Patents

Literature

74results about How to "Few facilities" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

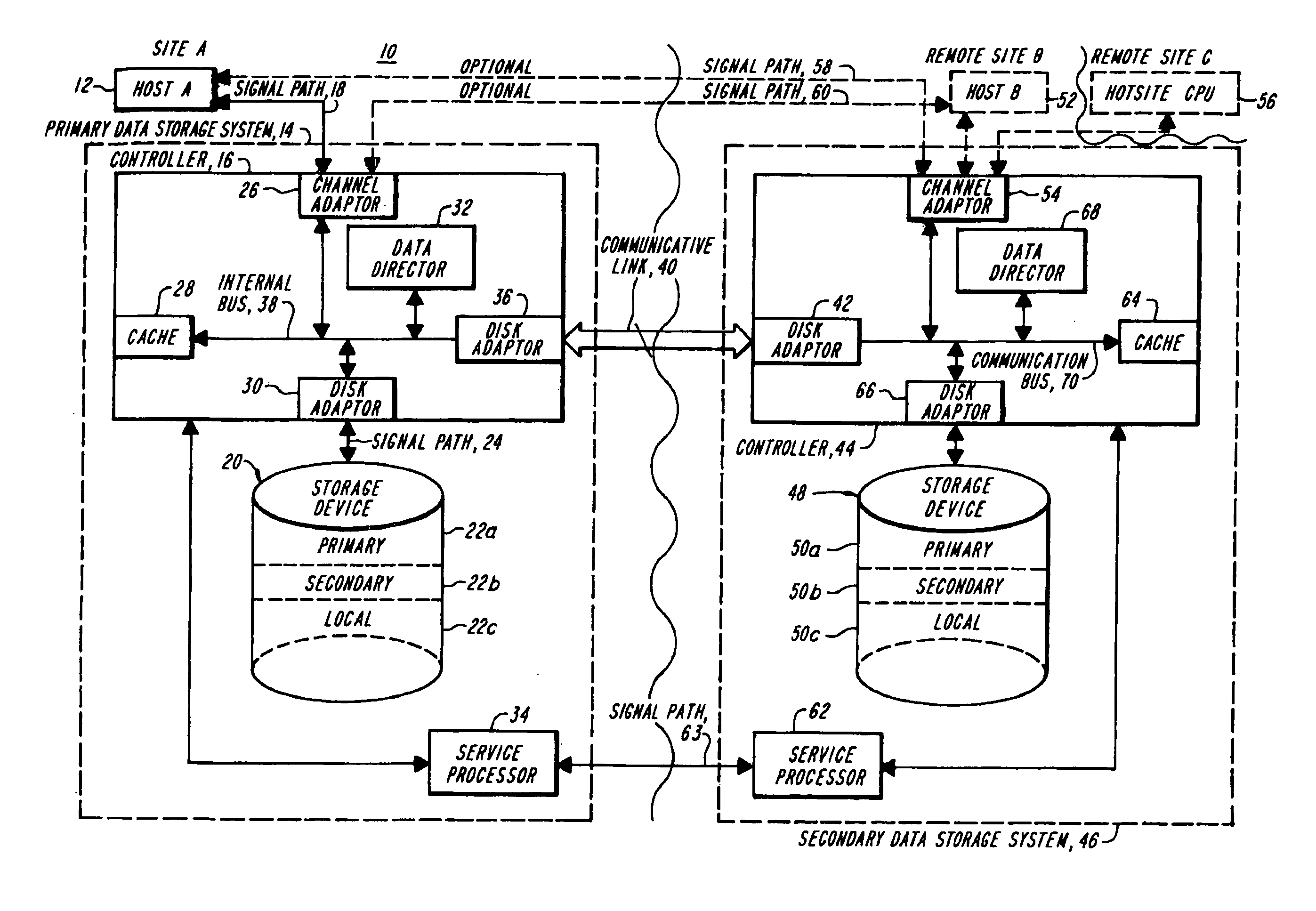

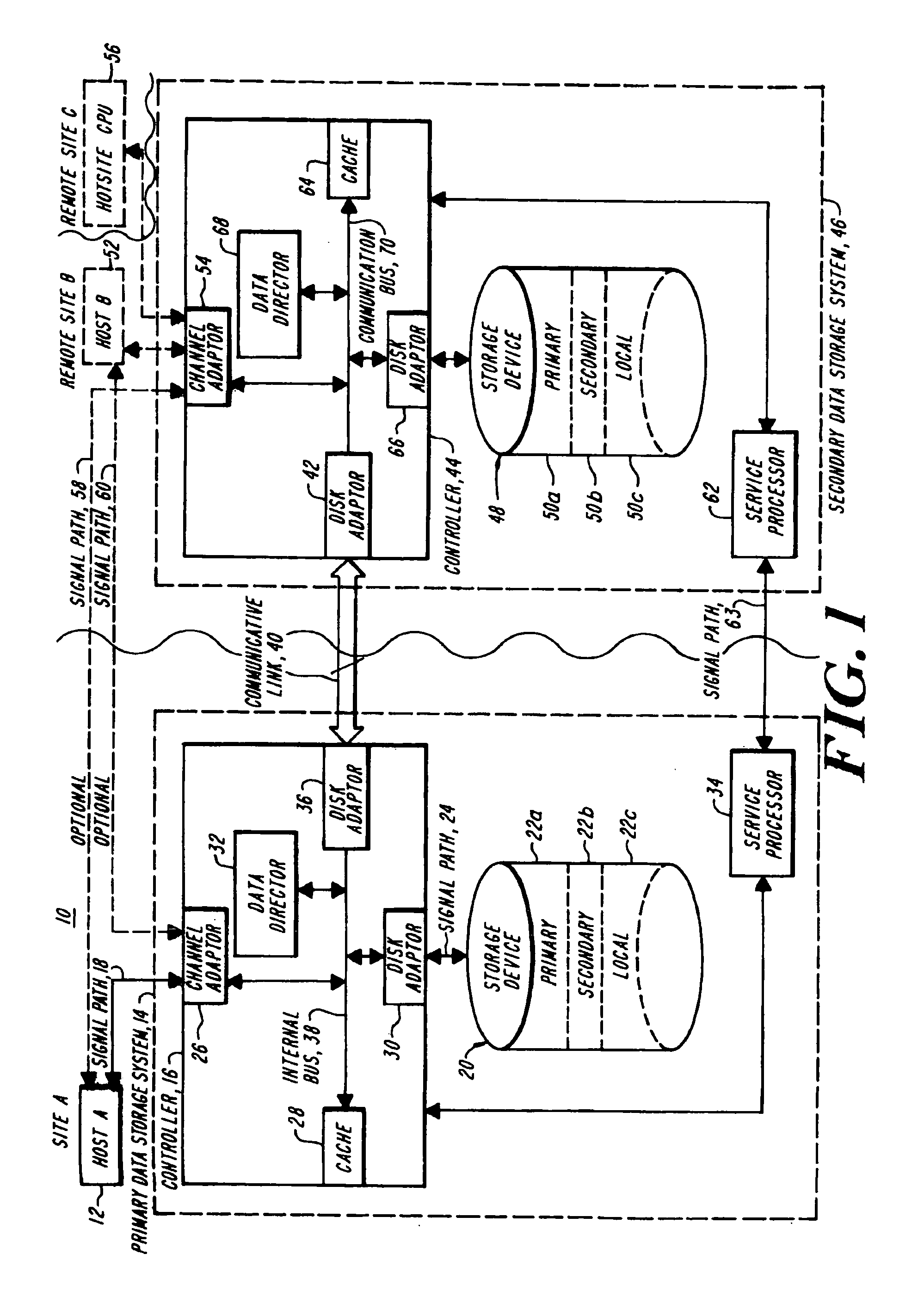

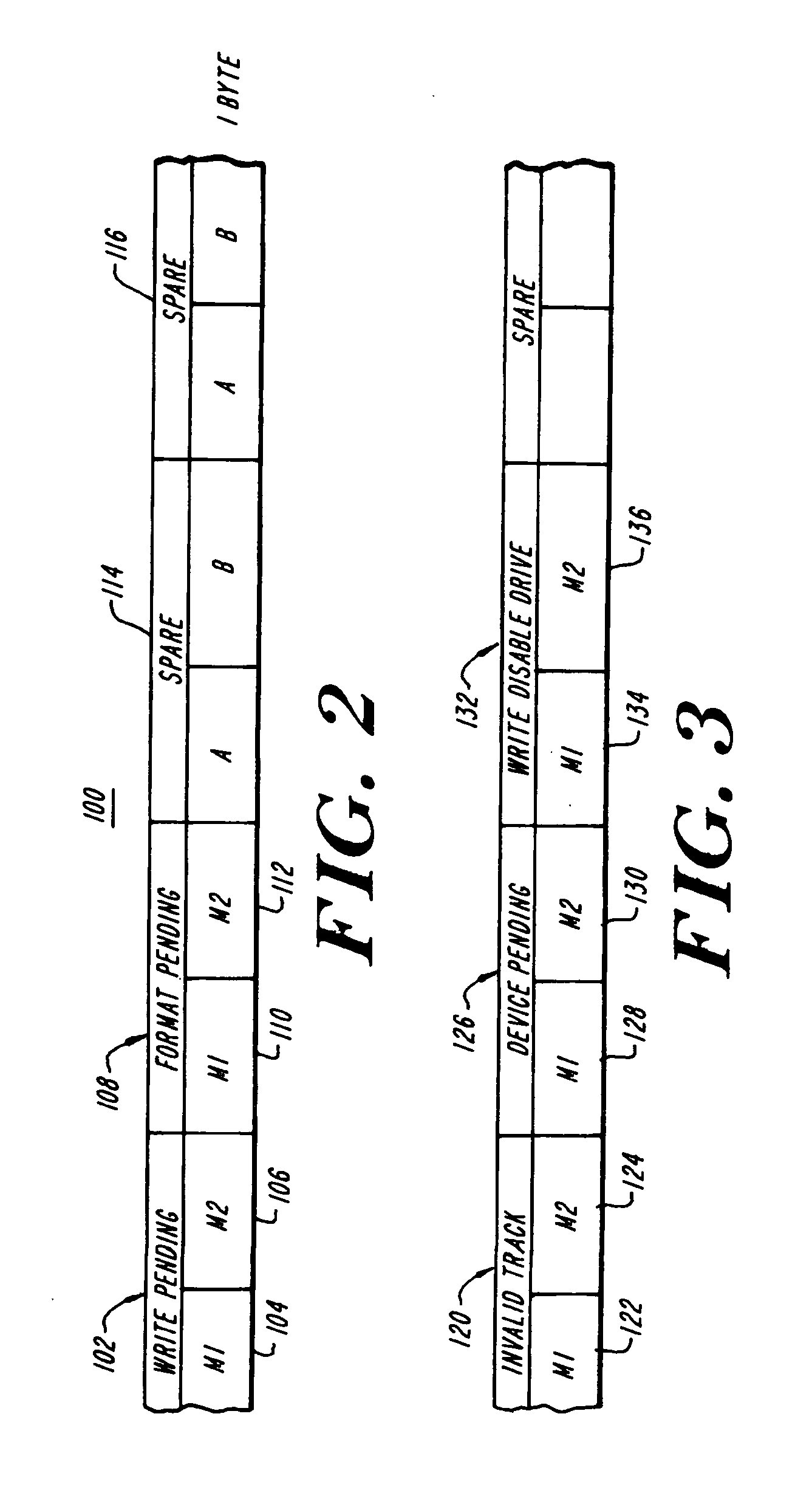

Remote data mirroring

InactiveUS20060005074A1Low costLess manpowerInput/output to record carriersData processing applicationsSelf adaptiveData store

Two data storage systems are interconnected by a data link for remote mirroring of data. Each volume of data is configured as local, primary in a remotely mirrored volume pair, or secondary in a remotely mirrored volume pair. Normally, a host computer directly accesses either a local or a primary volume, and data written to a primary volume is automatically sent over the link to a corresponding secondary volume. Each remotely mirrored volume pair can operate in a selected synchronization mode including synchronous, semi-synchronous, adaptive copy-remote write pending, and adaptive copy-disk. Direct write access to a secondary volume is denied if a “sync required” attribute is set for the volume and the volume is not synchronized.

Owner:EMC CORP

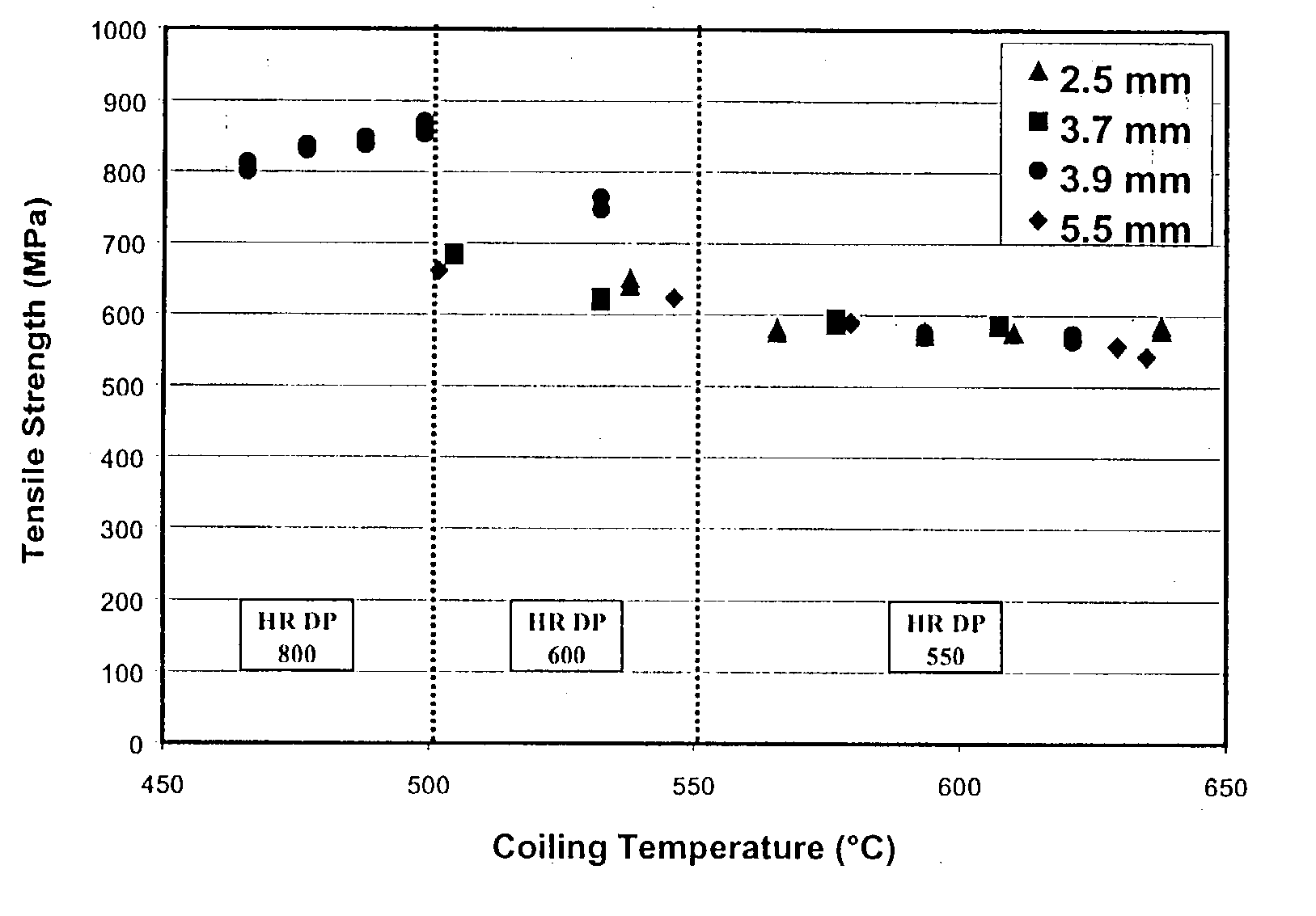

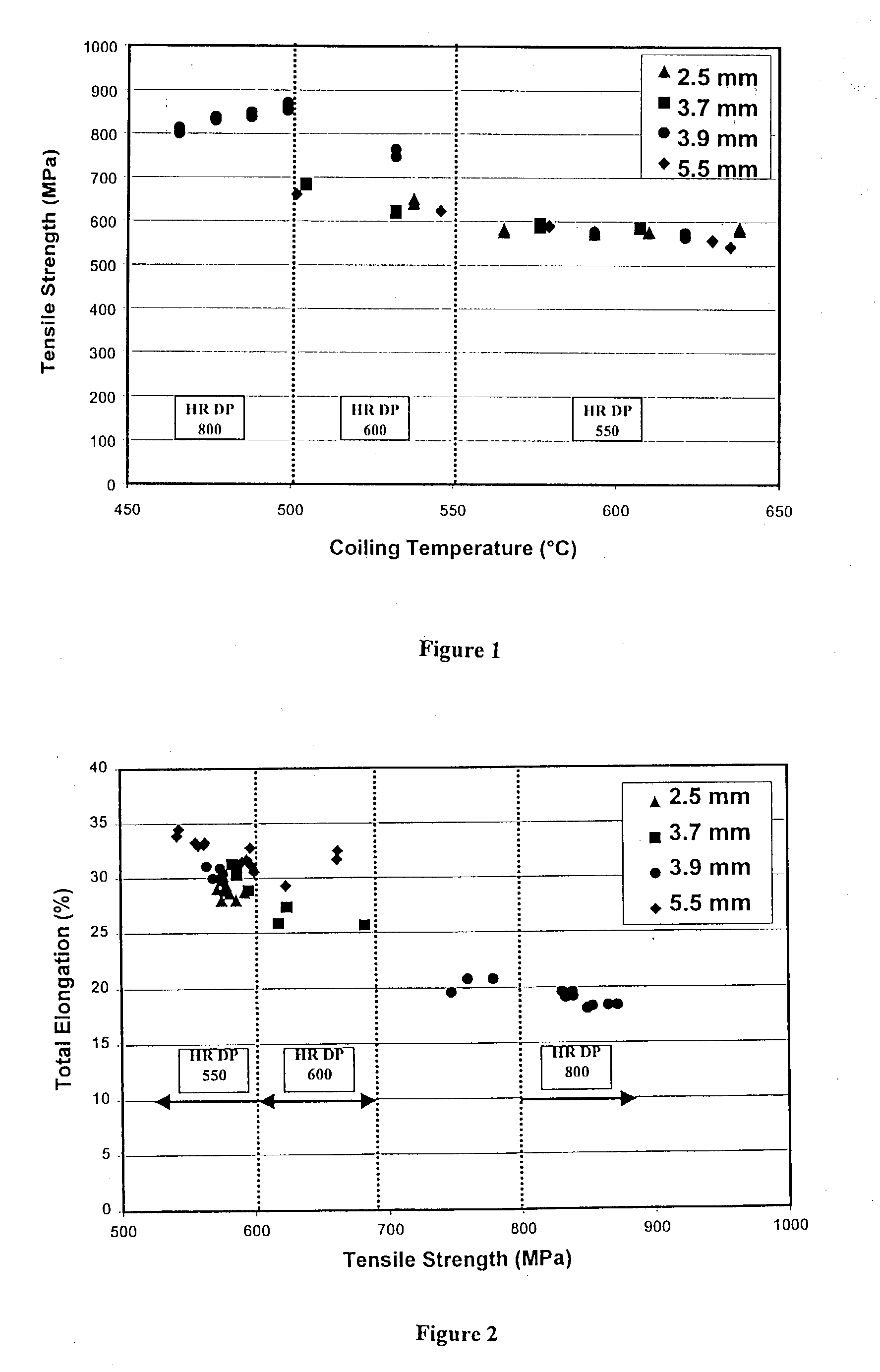

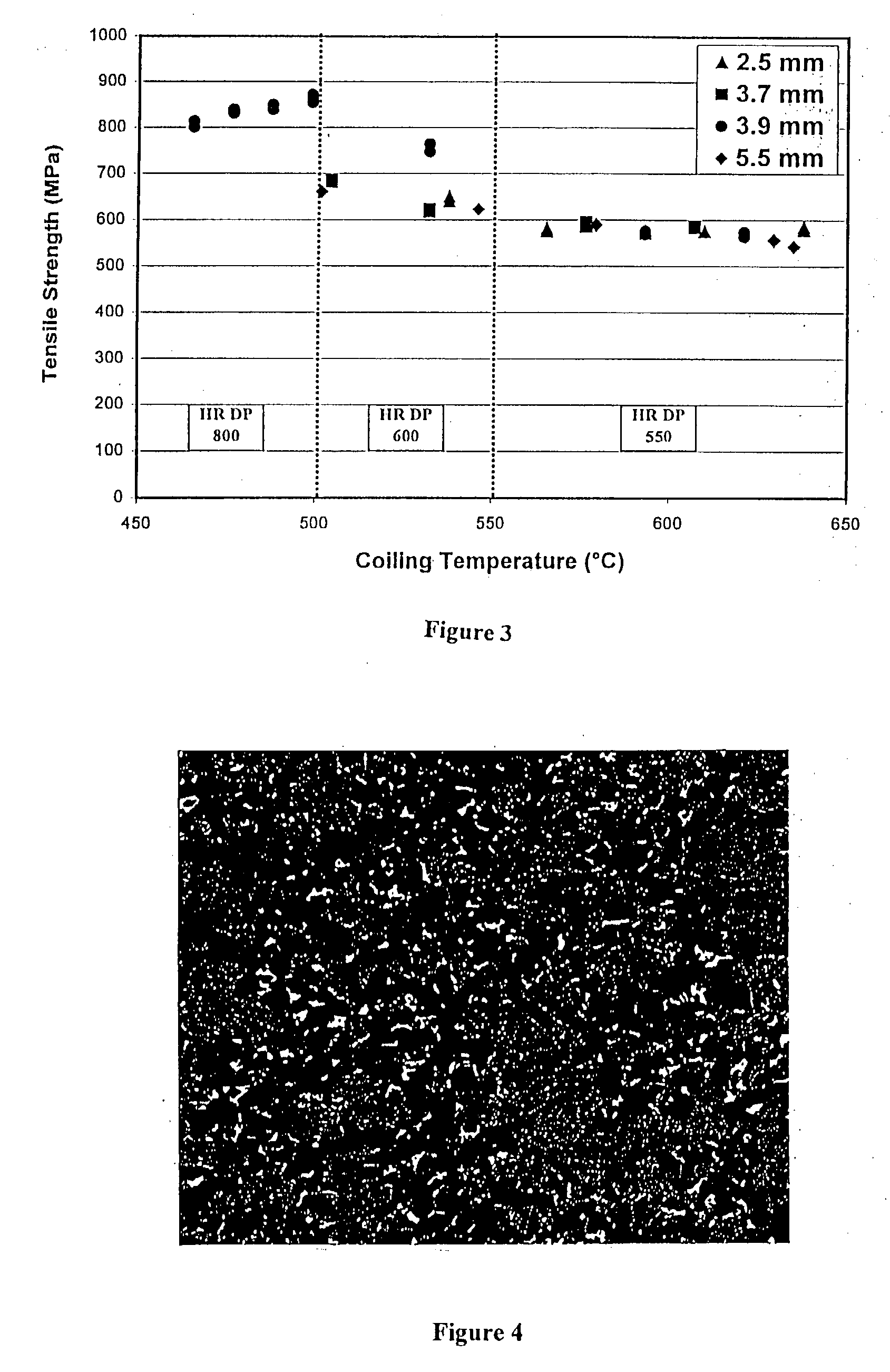

Dual phase hot rolled steel sheet having excellent formability and stretch flangeability

InactiveUS20040118489A1Few facilitiesGood formabilityFurnace typesHeat treatment furnacesIngotUltimate tensile strength

The present invention provides a process of producing a family of hot rolled dual phase steel sheets having excellent formability and stretch flangeability, with yield strengths of from about 500 MPa to about 900 MPa from a single steel chemistry consisting of, by weight percent, 0.02-0.15% of C, 0.3-2.5% of Mn, 0.1-2.0% of Cr, 0.01-0.2% Al, 0.001-0.01% Ca, not more than 0.1% P, not more than 0.03% S, not more than 0.2% Ti, not more than 0.2% V, not more than 0.2% Nb, not more than 0.5% Mo, not more than 0.5% Cu, not more than 0.5% Ni, the balance being Fe and unavoidable impurities. A slab or ingot of this composition is reheated to a temperature of between 1050° C. and 1350° C. and held at this temperature for at least 10 minutes, then hot rolled, completing the hot rolling at between 800° C. and 1000° C. The sheet is cooled, immediately after completion of hot rolling, at a rate of not lower than 10 C / sec., without requiring specific cooling patterns, and coiled at a temperature of not less than 450 C. The cooling temperature is controlled to produce the desired yield strength within the range of from about 500 MPa to about 900 MPa.

