Patents

Literature

183results about How to "Good for burnout" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Incineration processing method and device for wet sludge

ActiveCN1763431ASimplify the incineration processAchieving Low Level EmissionsIncinerator apparatusAir preheaterSludge

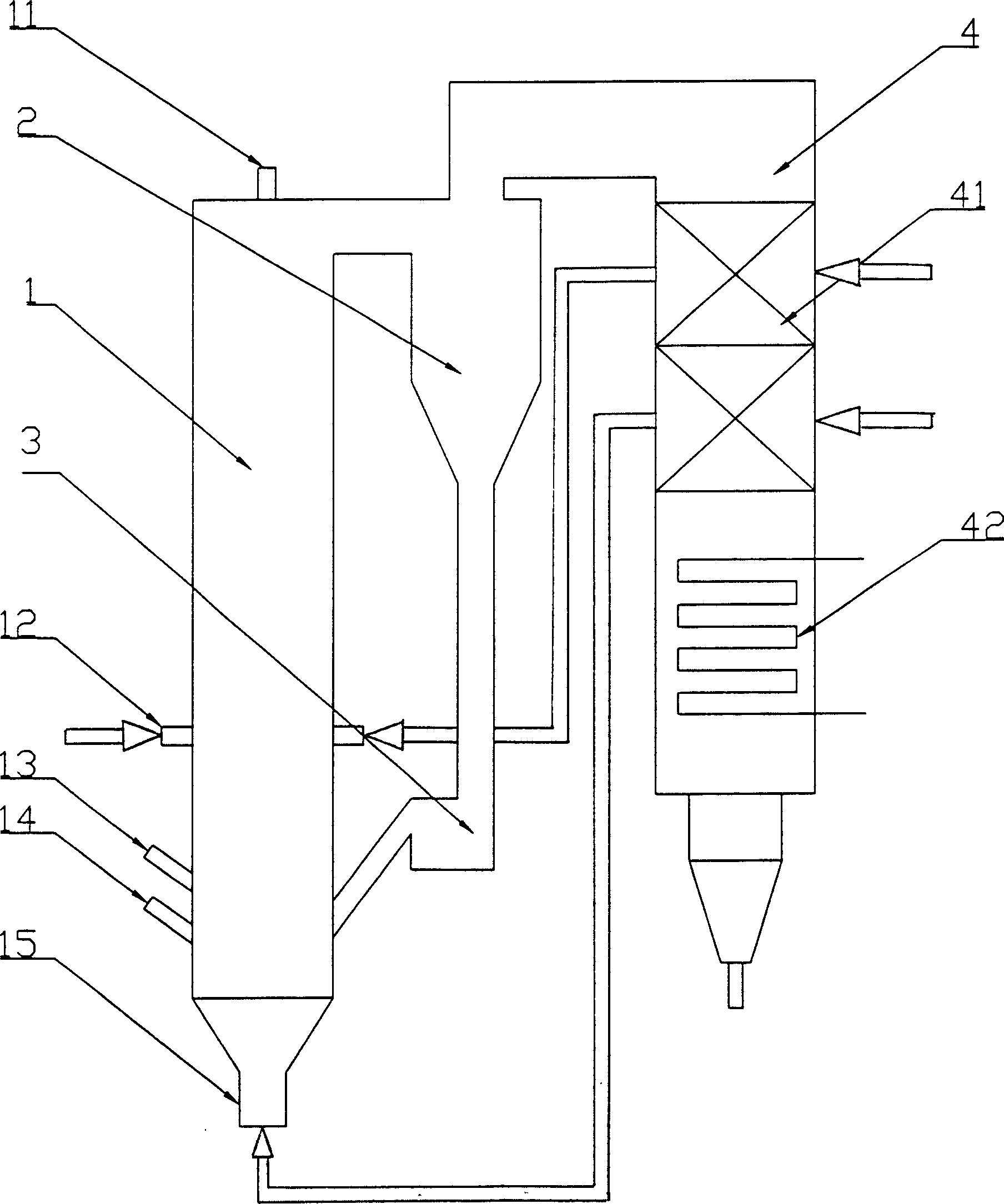

The invention discloses wet sludge burning disposal method and device, which comprises the following steps: burning the wet sludge in the furnace directly or adding auxiliary fuel; supplying air to the hearth step by step; adding limestone in the furnace to reduce the SO2 drainage. The device comprises the following parts: hearth, cyclone separator, refeed unit and rear flue, wherein the sludge filling inlet and auxiliary fuel filling inlet are set on the top and bottom of hearth separately; the high-temperature air preheater ranged from 300 to 600 deg.c is set in the rear flue. The invention simplifies the disposal technology due to drying, burning and smoke innocent treatment in one device, which discharges at low level.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

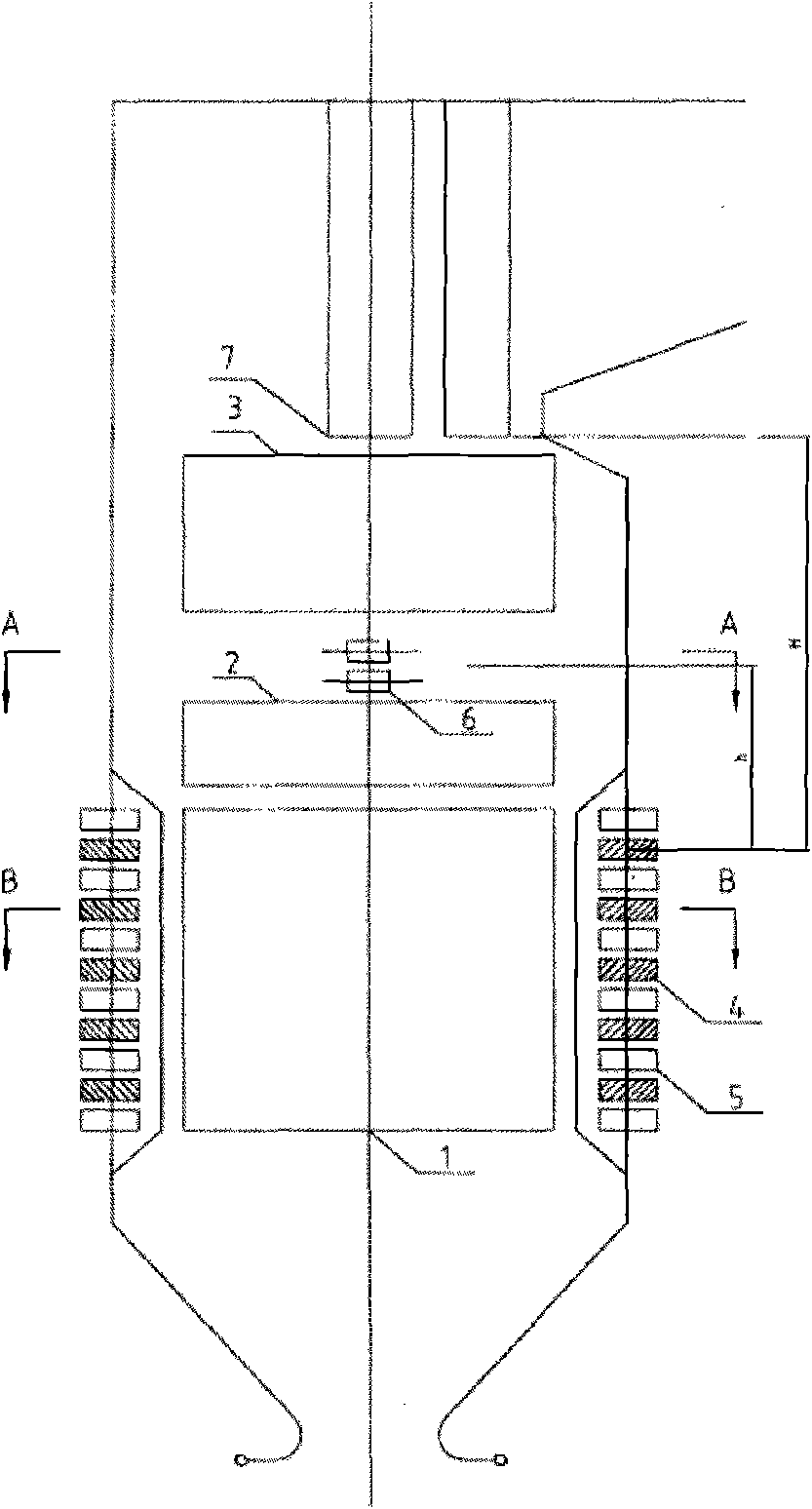

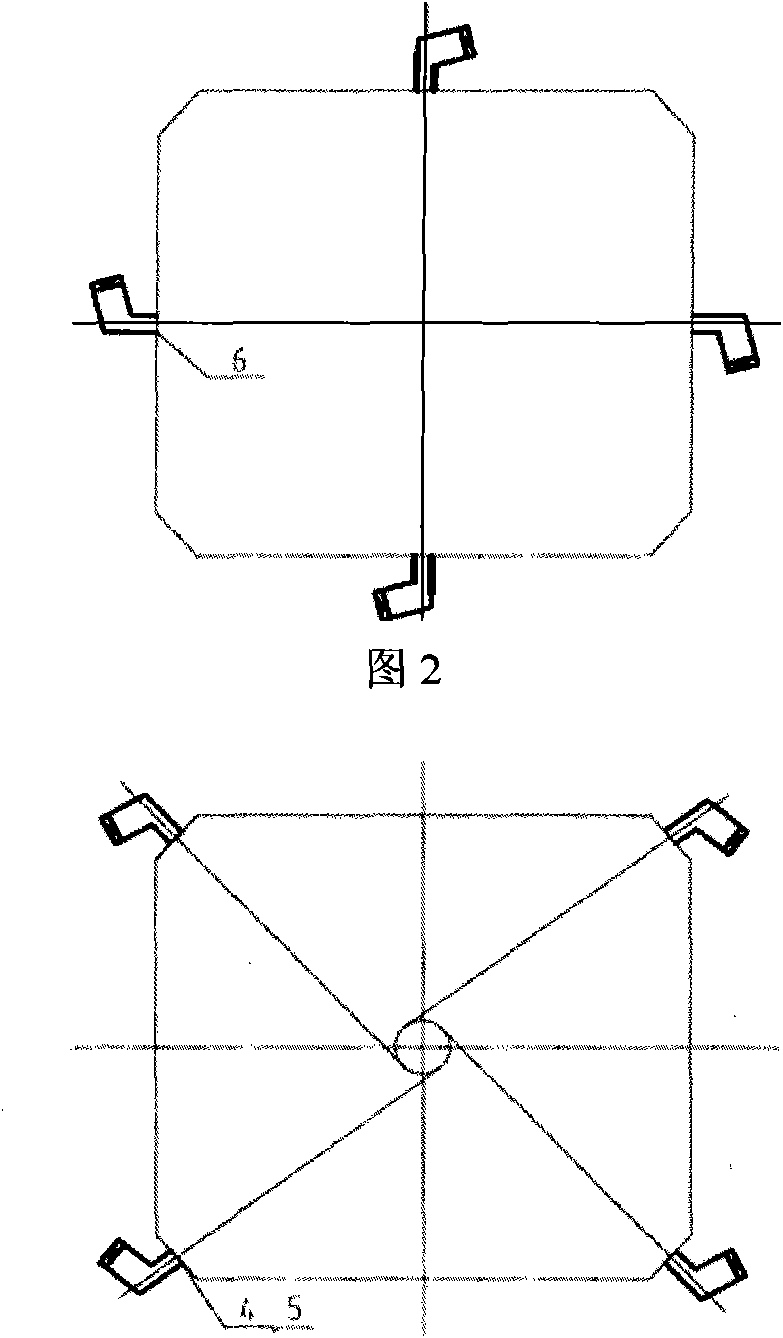

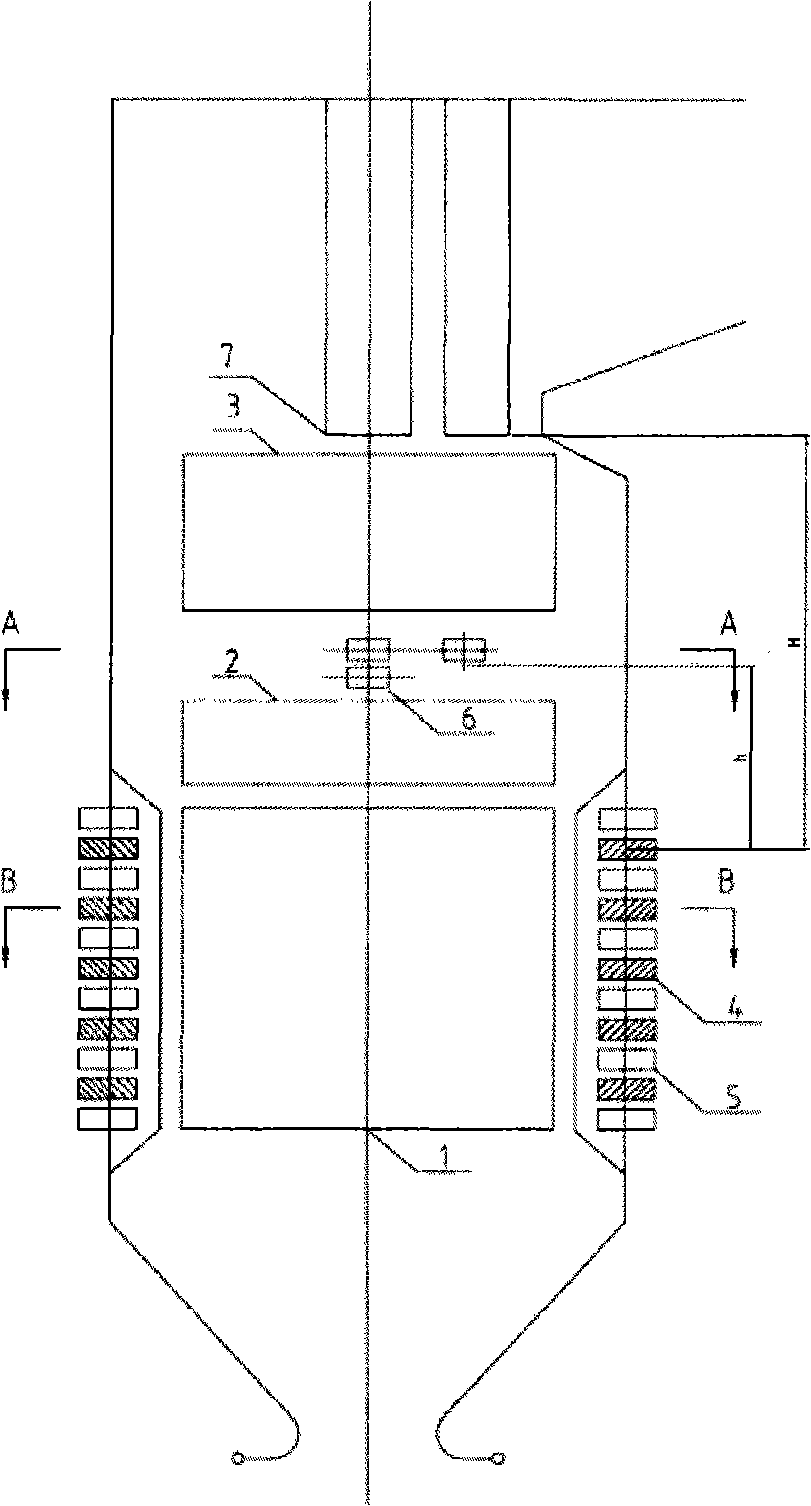

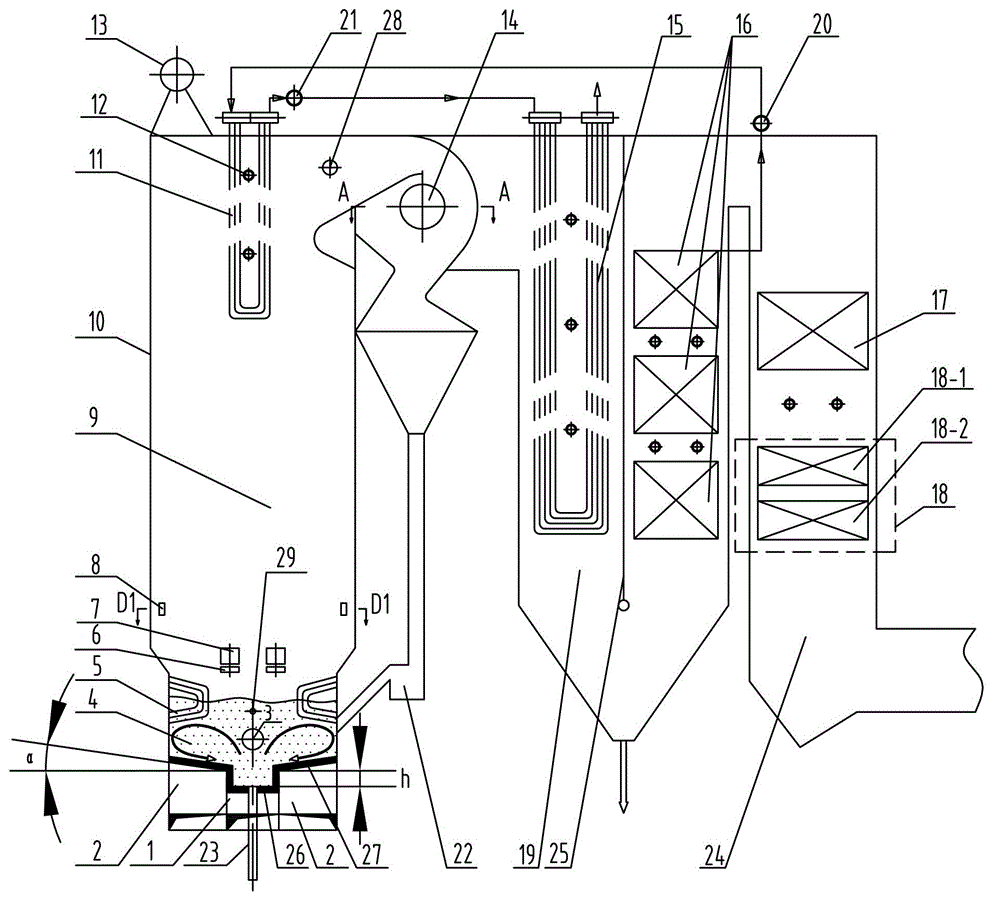

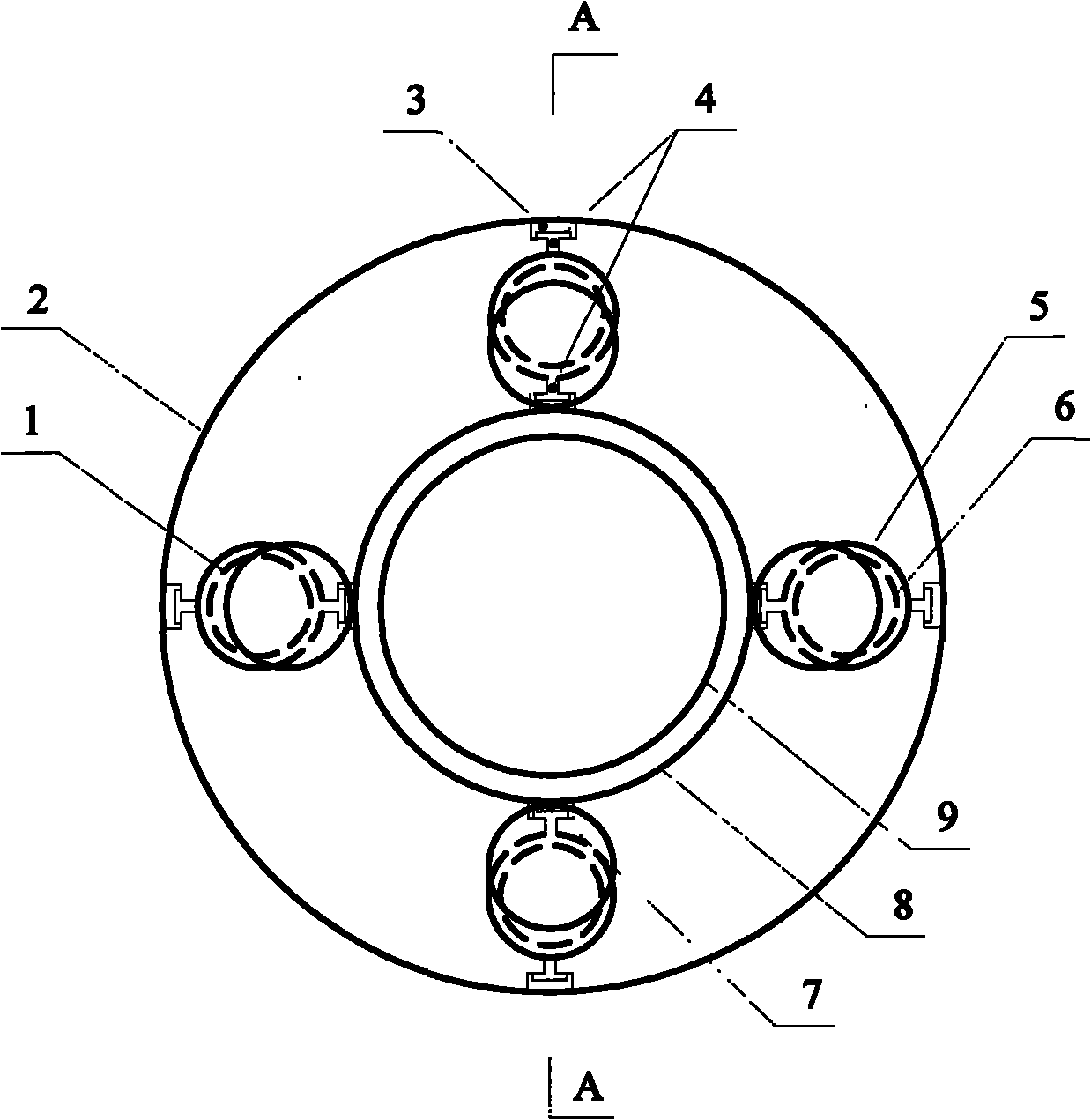

Low-nitrogen oxide discharging coal powder tangential combustion device

ActiveCN101598333AEnhanced turbulent mixingGood for burnoutPulverulent fuel combustion burnersCombustion apparatusLow nitrogenHearth

The invention provides a low-nitrogen oxide discharging coal powder tangential combustion device, comprising a hearth; wherein the four corners of a main combustion area of the hearth are provided with primary air spray nozzles and secondary air spray nozzles which are arranged at intervals, and the axis of the primary air spray nozzles or the secondary air spray nozzles positioned on the same horizontal plane is tangential to a supposed tangential circle taking the center of the hearth as a circle center. The low-nitrogen oxide discharging coal powder tangential combustion device is characterized in that the four walls of the hearth above the primary air spray nozzles and the secondary air spray nozzles are provided with at least one burning-out air spray nozzle group; each burning-out air spray nozzle group comprises four burning-out air spray nozzles, one burning-out air spray nozzle is respectively arranged on one wall of the hearth, and the four burning-out air spray nozzles are positioned on the same horizontal plane; and the axis of the burning-out air spray nozzles in the same group are tangential to one supposed tangential circle taking the center of the hearth as a circle center. The invention can realize the low discharging of NOx, solves the problems of high content of fly ash combustible substances caused by a whole air classification technique in a furnace, high fume speed at a hearth outlet, large temperature deviation of the hearth outlet and the like, and increases the running regulation performance aiming at different coal species and load changes simultaneously.

