Patents

Literature

105results about How to "Improve stable working range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

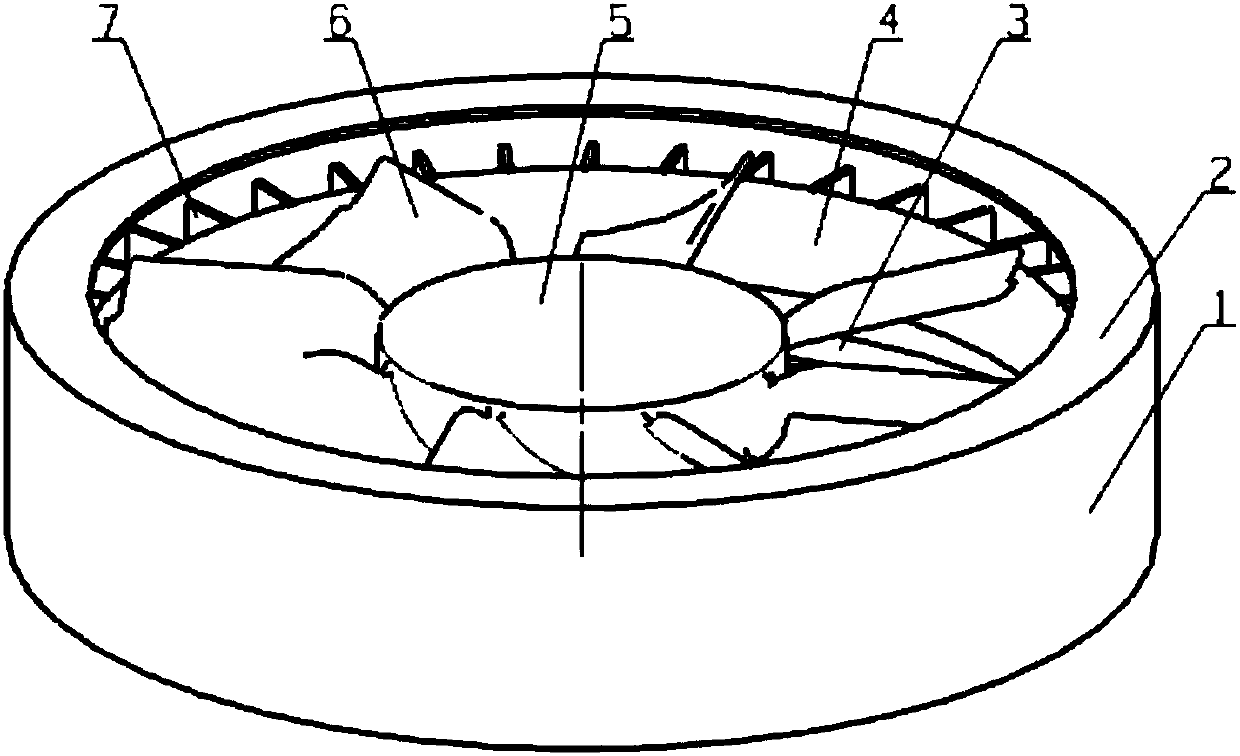

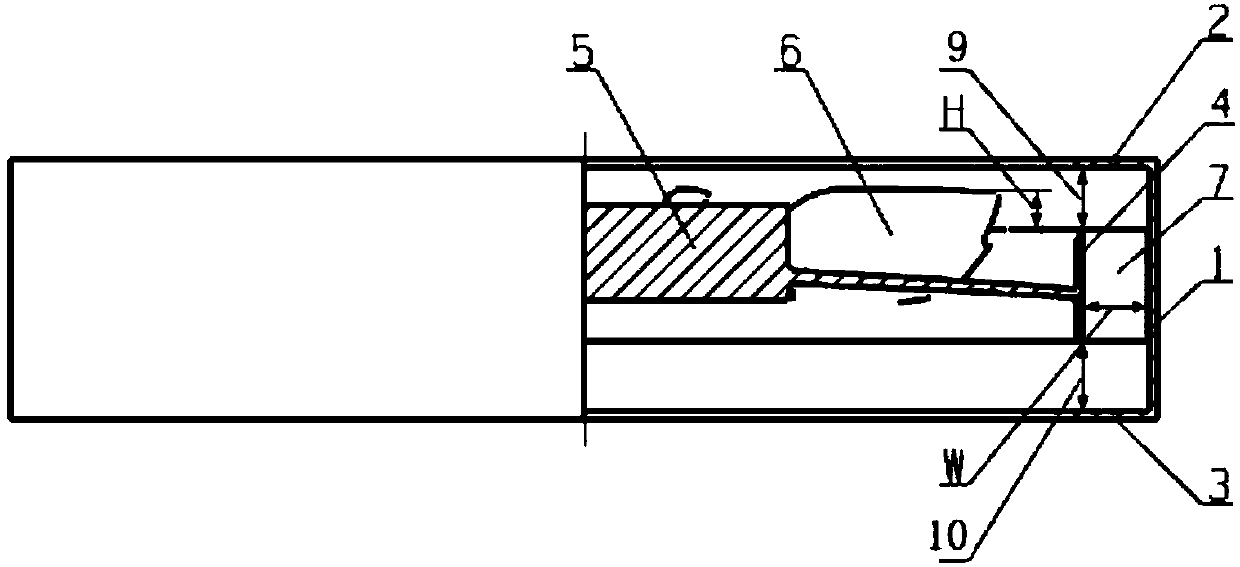

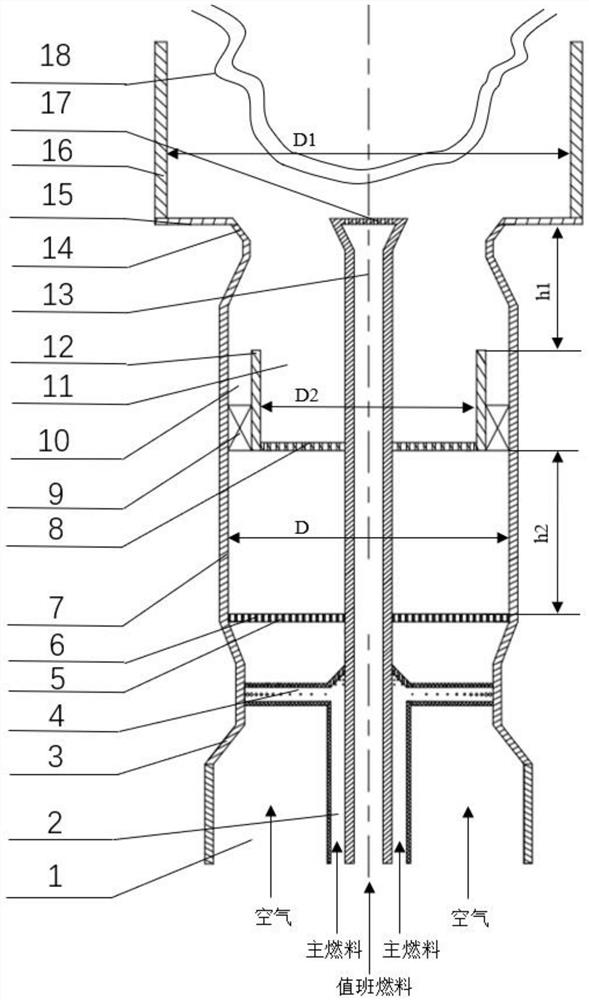

Low-pollution combustion chamber adopting fuel-grading and three-stage cyclone air inlet

ActiveCN103256633AEvenly distributedInhibition formationContinuous combustion chamberCycloneCombustion chamber

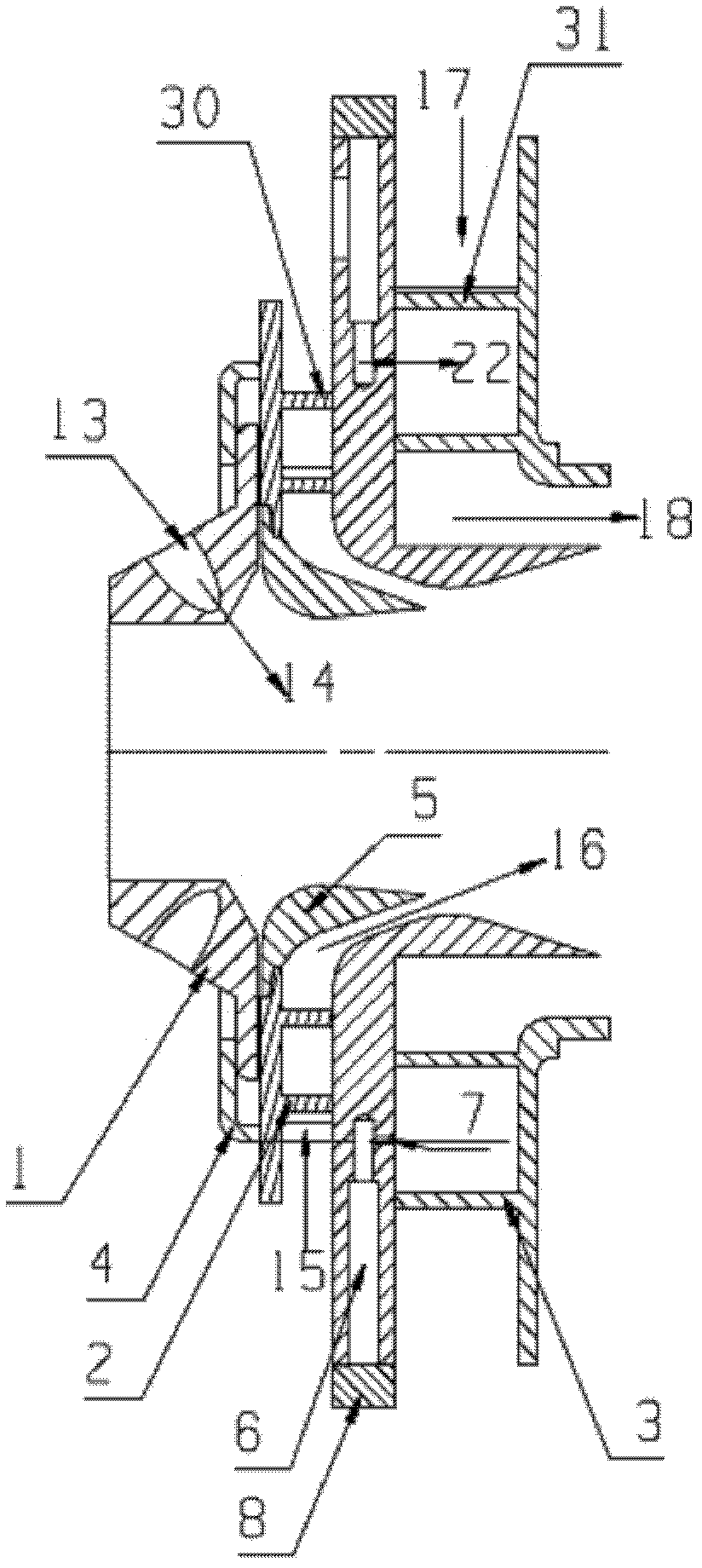

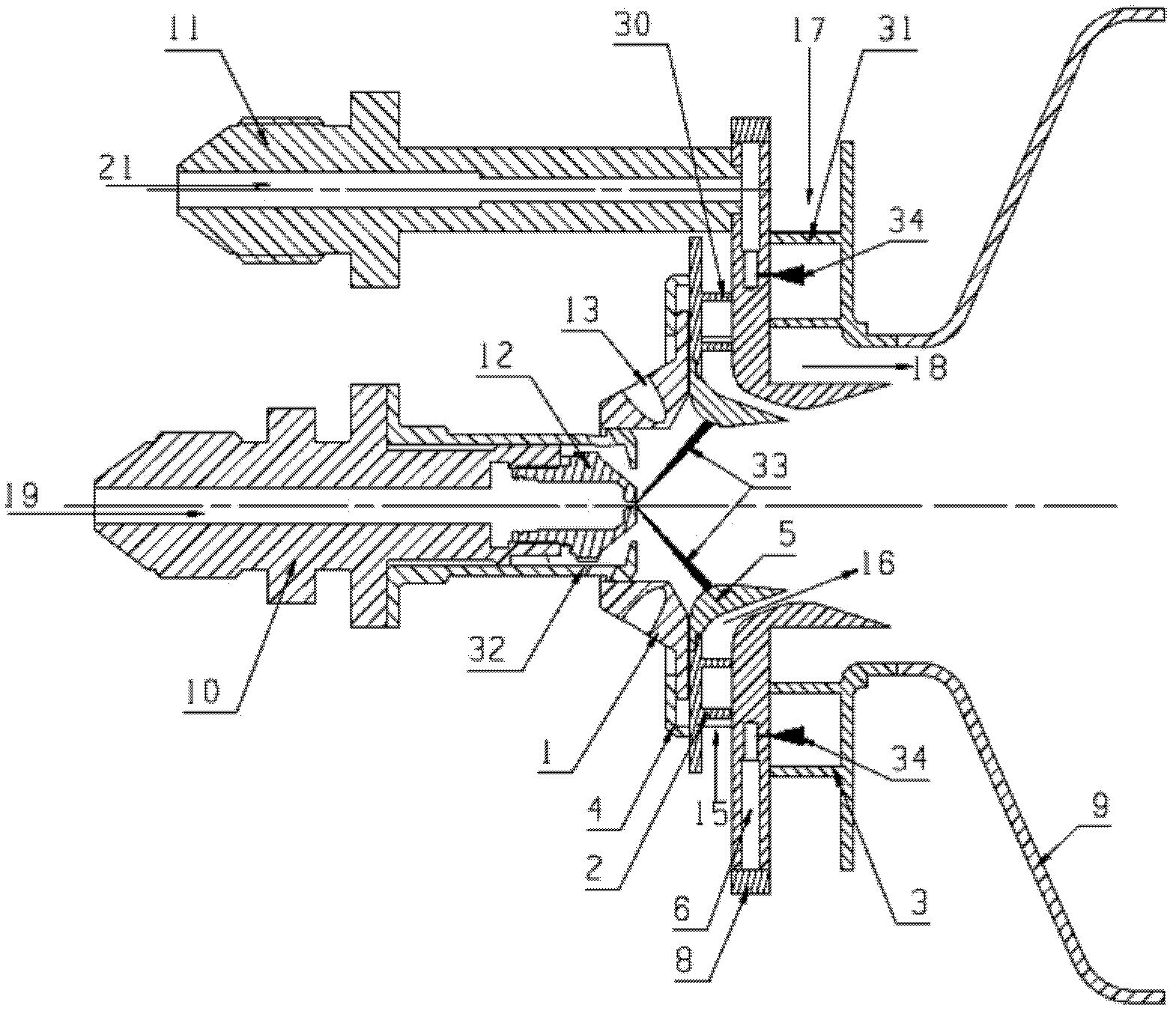

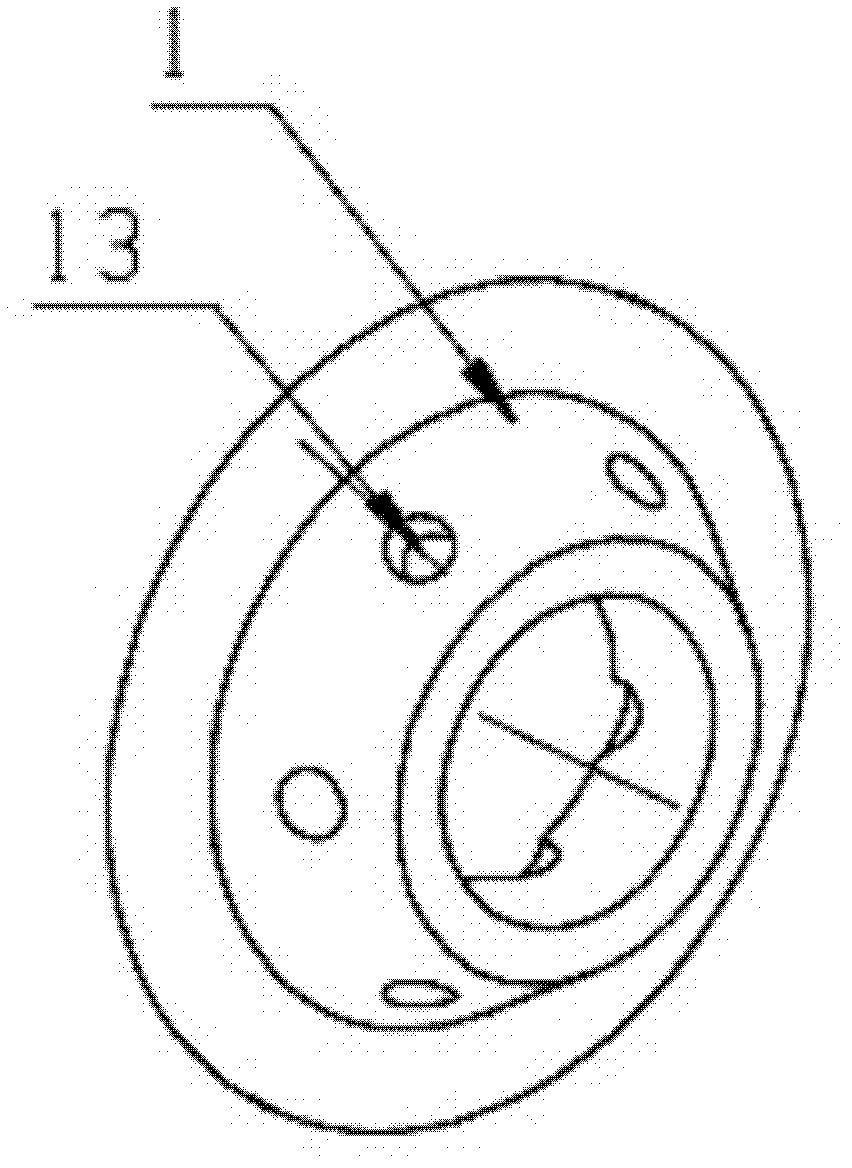

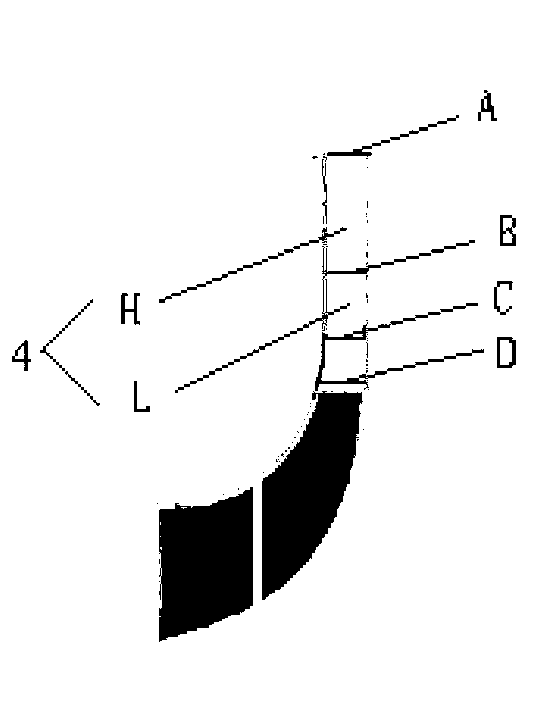

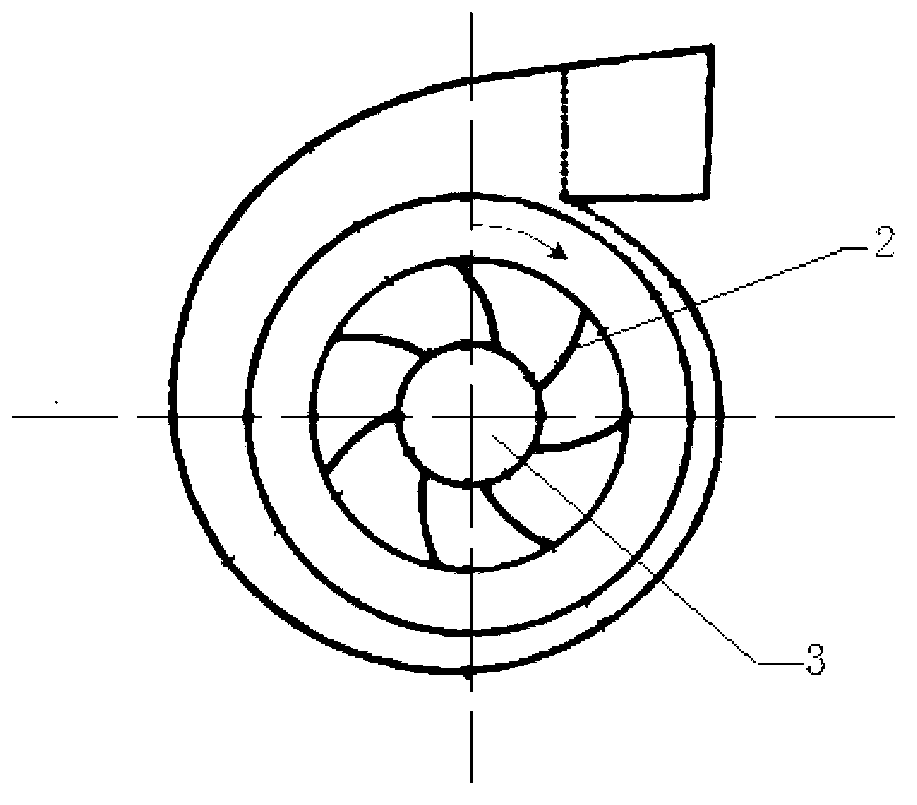

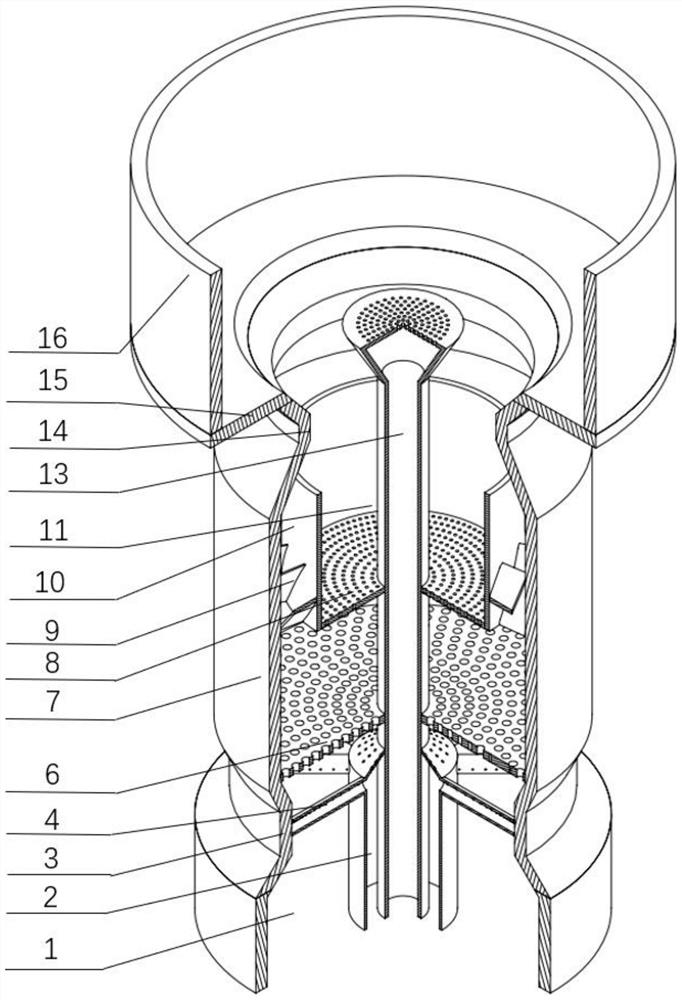

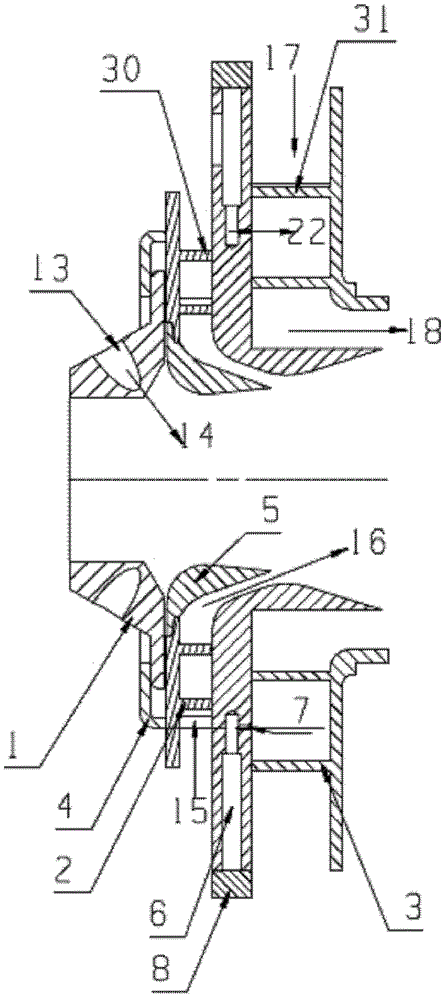

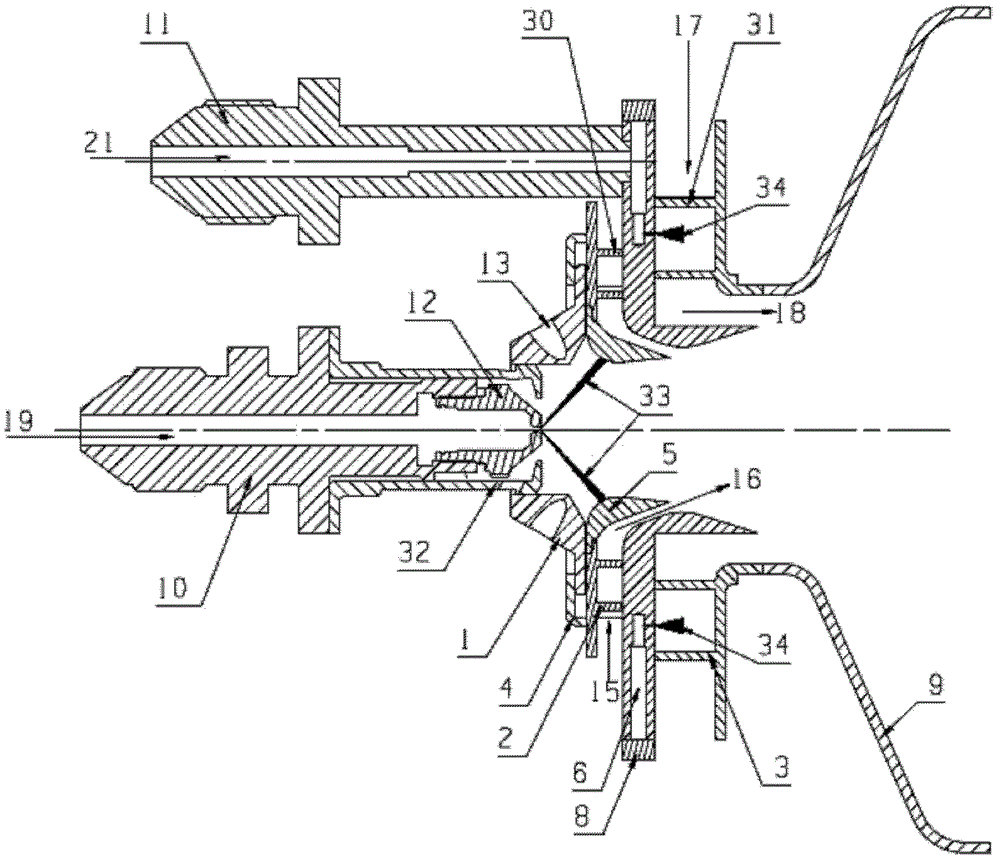

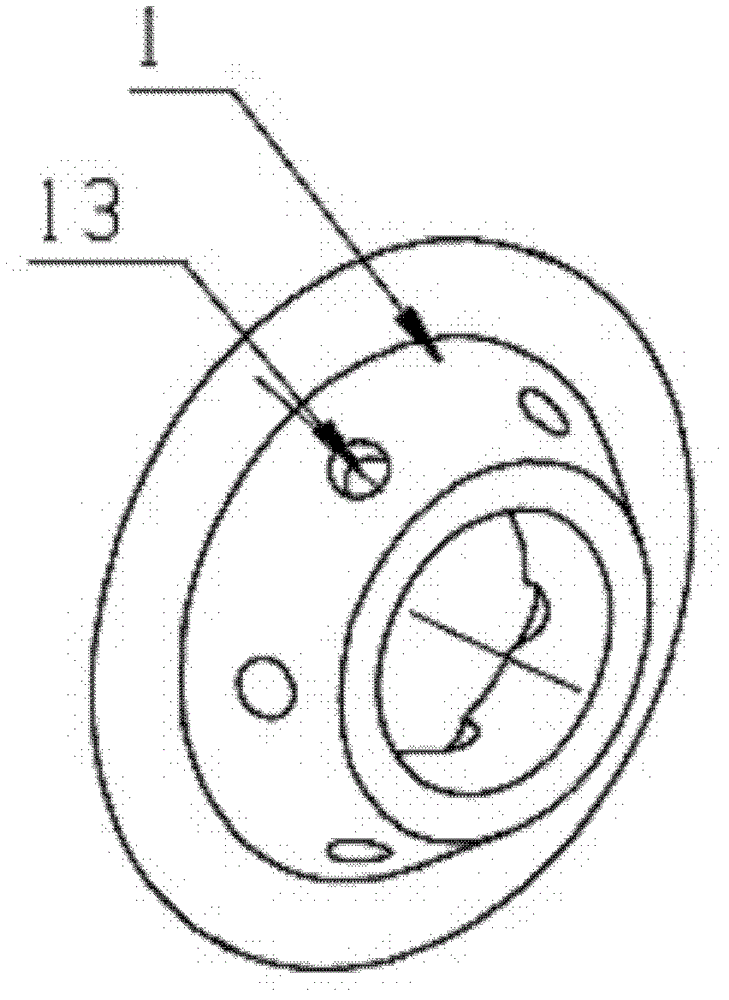

The invention discloses a low-pollution combustion chamber adopting fuel-grading and three-stage cyclone air inlet. The low-pollution combustion chamber comprises an on-duty oil supply nozzle, a primary-combustion oil supply nozzle, three-stage cyclones and a flame tube. Fuel is respectively provided for the on-duty oil supply nozzle and the primary-combustion oil supply nozzle in two ways, and the three-stage coaxial cyclones supply air to the head of a combustion chamber. The two stages of cyclones on the inner side of the combustion chamber refer to an oblique-cutting hole cyclone and a radial cyclone, cyclone of the two-stage cyclones are in opposite directions. A centrifugal atomizing nozzle is arranged at the center of the oblique-cutting hole cyclone, and the second-stage cyclone on the inner side are combined and matched with a center on-duty nozzle. The cyclone on the outside of the combustion chamber is a radial cyclone with cyclone direction opposite to that of a second-stage cyclone. Primary combustion fuel enters a cyclone blade channel from small holes of a front wall surface of a third-stage cyclones by way of multipoint direct injection and is accelerated to be crushed and atomized in a cyclone channel to be mixed with the air, and forms premixed or partly premixed fuel-air mixture at an exit of the tertiary swirling influx to enter a primary combustion zone to be combusted. The low-pollution combustion chamber is applicable to aircraft engine combustion chambers or industry fuel turbine combustion chambers.