Owner:NATIONAL STEEL CORP +1

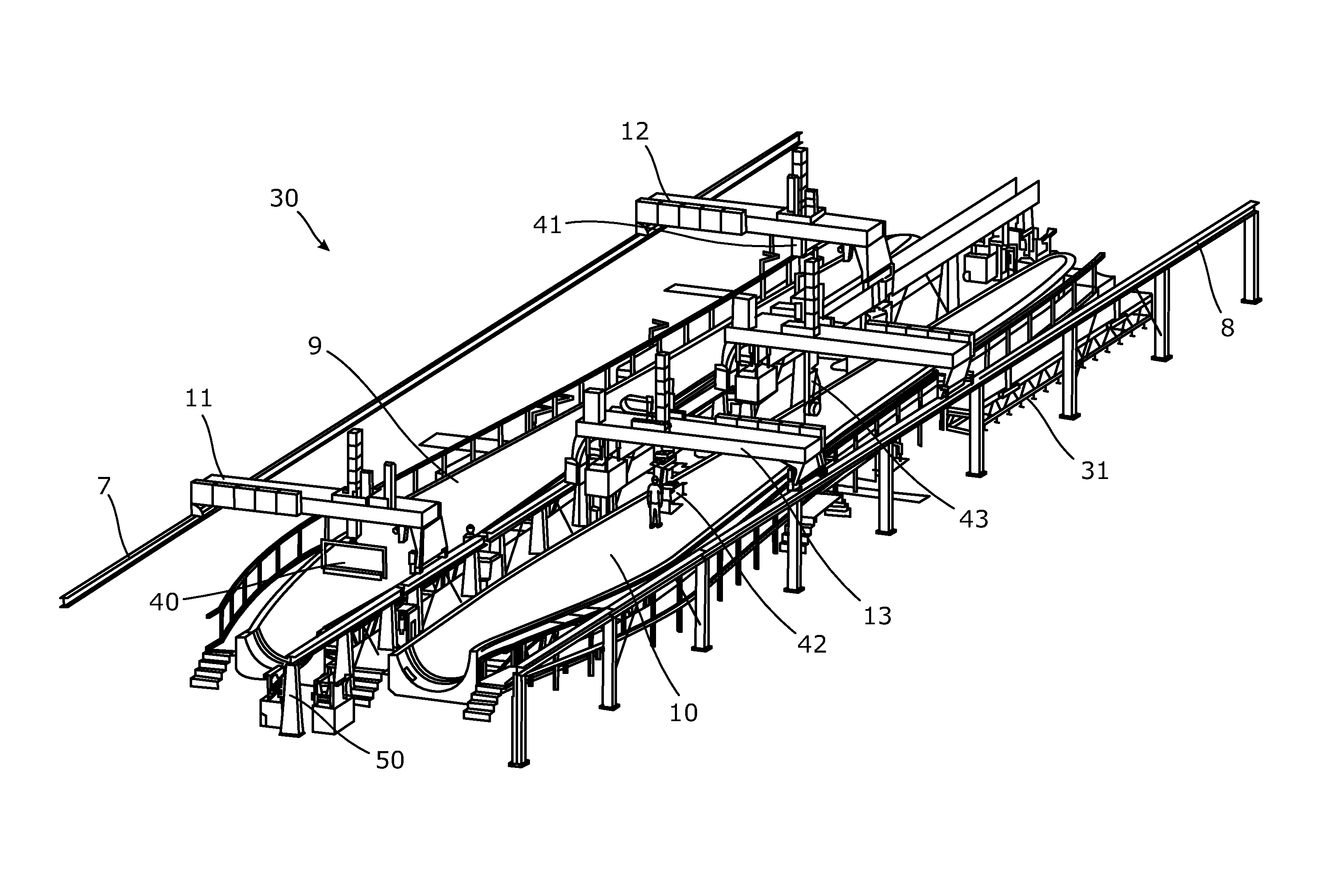

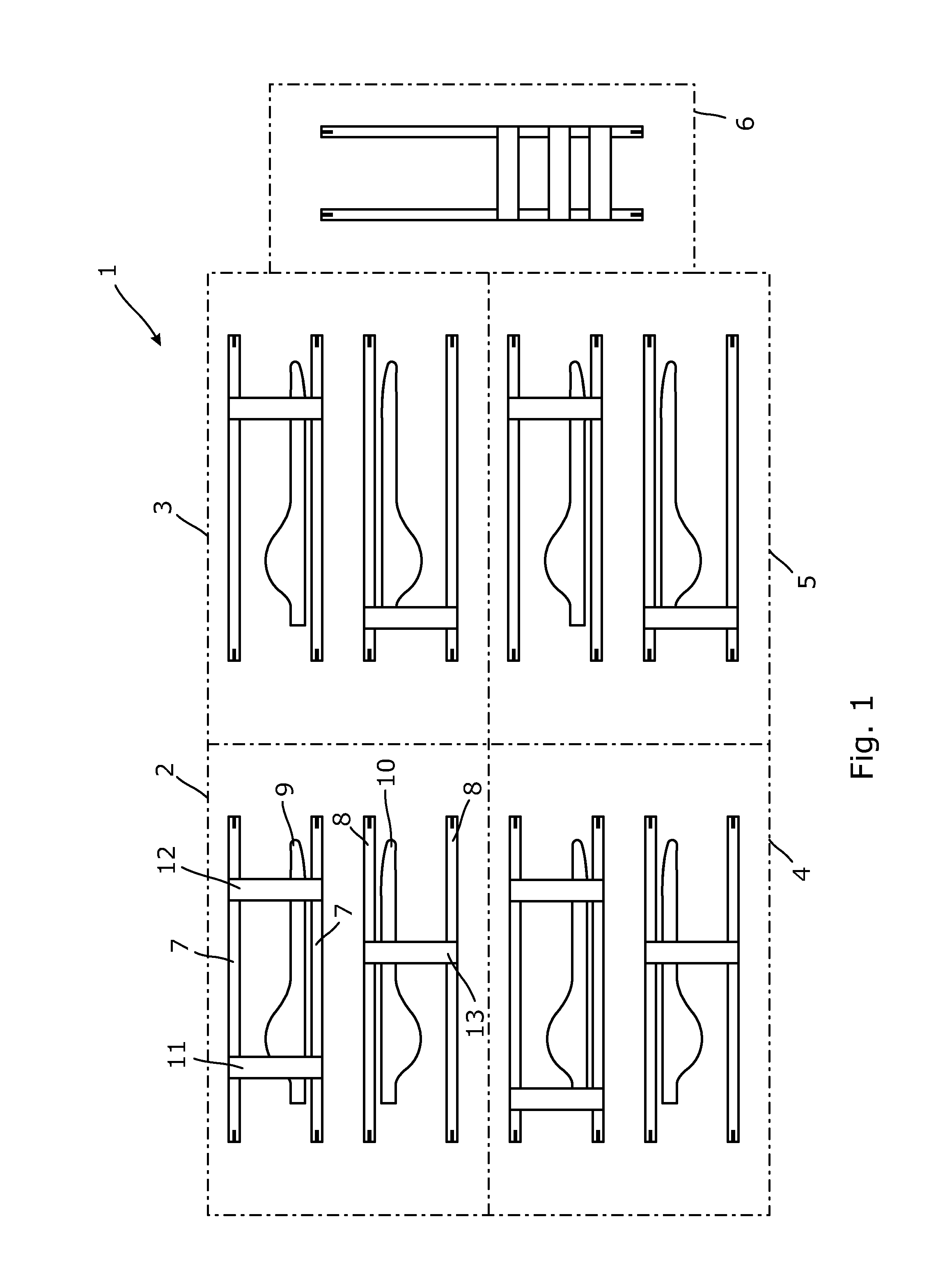

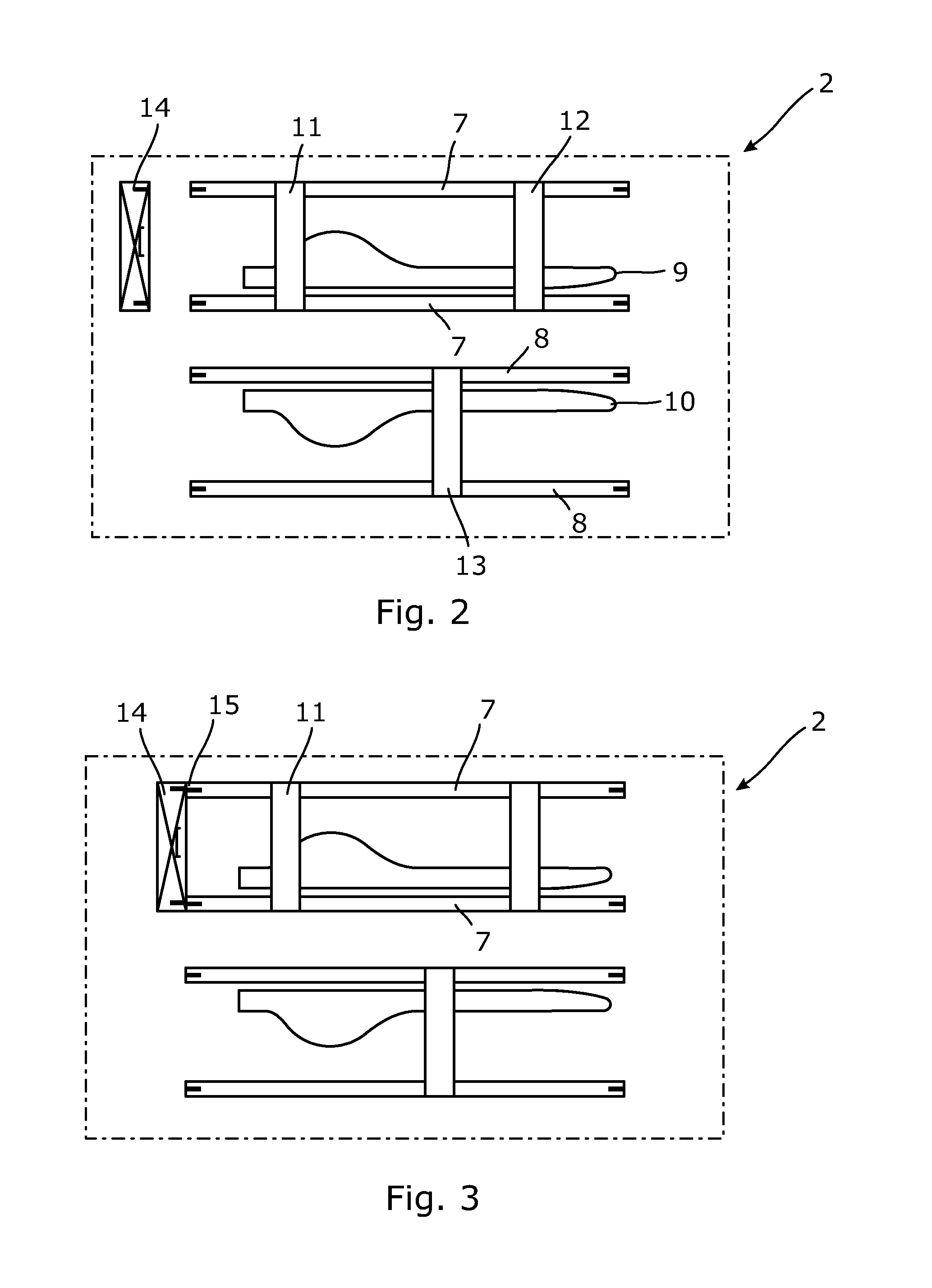

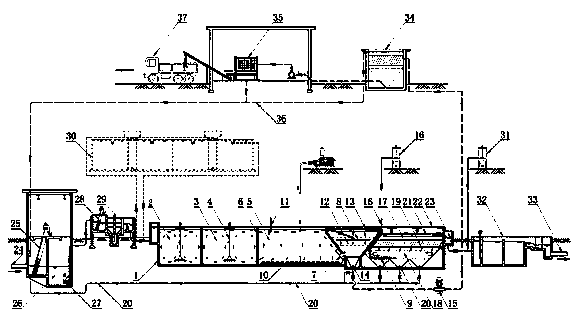

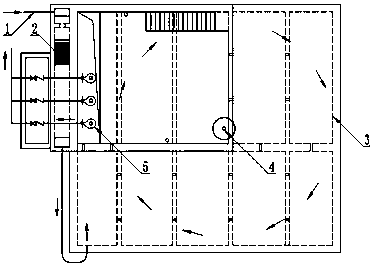

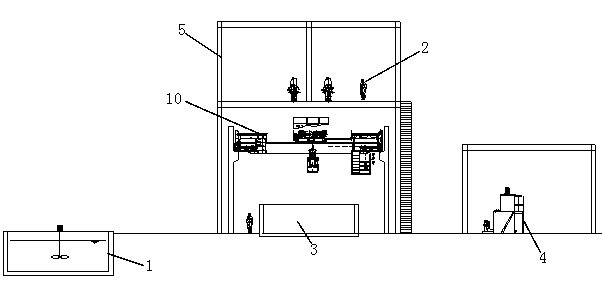

Method and production facility for manufacturing a wind turbine blade

ActiveUS20140322023A1Few facilitiesIncrease speedMetal-working apparatusReaction enginesTurbine bladeManufacturing engineering

The present invention relates to a method for manufacturing a wind turbine blade in a production facility. The method comprises the steps of positioning a first overhung gantry to extend transversely over an elongated first mould part for manufacturing one of a first part and a second part of the blade, performing a first working action at the first mould part with a first tool mounted on the first overhung gantry, moving the first overhung gantry from the first mould part to an elongated second mould part for manufacturing the other of the first and the second part of the blade, positioning the first overhung gantry to extend transversely over the second mould part, and performing a second working action at the second mould part by means of the first tool or a second tool mounted on the first overhung gantry.

Owner:VESTAS WIND SYST AS

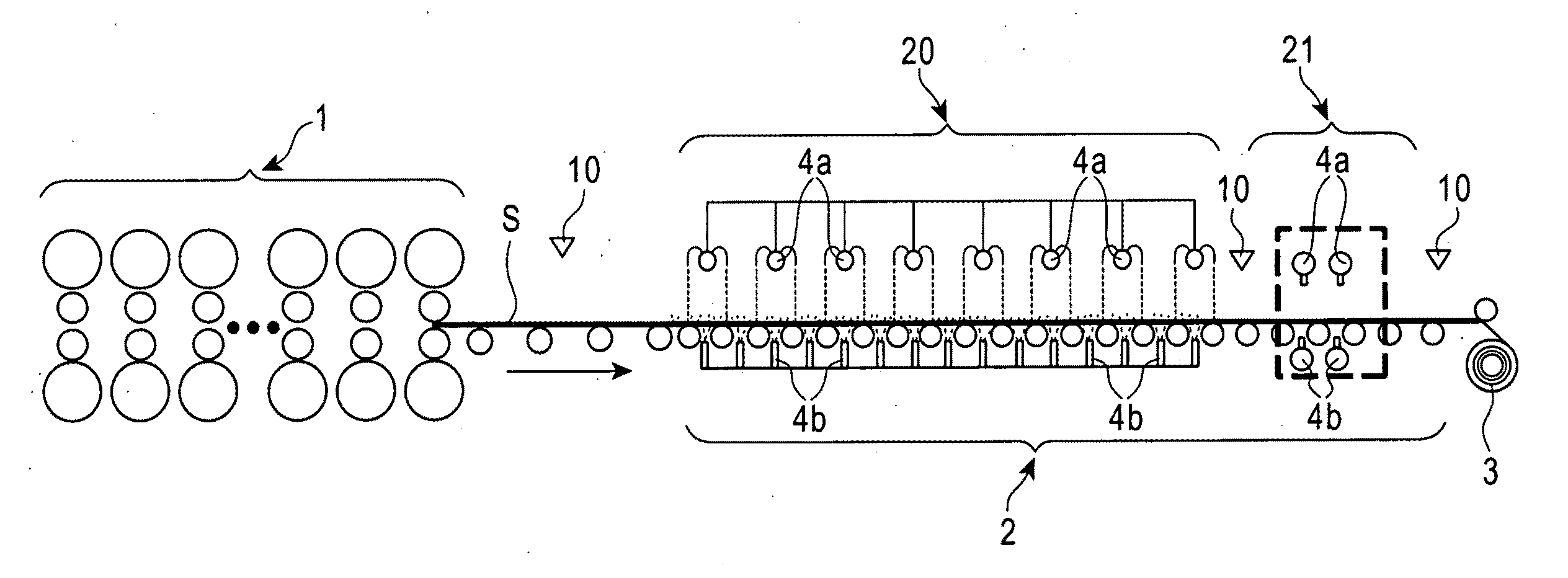

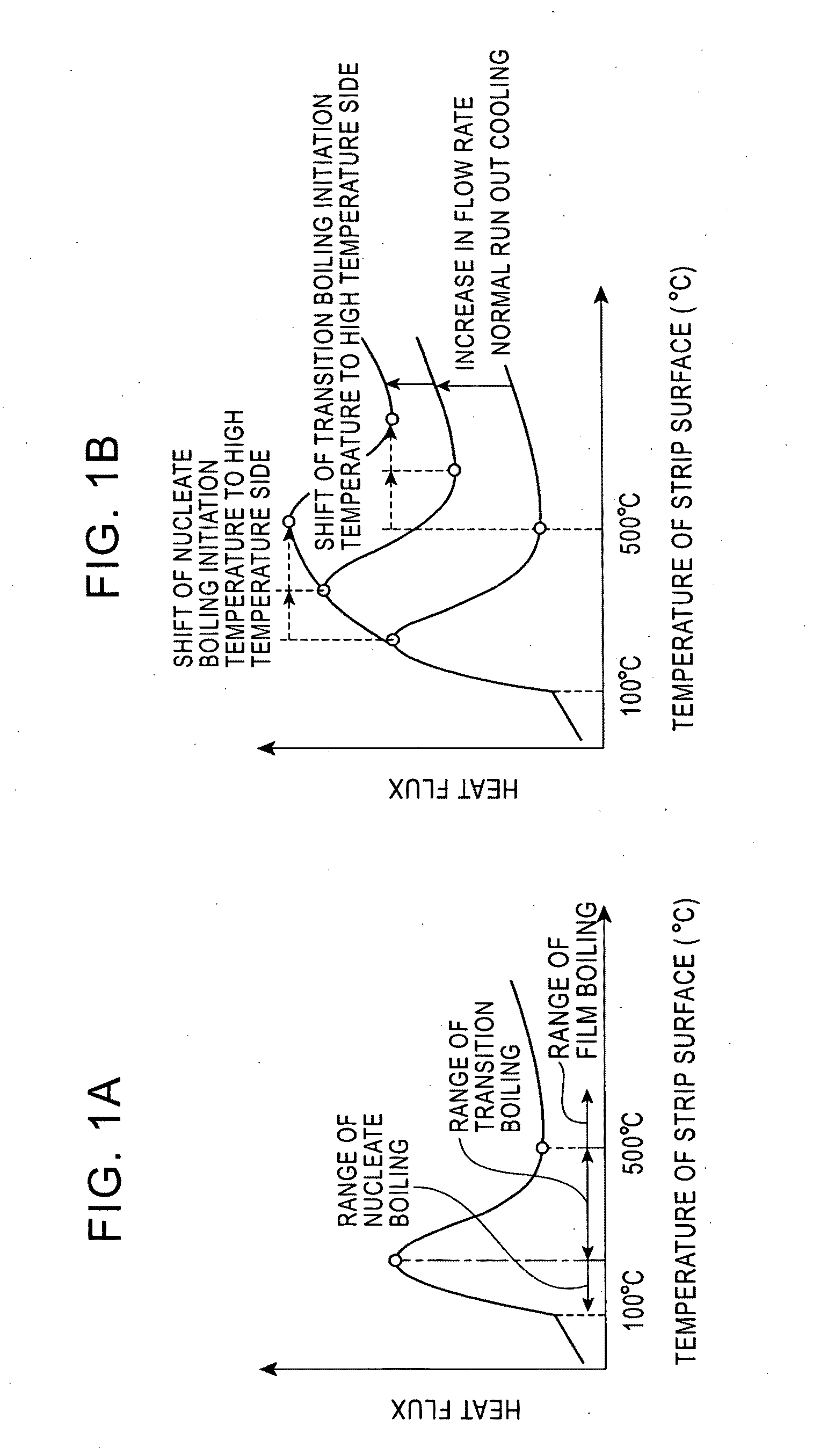

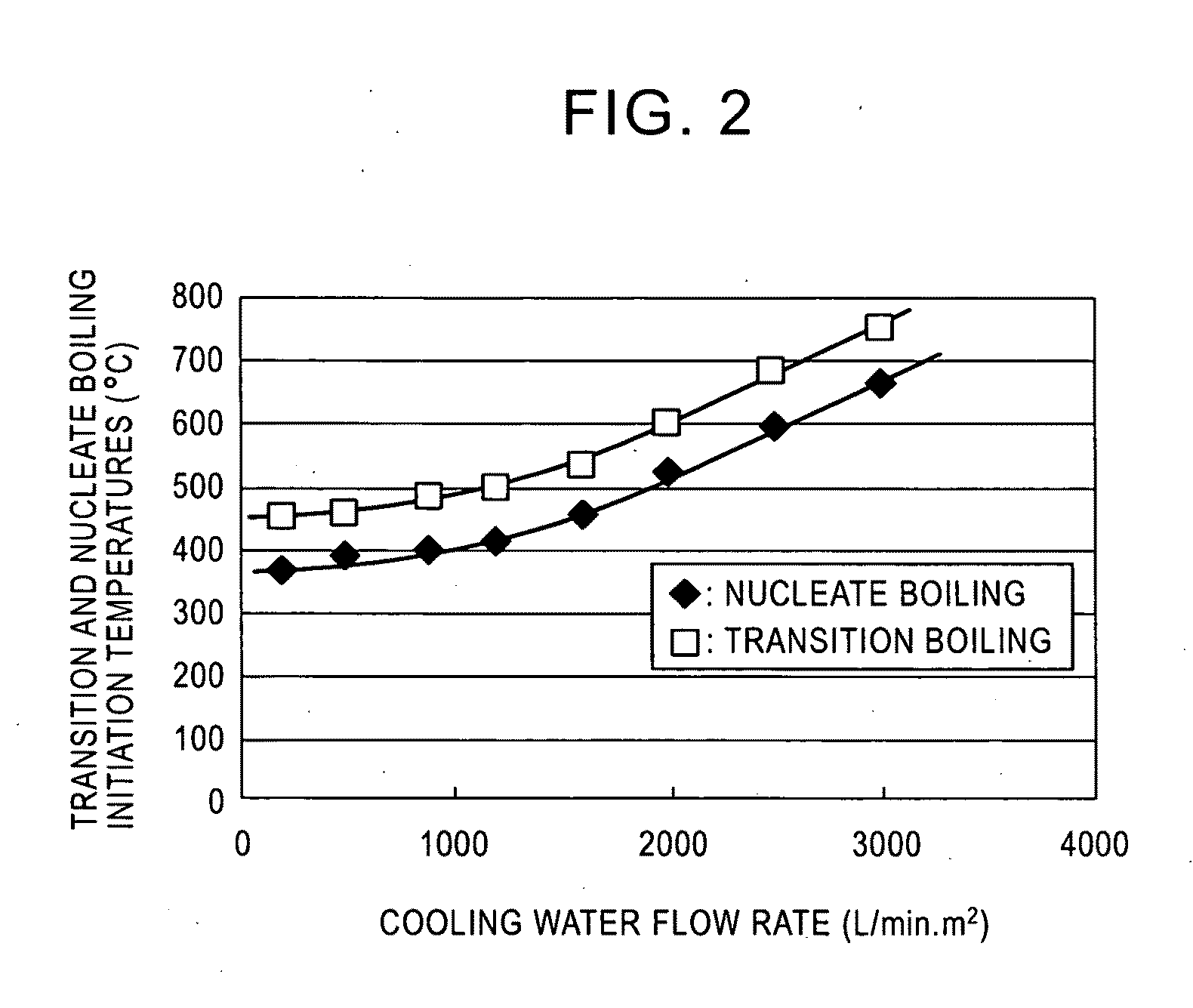

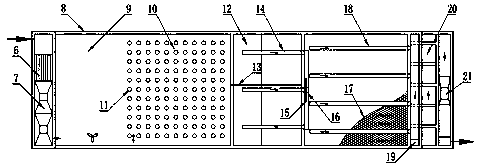

Method for cooling hot strip

ActiveUS20100192658A1Reduce temperature changesAvoid instabilityShaping toolsTemperature control deviceThermal instabilityWater flow

A method for cooling a hot strip with less facilities and processing costs in which the temperature variation of a strip after cooling is controlled to be small and a cooling end temperature can be precisely controlled particularly when the hot strip is cooled to the temperature range of 500° C. or less is provided. The method for cooling a hot strip, which is obtained after a hot rolling process, by bringing cooling water into contact with the hot strip, includes a first cooling step and a subsequent second cooling step. In this method, cooling is stopped at a strip temperature that is higher than a transition boiling initiation temperature in the first cooling step, and the cooling is conducted using the cooling water having a water flow rate that causes nucleate boiling in the subsequent second cooling step. Entering the temperature range of transition boiling can be completely prevented to avoid thermal instability in cooling resulting from the transition boiling, and the temperature variation of the strip after cooling is controlled to be small while the cooling end temperature can be precisely controlled.

Owner:JFE STEEL CORP

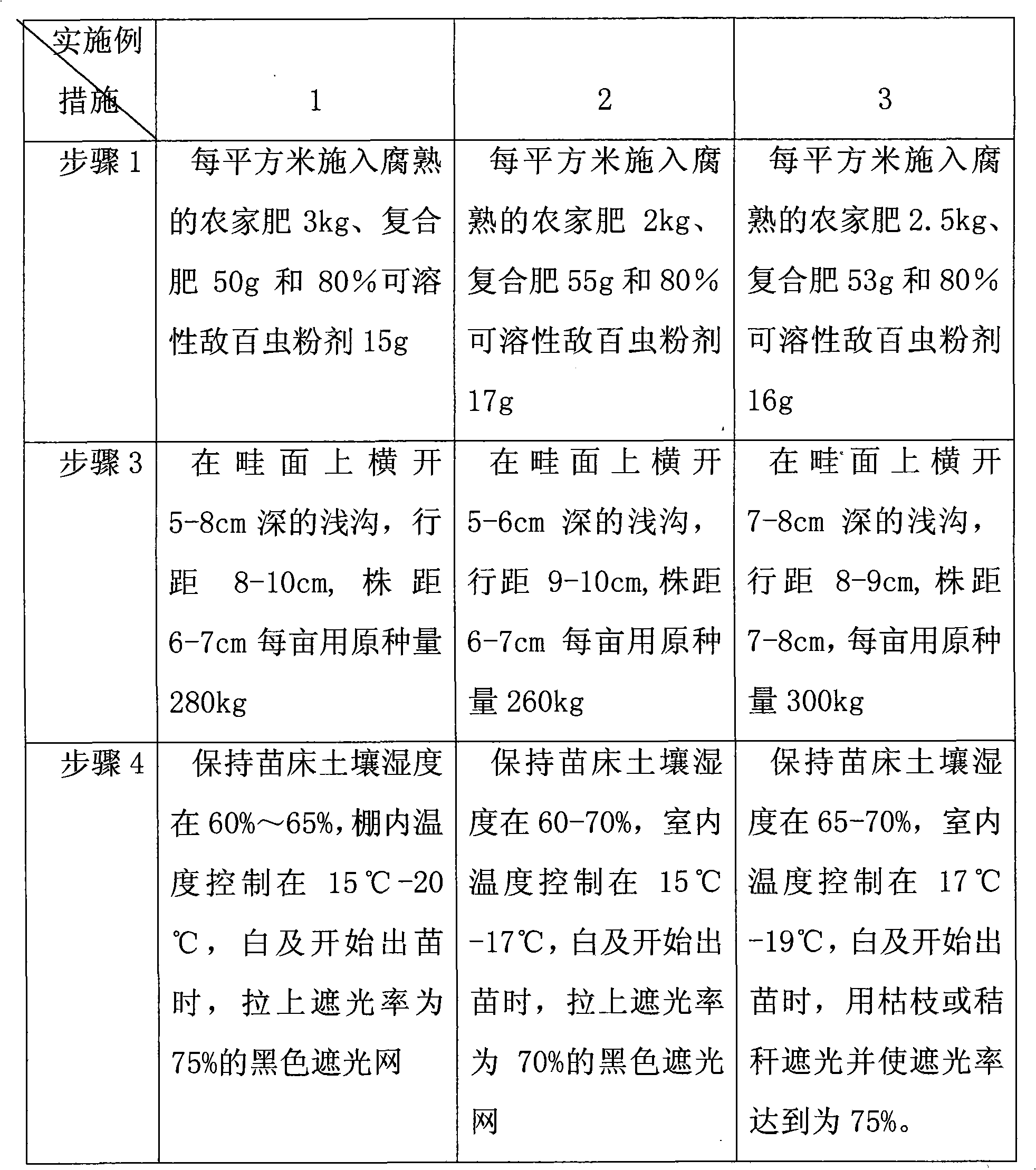

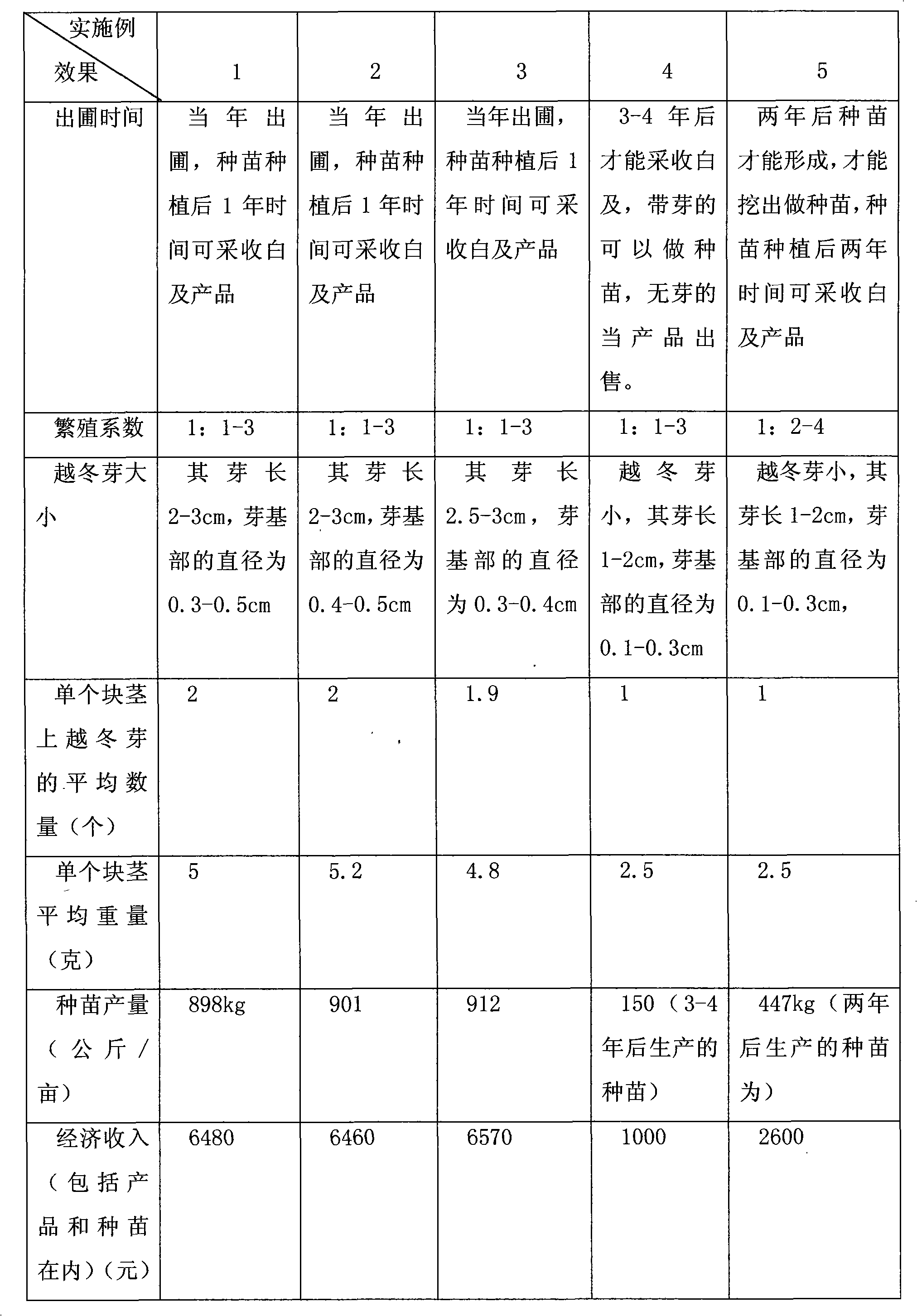

Bletilla germchit propagation method

ActiveCN101524030AShort multiplication timeShorten the breeding periodPlant protective coveringsSoil-working methodsComing outRoom temperature

The invention provides a bletilla germchit propagation method, belonging to the technical field of Chinese medical herb cultivation. The method consists of five steps of preparation of propagation field, preparation of protospecies, field planting propagation, seedbed management and germchit coming out of nursery, comprising the following steps: fertilizing 2-3kg of thoroughly decomposed farmyard manure, 50-55g of compound fertilizer and 15-17g of 80% soluble dipterex powder agent in the protected field to be evenly mixed with the soil; selecting the bletilla tuber having 3-5g of single tube with at least one hibernaculum as the protospecies; digging transversely shallow furrows with depth of 5-8cm on the border checks with the space between rows of 6-8cm*8-10cm, the seedbed soil humidity of 60-70%, and the room temperature of 15-20 DEG C; and covering a black lightproof net with the lightproof rate of 70-75% when the germchits coming out of the nursery. In the invention, the propagation period is one year earlier than the contrast and the average income of the germchits per mu can achieve * yuan. As the quality of the germchits is good, each mu can increase 100-240kg of production, thus increasing income.

