Patents

Literature

93results about How to "Guaranteed combustion stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

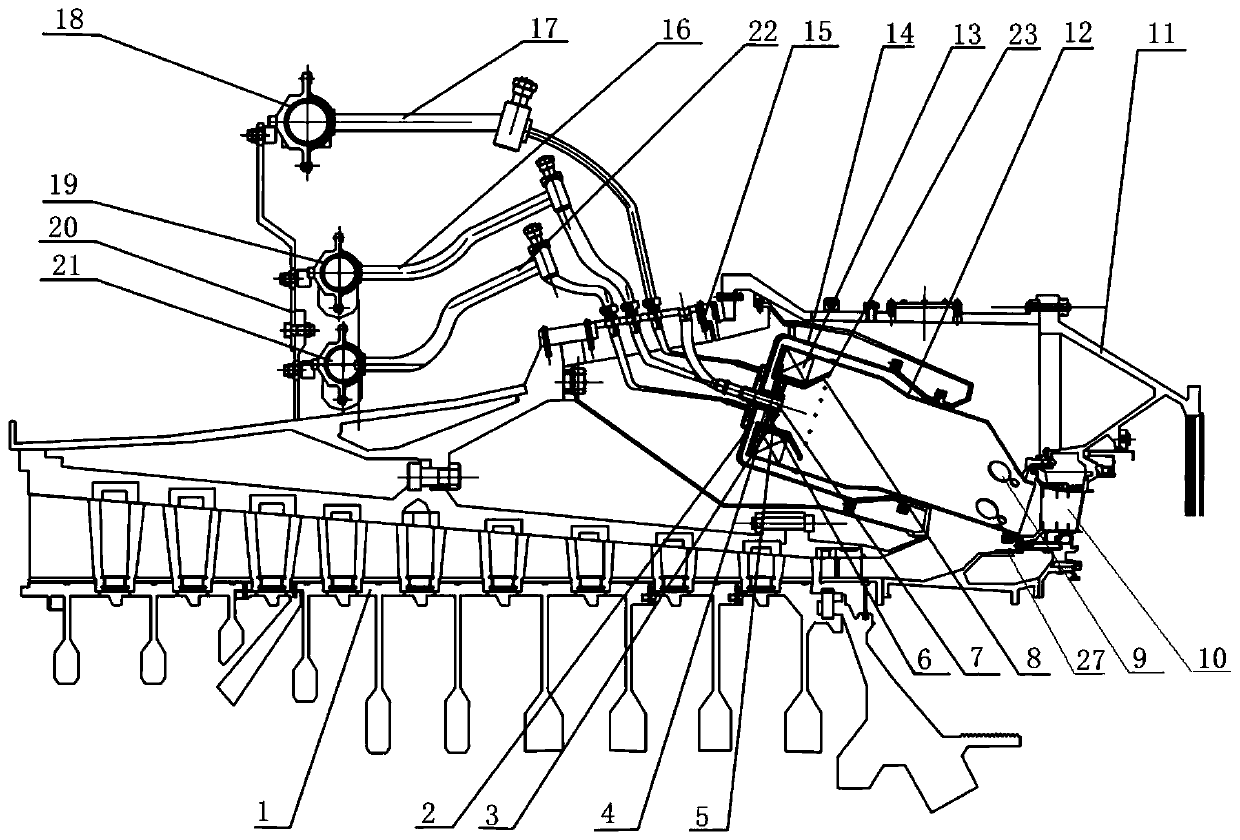

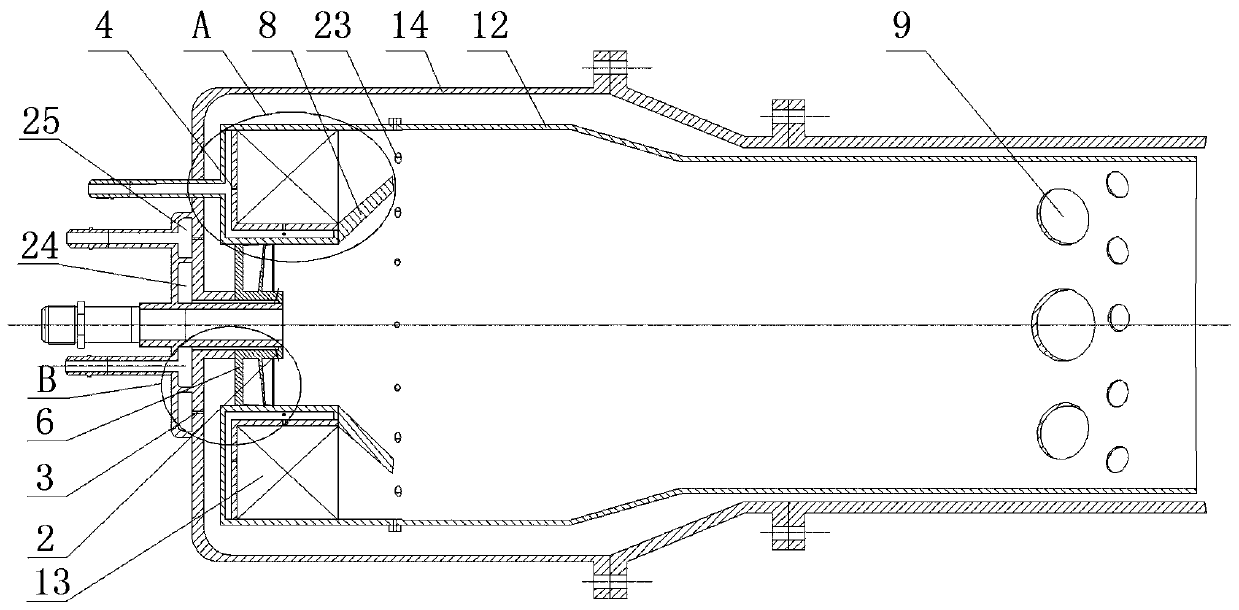

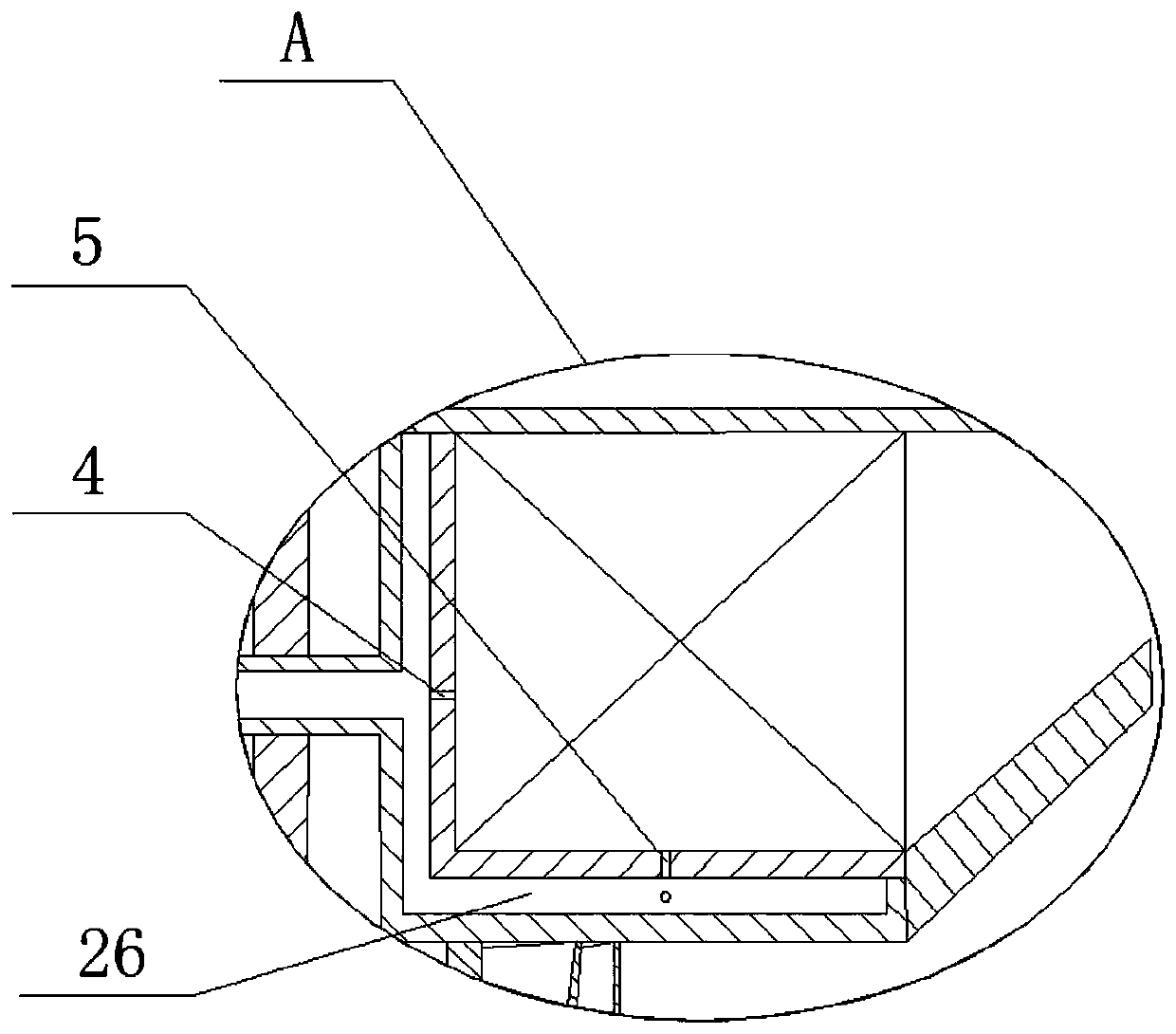

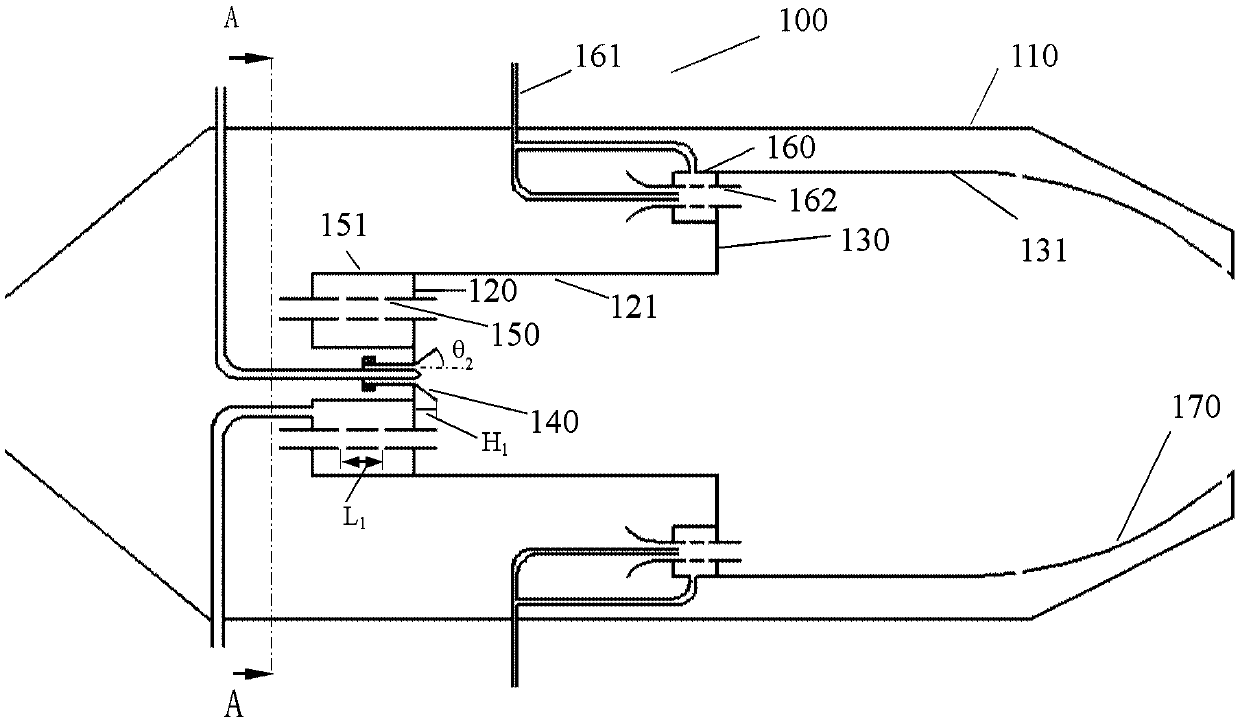

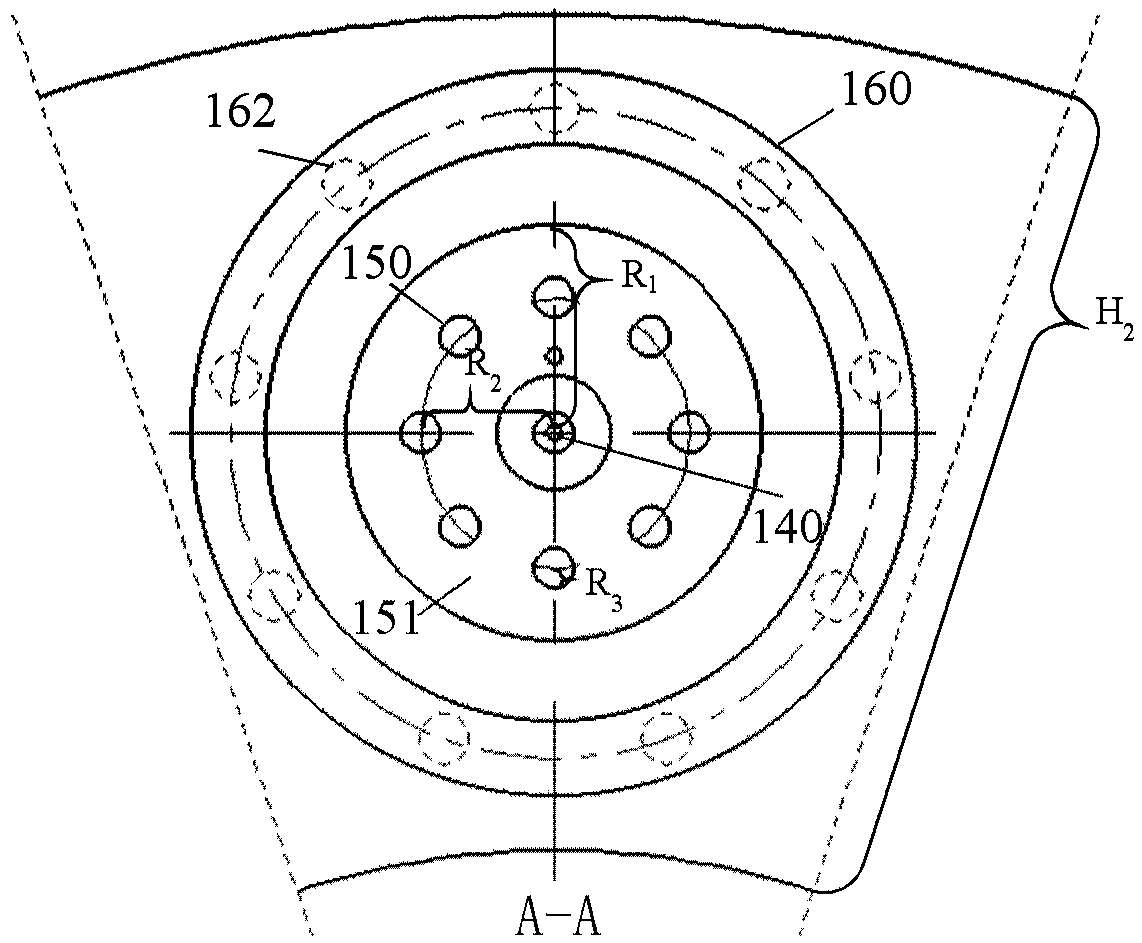

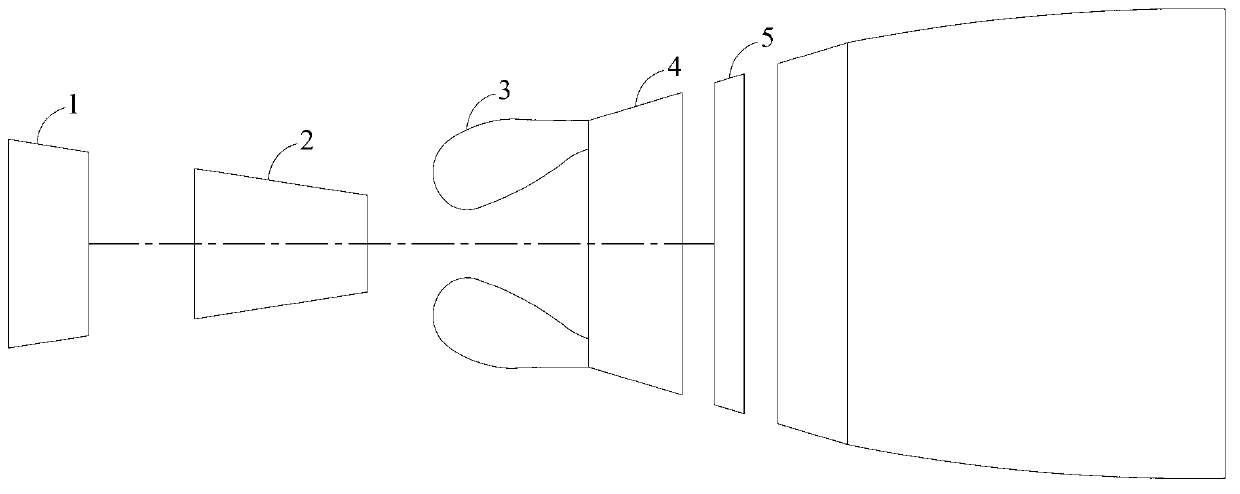

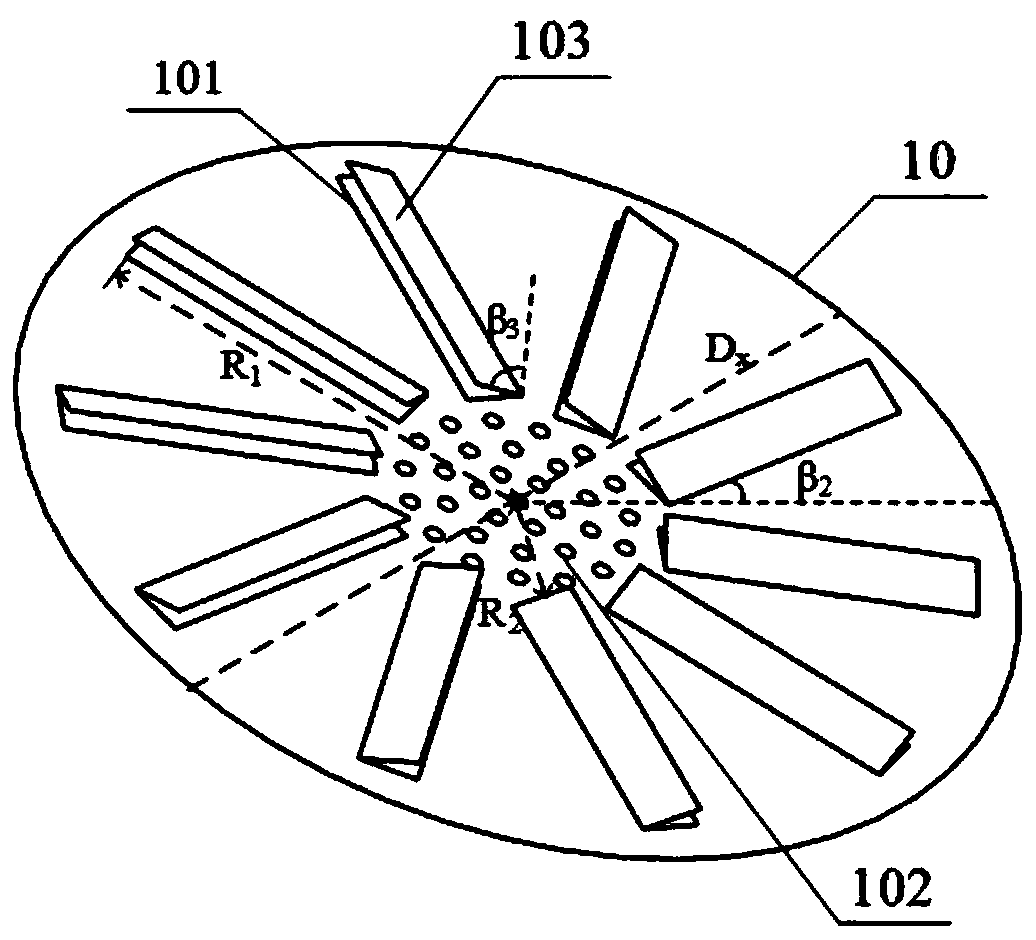

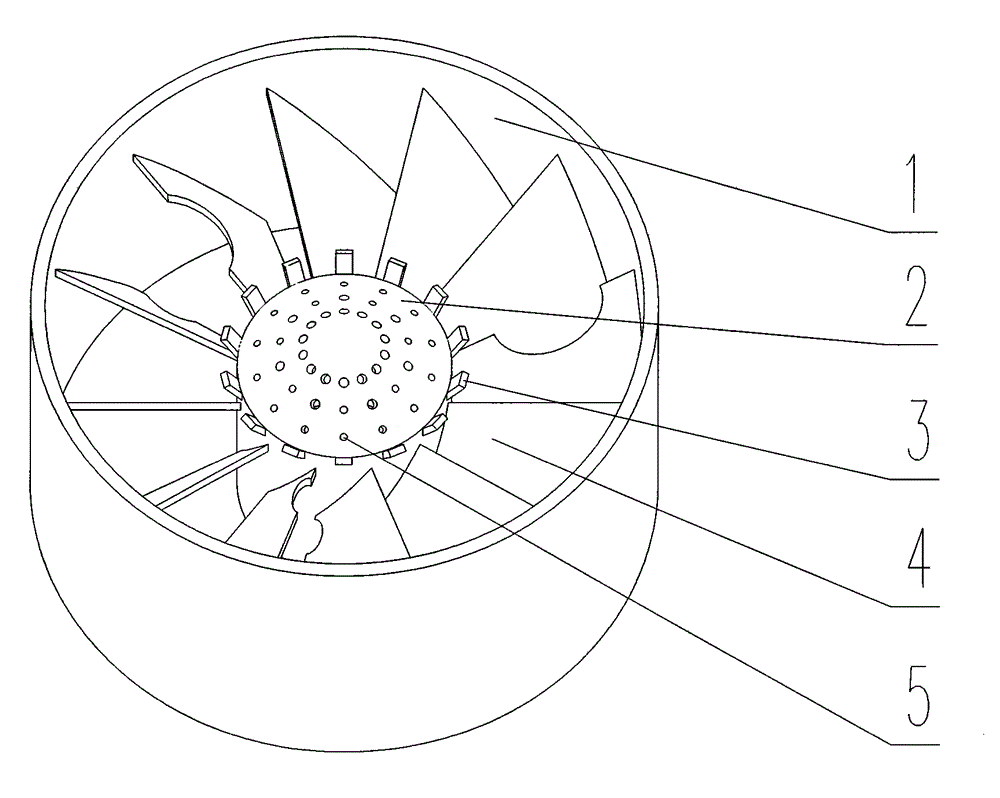

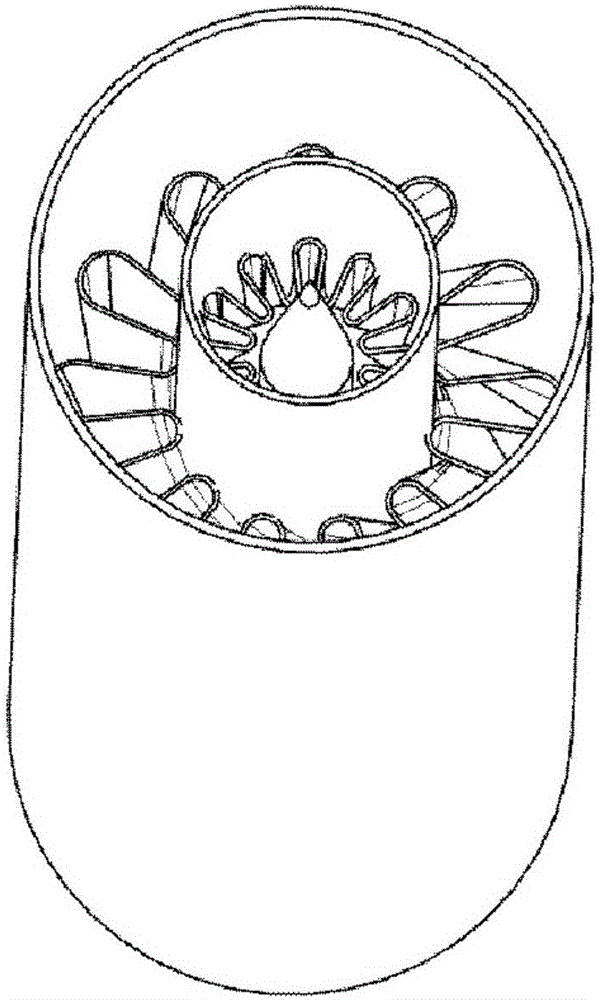

Fuel and air mixing device for low-pollution burning chamber of gas turbine

ActiveCN102506446AFast evaporationQuick blendContinuous combustion chamberIndustrial gasCombustion chamber

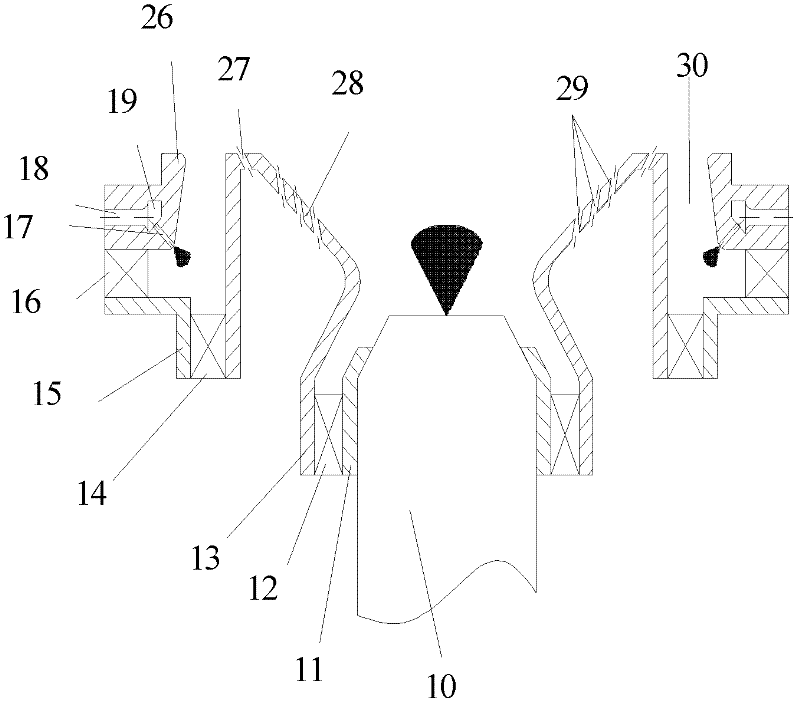

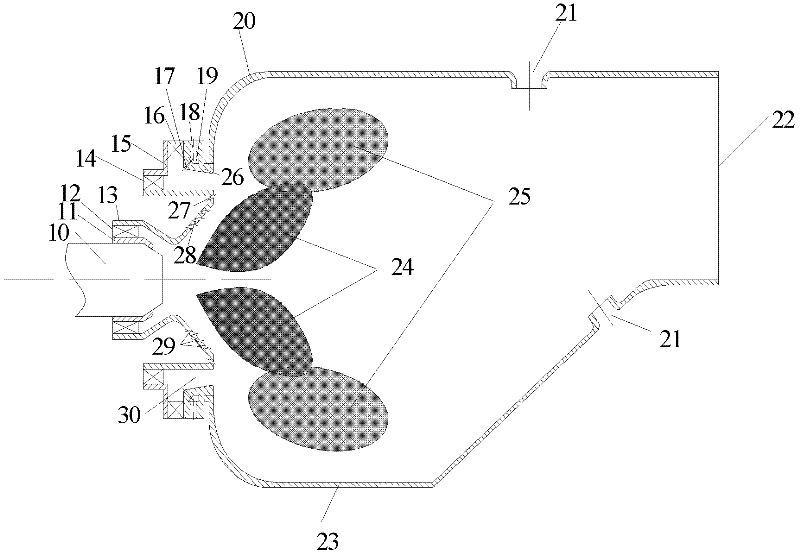

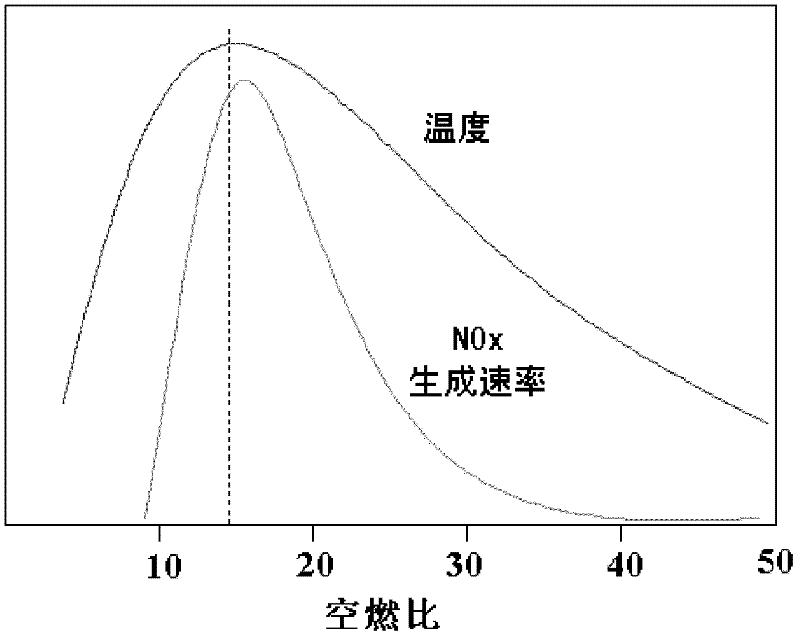

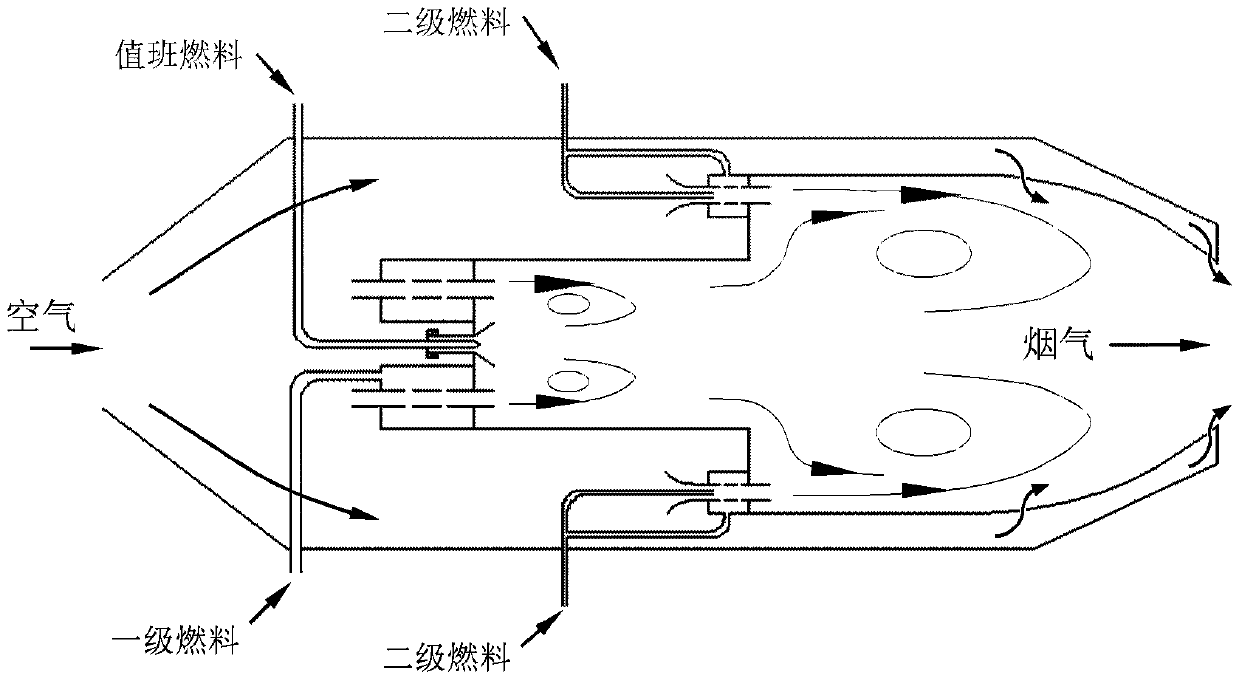

The invention discloses a fuel and air mixing device for a low-pollution burning chamber of a gas turbine. Fuel comprises a main burning level and a duty burning level; and air is supplied by a three-stage cyclone. The fuel and air mixing device is characterized in that the central duty level adopts diffusive burning, and the peripheral main burning level adopts premixing or semi-premixing burning. The central duty level consists of a centrifugal atomizing nozzle and first-stage cyclone air; and the rotating directions of the first-stage cyclone air and second-stage cyclone air are opposite. The fuel of the main burning level is supplied by a multipoint direct-injection type nozzle, the air is respectively supplied by the second-stage cyclone air and third-stage cyclone air, and the rotating directions of the second-stage cyclone air and third-stage cyclone air are opposite. The central duty level is used when in low working conditions such as starting and slowing and the like, so that the stable burning range can be widened, the burning efficiency can be improved and the emission of CO and UHC is reduced; and when in large working conditions, the duty level and the main burning level work simultaneously, the duty level provides a stable ignition source for the main burning level, a main burning area is in a lean-oil state, and the temperature is far lower than the temperatureof insulated flame, so that the emission of NOx under the large working conditions can be obviously reduced. The fuel and air mixing device can be used for an aerial gas turbine engine or an industrial gas turbine.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

