Method for producing polylactic acid and a highly conductive polymer, and apparatus for producing highly conductive polylactic acid polymer

A manufacturing method and technology of polylactic acid, which are applied in chemical instruments and methods, chemical/physical processes, chemical/physical/physical-chemical processes, etc., can solve problems such as increased production costs, decreased production costs, inability to obtain high concentrations of lactic acid, etc. The effect of optimizing frequency and output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

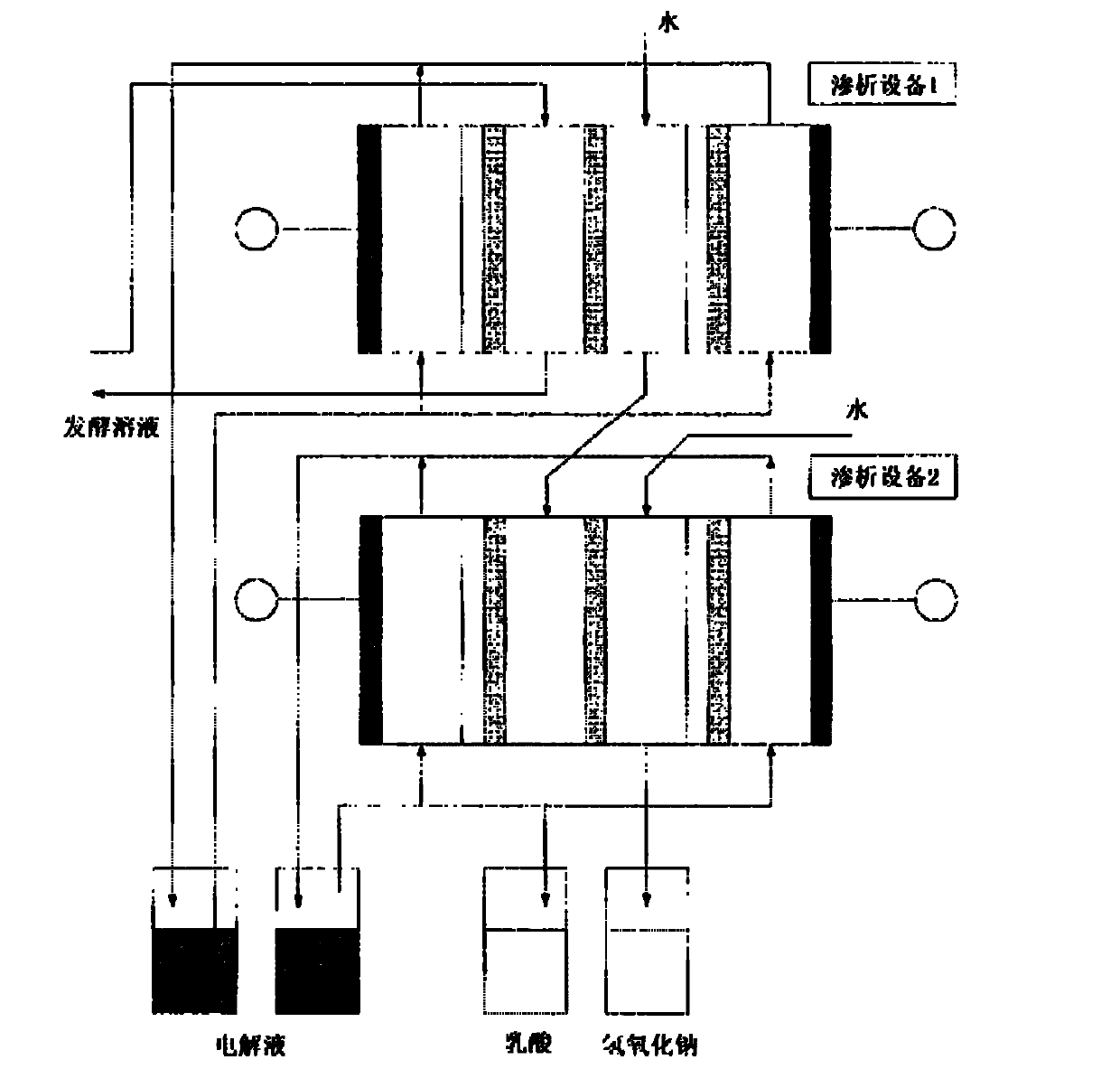

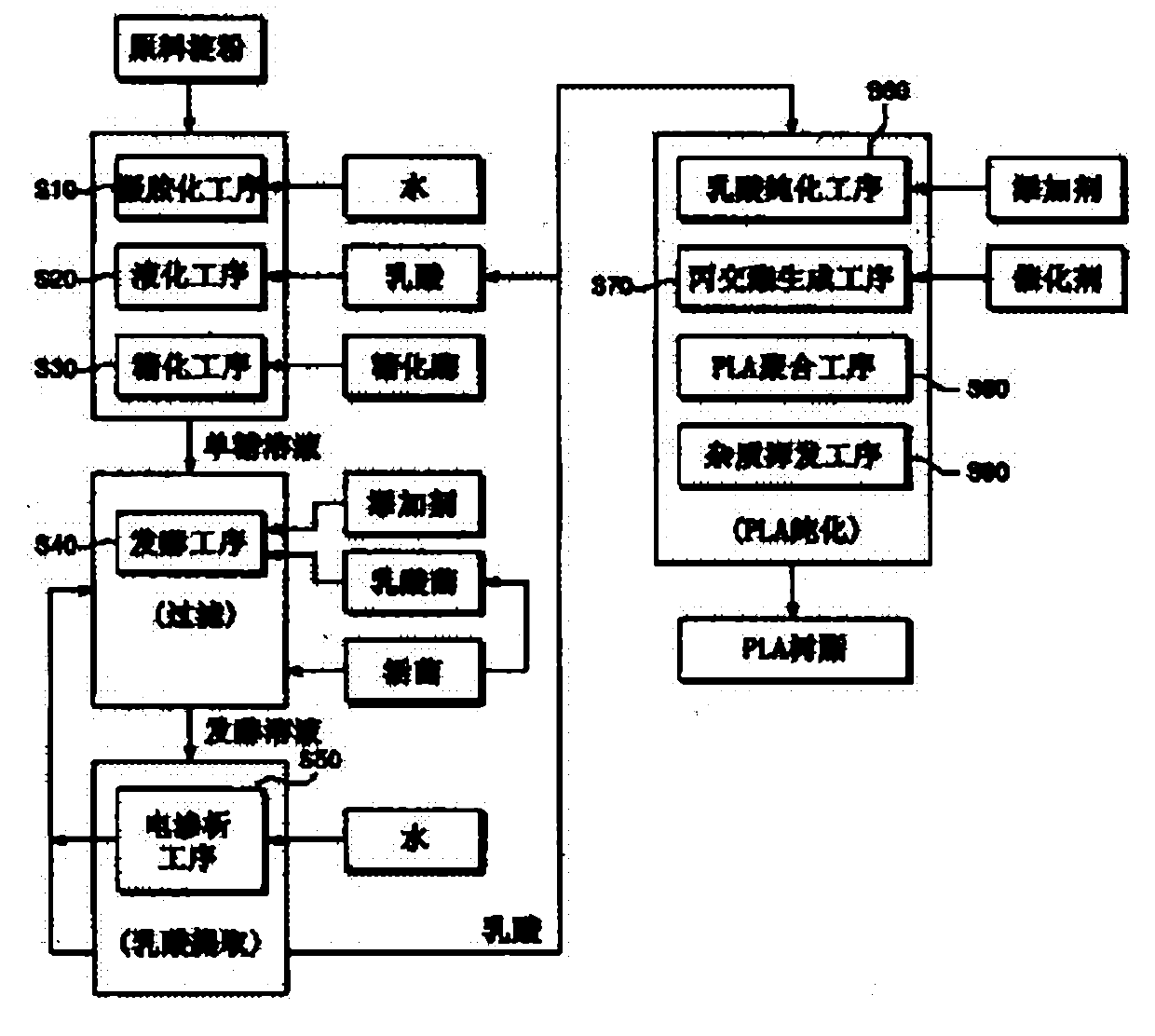

[0073] figure 2 It is a process diagram describing the embodiment of the preparation method of polylactic acid of the present invention, such as figure 2 As shown, the method includes a gelatinization step (S10) of mixing vegetable starch with water and then heating to gelatinize the starch; adding lactic acid to the gelatinized starch and then heating to liquefy the starch The liquefaction process (S20); the saccharification process (S30) of degrading the liquefied starch into a monosaccharide solution by using glucoamylase; the fermentation process (S40) of subjecting the monosaccharide solution to lactic acid fermentation to produce a fermentation solution; an electrodialysis process (S50) of separating and concentrating lactate in a solution and then separating lactic acid from the lactate; a lactic acid purification process (S60) of heating the separated lactic acid to remove water and impurities; a lactide production process (S70) of mixing oxides to produce lactide; ...

