Catalyst for preparing bridged tetrahydrodicyclopentadiene, preparation method and application

A technology of tetrahydrodicyclopentadiene and dicyclopentadiene is applied in the field of preparation of diene hydrogenation catalysts, which can solve the problems that the selectivity and stability need to be improved and the reaction temperature is high, and achieve the elimination of nickel-aluminum spinel. Tendency, high reduction degree, good effect of low temperature hydrogenation activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

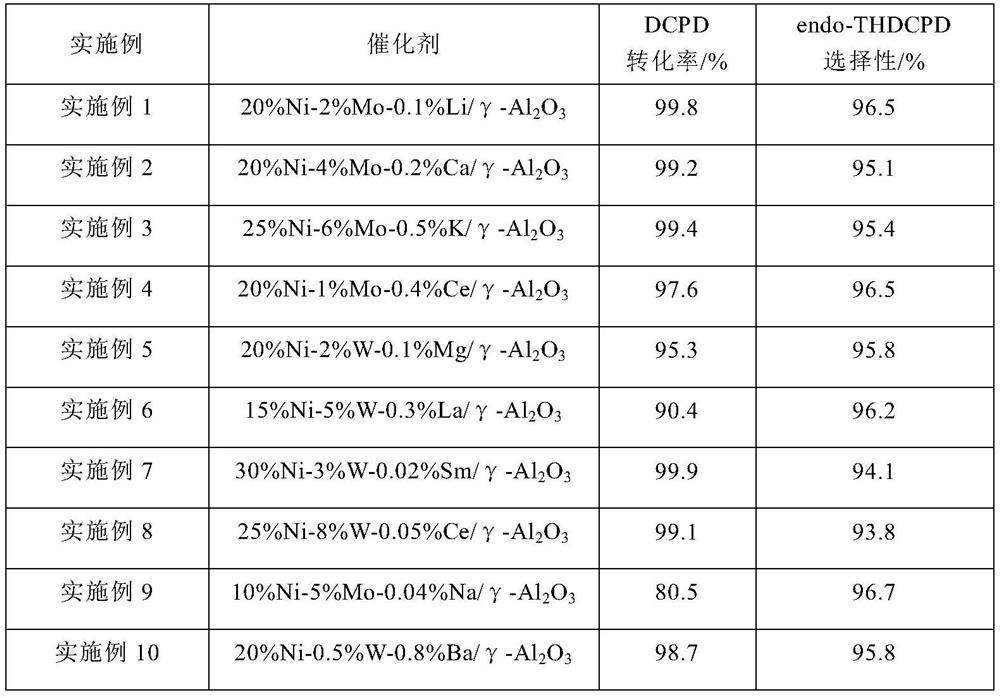

Examples

Embodiment 1

[0030] Weigh an appropriate amount of γ-Al 2 o 3 The carrier was subjected to vacuum treatment at 100° C. for 2 hours, and then cooled to room temperature for use. Weigh 0.01gLiNO 3 Add 10ml of deionized water, impregnate 10.0g of carrier after vacuum treatment, dry in the shade naturally, dry at 120°C for 12 hours, and bake at 400°C for 6 hours.

[0031] Weigh 12.72g Ni(NO 3 ) 2 ·6H 2 O and 0.472g (NH 4 ) 6 Mo 7 o 24 4H 2 Add O and 0.22g ethylene glycol to 30ml deionized water, mix well and impregnate the modified γ-Al 2 o 3 The carrier was dried naturally in the shade, dried at 120°C for 12 hours, reduced at 400°C for 6 hours in a hydrogen atmosphere, and cooled to room temperature, in 0.5% O 2 / N 2 Passivation in the atmosphere for 3 hours, the prepared catalyst is 20%Ni-2%Mo-0.1%Li / γ-Al 2 o 3 .

Embodiment 2

[0033] Adopt the γ-Al of vacuum pretreatment in embodiment 1 2 o 3 carrier.

[0034] Weigh 0.156gCa(NO 3 ) 2 4H 2 O Add 10ml of deionized water, impregnate into 10.0g of vacuum-treated carrier, dry in the shade naturally, dry at 120°C for 12 hours, and bake at 400°C for 6 hours.

[0035] Weigh 13.07g Ni(NO 3 ) 2 ·6H 2 O and 0.971g (NH 4 ) 6 Mo 7 o 24 4H 2 Add O and 0.22g ethylene glycol to 30ml deionized water, mix well and impregnate the modified γ-Al 2 o 3 The carrier was dried naturally in the shade, dried at 120°C for 12 hours, reduced at 400°C for 6 hours in a hydrogen atmosphere, and cooled to room temperature, in 0.5% O 2 / N 2 Passivation in the atmosphere for 3 hours, the prepared catalyst is 20%Ni-4%Mo-0.2%Ca / γ-Al 2 o 3 .

Embodiment 3

[0037] Adopt the γ-Al of vacuum pretreatment in embodiment 1 2 o 3 carrier.

[0038] Weigh 0.189g KNO 3 Add 10ml of deionized water, impregnate into 10.0g of vacuum-treated carrier, dry in the shade naturally, dry at 120°C for 12 hours, and bake at 400°C for 6 hours.

[0039] Weigh 18.08g Ni(NO 3 ) 2 ·6H 2 O and 1.612g (NH 4 ) 6 Mo 7 o 24 4H 2 Add O and 0.22g ethylene glycol to 30ml deionized water, mix well and impregnate the modified γ-Al 2 o 3 The carrier was dried naturally in the shade, dried at 120°C for 12 hours, reduced at 400°C for 6 hours in a hydrogen atmosphere, and cooled to room temperature, in 0.5% O 2 / N 2 Passivation in the atmosphere for 3 hours, the prepared catalyst is 25%Ni-6%Mo-0.5%K / γ-Al 2 o 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com