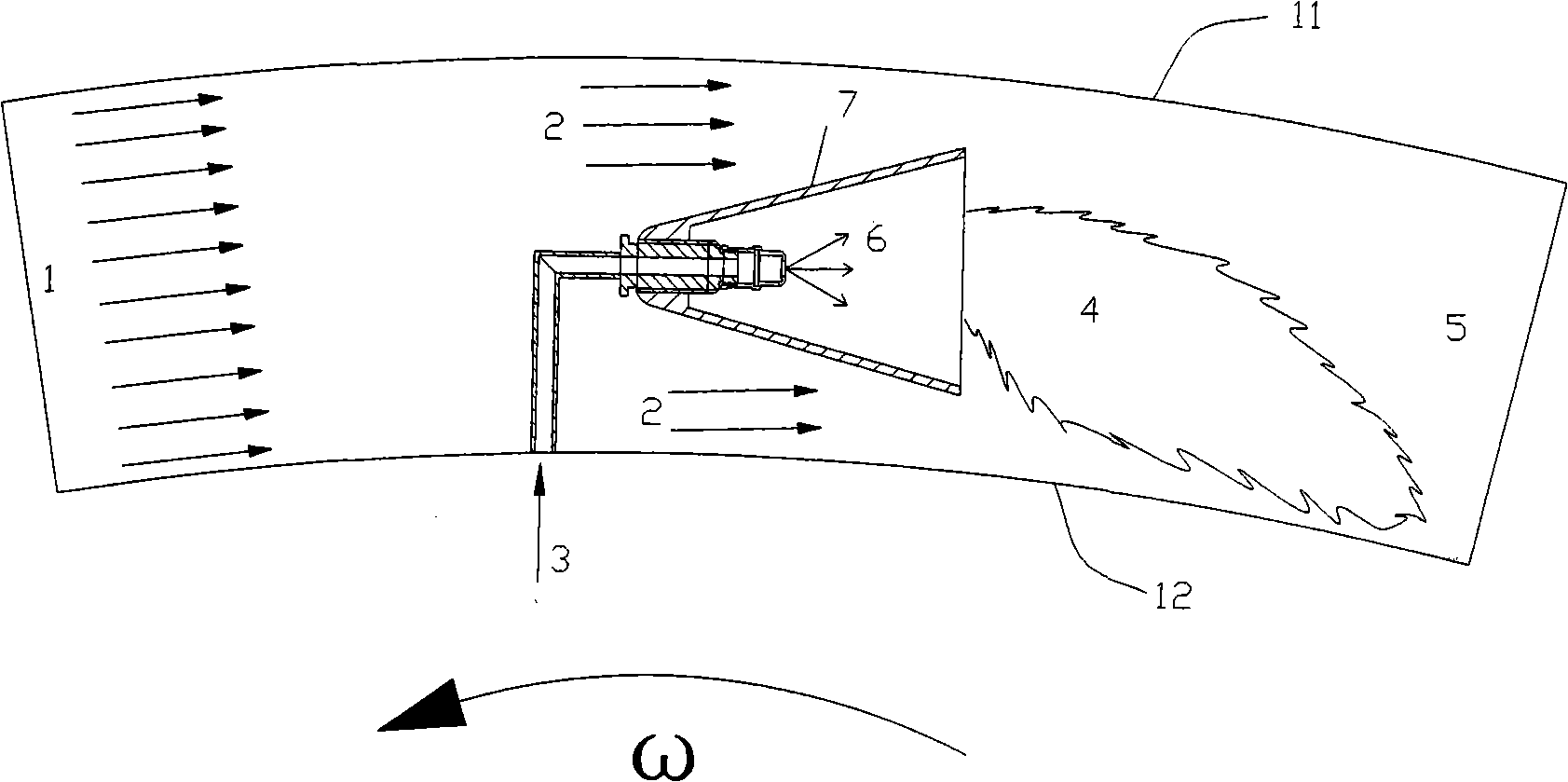

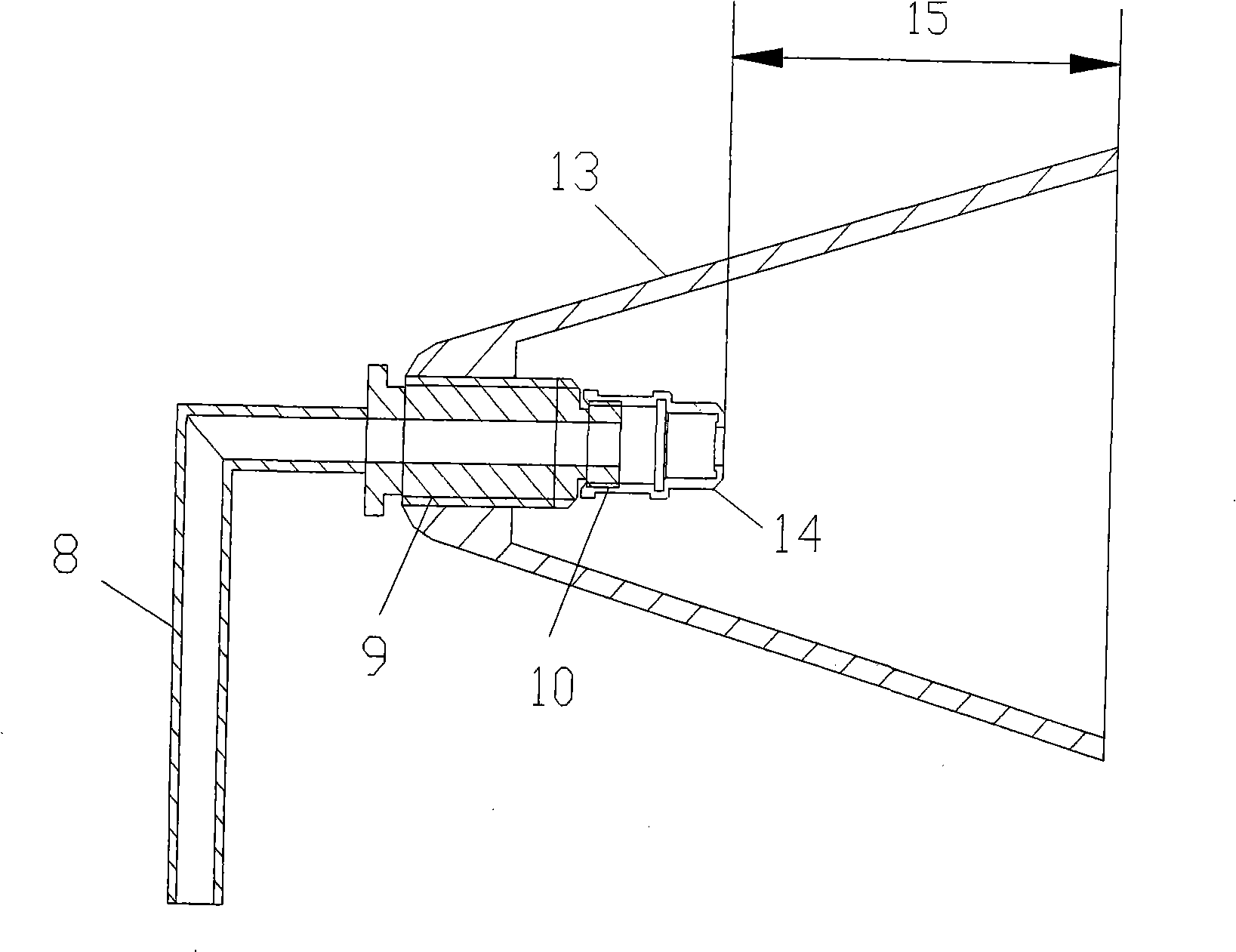

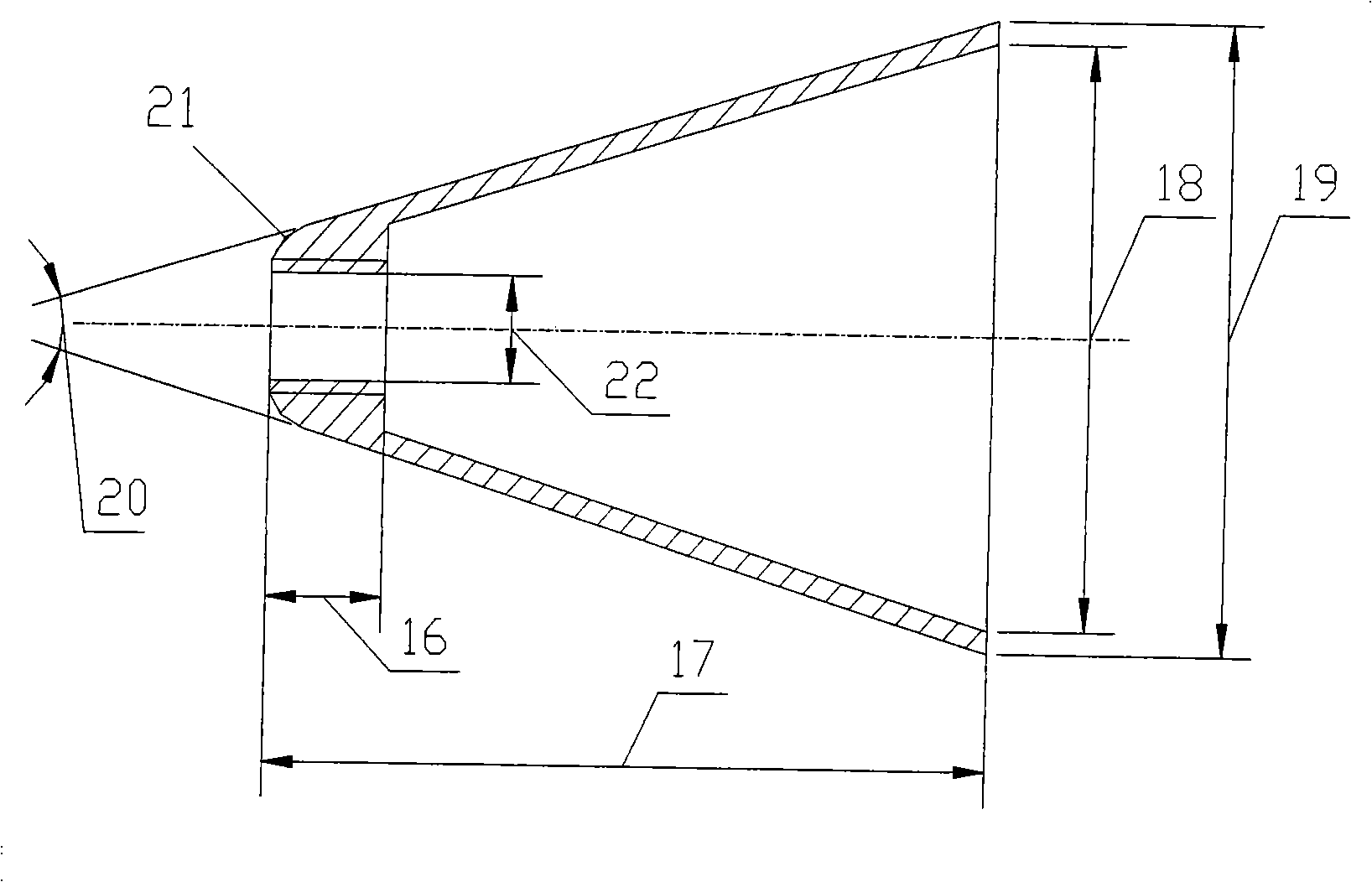

V -type cone flame holder for rotor engine

InactiveCN101334174AIncreased flame surface area and heat release rateGuaranteed combustion stabilityContinuous combustion chamberPre combustionEngineering

The invention discloses a V-shaped cone flame holder used for the rotor engine. The V-shaped cone flame holder is characterized in that the V-shaped cone flame holder comprises a supporting frame and a V-shaped cone, wherein, the V-shaped cone is connected and fixed with a V-shaped cone connecting seat on the supporting frame through a thread way and is positioned at the high position of a combustion passage; the supporting frame adopts a hollow structure, the feeding fuel enters the oil fuel passage in the middle of the supporting frame through the lower end opening of the supporting frame and is atomized to from nozzle oil mist through a centrifugal nozzle installed at the rear end of the supporting frame, and the nozzle oil mist is ignited to form the high temperature flame of the pre-combustion stage flame holder; when the whole device is rotated along the rotor engine, the high temperature flame of the pre-combustion stage flame holder is caused to float from the high position to the low position area of the internal radius from the high position by utilizing the characteristic of the high centrifugal force field on the high-speed rotor, the main combustion stage in the low position area is ignited, thus to enhance the combustion efficiency and guarantee the stability of the combustion. The V-shaped cone flame holder can provide stable high position fire source for the combustion system of the motor engine and guarantee the whole combustion system to be provided with wide and stable operating range and high efficient combustion.

Owner:BEIHANG UNIV

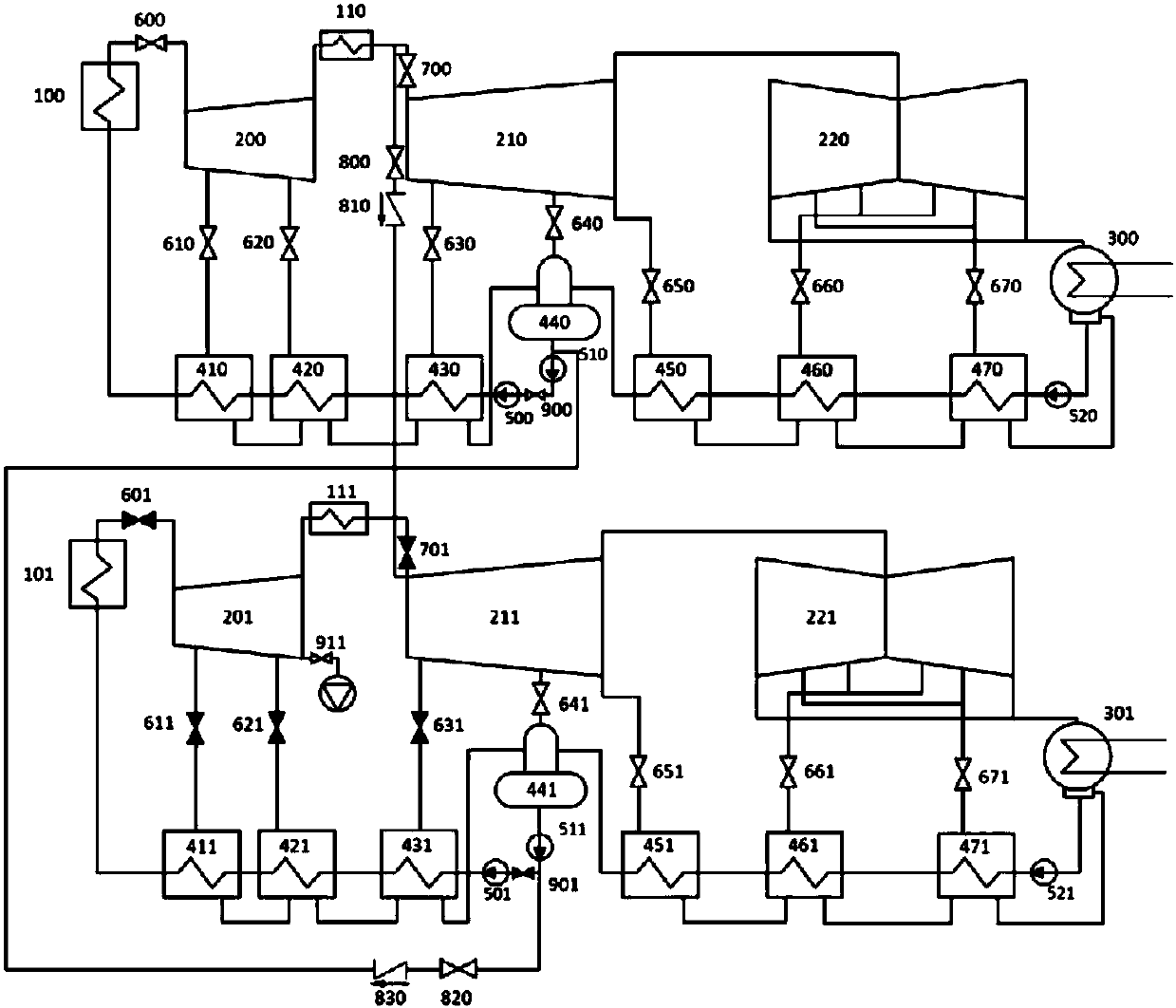

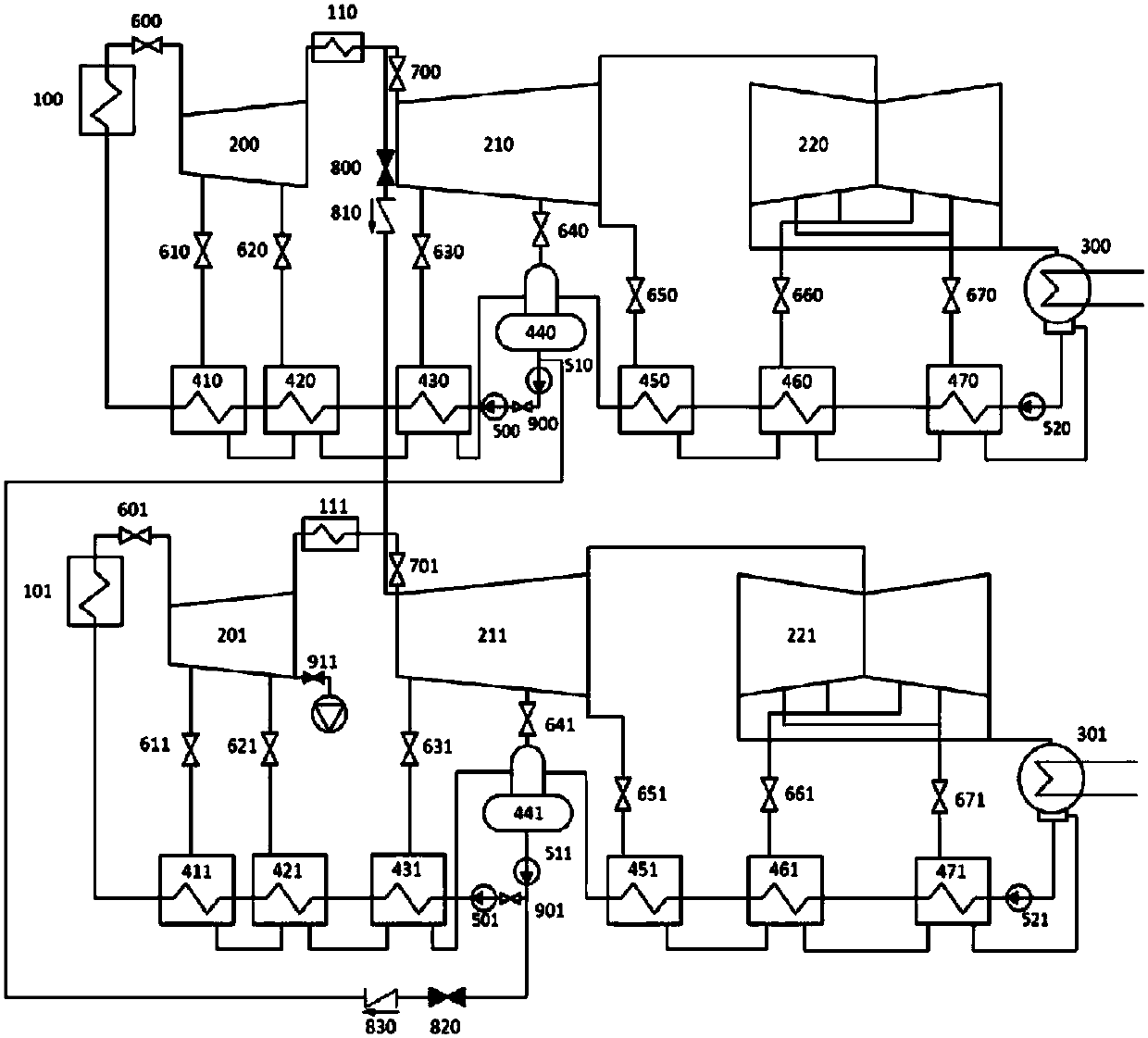

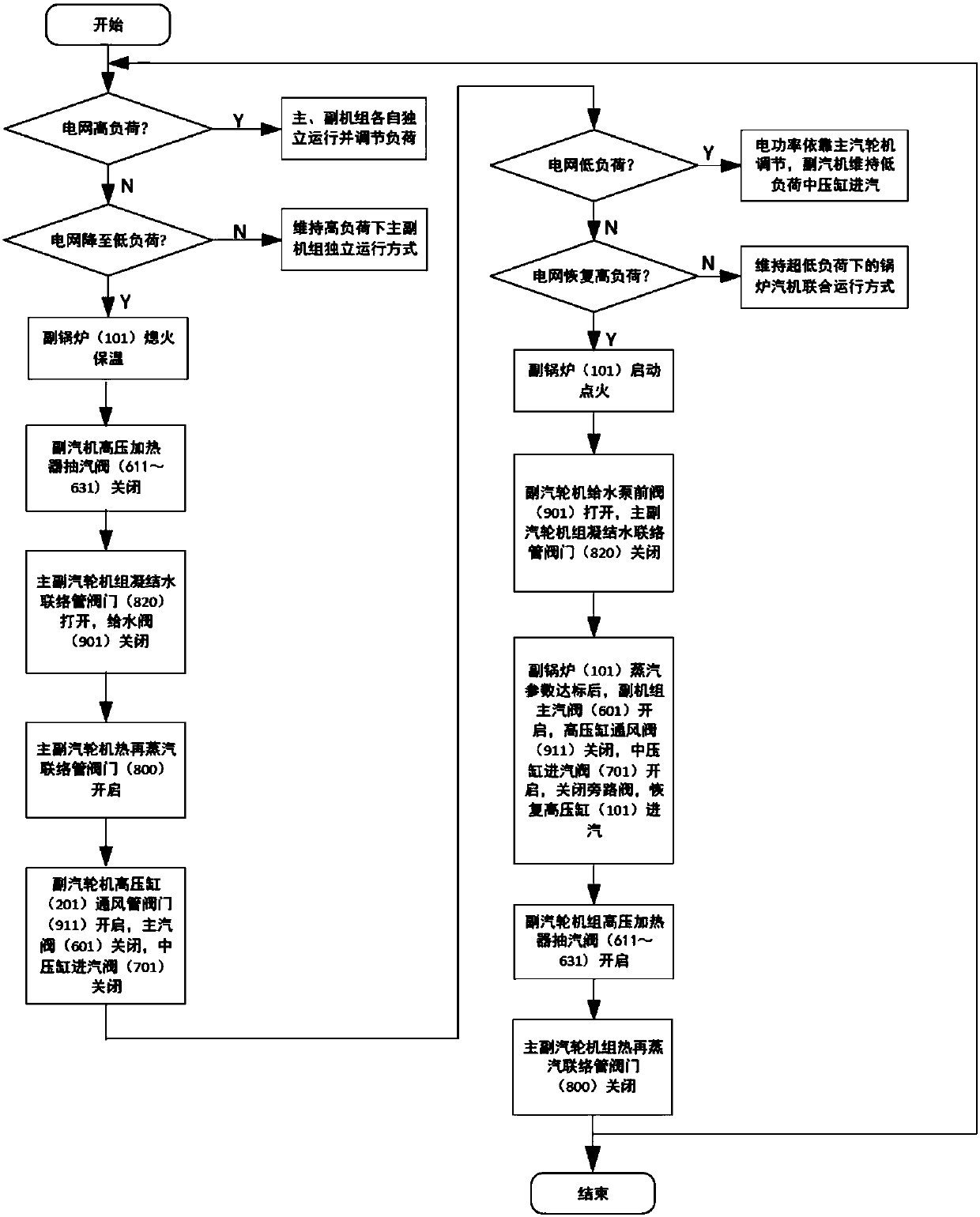

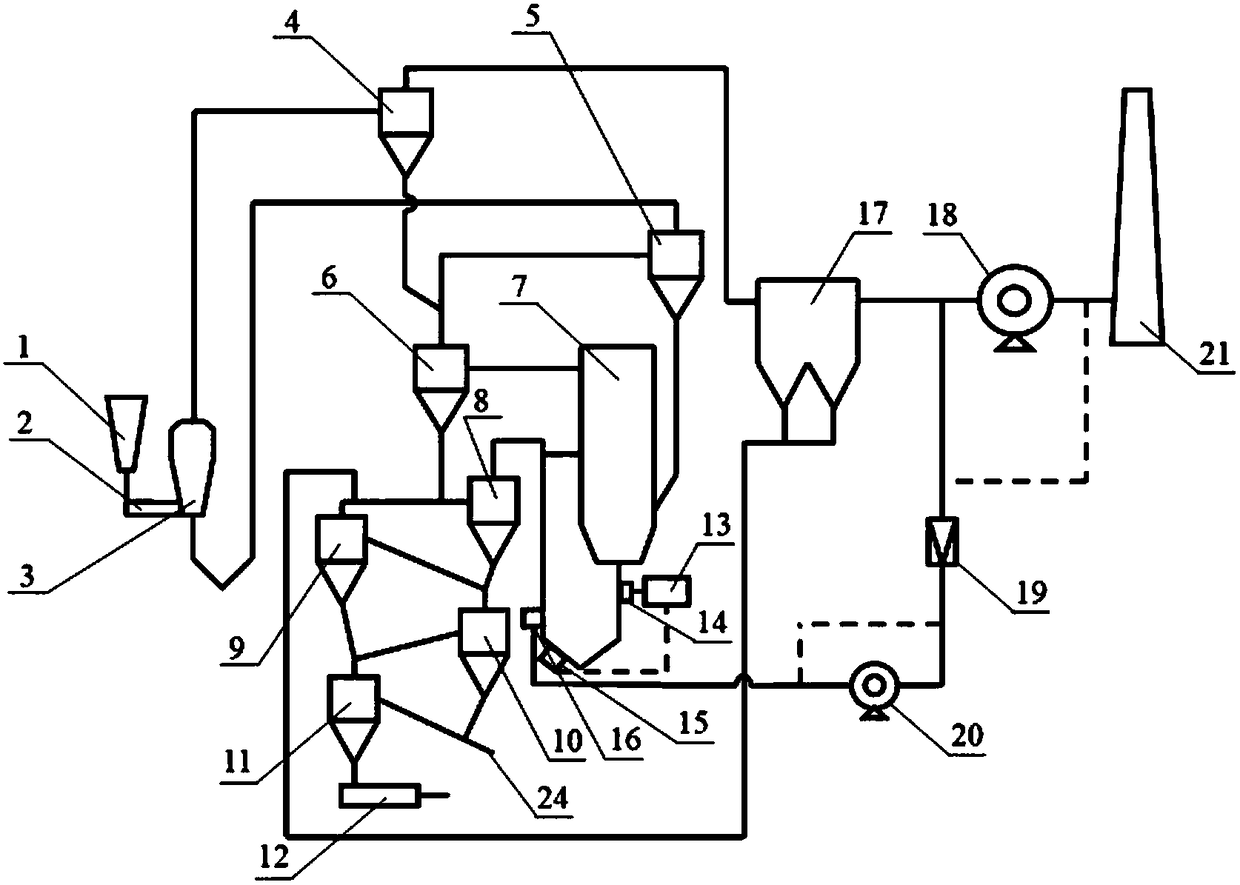

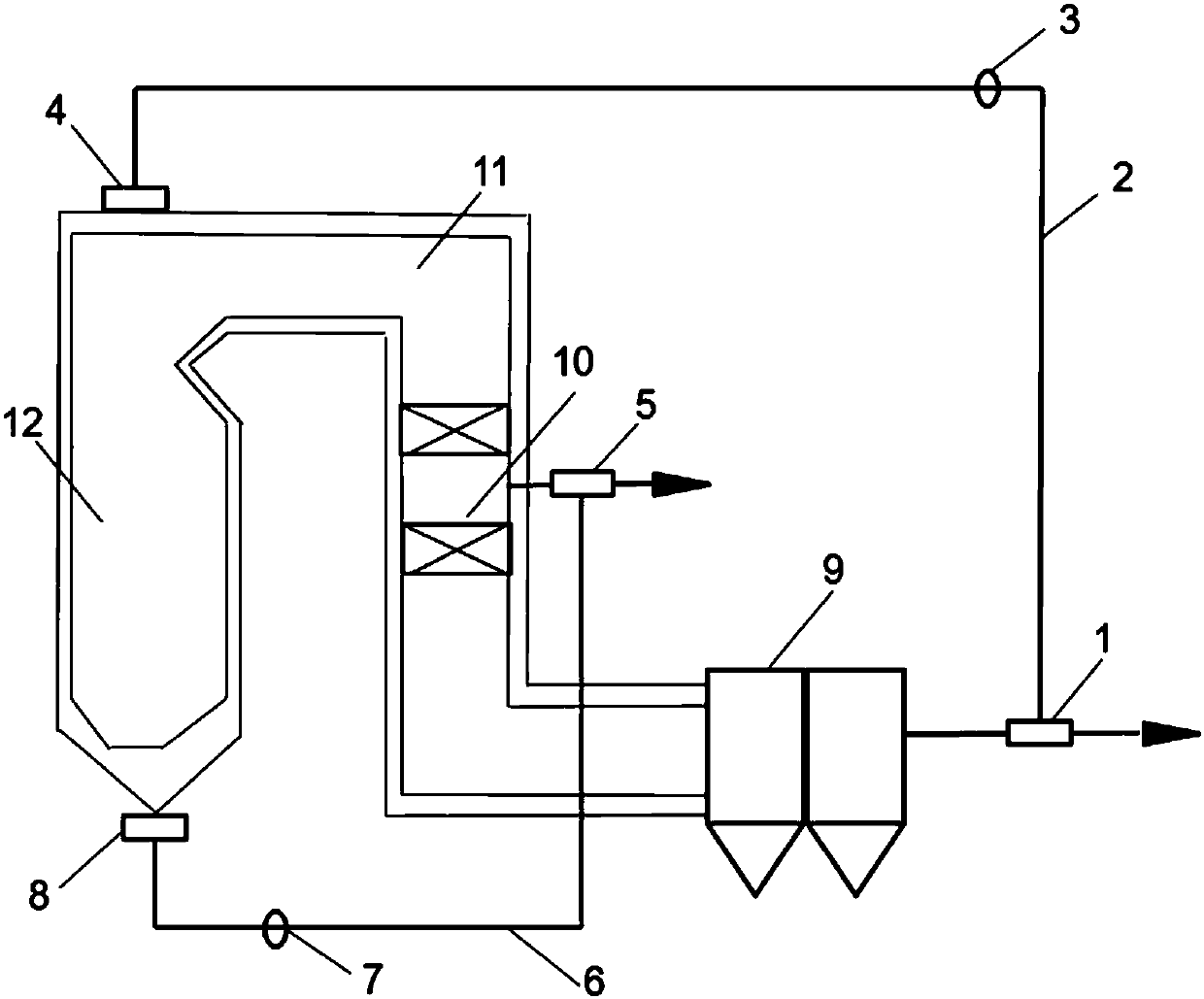

Ultra-low-load operation system and operation method for coal-fired generating units

InactiveCN107747503AIncrease peak shaving depthImprove peak shaving performanceSteam engine plantsProcess engineeringSteam system

The invention discloses an ultra-low-load operation system and an operation method for coal-fired generating units. The system is composed of two coal-fired generating units which operate in a unifiedmode, and each coal-fired generating unit consists of a steam turbine, a steam system, a vacuum air exhaust system, a condensed water system and a water feeding system; the steam systems of the generating units are connected through a heat steam connecting tube; and the water feeding systems of the generating units are connected through a water feeding connecting tube. The ultra-low-load operation system concentrates steam outlet force when the two units operate under ultra-low load on a main boiler, and solves the problems that boiler consumption is unstable, a coal mill, a fan and a denitrification reactor are unstable and the like when current coal-fired generating unit operates under the ultra-low load, and greatly improves safety and reliability of boiler operation control.

