Patents

Literature

102results about How to "Improve emission reduction effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

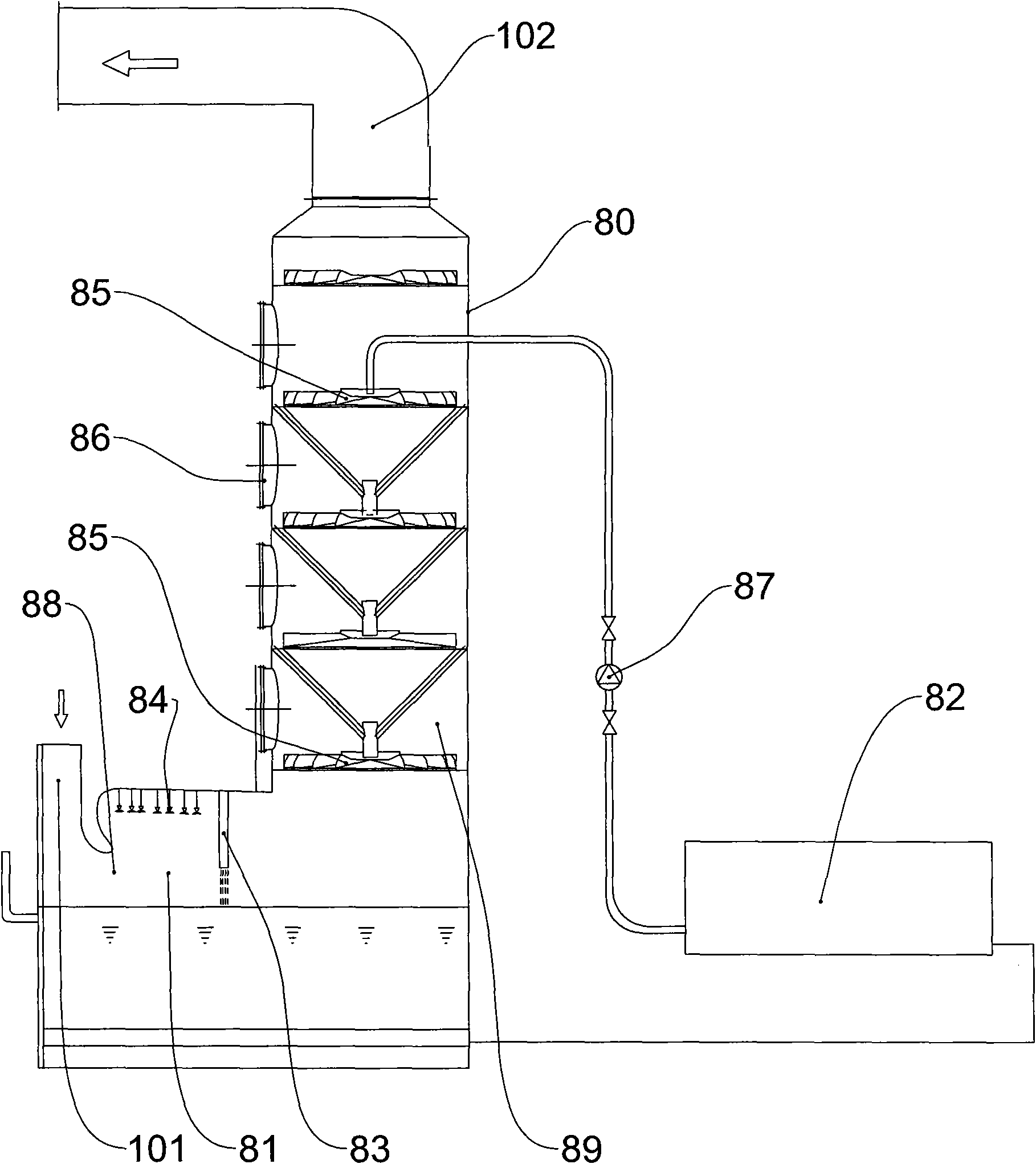

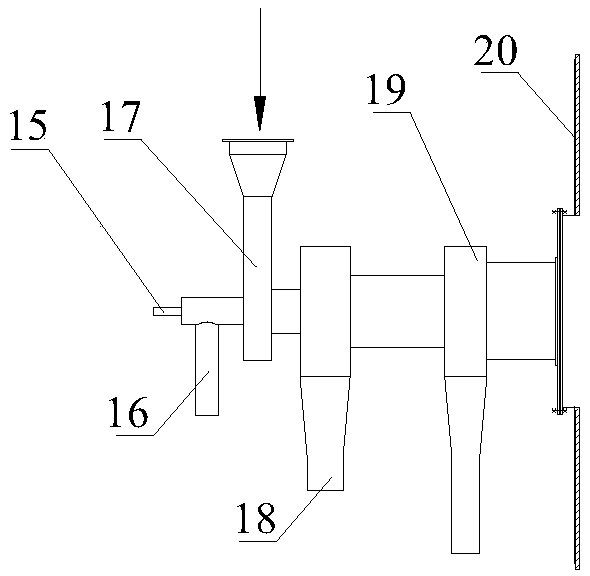

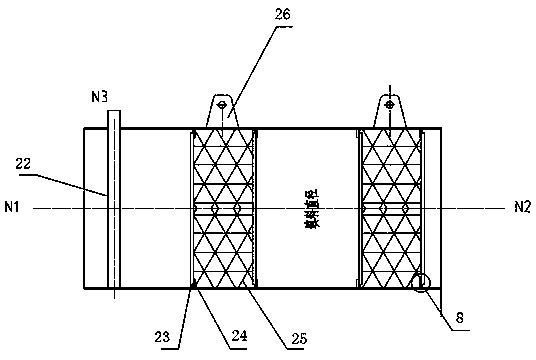

Method and apparatus for desulfurizing exhaust gas of seagoing vessel

InactiveCN101314106AGood technical effectImprove emission reduction efficiencyDispersed particle separationWater savingWater discharge

The invention relates to a method and a device for desulfurizing exhaust smoke of a sea-going ship, which uses sea water to reduce discharge of sulfur dioxide and other pollutants of the sea-going ship. The method comprises the following steps of: sea water scrubbing, acidic sea water transferring, acid separating treatment, water discharge and so on. The device comprises a scrubber and a water-saving acid separator, wherein, the upper part of the scrubber is provided with a scrubbing layer, and is communicated with a scrubbing sea water pump through a pipeline; the lower part of the scrubber is provided with a cooling layer; one end of the scrubber is communicated with a smoke exhaust pipe of a ship engine through a scrubbing inlet pipe, while the other end of the scrubber is connected with a scrubbing exhaust pipe; the lower part of the scrubber is communicated with the water-saving acid separator; and the water-saving acid separator is connected with a mixed sea water pump, a draught fan and a main discharge pipe for suitably discharging sea water which is subject to the acid separating treatment. The method and the device have the advantages of high desulfurizing efficiency, small sea water consumption, low equipment manufacturing cost and low running cost.

Owner:WUHAN SAFE ENVIRONMENTAL PROJECT TECH INC

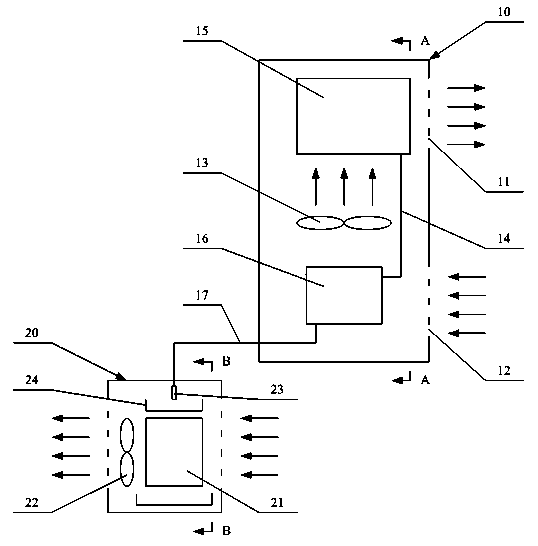

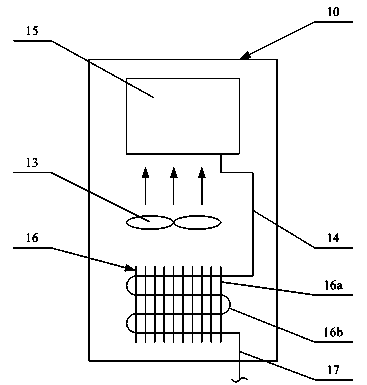

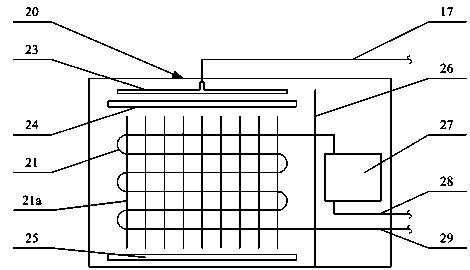

Split type air conditioner and condensate water recycling and energy saving method for same

ActiveCN103542466AImprove cooling effectReduce energy consumptionLighting and heating apparatusAir conditioning systemsEvaporationRoad surface

The invention provides a split type air conditioner and a condensate water recycling and energy saving method for the same. The split type air conditioner and the condensate water recycling and energy saving method have the advantages that air which flows into an air inlet of an indoor unit of the air conditioner is pre-cooled by the aid of first heat exchange on condensate water, so that refrigerating energy consumption of an evaporator in the indoor unit of the air conditioner can be reduced; radiating fins of a condenser in an outdoor unit of the air conditioner can be cooled by the aid of second heat exchange on the condensate water and evaporation heat absorption of the condensate water, so that the condenser radiating efficiency can be improved, consumption of refrigerants can be reduced, and a COP (coefficient of performance) value of an integral refrigerating system of the split type air conditioner can be increased; the condensate water is quickly evaporated in a second heat exchange procedure, so that liquid condensate water finally drained by the split type air conditioner can be greatly reduced, frequent inconvenience such as outdoor overhead water dripping and slippery roads due to a large quantity of drained condensate water can be prevented, problems of low condensate water utilization rate and voluntary condensate water drainage of split type air conditioners in the prior art can be solved, the refrigerating efficiency of the split type air conditioner can be improved, and purposes of saving the energy and protecting environments can be achieved.

Owner:CHONGQING UNIV

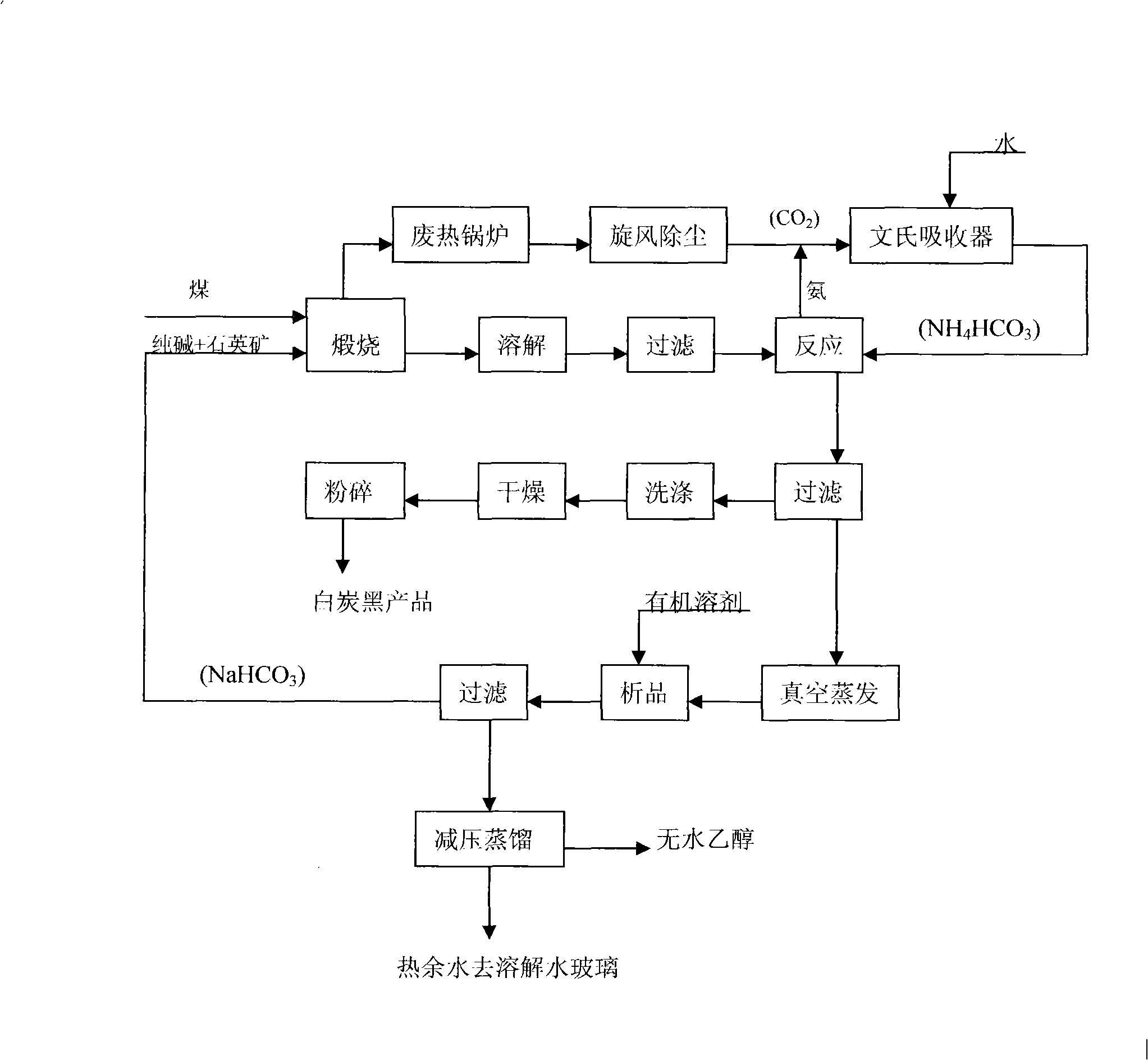

Circulation novel process for preparing white carbon black

InactiveCN101323453AAddressing effective recyclingHigh recycling valueSilicaSodium bicarbonateOrganic solvent

The invention relates to a new cycle technique for preparing white carbon black, comprising the following steps: 1) a water glass solution reacts with an ammonium hydrogen carbonate solution or solid ammonium hydrogen carbonate in the condition of the temperature of 30 to 50 DEG C, the white carbon black is obtained and ammonia escapes simultaneously; 2) the ammonia escaped from the step 1) is mixed with CO2 gas produced in the process of the preparation of the water glass solution and the obtained mixture is absorbed by water to obtain the ammonium hydrogen carbonate; 3) the white carbon black produced by reaction is filtered under the condition of vacuum to obtain a mother liquid A and a filter cake A, the mother liquid A is recovered and the filter cake A is washed, dried and crushed so as to obtain the white carbon black. The invention 1) solves the effective recovery of by-products in the production process, is used for self-production, improves the utilization value of materials, without three wastes discharge in the production process, and has high material utilization rate, good effect of discharge reduction and stable and reliable quality of products; 2) recovery of sodium bicarbonate is carried out after the mass concentration is increased by the evaporation in vacuum at low temperature, thus reducing the usage of organic solvent.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

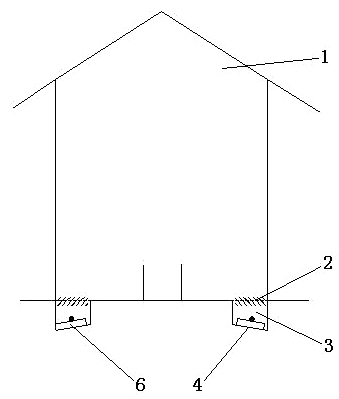

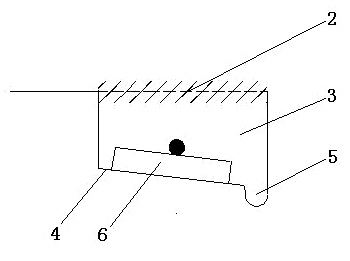

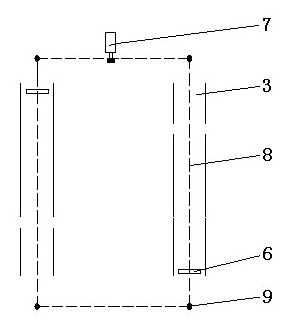

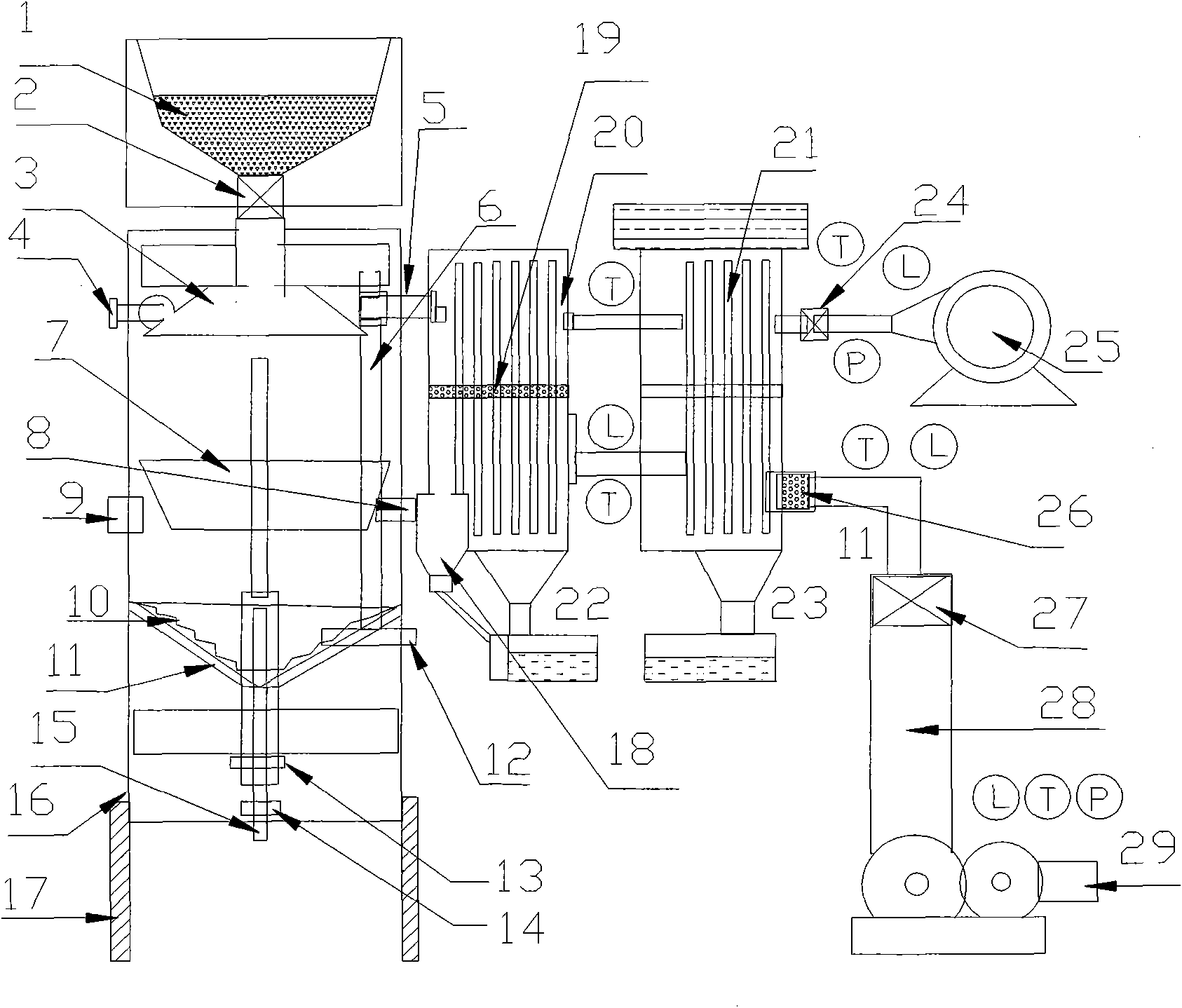

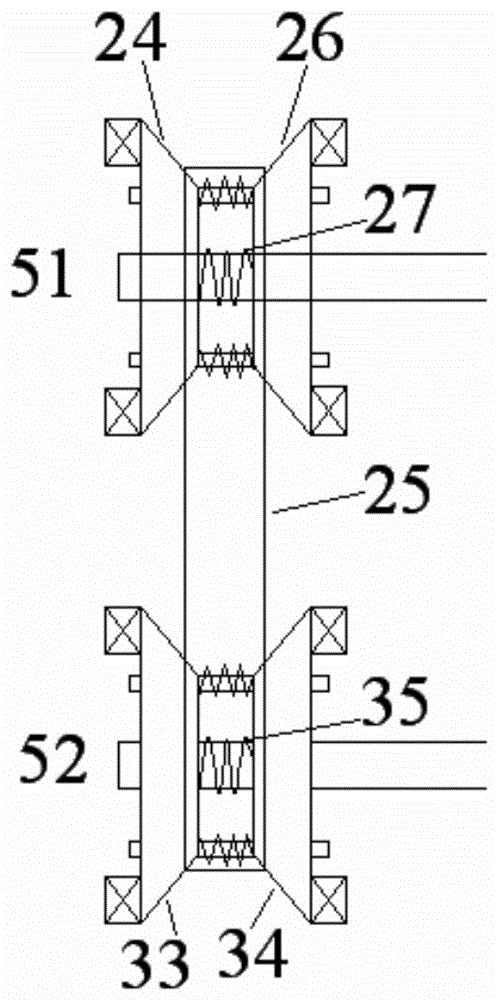

Device and method for mechanically cleaning manure of leaky pigsty

InactiveCN102487833AEmission reductionReduce the amount requiredAnimal housingMotor driveReciprocating motion

The invention relates to a device for mechanically cleaning manure of a leaky pigsty. The device comprises the pigsty and is characterized in that: the bottom of the pigsty is provided with at least one manure leaking plate; at least one manure trough is arranged below the manure leaking plate; the bottom of the manure trough is provided with at least one inclined plane; the lower side of the manure trough is provided with a drainage ditch; scrapers used for cleaning the manure and driven to reciprocate by a motor driving mechanism are arranged in the manure trough; and the motor driving mechanism comprises a motor, steel ropes connected with the scrapers and driven by the motor, and guide wheels for guiding the ropes. Meanwhile, the invention also relates to a pigsty structure and a corresponding method for mechanically cleaning manure of a leaky pigsty. By the invention, the manure sewage discharging amount can be reduced, the total amount of organic pollutants can be decreased, and the invention has the advantages that: the cost is low, the operation is simple and convenient, the manure cleaning efficiency is high, the discharge reduction effect is good, the pig manure which is mechanically cleaned and collected has low water content and is easily subjected to subsequent concentrated composting reutilization and the like.

