Method for refining tea seed oil

A technology for tea seed oil and camellia seed oil, which is applied in the direction of fat oil/fat refining, fat production, etc., can solve the problems of increasing cost, unfavorable energy saving and consumption reduction, increasing equipment investment and process operation, etc., to simplify the production process, reduce Equipment and facilities, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

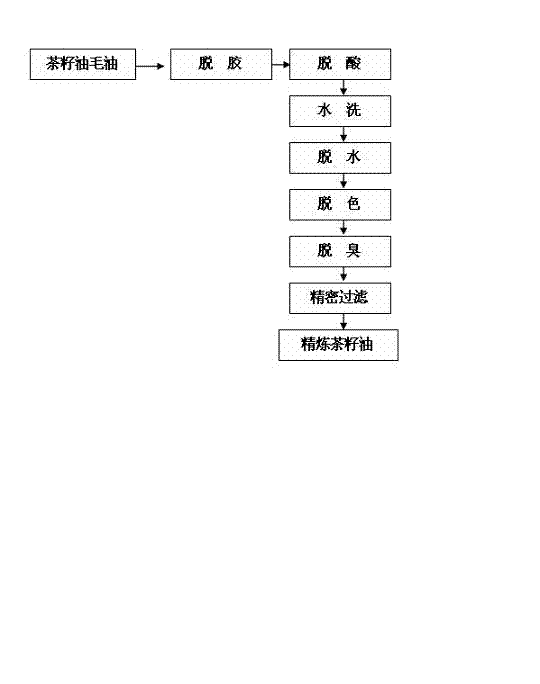

Image

Examples

Embodiment 1

[0020] The method for refining tea seed oil of the present invention, comprises the steps:

[0021] Pump 1000kg of tea seed oil crude oil into the degumming tank, add 1.5kg of food grade citric acid degumming agent, stirring speed is 100r / min, degumming temperature is 35°C, degumming time is 40min, let stand for 1 hour, and then discharge the lower water layer; Pump the degummed tea seed oil into the deacidification tank, add 5 kg of food-grade sodium hydroxide deacidification agent with a concentration of 25%, the temperature is 30 °C, the time is 25 min, the stirring speed is 100 r / min, and then the temperature is raised to 70 °C, static Set aside for 1 hour, drain the saponins, etc.; wash the oil with 30kg of hot water at 90°C each time, the oil temperature is 85°C, and the stirring speed is 90 r / min until the pH value of the water layer is equal to 7; pump the washed tea seed oil Put it into the dehydration tank, raise the temperature to 100°C, and the vacuum degree is 0.0...

Embodiment 2

[0024] Pump 800 kg of tea seed oil crude oil into the degumming tank, add 1.0 kg of food grade citric acid degumming agent, the stirring speed is 90r / min, the degumming temperature is 30°C, the degumming time is 40min, let stand for 1 hour, and then discharge the lower water layer; Pump the degummed tea seed oil into the deacidification tank, add 4.0kg of food-grade sodium hydroxide deacidification agent with a concentration of 25%, the temperature is 30°C, the time is 20min, the stirring speed is 110 r / min, and then the temperature is raised to 70°C, static Set aside for 1 hour, drain the saponins, etc.; wash the oil with 30kg of water, 90°C hot water, the oil temperature is 85°C, and the stirring speed is 80 r / min, until the pH value of the water layer is equal to 7; pump the washed tea seed oil into the dehydration tank, heated to a temperature of 100°C, and a vacuum degree of 0.09MPa, for drying and dehydration; the dehydrated tea seed oil was pumped into the decolorization...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pov | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com