Owner:SOUTHEAST UNIV +1

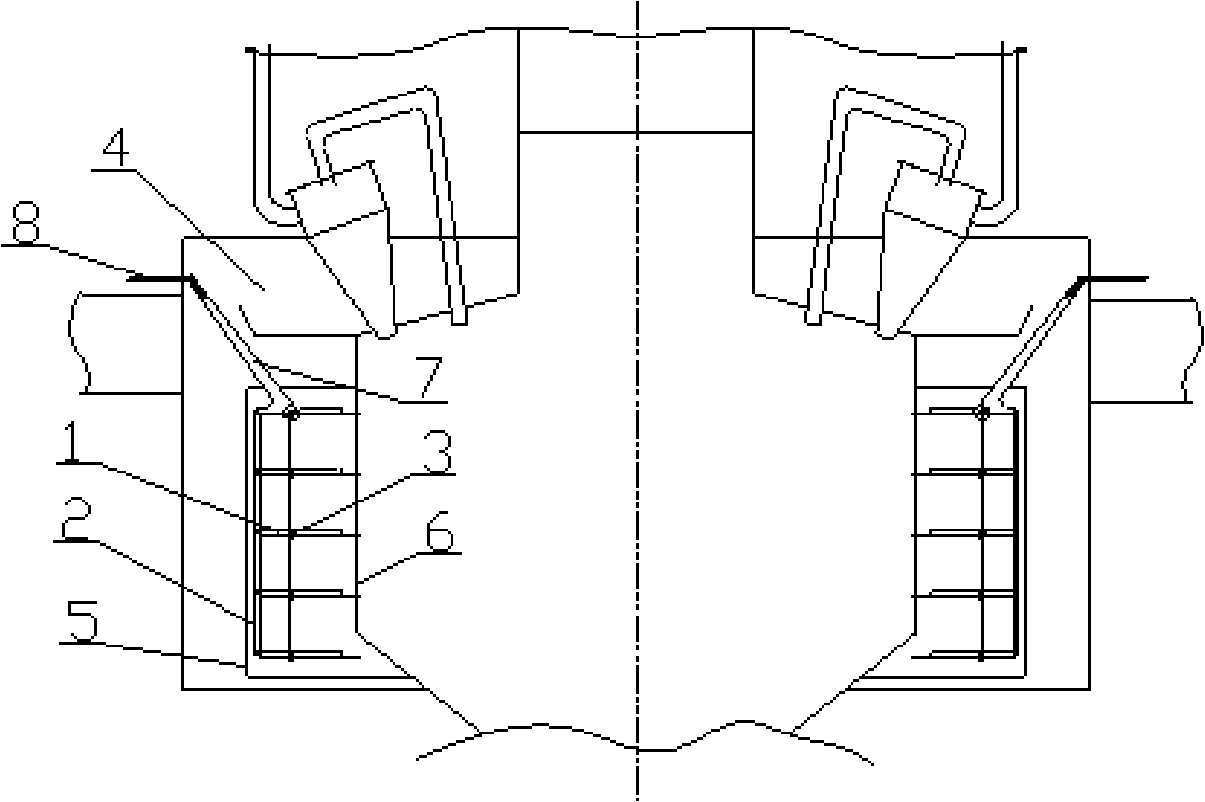

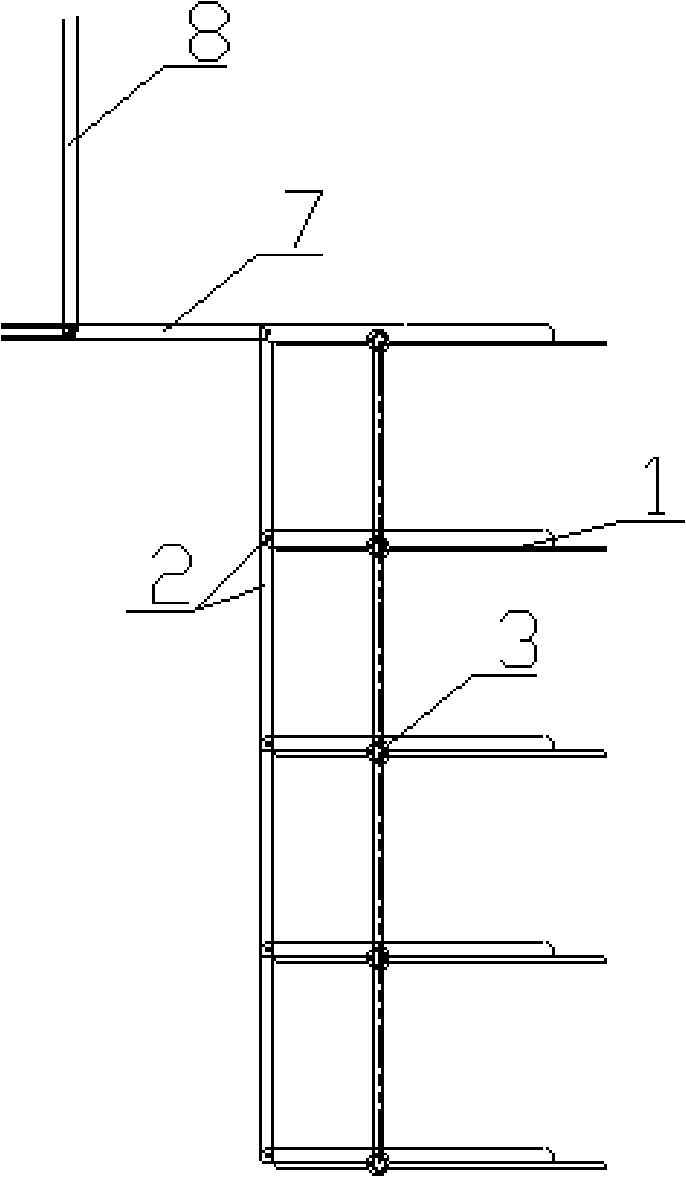

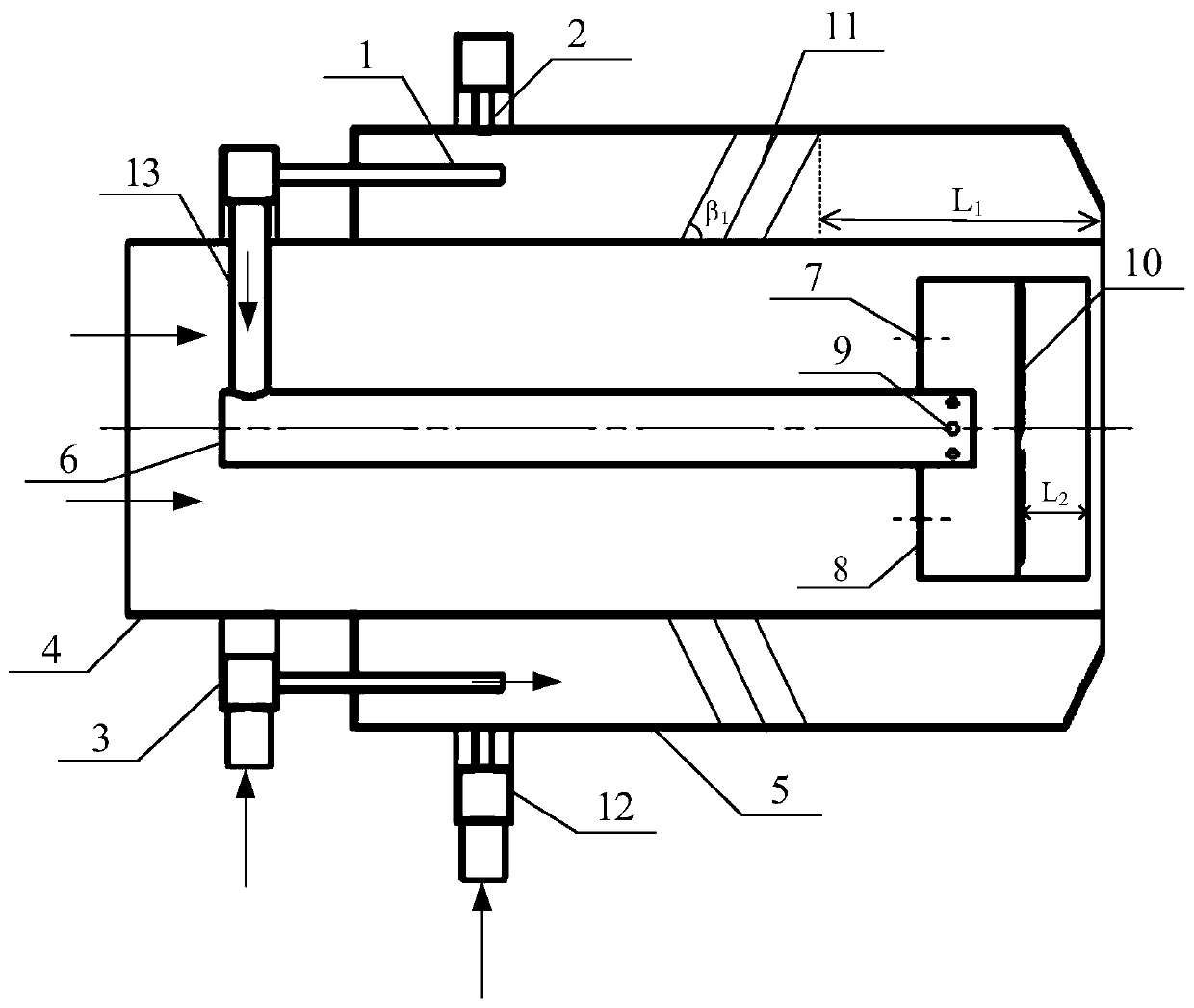

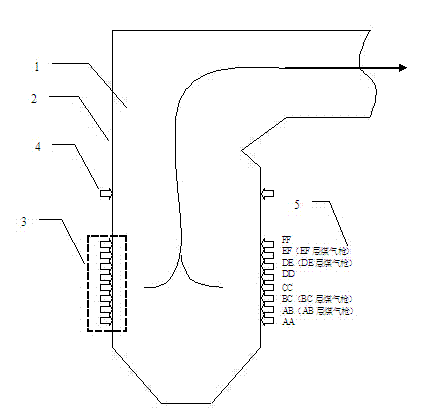

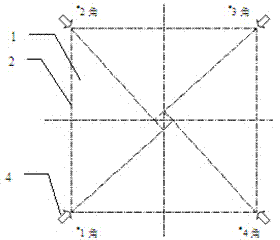

Apparatus for adjusting secondary wind direction under W type flame oven arch

InactiveCN101324340AImprove burnout rateReduce generationAir supply regulationCombustion apparatusRetention timeEngineering

The invention discloses a device for adjusting the direction of under-arch secondary air of a W-shaped flame furnace. More than two guide blades (1) are connected with each other through a connection hinge (2), a rotation shaft (3) is arranged on each guide blade (1), the guide blades (1) are arranged between an orifice plate (5) and a water-cooling wall pipe (6) of an under-arch secondary air chamber (4) of the W-shaped flame furnace, an adjusting arm (7) is arranged on one of the guide blades (1), and a pull rod (8) is connected with the adjusting arm (7). The device can set different under-arch secondary air inclination angle according to different conditions of each burner and can adjust the under-arch secondary air inclination angle to adapt to different areas (altitudes) and different coal qualities. Under proper lower inclination angle of the under-arch secondary air, the undershoot stroke of the flame and the coal retention time are increased remarkably, and the flame filling degree and uniformity in the lower furnace are improved remarkably, thus effectively improving the burn-out rate of pulverized coal and saving energy resource by about 30 to 50%.

Owner:ELECTRIC POWER SCI RES INST OF GUIZHOU POWER GRID CO LTD

Gas turbine low-emission combustion chamber using gas fuels

InactiveCN110131750AReduced flow areaGood mixing effectContinuous combustion chamberAutomotive engineeringCombustion chamber

The invention discloses a gas turbine low-emission combustion chamber using gas fuels, and belongs to the technical field of gas turbines. The combustion chamber comprises an on-duty grade, a main combustion grade, a high-pressure igniter, a mixing hole, an exhaust outlet, a bearing machine box, a flame cylinder, the flame cylinder outer machine box, a flange, a first on-duty grade gas fuel pipeline, a main combustion grade gas fuel pipeline, a main combustion grade fuel main pipe, a first on-duty grade fuel main pipe, a pipeline bracket, a second on-duty grade fuel main pipe, a second on-dutygrade gas fuel pipeline, an air conditioning device, a first on-duty grade fuel tank, a second on-duty grade fuel tank and a main combustion grade fuel tank; when a gas turbine is started in low-loadstates, only the on-duty grade works; when the gas turbine is started in high-load states, the on-duty grade and the main combustion grade work together; and through diffusion combustion of on-duty grade fuels, a stable ignition source is provided to a main combustion area, so that the low emission requirement is guaranteed, the combustion stability and the combustion efficiency are fully considered, and the performance requirements of the combustion chamber are comprehensively met.