Owner:中科航空动力(株洲)装备制造研究院有限公司

Low-pollution combustor for various fuels

InactiveCN101713546AEmission controlAvoid flashback of premixed combustionContinuous combustion chamberCombustion chamberAir cleaning

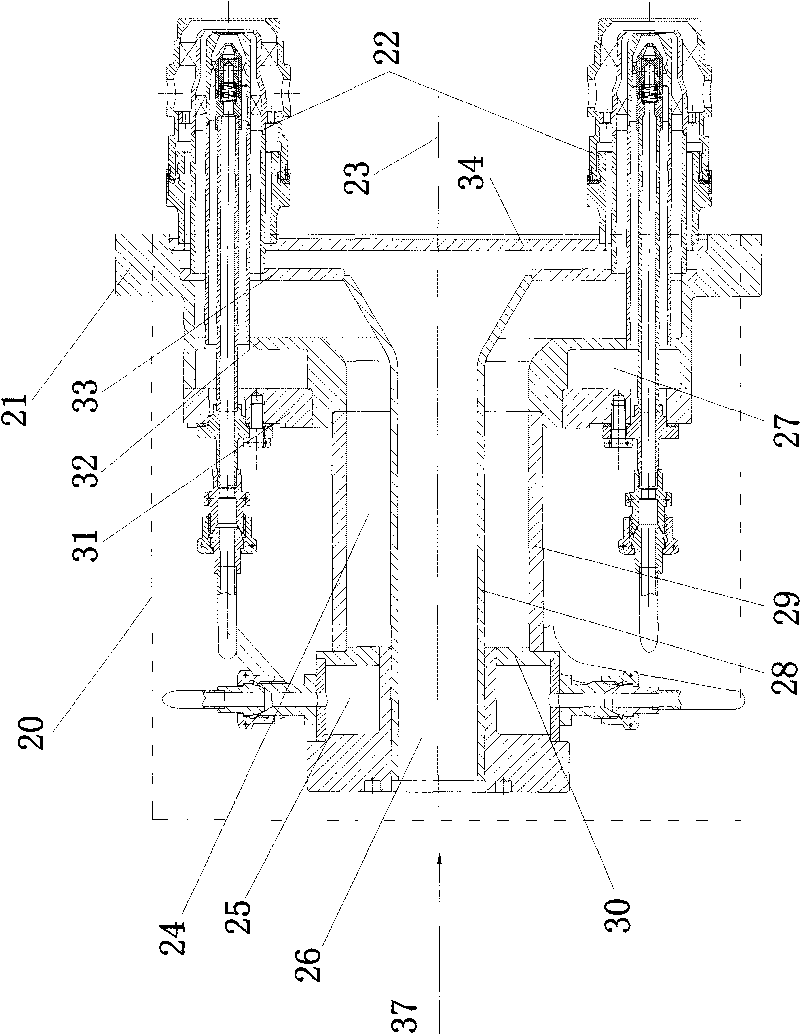

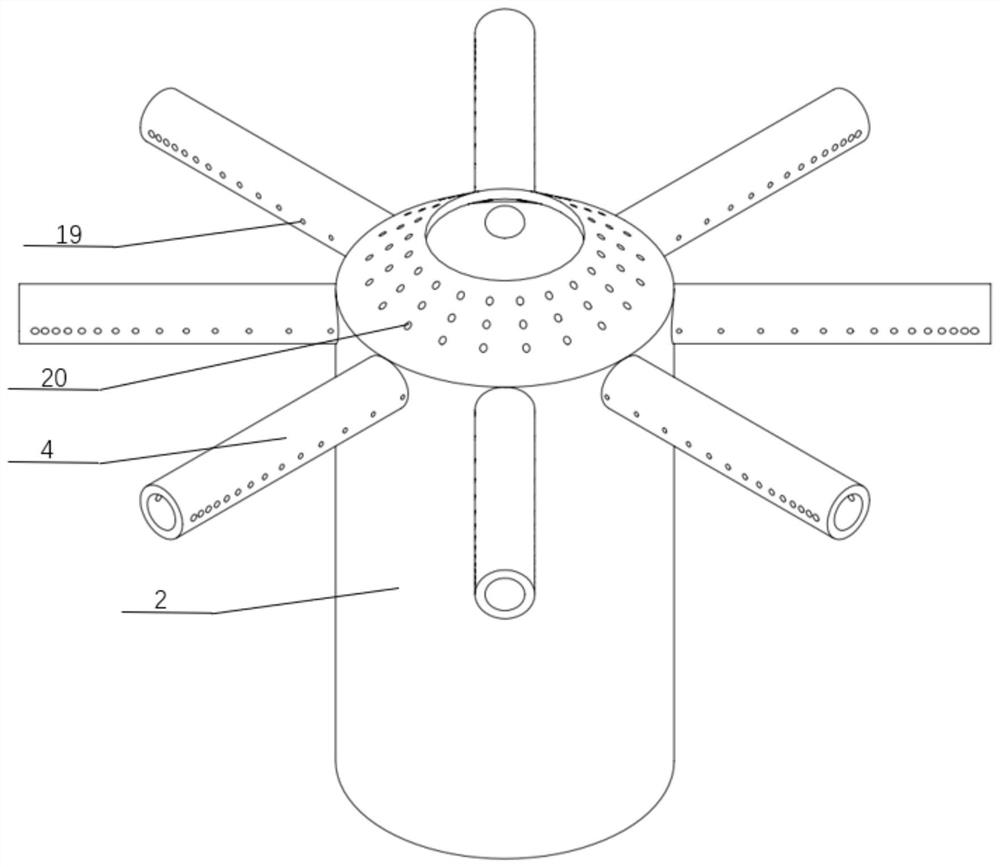

The invention discloses a low-pollution combustor for various fuels, which comprises a shunt system, a mounting edge and a plurality of double fuel nozzles, wherein the shunt system is connected with the plurality of double fuel nozzles through the mounting edge into a whole; the shunt system comprises a gas fuel subchannel, a liquid fuel subchannel, a diluent subchannel and an atomized air subchannel; and the double fuel nozzles are arranged circumferentially along the central line of the combustor. The low-pollution combustor for various fuels provided by the invention reduces the dischargeof pollutants such as NOX, solves the problems such as backfire and unstable combustion of premixing combustion of synthetic gases, simplifies an air cleaning and blowing protective system of a combustion chamber, avoids increasing the discharge of carbon monoxide, and can work with low and medium thermal value gas fuel such as coke oven gas, chemical tail gases and synthetic tail gases from IGCCpower plants and high thermal value gas fuel such as diesel oil and natural gas.