Embodiment 1

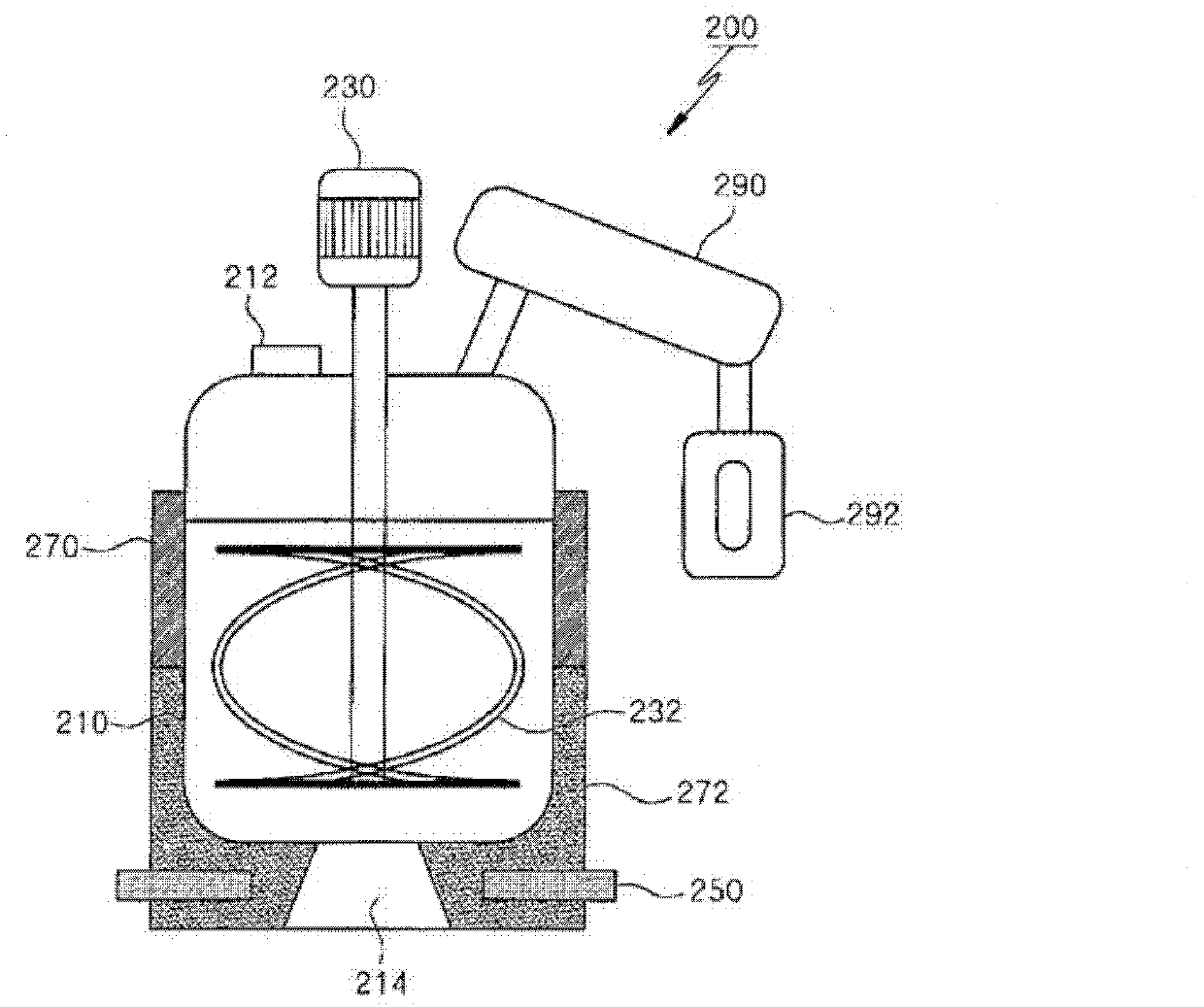

[0178] According to step S1, 100 parts by weight of polylactic acid with an average molecular weight of 5000-10000, 5-10 parts by weight of polyglycolic acid and 10-20 parts by weight of lactide are put into a reaction vessel. Next, 0.1 to 10 parts by weight of ammonium vanadate as a catalyst and 0.1 to 10 parts by weight of vanadium oxide are added to the reaction vessel, followed by stirring. At this time, the heater is operated to heat the reaction vessel at a temperature of 160° C. to 190° C., and the pressure inside the reaction vessel is adjusted to 0.1 to 0.5 atmospheres using a suction pump.

[0179] According to step S2, put 5-10 parts by weight of serine and 0.1-1 part by weight of dodecanol into the reaction container, and supply nitrogen and electromagnetic waves to the reactants through the nitrogen / electromagnetic wave supply unit. Use a magnetron oscillator with a rated output of 3KW to emit electromagnetic waves to generate a frequency of 2.45GHz and an output ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com