Industrial production quality analysis early warning method and system

A quality analysis and early warning system technology, applied in the field of data analysis, can solve problems such as abnormal detection, waste of manpower and time, and achieve the effects of optimizing production, improving product yield, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

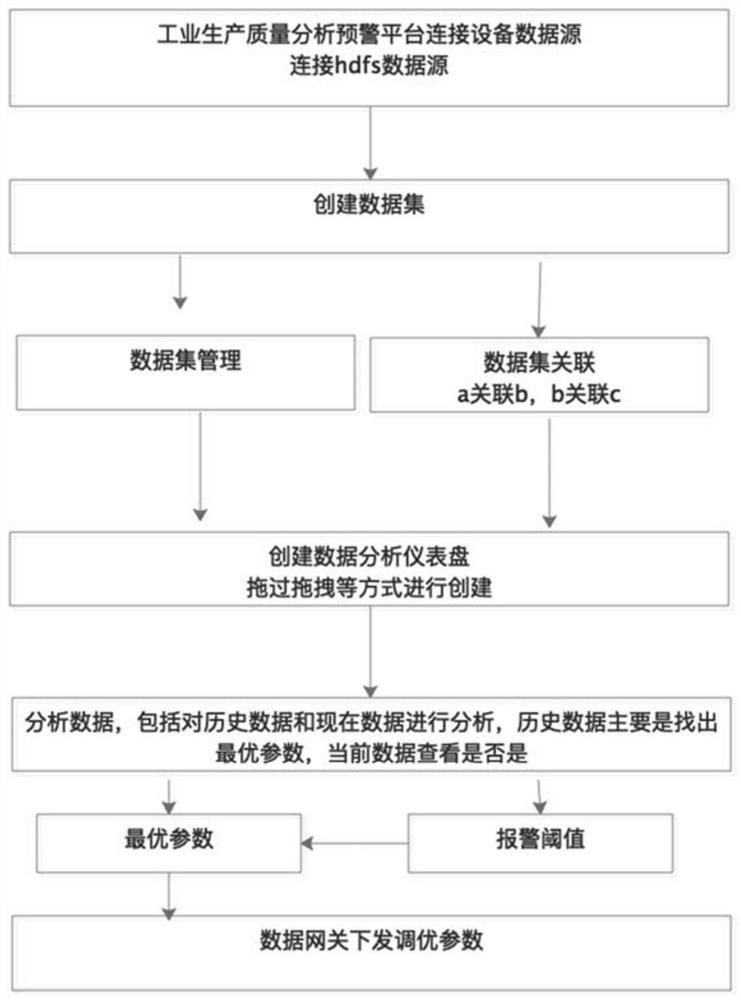

[0051]The industrial production quality analysis and early warning method connects each data layer through the self-developed industrial data analysis platform, and allows users to connect to private data, providing a rich number of data sources for self-service data analysis. Data sources are the basis of data analysis, generally IT / data research and development And other technical users will use it. Currently, industrial production quality analysis supports four types of cloud data sources, self-built data sources, file data sources and application data sources. The product data produced on-site by industrial equipment is analyzed through the industrial production quality early warning analysis platform. First, the industrial data will be connected to the industrial production quality analysis early warning platform. After connecting the data, it is necessary to create a data set and build a data model. Complete the preparations for data analysis. Then create a data dashboa...

Embodiment 2

[0063] Embodiment 2 can be regarded as a preferred example of Embodiment 1. The industrial production quality analysis early warning system described in embodiment 2 utilizes the steps of the industrial production quality analysis early warning method described in embodiment 1.

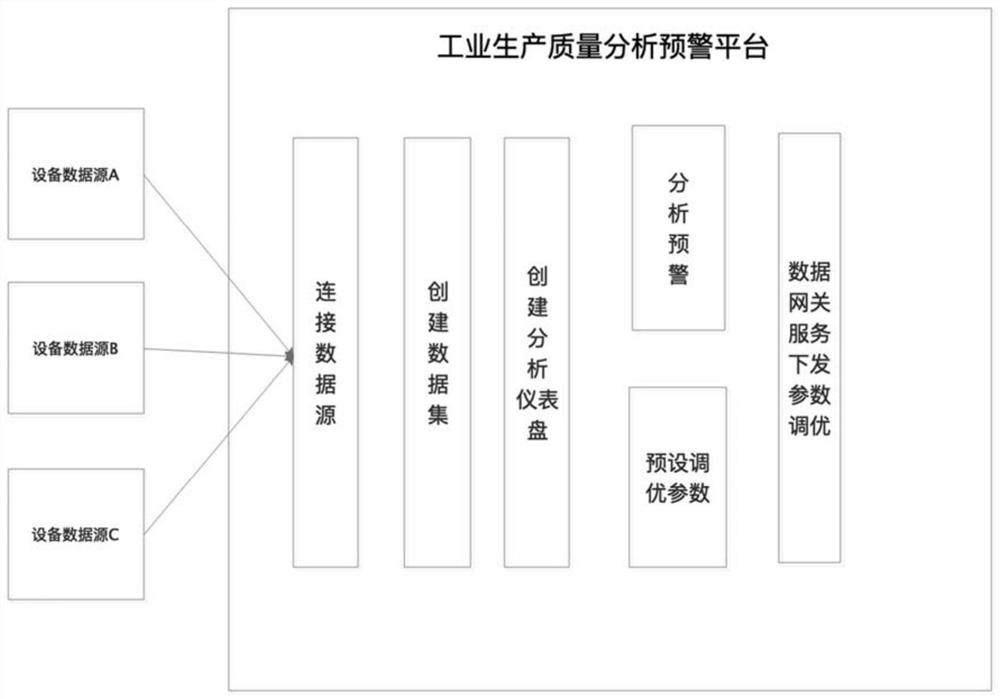

[0064] Such as figure 1 As shown, an early warning system for industrial production quality analysis, including:

[0065] Access data source module: Configure different access interfaces according to different data sources, set automatic operation procedures in the access interface, and access data sources from the industrial production data platform;

[0066] Create dataset module: use tables or SQL in the data source to create datasets, associate and rename multiple datasets to form basic datasets;

[0067] Analysis and early warning module: display the basic data set in the form of a chart board, highlight the key fields in the basic data set, add analysis warning signs on the chart board, and au...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com