Owner:SHENYANG AEROSPACE UNIVERSITY

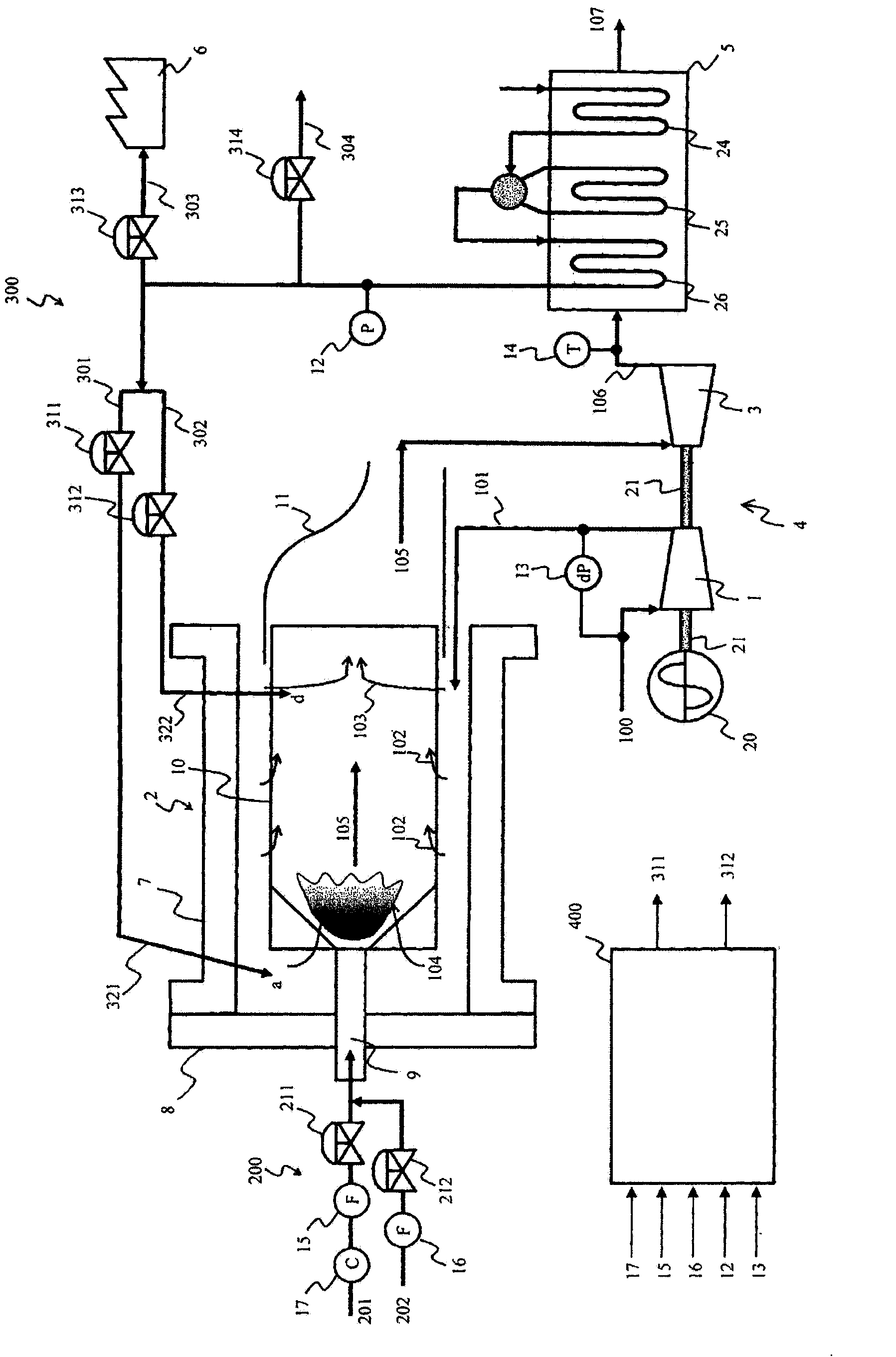

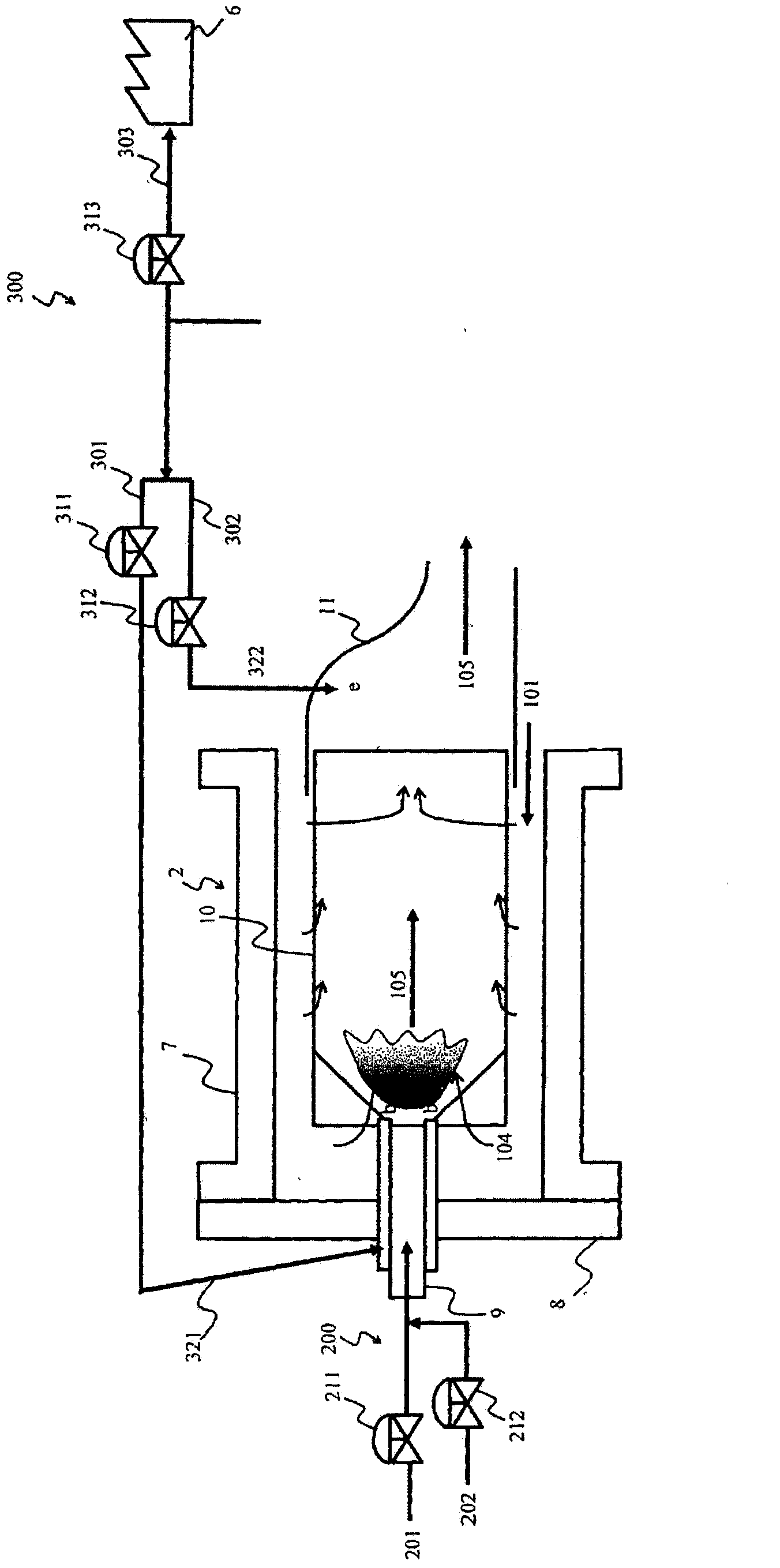

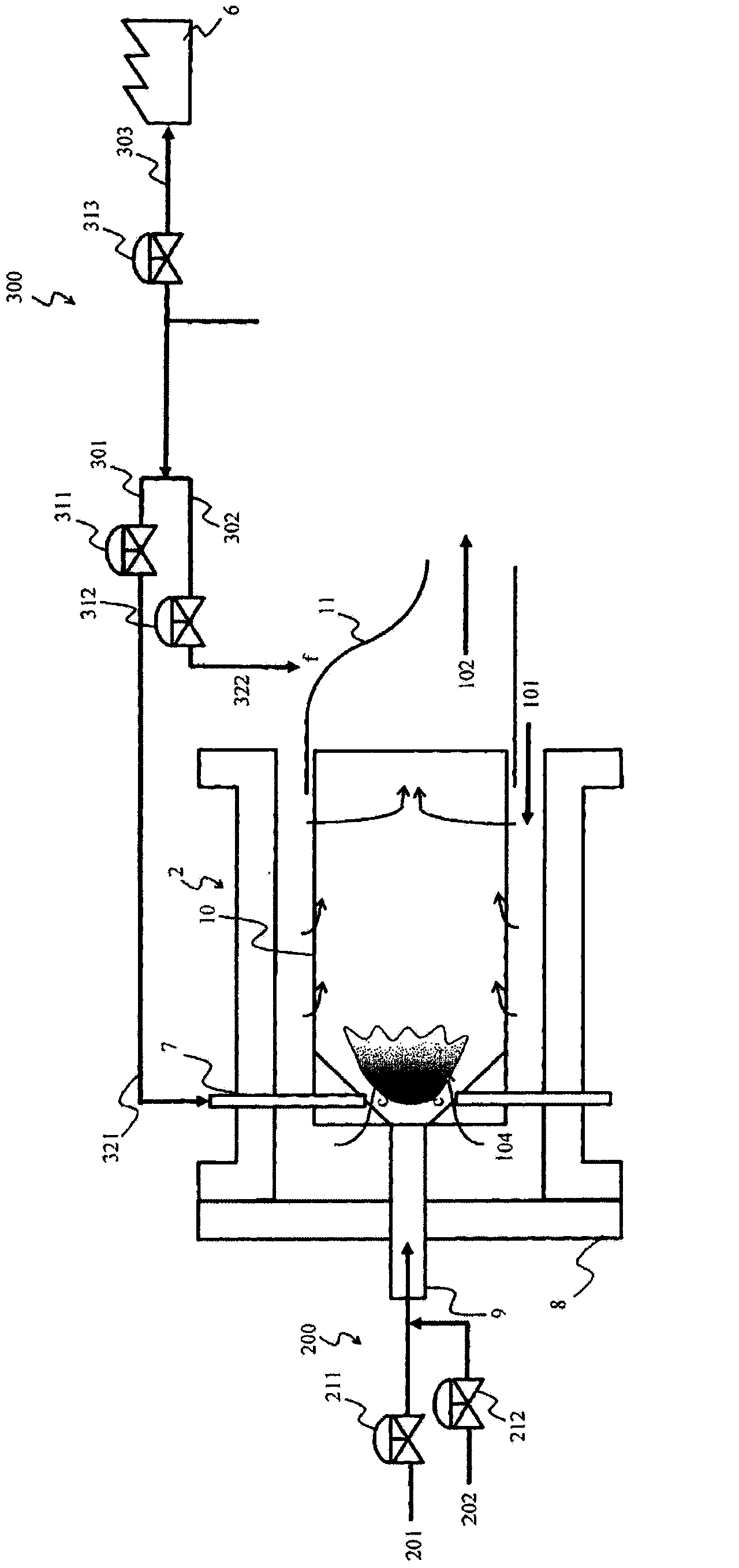

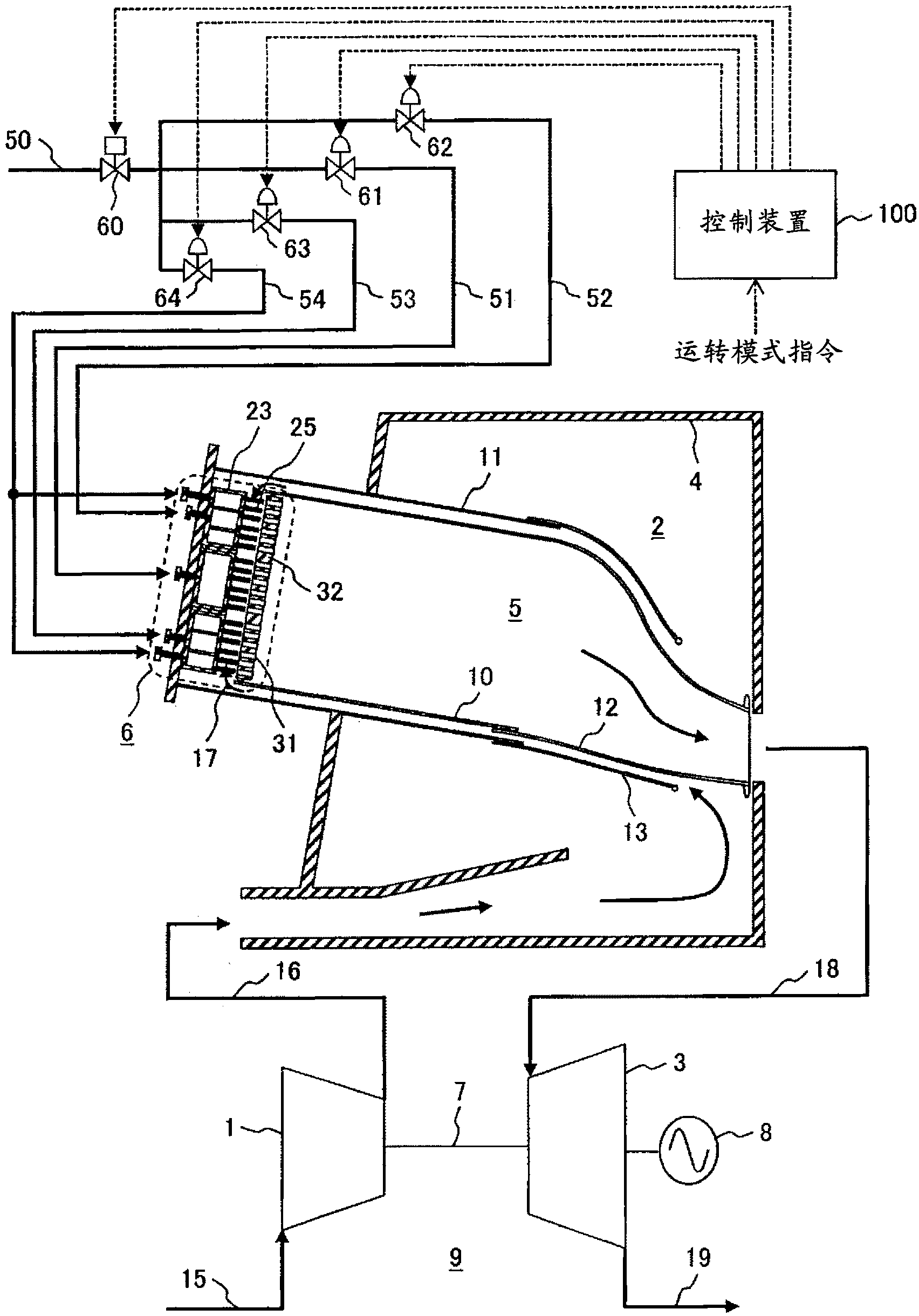

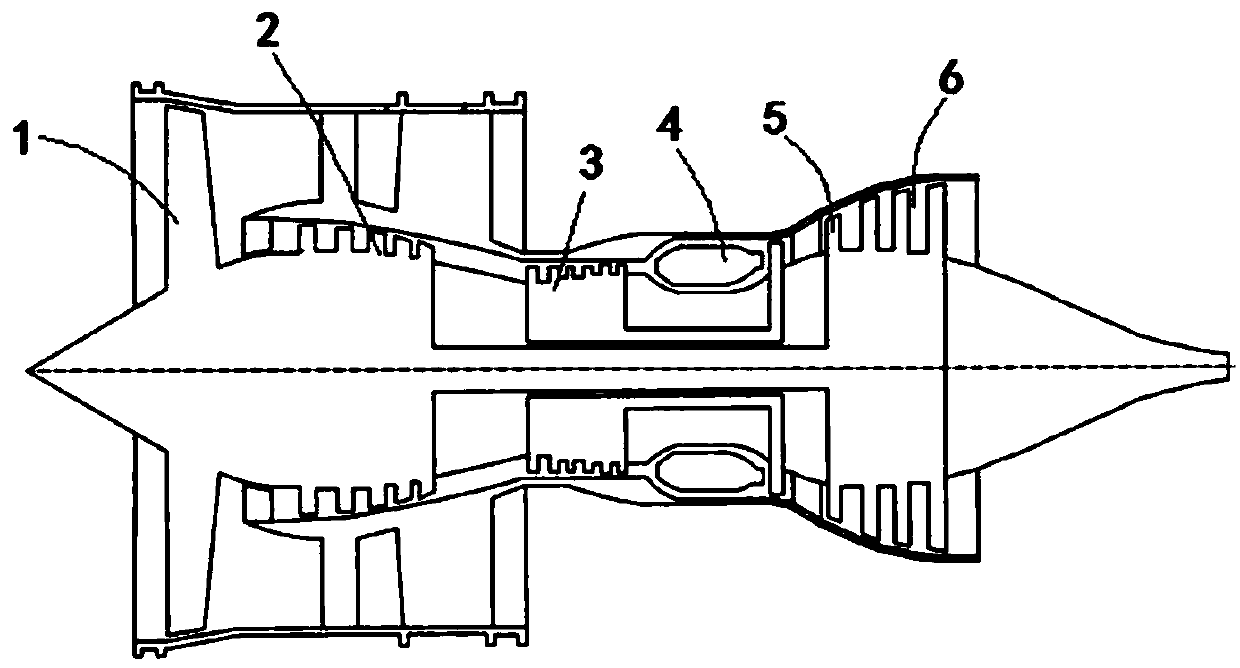

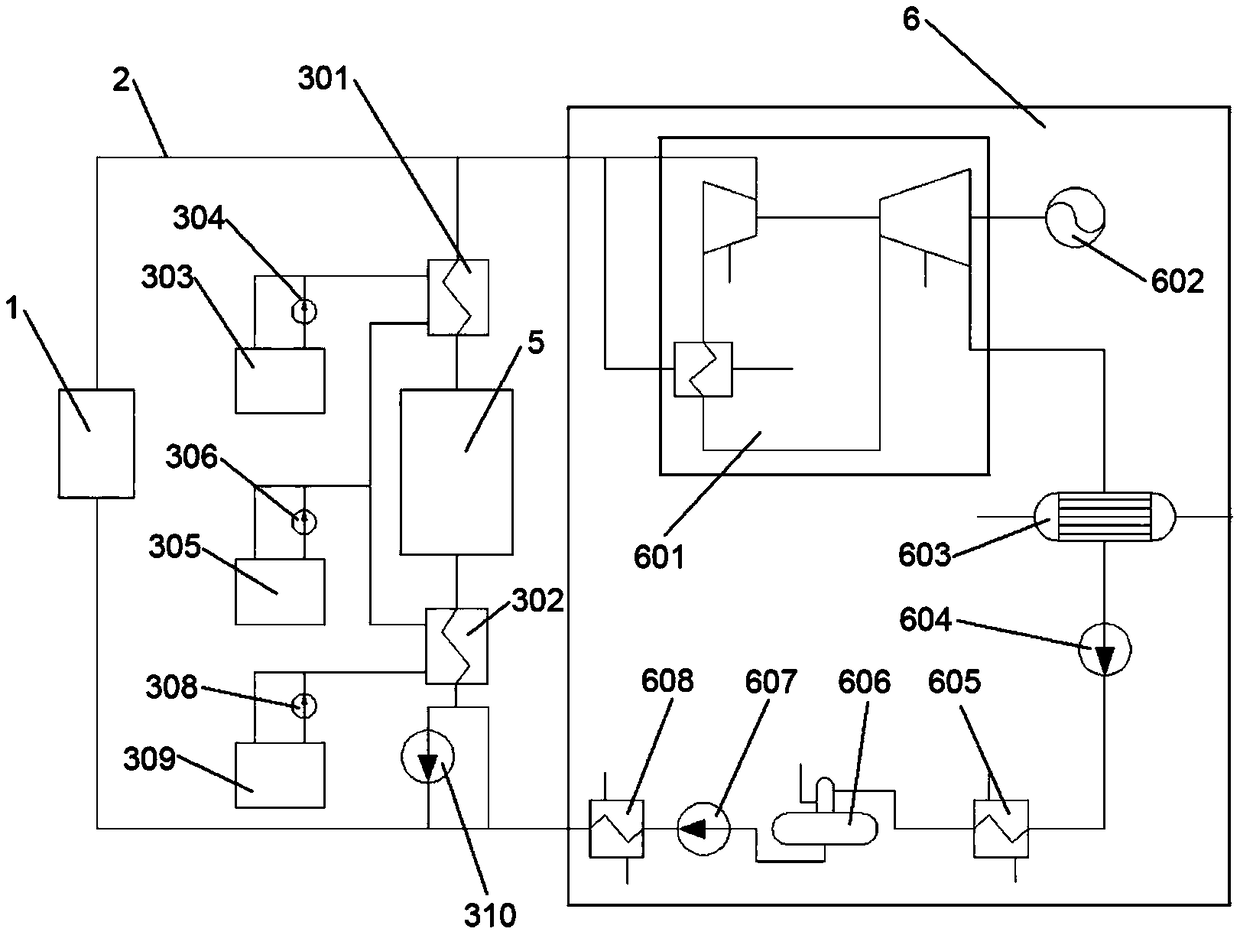

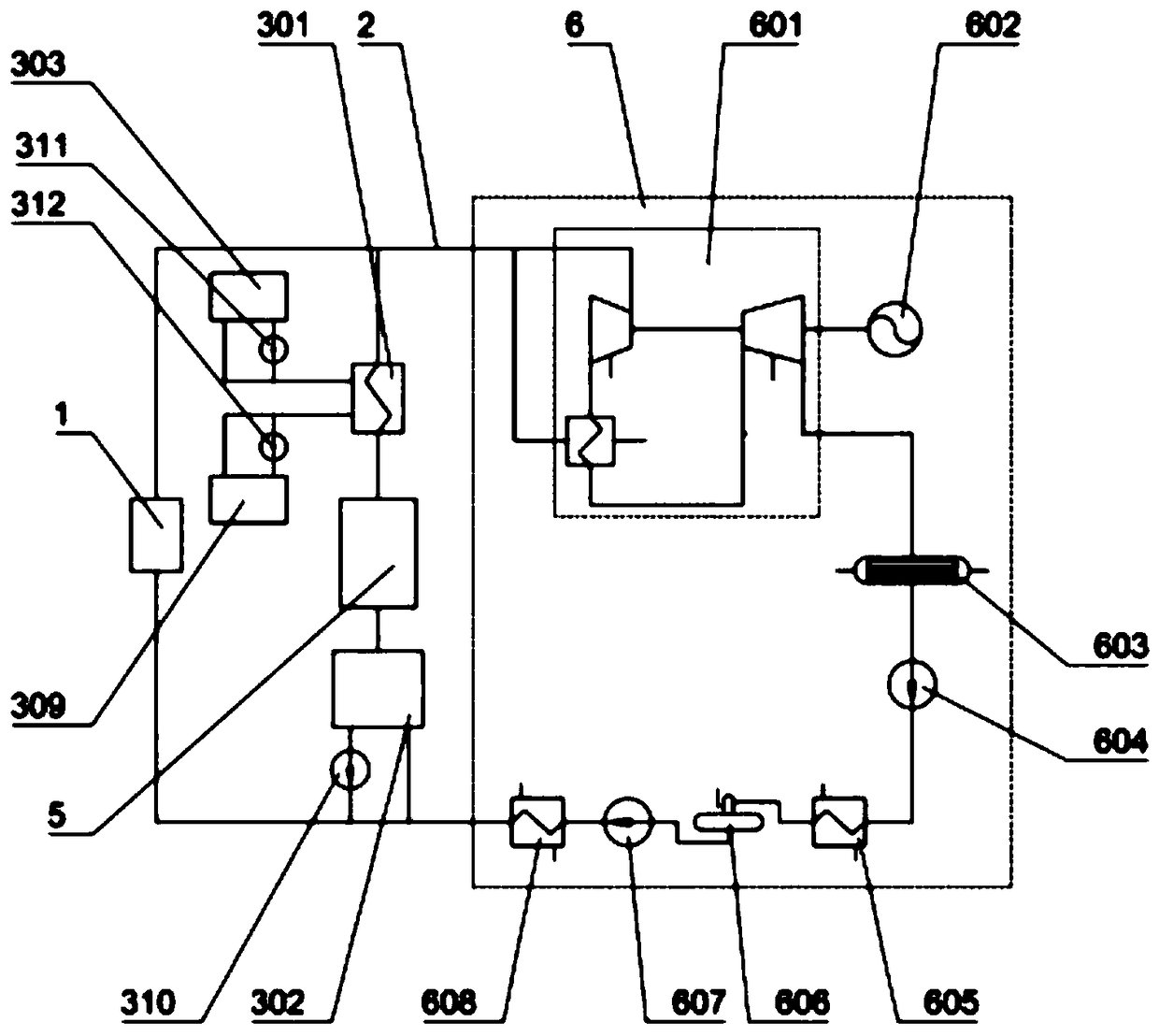

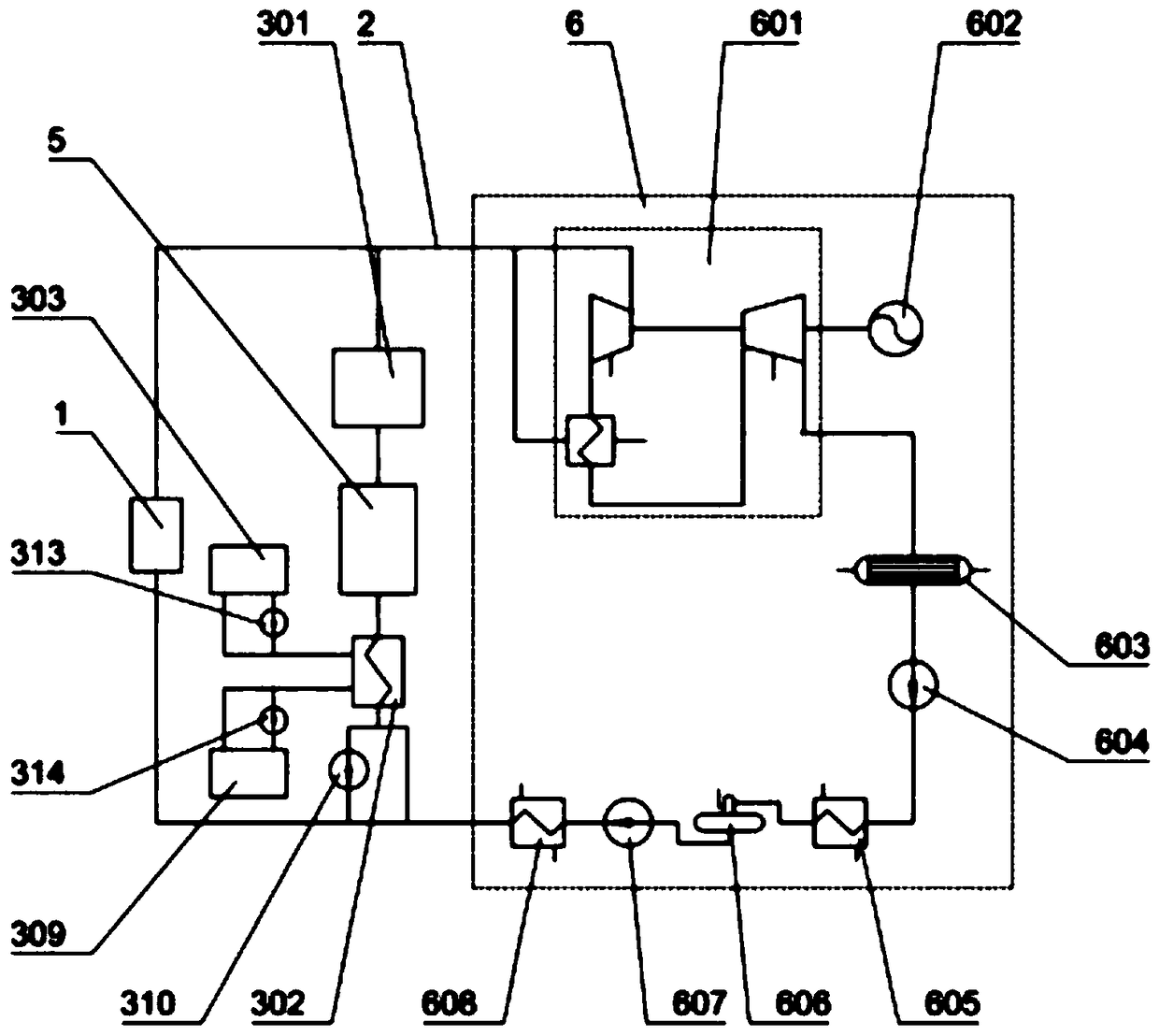

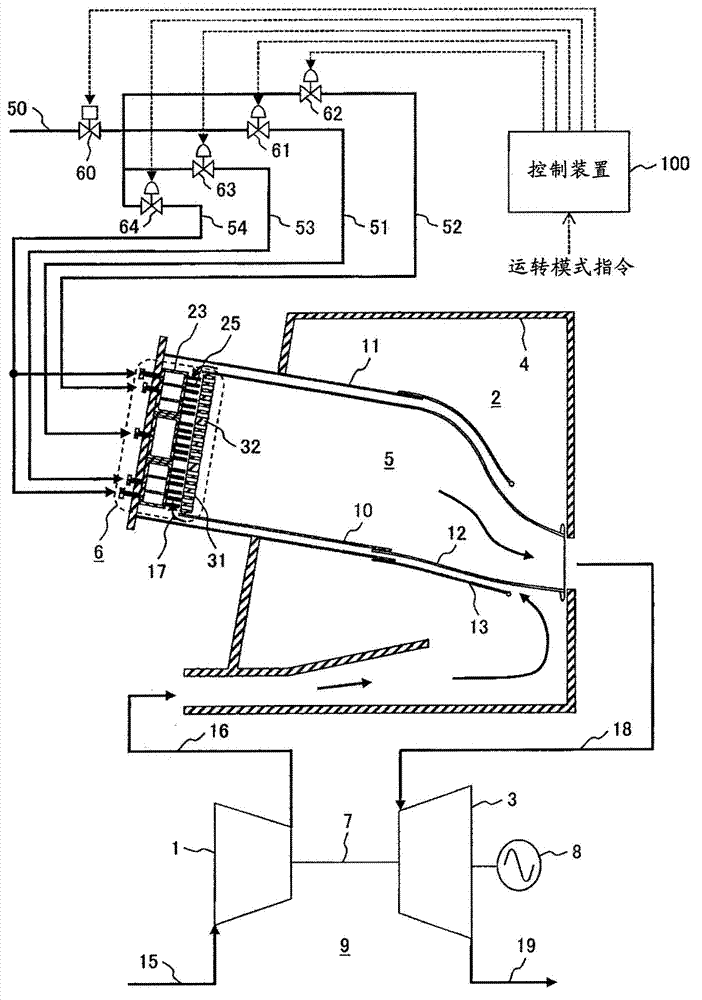

Variable Heat/power Ratio Cogeneration System

ActiveCN104048313AGuaranteed combustion stabilityReduce inhibitionSteam useEnergy industryCombustorLighter fuel

A variable heat / power ratio cogeneration system is provided, which is capable of suppressing the amount of NOx emission to the minimum level while ensuring the stability of combustion of a gas turbine combustor even when the ratio of gasification gas to be used to a normal fuel (such as natural gas or light fuel oil) to be used is changed or the composition of the gasification gas fuel are changed. The variable heat / power ratio cogeneration system includes: a first steam system (301) that injects extra steam on the upstream side of a flame zone with respect to the flow of combustion gas in the combustor (2); a second steam system (302) that is branched from the first steam system (301) and injects extra steam on the downstream side of the flame zone with respect to the flow of the combustion gas in the combustor(2); a first steam flow rate control valve (311) capable of controlling the flow rate of the steam to be injected by the first steam system (301); a second steam flow rate control valve (312) capable of controlling the flow rate of the steam to be injected by the second steam system (302); and a controller (400) that controls the first steam flow rate control valve (311) on the basis of the flow rate of the gasification gas and the flow rate of the normal fuel and controls the second flow rate control valve (312) on the basis of a demanded steam amount necessary for a steam consumption facility.

Owner:MITSUBISHI POWER LTD

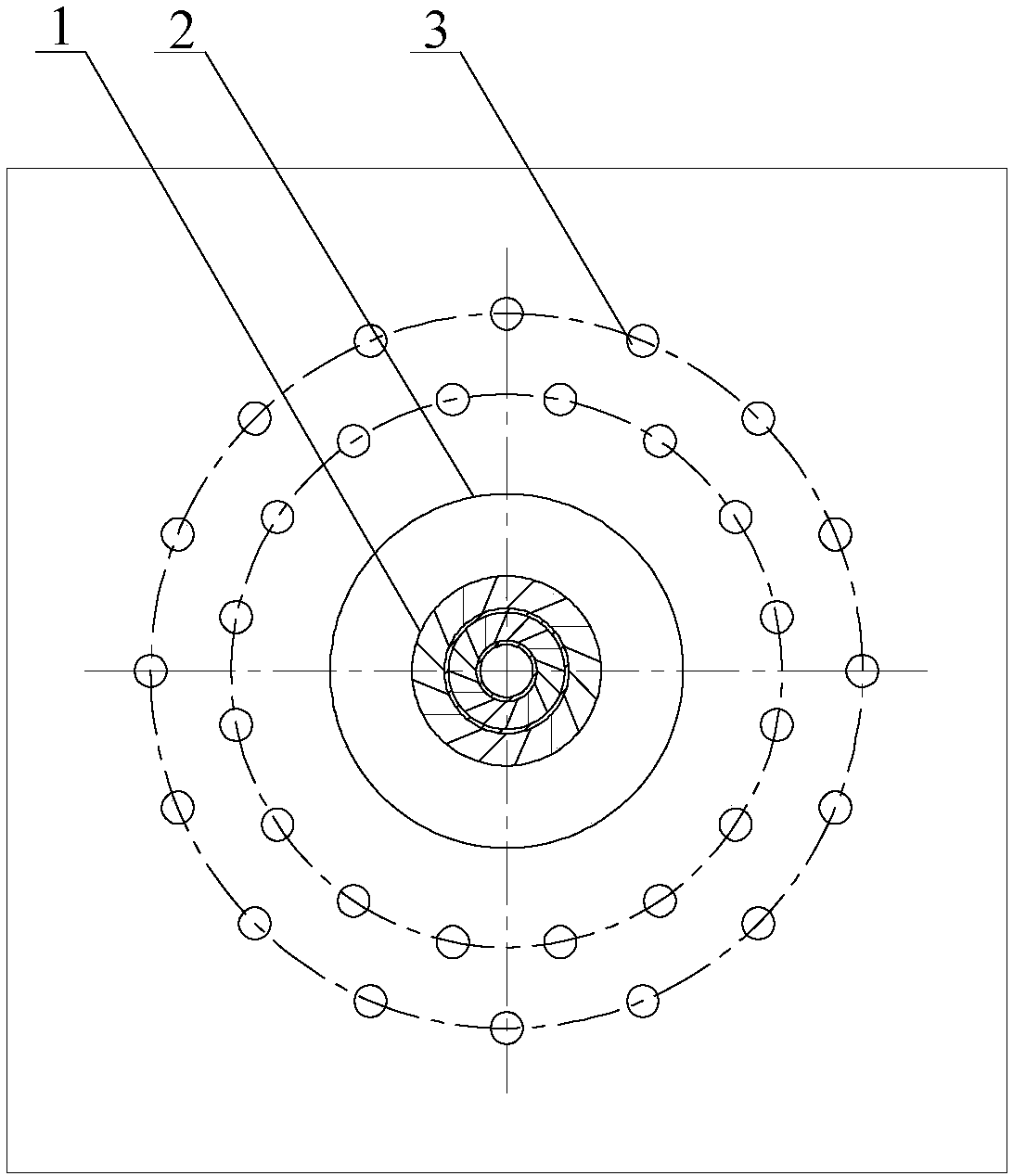

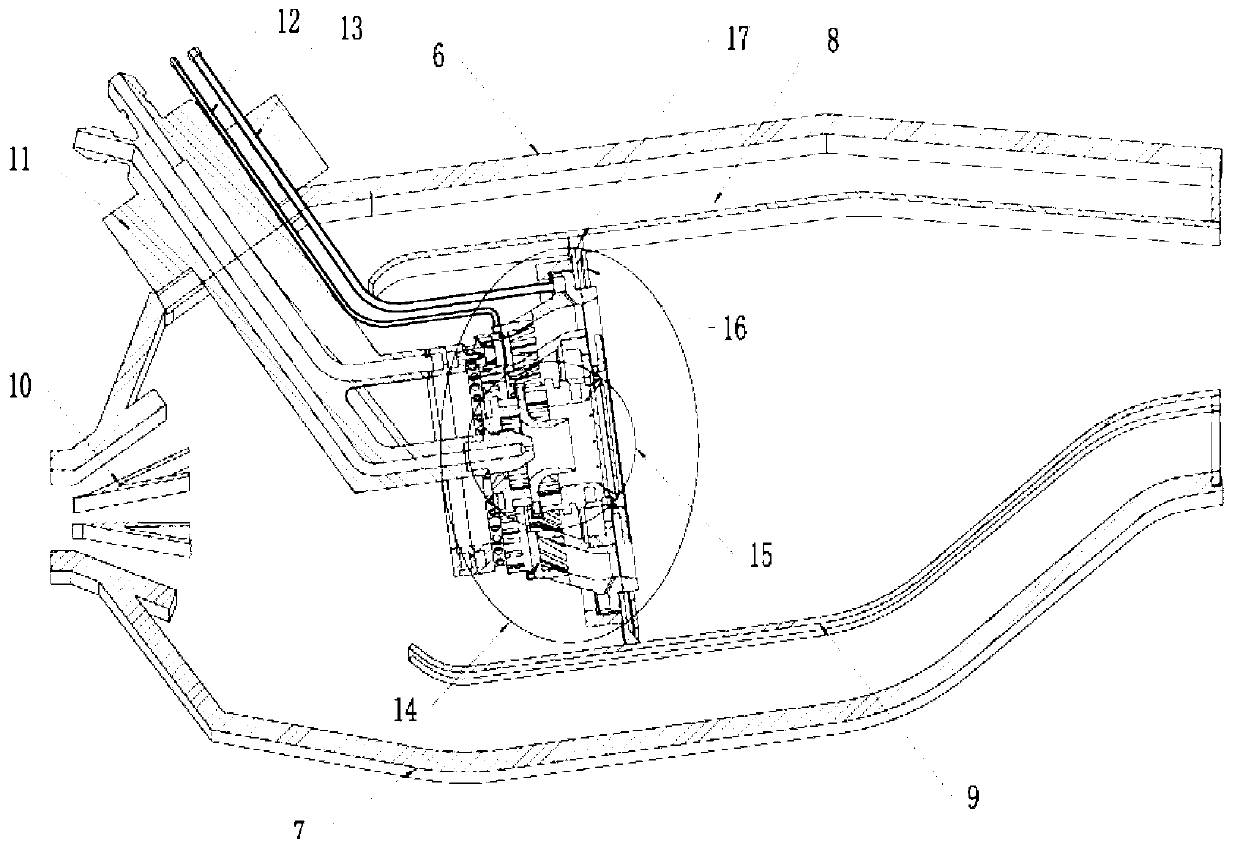

Axial grading combustion chamber of gas turbine and control method of axial grading combustion chamber

ActiveCN110878948AIncrease the reflux ratioStable combustionContinuous combustion chamberNitrogen oxidesCombustion chamber

The invention discloses an axial grading combustion chamber of a gas turbine and a control method of the axial grading combustion chamber. The axial grading combustion chamber comprises a combustion chamber structural assembly, a first-stage premixed jet nozzle assembly, a first-stage on-duty nozzle assembly and a second-stage premixed jet nozzle assembly. A head baffle of a first-stage combustionchamber and a front wall of a combustion chamber case form a head part of the combustion chamber, and the first-stage on-duty nozzle assembly is arranged in the center of the head part of the combustion chamber; the first-stage premixed jet nozzle assembly is arranged on a circumference of the head part of the combustion chamber by taking the center of the head part of the combustion chamber as acircle center; and the second-stage premixed jet nozzle assembly is positioned on a circumference of a head baffle of a second-stage combustion chamber by taking an axis of a flame tube of the first-stage combustion chamber as a circle center. According to the axial grading combustion chamber provided by the invention, through grading injection of fuel, residence time of the fuel in a high-temperature region is shortened while combustion efficiency is ensured, and two-stage soft combustion is realized, so that emission of nitrogen oxide by the combustion chamber of the gas turbine is greatlyreduced, and an outlet temperature of the combustion chamber can be further improved.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

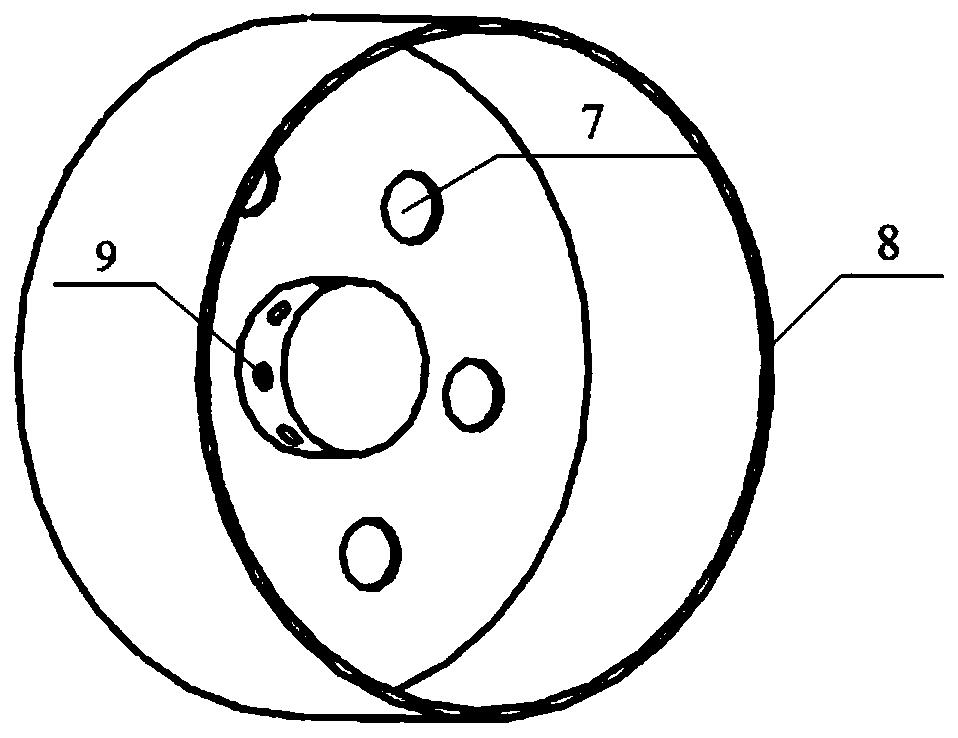

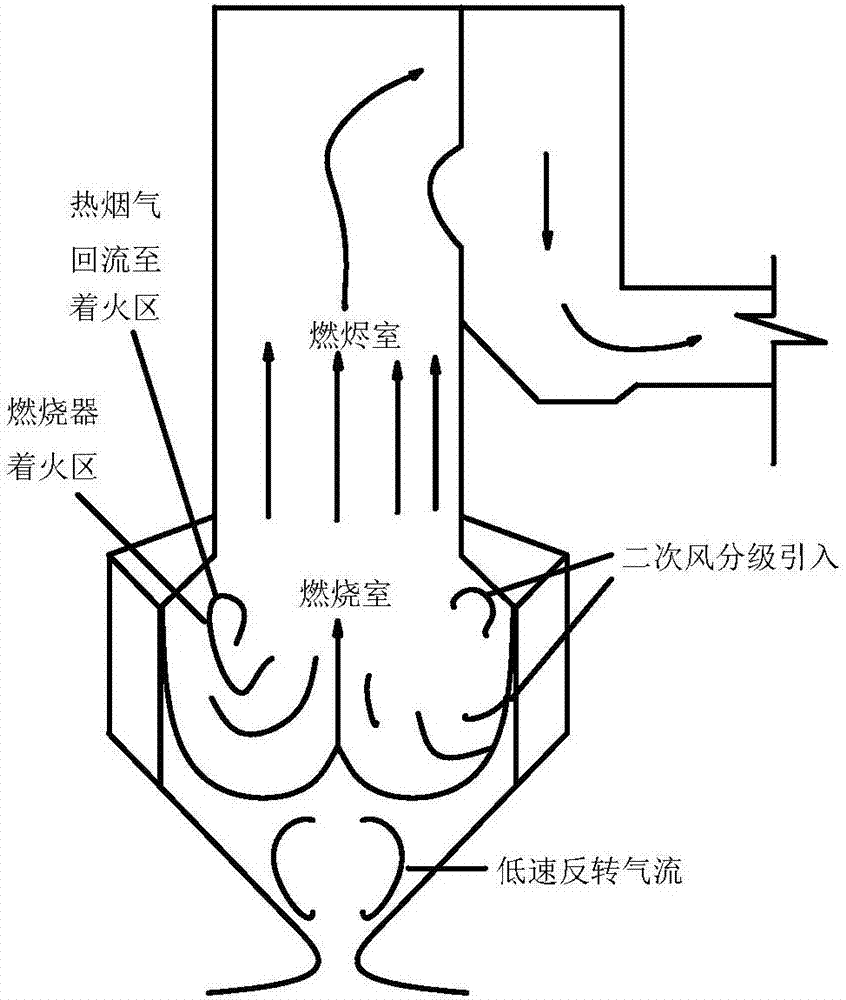

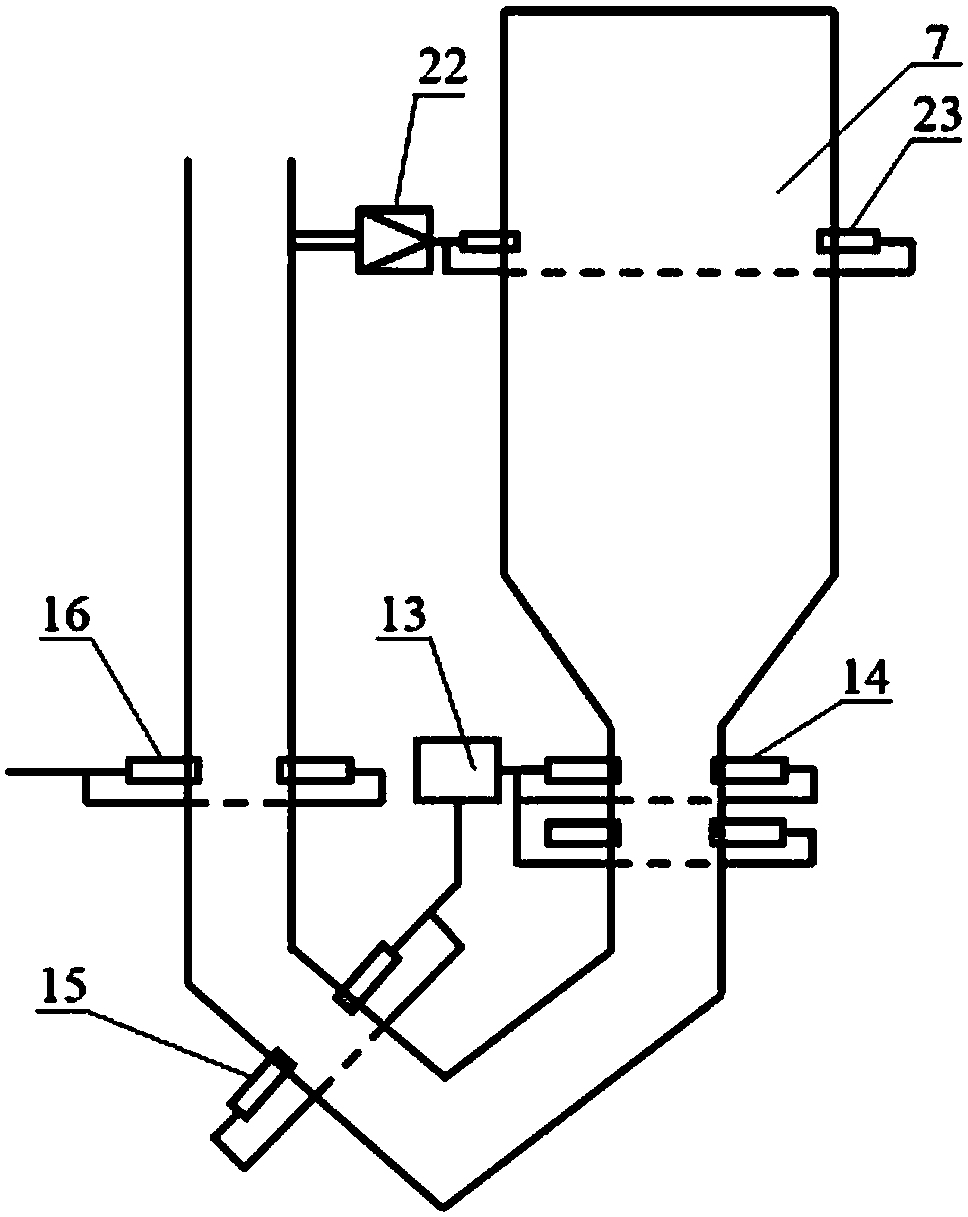

Center-feeding cyclone pulverized coal combustion device adopting pre-combustion chamber and double-layer jet flow to separate secondary air