Owner:INST OF AGRI ENG TECH FUJIAN ACAD OF AGRI SCI

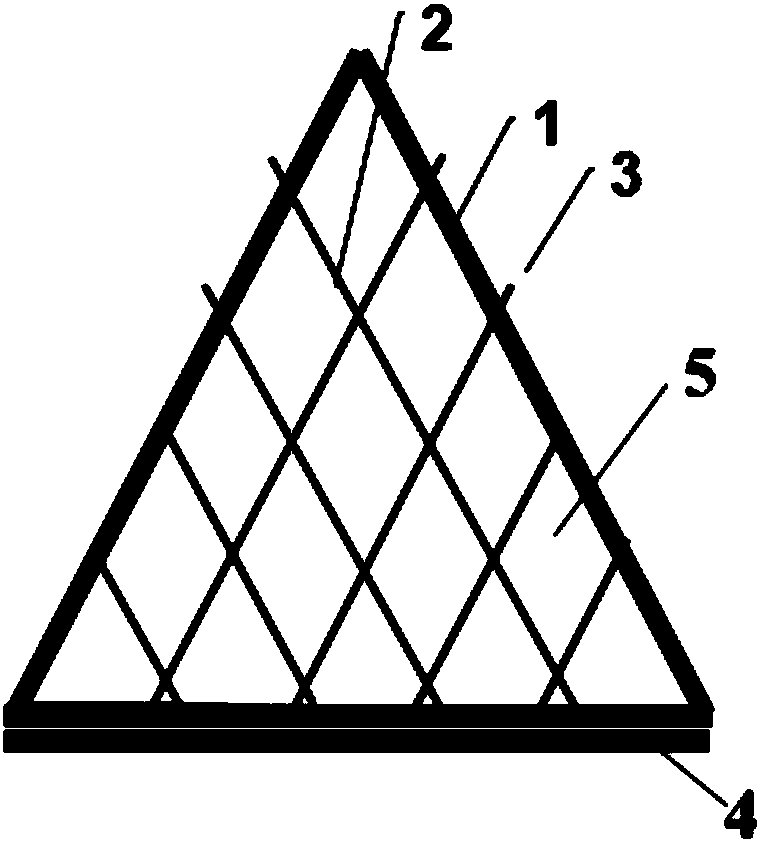

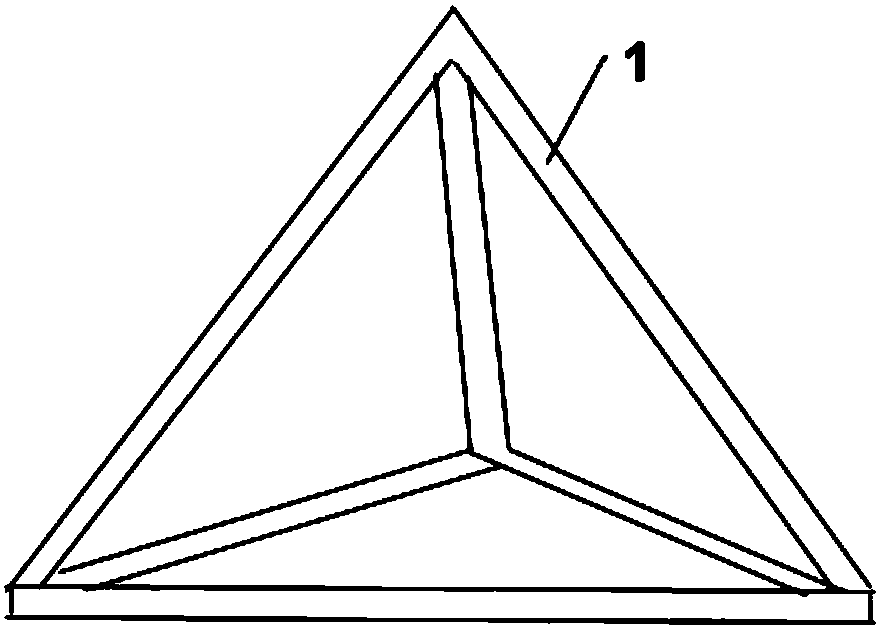

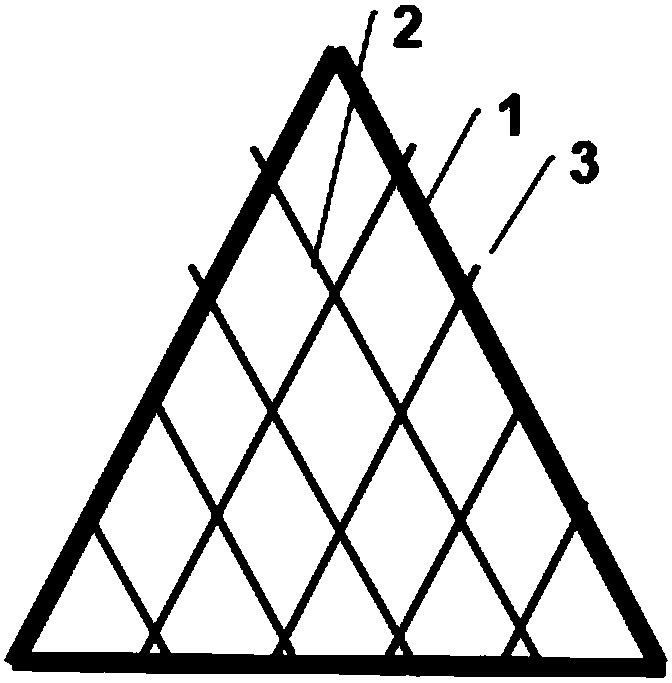

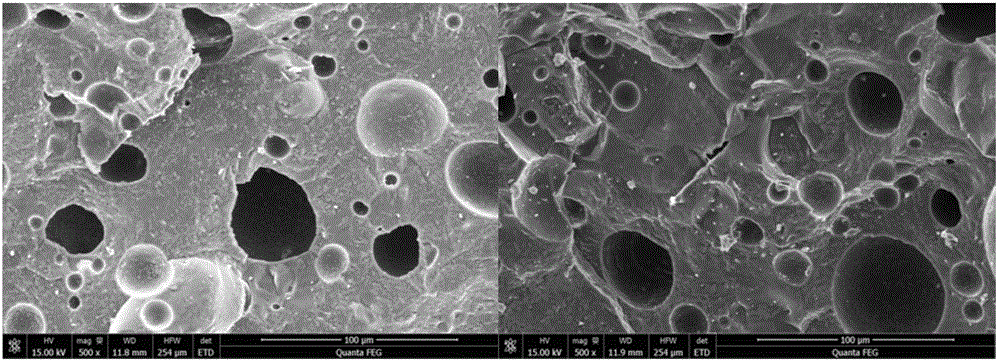

Artificial fish reef with waste mytilus shells as body and preparing method thereof

ActiveCN108353836ALow costLarge amount of energy saving and emission reductionClimate change adaptationPisciculture and aquariaOysterCement board

The invention discloses an artificial fish reef with waste mytilus shells as a body. The artificial fish reef comprises a frame structure formed by welding triangle steel, the top end of the frame structure is open, a base formed by a cement board is fixed at the bottom end of the frame structure, and each side face of the frame structure is laid with a slice-shaped component coincident with the side face in shape and size; the slice-shaped components are prepared by extruding meshes and the waste mytilus shells with which the meshes are filled, and young oysters are attached to the surfaces of the slice-shaped components. According to the artificial fish reef with the waste mytilus shells as the body, the artificial fish reef is prepared with a large quantity of waste mytilus shells, a preparing method is simple, convenient and easy to achieve, and compared with a traditional artificial fish reef, the emission reduction effect of the artificial fish reef is good; the artificial fish reef serves as an important facility of a marine ranch, and has the advantages that eco-environmental friendliness is achieved, the structure is stable, and hold time is long.

Owner:NINGBO UNIV

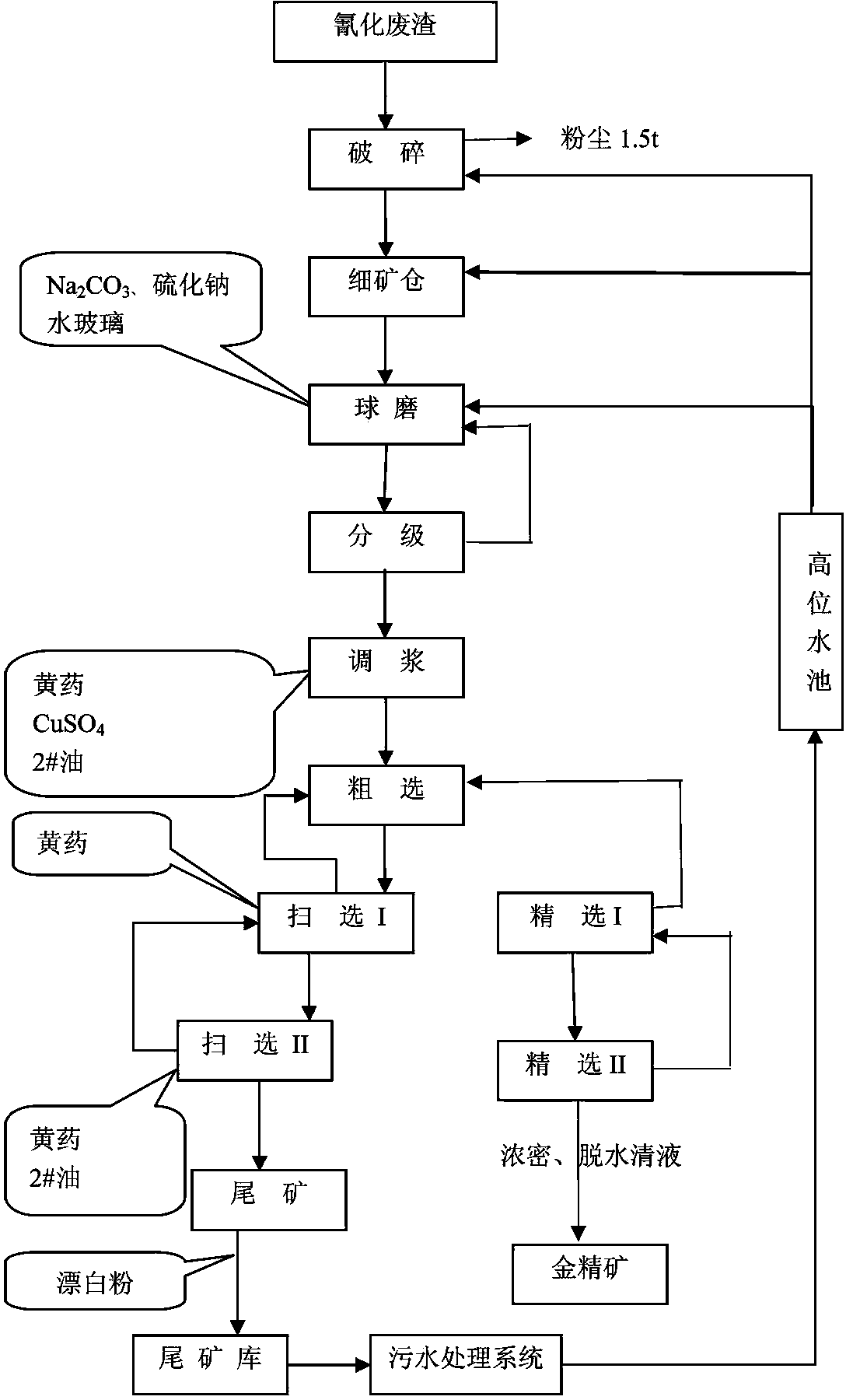

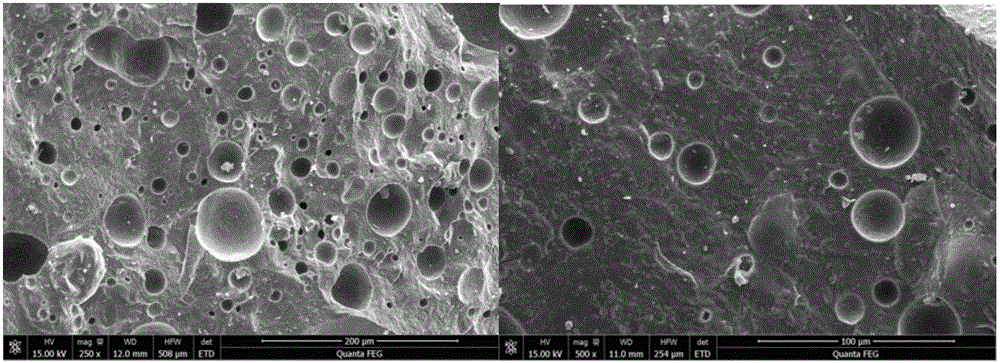

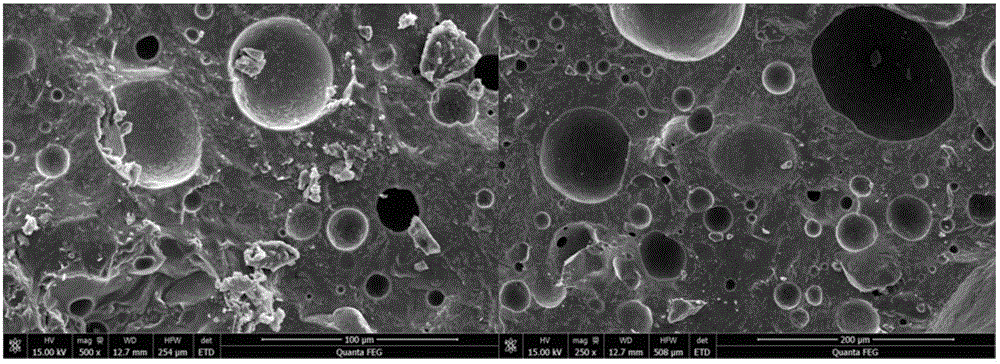

Harmless treatment method of gold cyanidation tailings highly containing arsenic

ActiveCN103831165AImprove emission reduction effectEliminate pollutionFlotationSortingXanthateMixing tank

A harmless treatment method of gold cyanidation tailings highly containing arsenic mainly includes the steps that the gold cyanidation tailings are crushed twice and then fed into a ball mill for ore grinding, sodium carbonate, sodium sulphide and soluble glass are added in the ball-milling process, ores are made to be fully dispersed and vulcanized, the ph value of ore pulp is adjusted to be 8 to 9, after classification, coarse sand returns to the ball mill for second-time grinding, fine sand qualified in overflow enters a mixing tank for pulp mixing, after xanthate and copper sulfate are added to the fine sand for pulp mixing, the floatation technology including one time of roughing, two times of concentration and two times of scavenging is used for making concentrated products serve as ores to be sold, after bleaching powder is added to the scavenged tailings, the scavenged tailings are fed to a tailing pond in a winnowing mode, and after being clarified, overflow water of the tailing pond is fed back to a dressing plant for cyclic utilization. After the tailings are treated through the method, the content of arsenic in the tailings is greatly reduced, and a large number of useful ores are recycled.

Owner:湖南黄金洞矿业有限责任公司

Method for preparing haydite by sintering sludge at low temperature

InactiveCN105016710AGood technical and economic effectIncrease profitCeramic materials productionClaywaresHydrogenPhosphate

The invention belongs to the types of building materials, and provides a method for preparing haydite by sintering sludge at low temperature. The method comprises the following steps of: 1) taking the following components in percentage by weight: 40%-45% of dewatered sludge, 40%-45% of high-alkali calcareous shale, 12%-18% of barium residues, 0.5%-0.8% of aluminum dihydrogen phosphate and 0.5%-1% of borax; and 2) uniformly mixing all the taken components so as to obtain a mixture, pressing and molding the mixture in balling molds by a static pressure molding method so as to obtain haydite, wherein the molding pressure is 8Mpa-12Mpa, after the haydite is molded, drying the molded haydite under the environment of 60-100 DEG C, preheating the dried haydite, raising temperature, sintering the preheated haydite, and slowly reducing temperature so as to obtain finished products. The method disclosed by the invention has the advantages of having a better solid waste utilization effect, having a good energy saving effect, and having a higher emission reduction effect; in conclusion, favorable economic effects are realized.