Owner:SHENYANG ENGINE DESIGN RES INST CHINA AVIATION IND CORP I

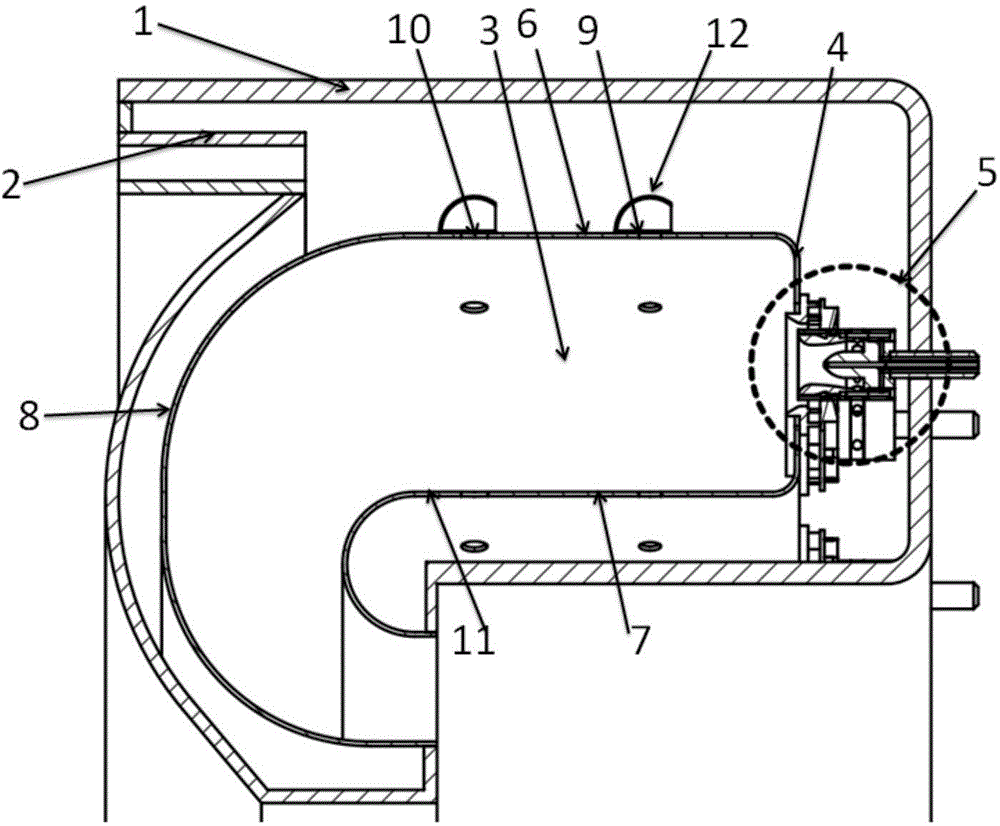

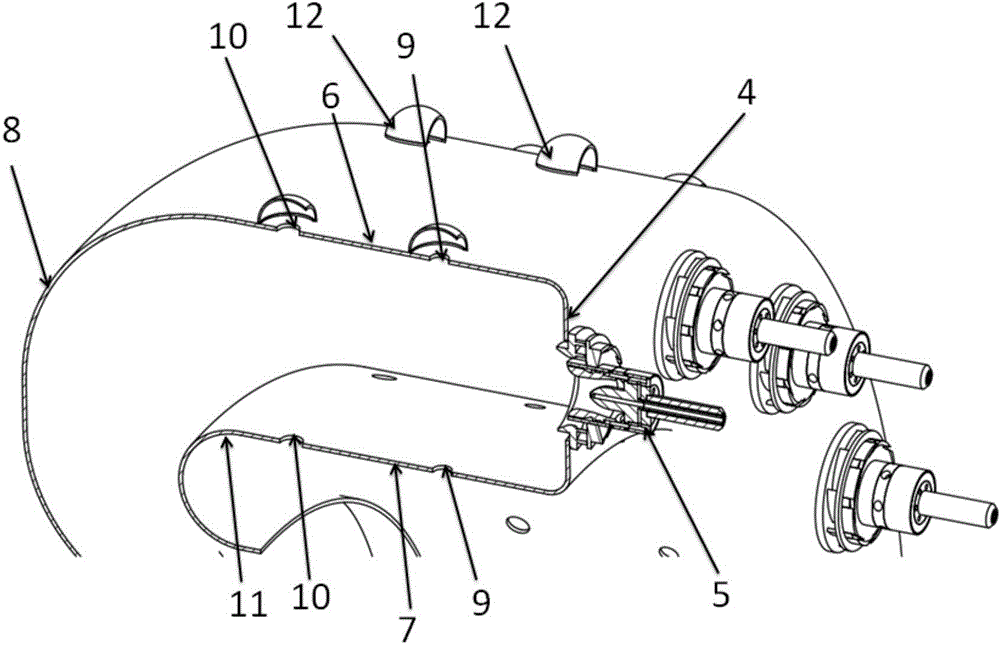

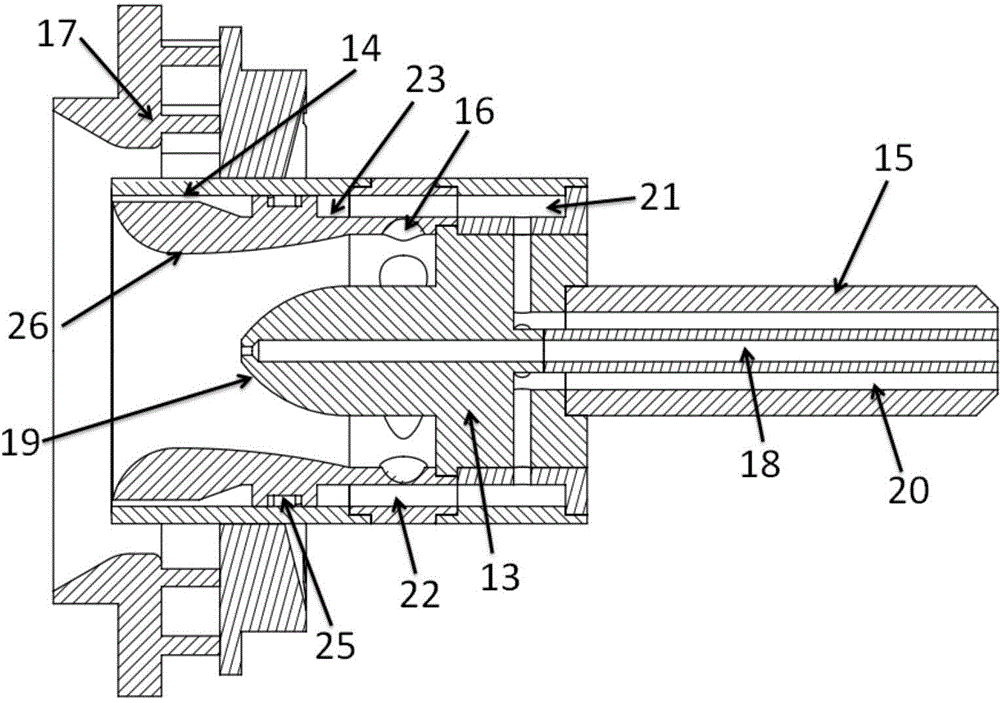

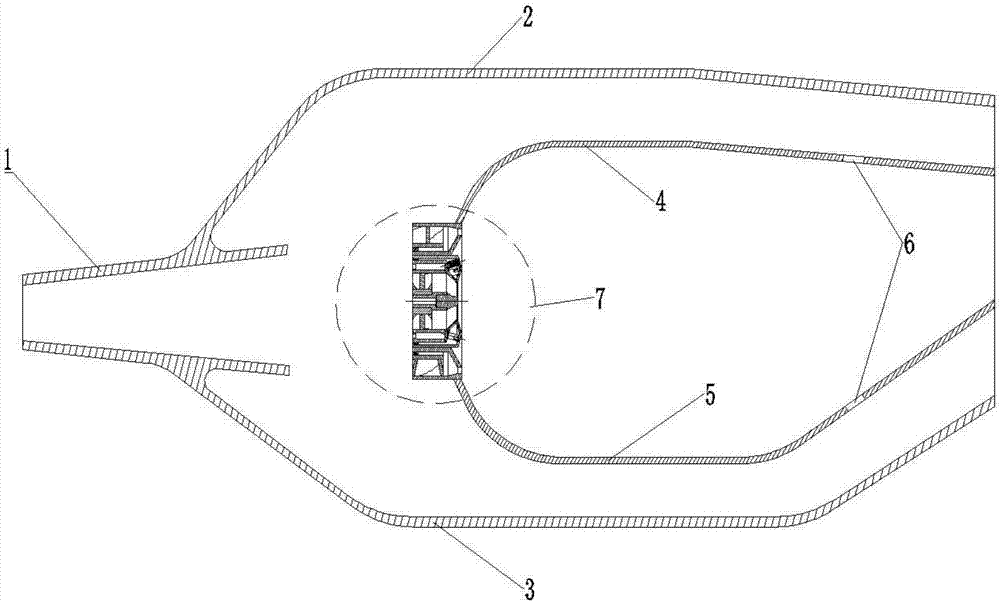

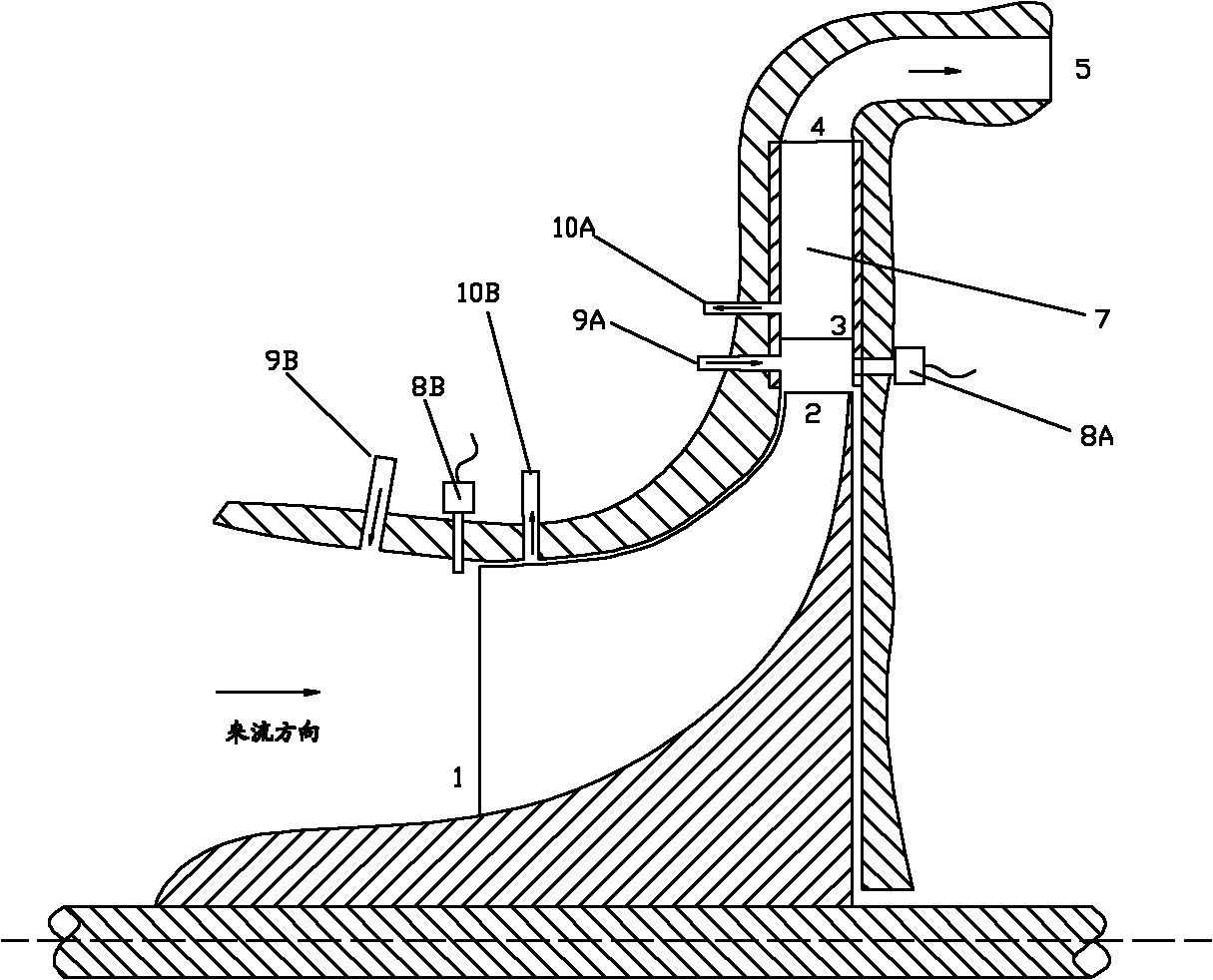

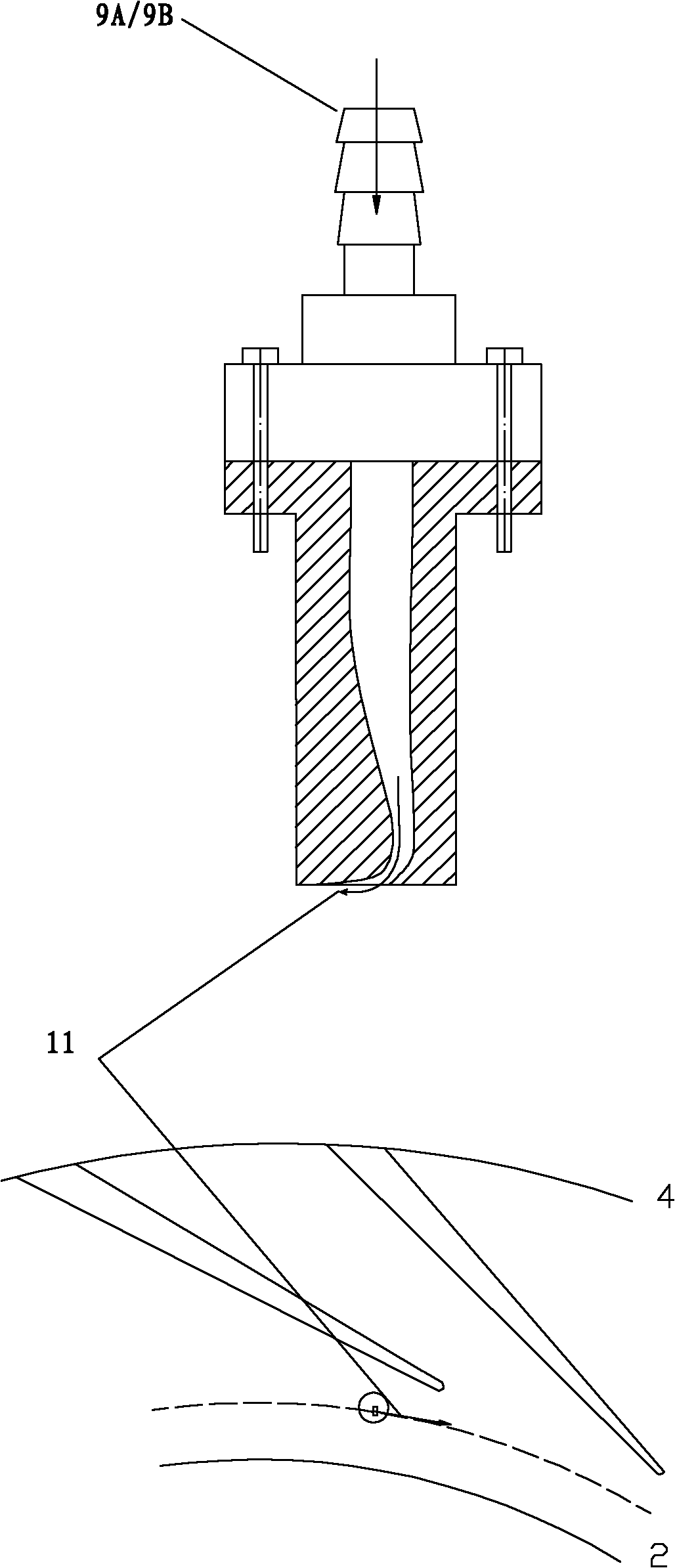

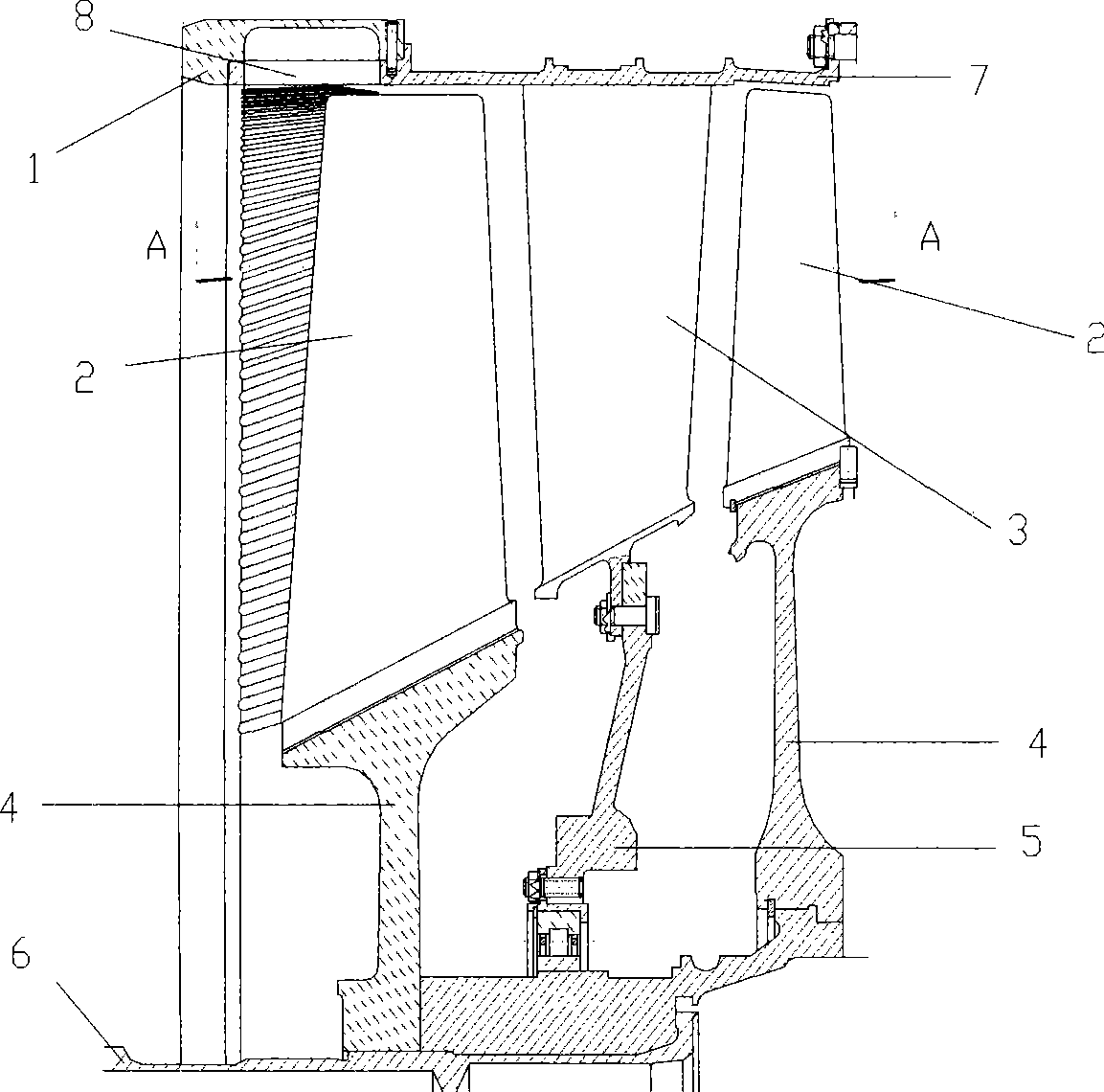

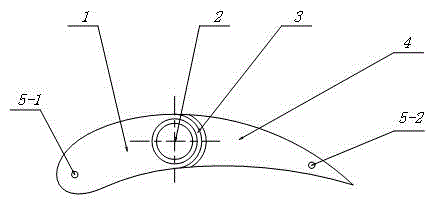

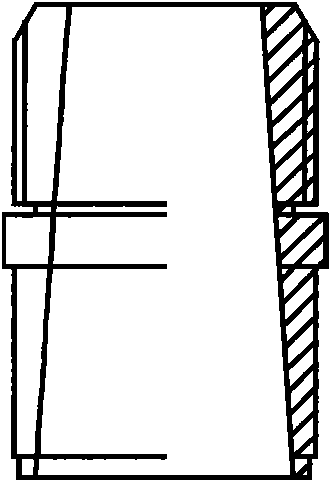

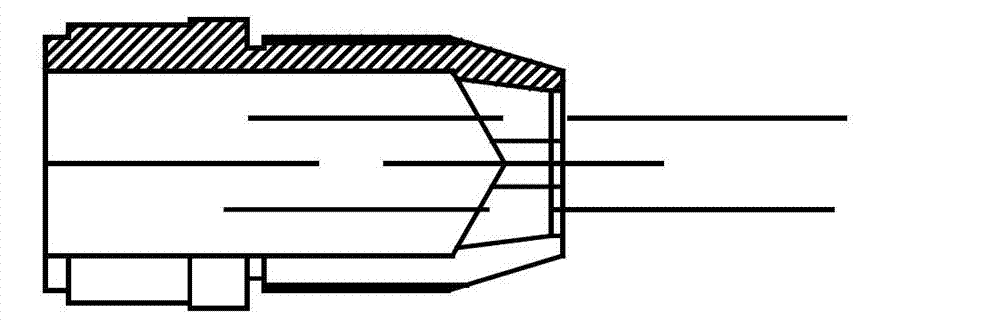

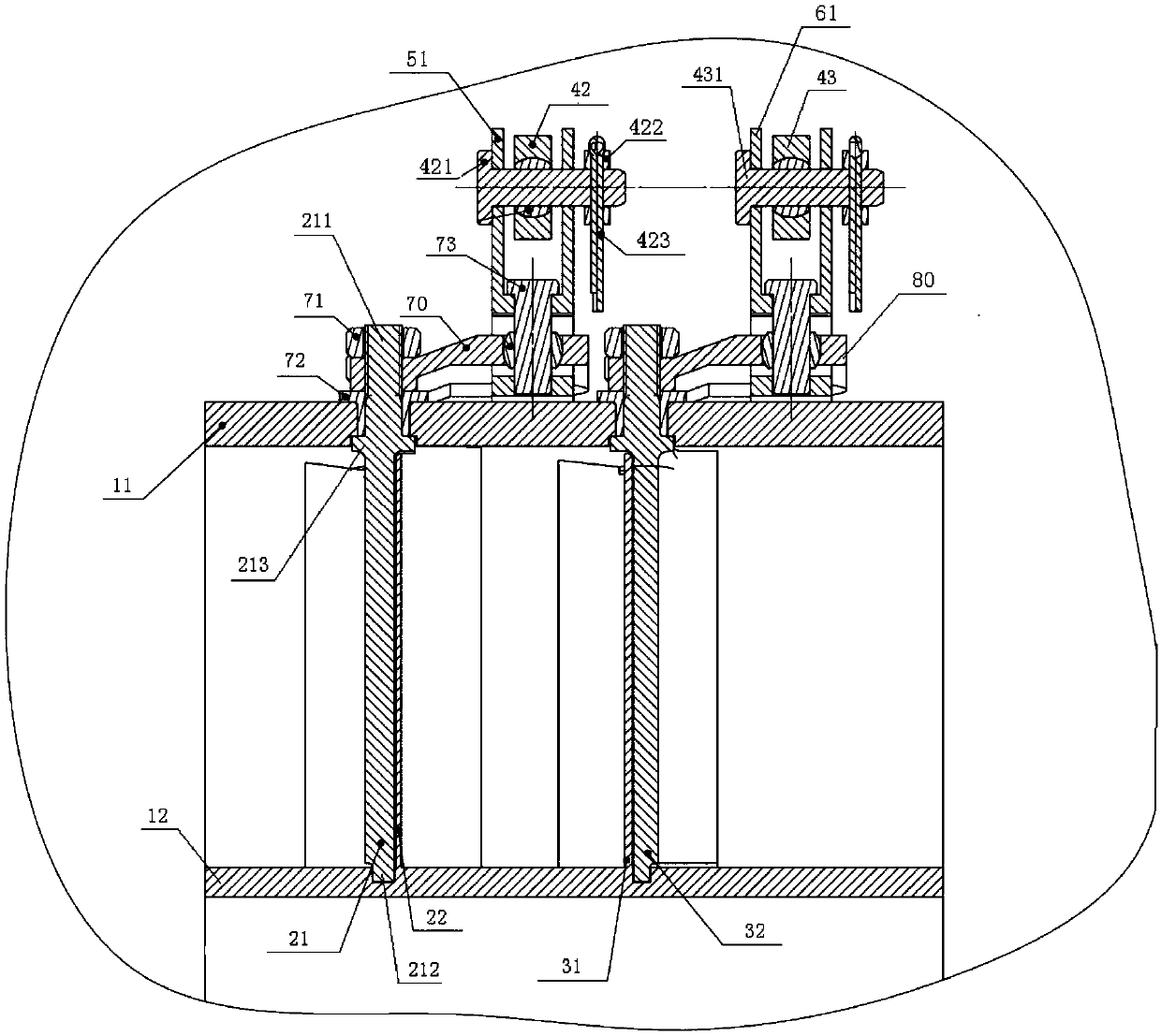

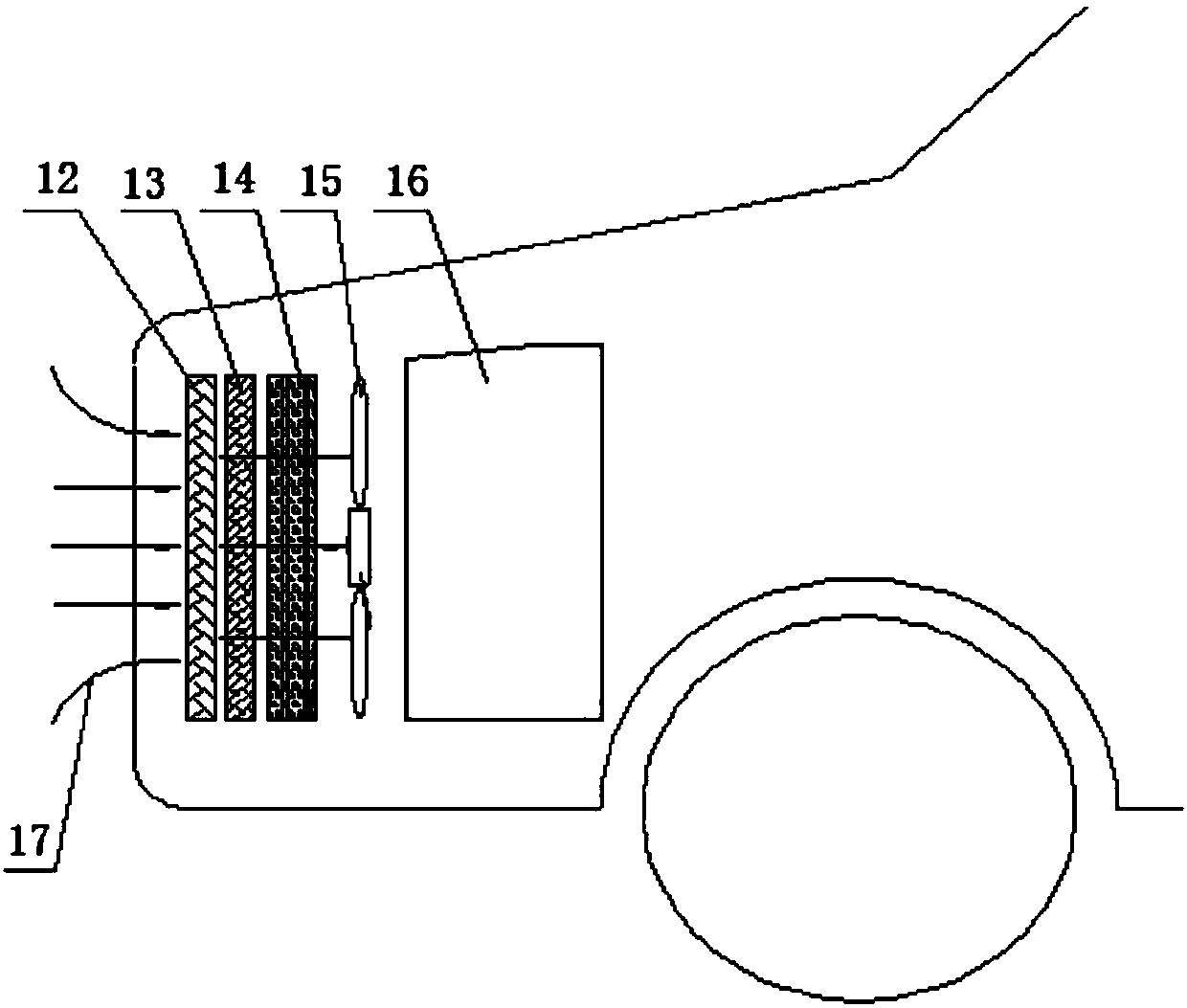

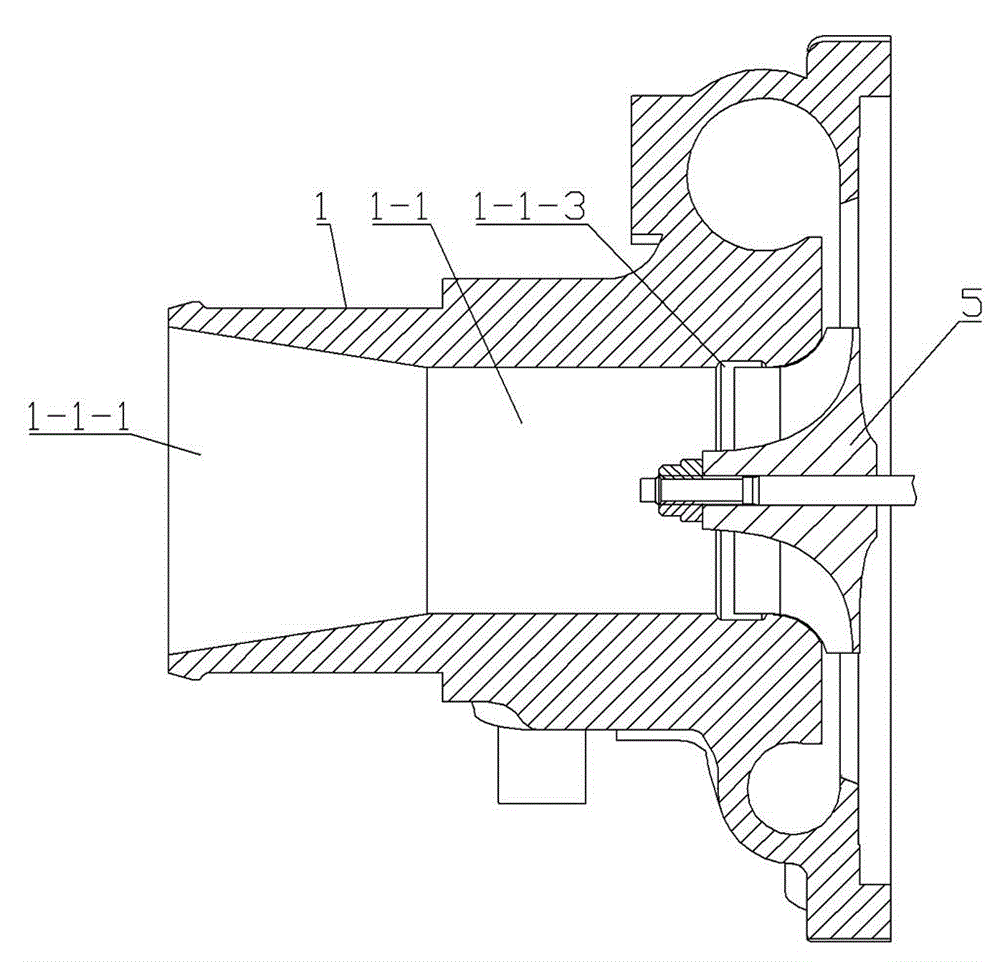

Reverse flow combustor allowing wider range of stable running

ActiveCN104676650AAvoid cokingGuarantee atomization qualityContinuous combustion chamberCombustorCombustion chamber

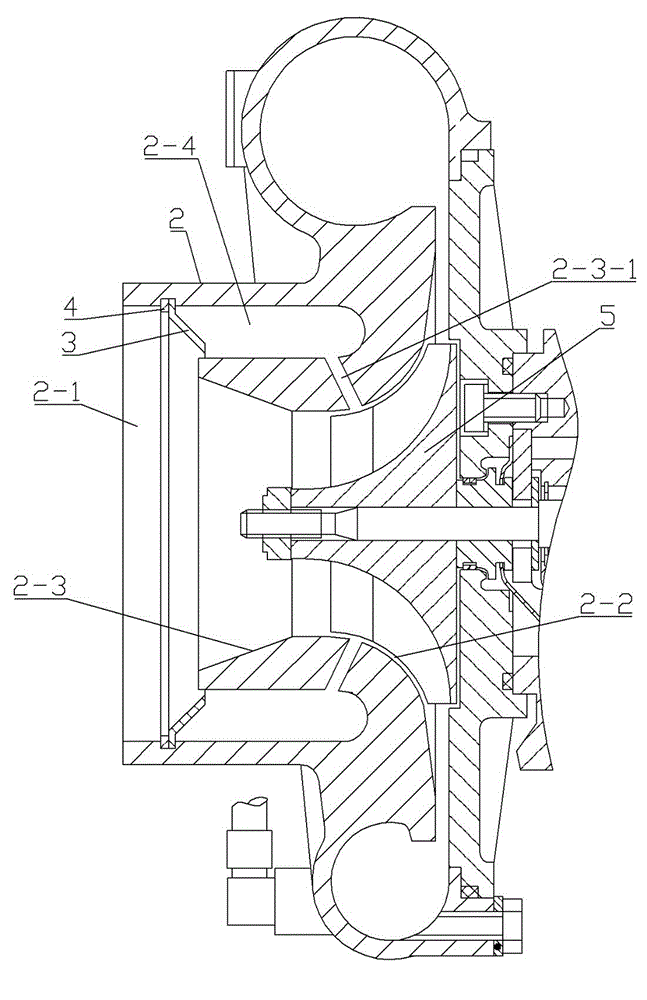

The invention provides a reverse flow combustor allowing a wider range of stable running. The reverse flow combustor comprises a diffuser, a combustor casing, a flame cylinder head end wall, a flame cylinder outer wall, a flame cylinder inner wall, a large elbow and a head atomizer. Air enters the combustor through the diffuser; part of the air enters a flame cylinder through the head atomizer; another part of the air enters through a main combustion hole of the flame cylinder and a mixing hole thereof, the remaining enters from a cooling structure. The air and fuel fully mix and combust in the flame cylinder. After passing by two 180-degree turns, the air leaves the combustor. The head atomizer performs atomizing in a mixed mode of pressure centrifugal atomizing and pre-swirling prior to pre-film air atomizing; the fuel is fed through a main oil circuit and an auxiliary oil circuit; the main combustion hole arranged in the outer wall of the flame cylinder and the mixing hole thereof are provided with a hood, jets are avoided flowing to the head, and inner and outer jets are ensured being symmetrical. The range of stable running of the reverse flow combustor can be expanded, and uniformity of fuel gas temperature of an outlet is guaranteed.

Owner:BEIHANG UNIV

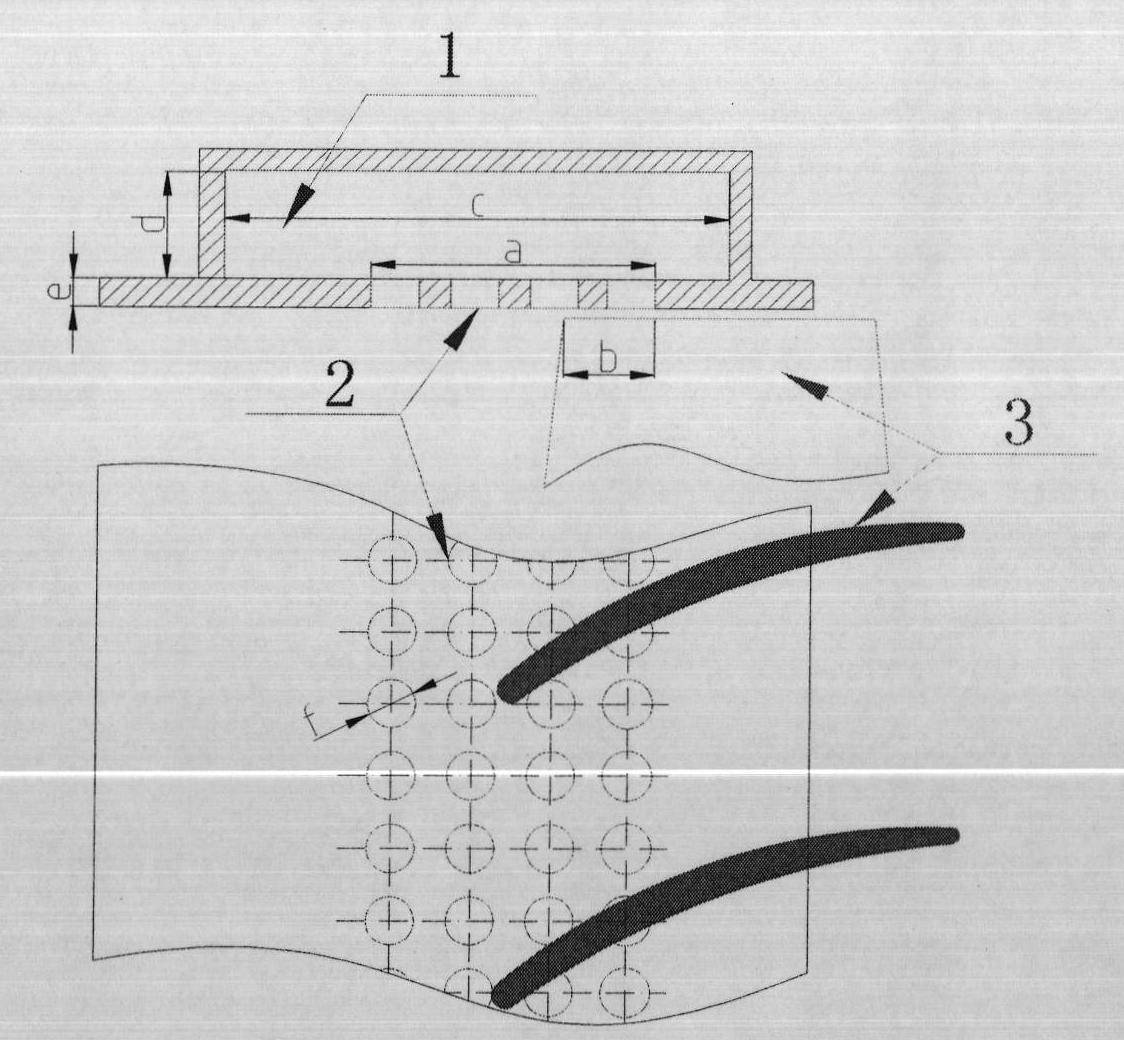

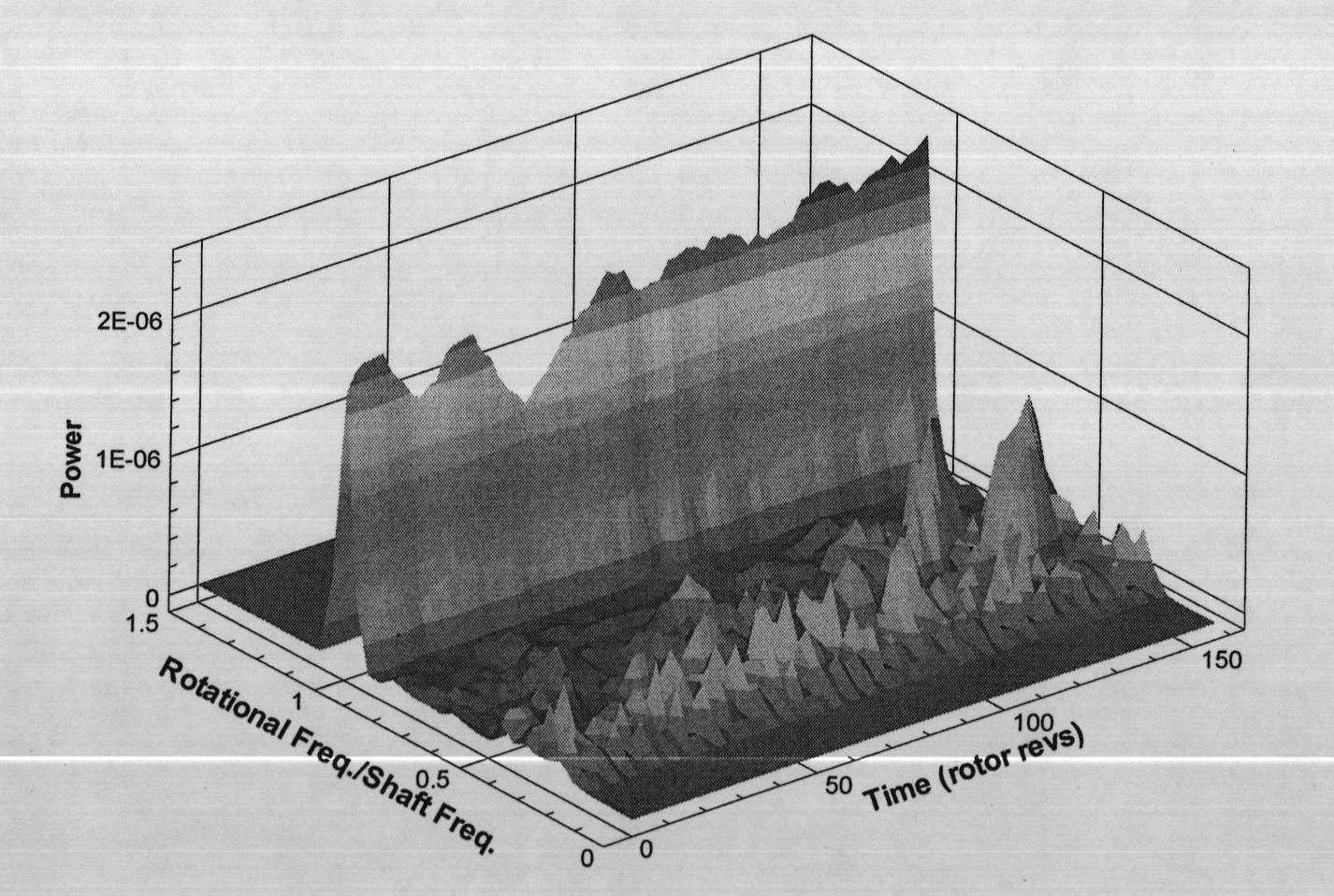

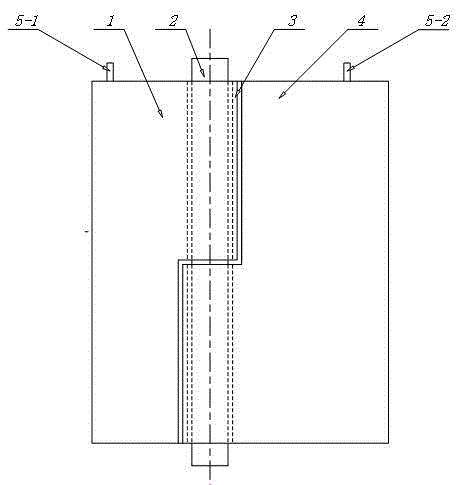

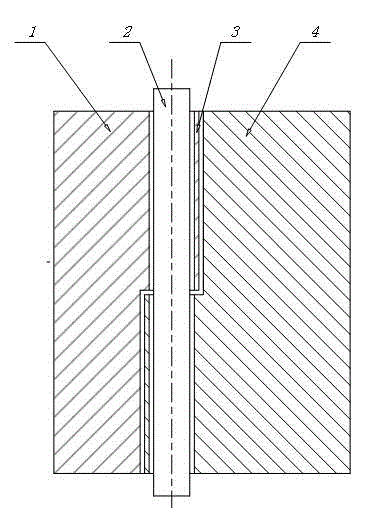

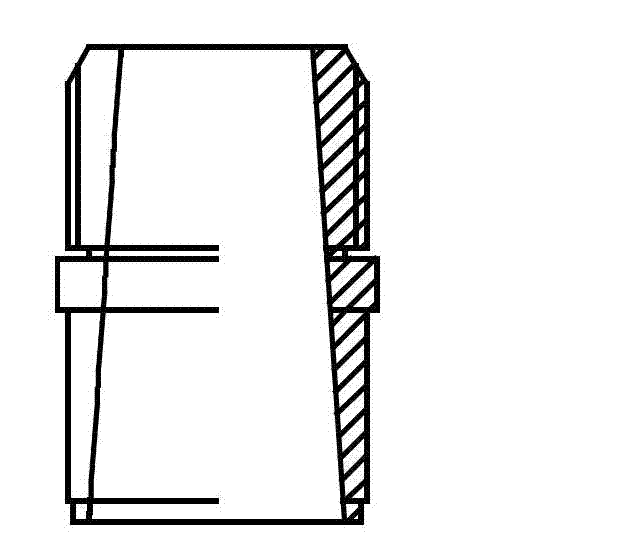

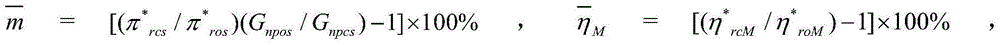

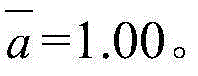

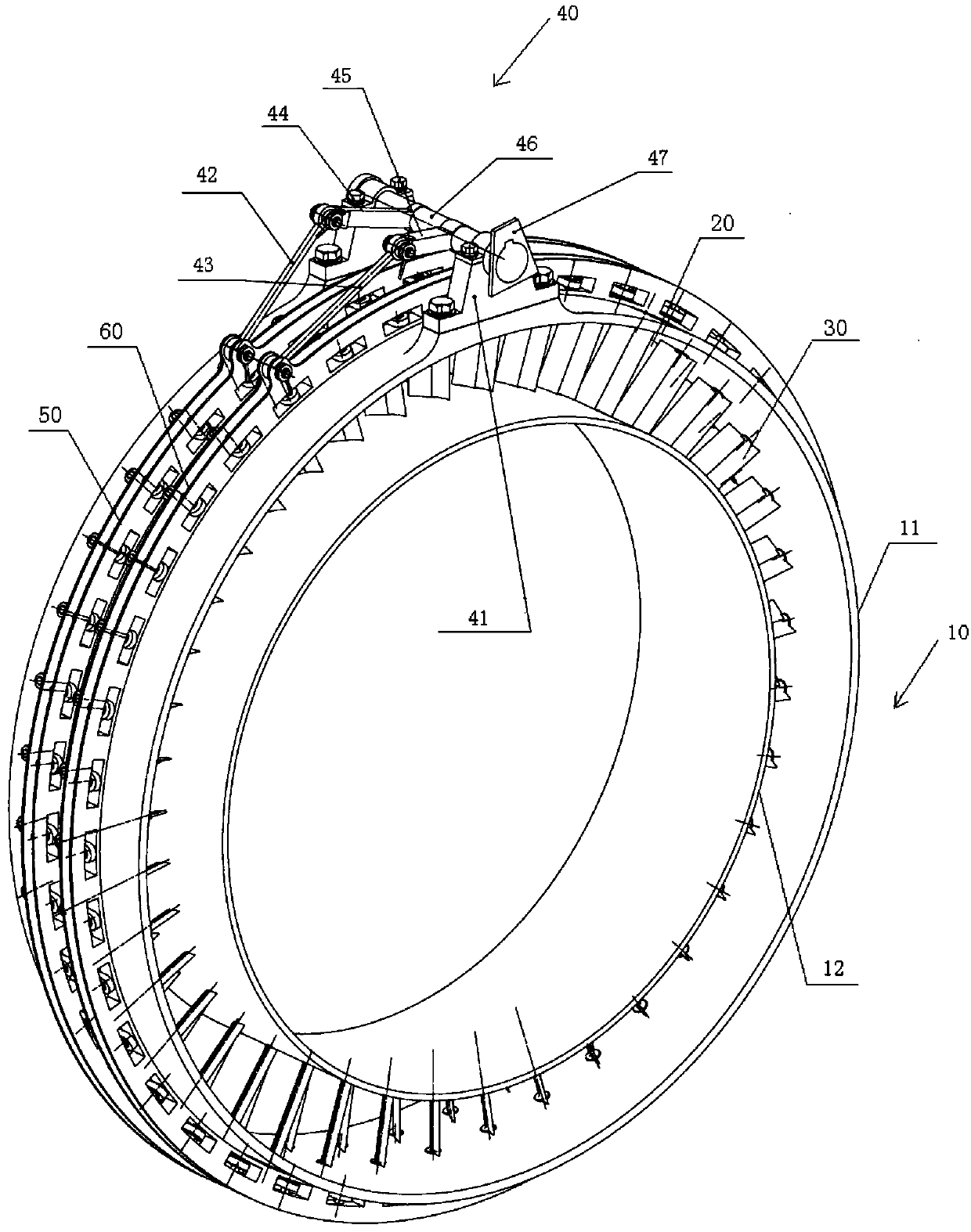

Back cavity-perforated plate-type casing treatment method

ActiveCN102032218AMeet size constraintsEffective absorptionPump componentsPumpsDirect effectsEngineering