Owner:SHANGHAI BOILER WORKS

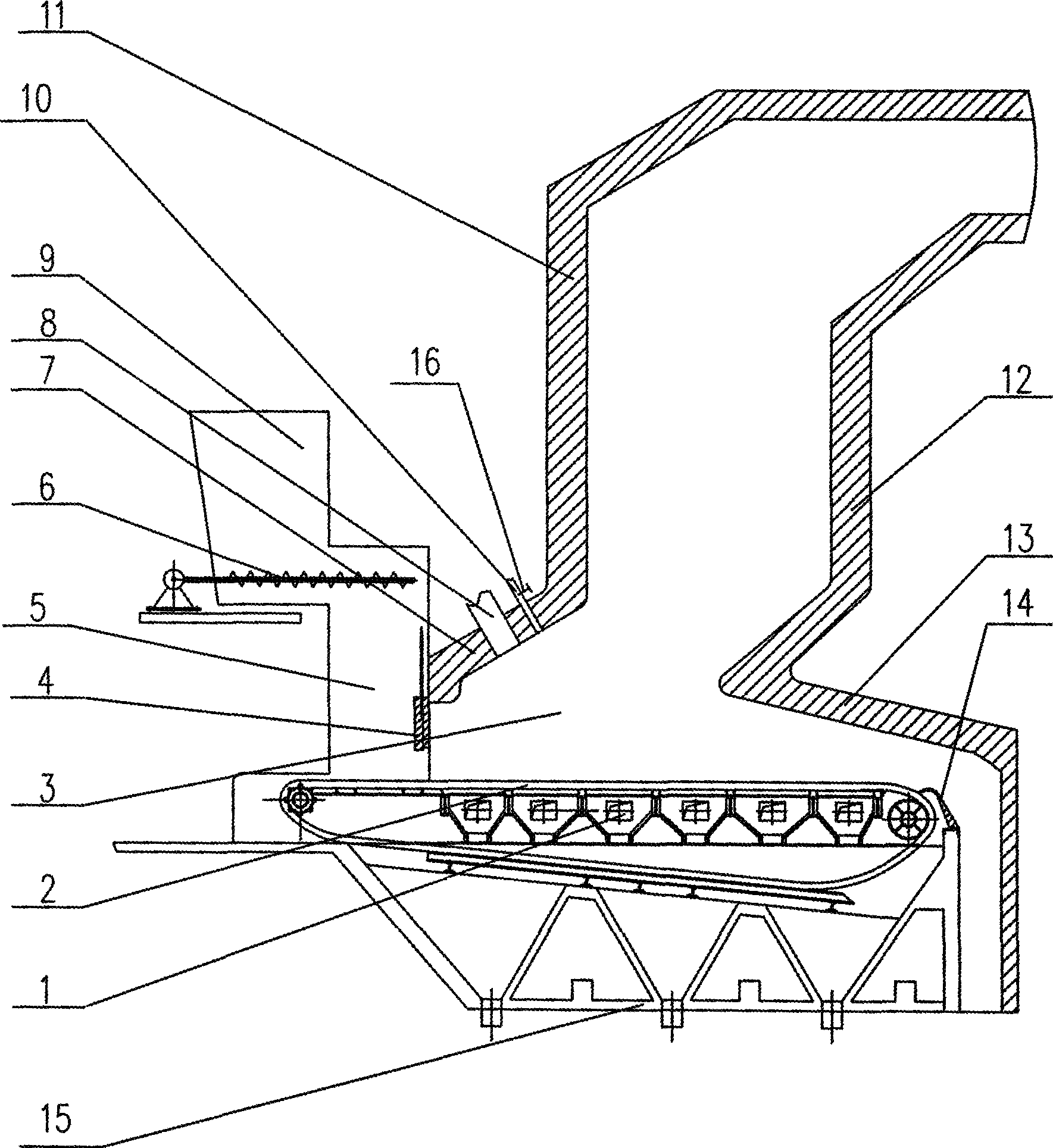

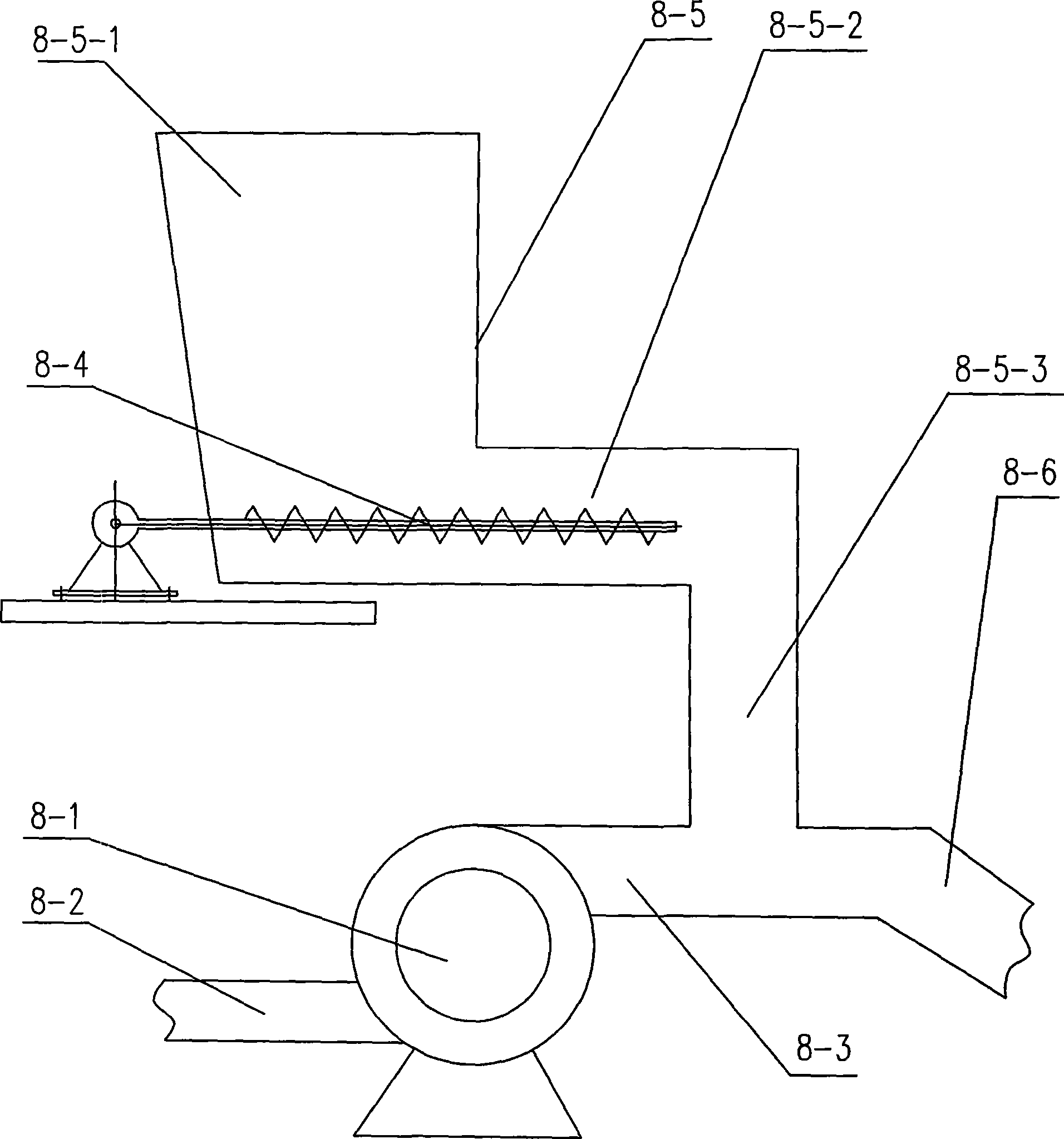

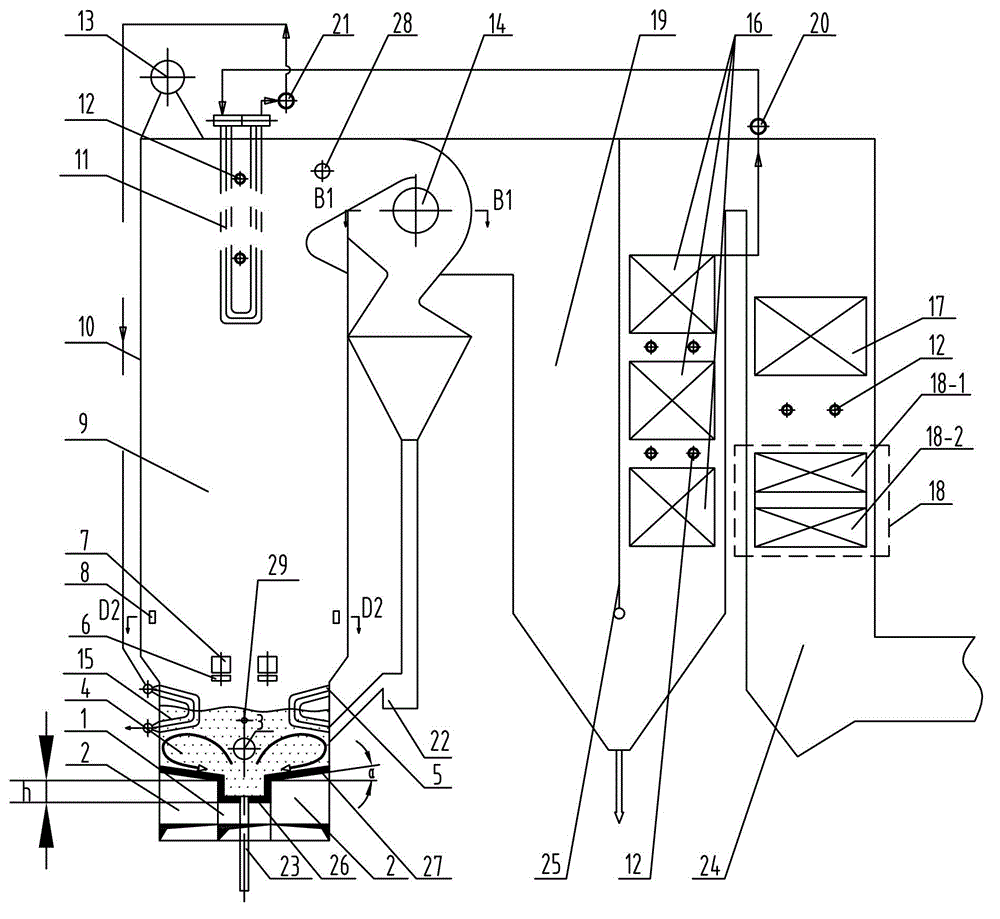

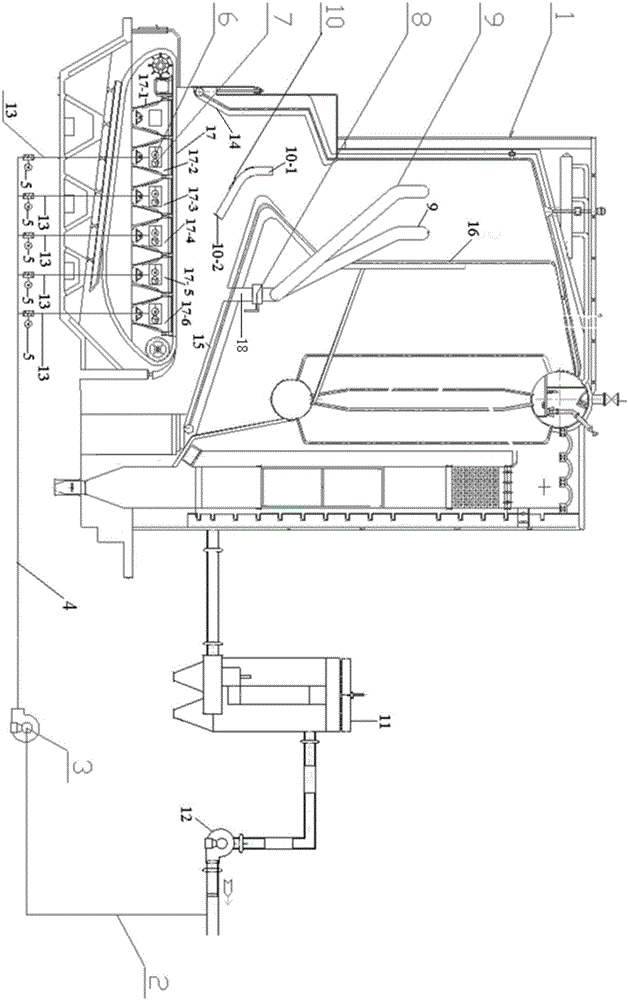

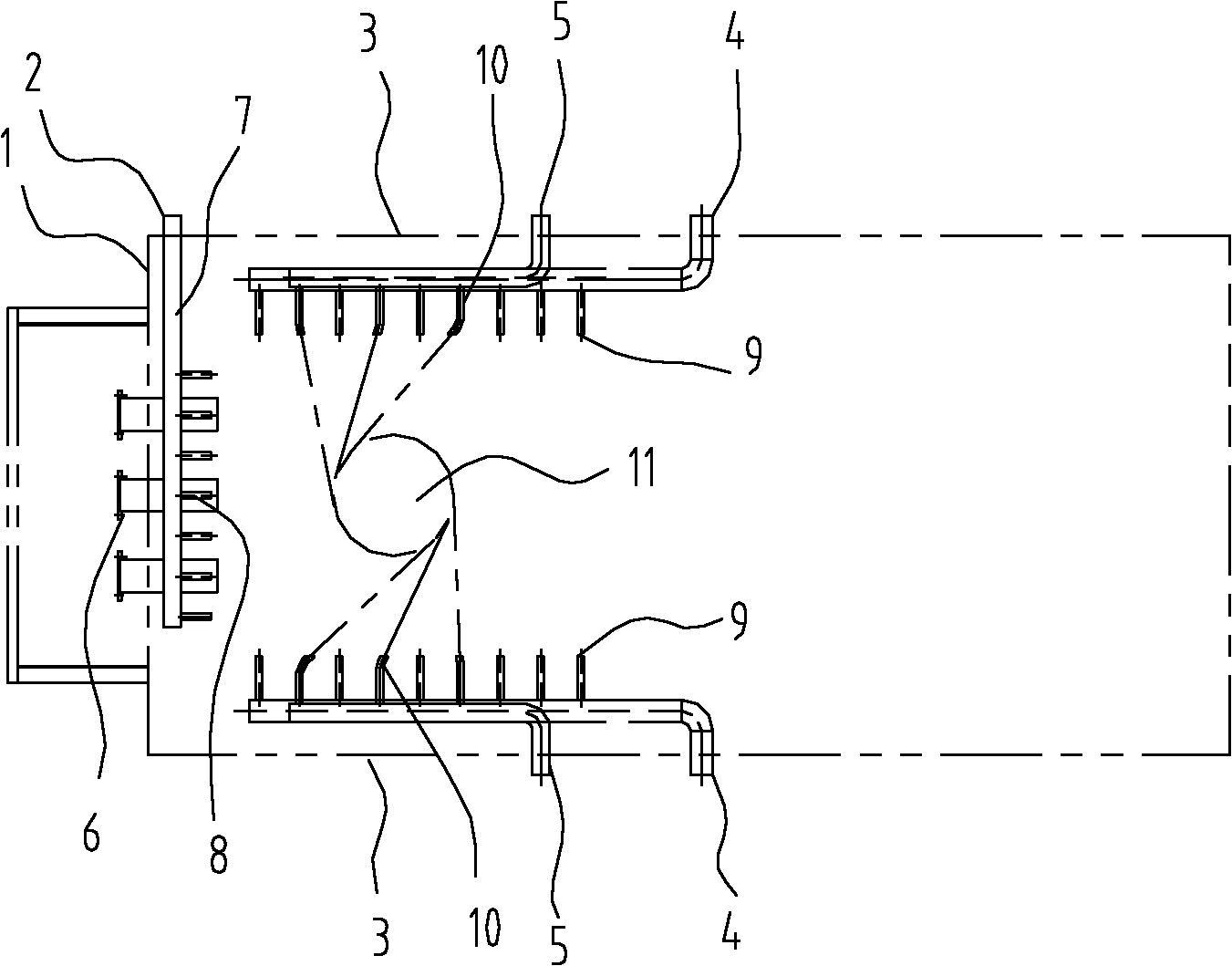

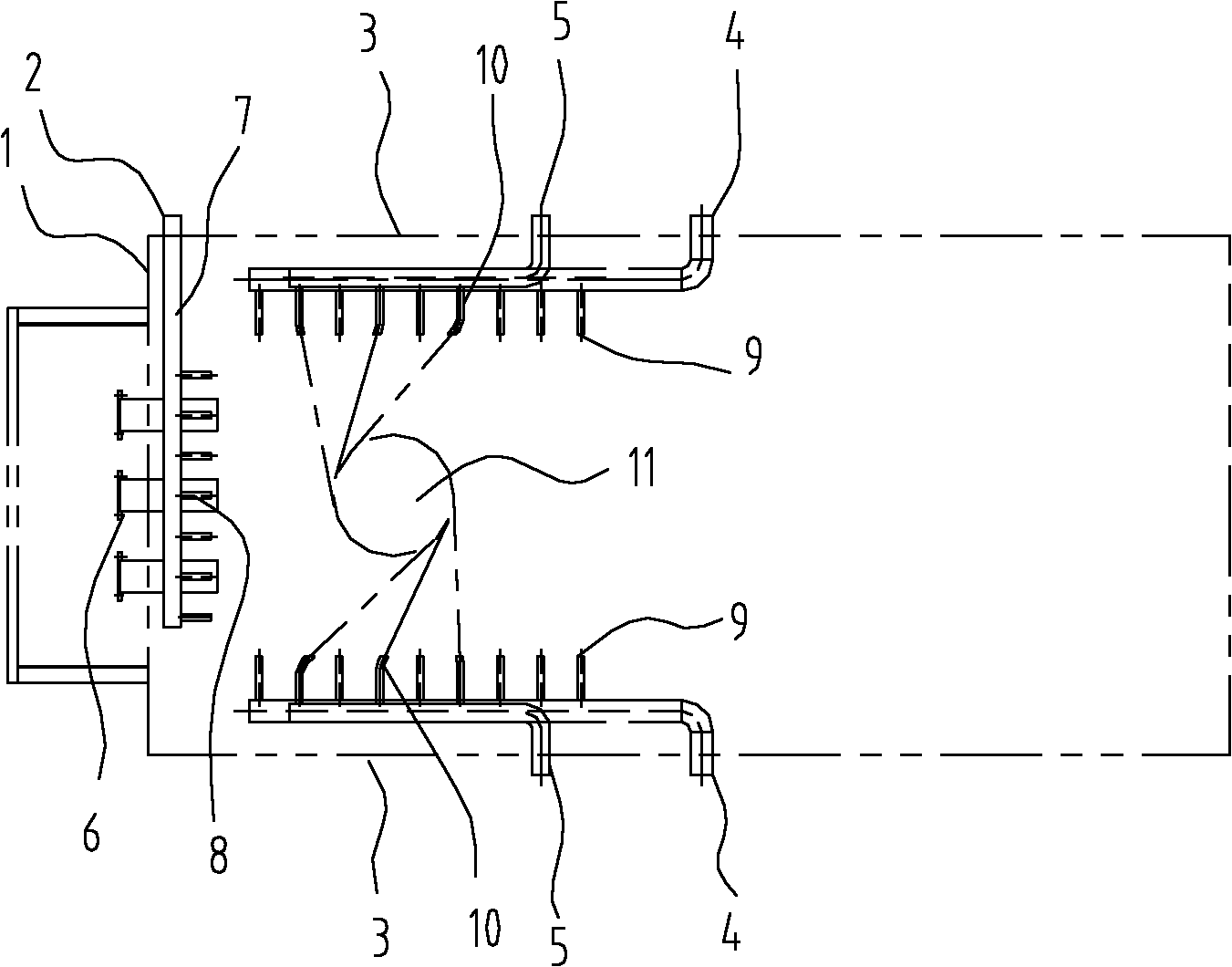

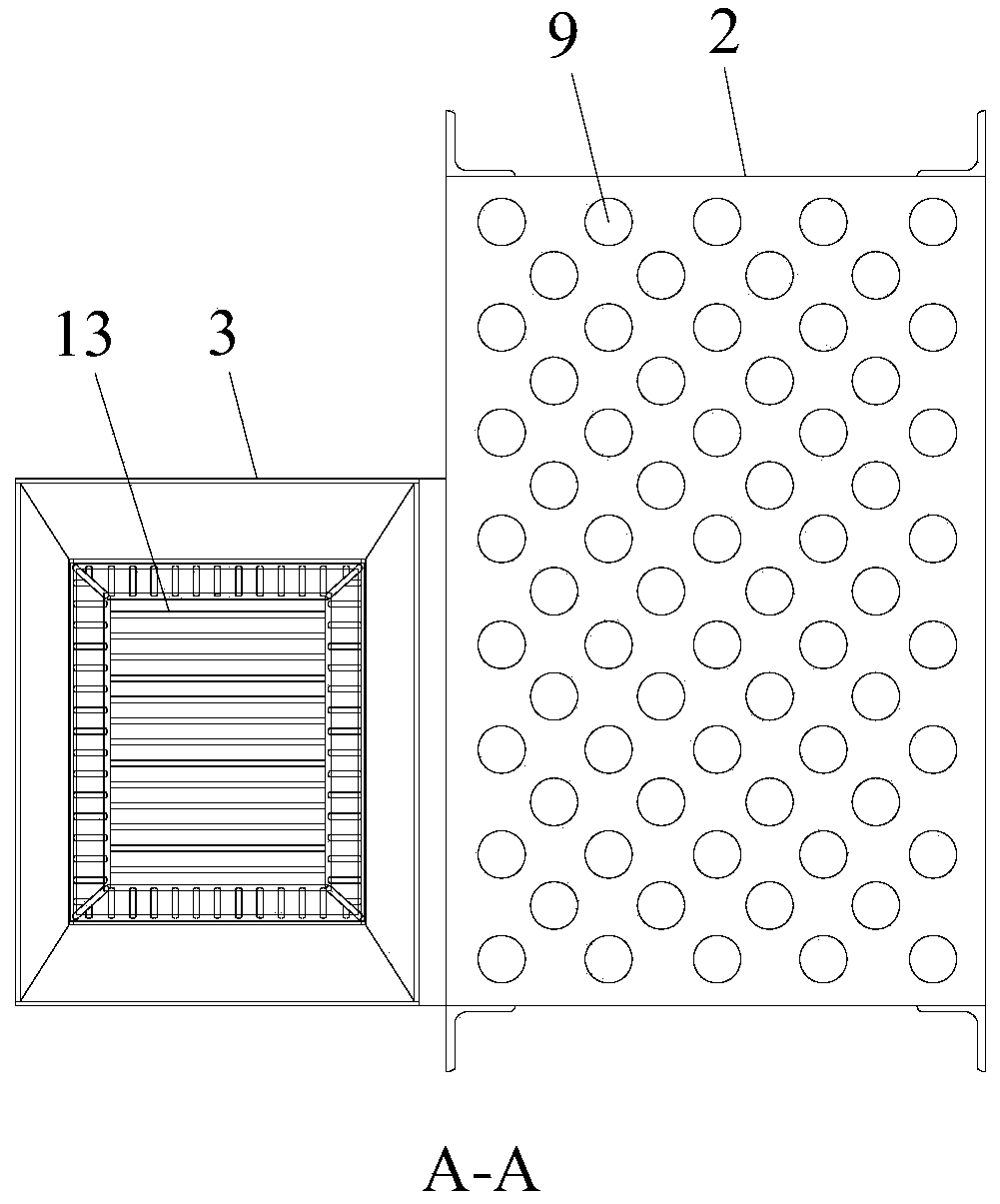

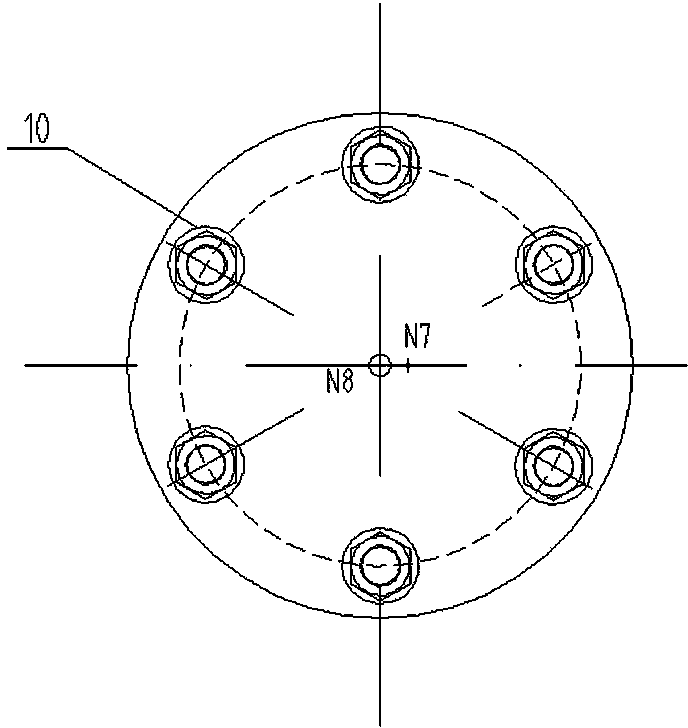

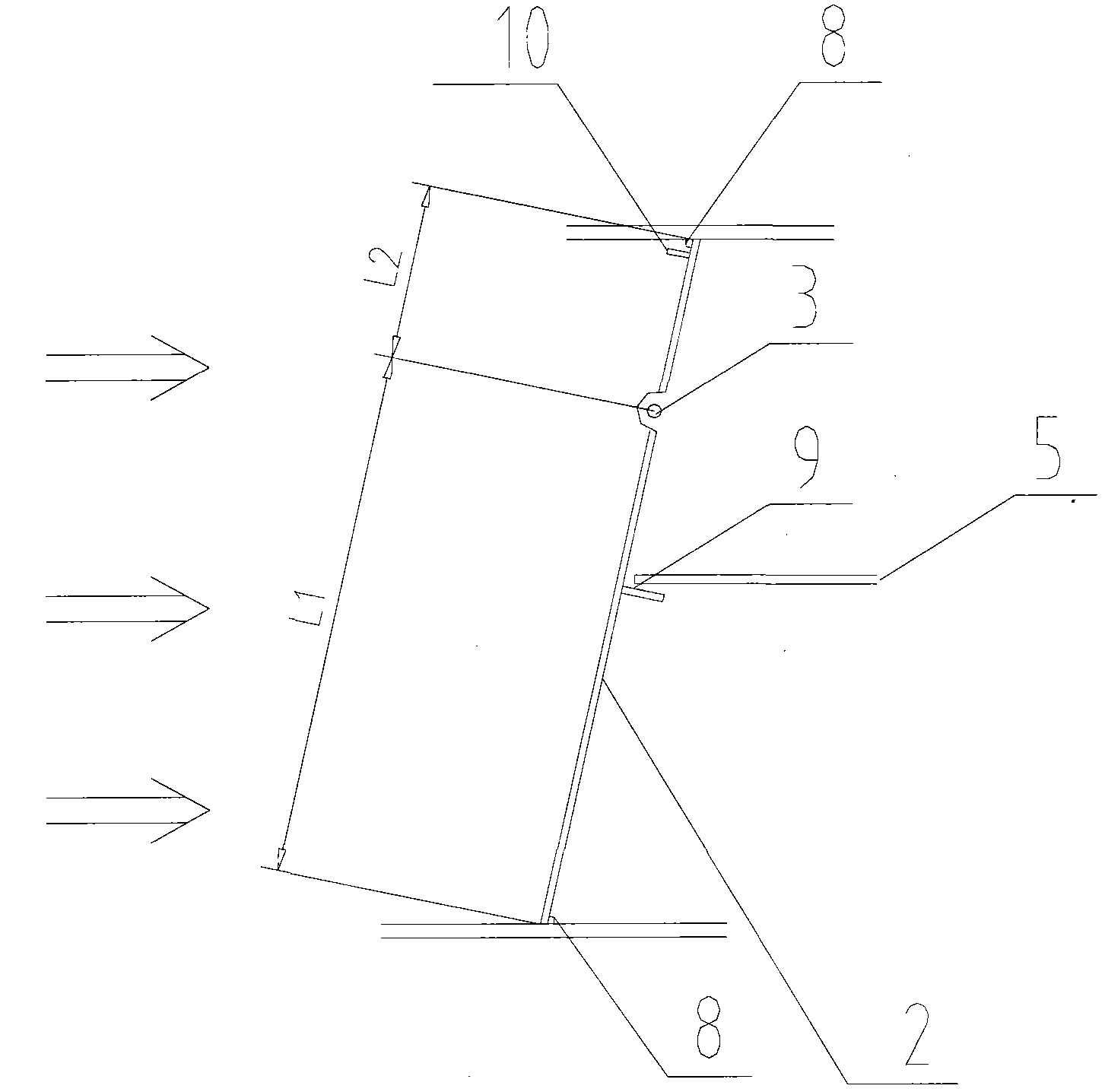

Chain boiler plant for burning multi-biomass fuels

InactiveCN101363618AEvenly loadedStrong seasonalitySolid fuel combustionNon-combustible gases/liquids supplyAir volumeBoiler plant

A chain-grate boiler device for burning a plurality of biomass fuels relates to a chain-grate boiler device. The chain-grate boiler solves the problems of unstable chain-grate boiler load and being difficult in adjusting the boiler load when the existing chain-grate boilers burn biomass. In the device, a biomass nozzle device (8) on an arch is obliquely arranged on a front arch (7) and is communicated with a hearth (3), a secondary air nozzle (10) on the arch is positioned at the slanting upper part of the biomass nozzle device (8) on the arch, the secondary air nozzle (10) on the arch is arranged on the front arch (7) and is communicated with the hearth (3), and the secondary air nozzle (10) on the arch is provided with an airflow regulating valve (16). The chain-grate boiler device adopts a combined feeding device composed of a biomass blanking hopper, the biomass nozzle device on the arch and the secondary air nozzle on the arch, thus causing the load of the chain-grate boiler for burning the biomass fuels to be stable and being convenient for adjusting the boiler load.