Owner:WUHAN UNIV OF TECH

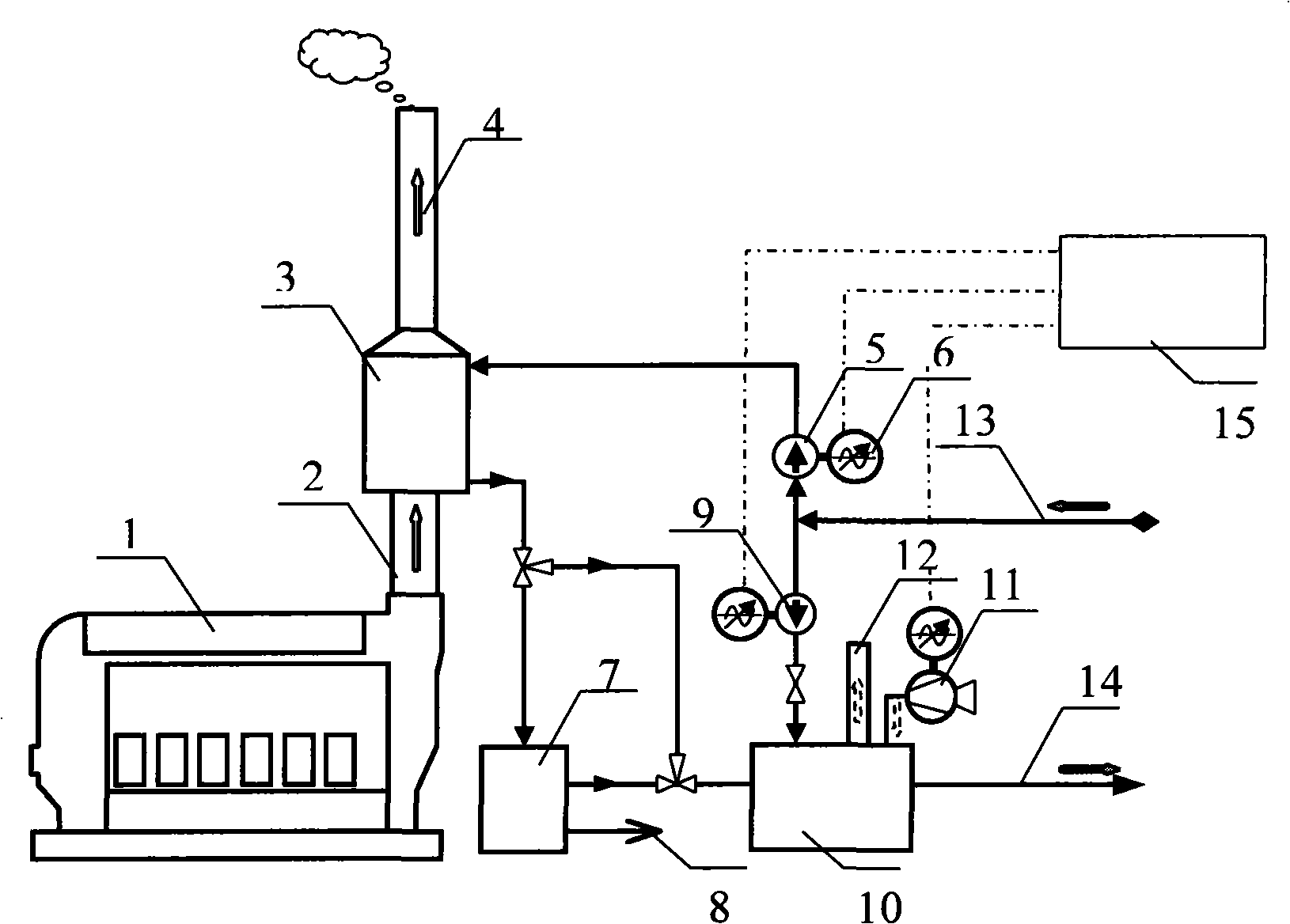

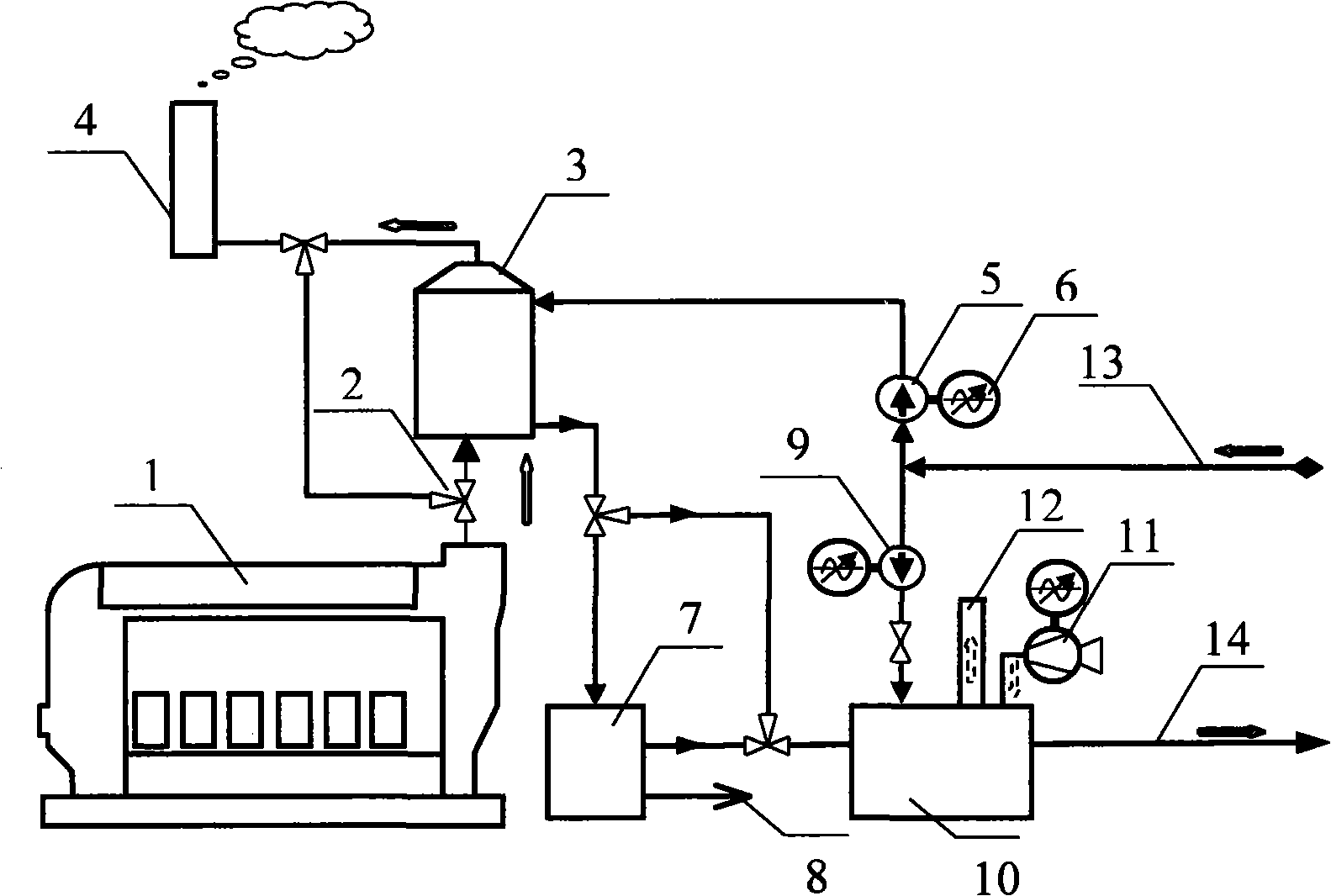

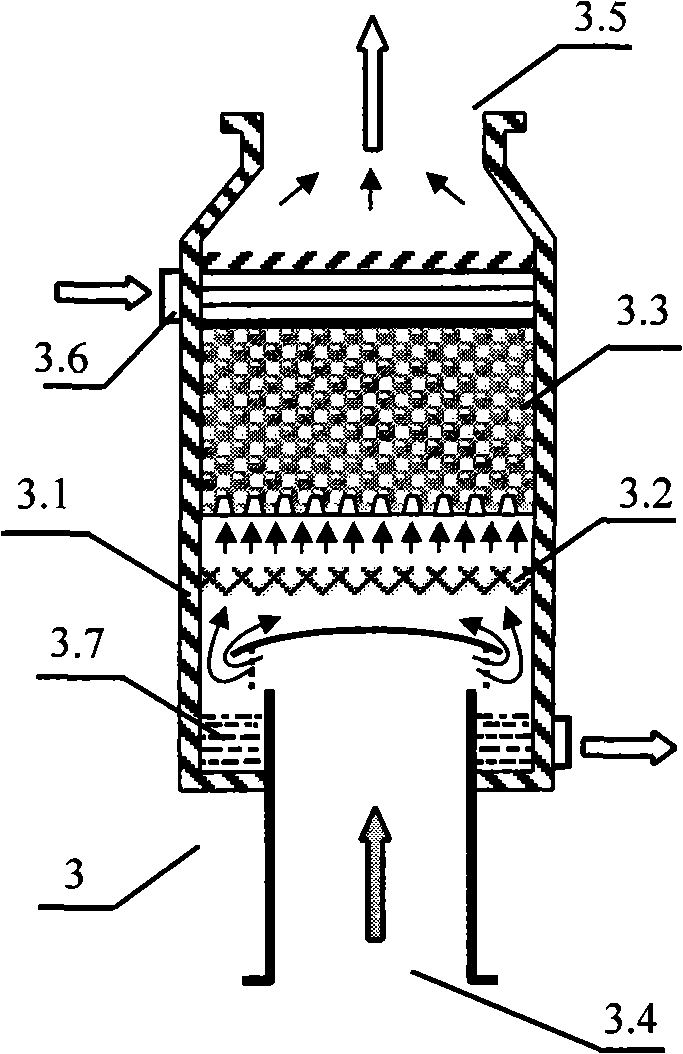

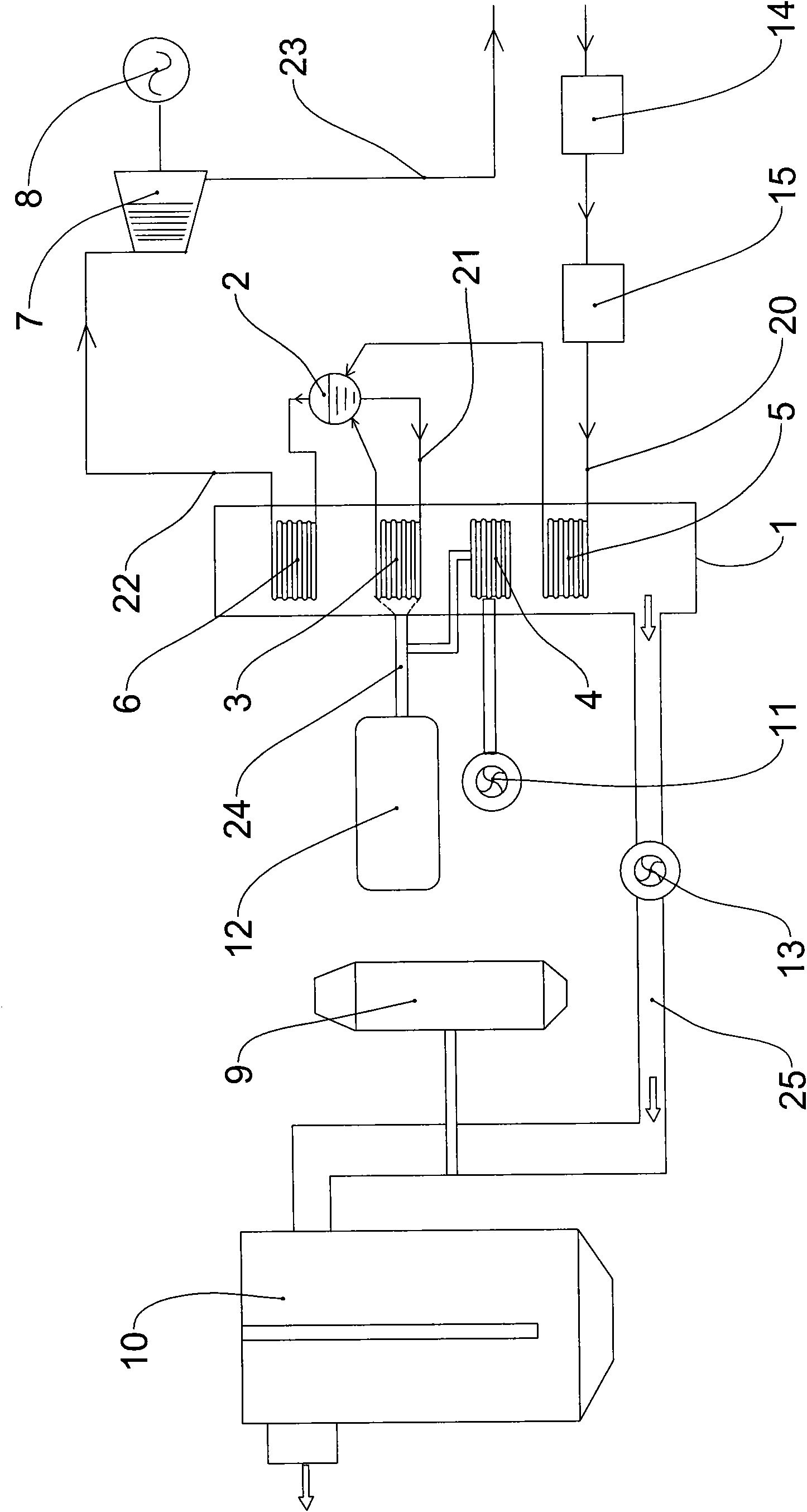

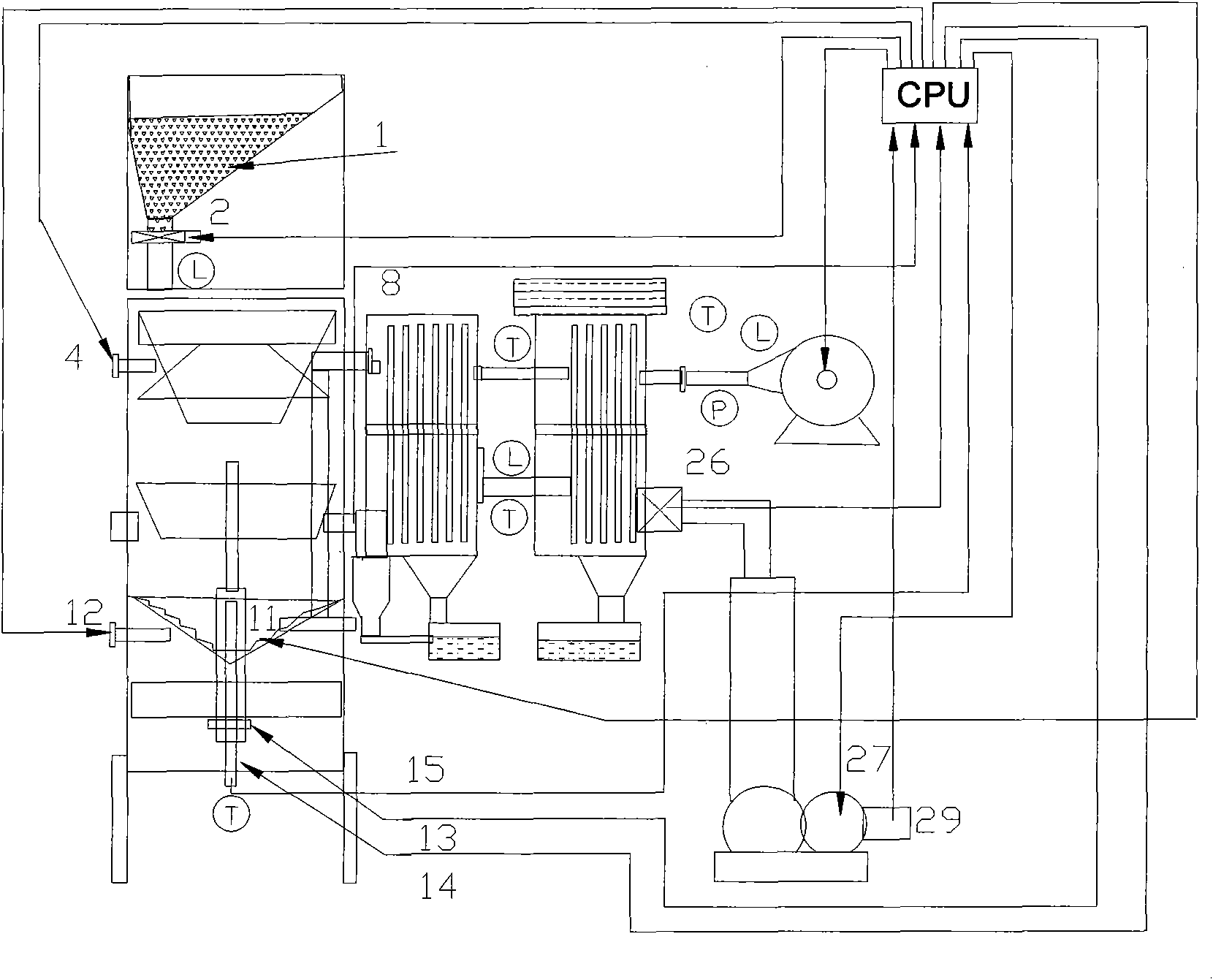

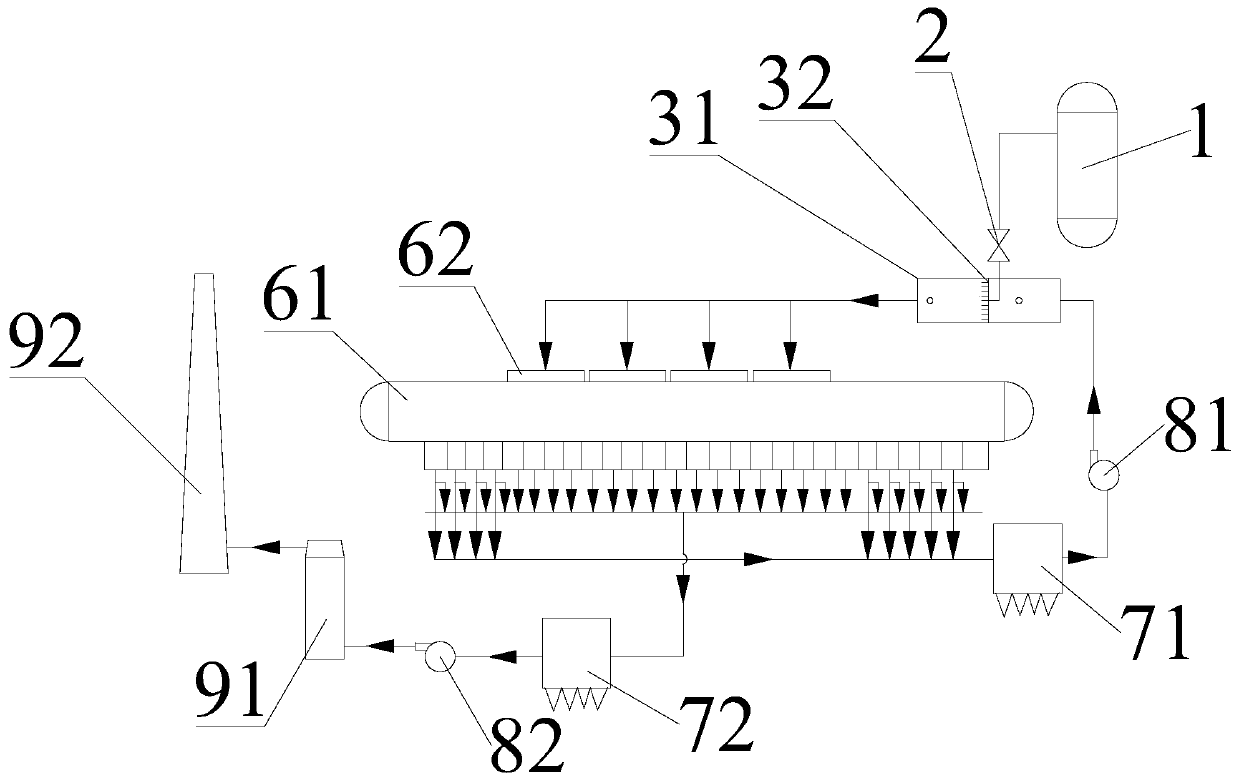

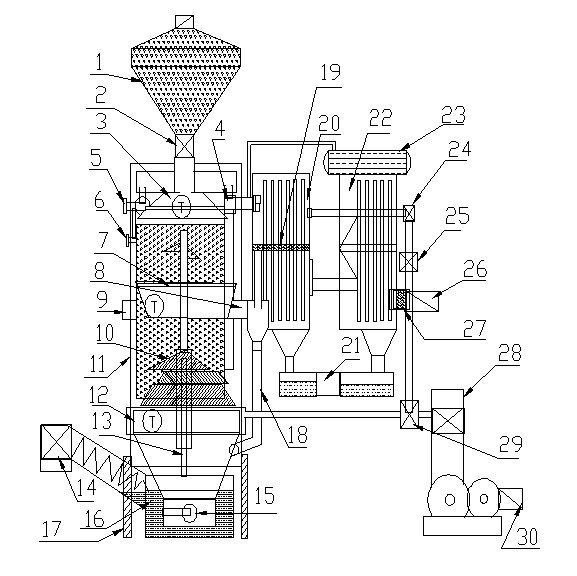

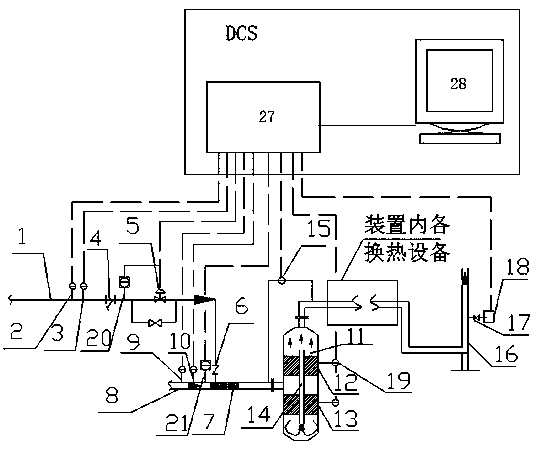

Integrated low-carbon micro-discharge energy-saving and emission-reduction boiler system

ActiveCN101986025AObvious superiorityLower discharge temperatureSteam generation plantsIndirect carbon-dioxide mitigationCombustionEngineering

The invention discloses an integrated low-carbon micro-discharge energy-saving and emission-reduction boiler system. The system comprises a boiler body (1), a steam drum (2), a heat exchanger (3), a preheater (4), an economizer (5), a superheater (6), a steam turbine (7), a generator (8), a secondary smoke combustion device (9), a desulfuration and dust collect unit (10), an air blower (11) and a smoke exhauster (13), wherein the steam drum (2) and the heat exchanger (3) constitute a hot-water heating circulation loop, the economizer (5) is connected with the steam drum (2), and the air blower (11) feeds air to the preheater (4); the steam drum (2) is connected with the superheater (6), and then connected with the steam turbine (7) by a superheated steam pipe (22); the steam turbine (7) is connected with a low-pressure steam pipe (23), and the generator (8) is linked with the steam turbine (7); and the outlet of a gas duct of the boiler body (1) is connected with a smoke pipe (25), and the smoke exhauster (13) is arranged on the smoke pipe (25), and sequentially feeds smoke into the secondary smoke combustion device (9) and the desulfuration and dust collect unit (10) so as to process and discharge the smoke.