The invention discloses a method for treating a back cavity-perforated plate-type casing treatment method. The method comprises the following steps of: designing a casting treater which only comprises an annular back cavity and is provided with a circular hole or an oblique groove perforated hole; and arranging a back cavity-perforated plate-type casing treater at the front end of the rotor inlet of an axial-flow air compressor and covering the back cavity-perforated plate-type casing treater on a position, which corresponds to the front edge part of a rotor blade, of the casing. In the back cavity-perforated plate-type casing treatment method, self-adaptive flow is formed in the back cavity, unsteady shedding vortex is produced on a perforated plate, and the energy of low-frequency disturbance waves in the flow field of the air compressor can be absorbed and dissipated effectively by the interaction of waves and the vortexes and nonlinear amplification of stall inception is suppressed, so that the occurrence of stall inception in the air compressor can be delayed and the stable working range of an air compressor system is expanded; moreover, the mainstream flow field structure of the air compressor is not influenced directly, so that reduction in pressure ratio and efficiency loss of the air compressor system are not caused, a simple and compact structure is achieved and the limiting requirement of engineering on casing size can be met.

Owner:BEIHANG UNIV

Lean oil direct injection and mixing low-pollution combustion chamber

ActiveCN107543201AGuarantee job stabilityReduce the temperatureContinuous combustion chamberSpontaneous combustionGasoline direct injection

The invention relates to a lean oil direct injection and mixing low-pollution combustion chamber. The lean oil direct injection and mixing low-pollution combustion chamber is composed of a diffuser, acombustion chamber outer case, a combustion chamber inner case, a combustion chamber head, a flame tube outer wall and a flame tube inner wall, wherein combustion air all enters a flame tube from thecombustion chamber head; the combustion chamber head is divided into an on-duty grade and a main combustion grade through a grading and partitioning combustion strategy; the on-duty grade and the main combustion grade both adopt a direct injection and mixing combustion method, the phenomena of spontaneous combustion and tempering are effectively avoided, and the risk of occurrence of oscillationcombustion is lowered; the lean oil direct injection and mixing low-pollution combustion chamber only works in an on-duty grade mode under an idling rating state, the designed partial equivalence ratio is higher, and the work stability of the combustion chamber is guaranteed; and with the increase of the work state of the combustion chamber, the main combustion grade is opened gradually, the maincombustion grade and the on-duty grade work simultaneously under a large state, the designed combustion area average equivalence ratio is lower, the average temperature of the combustion area is effectively lowered, and therefore the generation quantity of pollutants is lowered.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

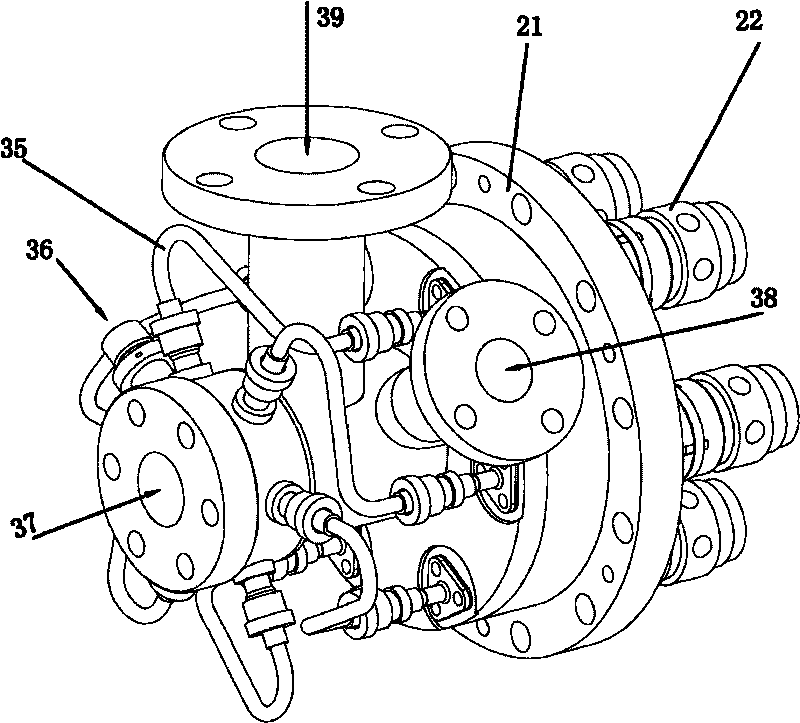

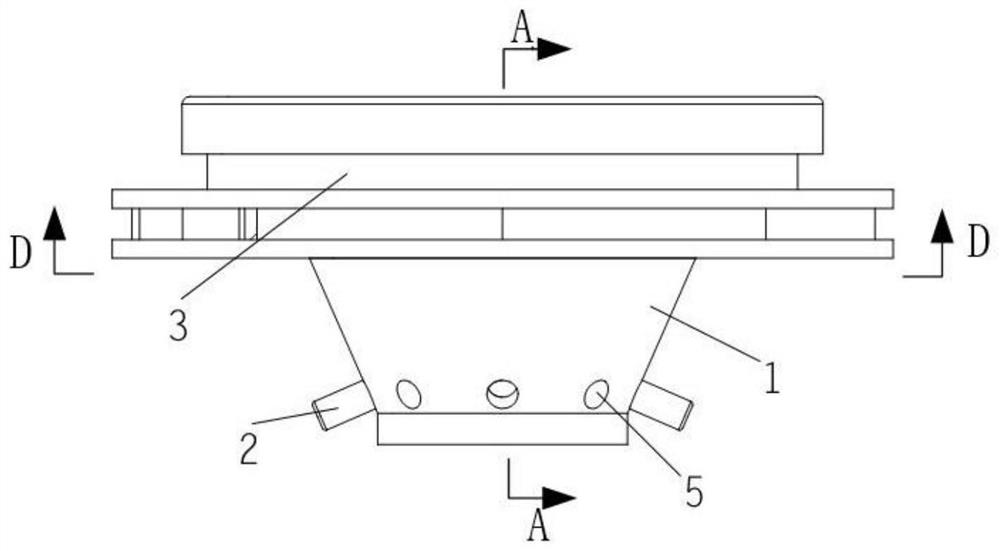

Device and method for widening stable operation area of centrifugal compressor and centrifugal compressor

ActiveCN102297149AExtended working range of stabilityImprove mobilityPump componentsPump controlSignal conditioningControl engineering

The invention discloses a device for widening a stable operation area of a centrifugal compressor. The device comprises a plurality of high frequency response dynamic pressure sensors, a high frequency response dynamic strain indicator, signal conditioning equipment, a signal processing digital signal processor (DSP) module, and an air jet device, wherein the dynamic pressure sensors and the dynamic strain indicator acquire dynamic signals of the compressor during operation; the signal conditioning equipment transmits the signals to the DSP module; and the DSP module processes the signals and sends a command to a controller so as to make the air jet device act. The device can widen the stable operation area of the centrifugal compressor, namely a stability working range, and eliminates or reduces the harm of flow instability, namely stall and surge. The invention also discloses a method for widening the stable operation area of the centrifugal compressor, and a centrifugal compressor provided with the device for widening the stable operation area of the centrifugal compressor.

Owner:上海和兰透平动力技术有限公司

Processing casing and air compressor

InactiveCN101451544ABest structure for smooth airflowImprove stable working rangePump componentsPumpsInner loopStator

The present invention discloses a processor case with non-rectilinear slot on it and adopts banana-shaped structure or structure of linear that connected with arc segments. A compressor includes a processor case, rotor blade, stator blade, dish of wheel, stator inner loop and axis; the processor case includes organic case body and process ring, wherein one end of the stator blade connects with the stator inner loop and the other end connects with the organic case body; one end of the dish of wheel connects with the rotor blade while the other end connects with the axis; the process ring connects with the organic case body; the invention is characterized in that a process cavity is formed inside the case body and the process ring; the rotor blade rotates and air draft flows in from the process ring and circulates inside the process cavity, then flows out from the process ring. The present invention changes structure of traditional cases, improves performance, expands stable work margin of the processor case, and can be applied on aerial engine shaft pressured gas flow development work and has a broad application prospect.

Owner:SHENYANG ENGINE DESIGN RES INST CHINA AVIATION IND CORP I

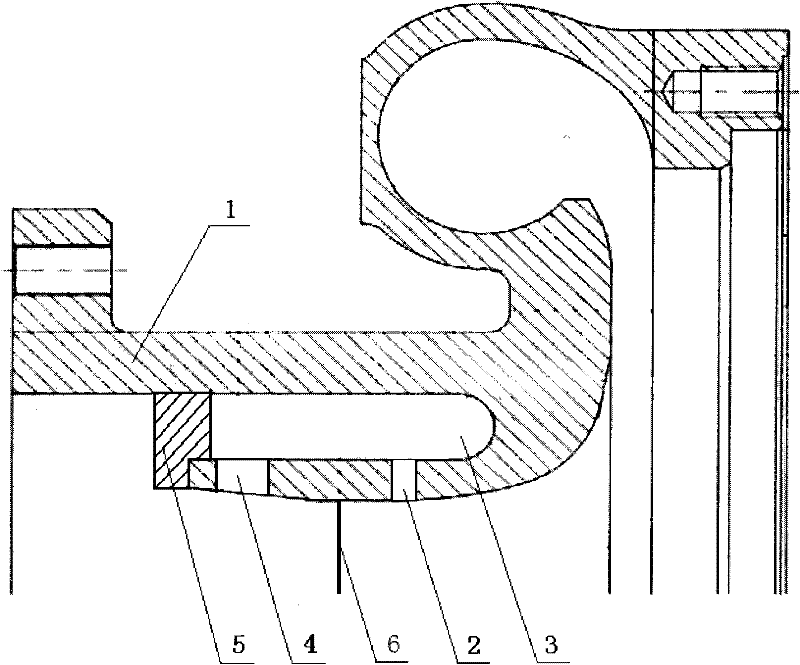

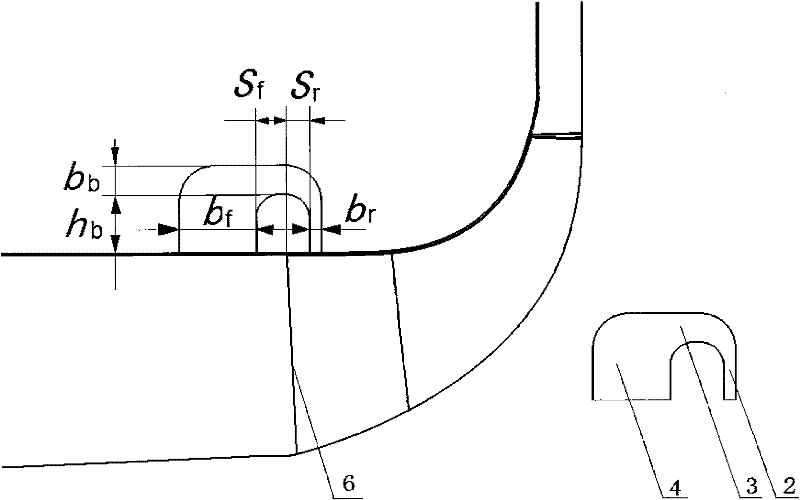

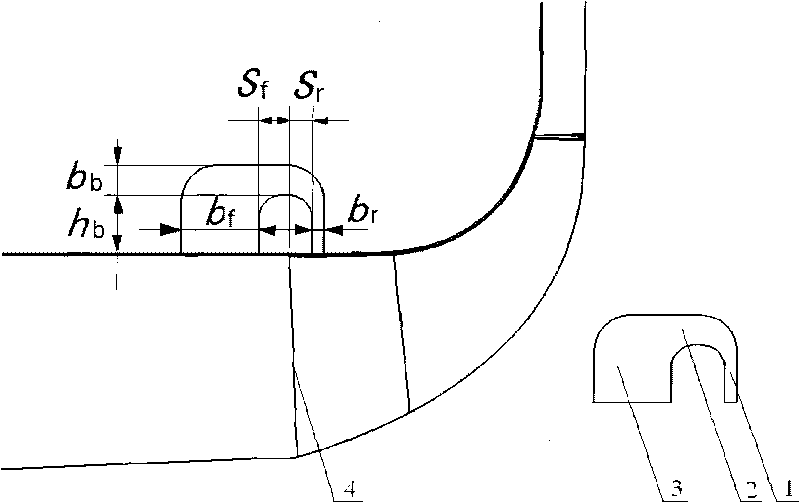

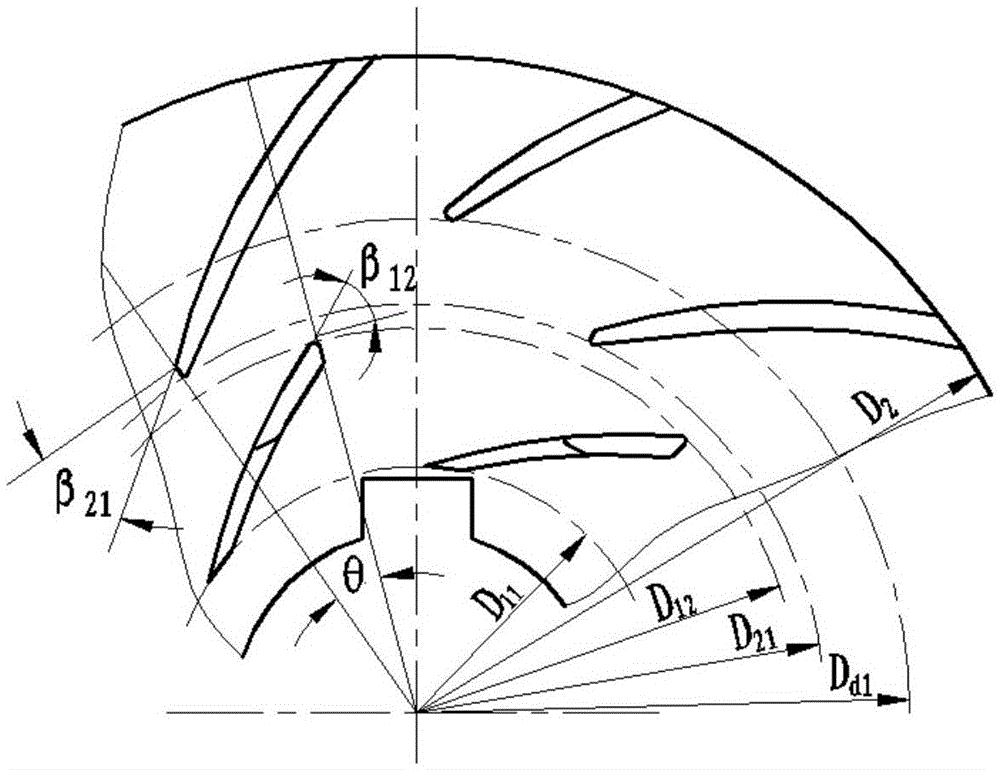

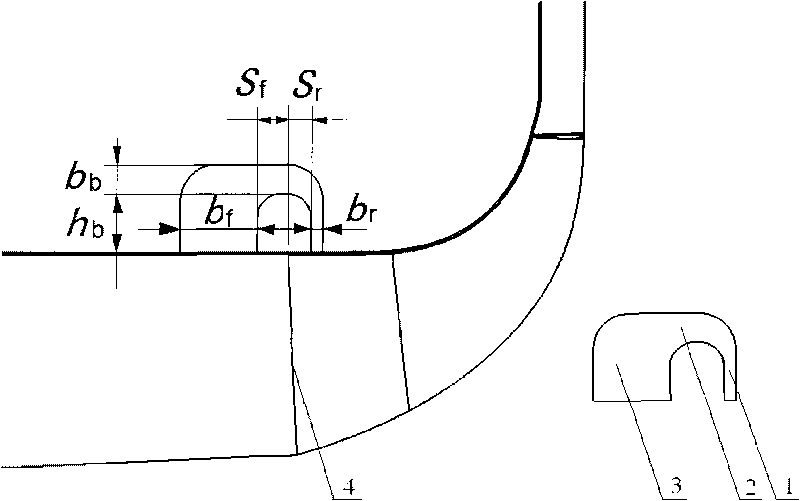

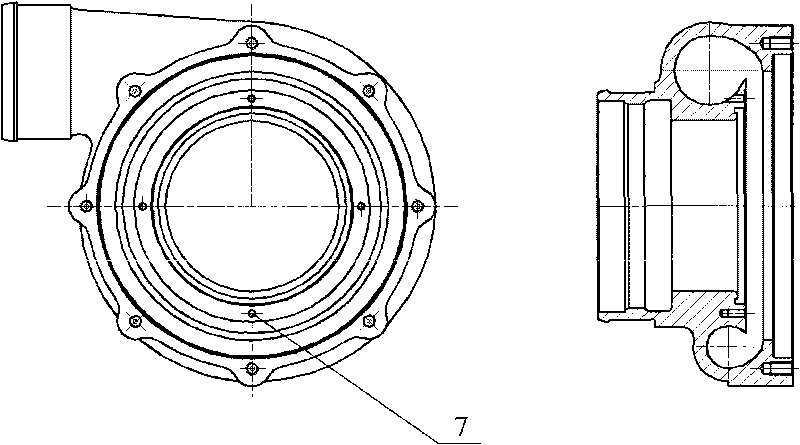

Centrifugal compressor asymmetric self-circulation treatment casing based on varied notching width

InactiveCN101749279AImprove stable working rangeImprove stabilityPump componentsPumpsEngineeringFront edge

A centrifugal compressor asymmetric self-circulation treatment casing based on varied notching position relates to a centrifugal compressor treatment casing and belongs to impeller machinery technical field. The treatment casing mainly comprises a compressor volute casing and a self-circulation channel machined on the wall surface of the volute casing in circumferential direction; the self-circulation channel is composed of a pumping annular slot, a backflow annular slot, a diversion annular slot and a blocking block; the distance from the front end surface of the pumping annular slot to the front edge of the main impeller is in non-axial symmetric distribution along the circumferential direction of the casing for optimizing the stability enhancing effect in the full circumferential direction of the casing treatment. Compared with the axially-symmetric self-circulation treatment casing with consistent notching position in the circumferential direction, the centrifugal compressor asymmetric self-circulation treatment casing based on varied notching position can greatly improve the stable working range of the centrifugal compressor and also and maintains efficiency basically the same.

