Nickel-based catalyst and preparation method therefor

A catalyst and nickel-based technology, applied in the field of nickel-based catalysts and their preparation, can solve the problems of poor hydrogenation stability and achieve good hydrogenation effect, long regeneration cycle and strong activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Preparation of vector

[0029] Take the specific surface area as 176m 2 / g , the pore volume is 0.7ml / g Bar Aluminum Oxide 100 g , impregnated with 50ml of titanium sulfate in a 0.6g / ml dilute sulfuric acid solution, stirred for 20 minutes, and dried at 110oC for 10 hours to obtain alumina-titanium oxide.

[0030] Then mix the prepared alumina-titanium oxide and ZSM-5 powder, add a certain amount of 2% dilute nitric acid solution, knead and extrude, dry at 110oC for 12 hours, and roast at 500oC for 6 hours. Alumina-titania, ZSM-5 composite carrier 1 was prepared.

[0031] Catalyst preparation

[0032] Add 5.02g of nickel nitrate to 5ml of water and stir to dissolve, add 0.45g of chromium nitrate while stirring, adjust the pH value to 5, impregnate on 10g of alumina-titanium oxide, ZSM-5 composite carrier 1, and dry at 120oC for 6 Hours later, it was calcined at 600°C for 5 hours to prepare catalyst A.

Embodiment 2-6

[0034] Preparation of vector

[0035] Choose 100g of alumina with different specific surfaces and different pore volumes respectively, which are respectively B: the specific surface is 140m 2 / g , the pore volume is 0.9ml / g ; C: Specific surface is 160m 2 / g , the pore volume is 0.9ml / g ; D: Specific surface is 170m 2 / g ,

[0036] The pore volume is 1.0ml / g ; E: Specific surface is 220m 2 / g , the pore volume is 0.9ml / g ; F: Specific surface is 190m 2 / g , the pore volume is 1.1ml / g; with the method of embodiment 1, change the ratio of alumina-titanium oxide and ZSM-5 powder and the content of active component nickel oxide to prepare catalyst B, C, D, E, F. Catalyst composition is as shown in table 1:

[0037] Table 1. Catalyst composition

[0038] Example 1 2 3 4 5 6 Catalyst number A B C D E F ZSM-5 content (weight%) 70 60 50 40 30 65 TiO 2 / Al 2 o 3 Content (weight%) 30 40 50 60 70 35 Nickel ...

Embodiment 7-10

[0040] Use embodiment catalyst B, E to C respectively 6 -C 9 The distillate was subjected to selective hydrogenation, and the reaction evaluation was in 100ml

[0041] It is carried out on the isothermal bed hydrogenation reaction device, the catalyst is first reduced under 450oC hydrogen medium for 10 hours,

[0042] Then, the reaction pressure is 2.0MPa and the reaction temperature is 50oC, and the constant feedstock oil space velocity of 2.0h- 1 , Evaluation of 100 hours, every 8 hours sampling analysis bromine value, diene, bromine value analyzed in the catalyst 100 hour evaluation, the average data of diene are shown in Table 3.

[0043] Table 2, raw material properties

[0044] project analysis results color yellow density 0.8659 Bromine value (g bromine / 100g oil) 31.85 Diene (g iodine / 100 g oil) 15.02

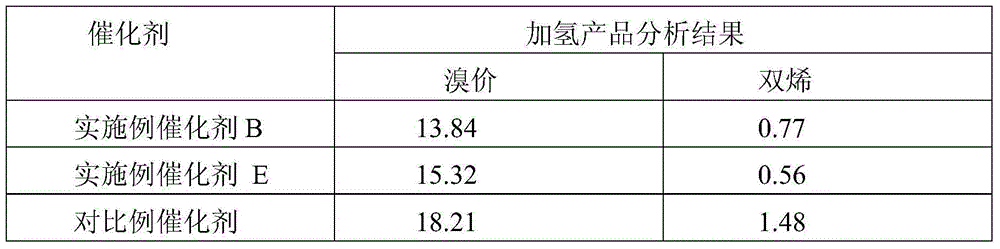

[0045] Table 3, embodiment catalyst 100 hours evaluation average data

[0046]

[0047] Note: The bromine value and diene ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com