Owner:慧生能源科技有限公司

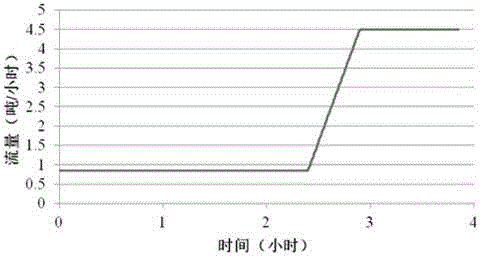

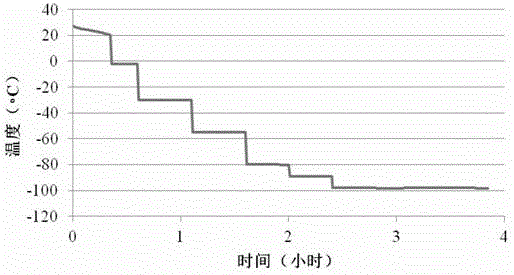

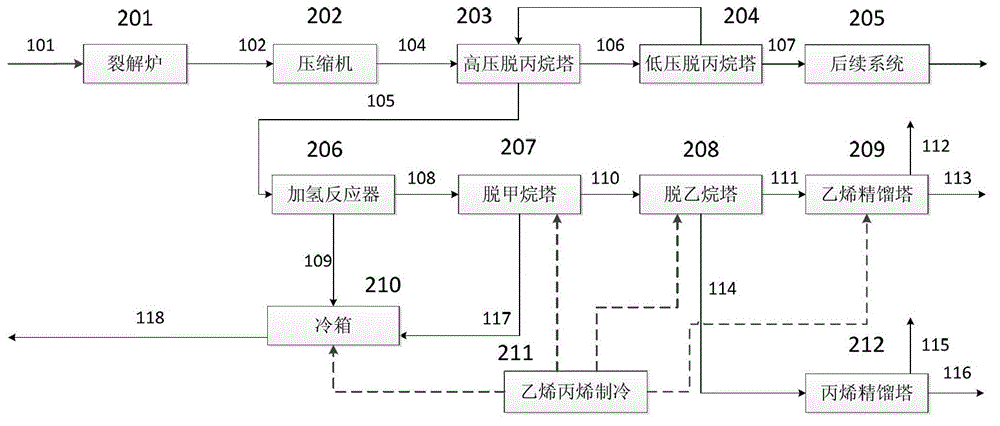

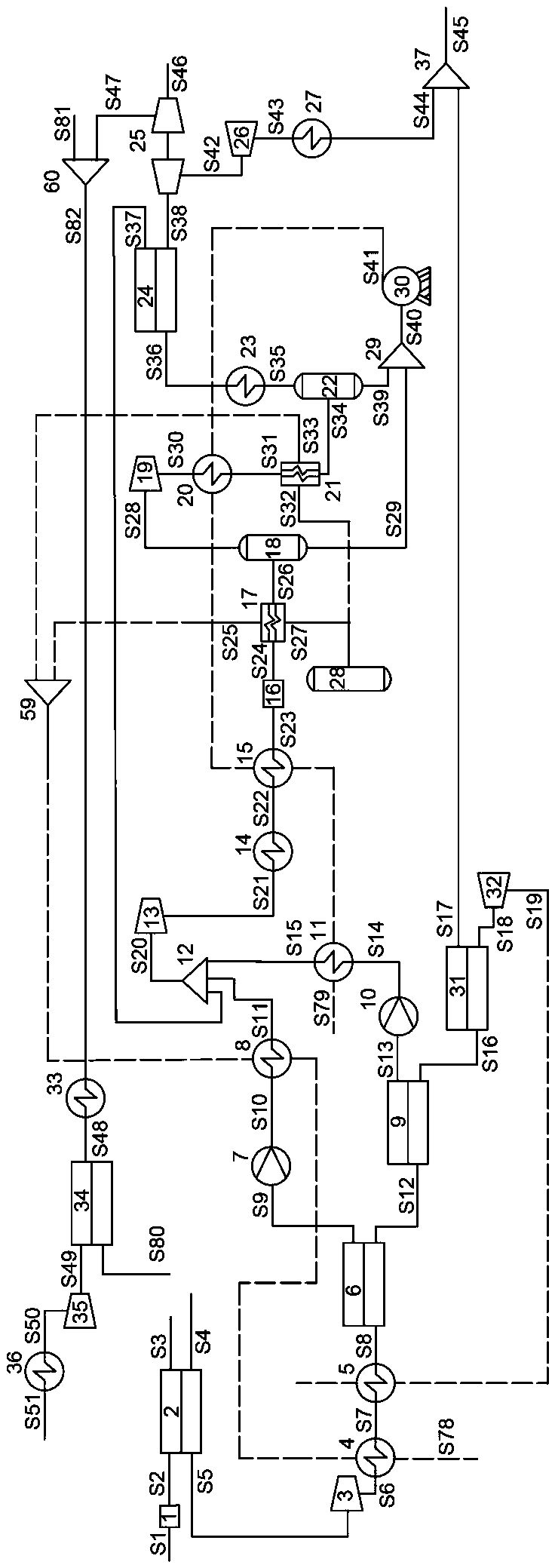

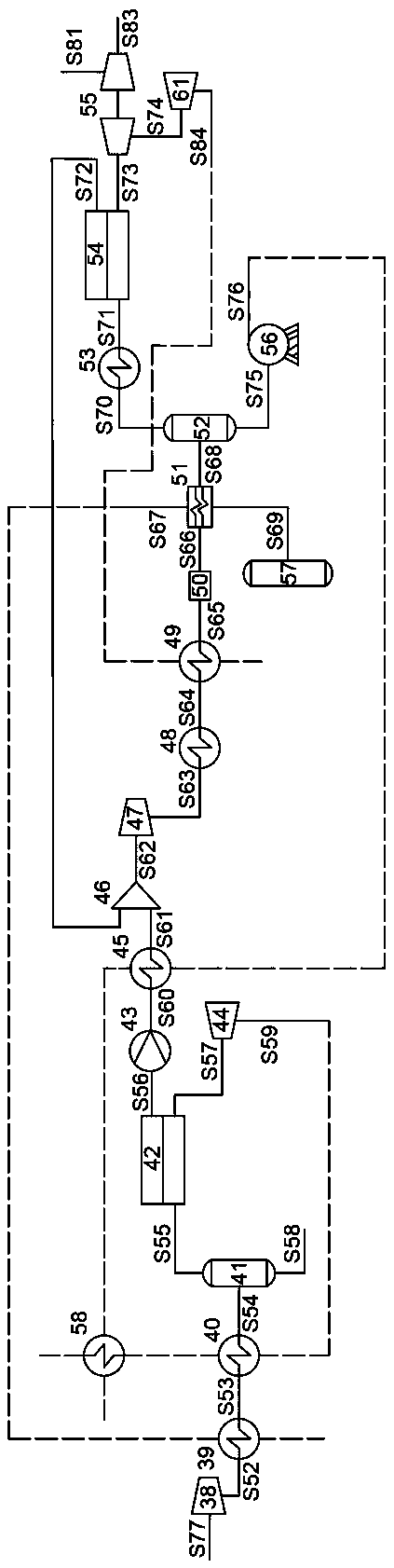

Starting emission reduction method for ethene device

ActiveCN104152173AShorten cooling timeEmission reductionThermal non-catalytic crackingEthylene productionRefluxGas compressor

The invention relates to a starting emission reduction method for an ethene device. The method comprises the following steps: first, an ethene and propylene refrigeration system is started and a refrigerating capacity is supplemented for cold box precooling; second, the cold box precooling is started; third, total reflux of an ethene rectifying tower, a propylene rectifying tower and an ethane removing tower is established; fourth, a cracking furnace is started; fifth, a cracked gas compressor is started; sixth, a subsequent device is started and starting of the ethene device is finished. Because the cold box is subjected to cooling before formal feeding, the product qualified time of the cold box is shortened greatly, the cooling process of the cold box is controllable, and leakage dangers are avoided. Through establishment of total reflux of a low-temperature depropanization tower, the total qualified time of a high-low-pressure depropanization tower is shortened. Because natural gases are introduced to supplement the feed of the compressor, the number of starting feeding cracking furnaces is decreased, and therefore the whole discharge capacity of torches is reduced.

Owner:PETROCHINA CO LTD +2

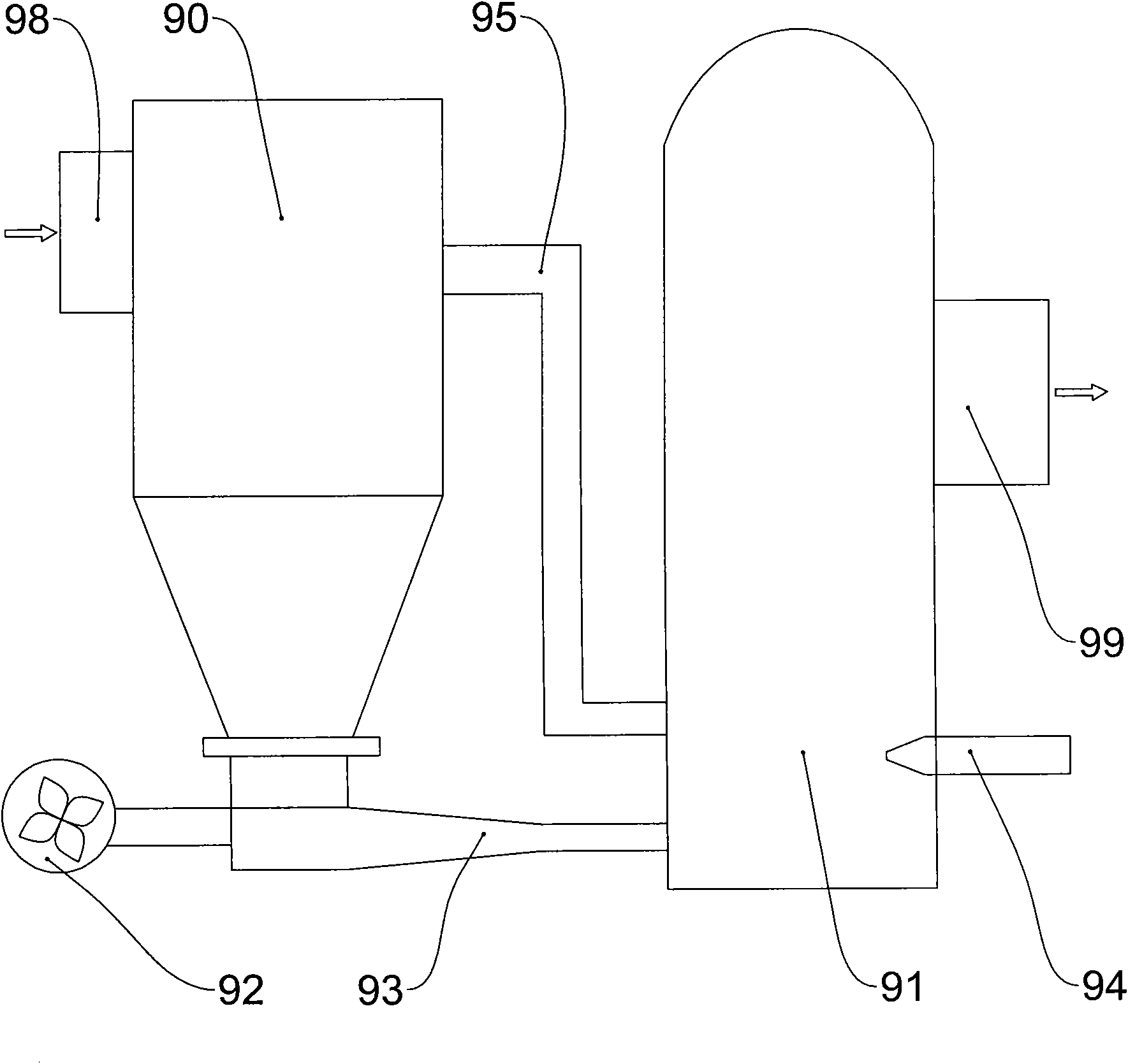

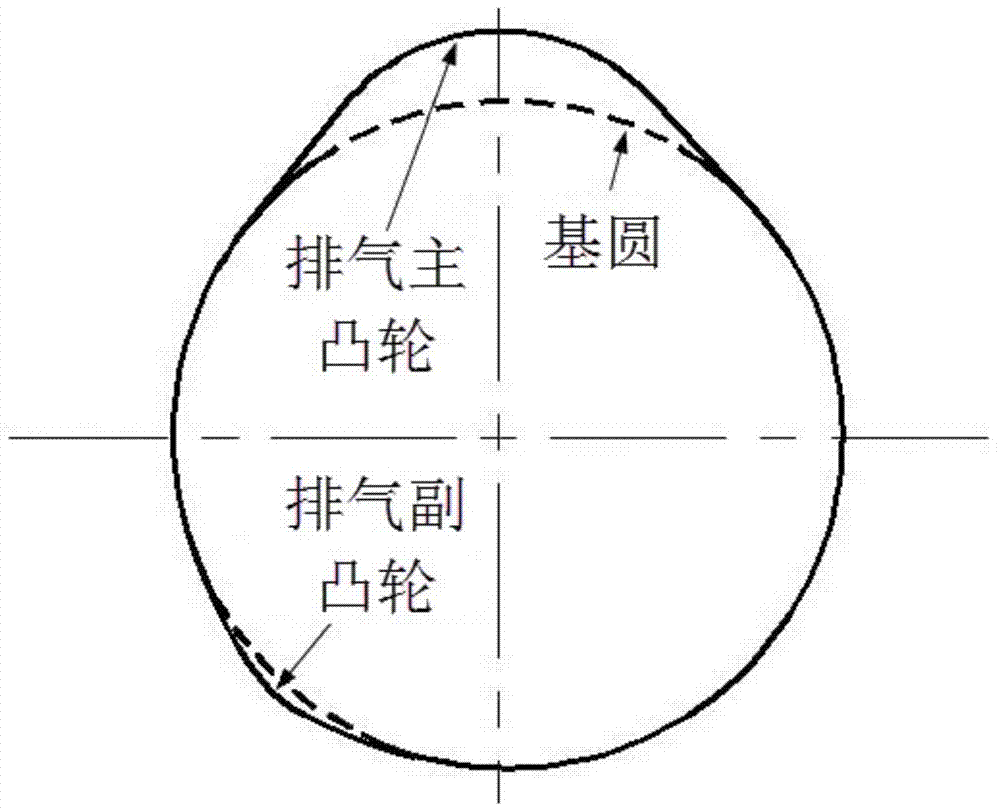

Gas making and poly-generation apparatus by using environmental friendly clean fuel gas

InactiveCN101586039ARelaxationWide adaptabilityOrganic chemistryLiquid hydrocarbon mixture productionAutomatic controlPollution

The invention discloses a gas making and poly-generation apparatus by using environmental friendly clean fuel gas. The apparatus is composed of a main furnace of a gasification furnace and a heat exchange and separator equipped with an automatic control system, which realizes automatic intellectualized operation. The apparatus can gasify any coal, for instance, soft coal, anthracite, coke, stone coal; and gasify (carbonize) biomass for instance, wood, bamboo, cotton stalk, rice hull and rubbish rod. When gasifying coal, by-products in gas making and purifying process can be recycled in the apparatus. Coal tar in the by-products can be pyrolyzed and gasified to make gas, residual heat making vapor for power generation of steam turbine, which realizes poly-generation and recycling. When gasify (carbonize) biomass, biomass diesel oil, acetic acid in coal producing, gas making and purifying process can be recycled in the apparatus, , residual heat making vapor for power generation of steam turbine, which realizes poly-generation and recycling. The poly-generation apparatus ensures environmental protection of whole gas making process in structure. The invention, except clinker, is of zero emission and pollution.

Owner:浙江华尚新能源股份有限公司

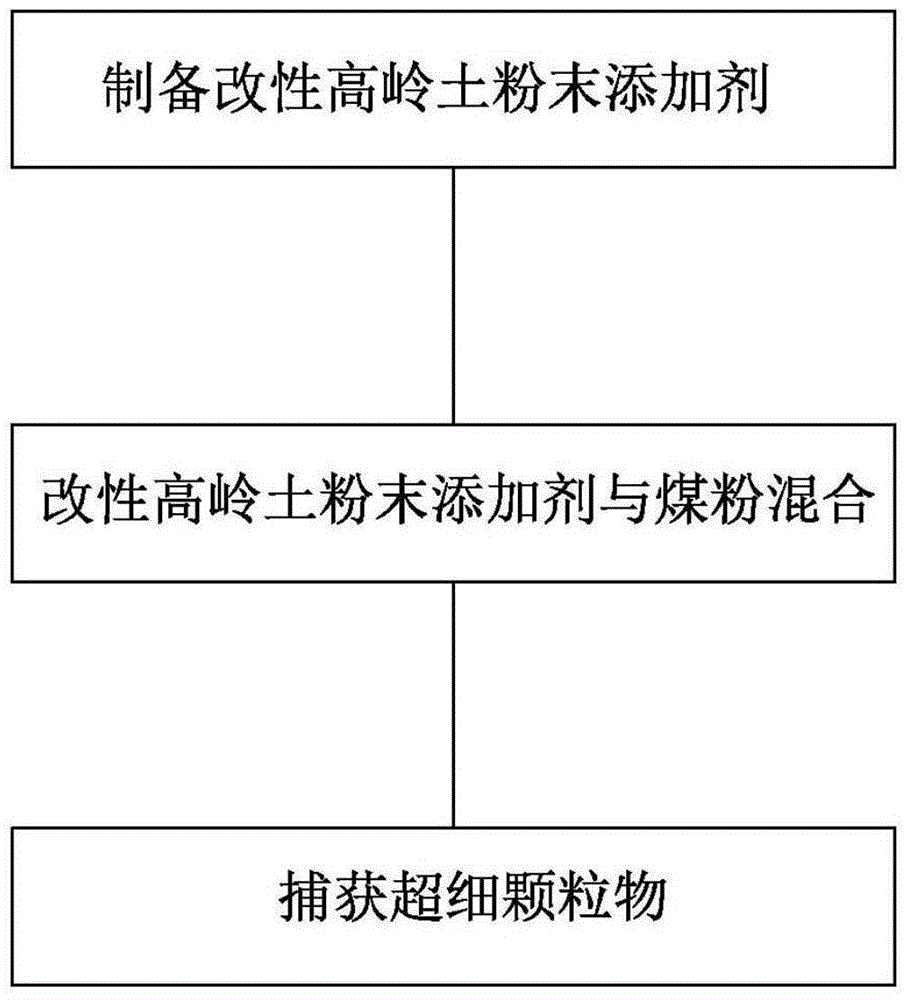

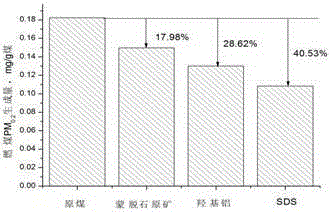

Control method for coal-fired ultra fine particles based on modified kaolin

ActiveCN104531262AEasy to manufactureSufficient raw materialsAuxillary pretreatmentFuel additivesPrillCombustion

The invention discloses a control method for coal-fired ultra fine particles based on modified kaolin. The method comprises the following steps: 1) preparing a modified kaolin powder additive; 2) feeding the modified kaolin powder additive and pulverized coal to a coal mill at the mass ratio of (3:100) to (5:100), and mixing; and 3) feeding the pulverized coal mixed with the modified kaolin powder additive to a hearth to burn, trapping ultra fine particles generated by combustion of the pulverized coal through the modified kaolin powder additive, and trapping the particles formed by combining the modified kaolin powder additive with the ultra fine particles by virtue of a dust collection device after passing through a flue. Compared with the kaolin before being modification, the modified kaolin powder additive disclosed by the invention has the advantages that the physical and chemical characteristics are changed; the trapping capability of the coal-fired ultra fine particles is obviously improved; and the emission-reduction effect on the fine particles caused by the modified kaolin can be further improved.

Owner:HUAZHONG UNIV OF SCI & TECH

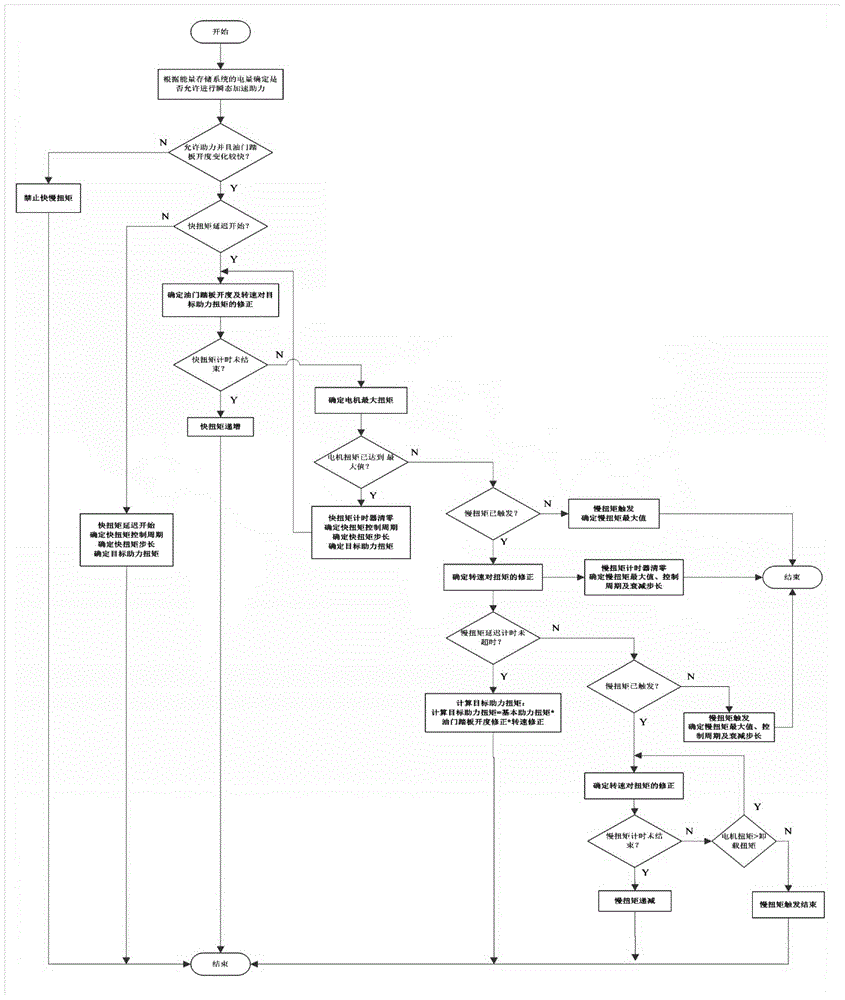

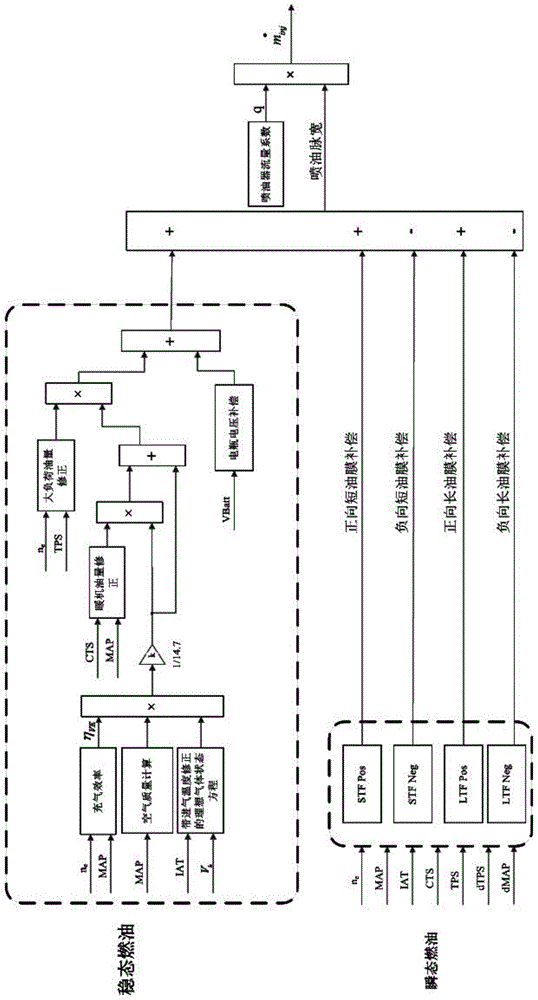

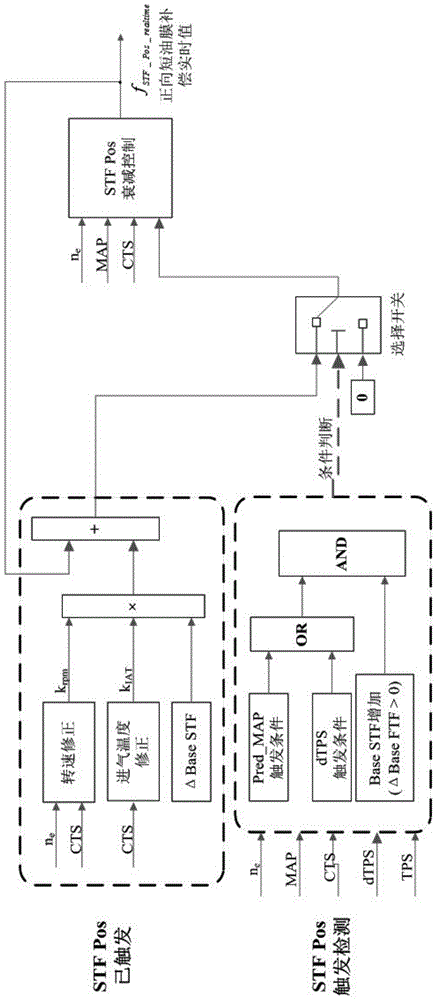

Acceleration control method for hybrid car

InactiveCN104554245AReduce HC emissionsReduce fuel consumptionHybrid vehiclesElectricityAcceleration control

The invention discloses an acceleration control method for a hybrid car. The method includes: fast torque, torque maintaining and slow torque, to be more specific, determining whether to allow transient acceleration assisting power or not according to the electricity quantity of an energy storage system, and forbidding the transient acceleration assisting power if electric quantity is low so as to guarantee that the electric quantity is sufficient to start the car; triggering the fast torque if the electric quantity is sufficient and an accelerator pedal is opened fast; increasing the torque with the increasing time and step length of the fast torque until the target assisting torque is reached when the timing time of the fast torque is not reached; judging whether a slow torque stage is entered or not if the timing time of the fast torque is reached, if not, entering a torque maintaining stage, and calculating the target assisting torque in delay timing time; entering the slow torque stage if delay timing overtime occurs; by motor assisting torque, controlling cycle degreasing minimum torque with the time and step length of the slow torque, and performing direct resetting.