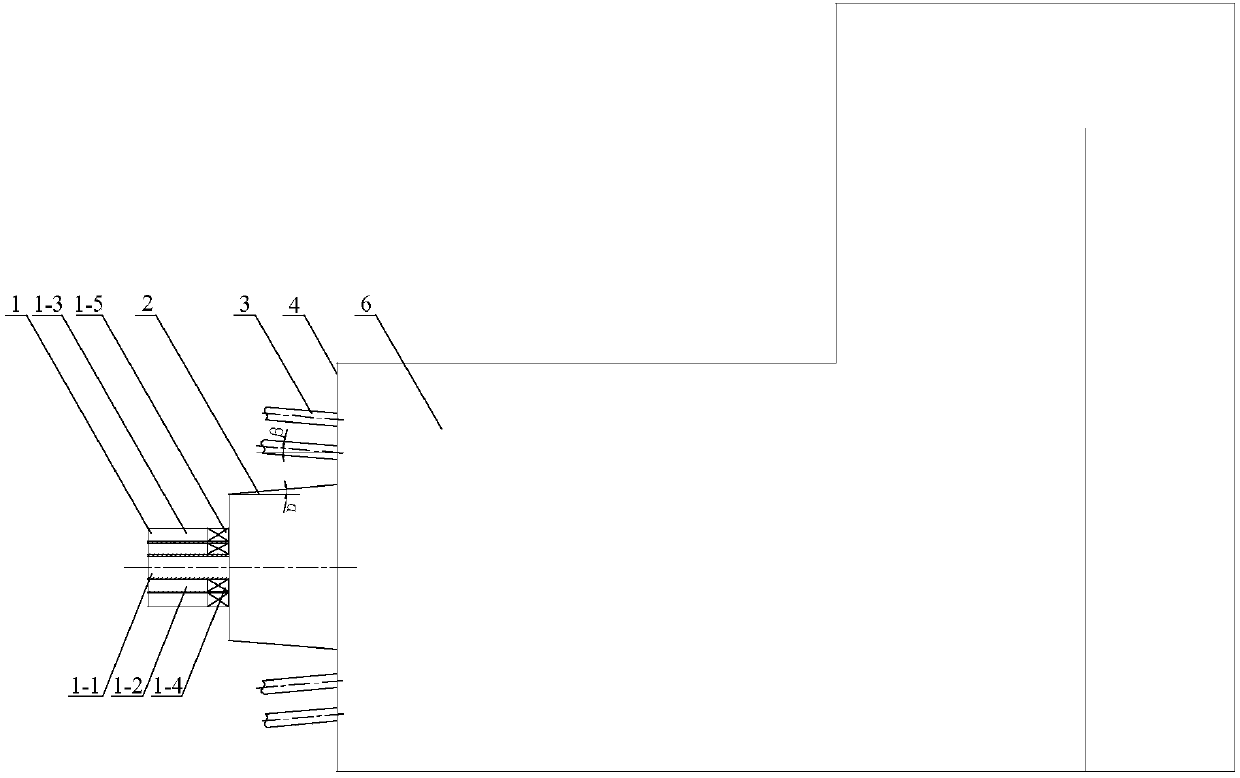

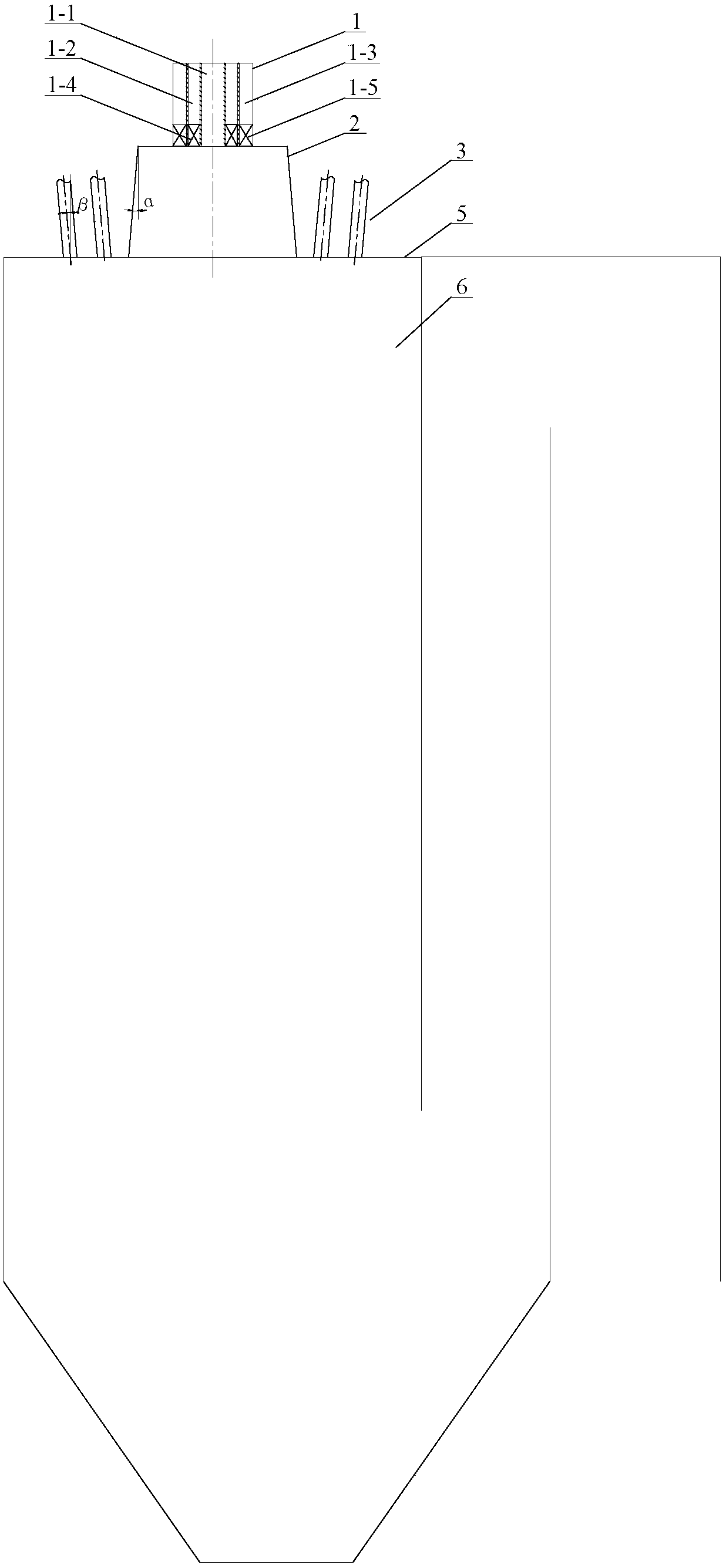

InactiveCN107559818AReduce generationEmission reductionPulverulent fuel combustion burnersNon-combustible gases/liquids supplyCycloneHigh concentration

The invention discloses a center-feeding cyclone pulverized coal combustion device adopting a pre-combustion chamber and double-layer jet flow to separate secondary air, and relates to a pulverized coal combustion device, and the center-feeding cyclone pulverized coal combustion device solves the problems that an existing pulverized coal combustion device is high in NOx discharge amount, is poor in flame stability, is severe in slag-bonding and is poor in after-combustion. High-concentration pulverized coal gas flow is conveyed in a primary air tube; a cyclone pulverized coal combustor is arranged at the front end of the pre-combustion chamber; the cyclone pulverized coal combustor and the pre-combustion chamber are coaxially arranged, and each pipeline spray hole of the cyclone pulverizedcoal combustor is flush to the inner wall of the pre-combustion chamber; a plurality of separating secondary air spray holes are distributed at the outer side of the pre-combustion chamber in a double-layer annular mode; a circle on which the centers of each layer of separating secondary air spray holes are located is coaxial with the cyclone combustor; the two layers of separating secondary airspay holes are uniformly crossed with one another; each separating secondary air spray hole is flush to the inner wall of a furnace hearth; and included angles beta between the center lines of the separating secondary air spray holes and the axis of the air tube at each stage of the cyclone combustor are 0-60 degrees. The center-feeding cyclone pulverized coal combustion device is used for an industrial pulverized coal boiler.

Owner:HARBIN INST OF TECH

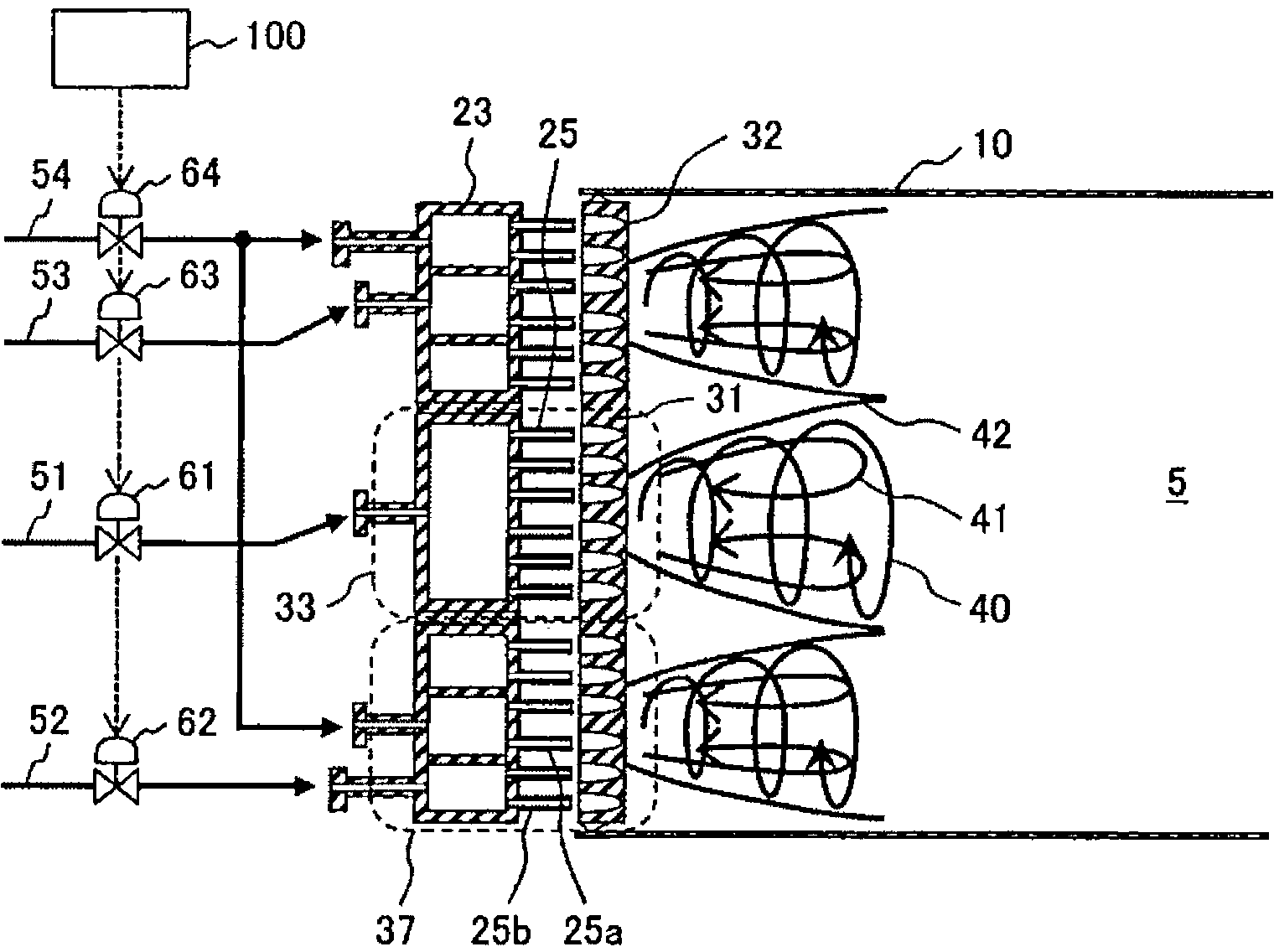

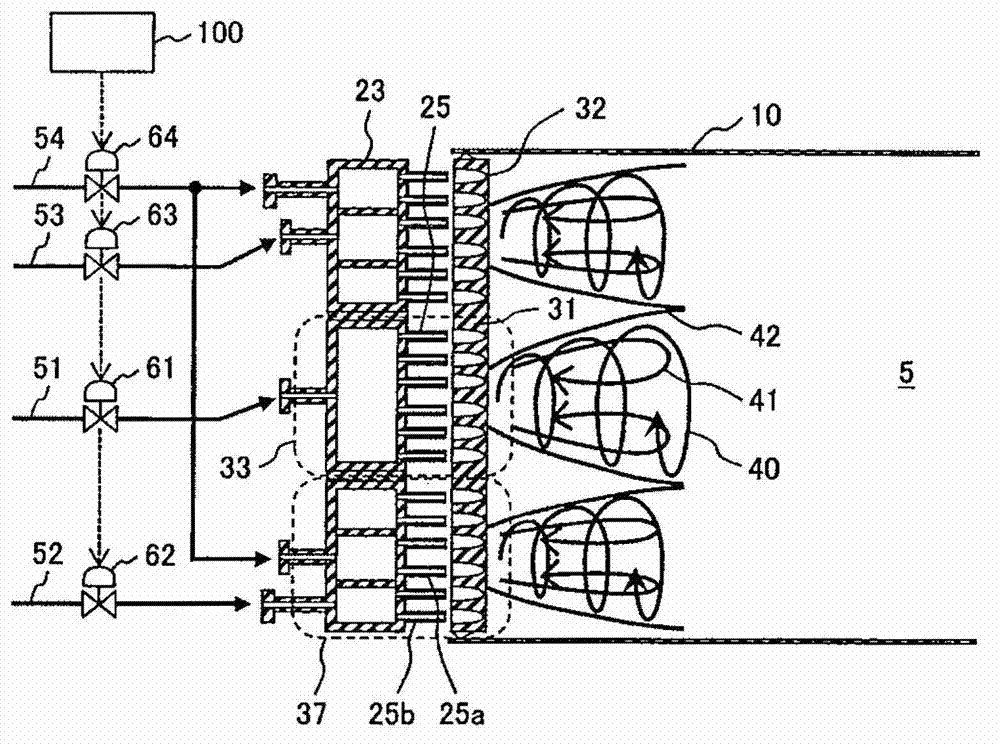

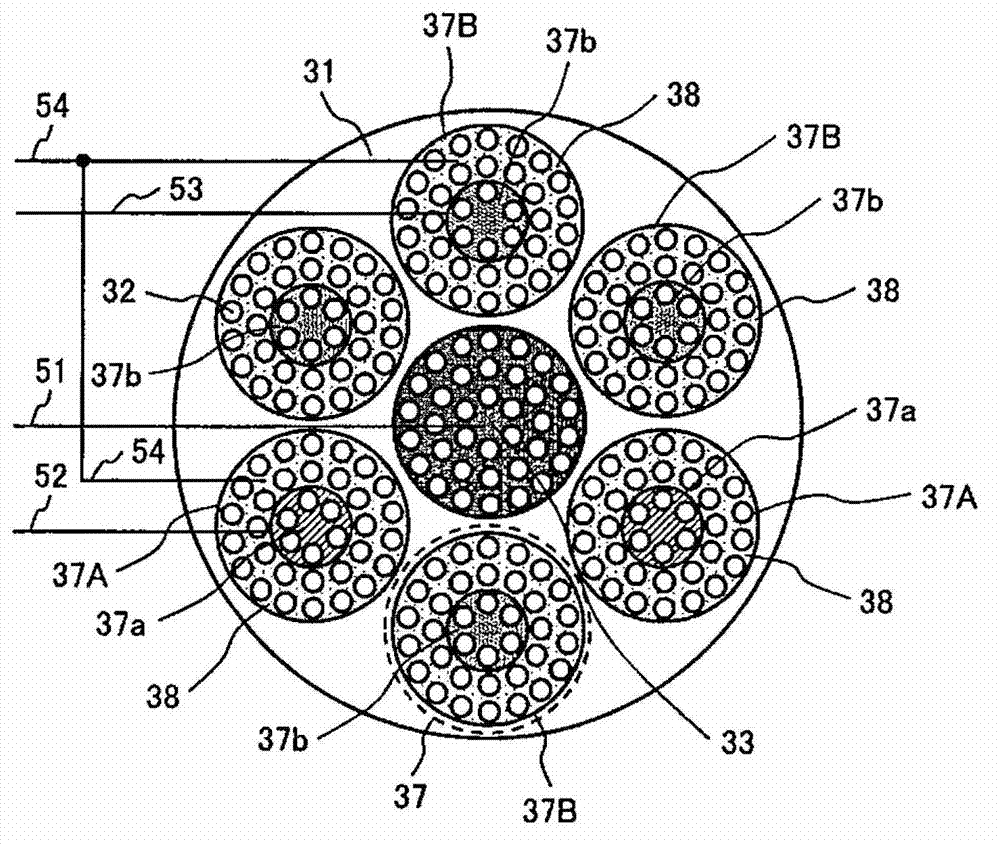

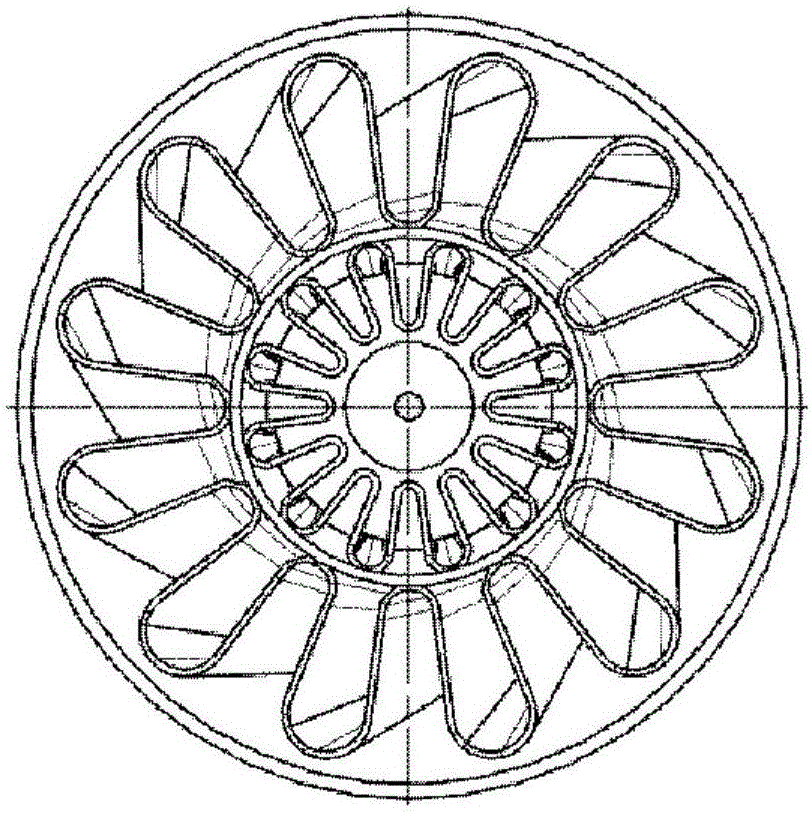

Gas turbine combustor and operating method thereof

ActiveCN103225822AAvoid temperature riseGuaranteed combustion stabilityBurnersFuel supply regulationCombustorCombustion chamber

An object of the present invention is to provide a gas turbine combustor and an operating method of the gas turbine combustor to allow the gas turbine combustor to ensure combustion stability in the entire range of load conditions of the gas turbine and reduce the generation of unburned combustibles and an increase in liner metal temperature at the same time in partial load conditions of the gas turbine. The gas turbine combustor comprises: a chamber supplied with fuel and air; an air hole plate located in an upstream side of the chamber, forming a plurality of air holes for supplying the air; and a multi-burner having a plurality of burners provided with fuel nozzles. The multi-burner is made up of a center burner disposed in the center and a plurality of outer burners around the center burner, the outer burners are divided into inner fuel nozzles and outer fuel nozzles to separately supply fuel through fuel systems, and the fuel is supplied to the fuel nozzles in the center burner or to the fuel nozzles in the center burner and the inner fuel nozzles in the outer burners disposed around the center burner in a partial load condition in which the load is lower than that of when all the fuel systems are used to supply fuel.

Owner:MITSUBISHI POWER LTD

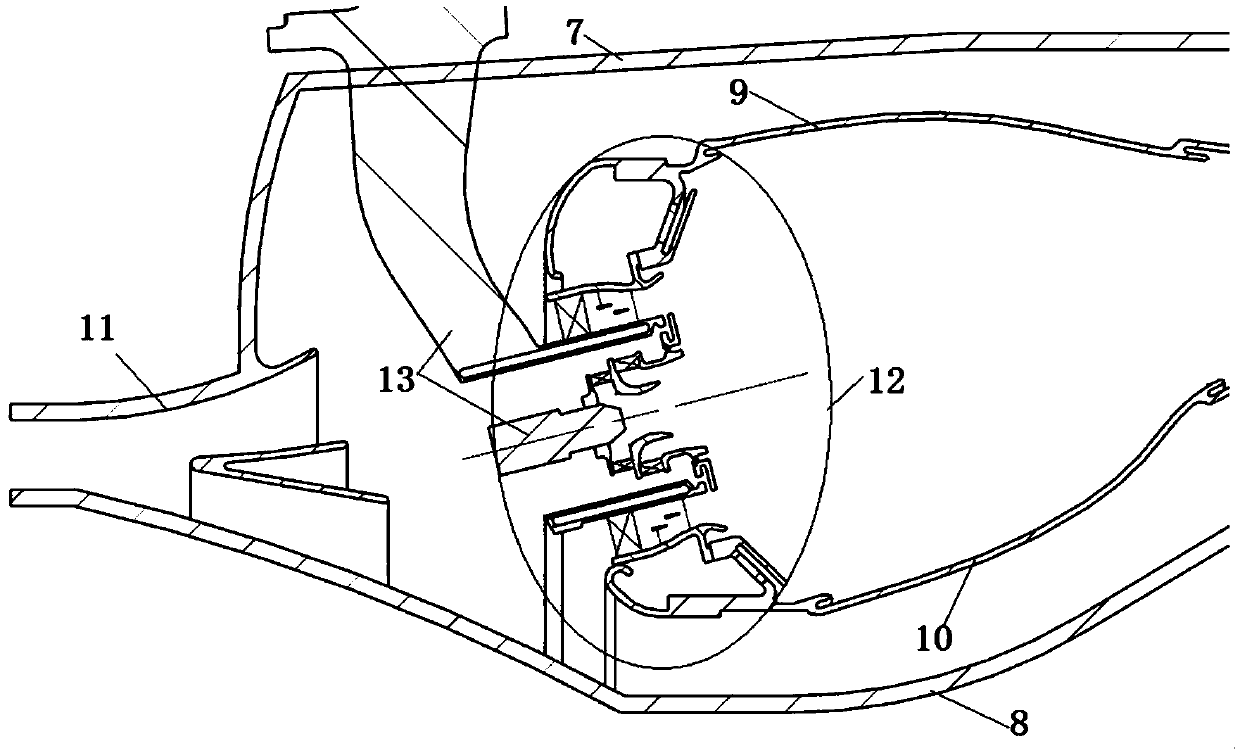

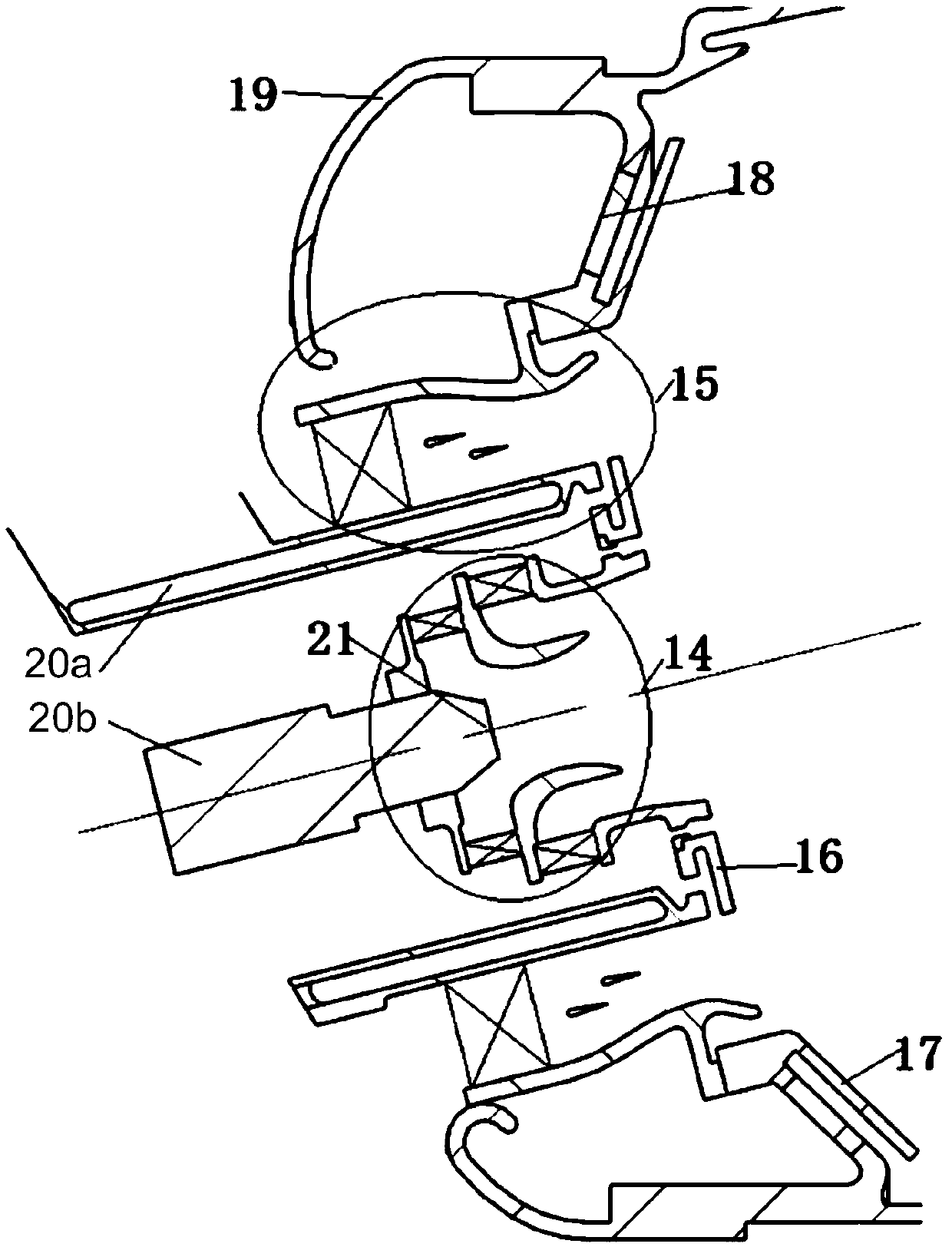

Low-pollution combustion chamber and combustion control method thereof

ActiveCN110657452ASmall penetration depthEvenly distributedBurnersContinuous combustion chamberCombustion chamberEngineering

The invention relates to a low-pollution combustion chamber and a combustion control method thereof. The low-pollution combustion chamber comprise a combustion chamber head, the combustion chamber head comprises a primary combustion stage and a pre-combustion stage, and the primary combustion stage comprises a primary combustion stage channel and a primary combustion stage swirler arranged in theprimary combustion stage channel. The low-pollution combustion chamber is characterized in that the primary combustion stage further comprises a pre-mold plate arranged in the primary combustion stagechannel, the pre-mold plate is divided into an outer-layer pre-mold plate and an inner-layer pre-mold plate in the radial direction, wherein the spraying point position and the spraying direction offuel oil of the primary combustion stage are arranged to control the primary combustion stage fuel oil to be sprayed into the primary combustion stage channel through a primary combustion stage fuel oil spray hole, the primary combustion stage direct-injection oil mist is partially formed, and the other part of the the primary combustion stage fuel oil is sprayed on the pre-mold plate close to theinner side of the primary combustion stage channel or sprayed on the two layers of pre-mold plates. Through cooperation of the double-layer pre-mold plate and the spraying point position and the spraying direction, and the combustible mixed gas is distributed more uniformly in a flame tube under different working conditions.

Owner:AECC COMML AIRCRAFT ENGINE CO LTD

Low-pollution combustor for emission reduction through hydrogenation during aviation fuel combustion

ActiveCN103277813APromote oxidationPromote disseminationContinuous combustion chamberCombustion chamberHydrogen

The invention relates to a low-pollution combustor for emission reduction through hydrogenation during aviation fuel combustion. As a whole, the combustor adopts a premixed lean combustion mode, wherein the head portion of the combustor adopts the mode that a preliminary combustion stage center and a main combustion stage center are in staged combustion, and the overall structure of a flame tube is a single-ring cavity. A preliminary combustion stage adopts a diffusive combustion mode to guarantee stable combustion. A main combustion stage adopts a premixed combustion to lower pollutant discharge of large working conditions. The preliminary combustion stage and the main combustion stage can adopt a hydrogenation auxiliary combustion mode respectively or simultaneously, therefore, the efficiency and the stability of extremely lean combustion are guaranteed, the limit of the lean combustion is expanded, the temperature and the combustion pulsation in a combustion zone are reduced, and the purpose of reducing the pollutant discharge of nitric oxides NOx is achieved. According to the low-pollution combustor for the emission reduction through the hydrogenation during the aviation fuel combustion, hydrogenation assistance is conducted on the aviation fuel combustion, the pollutant discharge of NOx is lowered substantially through the extremely lean consumption, the fuel is mainly aviation fuel, the hydrogenation only plays a role in assisting combustion, the total consumption of hydrogen is low, and the requirement for the improvement of an engine and aircraft hardware is low. The low-pollution combustor has the advantage of fuel flexibility.