Owner:HARBIN INST OF TECH

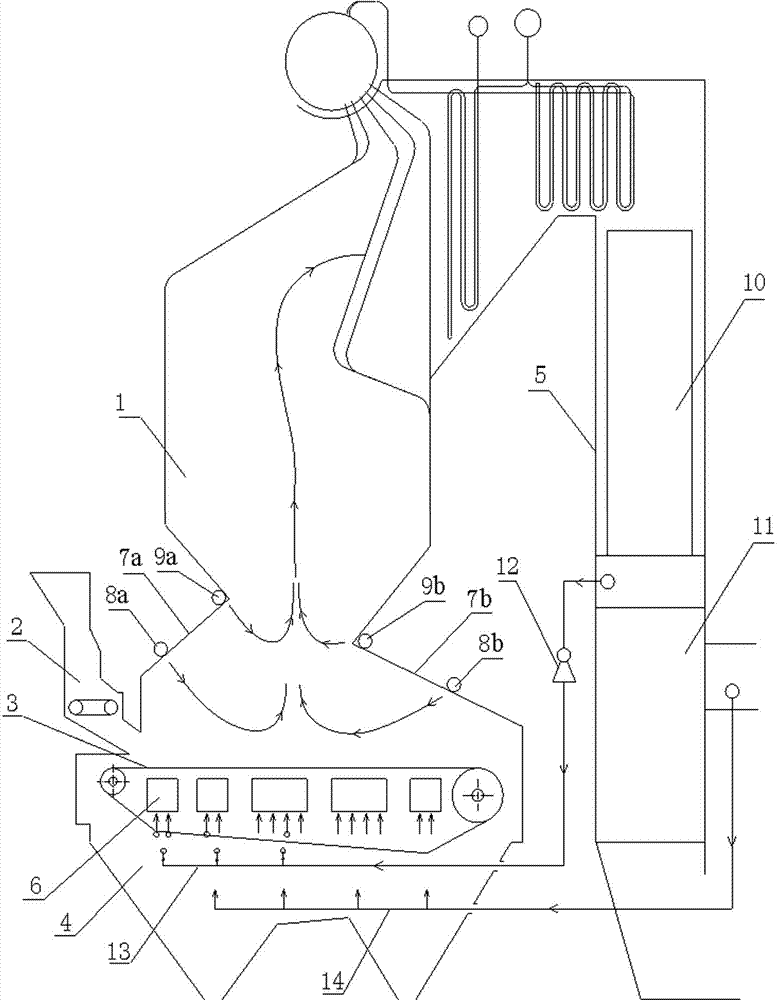

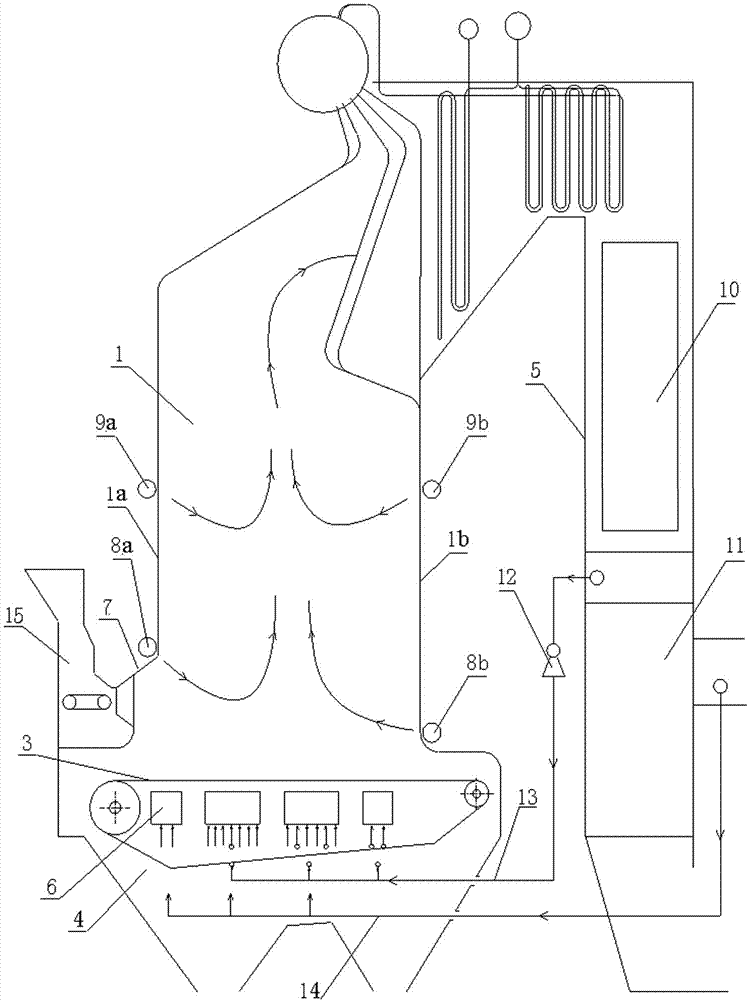

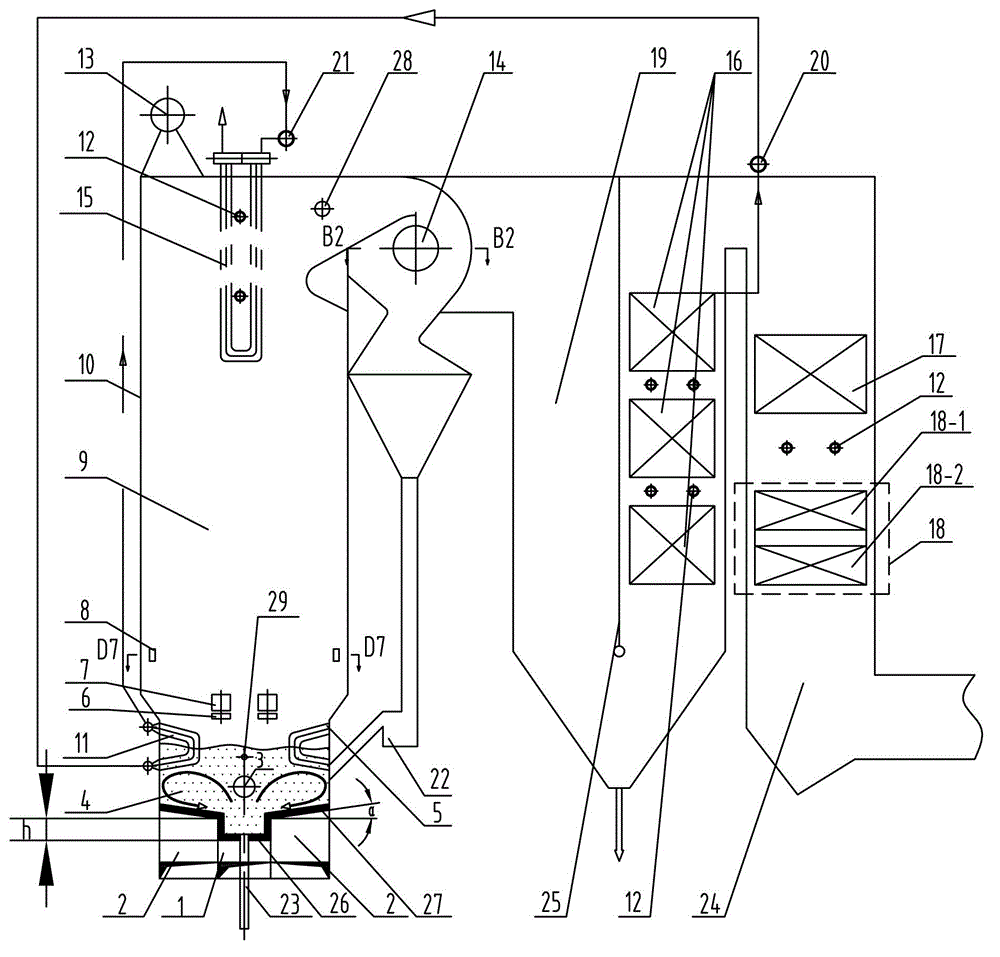

Coupling staged combustion and smoke recirculation low NOx chain grate furnace

ActiveCN104748104APromote fireStable combustion is goodSolid fuel combustionIndirect carbon-dioxide mitigationThermodynamicsSlag

The invention discloses a coupling staged combustion and smoke recirculation low NOx chain grate furnace. The chain grate furnace is composed of a hearth, a coal feeder, a chain grate stoker, a slag hopper and a tail flue. The hearth is divided into an upper hearth part and a lower hearth part through a front furnace arch and a rear furnace arch. Secondary air and over fire air are arranged in a suspension combustion area of the lower hearth body to organize staged combustion in the suspension combustion area, the secondary air of the lower hearth body is fed through secondary air spraying ports in the lower areas of the front furnace arch and the rear furnace arch, the over fire air is fed through over fire air spraying ports in the intersection of the upper hearth body and the lower hearth body, primary air is fed in a segmented mode below the stoker so as to organize the staged combustion of a stocker combustion area, low-temperature furnace smoke is extracted from the tail flue to be fed to the bottom of the stoker through a recirculation draught fan to perform recirculation, coal particles in the furnace are in the state far away from the stoichiometric ratio combustion state for a long time through two-layer staged combustion of the stocker combustion area and the suspension combustion area and smoke recirculation of the stoker combustion area, and efficient and low NOx combustion of the chain grate furnace is achieved.

Owner:江苏朗润环保科技有限公司

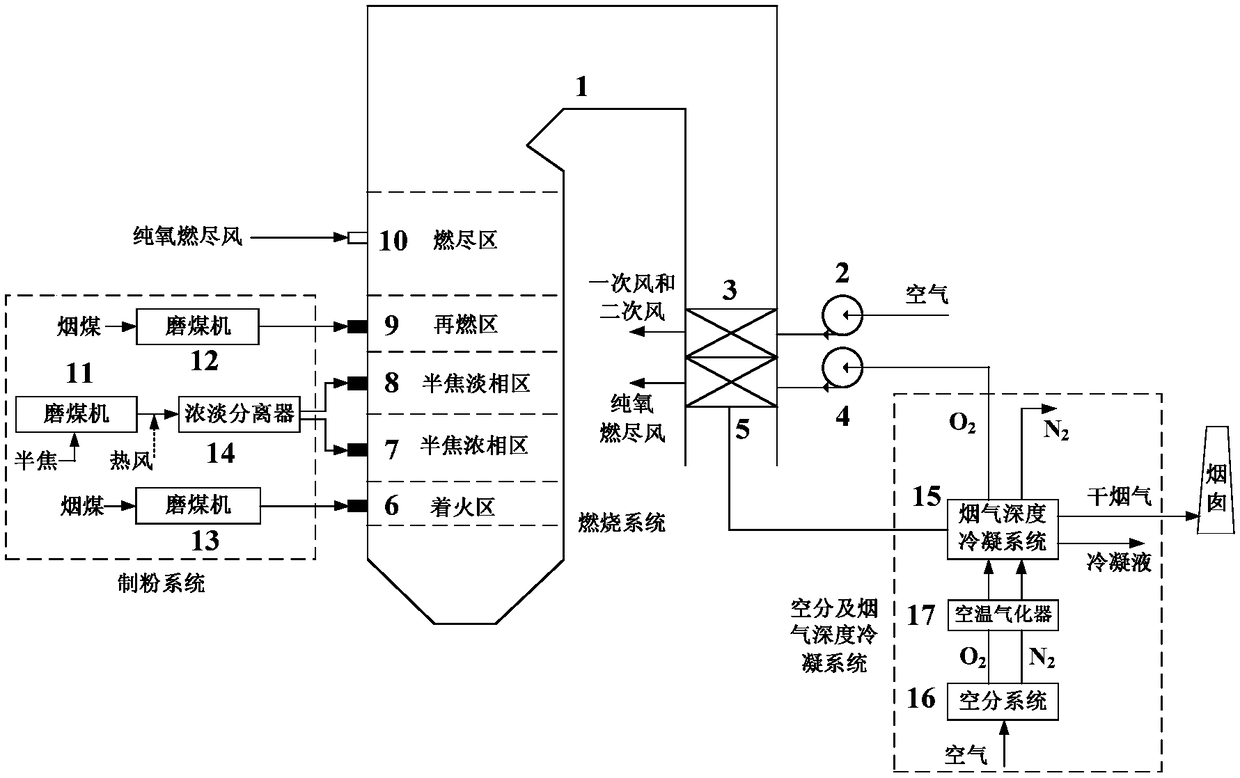

System and blending combustion method for coal-fired power station boiler for large-proportion blending combustion of semi-coke

ActiveCN108151051APromote fireImprove combustion characteristicsLump/pulverulent fuel feeder/distributionLump/pulverulent fuel preparationFlue gasEngineering

The invention relates to a system and a blending combustion method for a coal-fired power station boiler for large-proportion blending combustion of semi-coke. According to the system and the blendingcombustion method, the problems that the low-volatile semi-coke fuel is difficult to fire, poor in burnout performance and high in NOx emission during combustion are solved; optimization of a pulverizing system, dense-dilute regional combustion of semi-coke fuel, in-furnace layered blending combustion of the semi-coke and bituminous coal, pure oxygen over fire air arrangement and cold energy comprehensive utilization are comprehensively considered; a four-corner tangential combustion mode is adopted, a boiler hearth five-zone combustion environment is built, and a power station boiler systemfor large-proportion blending combustion of the semi-coke is developed, so that the proportion of blending combustion of the semi-coke is larger than or equal to 45%; low NOx emission of an outlet ofa hearth is realized while high-efficiency combustion of the semi-coke is realized; and low-temperature O2 and low-temperature N2 which are close to 0 DEG C and are obtained by air separation and obtained through an air-temperature type gasifier are used for realizing deep condensation of desulfurized clean flue gas, so that water in the clean flue gas is reduced to the maximum degree, corrosion of a chimney is reduced, white smoke is also eliminated, and visual pollution around a power station is reduced.

Owner:XI AN JIAOTONG UNIV

Method for reducing nitrogen oxide of powder coal boiler mixed burning gas fuel

InactiveCN101050853AGuaranteed combustion efficiencyEmission reductionCombustion using gaseous and pulverulent fuelBurnersOxygenMixed gas

A method for decreasing nitrogen oxide of mixed gas fuel used on pulverized-coal boiler includes dividing gas fuel to be two grades then leading them into pulverized-coal furnace tank, leading in primary gas fuel as combustion-assistant fuel at bottom of master burner at master combustion region to burn it by utilizing gradation air-combustion technique with low air overdose parameter, leading in secondary gas fuel at top of master combustion region to form reducing atmosphere of re-combustion region and leading in burn out air at top of re-combustion region.

Owner:HARBIN INST OF TECH

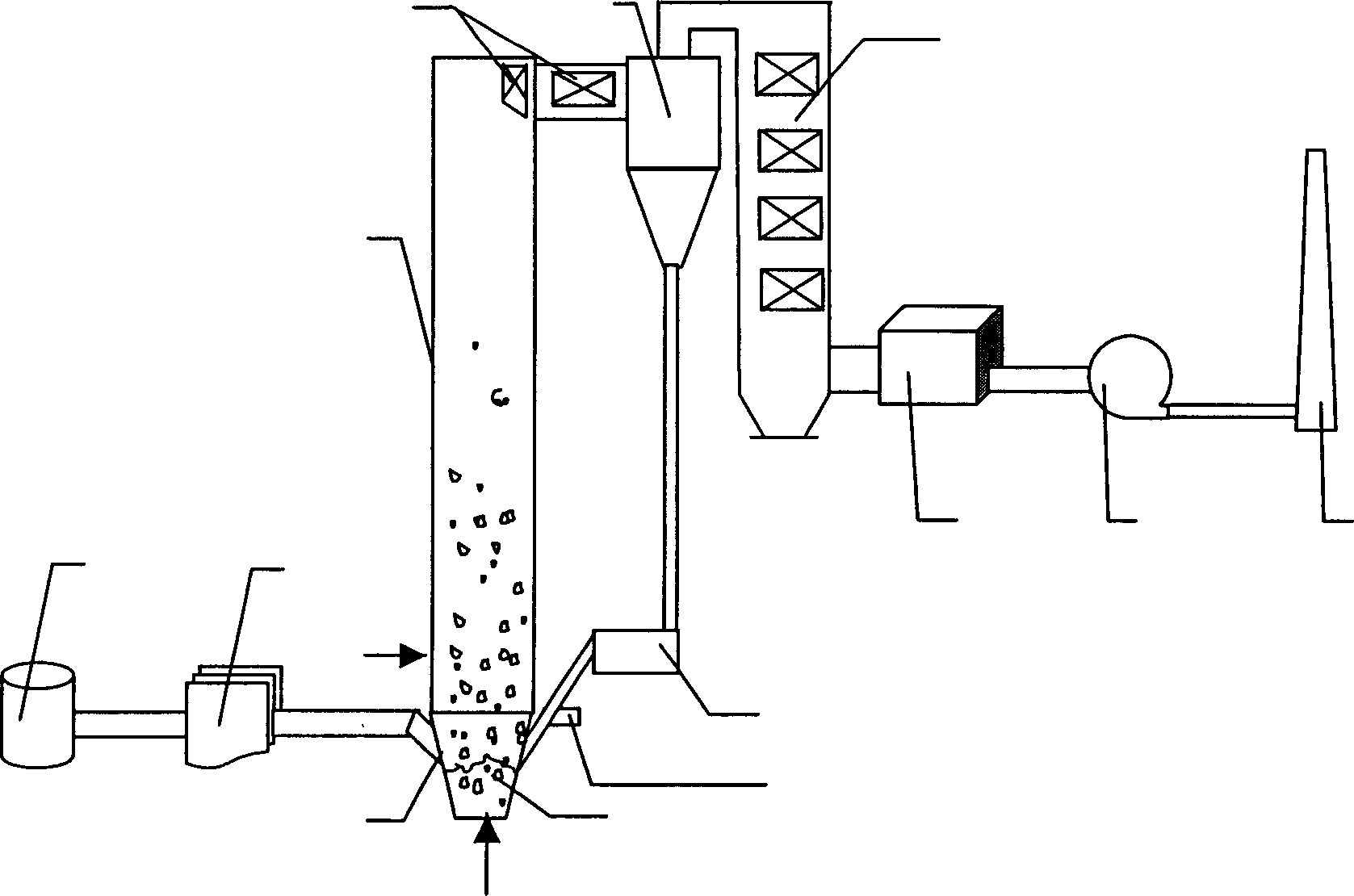

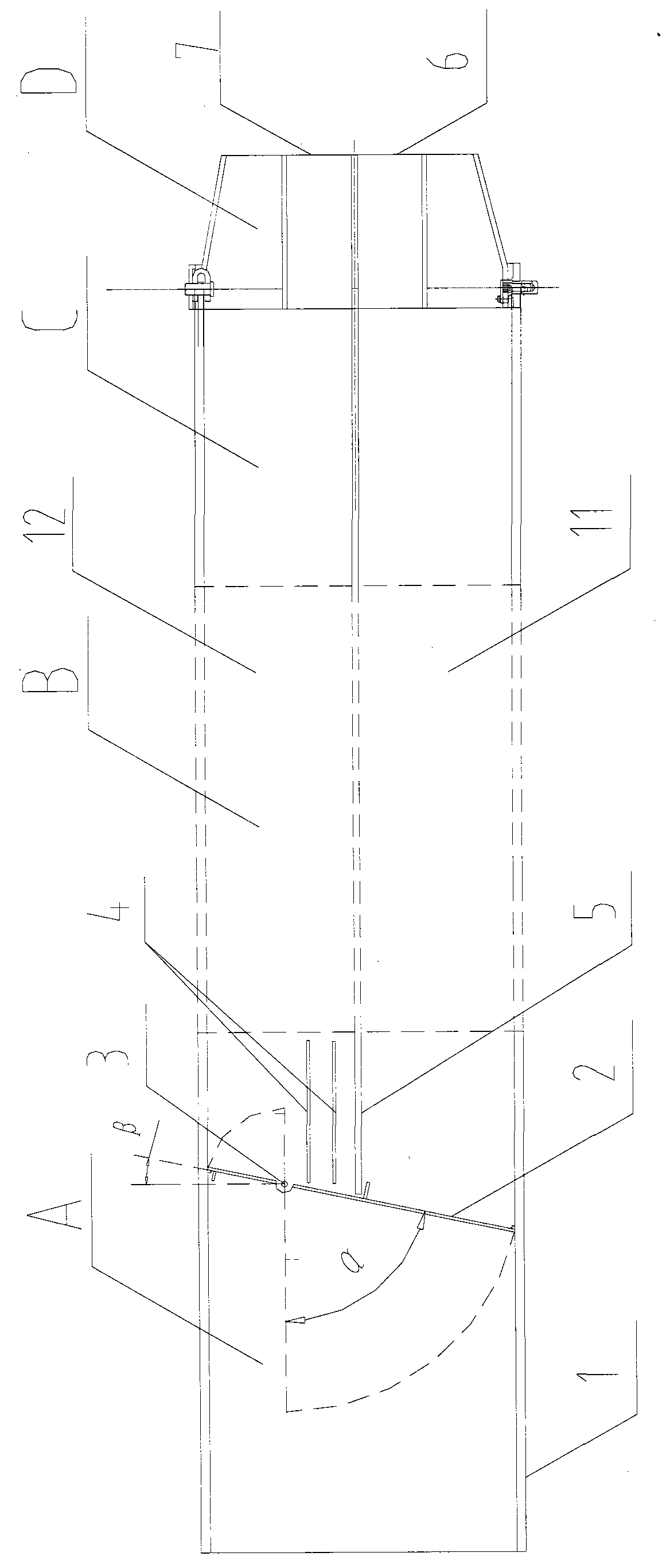

Circulating fluidized bed combustion device with biomass fuel and combustion method thereof

ActiveCN1804460AGuaranteed combustion spaceReduced risk of increased incomplete combustion lossesFluidized bed combustionIncinerator apparatusBiological materialsBiomass burning

The invention relates to a cycle fluid bed burning device and relative method which uses biological material as fuel. Said device comprises a furnace, a furnace outlet and a horizontal gas flue. Wherein, the horizontal gas flue has a heated surface, a cyclone separator with middle temperature connected with its back; the upper end of cyclone separator is connected to the tail gas flue, the dust cleaner, the wind guide device, and the chimney; the lower end of cyclone separator is connected to the cycle circuit and the furnace dense-phase area; the circle circuit is connected with bed material and additive feeding inlet to apply the additive which can solve the problem of alkali metal; the biological fuel via the parallel feeding inlets at the front of furnace, the breaking pretreatment is blown by the wind into the section-variable dense-phase area of furnace; and the straw should be first broken into 10cm. The invention has wider raw material and high burning efficiency while it can solve the problem of alkali metal.

Owner:ZHEJIANG UNIV +1

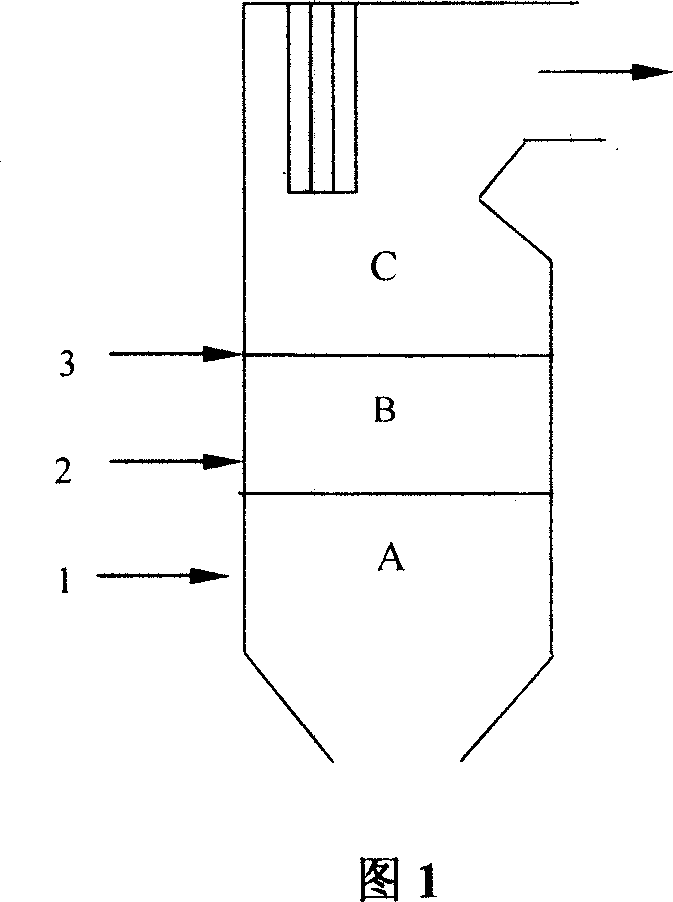

Firing system gradient combustion self-denitration technological method

ActiveCN108167860ALower concentration levelsGood for burnoutFuel supply regulationIndirect carbon-dioxide mitigationFlue gasEngineering

The invention relates to a firing system gradient combustion self-denitration technological method, and belongs to the technical field of cement industry flue gas denitration. According to the firingsystem gradient combustion self-denitration technological method, a gradient combustion environment with an extreme oxygen deficient area-oxygen deficient combustion area-oxygen enrichment burnout area is formed in a decomposing furnace; the gradient combustion environment is realized through classified feeding of decomposing furnace inlet fuel, tertiary air and decomposing furnace inlet materials; a furnace inlet tertiary air hose is divided into an upper branched pipe and a lower branched pipe, the tertiary air lower branched pipe is fed in from the lower portion of a decomposing furnace cylinder, and the upper branched pipe is fed in from the middle of the decomposing furnace cylinder; the decomposing furnace inlet fuel is divided into two layers and is further fed into the furnace, thelower layer of the fuel is fed in from a decomposing furnace cone, and the upper layer of the fuel is fed in from the decomposing furnace cylinder; the extreme oxygen deficient area refers to the decomposing furnace area located below the tertiary air lower branched pipe; the oxygen deficient combustion area refers to the area located between the tertiary air upper branched pipe and the tertiaryair lower branched pipe; and the oxygen enrichment burnout area refers to the decomposing furnace area located above the tertiary air upper branched pipe. The firing system gradient combustion self-denitration technological method has the advantages that the process is optimized, reliability is good and the flow path is reasonable.

Owner:TIANJIN CEMENT IND DESIGN & RES INST

Low-ratio biomass circulating fluidized bed with cooling chamber and pollutant control method thereof

ActiveCN102913900AReduce wearReduce dust accumulationFluidized bed combustionDispersed particle separationSuperheaterCirculating fluidized bed boiler

The invention relates to a low-ratio biomass circulating fluidized bed with a cooling chamber and a pollutant control method thereof and solves the problem that existing grate-fired furnaces and circulating fluidized beds cause grate slag bonding and bed material coking in biomass combustion and especially causes soot formation and high-temperature corrosion in combustion of low ash fusion point biomass. A smoke cooling chamber is disposed behind a cyclone separator and used to lower smoke temperature from 800 DEG C to within 650 DEG C, so that soot formation and corrosion of a superheater are relieved greatly. By in-furnace denitration and limestone desulfuration, denitration efficiency can reach 50-70% when mole ratio of NH3 to NOX is 1.0-1.1, denitration efficiency can reach 70-80% when mole ratio of Ca to S is 2.0-2.5, and emission concentration of SO2 and NOx can be effectively controlled within 100mg / m<3>. The low-ratio biomass circulating fluidized bed with the cooling chamber and the pollutant control method thereof are used to control biomass combustion and pollutants.

Owner:HARBIN INST OF TECH

Coal composite sulfur fixing agent

The invention relates to a coal composite sulfur fixing agent, belonging to the technical field of boiler combustion desulphurization. The composite sulfur fixing agent is made of the following raw materials in parts by weight: 40-70 parts of CaO, 5-10 parts of SiO2, 5-15 parts of Al2O3, 3-5 parts of Fe2O3, 0.5-1 parts of BaS, 0.5-1 parts of BaCO3, 0.1-1.5 parts of Zn, 0.02-0.05 parts of Cu, 0.05-0.1 parts of As, 0.01-0.05 parts of Pb, 1-5 parts of CaF2, 0.05-0.2 parts of MgO, 0.5-1.0 parts of TiO2, 0.5-1.0 parts of K2O, 0.1-1.0 parts of Na2O and 0.04-0.06 parts of Ag. The coal composite sulfur fixing agent of the invention can reduce the emission of SO2, the atmospheric pollution and the formation conditions for acid rain. Since pulverized fuel ash and coal cinder are converted to modified ash and can be used in cement production technology, the clinker production of common cement can be reduced generally, the mine resources and the energy consumed during cement production are reduced, and the emission of CO2 is reduced.

