Medium/low-temperature smoke double circulation device for preventing high-alkali coals from slagging and method thereof

A technology of low-temperature flue gas and high-alkali coal, which is applied in exhaust gas devices, combustion methods, lighting and heating equipment, etc., can solve the problems of low utilization efficiency of Zhundong high-alkali coal, and achieve low design material requirements, wear and corrosion The effects of weak resistance and low dust content in flue gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

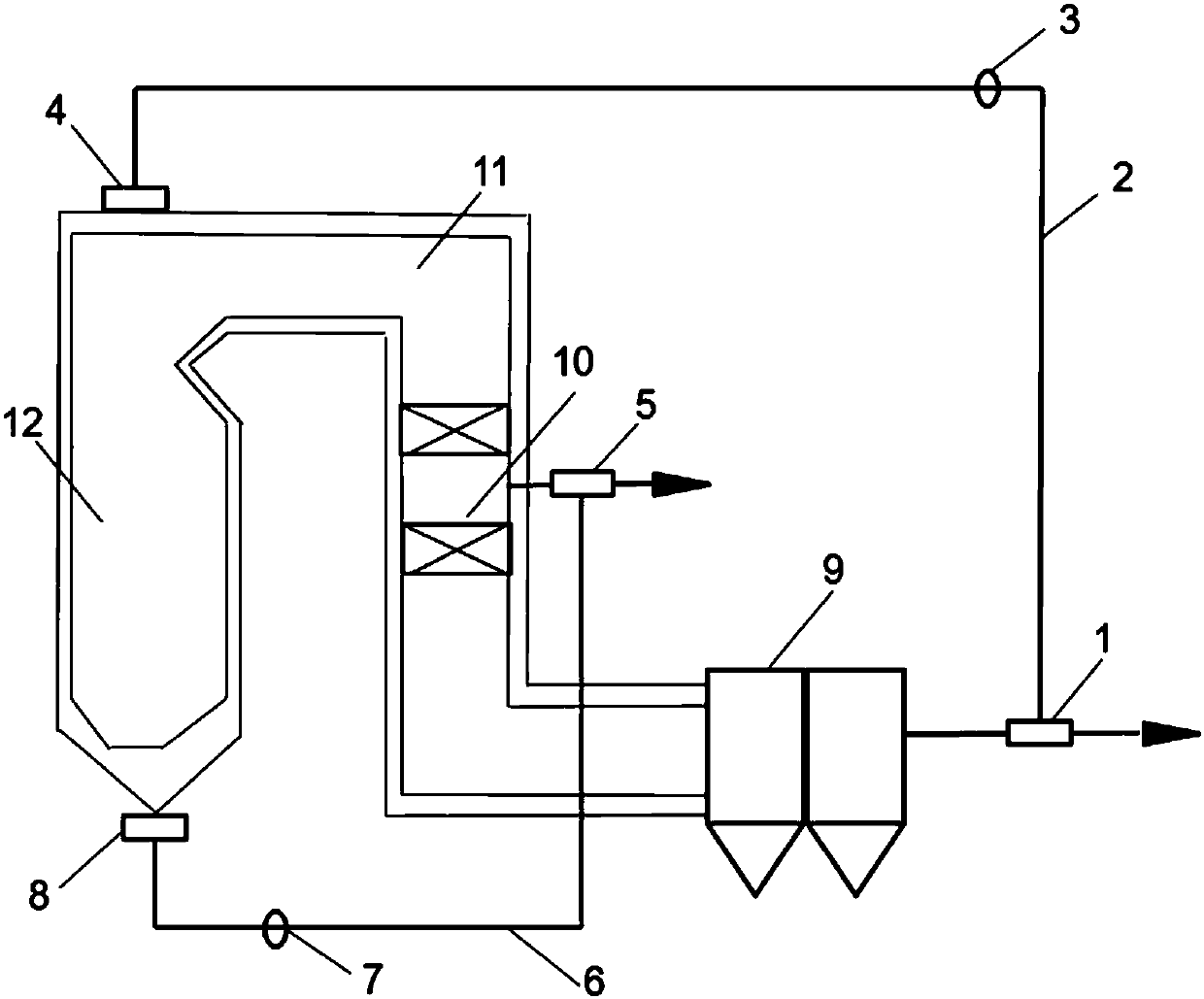

[0015] The medium and low temperature flue gas double circulation device for preventing high-alkali coal slagging of the present invention comprises: boiler furnace 12, boiler furnace and tail flue 10 are connected through horizontal flue 11, and a high-temperature heating A low-temperature heating surface is arranged in the tail flue, and there is a dust collector 9 at the tail flue. The low-temperature flue gas area after the outlet of the dust collector has a low-temperature flue gas exhaust port 1, a low-temperature flue gas exhaust port and a low-temperature flue gas recirculation flue. 2 connection, the low-temperature flue gas recirculation flue is connected with the low-temperature flue gas recirculation inlet 4 at the upper end of the furnace outlet, the low-temperature flue gas recirculation fan 3 is installed on the low-temperature flue gas recirculation flue, and the medium-temperature flue gas after the outlet of the tail flue 10 The zone has a medium-temperature f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com