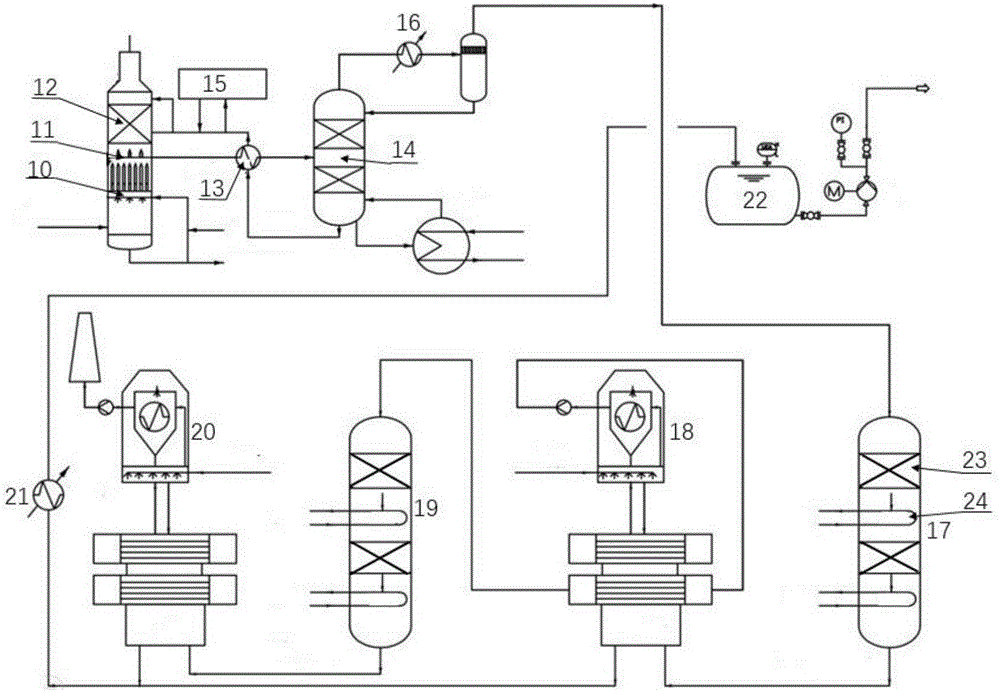

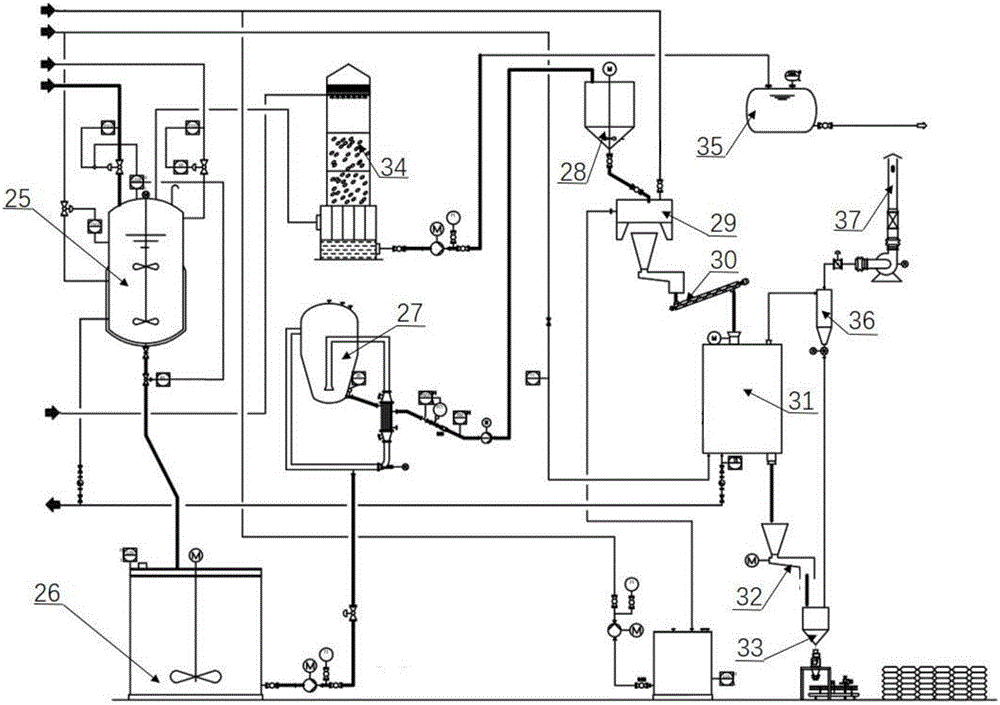

Method for comprehensively treating sulfur-containing flue gas and solid waste abraum salt

A comprehensive treatment, flue gas technology, applied in the direction of chemical instruments and methods, sulfate/bisulfate preparation, inorganic chemistry, etc., can solve the problems of increasing the cost of pollutant treatment, increasing the difficulty of environmental protection treatment and disposal, etc. The effects of sustainable development, realization of resource utilization, and reduction of environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] flue gas SO 2 The content is 1%, and the flue gas desulfurization is carried out by using the method described in the present invention, the pH of the washing liquid in the pre-scrubber is 1, the mass percentage of organic amine in the lean amine liquid is 30%, and the absorption temperature of the lean amine liquid is 45°C , the steam temperature of the steam in the regeneration tower is 110°C, the pressure in the regeneration tower is 0.16MPa, and 4% of the regenerated lean amine solution in each absorption cycle enters the amine liquid purification device for purification, SO 2 The removal rate is 99%, and the residual SO in the tail gas 2 The content is 28.57mg / m 3 . The temperature of the catalyst bed is 400°C, the absorbent is 94% sulfuric acid, and the concentration of the produced sulfuric acid is 96%. Add 2.18 tons of solid waste miscellaneous salts to the glass-lined reactor with stirrer, thermal resistance, pressure gauge, liquid level gauge, etc., and slo...

Embodiment 2

[0048] flue gas SO 2 The content is 3.5%, and the flue gas desulfurization is carried out by using the method described in the present invention, the pH of the washing liquid in the pre-scrubber is 2, the mass percentage of organic amine in the lean amine liquid is 25%, and the absorption temperature of the lean amine liquid is 40°C , the steam temperature of the steam in the regeneration tower is 120°C, the pressure in the regeneration tower is 0.18MPa, and 5% of the regenerated lean amine solution in each absorption cycle enters the amine liquid purification device for purification, SO 2 The removal rate is 96%, and the residual SO in the tail gas 2 The content is 20.35mg / m 3 . The temperature of the catalyst bed is 500°C, the absorbent is 95% sulfuric acid, and the concentration of the produced sulfuric acid is 97%. Add 2.18 tons of solid waste miscellaneous salts to the glass-lined reactor with stirrer, thermal resistance, pressure gauge, liquid level gauge, etc., and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com