Owner:TSINGHUA UNIV +1

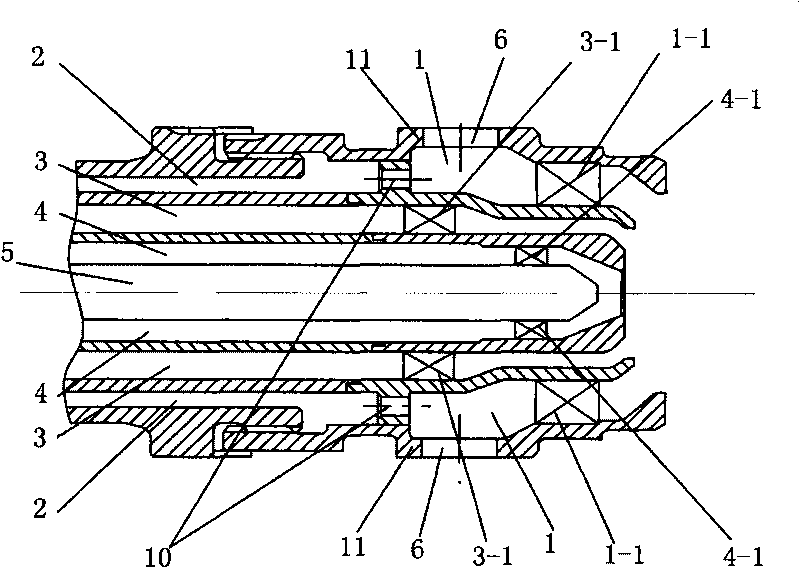

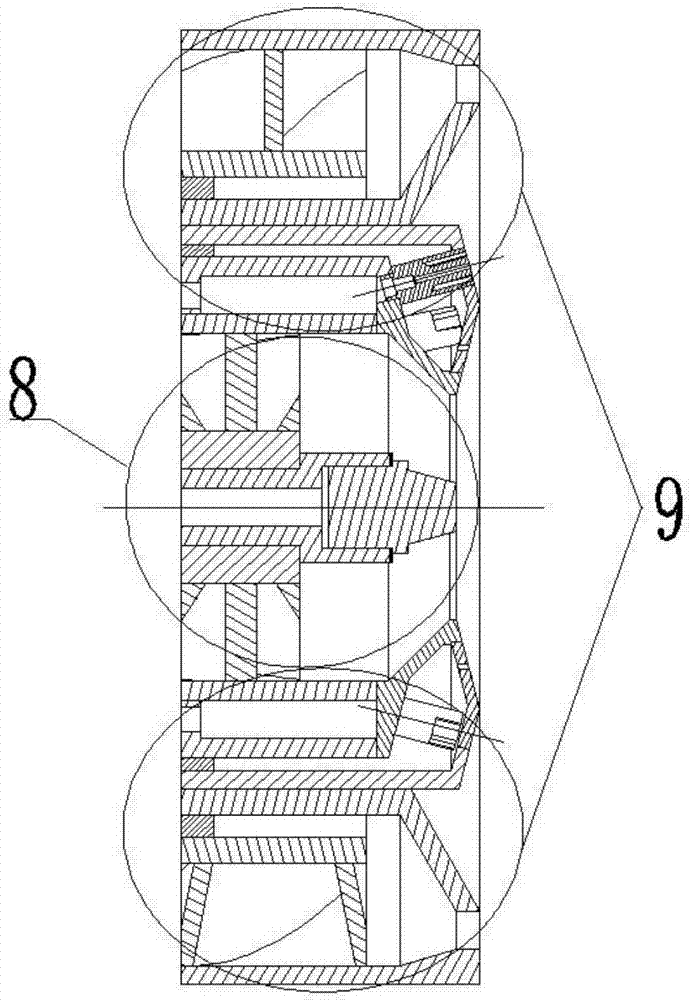

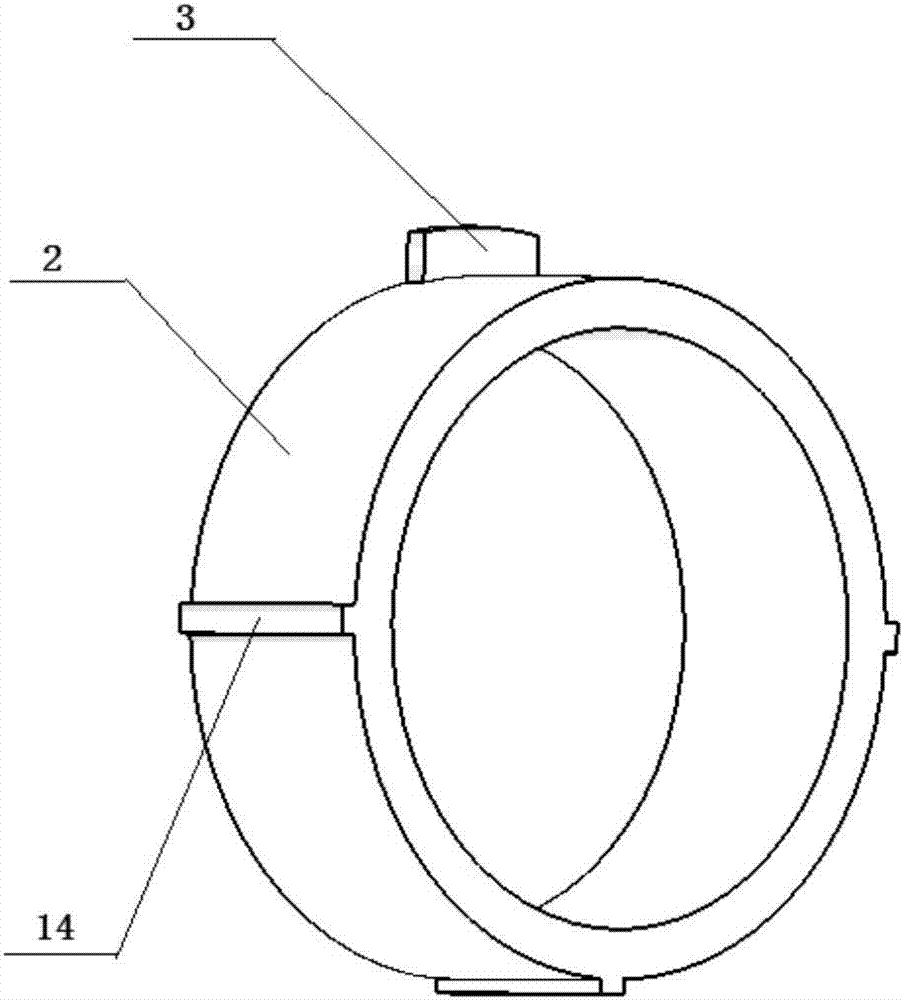

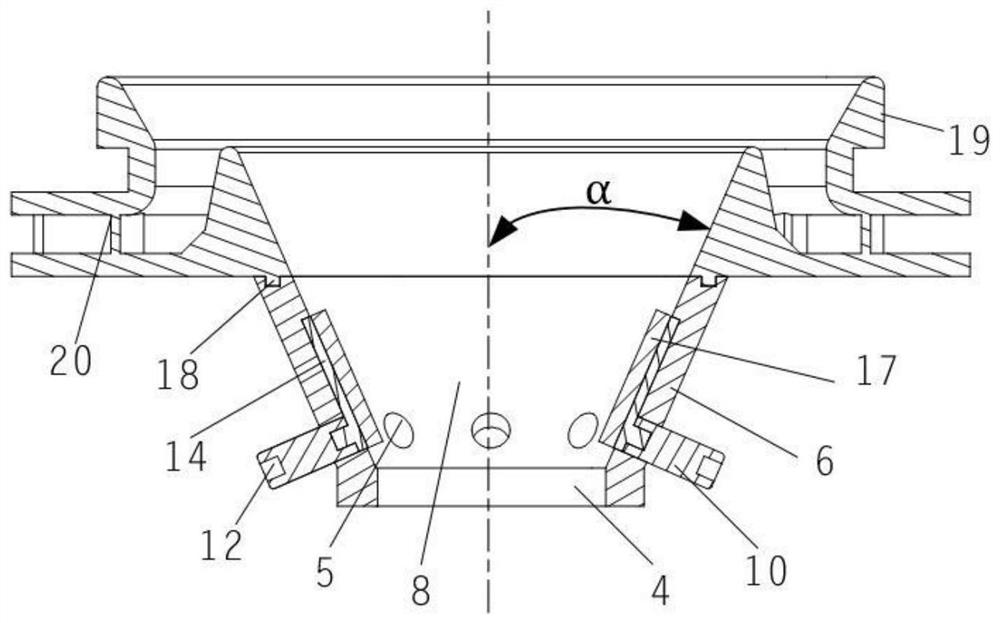

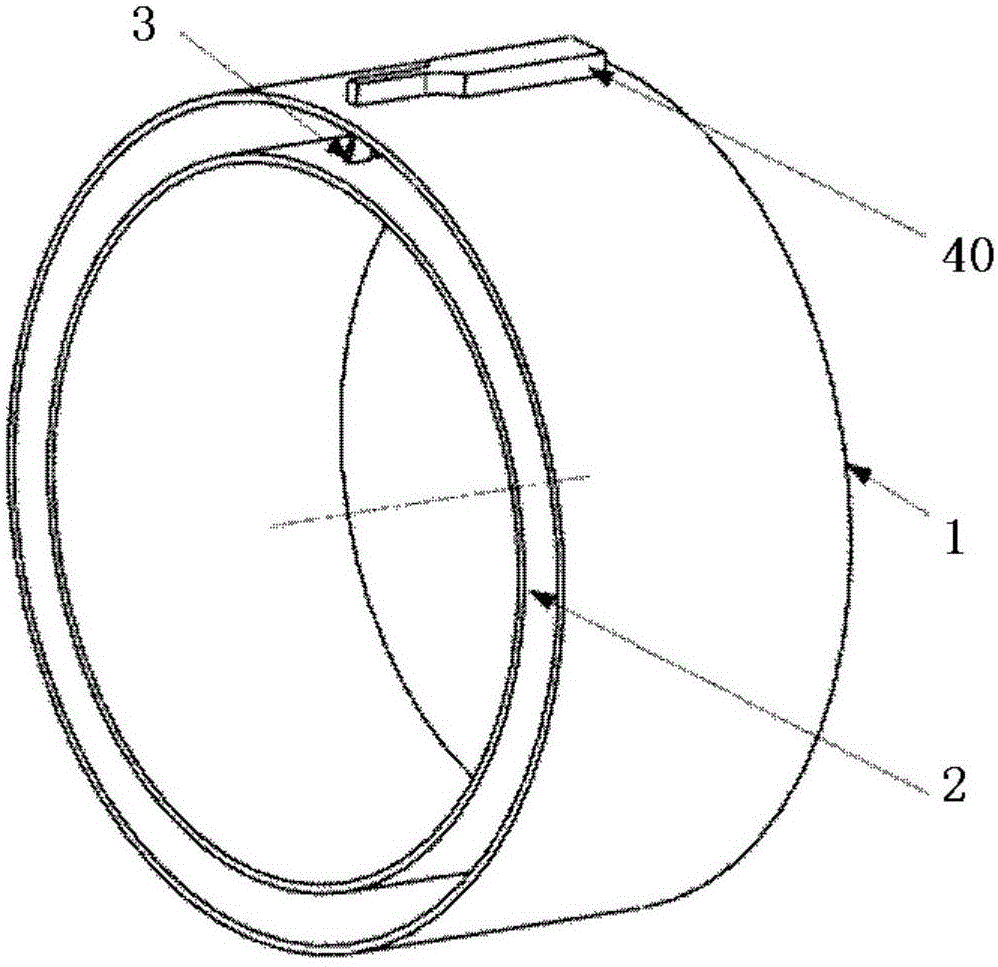

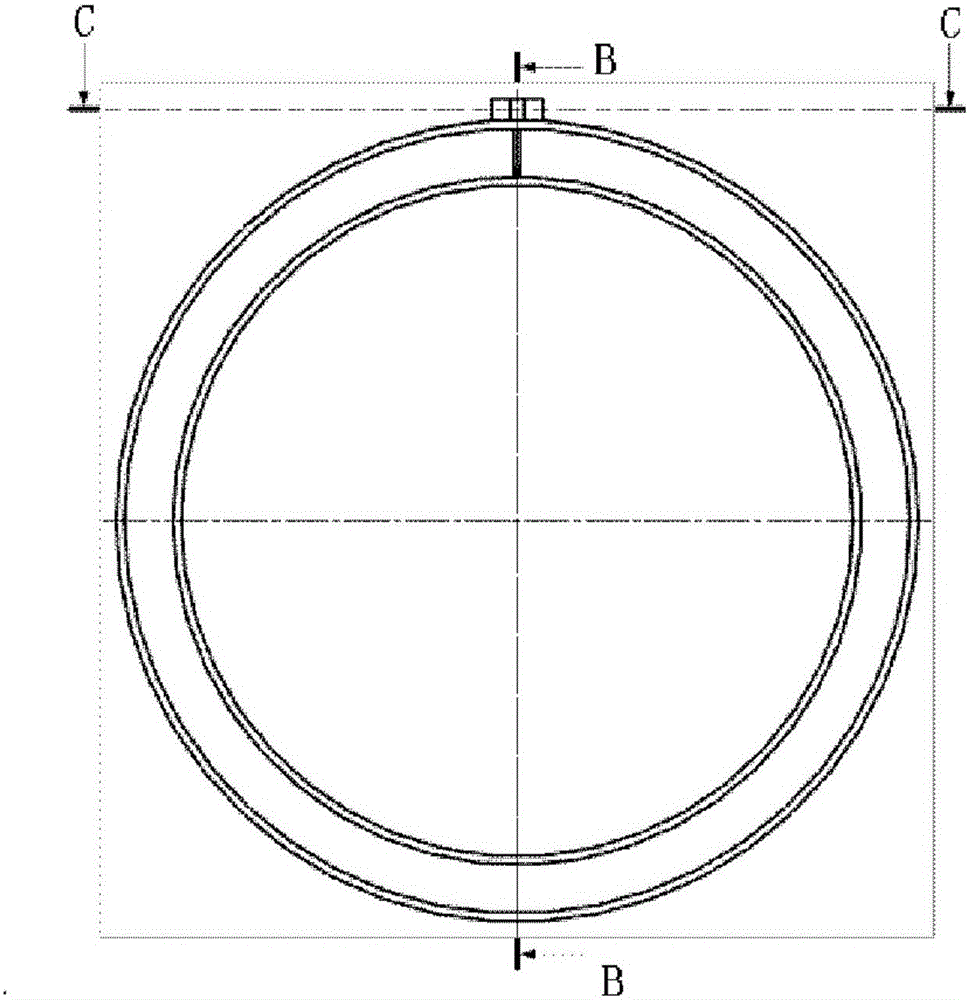

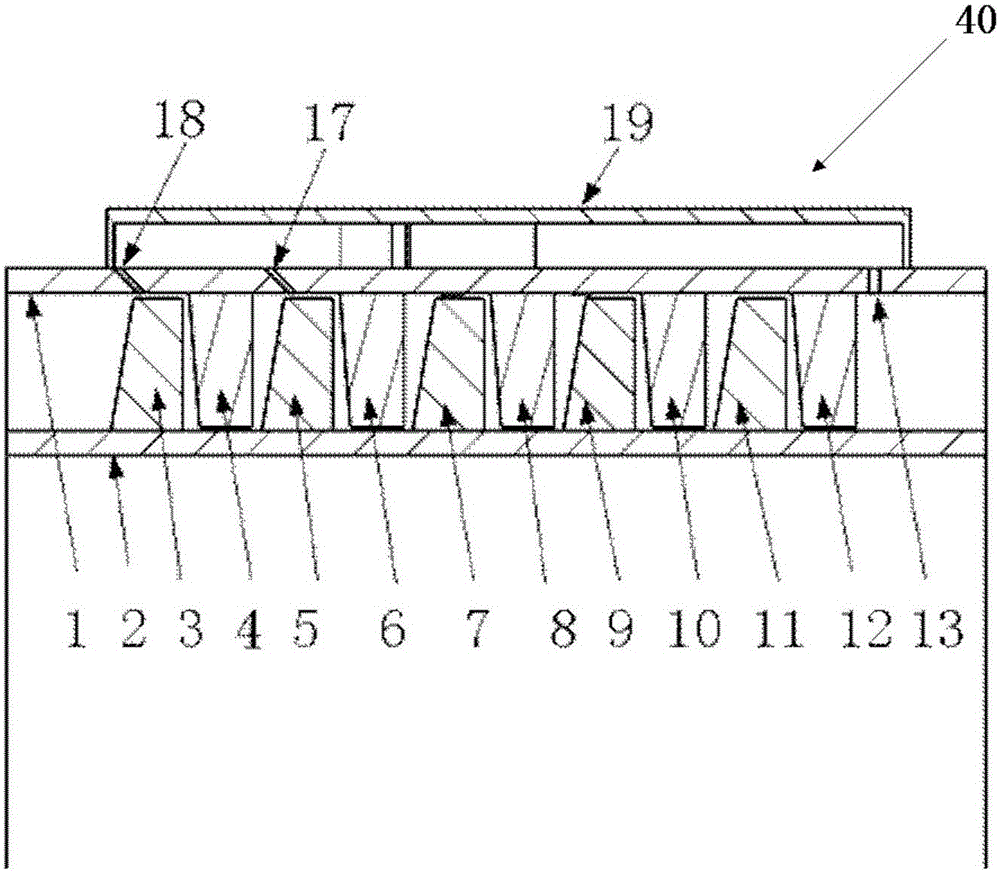

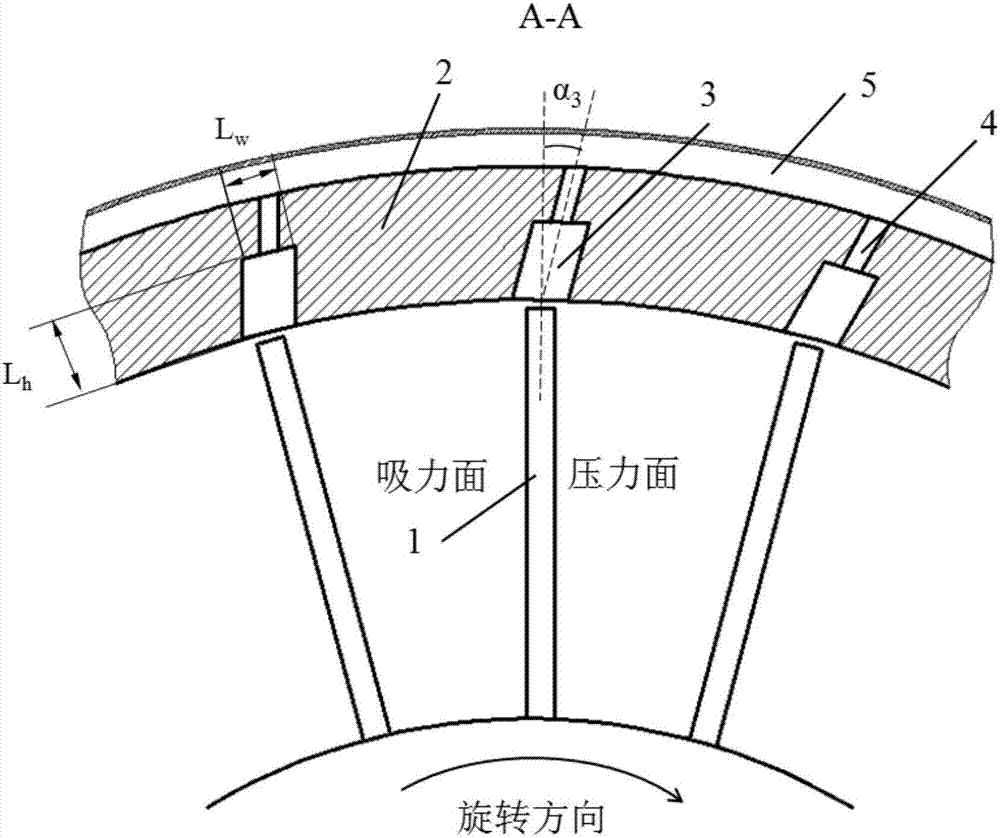

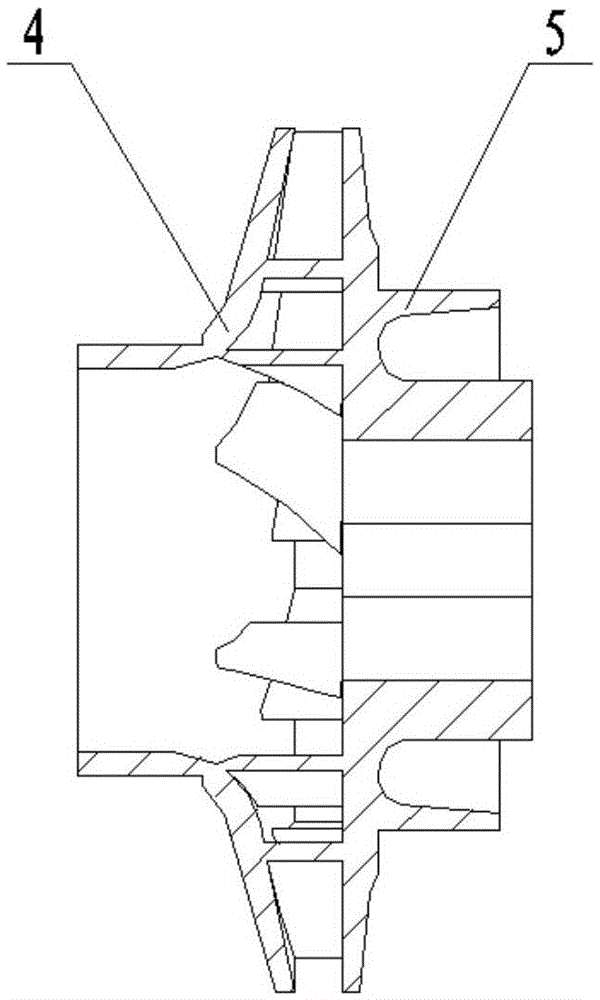

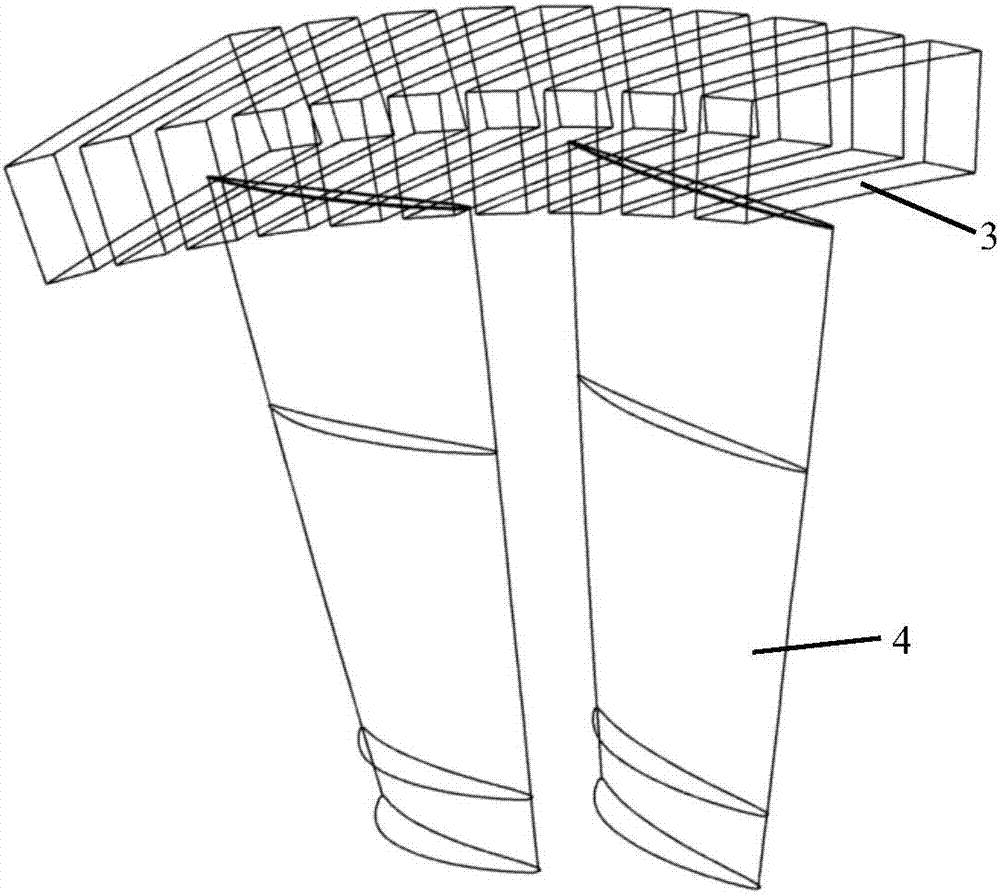

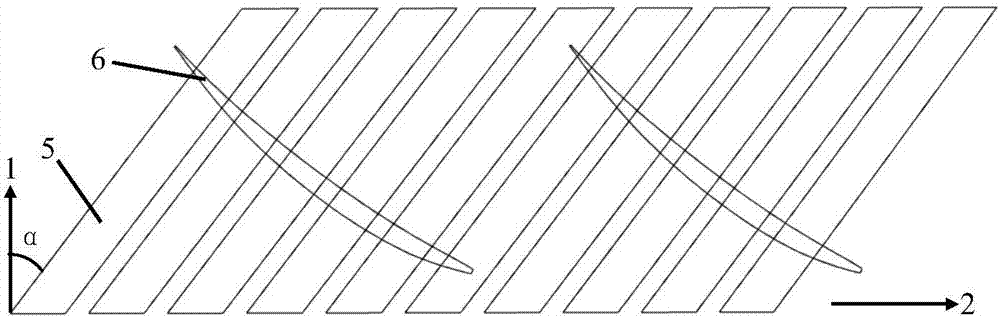

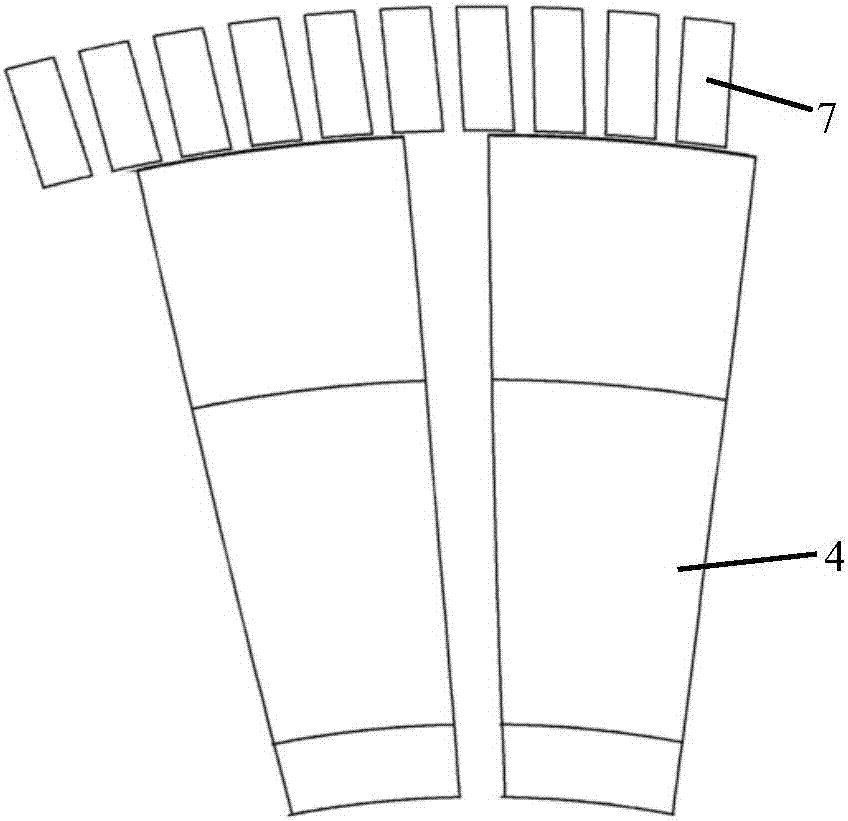

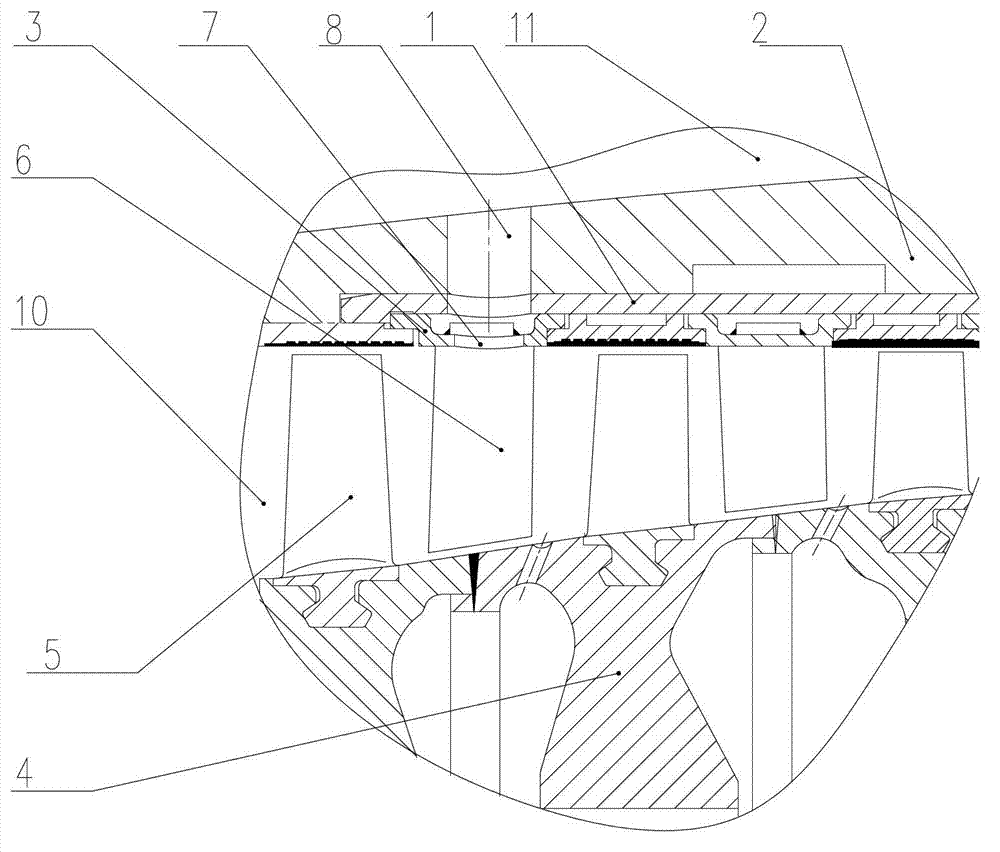

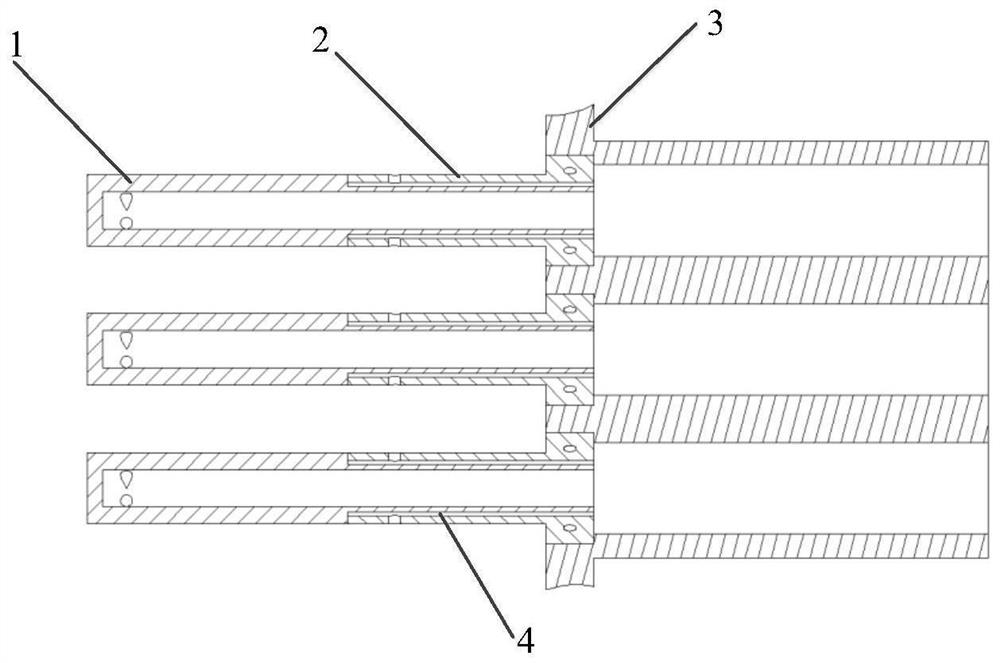

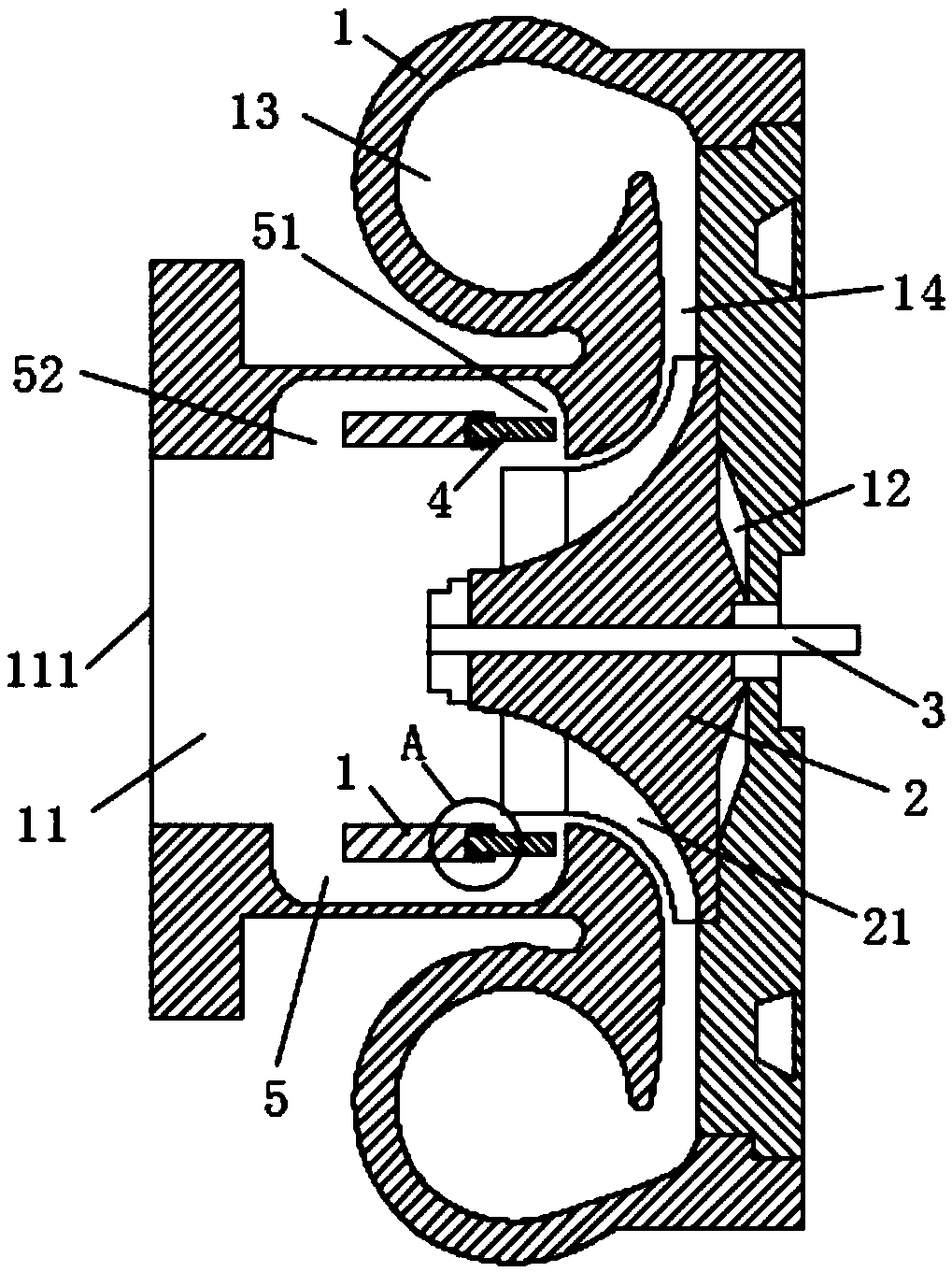

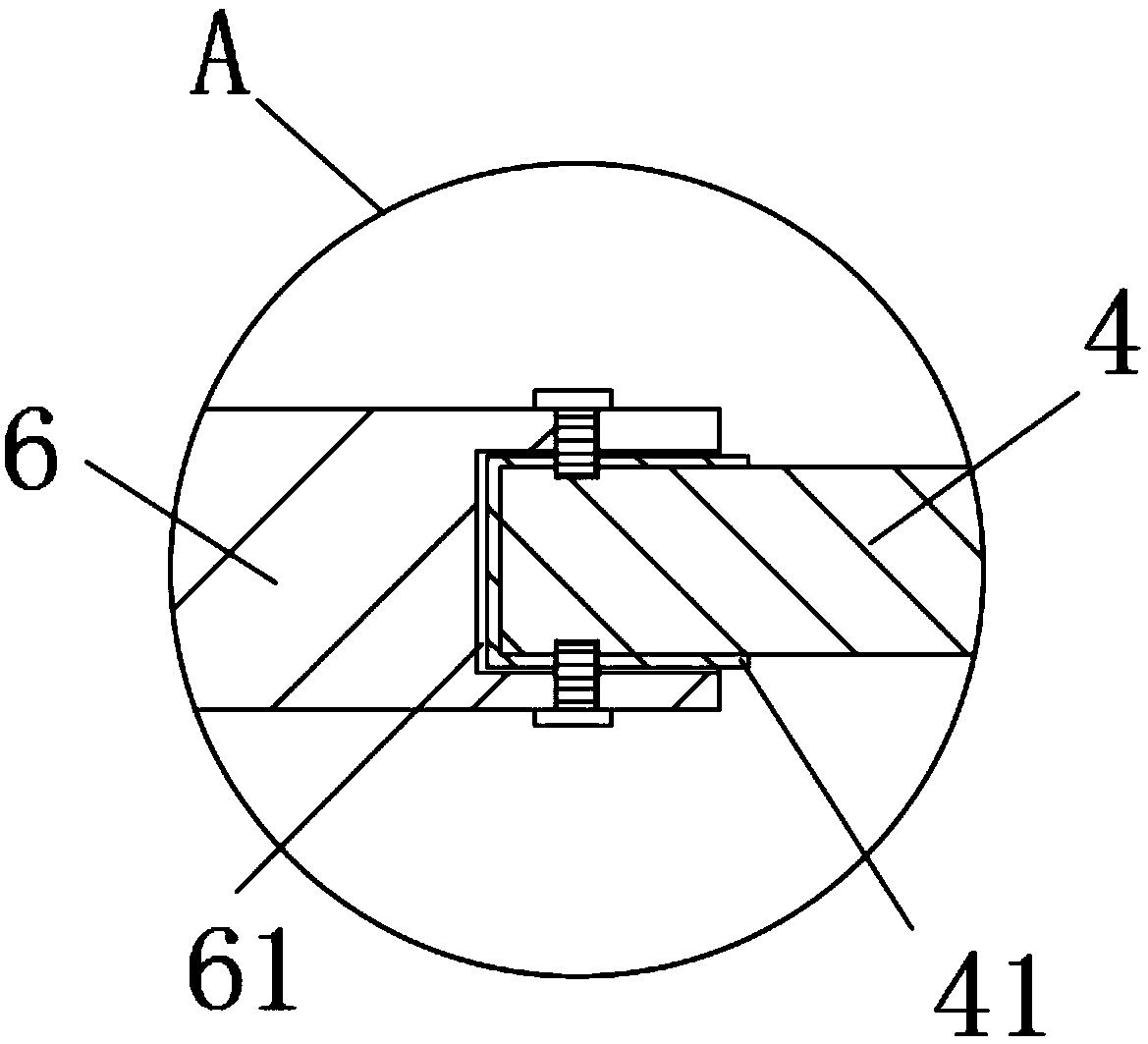

Axial-flow compressor stator blade system with adjustable first and second half of segments and working method thereof

InactiveCN104895839AEasy to implementIncreased efficient working rangePump componentsPumpsImpellerClassical mechanics

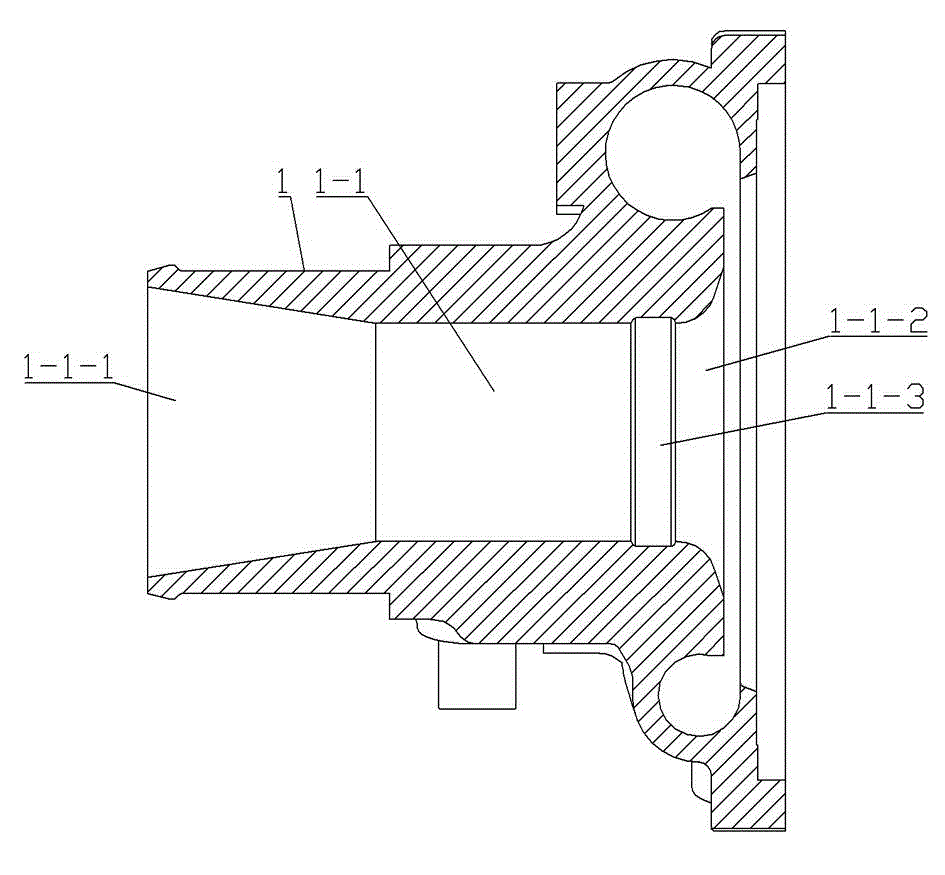

The invention relates to an axial-flow compressor stator blade system with adjustable first and second half segments and a working method thereof and belongs to the field of mechanical technology of impellers. A single-stage stator blade is divided into a first half segment adjustable blade (1) and a second half segment adjustable blade (4). Sleeve ring structures (3) of the first and second half segment adjustable blades are connected via a connection cylinder (2). The connection cylinder (2) is arranged at the biggest thickness part of the last-stage stator blade and installed between an external casing and a stator inner ring. A stepping motor rotates so as to drive a worm, a worm wheel, a rotation ring, a cylindrical pulling block, and the first half or second half segment blade to rotate and move successively, thereby achieving adjustment of angles. Compared with the prior art, the stator blade system is advantageous in that 1) for a middle-stage stator blade, by rotating the first half segment blade, the blade is arranged at a favorable attack angle, and by rotating the second half segment blade, a rotator at the backward position of the stator is arranged at a favorable attack angle; and 2) an adjusting mechanism is simple and easy to realize in engineering.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

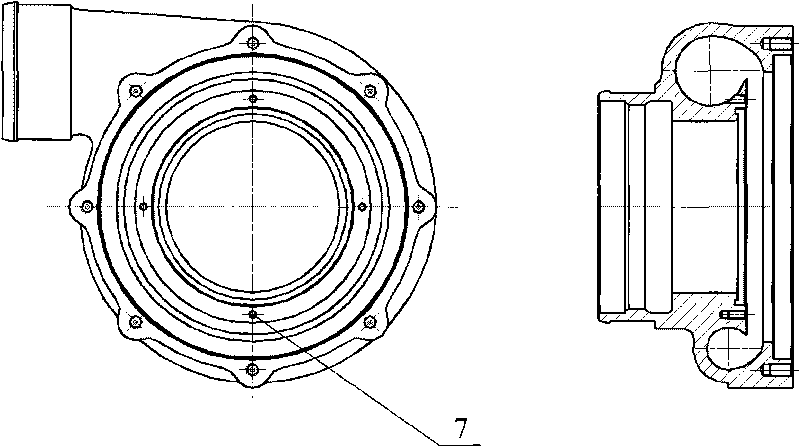

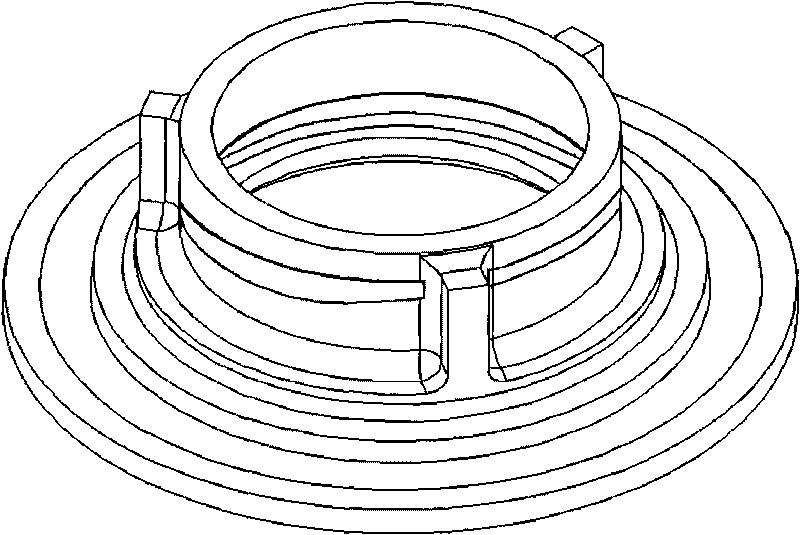

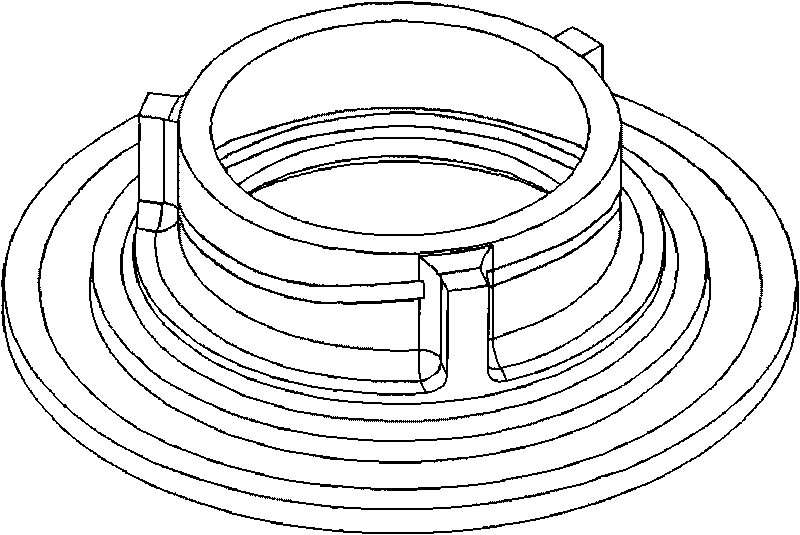

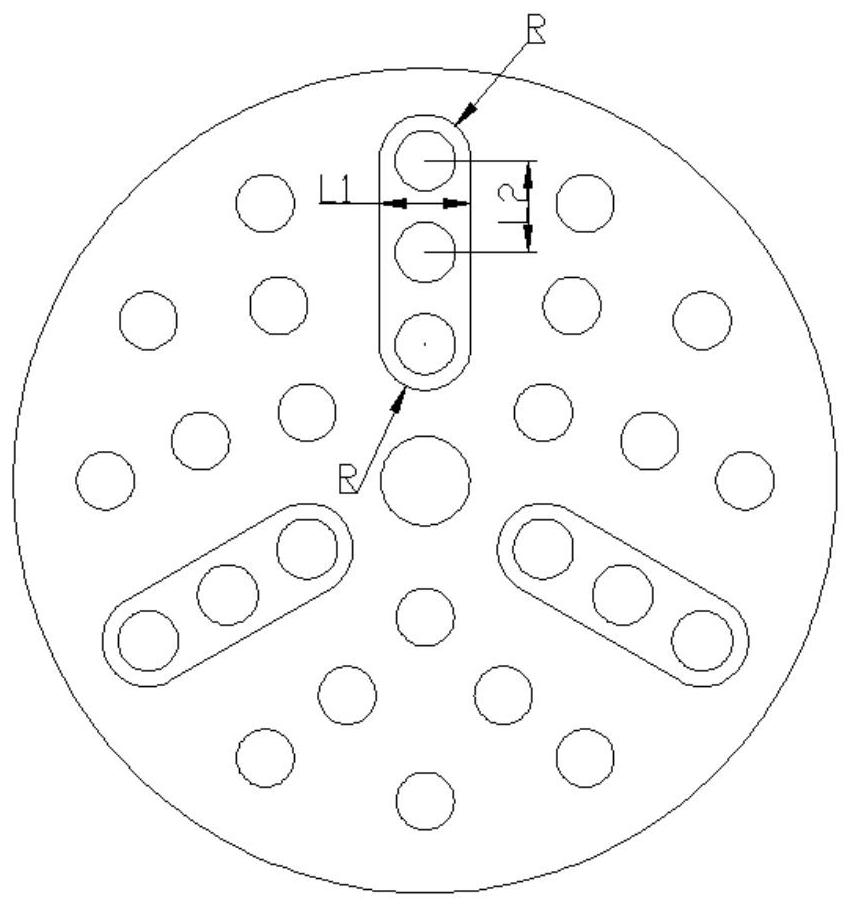

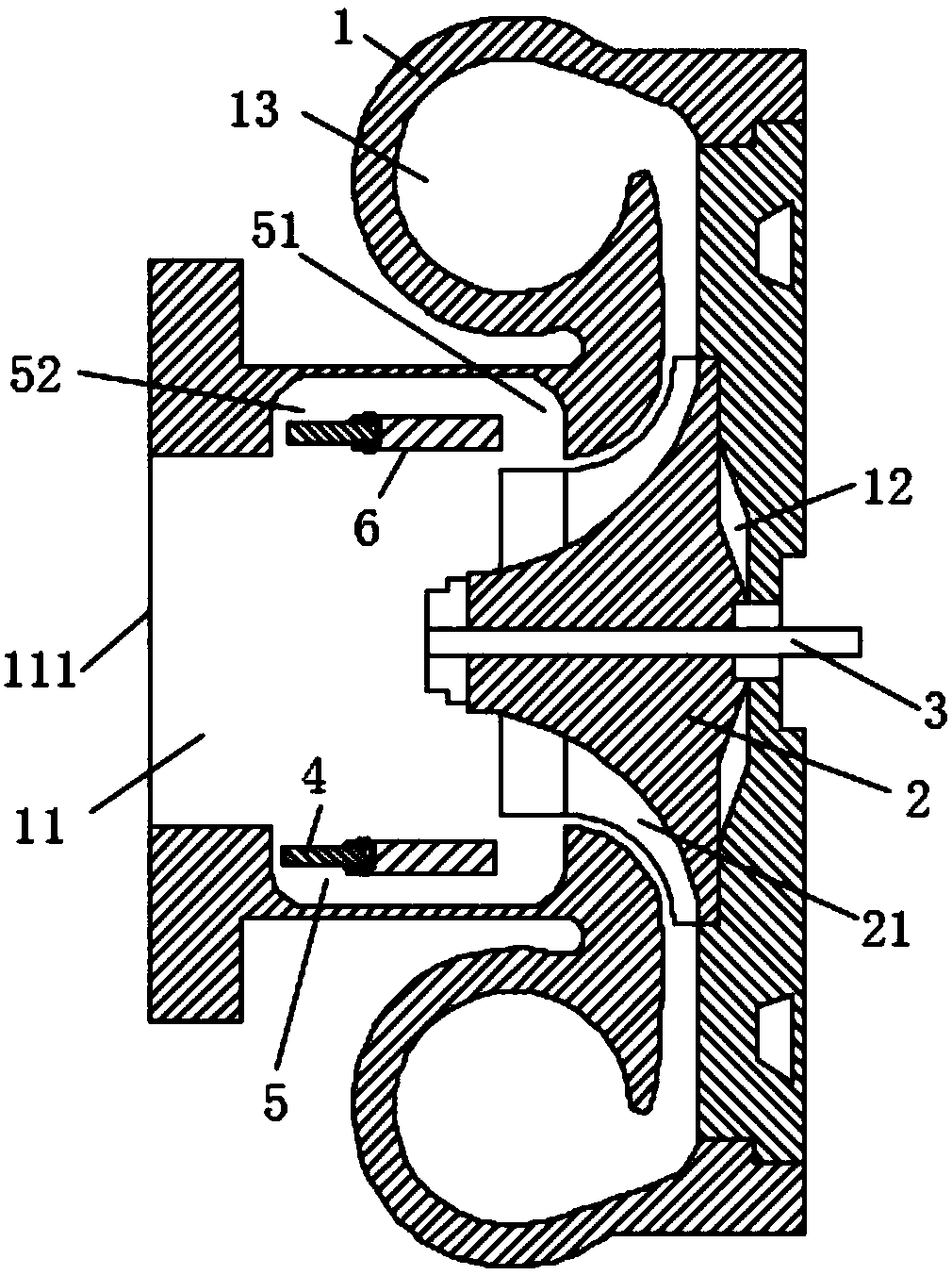

Treatment casing with adjustable grooving width of centrifugal air compressor

InactiveCN107035721AImprove stable working rangeImprove pressure ratio and heat insulation efficiencyPump componentsPump controlHollow cylinderWorking range

The invention discloses a treatment casing with an adjustable grooving width of a centrifugal air compressor. The casing comprises a self-circulation casing channel formed in a volute, and an adjustment device with the adjustable grooving width, wherein the adjustment device comprises a hollow cylinder, a cam structure and a spiral spring; the hollow cylinder is arranged in a flow guide ring groove and moves along the flow guide ring groove; and the cam structure comprises a cam, a cam shaft and a sealing hollow structure arranged on the upper part of the cam shaft, the interior of the sealing hollow structure is divided into two chambers, each chamber is connected with an air guide pipe, and the other ends of the air guide pipes are connected to the different positions in the circumferential direction of the volute. The cam shaft is pushed