Digital box type fast-assembling oil-gas gathering and transferring system

A kind of oil and gas gathering and transportation, box-type technology, applied in the field of oil transfer station, can solve the problems of complex pipeline network, large floor area, manual water replenishment of four-in-one combined device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

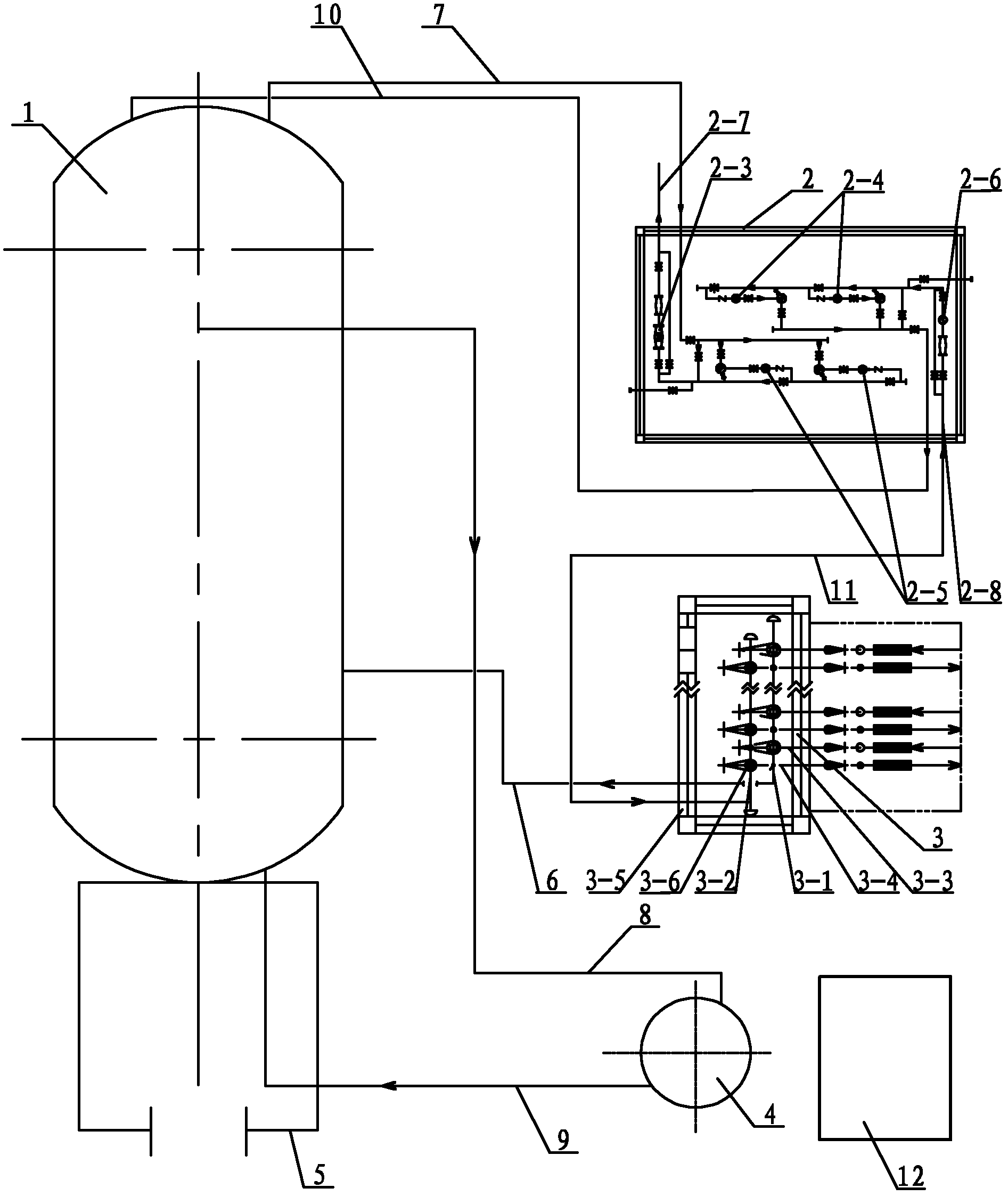

[0008] Specific implementation mode one: combine Figure 1 to Figure 5 Describe this embodiment, this embodiment includes an oil and gas treatment device 1, a numerically controlled oil-water pressurized metering box 2, a numerically controlled oil-collecting and water-distributing valve group box 3, a natural gas dryer 4, a skid-mounted fire room 5, a first pipeline 6, a second The pipeline 7, the third pipeline 8, the fourth pipeline 9, the fifth pipeline 10, the sixth pipeline 11 and the central control room 12, the skid-mounted fire room 5 is set on the fire pipe on the oil and gas treatment device 1 At the entrance 1-11-1, one end of the first pipeline 6 communicates with the liquid inlet 1-1-1 on the oil and gas treatment device 1, and the other end of the first pipeline 6 communicates with the numerical control oil collection and water distribution valve group box 3 The oil collection manifold 3-1 is connected, one end of the second pipeline 7 is connected with the oil ...