Owner:河南中上环保科技有限公司

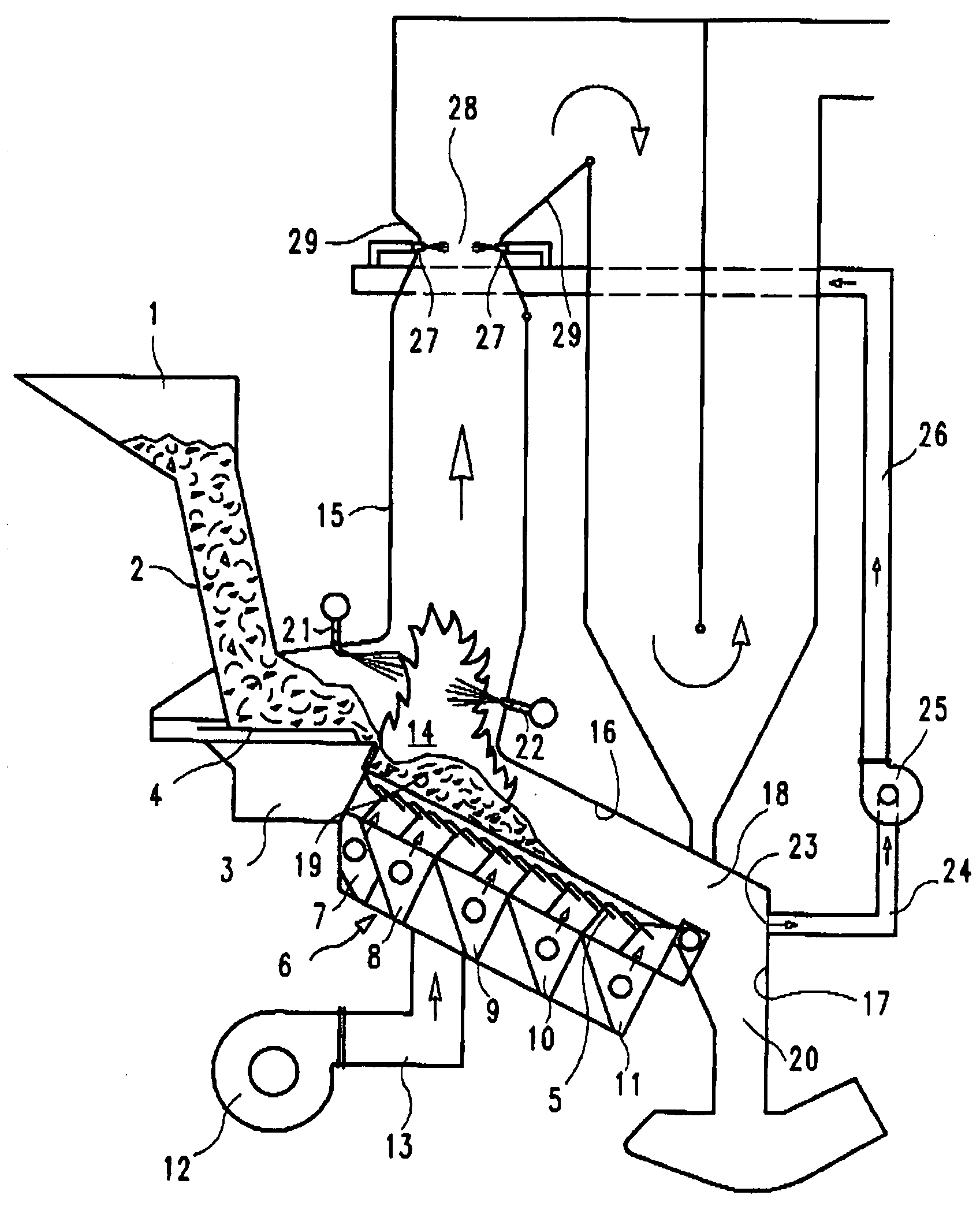

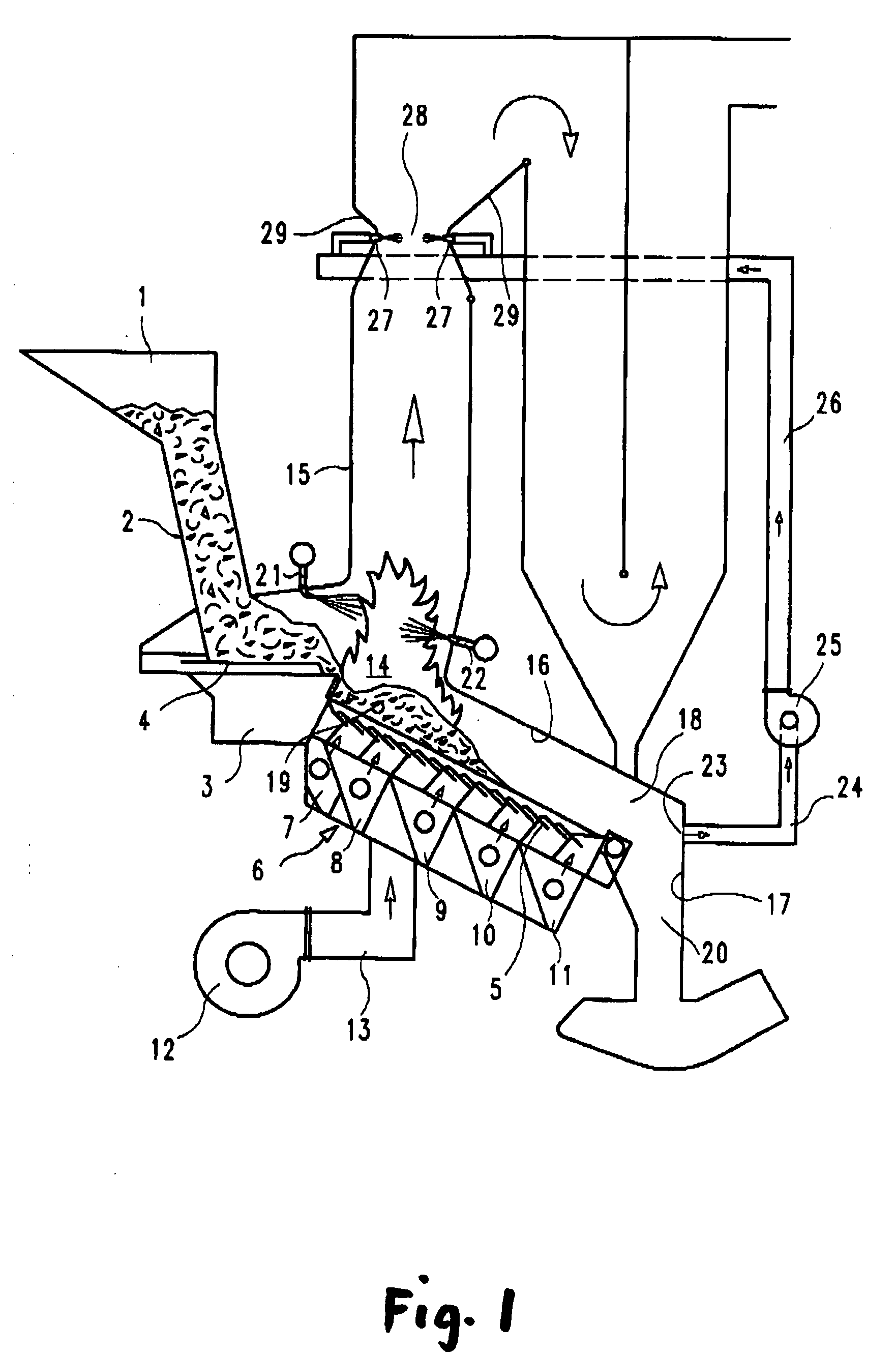

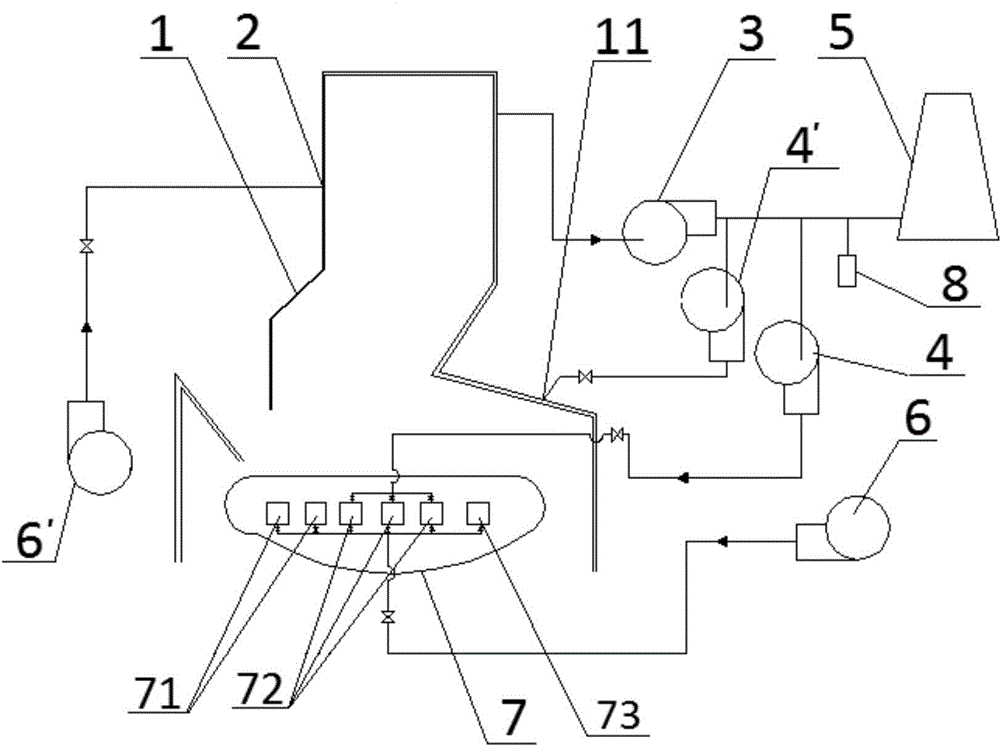

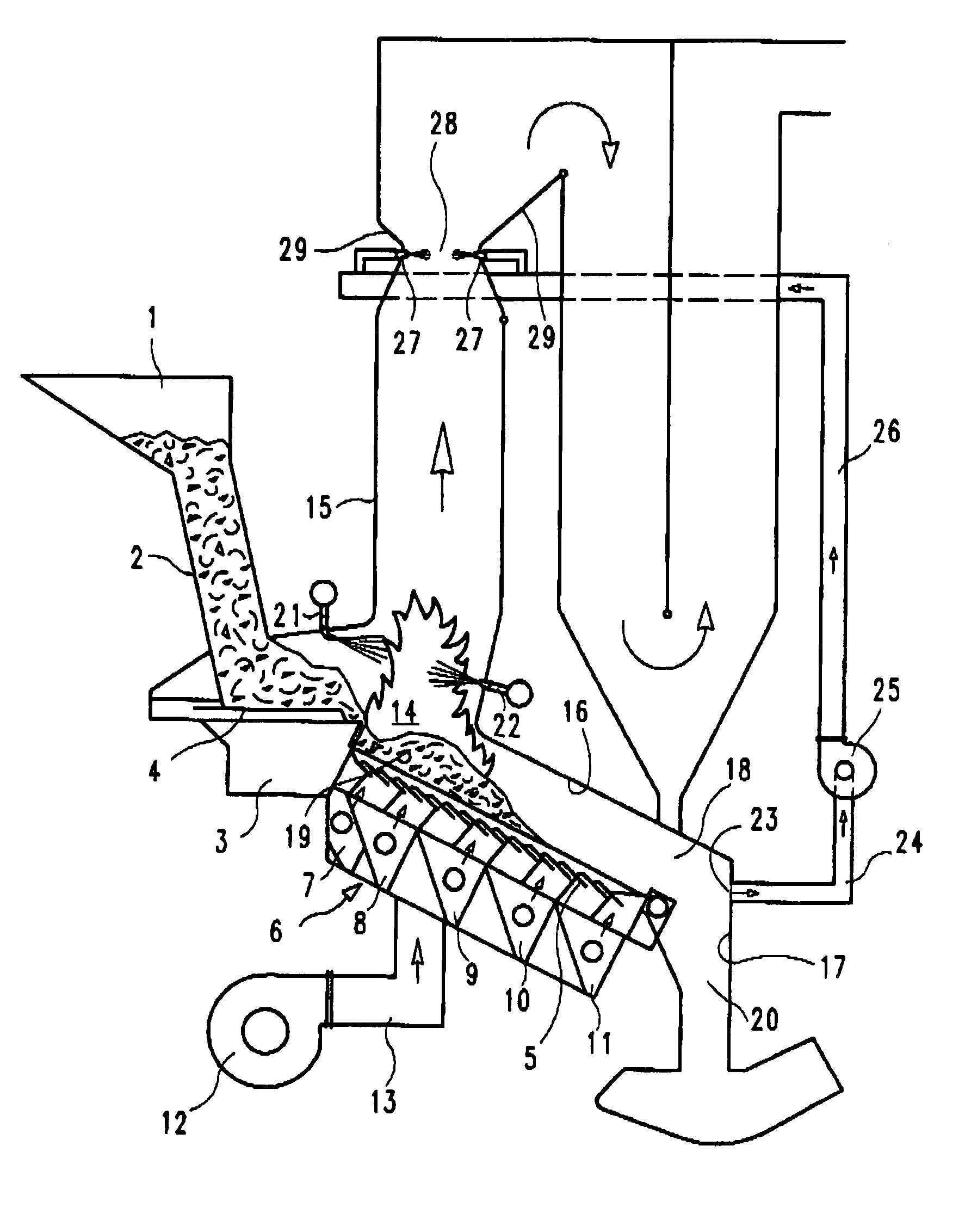

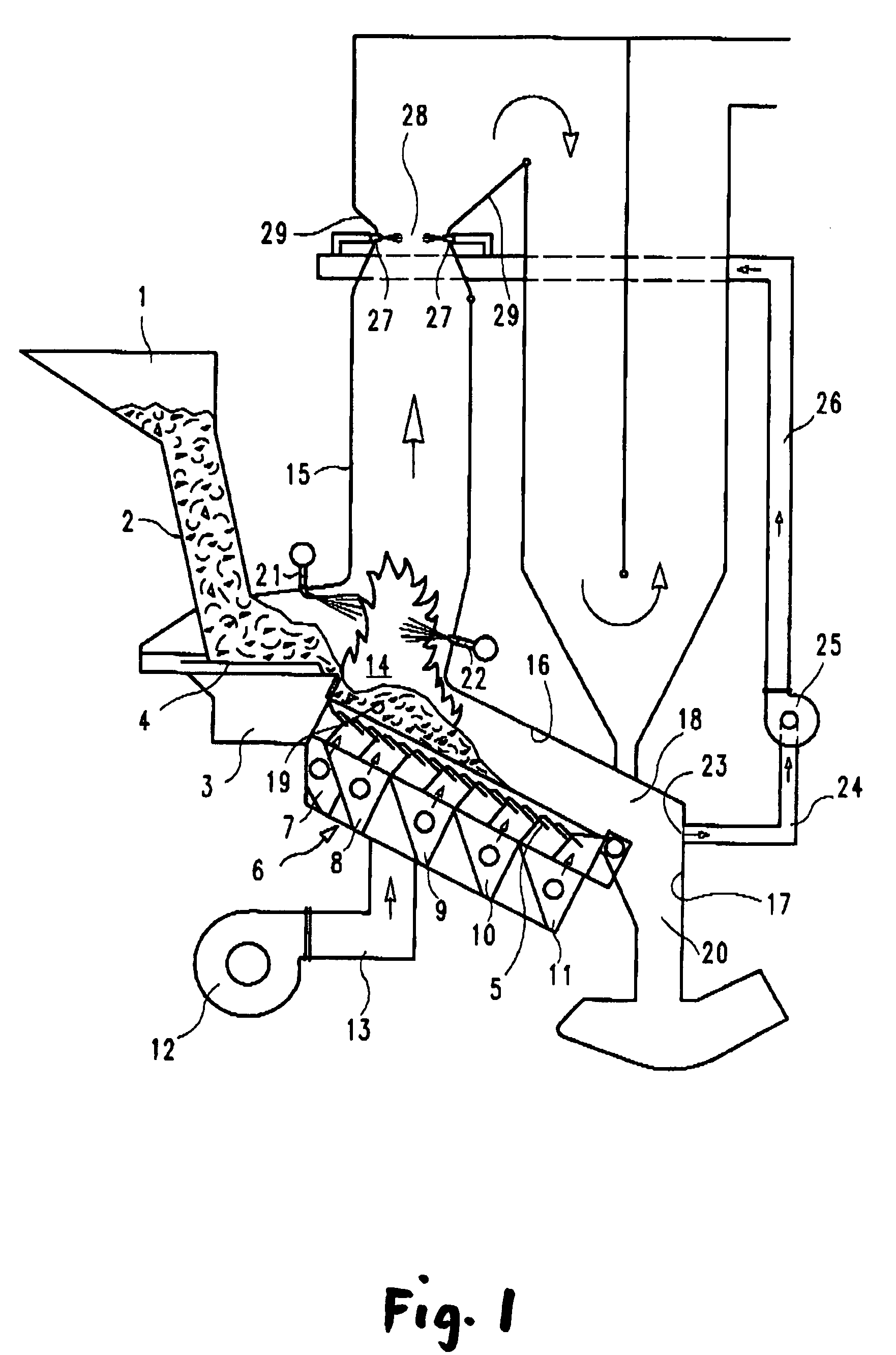

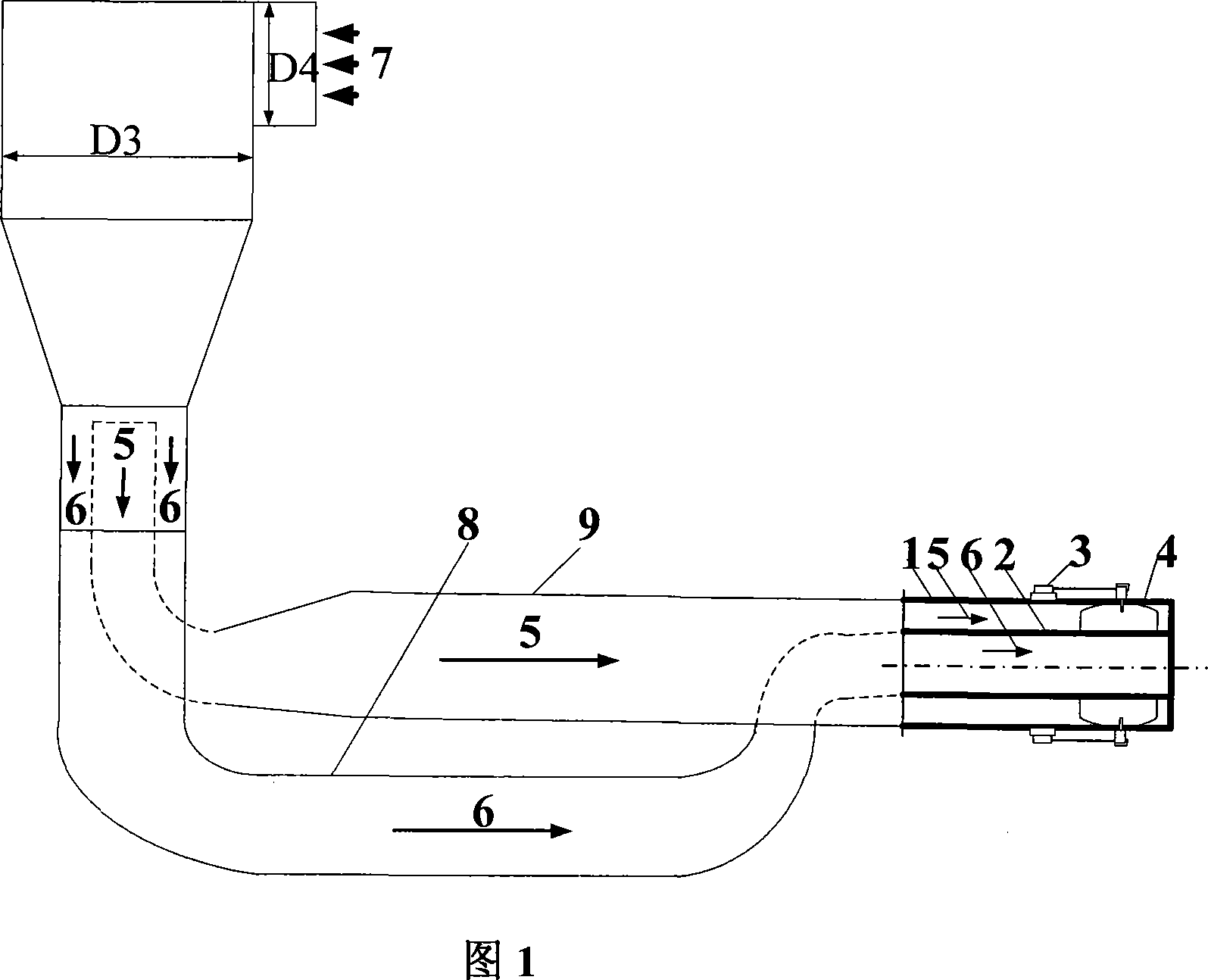

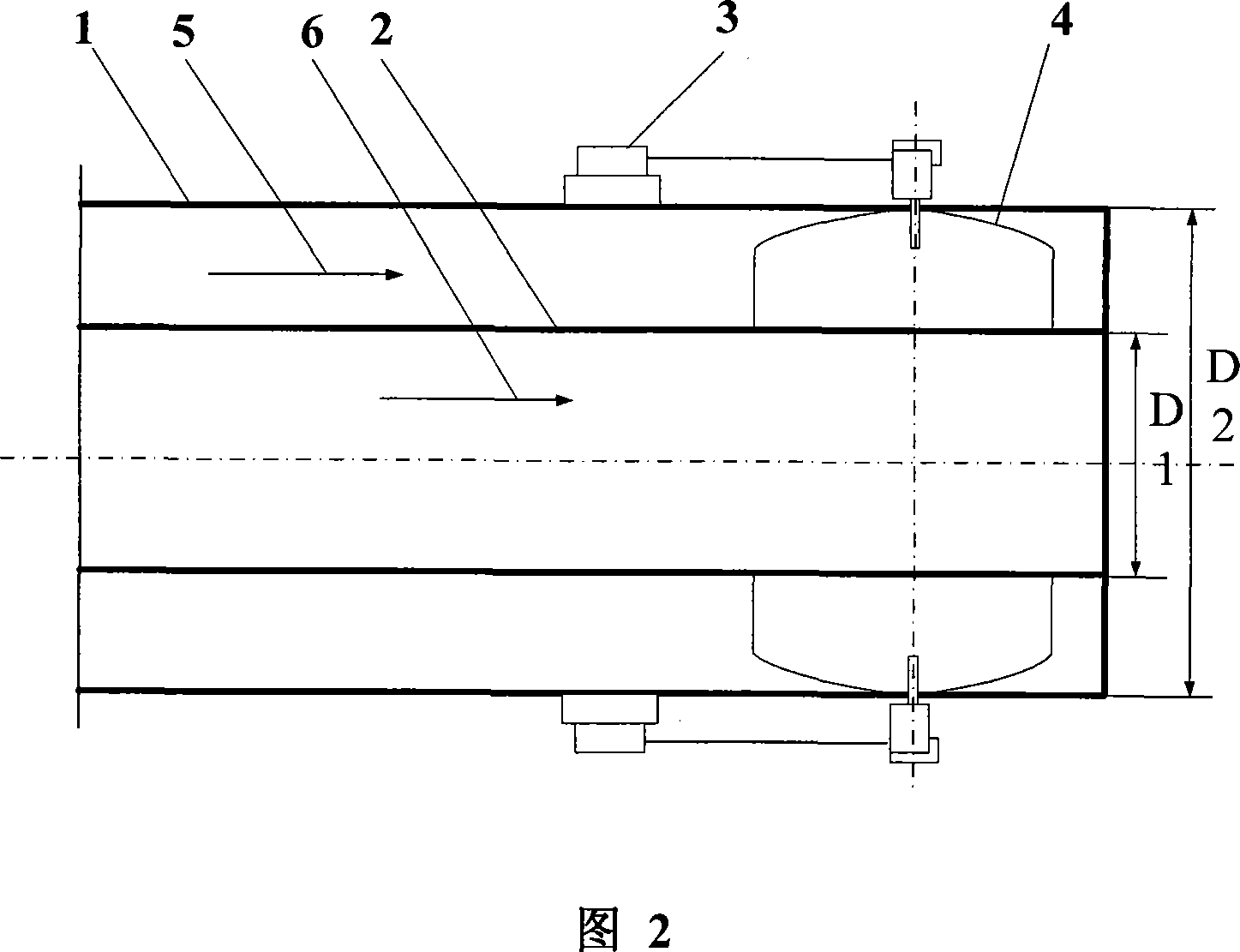

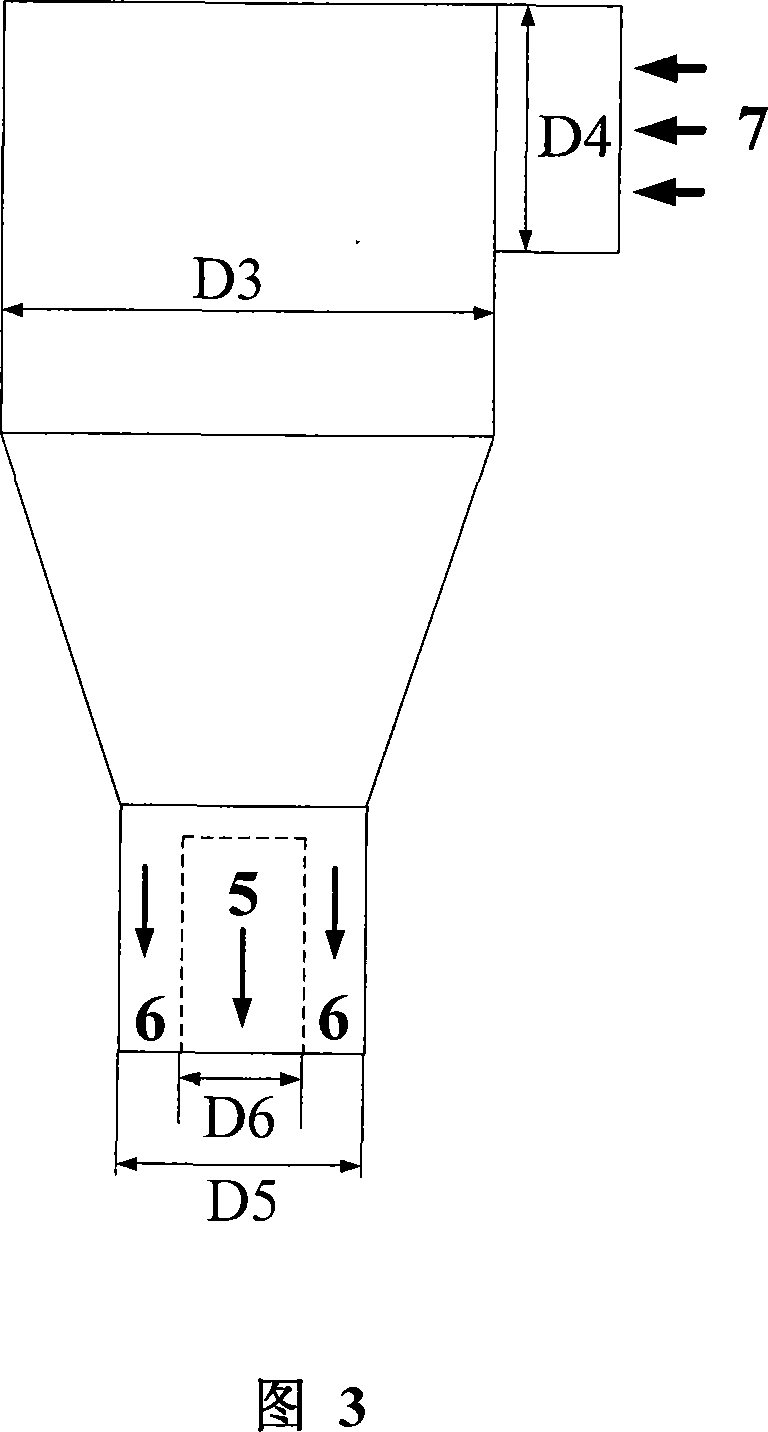

Method for supplying combustion gas in incineration systems

ActiveUS20080063992A1High impulseImprove the mixing effectSolid fuel combustionIndirect carbon-dioxide mitigationCombustion systemCombustion

The combustion system for implementing the process has a combustion grate, hoppers below the combustion grate for supplying primary combustion gas through the grate and nozzles that lead into the furnace above the combustion grate to supply secondary combustion gas. At least one extraction duct for flue gas is provided at the rear end of the furnace above the combustion grate. This duct is connected to the suction side of a fan. The pressure side is connected to nozzles arranged in the upper area of the flue gas pass. The nozzle height allows the flue gases a residence time of at least 1 second after secondary gas is supplied.

