Concentration and precipitation machine of high-concentration tailing waste water

A technology for wastewater concentration and sedimentation, which is applied in the sedimentation tank, the feeding/discharging device of the sedimentation tank, etc., can solve the problems of increased investment, increased facilities, increased floor space and maintenance costs, and achieves less floor space. , The effect of high processing efficiency and shortened residence time

Inactive Publication Date: 2012-01-18

HAIZHOU E P GRP CO LTD

View PDF3 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] At present, mining washing wastewater can also be used for tap water treatment projects and other industrial wastewater. During the treatment, coagulants need to be put into the sewage, so the investment increases and the number of facilities increases, resulting in an increase in floor space and maintenance costs.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

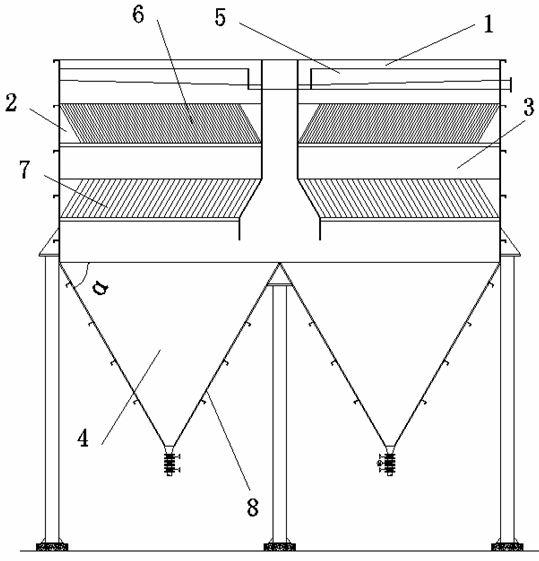

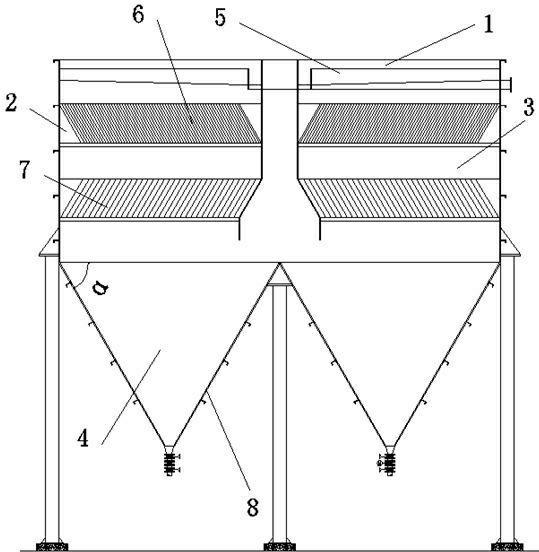

The invention provides a concentration and precipitation machine of high-concentration tailing waste water. The concentration and precipitation machine is characterized by comprising a clean water area (1), an inclined tube area (2), a separation area (3) and a concentration area (4). The clean water area (1) is located above the inclined tube area (2). The concentration area (4) is located below the inclined tube area (2). The separation area (3) is located between the inclined tube area (2) and the concentration area (4). A fundamental of the concentration and precipitation machine of high-concentration tailing waste water is a shallow precipitation theory. Based on the shallow precipitation theory, the residence time of water in a precipitator is greatly reduced; effects of the concentration and precipitation machine is two times better than that of a horizontal-flow sedimentation tank; and a sedimentation area is reduced. Therefore, the concentration and precipitation machine of high-concentration tailing waste water has the advantages of good adaptability for raw water with a wide change scope of turbidity, high treatment efficiency, small floor space, and good convenience of management.

Description

technical field [0001] The invention relates to a high-concentration tailings wastewater concentrating precipitator. [0002] Background technique [0003] At present, mining washing wastewater can also be used for tap water treatment projects and other industrial wastewater. During the treatment, coagulants need to be added to the sewage, so the investment and facilities increase, resulting in an increase in floor area and maintenance costs. [0004] Contents of the invention [0005] The main purpose of the present invention is to provide a high-concentration tailings wastewater concentrating precipitator for treating higher-concentration wastewater, especially suitable for mining washing wastewater, and can also be used in tap water treatment projects and other industrial wastewater treatment projects. The ground area is small, the surface load is large, and the treatment effect is remarkable. Technical scheme of the present invention is: The high-concentration ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B01D21/02B01D21/24

Inventor 黄生根

Owner HAIZHOU E P GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com