to rotate through the pressure difference of the two chambers to drive the hollow cylinder to move, so that a casing design that the width of a suction ring groove is adjusted with the working condition of the air compressor. According to the technical scheme of the invention, compared with a self-circulation treatment casing with a fixed-width suction ring groove, the width of the suction ring groove can be adjusted, so that the stable working range of the centrifugal air compressor can be greatly expanded, and the pressure ratio and the adiabatic efficiency of a part of working conditions are increased.

Owner:HEFEI UNIV OF TECH

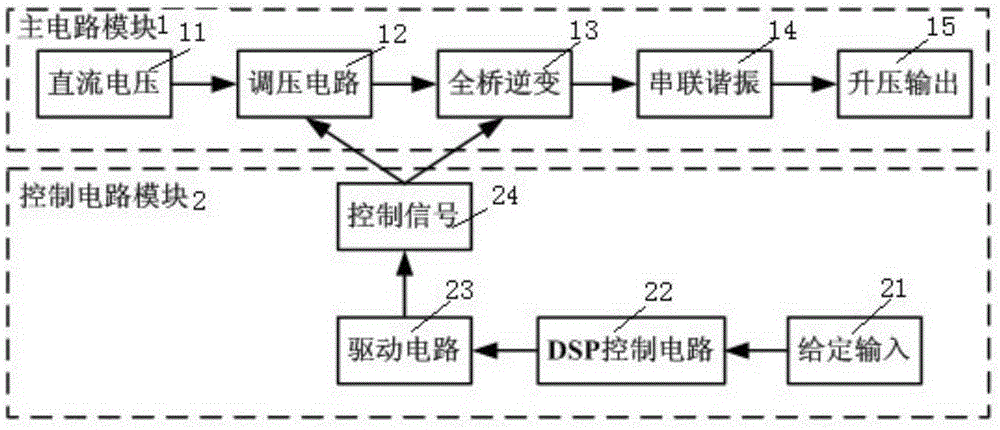

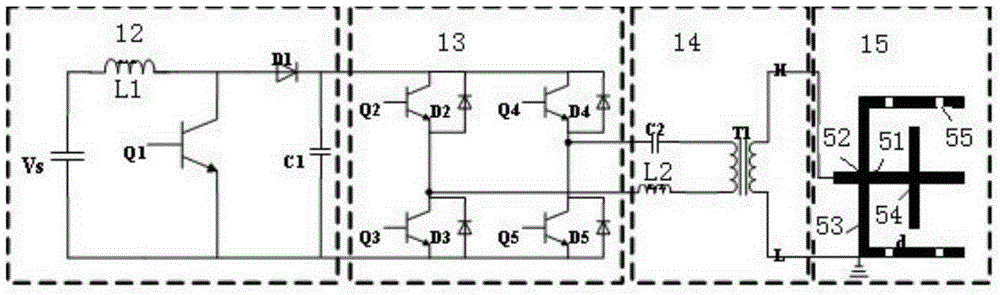

Low-temperature-plasma ignition power supply and ignition system

ActiveCN105201657AMeet ignition requirementsShorter ignition delay timeGas turbine plantsRocket engine plantsDigital signal processingOn board

The invention discloses a low-temperature-plasma ignition power supply. The low-temperature-plasma ignition power supply comprises a main circuit module and a control circuit module, wherein the main circuit module comprises a direct-current power supply, a voltage regulating circuit, a full-bridge inverter circuit, a series resonance circuit and a step-up output circuit which are sequentially connected, and the control circuit module comprises a given input control, a DSP (Digital Signal Processing) control circuit, a driving circuit and a control signal which are sequentially connected and is used for supplying control signals to a voltage regulating circuit switch and a full-bridge inversion switch in the main circuit module. A low-temperature-plasma ignition system is further disclosed and consists of the low-temperature-plasma ignition power supply and a boss discharge load. According to the power supply and the system, the low-temperature-plasma ignition power supply can generate low-temperature plasma according to certain frequency and pulse width; the energy consumption is low; the efficiency of ignition is high; laboratory power supplies are wide in parameter range and are adjustable; on-board power supplies are fixed in parameters; the size is small; the reliability is high, and thus the requirement of an engine for ignition is met.

Owner:PEKING UNIV

Asymmetric self-circulation processing machine box of centrifugal compressor with parabolic grooving widths

ActiveCN101761511AImprove stable working rangeMaintain efficiencyPump componentsPumpsWorking rangeCentrifugal compressor

An asymmetric self-circulation processing machine box of a centrifugal compressor with parabolic grooving widths relates to a processing machine box of the centrifugal compressor and belongs to the technical field of impeller machineries. A self-circulation channel is formed by installing a pumping ring groove, a reflux ring groove and a flow guiding ring groove on the wall surface of a turbine shell of the compressor, the widths br values of the pumping ring groove are distributed in a parabola shape in the circumference direction to optimize the expanding stability effect of the asymmetric self-circulation processing machine box on the centrifugal compressor. By adopting the asymmetric self-circulation processing machine box of the centrifugal compressor with the parabolic grooving widths, compared with an axisymmetric self-circulation processing machine box with coincident grooving widths in the circumference direction, the stable working range of the centrifugal compressor can be greatly increased, and the efficiency remains almost unchanged.