Owner:MARTIN GMBH FUR UMWELT UND ENERGIETECHNIK

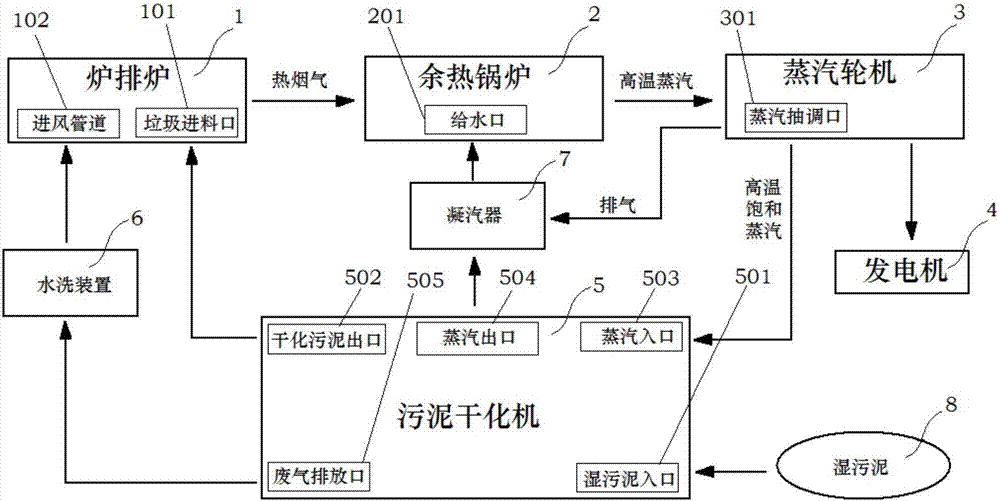

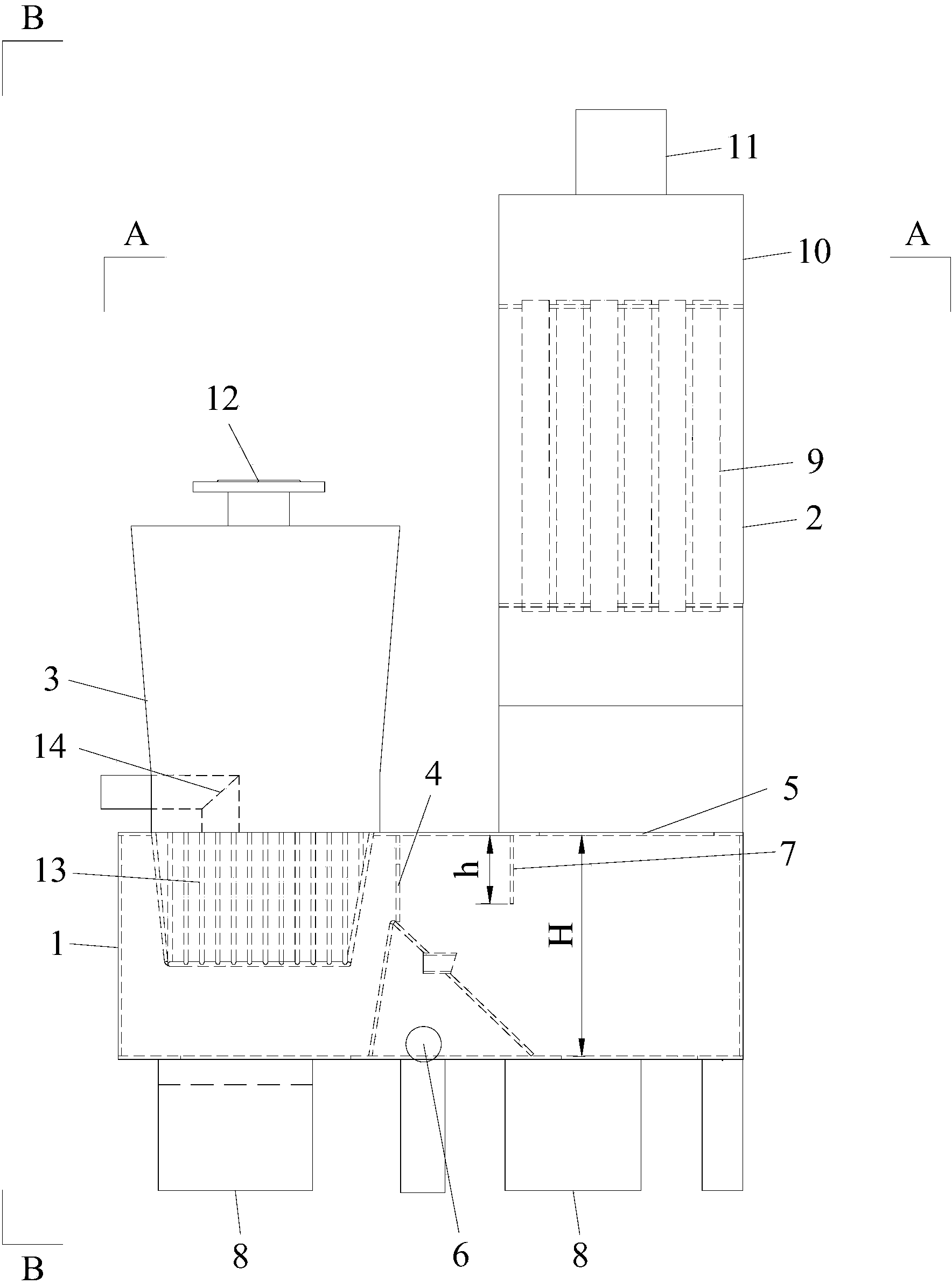

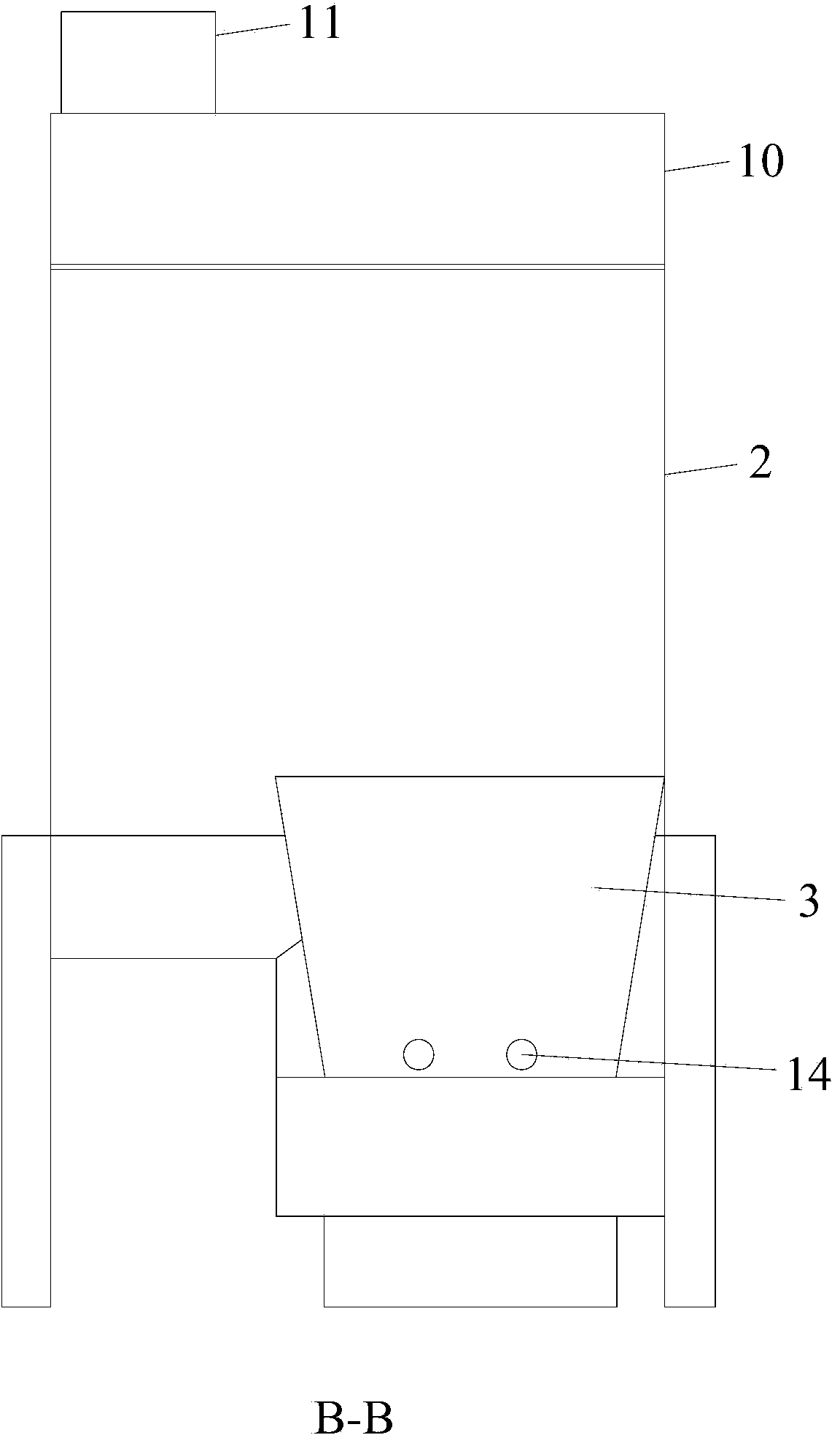

Method and system for cooperatively treating sludge through grate furnace waste incineration

PendingCN107013928AEasy to handleTechnically feasibleSludge treatment by de-watering/drying/thickeningIncinerator apparatusSludgeProcess engineering

The invention discloses a method and system for cooperatively treating sludge through grate furnace waste incineration, and belongs to the field of sludge treatment. Steam generated by grate furnace waste incineration is firstly utilized for carrying out indirect heat exchange drying on the sludge, and then the sludge dried to a certain degree and in-furnace waste are mixed and incinerated in a grate furnace according to a certain proportion. According to the method and system, the existing and mature grate furnace waste incineration technology is utilized for achieving effective drying and cooperative incineration on the sludge, the sludge independent drying cost and the building and operating cost of an incineration treatment project can be greatly reduced, and harmlessness, reduction and recycling of sludge treatment are achieved.

Owner:CHONGQING SANFENG COVANTA ENVIRONMENTAL IND

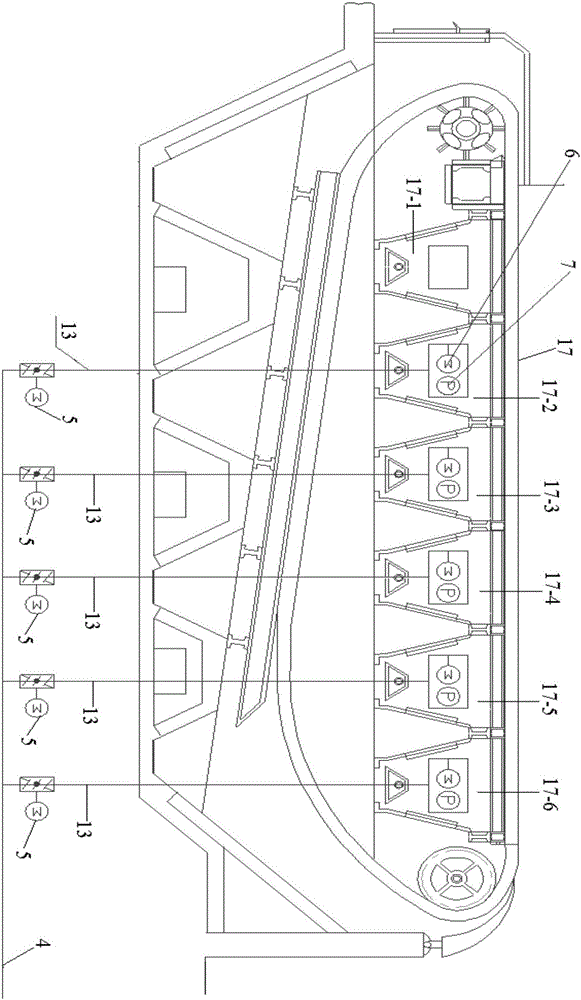

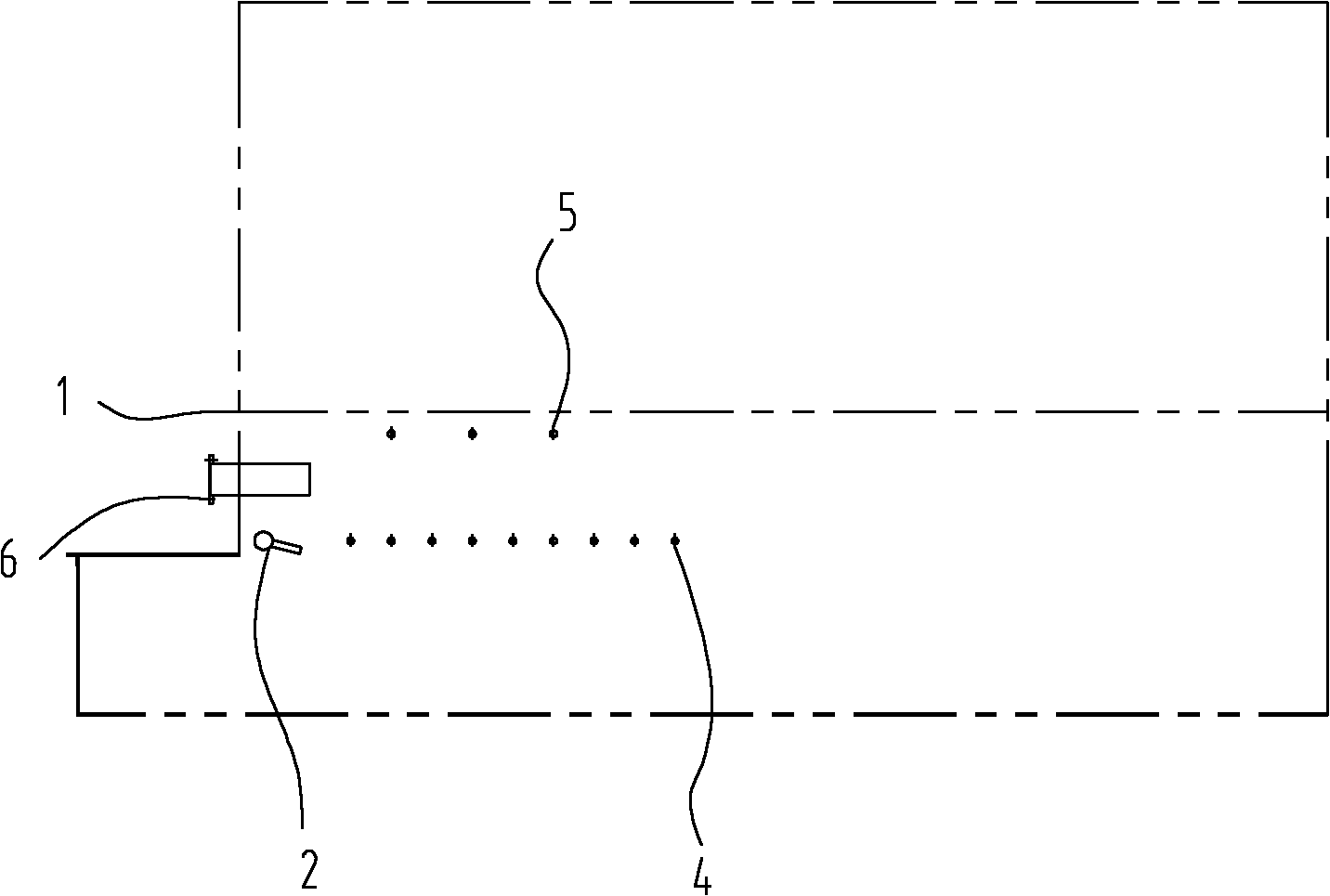

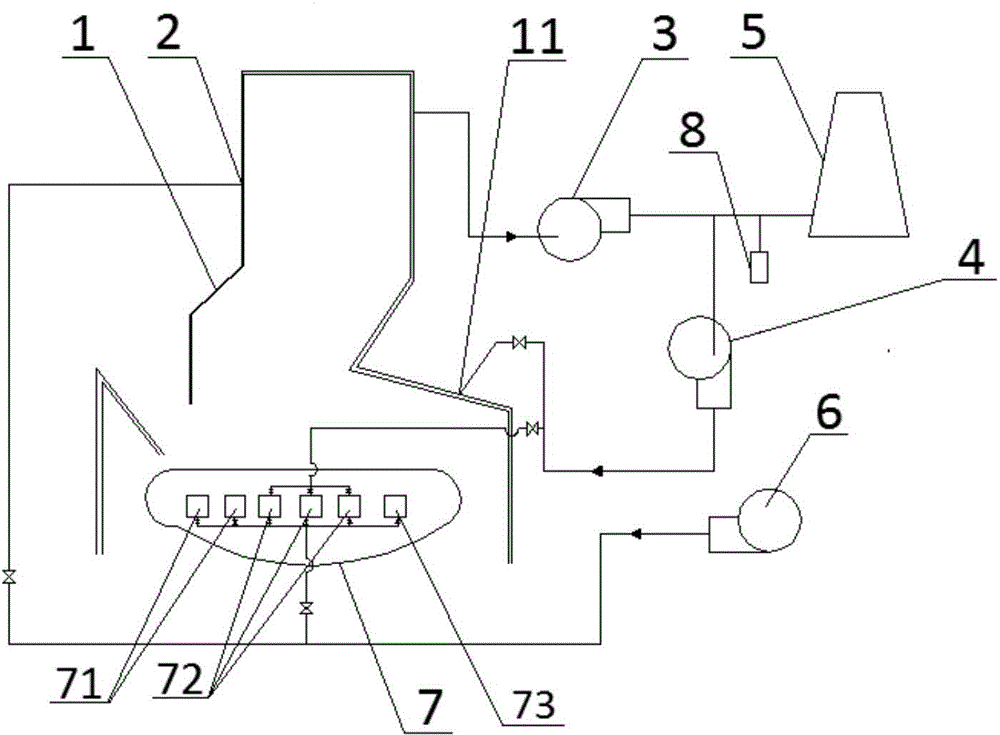

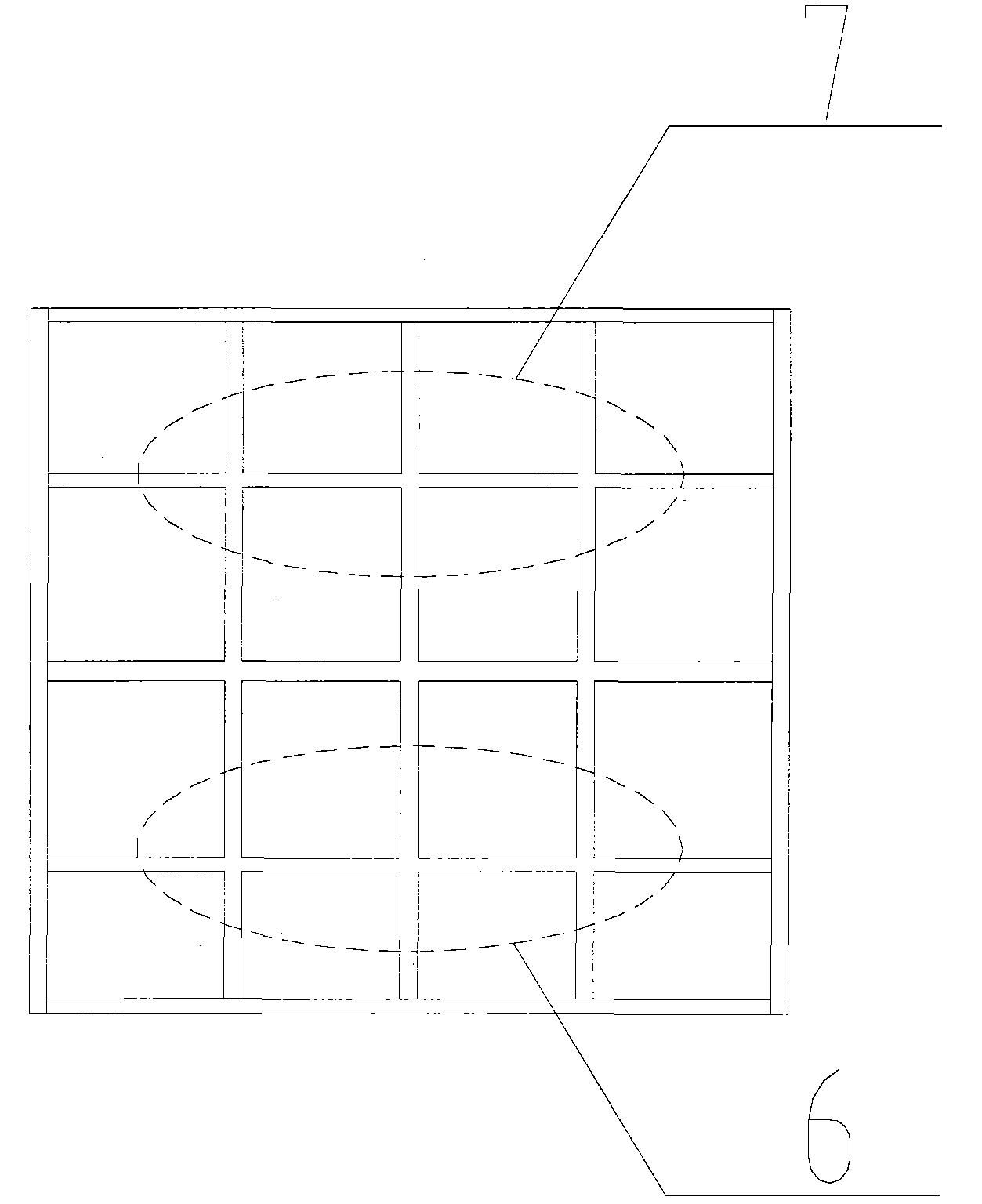

Independent partitioned grate firing flue gas circulation combustion system and use method thereof

ActiveCN106594710ARealize the reduction reactionAchieve burnoutSolid fuel combustionAir/fuel supply for combustionCombustion systemLow nitrogen

The invention provides an independent partitioned gate firing flue gas circulation combustion system and a use method of the independent partitioned gate firing flue gas circulation combustion system and relates to a low-nitrogen combustion system and a use method of the low-nitrogen combustion system. The independent partitioned gate firing flue gas circulation combustion system aims at solving the technical problem of generating a large amount of NOx in the combustion process of an existing gate firing boiler. The system is composed of a recirculation induced draft fan, branch pipeline electric regulating valves, a flue gas communication pipeline from a rear arch to the back wall of a boiler, a communication pipeline regulating valve and a partitioned arch. An inlet of the recirculation induced draft fan communicates with an outlet of a gate firing boiler induced draft fan. An outlet of the recirculation induced draft fan communicates with fire grate air chambers. Each recirculation branch pipeline is provided with the electric regulating valve. The flue gas communication pipeline which is on the rear arch of a hearth and is guided out of the rear arch of the hearth to the back wall of the boiler is provided with the regulating valve. The partitioned arch is arranged below the rear arch of the hearth. The use method of the system includes the steps that firstly, the total amount of recirculation flue gas is controlled; secondly, the recirculation flue gas amount in all the air chambers is controlled; and thirdly, the communication pipeline regulating valve is controlled. The independent partitioned gate firing flue gas circulation combustion system and the use method have the following beneficial effect that the nitrogen reduction efficiency ranges from 25% to 27%.

Owner:HARBIN INST OF TECH

Air distribution system of biomass moulding fuel boiler

InactiveCN102012038APromote combustionBurn fullyBlast-producing apparatusAir volumeDistribution system

The invention discloses an air distribution system of a biomass moulding fuel boiler, comprising a stokehole air pipe arranged on the front wall of the boiler, a bottom air pipe arranged on the side wall of the boiler, and a cyclone air pipe arranged above the bottom air pipe. In the invention, the stokehole air pipe is additionally arranged to ensure that biomass moulding fuel entering the boiler from a feed port of the boiler is rapidly dried and subjected to volatile matter separation so as to further burn rapidly; the biomass moulding fuel sufficiently burns under the condition of air compensation by the bottom air pipe at the side wall of the boiler; and the cyclone air pipe arranged above the bottom air pipe ensures the BMF (Biomass Moulding Fuel) to further burn sufficiently on one hand and ensures that powdery ash residues fall on a fire grate under the cyclone action so as to reduce the content of the powdery ash residues entering a radiation area along with high-temperature gas fume.

Owner:GUANGZHOU DEVOTION THERMAL TECH

Method for burning of low nitrogen oxides in coal-burning boiler

InactiveCN101016986ARapid responseAchieve the purpose of burningSolid fuel combustionCombustion apparatusSlagLow nitrogen

A method used to burn low-nitrogen oxide in coal boiler, which can form stable reduction gas, comprises that 1, burning general coal in main burning area via horizontal wind technique, 2, using fine coal powder as burning fuel to burn via dense-dilute burning technique to form a reburning area with reduction gas and the smoke in the nitrogen oxide of main burning area is reduced when passes reburning area, 3, injecting burnt air above the reburning area to form a burnt area, while the not burnt product is burnt in the burnt area. The invention can reduce 50-65% of nitrogen oxide discharge, to reduce high temperature corrosion and slag.