Owner:云南省农业科学院高山经济植物研究所 +1

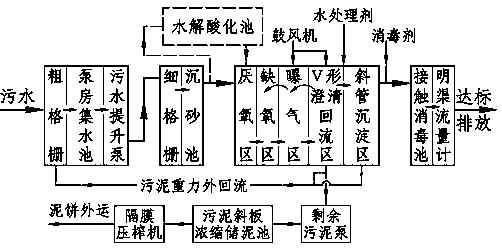

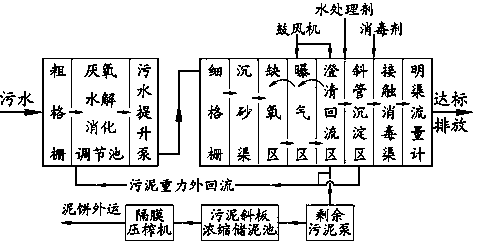

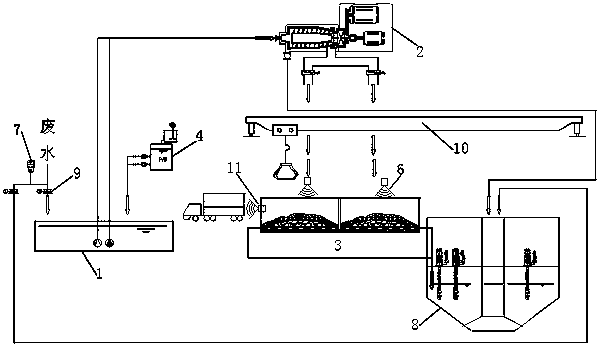

V-shape air-stripping technology for removing nitrogen and phosphorus of large and medium-sized sewage processing

ActiveCN103395950AGood removal effectLarge particle sizeSludge treatment by de-watering/drying/thickeningMultistage water/sewage treatmentActivated sludgeReflux

The invention provides a V-shape air-stripping technology for removing nitrogen and phosphorus of large and medium-sized sewage processing. The technology comprises following steps: introducing sewage, subjecting the sewage to go through a coarse screen to remove the slag, then adding water, lifting by a sewage pump, subjecting the sewage to a fine screen, transporting the sewage to a sand settling pool, transporting the sewage to a hydrolysis acidification pool, transporting the sewage to an integral processing pool of V-shape air stripping reflux and two-grade precipitation, transporting the sewage to a disinfecting pool and finally discharging the sewage if the quality of the sewage meets the standard. In the technology, the integral sewage processing pool of V-shape air stripping reflux and two-grade precipitation substitutes the biochemical reaction pool of A / A / O activated sludge process, the nitrated liquid internal reflux pump pool, the secondary precipitation pool, the sludge internal influx and external influx pump pool, the coagulation reaction pool and the inclined tube precipitation pool, and thus the high efficiency and compactness of removing nitrogen and phosphorus in sewage are achieved. Compared to the conventional processing technology, the V-shape air-stripping technology has the advantages of small occupied area, low investment, little drug consumption, little sludge discharge, low energy consumption, low cost, stable and controllable water quality, and convenient operation management.

Owner:WUHAN PURGELON ENVIRONMENTAL ENG TECH

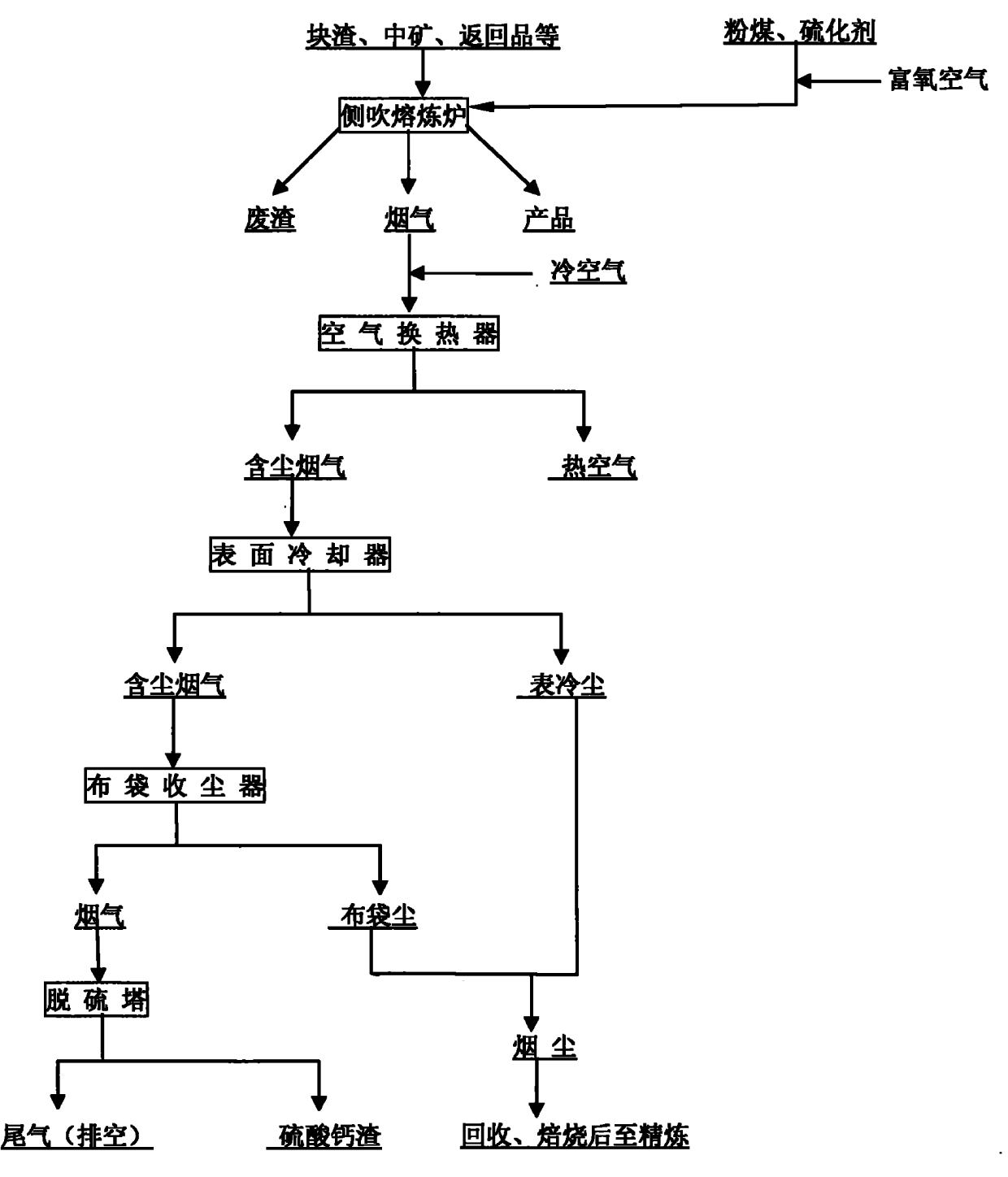

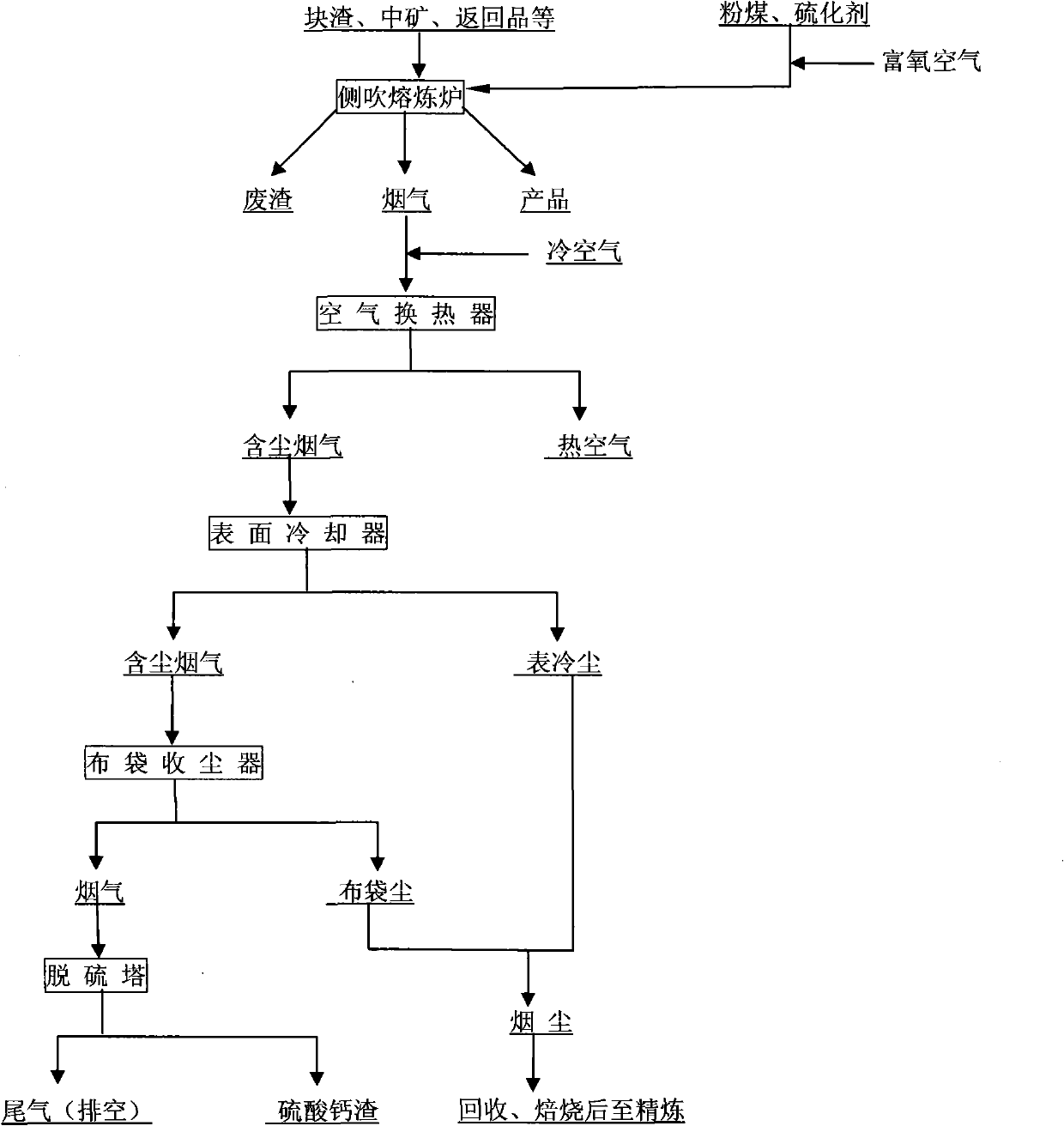

Solder splash side blowing molten pool smelting furnace cold metal direct making fuming volatilization method

InactiveCN101906540AAdaptableImprove emission reduction effectProcess efficiency improvementMelting tankAir volume

The invention relates to a side blowing molten pool smelting material cold metal fuming volatilization direct making method, belonging to the non-ferrous metallurgy technical field. The invention includes the following technological steps: (1) crushed gold-containing metal slag charge and solvent are mixed by slag silicate degree calculated value in complete reaction, and stirring to be uniform is carried out, so as to form furnace burden; (2) ignition and blowing in are carried out on a side blowing molten pool smelting furnace, and a melt with the depth of 200-500mm is produced in the molten pool; (3) the charging speed of furnace burden is consistent with the smelting speed, wind pressure, blowing rate, coal dust charging quantity and smelting temperature are controlled, reduction smelting is carried out, charging is stopped when the height of molten layer is 800-1300mm, and reduction smelting is further enhanced; (4) vulcanizer is added in steps in calculated quantity, the wind pressure, blowing rate and coal dust charging quantity are controlled, sulfiding volatilization is carried out, waste slag is discharged, the bed charge melt with the depth of 200-500mm is remained, and operation of the next round is carried out. The invention has less investment, high heat utilization ratio, rapid smelting, low energy consumption, less occupying area and short production period and is convenient for mass production.

Owner:杨龙安 +1

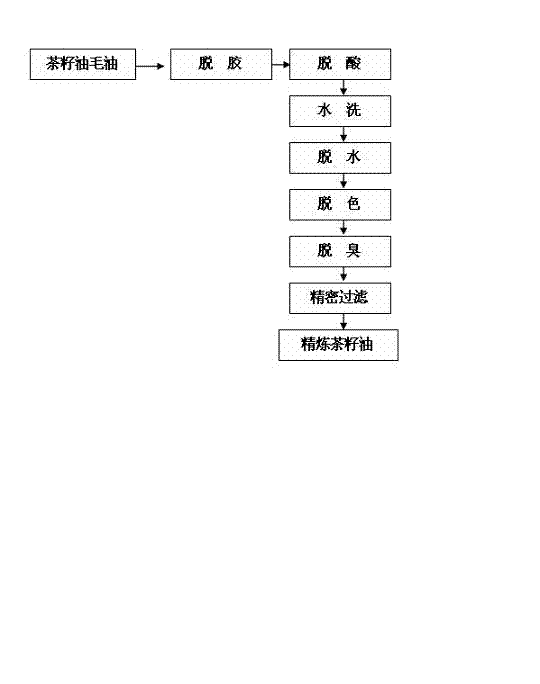

Method for refining tea seed oil

ActiveCN103087819ASimple production processFew facilitiesFatty-oils/fats refiningProcess engineeringWinterization

A method for refining tea seed oil includes taking tea seed oil crude oil as a raw material, and producing refined tea seed oil by processes of degumming, deacidifying, washing, decoloring, deodorizing and precisely filtering. Precise filtration is used for removing wax and other substances, and takes the place of the conventional winterization in tea seed oil refining production technology. The product reaches the quality using the winterization technology. The method helps to simplify the production process, reduce equipments and facilities needed for winterization, and reduce the production cost.

Owner:GUANGXI FORESTRY RES INST +1

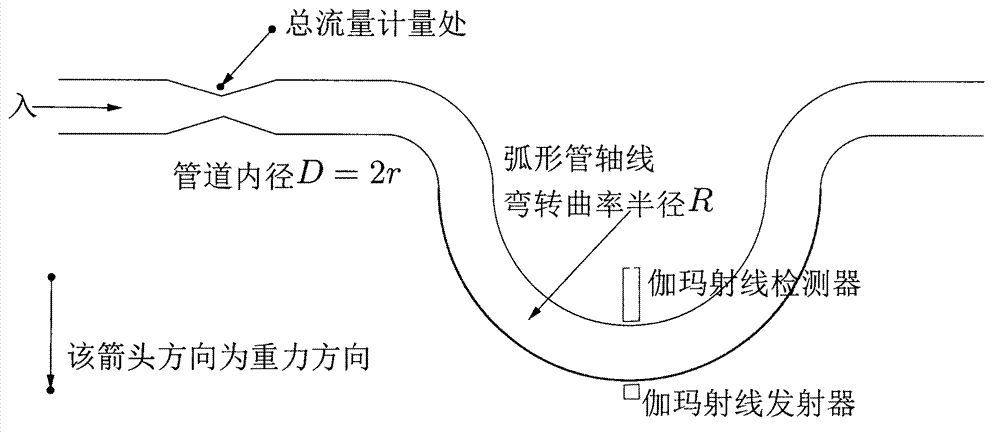

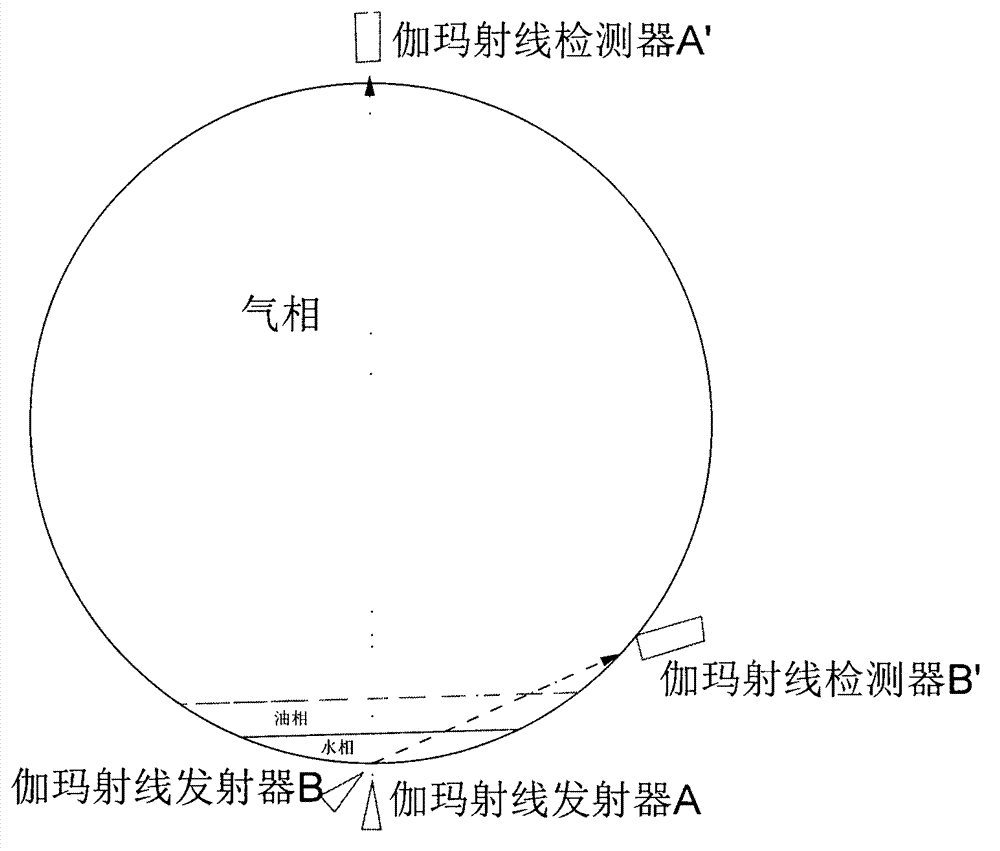

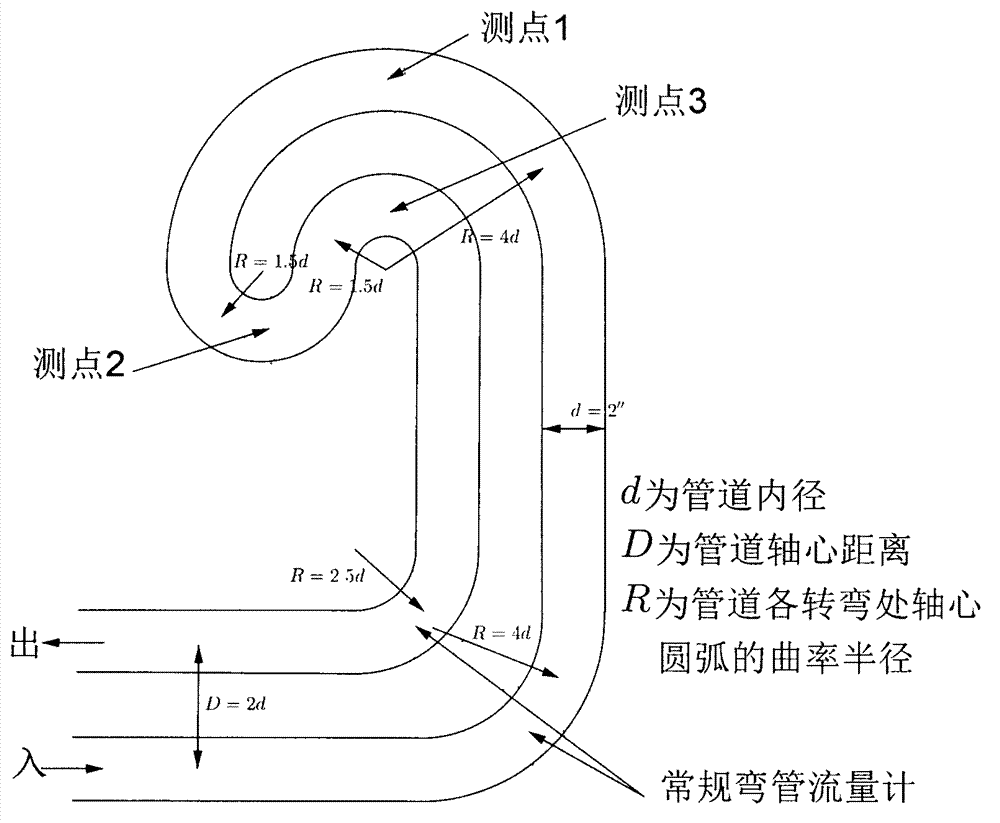

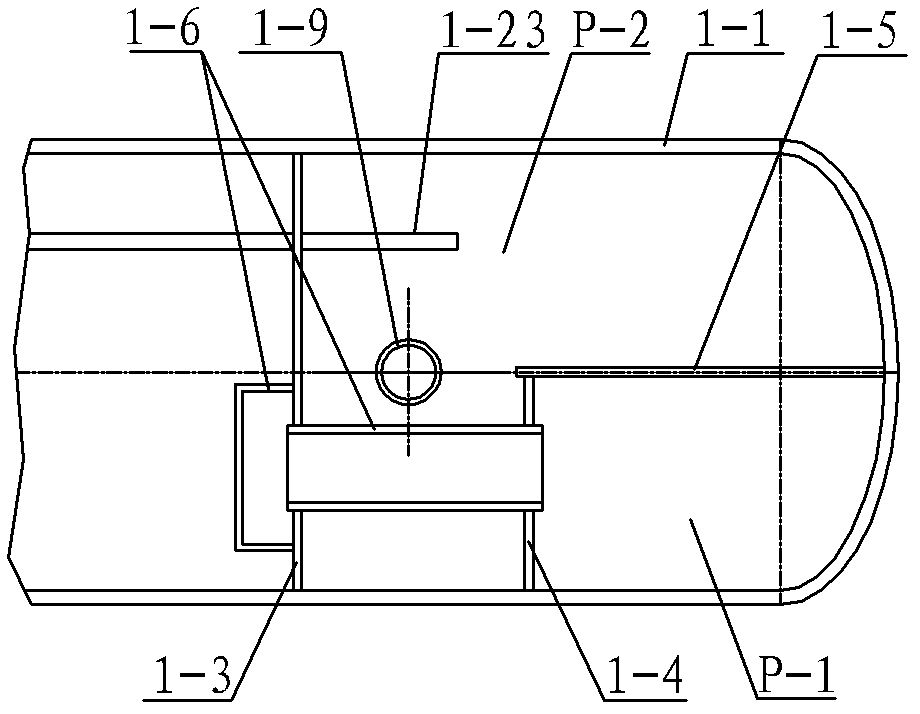

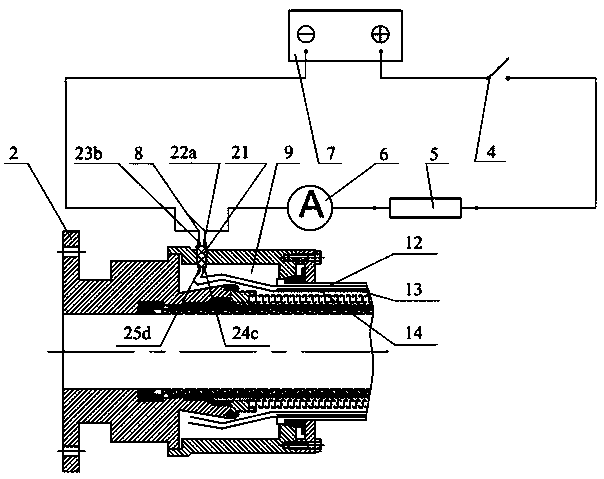

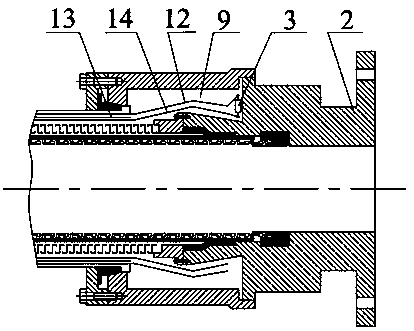

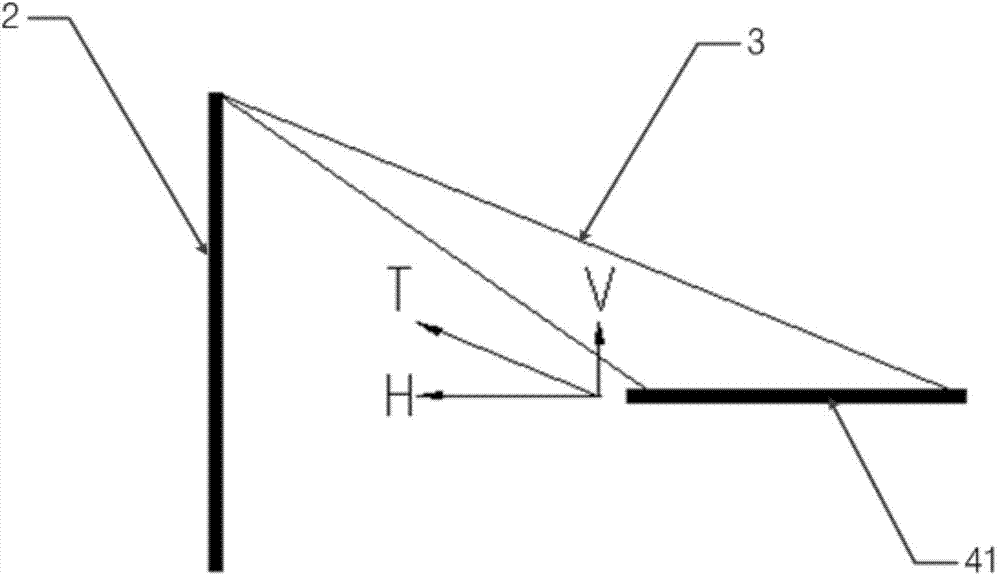

Arc-shaped pipe based flow metering device and metering method for multiphase flow

ActiveCN103090917AGuaranteed representationFew facilitiesVolume flow proportion measurementVolume/mass flow by dynamic fluid flow effectEngineeringMechanical engineering

The invention relates to a flow metering device for multiphase flow. The flow metering device for multiphase flow comprises the following constructional elements: a pipeline containing at least one section of an arc-shaped pipe, wherein the cross section of the arc-shaped pipe is in a circular shape, the plane where the arc-shaped pipe is located is vertical-oriented, and the arc-shaped pipe is provided with at least one vertical-oriented cross section; a gamma-ray explorer, wherein the gamma-ray detector comprises a gamma-ray emitter and a gamma-ray detector, the gamma-ray emitter and the gamma ray detector are respectively arranged on the upper side and the lower side of the vertical-oriented cross section of the arc-shaped pipe in a distributed mode, gamma ray emitted by the gamma-ray emitter passes through in a radial or non-radial mode along the vertical-oriented cross section of the arc-shaped pipe and arrives at a gamma-ray receiver, and the gamma-ray explorer is a monoenergetic gamma-ray explorer or a dual-energetic gamma-ray explorer; and total volume flow measurement equipment, wherein the total volume flow measurement equipment is placed in the upstream or downstream of the arc-shaped pipe and is used for calculating multiphase flow total volume flow. The invention further relates to a method measuring each phase volume flow in multiphase flow by utilizing the flow metering device for multiphase flow.

