Method and device for pretreating post-etherification C4 raw material

A pretreatment device, the technology of C4 after ether, which is applied in chemical instruments and methods, ether preparation, hydrocarbons, etc., can solve the problems of high operation cost, complicated process, long process, etc., and achieve high promotion value and cost saving. , the effect of improving the economic efficiency of the industry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

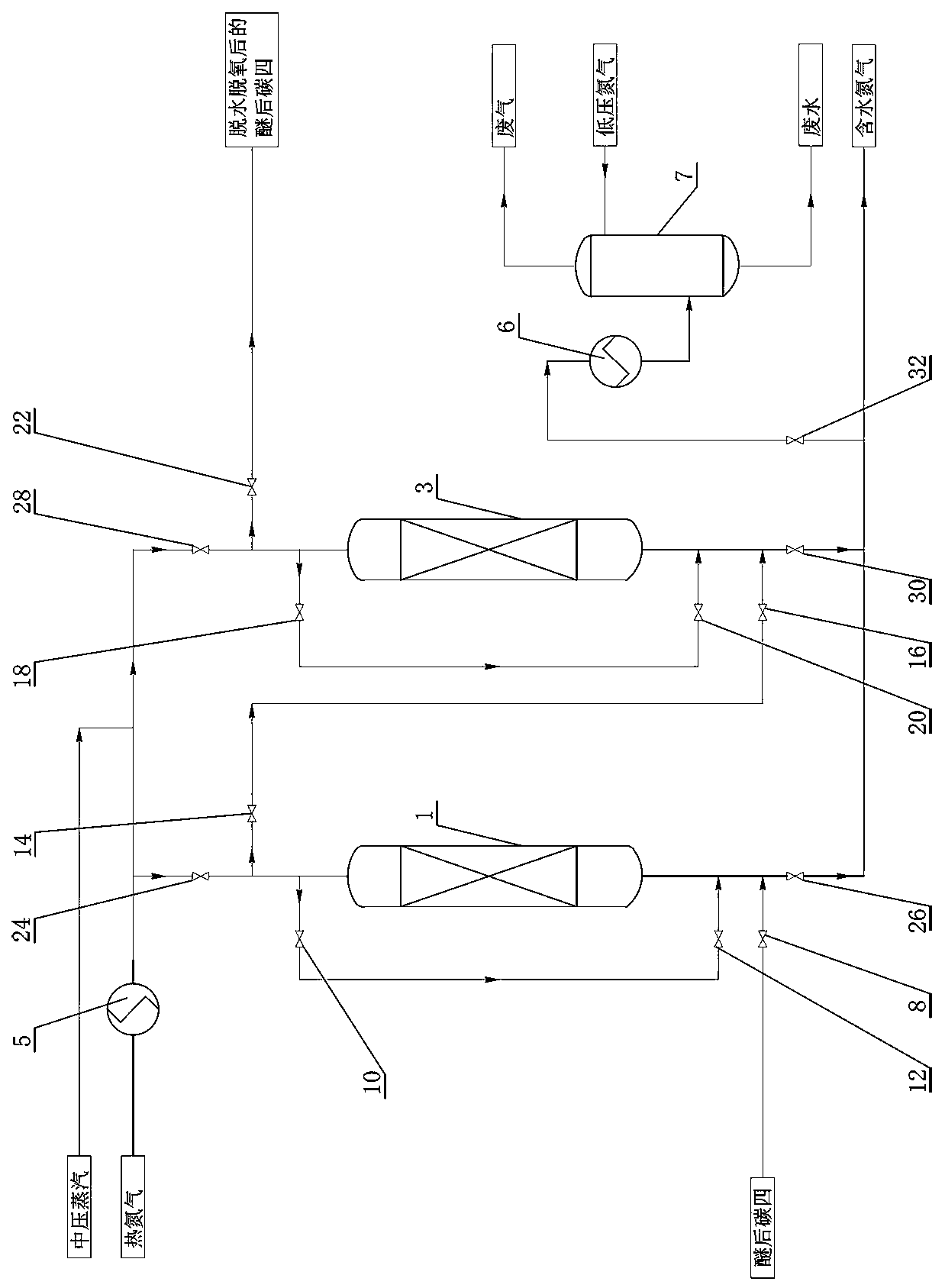

[0052] Please refer to figure 1 , figure 1 A process flow chart of a pretreatment method for C4 raw material after ether is shown in the present invention. The post-ether C4 raw material pretreatment device includes a dehydration treatment device, a deoxidation treatment device, a nitrogen cooler, an exhaust gas condenser and an empty tank.

[0053] In this embodiment, the dehydration treatment device is a dehydration tank 1, and each dehydration tank 1 is filled with a dehydrating agent; the deoxidation treatment device is a deoxidation tank 3, and each deoxidation tank 3 is filled with a deoxidizer.