Owner:TSINGHUA UNIV +1

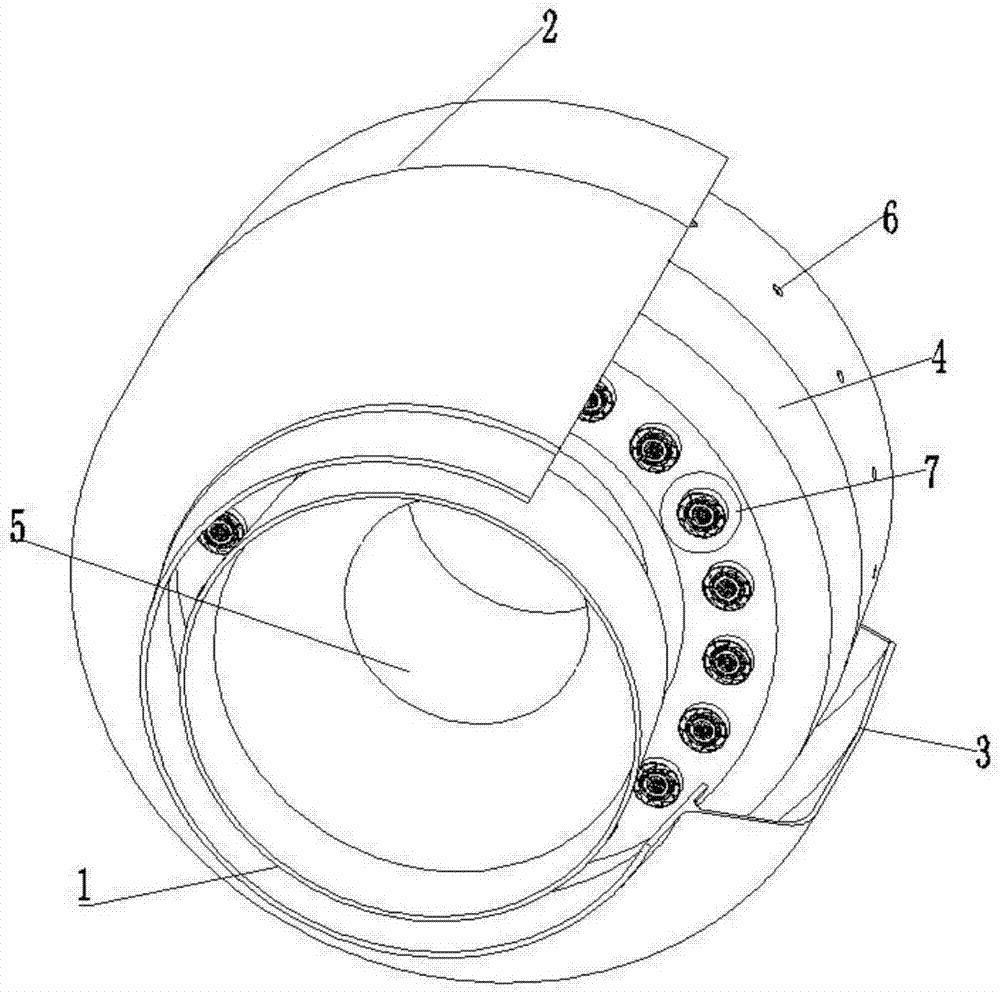

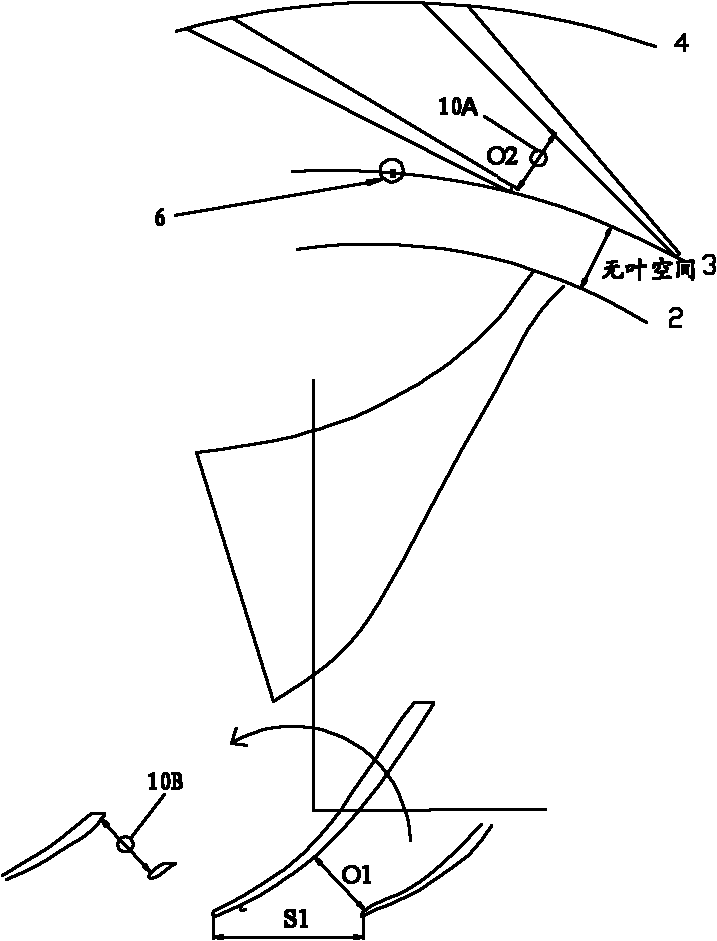

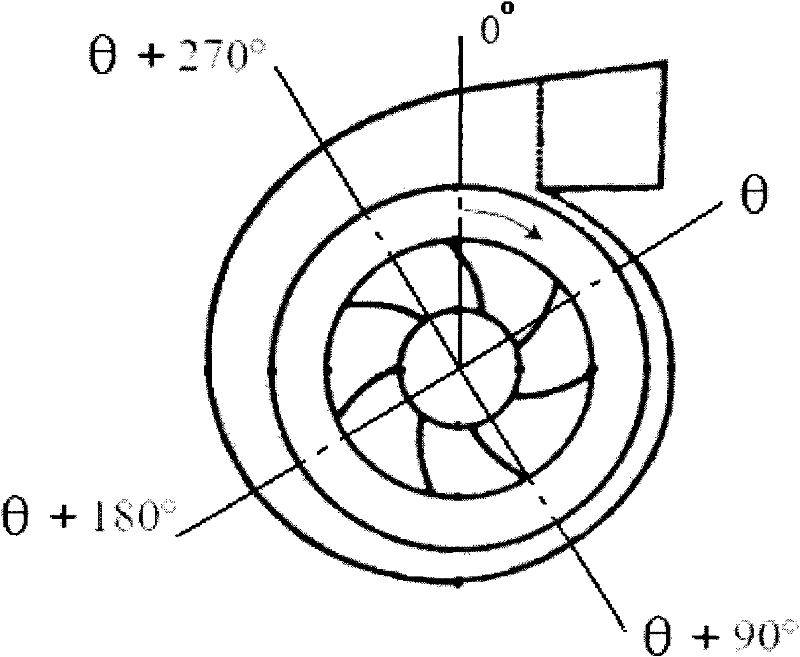

Centrifugal compressor with asymmetrical vaneless diffuser and automobile with same

ActiveCN103277324AImprove stable working rangeImprove efficiencyPump componentsRadial flow pumpsEngineeringCentrifugal compressor

The invention discloses a centrifugal compressor with an asymmetrical vaneless diffuser and an automobile with the centrifugal compressor. The centrifugal compressor comprises a volute, a vane wheel and the vaneless diffuser. The volute comprises a first shell portion and a second shell portion, wherein the first shell portion and the second shell portion are mutually communicated, a volute chamber is defined inside the first shell portion, and a vane wheel installation space is defined inside the second shell portion. The vane wheel rotates around a rotating shaft and is arranged inside the vane wheel installation space in a rotatable mode. The width of the vaneless diffuser is distributed in a non-axis-symmetrical in the circumferential direction. The vaneless diffuser comprises a maintaining segment and a transition segment, the outlet end of the maintaining segment is communicated with the first shell portion, the inlet end of the maintaining segment is communicated with the outlet end of the transition segment, the inlet end of the transition segment is communicated with the second shell portion, the width of the maintaining segment is even at the same circumferential position in the radial direction, and the width of the transition segment is uneven at the same circumferential position in the radial direction. The centrifugal compressor with the asymmetrical vaneless diffuser can reduce the non-axis-symmetrical property of a flow field of the fluid inside the centrifugal compressor and broaden the stable working range of the centrifugal compressor.

Owner:TSINGHUA UNIV +1

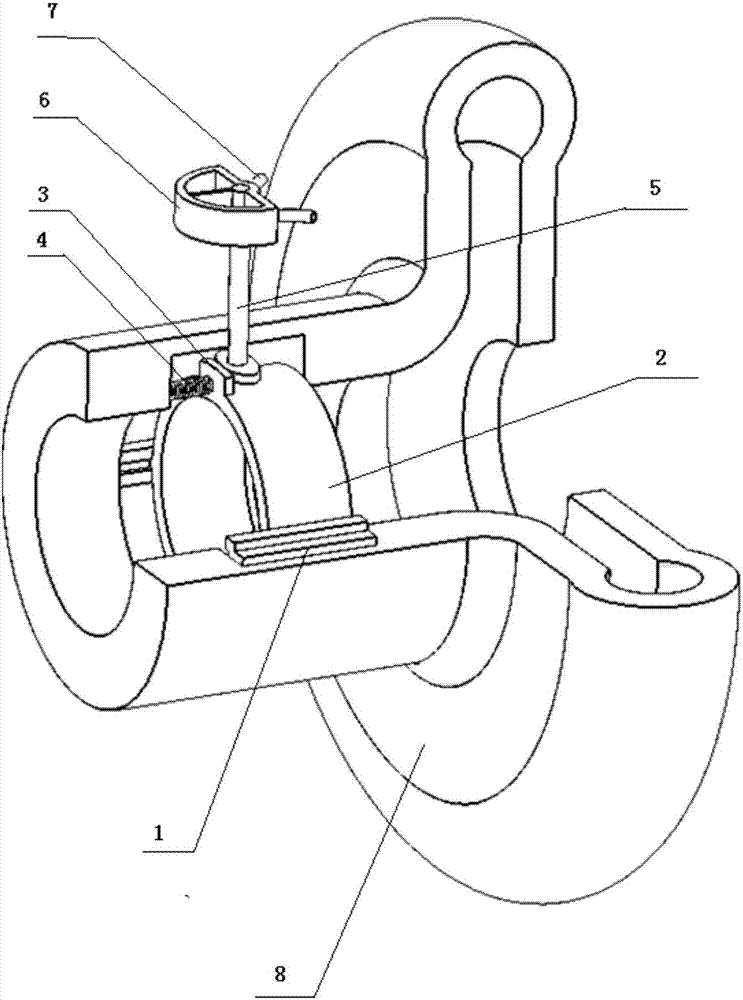

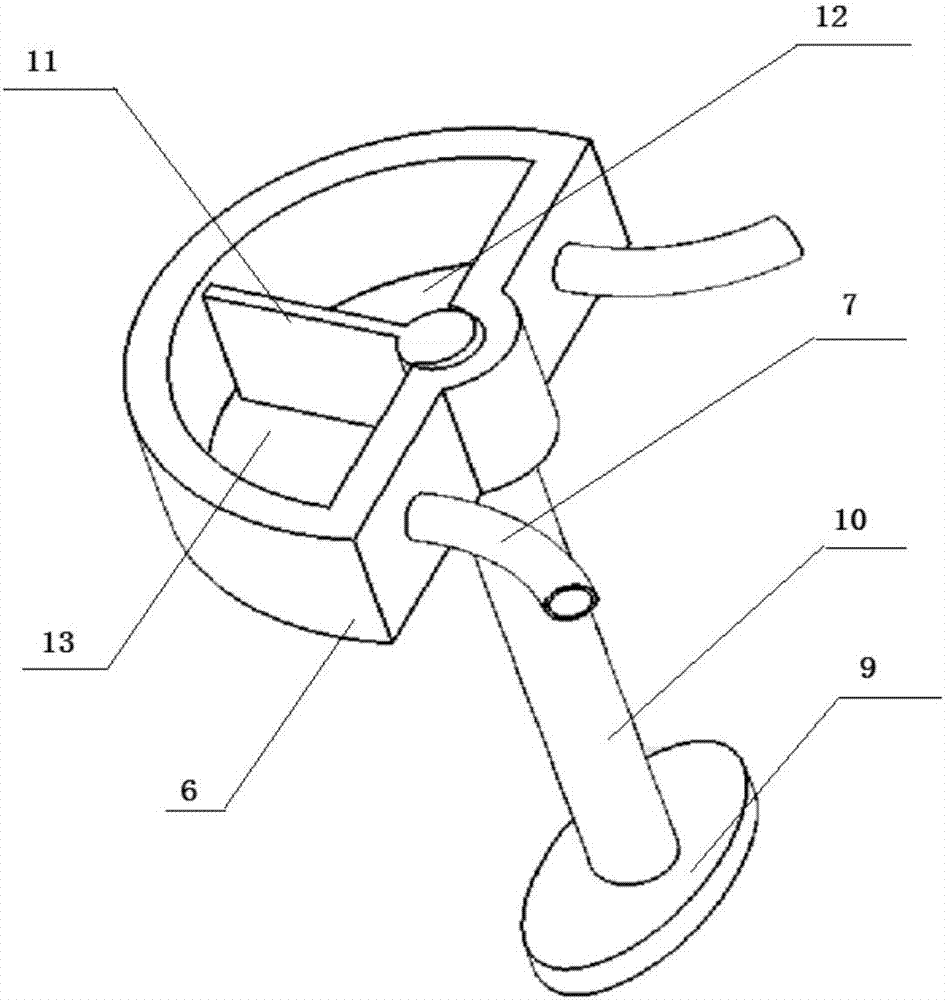

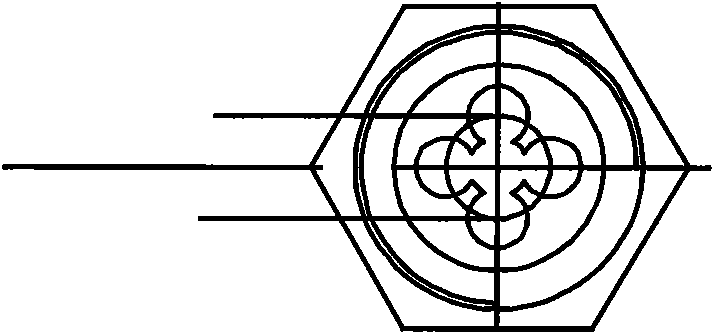

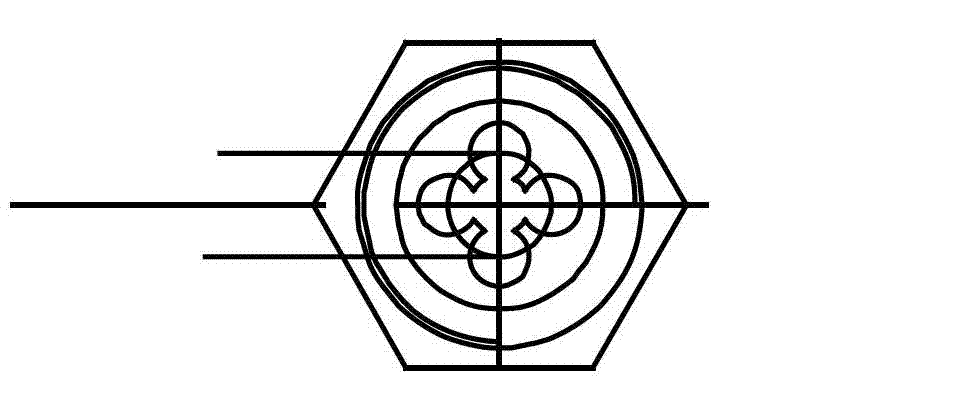

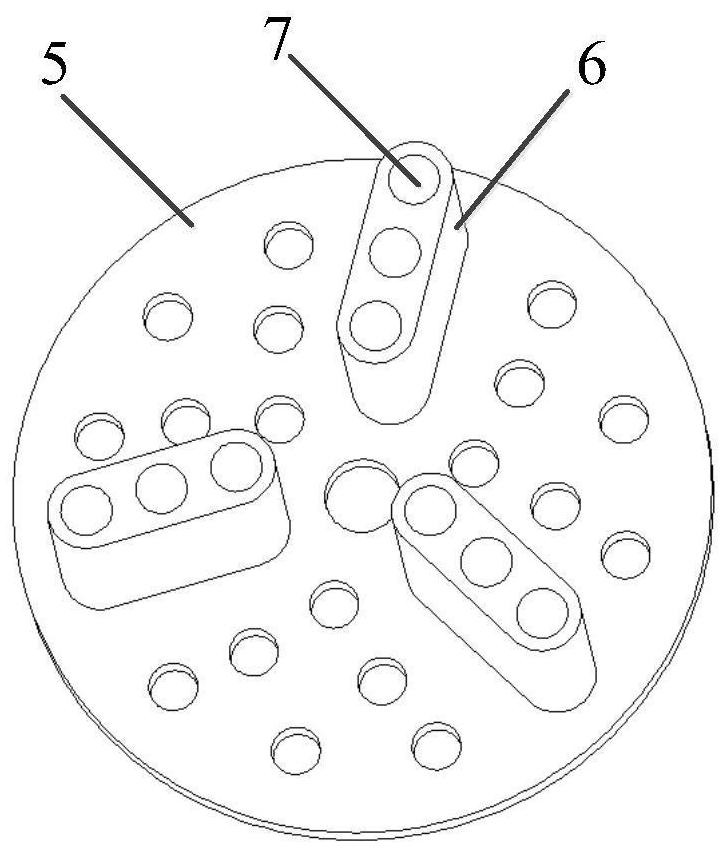

Filamentous arc plasma exciter based on swirl holes

ActiveCN111734532ASimple structureThe effect is obviousGas turbine plantsJet propulsion plantsCombustion chamberEngineering

Provided is a filamentous arc plasma exciter based on swirl holes. An inner layer plasma swirler and an outer layer swirler are of a split type structure. The plurality of swirl holes are evenly distributed in a shell body of the inner layer plasma swirler. Two to five electrodes are disposed in the swirl holes through electrode installing bases correspondingly and divide the circumference of theshell body of the inner layer plasma swirler into n equal-length arc sections. The outer layer swirler is disposed on the upper end face of the inner layer plasma swirler. The filamentous arc discharge as one type of plasma discharge has huge advantages in the aspect of ignition and combustion supporting of a combustion chamber of an aero-engine, and the plasma exciter is combined with the head portion of the combustion chamber, so that ignition and combustion supporting can be integrated, and meanwhile active particles generated by plasma discharge are easily mixed with fuel oil molecules. The filamentous arc plasma exciter overcomes the defect that sliding arc plasmas cannot realize discharging when an inlet air flow rate is 0, improves combustion efficiency, is simple in structure and does not need to be equipped with a special air supply system or a special oil supply system.

Owner:AIR FORCE UNIV PLA

Gas compressor with stability enhancing and effect improving device

ActiveCN105927560AImprove stabilityIncrease flexibilityPump componentsPump controlGas compressorProduct gas

The invention provides a gas compressor with a stability enhancing and effect improving device. The gas compressor comprises a casing, a wheel hub and the stability enhancing and effect improving device. A high-pressure gas suction hole, a gas ejecting hole and M gas jetting holes are formed in the casing. High-pressure gas is sucked into the stability enhancing and effect improving device through the high-pressure gas suction hole. Gas at the top of an intermediate-stage movable blade and gas at the root of an intermediate-stage static blade are sucked into the stability enhancing and effect improving device through the gas ejecting hole. The mixed gas is ejected to the top of a low-pressure-stage movable blade through the gas ejecting hole. By means of the gas compressor with the stability enhancing and effect improving device, the gas at the root of the intermediate-stage static blade and the gas at the top of the intermediate-stage movable blade can be sucked out, the thickness of a boundary layer of the area at the root of the intermediate-stage static blade and the vortex strength of an angle area can be reduced, flow separation of the areas is inhibited, the functions of reducing flowing losses and improving the efficiency of the gas compressor can be achieved, flowing blockage and gas backflow of the areas during instable work of the gas compressor are relieved, and the function of enlarging the stable work range of the gas compressor can be achieved.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

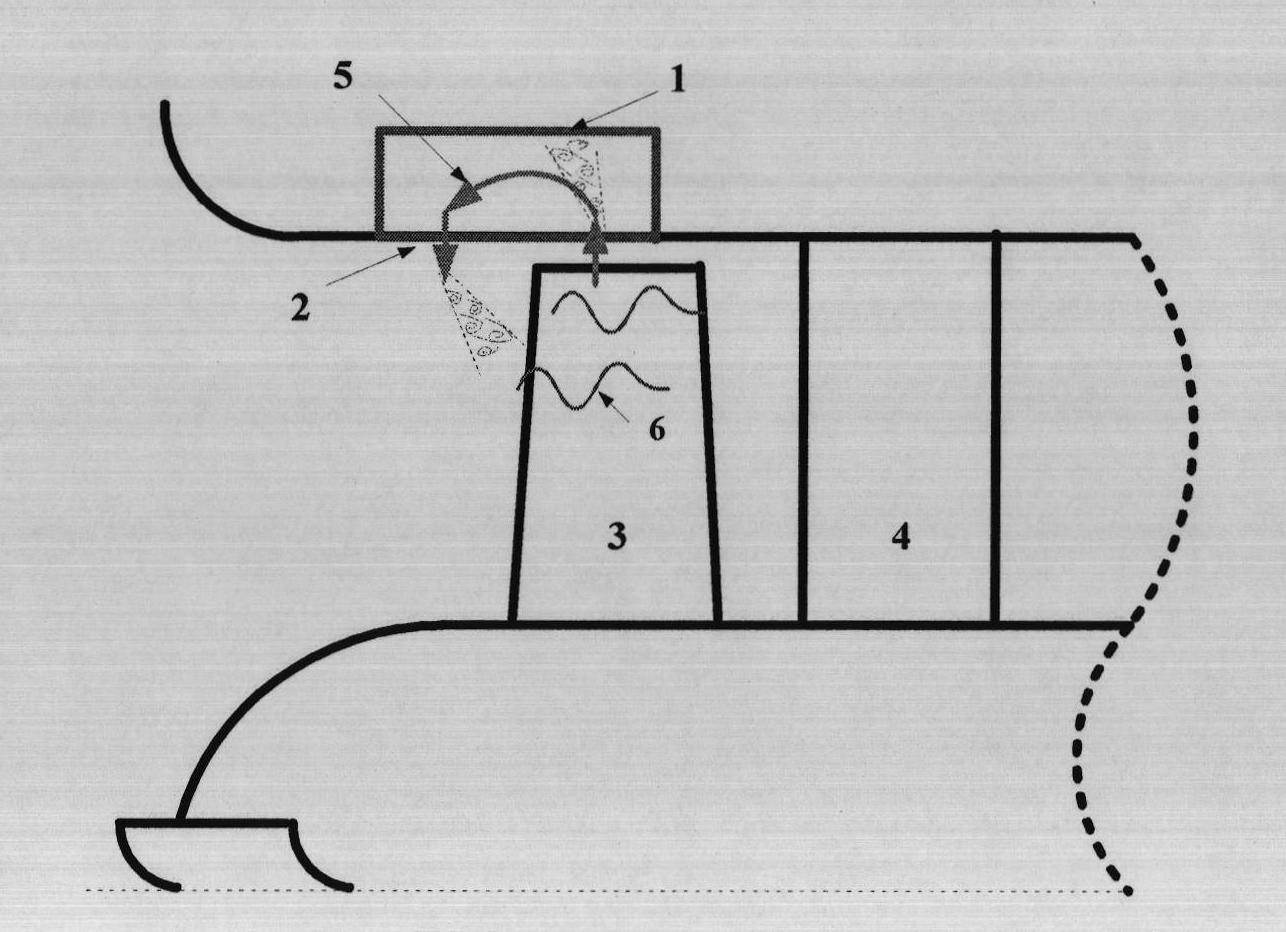

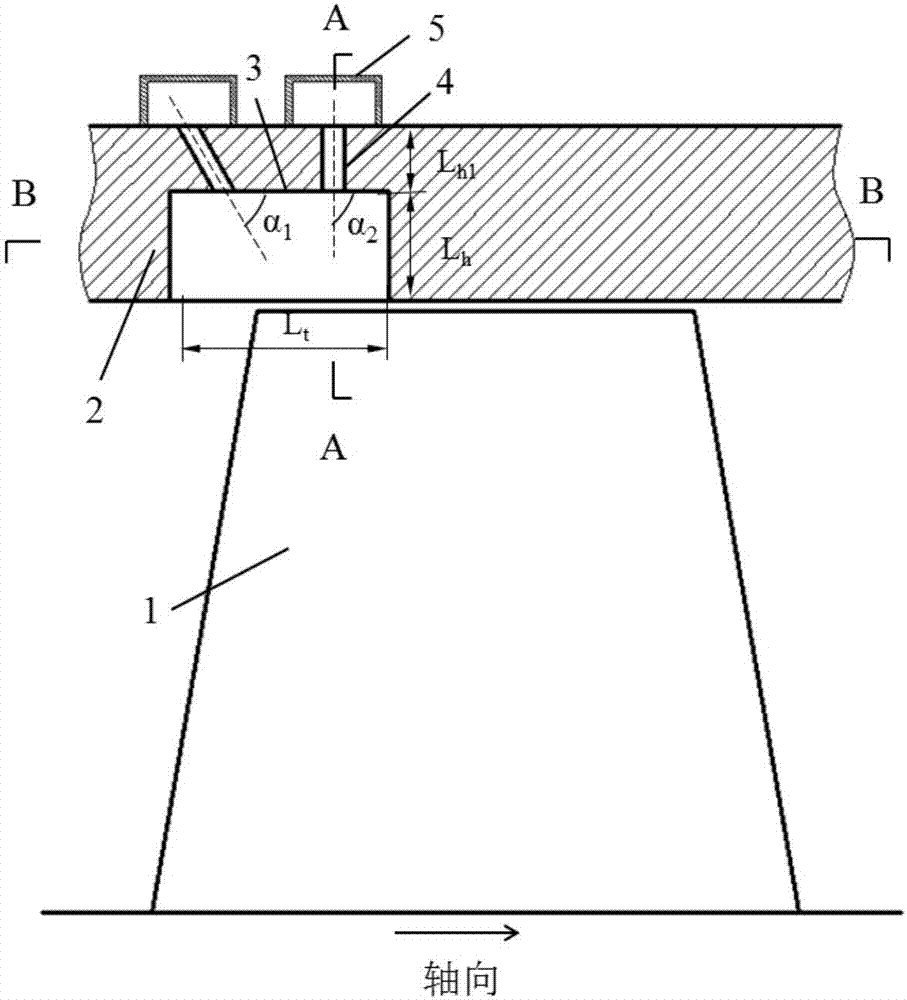

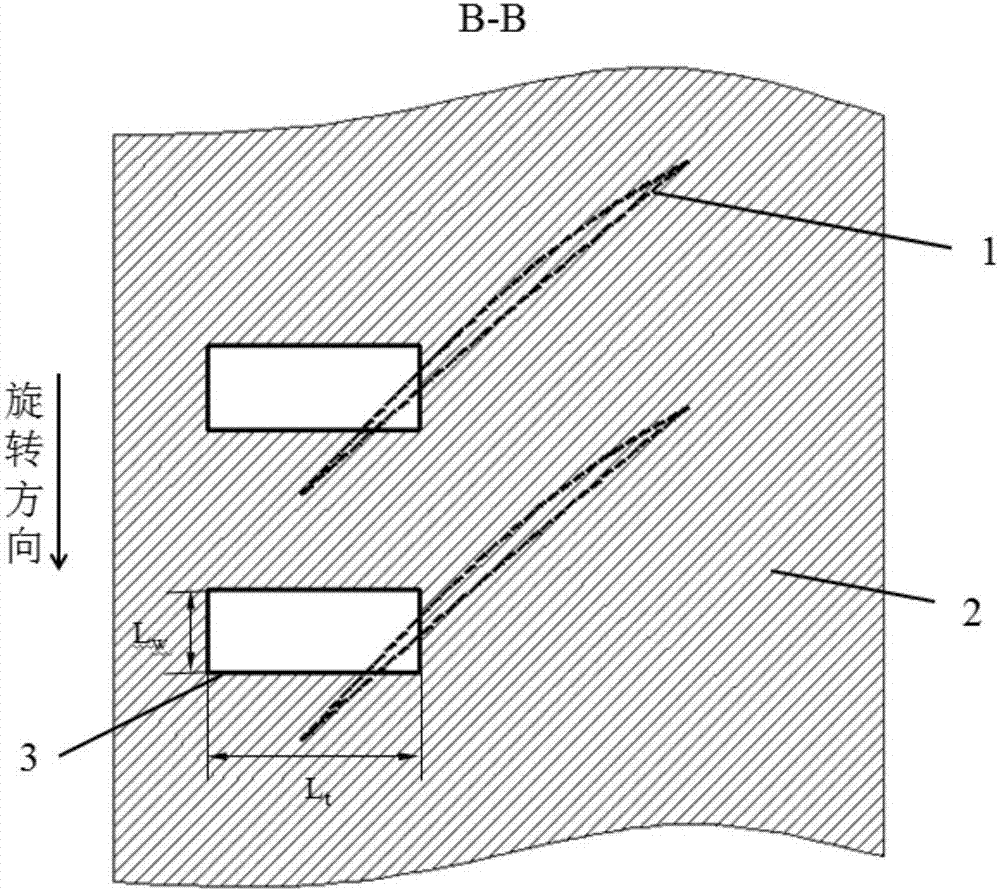

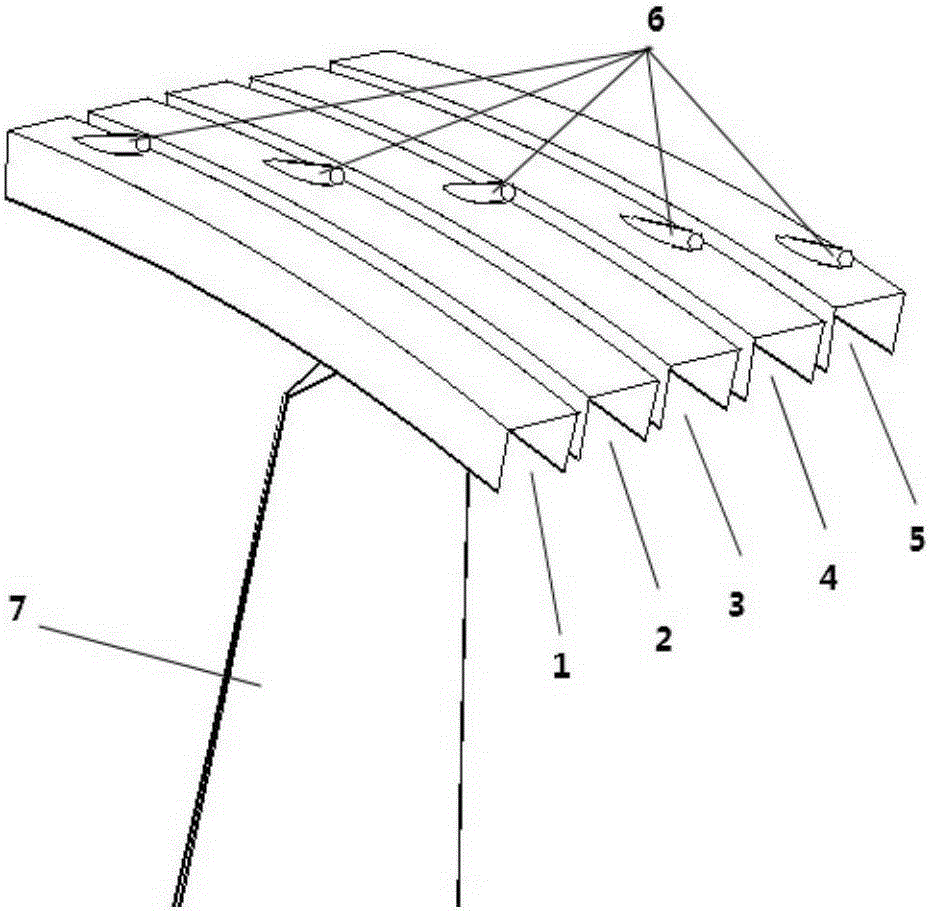

Suction type discrete and inclined seam casing treatment control device and method of compressor

ActiveCN107965465AImprove stable working rangeReduce intensityPump componentsPump controlMomentumAir pump

The invention discloses a suction type discrete and inclined seam casing treatment control device and method of a compressor. A plurality of discrete and inclined seams are formed in the wall surfaceof a compressor treatment casing in the circumferential direction, and the seams are inclined to the rotor rotation direction by a certain angle; then a certain number of suction holes are formed in the tops of the seams, and a back cavity is additionally arranged on the upper portion of the suction holes; by adjusting the angle of the suction holes, the air pumping volume and the air pumping position, flow vortex structures in the discrete and inclined seams and axial flow amount of the air flow of inflow and outflow of the discrete and inclined seams can be changed, and then the momentum ofa tip leakage flow and a mainstream can be changed; and the position of the interface of the tip leakage flow and the mainstream and flow loss caused by interaction between the seams and the tip flowfield can be adjusted. Compared with traditional discrete and inclined seam casing treatment, suction type discrete and inclined seam casing treatment can achieve the goal of reducing the efficiency loss while increasing the stable working range of the compressor.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Biogas burner

ActiveCN101749707AImprove stable working rangeReduce pollution emissionsGaseous fuel burnerCombustorFlow sheet

The invention relates to a biogas burner, which includes an ejector and a nozzle. The biogas burner is characterized in that the ejector includes a lead-in section and mixing section which are coaxially arranged; the caliber of the mixing section is more than that of the lead-in section so as to form a clearance and lead in air for mixing; the mouth part of the nozzle is provided with a pluralityof channels with small calibers which are arranged in a plum blossom shape and are communicated; or a plurality of channels with small calibers are arranged in a circular shape separately; the circular-shaped channels with small calibers are arranged in multi-layers; the calibers of the inner layer are small and the calibers of the outer layer are big. The inlet end of the lead-in section is uniformly provided with a circle of small holes along a side wall; the upper port of the mixing section is uniformly provided with a circle of small holes along the side wall. The mixing section or the lead-in section is provided with swirling flow sheets; and the upper port of the mixing section is provided with a gridded flame holder. The biogas burner solves a plurality of problems like safely and effectively burning biogas in current fermentation biogas processing and utilizing system with none pollution, etc.