Owner:SHANGHAI HUAZHAO MECHANICAL&ELECTRICAL

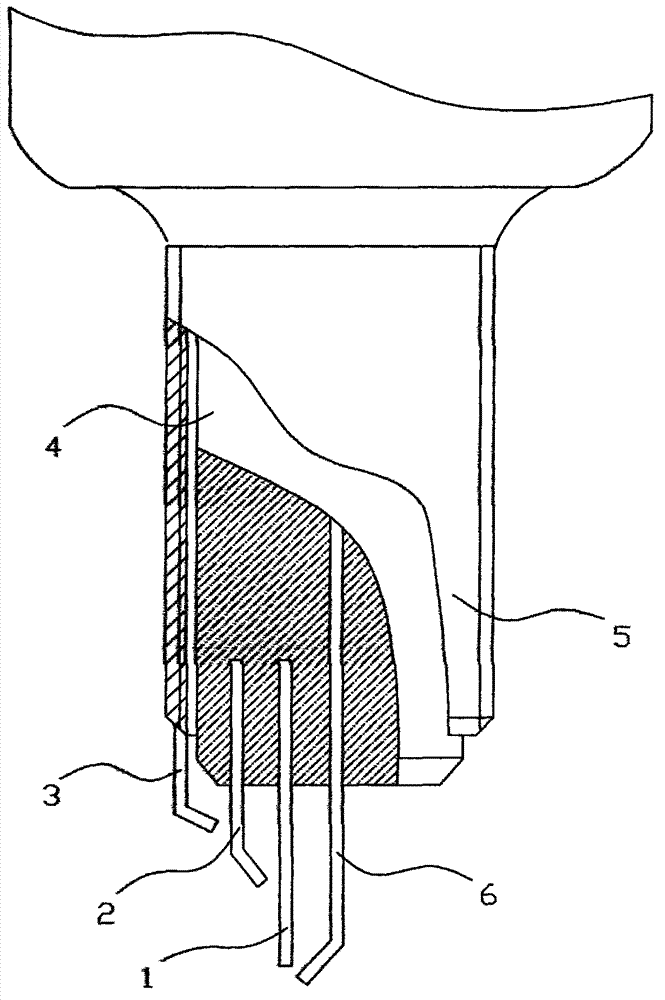

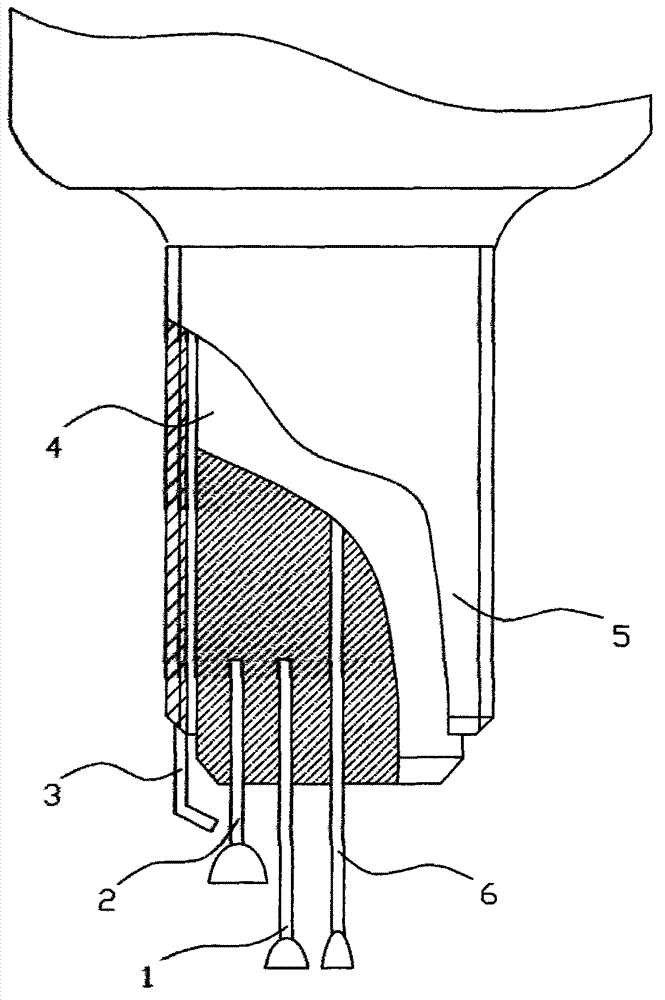

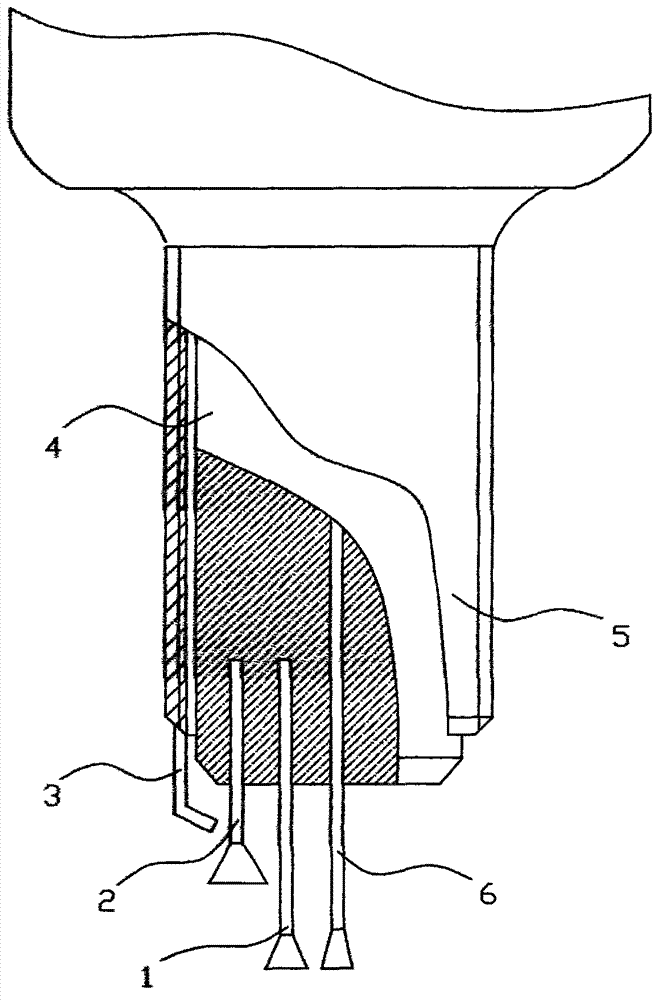

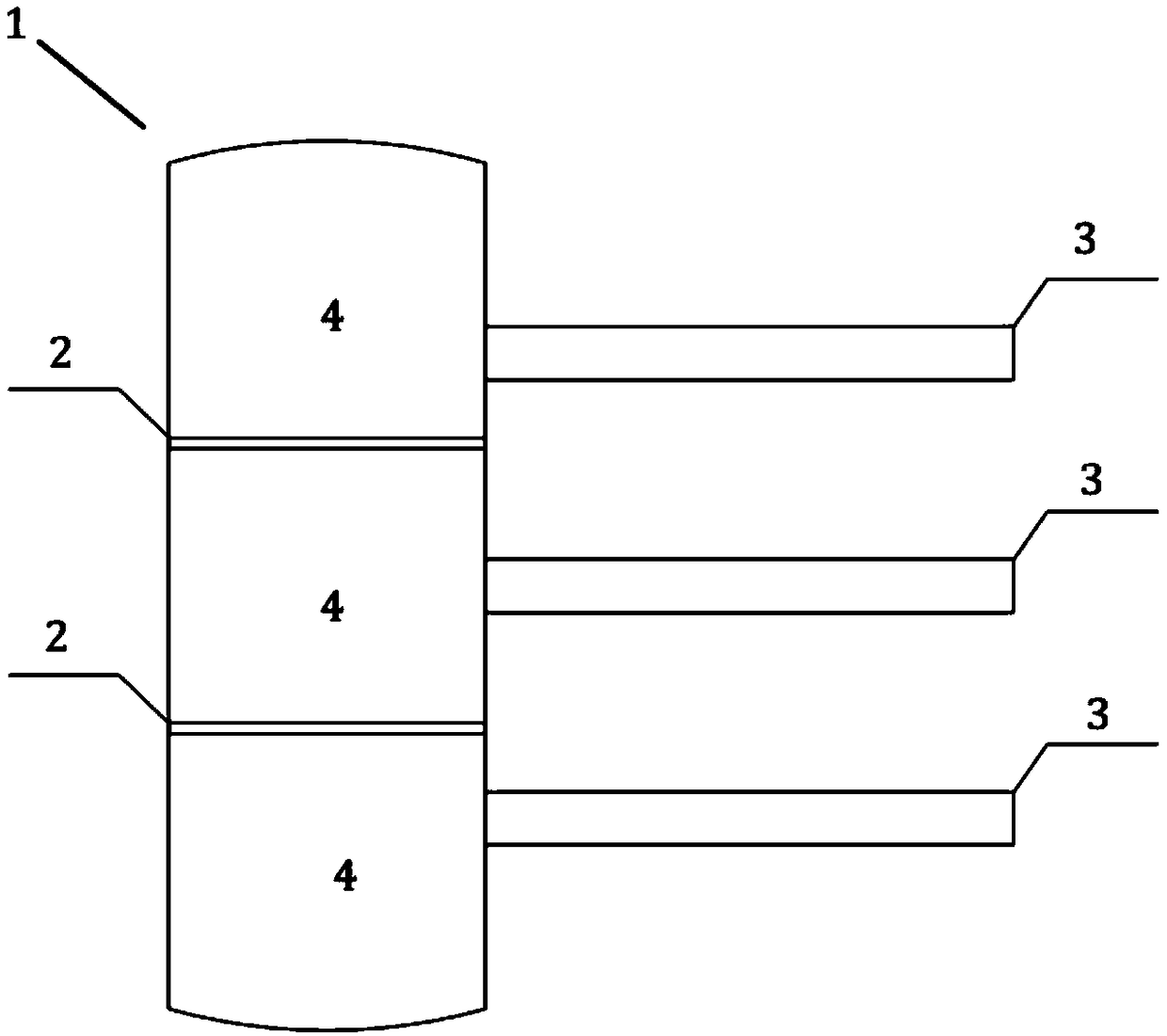

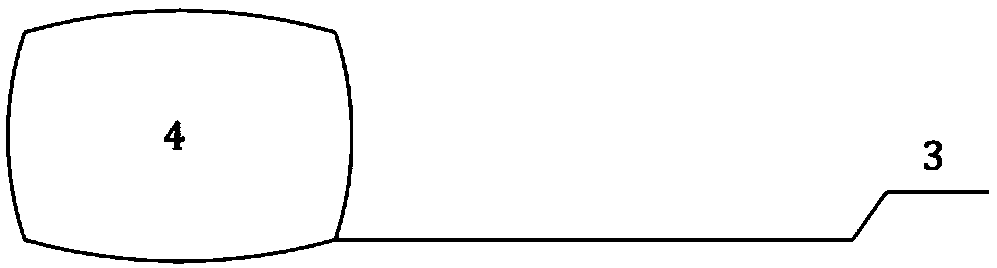

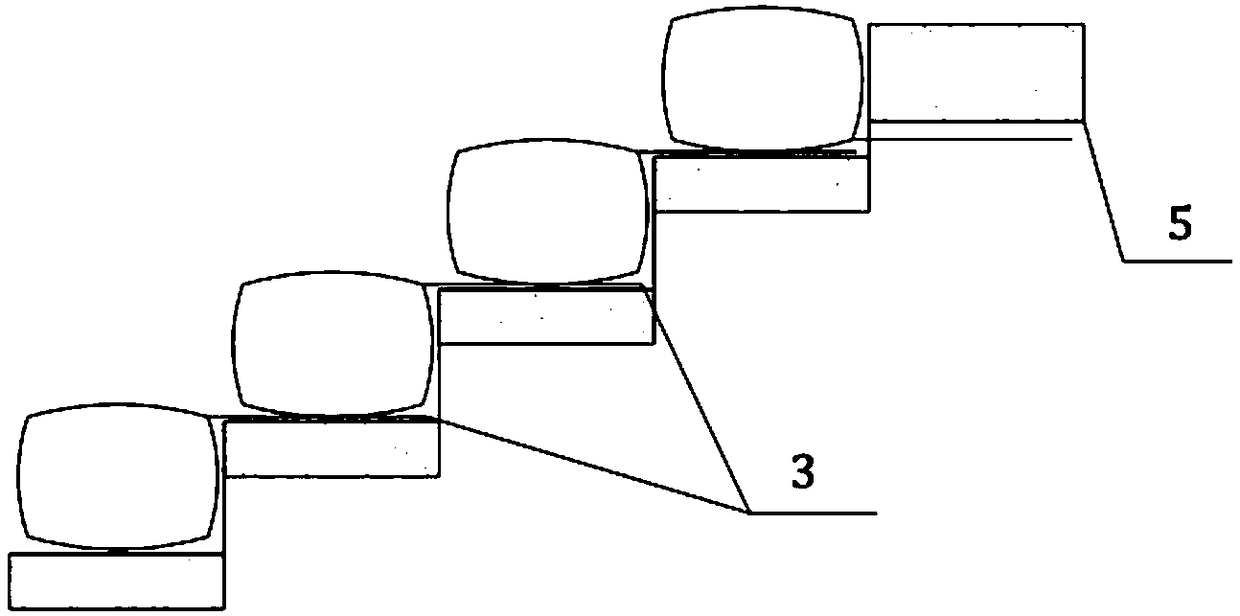

High energy spark plug

The invention provides a high energy spark plug. The high energy spark plug comprises a metal shell and an insulated porcelain core in the metal shell; a side electrode is connected with the metal shell; a central electrode is arranged in the insulated porcelain core; at least one transition electrode is arranged on the insulated porcelain core between the side electrode and the central electrode; the distance between the top end of a first transition electrode and the top end of the central electrode is less than the distance between the first transition electrode and two adjacent surfaces of the central electrode; the top end of a secondary transition electrode is lower than the top end of the first transition electrode; the distance between the top end of the secondary transition electrode and the adjacent surfaces of the first transition electrode is less than the distance between the secondary transition electrode and the two adjacent surfaces of the first transition electrode until a back transition electrode; the top end of the side electrode is lower than the top end of the back transition electrode; and the distance between the top end of the side electrode and the adjacent surfaces of the back transition electrode is less than the distance between the side electrode and two adjacent surfaces of the back transition electrode.

Owner:张景明

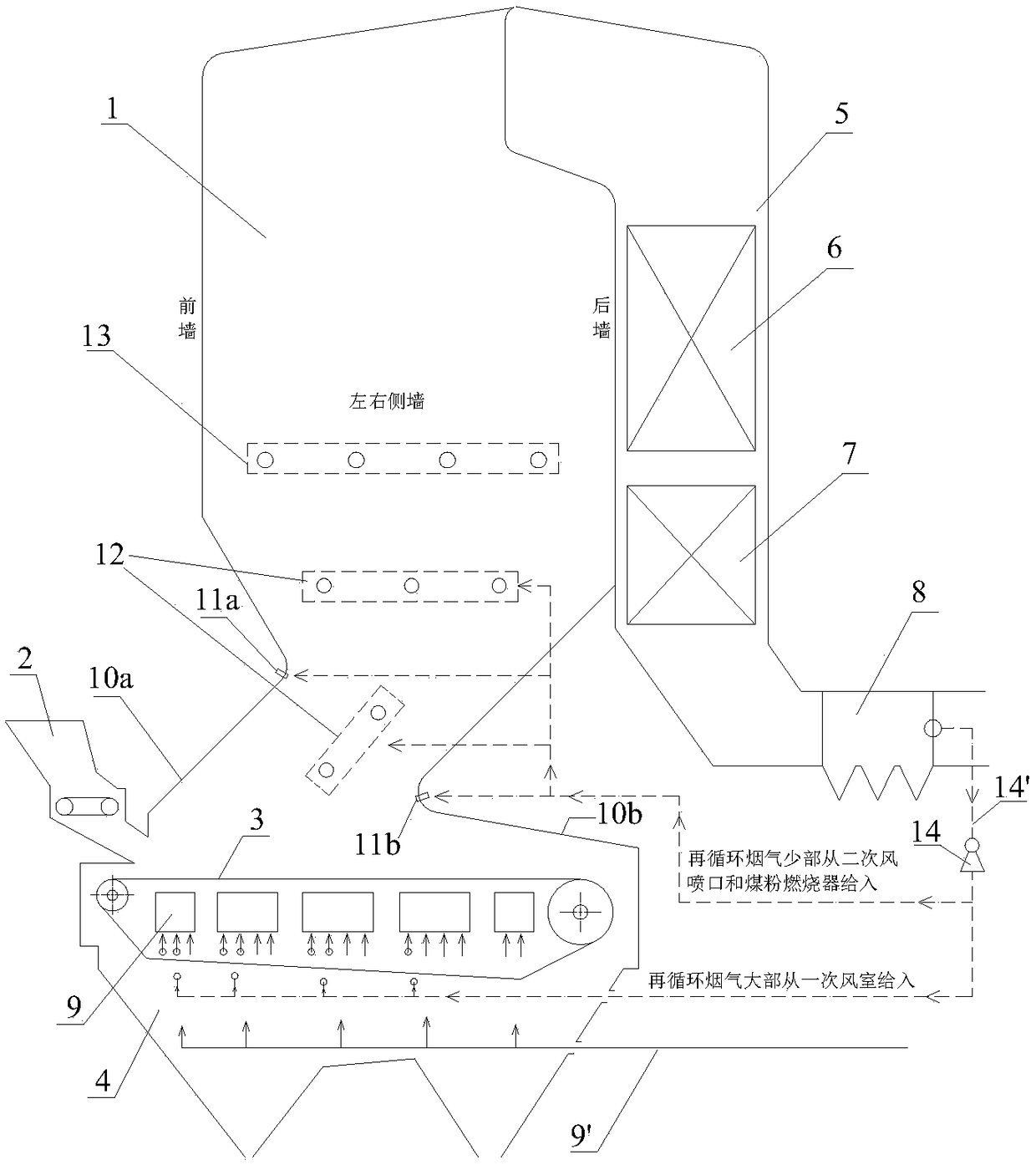

Efficient low NOx chain grate furnace coupled with swirling pulverized coal combustion and enhanced flue gas recirculation

InactiveCN108895430ALow burn shareGood for burnoutSolid fuel combustionAir/fuel supply for combustionLow nitrogenSlag

The invention discloses a high-efficiency low-NOx chain grate furnace coupled with swirling pulverized coal combustion and enhanced flue gas recycling, By reducing the fraction of combustion in gratezone, A low NOx swirl pulverize coal burner and a burned-out air are arrange on that left and right side walls, and an enhanced flue gas recirculation is constructed (i. E., flue gas recirculation isintroduce from a primary air chamber at the lower part of the grate, a front and rear arch secondary air burner and a swirl burner respectively), Deep-air staged low-nitrogen combustion conditions including horizontal staging and suspension staging and enhanced flue gas recirculation low-nitrogen combustion conditions are formed to significantly inhibit NOx formation. A low NOx swirl pulverize coal burner is added to increase that combustion fraction of the suspension combustion zone, Flue gas temperature level and hot air utilization ratio can reduce exhaust gas loss and increase fly ash burnout. In addition, reasonable distribution of flue gas in grate combustion zone and reduction of combustion share can help to improve slag burnout rate, thus achieving the effect of significantly improving boiler thermal efficiency.

