Electroplating effluent atmosphere concentration unit

A technology for concentrating device and electroplating waste liquid, applied in water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of unsuitability for widespread use, poor concentration effect, complex structure, etc. , to achieve the effect of small footprint, compact and reasonable structure, and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

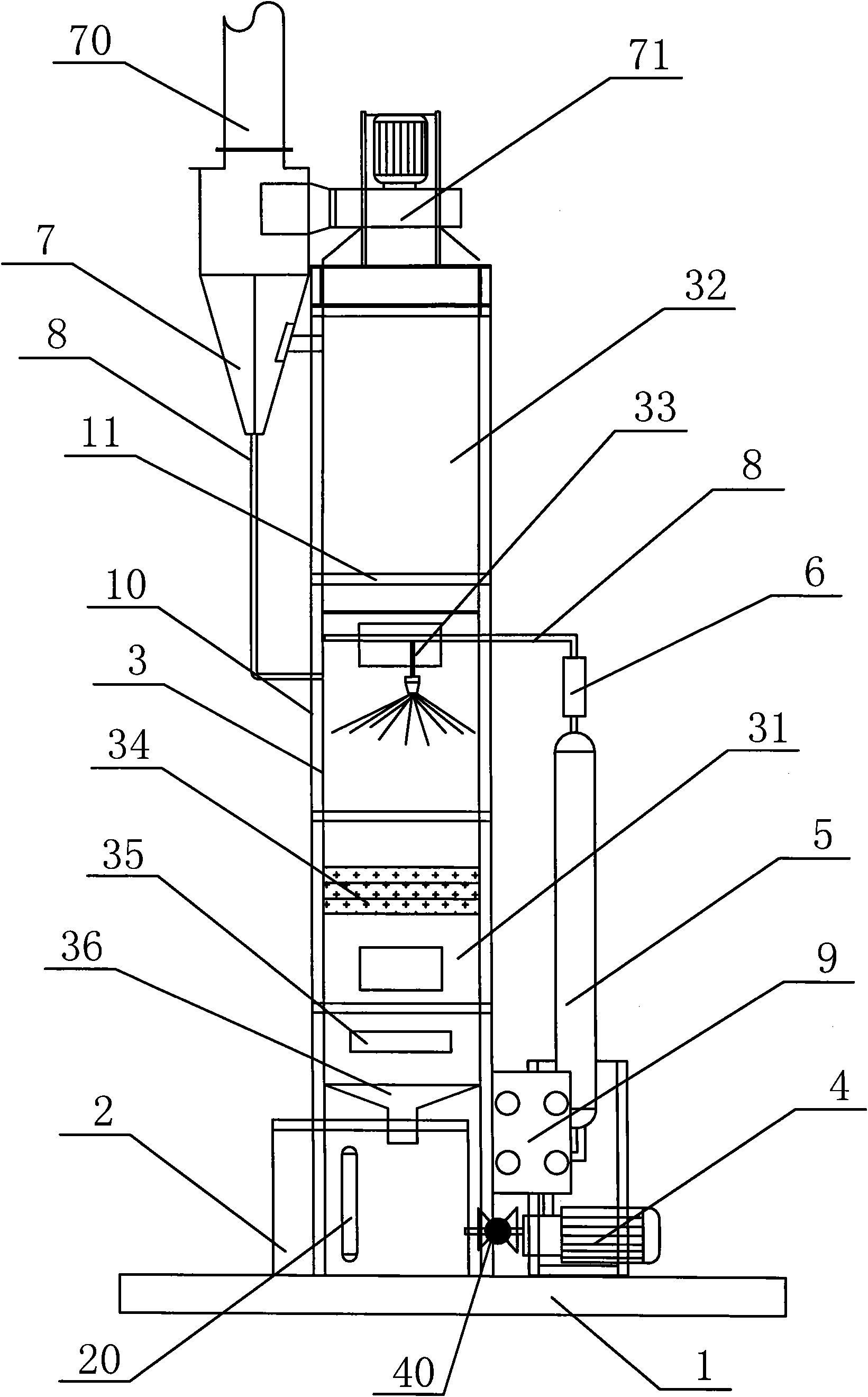

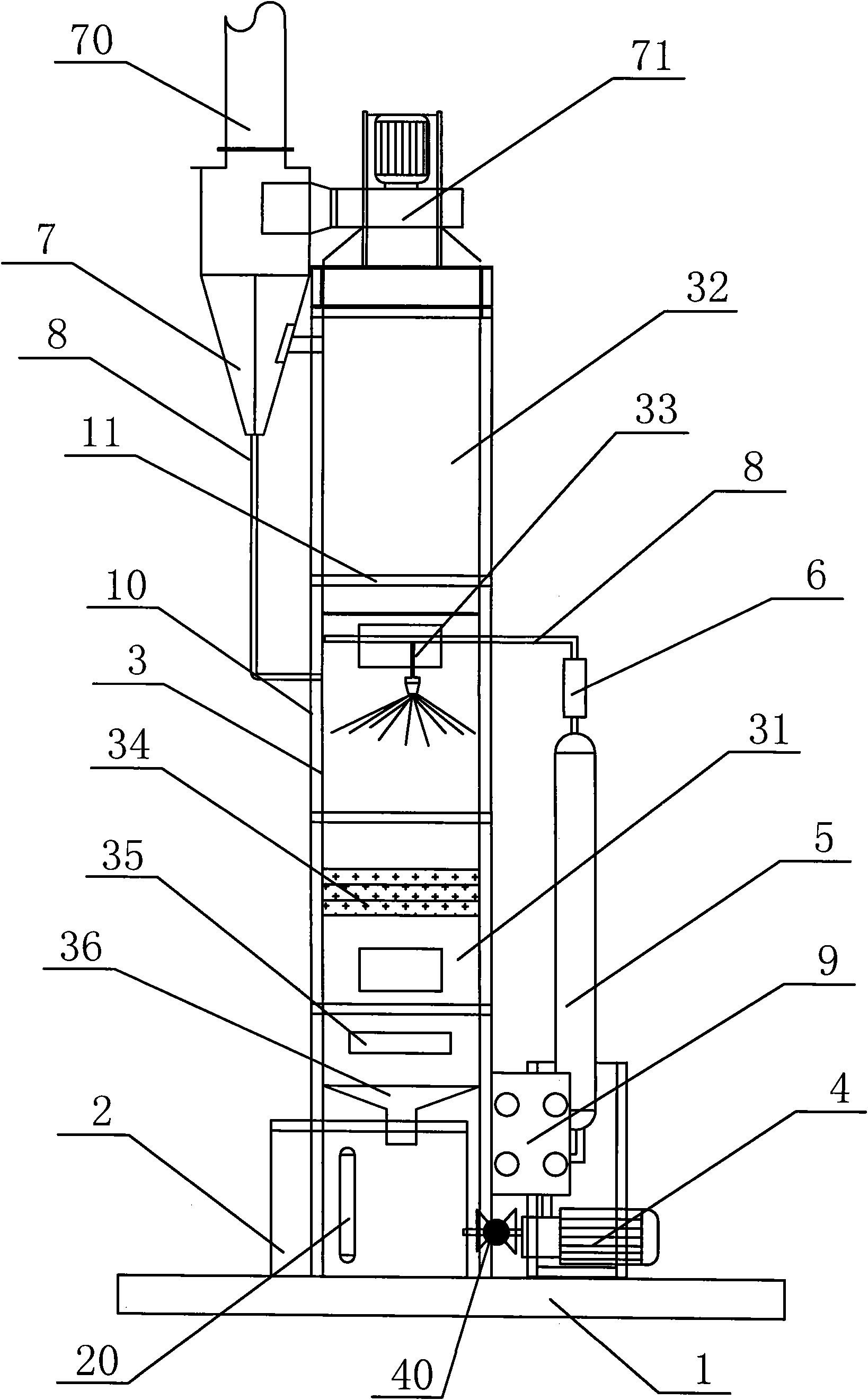

[0018] see figure 1 as shown, figure 1 It is a structural schematic diagram of an electroplating waste liquid atmospheric concentration device of the present invention. In this embodiment, an electroplating waste liquid atmospheric concentration device includes a frame base 1, and a liquid storage tank 2 is arranged on the frame base 1. The liquid storage tank 2 is provided with a liquid storage tank sight glass 20 for detecting the height of the liquid in the liquid storage tank 2, and the top of the liquid storage tank 2 is provided with a concentrating tank 3 through a funnel-shaped liquid collection bucket 36. The frame base 1 is provided with a support 10 in accordance with the shape of the enrichment box 3, and the support 10 is provided with a cross bar 11 to facilitate detection and maintenance of the equipment. The concentration box 3 includes a stuffing box 31 and a defogging box 32. The defogging box 32 is arranged above the stuffing box 31, the top of the stuffing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com