Plating waste gas treatment device

A waste gas treatment device and waste gas collection technology, which are applied in the electrolysis process, electrolysis components, and smoke removal, etc., can solve the problems of unsuitability for widespread use, poor concentration effect, short service life, etc., saving pipeline facilities and compact structure. Reasonable, convenient maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

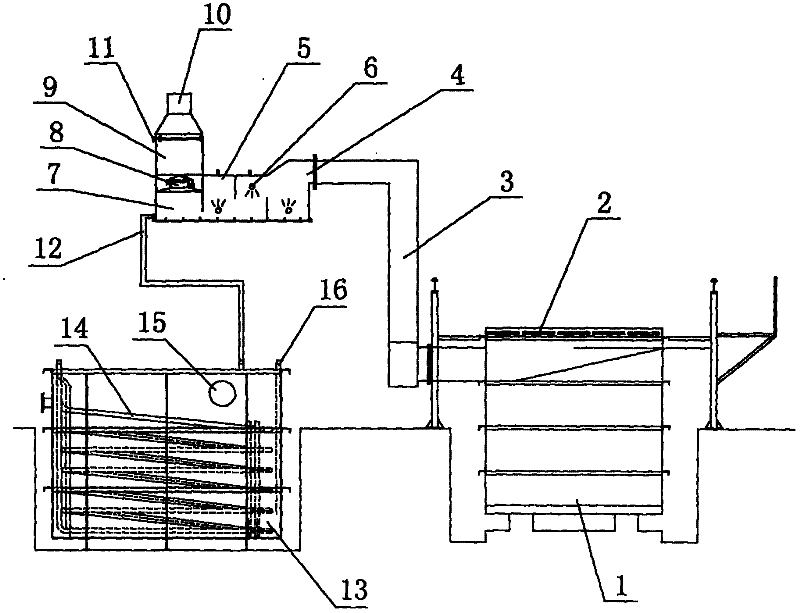

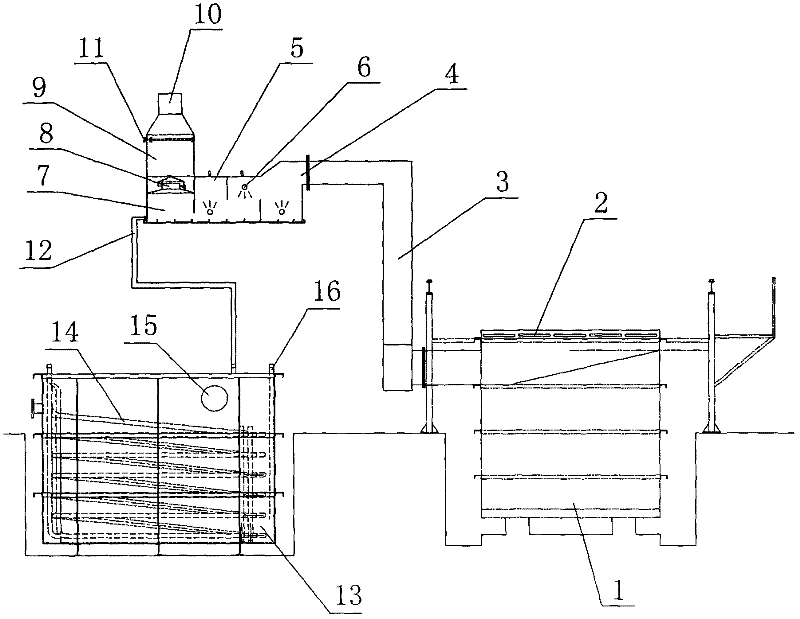

[0025] see figure 1 as shown, figure 1 It is a structural schematic diagram of the electroplating waste gas treatment device of the present invention. In this embodiment, the electroplating exhaust gas treatment device includes a suction hood 2 arranged above the electroplating tank 1, the suction hood 2 is connected to a suction pipe 3, and the suction pipe 3 is connected to the spray cabin 5 The air inlet 4, the spray cabin 5 includes the first compartment, the second compartment and the third compartment communicated with each other, the three compartments are all provided with a communication circulating cooling pump (not shown in the figure ) of the sprinkler head 6.

[0026] One side of the spray cabin 5 is provided with a gas-liquid separation tower designed integrally with the spray cabin 5, and the bottom of the gas-liquid separation tower is provided with a recovery liquid collection tank 7 communicating with the spray cabin 5. The top of recovery liquid collectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com