Owner:NINGBO UNIV +1

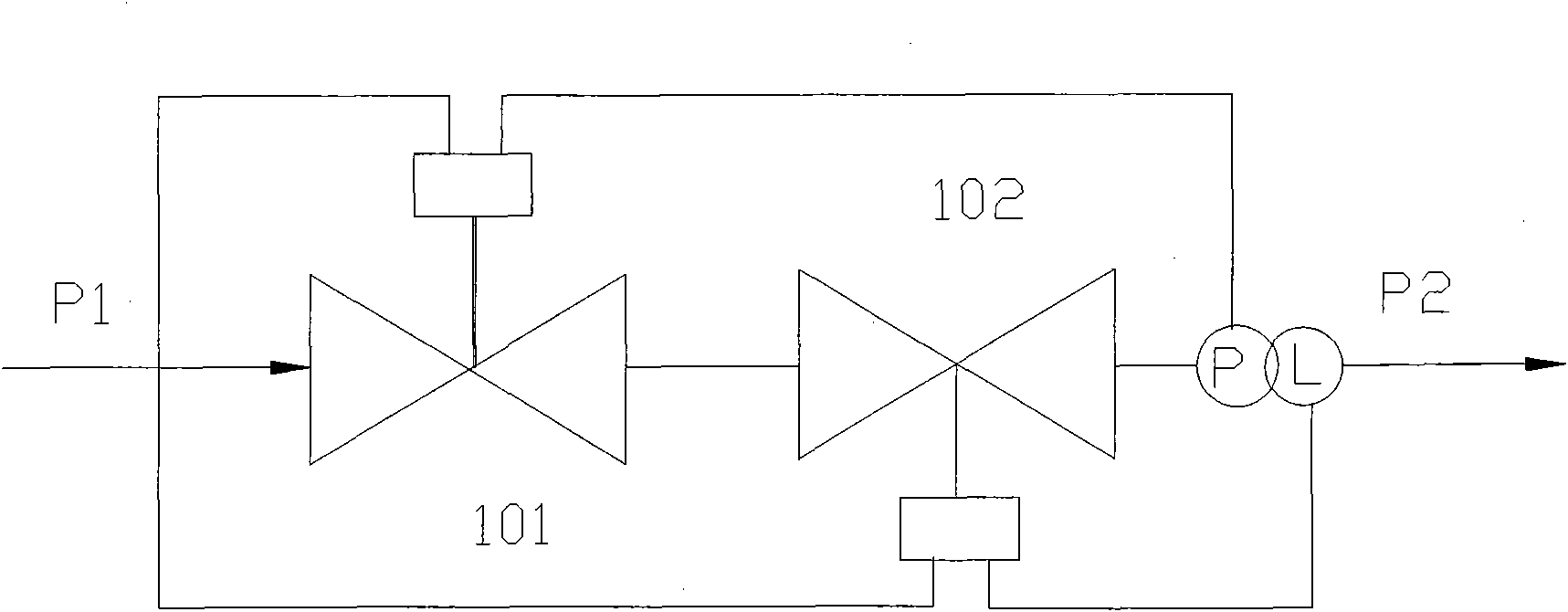

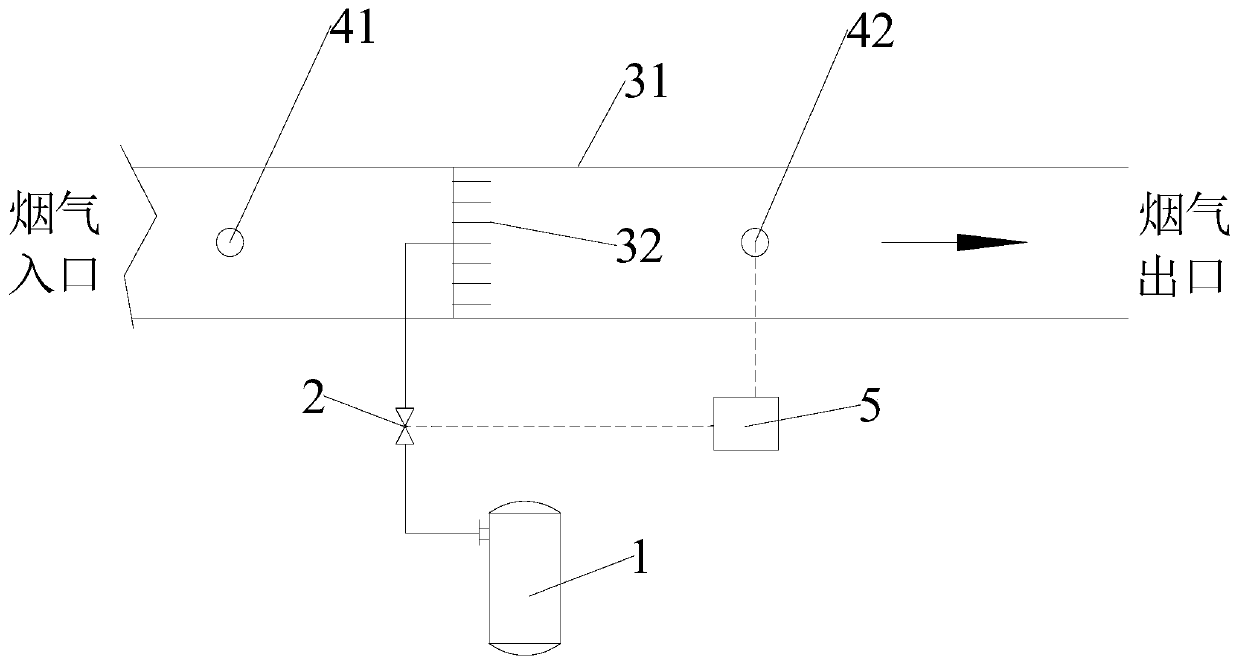

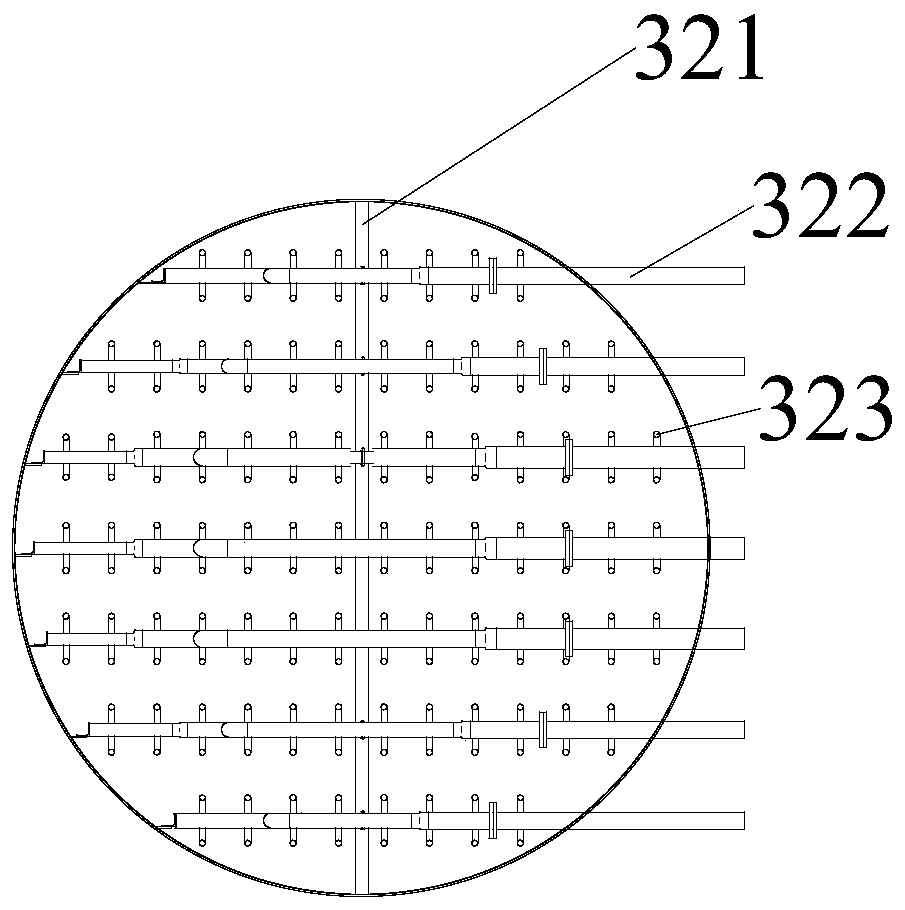

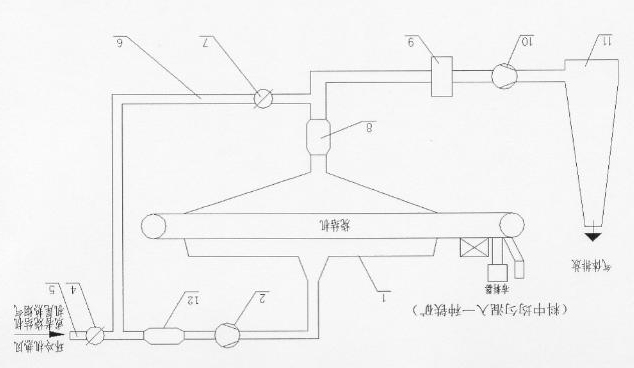

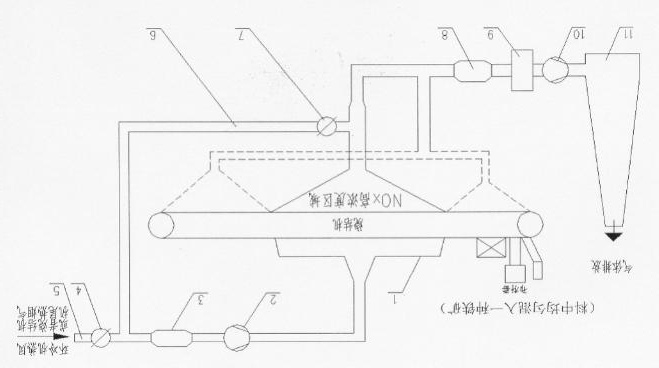

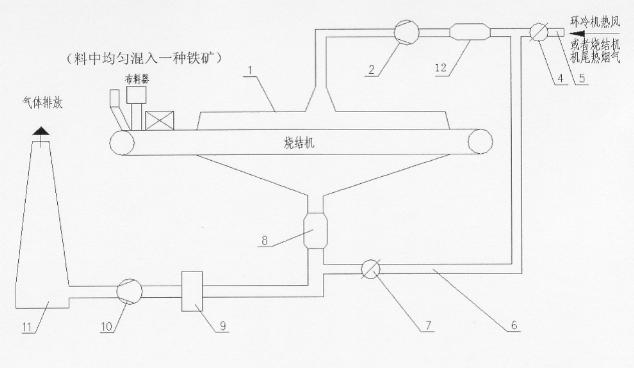

Oxygen-enriched sintering flue gas circulation system and application thereof

InactiveCN110553516ASimple structureEasy to adjustControl devices for furnacesWaste heat treatmentFlue gasExhaust fumes

The invention relates to an oxygen-enriched sintering flue gas circulation system and application. The oxygen-enriched sintering flue gas circulation system involves a sintering machine, a first dustremover, a first fan, an oxygen adding system, a second dust remover, a second fan and a post-treatment unit; the oxygen adding system enables oxygen to be uniformly mixed with circulation flue gas, so that the stability of the sintering yield and the quality is ensured; and a detection unit detects the content of the oxygen in the circulation flue gas in real time, the adding amount of the oxygenis adjusted through a control unit, the content of the oxygen in the mixed flue gas is detected in real time, and the control unit adjusts a flow adjusting device according to the feedback to enablethe content of the oxygen in the circulation flue gas to be 18%-30%. According to the oxygen-enriched sintering flue gas circulation system, the oxygen adding system is simple in structure, the oxygenflow can be accurately and quickly adjusted, the defect that the circulation flue gas flow is reduced due to additionally-added annular cold waste gas or air is avoided, the flue gas circulation ratecan be increased to 60% at the highest, and the flue gas emission reduction effect is improved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

Superfine fire coal particle control method based on pillared modified montmorillonite

InactiveCN105219476AGet rid of the status quoIncrease layer spacingSolid fuelsDust controlPhysical chemistry

The invention discloses a superfine fire coal particle control method based on pillared modified montmorillonite. The superfine fire coal particle control method comprises the steps of adding a modified montmorillonite additive into pulverized coal; after uniformly mixing, combusting the pulverized coal mixed with the modified montmorillonite additive in a boiler; and inhibiting the generation of the superfine particles and adsorbing the generated superfine particles through the physical and chemical effects of the modified montmorillonite additive, and enabling the superfine particles to transfer towards particles with large particle sizes to form large particles which can be captured by a dust collecting device. The modified montmorillonite is added to remove the superfine particles, so that the rate for capturing the superfine particles by the original montmorillonite can be remarkably increased, and the discharge of the superfine particles can be effectively reduced.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

Synergistic natural gas

InactiveCN101805646AHigh calorific valueReduce consumptionGaseous fuelsSodium bicarbonateNitromethane

The invention relates to a synergistic natural gas; each cubic meter of natural gas contains 6 to 10ml of synergistic additive; and the synergistic additive is mixed from potassium permanganate, nitromethane, hydrogen peroxide, sodium bicarbonate and solvent water. Every 1000 mass parts of water is mixed with 3 to 5 parts of potassium permanganate, 3 to 5 parts of nitromethane, 3 to 5 parts of hydrogen peroxide and 2 to 3 parts of sodium bicarbonate. The mixed gas provided by the invention has high heat under the same pressure condition, improves the heat efficiency to reach above 3000DEG C, realizes low loss of the same heat, and can realize low-cost use; and the high burning temperature realizes very significant advantages in industrial application (e.g. metal cutting, punching and the like); because the gas can be lit only by naked fire, the user conditions are relaxed and the use is safer; and the product can reduce the emission of waste gas, has better emission reduction effect, and realizes the purposes of cleanliness and environment protection.

Owner:李勇伯

Environment-friendly backfire clean coking and gas making and electricity generating polygeneration device

InactiveCN102093914ARelaxationWide adaptabilityMachines/enginesSpecial form destructive distillationAutomatic controlCoal

The invention discloses an environment-friendly backfire clean coking and gas making and electricity generating polygeneration device. The whole set of device comprises a coking and gas making furnace body, a heat exchanger, a separator, a booster fan and the like. An automatic control system is equipped to realize full-automatic intelligent operation. The device can adapt to coking, gas making and electricity generating of vast majority of coal, also can prepare biomass charcoal from biomass, such as wood, bamboo, stalks, rice hulls, garbage bars and the like, and generates clean fuel gas to generate electricity while preparing the charcoal so as to realize polygeneration. When the device performs pressure operation, the rate of coking and making charcoal can be controlled by adjusting the pressure (even negative pressure). The device also can completely prepare fuel gas for generating electricity when the charcoal is not needed to be made. The device can meet various requirements of different users in different places, and ensures that sewage is not discharged in the whole process of coking (making charcoal) and generating gas and electricity on the structure. Zero emission is achieved except the noise and tail gas of a generator.

Owner:许荣根

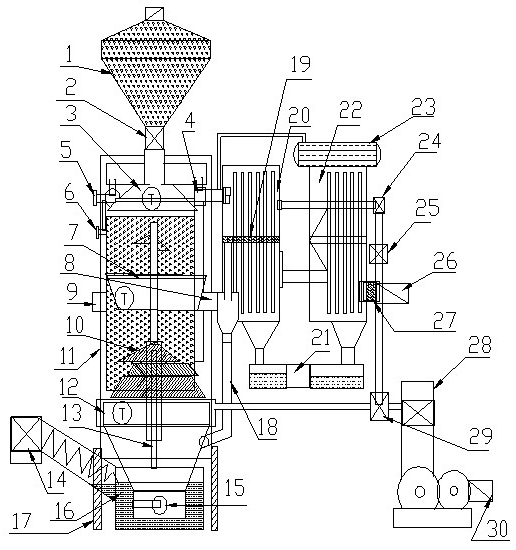

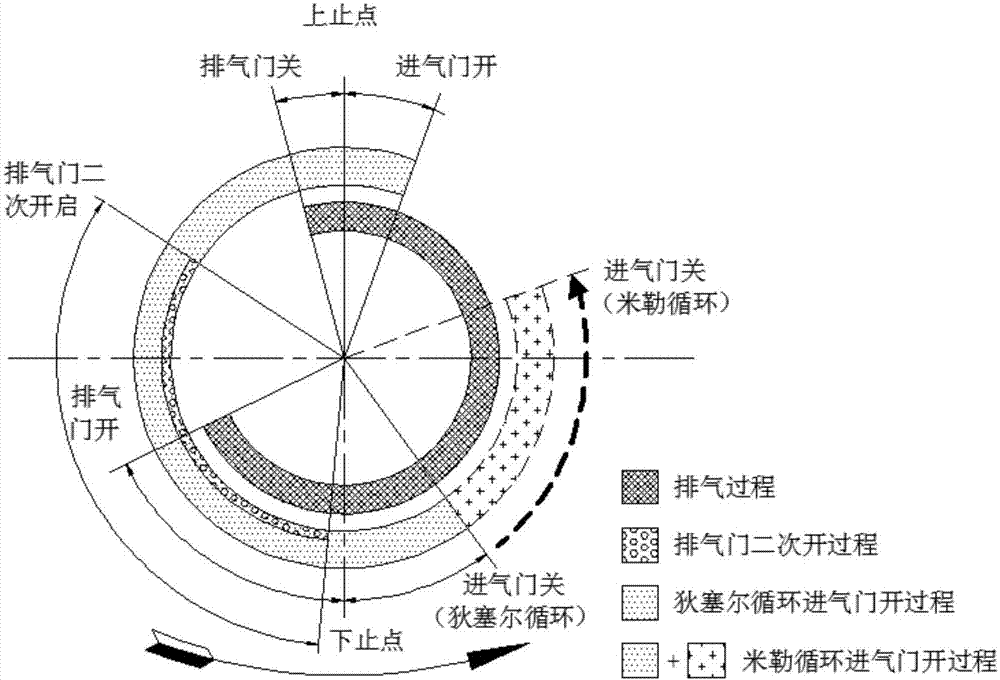

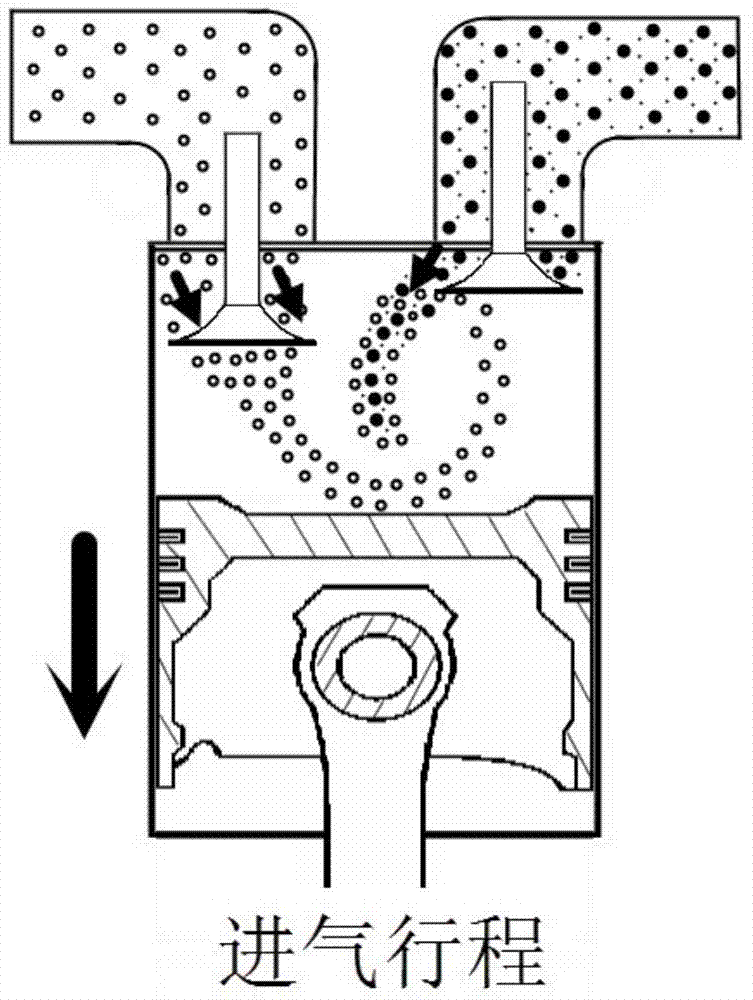

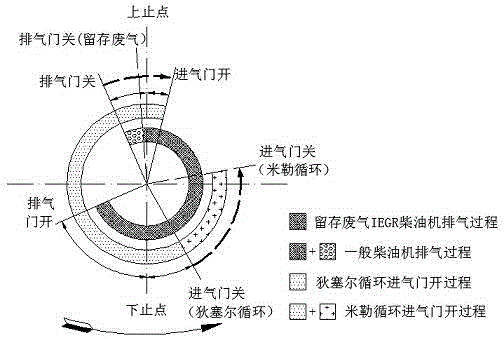

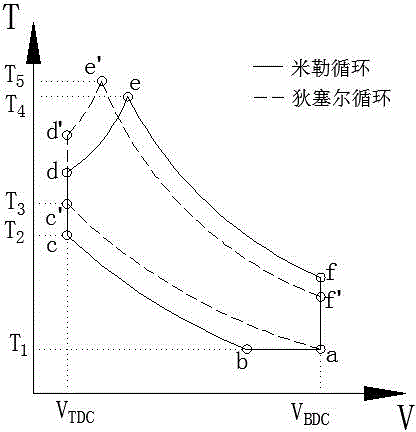

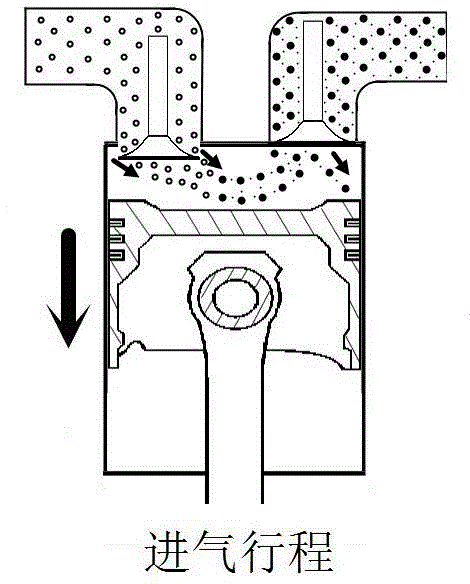

EVRO (exhaust valve secondary opening) IEGR (internal exhaust gas recirculation) method based on Miller cycle

InactiveCN104329162AWide applicabilityLow costInternal combustion piston enginesEngine operationsPistonProduct gas

The invention discloses an EVRO (exhaust valve secondary opening) IEGR (internal exhaust gas recirculation) method based on a Miller cycle. According to the method, through the cam profile design, an air inlet valve of a diesel engine is closed on a piston in a path, partial air in an air cylinder is pushed into an air inlet pipe, and the later closed Miller cycle work process of the air inlet valve of the diesel engine is realized; a double-peak exhaust cam is adopted, so an exhaust valve is opened once again in the gas inlet stroke of the diesel engine; under the effect of internal and external pressure differences in the cylinder, exhaust gas exhausted into the exhaust pipe is sucked into the air cylinder again, and the IEGR is carried out. According to the method, firstly, the LIVC Miller cycle and an EVRO-IEGR technology are combined, compared with the IEGR technology in the traditional Diesel engine diesel cycle, the method has the characteristic that the temperature of gas in the cylinder after heat insulation compression is reduced, the high-temperature environment in the cylinder is favorably improved, the generation of NOx is reduced, and the NOx emission reduction effect which cannot be achieved by the single IEGR technology is achieved.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Construction method for ecological bank protection of straw biochar planting bag

PendingCN109339076ARealize resource utilizationGood emission reduction effectGrowth substratesCulture mediaPlant nutritionEngineering

The invention provides a construction method for ecological bank protection of a straw biochar planting bag. The construction method comprises the steps that after crop straws is subject to carbonizing granulation, a planting bag is filled with particles of straw biochar, a bank slope is trimmed and the planting bag is installed, finally, the ecological bank protection is realized through growingplants of the planting bag. According to the construction method for ecological bank protection of the straw biochar planting bag, by filling the planting bag with the particles of the straw biochar,the planting bag is installed on the bank slope, the utilization of straw resources is realized, water and soil loss on ditches, river channels and other edge slopes can be effectively prevented, carbon reducing effect of the environment is achieved, trophism pollutants in river channel water bodies can be effectively adsorbed, and the plant nutrition is further provided.

