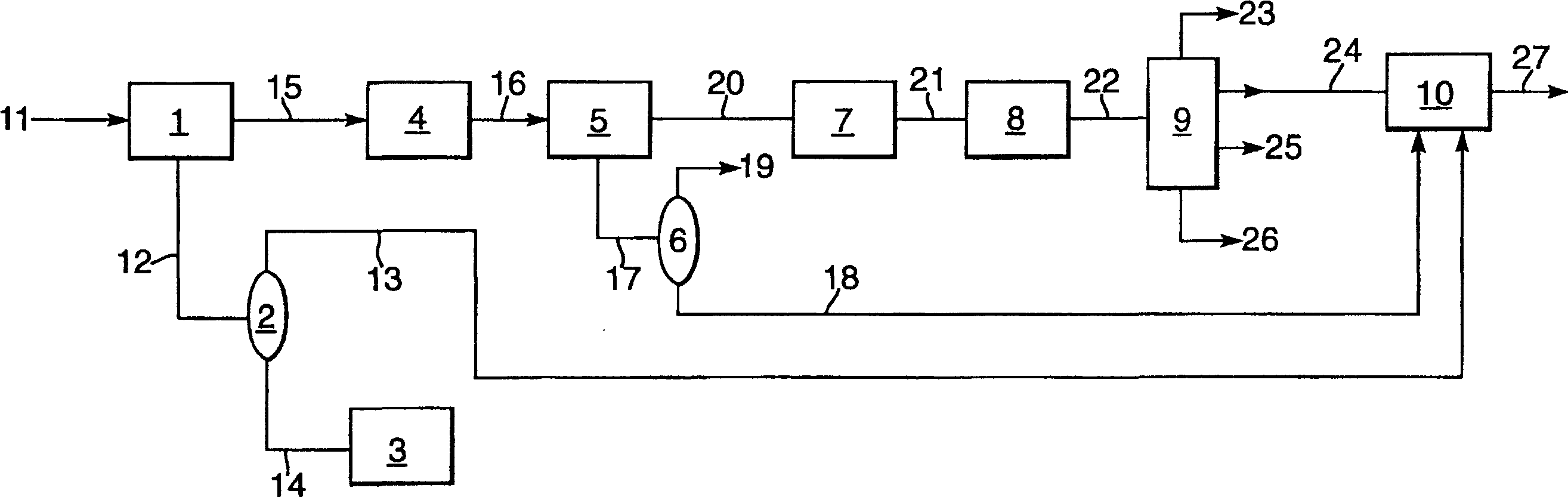

Image

Examples

Embodiment Construction

[0016] Step (a) can be carried out according to well-known methods. Typically, natural gas is obtained from underground wells. After the gas reaches the surface, gaseous hydrocarbons of 1-5 carbon atoms are typically combined with C 5 + Hydrocarbon separation, for example in so-called slug traps. The resulting liquid product is also known as oilfield condensate and may have very high sulfur levels, for example above 1500 ppm, or even above 1900 ppm. A typical lower level is 1000 ppm sulfur. Natural gas from which oilfield condensates have been separated is called pre-cleaned natural gas.

[0017] This liquid condensate obtained from step (a) may have a very high final boiling point, even above 300°C, but at the same time most of the product boils below 300°C. Separation of the high boiling fraction, preferably by eg a flashing step or a distillation step, results in a low boiling fraction comprising sulfur compounds and meeting the boiling range requirements for use as ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com