A solid chemical raw material crushing and drying equipment

A technology for chemical raw materials and drying equipment, applied in grain processing and other directions, can solve the problem of single reduction of chemical raw materials, and achieve the effect of improving thermal reaction rate, facilitating heating and baking, and distinguishing obvious effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The preferred technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

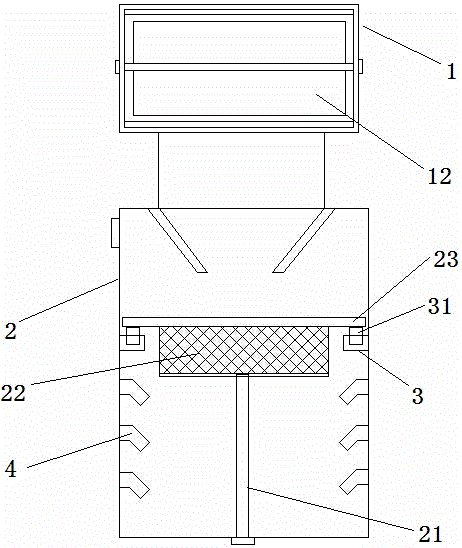

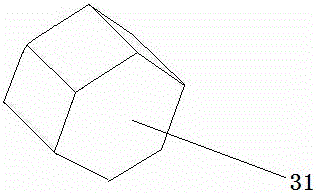

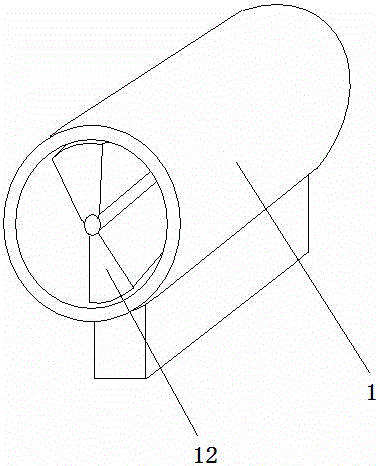

[0031] As shown in the figure, a crushing and drying equipment for solid chemical raw materials includes a crushing drum part 1 and a heating drum part 2 connected to each other. The vertical position of the center of the inner end surface of the crushing drum part 1 has a first rotating shaft, and several rotating shafts are arranged around the first rotating shaft. The crushing cam 12 is close to the inner wall of the crushing drum part 1, and the inner wall of the crushing drum part 1 has a friction layer.

[0032] A second rotating shaft 21 with a telescopic function is arranged at the center of the inner bottom of the heating cylinder part 2, and a storage basket 22 for containing chemical raw materials is arranged on the upper part of the second rotating shaft 21. The inner wall of the heating cylinder part 2 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com