Owner:HARBIN INST OF TECH

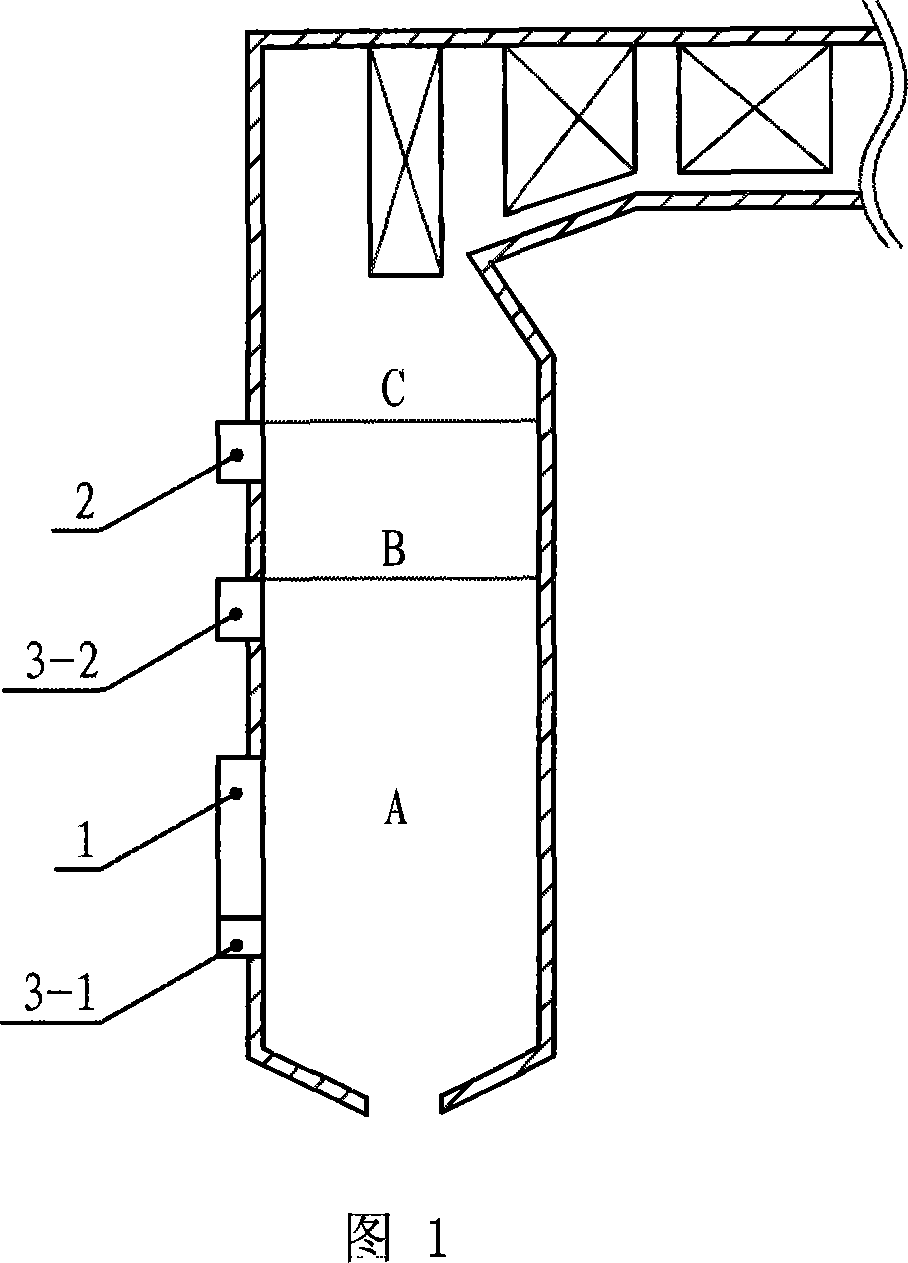

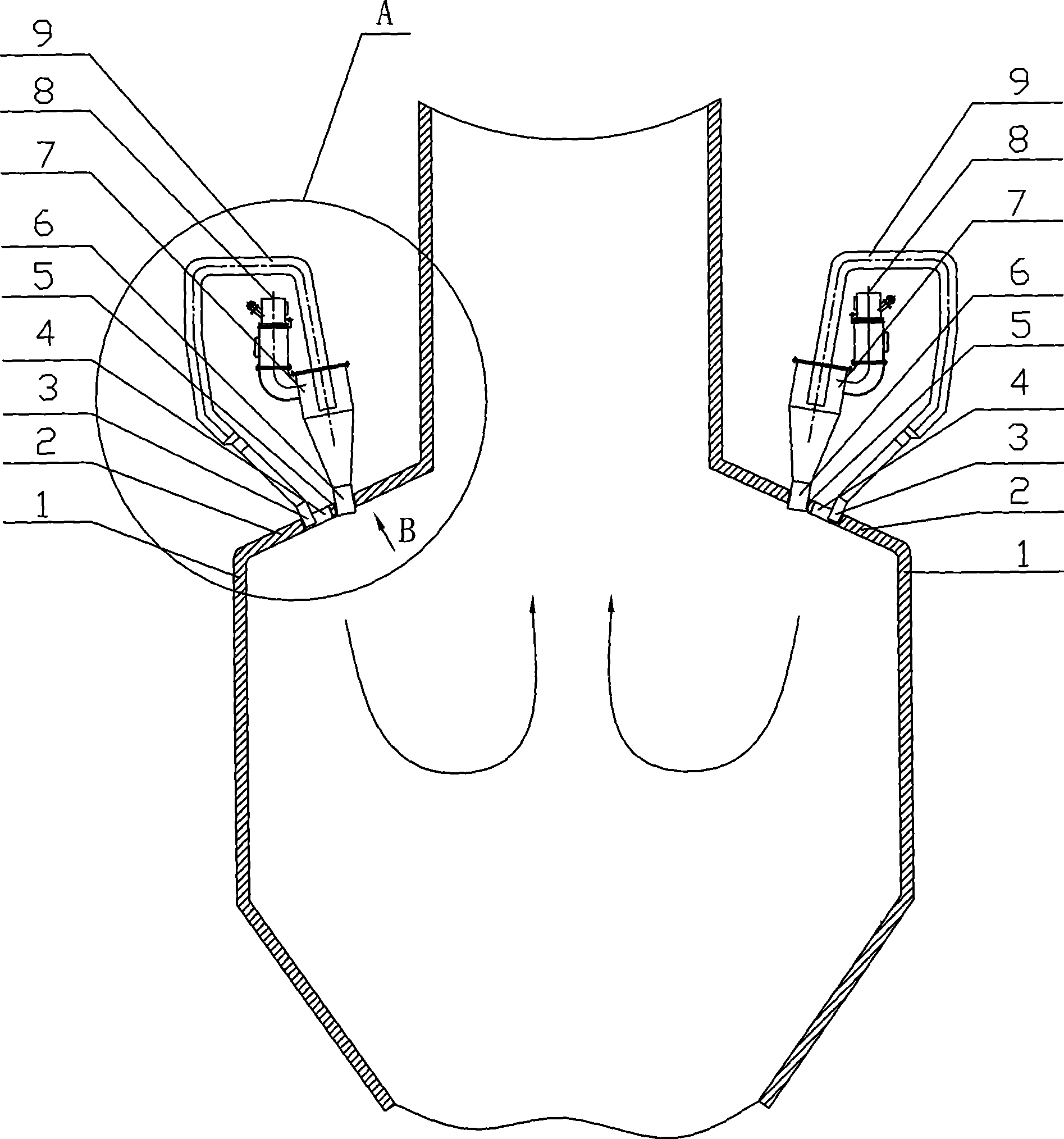

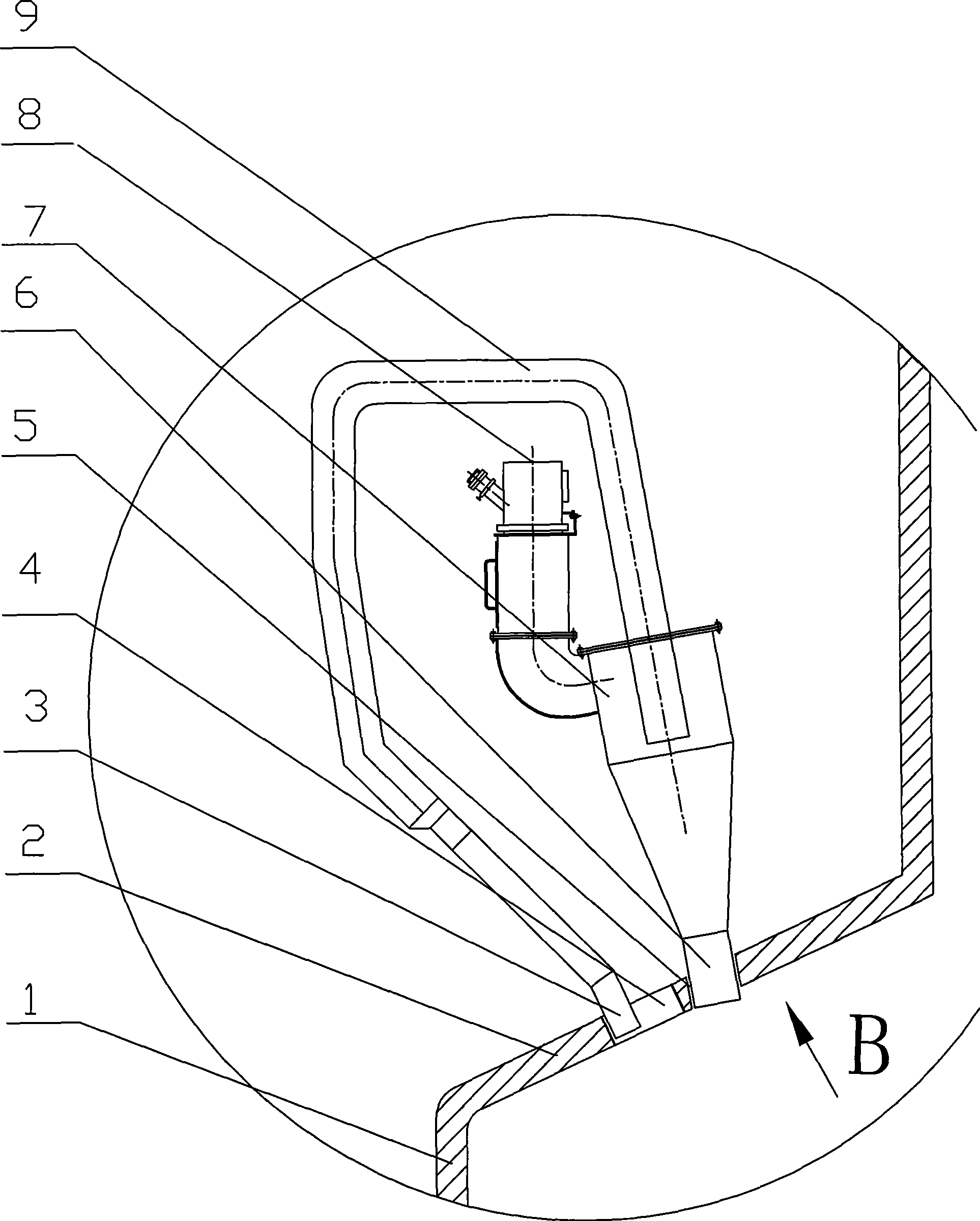

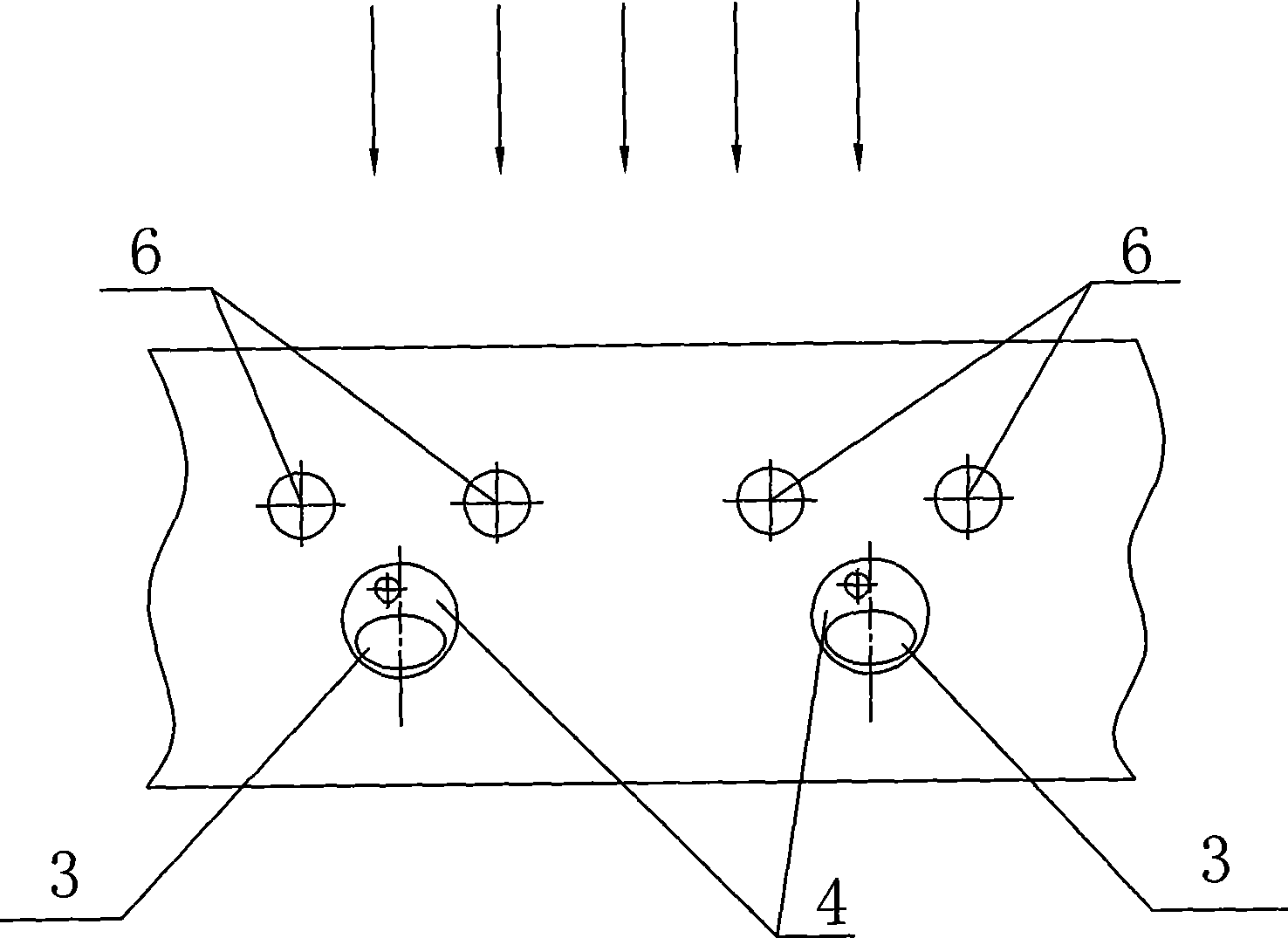

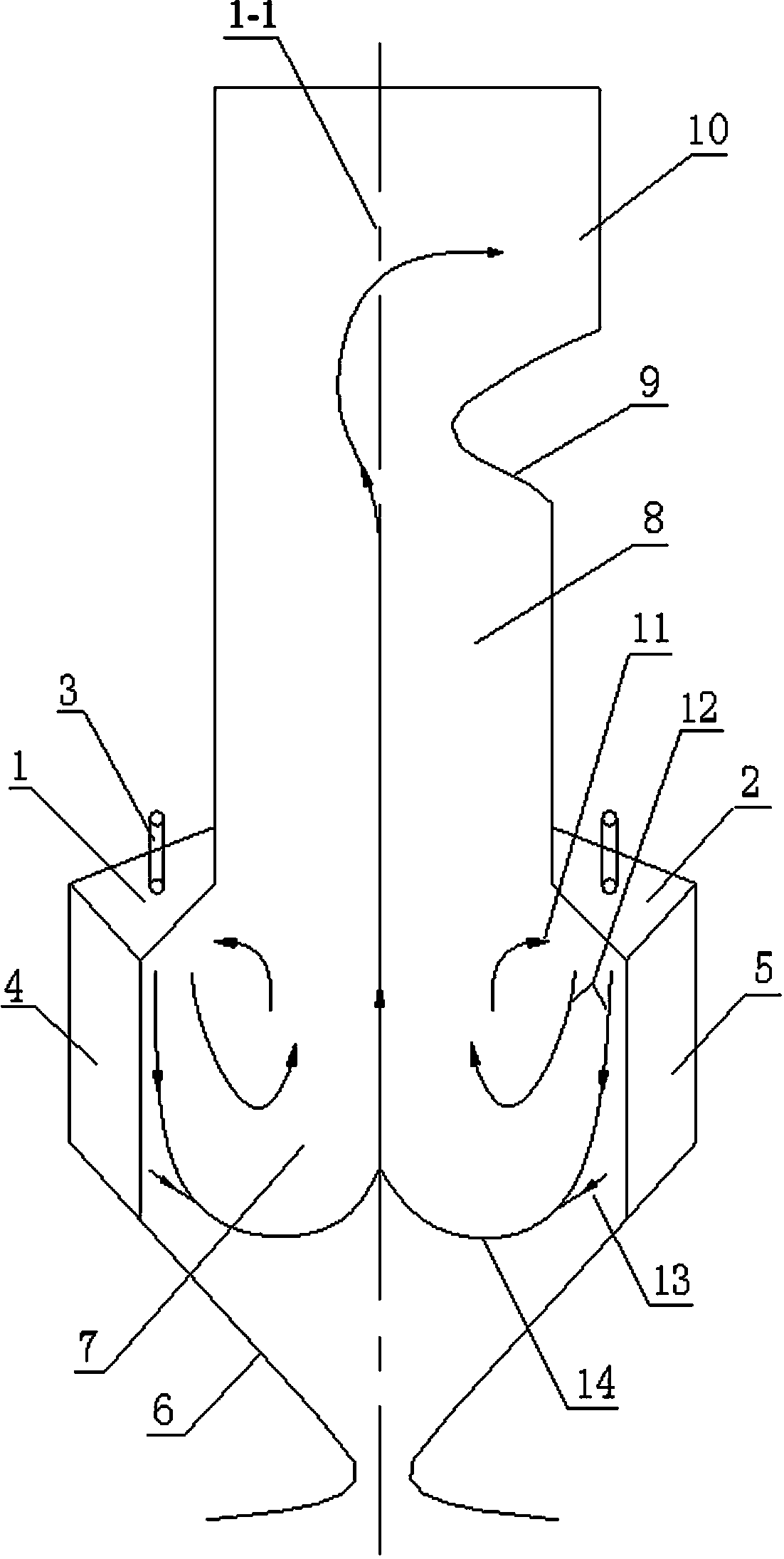

Combustion device with thin and thick breeze airflow stagger arrangement used for W-shaped flame furnace

InactiveCN101476719AEmission reductionReduce combustible contentCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelHearthEngineering

The invention provides a combustion device used for staggeredly arranging rich / lean pulverized coal airflow on a W-shaped flame furnace, and relates to the combustion device. The combustion device solves the problems of unstable combustion and non timely ignition of the prior W-shaped flame furnace. A lean pulverized coal airflow nozzle (3) is inserted into an oil secondary air spout (4) and communicated with a furnace hearth, and the oil secondary air spout (4) is arranged on a furnace arch (2) close to a front wall or a rear wall (1). Rich pulverized coal airflow nozzles (6) are arranged on the furnace arch (2) close to the center of the furnace hearth and communicated with the furnace hearth, and a gap between the rich pulverized coal airflow nozzles (6) and the side wall of the furnace arch (2) is a perimeter air port (5); and the lean pulverized coal airflow nozzle (3) is arranged between the two rich pulverized coal airflow nozzles (6). The invention provides the rich / lean pulverized coal combustion device with high-efficiency and stable combustion and low NOx. The device can make the lean pulverized coal airflow receive radiant heat from a high temperature area in the middle of the furnace hearth well, ignite in time, reduce the fly ash combustible content, and realize low NOx combustion.

Owner:HARBIN INST OF TECH

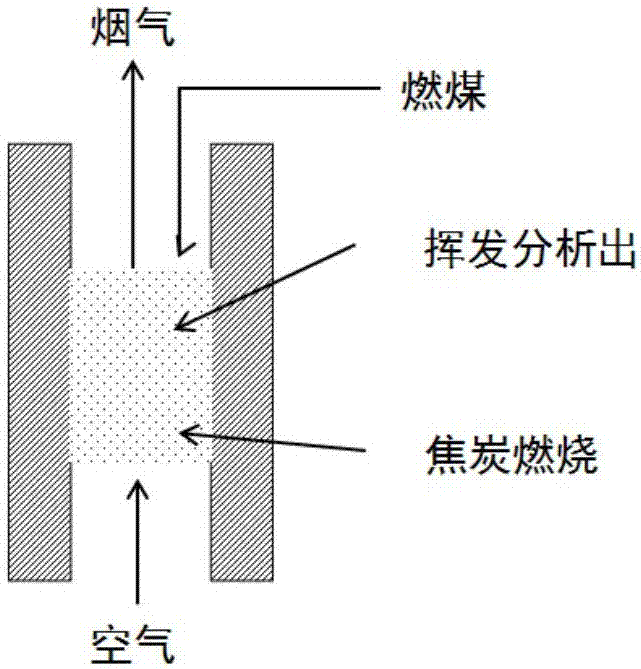

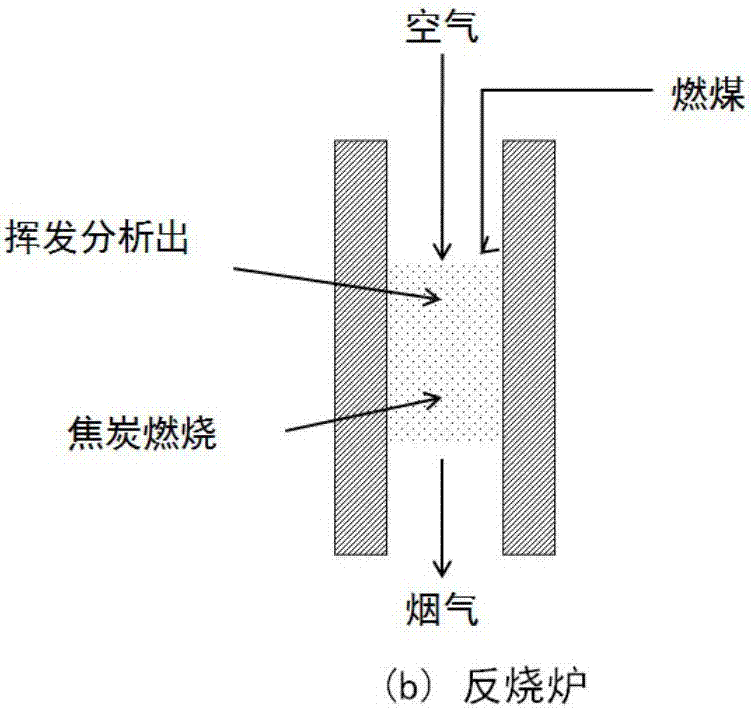

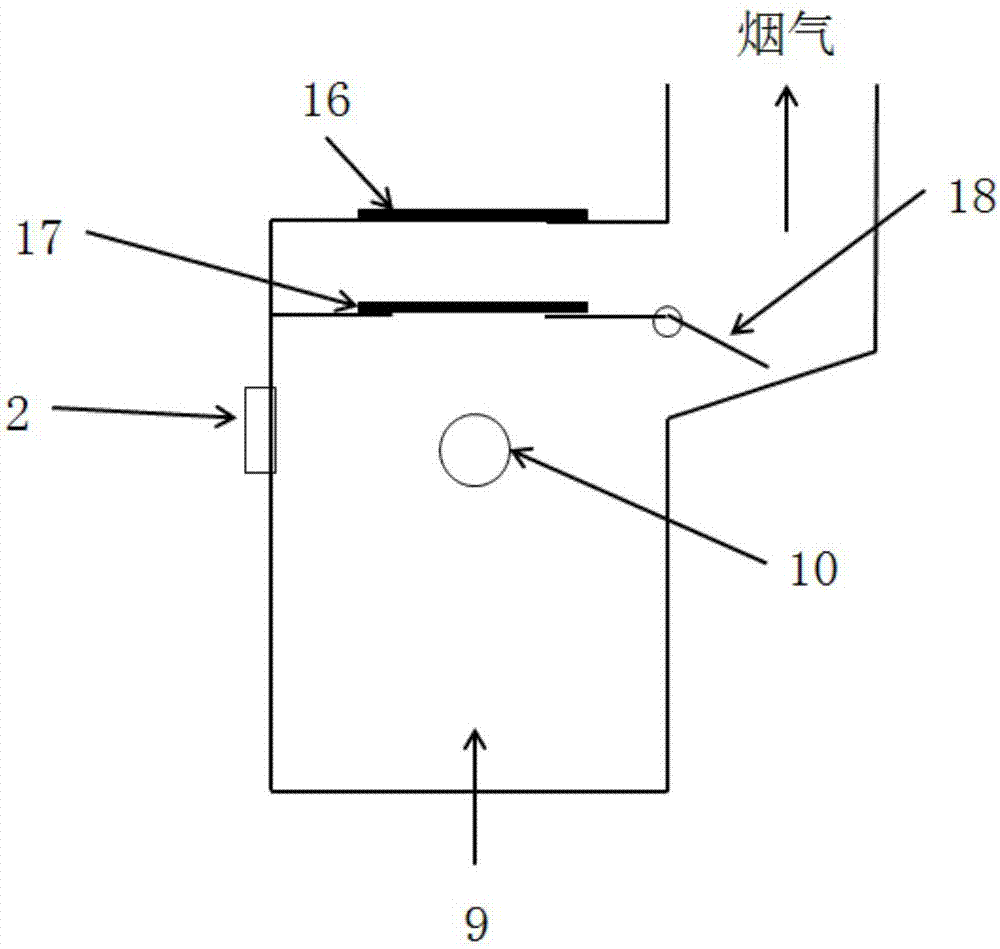

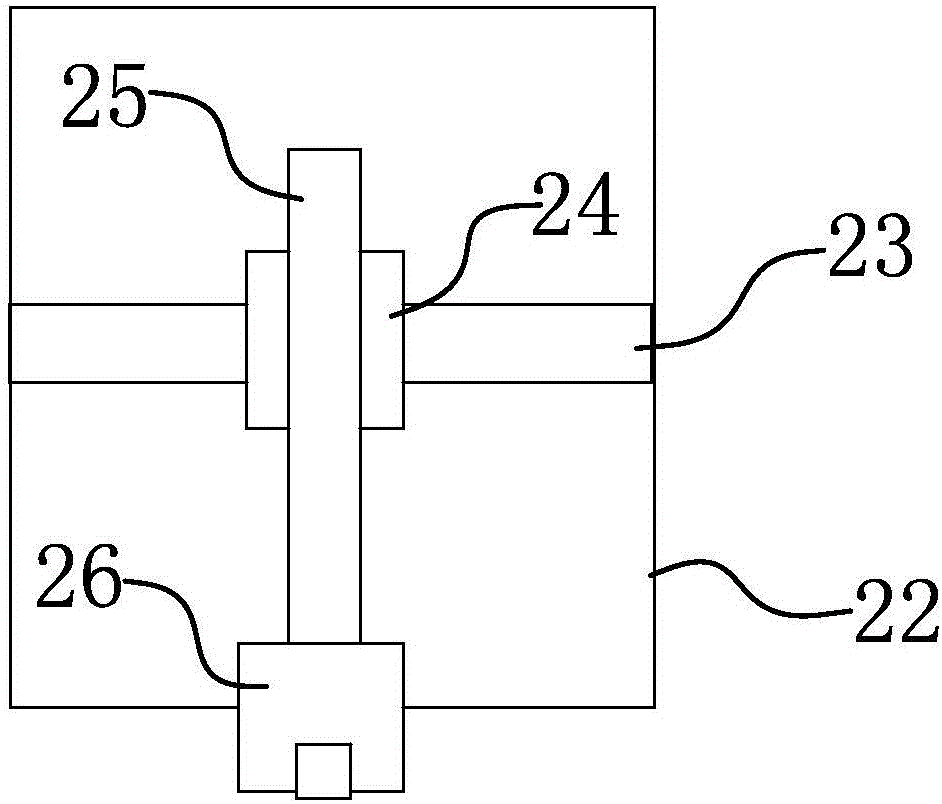

Environment-friendly gasification counter-flow combustion hot-blast stove

The invention discloses an environment-friendly gasification counter-flow combustion hot-blast stove. The environment-friendly gasification counter-flow combustion hot-blast stove comprises a combustion chamber, a heat exchange chamber and a gasification chamber for gasification and combustion of fuel. The combustion chamber is horizontally arranged, and both the gasification chamber and the heat exchange chamber are vertically arranged above the combustion chamber to form a gasification section type combustion U-shaped stove structure. The bottom of the gasification chamber and the bottom of the heat exchange chamber are connected with the combustion chamber through a first channel and a second channel respectively. The position, close to the first channel, of the inner side of a top plate of the combustion chamber stretches downwards to form a turbulent flow baffle. Positions, corresponding to the gasification chamber and the heat exchange chamber, of the bottom of the combustion chamber are respectively provided with a slag pit. The environment-friendly gasification counter-flow combustion hot-blast stove is simple in structure, convenient and quick to operate, high in combustion efficiency and small in environment pollution, and investment cost and operation cost are reduced.