Owner:LANZHOU HAIMO TECH CO LTD

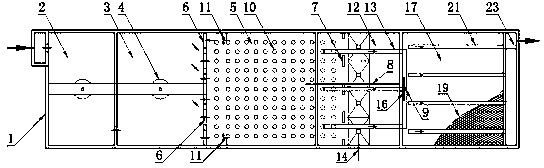

Small sewage treatment hydrolysis and gas-stripping and precipitation technique method

ActiveCN103408194AHigh originalityGood effectMultistage water/sewage treatmentActivated sludgeFlocculation

The invention provides a small sewage treatment hydrolysis and gas-stripping and precipitation technique method which comprises the following steps of: underground sewage, integrated anaerobic hydrolysis acidifying adjustment lift pump pond, integrated sewage treatment pond for Z type gas-stripping reflux two-stage precipitation, and up-to-standard emission. The anaerobic hydrolysis acidifying adjustment lift pump pond is adopted to replace various conventional and non-conventional comprehensive pretreatment procedures, the integrated sewage treatment pond for Z type gas-stripping reflux two-stage precipitation is adopted to replace procedures of a fine-rack girt chamber, an A / O biochemical reaction basin, a nitration liquid internal-reflux pump basin, a secondary precipitation basin, a sludge internal-reflux pump basin, a sludge external-reflux pump basin, a coagulation-flocculation reaction basin and an inclined-tube precipitation basin, a contact sterilization basin and the like in an A / O activated sludge method. The method has the advantages of being small in occupied space, less in investment and medicine consumption and sludge discharge, low in energy consumption and cost, stable and controllable in water quality, simple and convenient to run and manage, especially suitable for high-efficiency and compact treatment of nitrogen and phosphorus removal of sewage of ten thousand tonnage / per day and below.

Owner:WUHAN PURGELON ENVIRONMENTAL ENG TECH

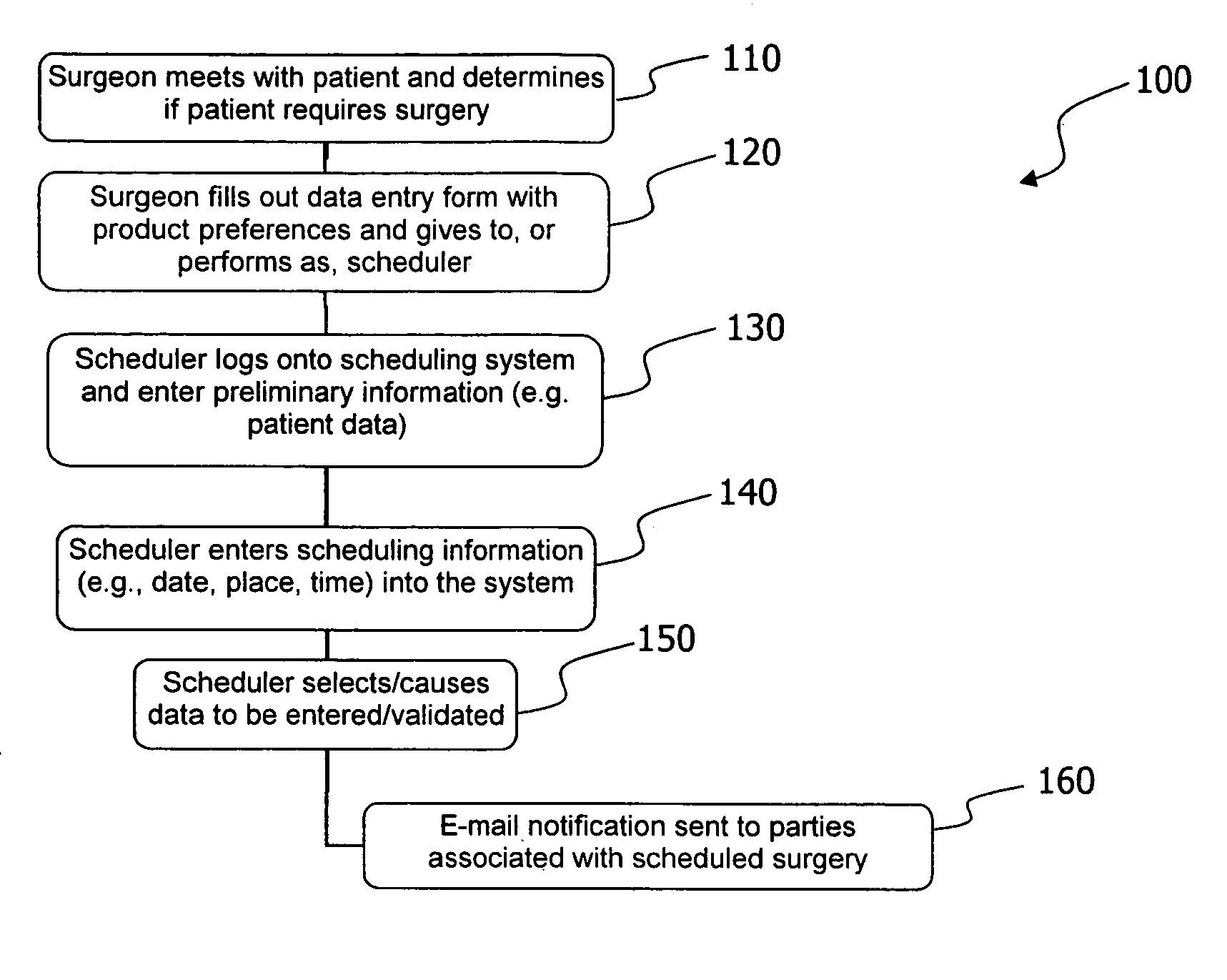

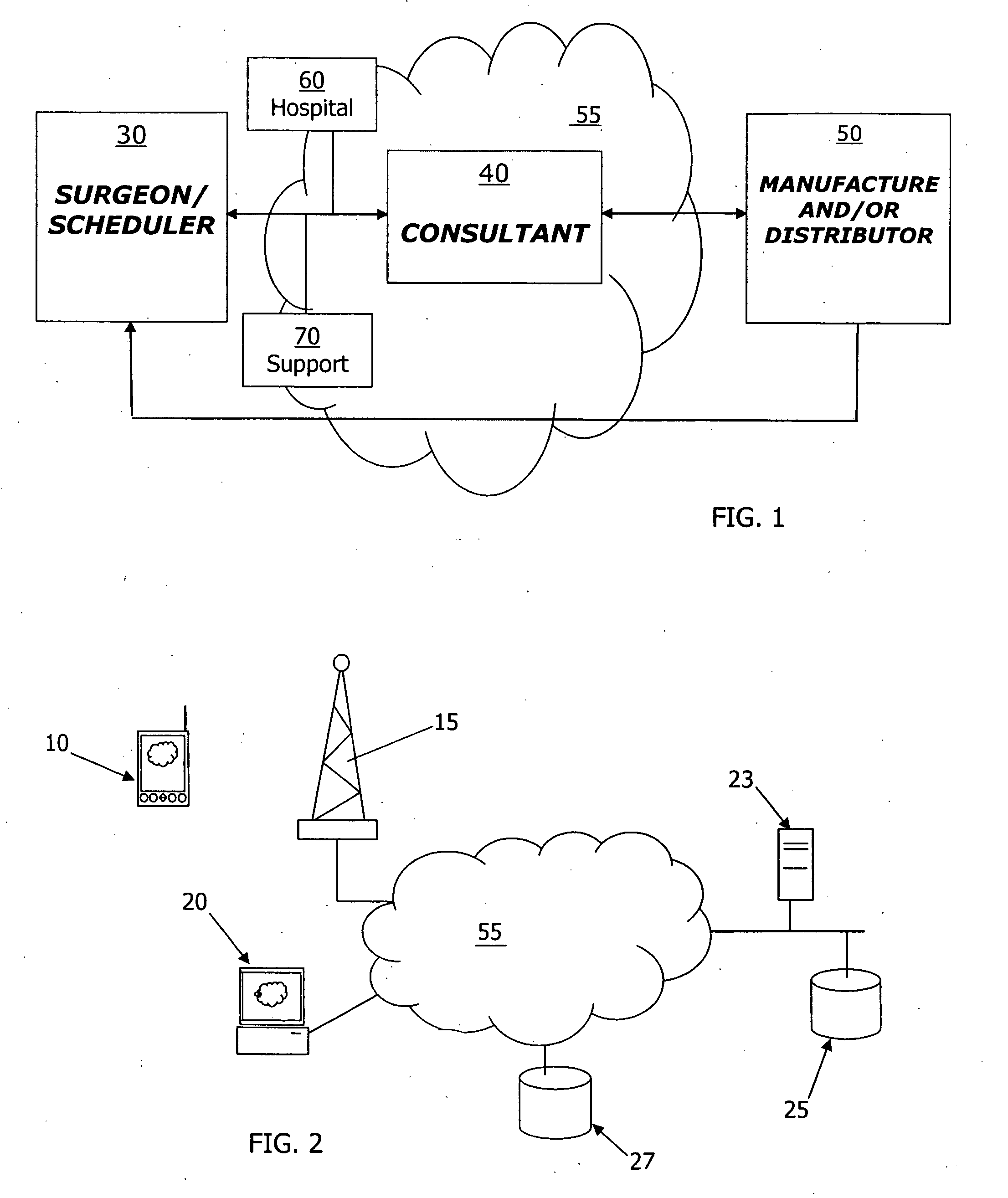

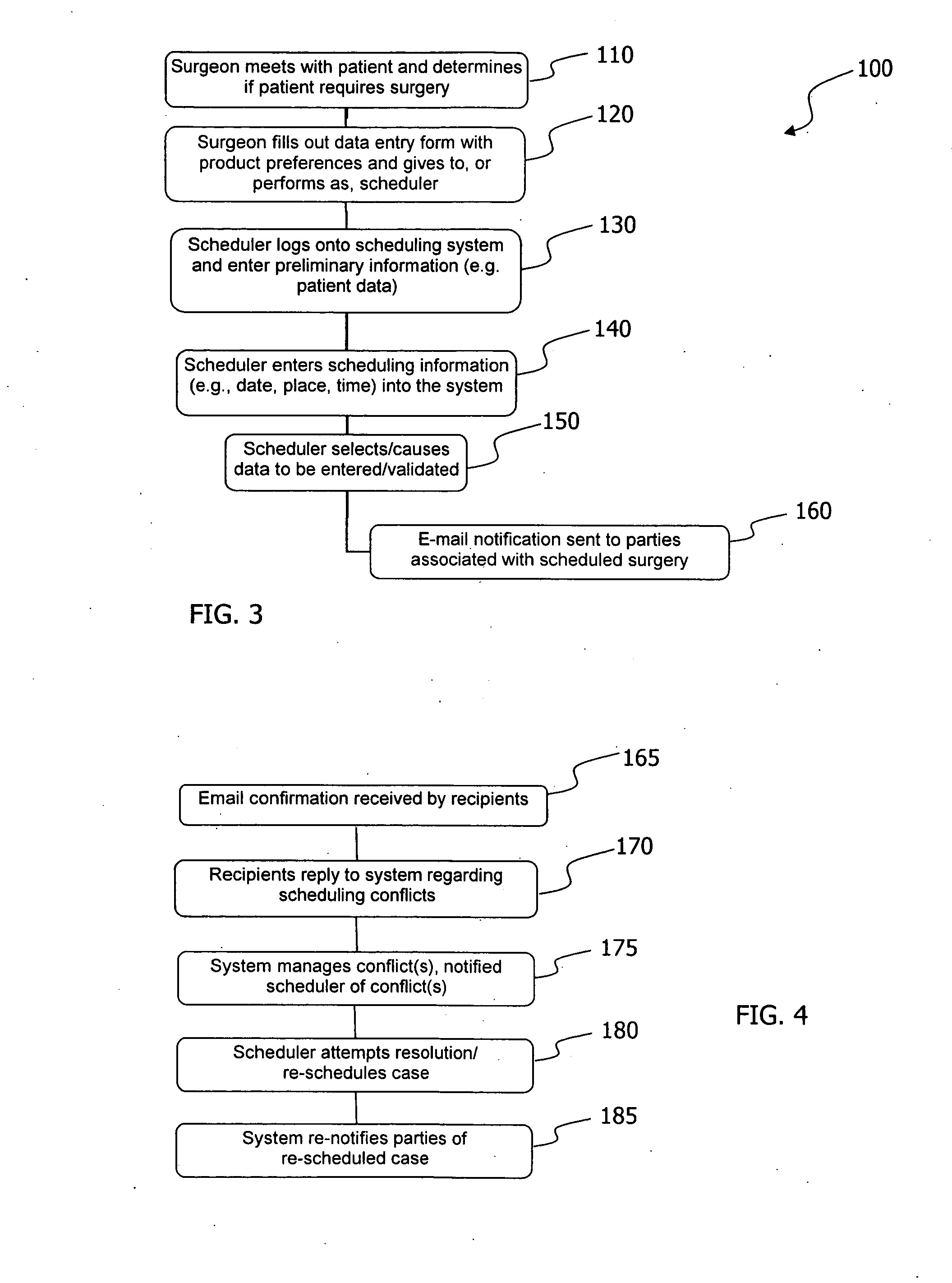

Medical case scheduling, logistics management and associated data management

InactiveUS20070185733A1Reduce decreaseAccurate dataMechanical/radiation/invasive therapiesOffice automationLogistics managementData management

Methods and systems enable the electronic scheduling of medical procedures. Schedulers log into a scheduling system to electronically submit medical procedure requests. Requests include entry of patient data together with at least one of: procedure date, procedure place, procedure time, required equipment, requested medical personnel, as part of the first medical procedure request. Once request is accepted by the scheduling system, electronic notifications about the request are automatically sent over a data network to parties associated with the medical procedure (e.g., medical facility, medical personnel, equipment distributors). System enables rescheduling or resolution where scheduling conflicts are indicated.

Owner:ROADY MARK

Casting mold for single cylinder diesel body, external casting mold for horizontal parting multi-cylinder diesel body and cast parts, and energy-saving low-carbon casting process of external casting mold

The invention provides an energy-saving low-carbon casting process for a single cylinder diesel body, which comprises manufacture of the mold, wherein a resin sand and triethylamine curing technique is used during the manufacture of an external mold; a mold gate is located at a spindle hole of the diesel body; and an exhaust port is arranged on a balance axle hole of the diesel body. By using thenovel process provided by the invention, defects of the single cylinder diesel production in the prior art, such as low quality, low efficiency, high energy consumption, serious pollution and intensive labor, can be solved. The invention also provides the mold used in the process. The invention further provides an external casting mold for the horizontal parting multi-cylinder diesel body and thecast parts, and the casting process of the external casting mold.

Owner:平遥县嵘兴机械制造有限公司

Plating waste gas treatment device

ActiveCN102330141AClosed loopSave raw materialsCellsUsing liquid separation agentTemperature controlEvaporation

The invention discloses a plating waste gas treatment device used for evaporation concentration of a solid-containing aqueous solution in the industries of plating, chemistry, chemical engineering and the like. The device comprises an air suction cover arranged on a plating tank, wherein the air suction cover is communicated with a spray compartment through an air suction pipe; the spray compartment is communicated with a gas-liquid separation tower, and a plurality of spray heads are arranged in the spray compartment; the bottom of the gas-liquid separation tower is provided with a reclaiming liquid collecting compartment communicated with the spray compartment; a collision cap is arranged above the reclaiming liquid collecting compartment; a filler layer is arranged above the collision cap; the upper part of the filler layer is connected with an air outlet pipe; the air outlet pipe is connected with a fan, and the bottom of the reclaiming liquid collecting compartment is connected with a reflux pipe; the reflux pipe is communicated with a temperature controlled evaporation tank; and the spray heads are communicated with a temperature controlled evaporation device through circulating cooling pumps. The plating waste gas treatment device has the advantages of small volume, convenience for maintenance, remarkable energy conservation, controllable concentration and long service life.

Owner:无锡出新环保设备有限公司

Thermal process for food enhancement

ActiveUS9060523B1Alter appearanceAlter flavorClimate change adaptationSteam cooking vesselsFlavorWater activity

A thermal process used to modify the moisture content and appearance of food, primarily meat, poultry and fowl, so that the resulting product will meet the USDA label requirement as “Jerky”. The process takes place in one or more enclosed insulated chambers which have temperature and relative humidity controls and reversing horizontal air flow. The process preconditions the product and also controls the application of superheated steam to the product, thereby controlling the reduction of free and bound moisture (water activity) exiting from the product. In addition, enhanced heated vapors can be added to be absorbed into the product's surface pours, thereby changing the appearance and flavor of the product and improving the end products' yields. The completed process also has the advantages of meeting lethality treatment requirements while also reducing the thermal processing time and energy associated with existing Jerky manufacturing methods.

Owner:BULLER COLTHURST GUY E

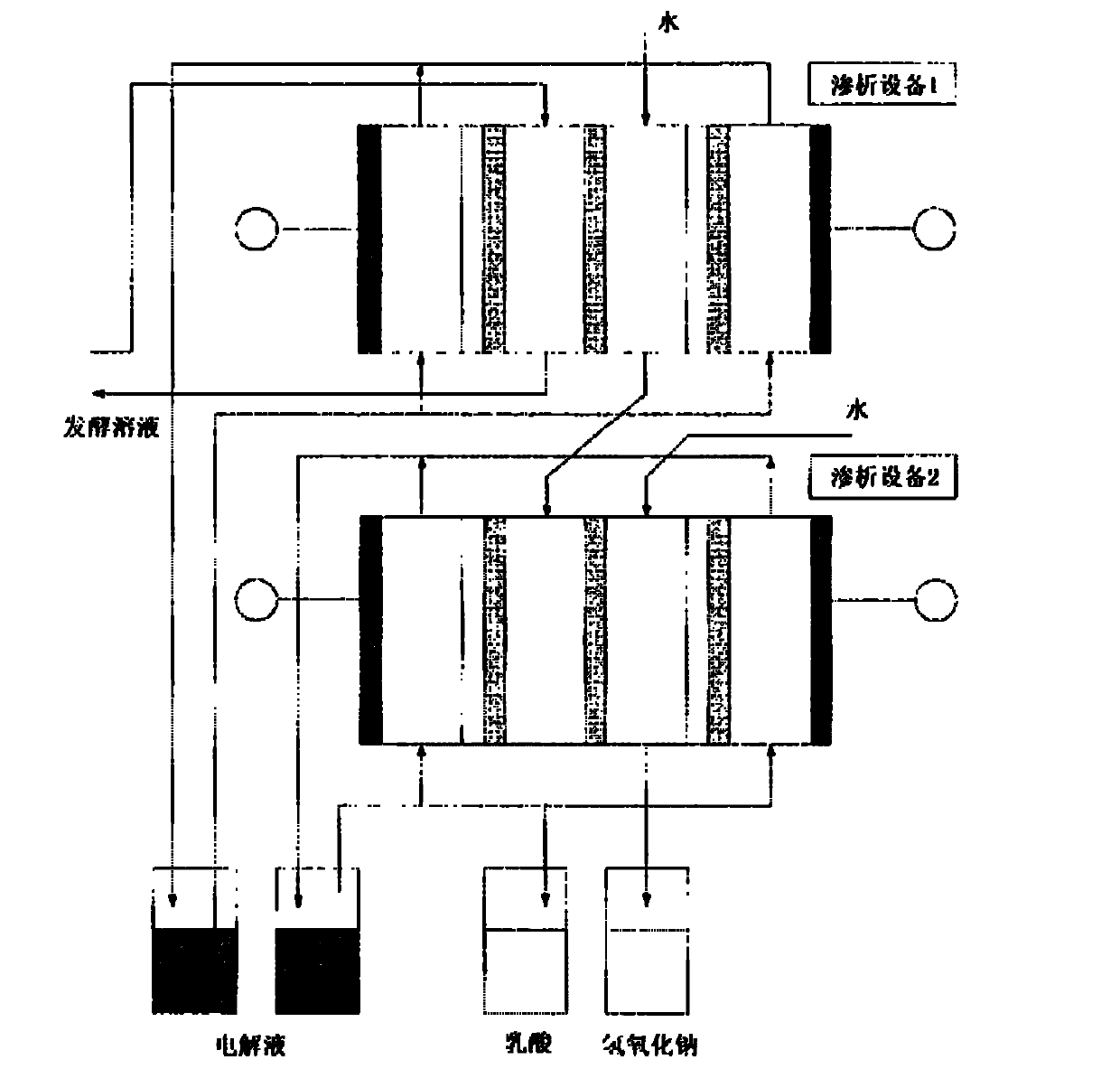

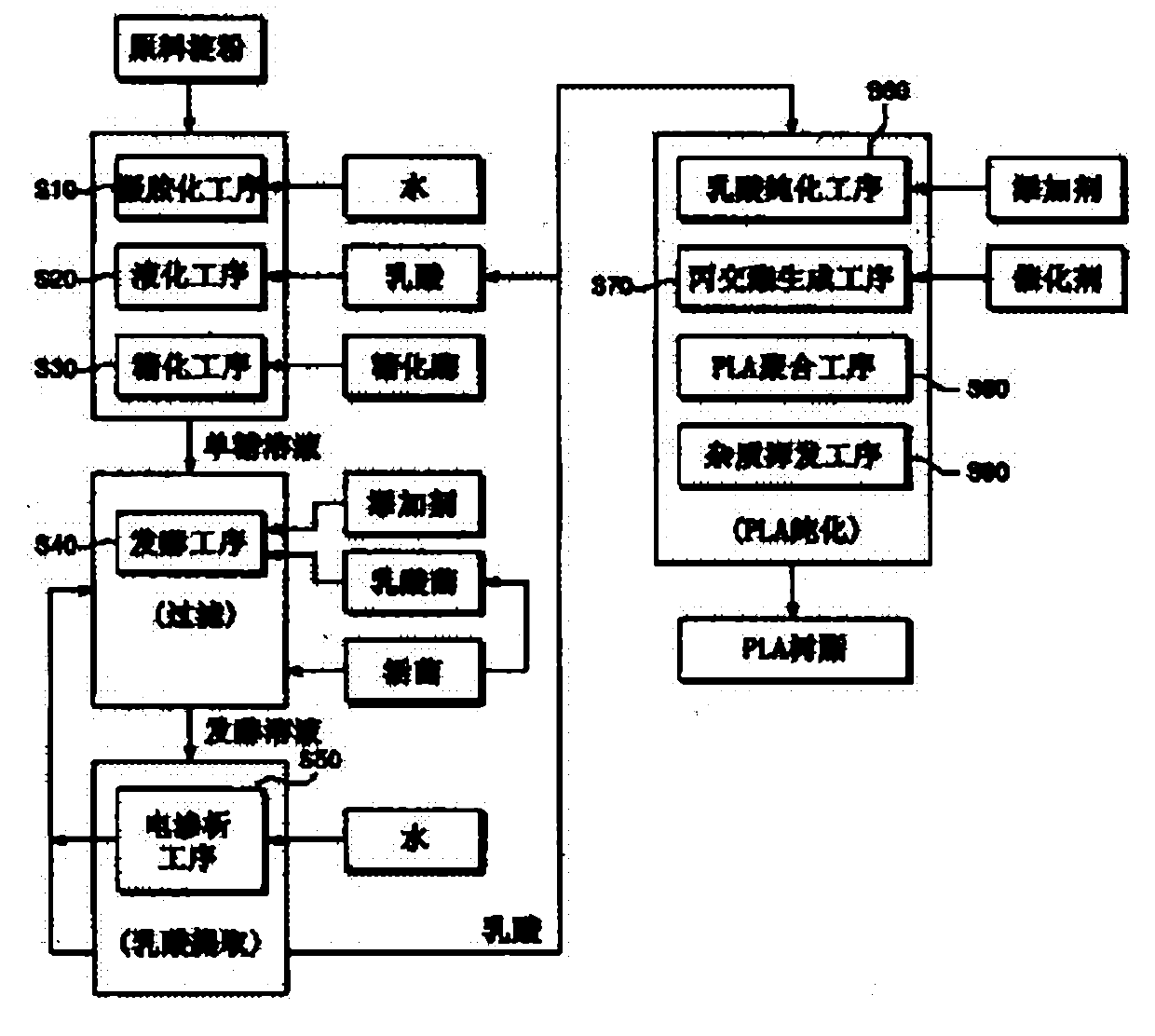

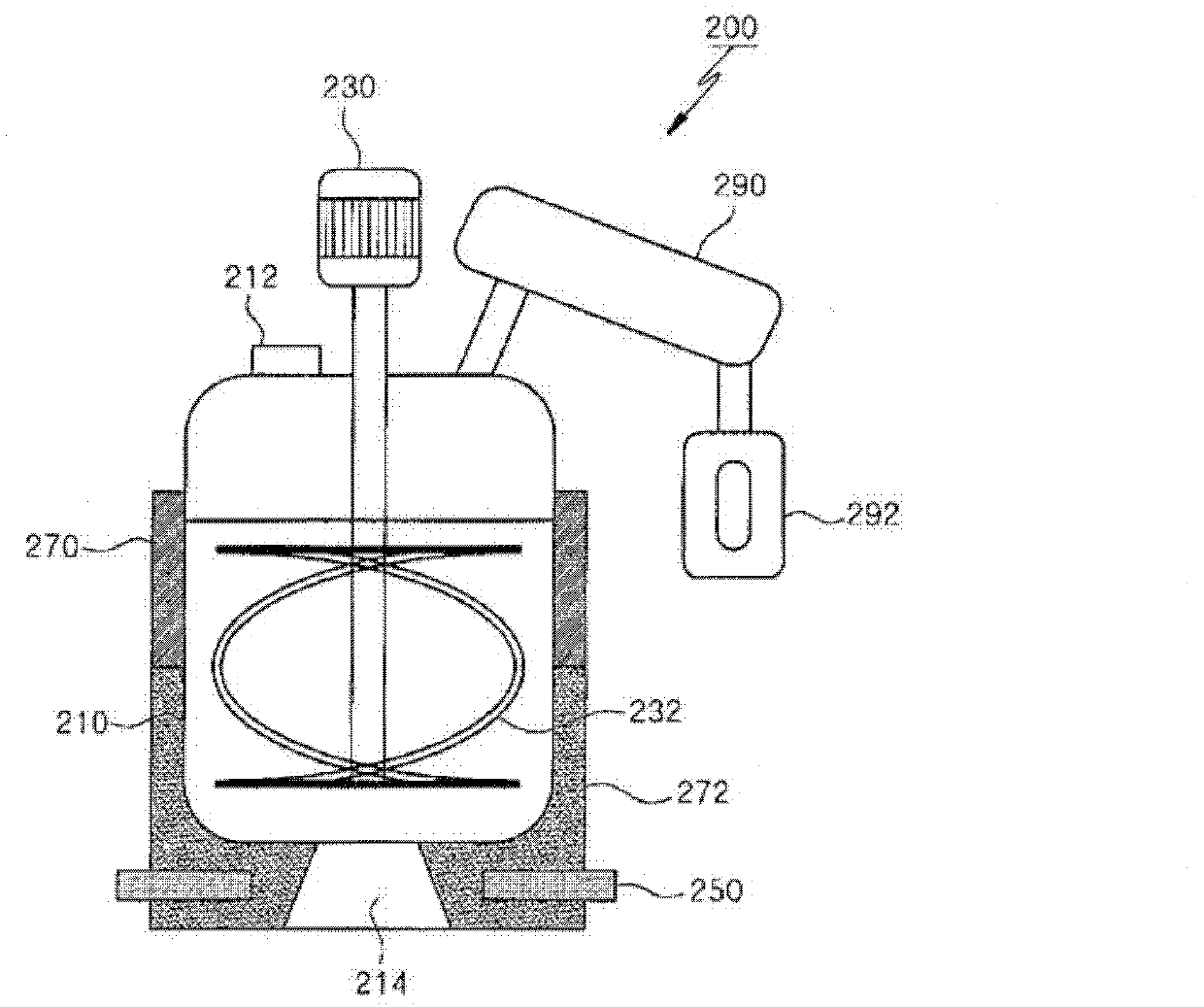

Method for producing polylactic acid and a highly conductive polymer, and apparatus for producing highly conductive polylactic acid polymer

InactiveCN102712745AEasy to manufactureFew facilitiesChemical/physical/physico-chemical stationary reactorsEnergy based chemical/physical/physico-chemical processesAcetic acidConductive polymer

The present invention relates to a method for producing polylactic acid, and more particularly, to a method for producing polylactic acid, which can increase production yield and reduce costs, and which can more conveniently produce a high molecular weight polylactic acid according to the use thereof. Also, the present invention relates to a method for producing a highly conductive polylactic acid polymer, which is economical in terms of time and cost as a highly conductive polylactic acid can be efficiently produced, and to an apparatus for producing the highly conductive polylactic acid polymer. According to the present invention, the method for producing the highly conductive polylactic acid comprises: a step S1 of adding and mixing 100 parts by weight of polylactic acid, 10 to 20 parts by weight of lactide, and 5 to 10 parts by weight of polyglycolic acid in a reaction vessel; a step S2 of adding 5 to 10 parts by weight of serine and 0.1 to 1 part by weight of dodecyl alcohol into the reaction vessel, and then feeding inert gas therein and irradiating same with electromagnetic waves; and a step S3 of adding 0.1 to 1 part by weight of acetic acid selenium into the reaction vessel, and then mixing.

