Independent partitioned grate firing flue gas circulation combustion system and use method thereof

A flue gas circulation and combustion system technology, applied in the direction of combustion methods, solid fuel combustion, combustion equipment, etc., can solve the problems of large amount of NOx, achieve the effect of promoting combustion, promoting burnout, and stable conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

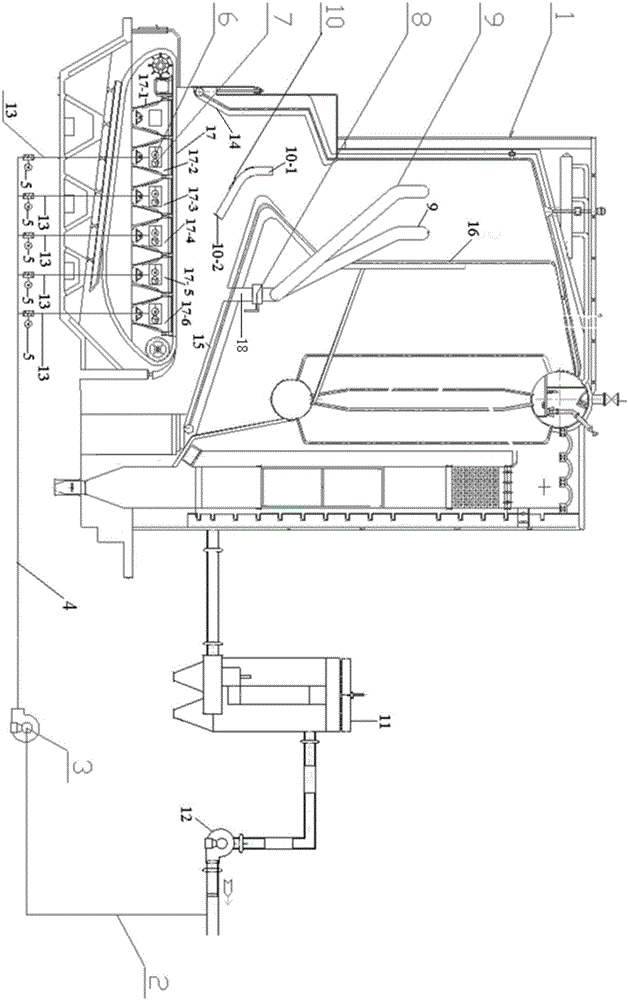

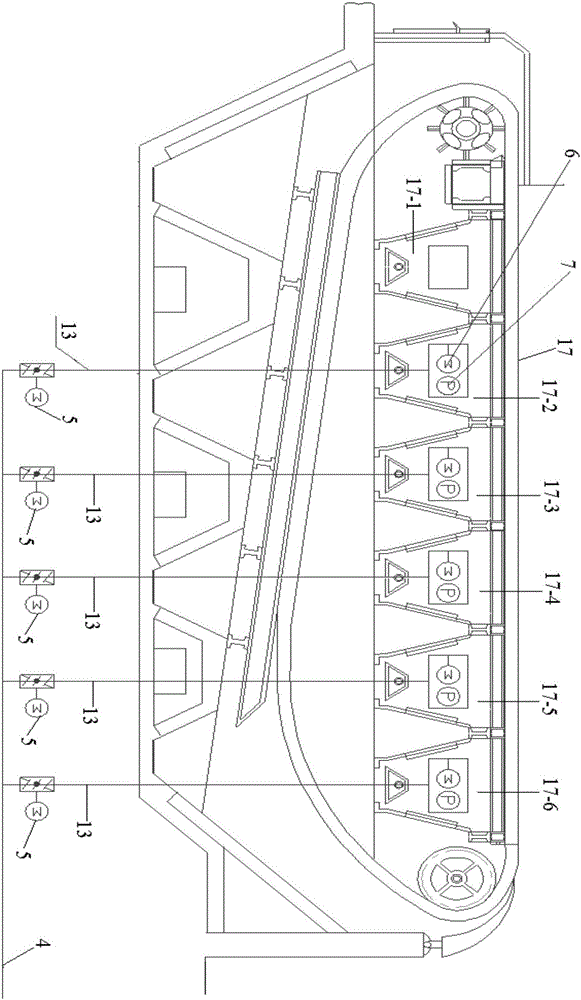

[0025] Specific implementation mode one: as Figure 1-2 , the present embodiment is an independent zoned layer combustion flue gas circulation combustion system which is composed of a layer combustion boiler 1, a dust collector 11, a layer combustion boiler induced draft fan 12, a recirculation induced draft fan input pipeline 2, a recirculation induced draft fan 3, and a recirculation induced draft fan 3. Circulation induced draft fan output pipeline 4, recirculation branch pipeline 13, branch pipeline electric control valve 5, air chamber electric control valve 6, air chamber pressure measurement gauge 7, flue gas communication pipeline from rear arch to boiler rear wall 9 , the connecting pipeline regulating valve 8 and the partition arch 10 are composed;

[0026] The inlet of the dust collector 11 is connected with the flue outlet of the boiler, the outlet of the dust collector 11 is connected with the inlet of the induced draft fan 12 of the layer-fired boiler, and one en...

specific Embodiment approach 2

[0034] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the flue gas communication pipeline 9 from the rear arch to the boiler rear wall is made of high temperature resistant stainless steel 310S. Others are the same as the first embodiment.

specific Embodiment approach 3

[0035] Specific implementation mode three: This implementation mode is a method of using an independent partition layer combustion flue gas circulation combustion system in specific implementation mode one, specifically:

[0036] 1. Turn on the recirculation induced draft fan 3, and the hot flue gas in the stable section of the outlet of the layer-fired boiler induced draft fan 12 is sucked by the recirculation induced draft fan 3, which in turn passes through the recirculation induced draft fan input pipeline 2, and the recirculation induced draft fan output pipeline 4 , The recirculation branch pipeline 13 enters the second to sixth air chambers below the fire grate 17 of the floor-fired boiler, and the recirculation flue gas volume is controlled by the recirculation induced draft fan 2 to account for 15% to 25% of the actual total flue gas load of the boiler ; Among them, when the load of the boiler is greater than or equal to 85% of the rated load, the total amount of recir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com