Owner:GUANGDONG EMICRONET NEW ENERGY TECH

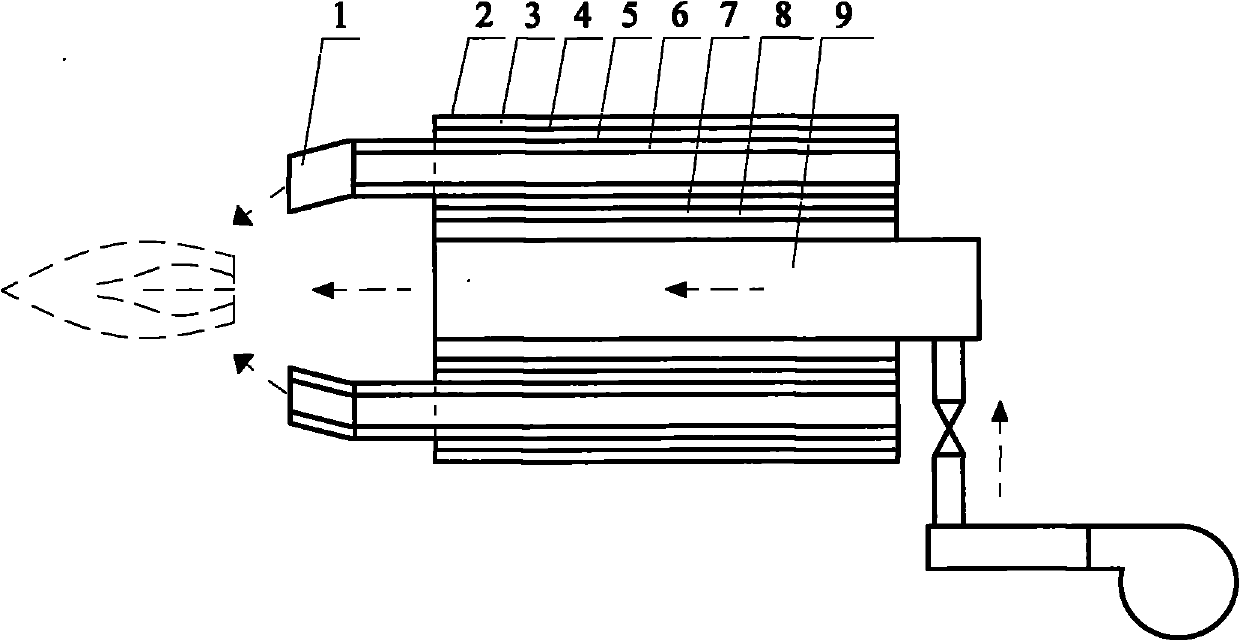

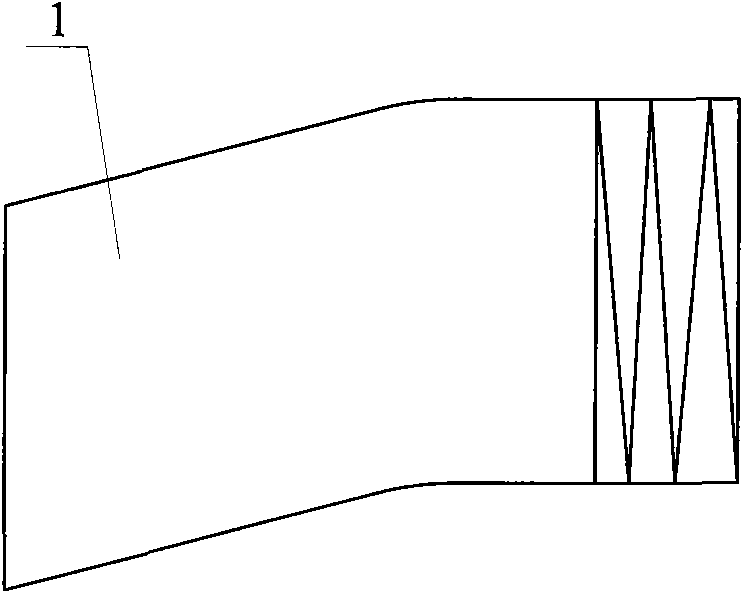

Supercritical water heat combustion reactor for thick oil injection production

InactiveCN103900094AStable combustionGood for burnoutFluid removalIncinerator apparatusCombustion chamberThermodynamics

The invention belongs to the field of energy and environments, and particularly relates to a supercritical water heat combustion reactor for thick oil injection production. The supercritical water heat combustion reactor for thick oil injection production comprises a reaction chamber, an upper top cover and a lower bottom cover, wherein the reaction chamber is hollow, openings are formed in the upper end and the lower end of the reaction chamber respectively, the upper top cover is connected with the opening formed in the upper end of the reaction chamber in a sealed mode, the lower bottom cover is connected with the opening formed in the lower end of the reaction chamber, and a closed space is formed by the reaction chamber, the upper top cover and the lower bottom cover; a cylindrical stepped hollow portion is formed in the center of the upper top cover, a stepped hollow portion on the lower portion of the cylindrical stepped hollow portion serves as a combustor, a stepped hollow portion on the upper portion of the cylindrical stepped hollow portion serves as a communicated fuel inlet, an annular groove is formed in the outer side of the lower end of the stepped hollow portion on the upper portion of the cylindrical stepped hollow portion, the lower portion of the annular groove is communicated with the combustor, and the annular groove is communicated with an oxidizing agent inlet formed in the side face of the upper top cover; a mixing chamber is arranged at the bottom of the combustor, an annular gap formed between the upper top cover and the reaction chamber is formed in the side of the combustor, and the annular gap is communicated with a supplementary water inlet formed in the side face of the reaction chamber.

Owner:TAIYUAN UNIV OF TECH

Pulverized coal flame preheating reburning system

ActiveCN103791493AImprove efficiencyLow costPulverulent fuel combustion burnersInjection portNitrogen

A pulverized coal flame preheating reburning system comprises a main boiler burner and a reburning device. A plurality of sets of primary air pipes are arranged at the front end of a preheating chamber of the reburning device, an injection port communicated with a reburning area of the main boiler burner is arranged at the rear end of the preheating chamber of the reburning device, the primary air pipes comprise inner primary air pipes and outer primary air pipes, and inlets of the inner primary air pipes are communicated with a pulverized coal feeding device; the inlet of a gas burner preheating chamber is provided with an ignition detection electrode and a gas burner air-supporting pipeline, and a gas pipeline with a gas burner gas spray head is arranged in the gas burner preheating chamber. The amount of gas needed for the system accounts for 0.3-0.5% of total boiler heat input, gas burns in the preheating chamber of the reburning device, formed naked light is used for providing a stable ignition source, and heat in the preheating chamber of the reburning device is provided by volatile matter generated through pyrolysis of pulverized coal, namely heat is provided by the pulverized coal feeding device. Meanwhile, O2 in primary air for conveying the pulverized coal can be completely consumed away, and nitrogen-containing compounds generated by the pulverized coal which is heated and pyrolyzed can be effectively reduced to N2 under the strong reducing atmosphere.

Owner:XI AN JIAOTONG UNIV

High-efficiency coal heating furnace simultaneously reducing smoke, sulfur dioxide and nitrogen oxide emission, heating method and application

PendingCN107238111ALow universalityReduce generationLighting and heating apparatusStove/ranges for heating waterWater jacketSulfur dioxide

The invention provides a coal heating furnace simultaneously reducing smoke, sulfur dioxide and nitrogen oxide emission, a heating method and application. A coal feeding port is formed in one side of the top of a coal heating furnace body, and a chimney is arranged on the side, opposite to the coal feeding port, of the top of the main body. A water jacket partition plate is vertically arranged on the upper portion inside the coal heating furnace body and divides the upper portion inside the coal heating furnace body into a dry distillation pyrolysis zone which is connected with the coal feeding port and a smoke burnout heat exchanging zone which is connected with the chimney. The zone which is not provided with a partition plate on the lower portion inside the coal heating furnace body is a semi-coke burning zone. A furnace grate is obliquely arranged on the lower portion of the semi-coke burning zone, and a primary air opening is formed below the furnace grate. A burnout zone above the semi-coke burning zone is provided with a secondary air opening. The burnout zone is internally provided with water heat exchanging pipes for heating. The coal heating furnace is stable in burning, high in heat efficiency and suitable for smoke-free emission of all kinds of soft coal, biomass and other fuels, especially when high-sulfur smoke-free burns, and meanwhile the smoke, SO2 and NOx emission is effectively reduced.

Owner:YANKUANG GRP CO LTD +1

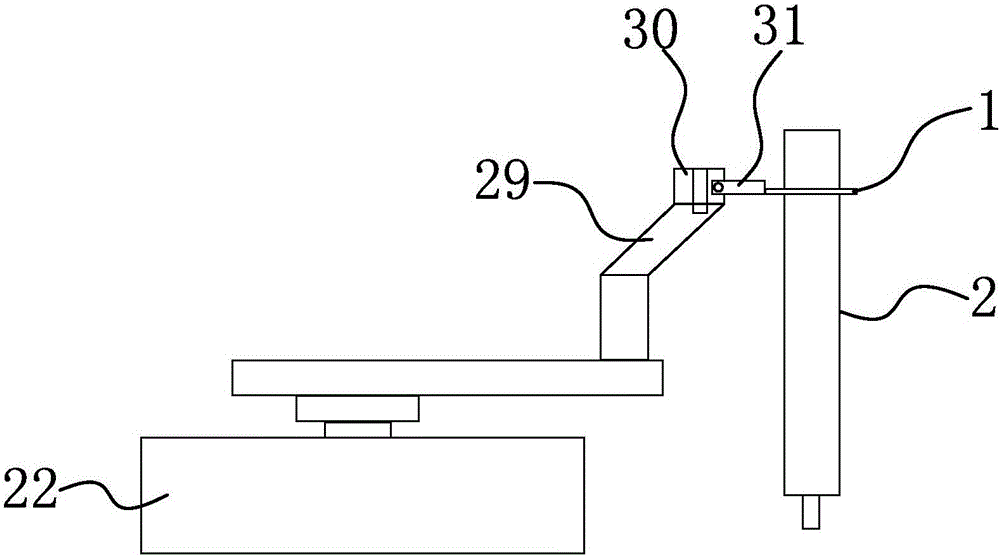

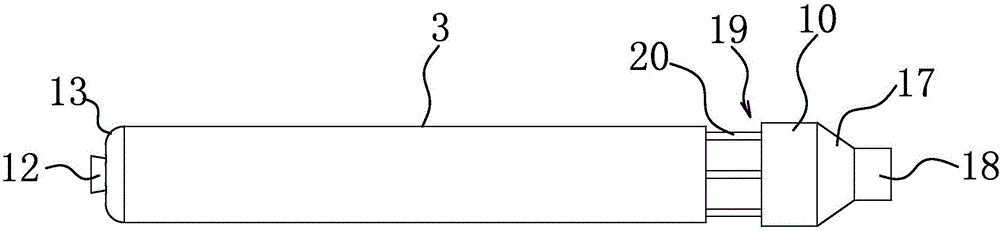

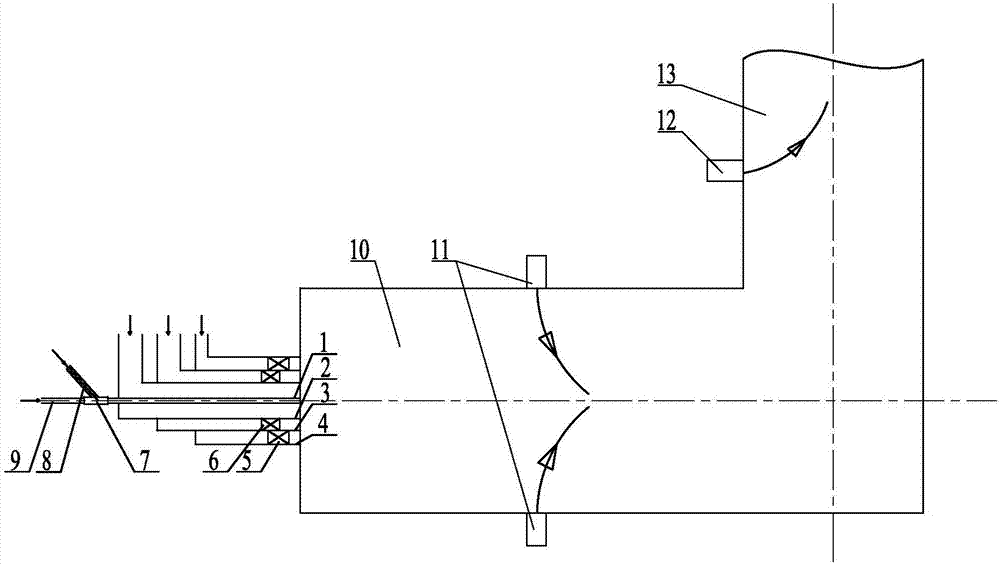

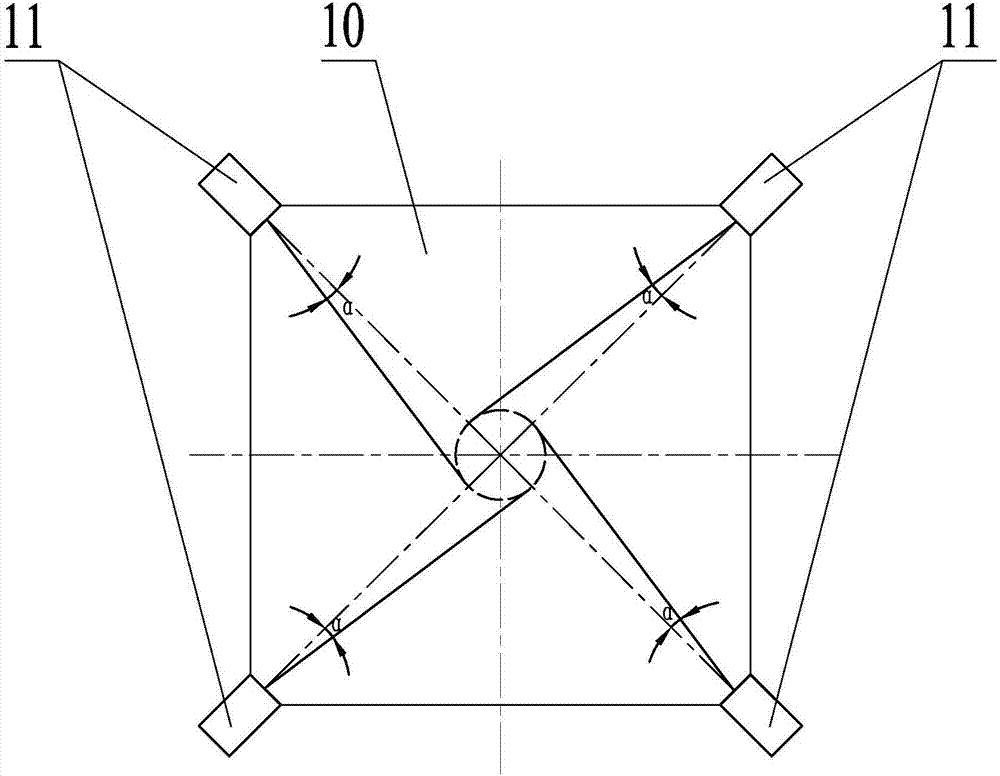

Self-controlled moxibustion device

PendingCN106726534ARealize automatic controlReasonable designDevices for heating/cooling reflex pointsAcupuncture needlesAutomatic control

The invention belongs to the technical field of moxibustion supplies, and particularly relates to a self-controlled moxibustion device. The device includes a mechanical arm, a moxa stick installation box filled with a moxa stick is detachably installed on the mechanical arm, the moxa stick is placed in the moxa stick installation box, the moxa stick includes a moxa stick body, a heat radiation body made of heat conduction materials penetrates through the moxa stick body in the axial direction of the moxa stick body, and the heat radiation end of the heat radiation body stretches out of the lower end of the moxa stick body and is exposed at the lower end of the moxa stick installation box; the moxa stick installation box is provided with a distance sensor and a temperature sensor, wherein the distance sensor can detect the distance between a body surface acupuncture point and the heat radiation end of the heat radiation body and the temperature sensor can detect the moxibustion temperature output by the heat radiation end of the heat radiation body, and the mechanical arm, the distance sensor and the temperature sensor are all connected with a controller. The self-controlled moxibustion device has the advantages that the acupuncture needle function and the moxa stick hot smoking function are combined, dust generated by the combustion of the moxa stick can be isolated, special dust removal is not needed, and automatic control over the distance between the body surface acupuncture point and the top point of the heat radiation moxa stick and the hot smoking temperature of the heat radiation moxa stick is achieved.

Owner:江苏中炜医疗科技有限公司

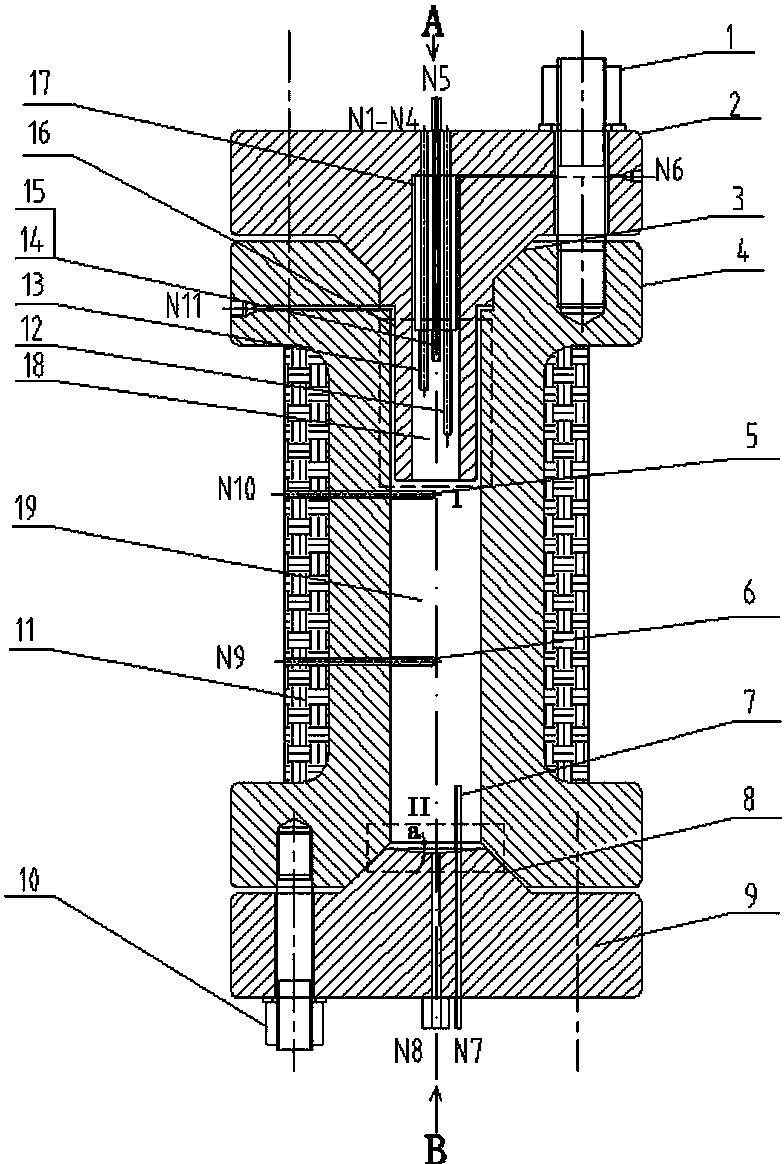

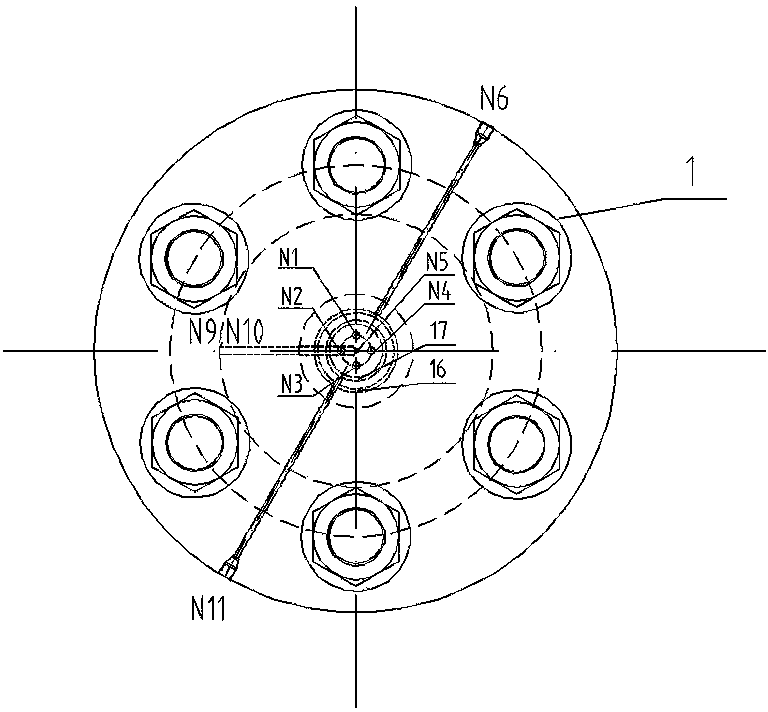

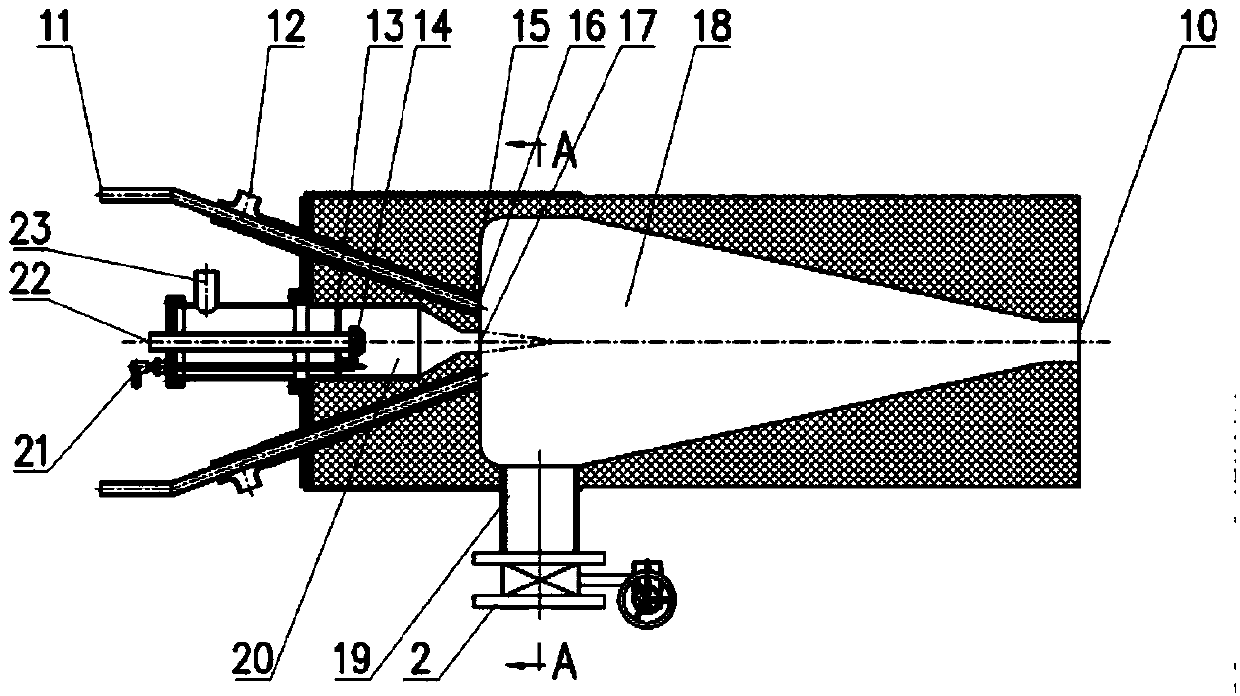

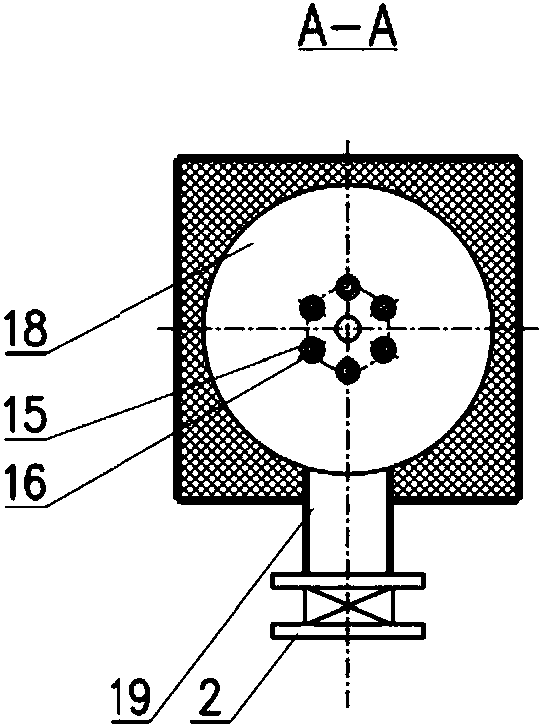

Industrial pulverized coal boiler burning device used for spraying ammonia in center of burner

ActiveCN107477573AEmission reductionImprove reducibilityPulverulent fuel combustion burnersCombustion apparatusCombustorEngineering

The invention provides an industrial pulverized coal boiler burning device used for spraying ammonia in the center of a burner, and relates to the technical field of industrial pulverized coal boilers. The problems that according to an existing horizontal industrial pulverized coal boiler, the NOx emission amount is high, the NOx emission reduction cost is high, the burnout condition of pulverized coal is poor, the adjusting capacity for load change is poor, the boiler thermal efficiency is low, and slagging is severe are solved. The burning device comprises a primary air pipe, a direct flow secondary air pipe, a rotational flow inner secondary air pipe, a rotational flow outer secondary air pipe, a mixer, an amino reducing agent conveying pipe, a concentrated pulverized coal conveying pipe, a hearth and a two-stage over-fire air system. The primary air pipe, the direct flow secondary air pipe, the rotational flow inner secondary air pipe and the rotational flow outer secondary air pipe are sequentially arranged from inside to outside. The amino reducing agent conveying pipe and the concentrated pulverized coal conveying pipe are connected with the inlet end of the mixer. The outlet end of the mixer is connected with the inlet end of the primary air pipe. The two-stage over-fire air system is arranged on the wall of the hearth. The burning device is used for an industrial pulverized coal boiler.

Owner:HARBIN INST OF TECH

Oxygen-enriched burning device burning inferior coal

InactiveCN101769537ASave moneyShorten the construction periodIndirect carbon-dioxide mitigationNon-combustible gases/liquids supplyCoalOxygen enrichment

The invention relates to an oxygen-enriched burning device burning inferior coal. The device comprises oxygen-enriched nozzles, an outer sleeve, a sliding device, oxygen-enriched channels, an inner sleeve and a burning part, wherein the burning part, the inner sleeve and the outer sleeve are distributed in a concentric circle way, and the burning part is arranged at the innermost layer. The oxygen-enriched channel consists of a heat-resisting pipe and a ceramic pipe, and the ceramic pipe is sleeved in the heat-resisting pipe; and the oxygen-enriched channels are nested and fixed in the sliding device and can slide radially between the inner and the outer sleeves. The sliding device is composed of a sliding block fixed on the heat-resisting pipe, an outer chute fixed on the outer sleeve and an inner chute fixed on the inner sleeve. More than two oxygen-enriched channels are uniformly distributed between the inner and the outer sleeves; and a group of oxygen-enriched nozzles are arranged on each oxygen-enriched channel. The oxygen-enriched nozzles are arranged at the outlets of the oxygen-enriched channels, and each oxygen-enriched nozzle has a 15-75-degree angle with the axis of the burning part. The device solves the problems of unstable burning, low burning intensity and narrow adaption range of coal when the inferior coal is used on a furnace and a kiln, thereby improving the burning efficiency of the inferior coal.

Owner:TSINGHUA UNIV +1

Chain-grate boiler and burning method

ActiveCN105627295AImprove combustion efficiencyDry fastAir supply regulationSolid fuel combustionEngineeringCoal

The invention relates to a chain-grate boiler and a burning method. The chain-grate boiler comprises a boiler body, an induced draft fan, a circulation fan, a primary fan and an air supply bin; primary air pumped from natural air is fed into the air supply bin through the primary fan, and therefore drying, burning and burnout of coal are promoted; and circulation smoke pumped from total smoke passing through the induced draft fan is fed into a burning air supply bin in the air supply bin through the circulation fan, and generation of NOx is restrained. Furthermore, part of the circulation smoke pumped from the total smoke passing through the induced draft fan is fed into a backwards-arched air distribution opening through the circulation fan, mixing of smoke in a hearth is strengthened, burning of fuel is promoted, and the burning efficiency of the chain-grate boiler is improved. By means of the burning method of the chain-grate boiler, generation of the NOx is correspondingly restrained, and the burning efficiency of the chain-grate boiler is improved.

Owner:YANTAI LONGYUAN POWER TECH

Method for supplying combustion gas in incineration systems

ActiveUS7975628B2Good for burnoutNitrogen oxide formation/emission is minimizedSolid fuel combustionIndirect carbon-dioxide mitigationCombustion systemCombustion

Owner:MARTIN GMBH FUR UMWELT UND ENERGIETECHNIK

Crude and fine coal powder separation and burn method and device

InactiveCN101055077AImprove combustion stabilityPromote fireCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorJet flow

A coal powder thickness separation burning method and a device thereof belong to coal powder burning technology field and are adapted to coal powder burning boiler. The method includes: (1) separating step, separating the conventional coal powder to fine coal powder and thick coal powder; (2) flow lead burning step, setting the thick coal powder to the middle part of the burning jet flow, leading the fine coal powder to the external of the thick coal powder air flow to burn, forming a stable fire source around the thick coal powder air flow to strength the fire and stable burning for the thick coal powder air flow. The device of the invention is mounted with a cyclone separation apparatus on the front part of the main burner, the outlet of the cyclone separation apparatus is disposed with a double layer circular bushing, the inner pipe of the double layer circular bushing is connected to a hypo-wind circular tube outside of the main burner by a connection device, the outer pipe of the double layer circular bushing is connected to a hypo-wind circular tube in the main burner by a connection device. The invention has good fire characteristic, strong stable fire ability, high coal burnt rate, low NOx exhaust amount, strong adaptability for load and coal kinds and realizes high efficiency low-pollution combustion for coal powder.