Owner:POLY ENERGY

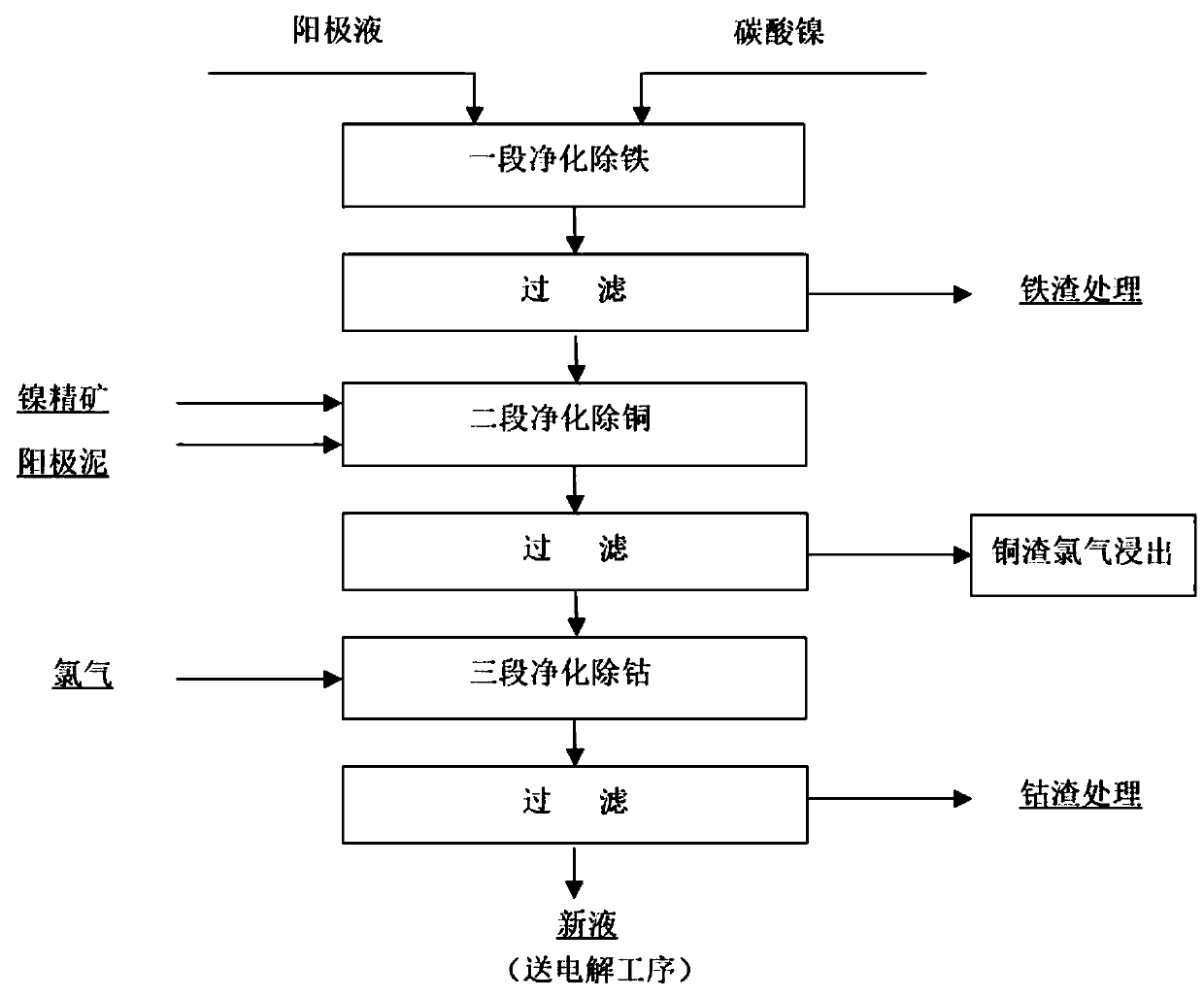

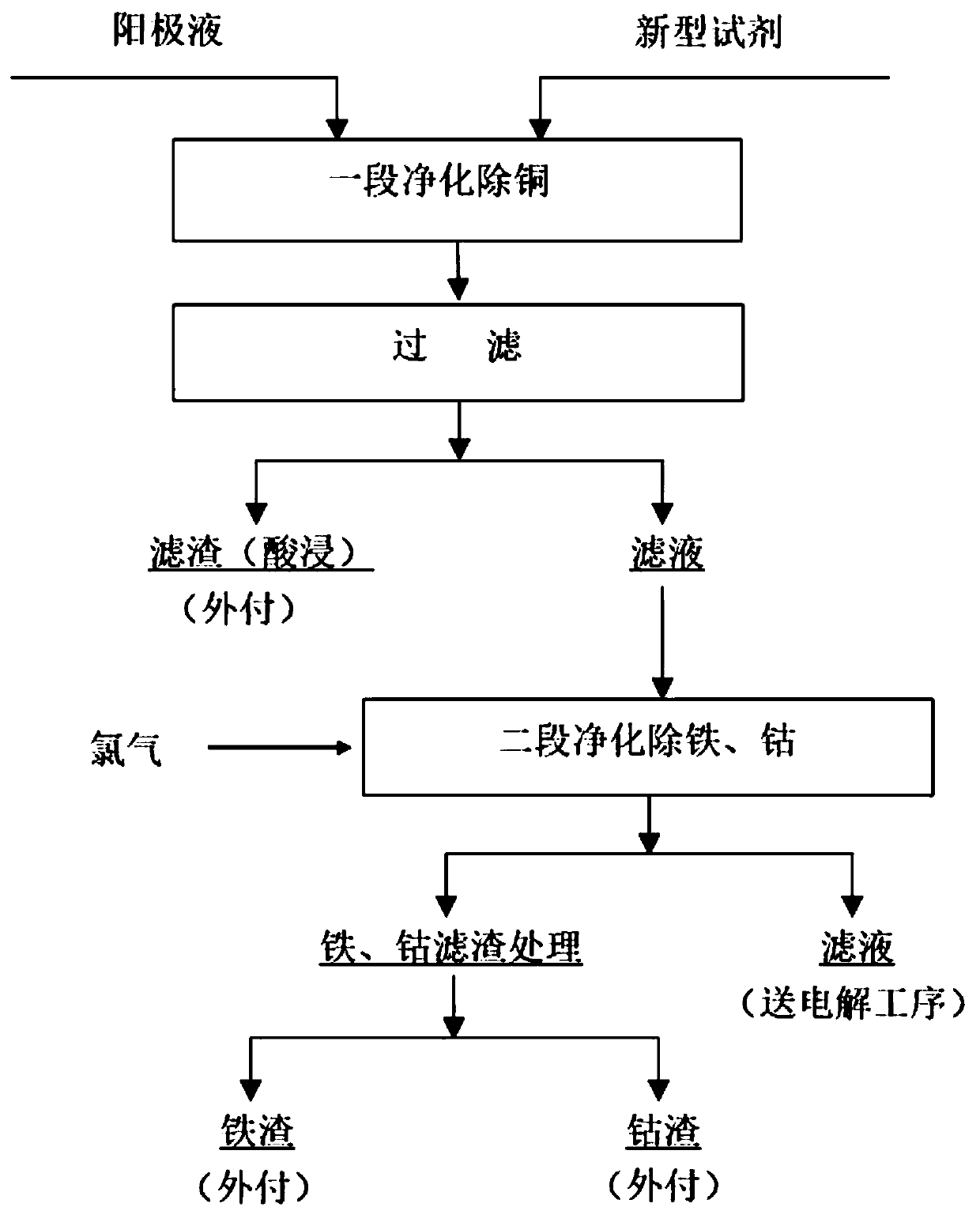

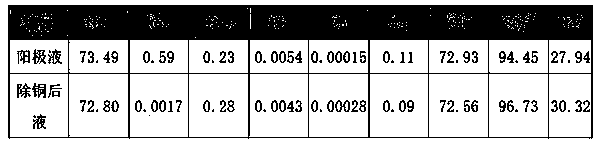

Two-stage impurity removing technology for electrolytic purification of nickel sulfide soluble anode nickel

ActiveCN109797410AReduce manufacturing costShort processElectrolysis componentsPhotography auxillary processesElectrolysisSlag

The invention discloses a two-stage impurity removing technology for electrolytic purification of nickel sulfide soluble anode nickel. According to the technology, alkaline copper removing reagent ismainly adopted under the circumstance without adjusting acid, at first, the working procedure of anode liquid copper removing is carried out, and after copper is removed, PH of a solution rises naturally; after the copper is removed, slag liquid is filtered through a pipe type filter, and after filtering is carried out, the slag is subjected to acid leaching to recover main metal nickel, copper and the like; the solution enters a solution intermediate groove, then the working procedure of iron and cobalt removing is carried out by means of the chlorine oxidation reaction, after iron and cobaltare removed, the generated slag enters the slag treatment working procedure through the pipe type filter so that iron slag and cobalt slag can be separated to recover valuable metal, the solution obtained after iron and cobalt are removed is filtered and conveyed to the electrolytic working procedures for electrolytic production, and the original three-stage purification technology of removing iron, copper and cobalt is changed into two-stage purification technology of copper and iron removing, the technology flow is reduced, and the production cost is reduced.

