V -type cone flame holder for rotor engine

A technology of rotary engine and flame stabilizer, which is applied in the direction of combustion method, combustion chamber, combustion equipment, etc., to achieve the effect of strong fire stability, simple structure and easy flame

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

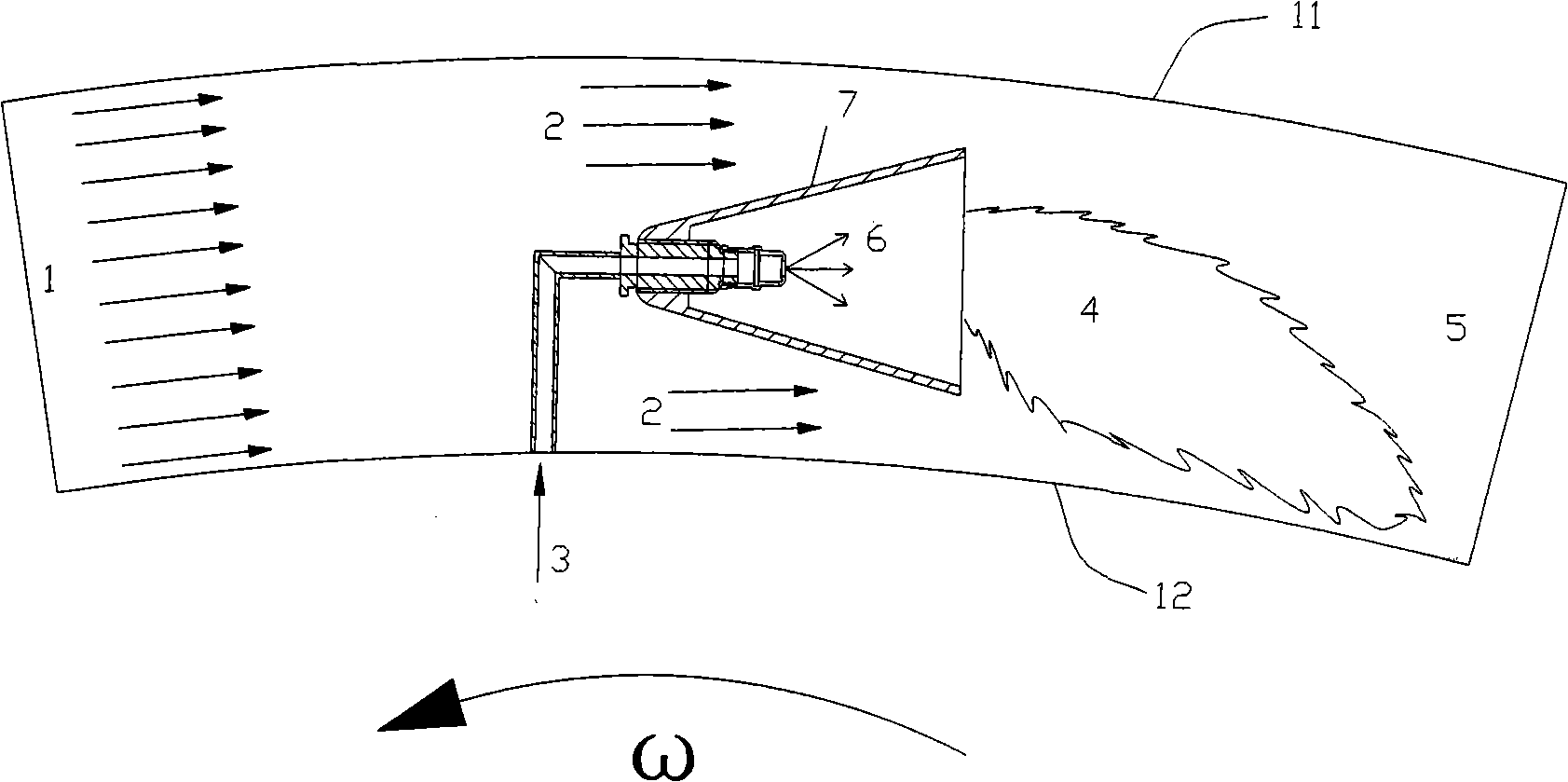

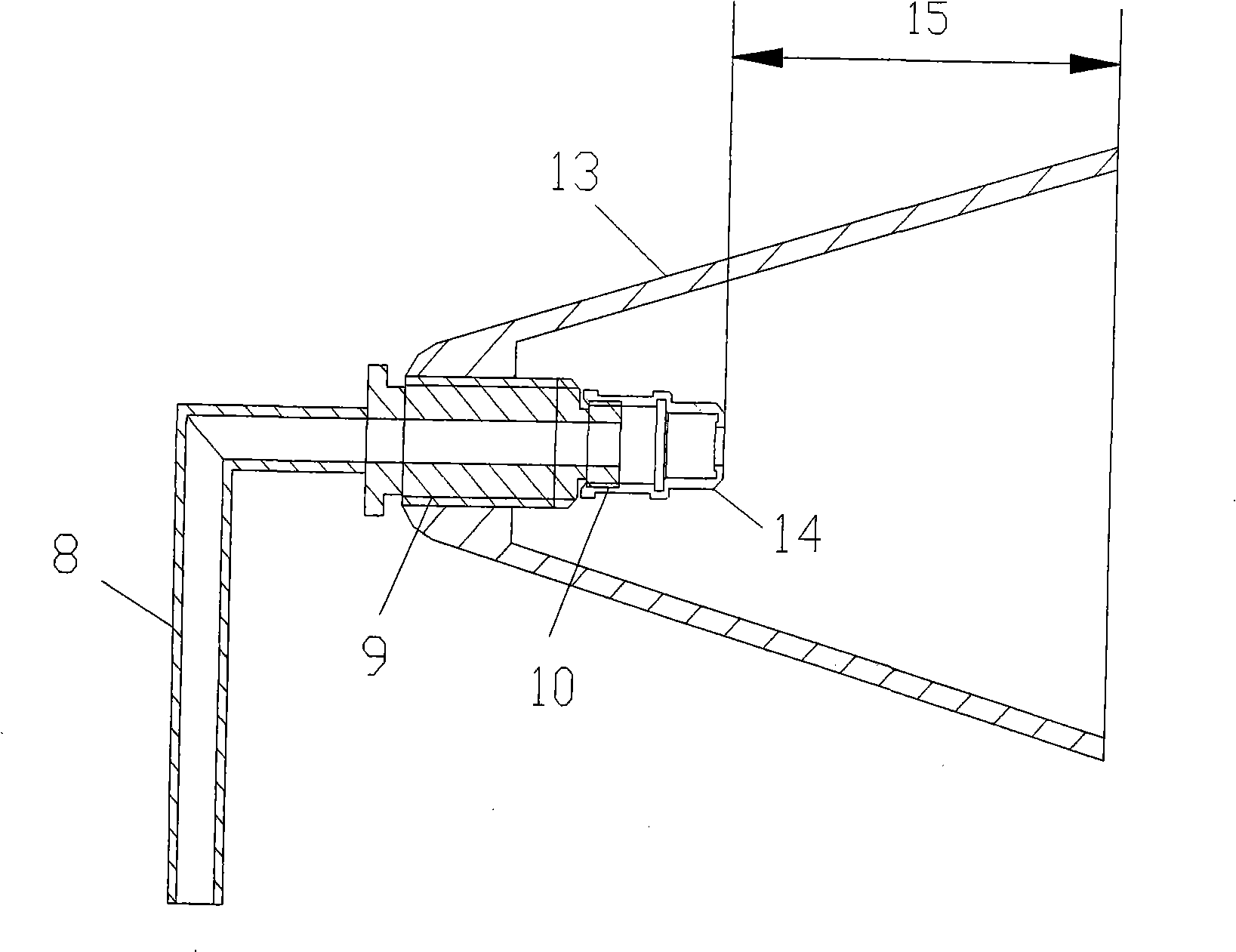

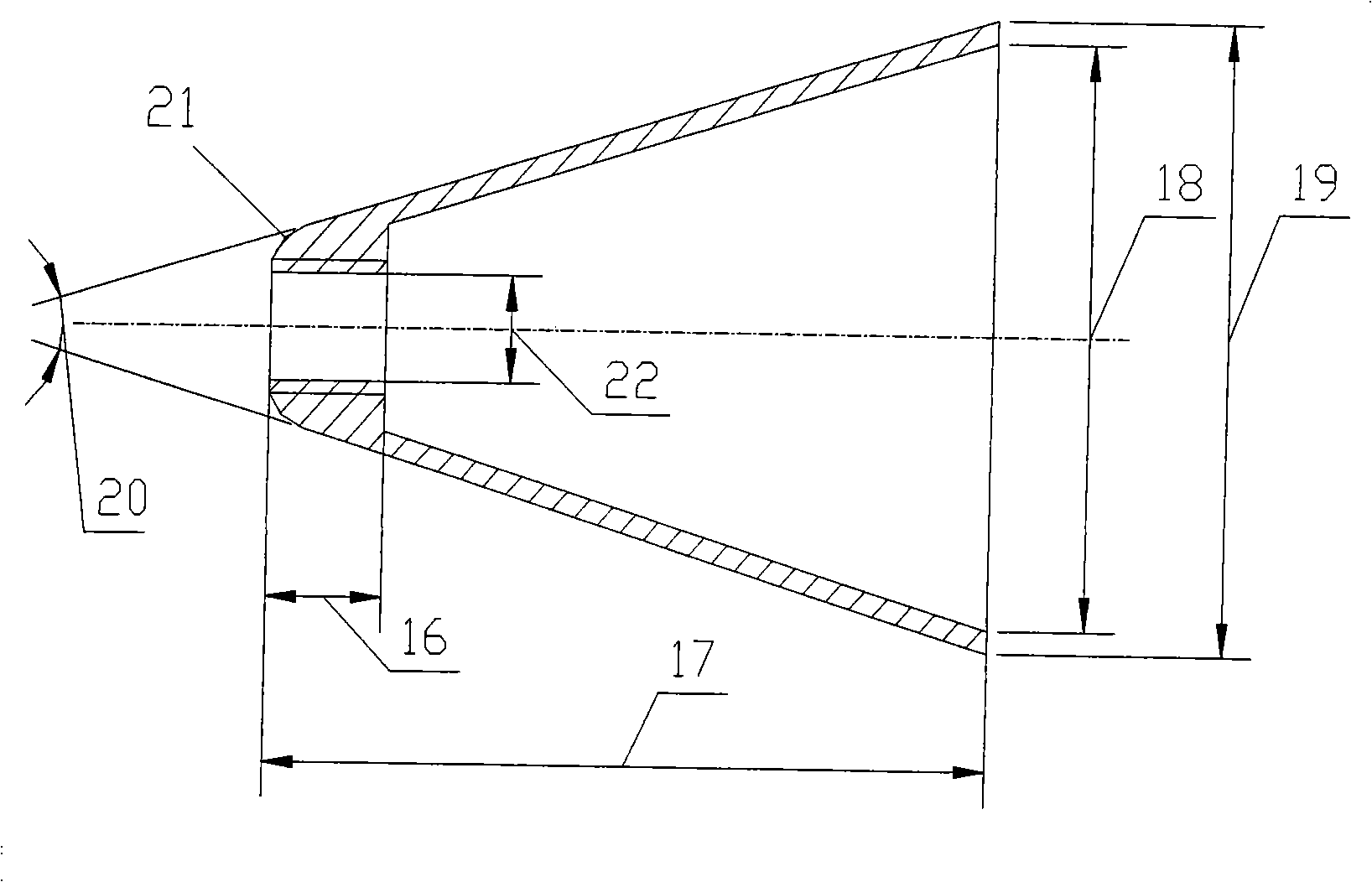

[0027] Install V-cone flame holders on rotary engines such as figure 1 As shown; on the rotary engine, the casing 12 inside the combustion chamber rotates together with the rotor, and the rotation angular velocity is ω, while the casing 11 outside the combustion chamber can rotate with the rotor due to the different structural design of the rotary engine, or it can be stationary The main flow 1 of the combustion chamber flows into the combustion chamber at a certain relative speed, and the relative Mach number of the air flow in the current typical ram rotor engine is above 0.2; when flowing through the V-shaped cone 13 in the V-shaped cone flame stabilizer 7, The flow air flow 2 on the outer wall of the V-shaped cone forms a recirculation zone due to viscosity at the trailing edge of the V-shaped cone 13. This low-speed recirculation zone is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vertex angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com