A method for producing aromatic hydrocarbon solvent oil by hydrogenation of ethylene cracking C9 aromatic fraction

A technology for ethylene cracking and aromatic hydrocarbons, which is applied in the treatment of hydrocarbon oil, hydrocarbon oil treatment products, hydrogenation process, etc. It can solve the problems of multiple equipment, complicated process flow, and high operating cost, so as to ensure the operating cycle and reduce operating costs. , the effect of high operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

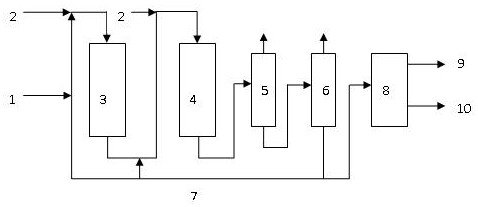

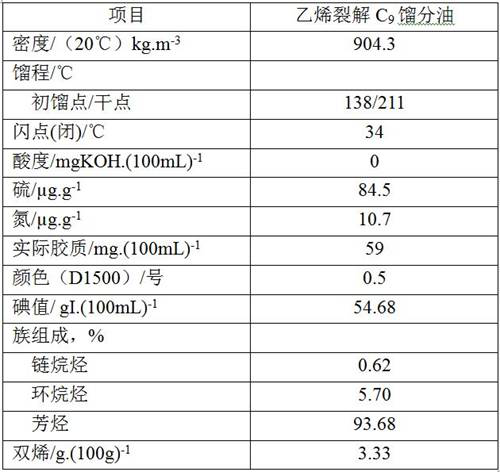

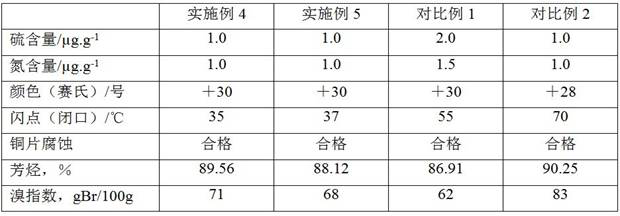

[0030] Such as figure 1 Shown, the ethylene cracking C of the present invention 9 The process flow of distillate liquid phase hydrogenation process is: ethylene cracking C 9 Fraction 1 is mixed with circulating oil 7, and after being fully dissolved with hydrogen 2, it enters the first-stage hydrofinishing reaction zone 3, and contacts with the noble metal hydrofinishing catalyst. Under relatively mild process conditions, selective hydrotreating is easy to coke Diolefins, styrene and their derivatives. Ethylene Cracking for Diene Removal 9 The aromatic fraction is fully dissolved with hydrogen again and enters the second-stage hydrofinishing reaction zone 4, where it reacts with hydrogenation protection catalyst, hydrofinishing catalyst A, hydrofining catalyst B and hydrofining catalyst successively, and saturates monoolefins under suitable conditions , and remove sulfur, nitrogen impurities and colloids, the reaction effluent enters the separator 5 for gas-liquid separatio...

Embodiment 1

[0041] Prepare solid sodium aluminate to a concentration of 200gAl 2 o 3 / L concentrated sodium aluminate solution, diluted to a concentration of 40gAl 2 o 3 / L sodium aluminate working solution 20L (a), take and dilute to a concentration of 50gTiO 2 / L titanium sulfate working solution 2L (b). Take a 30L steel plastic tank, open the container valves of (a) and (b) at the same time, and ventilate and introduce CO with a concentration of 40v% at the same time 2 Gas, set the flow rate of (a) and (b) so that the reaction time is 50 minutes, and quickly adjust the CO 2 flow rate, keep the pH value of the system at about 10, and the reaction temperature is 35°C. 2 CO 3 The reaction mother liquor, by adjusting Na 2 CO 3 Solution flow, keep the pH value at 9.5, the reaction time is 0.5 hours, stop feeding CO 2 , and then the air was stabilized for 40 minutes, and the slurry was filtered and washed with 60°C deionized water until neutral. Microwave drying at 120°C for 20 min...

Embodiment 2

[0043] Use 1000g of aluminum hydroxide powder, add 20mL of nitric acid, 700mL of deionized water, 450g of silica sol and additives, mix and roll, extrude into a clover shape, dry at 110°C for 3 hours, and roast at 550°C for 3 hours to obtain the carrier; Mix 21g of nickel, 75g of molybdenum oxide, 7g of cobalt carbonate, 20g of phosphoric acid and 130mL of deionized water, and dissolve at 95°C for 3 hours to obtain 200mL of Mo-Ni-Co-P co-immersion solution. Impregnated at room temperature, dried at 120°C for 3 hours, and calcined at 500°C for 3 hours to obtain Hydrofining Catalyst A. The physical properties of hydrofining catalyst A are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com