Owner:BEIHANG UNIV

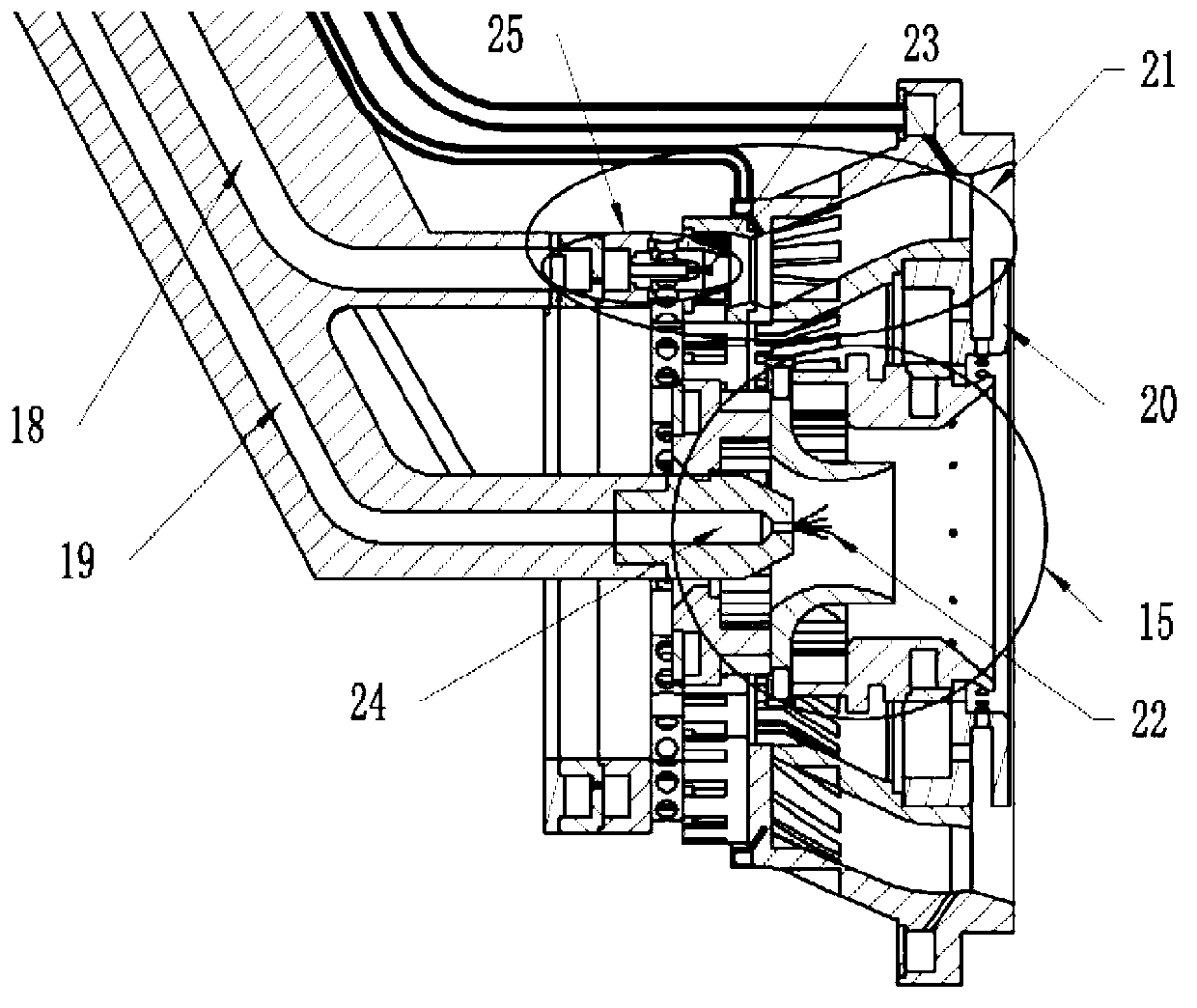

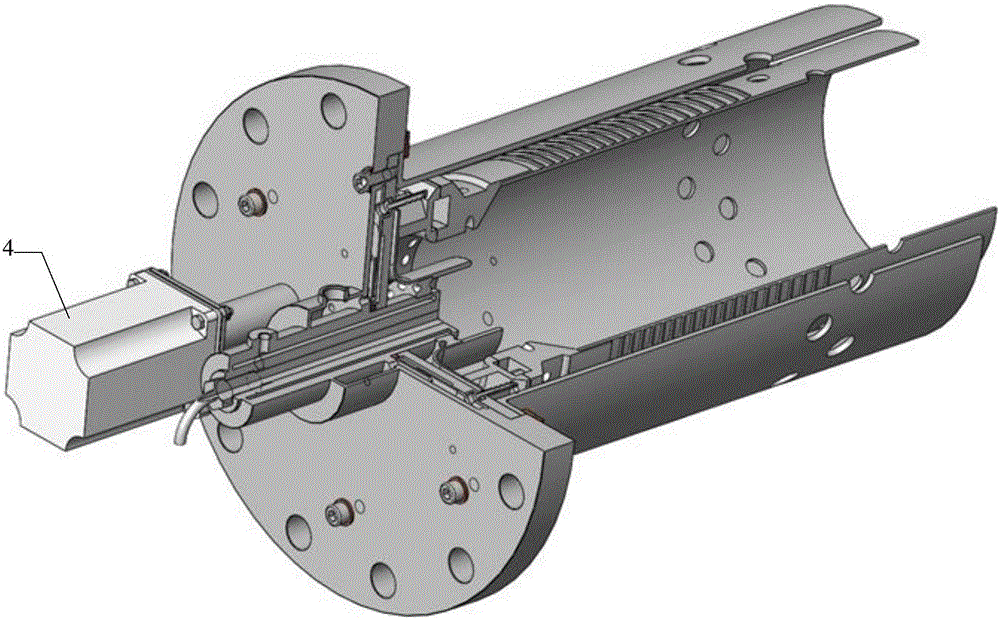

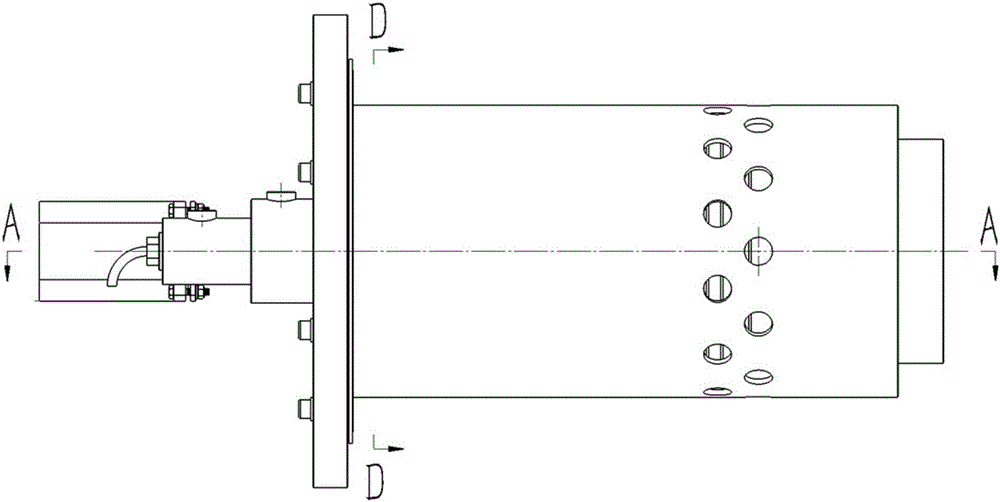

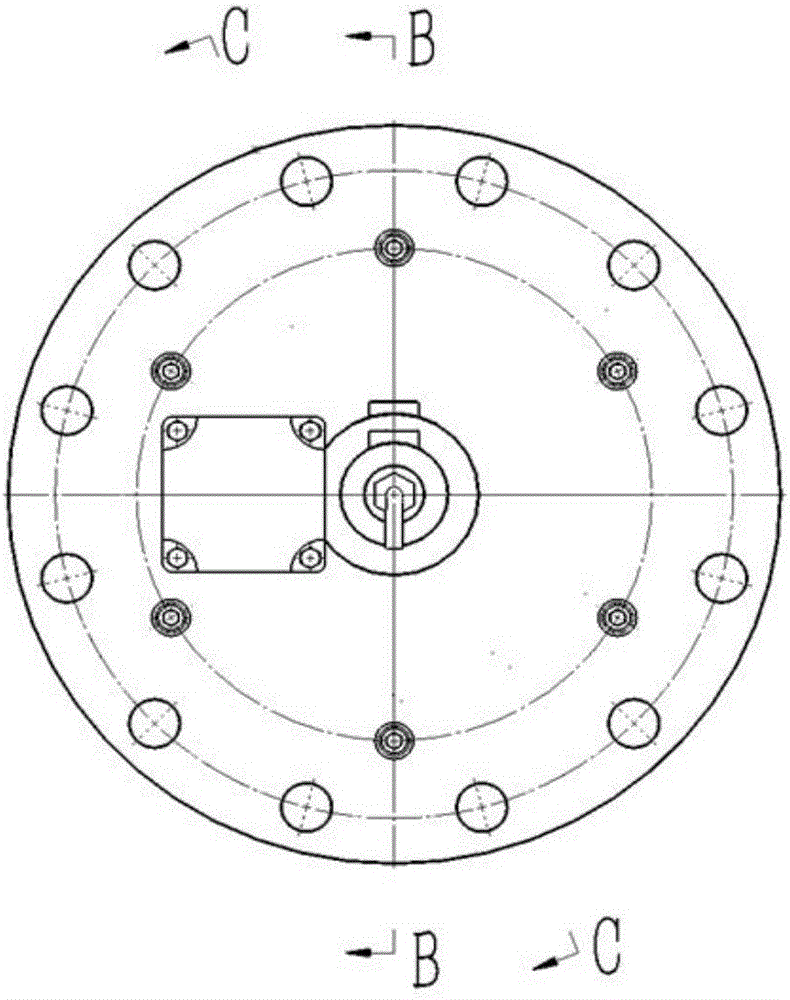

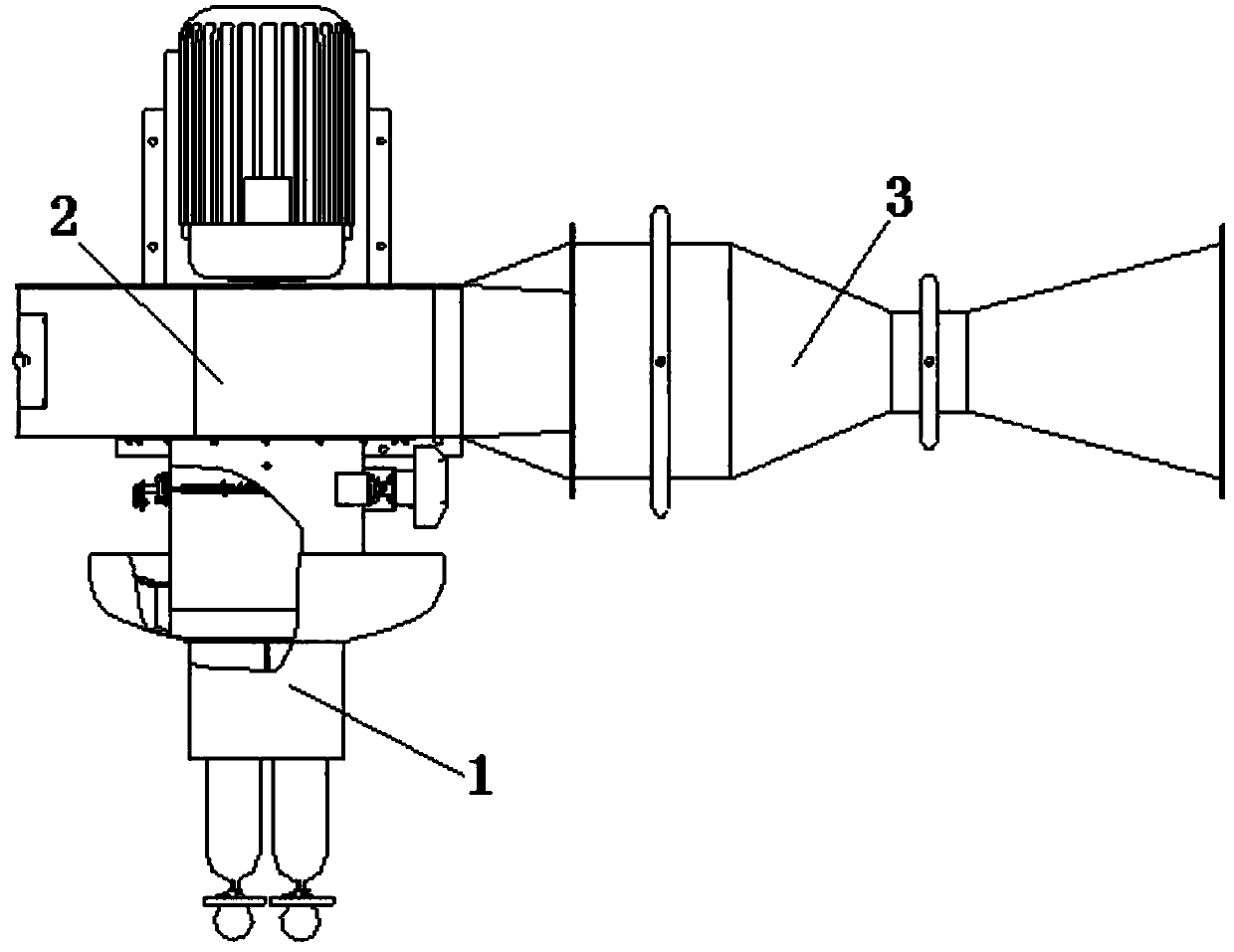

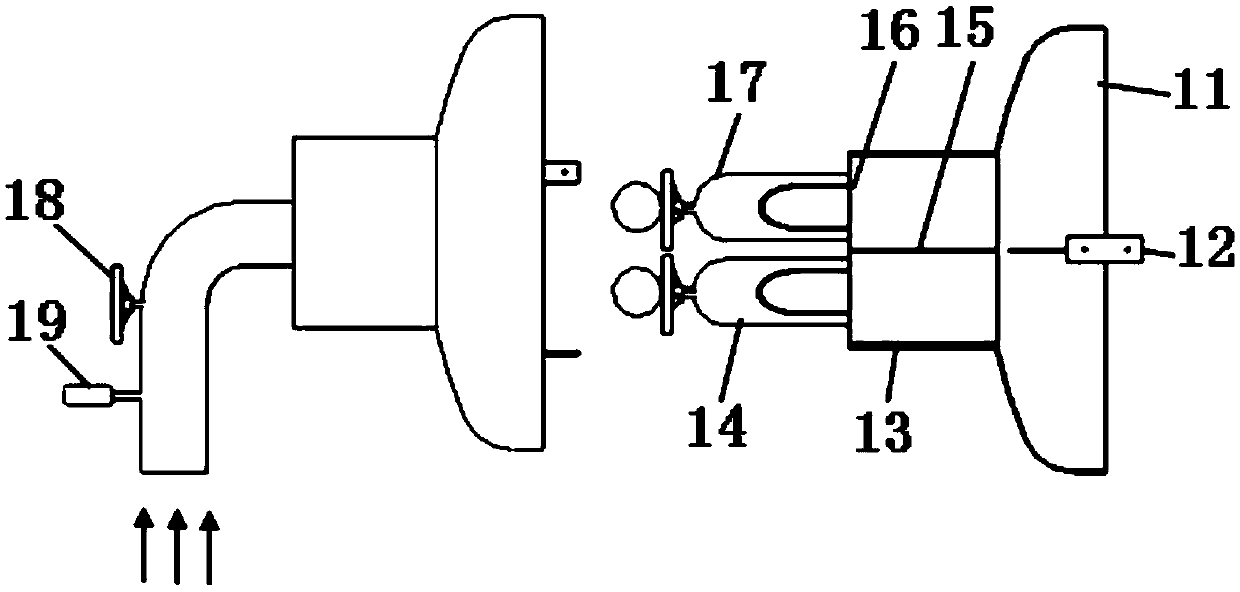

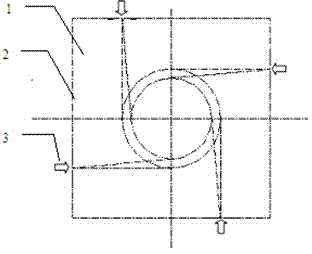

Gas turbine combustor with active fuel distribution control function

InactiveCN106091009AIncrease the degree of premixingEmission reductionContinuous combustion chamberCombustion chamberCombustor

Disclosed is a gas turbine combustor with an active fuel distribution control function. The gas turbine combustor comprises an end cover, a fixing plate and a fuel distribution control unit. The fuel distribution control unit comprises a motor, a transmission mechanism and a rotating plate. The end cover is fixedly connected with the fixing plate, and an internal cavity is formed between the end cover and the fixing plate. The fixing plate is provided with K positioning holes located at a first circumference, and a main fuel tube is arranged in each positioning hole. The motor is arranged outside the end cover. The rotating plate is arranged in the internal cavity. The motor is connected with the rotating plate through the transmission mechanism. The rotating plate is provided with m groups of allocation holes located at a second circumference. The numbers Qi of the allocation holes in the groups are different, and Qi is smaller than or equal to K. The motor drives the rotating plate to rotate so that the i group of allocating holes can be aligned with the Qi main fuel tube, and accordingly Qi main fuel channels are formed. According to the gas turbine combustor, different numbers of main fuel channels are formed on different load conditions, so that the combustion stability of the combustor is guaranteed and the pollution emission amount is lowered.

Owner:HARBIN INST OF TECH

Fuel-side flue gas recirculation low-nitrogen combustor and combustion method thereof

PendingCN111121023AGuaranteed adaptabilityGuaranteed combustion stabilityGaseous fuel burnerCombustorCombustion chamber

The invention discloses a fuel-side flue gas recirculation low-nitrogen combustor and a combustion method thereof. The fuel-side flue gas recirculation low-nitrogen combustor comprises a pilot fuel pipe, an air flow channel, a main fuel mixing channel, a fuel distribution ring pipe and a recirculating flue gas distribution ring pipe. Fuel forms main fuel and pilot fuel through the fuel distribution ring pipe, and the main fuel and recirculating flue gas are rapidly mixed through the main fuel mixing channel to form mixed flue gas fuel which is then jetted into a combustion chamber. Meanwhile,the pilot fuel is pre-mixed with central air in a pilot fuel pre-mixing cavity to form a swirling lean fuel pre-mixed pilot flame in a swirling disc. The rest of air forms a high-speed jet through anannular air nozzle between the pilot fuel premixing cavity and the air flow channel and is quickly mixed with the mixed flue gas fuel, flameless combustion of the main fuel is achieved, and the generation of NOX is greatly reduced. The fuel-side flue gas recirculation low-nitrogen combustor and the combustion method thereof have the advantage of stable combustion, solve the contradiction between great reduction of the oxygen content in low-NOx combustion and combustion stability, and can achieve low-NOx emission.

Owner:TSINGHUA UNIV

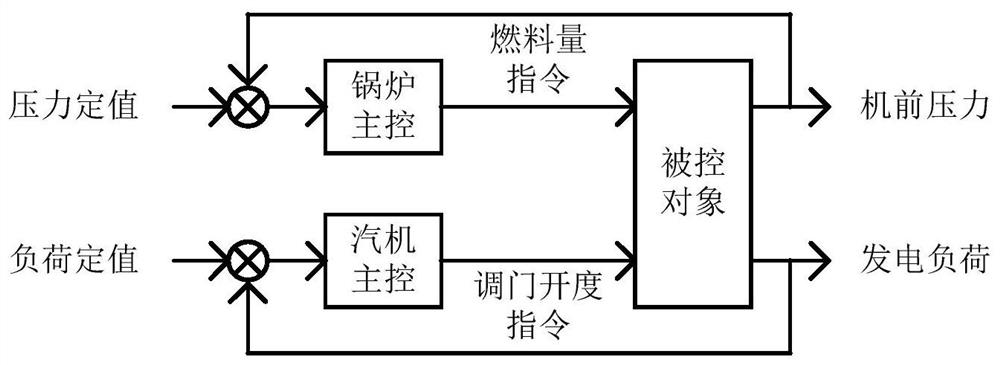

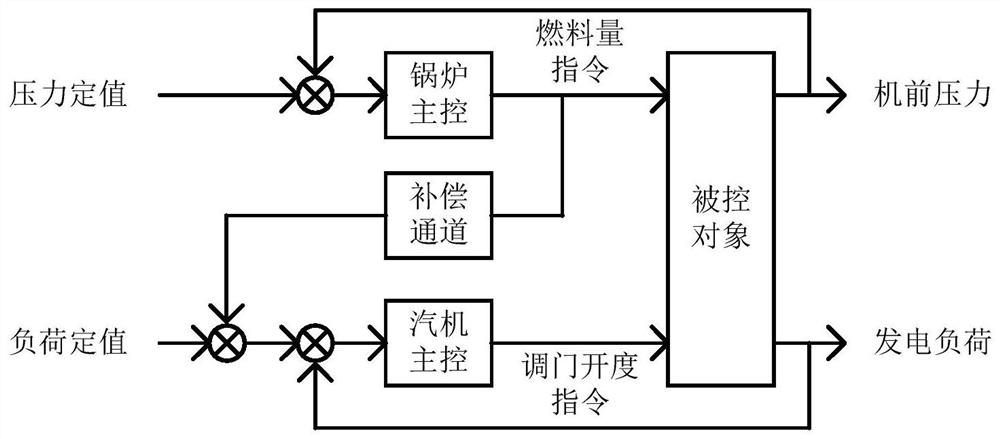

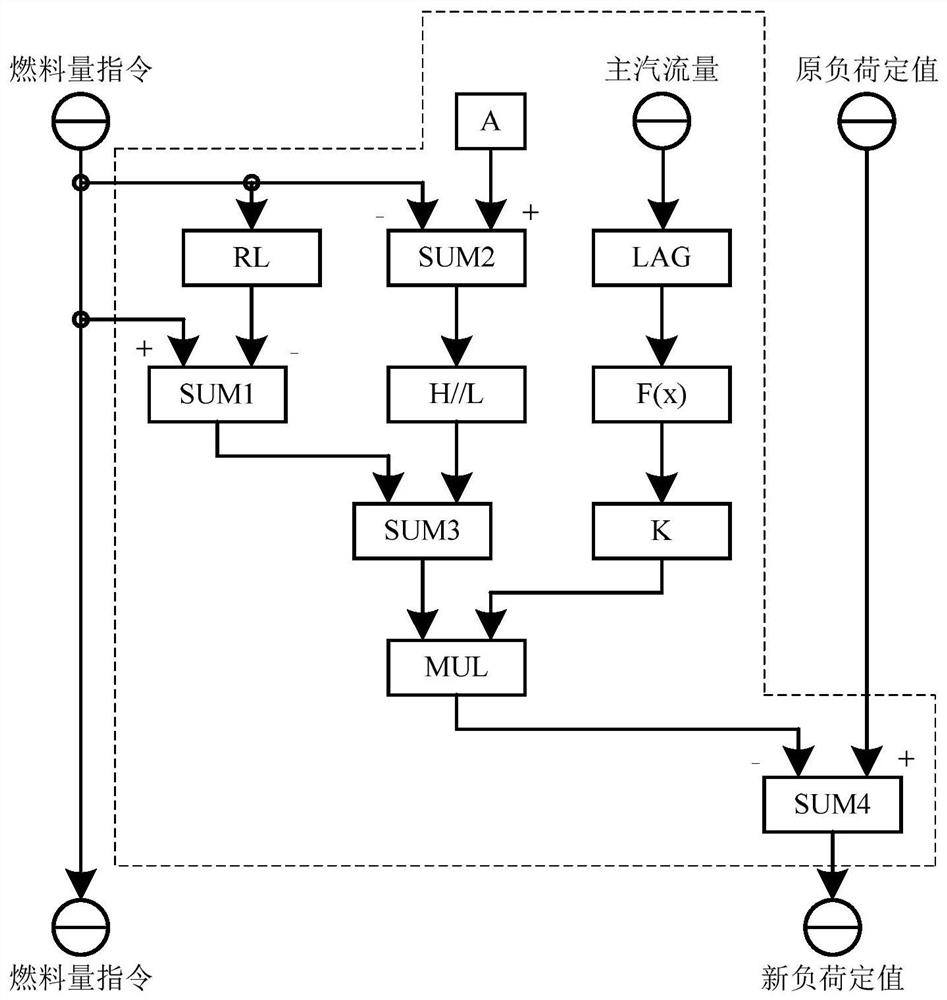

Thermal power generating unit flexible coordination control method suitable for deep peak regulation operation

ActiveCN112162484AReduce rateWeakening rangeBoiler controlEngine controlSteam pressureControl system

The invention relates to a thermal power generating unit flexible coordination control method suitable for deep peak regulation operation. The method is characterized in that a reverse compensation channel of a fuel quantity instruction to a power generation load instruction is added on the basis of a traditional machine-furnace following mode coordination control system, and meanwhile, a main steam flow signal is used for constructing a flexible factor; the gain of the reverse compensation channel is corrected by the flexible factor in a product mode to obtain a reverse power generation loadinstruction bias value, and the unit power generation load instruction is corrected by using the reverse power generation load instruction bias value, so that the control quality of the power generation load and the steam pressure in front of the steam turbine is preferentially ensured under the conventional load working condition; and the combustion stability is preferentially ensured under the deep peak shaving working condition. The change rate and the downward change amplitude of the fuel quantity instruction are reduced through the reverse compensation channel of the fuel quantity instruction for the power generation load instruction, the control effect under various working conditions is guaranteed, and the control requirements of the thermal power generating unit on the conventionalload working condition and the deep peak regulation working condition can be met.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING) +1

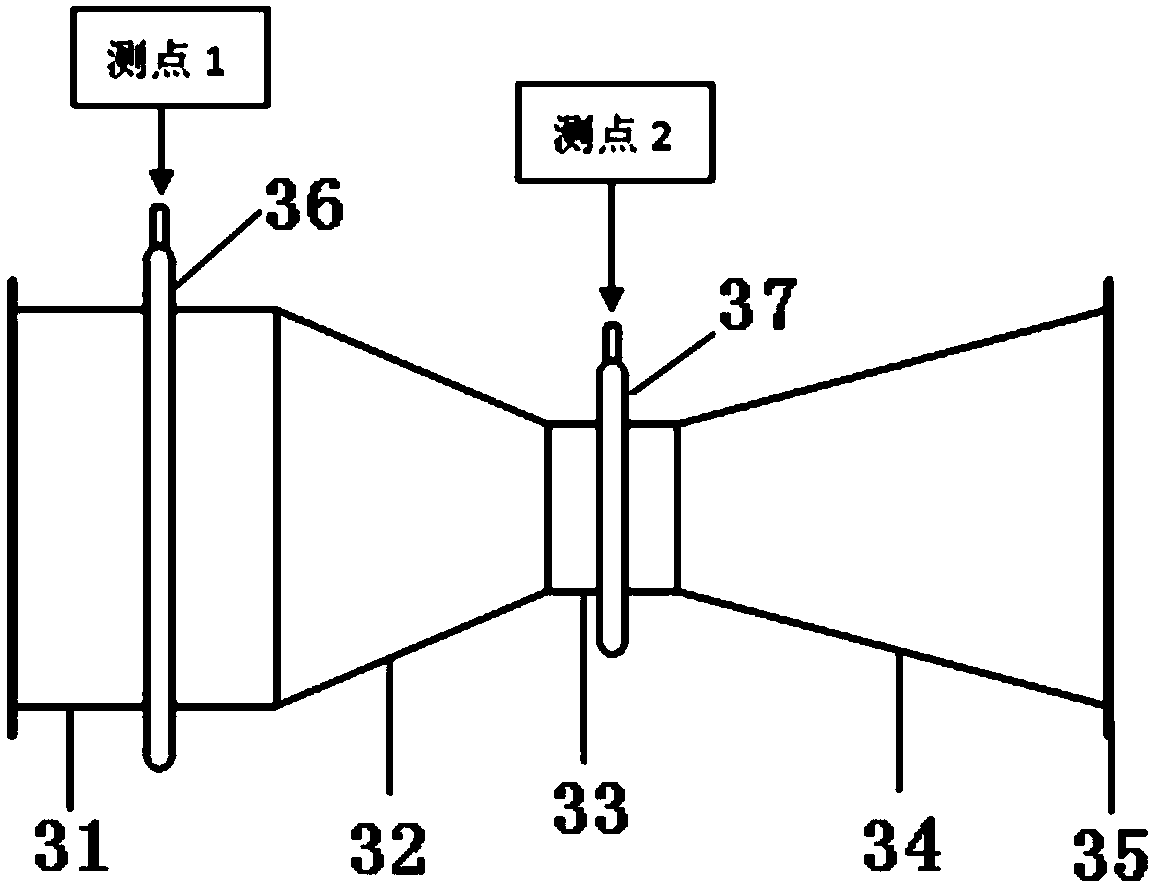

Combustor air distribution device and air distribution method

ActiveCN109539248AAchieve recyclingFully stable combustionBurnersAir supply regulationCombustorAir volume

The invention discloses a combustor air distribution device and an air distribution method. The combustor air distribution device comprises an air inlet device, an air blower and an air blower outputair volume detection device, wherein an outlet of the air inlet device communicates with the air blower, air blown by the air blower is conveyed to a combustor, a flow detection sensor is arranged onthe air inlet device, and is used for carrying out real-time detection on the flow of gas entering the air blower through the air inlet device, an air inlet is formed in the air blower and used for sucking fresh air, the air blower output air volume detection device is used for detecting the output air volume of the air blower in real time, namely the total air supply volume of the air distribution device, the air blower is provided with an air blower output air volume adjusting device, and is used for adjusting the output air volume of the air blower, the air inlet device comprises a combustible waste gas pipeline and / or a recycled smoke gas pipeline, and the air blower output air volume detection device is a venturi tube device. Thus, accurate air distribution is achieved, and the combustion efficiency and the stability are guaranteed.

Owner:JIANGSU XCMG CONSTR MASCH RES INST LTD

Composite heat storage and extraction system and method suitable for peaking power generation

PendingCN108709176AReasonable designWater cycle safety avoidHeat storage plantsFeed water supplyWater circulationLatent heat storage

The invention provides a composite heat storage and extraction system and method suitable for peaking power generation. The system comprises a heat source system, a sensible heat storage and extraction system, a latent heat storage and extraction system and a power generation system. The heat source system is used for heating supercooled water into superheated steam. The sensible heat storage andextraction system is connected with the heat source system and the latent heat storage and extraction system through a pipeline and used for carrying out heat energy storage and extraction through sensible heat when the temperature changes in the conversion process of the supercooled water and the superheated steam. The latent heat storage and extraction system is used for carrying out heat energystorage and extraction through latent heat when phase changes happen in the conversion process of the supercooled water and the superheated steam. The power generation system is used for converting heat energy into electric energy and is connected with the heat source system end to end to form a circulation pipeline. According to the composite heat storage and extraction system and method, the peaking capacity of the lower load depth of a power station boiler is achieved, meanwhile, the combustion stability and water circulation safety of the boiler during deep peaking are guaranteed, and theloss of the service life of the boiler under low loads is avoided; and the energy at the electricity trough period of a power plant can be converted to the electricity peak period, and operation economic performance of the power plant is improved.