specific Embodiment approach 2

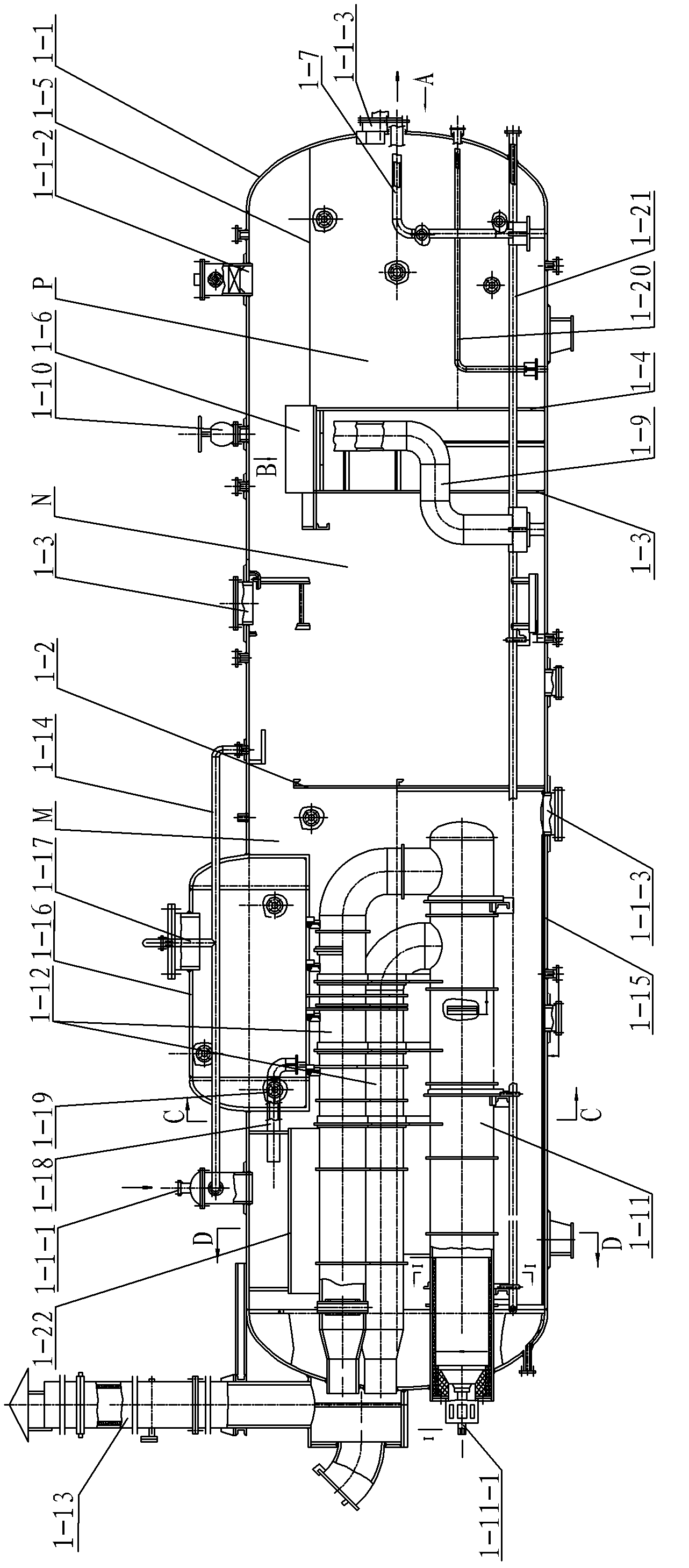

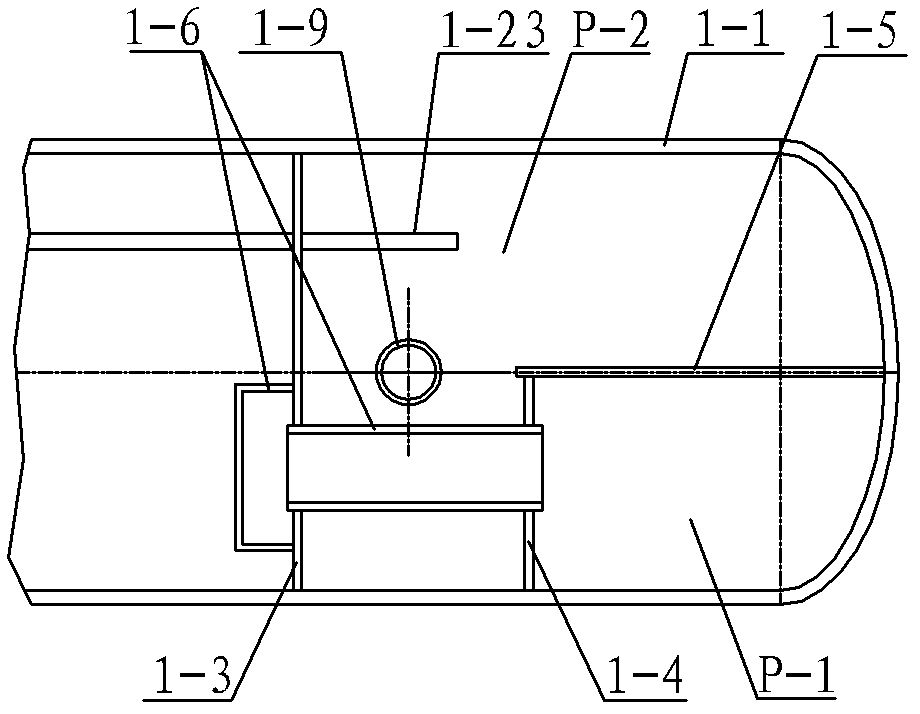

[0009] Specific implementation mode two: combination Figure 2 ~ Figure 4Describe this embodiment, the oil and gas treatment device 1 of this embodiment includes a tank body 1-1, a first partition 1-2, a second partition 1-3, a third partition 1-4, a fourth partition 1- 5. Oil collection tank 1-6, oil outlet pipe 1-7, water outlet pipe 1-8, adjustable weir pipe 1-9, adjustable weir pipe valve 1-10, fire pipe 1-11, smoke pipe 1-12, chimney 1-13, main air balance pipe 1-14, balance water tank 1-16, auxiliary air balance pipe 1-17, water supply pipe 1-18, water supply valve 1-19, buffer weir plate 1-22, water weir pipe 1- 23 and two fuel oil pipes 1-20, the first partition 1-2 and the second partition 1-3 are sequentially arranged in the tank body 1-1 along the cross-sectional direction of the tank body 1-1, the first partition The cavity between the plate 1-2 and the inner wall of the tank body 1-1 is the heating section M, the cavity between the first partition 1-2 and the sec...

specific Embodiment approach 3

[0010] Specific implementation mode three: combination figure 2 with Figure 4 This embodiment is described. The difference between this embodiment and the second embodiment is that it also adds a heating coil 1-21. The heating coil 1-21 is arranged at the bottom of the inner cavity of the tank body 1-1. The heating coil 1-21 The water inlet and outlet of 21 are all arranged outside the tank body 1-1, and the temperature and pressure of the heating coil 1-21 are transmitted to the central control room through data transmission (data transmission methods include cable transmission, wireless network bridge, GPRS) 12 for monitoring. The water outlet of the heating coil 1-21 is connected to the user, and the heat of the heating section M is used to heat the water in the heating coil 1-21, so that the heat of the heating section M is effectively used. Other components and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com