Owner:JINCHUAN GROUP LIMITED

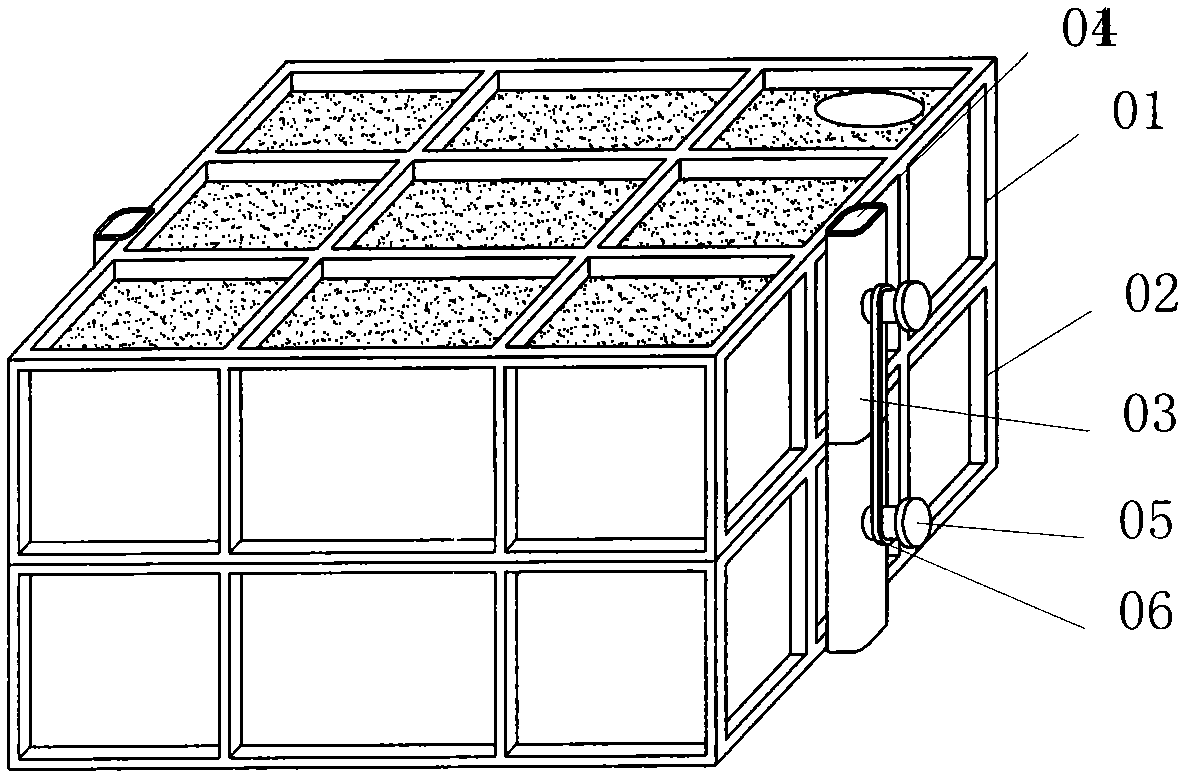

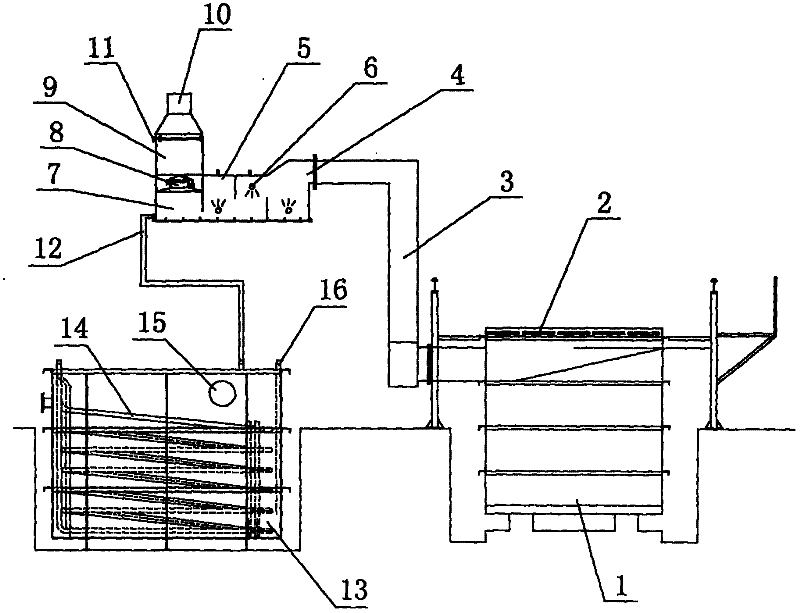

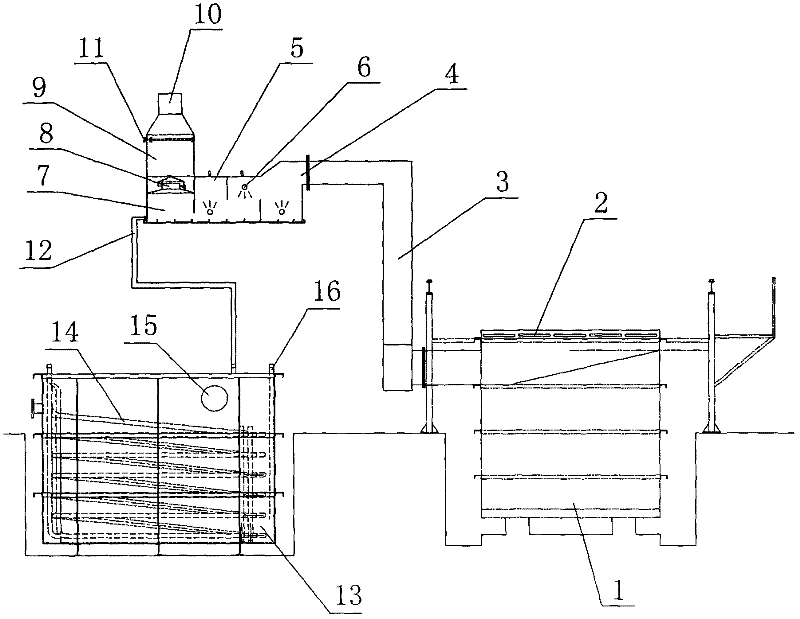

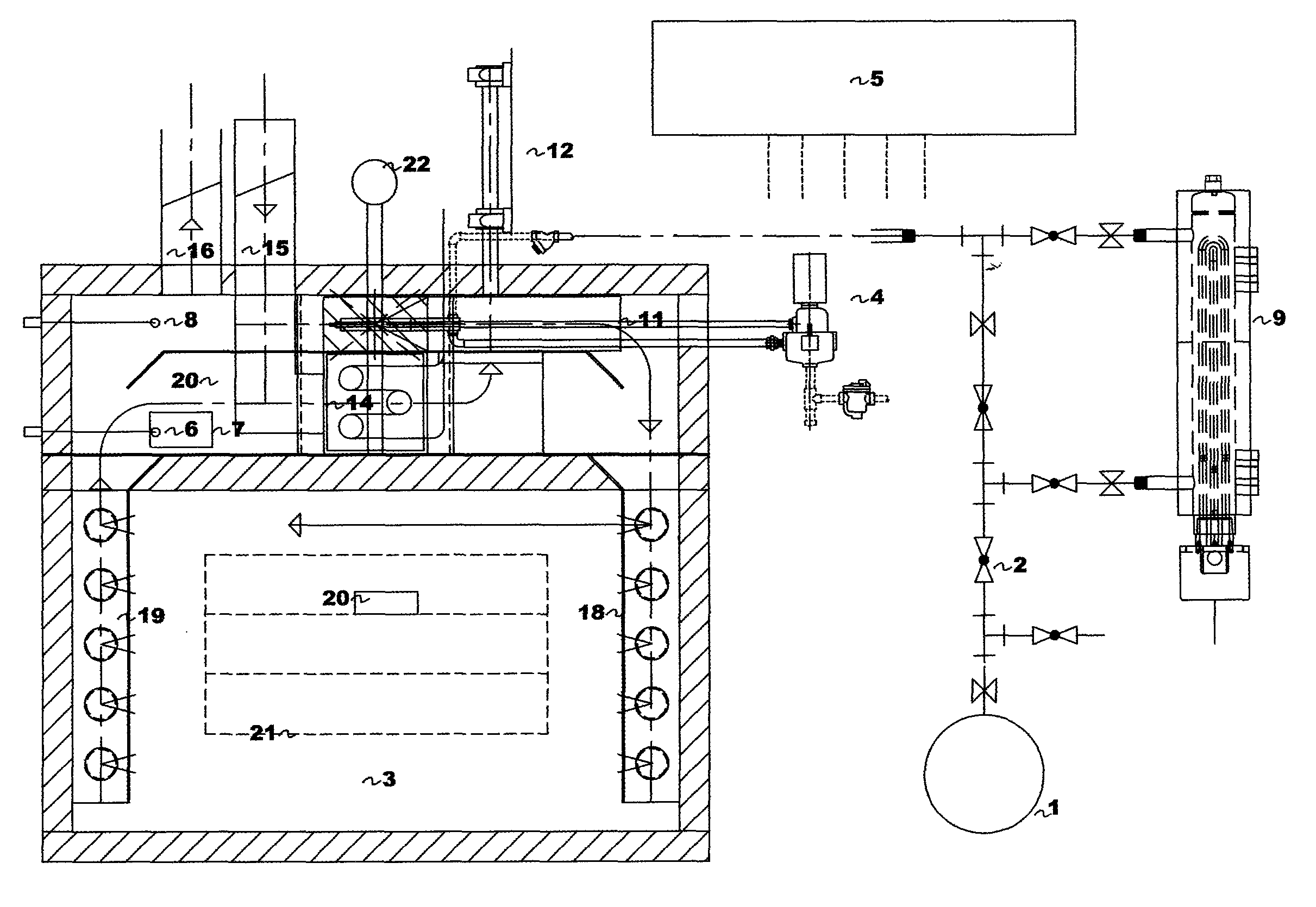

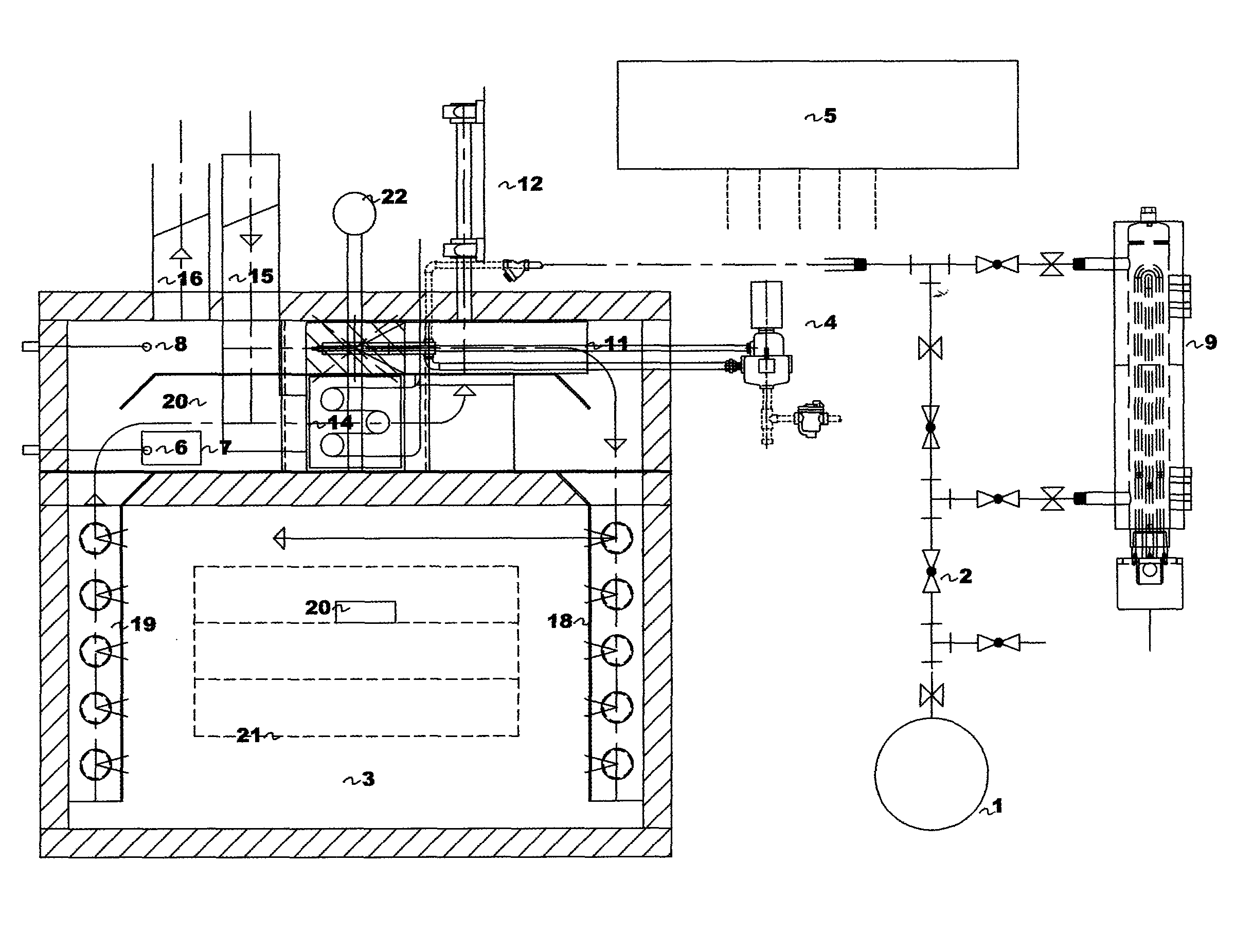

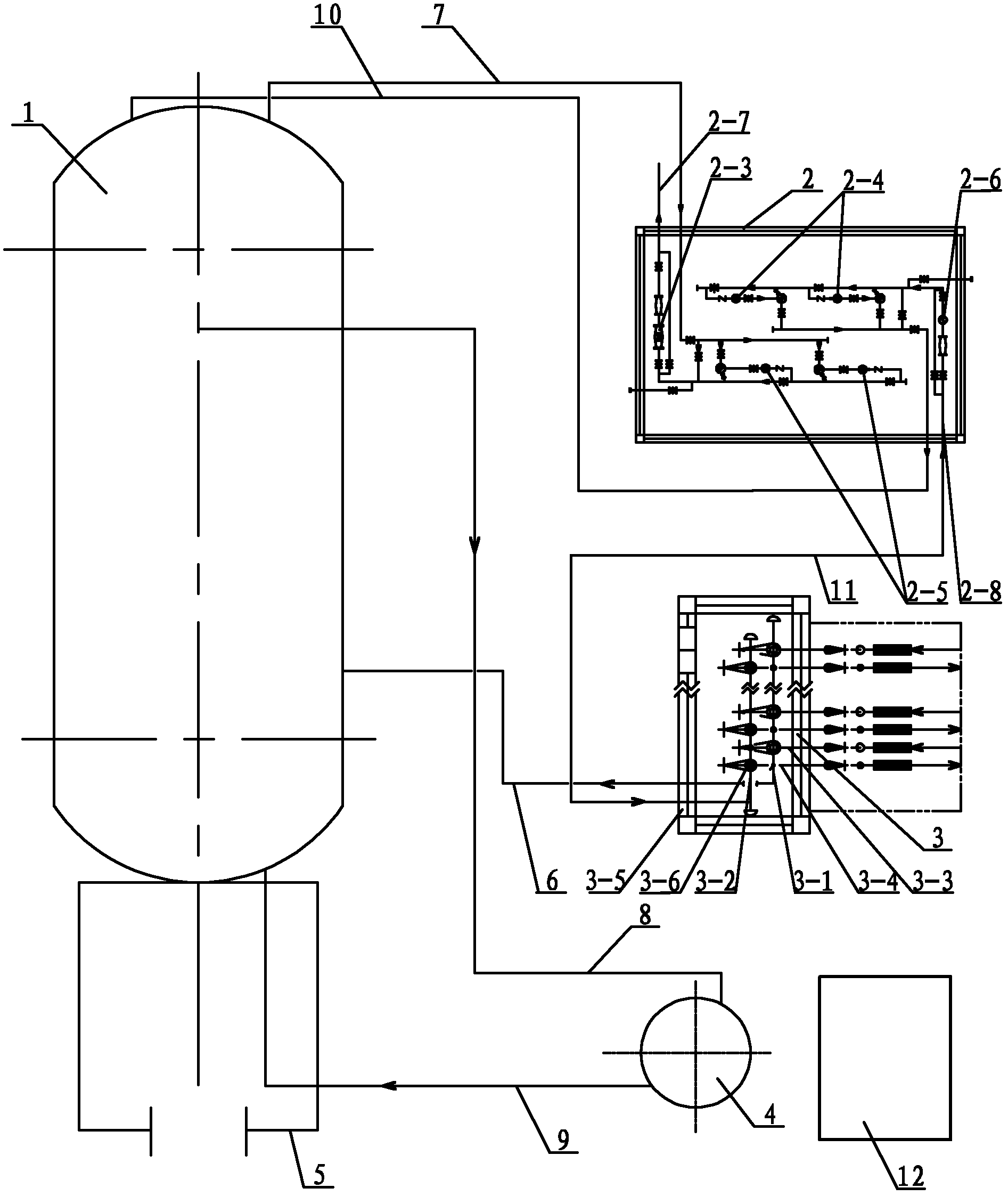

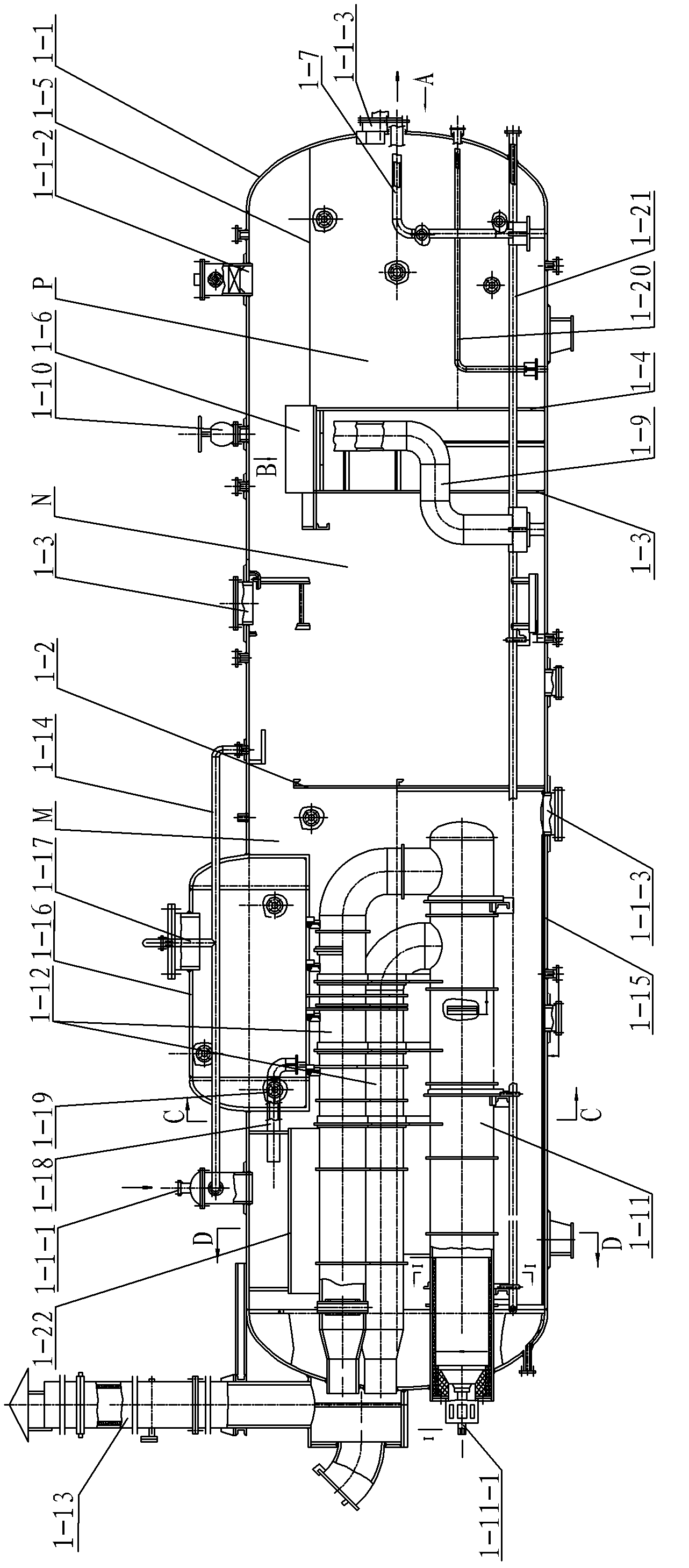

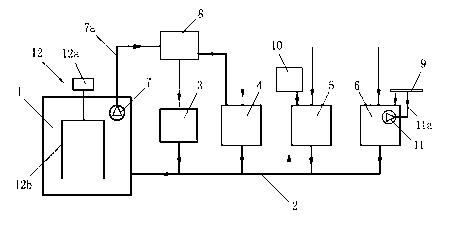

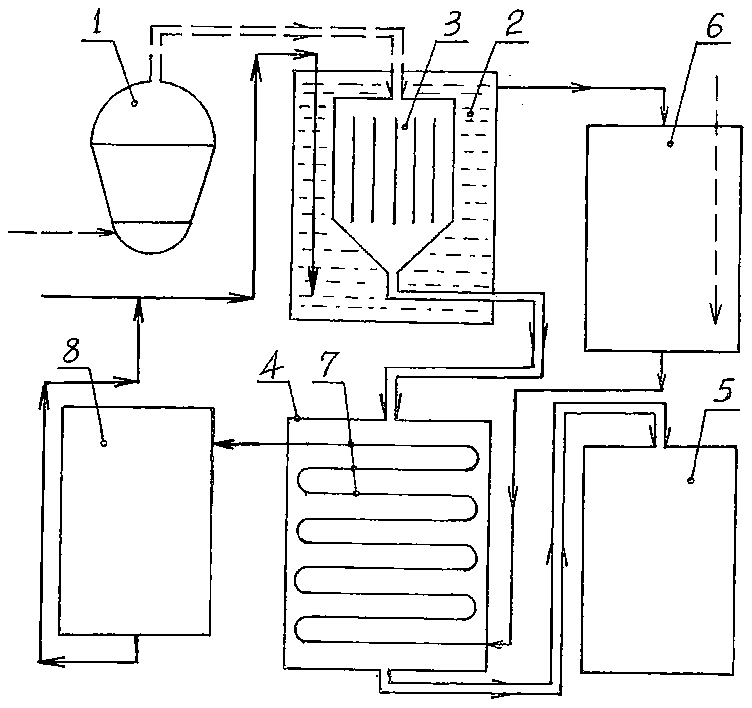

Digital box type fast-assembling oil-gas gathering and transferring system

InactiveCN102424351AStable productionFew facilitiesLiquid transferring devicesData transmissionTransfer system

The invention discloses a digital box type fast-assembling oil-gas gathering and transferring system, which relates to an oil transfer station and is used for solving the problems of a large amount of assorted equipment, complex internal pipe network, large floor area, a large quantity of operating personnel and high running cost existing in the conventional oil transfer station as well as difficulty in controlling the water replenishing amount due to the adoption of manual water replenishment during the running of a four-in-one combined device. An oil-gas treatment device is connected with adigitally-controlled oil collecting water distribution valve bank box through a first pipeline; the oil-gas treatment device is connected with a digitally-controlled oil-water boosting metering box through a second pipeline; the oil-gas treatment device is connected with a natural gas drier through a third pipeline; one end of a fourth pipeline is connected with the natural drier, and the other end of the fourth pipeline is connected with the inlet of a fire pipe; one end of a fifth pipeline is communicated with a water outlet pipe, and the other end of the fifth pipeline is communicated withthe inlet of a water pipe; one end of a sixth pipeline is communicated with the outlet of the water pipe, and the other end of the sixth pipeline is communicated with a water doping header; and the oil gas treatment device, the digitally-controlled oil-water boosting metering box, the digitally-controlled oil collecting water distribution valve bank box and the natural gas drier are monitored through data transmission. The digital box type fast-assembling oil-gas gathering and transferring system is applied to oil-gas gathering and transferring.

Owner:鲍云波 +1

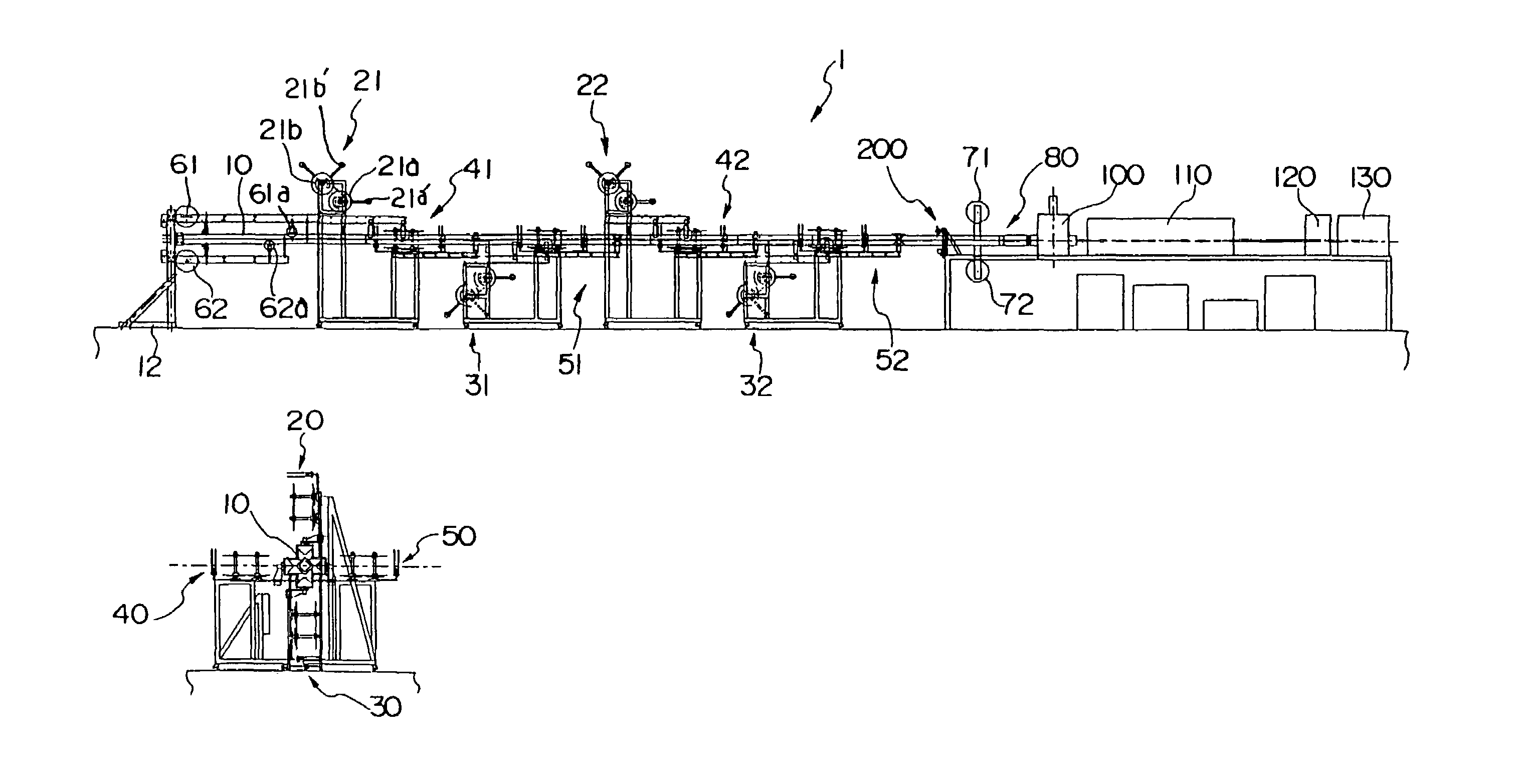

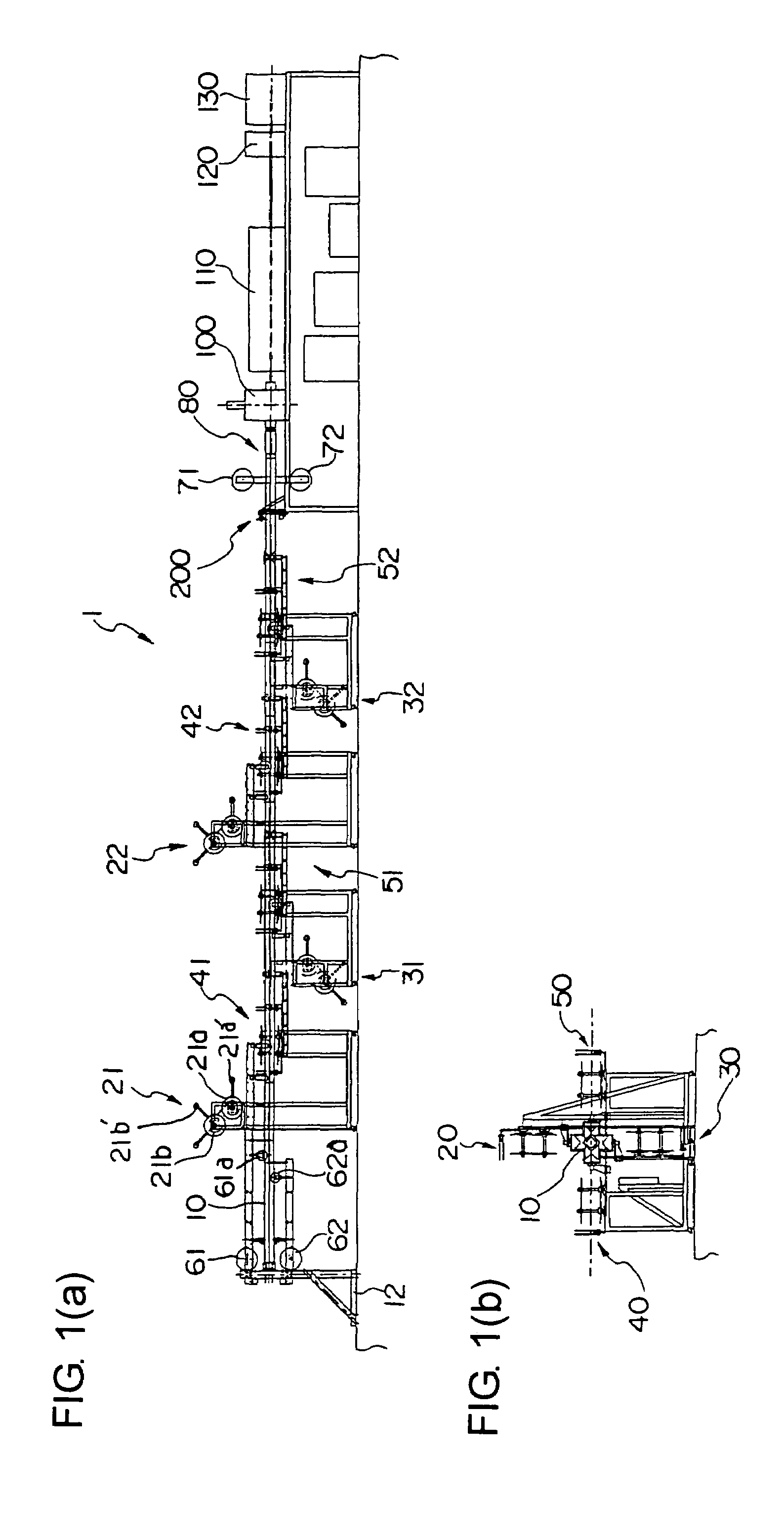

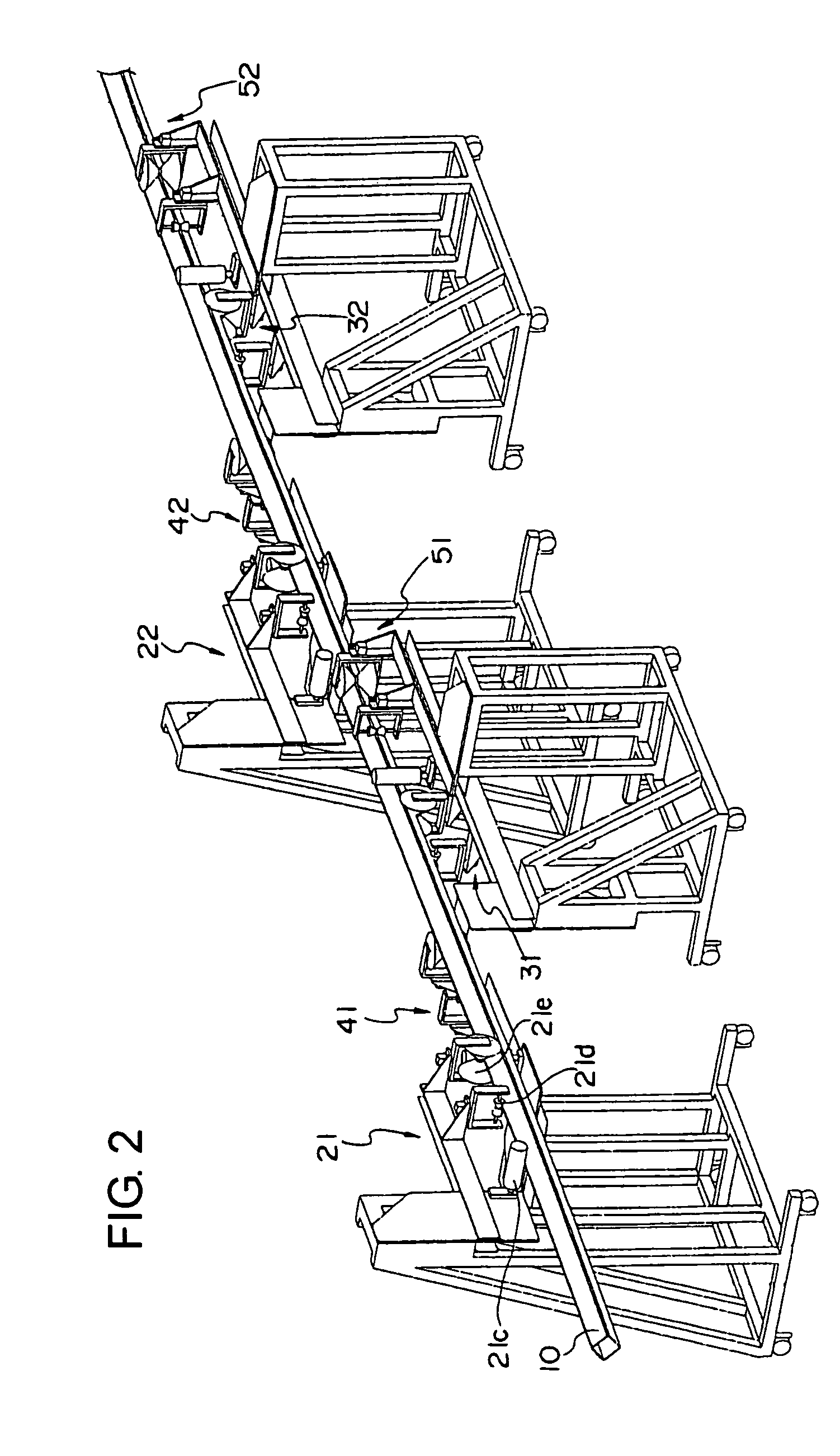

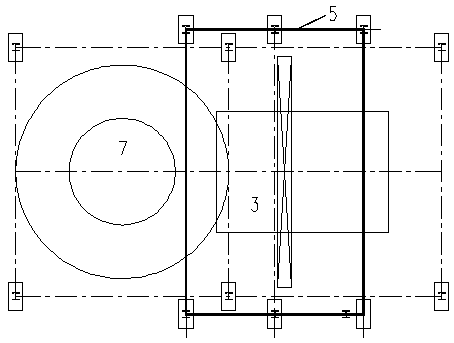

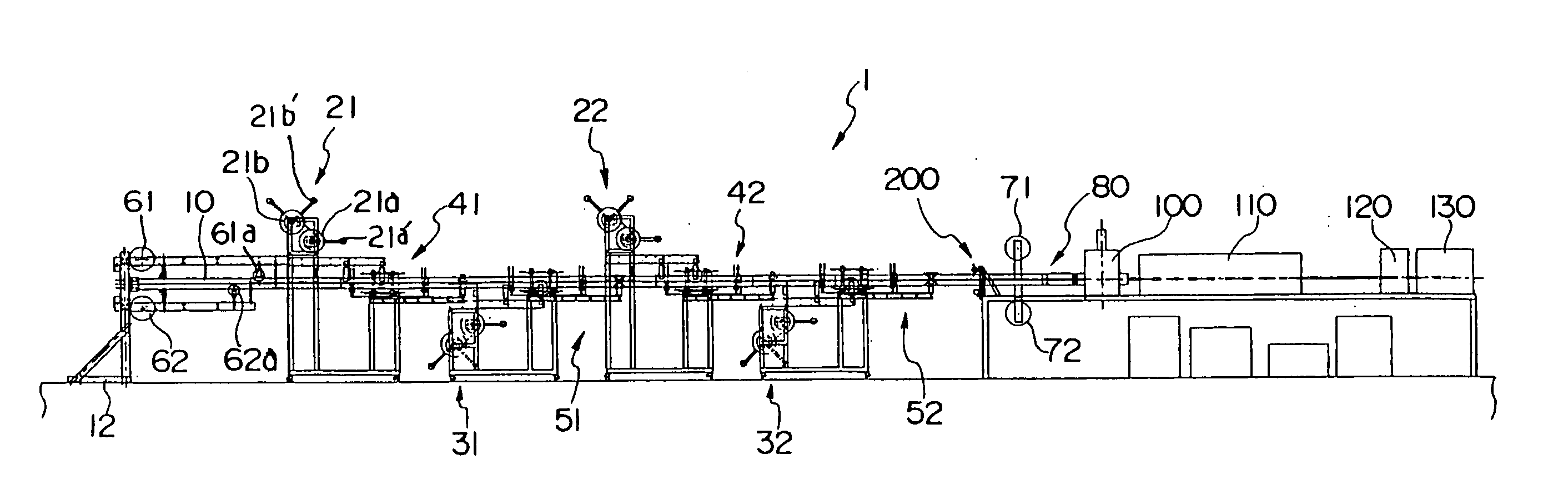

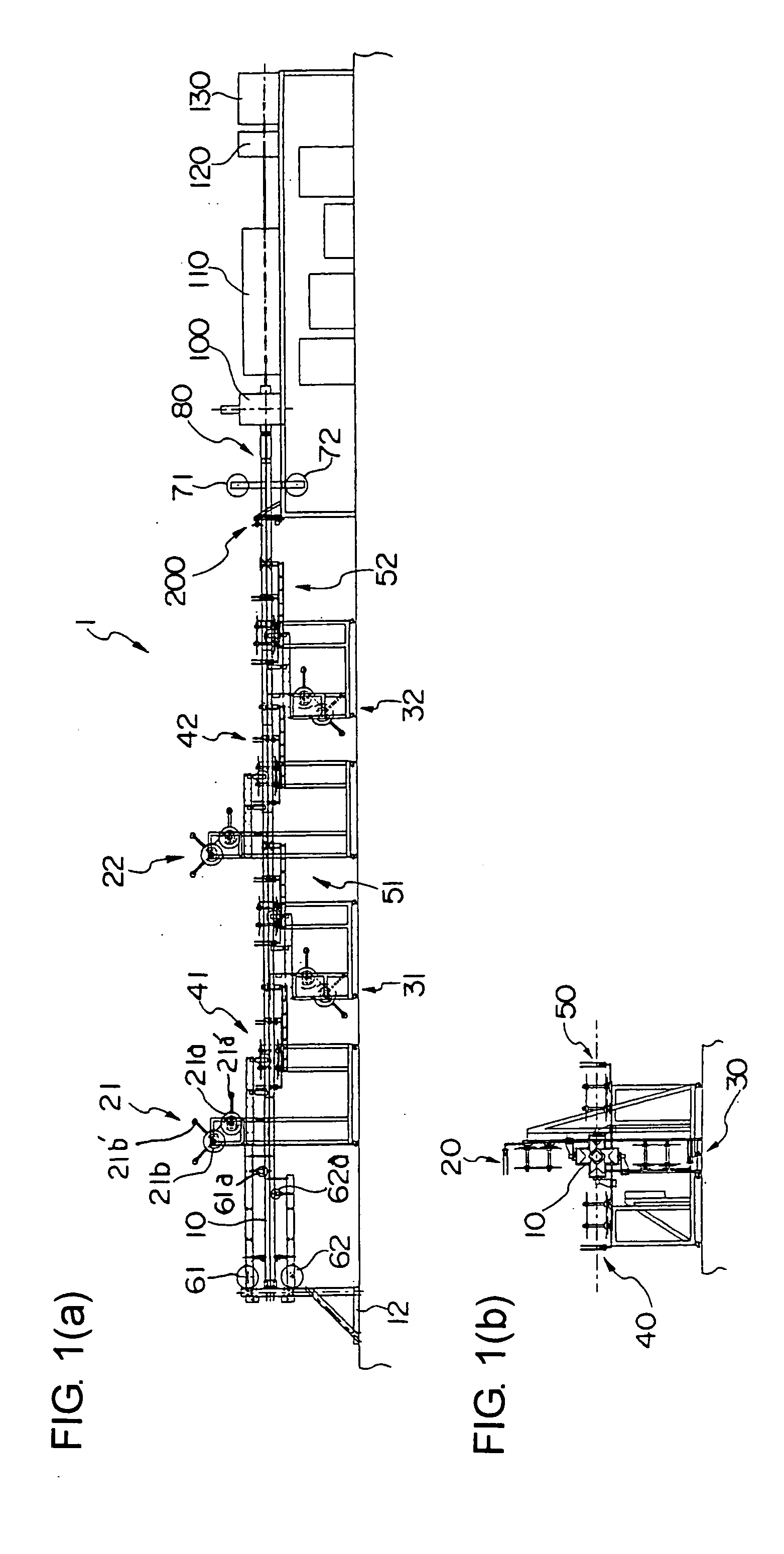

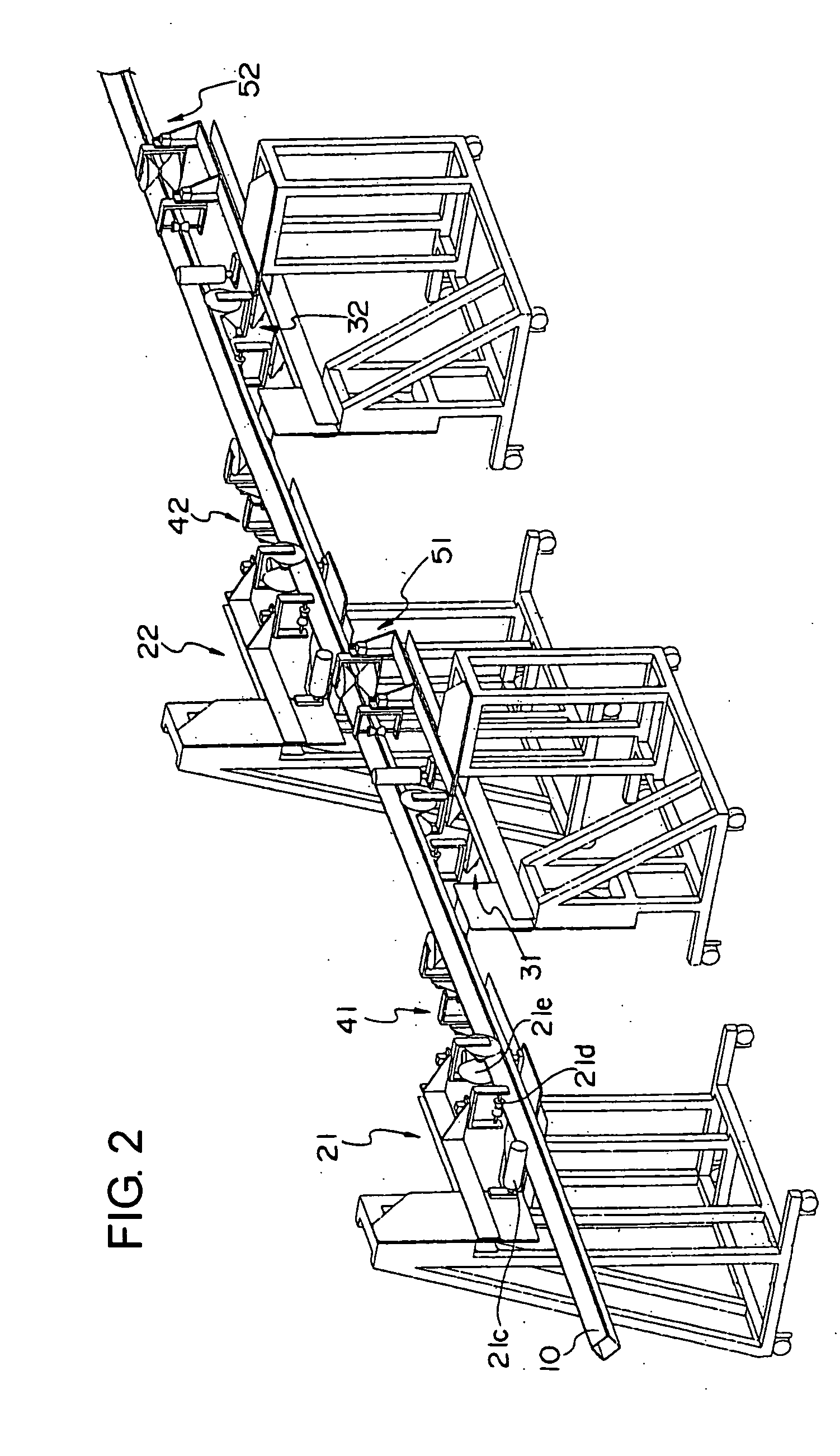

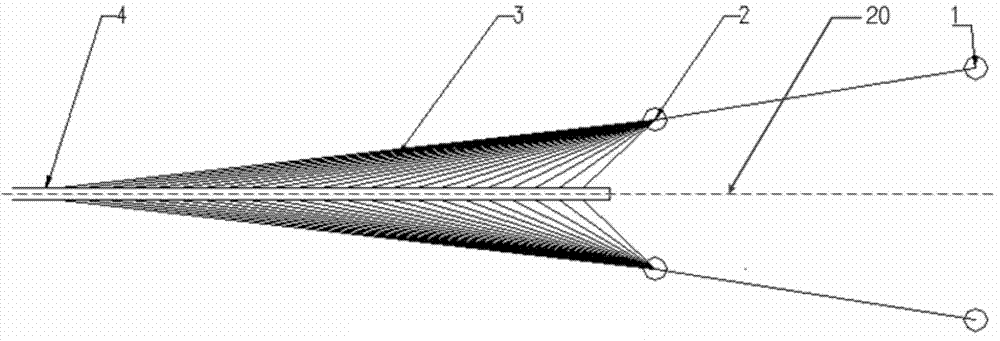

Apparatus for continuously forming FRP square pipe

ActiveUS7204286B2Uniform thicknessFew facilitiesMechanical working/deformationTubular articlesEngineeringMechanical engineering

An apparatus 1 for continuously forming an FRP square pipe comprises a long core 10 for laminating prepreg sheets, and to this core 10 are fed prepreg sheets from prepreg laminating devices 20, 30, 40 and 50 with a release film interposed between the core, so as to be laminated into square pipe form. The core 10 has an outer diameter size smaller than the inner diameter size of the square pipe to be formed. The outer circumference of the square pipe is wrapped with a tape-like film fed from a tape-like release film wrapping device 200 in spiral fashion, and the work is heated and pressed in a hot press 100. The work is then subjected to additional heating in a postcure furnace 110 to form the FRP square pipe. The square pipe is intermittently pulled by a puller 130 disposed downstream of a clamp 120. The pipe is then cut to predetermined lengths by a cutter not shown to be completed as a product.