[0054] The bottom of each dehydration tank 1 is connected with the feed pipeline of C4 after ether and the outlet pipeline of hot nitrogen, and the top of each dehydration tank 1 is connected with the inlet pipeline of hot nitrogen and the discharge pipe of C4 after dehydration road. A circulating dehydration pipeline for C4 after ether is also connected between the discharg...

Embodiment 2

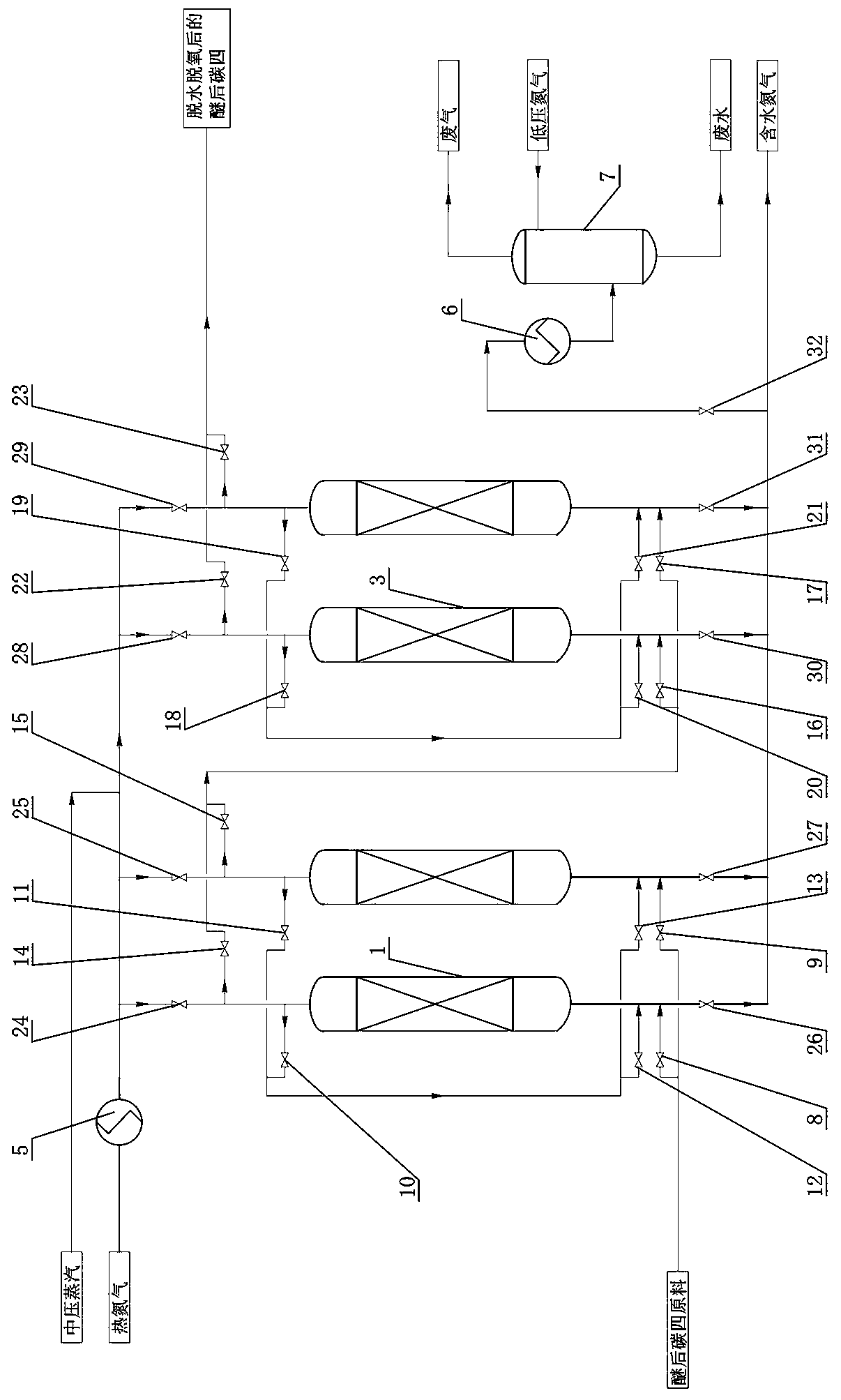

[0078] Please refer to figure 2 , figure 2 It shows a process flow chart of another pretreatment method for post-ether C4 raw material of the present invention. The post-ether C4 raw material pretreatment device includes a dehydration treatment device, a deoxidation treatment device, a nitrogen cooler, an exhaust gas condenser and an empty tank.

[0079] In this embodiment, the dehydration treatment device is two dehydration tanks 1, that is, dehydration tank A and dehydration tank B. The two dehydration tanks 1 are arranged in parallel. During normal operation, a single dehydration tank is used, and the other is for standby; the dehydration treatment device is two dehydration tanks. Two deoxygenation tanks 3, i.e. deoxidation tank A and deoxidation tank B, are arranged in parallel, one deoxygenation tank runs during normal production, and the other is standby.

[0080] The pipeline switching process of the dehydration tank A is not repeated as described in Embodiment 1; t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com