Small sewage treatment hydrolysis and gas-stripping and precipitation technique method

A technology of sewage treatment and process method, which is applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. It can solve the problems of large amount of chemicals, inability to denitrify, death, corrosion and floating, etc. achieve remarkable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

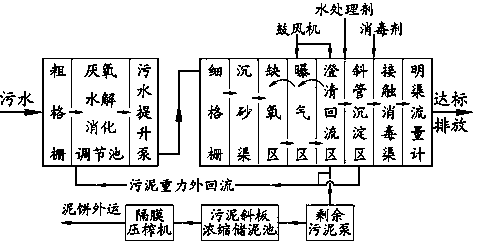

[0056] In the following, the present invention will be further described with reference to the accompanying drawings, and at the same time, the small-scale sewage treatment hydrolysis, air-stripping and sedimentation process of the present invention is used as an example in conjunction with the sewage treatment of a small town in a certain water source protection affected area.

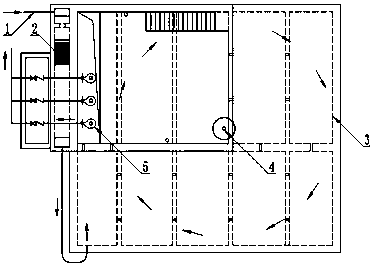

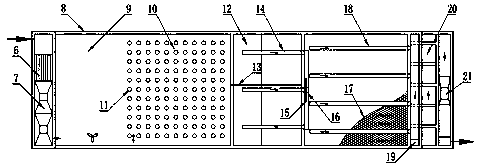

[0057] Such as figure 1 flow chart and Figure 4 As shown in the system flow chart of the system, the process of the small-scale sewage treatment hydrolysis, air-lifting and sedimentation process of the present invention is simple and smooth, and the process is completed in one go. The sewage reaches the standard discharge from the beginning of entering the system. Only two pools are needed to realize all the processing functions and meet the requirements of the project. The "Pollutant Discharge Standards for Urban Sewage Treatment Plants" (GB18918-2002) Grade A standard, and can operate stably. The ...

Embodiment 2

[0103] A county needs to plan and build a new city sewage treatment plant with a planned scale of 10,000m 3 / d, construction in two phases, the first phase is 5000m 3 / d scale, and reserve 5000m 3 At / d position, the sewage contains some industrial wastewater that meets the standard, and the biodegradability of the mixed sewage entering the plant is slightly poor, but the quality of the effluent water meets the "Pollutant Discharge Standards for Urban Sewage Treatment Plants" (GB18918-2002) Class B Standard. Adopting the small-scale sewage treatment hydrolysis air-stripping sedimentation process of the present invention, the first phase of the plant mainly includes an underground anaerobic hydrolysis acidification regulating lifting pump pool, a 5000m 3 / d ground-type Z-type gas lift and reflux two-stage sedimentation integrated tank, and a comprehensive equipment room (Roots blower, diaphragm press, dosing machine, etc.) and a comprehensive management room (one-story house, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface load factor | aaaaa | aaaaa |

| surface load factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com