Owner:GUODIAN LONGYUAN ENERGY SAVING TECH

Zigzag gas burner

InactiveCN104421939AAdaptableIgnition and stable combustionBurner safety arrangementsGaseous fuel burnerGas burnerFuel gas

The invention discloses a zigzag gas burner. A tapered gas nozzle is formed in the center of the inside of a jet. Air distribution blades are circumferentially formed between the jet and the tapered gas nozzle. Zigzag flame stabilizing bodies are arranged on the circumference of the taped gas nozzle. Gas spraying holes are formed in the tapered gas nozzle. Gas enters from the tapered gas nozzle and is sprayed out through the gas spraying holes. Gas distributed air enters a circular channel between the jet and the tapered gas nozzle and generates rotational-flow distributed air by the aid of the air distribution blades with angles. At the front end of the jet, the gas and the rotational-flow distributed air are intensely mixed and then meet an igniting device to fire. The zigzag gas burner is effective in preventing the flame from lifting, returning and extinguishing.

Owner:SHAANXI SHENGHUIYUAN INFORMATION SCI & TECH

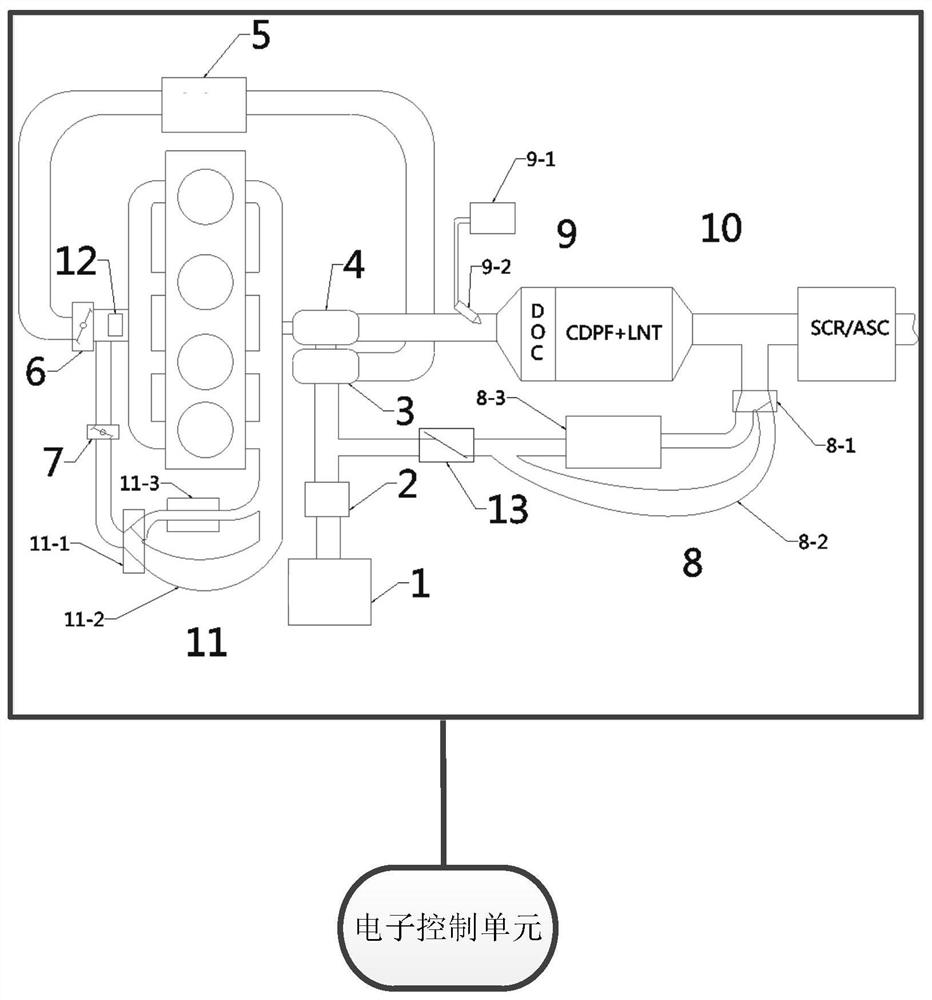

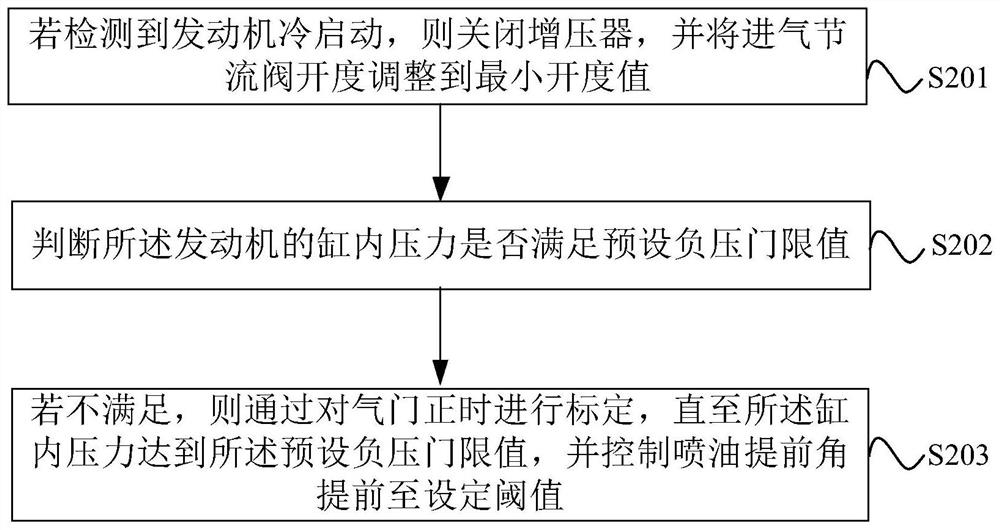

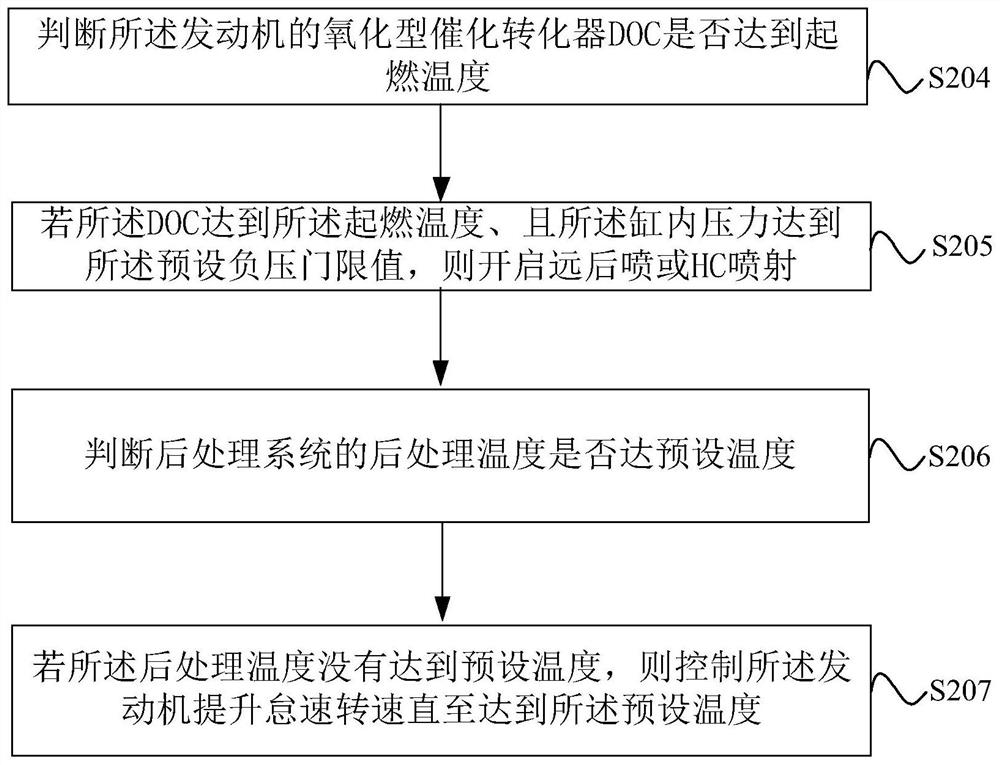

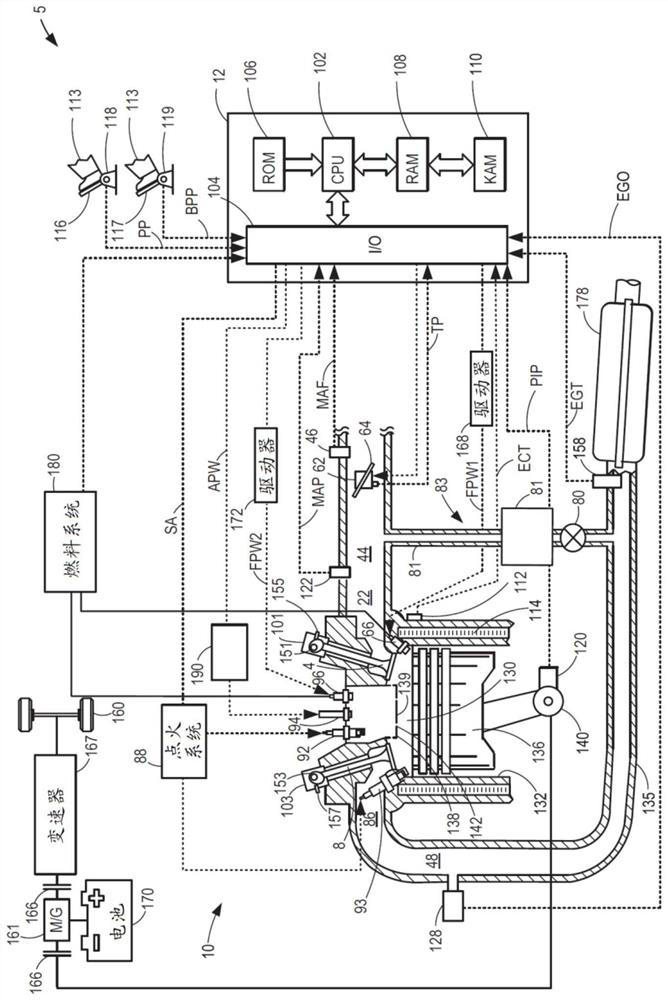

Cold start warm-up control method and device

ActiveCN112324583APremix wellEmission reductionElectrical controlInternal combustion piston enginesEngineeringMechanics

The embodiment of the invention provides a cold start warm-up control method and device. The method comprises the steps that in the cold start process of an engine, by turning off a supercharger and adjusting the opening degree of an air inlet throttle valve to a minimum opening degree value to reduce the air inflow, the quick warm-up of the engine is achieved quickly, and the exhaust temperaturedemands of after-treatment are met; and meanwhile, when the in-cylinder pressure does not meet the preset negative pressure threshold value, by calibrating the valve timing to make the in-cylinder pressure meet the preset negative pressure threshold value and controlling the fuel injection advance angle to be advanced by a certain angle, fuel can be sufficiently premixed, the combustion stabilityis guaranteed, the engine can be in a premixed charge compression ignition (PCCI) mode, and therefore, emission of oxynitride NOx and particulates PM during cold start of the engine is reduced.

Owner:WEICHAI POWER CO LTD

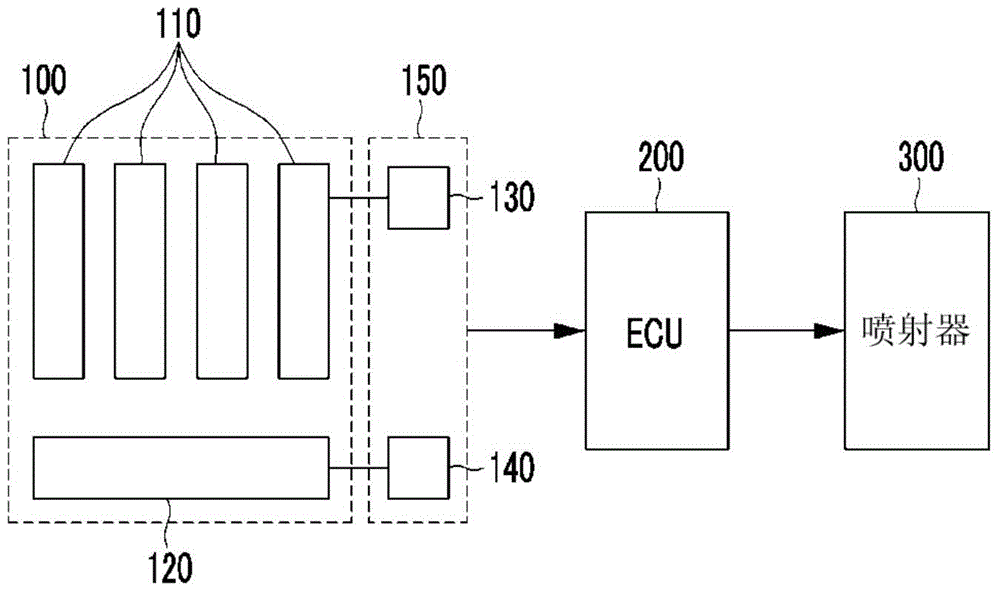

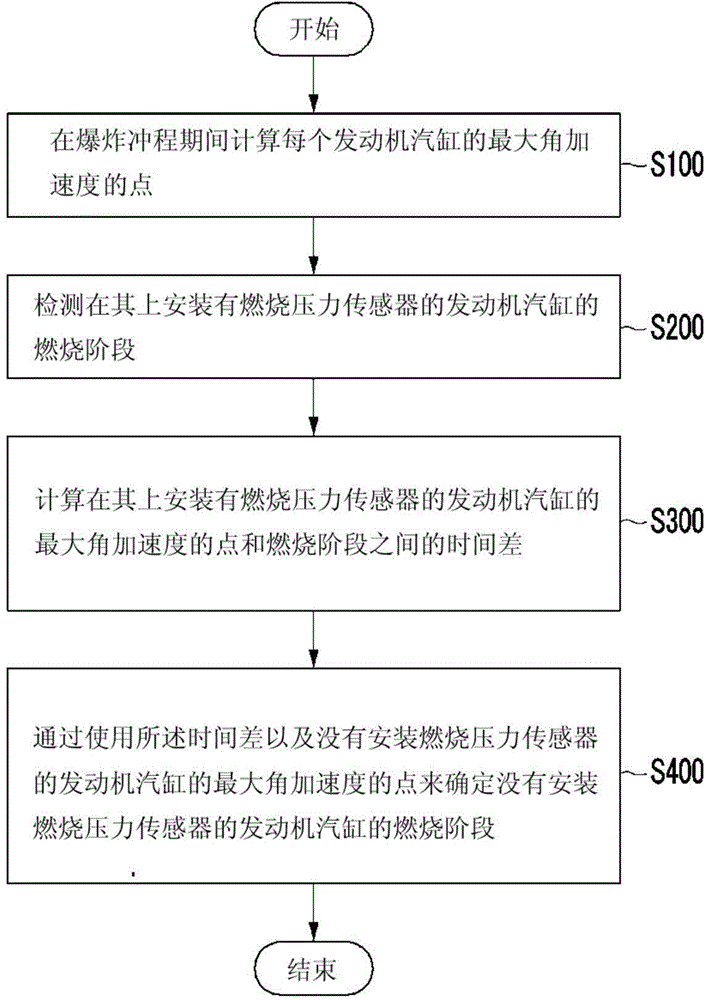

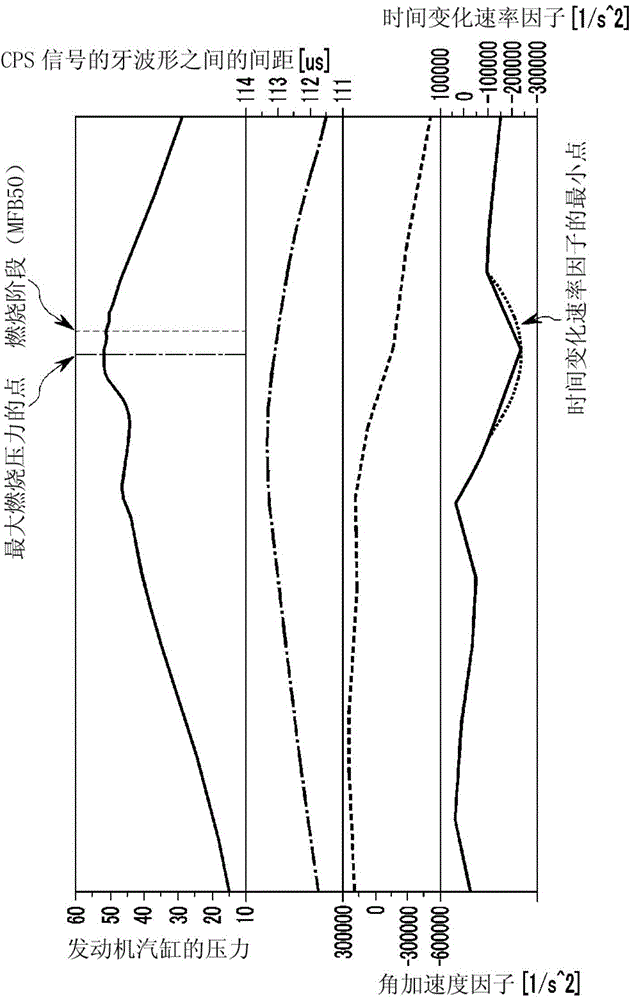

Method and apparatus for detecting combustion phase of engine

ActiveCN104697800ASpacing correctionAdjust injection volumeInternal-combustion engine testingElectrical controlCombustionEngineering

Disclosed are a method and an apparatus of detecting a combustion phase of an engine by an angular acceleration signal and combustion data of a single cylinder. The method may include calculating a point of maximum angular acceleration of each engine cylinder during an explosion stroke, detecting a combustion phase of an engine cylinder provided with a combustion pressure sensor, calculating a time difference between the point of maximum angular acceleration and the combustion phase of the engine cylinder provided with the combustion pressure sensor, and determining a combustion phase of an engine cylinder where the combustion pressure sensor is not mounted by using the time difference and the point of maximum angular acceleration of the engine cylinder where the combustion pressure sensor is not mounted.

Owner:HYUNDAI MOTOR CO LTD +1

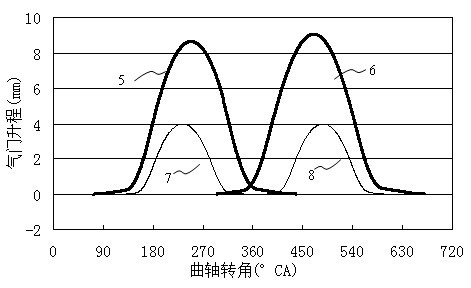

EGR (exhaust gas recirculation) control system of engine and control method thereof

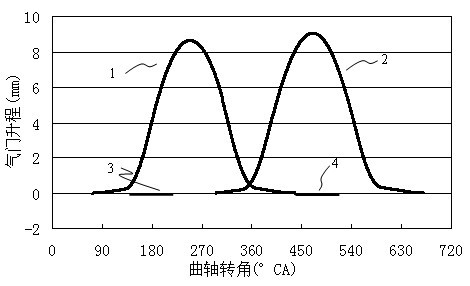

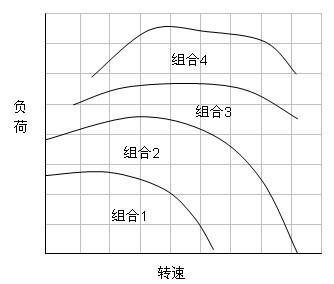

ActiveCN102168615AHigh thermal efficiencySimple structureOutput powerMachines/enginesCylinder blockCam

The invention provides an EGR (exhaust gas recirculation) control system of an engine and a control method thereof. The EGR control system comprises an electric control unit and a valve mechanism, wherein corresponding to each cylinder, the valve mechanism is provided with an inlet valve consisting of a first inlet valve and a second inlet valve, and an exhaust valve consisting of a first exhaustvalve and a second exhaust valve; the inlet valve is subject to control of an inlet cam shaft, and the exhaust valve is subject to an exhaust cam shaft; the first inlet valve and the second inlet valve are respectively subject to control of two cams that are arranged on the inlet cam shaft and different in lift range; the first exhaust valve and the second exhaust valve are respectively subject to control of two cams that are arranged on the exhaust cam shaft and different in lift range; and the electric control unit controls the work of the cams on the inlet cam shaft and the exhaust cam shaft through a transmission mechanism and changes valve timing and valve lift. With different loads, the electric control unit adopts different lift and phase combination ways to control the EGR rate ofresidues in the cylinder, thus improving the thermal efficiency of the engine.

Owner:CHERY AUTOMOBILE CO LTD

Combustion adjustment method for supercritical boiler capable of performing blending combustion of coke oven gas

ActiveCN104713064AReduce air volumeReduce smoke temperature deviationAir supply regulationSteam generationSupercritical steam generatorDetonation

The invention discloses a combustion adjustment method for a supercritical boiler capable of performing blending combustion of coke oven gas. The device comprises a supercritical boiler capable of performing blending combustion of coke oven gas. The combustion adjustment method comprises the following steps: adopting nonlinear normal pagoda type air door air distribution openings by virtue of an eight-layer secondary air door, sequentially reducing the air door opening upwards, allowing the air door opening of a burnout air door at a diagonal part to be smaller than the air door opening at another diagonal part, and feeding two layers of secondary air at least by virtue of a gas gun by adopting a normal pagoda type air distribution mode. The normal pagoda type air door distribution opening of the secondary air door and different air door openings at two diagonal parts of the burnout air door are adopted, and multilayer air is fed by virtue of the gas gun, so that the fume temperature deviation at the hearth outlet can be effectively reduced, and the detonation accidents of the boiler are reduced. Moreover, according to stable combustion in a fuel enriched area on the middle lower part of the hearth and feeding of the gas gun, the NOx generation amount is greatly reduced, the boiler operates in a high-efficiency economic performance area, the comprehensive operating cost is reduced, and the adjustment method is simple.

Owner:ELECTRIC POWER SCI RES INST OF GUIZHOU POWER GRID CO LTD

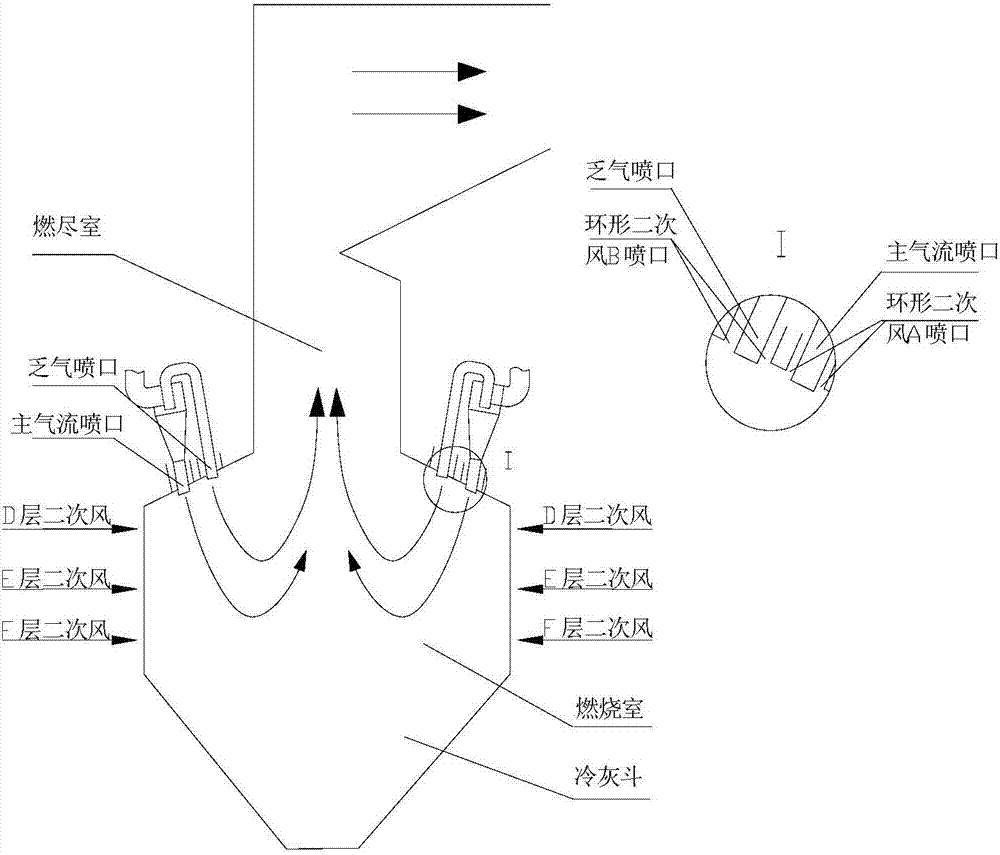

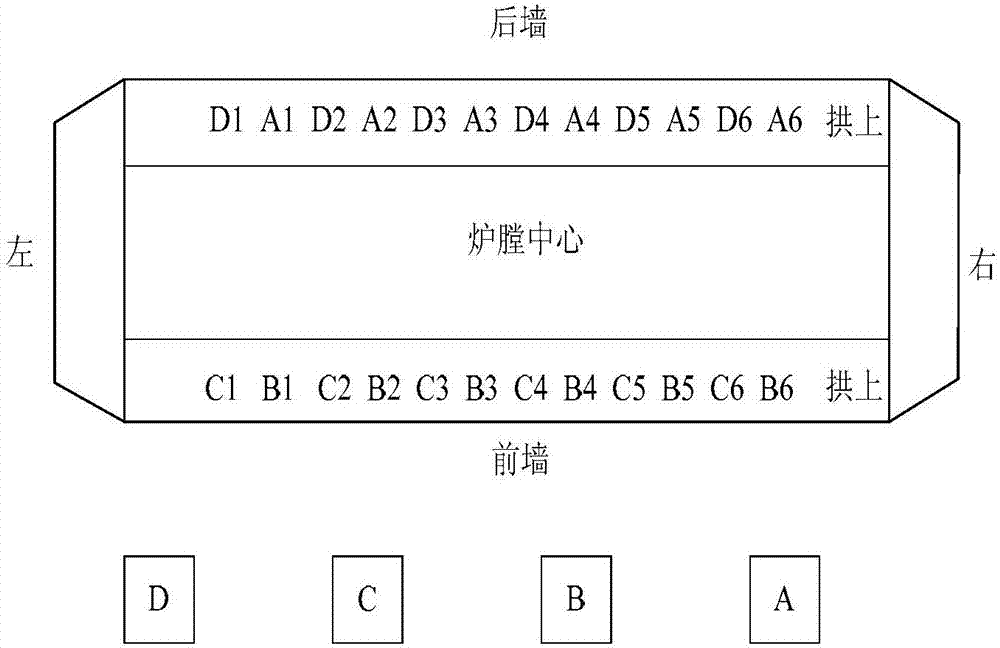

W-shaped flame boiler air distribution way optimization method

ActiveCN107355807AImprove adaptabilityImprove stabilitySolid fuel pretreatmentStaged combustionCombustionEngineering

The invention relates to a W-shaped flame boiler air distribution way optimization method. The method comprises steps of analyzing an acquired boiler operation condition, determining an F wind downward inclination angle and D,E wind opening degree, in which for a back wall, the F wind downward inclination angle is 25,25,5,5,30,30,30,30,5,5,25,25, the E wind opening degree is 25,25,5,20,20,20,20,20,5,5,10,10, the D wind opening degree is 5,5,5,5,5,5,5,5,5,5,5,5 and for a front wall, the F wind downward inclination angle is 25,25,5,5,30,30,30,30,5,5,25,25, the E wind opening degree is 25,25,5,20,20,20,20,20,5,5,10,10 and the D wind opening degree is 5,5,5,5,5,5,5,5,5,5,5,5. An in-furnace combustion work condition can be improved; and CO can be reduced and flying ash carbon content can be also reduced at the same time.

Owner:中国大唐集团科学技术研究总院有限公司

Coal firing method with low discharged nitrous oxides

ActiveCN100504164CReduce generationSuppress generationFluidized bed combustionAir supply regulationBack burnsCombustion chamber

The invention discloses a fire coal method to discharge low nitrogen oxide, which is characterized by the following: adopting high temperature oxygen-enriched smoke gas from circulating fluidized bed burner as high temperature low oxygen twice wind of pulverized coal fired boiler; burning coal dust in high temperature low oxygen coordinating wind with temperature at 800-950 deg. c; decreasing generated quantity of nitrogen oxide (NOx)greatly; controlling circulating fluidized bed burner and main combustion area of coal dust burner fire box at reducing atmosphere; controlling burning temperature; inhibiting the generation of NOx; keeping stability and complete burning property of burning; realizing low NOx discharge of boiler; decreasing the discharging quantity of NOx below 130mg / Nm3.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

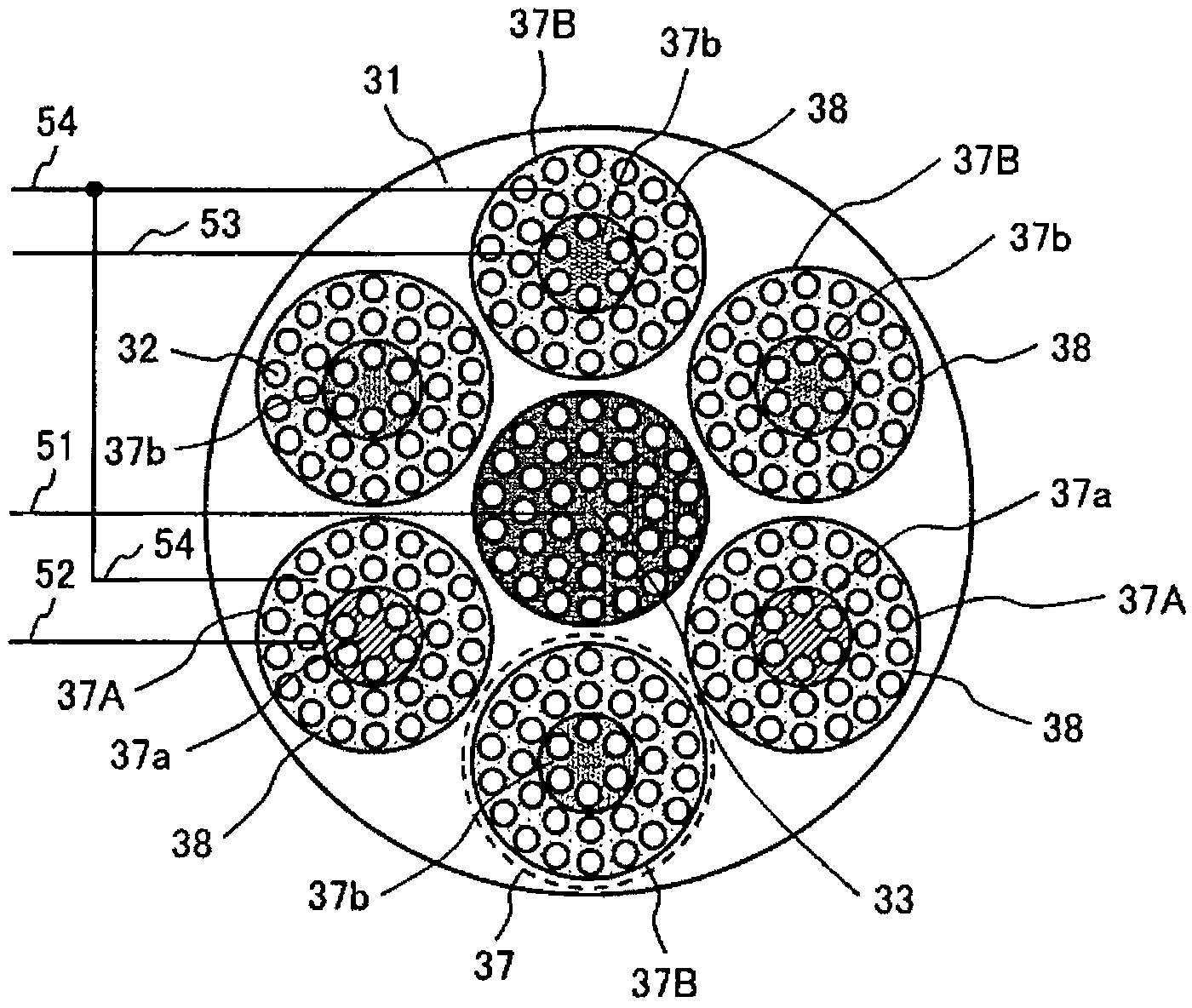

Gas turbine combustor and operating method thereof

ActiveCN103225822BAvoid temperature riseGuaranteed combustion stabilityBurnersFuel supply regulationCombustorCombustion chamber

A gas turbine combustor has a chamber supplied with fuel (50) and air (16) and a multi-burner (6) having a plurality of burners provided with an air hole plate (31) having a plurality of air holes (32), and fuel nozzles (25) for supplying fuel (50) to the air holes (32) in the air hole plate (31); the multi-burner (6) is made up of a center burner (33) disposed in the center and a plurality of outer burners (37) around the center burner (33), the outer burners (37) are divided into inner fuel nozzles (25) and outer fuel nozzles (25) to separately supply fuel through fuel systems (51 - 54), and the fuel (50) is supplied to the fuel nozzles (25) in the center burner (33) or to the fuel nozzles (25) in the center burner (33) and the inner fuel nozzles (25) in the outer burners (37) disposed around the center burner (33) in a partial load condition in which the load is lower than that of when all the fuel systems (51 - 54) are used to supply fuel (50).