Owner:HUAZHONG UNIV OF SCI & TECH

Burning-out air and secondary air adjusting device of pulverized coal boiler

The invention discloses a burning-out air and secondary air adjusting device of a pulverized coal boiler and relates to a volume adjusting device of the pulverized coal boiler. The invention aims at solving the problem that when an existing pulverized coal boiler runs with a low load, or the volume of the secondary air needs to be controlled by adopting air staging, the amount of the burning-out air or secondary air is reduced and the rigidity is insufficient, is solved. According to the burning-out air and secondary air adjusting device of the pulverized coal boiler, an air channel and a spray opening are partitioned into two or three parts by separation boards; the flow rate is adjusted through an eccentric air door baffle, a group of small separation boards and two small spoilers; at least part of air is jet flow with different openness degrees of an air door at the outlet so as to guarantee relatively good penetrability of the jet flow. The burning-out air and secondary air adjusting device is mainly used for air amount adjustment of a coal boiler.

Owner:DATANG BEIJING ENERGY MANAGEMENT

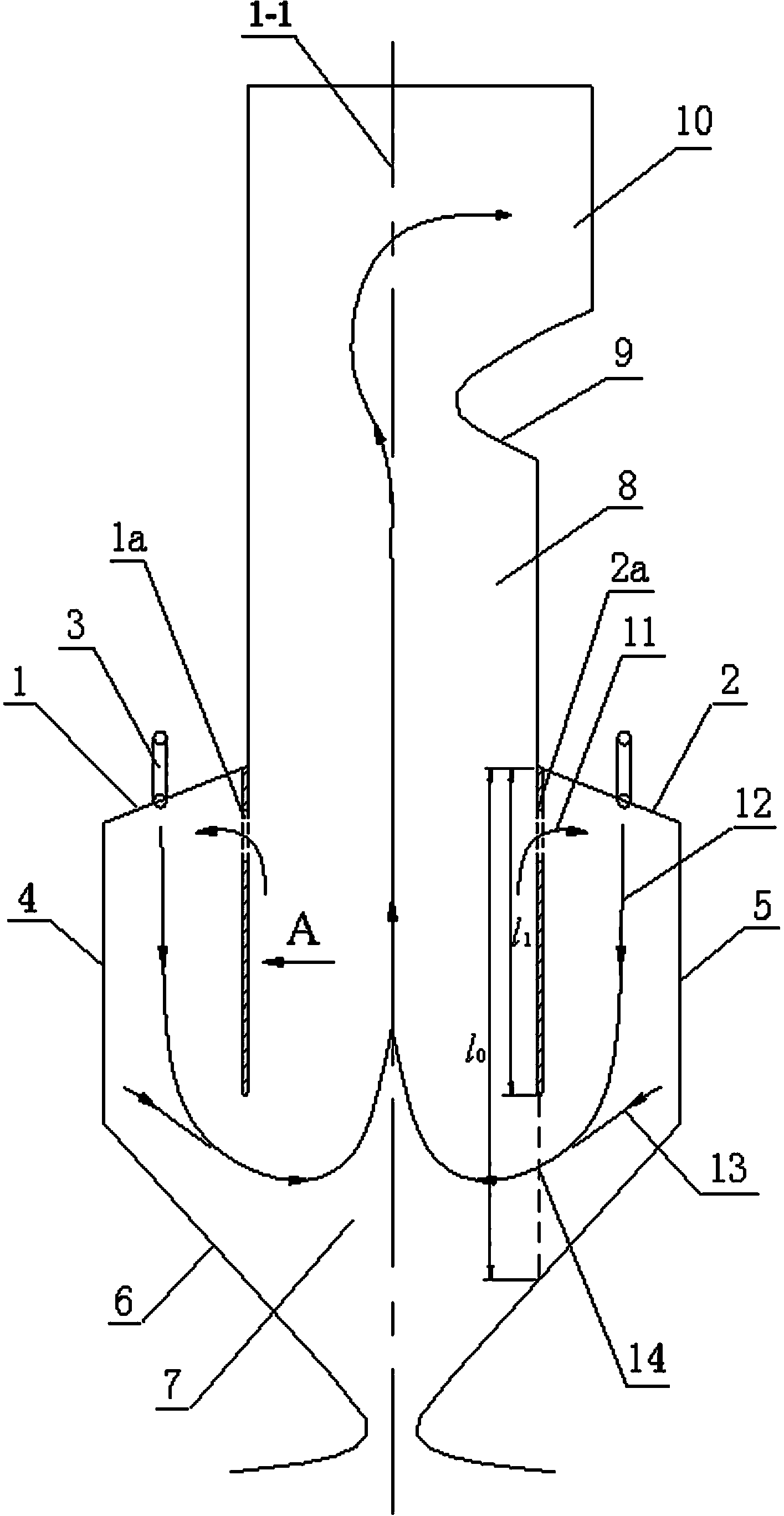

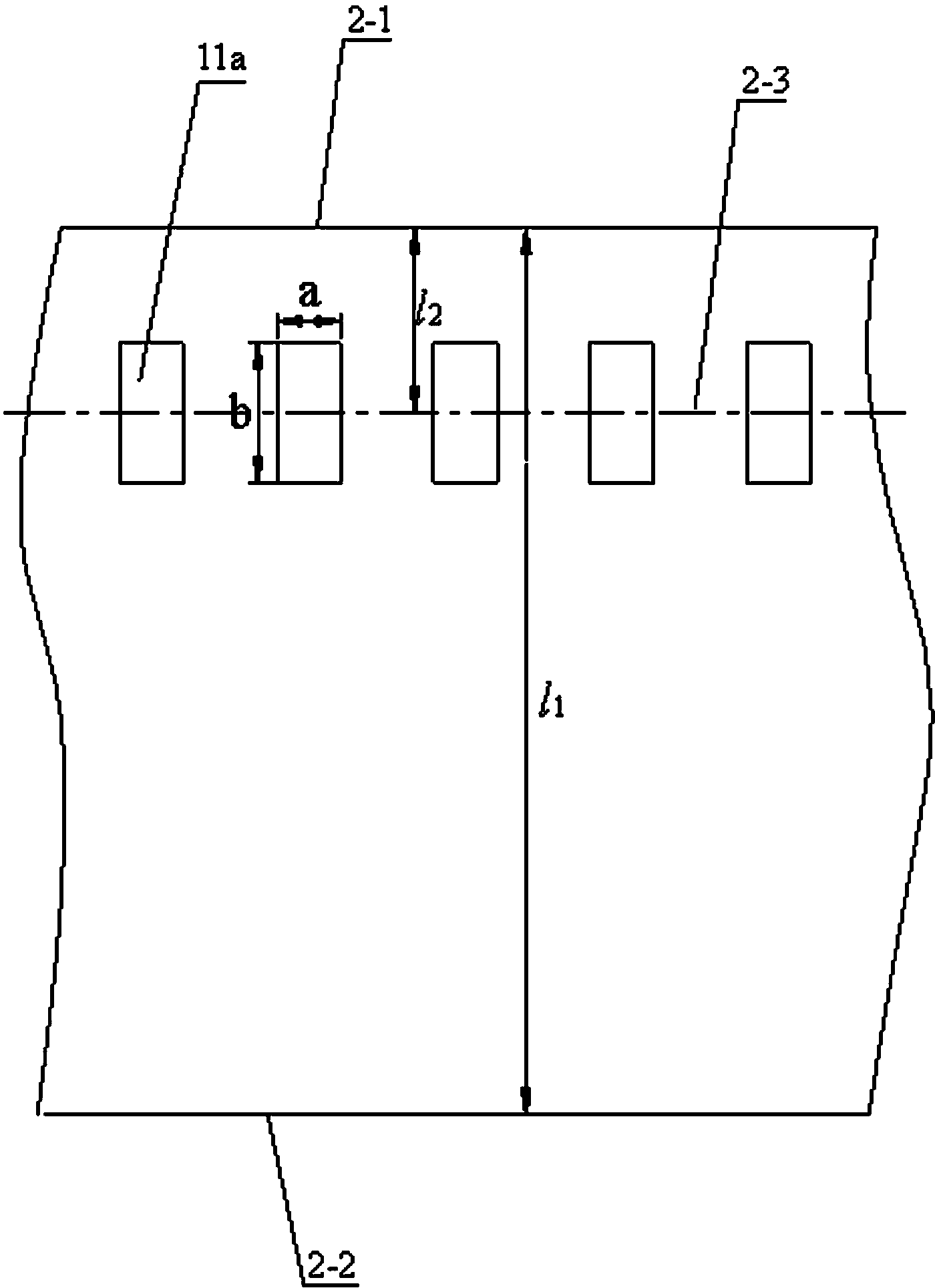

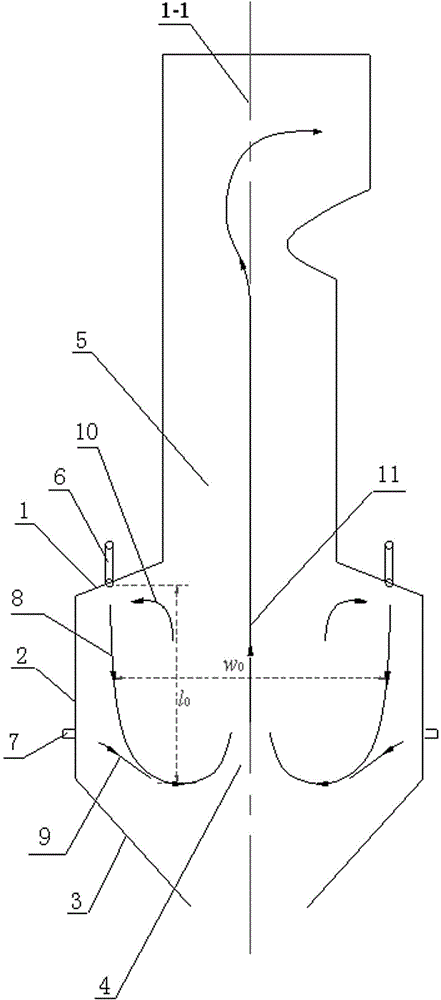

Symmetrical-combustion W-Type flame boiler

ActiveCN104296129ASolve the problem of poor burnoutAvoid crowdingCombustion chambersCombustorPowder mixture

The invention discloses a symmetrical-combustion W-Type flame boiler. Connecting wallsunder arches arearranged at the junction of an upper hearth and a lower hearth, extend downwards and vertically so as to approach a cold ash bucket area, and extend to left and right walls of the boiler in the width direction of the boiler so as to form a semi-closed area under a front arch and a rear arch. Limited in the semi-closed area, the gas-powder mixtures of burners are expanded to move down to finally arrive the middle upper area of the cold ash bucket and then are turned to move upward, thereby ensuring that two symmetrical U-type flames are formed at the front and rear walls and meet at the centers of the hearths to form a symmetrical W-type flame. A row of backflow flue gas ports are formed in the upper part of the connecting wall under the arch and are in one-to-one correspondence with the burners at the arches along the width direction of the boiler, so that the gas-powder mixtures in the areas of the burners are conveniently heated by high-temperature backflow flue gas under the arches; the height size of the connecting wall under the arch meets the expression of l1 / l0=0.6-0.7; the positioning in the height direction of the backflow flue gas ports meets the expression of l2 / l1=0.25-0.35; the width of the backflow flue gas ports is approximately twice of the equivalent diameter of burner nozzles, and the height / width ratio is 1.5-2.

Owner:NINGBO UNIV

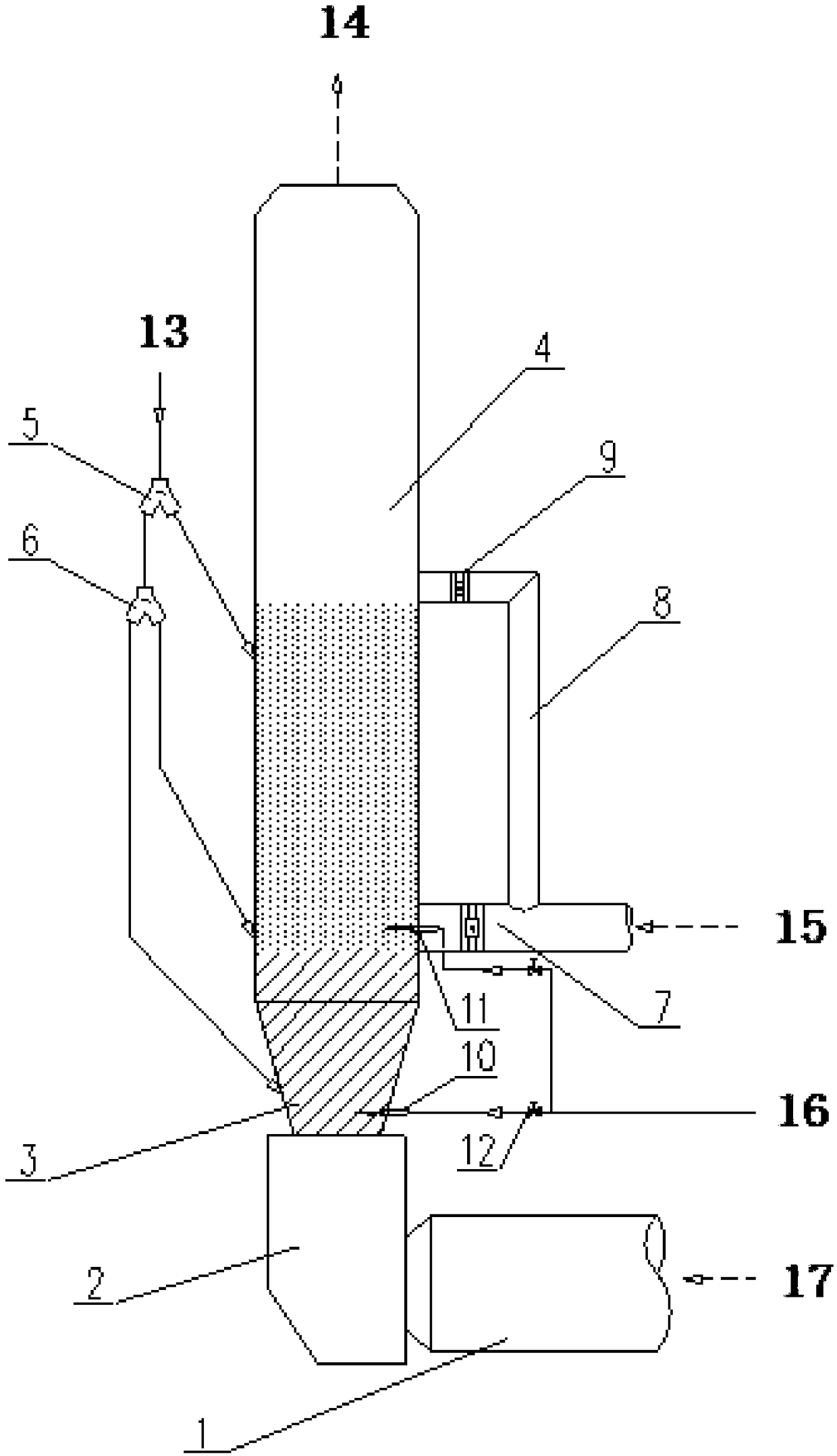

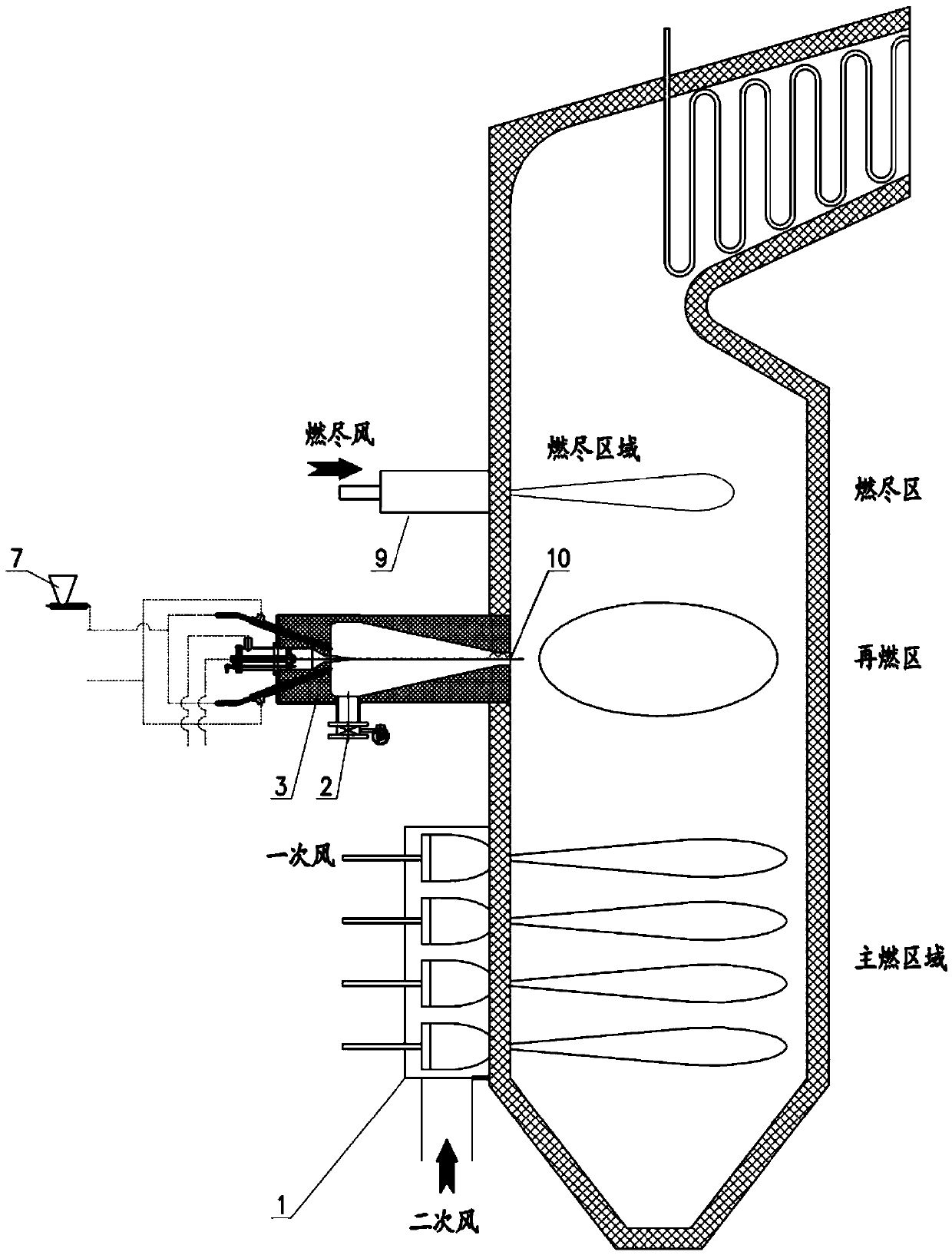

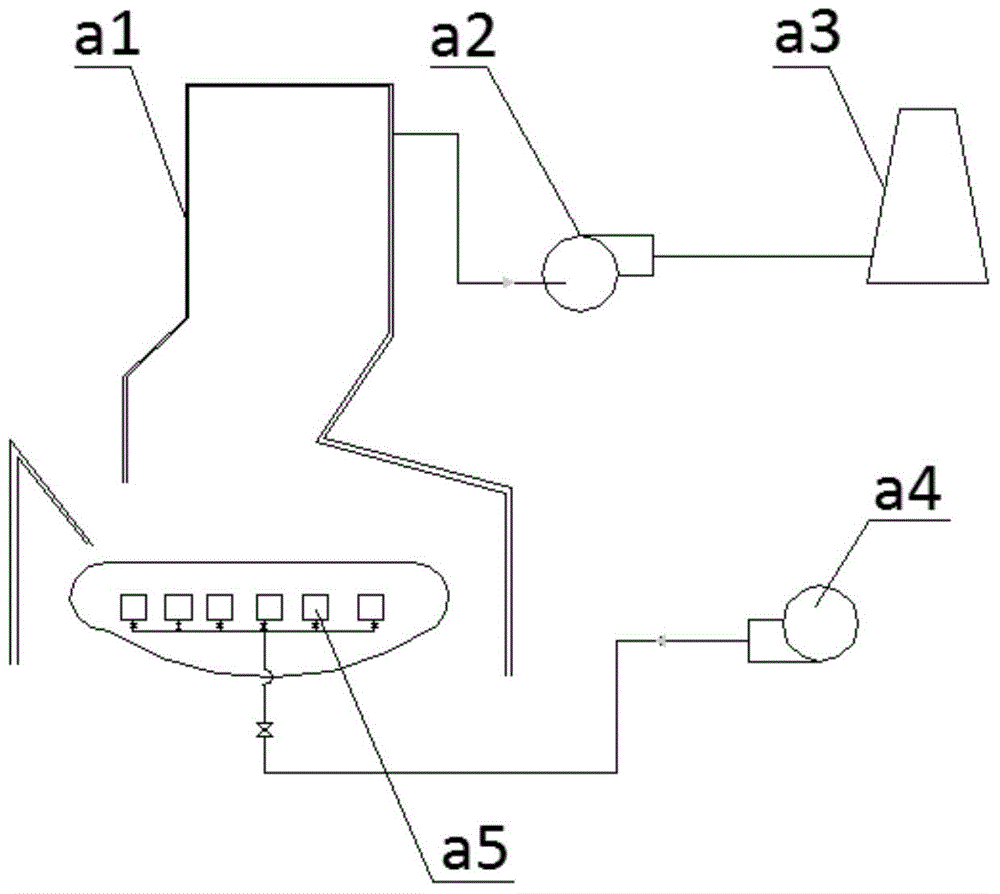

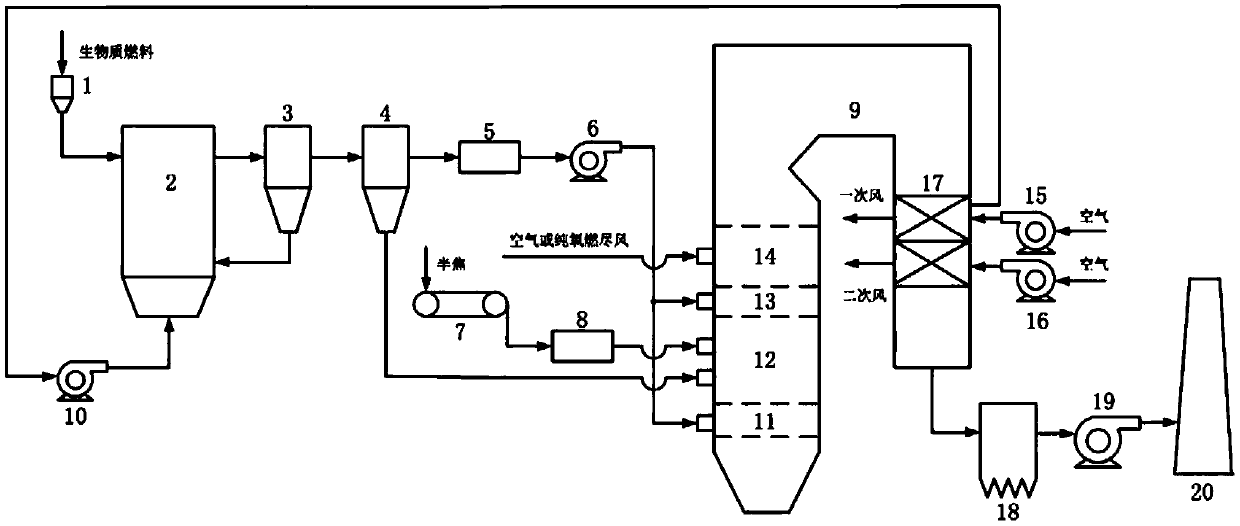

Biomass fuel and semi-coke mixed burning system and method

ActiveCN109539243AEmission reductionSolve the problem of semi-coke burningSolid fuel combustionIndirect carbon-dioxide mitigationAir preheaterCyclone

The invention discloses a biomass fuel and semi-coke mixed burning system and method. Aiming at the problems of low calorific value of biomass gasification products, difficulty of semi-coke ignition steady burning, high discharge of NOx and the like, the biomass fuel and semi-coke mixed burning method is adopted, gasification is performed on biomass fuel through a gasification furnace, flammable gaseous products are fed into an ignition area and a reburning area which are arranged inside a furnace cavity, meanwhile, solid residues are fed into a main burning area for mixed burning with semi-coke, the problem of difficulty of semi-coke ignition steady burning is solved, and by means of layering mixed burning inside the furnace, a reducing atmosphere area is formed at the upper portion of the main burning area, so that burning optimization is realized, the NOx discharge quantity is reduced at the same time, and meanwhile, part of hot air inside an air preheater is fed into the gasification furnace and a two-stage cyclone separator is adopted, so that the air fan investment is reduced, the energy utilization rate is increased, and the gasification furnace efficiency is improved.

Owner:XI AN JIAOTONG UNIV

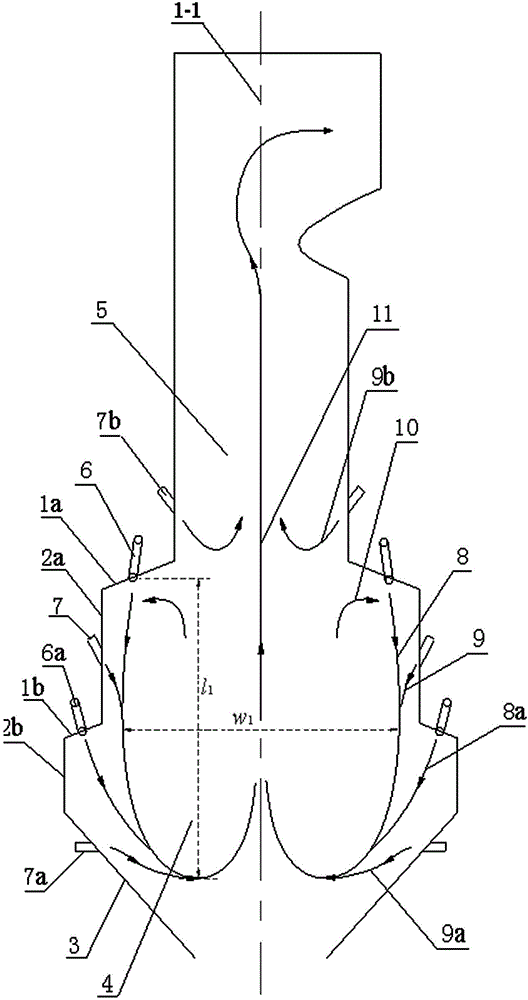

Low-NOx four-arch type W flame boiler for coupling air staging and fuel staging

ActiveCN104406160ALower shot depthImprove interception abilityCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelThermodynamicsCombustor

The invention discloses a low-NOx four-arch type W flame boiler for coupling air staging and fuel staging. A furnace chamber is divided into two parts, namely the lower furnace chamber and the upper furnace chamber, and the lower furnace chamber consists of four furnace arches, a two-stage type front and rear wall and a dry bottom hopper; a pulverized coal burner inclined outwards is arranged on the upper furnace arch, declined staging air noozles are formed in the upper part of the front and rear wall, an ultrafine powder burner inclined inwards is arranged on the lower furnace arch, protective air noozles are approximately horizontally formed in the upper part of the dry bottom hopper, and over-fire air noozles inclined downwards are formed in the lower part of the upper furnace chamber. Therefore, the condition of coupling deep air staged combustion and fuel staged combustion is constructed in the furnace, and the boiler is supplemented with prolonged flame travel caused by unique combustion design and added flame fullness degree, so that low NOx combustion and high-efficiency after-combustion for the W flame boiler are realized.

Owner:CHINA JILIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com