Owner:上海夕露环境科技有限公司

Low-carbon method for improving emission reduction efficiency of oxynitride in circulated flue gas from sintering machine

InactiveCN102188905AImprove catalytic emission reduction efficiencyNo need for additional facilitiesDispersed particle separationFurnace typesFlue gasOxygen

The invention relates to a low-carbon method for improving the emission reduction efficiency of oxynitride in circulated flue gas from a sintering machine, and the method comprises the following steps: (1) taking the flue gas in the middle of the total flue gas from a main flue, circulating the taken flue gas, wherein the flue gas is specifically taken from the area 20-70% from the head of the sintering machine to the bottom of the sintering machine, and the content of the oxygen in the flue gas in the upper circulating hood of a sintering pallet is no less than 18%; and (2) uniformly allocating an iron ore into sintering auxiliaries to serve as a catalyst. The invention provides a technical method for improving the circular denitration for the flue gas from the sintering machine with lowcost and low energy consumption. The technical method is characterized in that the iron ore is uniformly added into the sintering auxiliaries based on the flue gas circulation of the sintering machine, so as to improve the efficiency for denitration of the oxynitride. The technology provided by the invention is implemented based on the flue gas circulation of the sintering machine, the efficiencyfor denitrating the oxynitride from the circulated flue gas can be increased to 80-90% on the premise of not increasing the investment on equipment and construction, and the cost for energy consumption and operation.

Owner:BAOSTEEL ENG & TECH GRP

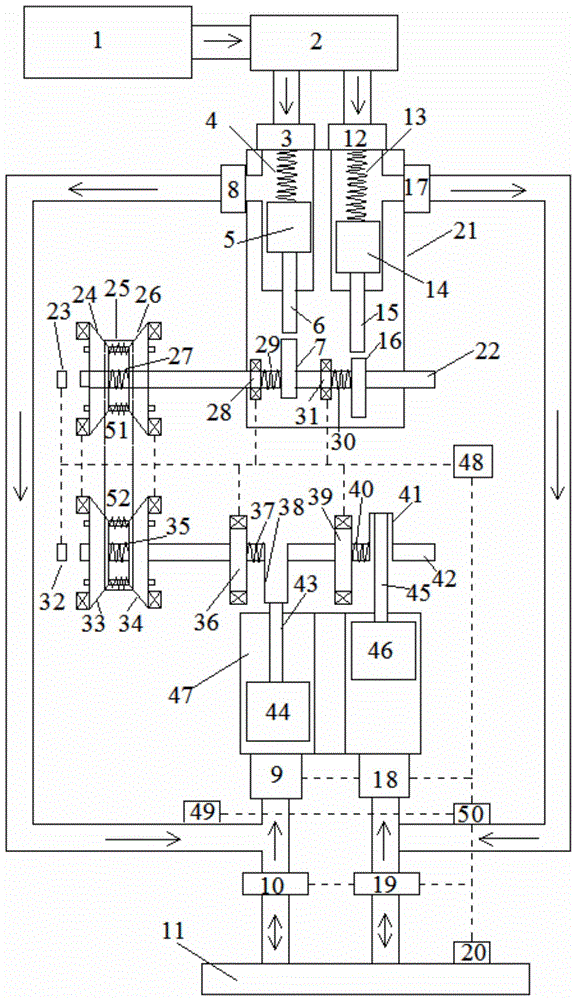

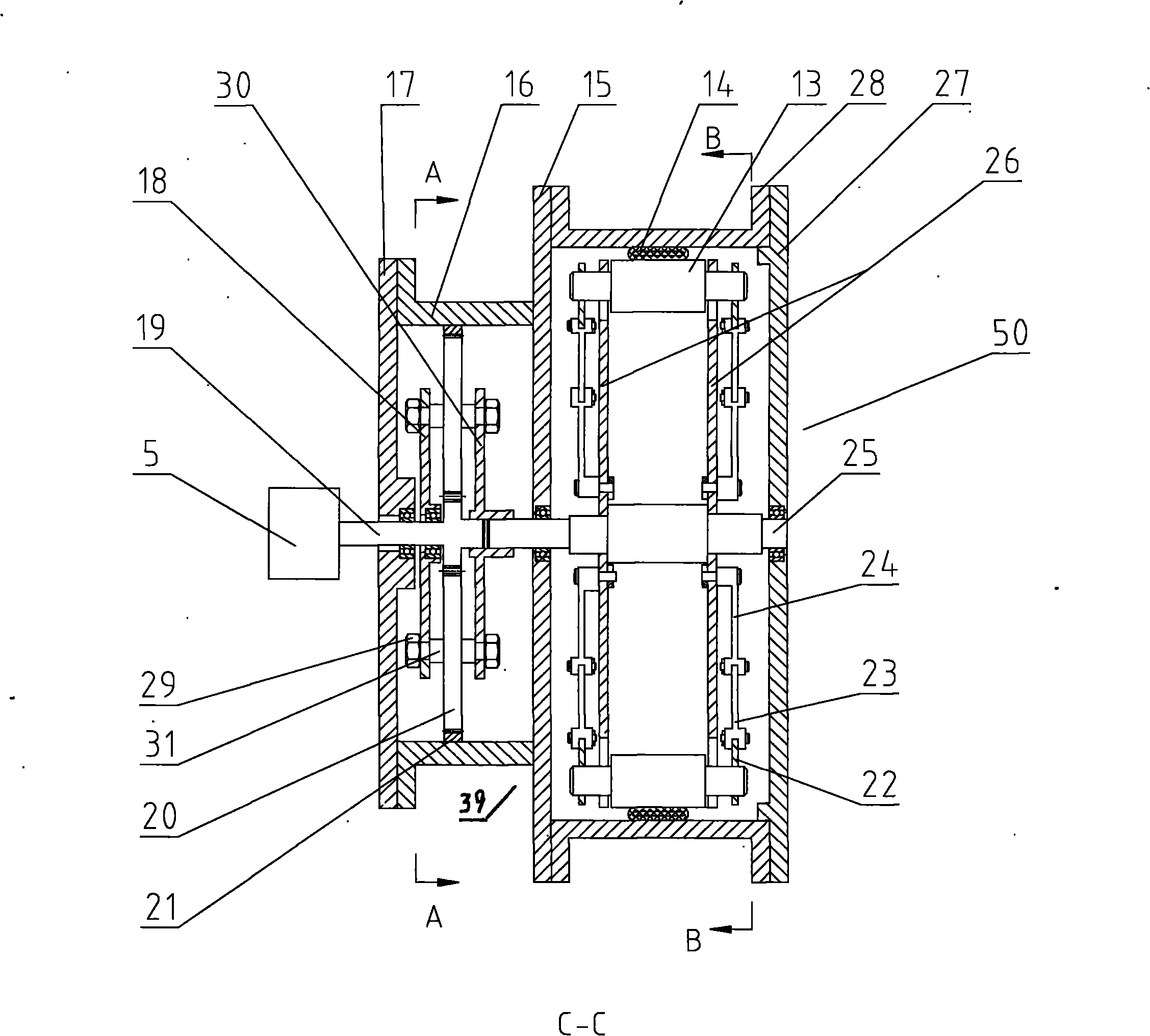

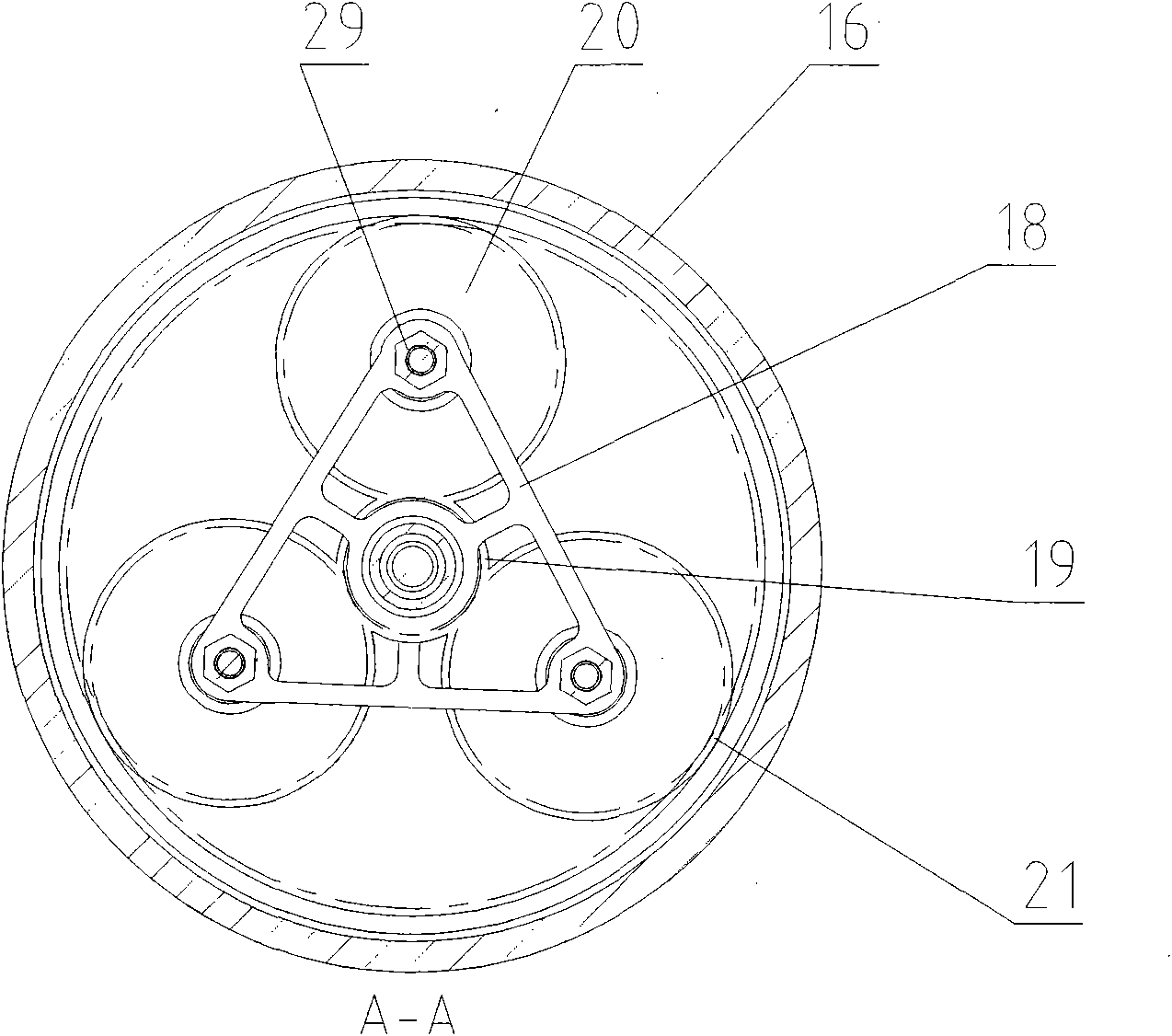

Energy-saving diesel engine having multistage variable oil-supply transmission ratio and multiple running modes

ActiveCN106762507AImprove efficiencyImprove stabilityPositive displacement pump componentsPiston pumpsLow speedHigh pressure

The invention discloses an energy-saving diesel engine having a multistage variable oil-supply transmission ratio and multiple running modes. The energy-saving diesel engine comprises a high-pressure oil pump, a diesel engine body and an oil tank, the high-pressure oil pump is of a double-oil-cylinder structure, the diesel engine body is of a double-piston-cylinder structure, two piston cylinders are respectively communicated with two oil cylinders correspondingly through electric-control oil injectors, plungers of the two oil cylinders correspondingly contact with two cams on a cam shaft respectively through pushing rods, pistons of the two piston cylinders are correspondingly connected with two connecting rod drivers on a crankshaft respectively through connecting rods, an oil supply speed-variable transmission mechanism is arranged between the cam shaft and the crankshaft, and the two electric-control oil injectors are communicated with a pressure-storage energy storing tank respectively through electric-control one-way valves. The multistage variable oil-supply transmission ratio can be automatically adjusted according to rotating speed of the diesel engine, low-speed oil-supply efficiency and stability can be improved, and high-speed oil-supply energy waste can be reduced; the multiple running modes can be started according to road conditions, so that fuel consumption of the diesel engine can be reduced, and emission pollution can be lowered.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

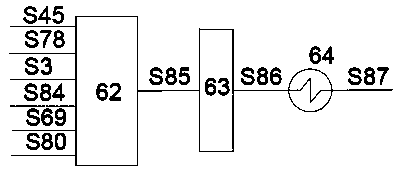

Process for capturing rubbish landfill gas carbon dioxide

InactiveCN107758664AImprove emission reduction effectEfficient integrationSolidificationLiquefactionNitrogen gasDecarburization

The invention discloses a process for capturing rubbish landfill gas carbon dioxide. The process combines technologies of gas membrane separation, low temperature liquidation and the like, and a landfill gas decarburization oxygen enrichment section and a carbon dioxide capturing section after landfill gas combustion are effectively integrated; liquefied natural gas is used as a fuel in the landfill gas combustion process after cooling in stages of the system, so that the concentration and calorific value of landfill gas methane component are increased; oxygen-enriched air is used as purging gas of landfill gas decarburization oxygen enrichment membrane component, so that the oxygen content in the mixed gas after entrapment gas in a carbon dioxide capturing and backflow link is mixed withosmotic gas of a third-level membrane component is increased, a nitrogen component in flue gas after landfill gas is combusted is effectively reduced, and the energy consumption of the carbon oxide capturing section after landfill gas combustion is reduced; in the membrane component oxygen enrichment section, the pressure of feeding gas is increased by utilizing energy provided by a compressing turbine expander in the two sections; the requirements of each link for heat energy and cold energy in the process are integrated effectively by a heat exchanger, and the energy utilization rate is increased.