Owner:MITSUBISHI POWER LTD

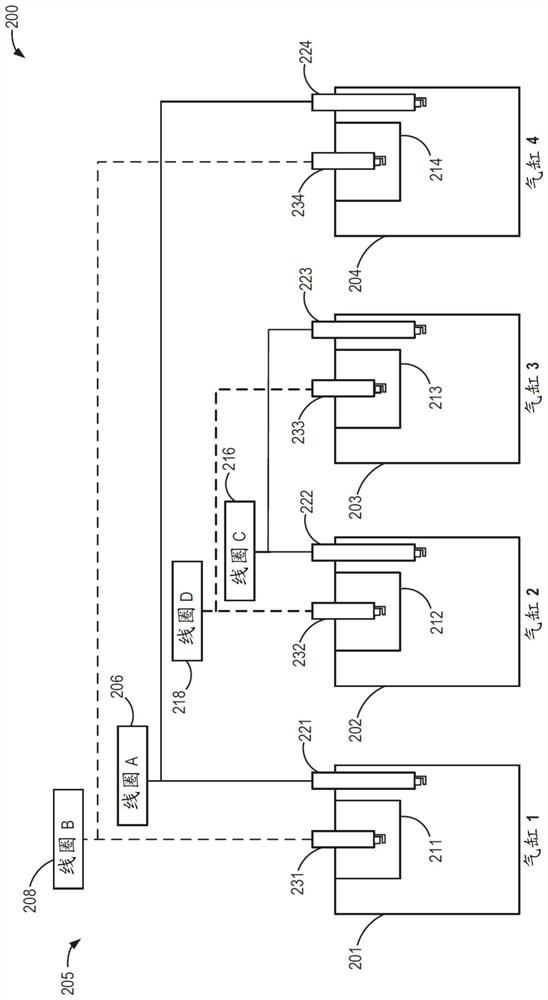

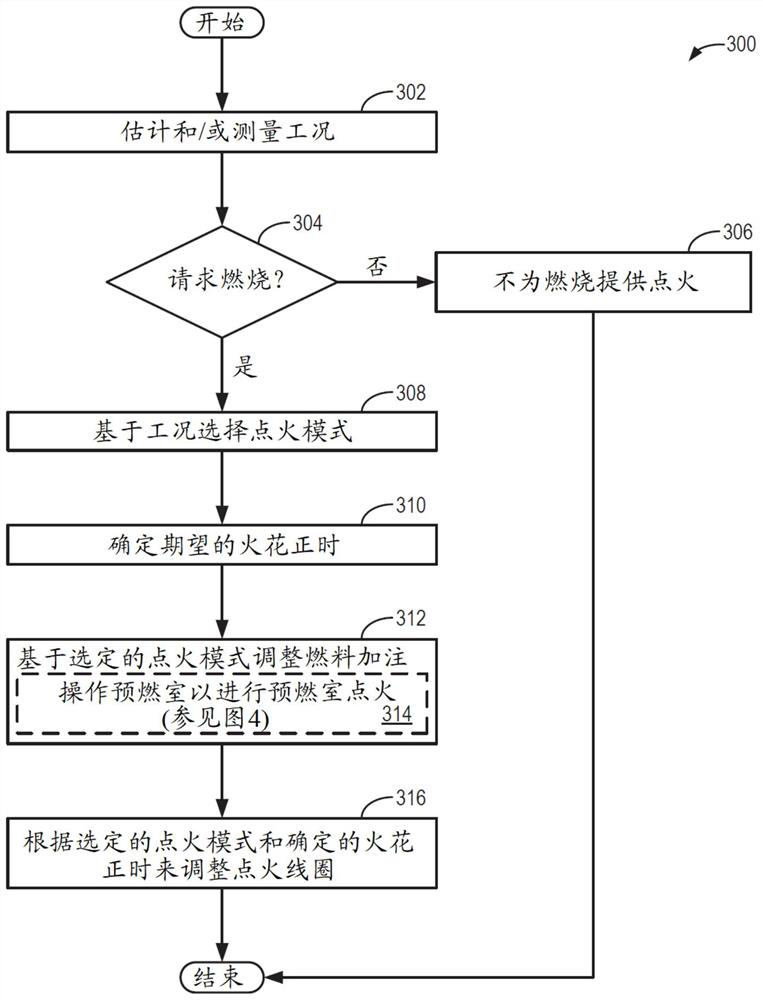

Systems and methods for ignition coil multiplexing in a pre-chamber system

PendingCN113882986AGuaranteed combustion stabilityLow costElectrical controlInternal combustion piston enginesIgnition coilEngineering

Systems and methods for ignition coil multiplexing in a pre-chamber system are provided. Methods and systems are provided for adjusting multiplexed ignition signals in an engine system based on engine operating conditions, each cylinder of the engine system including a main chamber spark plug and a pre-chamber system. In one example, a method may include multiplexing spark signals to a first spark plug, a second spark plug, a third spark plug, and a fourth spark plug, with the first spark plug coupled to a pre-chamber of a first cylinder, the second spark plug coupled to a pre-chamber of a second cylinder, the third spark plug coupled to a main chamber of the first cylinder, and the fourth spark plug coupled to the main chamber of the second cylinder. In this way, one ignition coil may be used to actuate two different spark plugs coupled to separate cylinders.

Owner:FORD GLOBAL TECH LLC

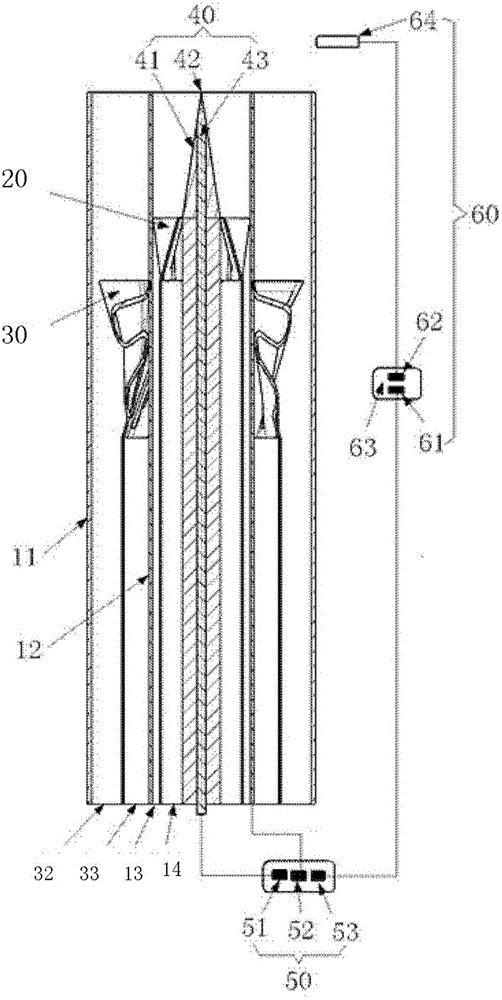

Aluminum hydroxide roasting system and method

ActiveCN108178173AGuaranteed combustion stabilityReduce the temperatureAluminium oxide/hydroxide preparationNitrogen oxidesProcess engineering

The invention discloses an aluminum hydroxide roasting system and method. The system includes a feeder, a dryer, a preheater, a roaster, and the like, and also includes a flue gas recirculation deviceand a fuel gas distribution device. The outlet end of a recirculating flue gas pipe is disposed on a gas communication pipe between a cooler and the roaster. The fuel gas distribution device includesa fuel gas header, a main burner and an auxiliary burner. A secondary air nozzle and a secondary air regulating valve are also disposed in the middle upper portion of the roaster. The roaster roastsaluminum hydroxide to generate hot flue gas, the hot flue gas is cooled, and dedusted, the cooled and dedusted flue gas as recirculating flue gas and hot air are mixed and partly burnt by the auxiliary burner to form high-temperature low-oxygen combustion-supporting air, and through the classification ratio and staged combustion of primary and secondary air, the initial concentration of nitrogen oxides can be reduced. Through use of a low-oxygen combustion mode and a staged combustion structure, the temperature of a main combustion zone is significantly reduced, and complete combustion of a fuel can be ensured while suppresses of formation of the nitrogen oxides.

Owner:TSINGHUA UNIV

Medium/low-temperature smoke double circulation device for preventing high-alkali coals from slagging and method thereof

PendingCN107906511AGuaranteed uptimeLow design material requirementsCombustion apparatusChimneysThermodynamicsBoiler furnace

The invention discloses a medium / low-temperature smoke double circulation device for preventing a high-alkali coal boiler from slagging and a method thereof. The device comprises a boiler hearth, a tail flue, a horizontal flue, a low-temperature smoke recirculation flue and a medium-temperature smoke recirculation flue; less medium-temperature smoke is selected in a tail flue area behind a dust remover, and is ejected into the hearth through a medium-temperature circulation smoke inlet at the bottom of the hearth; and less low-temperature smoke is selected, and is ejected to a hearth outlet through a low-temperature circulation smoke inlet at the upper end of the hearth outlet. The device can effectively reduce and control the temperature of the hearth outlet and the concentration of alkali metal in smoke in the hearth outlet; circulating smoke achieves a scouring effect on such heated surfaces as a superheater; and the temperature of the hearth can be effectively controlled, so that the temperature of the hearth outlet is controlled, the slagging, dirt staining and dust accumulation conditions of heated surfaces of the horizontal flue and the tail flue can be greatly relieved, andthe full-load, safe and stable operation of the boiler can be guaranteed when high-sodium metal coals are burnt.

Owner:ZHEJIANG UNIV

Integrated plasma exciter, nozzle array and burner

ActiveCN105783031AAdjust working statusImprove combustion stabilityContinuous combustion chamberWave structureCombustor

The invention provides a nozzle of an integrated plasma exciter. The nozzle comprises an inner cylinder, an outer cylinder, M inner wave structures, N outer wave structures and a central electrode structure arranged inside the inner cylinder, wherein the M inner wave structures are clamped between the inner cylinder and the central electrode structure; the N outer wave structures are clamped between the inner cylinder and the outer cylinder; the inner cylinder and the central electrode structure extrude out of the inner wave structures in the fluid outlet direction; and the central electrode structure and the inner cylinder from a plasma exciter. According to the nozzle, the voltage value of the central electrode structure is adjusted, so that the working state of the nozzle can be adjusted, the flameout and backfire situations are effectively avoided, and the combustion stability of the nozzle is improved.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

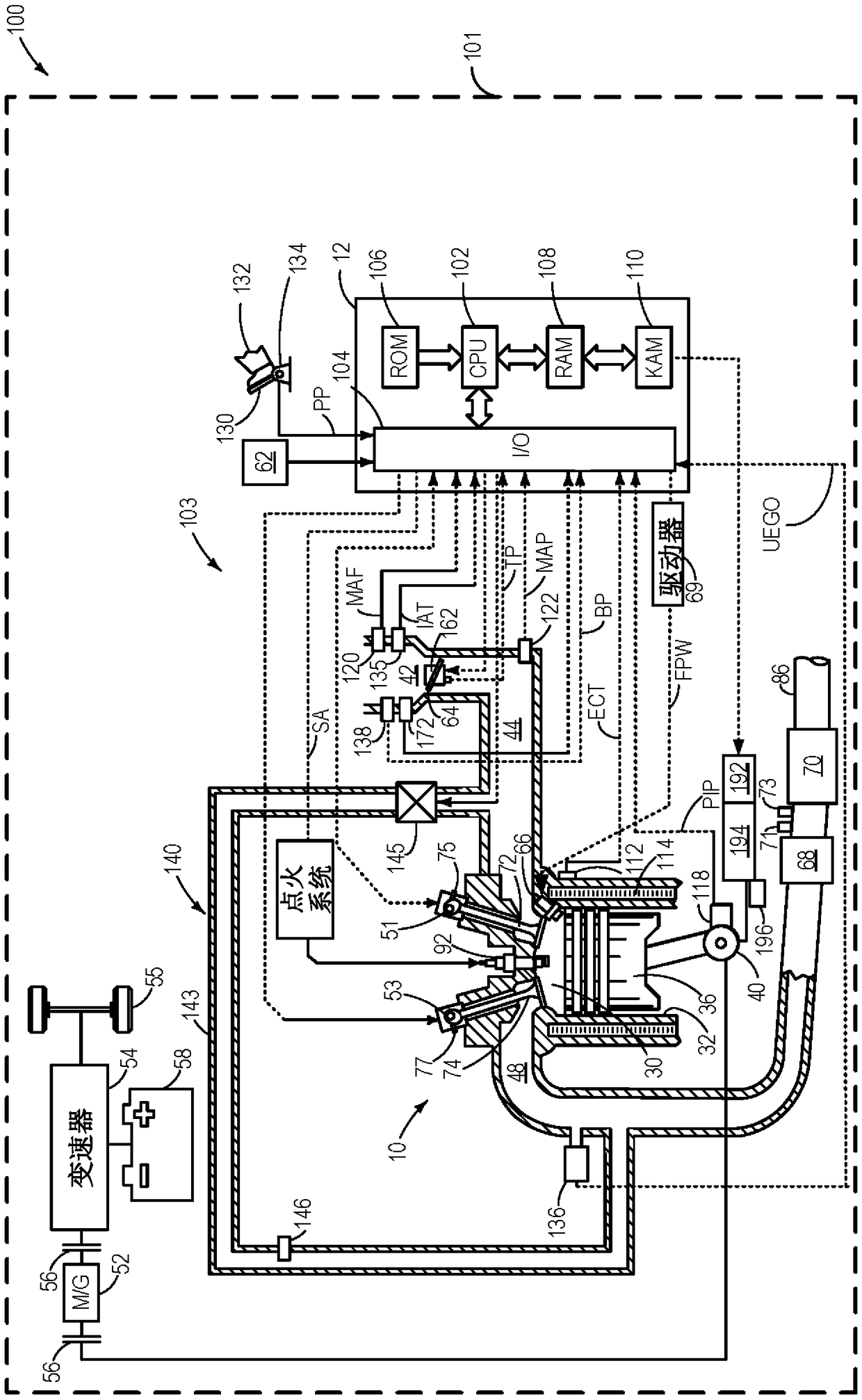

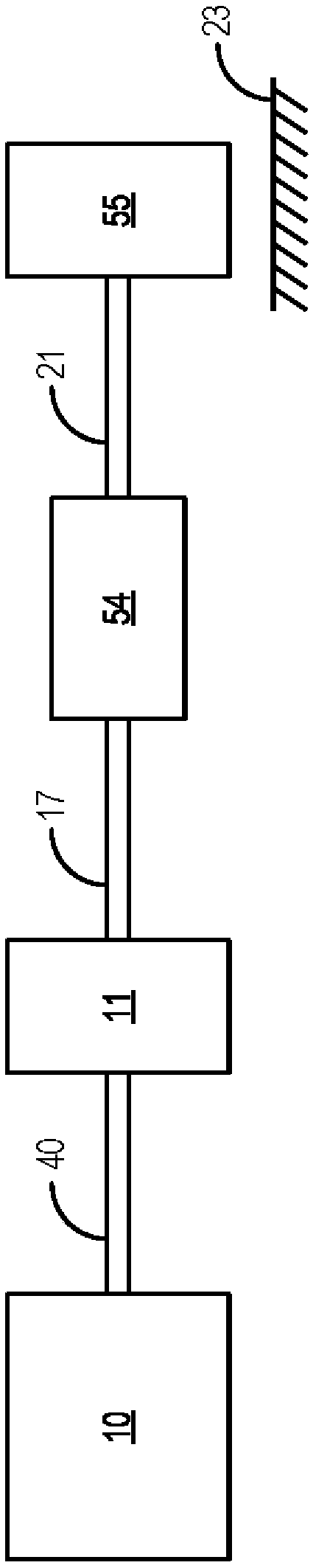

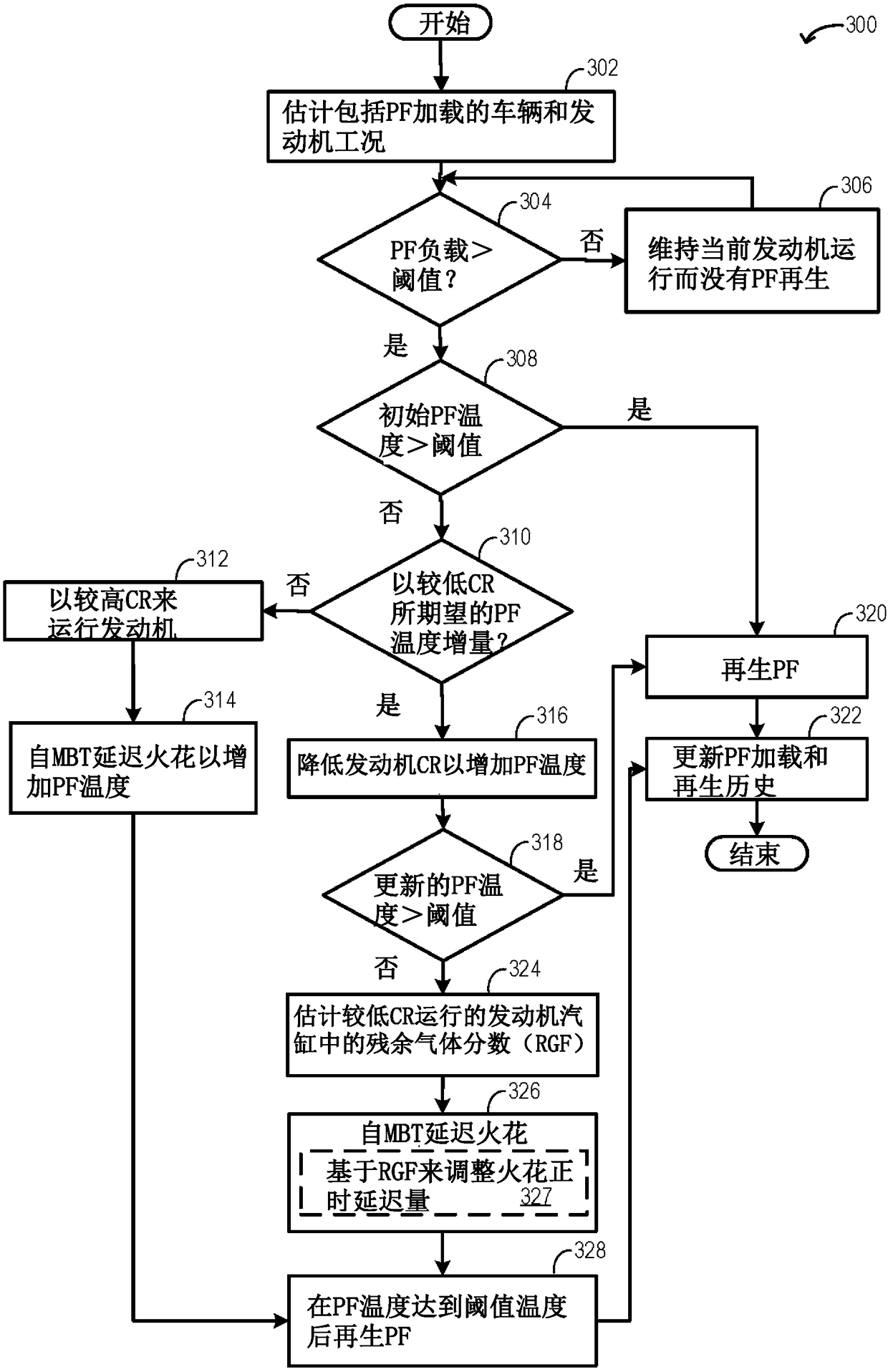

Systems and methods for particulate filter regeneration

PendingCN109268105AImprove smoothnessReduce dependenceElectrical controlInternal combustion piston enginesParticulatesEngineering

The invention relates to systems and methods for particulate filter regeneration. Methods and systems are provided for adjusting engine compression ratio (CR) and spark timing to attain particulate filter (PF) regeneration temperature. In one example, a method may include, in response to PF load reaching a threshold and PF temperature being lower than the PF regeneration temperature, lowering theCR and then selectively adjusting spark timing based on an estimated residual gas fraction (RGF) at the lower CR.

Owner:FORD GLOBAL TECH LLC

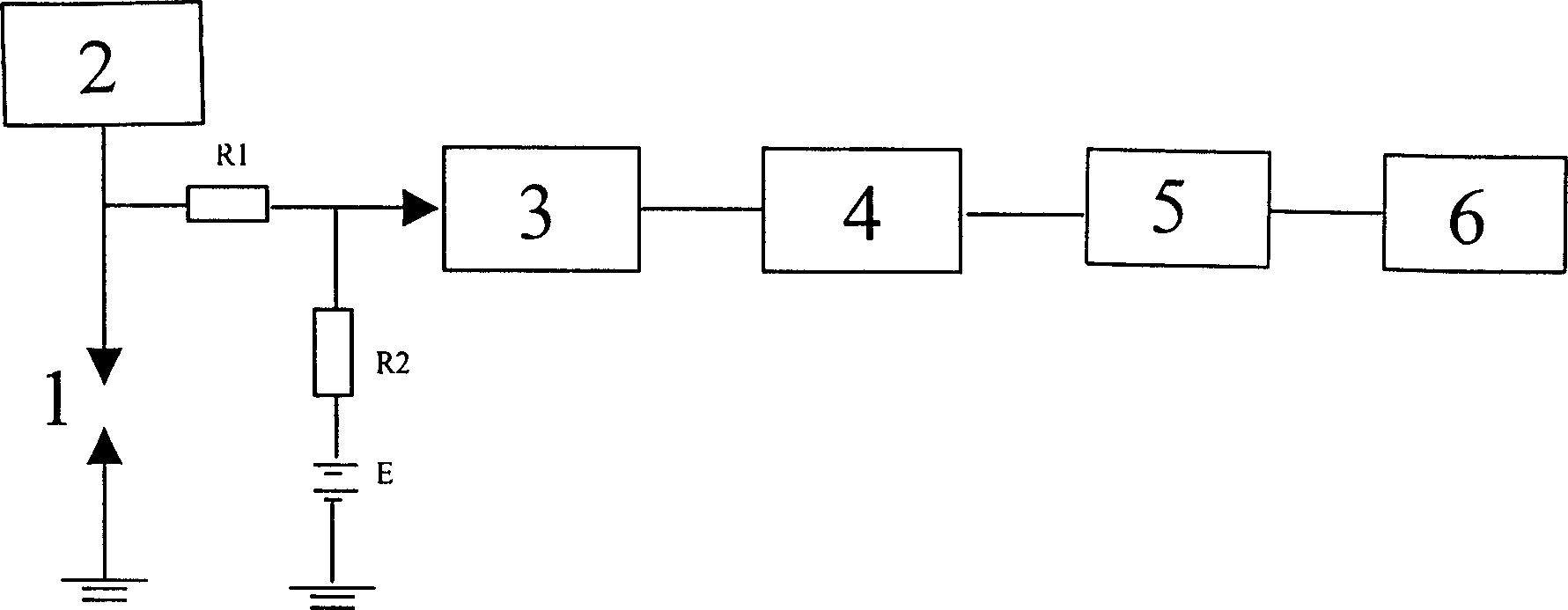

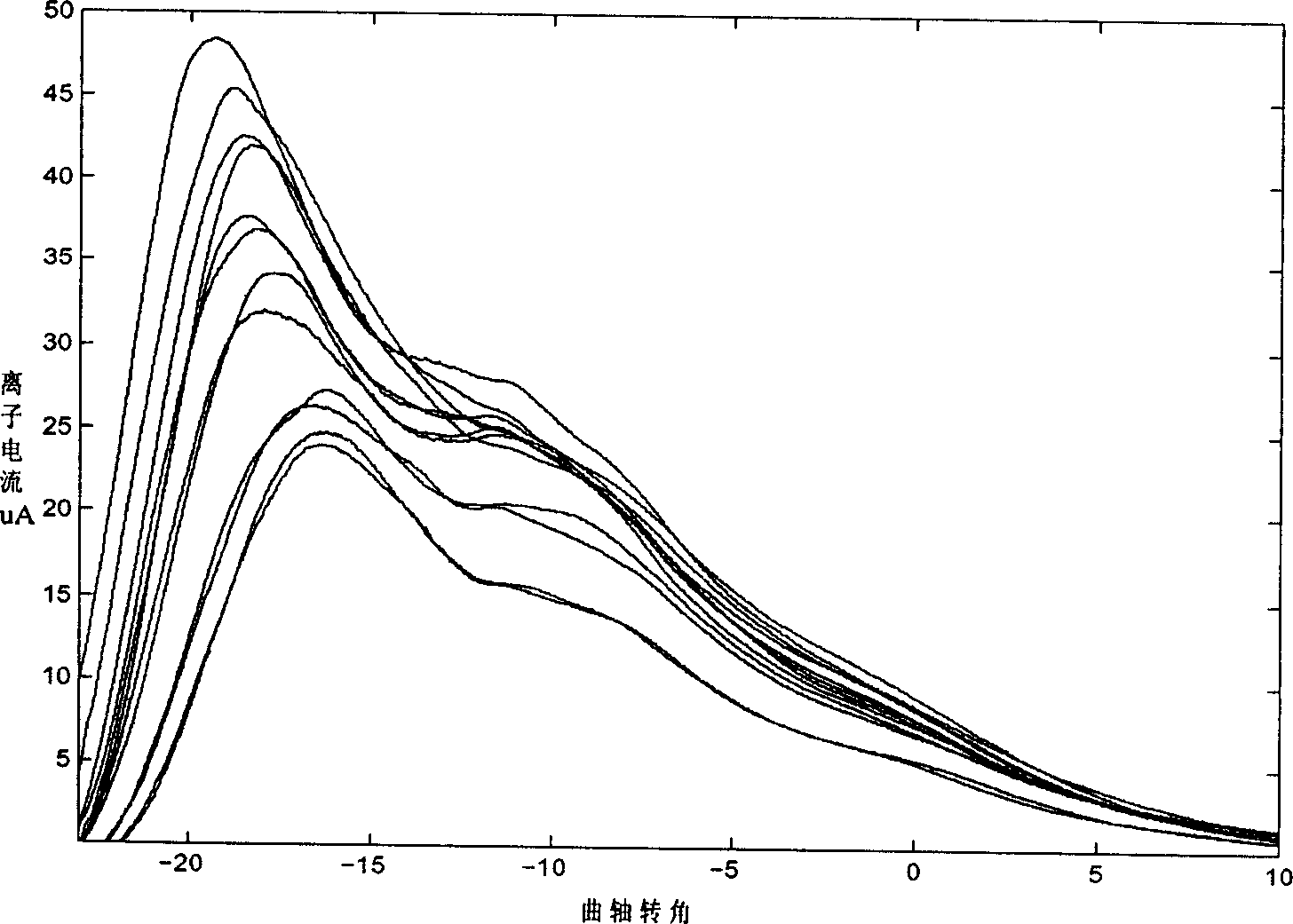

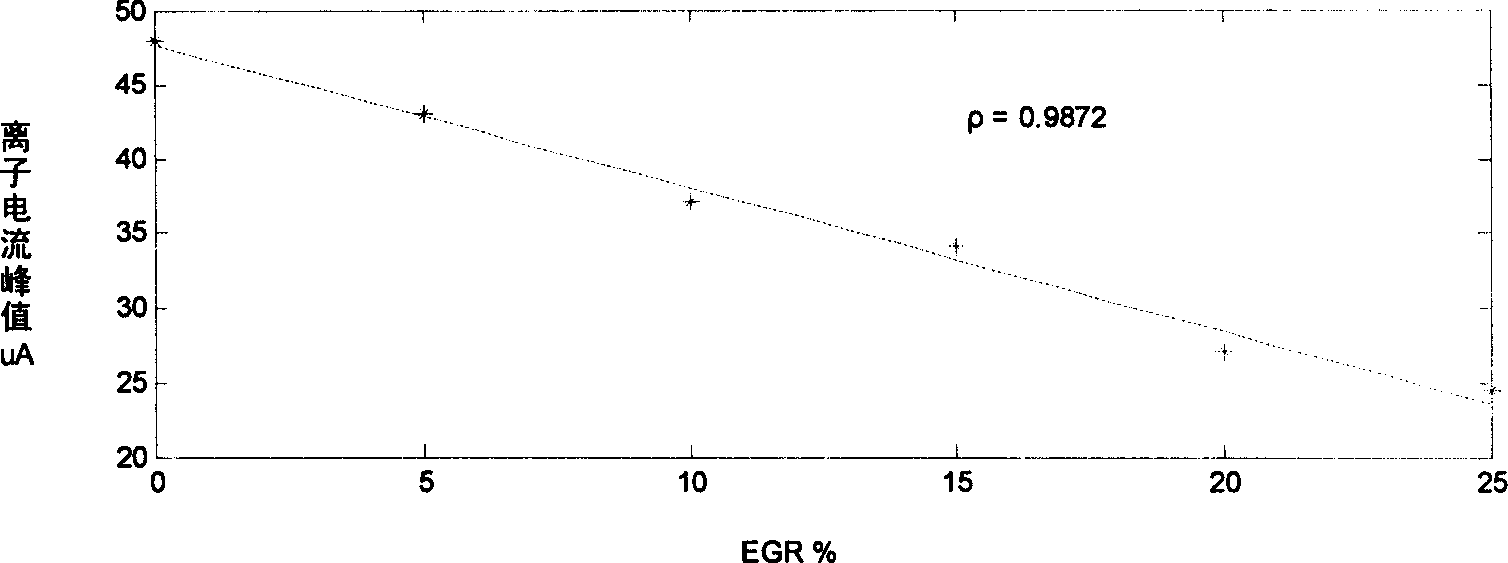

Method and apparatus for on-line measuring vehicle petrol engine exhaust recirculating rate

InactiveCN1584540ARealize closed-loop controlGuaranteed combustion stabilityEngine testingMicrocontrollerEngineering

A method for on-line measuring waste gas recirculation ratio of vehicle gasoline engine includes executing DC bias voltage forward direction in between spark plug and electrode to change ion directional movement to be ion current; sending it to monolithic computer for sampling and recording after isolating, filtering and amplifying; measuring out waste gas recirculation ratio based on linear coorelation of recirculation ratio to peak value and peak value area. A device for realizing the method is also disclosed by the present invention.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com