Owner:北京时代桃源环境科技股份有限公司

Biogas burner

ActiveCN102853427AImprove stable working rangeReduce pollution emissionsGaseous fuel burnerCombustorEngineering

Owner:无锡时代桃源环保设备有限公司

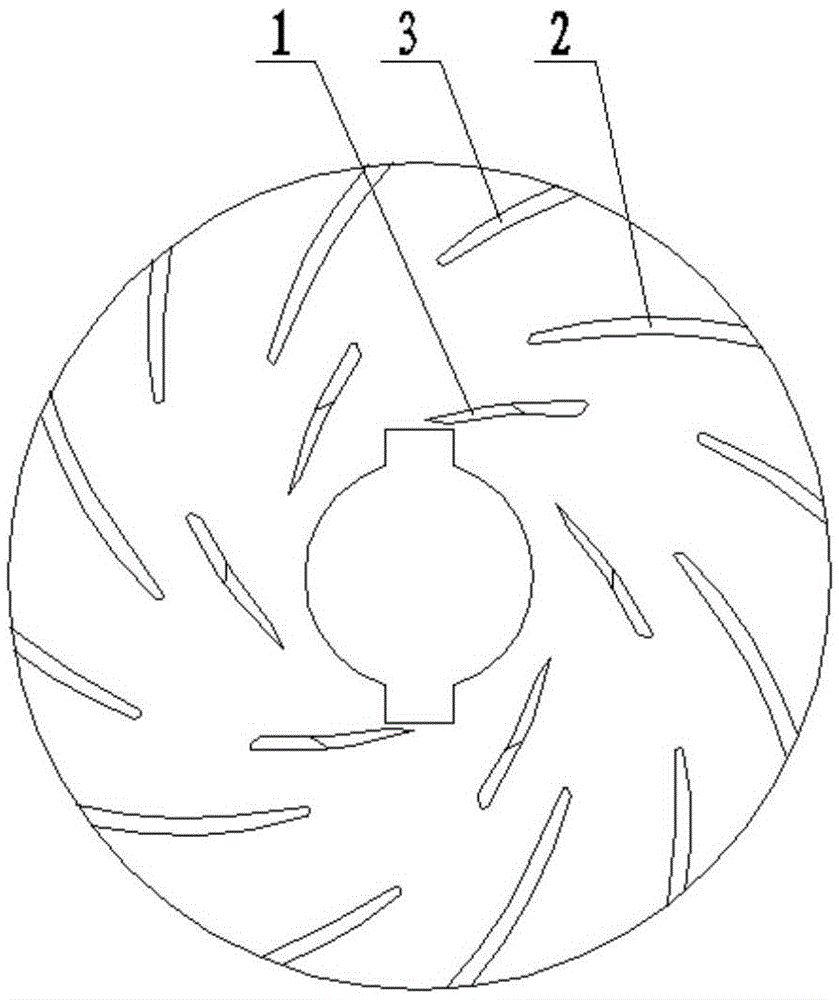

Multi-level blade centrifugal wheel

InactiveCN105626575AStable working range is wideImprove flow uniformityPump componentsPumpsEngineeringFront cover

The invention discloses a multi-level blade centrifugal wheel which comprises a front cover plate, multiple groups of blades and a hub, wherein the multiple groups of blades comprise first-level blades, second-level blades and short blades; multiple blades of the first-level blades are arranged at the inner circumference on one surface of the hub according to same setting angles; multiple blades of the second-level blades are arranged at the outer circumference according to same setting angles; the first-level blades and the second-level blades are alternatively distributed step by step; and the multiple short blades are distributed among the second-level blades. The centrifugal wheel disclosed by the invention can effectively inhibit flow separation of a pump in a blade passage in operation deviating from design conditions, so that the flow uniformity is improved, and the purpose of reducing the vibration magnitude of the pump is achieved.

Owner:XIAN AEROSPACE PROPULSION INST

Asymmetric self-circulation processing case with slotting position of parabola distribution for centrifugal compressor

ActiveCN101737358AImprove stable working rangeMaintain the same efficiencyPump componentsPumpsCentrifugal compressorWorking range

The invention discloses an asymmetric self-circulation processing case with slotting position of parabola distribution for a centrifugal compressor, relating to a processing case of a centrifugal compressor, and belonging to the technical field of impeller machineries. A self-circulation channel is formed by arranging a pumping and sucking ring slot, a reflow ring slot and a guide ring slot on the wall surface of a compressor volute casing, and the distance Sr from the front end face of the pumping and sucking ring slot to the front edge of a main stream blade of a compressor impeller is in parabola distribution on the circumference direction to optimize the stability enhancing effect of the asymmetric self-circulation processing case on the centrifugal compressor. By adopting the asymmetric self-circulation processing case with the slotting position of parabola distribution for the centrifugal compressor, compared with the shaft symmetric self-circulation processing case with consistent slotting width on the circumference direction, the stable working range of the centrifugal compressor can be greatly improved while the efficiency is maintained unchangeable.

Owner:TSINGHUA UNIV +1

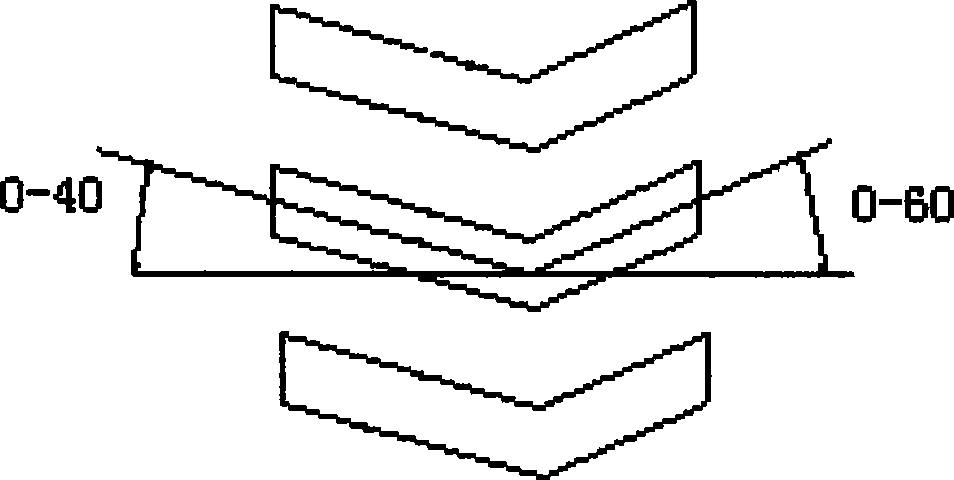

Axial forward-moving and radial slanting reverse-vane angle-direction seam processing box

InactiveCN106968988AImprove interstitial flowImprove stable working rangePump componentsPumpsGas compressorForm processing

The invention discloses an axial direction moving forward and radial direction slanting reverse-vane angle-direction seam type processing engine box. A certain number of seams are formed in a gas compressor box in the direction which forms an included angle with the axial direction and are evenly distributed in the circumference direction to form the reverse-vane angle-direction seam type processing engine box, and the included angle is 37.1 degrees. The processing width of the reverse-vane angle-direction seam type processing engine box covers the axial chord length of a total vane top. On the basis of the reverse-vane angle-direction seam type processing engine box, axial forward moving is further conducted by 10 mm, and radial slanting is conducted by 60 degrees, stability margin of a gas compressor is further improved, and meanwhile, loss of compression ratios and efficiency is reduced. A comparison research is carried out on a subaudio axial flowing gas compressor rotor test table, one is a reverse-vane angle-direction seam type processing engine box, and the other is the newly formed radial direction slanting reverse-vane angle-direction seam type processing engine box. The result shows that compared with the reverse-vane angle-direction seam type processing engine box, the newly formed processing engine box further improves comprehensive stall margin and reduces efficiency loss at the same time.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Surge-preventing structure for aero-engine compressor

ActiveCN103047193AIncrease pressure ratioImprove efficiencyPump componentsPumpsAero engineElectrical and Electronics engineering

The invention relates to a surge-preventing structure for an aero-engine compressor. A stator ring is mounted inside a compressor case, uniformly and peripherally distributed stator vanes are arranged on the stator ring, a compressor rotor is positioned inside the compressor case 1 and is provided with rotor vanes, a radial vent hole is reserved between each two stator vanes and at the peripheral position of the stator vanes on the stator ring, and vent holes with the diameter larger than that of each radial vent hole are reserved at the corresponding positions on an intermediate case and the compressor case. Speed loss and surge due to overlarge attack angles are eliminated; and flow condition is improved, thereby surge can be prevented effectively. The surge-preventing structure has the advantages that compressor characteristics can be improved, stable working range can be widened, and the surge-preventing structure can be used for preventing 'front-surge and rear-vortex' type surges and is convenient to process, low in size required accuracy, simple, low in cost and reduced in gas loss.

Owner:HARBIN DONGAN ENGINE GRP

Axial flow compressor blowing-type circumferential groove casing treatment method

InactiveCN105179321AImprove stabilityImprove efficiencyPump componentsPumpsEngineeringStability margin

The invention discloses an axial flow compressor blowing-type circumferential groove casing treatment method to solve the technical problem that the stability margin of a compressor treated by the conventional axial flow compressor casing treatment method is poor. The method is characterized in that based on a circumferential groove type treatment casing, tangentially blown air is added to circumferential grooves of the treatment casing, and through experimental measures, the best blowing groove design scheme which obviously improves the stability margin and the efficiency of the compressor is sought. An experimental result shows that with the adoption of the axial flow compressor blowing-type circumferential groove casing treatment method, the flow capacity of an blade top area of an axial flow compressor is improved, the separation of a boundary layer is retarded, the loss of the boundary layer is reduced, a blocking situation of a blade top end wall area is improved, the stable working range of the axial flow compressor is enlarged effectively, and the efficiency of the axial flow compressor is improved to some extent.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Variable camber blade type tandem stator and air compressor

ActiveCN109578335AImprove stable working rangeReduced flow separationPump componentsPumpsWorking rangeStator

The invention discloses a variable camber blade type tandem stator. A driving mechanism drives a first linkage ring and a second linkage ring to rotate, front blades of a front row of stators are driven to rotate and rear blades of a rear row of stators are driven to rotate to realize simultaneous adjustment of the installation angle of front blades of the front row of stators and rear blades of the rear row of stators to enable inlet airflow attach angle of the front row of stators to maintain in an appropriate range under different working conditions, the reduction of the flow separation isfacilitated, the occurrence of rotational stall or surge is avoided, and the stable working range of an air compressor is increased; and meanwhile, the requirements of a downstream rotor for the inletairflow angle are met, and the performance is improved. Through the driving structure, the simultaneous adjustment of different angles of the front blades of the front row of stators and the rear blades of the rear row of stators is achieved, the number of times of operation in the actual use process is reduced, and the operation efficiency is improved. The invention further provides the air compressor comprising the variable camber tandem stator.

Owner:AECC HUNAN AVIATION POWERPLANT RES INST

Partition plate nozzle structure of pre-combustion chamber

ActiveCN114165358AImprove stable working rangeSuppression of tangentially unstable combustionInternal combustion piston enginesRocket engine plantsThermodynamicsCombustion chamber

A pre-combustion chamber partition plate nozzle comprises an oxidizing agent nozzle, a fuel nozzle and a bottom. One end of the oxidant nozzle extends into the fuel nozzle and forms an annular gap with the fuel nozzle; a plurality of columns of partition plate sleeves are uniformly distributed on the panel along the circumferential direction; the panel and the partition plate sleeve are integrally formed to form a bottom; a fuel nozzle is mounted at the position, provided with the partition plate sleeve, of one bottom; longitudinal partition plate through holes are formed in the partition plate sleeve, and the partition plate through holes and the fuel nozzles are in one-to-one correspondence and are communicated with each other; a rotational flow hole is formed in the end head of one end of the fuel nozzle installed at the bottom and enables two end faces of the end head to be communicated, and a radial hole is formed in the end, connected with the oxidizing agent nozzle, of the fuel nozzle. By means of the reasonable design of the partition plate nozzle structure, unstable combustion is effectively restrained, and meanwhile high combustion efficiency and good outlet gas temperature uniformity are guaranteed.

Owner:BEIJING AEROSPACE PROPULSION INST

Double-flow-guiding annular fan with blade type air separator

PendingCN107676299AReduce erratic flowReduce flow leakagePump componentsPumpsEngineeringMechanical engineering

The invention discloses a double-flow-guiding annular fan with a blade type air separator. An inner ring and an outer ring are added at the position of each blade tip of the fan, and separately have aflow guiding effect and a flow distributing effect. The center axis of each inner ring and the center axis of the corresponding outer ring are consistent to the center axis of the fan, and the innerrings are connected with the tops of blades so that the inner rings are fixed on the fan. The diameter and the width of each outer ring are greater than those of the corresponding inner ring, ring baffle plates with the same ring widths are separately arranged at two ends of each outer ring, and the ring width of each ring baffle plate equals to the difference between the radius of the corresponding inner ring and the radius of the corresponding outer ring. Each inner ring and the corresponding outer ring are connected with each other by a plurality of straight blades which are arranged in theperipheral directions of the rings and are distributed at equal intervals, the straight blades divide the inner rings and the outer rings to form air channels with the same sizes, and the air channels have rectification effect. By flow guiding, flow distributing and rectification, unsteady flow in the fan is relieved effectively, and the working stability of the fan is improved.

Owner:SOUTH CHINA UNIV OF TECH

Low-emission low-swirl direct-injection combustor for gas turbine

PendingCN112128800AEnhanced blendingInhibit growthContinuous combustion chamberSpontaneous combustionThermodynamics

The invention discloses a low-emission low-swirl direct-injection combustor for a gas turbine. The low-emission low-swirl direct-injection combustor comprises a buffer cavity, a premixing air inlet pipe and a flame tube which are connected and communicated from bottom to top; air enters the buffer cavity through the bottom of the combustor, a main fuel spray pipe and a low-swirl combustor are arranged in the premixing air inlet pipe; the main fuel spray pipe is connected with main fuel through a central air delivery pipe; the low-swirl combustor is located above the main fuel spray pipe; a lean-burn direct spray pipe is arranged in the premixing air inlet pipe and the buffer cavity in the axial direction, the bottom end of the lean-burn direct spray pipe is connected with on-duty fuel, andthe top end of the lean-burn direct spray pipe is higher than the low-swirl combustor and faces the flame tube; and premixed gas is mixed with the on-duty fuel sprayed out from the downstream of thelean-burn direct spray pipe through a swirl channel and a straight-flow channel of the low-swirl combustor to be combusted. According to the low-emission low-swirl direct-injection combustor for the gas turbine provided by the invention, a weak swirl fluid field is guaranteed while an geometric angle of a blade and the blockage ratio of a pore plate are increased, the premixing uniformity of fuel / air is improved, formation of NOx is reduced, risks of spontaneous combustion, tempering, lean-burn flameout and combustion oscillation are reduced, the combustion efficiency is improved, and the combustor is suitable for various combustion modes.

Owner:XI AN JIAOTONG UNIV

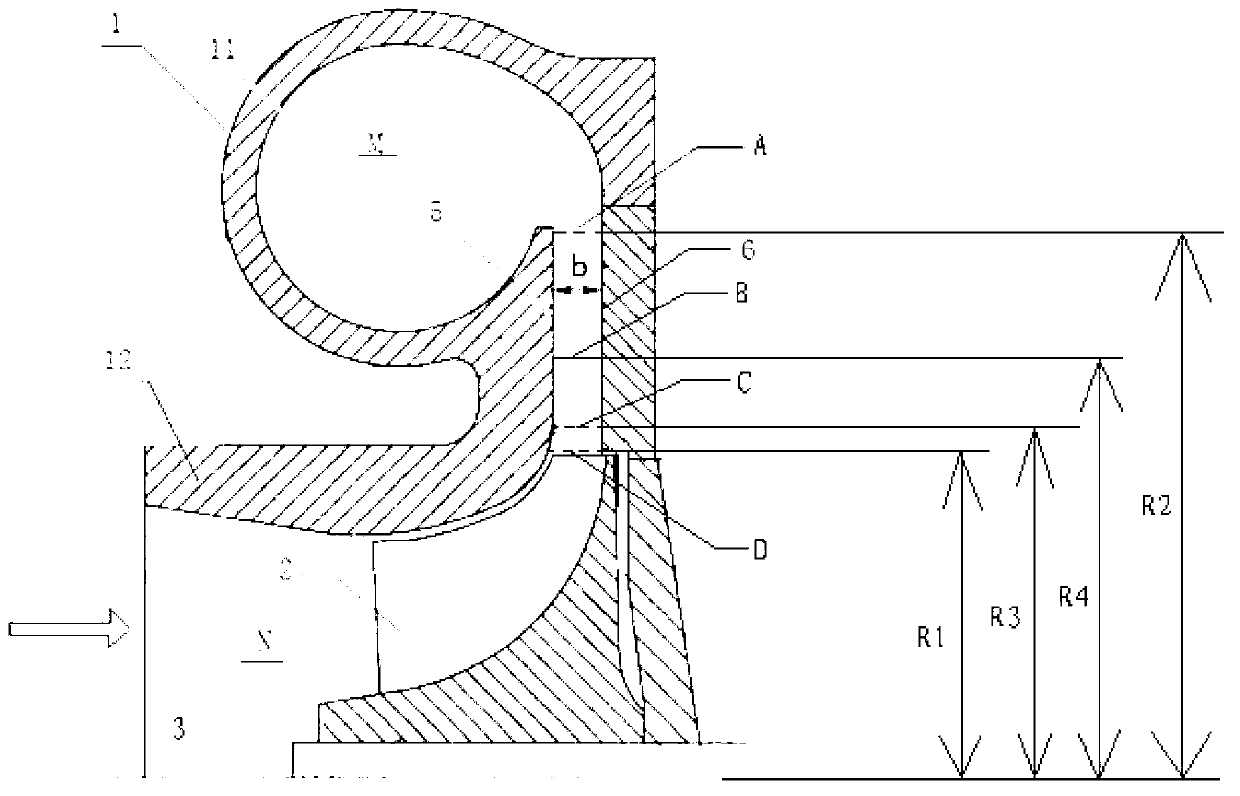

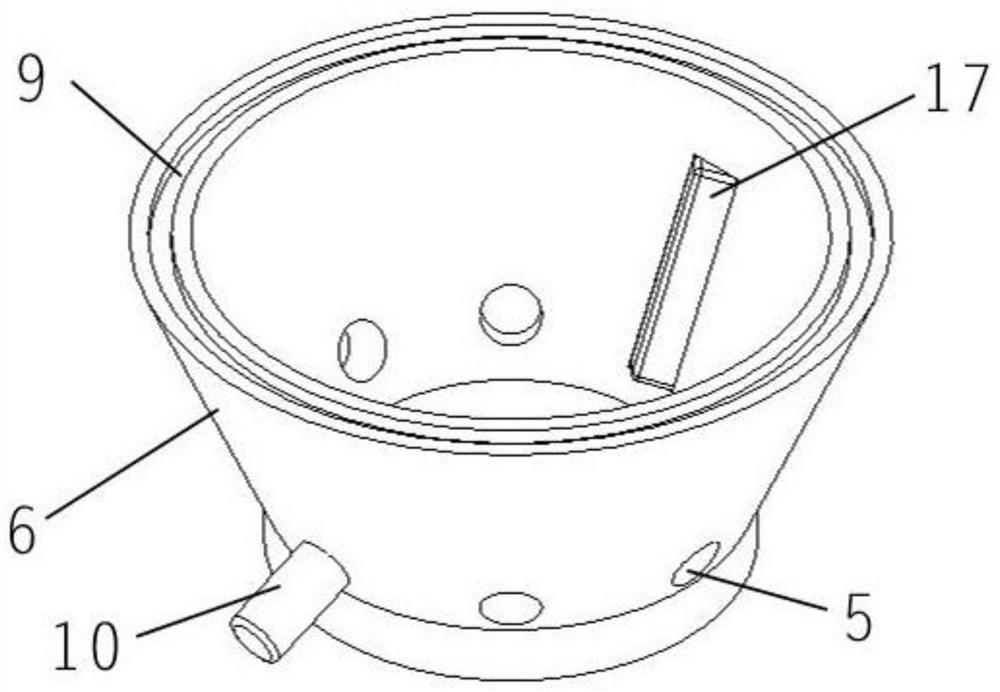

Surging-prevent compressor volute structure for turbocharger

InactiveCN104879320AImprove stable working rangeRelieve surgePump componentsPumpsImpellerTurbocharger

A surging-prevent compressor volute for a turbocharger adopts the structure that a tapered air inlet is formed in one end of the air intake passage of the compressor volute; an arc-shaped end matched with the outer contour of an arc-shaped blade of an impeller is arranged at the other end of the air intake passage; a circular flow guiding cavity is formed in the inner wall at the joint edge between the air intake passage and the arc-shaped end. During use, the impeller is mounted at the arc-shaped end of the compressor volute; the front edge end of the main blade of the impeller is arranged in the middle of the circular flow guiding cavity. When air disturbance is transmitted to an impeller inlet along the hub line of the impeller, and reaches the front edge of the main blade of the impeller, part of inlet air enters the flow guiding cavity in the form of a vortex after distorting circumferentially, so that a fluid field distorts to be transferred out of the impeller body, and the disturbance distortion of airflow at the impeller inlet is reduced, and is prevented from being further transmitted into the impeller; the airflow angle of inlet air at the impeller inlet is changed, so as to prevent distortion of the fluid field of the airflow at the air inlet end of a compressor, and enlarge the stable working range of the compressor.

Owner:HUNAN TYEN MACHINERY

Flexible casing treatment centrifugal compressor

InactiveCN109356866AImprove stable working rangeLow efficiencyPump componentsPump controlInlet channelEngineering

The invention discloses a flexible casing treatment centrifugal compressor. The flexible casing treatment centrifugal compressor comprises a volute and an impeller, air outlet channels are formed in the two side ends in the volute, an air inlet is formed in the position, on an air inlet channel, of the front side surface of the volute, air outlets are formed in the positions, on the air outlet channels, of the two side ends in the volute, an impeller mounting cavity communicates with the air inlet channel and the air outlet channels, casing grooves are formed in the two side walls of the air inlet channel, partition boards are transversely and fixedly arranged in the casing grooves, flexible baffles are arranged on the side surfaces of the partition boards, and gaps are formed between theouter side ends of the flexible baffles and the bottom surfaces of the casing grooves. The compressor carries out operation on the basis of not changing an original centrifugal compressor volute casing treatment mechanism, the compressor is simple and convenient, flowing losses are avoided to a certain degree while the stable work range of the centrifugal compressor is further widened, and the reduction of the efficiency of the centrifugal compressor is effectively prevented.

Owner:汪陈芳

Low-pollution combustion chamber adopting fuel-grading and three-stage cyclone air inlet

ActiveCN103256633BEvenly distributedInhibition formationContinuous combustion chamberCycloneAviation

The invention discloses a low-pollution combustion chamber adopting fuel-grading and three-stage cyclone air inlet. The low-pollution combustion chamber comprises an on-duty oil supply nozzle, a primary-combustion oil supply nozzle, three-stage cyclones and a flame tube. Fuel is respectively provided for the on-duty oil supply nozzle and the primary-combustion oil supply nozzle in two ways, and the three-stage coaxial cyclones supply air to the head of a combustion chamber. The two stages of cyclones on the inner side of the combustion chamber refer to an oblique-cutting hole cyclone and a radial cyclone, cyclone of the two-stage cyclones are in opposite directions. A centrifugal atomizing nozzle is arranged at the center of the oblique-cutting hole cyclone, and the second-stage cyclone on the inner side are combined and matched with a center on-duty nozzle. The cyclone on the outside of the combustion chamber is a radial cyclone with cyclone direction opposite to that of a second-stage cyclone. Primary combustion fuel enters a cyclone blade channel from small holes of a front wall surface of a third-stage cyclones by way of multipoint direct injection and is accelerated to be crushed and atomized in a cyclone channel to be mixed with the air, and forms premixed or partly premixed fuel-air mixture at an exit of the tertiary swirling influx to enter a primary combustion zone to be combusted. The low-pollution combustion chamber is applicable to aircraft engine combustion chambers or industry fuel turbine combustion chambers.

Owner:中科航空动力(株洲)装备制造研究院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com