Owner:杨正山

Catalytic converter

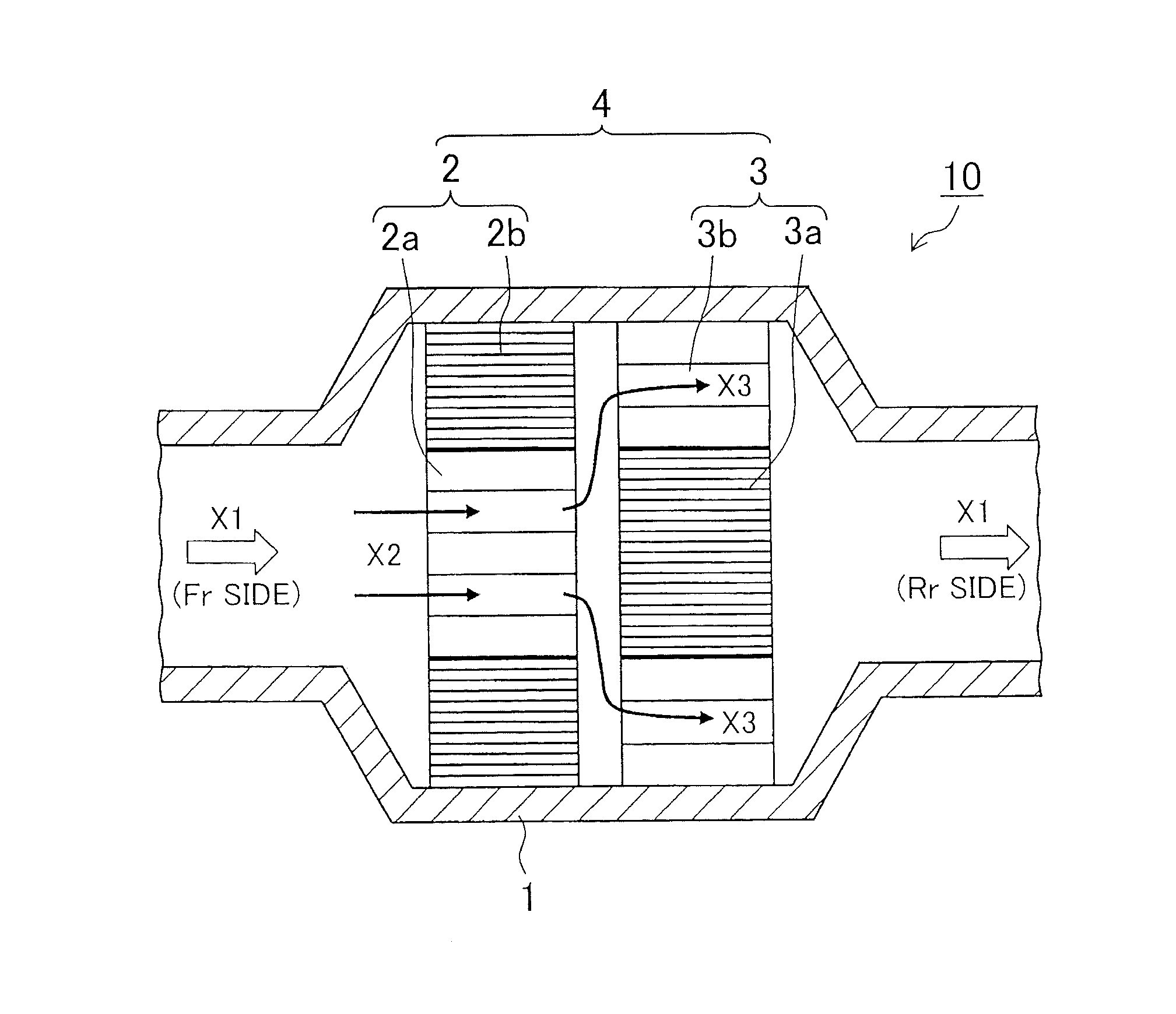

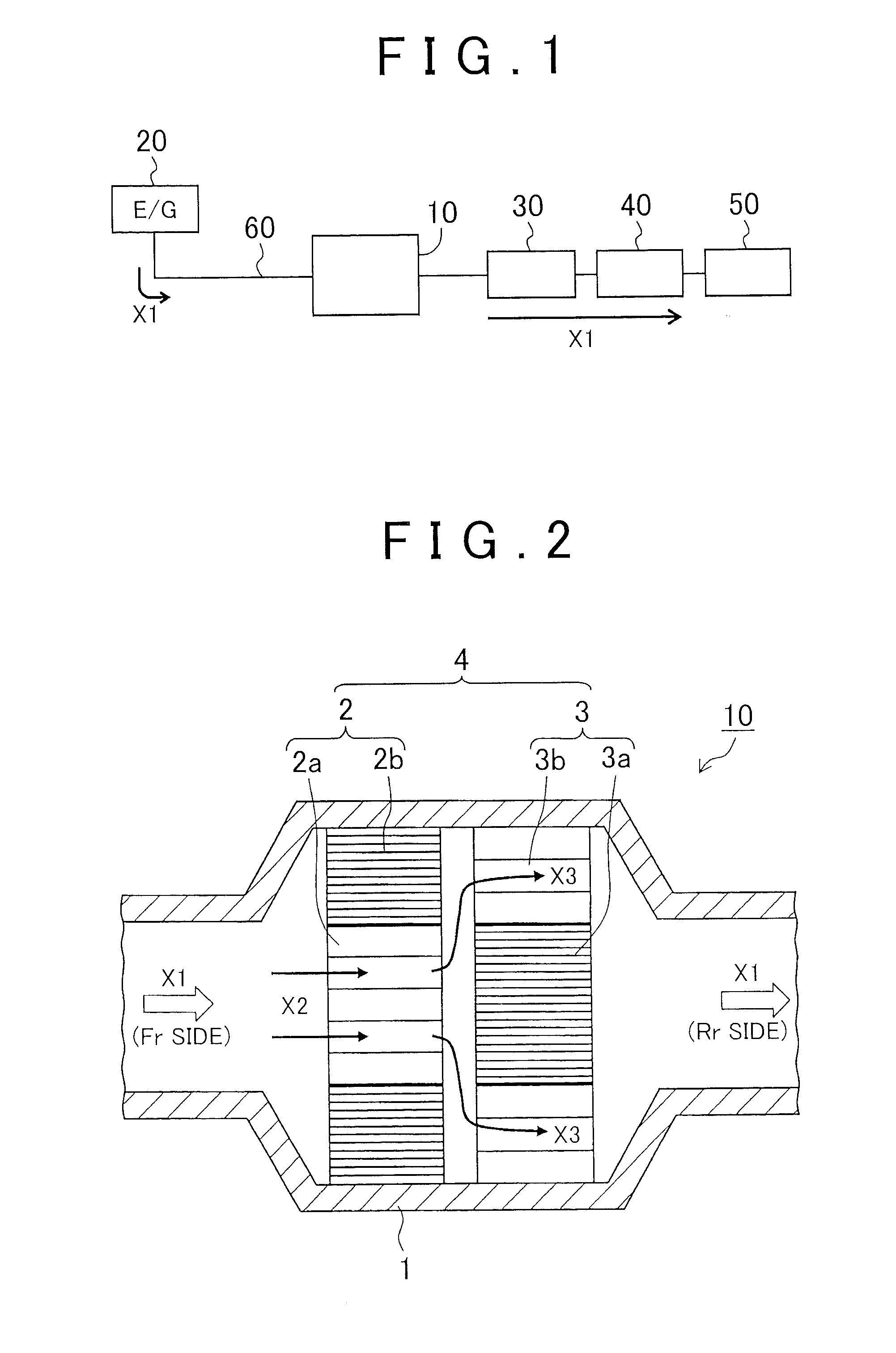

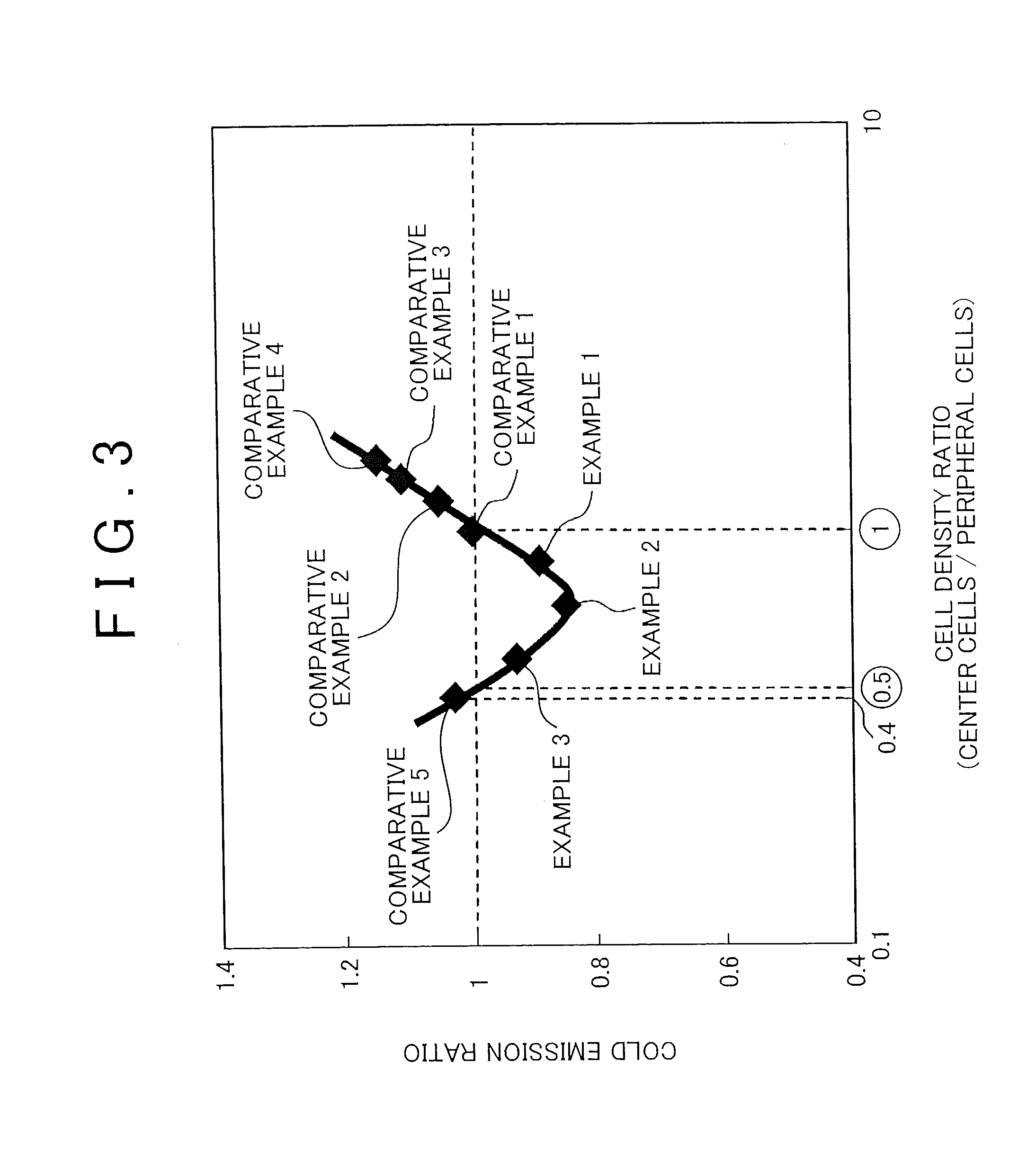

InactiveUS20130315788A1Low pressure lossIncrease in amount of exhaust gasCombination devicesExhaust apparatusCatalytic transformationConverters

A catalytic converter has a carrier with a cell structure, and a precious metal catalyst carried on the carrier. The carrier includes a first carrier and a second carrier. The second carrier is provided downstream of the first carrier in a gas flow direction of gas that flows into the catalytic converter. The first carrier has a first peripheral region and a first center region that has a lower cell density than the first peripheral region. The second carrier has a second center region and a second peripheral region that has a lower cell density than the second center region.

Owner:TOYOTA JIDOSHA KK +1

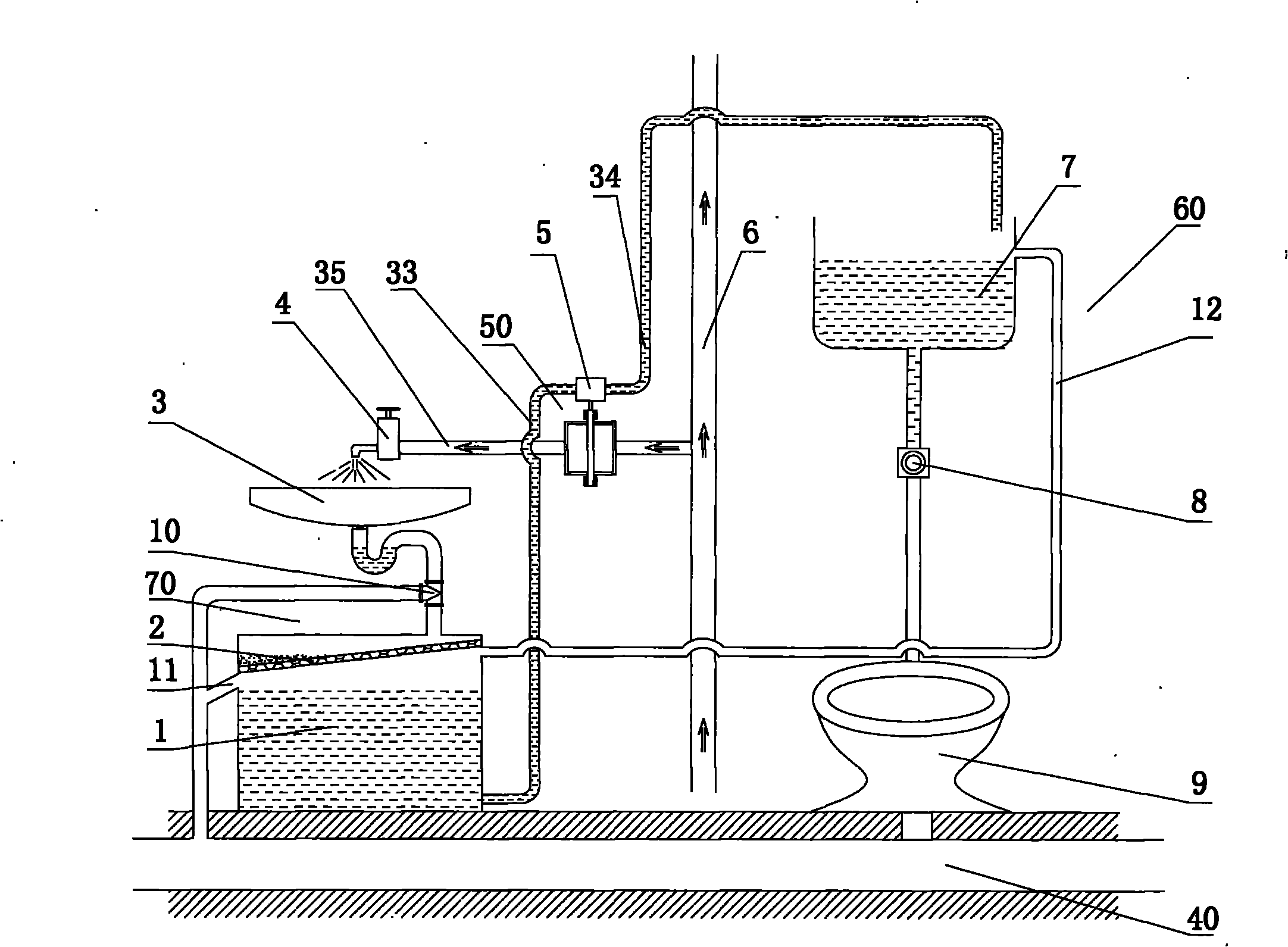

Graywater recycling device based on hose water pressure drive motor

InactiveCN101876178ASimple structureEasy to useDomestic plumbingEngine componentsMotor driveWater resources

The invention relates to a graywater recycling device based on a hose water pressure drive motor, which comprises a graywater collecting and processing device, a water pump and a graywater using device. The graywater recycling device is characterized by also comprising a hose water pressure drive motor which has a structure that a main shaft installed at the center of a main body is fixedly connected with rotating disks and a right planet carrier, three rollers which are uniformly distributed are hinged between the rotating disks, a hose is wound around the three rollers which are uniformly distributed and is in contact with the inner wall of a right housing, the right planet carrier is fixedly connected with a left planet carrier by three planet wheel shafts, each planet wheel shaft is hinged with a planet wheel, the inner side of a left housing is fixedly connected with a sun wheel, a gear shaft is installed at the center of the main body, teeth of the sun wheel, the three planet wheels and the gear shaft are sequentially meshed, and the gear shaft and the water pump are coaxially and fixedly connected. While using tap water, the motor drives the water pump to automatically recycle the graywater. The device has the advantages of simple structure, wide application range, good energy saving and emission reduction effects and the like, and can more effectively make full use of water resources.

Owner:BEIHUA UNIV

Emission reduction method for retained waste gas in diesel engine in Miller cycle

InactiveCN104533559AImprove emission reduction effectLower spawn conditionsElectrical controlInternal combustion piston enginesExhaust valveCombustion

The invention discloses an emission reduction method for retained waste gas in a diesel engine in a Miller cycle. As the phase position design is performed for an admission cam, an intake valve of the diesel engine is closed in the ascending process of a piston, and part gas entering a cylinder is pushed into an intake pipe to realize the delayed-closing type Miller cycle working process of the intake valve of the diesel engine; and as the phase position design is performed for an exhaust cam, an exhaust valve is closed beforehand, so that part burnt waste gas is retained in the cylinder, and is mixed with fresh mixed gas to participate in the next circulating combustion. The diesel engine solves the difficulty of excessive impulse temperature in the cylinder in a traditional IEGR technology; compared with an EEGR technology, the method can be applied to various complex working conditions, is wider in adaptability and lower in cost, and can achieve better emission reduction efficiency; and compared with a traditional IEGR technology under a diesel cycle, the method has the characteristics of reducing the temperature of the gas in the cylinder after the adiabatic compression, facilitates to improve the high-temperature environment in the cylinder, weakens the NOx generation, and achieves the NOx emission reduction effect which can not be achieved by the single IEGR technology.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Nitric acid tail gas denitration method

InactiveCN109173639AReduce the difficulty of recyclingReduce usageDispersed particle separationChemistryNitrogen gas

The invention belongs to the technical field of nitric acid production devices and discloses a nitric acid tail gas denitration method. The method comprises: injecting purge gas of an ammonia tank forammonia synthesis as a reducing agent into nitric acid tail gas at a certain temperature (depending on the initial activation temperature of the catalyst), carrying out uniform mixing, feeding the mixture into a denitration reactor, wherein hydrogen reacts with oxygen to form water and gas ammonia decomposes NOx in the exhaust gas into nitrogen gas and water vapor that are environmentally friendly, and discharging the gas into air. The reducing agent is purge gas of the ammonia tank for ammonia synthesis so that the difficulty and energy consumption of the purge gas recovery are reduced and the raw material ammonia use is reduced. The ammonia gas easily reacts with oxygen so that the catalyst can be activated at a lower temperature the selective reaction of ammonia and NOx is easy. The purge gas pressure is higher than the pressure of nitric acid tail gas and is stable so that the compression or pressurized vaporization process required for the use of the gas ammonia is avoided. The whole process reduces an investment, is stable in operation, realizes a low operation cost and has good emission reduction effects.

Owner:SICHUAN GOLDEN ELEPHANT SINCERITY CHEM CO LTD

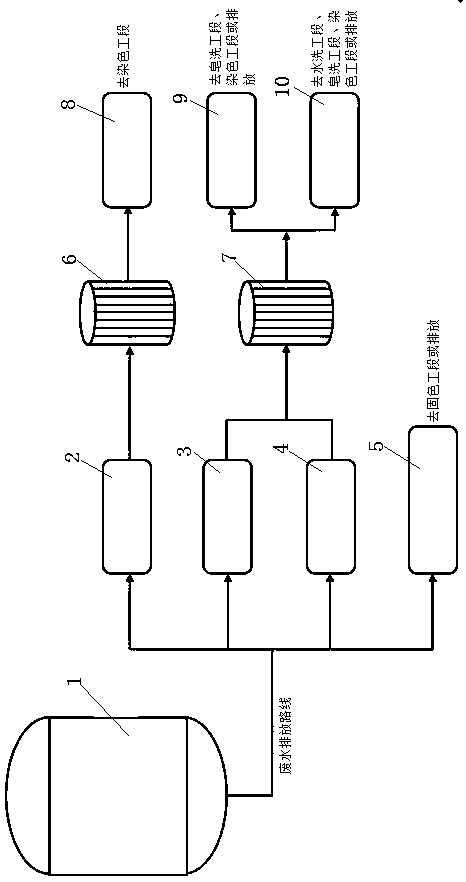

Whole-process circular dyeing method of real silk fabric and dyeing system

ActiveCN110983684AIncrease the difficulty of the processIncrease processing costTextile treatment machine arrangementsTextile/flexible product manufactureRing dyeingPulp and paper industry

The invention relates to a whole-process circular dyeing method of a real silk fabric and a dyeing system, and belongs to the technical field of printing and dyeing. The method comprises the followingsteps that (1) a reactive dye is used for dyeing, meanwhile, residual dyeing liquid is separated by a dyeing wastewater pool and a first dye separator to obtain colorless clear water, and the colorless clear water is stored in a dyeing clear water pool and is circularly used for a dyeing section; (2) wastewater in a soaping section is separated by a soaping wastewater pool and a second dye separator to obtain colorless clear water, and the colorless clear water is stored in a soaping clear water pool and is circularly used for the soaping section and the dyeing section or is discharged; and (3) wastewater in a water washing section is separated by a water washing wastewater pool and the second dye separator to obtain colorless clear water, and the colorless clear water is stored in a water washing clear water pool and is circularly used for the water washing section, the soaping section and the dyeing section or is discharged; and (4) wastewater in a color fixing section is directly circularly used for the color fixing section or is discharged after being temporarily stored in a color fixing wastewater and clear water pool.

Owner:ZHEJIANG SILK TECH

Natural gas for cutting metals

InactiveCN106244270AGood volatilization effectLess corrosiveGaseous fuelsFuel additivesTert-butylcatecholTurpentine

The invention discloses a natural gas used for cutting metals; it comprises natural gas with a purity higher than 95% by weight, and a liquid-phase synergistic additive accounting for 0.3-0.5% by weight of the aforementioned natural gas; the liquid-phase synergistic additive includes the following raw materials : 200# solvent oil, acetylene, petroleum ether, ethylene glycol monoethyl ether, turpentine, tung oil, isooctyl nitrate, dimethyl carbonate, tert-butyl ferrocene or ferrocene, methyl tert-butyl ether or n- Octyl ferrocene, p-tert-butyl catechol, azobisisobutyronitrile, polyether; the natural gas used for cutting metal can obviously increase the combustion temperature and combustion efficiency by adding a small amount of liquid-phase synergistic additives to the natural gas; At the same time, the liquid-phase synergistic additive of the present invention has little corrosion to the container and good volatility.

Owner:谢光玉

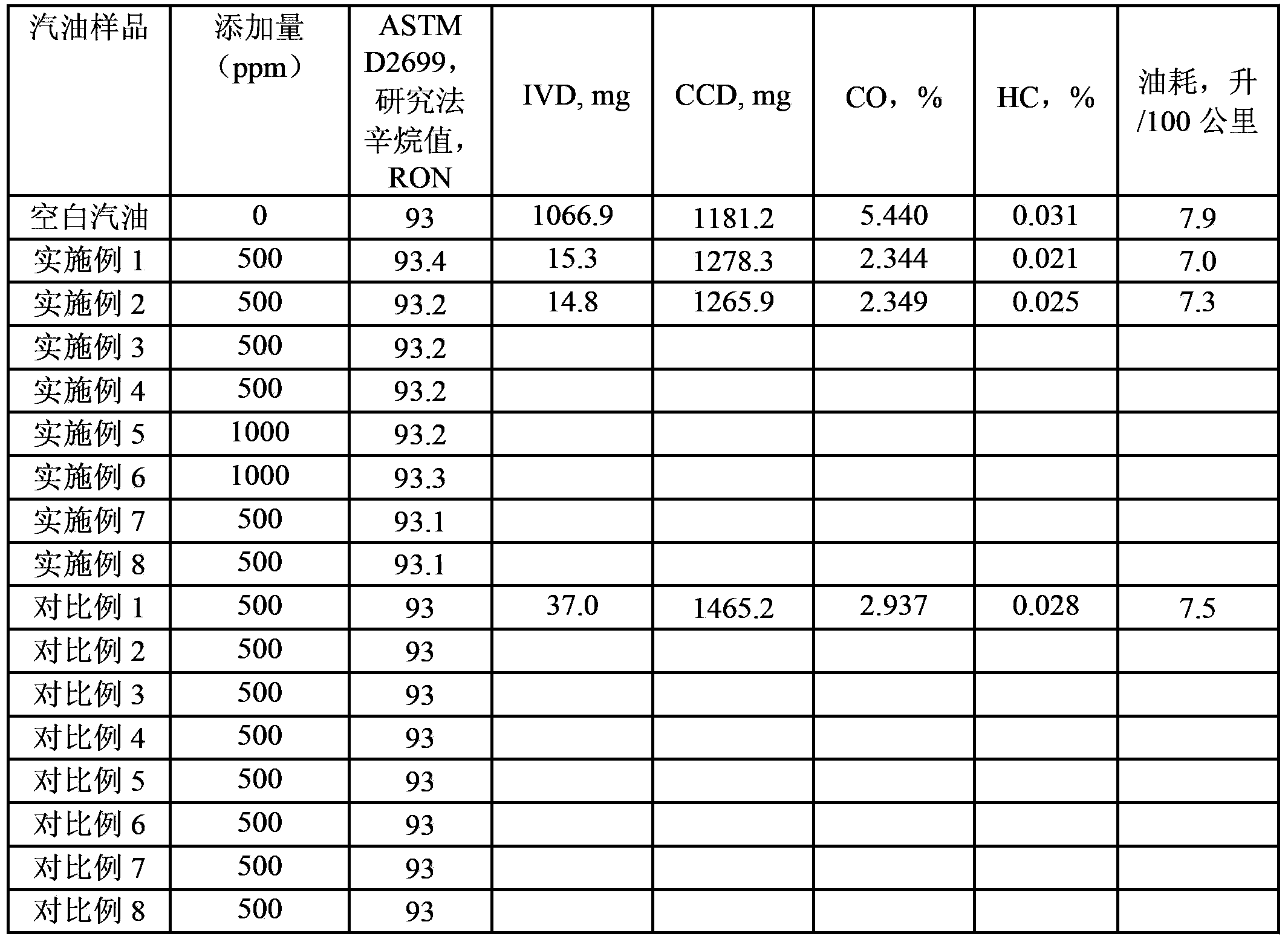

Bioenzyme-containing gasoline composite additive as well as preparation method and application for same

InactiveCN103450957AImprove combustion effectGood effectLiquid carbonaceous fuelsGasolineClearing Agent

The invention discloses a bioenzyme-containing gasoline composite additive. The bioenzyme-containing gasoline composite additive comprises a clearing agent, a carrying agent and a bioenzyme. By utilizing the characteristics of non-toxicity, environmental friendliness, moderate reaction conditions and the like of the bioenzyme and cooperatively using the bioenzyme, the clearing agent and the carrying agent, the quality of gasoline is further improved, and the effects of gasoline conservation and emission reduction of gasoline are enhanced.

Owner:英杰惠能(北京)能源新技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com