Owner:JAMCO

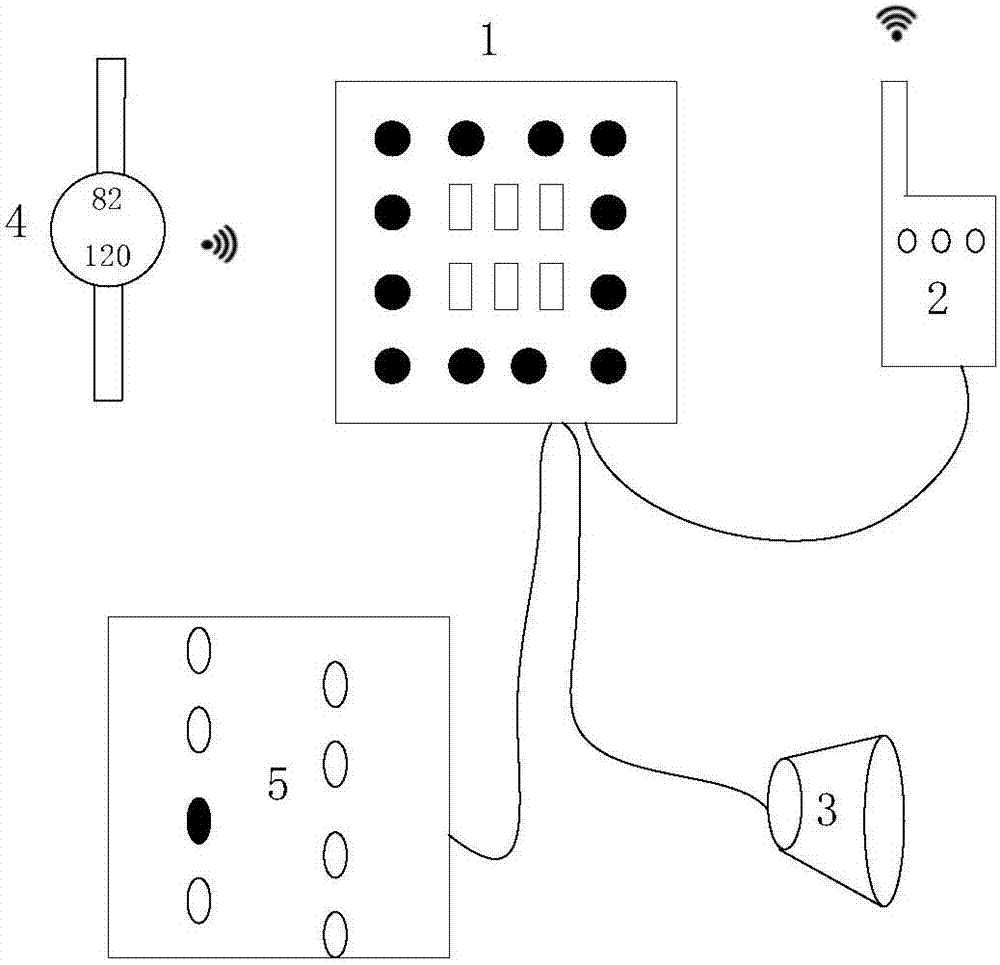

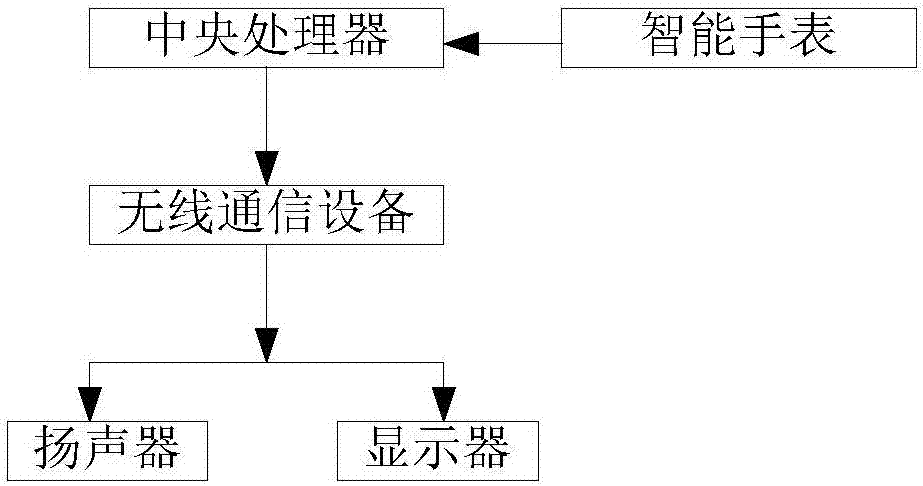

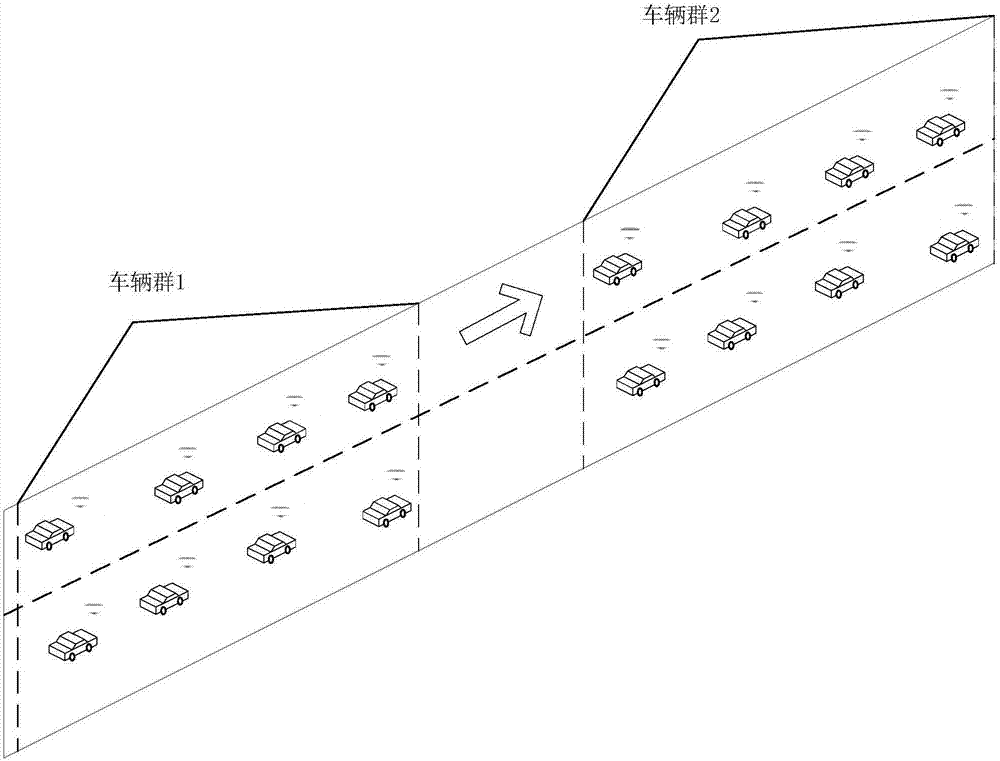

Expressway vehicle group operation risk state warning system and method

PendingCN106935078AReduce safety incidentsImprove securityAnti-collision systemsDriver/operatorDisplay device

The invention discloses an expressway vehicle group operation risk state warning system. The expressway vehicle group operation risk state warning system includes a central processing unit, a wireless communication device, a loudspeaker, an intelligent watch and a display; the wireless communication device, the loudspeaker and the display are all connected with the central processing unit through cables; the central processing unit is used for obtaining processing information according to acquired vehicle information and driver information, wherein the processing information can indicate whether vehicles are in operation risk states; the wireless communication device includes an information receiving terminal and an information transmitting terminal; the intelligent watch is used for transmitting the acquired driver information to the central processing unit; and the loudspeaker and the display are used for broadcasting and displaying. The invention also discloses an expressway vehicle group operation risk state warning method. According to the expressway vehicle group operation risk state warning system and method of the invention, vehicle groups which are in operation risk states can be warned in advance scientifically and reasonably, and the rear-end and pile-up accidents of vehicles can be avoided. The expressway vehicle group operation risk state warning system and method are of great practical significance for reducing the safety accidents of expressways and improving the safety level of the expressways.

Owner:SOUTH CHINA UNIV OF TECH

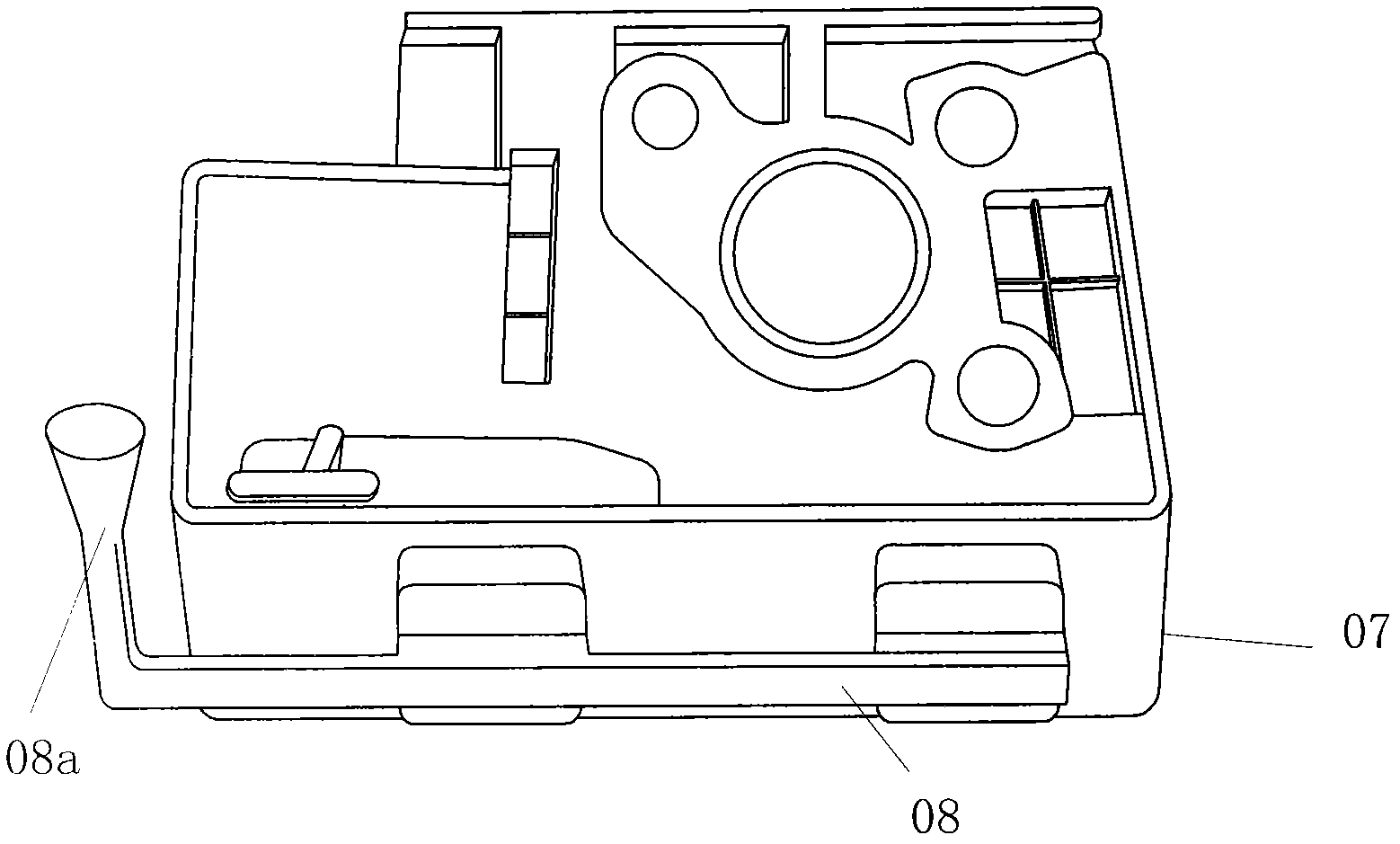

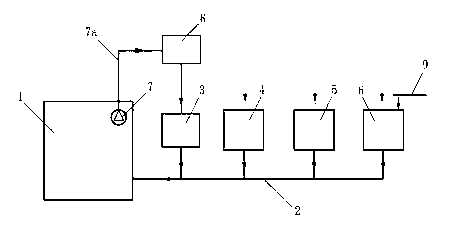

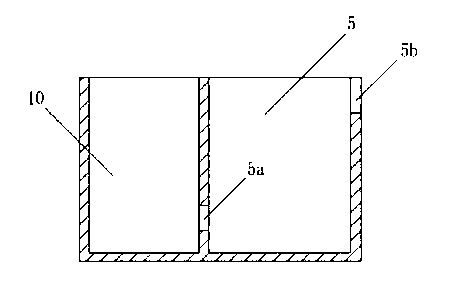

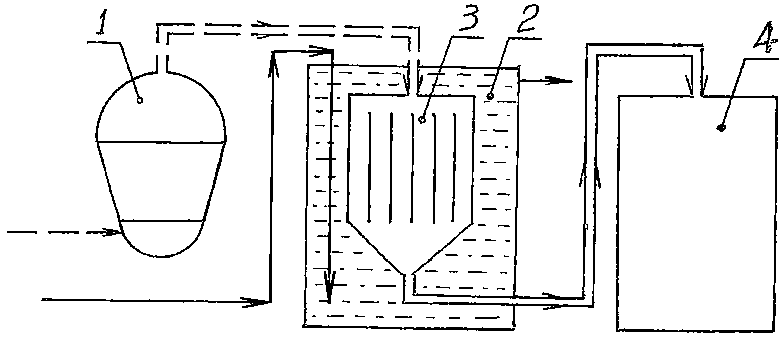

Zero-emission recycling device for water paper or raw cement board papermaking wastewater

ActiveCN103058434ARealize zero discharge of waste waterAvoid pollutionMultistage water/sewage treatmentWaste water treatment from plant processingWaste pondCement board

The invention discloses a zero-emission recycling device for water paper or raw cement board papermaking wastewater. The outlet of a wastewater conveying component (2) is communicated with a total wastewater collecting tank (1); exhaust ports of a pulping wastewater pond (3), a screening wastewater pond (4), a sheet forming wastewater pond (5) and a squeezing wastewater pond (6) are communicated with the wastewater conveying component; a water inlet of a first wastewater recycling pump (2) is communicated with the total wastewater collecting tank (1); a water outlet of the first wastewater recycling pump (7) is connected with a recycle water conveying tube (7a) for providing recycle water to a pulper (8); the sheet forming wastewater pond is provided with a wastewater outlet for providing dilution water to a paper pulp diluting pond (10); the screening wastewater pond is provided with a wastewater outlet for providing recycle water to the pulper; the water inlet of the second wastewater recycling pump (11) is connected with the squeezing wastewater pond; and the water outlet of the second wastewater recycling pump (11) is connected with a recycle water tube (11a) for cleaning a papermaking blanket. According to the zero-emission recycling device disclosed by the invention, the wastewater can be completely recycled without emission; and precipitates and suspended solids of each wastewater pond are recycled for producing, so that the preparation cost and the operation cost are reduced.

Owner:钟立福

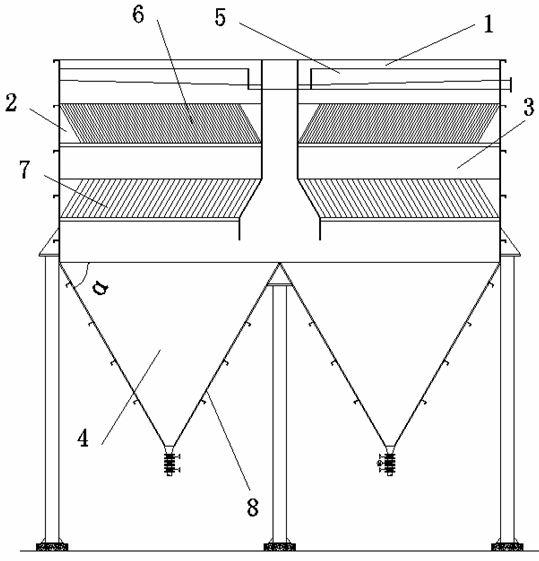

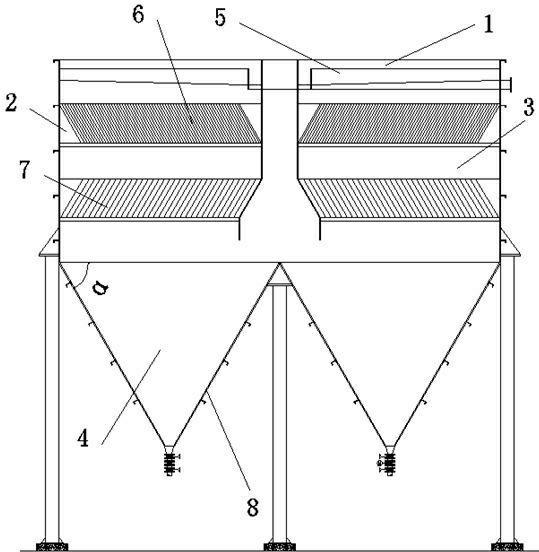

Concentration and precipitation machine of high-concentration tailing waste water

InactiveCN102319520ANot easy to hardenEasy to transportSettling tanks feed/dischargeSedimentation settling tanksHigh concentrationWater quality

The invention provides a concentration and precipitation machine of high-concentration tailing waste water. The concentration and precipitation machine is characterized by comprising a clean water area (1), an inclined tube area (2), a separation area (3) and a concentration area (4). The clean water area (1) is located above the inclined tube area (2). The concentration area (4) is located below the inclined tube area (2). The separation area (3) is located between the inclined tube area (2) and the concentration area (4). A fundamental of the concentration and precipitation machine of high-concentration tailing waste water is a shallow precipitation theory. Based on the shallow precipitation theory, the residence time of water in a precipitator is greatly reduced; effects of the concentration and precipitation machine is two times better than that of a horizontal-flow sedimentation tank; and a sedimentation area is reduced. Therefore, the concentration and precipitation machine of high-concentration tailing waste water has the advantages of good adaptability for raw water with a wide change scope of turbidity, high treatment efficiency, small floor space, and good convenience of management.

Owner:HAIZHOU E P GRP CO LTD

Method for accelerating aging of liquor by circulating utilization of distillation cooling water of liquor

ActiveCN103343079AAccelerated agingEasy to storeAlcoholic beverage preparationDistillationAccelerated aging

The invention discloses a method for accelerating aging of liquor by circulating utilization of distillation cooling water of the liquor, relating to the technical field of brewing. A device is as follows: a liquor cooler is arranged in a water tank of a cooler, a steam pipe is arranged at the bottom end of a liquor distillation device, the liquor distillation device, the liquor cooler, a liquor aging tank and a liquor storage tank are fixed through a liquor pipeline, a heat exchanger is arranged in the liquor aging tank, a water inlet pipe is inserted into the water tank of the cooler, and the water tank of the cooler, a transfer tank A, the heat exchanger, a transfer tank B and the water tank of the cooler are fixed through a water pipe. A method is as follows: injecting the cooling water, distilling fermented grains, condensing liquor steam, circulating the cooling water from the water tank of the cooler to the transfer tank A to the heat exchanger to the transfer tank B to the water tank of the cooler, and keeping the heat exchanger at the temperature of 50-60 DEG C to always keep the aging temperature of the liquor in the liquor aging tank at 40-50 DEG C so as to be conductive to aging of the liquor and storage of the liquor in a constant-temperature state with molecular association. The method is used for accelerating the aging of the liquor. The method has the advantages of scientific and reasonable concept and structure, and stable and reliable method effects.

Owner:湖北黄山头酒业有限公司

Waste gas treatment process

InactiveCN106807188ALow running costLow priceGas treatmentDispersed particle separationMaleic anhydrideBenzene

The invention relates to a waste gas treatment process, which is characterized by sequentially comprising the following steps of heating heat storage chambers; uniformly conveying waste gas into the partial heat storage chambers through a gas distributor; heating the waste gas to the temperature of the decomposing point temperature of organic maters (benzene, n-butane and carbonic oxide) in the waste gas; conveying waste gas heated by a heat storage body into a heat oxidization chamber to be burnt so that the organic matters are converted into carbon dioxide and water vapor to become harmless high-temperature smoke gas; conveying one part of the high-temperature smoke gas into the rest heat storage chambers to perform heat exchange with the heat storage body so that the high-temperature smoke gas is cooled and the cooled smoke gas is exhausted into the atmosphere; conveying the rest high-temperature smoke gas into an afterheat recovery device; recovering the heat energy so that the high-temperature smoke gas entering the afterheat recovery device is cooled to become low-temperature smoke gas reaching the exhaust requirements; performing back flowing, dust removal and the like on each heat storage chamber in turns, and the like. By using the process, the one-time investment and the operation cost can be reduced; the atmospheric pollution is reduced. The process is applicable to the heat storage oxidization treatment on the waste gas exhausted in the maleic anhydride production process.

Owner:周子童

Sludge treatment system

InactiveCN109205976AHigh pre-dehydration efficiencyImprove efficiencySludge treatment by de-watering/drying/thickeningWaste water treatment from metallurgical processHigh concentrationSlag

The invention relates to a sludge treatment system. The sludge treatment system comprises an adjusting tank, a centrifugal dehydrator, a sludge groove, a flocculant feeding device and the like. The sludge treatment system has the advantages that the adjusting tank is used for selecting and collecting high-concentration hot-rolling or continuous-casting turbid circulating wastewater, so that the efficiency of the sludge treatment system is improved, and the sludge treatment scale is reduced; the centrifugal dehydrator is small in size, high in pre-dehydration efficiency and low in equipment operation requirement; the sludge groove is used as a turbid circulating water treatment slag pit and is also used as a sludge dehydration facility for collecting oxidized steel and hot-rolling or continuous-casting sludge; the flocculant feeding device only needs to feed a flocculant into the adjusting tank; the sludge treatment system is simple in process, less facilities and less equipment are needed, continuous operation is realized, and the investment cost is low; a large amount of chemical agents do not need to be added in sludge treatment, lime does not need to be added, the amount of generated dry sludge is small, the operation is convenient, and the personnel management cost is low; and the system adopts the three-dimensional arrangement, the occupied area of a water station is optimized to the maximum degree, the general layout is very convenient, every single space can be made use of, and the sludge treatment system is suitable for a new project and is also suitable for technical innovation.

