Integrated plasma exciter, nozzle array and burner

A plasma exciter and nozzle technology, applied in combustion chambers, combustion methods, combustion equipment, etc., can solve problems such as easy oscillation and combustion instability, and achieve suppression of flow separation, prevention of flameout and flame pulsation, and improved mixing. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

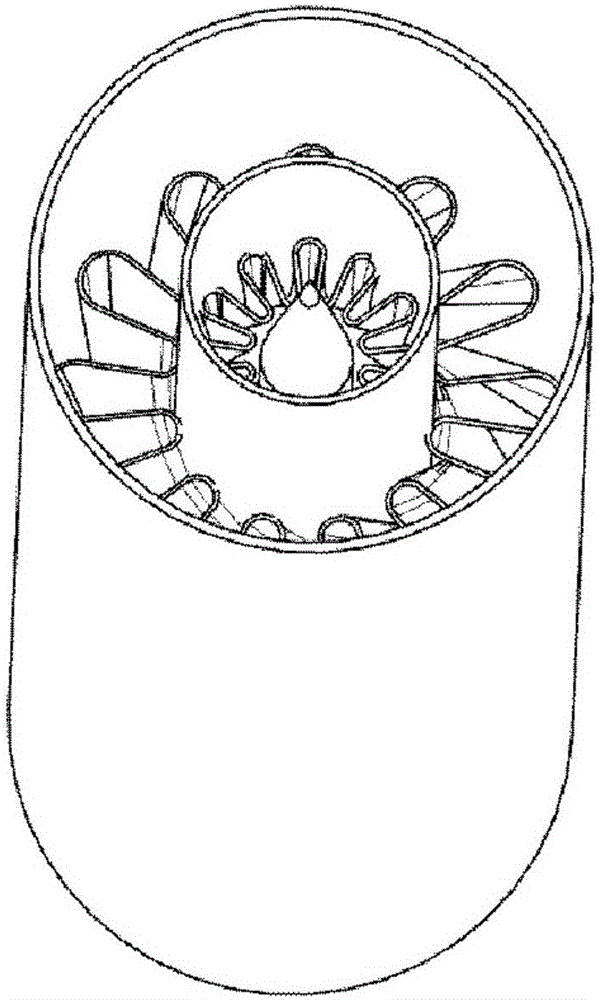

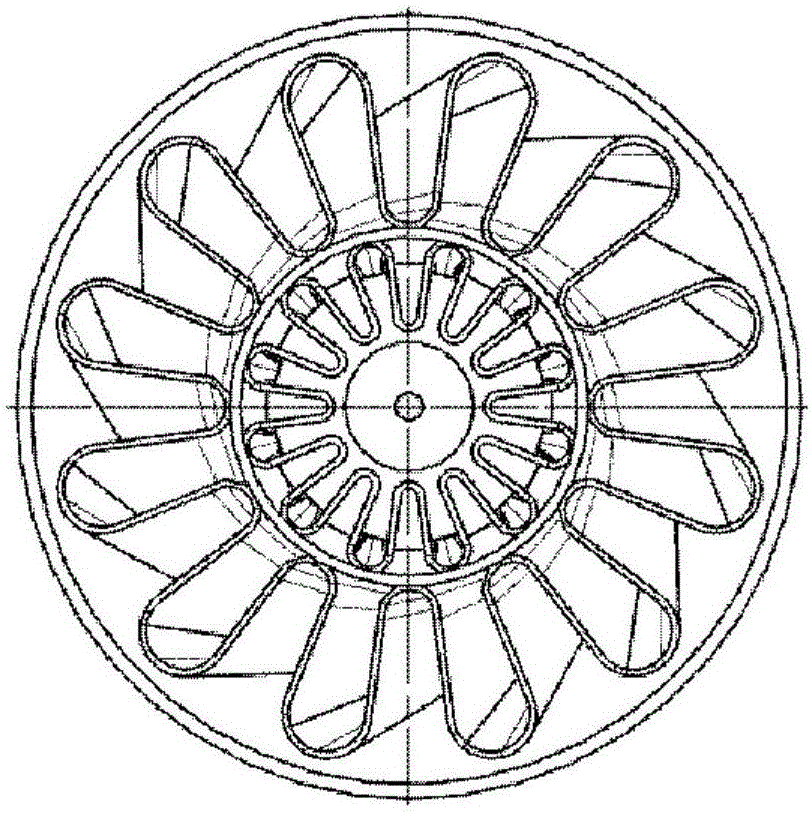

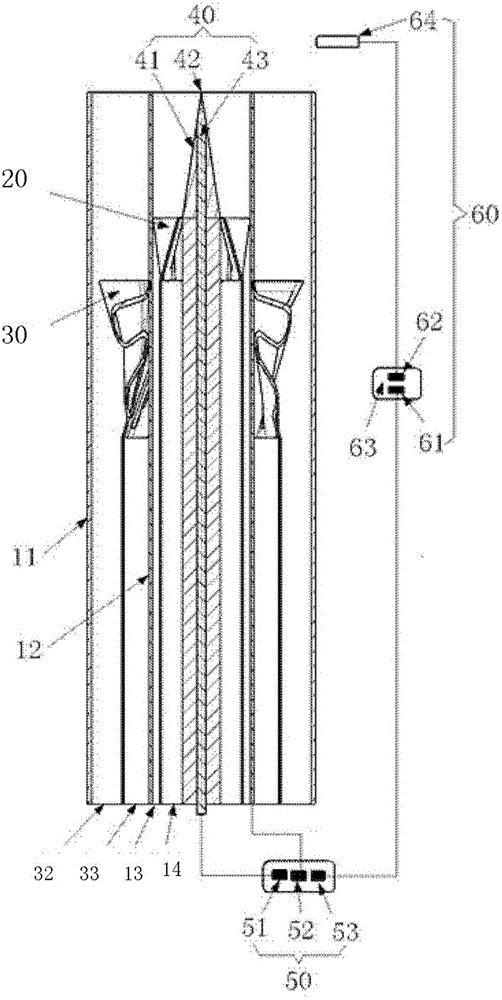

[0031] see figure 1 Referring to FIG. 7 , the nozzle of the integrated plasma actuator according to the first embodiment of the present invention includes: an inner cylinder 12, an outer cylinder 11, and a center electrode structure 40 disposed in the inner cylinder; an inner layer of M layers The wave structure 20 is sandwiched between the inner cylinder 12 and the central electrode structure 40, which are arranged in sequence along the radial direction of the cylinder, and N outer layer wave structures 30 are sandwiched between the inner cylinder 12 and the outer cylinder 11 Between them, they are arranged in sequence along the radial direction of the cylinder; between adjacent inner wave structures, between adjacent ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com