Environment-friendly gasification counter-flow combustion hot-blast stove

A hot blast stove and countercurrent technology, which is applied in the field of environmental protection gasification countercurrent combustion hot blast stoves, can solve the problems of increased investment cost and operating cost, difficult popularization and application of hot blast stoves, cumbersome manual operation, etc., so as to reduce operating costs and improve energy-saving performance. and safety performance, the effect of reducing manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

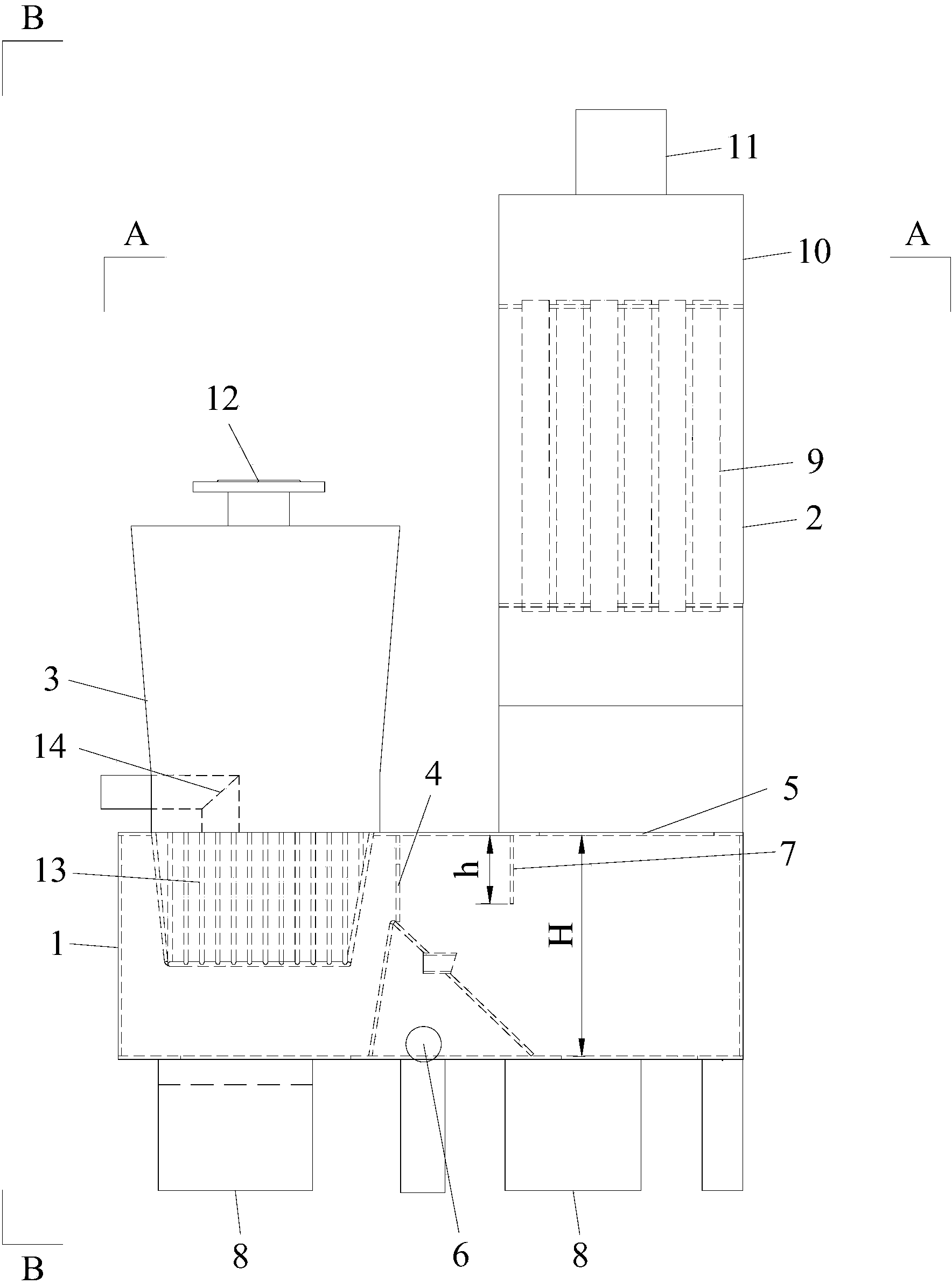

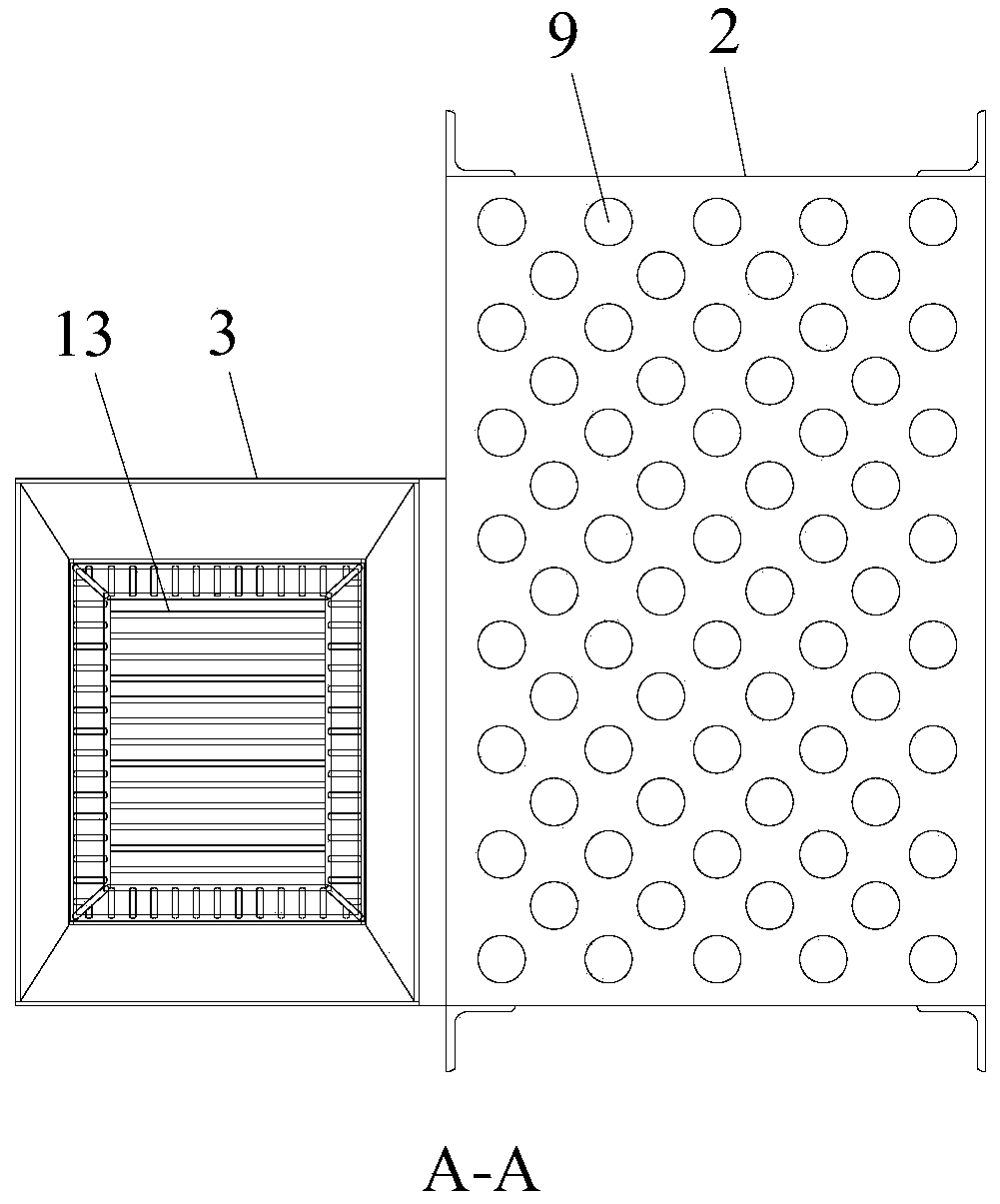

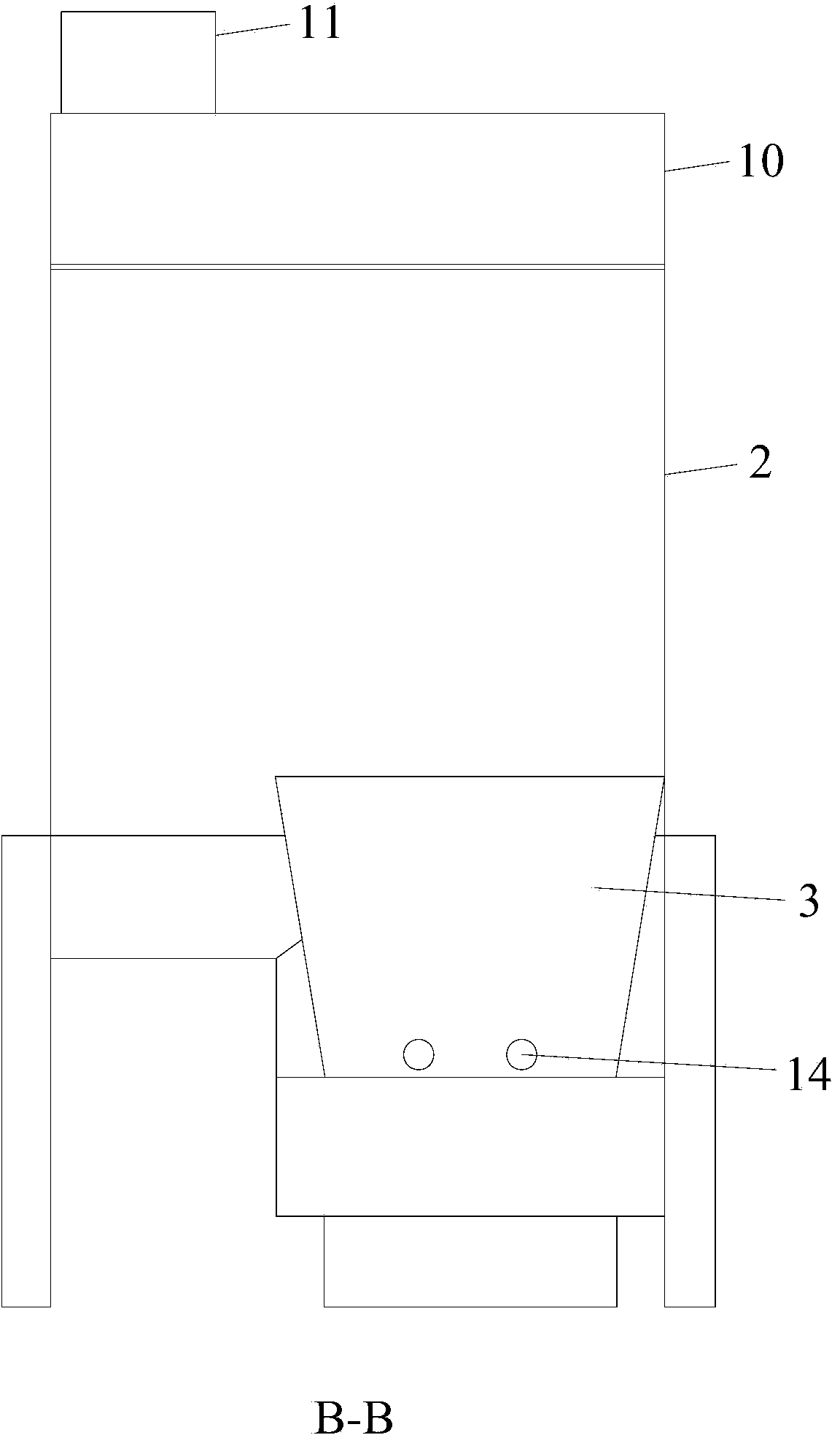

[0025] Please refer to Figure 1-3 , the environmentally friendly gasification countercurrent combustion hot blast stove includes a combustion chamber 1, a heat exchange chamber 2 and a gasification chamber 3 for gasification and combustion of fuel. The combustion chamber 1 is arranged horizontally, and the gasification chamber 3 and the heat exchange chamber 2 are arranged vertically above the combustion chamber 1 to form a U-shaped furnace structure for gasification staged combustion, and the gasification The bottom of the chamber 3 and the bottom of the heat exchange chamber 2 are connected to the combustion chamber 1 through the first channel 4 and the second channel 5 respectively. The vertical arrangement of the gasification chamber 3 is conducive to the storage and accumulation of fuel in the gasification chamber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com