Method and apparatus for on-line measuring vehicle petrol engine exhaust recirculating rate

A technology of exhaust gas recirculation rate and gasoline engine, which is applied in the direction of measuring device, engine test, machine/structural component test, etc. It can solve the problems of inability to realize EGR rate closed-loop control, lack of EGR rate, combustion instability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

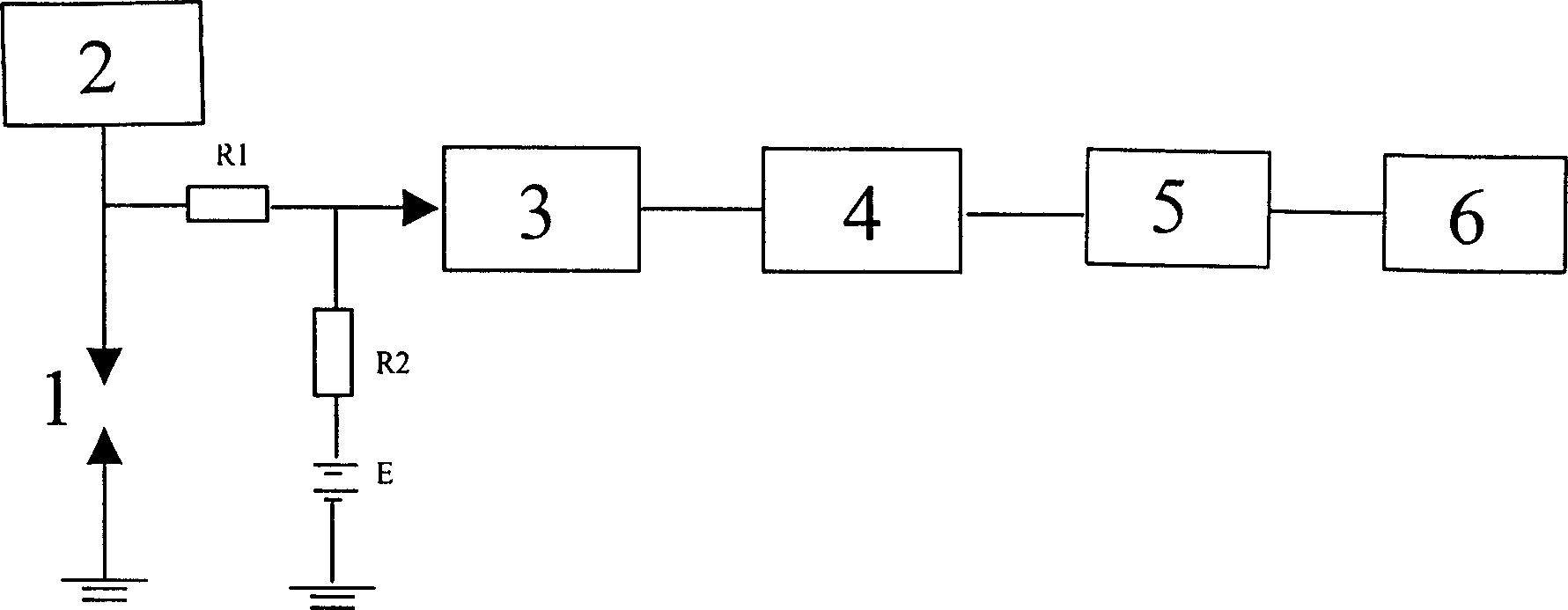

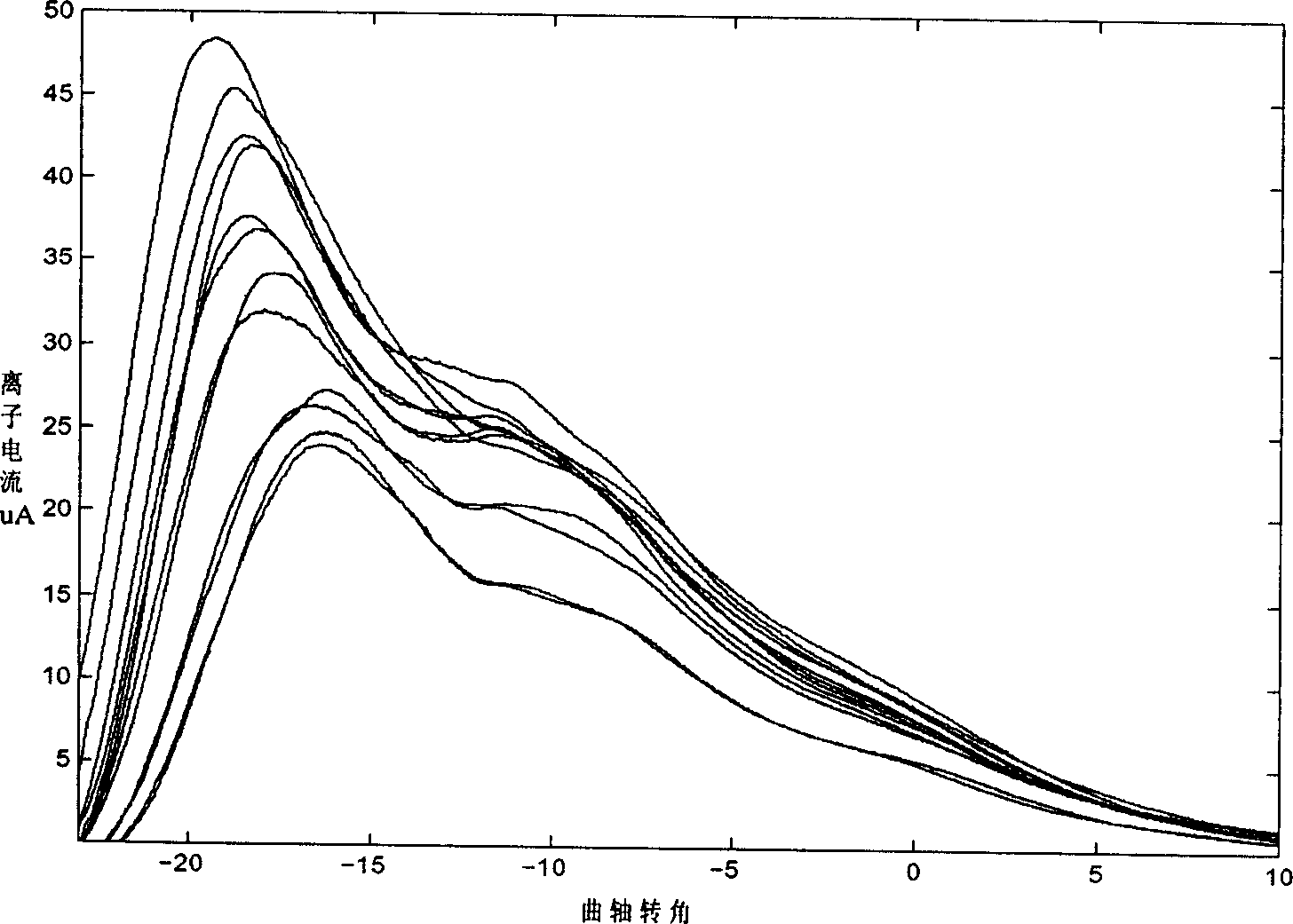

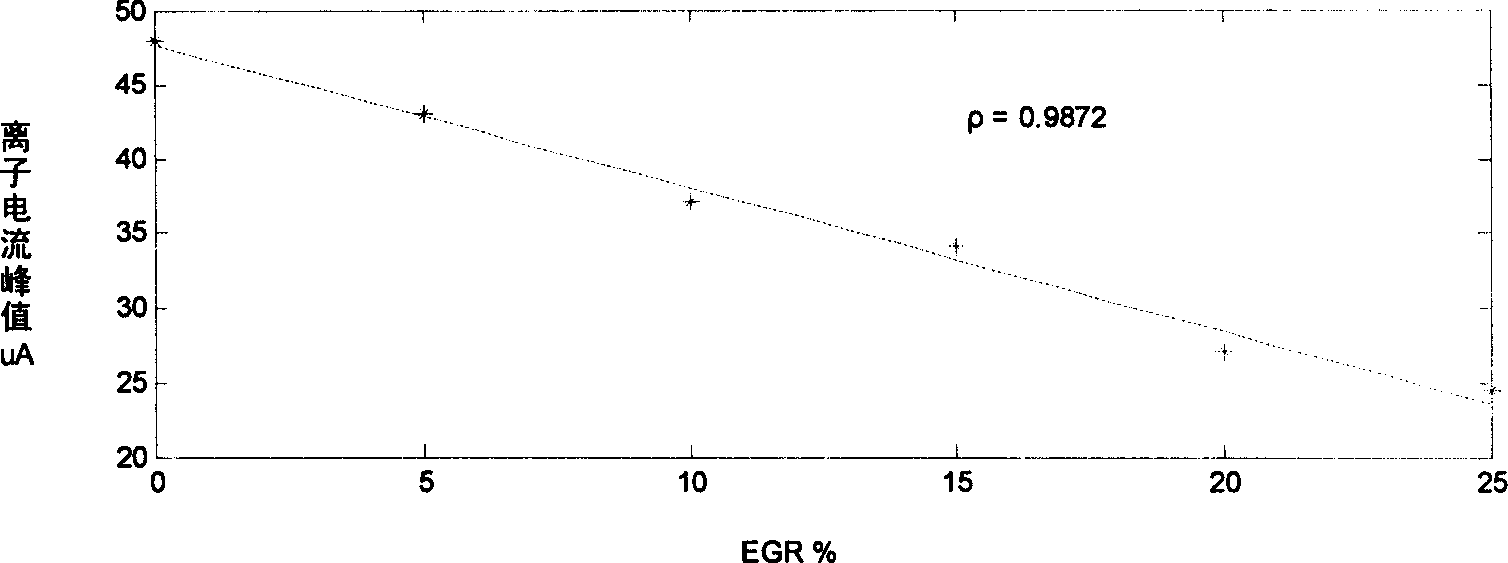

[0066] refer to figure 1 , the measuring device specially designed for implementing the above measuring method is to connect a sequentially connected resistor R1, R2 and power supply E at the junction of the spark plug 1 and the distributor 2 of the gasoline engine cylinder of the vehicle, and connect it in parallel with the spark plug 1; The connection of R1 and R2 is connected with an isolation circuit 3, a filter circuit 4, an amplifier circuit 5, and a single-chip microcomputer 6, in which a DC bias voltage of 200--500V is positively applied between the electrodes of the spark plug 1, after isolation and filtering , After being amplified, it is sent to the single chip microcomputer for sampling and recording. The sampling frequency is 10KHz. The EGR rate of the test engine is controlled by a linear proportional valve driven by a stepping motor, and its opening is determined by the PWM output of the microcontroller. Under the condition that other conditions remain unchang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com