Owner:宝武水务科技有限公司

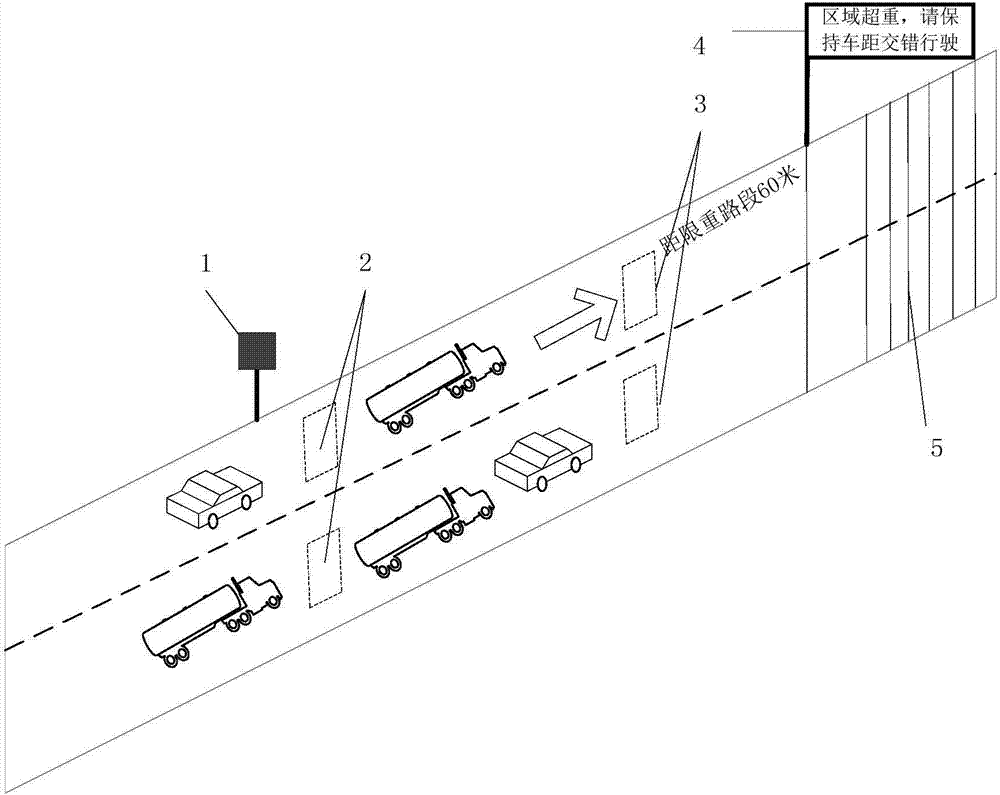

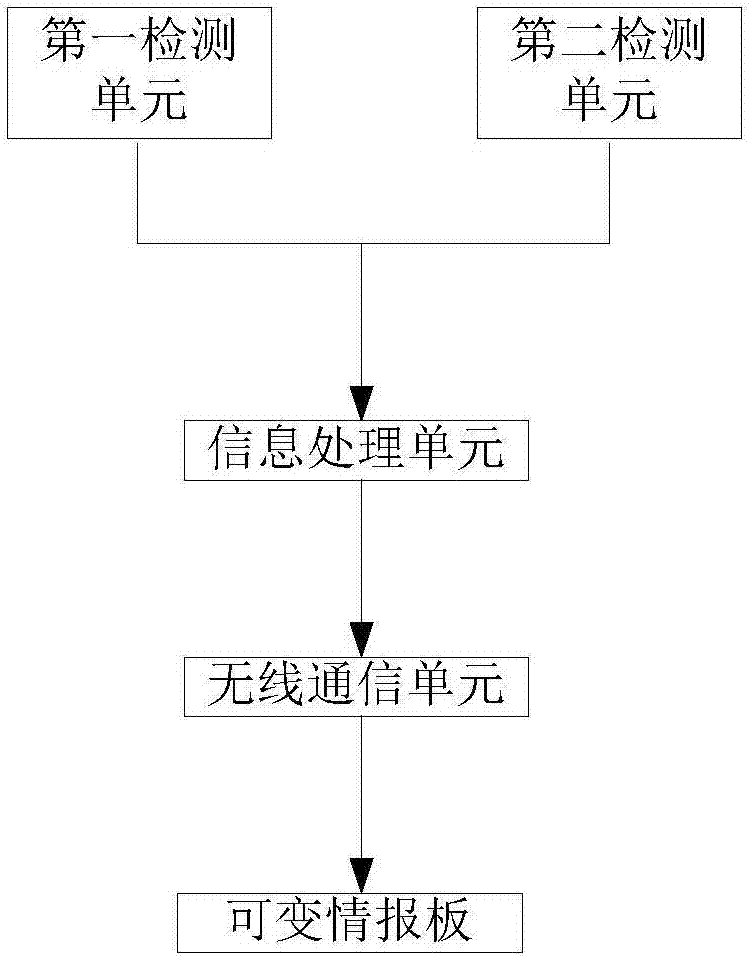

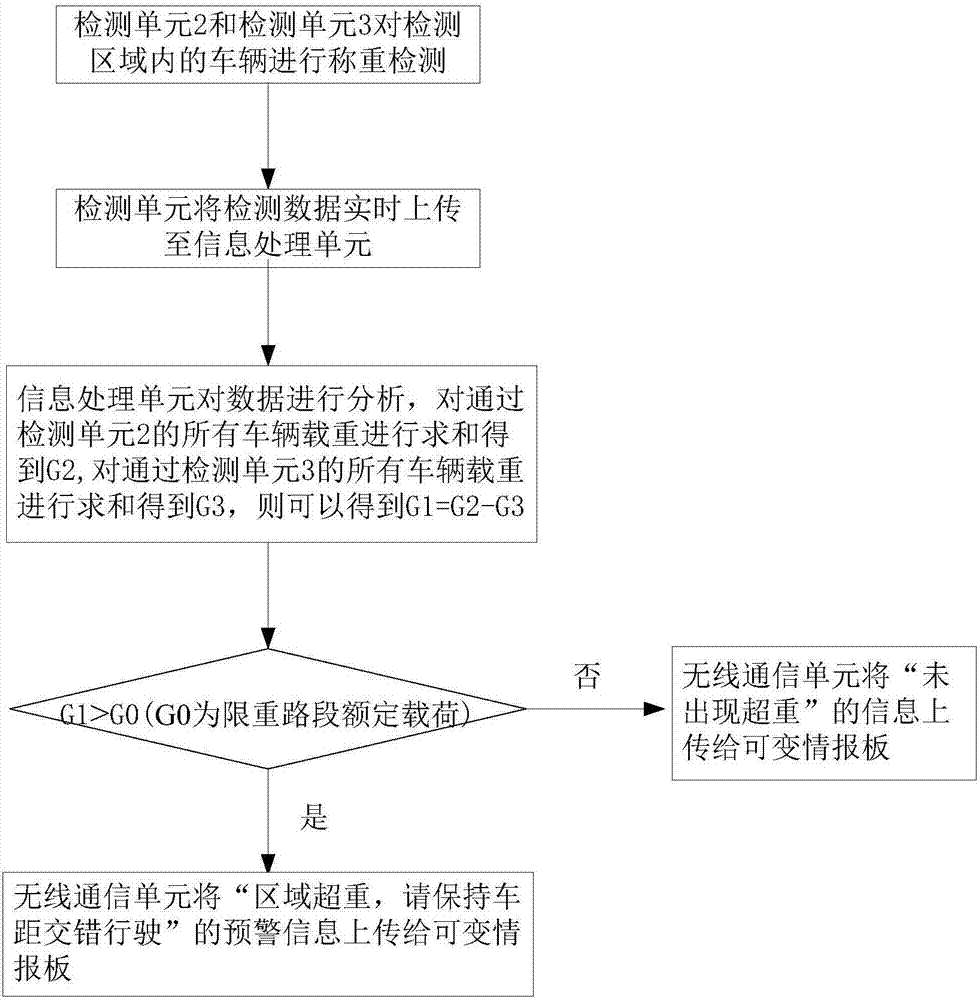

Intelligent area vehicle overweight detection and early warning system and method

ActiveCN106908129APrevent collapsePrevent damage accidentsSpecial purpose weighing apparatusInformation processingEarly warning system

The invention discloses an intelligent area overweight detection and early warning system. The system comprises a crate, a variable information board, first detection units and second detection units. The crate and the variable information board are arranged on one side of a lane. The first detection units and the second detection units are embedded in each lane at a certain distance along the driving direction. The crate comprises an information processing unit and a wireless communication unit. The information processing unit is in circuit connection with the first detection units and the second detection units. The first detection units and the second detection units are used for carrying out weighing detection on a vehicle in a detection area, and transmitting the detection data to the information processing unit in real time. The information processing unit is used for transmitting overweight early warning information based on the detection data. The wireless communication unit is used for uploading an overweight early warning signal to the variable information board for displaying. The invention further discloses an intelligent area overweight detection and early warning method. According to the invention, the phenomenon of overweight caused by non-overweight single vehicles traveling in parallel is prevented, and crash and damage accidents caused by parallel multi-vehicle overweight on a weight limit road are prevented.

Owner:SOUTH CHINA UNIV OF TECH

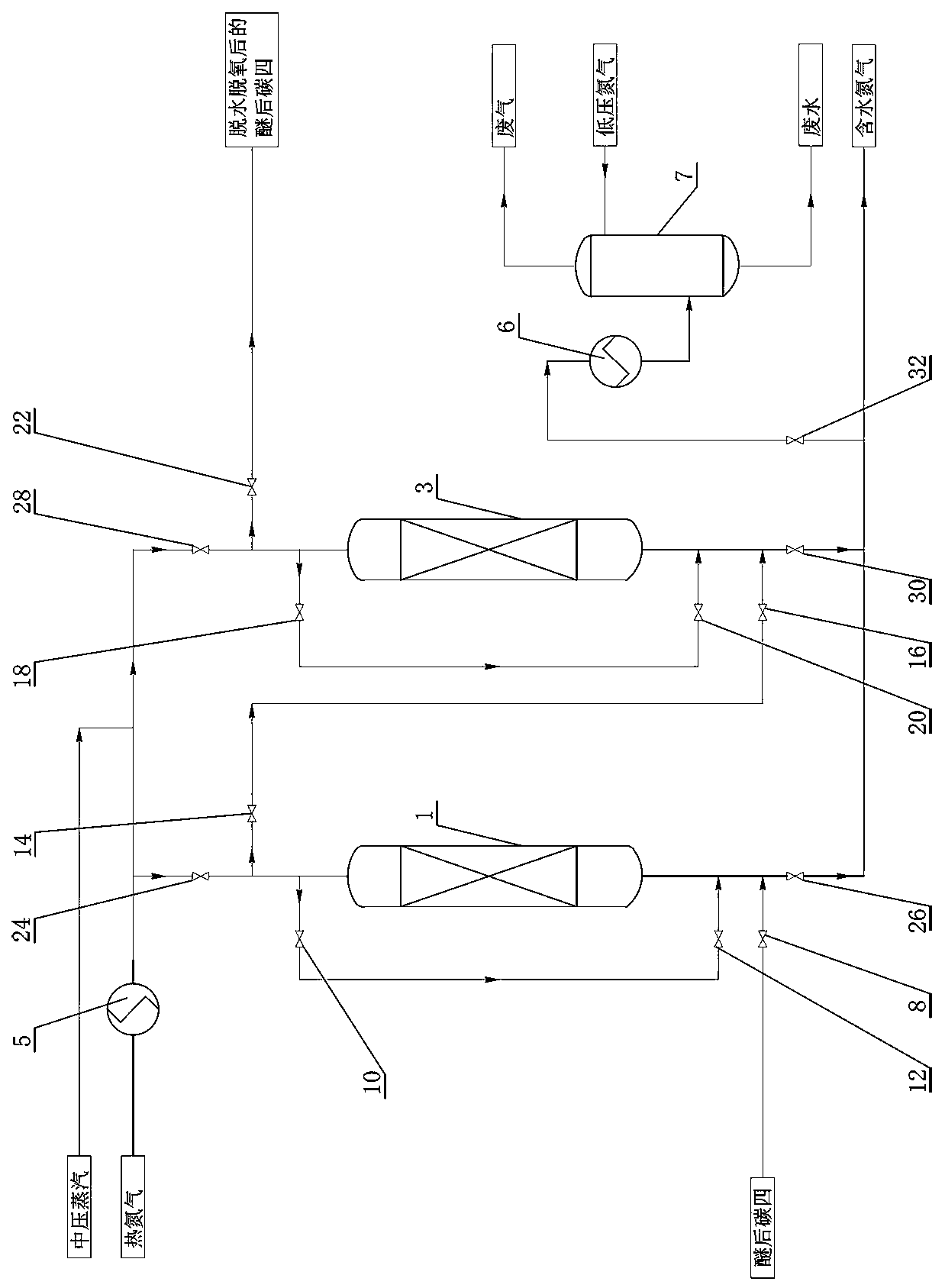

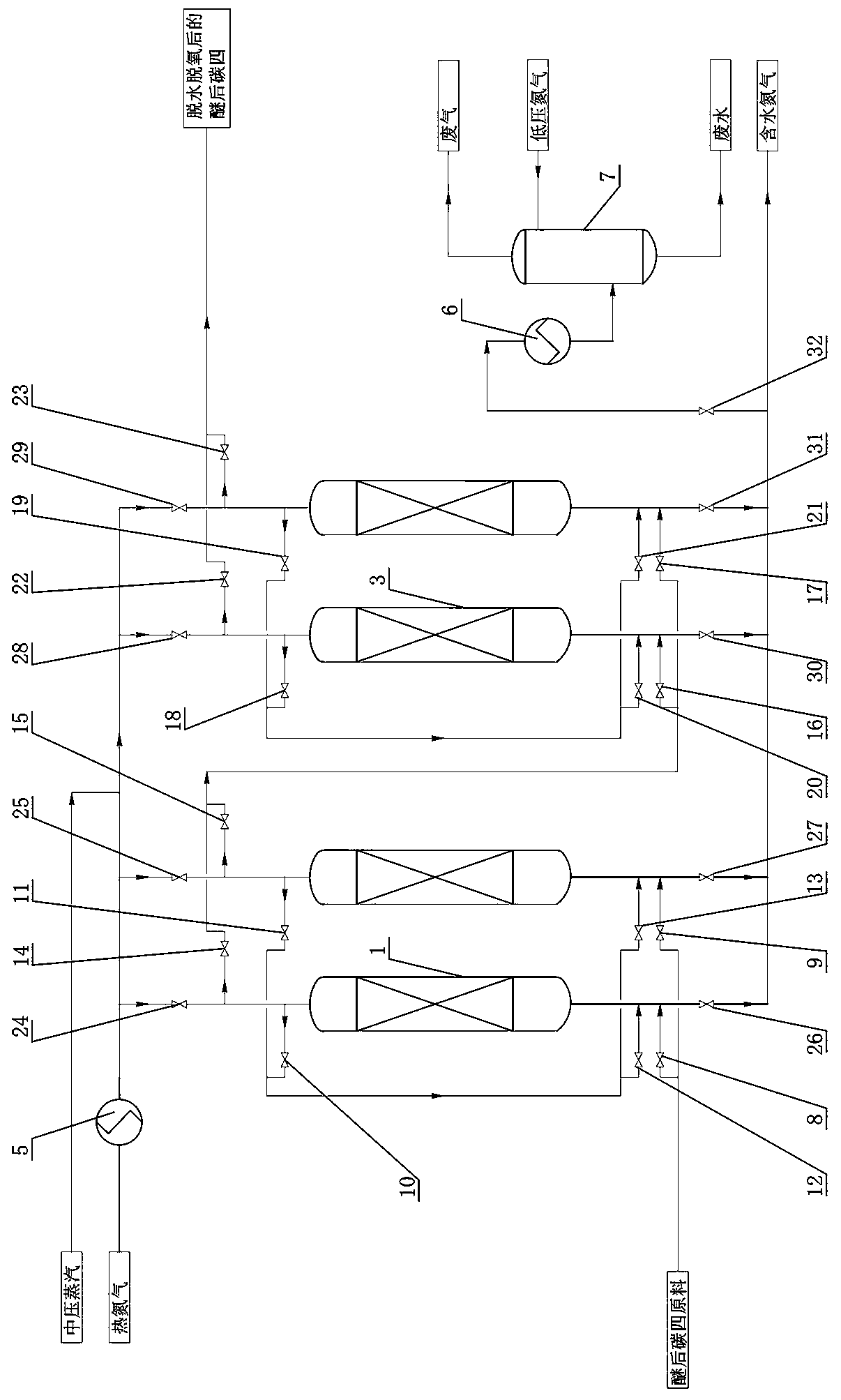

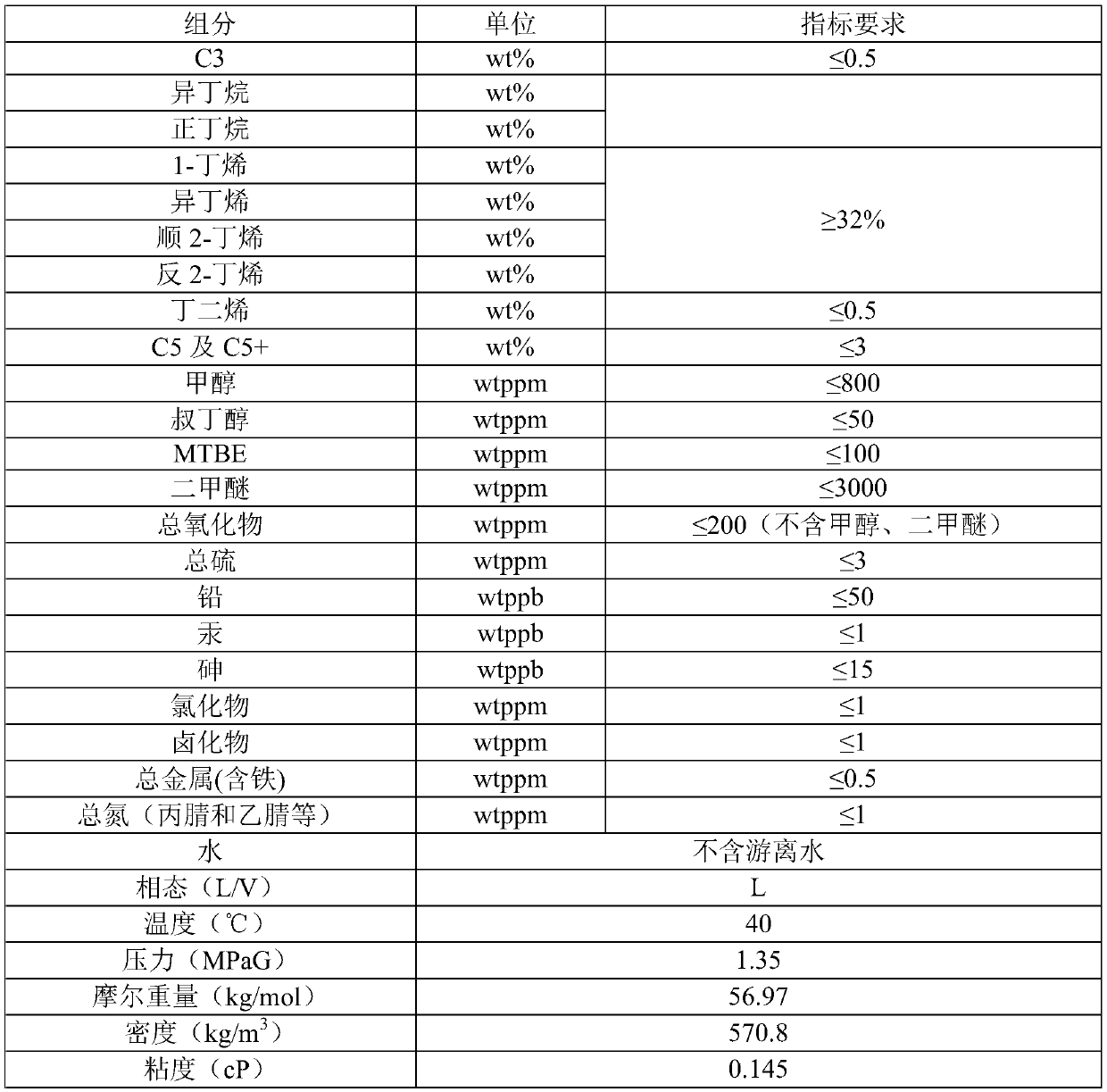

Method and device for pretreating post-etherification C4 raw material

PendingCN110256209AGuaranteed operating cycleFew facilitiesHydrocarbonsAdsorption purification/separationIsomerizationPretreatment method

The invention relates to a method and device for pretreating a post-etherification C4 raw material, belonging to the technical field of treatment of chemical raw materials. The method comprises the following steps: dehydrating the post-etherification C4 raw material; subjecting the dehydrated post-etherification C4 raw material to deoxidation; regenerating a dehydrating agent used in dehydration; and regenerating a deoxidizer used in deoxidation. According to the pretreatment method of the invention, impurities such as micro water, ethers and alcohols in the post-etherification C4 raw material can be removed after dehydration and deoxidation, and the indexes of the pretreated post-etherification C4 raw material reach the requirements of n-butene isomerization units and selective hydrogenation units on the limit values of impurity contents of raw materials, so catalysts in the hydrogenation units and catalysts in the n-butene isomerization units are protected, and the normal operation cycle of the entire MTBE device is ensured; and compared with conventional pretreatment processes for raw materials, the method of the invention reduces investment and operating cost, improves the economic benefits of the industry and has a high promotion value.

Owner:山东东明石化集团有限公司

Polyacrylamide gel preparation method capable of preventing solution leakage

ActiveCN106568825AThe operation process is simple and convenientPracticalMaterial analysis by electric/magnetic meansGel preparationPolymer science

The invention relates to a polyacrylamide gel preparation method capable of preventing solution leakage, and belongs to the technical field of physical or chemical apparatus. The bottoms of two pieces of glass are sealed by agarose gel; two pieces of glass are placed on two tables with a same height, two ends, which are connected to each table, of each glass are horizontal, a gap exists between the lower end of each glass and the surface of an operation table, a gel forming area is formed in the gap above the bottoms of two pieces of glass, and gel forming raw materials are added into the gel forming area to start gel production. The preparation method is used to prepare polyacrylamide gel, has the advantages of simpleness, convenience, and rapidness, and is capable of reducing solution waste and guaranteeing the number of gel blocks.

Owner:ZHEJIANG FORESTRY UNIVERSITY

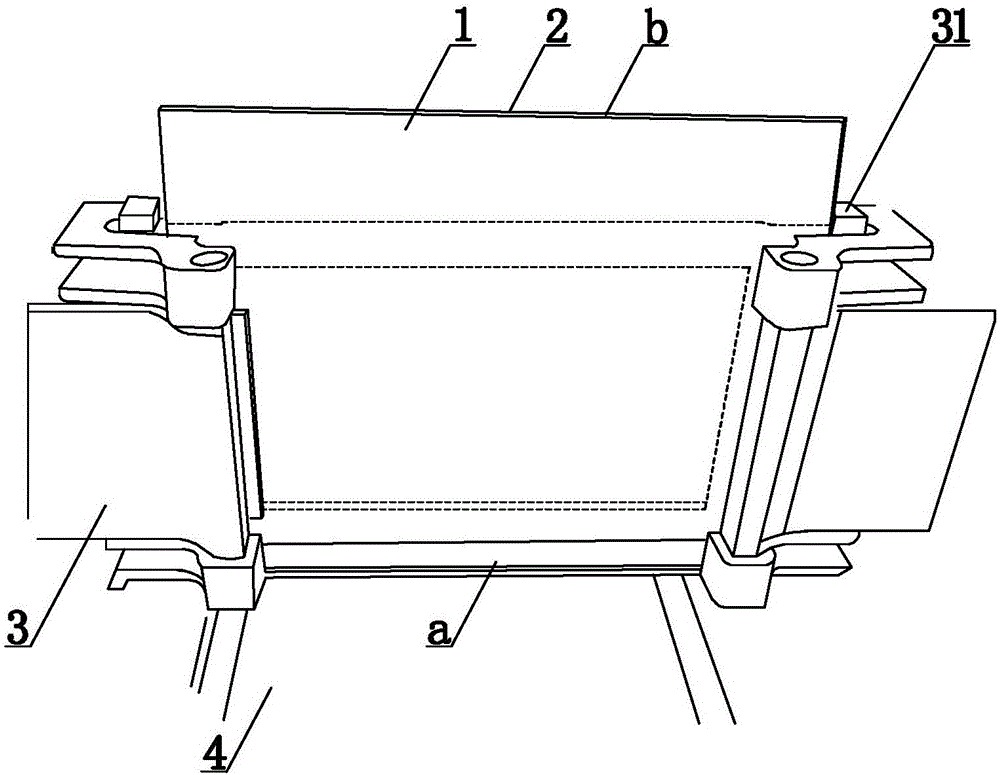

Apparatus for continuously forming FRP square pipe

ActiveUS20050126714A1Uniform thicknessFew facilitiesMechanical working/deformationTubular articlesHot pressHelix

An apparatus 1 for continuously forming an FRP square pipe comprises a long core 10 for laminating prepreg sheets, and to this core 10 are fed prepreg sheets from prepreg laminating devices 20, 30, 40 and 50 with a release film interposed between the core, so as to be laminated into square pipe form. The core 10 has an outer diameter size smaller than the inner diameter size of the square pipe to be formed. The outer circumference of the square pipe is wrapped with a tape-like film fed from a tape-like release film wrapping device 200 in spiral fashion, and the work is heated and pressed in a hot press 100. The work is then subjected to additional heating in a postcure furnace 110 to form the FRP square pipe. The square pipe is intermittently pulled by a puller 130 disposed downstream of a clamp 120. The pipe is then cut to predetermined lengths by a cutter not shown to be completed as a product.

Owner:JAMCO

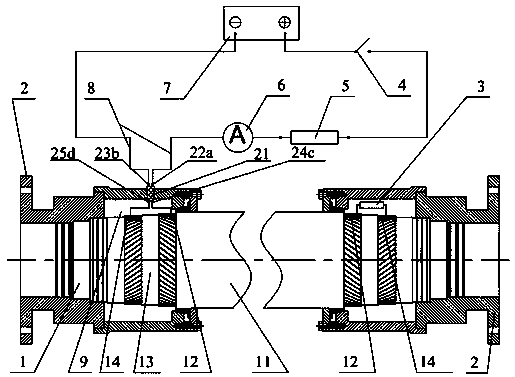

Detection device and method for ocean non-coking flexible pipeline outer sheath layer damage

InactiveCN110044550ADoes not affect normal workSimple processDetection of fluid at leakage pointSurface oceanCurrent meter

The invention discloses a detection device and method for ocean non-coking flexible pipeline outer sheath layer damage. The detection device comprises an ocean non-coking flexible pipeline, joints, aload resistor, a switch, a protective resistor, an ammeter, a power supply, an electric wire and a sealing plug, wherein the head end and the tail end of the ocean non-coking flexible pipeline are independently connected with the joint; the load resistor is communicated with an external tensile armored wire and an internal tensile armored wire on the tail end of the ocean non-coking flexible pipeline; the positive electrode and the negative electrode of the electric wire are independently connected with the external tensile armored wire and the internal tensile armored wire on the head end ofthe ocean non-coking flexible pipeline through sealing plug electrodes; and the power supply, the switch, the protective resistor, the ammeter, the external tensile armored wire, the load resistor andthe internal tensile armored wire are connected in series to form a closed loop. When the ocean non-coking flexible pipeline outer sheath layer is damaged, seawater permeates into the pipeline, the load resistor is subjected to short circuit, and the reading of the ammeter changes so as to detect the ocean non-coking flexible pipeline outer sheath layer damage.

Owner:SOUTHWEST PETROLEUM UNIV

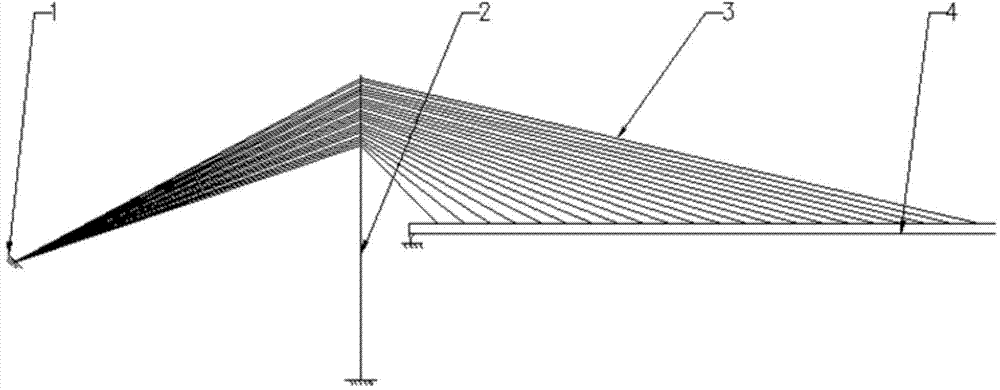

Cable-stayed bridge construction method

ActiveCN104775365ALight weightReduce dead loadCable-stayed bridgeBridge structural detailsCable stayedBridge type

The invention provides a cable-stayed bridge construction method. According to the design idea, in the conventional construction method, a cable-stayed bridge main beam is arranged on a far tower position firstly instead of being arranged from a near-tower position to mid-span, and the load is delivered onto a tower through a cable. Opposite force on the other sides of tower and the beam is synchronously delivered onto a beam and a tower on the other side or an anchorage, and the beam carries tensile stress, so that the rigidity of the main beam is enhanced greatly. When the cable-stayed bridge construction method is applied to a long-span bridge, the beam section does not need to be increased, and the dead weight can be reduced by applying a high-strength material. Compared with other bridge types, the spanning capability and economical efficiency of a bridge constructed on the basis of the method are superior.

Owner:DONGHONG CONSTR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com